Patents

Literature

78 results about "Limit strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

EMG controlled air-operated soft body rehabilitative mechanical hand

ActiveCN106309083AImprove securityReduce weightProgramme-controlled manipulatorDiagnosticsLow noiseFiber

The invention discloses an EMG controlled air-operated soft body rehabilitative mechanical hand. The mechanical hand can help a stroke patient or a patient suffering from hand disability conduct hand rehabilitation activity. Different from a traditional rigid body type mechanical hand, every finger of the soft body mechanical hand is a hollow cavity structure composed of soft materials (super-elastic materials like silicone rubber and the like), a fiber and a limit strained layer is arranged on the periphery, soft body fingers are designed by combining structures of bending distortion, extending distortion, distortion, torsional and extending distortion, and motion distortion is achieved through air-operated driving. The EMG controlled air-operated soft body rehabilitative mechanical hand can achieve multi-section type bending similar to human's fingers, drives bending and stretching of stroke fingers, and restores a patient's athletic ability. The air-operated soft body rehabilitative mechanical hand has the advantages of low rigidity, high safety, high comfort, low weight, low noise and the like, has more remarkable superiority compared with current traditional mechanical rigid body type rehabilitative hand, and has very wide application prospect in the field of rehabilitation.

Owner:XI AN JIAOTONG UNIV

Method and system for numerically simulating and predicting necking failure in sheet metal forming

InactiveCN102262688AEasy to useEasy to observeDesign optimisation/simulationAerodynamics improvementForming limit diagramElement analysis

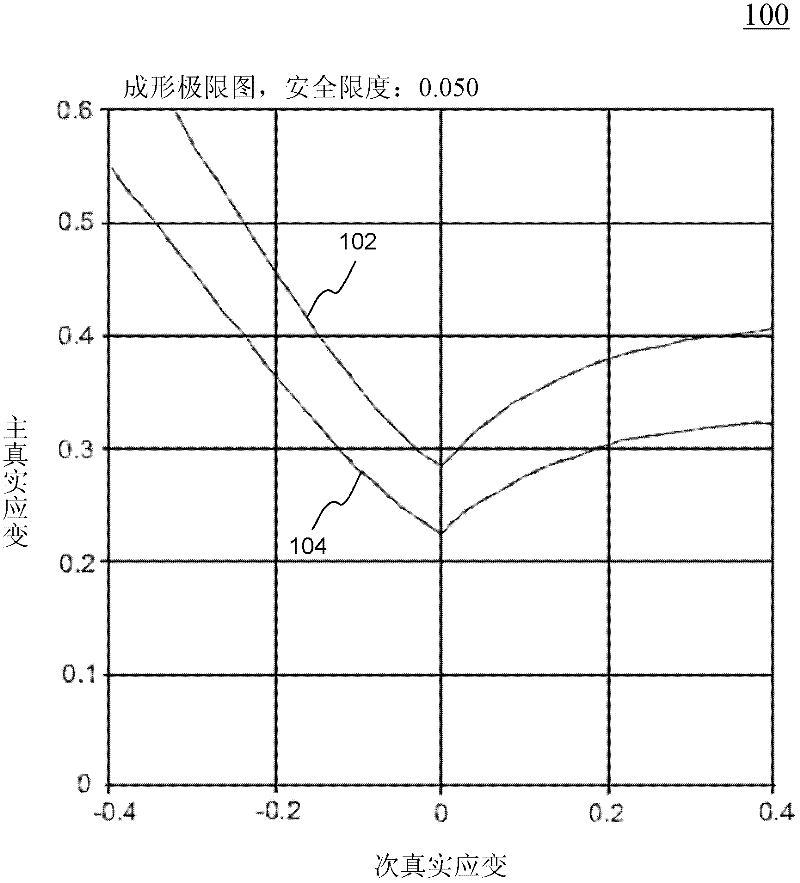

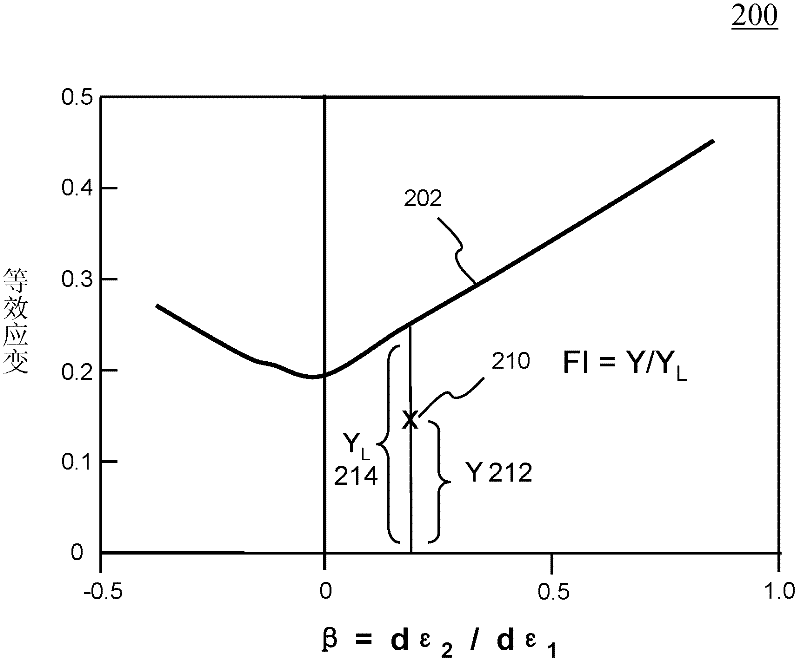

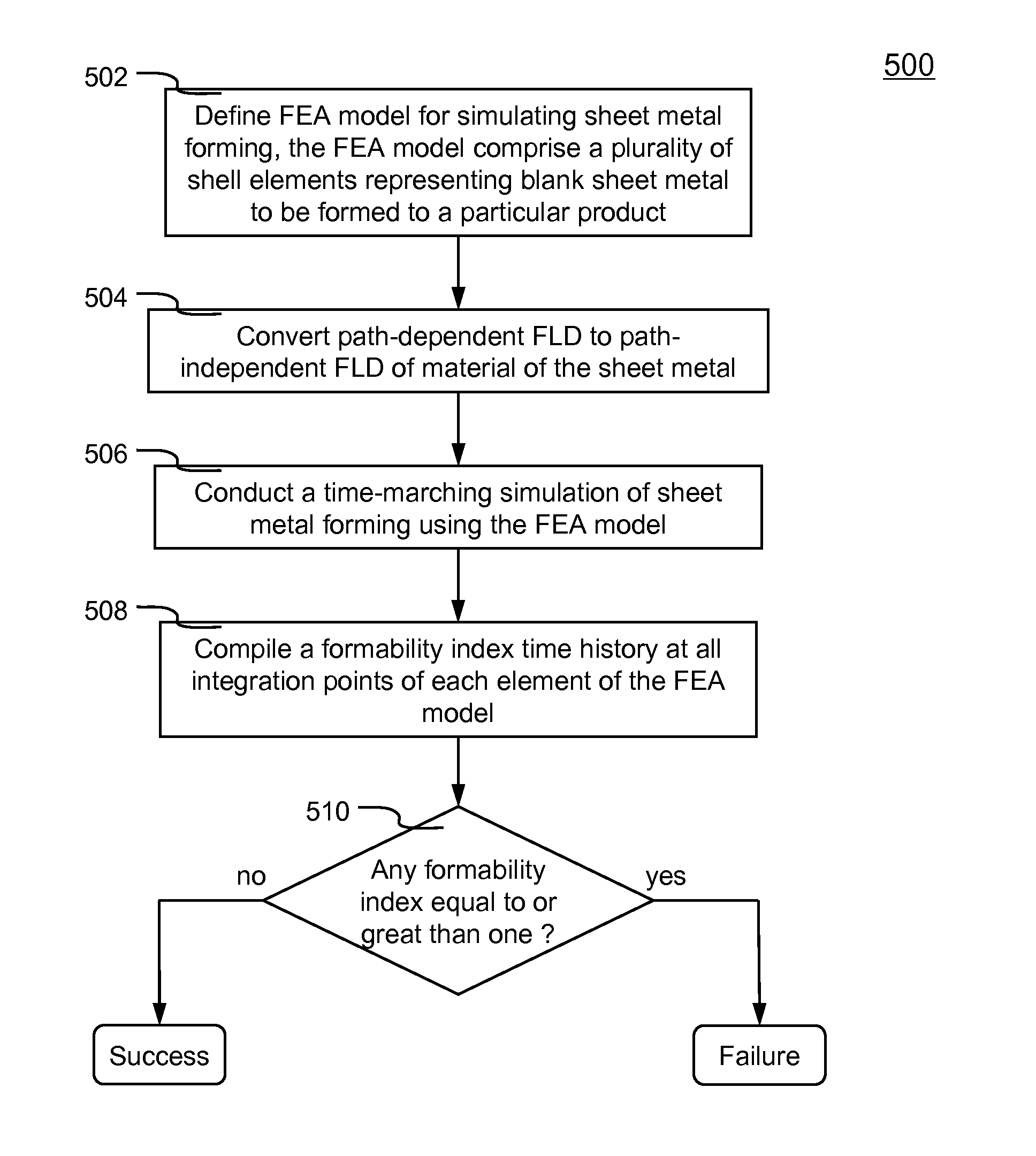

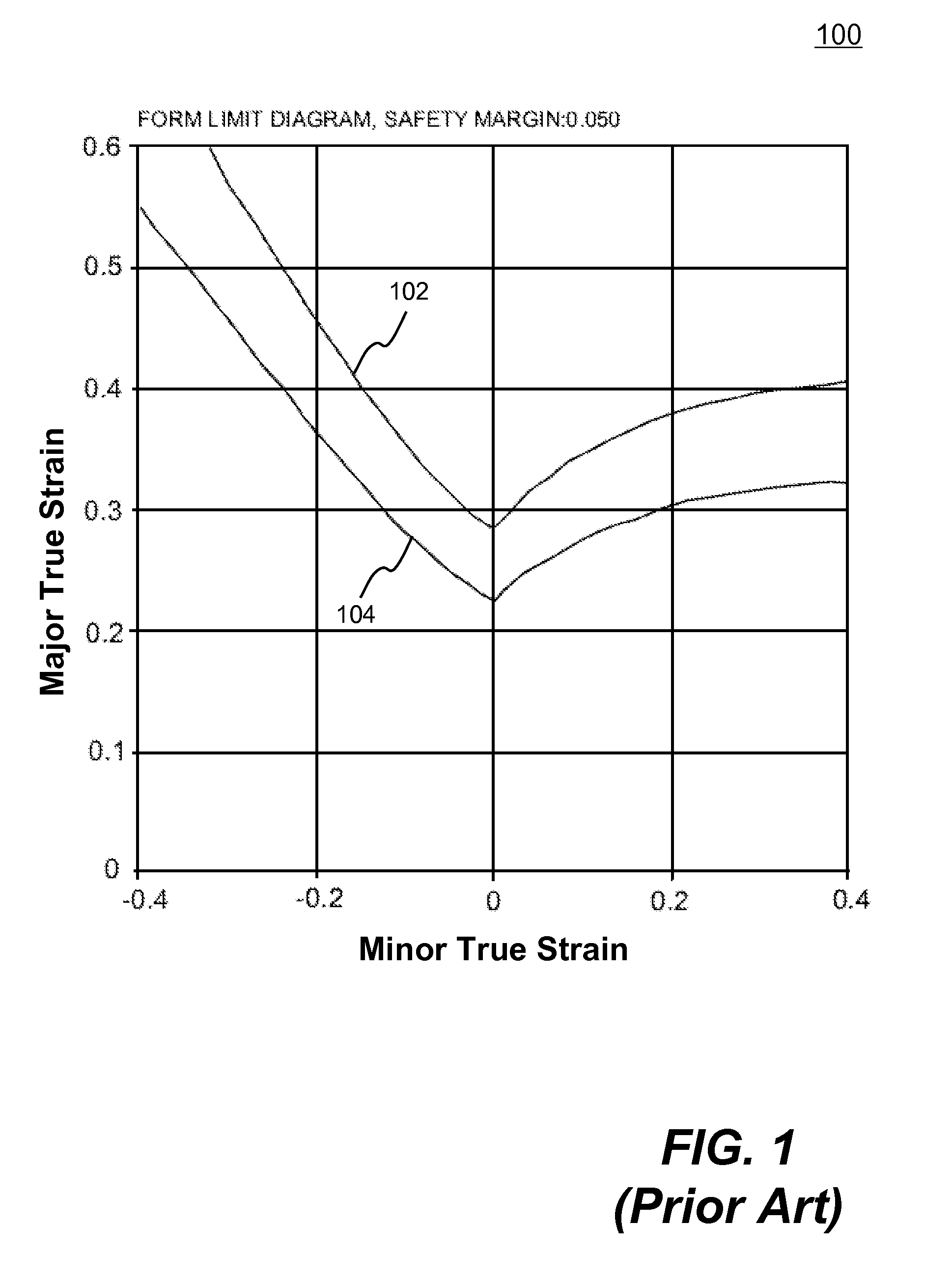

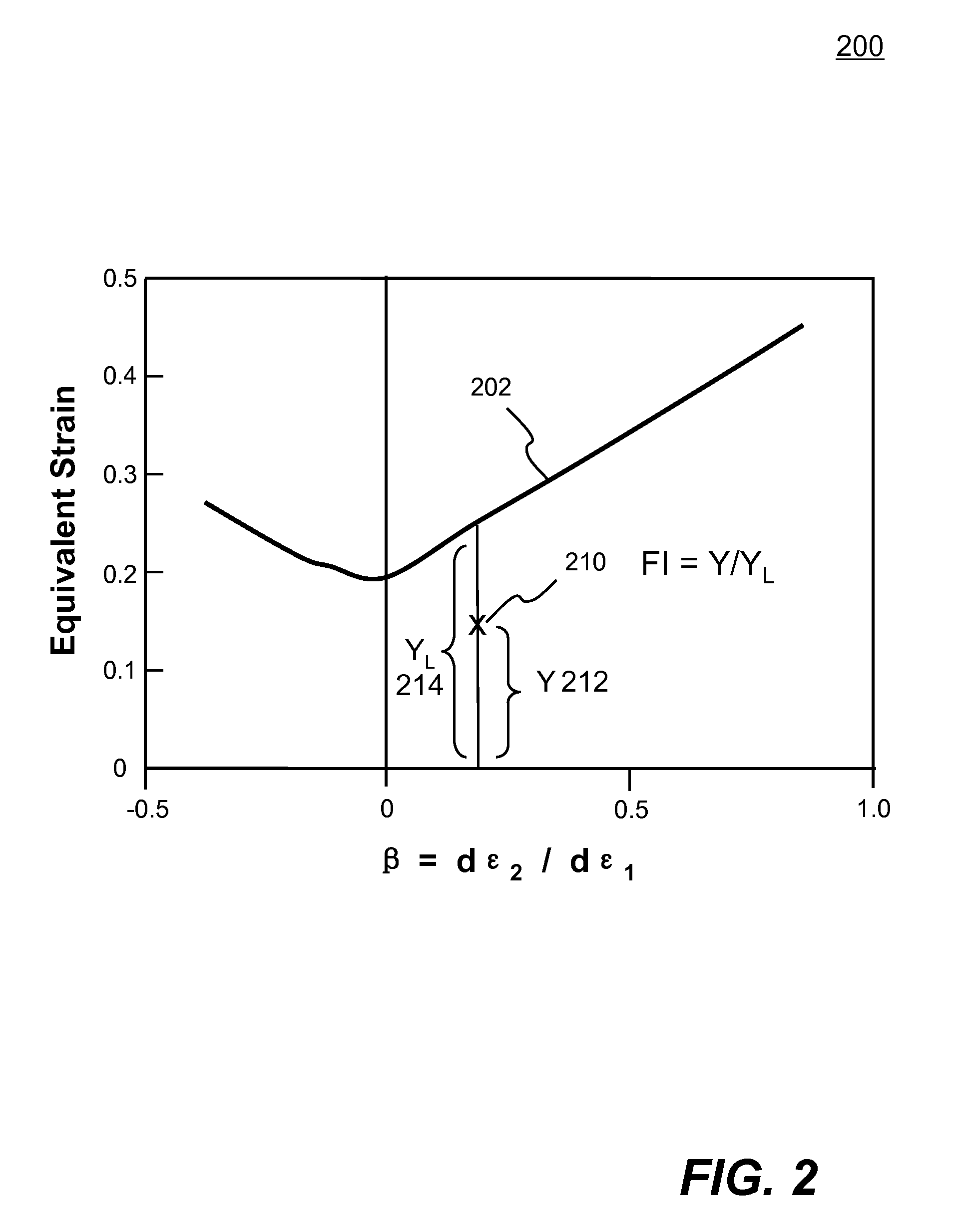

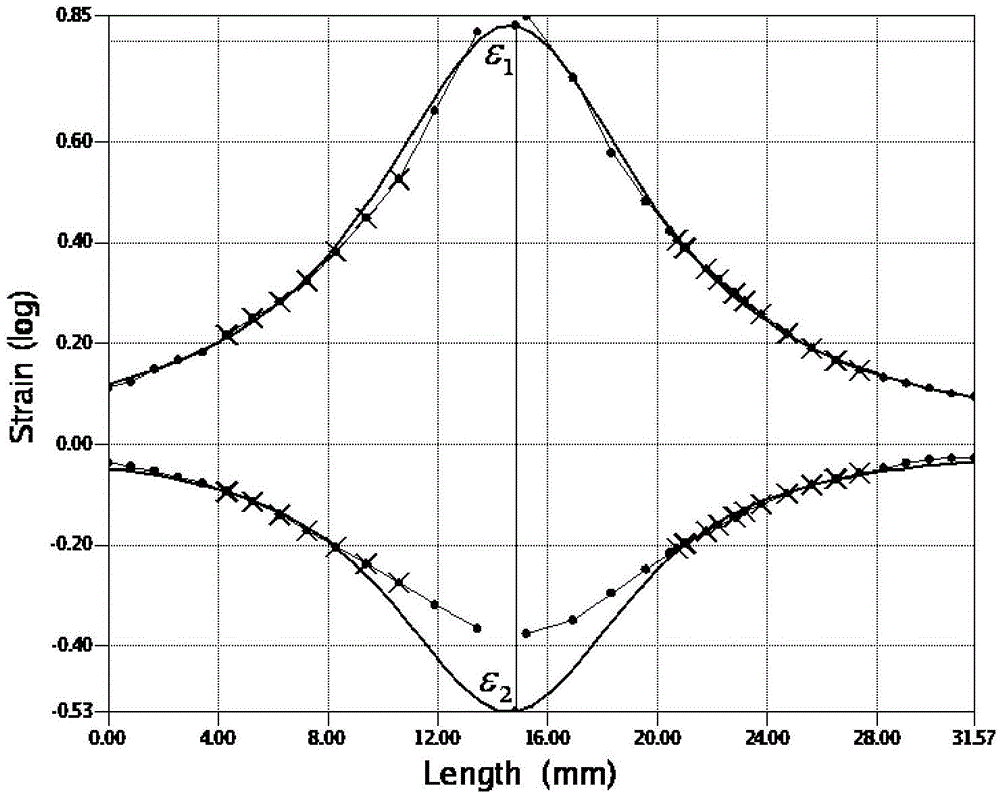

Systems and methods of predicting sheet metal forming failure using numerical simulations (e.g., finite element analysis) are disclosed. A FEA model is defined for a particular sheet metal forming process. Blank sheet metal is modeled with a plurality of shell elements. Additionally, a deformation path-dependent forming limit diagram (FLD) is converted to a path-independent FLD. A time-marching simulation of the sheet metal forming process is conducted using the FEA model. At each solution cycle, equivalent strain at each integration point of shell element is checked against the corresponding forming limit strain value of the path-independent FLD. The ratio of the equivalent strain and the forming limit strain is defined as formability index. A time history of the formability index of each shell element is saved into a file and displayed to a monitor upon user's instructions. When a particular element's formability index reaches one or higher, a localized necking is predicted.

Owner:LIVERMORE SOFTWARE TECH

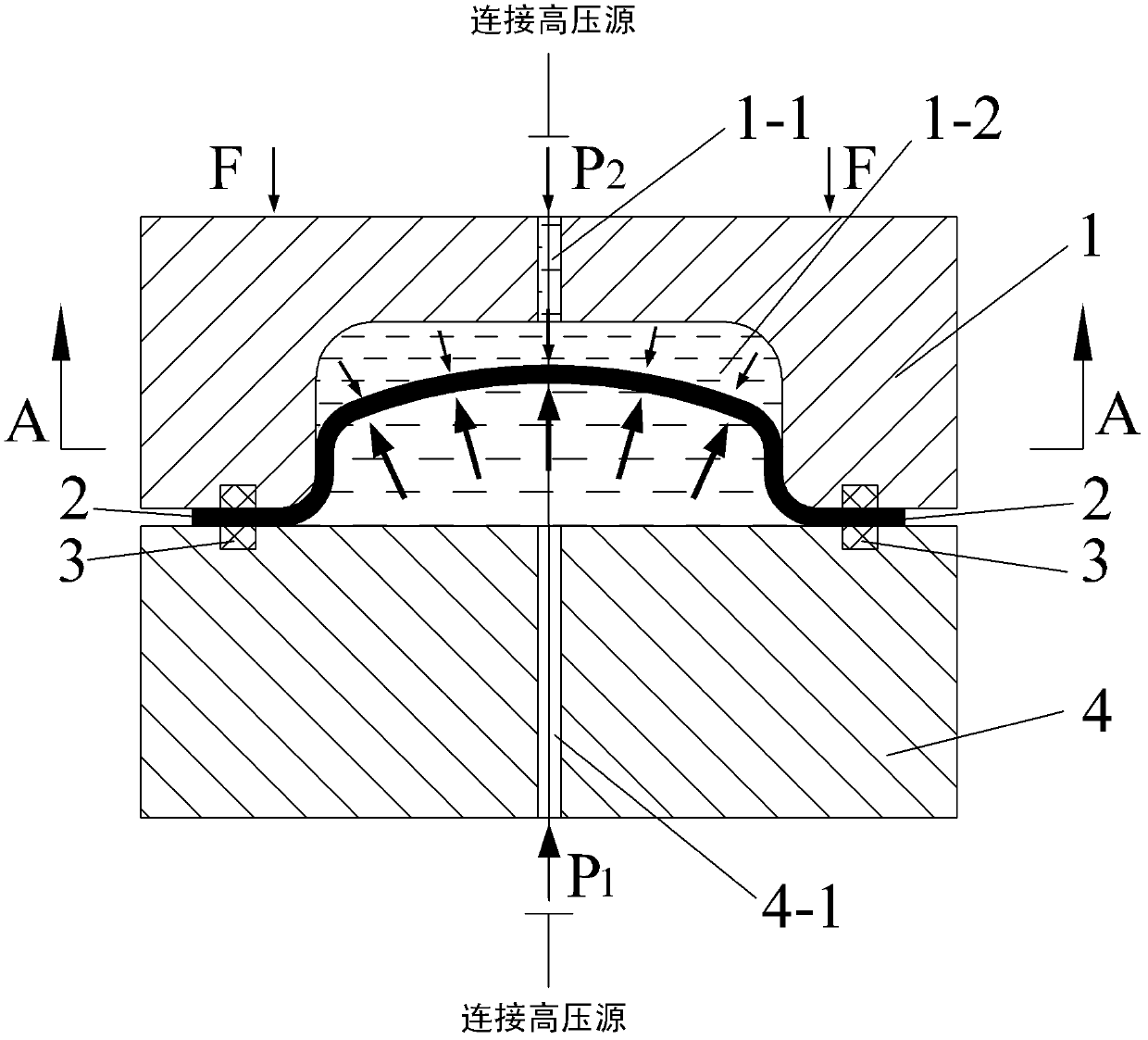

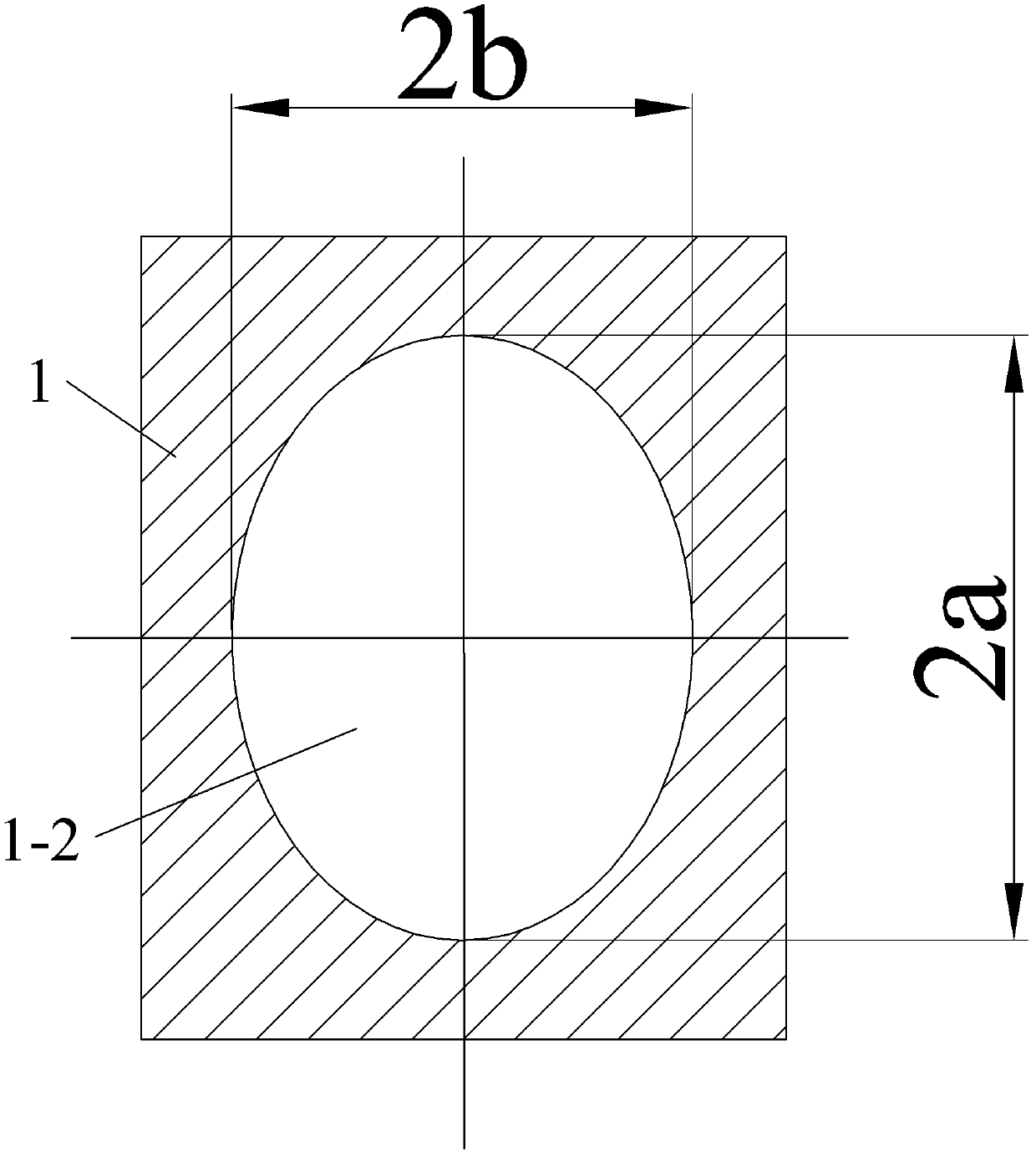

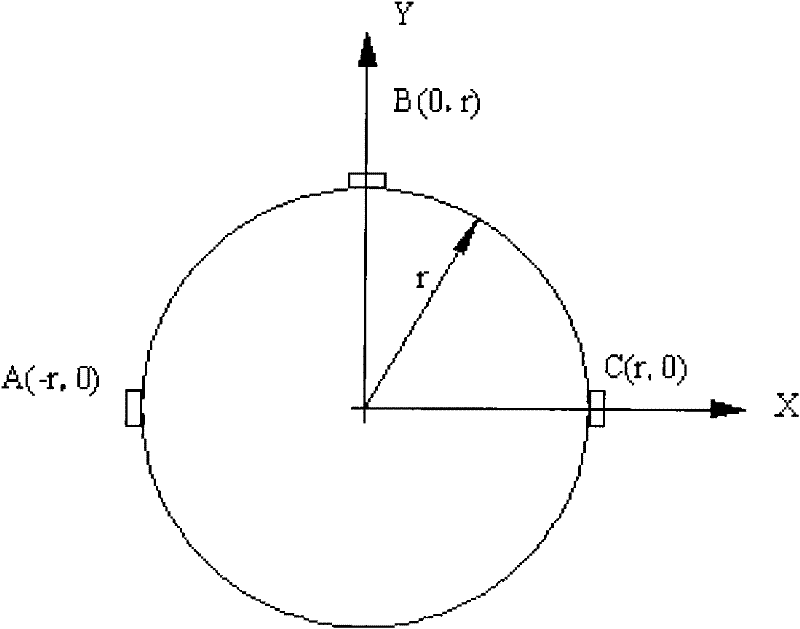

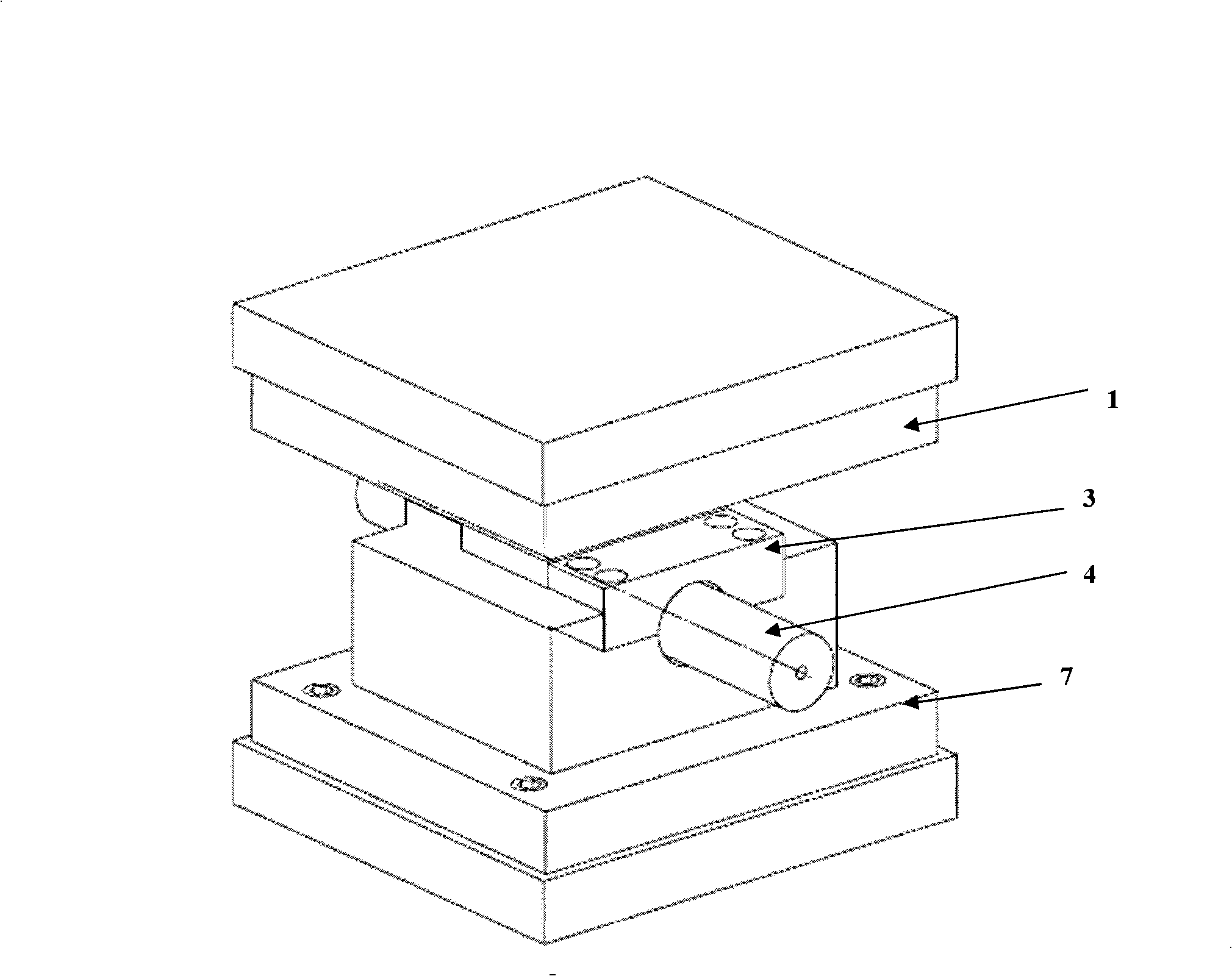

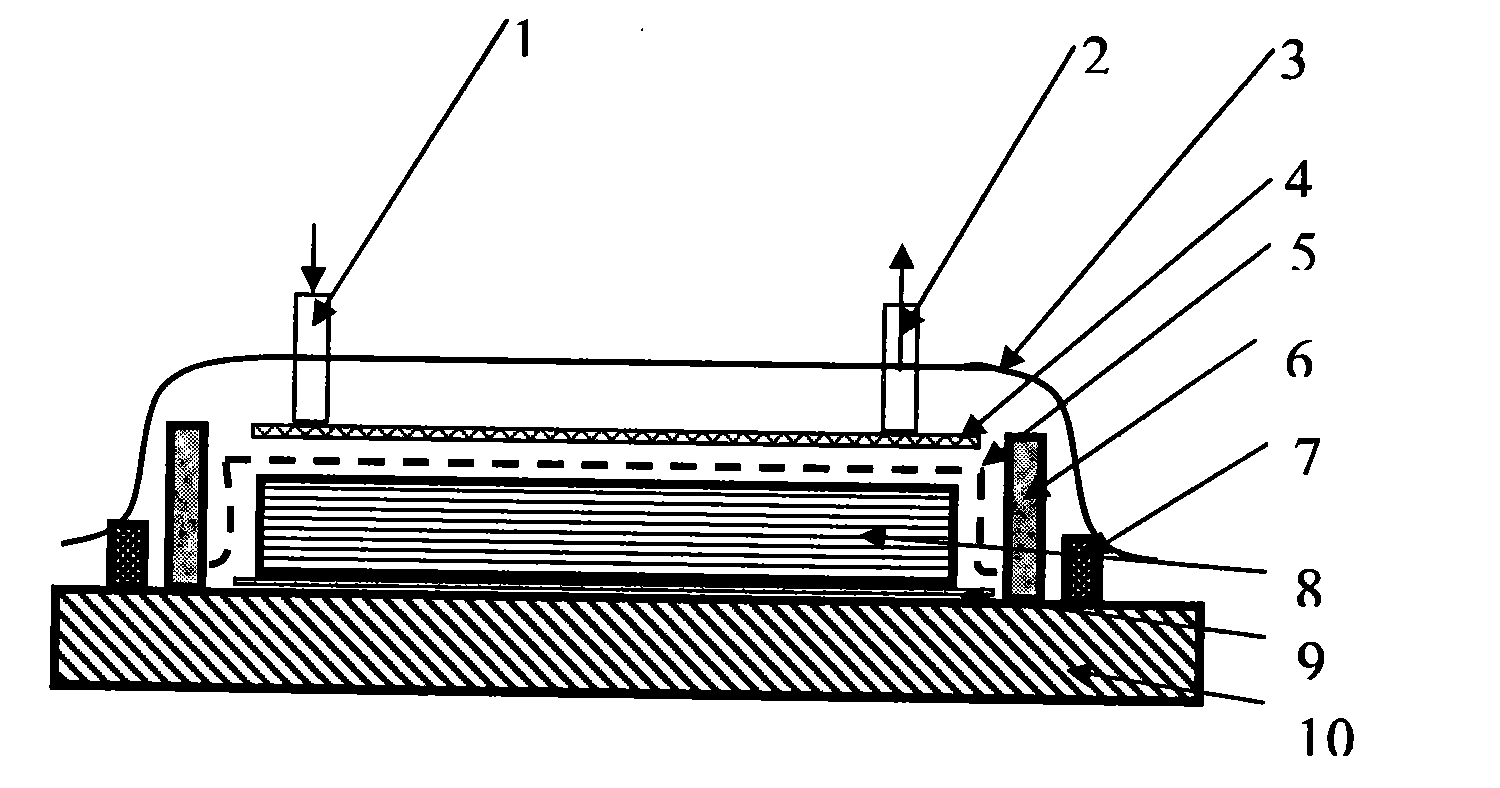

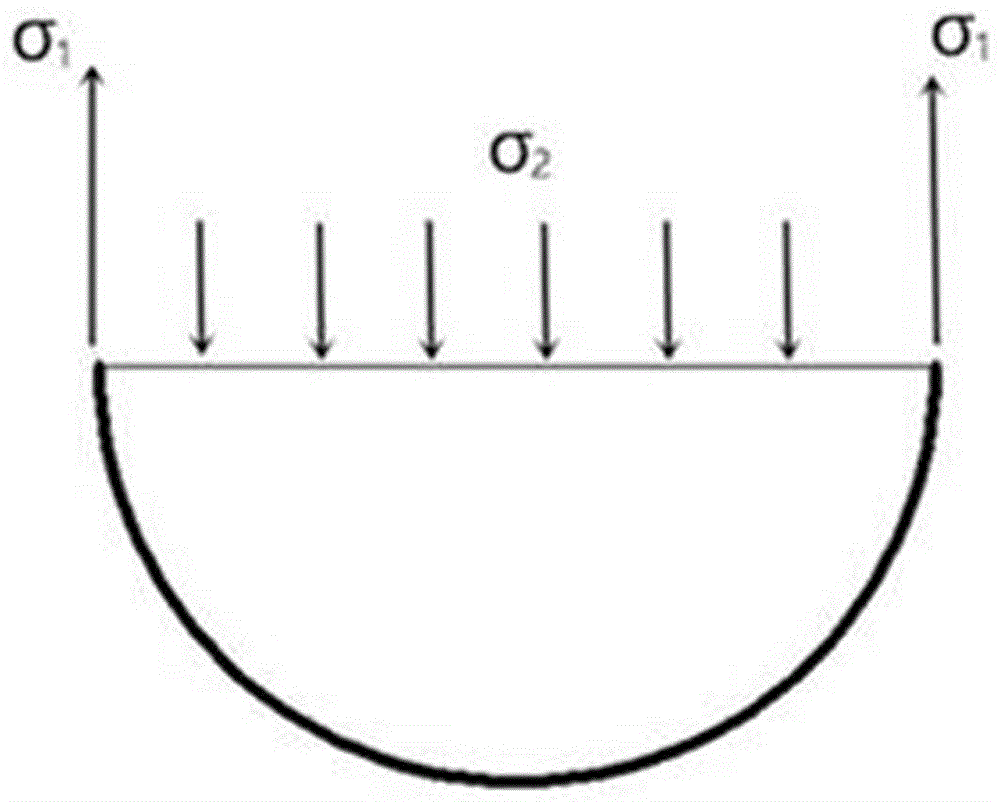

Device and method for testing forming limit of sheet material in three-dimensional stress state

InactiveCN102607969ASimple methodEasy to implementInvestigating material ductilityTest sampleLimit strain

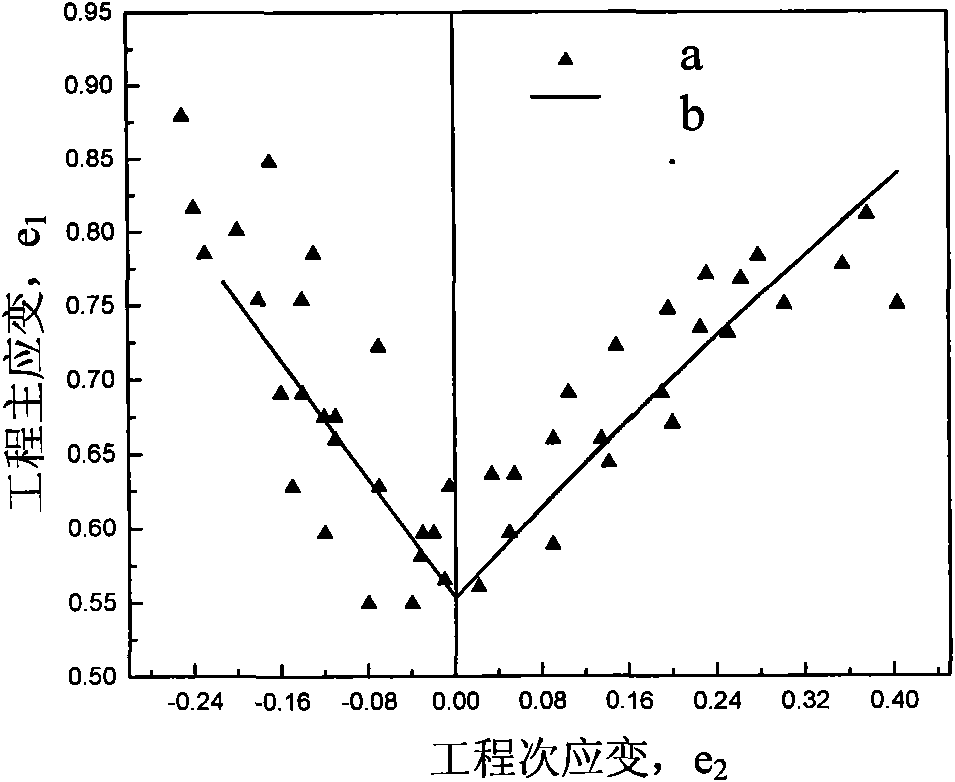

The invention provides a device and a method for testing a forming limit of a sheet material in a three-dimensional stress state, relating to the device and the method which are used for testing the forming limit of the sheet material. Aiming to the problems that the forming limit of the sheet material in the three-dimensional stress state is difficult to test and an influence of normal pressure to the forming limit is difficult to estimate, the device comprises an upper die and a lower die. In a test, a fluid medium is injected into the lower die, a test sample of the sheet material is placed, mold clamping force is applied, the fluid medium is injected into the upper die, and pressurized deformation is carried out by controlling pressure in the upper die and the lower die in sequence. Braking strains of the test sample of the metal sheet material can be calculated according to measured data before and after circular or square mesh deformation, namely epsilon 1=Ln[d1-d / d] and epsilon 2=Ln[d-d2 / d]; a plurality of groups of different limit strain data points can be obtained by changing a ratio of a long shaft to a short shaft of an oval cross section of a cavity; and the obtained data points can be connected or fitted by respectively using the epsilon 1 and the epsilon 2 as a transverse coordinate and a vertical coordinate, so as to obtain the sheet material forming limit curve at the three-dimensional stress state at a certain normal pressure condition to estimate the influence of the normal strain to the forming limit in the three-dimensional stress state.

Owner:HARBIN INST OF TECH

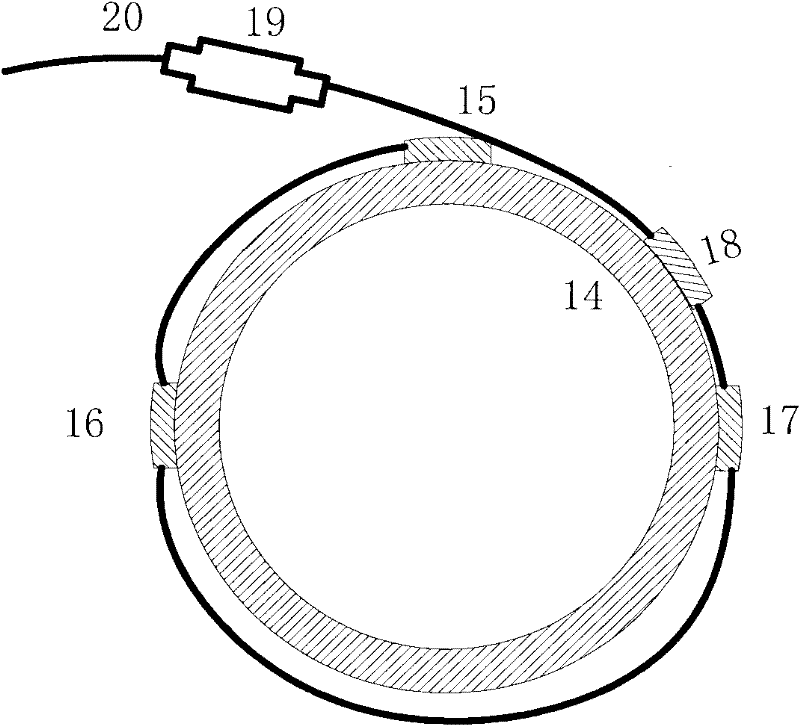

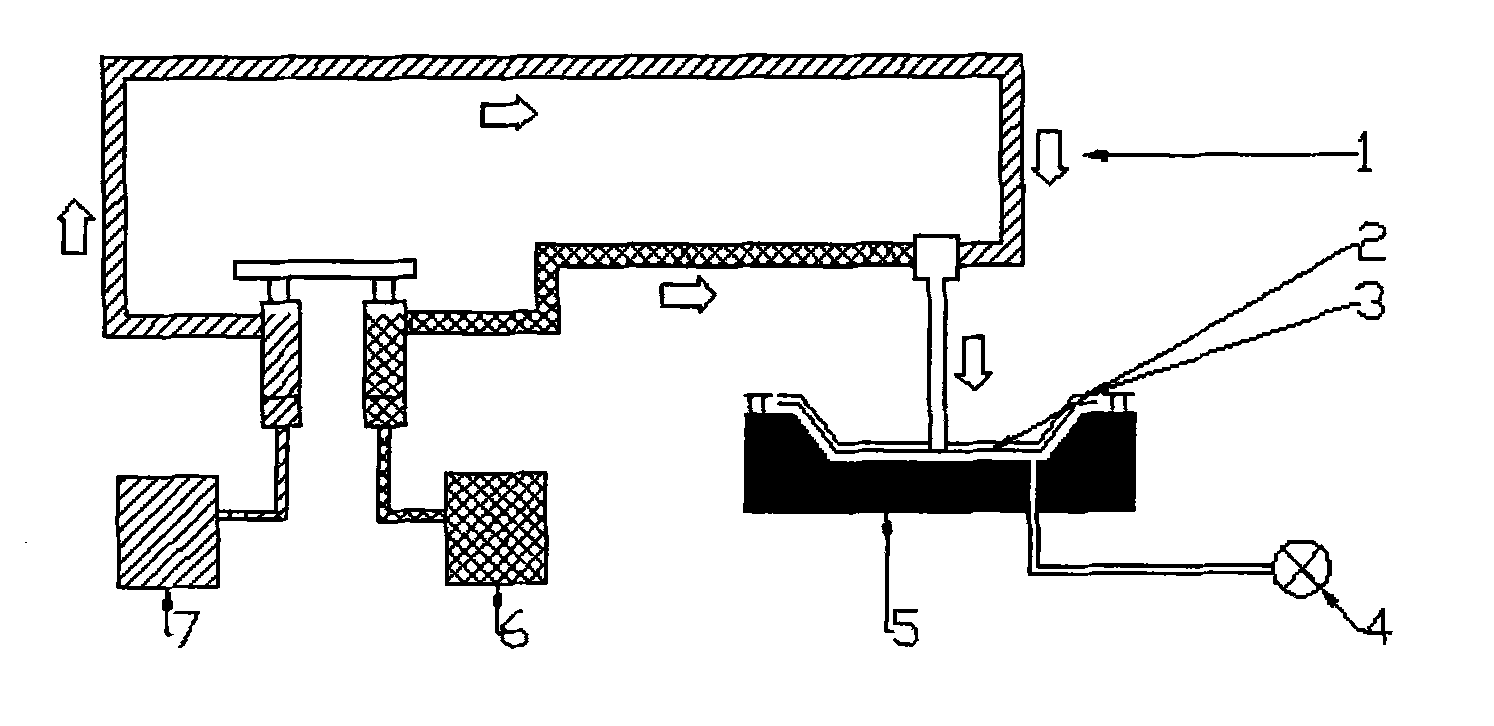

Method for monitoring oil-gas pipeline in mining subsidence area

ActiveCN102345796AReveal Security WarningReveal collapse featuresPipeline systemsUsing optical meansRelative displacementGrating

The invention discloses a method for monitoring an oil-gas pipeline in a mining subsidence area based on a fiber grating sensing technology. The method comprises the following steps of: monitoring pipe body axial strain with a fiber grating strain sensor, monitoring pipe-soil relative replacement with a fiber grating displacement sensor, and monitoring soil body horizontal deformation with a fiber grating sensing network; demodulating and preprocessing signals acquired by the sensors, and transmitting the signals to a remote monitoring center; further analyzing and processing data in the monitoring center, and computing mining subsidence soil body horizontal deformation change, pipe body axial strain change and pipe-soil relative displacement change; judging the state stabilities of the pipe body strain change and the soil body strain change, and judging whether the data surpass threshold values; when three parameter values are smaller than respective threshold values, judging that the pipeline is in a safe state; and when the pipe body axial strain reaches 70 percent of a pipe body limit strain value, or a pipe-soil relative displacement value reaches a threshold value and keeps constant, or a soil body horizontal deformation curve changes suddenly, performing pipeline safety joint early-warning.

Owner:PIPECHINA SOUTH CHINA CO

Sheet Metal Forming Failure Prediction Using Numerical Simulations

InactiveUS20110295570A1Computation using non-denominational number representationDesign optimisation/simulationForming limit diagramElement analysis

Systems and methods of predicting sheet metal forming failure using numerical simulations (e.g., finite element analysis) are disclosed. A FEA model is defined for a particular sheet metal forming process. Blank sheet metal is modeled with a plurality of shell elements. Additionally, a deformation path-dependent forming limit diagram (FLD) is converted to a path-independent FLD. A time-marching simulation of the sheet metal forming process is conducted using the FEA model. At each solution cycle, equivalent strain at each integration point of shell element is checked against the corresponding forming limit strain value of the path-independent FLD. The ratio of the equivalent strain and the forming limit strain is defined as formability index. A time history of the formability index of each shell element is saved into a file and displayed to a monitor upon user's instructions. When a particular element's formability index reaches one or higher, a localized necking is predicted.

Owner:LIVERMORE SOFTWARE TECH

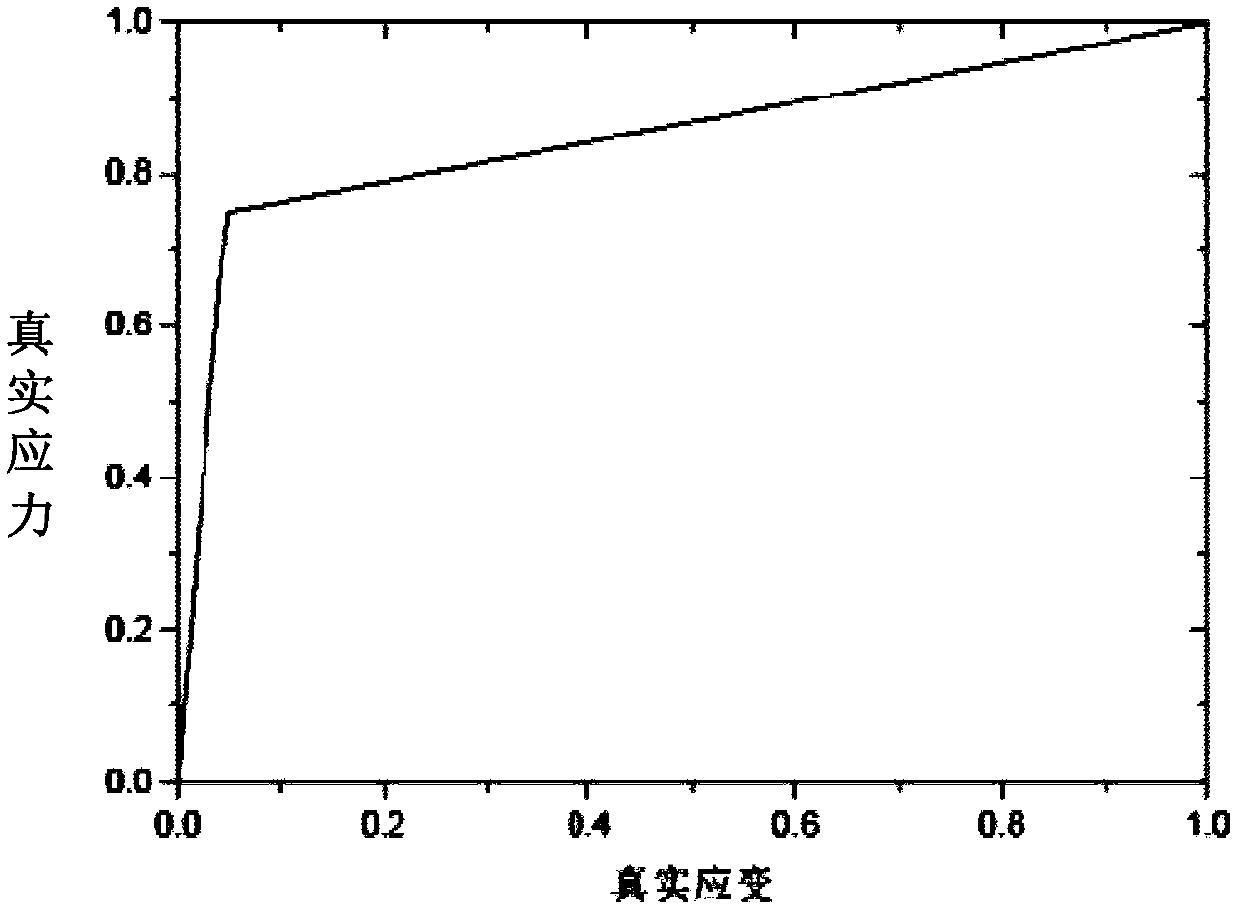

FLC (forming limit curve) testing method based on variation of strain rate

InactiveCN104155194AAccurate and reliable forming limit curveAvoid the influence of cross-sectional strain distribution shapeInvestigating material ductilitySpecial data processing applicationsTest sampleLimit strain

The invention relates to an FLC (full-load current) testing method based on the variation of a strain rate. The method comprises the following steps: acquiring a surface strain distribution cloud chart of a test sample; exporting epsilon(t) of each location point; calculating a strain rate of the point-in-time on each location point epsilon(t) to form (described in the specification), calculating a first derivative value of the strain rate of each point-in-time on (described in the specification), and recording the point-in-time corresponding to the moment when a negative value or a maximum value first appears in the first derivative value as t1; repeating the steps to obtain t2 to tn; comparing the values of t1 to tn, adopting the point-in-time with the value being most repeated as a moment t0 when the test sample begins to be necked, finding out an epsilon major and a corresponding epsilon minor in the test sample necking area on the surface strain distribution cloud chart at the moment t-1, wherein the epsilon major and the corresponding epsilon minor are used as a limiting strain point of the material; repeating the steps to obtain 5 to 8 limiting strain points; marking the limiting strain points on a main / secondary strain plane, and connecting the limit strain points to obtain the FLC. By adopting the method, the influence caused by a cross-section strain distribution pattern can be effectively avoided, and the accurate and reliable FLC can be acquired.

Owner:武汉钢铁有限公司

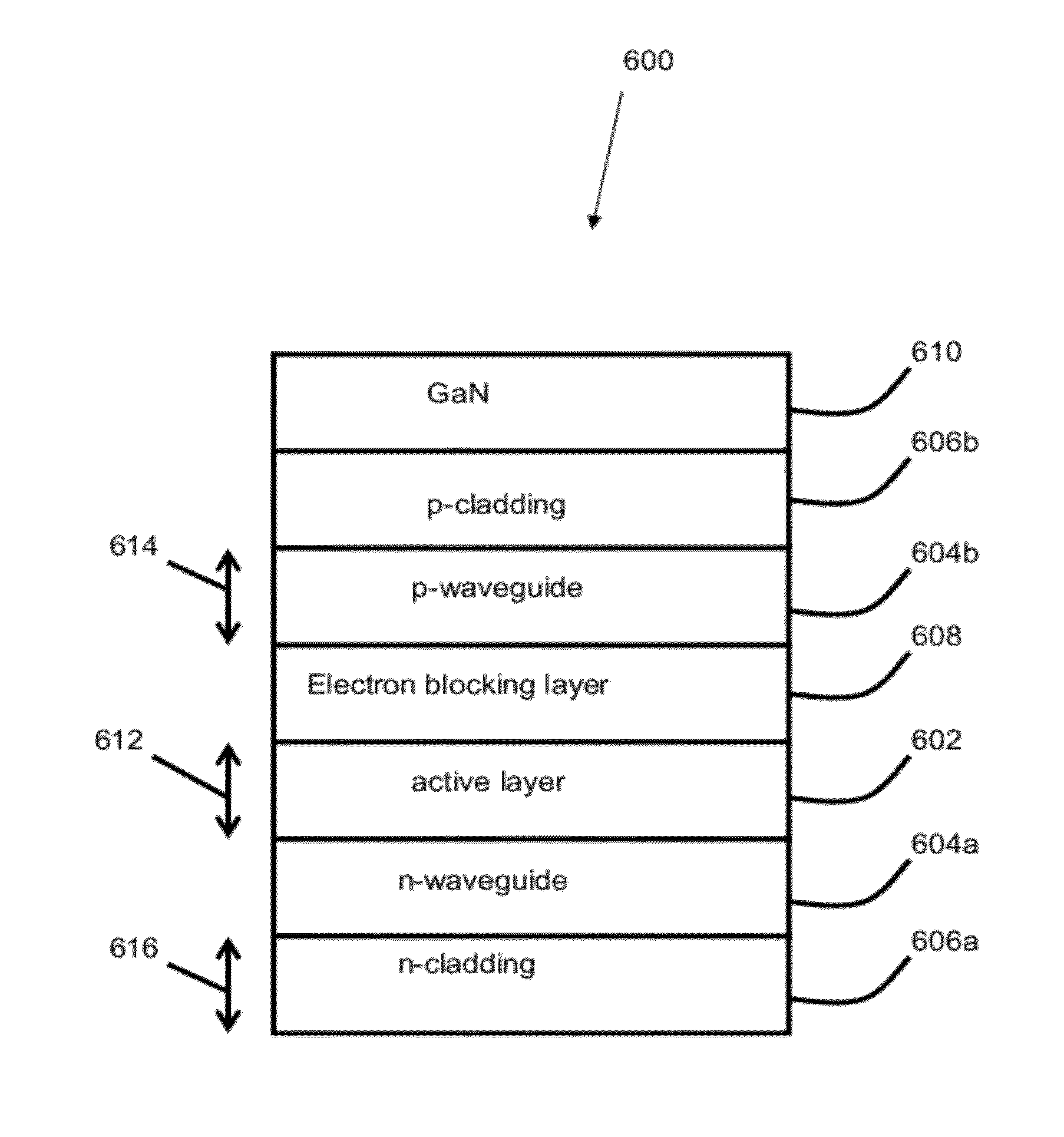

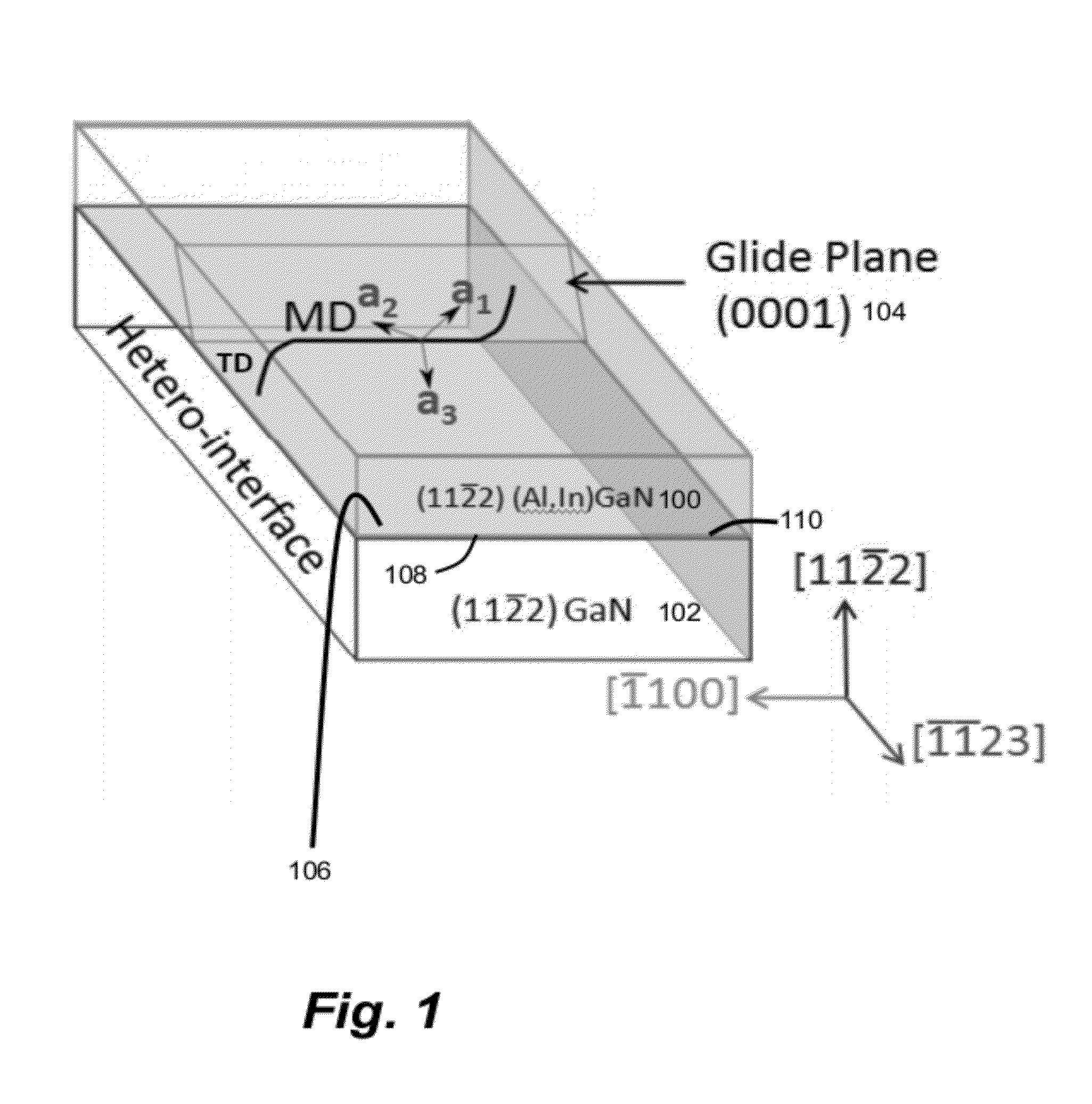

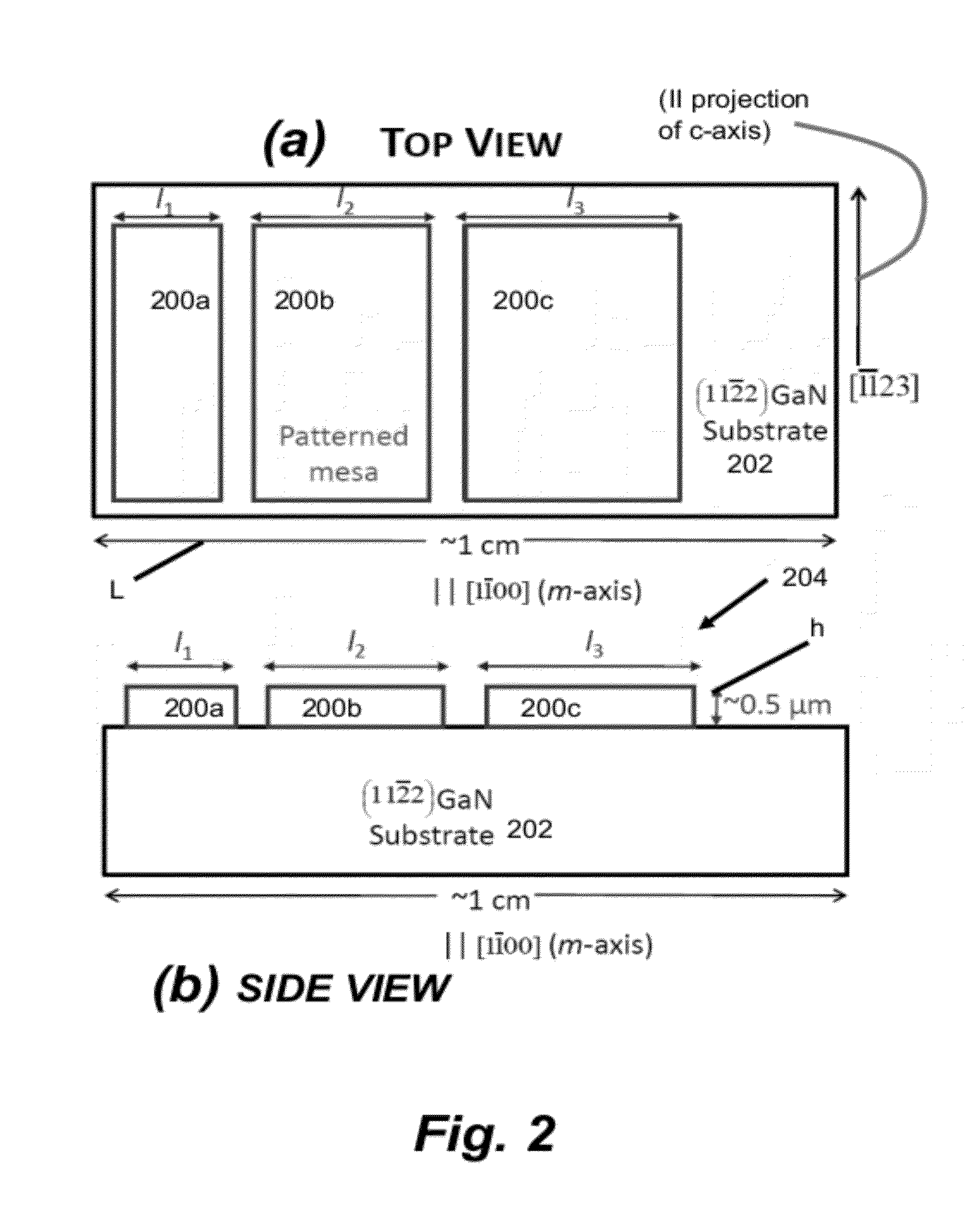

Limiting strain relaxation in iii-nitride hetero-structures by substrate and epitaxial layer patterning

ActiveUS20120097919A1High compositionSemiconductor/solid-state device manufacturingNanoopticsLimit strainNitride

A method of fabricating a substrate for a semipolar III-nitride device, comprising patterning and forming one or more mesas on a surface of a semipolar III-nitride substrate or epilayer, thereby forming a patterned surface of the semipolar III-nitride substrate or epilayer including each of the mesas with a dimension / along a direction of a threading dislocation glide, wherein the threading dislocation glide results from a III-nitride layer deposited heteroepitaxially and coherently on a non-patterned surface of the substrate or epilayer.

Owner:RGT UNIV OF CALIFORNIA

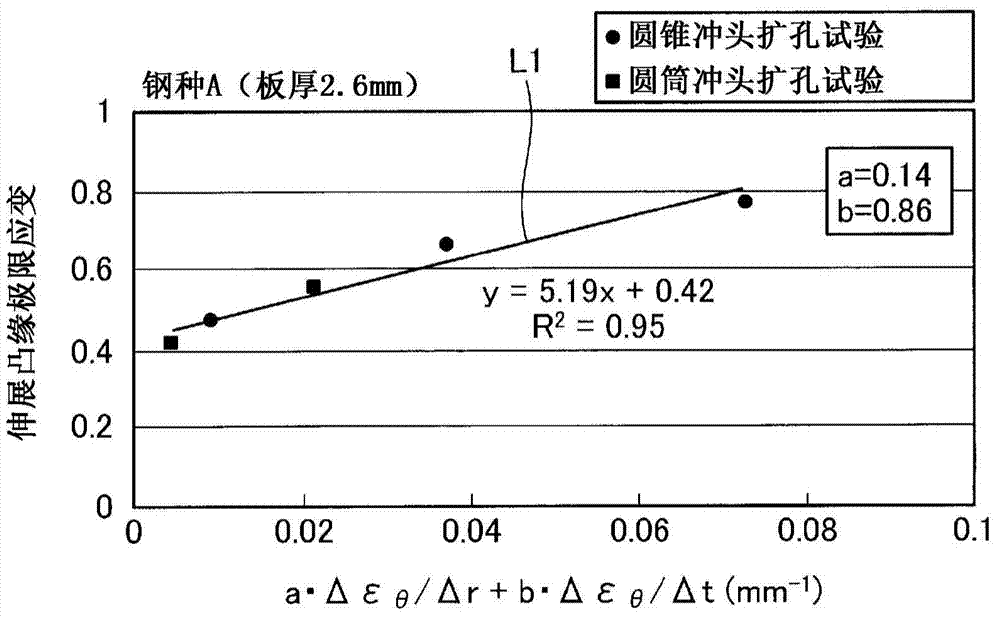

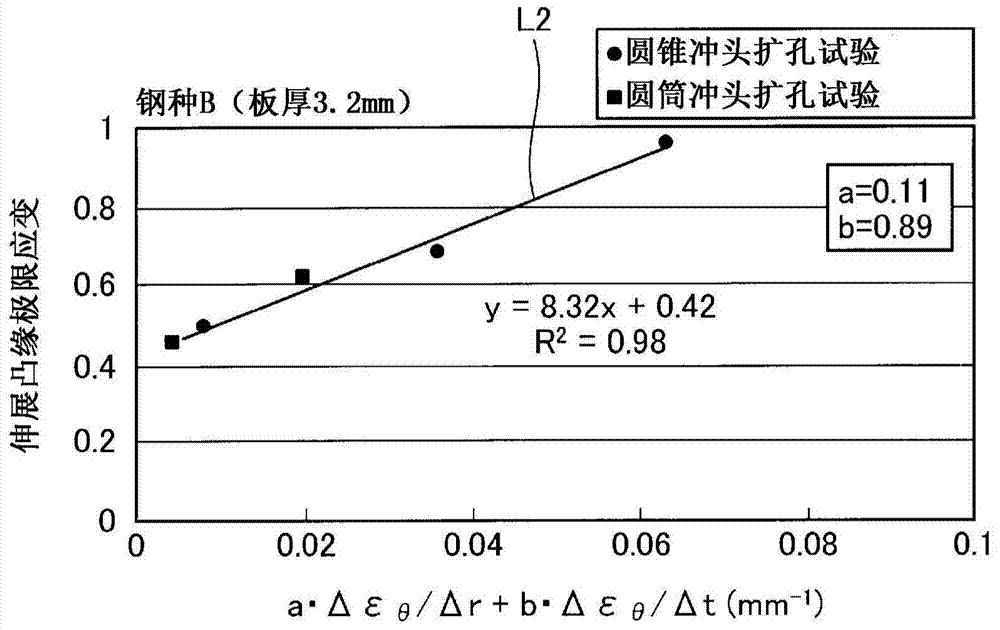

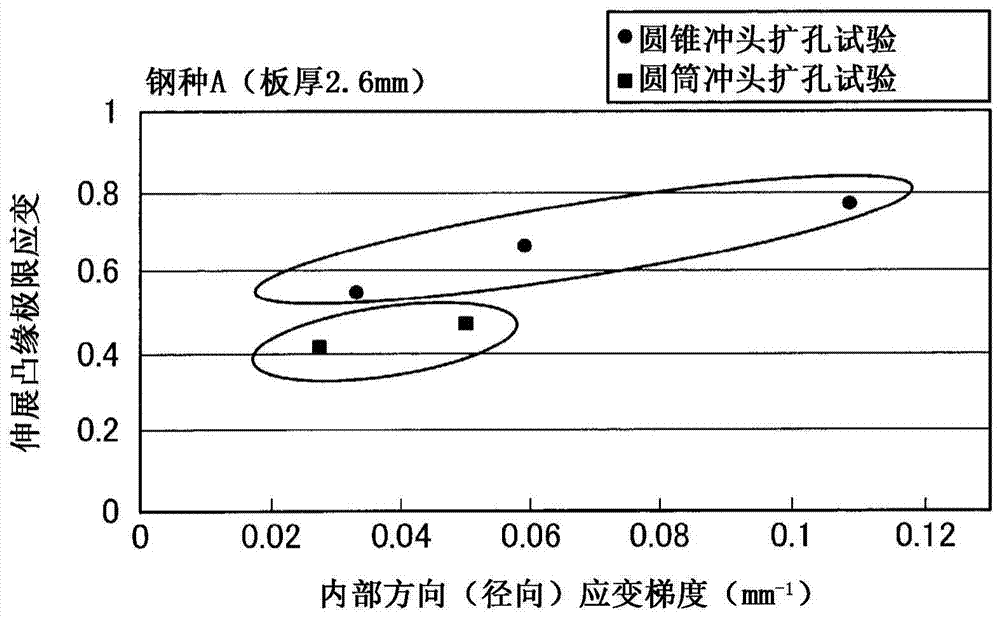

Method for determining stretch flange limit strain and method for assessing press forming feasibility

This method for setting stretch flange limit strain is characterized in that the stretch flange limit strain is set so as to satisfy the relationship in the following equation using the strain gradient from the end part of a metal sheet toward the inside when a press load is added, and the strain gradient in the thickness direction of the metal sheet crossing the loading direction. εθlim = A{a•Δεθ / Δr+b•Δεθ / Δt}+c Provided that: εθlim represents the stretch flange limit strain (tangential to the sheet edge) Δεθ / Δr represents the strain gradient toward the interior Δεθ / Δt represents the strain gradient in the thickness direction A, a, b are influence coefficients c is the limit strain when the strain gradient is zero

Owner:JFE STEEL CORP

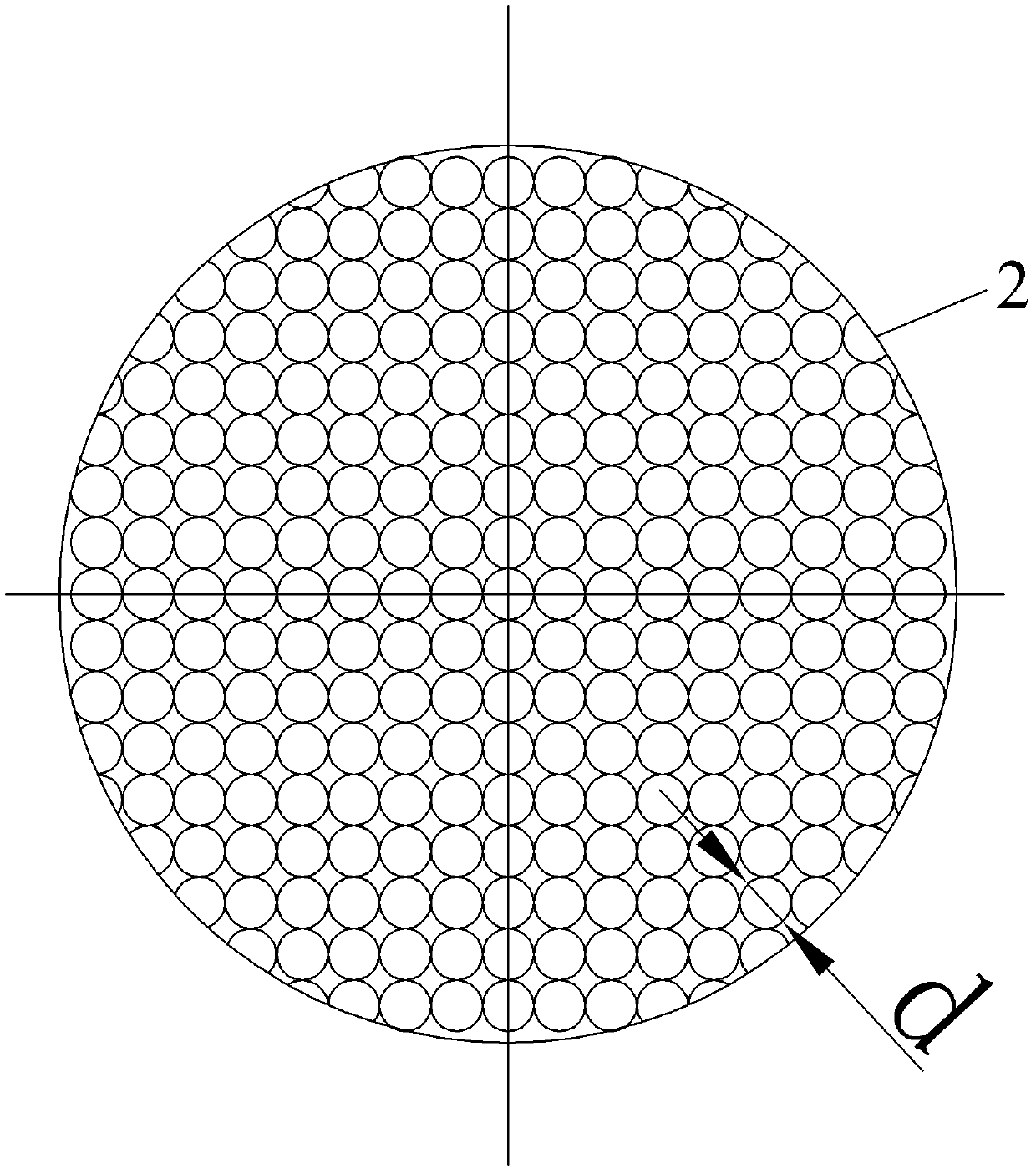

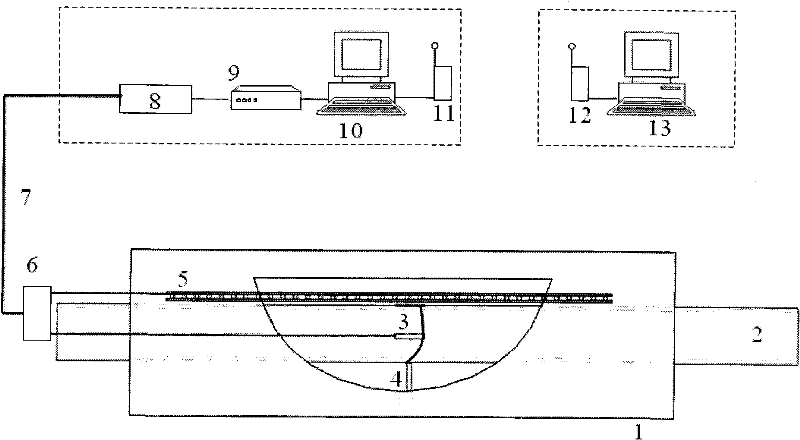

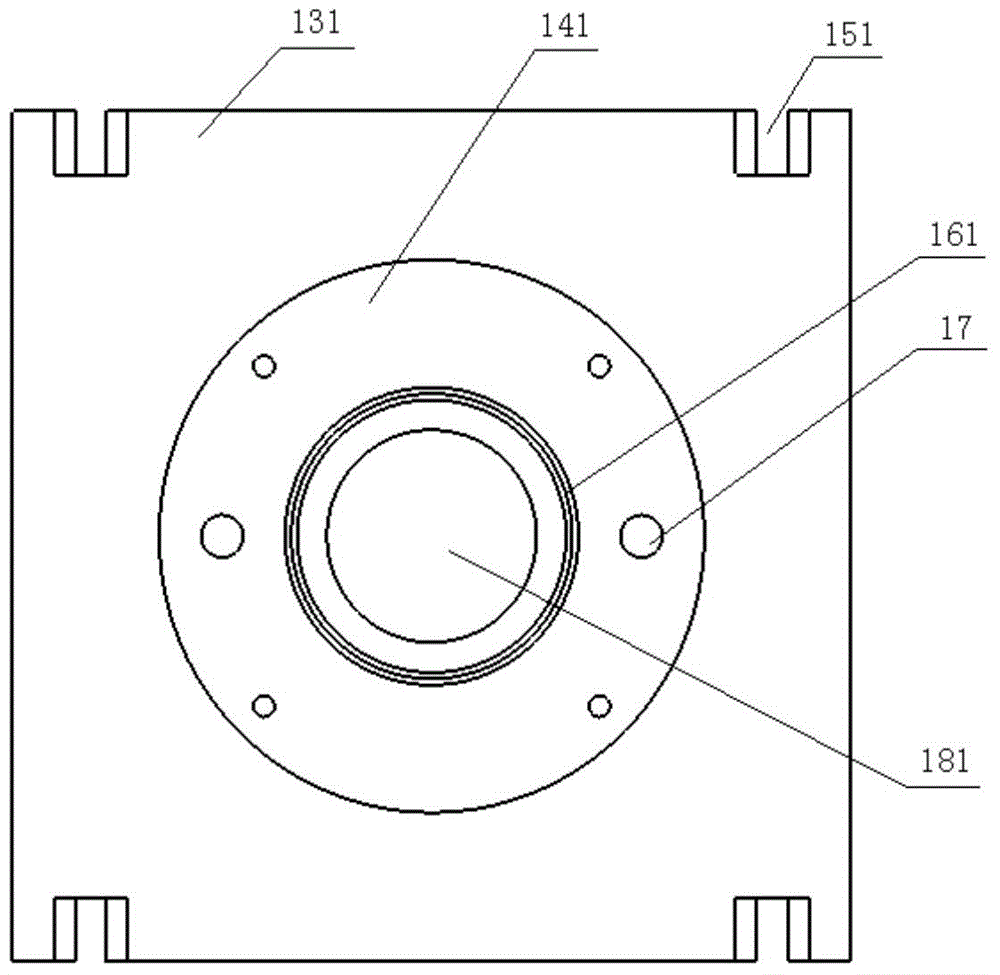

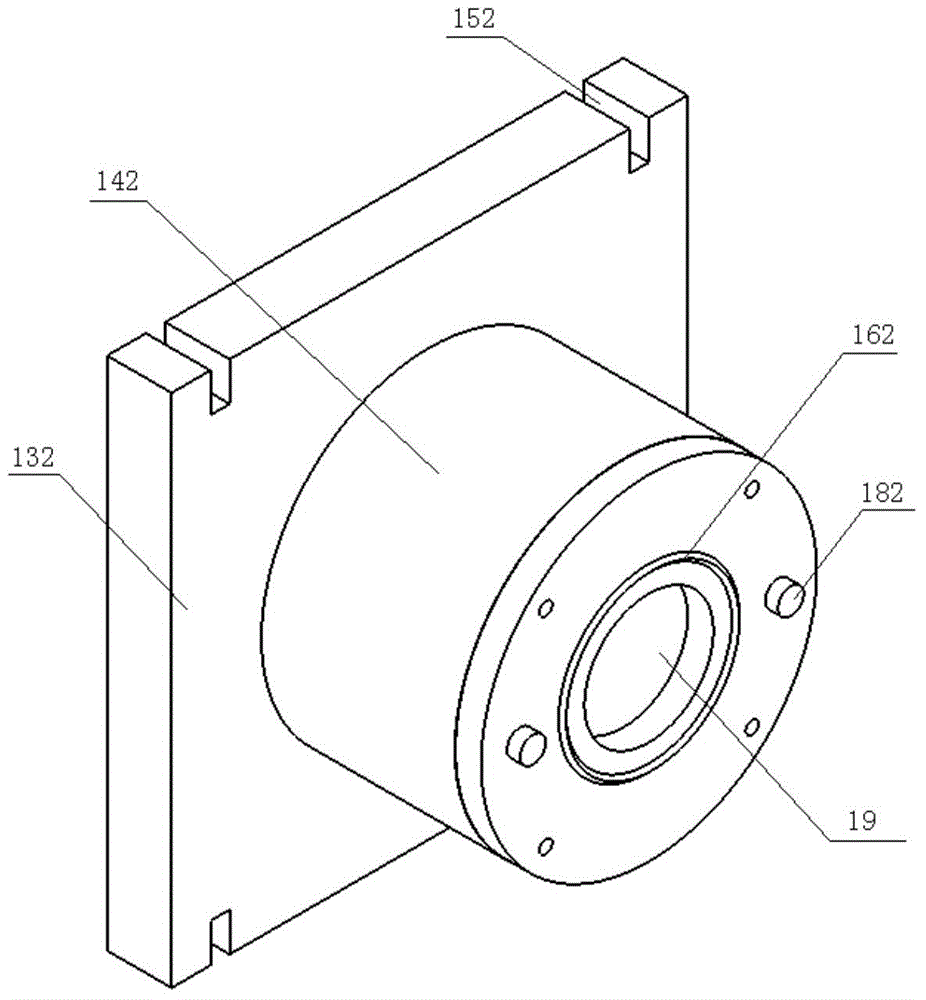

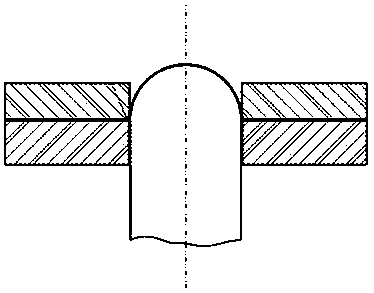

Pipes shaping limit curve test device for hydraulic bulging process

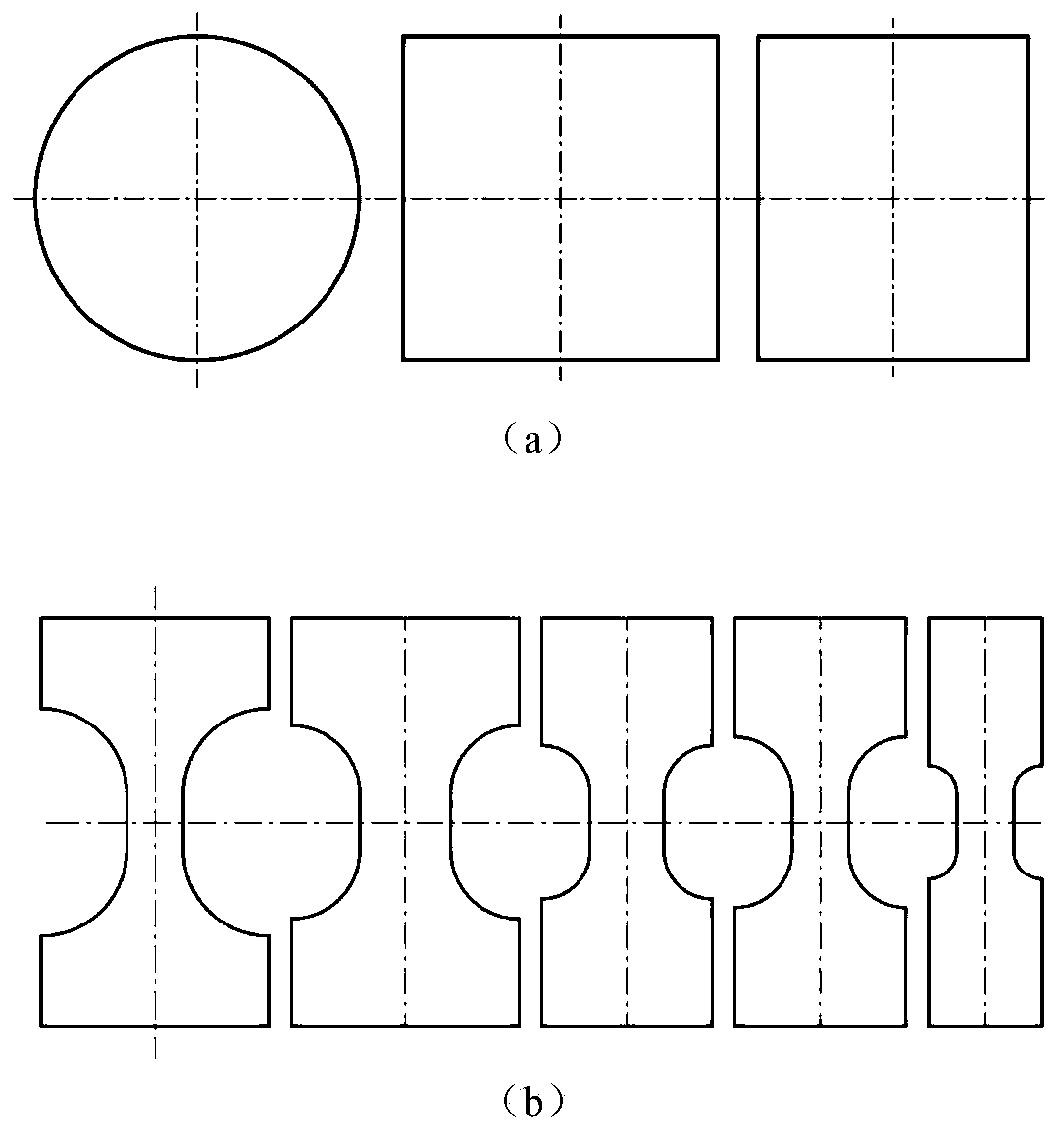

InactiveCN101285749AStrain state changeInvestigating material ductilityMaster cylinderMechanical engineering technology

The invention relates to a testing device for a tube forming limit curve used for the hydraulic bulging technique in the mechanical engineering technical field, comprising an upper die, a lower die and a push rod, wherein, the upper die comprises an upper connecting plate and an upper insert block; the upper connecting plate is connected to a main cylinder of a hydraulic bulging machine; the upper insert block is fixed on the upper connecting plate and positioned through a pin stop; the lower die comprises fixed blocks, a lower die set and a lower insert block; the lower die set is fixed on a worktable of the hydraulic bulging machine and adopts a symmetrical structure; both ends of the lower die set have semi-cylindrical die cavities; the lower insert block is fixed inside a lower die set die cavity; the number of the fixed blocks is two; a semi-cylindrical die cavity is arranged on each fixed block; and the two fixed blocks are fixed on both ends of the lower die set and form two cylindrical die cavities respectively with the two semi-cylindrical die cavities of the lower die set. The testing device not only can make a tube be able to deal with path distortion with linearity or quasi-linearity and reach the state of limit strain but also can make the strain ratio change between -1 and 1.

Owner:SHANGHAI JIAO TONG UNIV

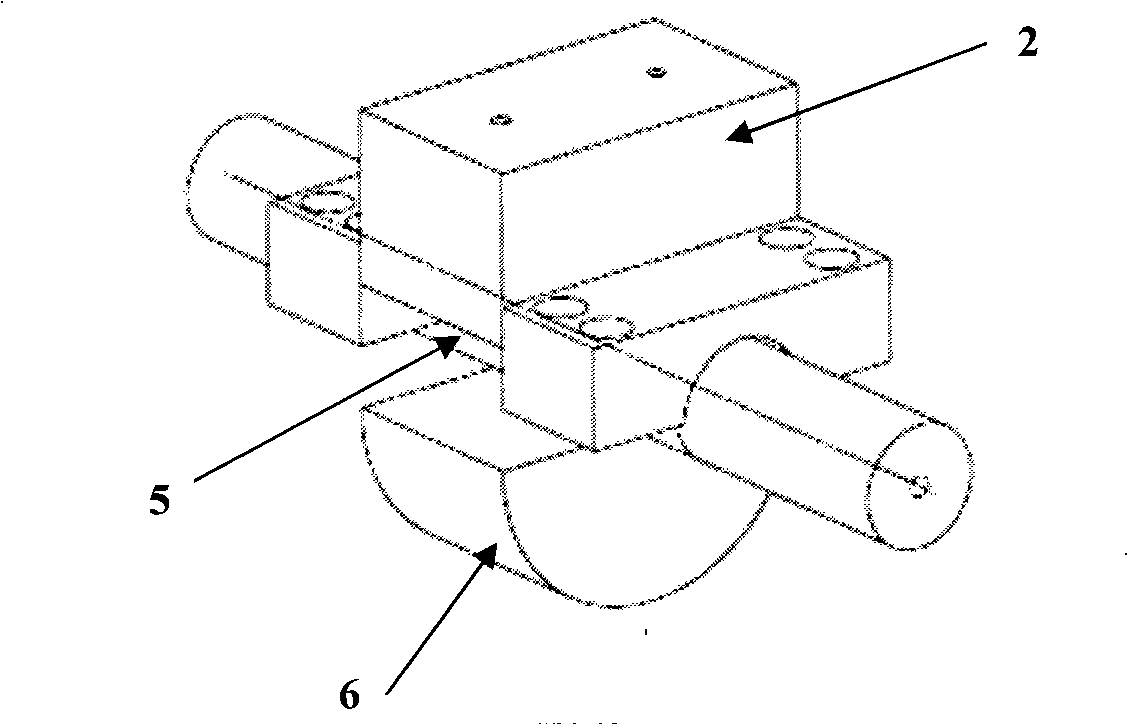

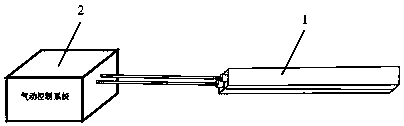

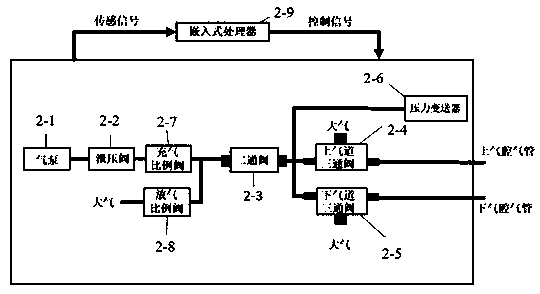

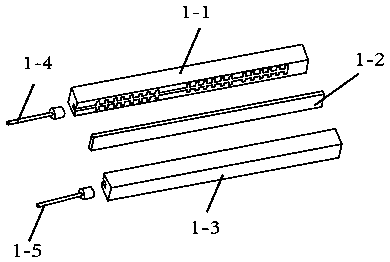

Soft body finger capable of dual-direction bending and manufacturing method thereof

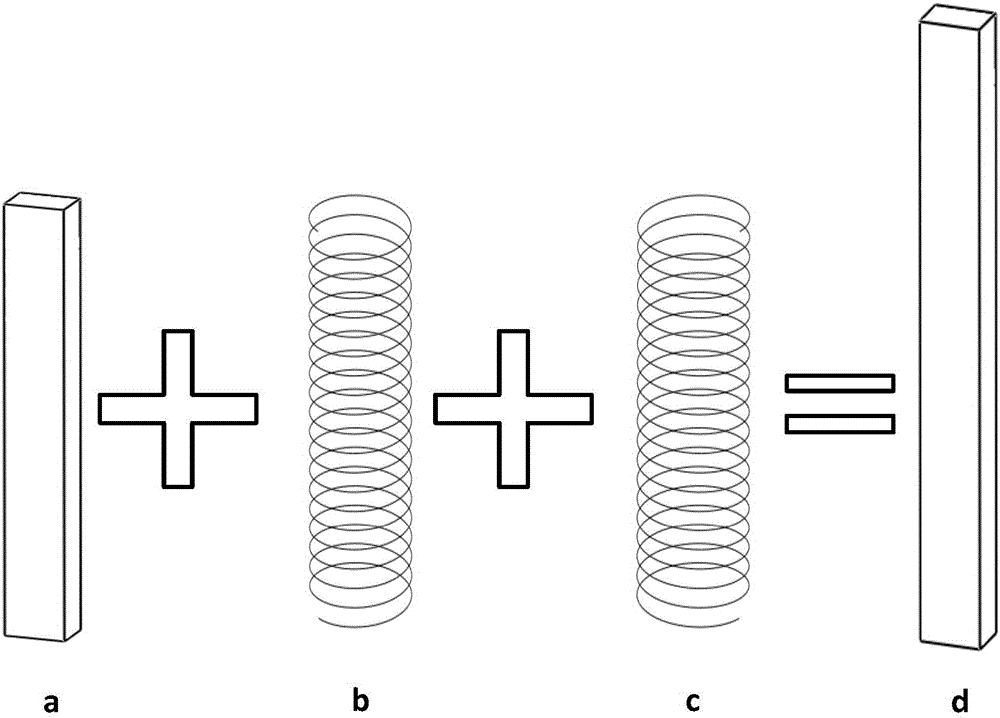

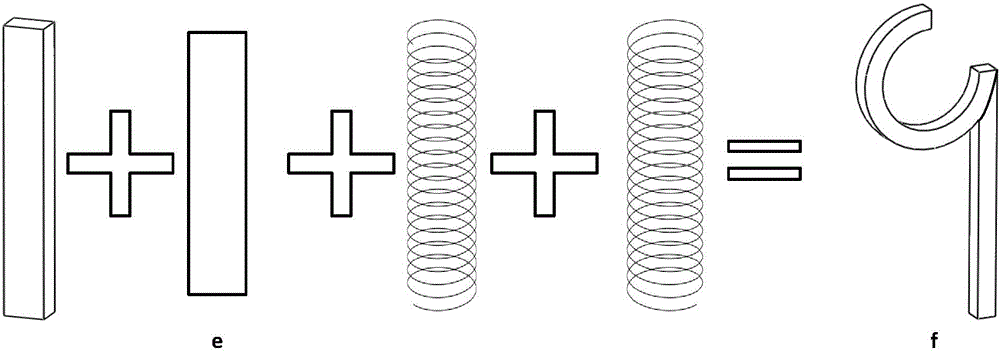

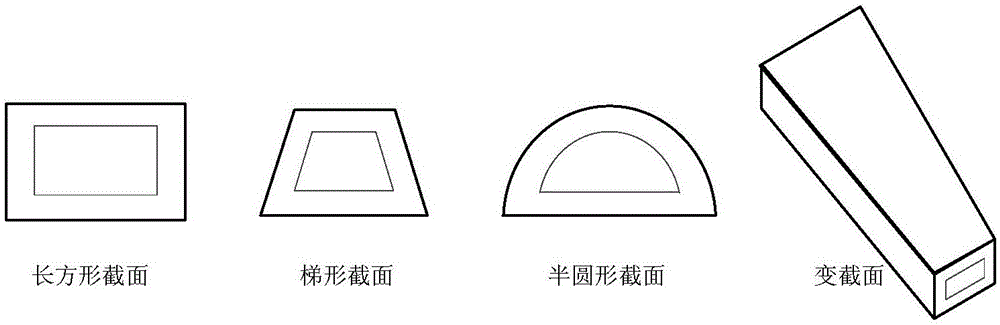

InactiveCN110142796ASolve the inability to achieve the reverse bending effectSolve the problem of poor bendingGripping headsControl systemLimit strain

The invention discloses a soft body finger capable of dual-direction bending and a manufacturing method thereof. The soft body finger capable of dual-direction bending is formed by connecting a soft body finger to a pneumatic control system; the soft body finger comprises an upper soft body enveloping layer, a limiting strain layer, a lower soft body enveloping layer and a pneumatic pipeline whichis connected to the soft body finger; the upper soft body enveloping layer and the soft body enveloping layer are soft body structures made of a silica gel material; the upper soft body enveloping layer and the soft body enveloping layer are axially symmetrical about the limiting strain layer at the middle part, and are bonded into the integral finger through the same silica gel material; the pneumatic control system can receive a command of a user and outputs air according to the command, so that the soft body finger bends and deforms to a required state; and changing of an inflation air cavity of the soft body finger is realized by adjusting the air path, so that dual-direction bending is realized, and requirements of grabbing or assistant rehabilitation training are met. By adopting the soft body finger capable of dual-direction bending, the application range of the soft body finger is expanded; and the soft body finger can be applied to the fields of soft body grabbing, soft bodycapturing, soft body rehabilitation and the like.

Owner:SHANGHAI UNIV

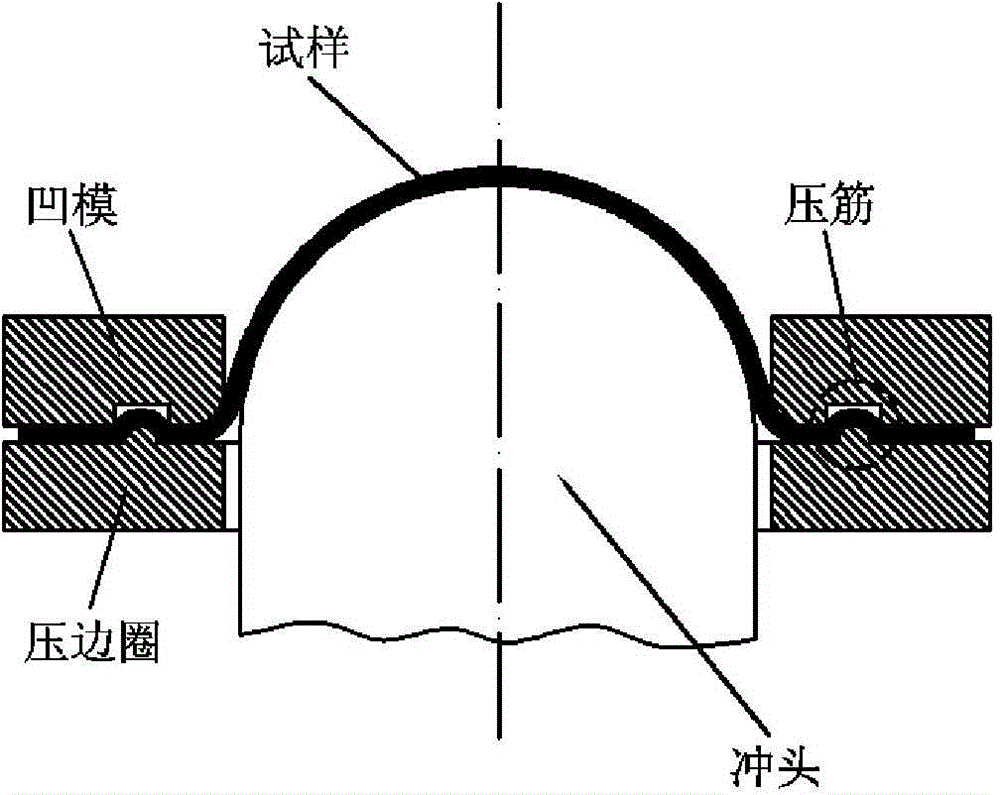

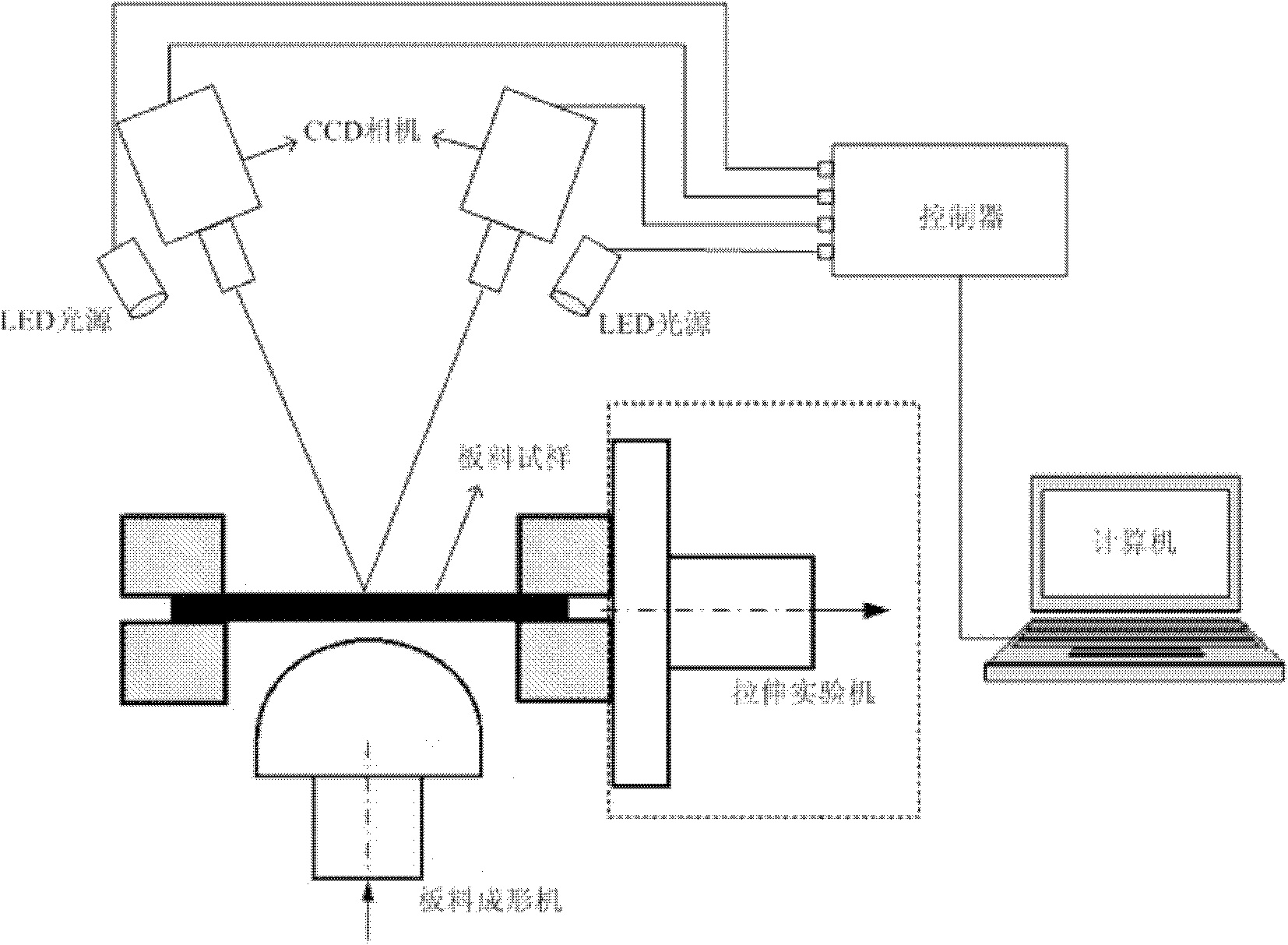

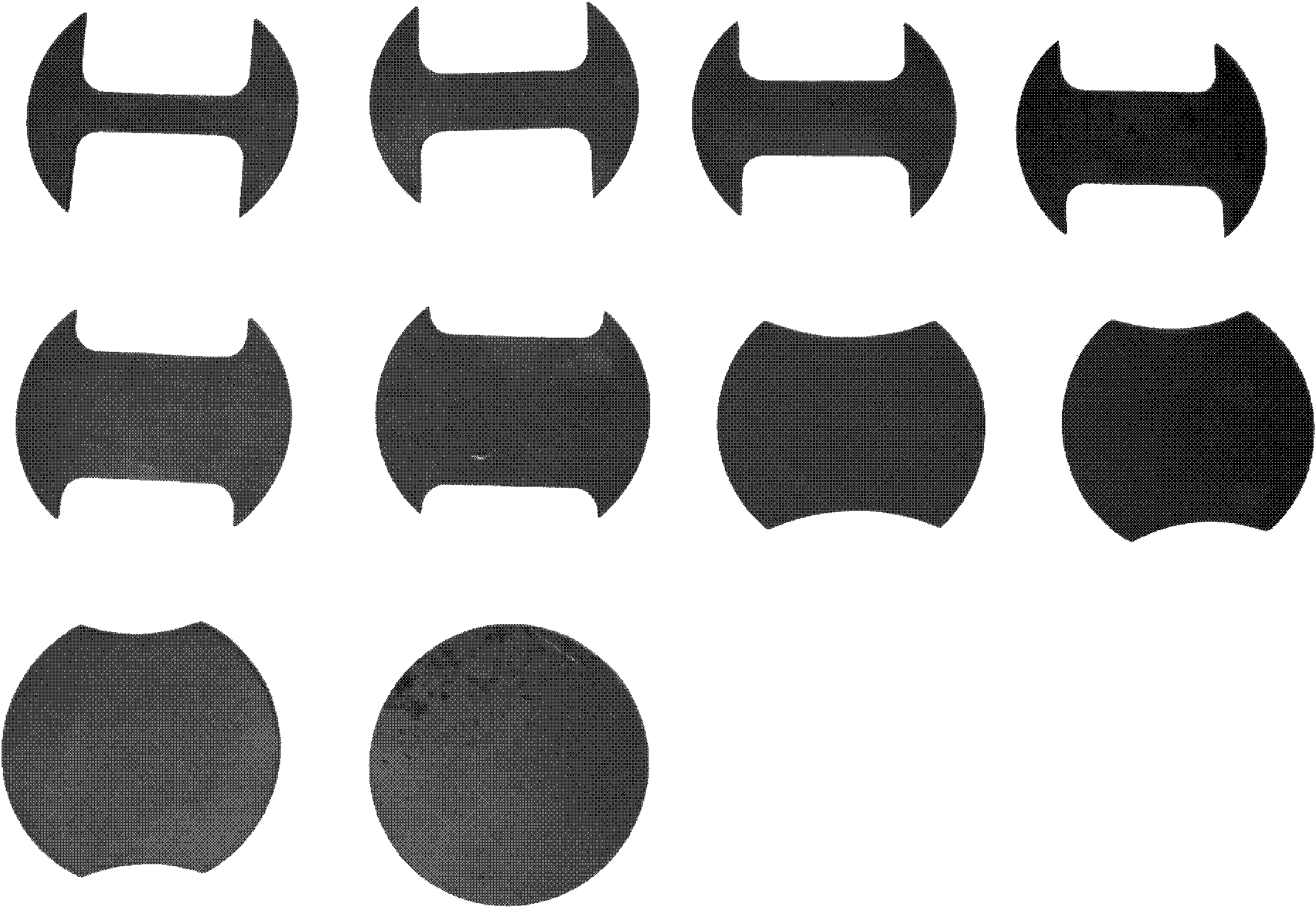

DIC technology-based automobile thin plate FLC curve determination device and method

InactiveCN105223090AReduce usageEasy to observeInvestigating material ductilityHydraulic cylinderTest sample

The invention discloses a DIC technology-based automobile thin plate FLC curve determination device and method. The device comprises a material tester, a video camera, a computer and a bulging tester. The bulging tester comprises an upper base, a female die, a blank holder, a lower base and a puncher pin. The upper base is fixed to an installation platform of the material tester, the female die is connected to the lower surface of the upper base, the blank holder is installed on the upper surface of the lower base, the lower base is fixed to a lifting platform of the material tester and the puncher pin is installed on a hydraulic cylinder. The method comprises tightly clamping a test sample between the female die and the blank holder by the lifting platform, punching the test sample to produce cracks by the puncher pin under the action of the hydraulic cylinder, shooting a test sample mesh deformation process by the video camera, computing a limiting strain value by the computer through DIC software, changing the test sample until all limiting strain values of all the samples are obtained, and drawing a FLC curve of an automobile thin plate by connection of all the limiting strain value points. The device and method are convenient for operation, save time and labor, greatly improve a measurement precision and are convenient for observation and research of necking phenomenon.

Owner:ANGANG STEEL CO LTD

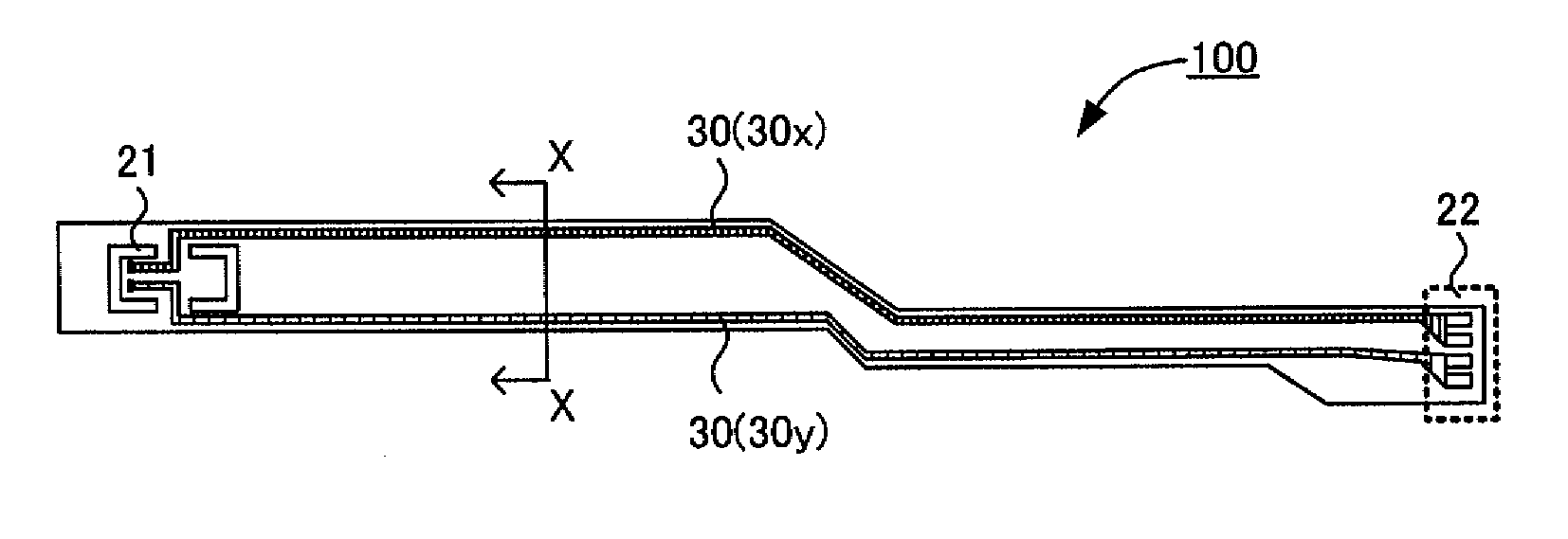

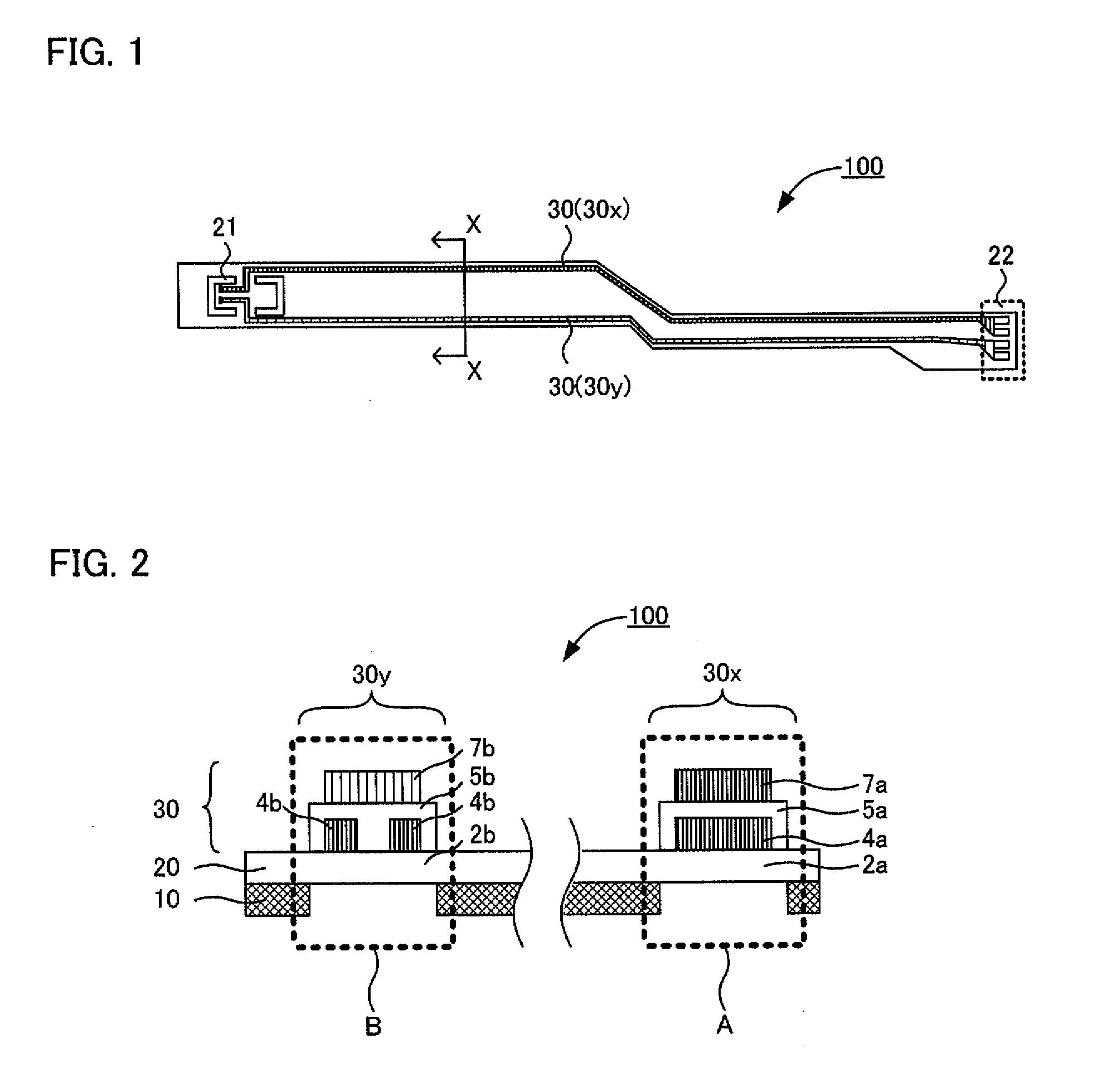

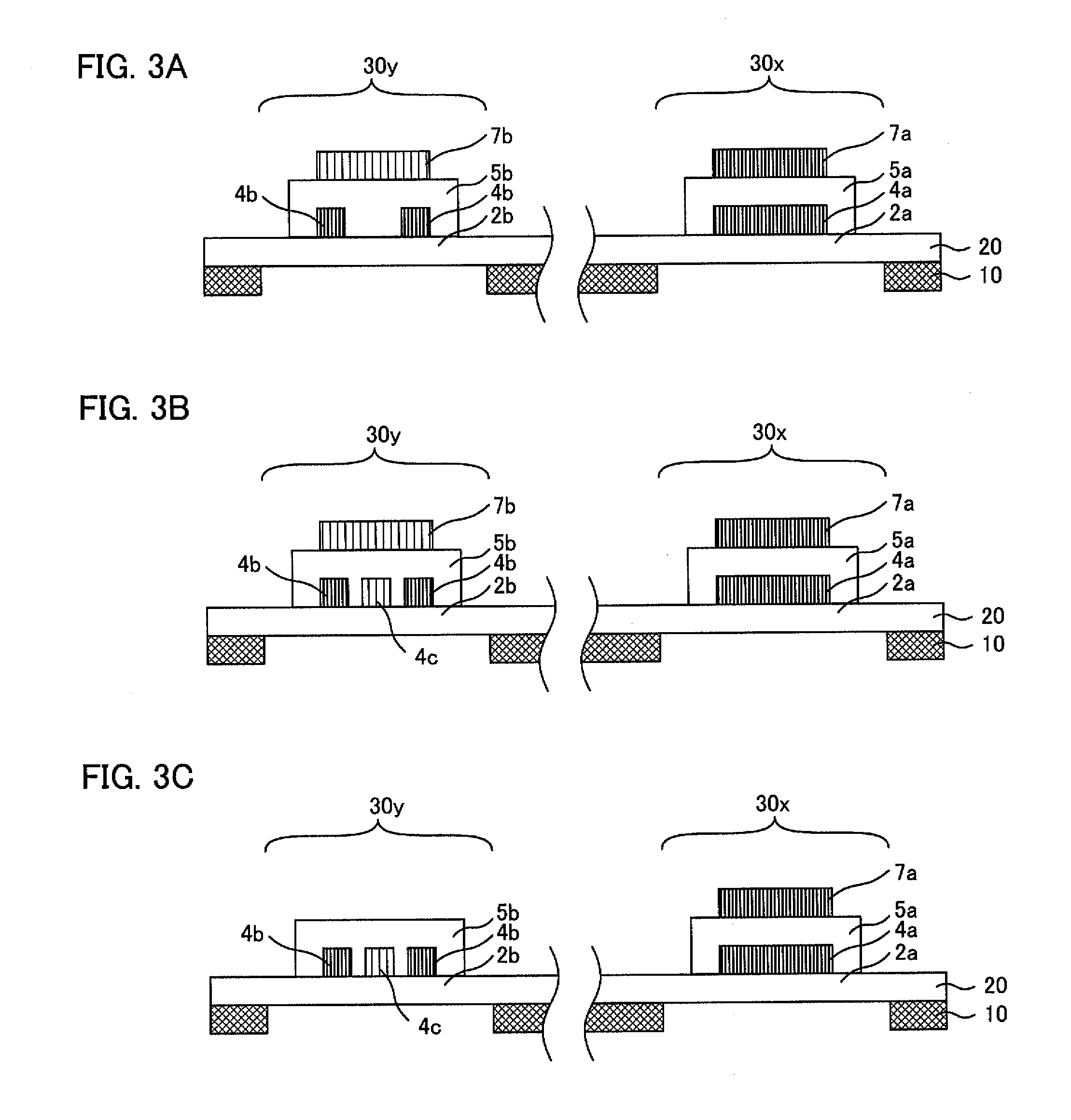

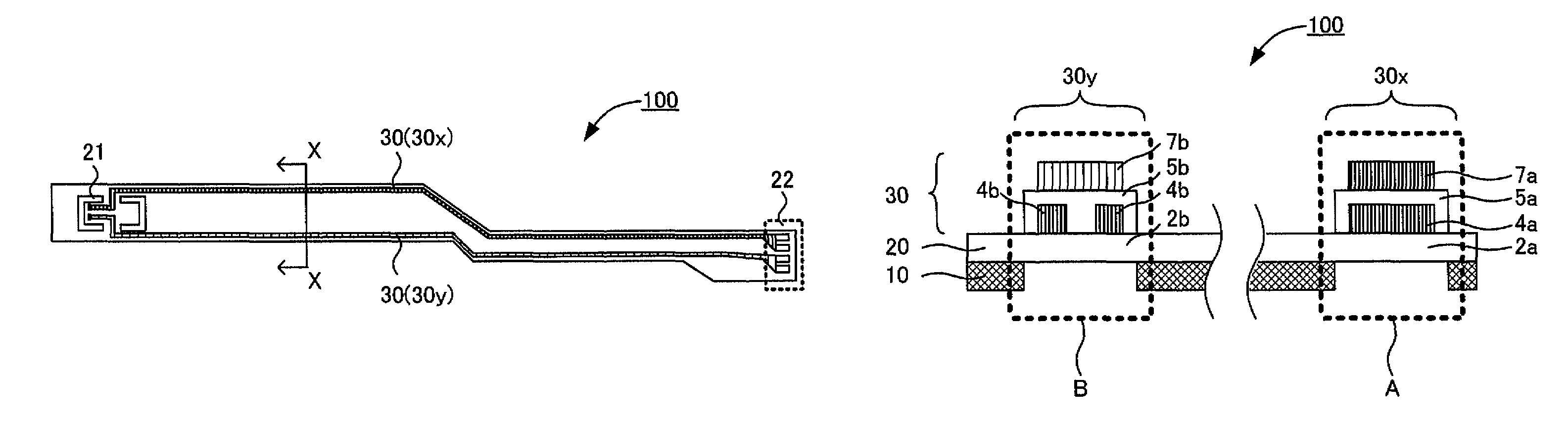

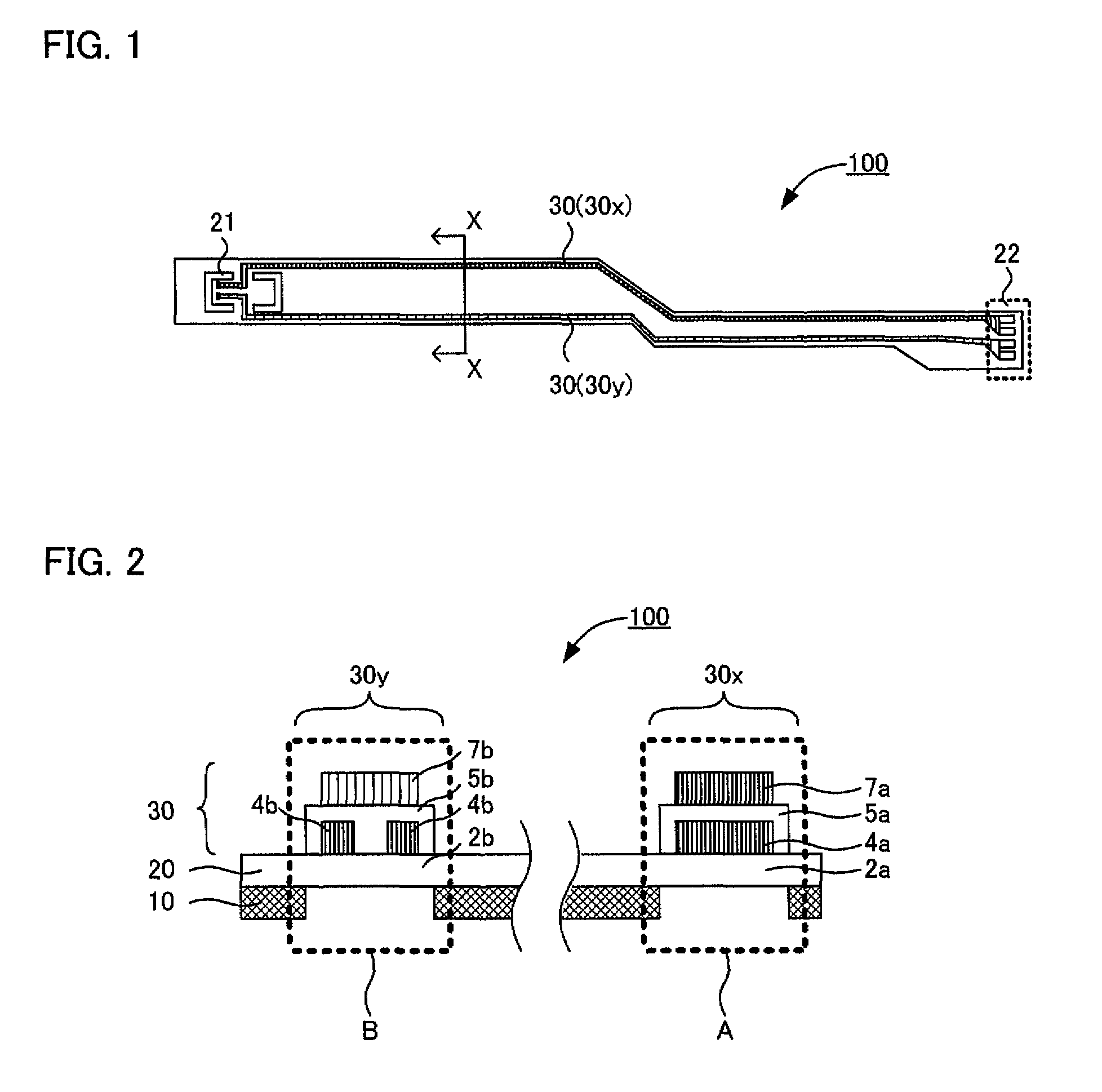

Suspension substrate, suspension, head suspension and hard disk drive

InactiveUS20100142097A1Relieve pressureDisposition/mounting of recording headsPrinted circuit aspectsHard disc driveInsulation layer

It is a primary object of the present invention to provide a suspension substrate having reduced strain. The present invention solves the problem by providing a suspension substrate comprising: a fundamental structure in which a metal substrate, a first insulation layer, and a wiring are laminated in this order; a wide wiring laminate structure provided with a wide wiring first insulation part of the first insulation layer, a first wide wiring formed on the wide wiring first insulation part, a second insulation part formed on the first wide wiring, and a second wide wiring formed on the second insulation part; and a narrow wiring-containing structure provided with a narrow wiring first insulation part of the first insulation layer and a first narrow wiring formed on the narrow wiring first insulation part, wherein the narrow wiring-containing structure is provided with a strain-limiting part formed to limit strain generated in relation to the wide wiring laminate structure.

Owner:DAI NIPPON PRINTING CO LTD

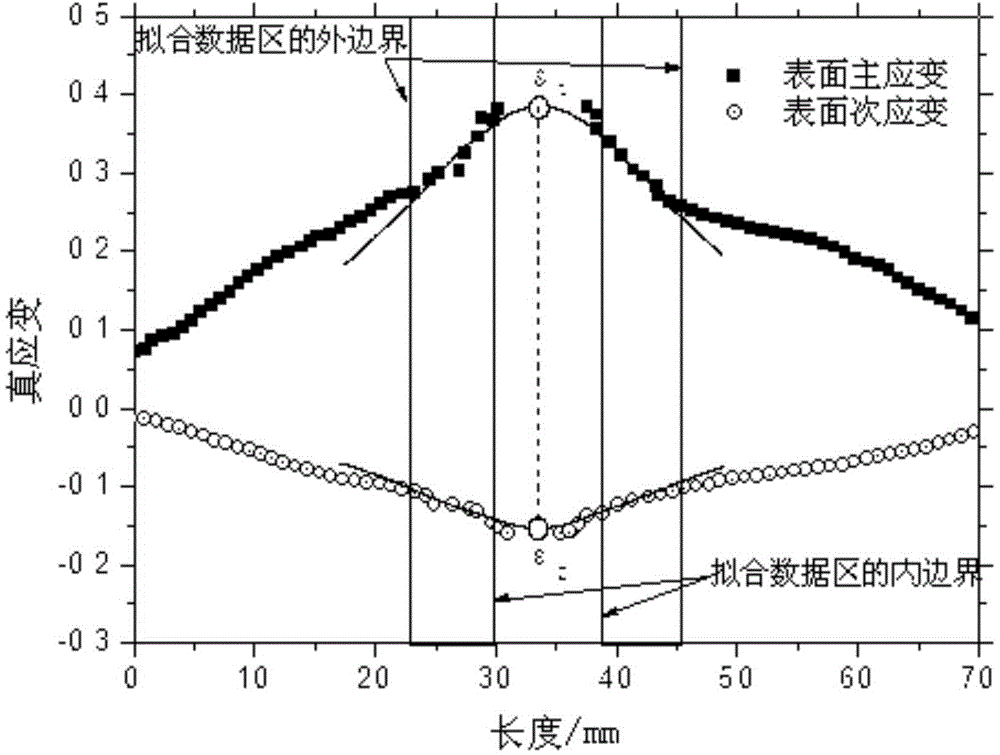

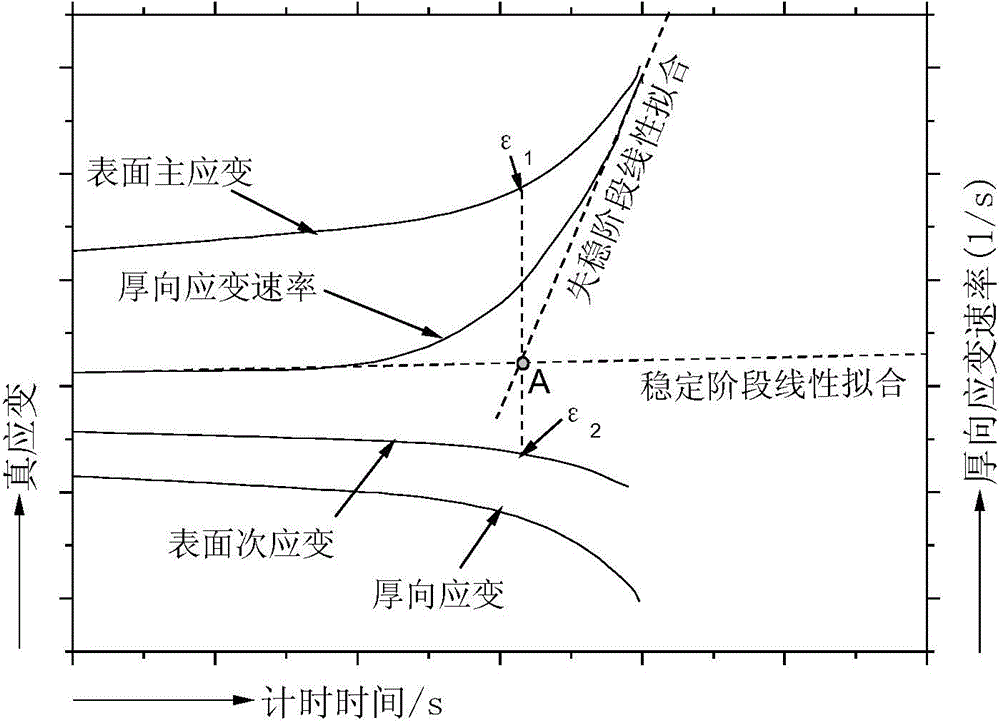

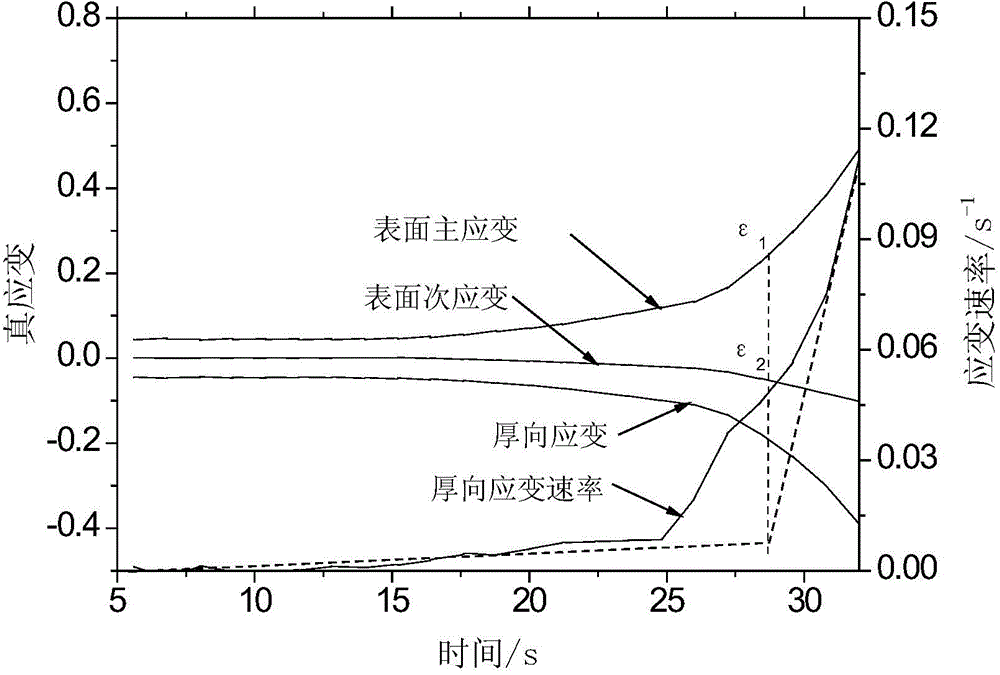

Time-based sheet forming limit determination method

The invention discloses a time-based sheet forming limit determination method and belongs to the technical field of stamping processes. The time-based sheet forming limit determination method comprises the following steps: establishing a steel ball die bulging test; performing the steel ball die bulging test on a sheet material, and shooting a bulging sample until the sheet material is broken; obtaining a previous frame of image of the sample which is just broken according to a shot photo, taking a breaking point as a center, and selecting a region near the part close to the breaking point as an inspection region; obtaining primary and secondary surface strain mean values of the inspection region; performing calculation to obtain primary thickness direction strain and thickness direction strain rate; and obtaining data at stable and instable stages according to the thickness direction strain rate, and comparing the data at stable and instable stages to obtain a forming limit point. The time-based sheet forming limit determination method is capable of really determining limit strain of just happened tightening or cracking to fully reflect in-situ deformation situation of an inspection point.

Owner:SHOUGANG CORPORATION

Thermoset hybrid fabric composite material and preparation method and application thereof

ActiveCN101845166AImprove performanceImprove impact resistanceSuperstructure subunitsInterlaminar shearLimit strain

The invention discloses a thermoset hybrid fabric composite material and a preparation method and application thereof. The thermoset hybrid fabric composite material is mainly prepared from the following raw materials in percentage by volume: 10-65% of carbon fiber, 5-60% of UHMWPE fiber, 20-30% of vinyl resin, 0.5-2% of curing agent and 0.6-2% of accelerator. The composite material enables the carbon fiber and the UHMWPE fiber to be in hybrid use at a specific ratio so as to complement the advantages of the two to obtain the thermoset composite material with favorable combination property, the elastic modulus thereof approaches to 45 GPa, and limiting strain reaches 2-3%. Compared with the common carbon fiber reinforced composite material, the thermoset hybrid fabric composite material has obvious yield behavior, high interlaminar shear strength and favorable adhesive property and can be used for preparing automobile structures so as to improve the shock resistance of the automobiles.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

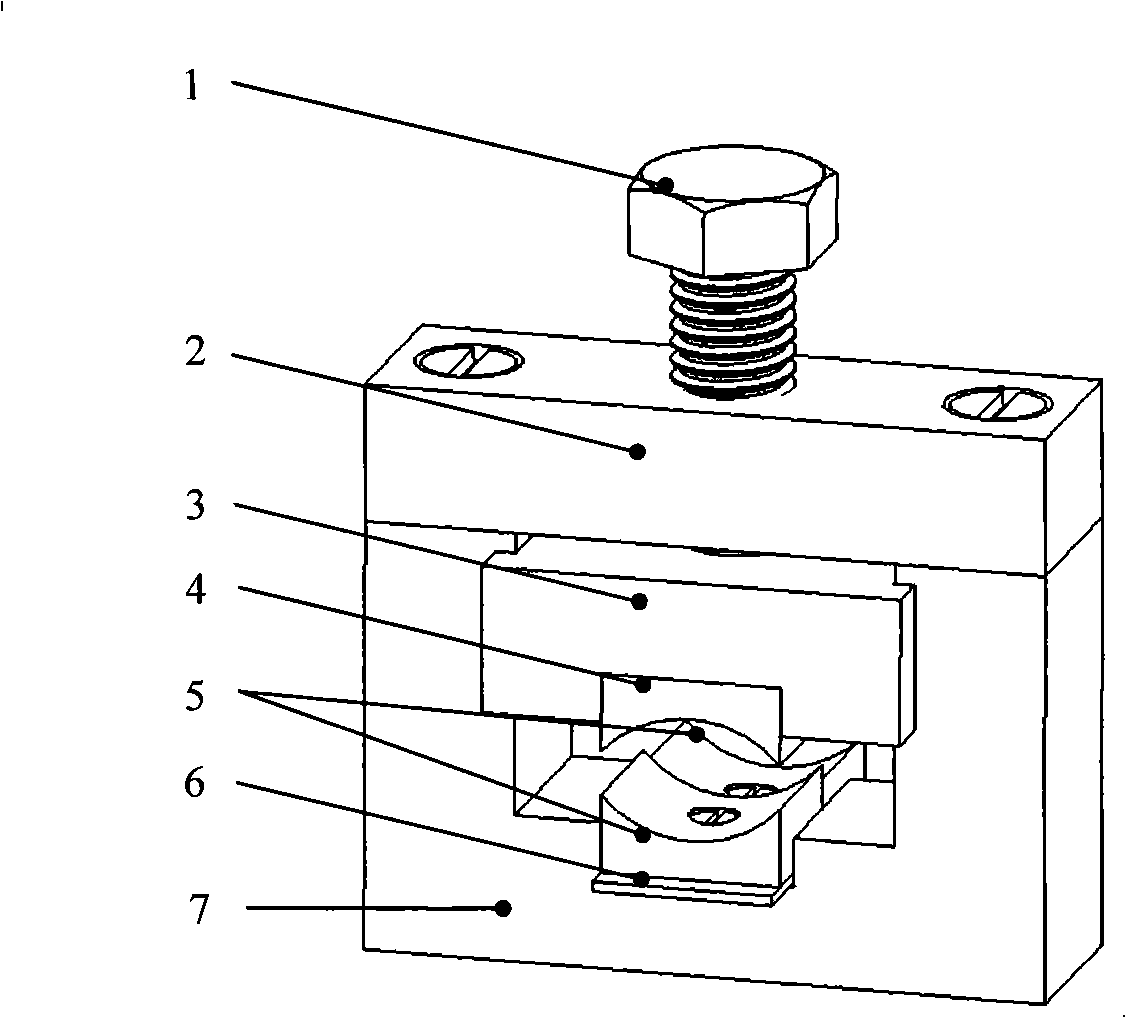

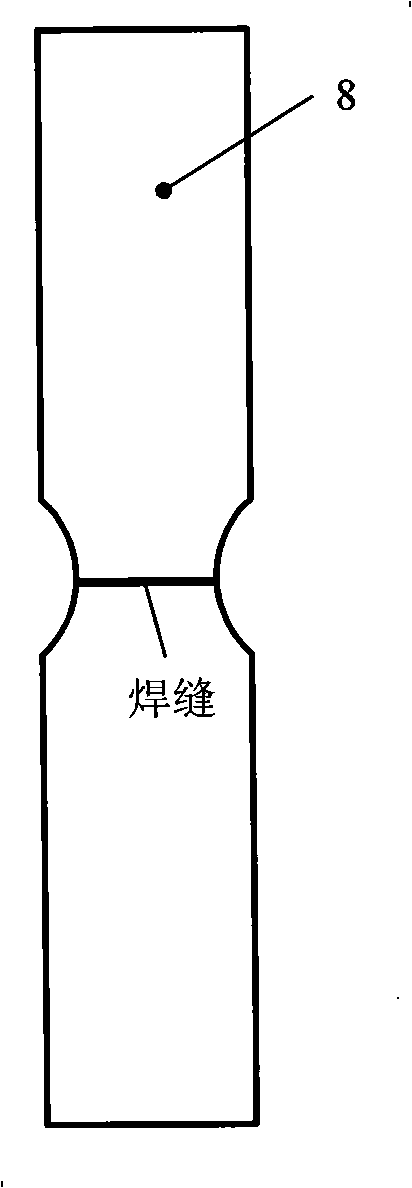

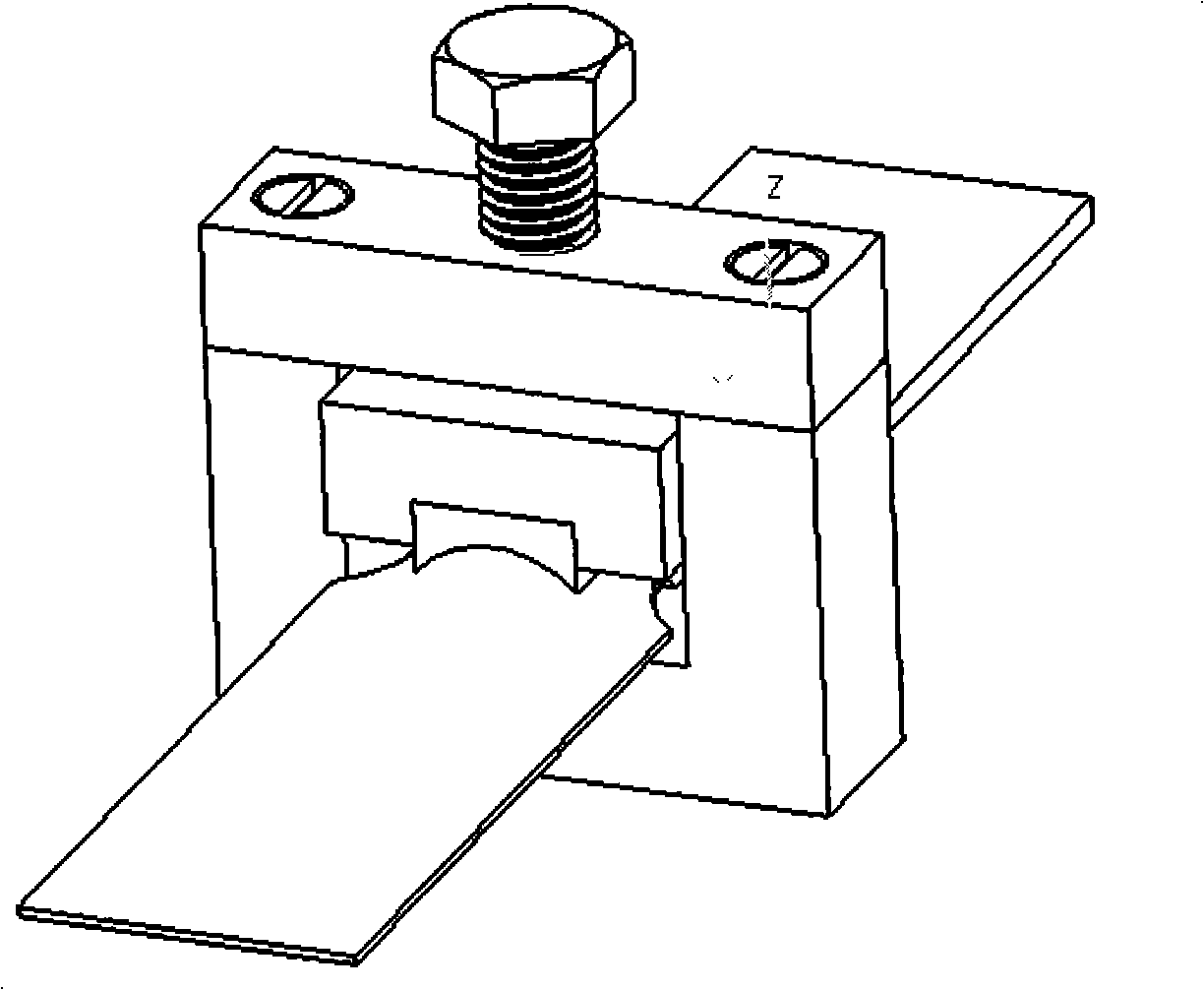

Test device and method for acquiring limit strain of laser tailor welded plate plane with different thickness

InactiveCN101294947AAccurately obtainedEasy accessTesting metalsWelding apparatusTest efficiencyLimit strain

The invention discloses a tester and method for obtaining plane limiting strain of a differential tailor welding blank; the method comprises the following steps: a splint mechanism consisting of an upper clip and a sectional lower clip, a welding blank tensile sample is positioned between the upper clip and the sectional lower clip; a height adjusting sheet is arranged between sectional lower clip and a base, the sectional lower clip and the height adjusting sheet are fixed on the base, a sliding block is arranged between the upper clip and a top pressing plate, the upper clip and the sliding block are fixedly connected by adopting a bolt passing through the middle of the top pressing plate, the tester is arranged in a conventional plate tensile test machine for uniaxial tension test and the limiting strain value is measured; the tester and method of the invention can obtain better plane strain state, have stable test result, simple structure, low test cost, simple and convenient operation, and high test efficiency and the sample is flat after the test.

Owner:JIANGSU UNIV

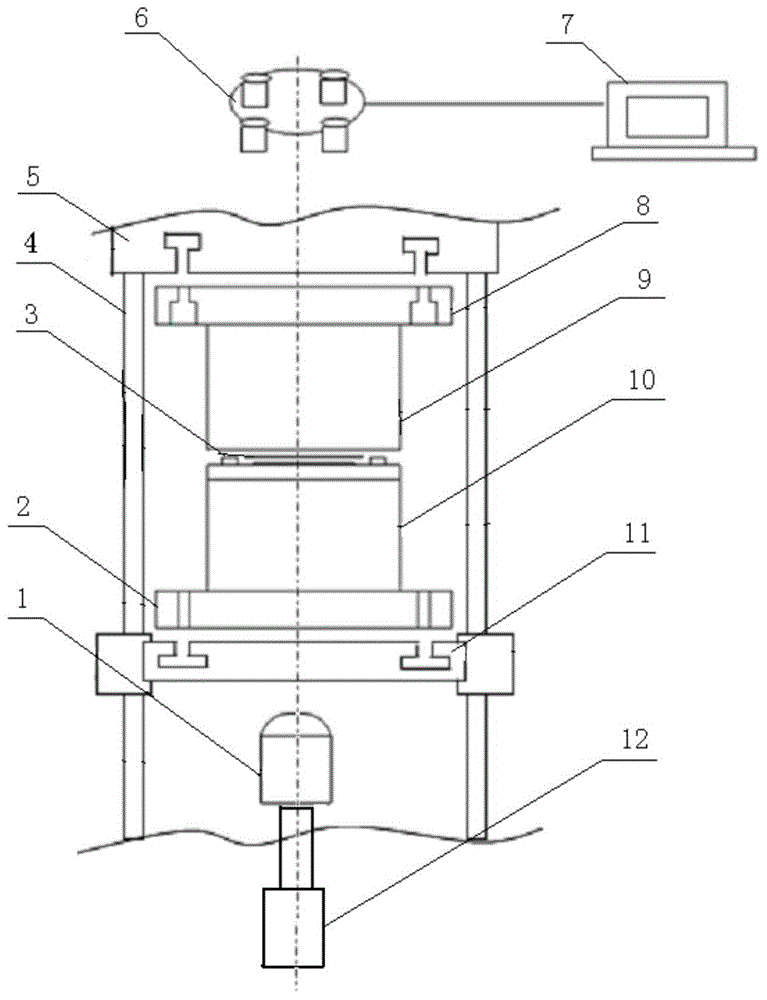

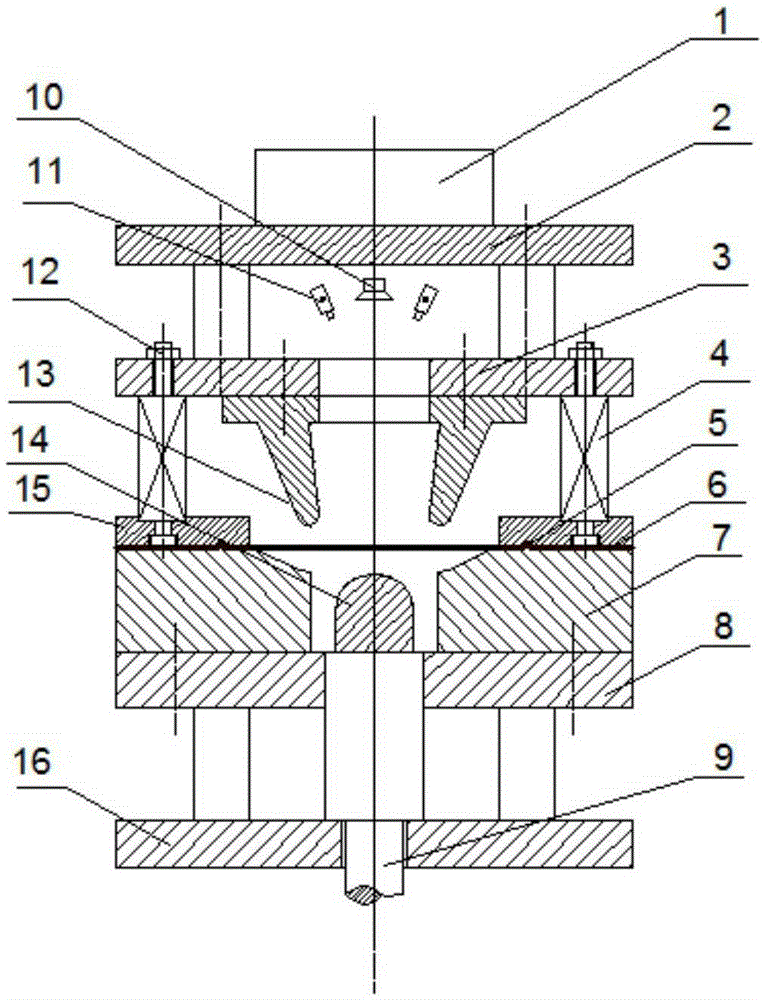

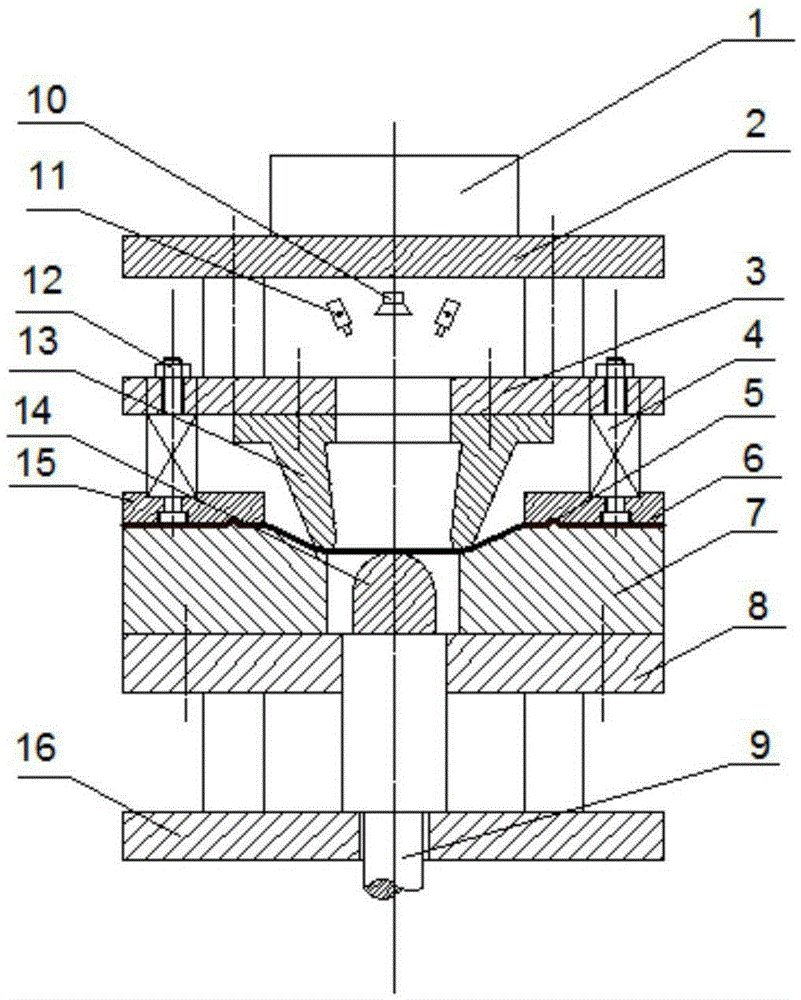

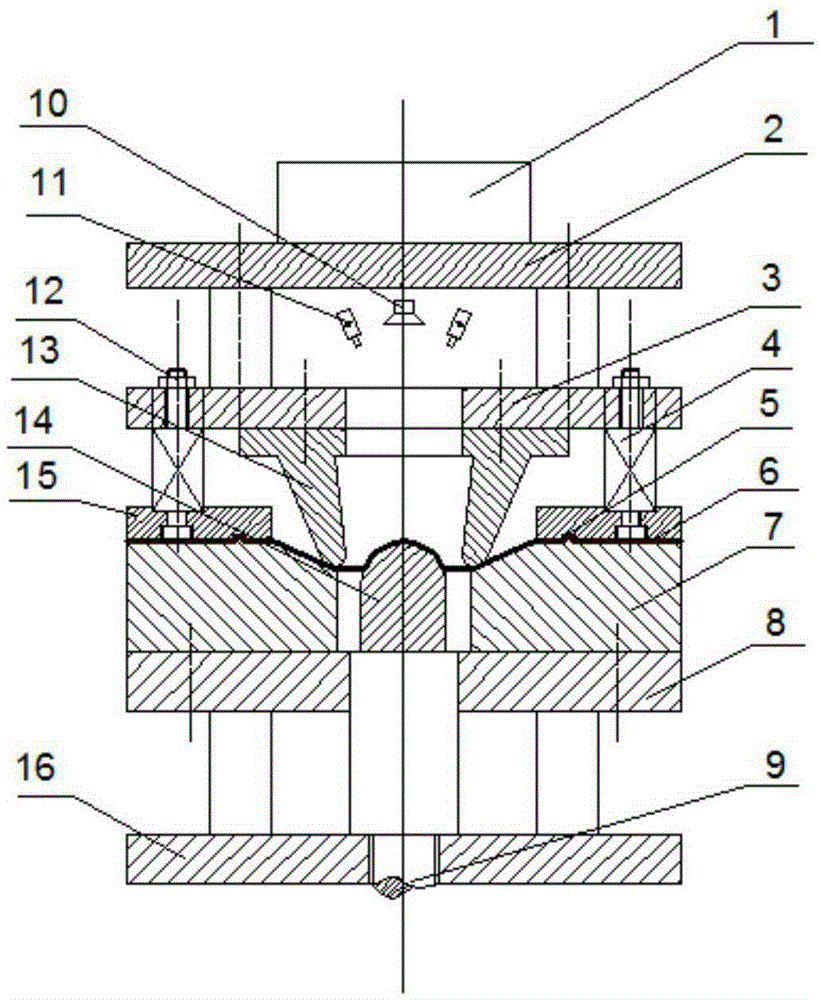

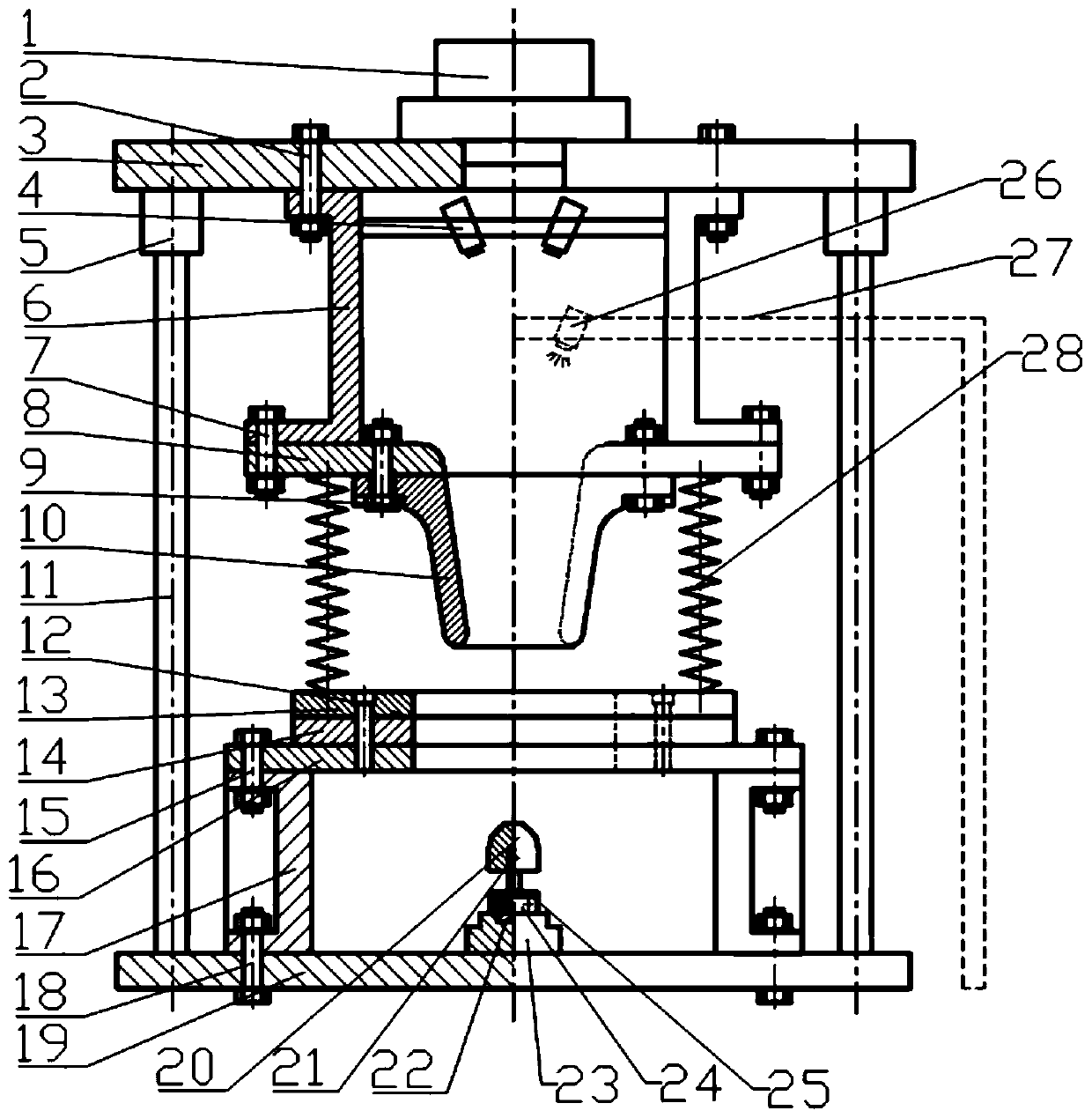

Forming limit measuring device under bilinear strain path and testing method

InactiveCN105300816ARealize the forming limit measurement problemSolve the problem of not being able to accurately evaluate the instability of the partInvestigating material ductilityTest sampleLimit strain

The invention provides a forming limit measuring device under a bilinear strain path and a testing method, and belongs to the technical field of metal sheet forming. The forming limit measuring device comprises a main cylinder, an upper cross beam, a blank pressing cross beam, a blank pressing spring, a draw bead and the like. The method comprises the steps that a test sample is fixed on a blank pressing ring, a camera and an illuminating lamp are fixed on the upper cross beam, and focusing of a measuring system is completed; an upper male die moves downwards to drive the test sample to generate stain, and after the upper male die makes contact with and tightly presses a female die, a reverse-drawing male die moves upwards under the driving action of a lower ejection cylinder until the test sample is necked or broken; stain at the necked or broken position is measured by adopting a strain testing and analyzing system to obtain the forming limit of the material under the bilinear strain path. The forming limit measuring device under the bilinear strain path and the testing method have the advantages that the limit strain of the sheet under the bilinear strain path can be quickly and accurately measured.

Owner:SHOUGANG CORPORATION

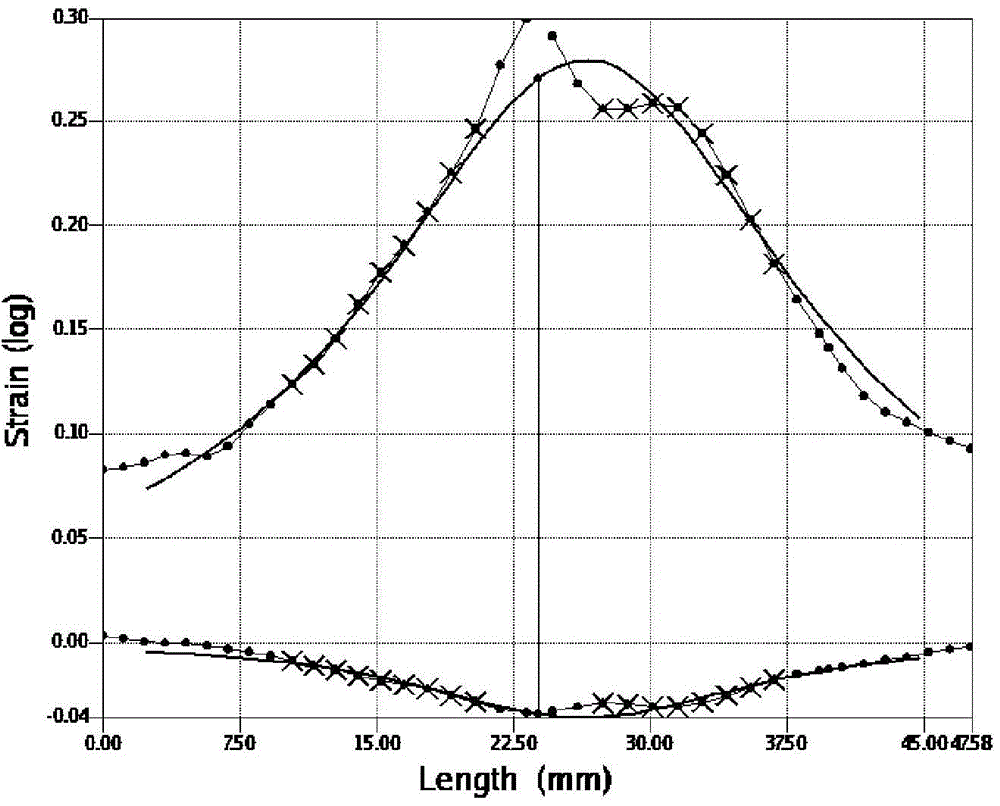

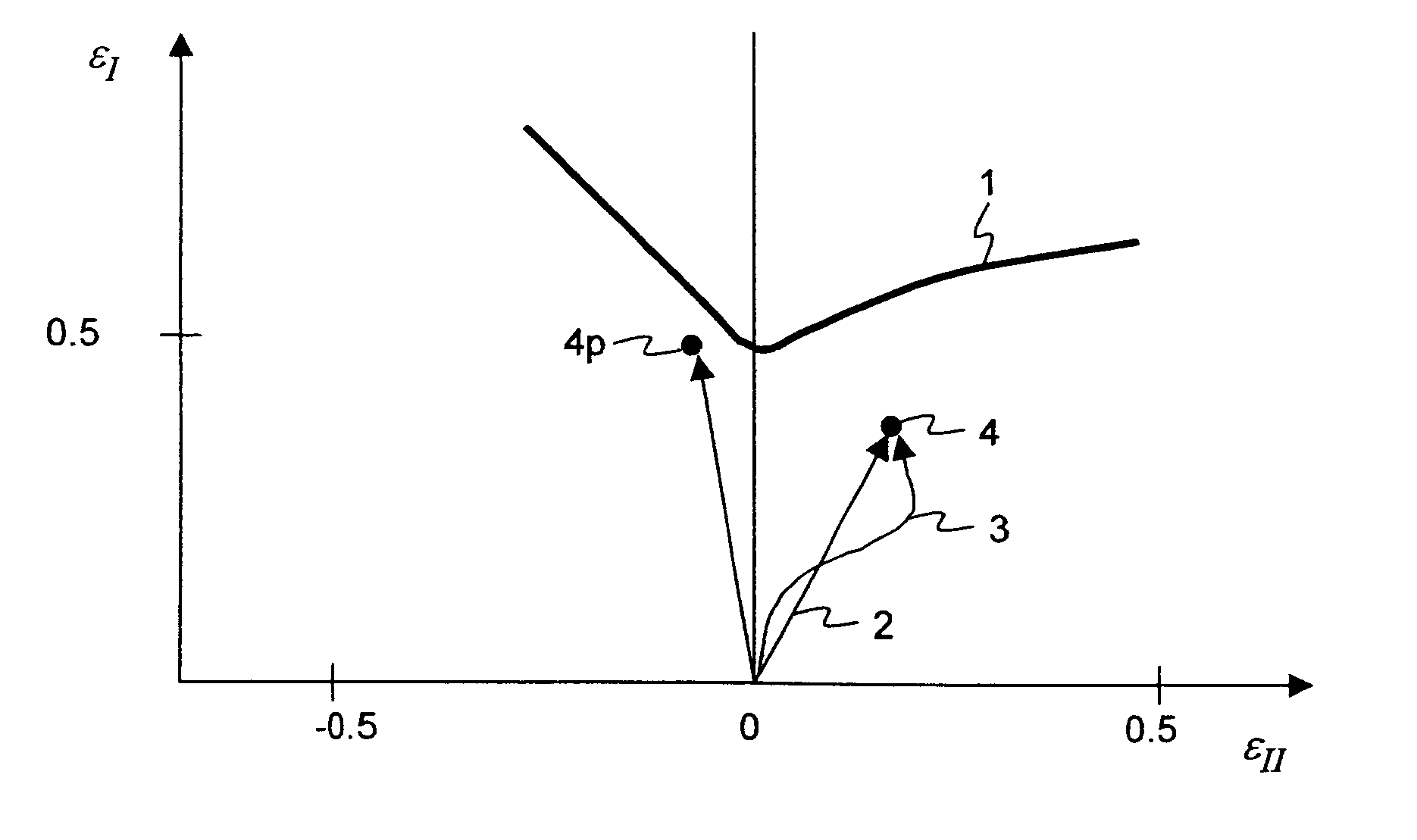

Forming limit strain analysis

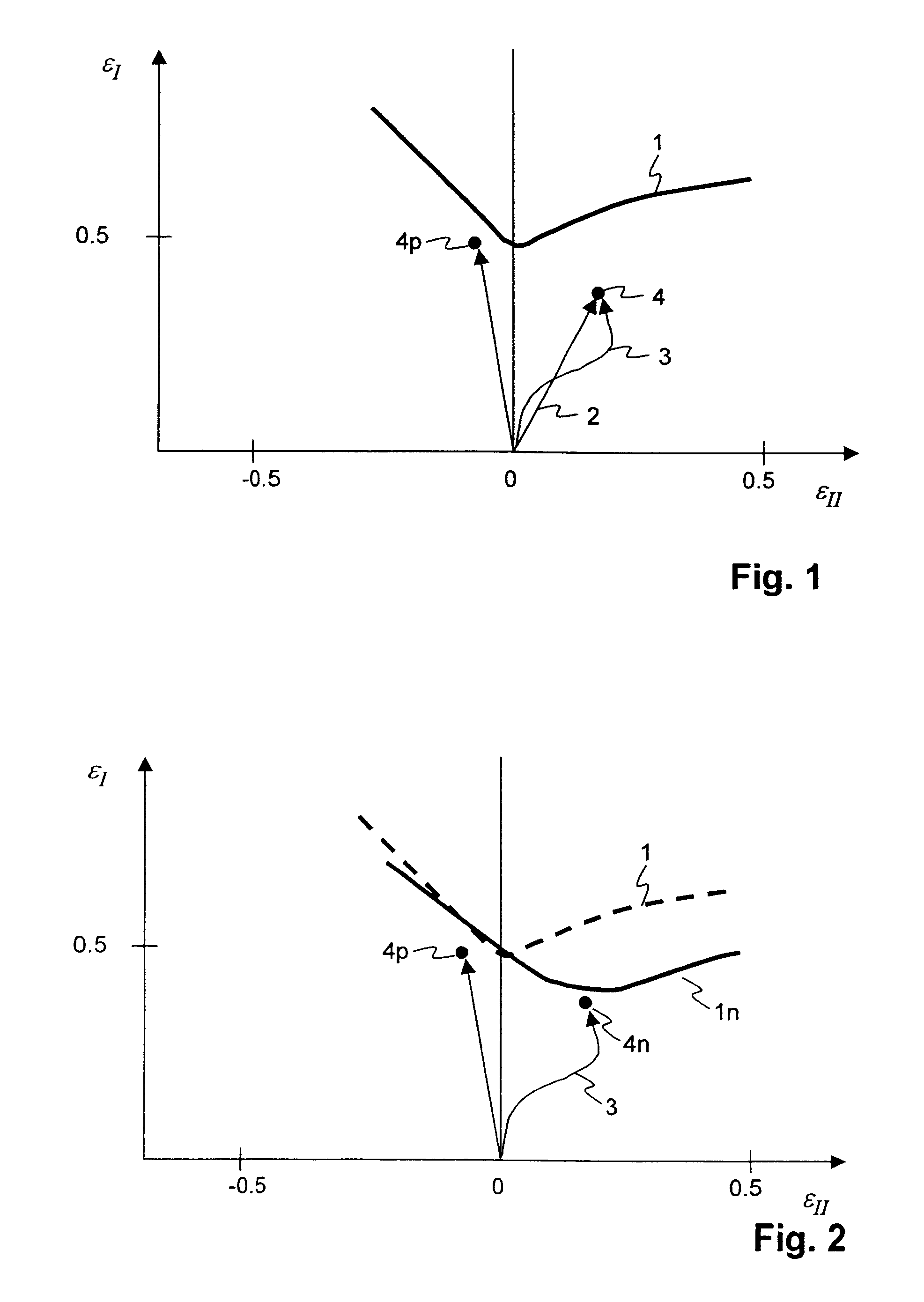

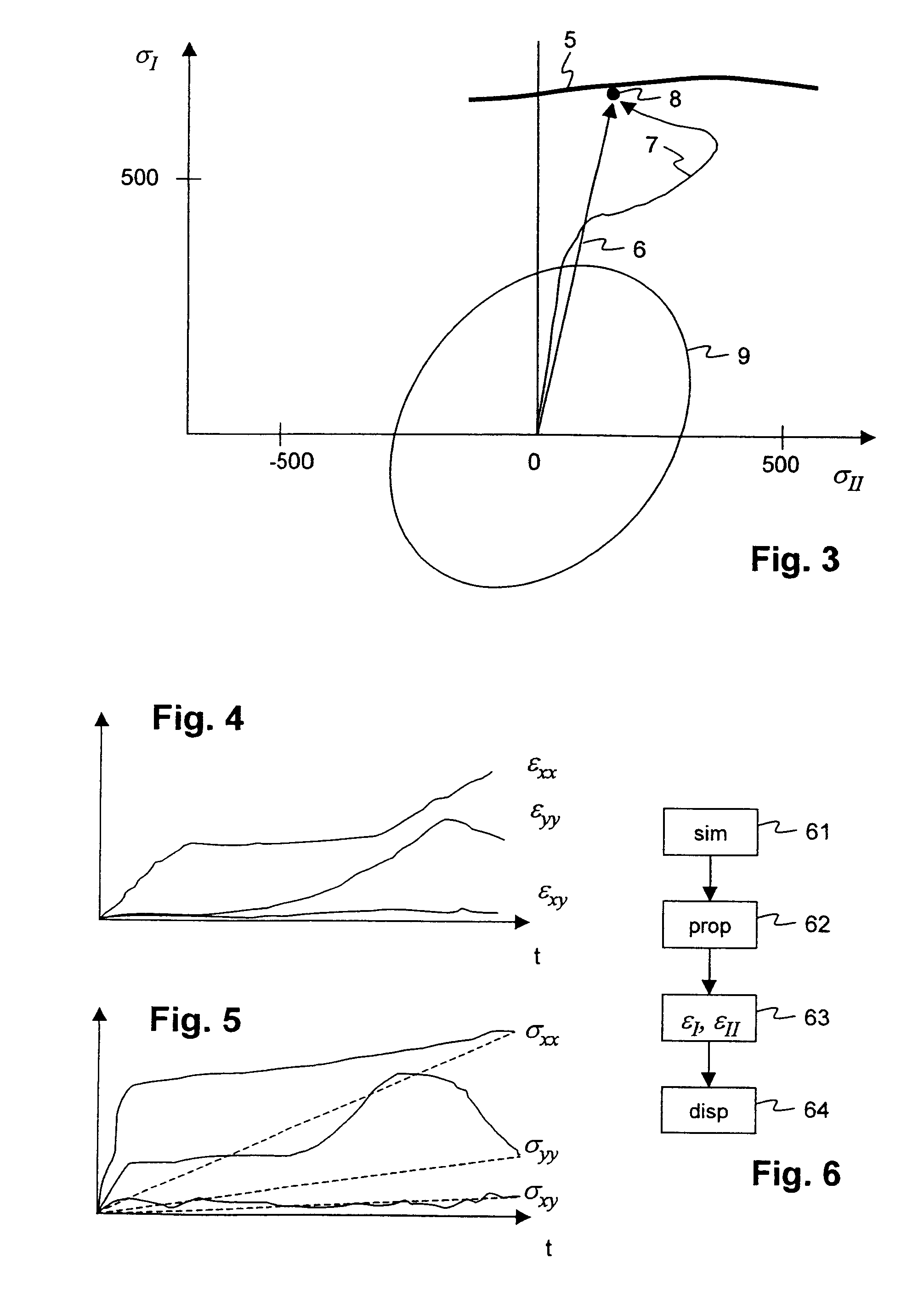

ActiveUS7870792B2Simplified representationEnhanced informationGeometric CADMaterial strength using tensile/compressive forcesState variableLimit strain

In the computed-based analysis of forming processes, for example, manufacturing sheet metal parts for the automobile industry, the material loading is represented by major and minor strains εI, εII and is visualised with respect to a forming limit strain curve. In the method according to the invention, one proceeds from a target state (4n) of the material, as has been determined in the computed simulation of the forming process. A proportional trajectory of a loading and thus of the state variables of the material, in particular of the stresses (σ), is determined, which leads to the same target state. The associated proportional strain trajectory is evaluated for this proportional loading trajectory. The strain state (4p) which results from this strain trajectory, is called the equivalent strain state (4p) and may be used in the forming limit strain diagram for assessing the target state. Thereby, the equivalent strain state is set in relation to the forming limit strain curve (1) for the proportional trajectories.

Owner:NETABTAL MASCHEN

Experimental method for building forming limit diagram of transformation induced plasticity steel plate

InactiveCN101599094AEfficient evaluation of formabilityReduce testing workloadSpecial data processing applicationsForming limit diagramPunching

The invention discloses an experimental method for building forming limit diagram of transformation induced plasticity steel plates, relating to the building method of forming limit diagrams. The method of the invention comprises the following steps: (1) the thickness and the strain hardening index of the transformation induced plasticity steel plate are determined; (2) the limit strain value of the transformation induced plasticity steel plate under the condition of plane strain state is calculated; (3) a strain coordinate system is built, data is synthesized on the coordinate system so as to build the forming limit diagram of the transformation induced plasticity steel plate. The invention is an effective tool for solving the transformation induced plasticity steel plate material punching problem, can successfully predict transformation induced plasticity steel plate material invalidation, effectively estimates the forming performance and reduces the existing measuring workload for building a shaping limit diagram.

Owner:NORTHEASTERN UNIV

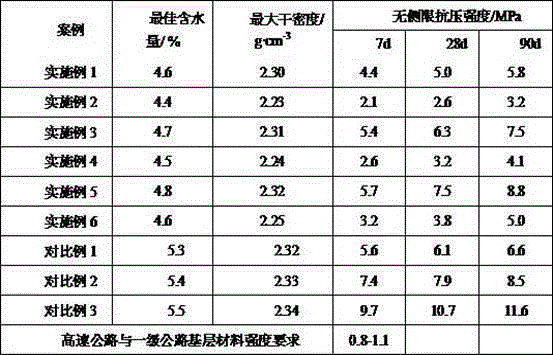

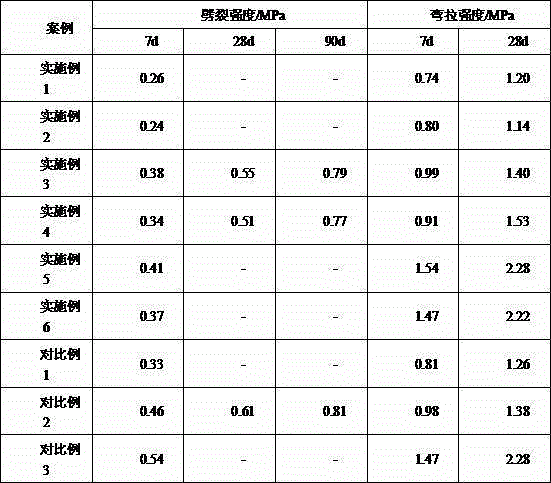

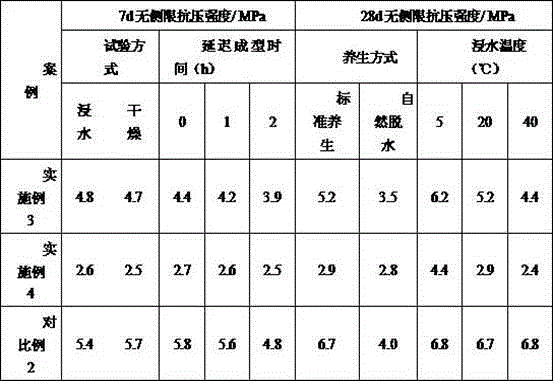

Emulsified asphalt cement stabilized macadam

The invention belongs to the technical field of road building materials and discloses emulsified asphalt cement stabilized macadam. The emulsified asphalt cement stabilized macadam is prepared from, by the weight ratio to macadam, 2-4 parts of mixed emulsified asphalt, 3.5-5.5 parts of mixed cement, 4.5-6.0 parts of water and 100 parts of macadam. The emulsified asphalt cement stabilized macadam has a hardness and softness feature and good water-damage-resistant performance, compared with common cement stabilized macadam, compression resistance and splitting strength of mixed materials are lowered, and flexural-tensile strength is approximate at the normal temperature of 20 DEG C and obviously improved at the low temperature of 5 DEG C. The dry shrinkage water-loss rate, dry shrinkage coefficient and dynamic modulus are lowered, and the limit strain capacity is increased; construction performance is excellent; compaction is easy, little segregation is generated, strength variability is small, and bad influences of delay forming and dry maintenance are weakened; the requirements for mechanical strength of pavement bases of high-grade highways and urban roads can be met, and base shrinkage cracks can be effectively reduced or prevented.

Owner:TONGJI UNIV

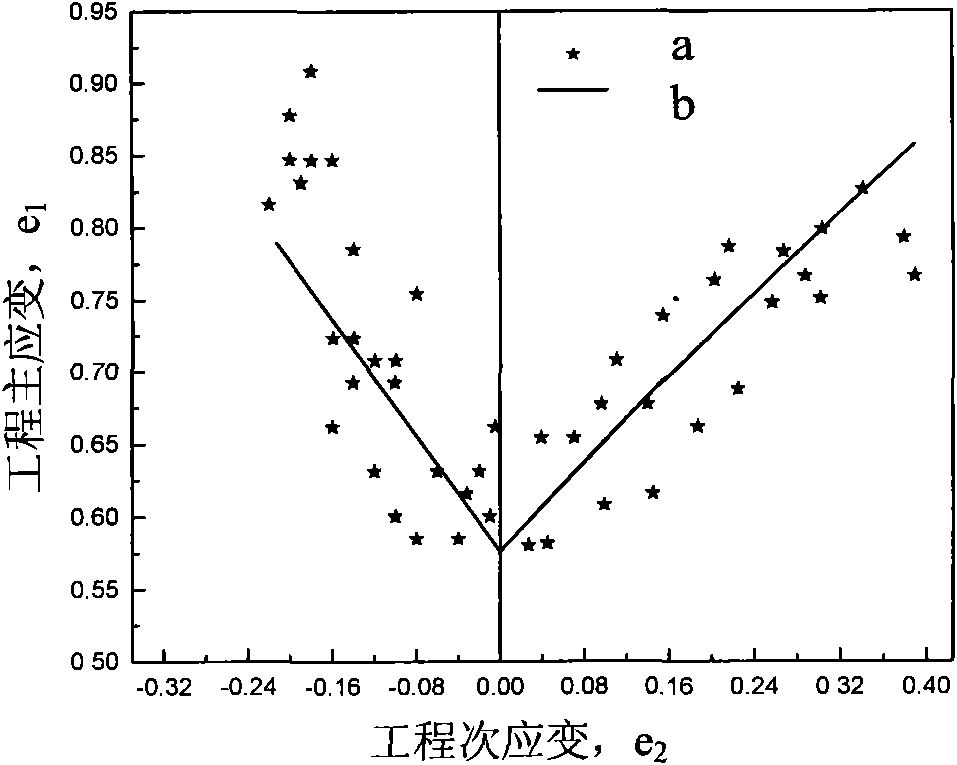

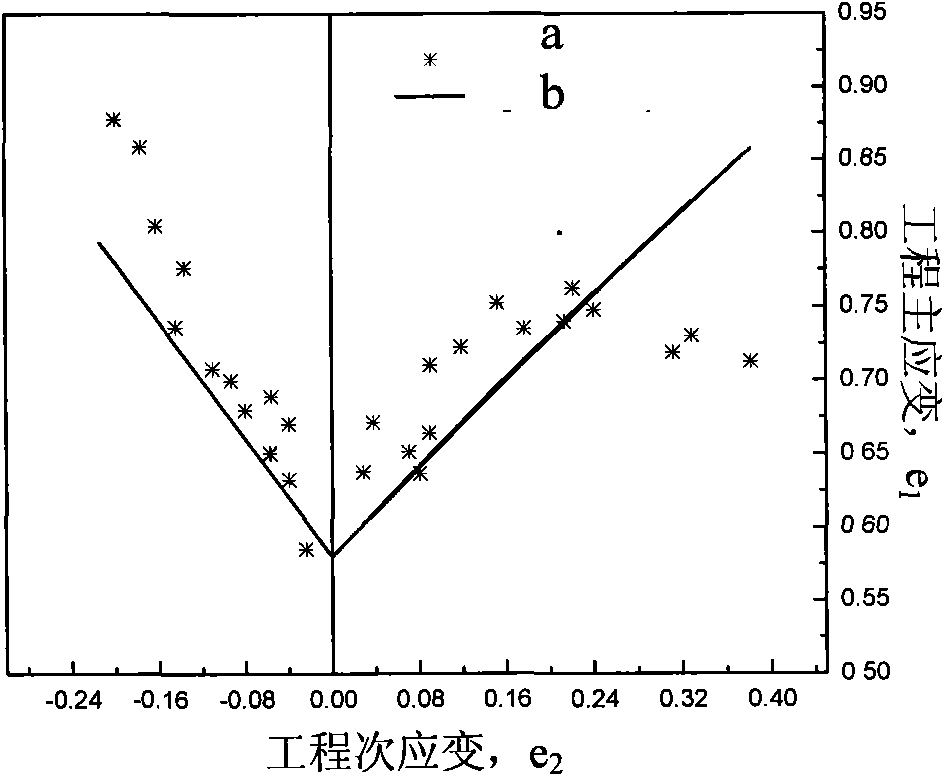

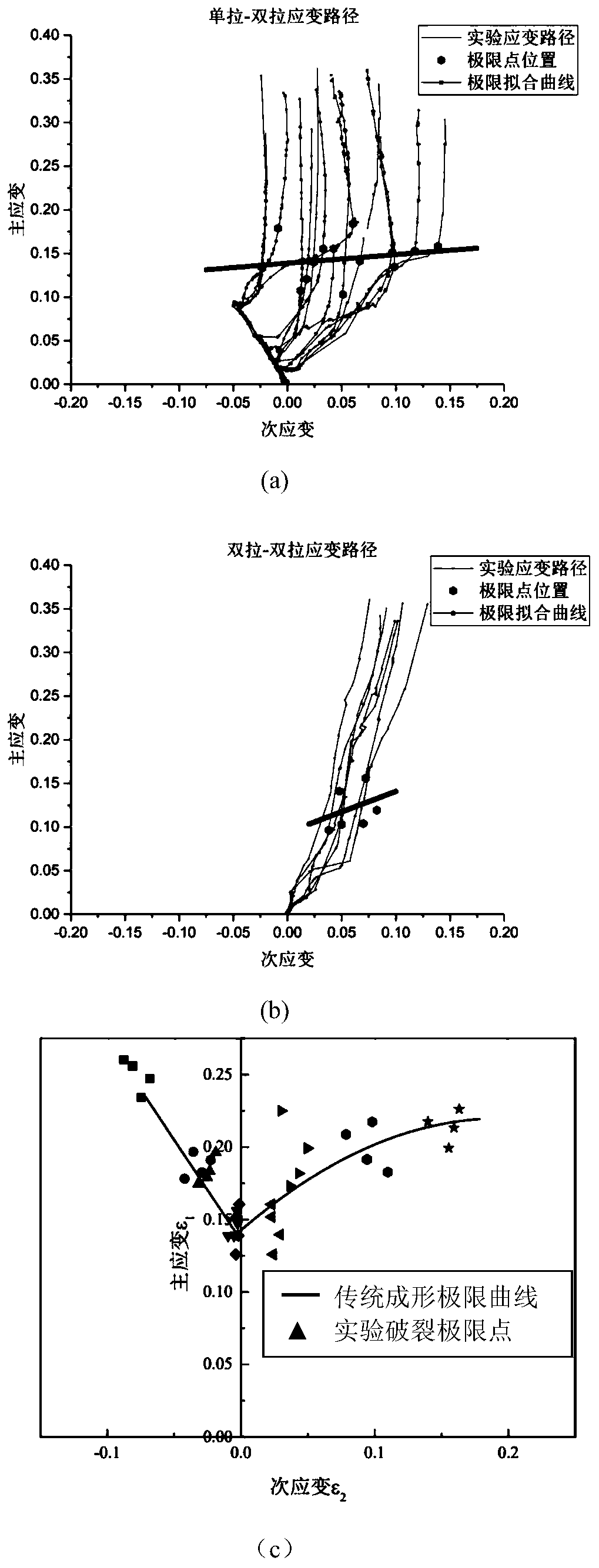

Application method of forming limit strain diagram under nonlinear strain path

PendingCN111260184AImprove forecast accuracyIt is feasible to predict the location of complex forming pathsDrawing from basic elementsCharacter and pattern recognitionForming limit diagramDatasheet

The invention discloses an application method of a forming limit strain diagram under a non-linear strain path. The application method comprises the following steps: step 1, determining basic parameters of a sample material, and constructing a non-linear forming limit diagram; 2, carrying out finite element Dynaform simulation calculation to output primary and secondary strain data tables; 3, thedata processing program classifies the data into one-way stretching-two-way stretching, two-way stretching-two-way stretching and other strain paths, and a data file is output; and step 4, predictingthe forming performance of the part by two nonlinear forming curves and linear forming limit curves in the nonlinear forming limit diagram and corresponding classification paths, finding out a nonlinear path characteristic rupture unit, and modifying the mathematical model to determine an actual machining process scheme. According to the method, strain data output by a simulation model is classified into uniaxial tension-biaxial tension, biaxial tension-biaxial tension and other paths according to nonlinear strain path features, and model feature regions are accurately evaluated in one-to-onecorrespondence with constructed nonlinear forming limit diagrams.

Owner:华瞬(深圳)智能装备有限公司

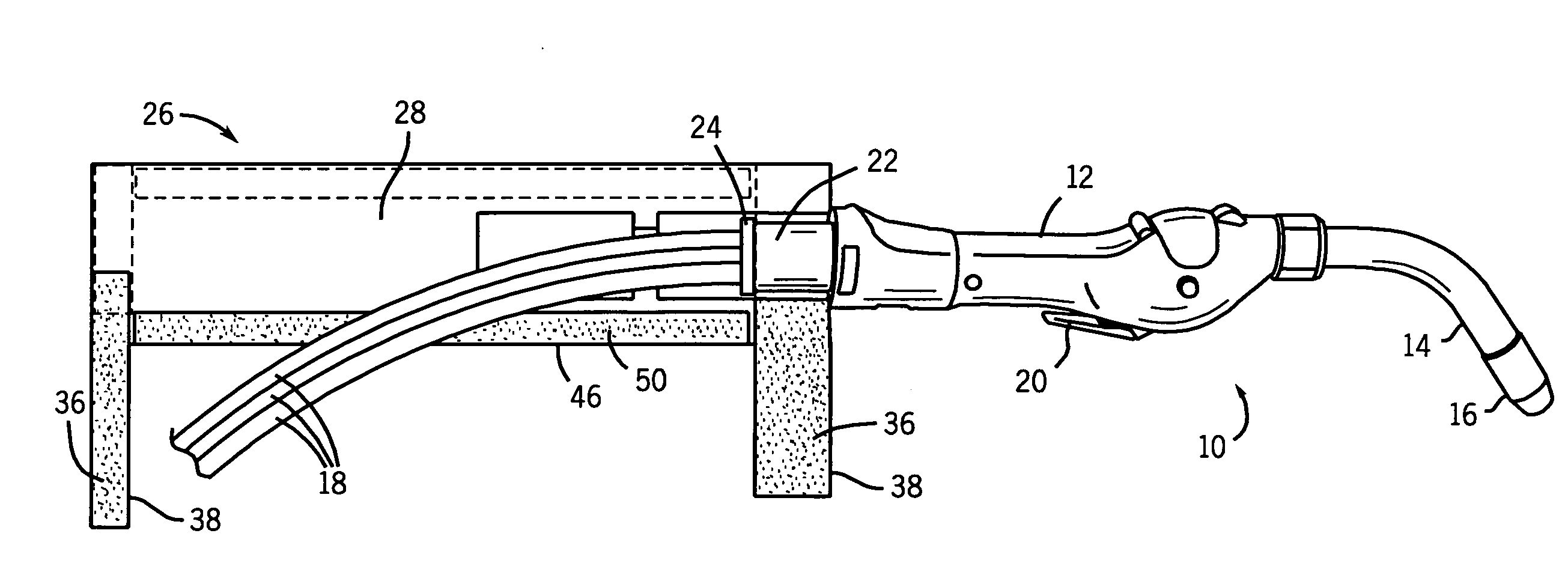

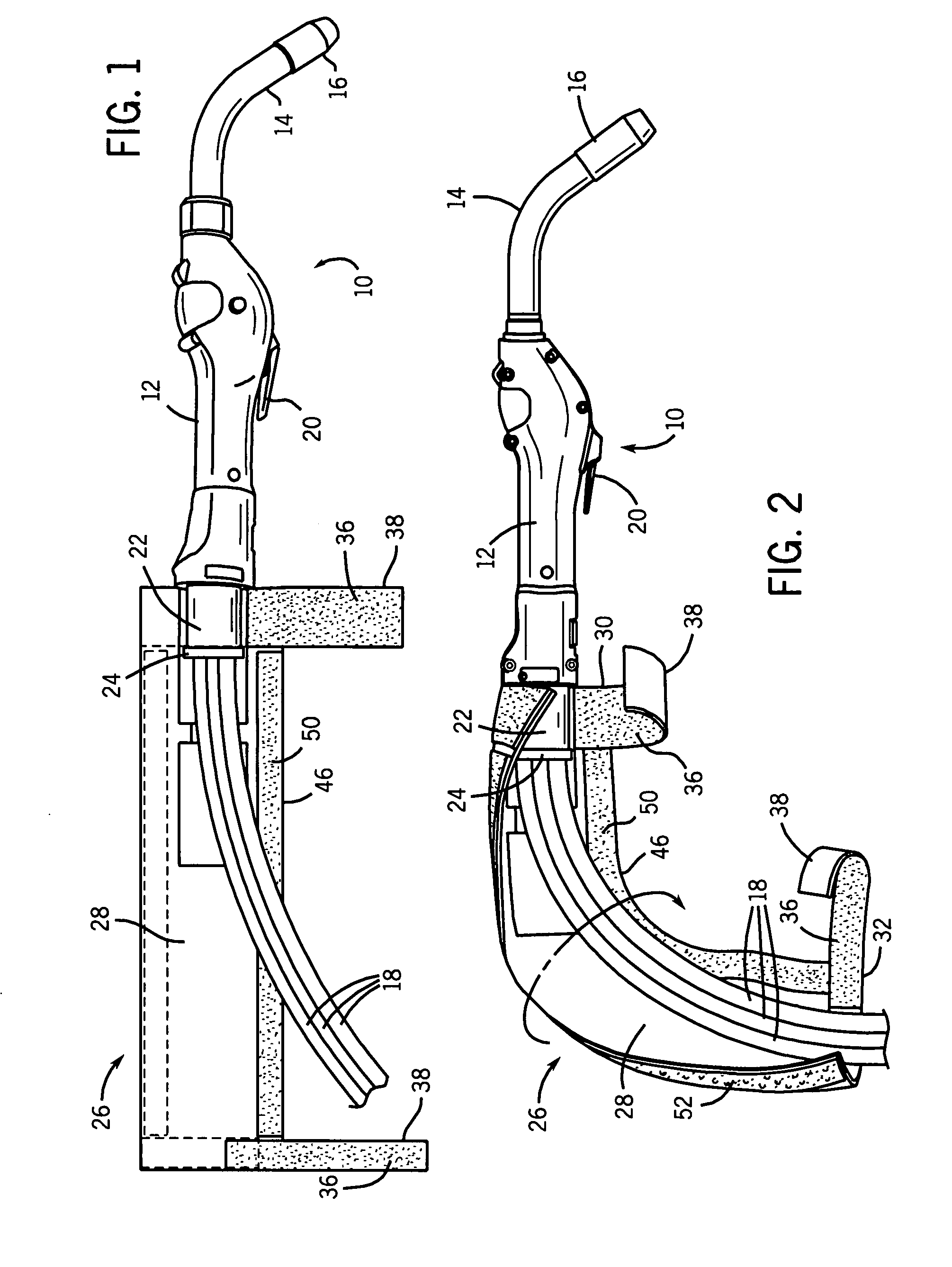

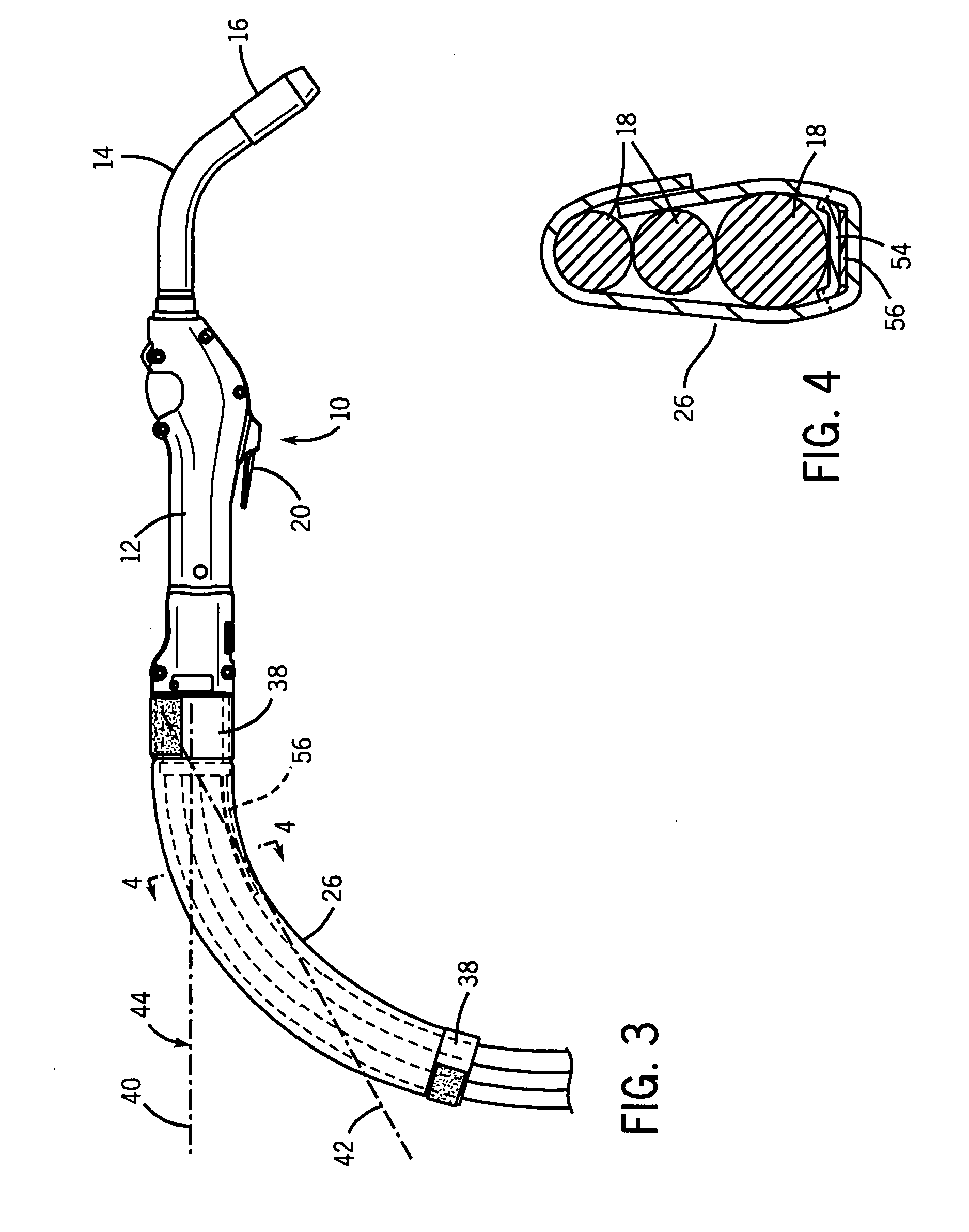

Welding torch cable strain relief system and method

InactiveUS20080283505A1Avoiding and reducing strainEasily removed and withdrawnWelding/cutting media/materialsSoldering mediaLimit strainEngineering

Conduits exiting from a welding torch handle are supported by a stiffening arrangement to limit the angle or radius of curvature of the conduits and thereby to limit strain and possible damage. The stiffening arrangement may include a stiffener that does not extend completely around the conduits, but is captured in a jacket that may be secured to the torch handle and wrapped around the conduits. Alternatively, an integral stiffener or stiffener assembly may include a tongue-like-stiffener extending from the handle to support the conduits and to limit their radius of curvature as they exit the handle.

Owner:ILLINOIS TOOL WORKS INC

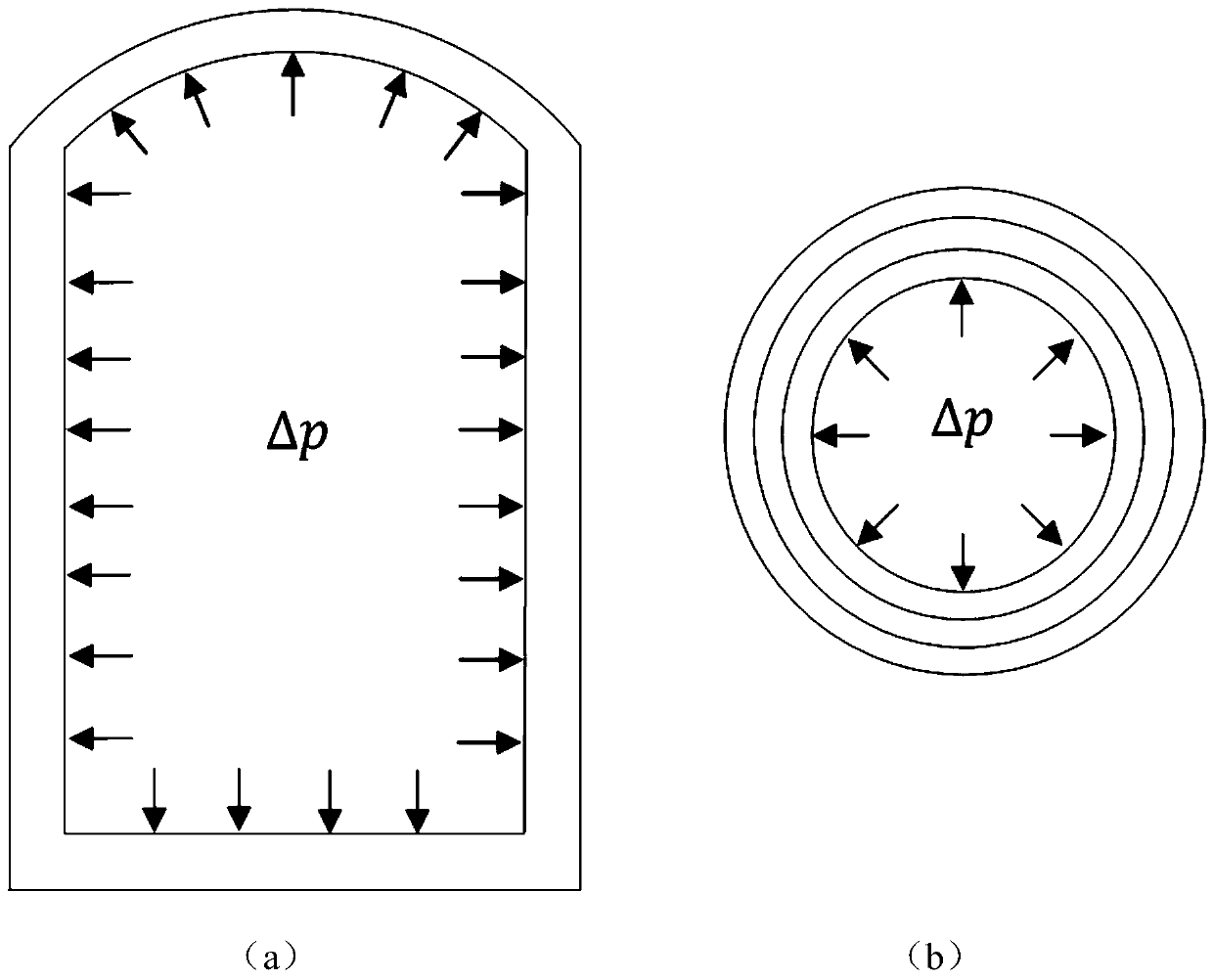

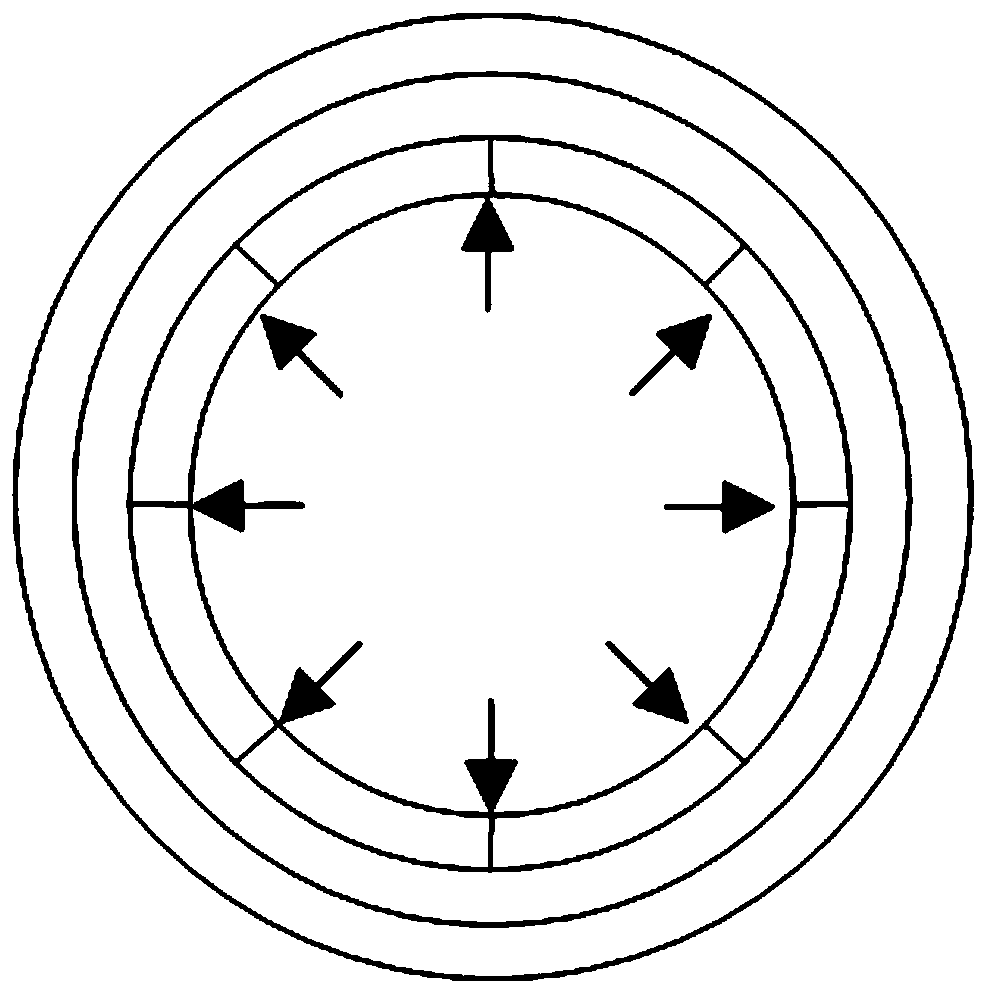

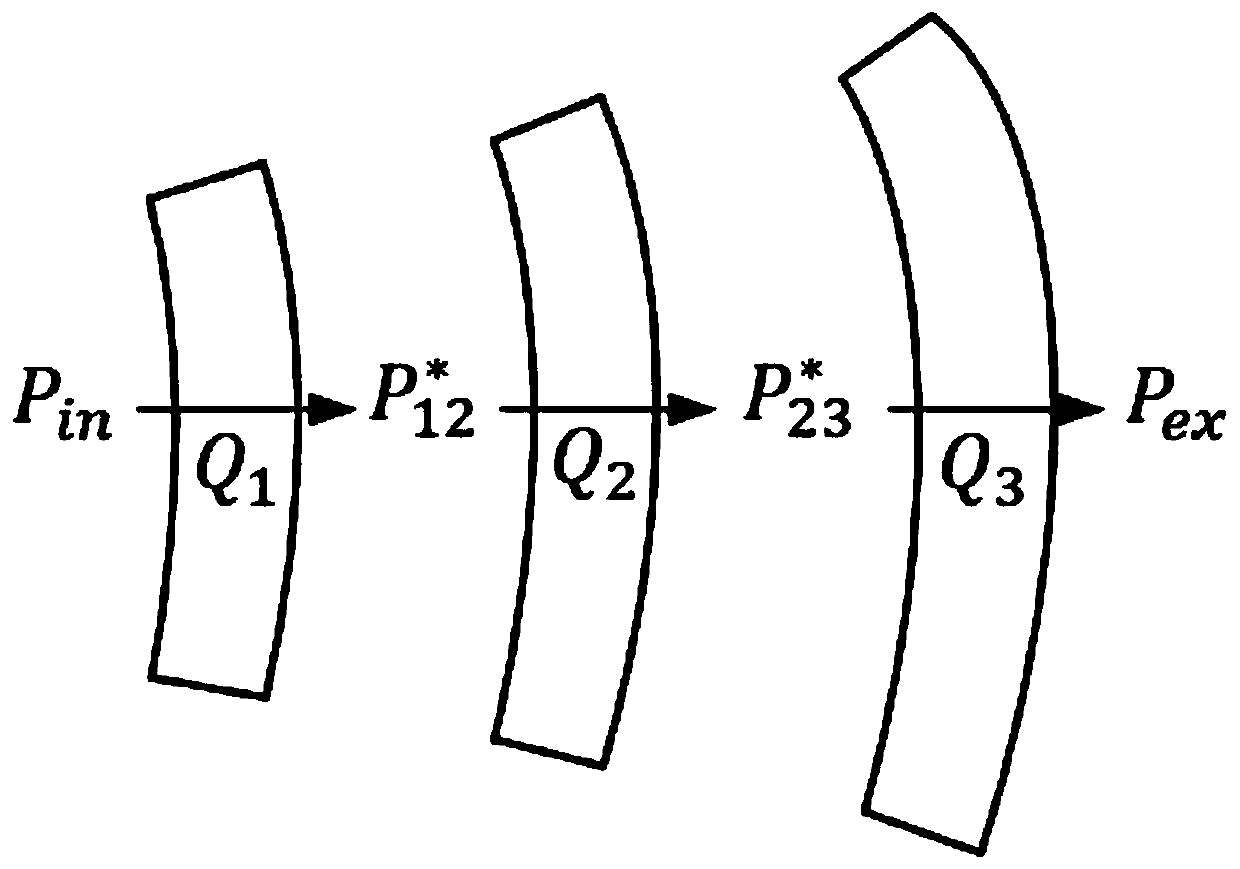

Method for quickly evaluating leakage rate of multi-layer pressure-bearing shell based on flow conservation theorem

ActiveCN111189594AQuickly assess leak ratesQuickly assess gas leak ratesMeasurement of fluid loss/gain rateInternal pressureCircumferential strain

The invention discloses a method for quickly evaluating the leakage rate of a multilayer pressure-bearing shell based on a flow conservation theorem, and belongs to the field of evaluation of the leakage rate of a damaged pressure-bearing structure. The main principle of the method is as follows: based on an ideal elastic-plastic constitutive, considering the cracking process and the failure mechanism of the multilayer pressure-bearing shell, quickly estimating the circumferential strain distribution of each layer of shell, and estimating the circumferential crack opening on the basis of exceeding the tensile limit strain of the material; and based on the flow conservation theorem, calculating the overall leakage rate of the shell structure with inconsistent cracking degree of each layer.According to the method, the cracking condition of the multi-layer pressure-bearing shell under the action of the internal pressure of a serious accident can be estimated, and the gas leakage rate ofthe multi-layer shell walls with different cracking degrees can be quickly estimated.

Owner:DALIAN UNIV OF TECH

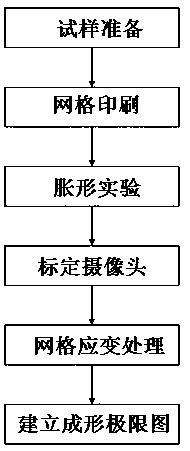

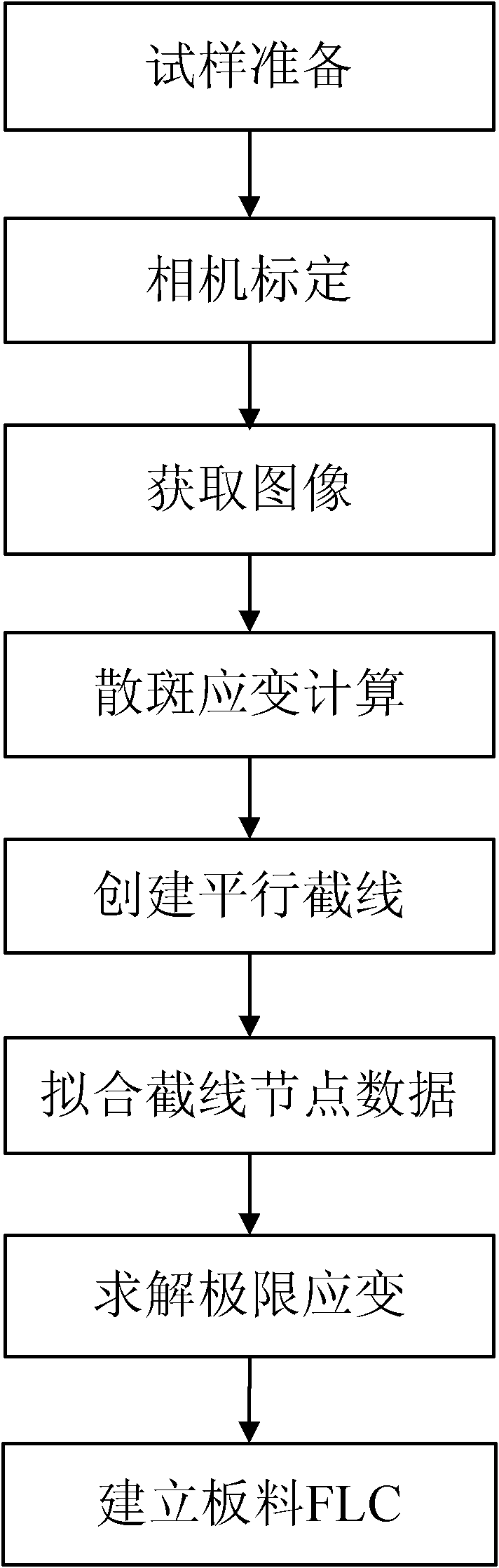

Optical non-contact plate formation limit measurement method

InactiveCN110455212AAccurate and efficient measurementEasy to operateUsing optical meansForming limit diagramLimit strain

The invention relates to an optical non-contact plate formation limit measurement method, and belongs to the technical field of metal plate formation. The optical non-contact plate formation limit measurement method comprises the steps of preparation a sample, in which a plate blank is cut to a test piece with a size and geometrical shape conforming to standard requirement; performing grid printing, in which grids are printed on the test piece by an electrolyte corrosion method; performing expansion experiment, in which expansion experiment is performed on a formation experiment machine untilthe test piece is necked or broken; calibrating a camera, in which the camera is calibrated by an optical strain measurement equipment; processing grid strain, in which image information of a sample surface is recorded from a plurality of angles, and analysis and processing are performed to primary and secondary strain distribution of a deformation unstable part of the experiment piece; and building a formation limit diagram, fitting obtained limit strain points to form an appropriate curve or constructing a strip-shaped region so as to build a plate formation limit diagram. The optical non-contact plate formation limit measurement method has the characteristics of measurement operation convenience, high automation, accurate measurement result and reliability and has good universality.

Owner:JILIN UNIV

Suspension substrate, suspension, head suspension and hard disk drive

InactiveUS8208226B2Relieve pressureDisposition/mounting of recording headsPrinted circuit aspectsHard disc driveInsulation layer

Owner:DAI NIPPON PRINTING CO LTD

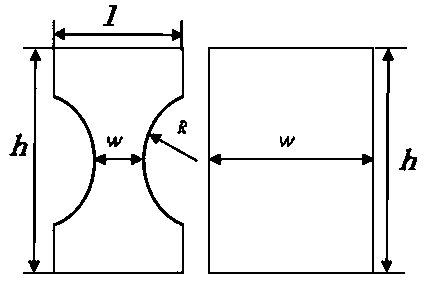

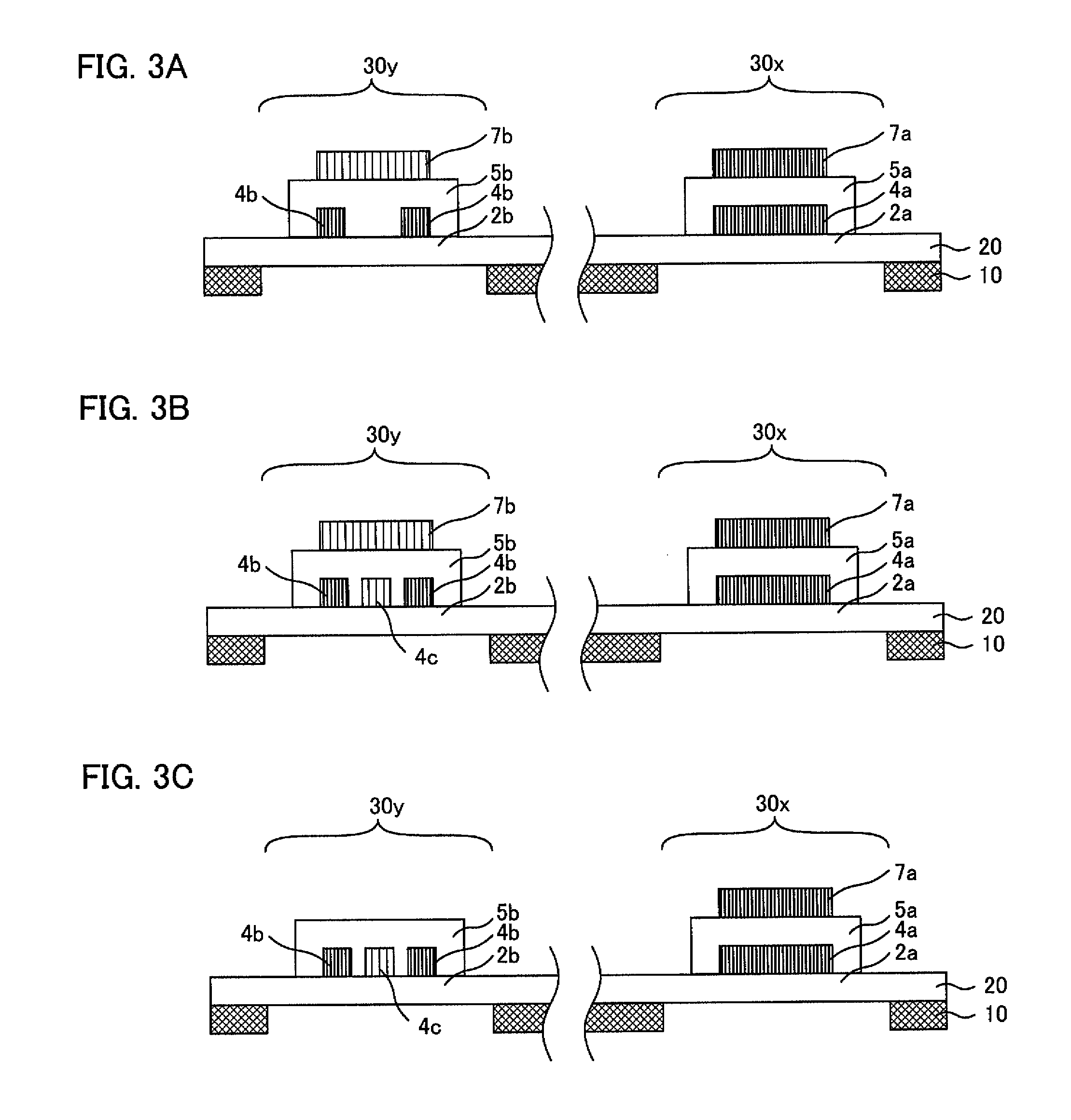

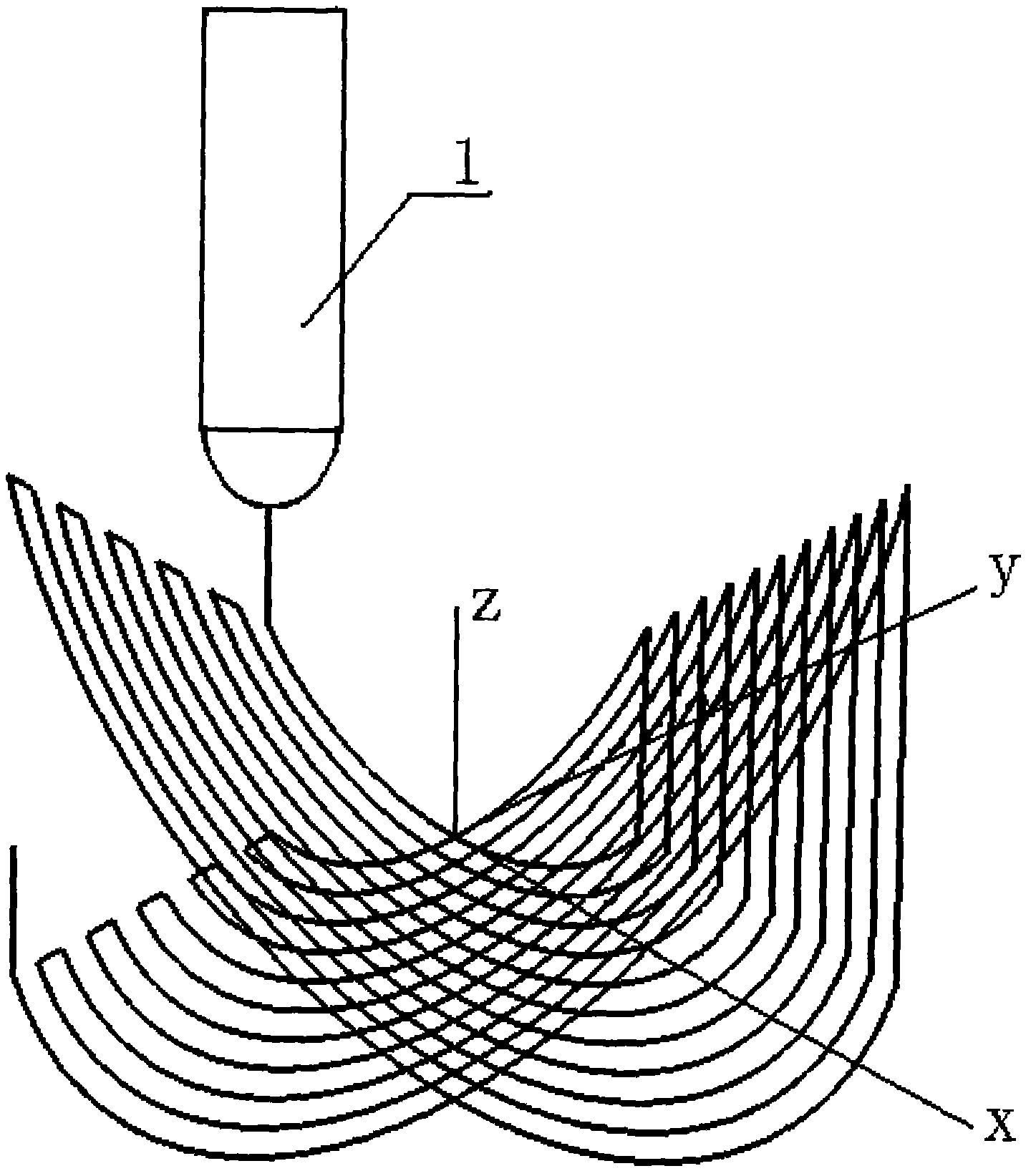

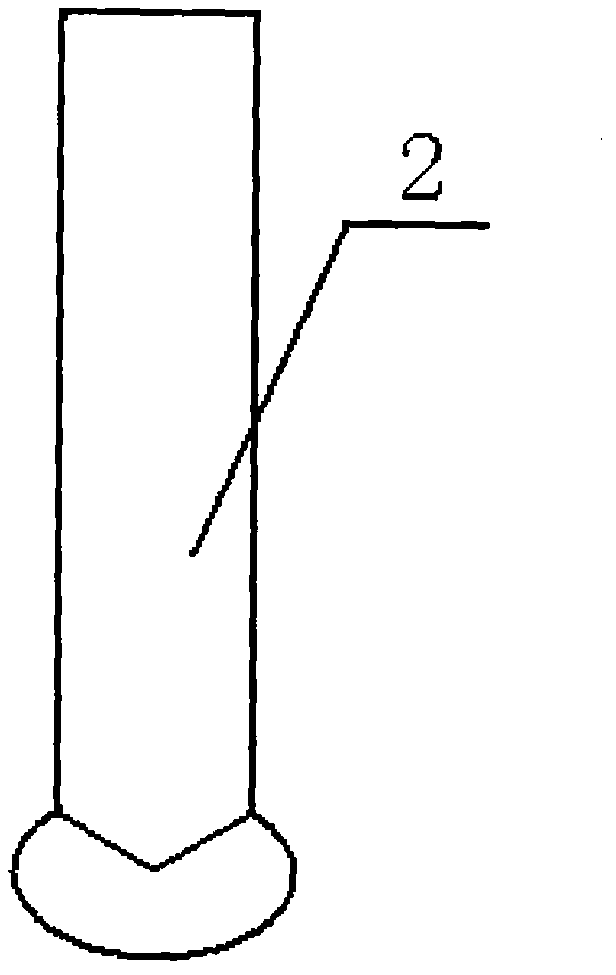

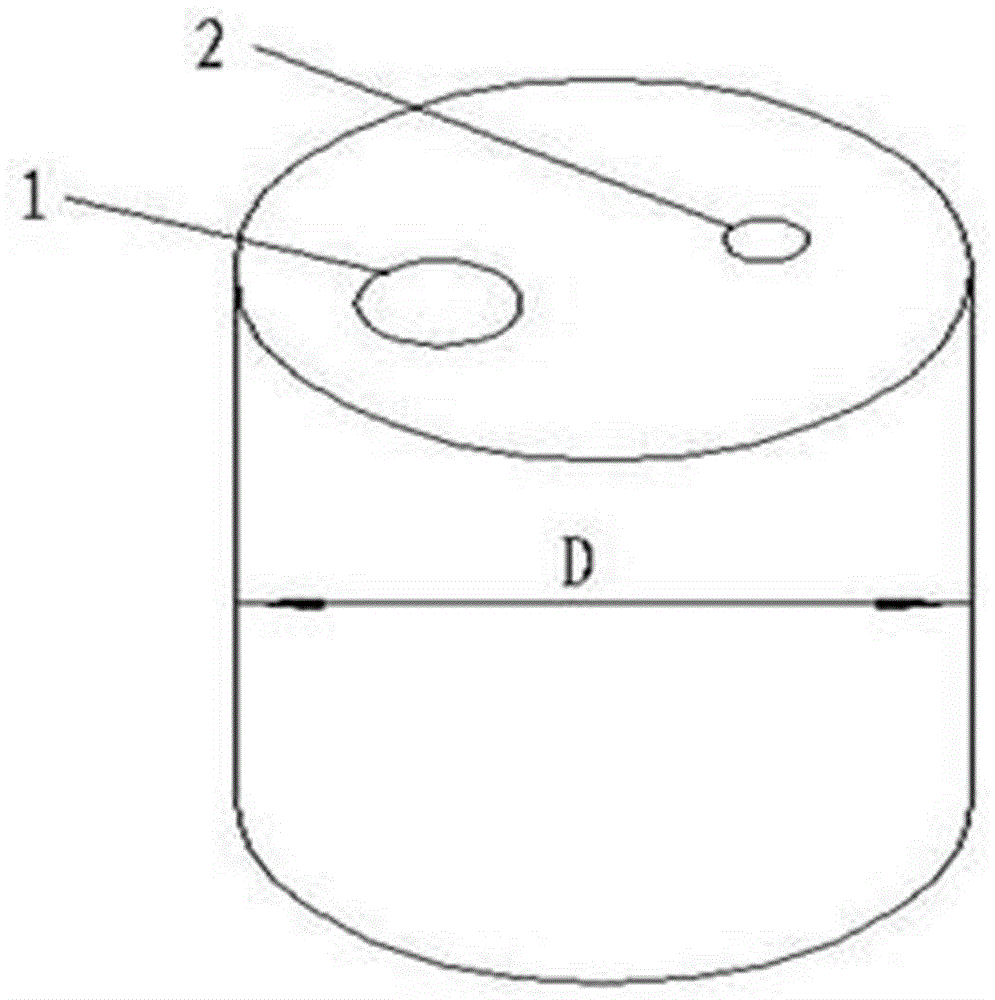

Determination method for plate incremental forming limit diagram

InactiveCN103324779AHigh precisionThe method is reasonable and simple and fastSoftware testing/debuggingSpecial data processing applicationsForming limit diagramLimit strain

The invention discloses a determination method for a plate incremental forming limit diagram. The plate incremental forming limit diagram is finally obtained by drawing curves, generating a processing program, preparing samples, forming arc grooves, obtaining a plate plane limit strain value and establishing a plate plane strain coordinate system. A hemispherical head forming tool is adopted to form a unidirectional arc groove and equal-width cross arc grooves, an ellipsoidal head forming tool different in long axis and short axis proportions is adopted to respectively form unequal-width cross arc grooves, and the plate plane limit strain value is obtained by analysis. The method is reasonable, simple and rapid, the plate incremental forming limit diagram high in accuracy can be obtained, guarantee is provided for making a reasonable production process, and criteria are provided for numerical simulation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Manufacturing method of carbon fiber cloth pre-constrained ultra-high performance concrete column

The invention discloses a manufacturing method of a carbon fiber cloth pre-constrained ultra-high performance concrete column and belongs to the field of building structures. A carbon fiber cloth is used to make a closed cylindrical drum, and a filler hole and an inflation hole are formed in one circular surface of the closed cylindrical drum; the filler hole is sealed and the closed cylindrical drum is filled with compressed air through the inflation hole to form an upright and plump cavity cylinder; the cylinder is filled with reactive powder concrete (RPC) through the filler hole till the cylinder is full of the RPC, and the RPC is vibrated and compacted to form a RPC column; certain pressure is applied on the upper and lower bottom faces of the RPC column; the RPC column is maintained through steam at a certain temperature to a suitable time; the pressure is removed, steam maintenance is stopped, and the RPC column is subjected to concrete standard maintenance to form a finished column; and a fireproof coating is smeared on the side wall of the finished column, the carbon fiber cloth fully reaches the strength when the RPC reaches the limiting strain, and the strength is fully utilized at the time of structural failure.

Owner:SHIJIAZHUANG TIEDAO UNIV

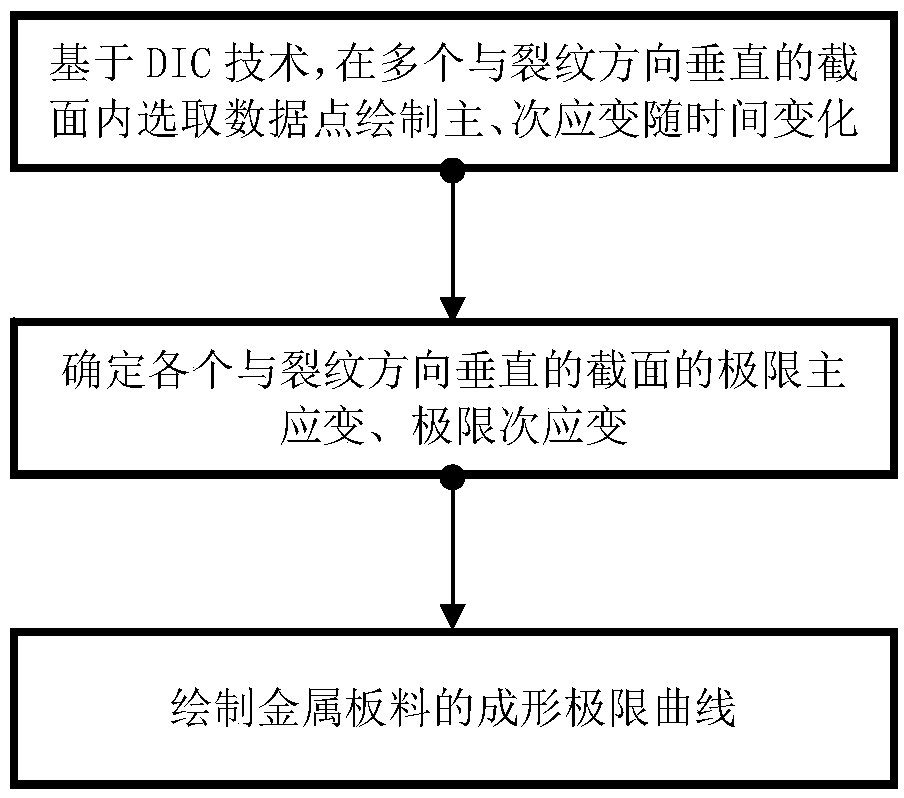

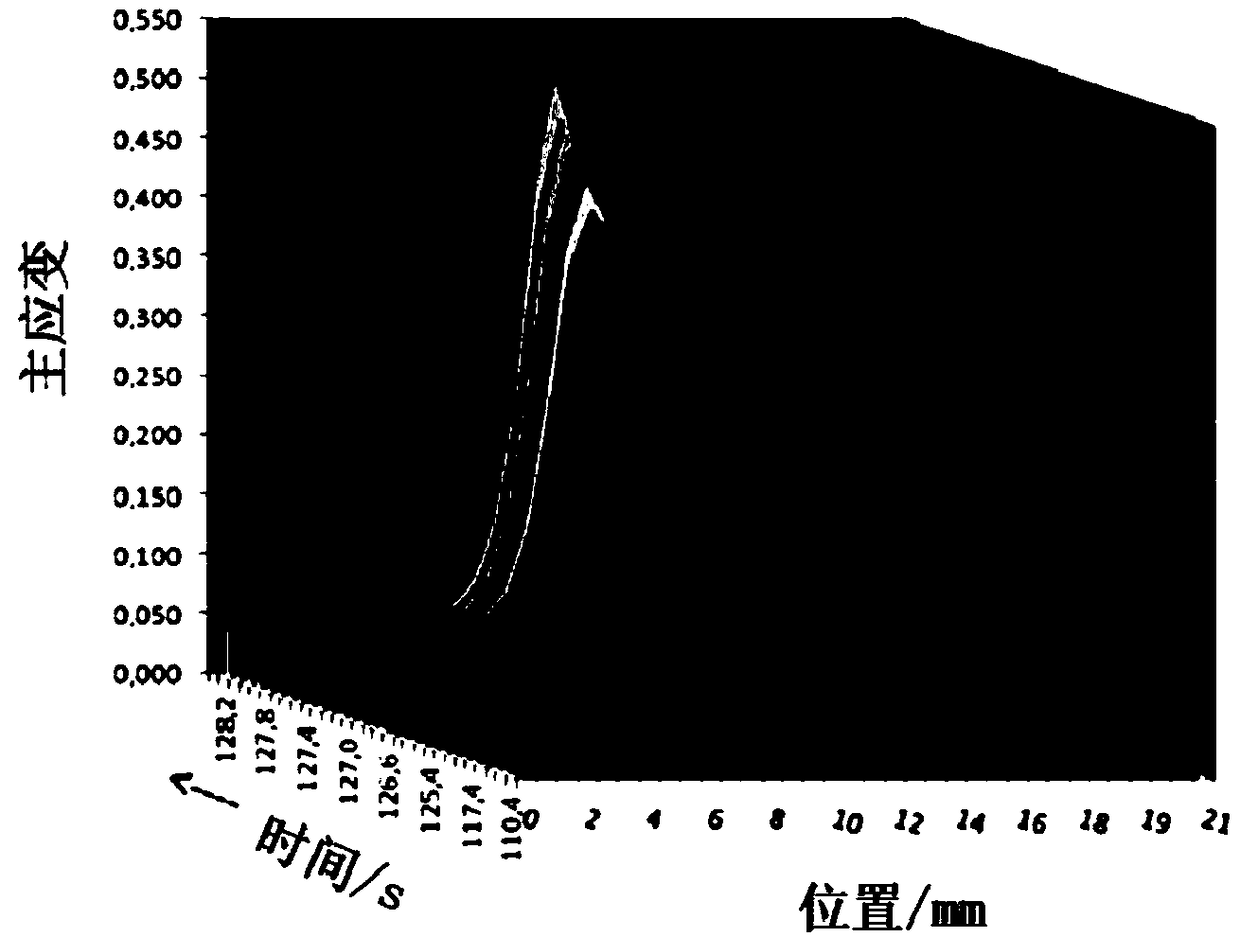

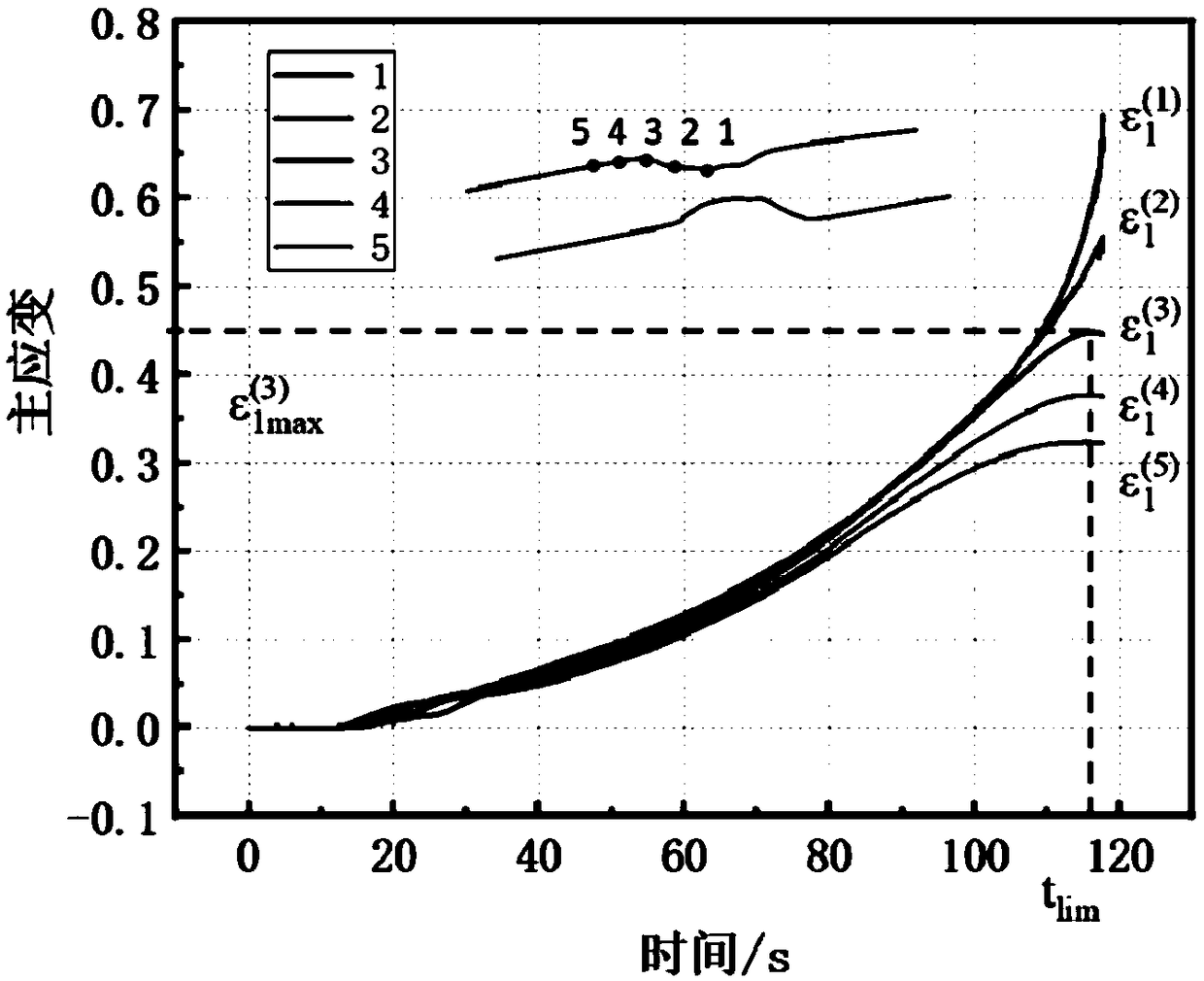

Necking failure limiting strain detection method based on DIC

ActiveCN109470559AGet results quickly and directlyObtain results concisely and effectivelyMaterial strength using tensile/compressive forcesLimit strainEngineering

The invention provides a necking failure limiting strain detection method based on DIC. The method comprises the following steps: S1, based on a DIC technique, selecting data points in a plurality ofsections vertical to a crack direction to draw a curve of primary and secondary strains varying along with time; S2, determining the limiting primary strain and the limiting secondary strain of the sections vertical to the crack direction based on the curve of primary and secondary strains varying along with time; and S3, based on the limiting primary strain and the limiting secondary strain of the sections vertical to the crack direction, drawing the limiting primary strain and the limiting secondary strain as vertical axis and cross axis in a coordinate map to obtain a formed limiting curveof a metal panel material, wherein necking failure limiting strain detection of the metal panel material is achieved. The method is quick, direct, concise and effective, and has very good universality.

Owner:SHANGHAI JIAO TONG UNIV

Vibration reduction method for blowdown pipeline of air-conditioner outdoor unit

The invention discloses a vibration reduction method for a blowdown pipeline of an air-conditioner outdoor unit. The vibration reduction method comprises the steps that a general motion equation is solved to obtain displacement functions of nodes in the gridded blowdown pipeline by obtaining the gridded blowdown pipeline and an excitation source, then strain functions of units in the gridded blowdown pipeline are calculated to solve strain values of the units, the strain values are compared with a set upper limit strain value, the bending radiuses and number of U-shaped turns and the number and installing positions of vibration reduction parts of an initial blowdown pipeline model are modified if the strain values are greater than the upper limit strain value till the calculated strain values are not greater than the upper limit strain value, and finally the blowdown pipeline model having good vibration reduction performance is determined. The blowdown pipeline model serves as a blowdown pipeline model of a sample piece to manufacture the blowdown pipeline of the sample piece, the vibration reduction performance is good, and the blowdown pipeline is applied to the air-conditioner outdoor unit to enable the overall performance of an air conditioner to be improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

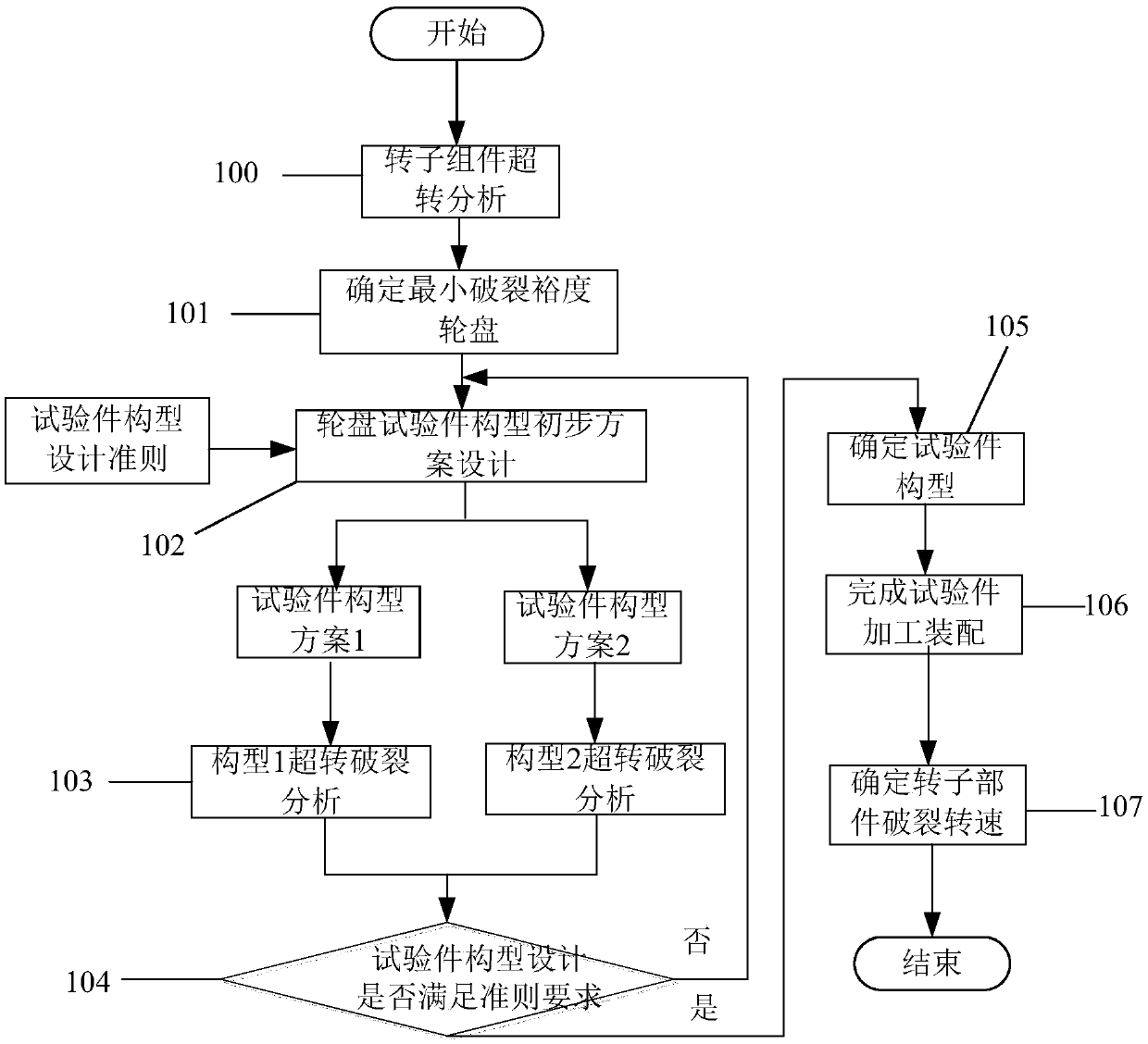

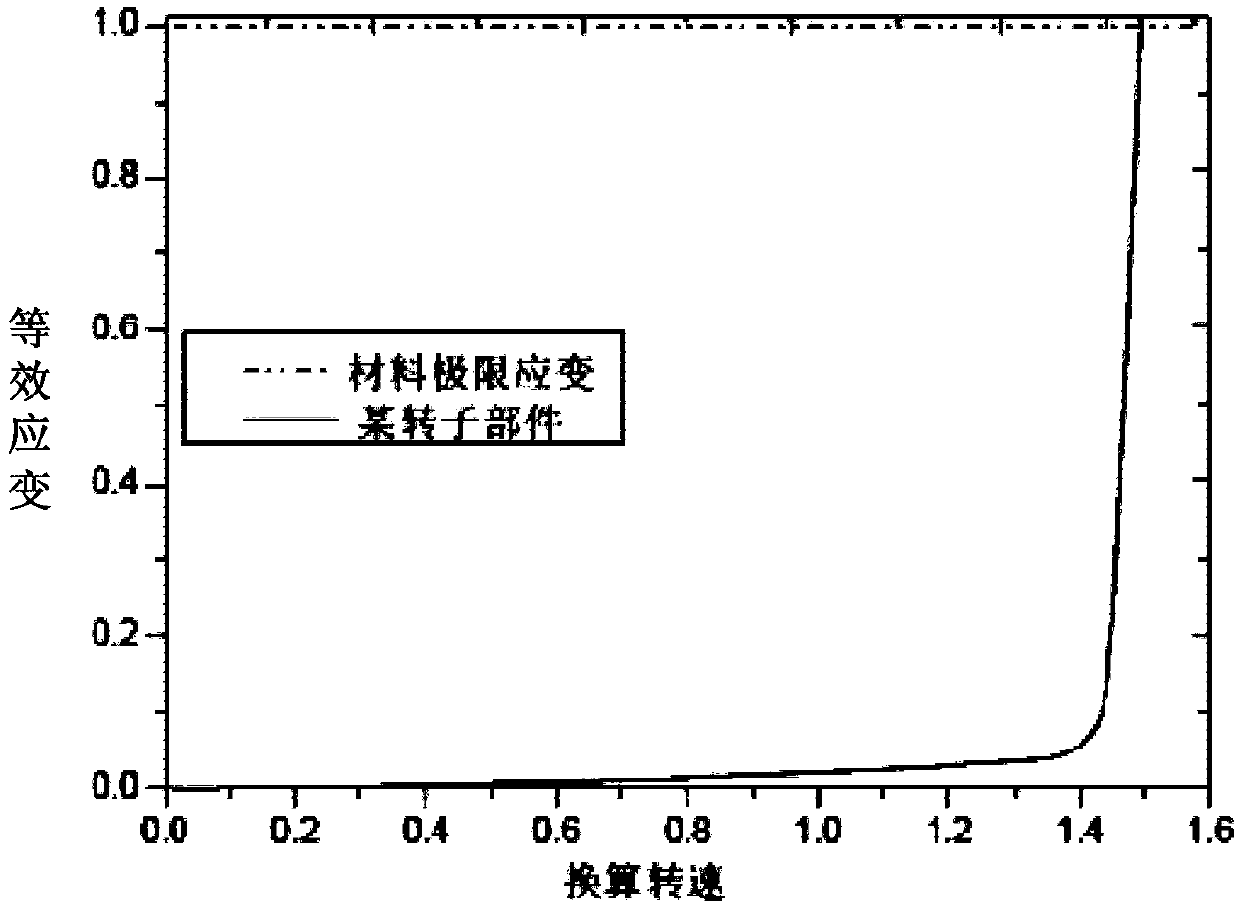

Test piece configuration method for overrun fracture test of aero-engine rotor

ActiveCN111238804ASimple test verificationThe test verifies directlyMachine gearing/transmission testingControl engineeringLimit strain

The invention provides a test piece configuration method for an overrun fracture test of an aero-engine rotor. The test piece configuration method comprises the following steps of: S1, carrying out overrun analysis on a rotor assembly of an aero-engine, S2, determining a minimum fracture margin wheel disc in the rotor assembly, S3, constructing a preliminary design scheme of the test piece configuration, S4, performing overrun fracture analysis on the configuration of the test piece, S5, judging whether the test piece configuration design meets criterion requirements or not, S6, determining the configuration of the test piece, S7, finishing processing and assembling of the test piece, and S8, determining the fracture rotating speed of the rotor part. The method is based on an extreme strain method, does not contain any coefficient and factor, is simple and direct in test verification, and can save a large amount of test expenditure and time. Therefore, the fracture starting position ofthe rotor can be predicted accurately, the worst combination within the position tolerance range can be directly selected as the worst size of the fracture, the operability is high, a theoretical basis is provided, and the method is suitable for being applied to the engineering development process.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Visual measurement method of plate forming limit curve (FLC)

ActiveCN102435512BEasy to operateEasy to useInvestigating material ductilityLimit strainComputer vision

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com