Optical non-contact plate formation limit measurement method

A non-contact, forming limit technology, used in measuring devices, optical devices, instruments, etc., can solve the problems of inability to accurately judge sheet instability, limited application scope, and few applications, and achieve a wide and clear application range. Physical meaning, high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and the forming limit determination experiment of a 6016-T4 aluminum alloy plate with a thickness of 1 mm.

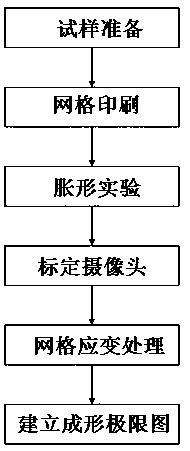

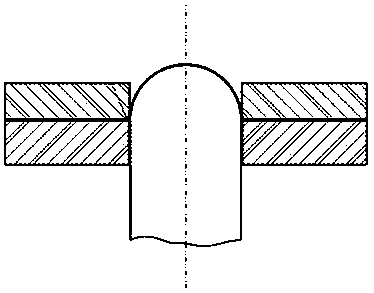

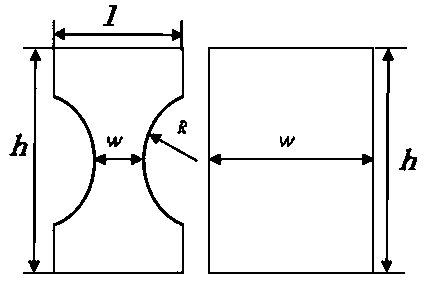

[0045] The present invention proposes a measurement method based on optical non-contact sheet material forming limit, the specific operation steps are as follows figure 1 shown. The hardware principle structure of the experimental device used is as follows: figure 2 As shown, the punch bulging experiment uses the EC series standard sheet metal forming testing machine. The main parameters of the equipment are: the blank holder force is set to 1200KN, the tensile force is set to 1500KN, the diameter of the punch is 100mm, the radius of the die fillet is 5mm, the rising speed of the punch is 1mm / min, the total electric power is 5.5KW, the shape The size is 1510*1010*1700mm, and the total weight is 1500KG. The dome punch is controlled by a hydraulic stretc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com