Patents

Literature

581results about How to "Improve production accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

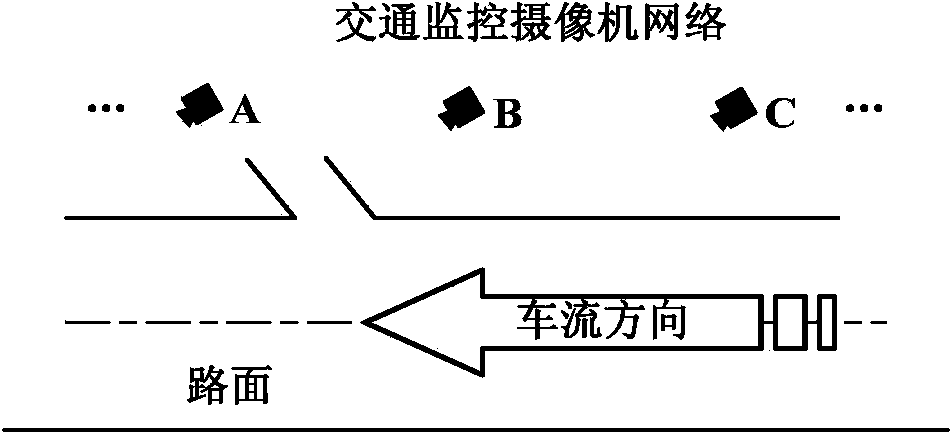

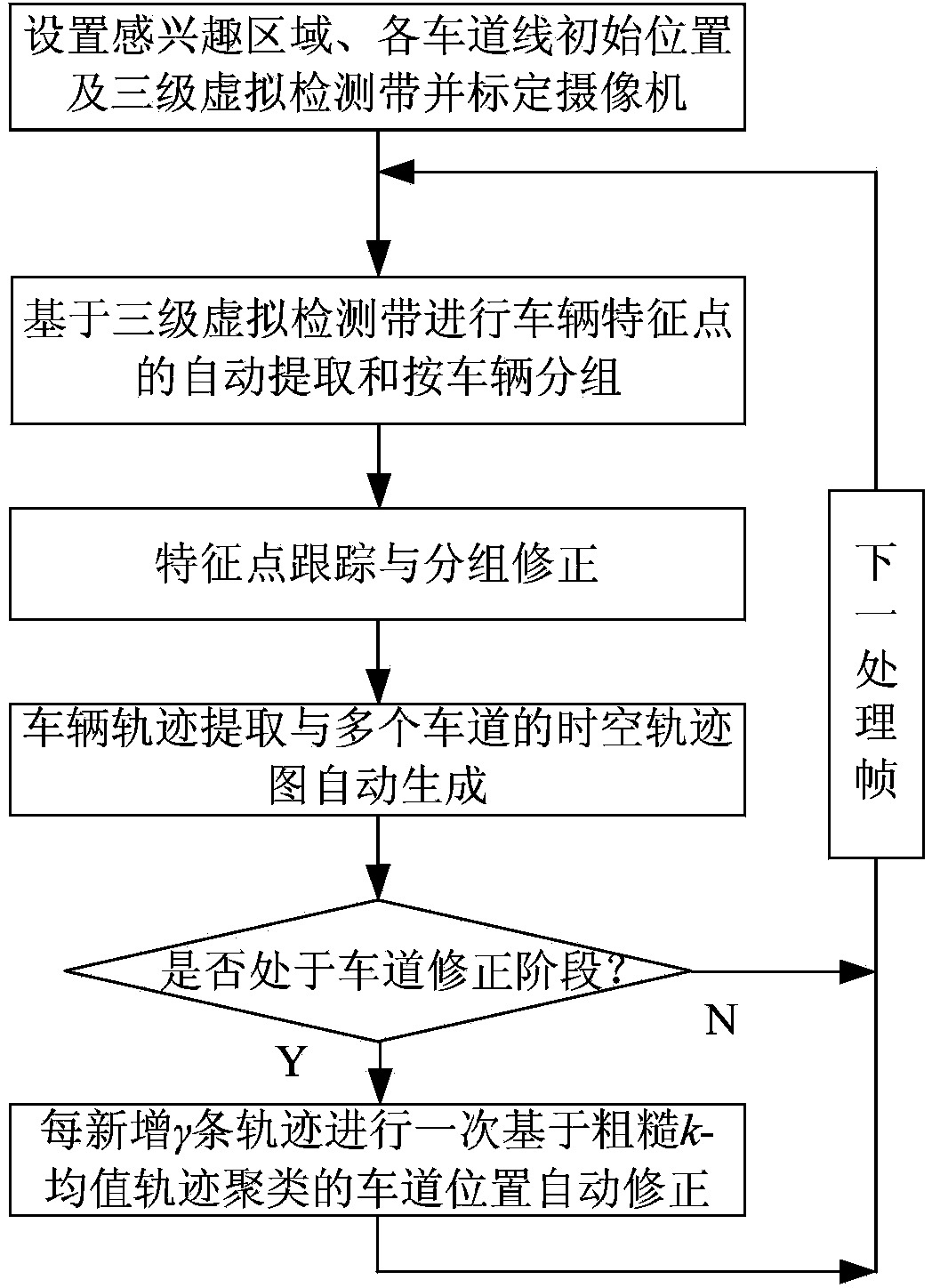

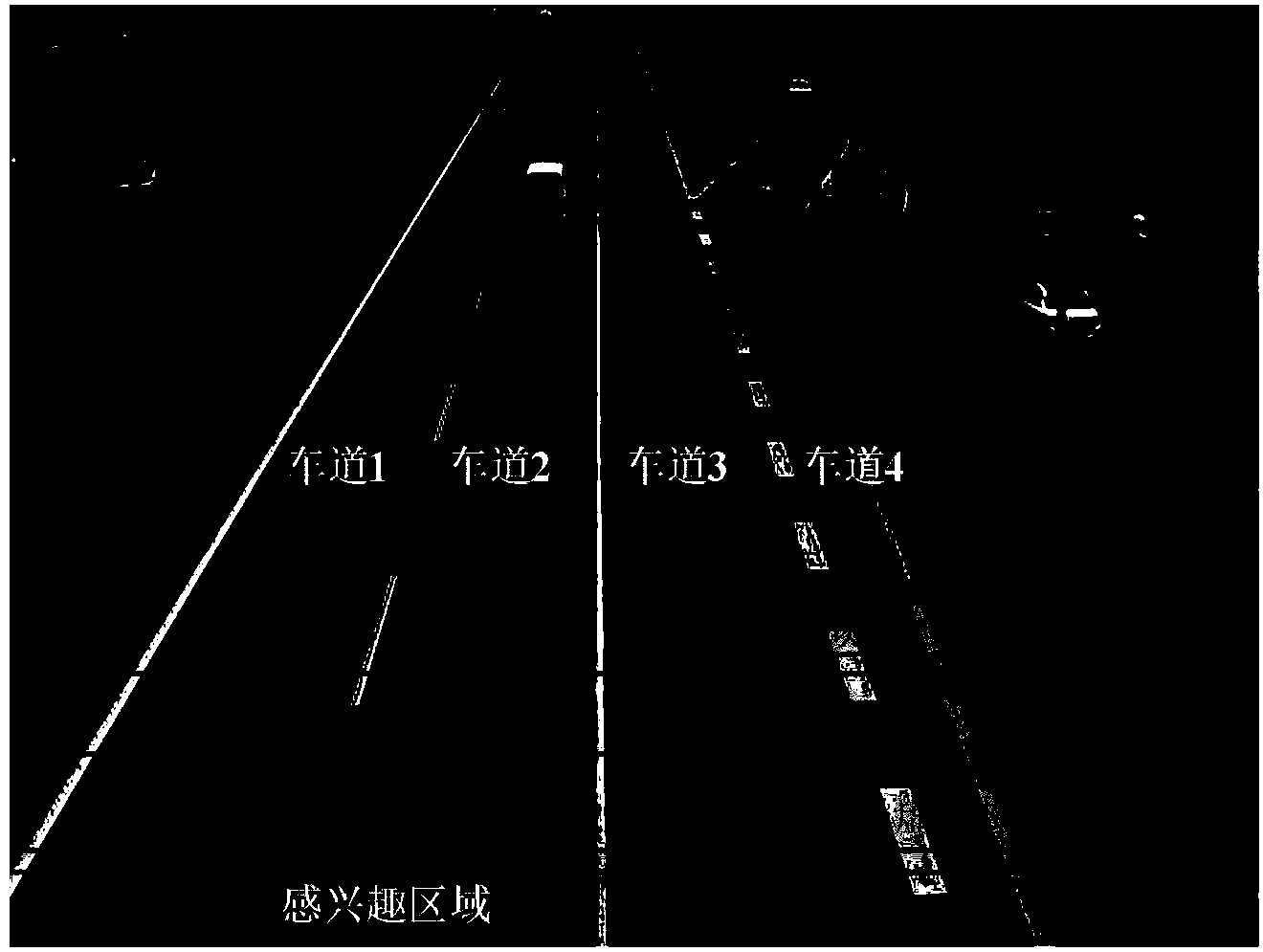

Automatic generating method for multi-lane vehicle track space-time diagram

ActiveCN103903019ALittle impact on accuracyHigh precisionImage analysisCharacter and pattern recognitionState of artSimulation

The invention relates to an automatic generating method for a multi-lane vehicle track space-time diagram. The method comprises the steps that firstly, a camera is utilized for obtaining internal parameters and external parameters of the camera through off-line calibration, an area of interest is set according to the actual monitoring requirement, and three virtual detecting belts are set at the upstream initial position of the traffic flow; secondly, the vehicle feature points are extracted based on the three virtual detecting belts, the feature point tracking and grouping correction are carried out according to vehicle grouping, the vehicle tracks are extracted in a high-precision mode, a longitudinal space-time track diagram of passing vehicles is automatically generated for each lane, and a transverse space-time track diagram comprising all lanes is generated; finally, whether it is in the lane line correction stage or not is automatically judged, wherein if yes, the lane line position is automatically corrected based on the track clustering method. Compared with the prior art, the method improves the robustness of the target luminance change, improves the precision of vehicle detecting and track tracing, is capable of well automatically correcting the lane line on line and avoids misjudgment on the lane number to which the vehicle track point belongs.

Owner:JIANGSU ZHONGHAI HUA HE ENVIRONMENTAL PROTECTION CO LTD

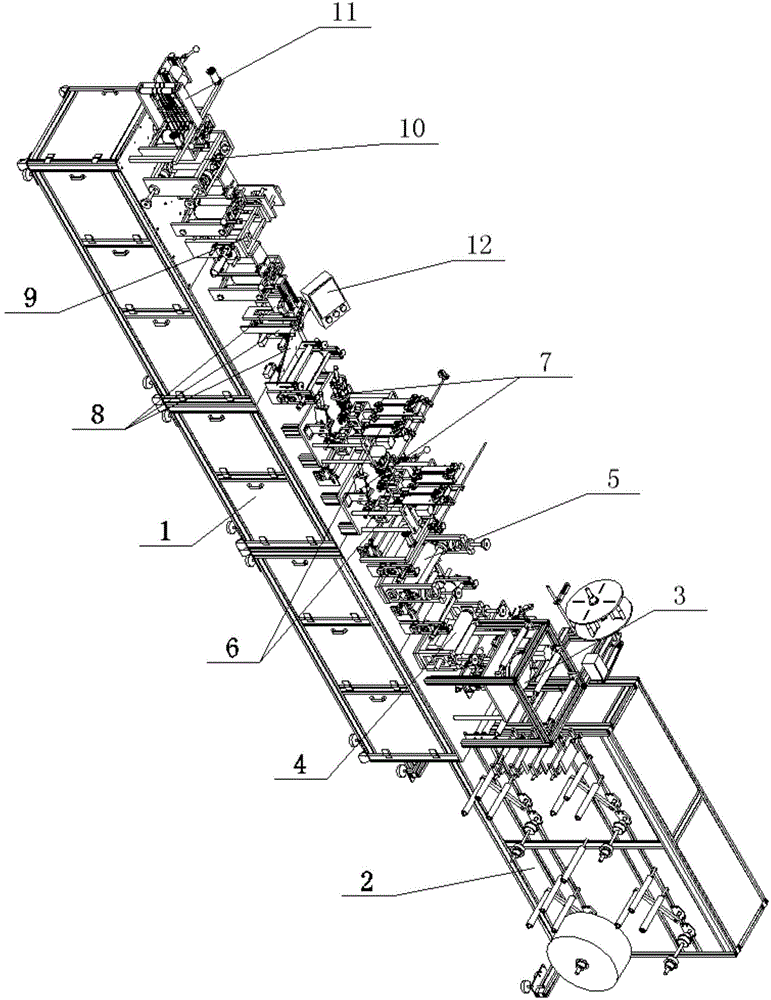

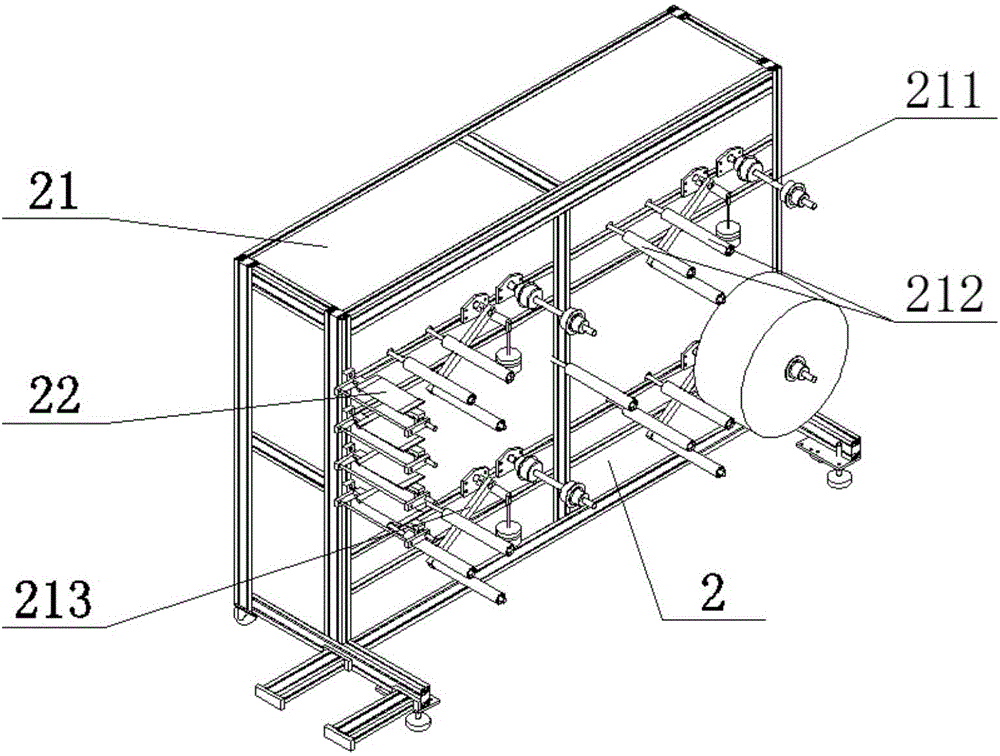

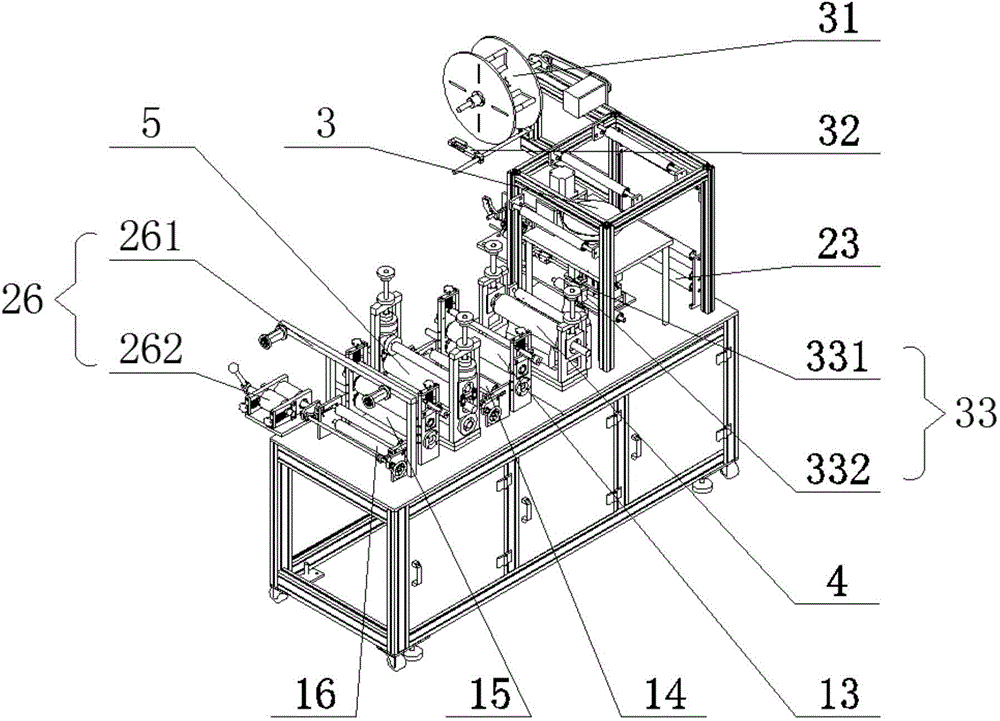

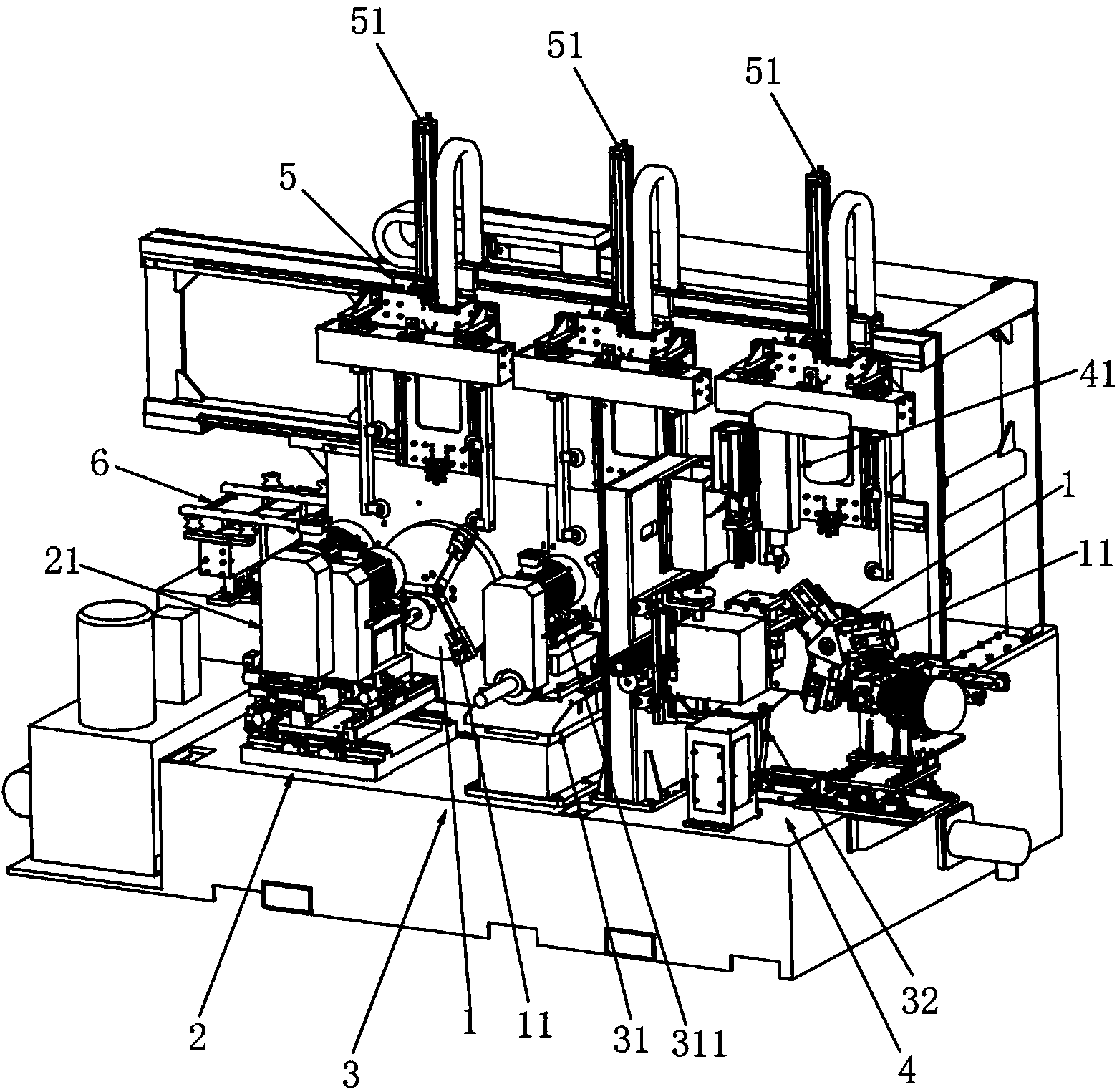

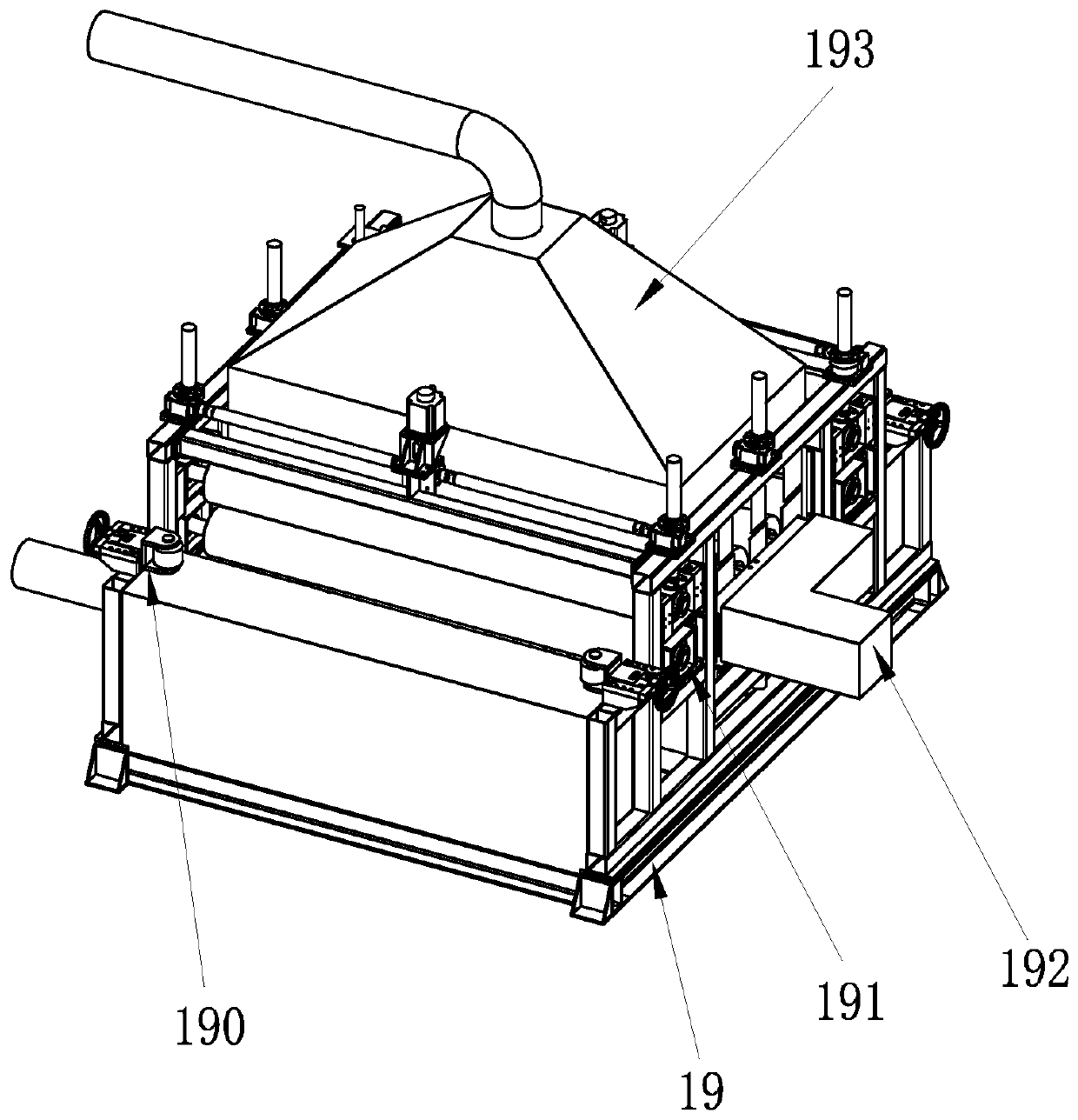

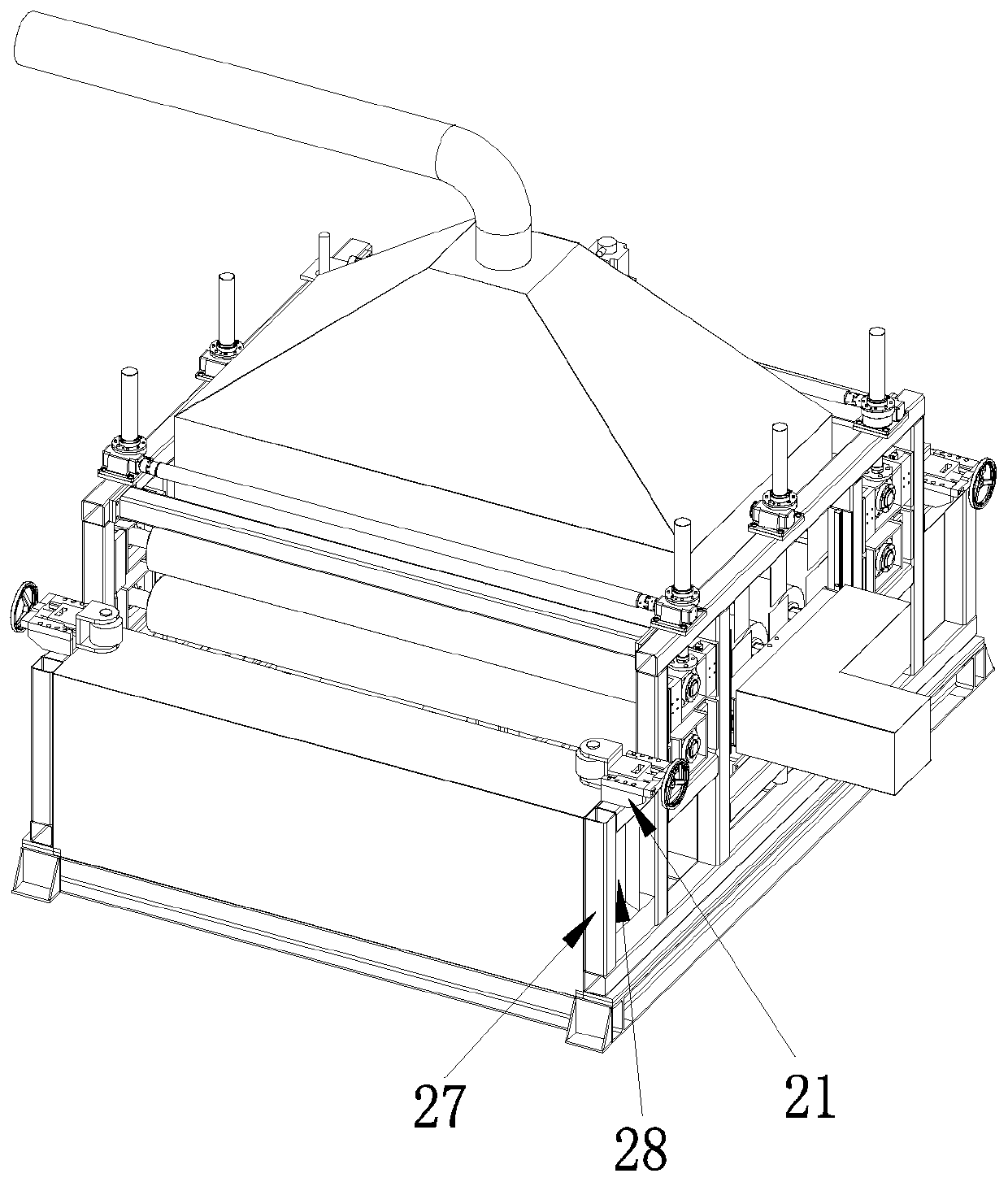

Full-automatic machine for producing foldable masks

ActiveCN104872866AImprove aestheticsRealize automated productionProtective garmentProduction lineRespirator

The invention relates to the technical field of mask machining equipment, in particular to a full-automatic machine for producing foldable masks. The full-automatic machine comprises a frame body. A mask body feeding device, a nose bridge part gripping and welding device, a roller welding device, a roller cutting device, an ear strap welding device, an ear strap cutting device, a folding device, a crease welding device, and a finished product cutting device, wherein the frame body is provided with a control device, and the control device is connected with the mask body feeding device, the nose bridge part gripping and welding device, the roller welding device, the roller cutting device, the ear strap welding device, the ear strap cutting device, the folding device, the crease welding device, and the finished product cutting device. Compared with the prior art, the full-automatic machine has the advantages that the full-automatic machine is a full-automatic production line for producing the foldable masks, batch production is achieved, manpower cost is saved, work efficiency is increased, and product quality is increased.

Owner:东莞快裕达自动化设备有限公司

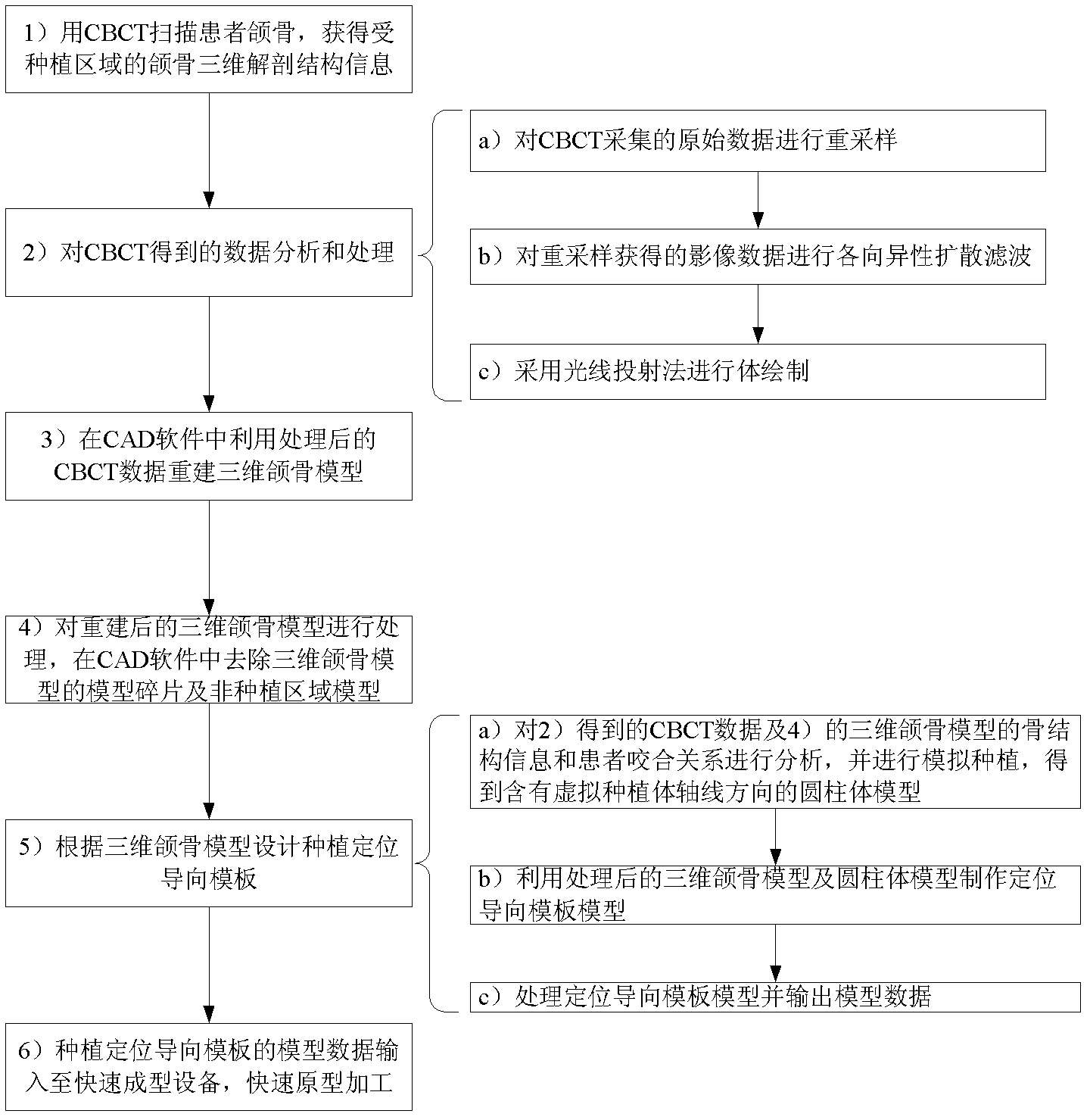

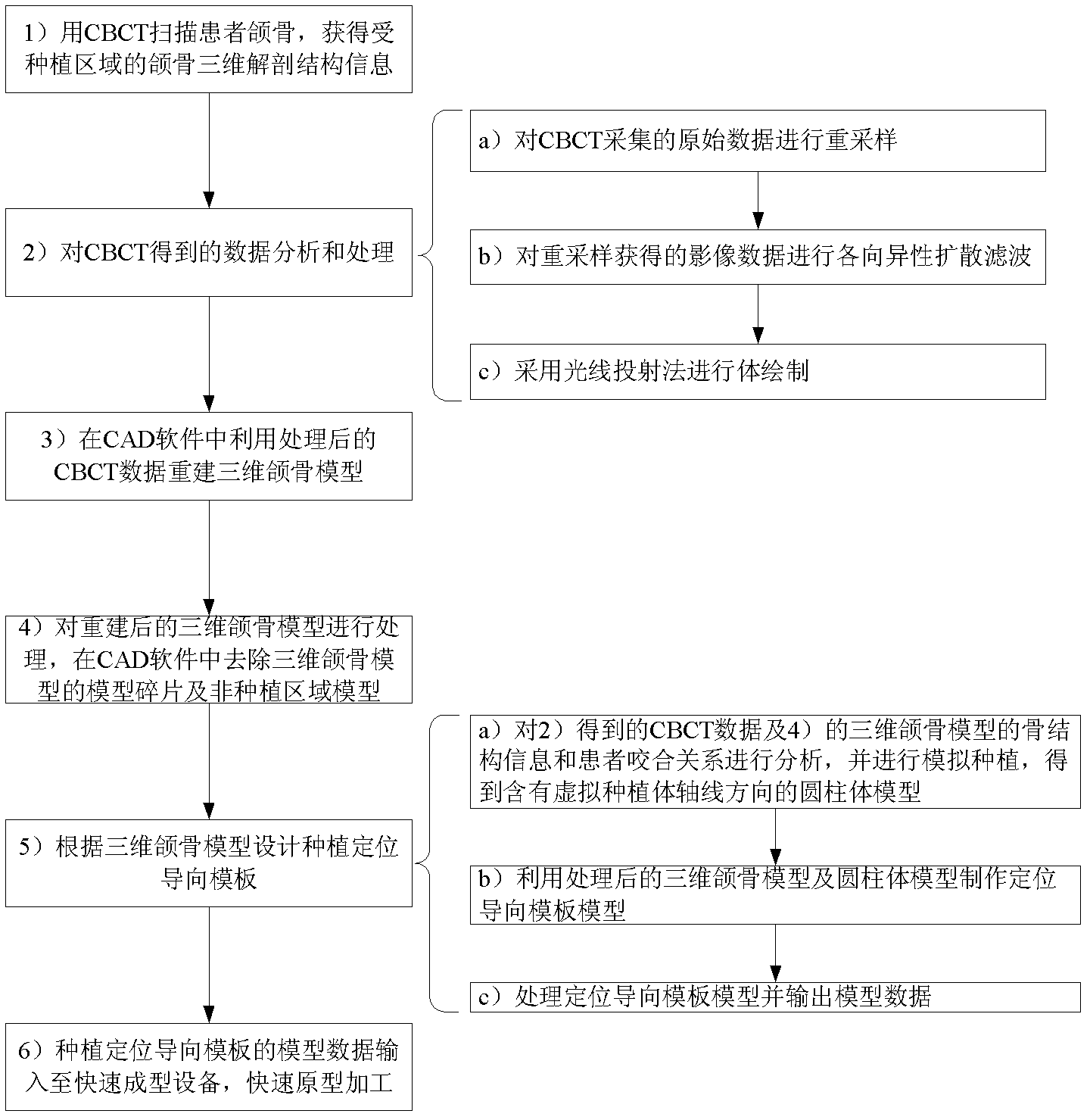

Method for manufacturing oral implant positioning guiding template based on CBCT data

InactiveCN102626347AGuaranteed accurate reconstructionImprove production accuracyDental implantsAnatomical structuresModel reconstruction

The invention discloses a method for making oral implant positioning guiding template based on CBCT data. The method comprises the steps: 1) scanning patient jaw bones through CBCT to mainly obtain jaw bone three-dimensional anatomic structure information of a implant region; 2) analyzing and processing CBCT data; 3) using the processed CBCT data to reconstruct a three-dimensional jaw bone model; 4) processing the reconstructed three-dimensional jaw bone model; 5) designing an oral implant positioning guiding template based on the three-dimensional jaw bone model; and 6) carrying out rapid prototype processing; Amount of influence data is effectively reduced through carrying out resampling, anisotropic diffusion filtering to original image data obtained through CBCT scanning, carrying out volume rendering through a ray-casting method, and noise of the data is further removed, thereby accurate reconstruction of the three-dimensional jaw bone model is guaranteed. Furthermore, accuracy of manufacturing the oral implant positioning guiding template is substantially improved through removing model fragments caused by image artifact and non-implant region models in the process of three dimensional jaw bone model reconstruction.

Owner:UNIVERSAL ENTERPRISES GRP CO LTD

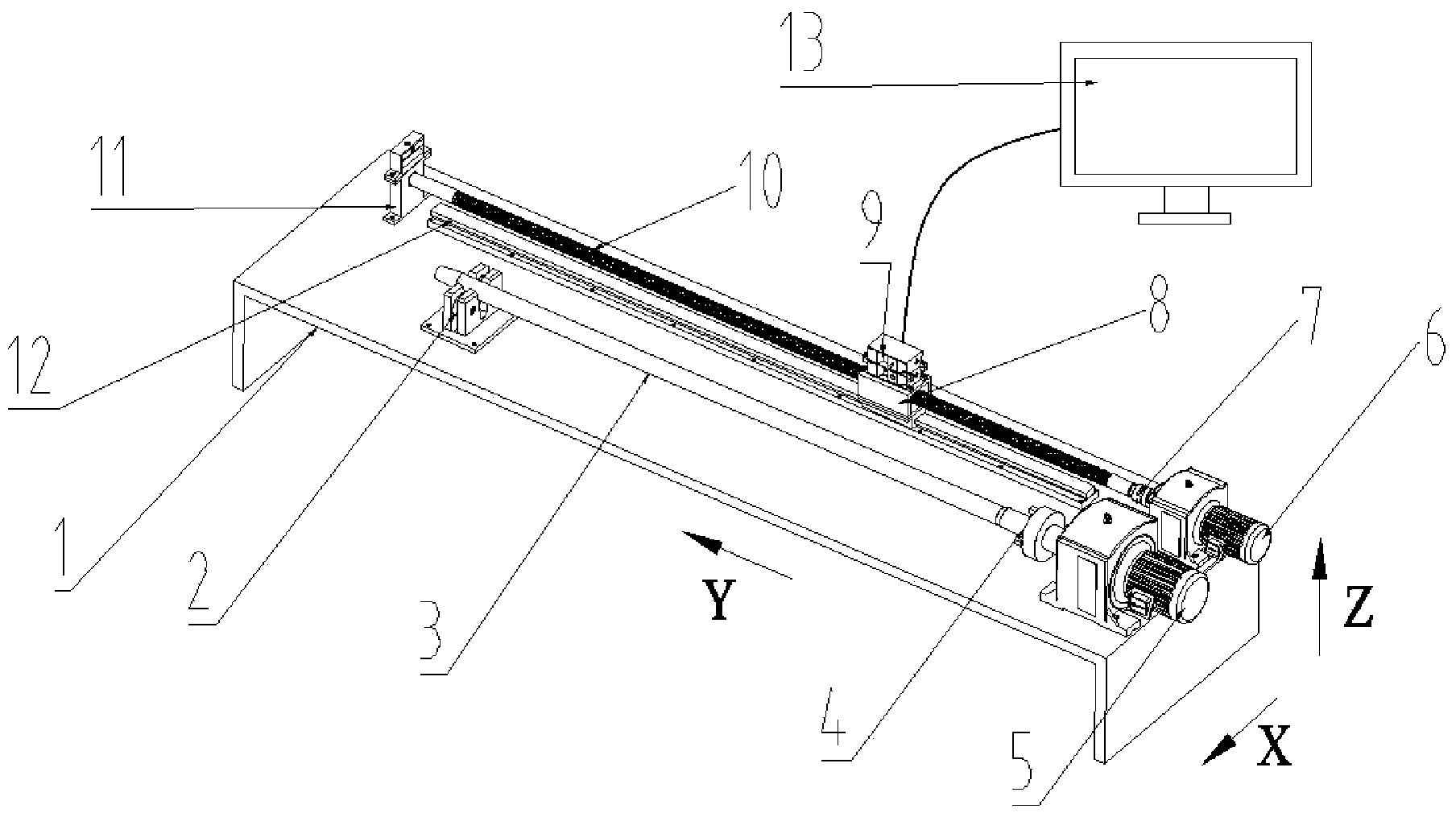

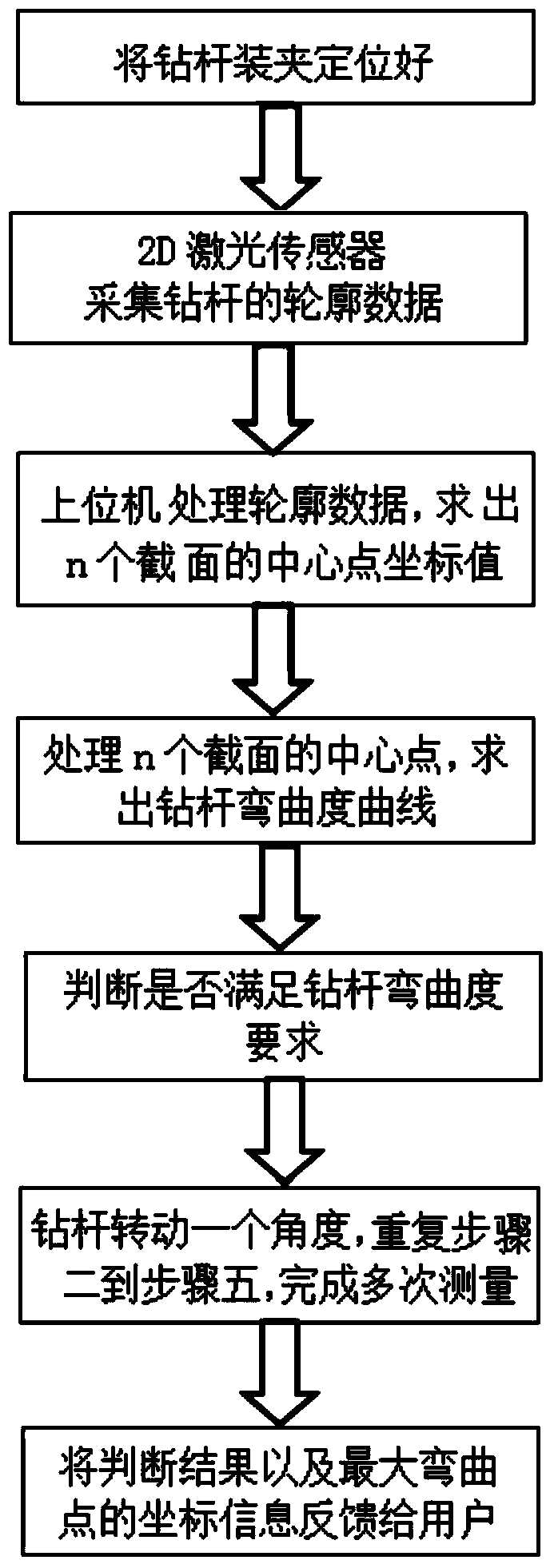

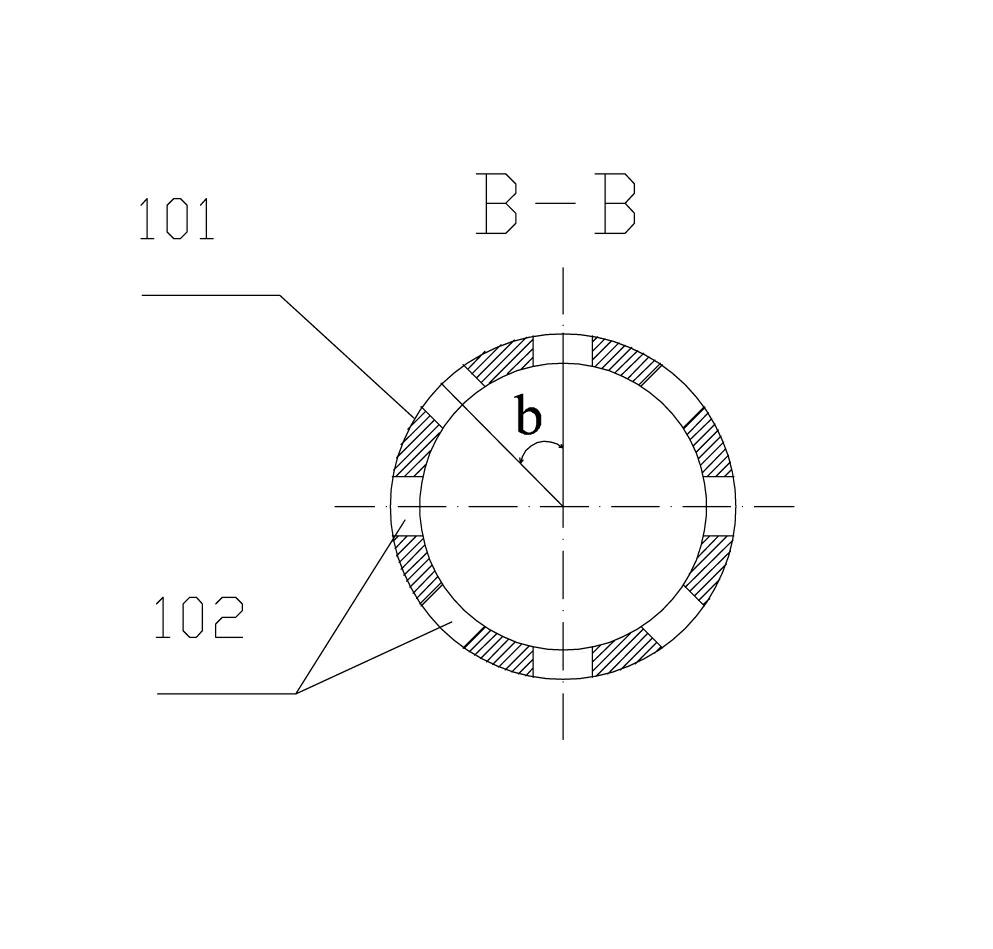

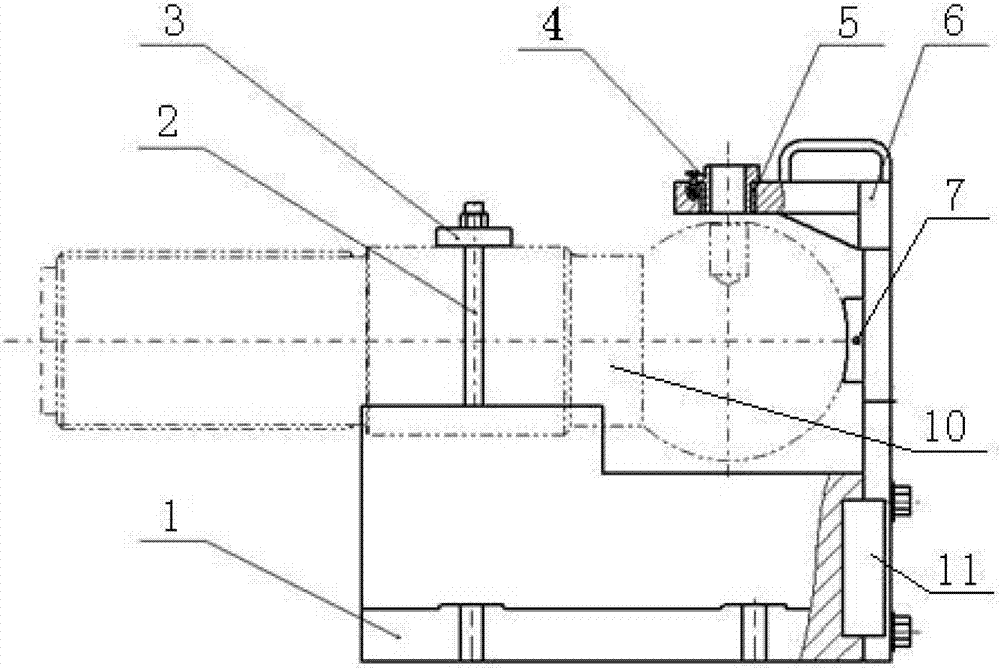

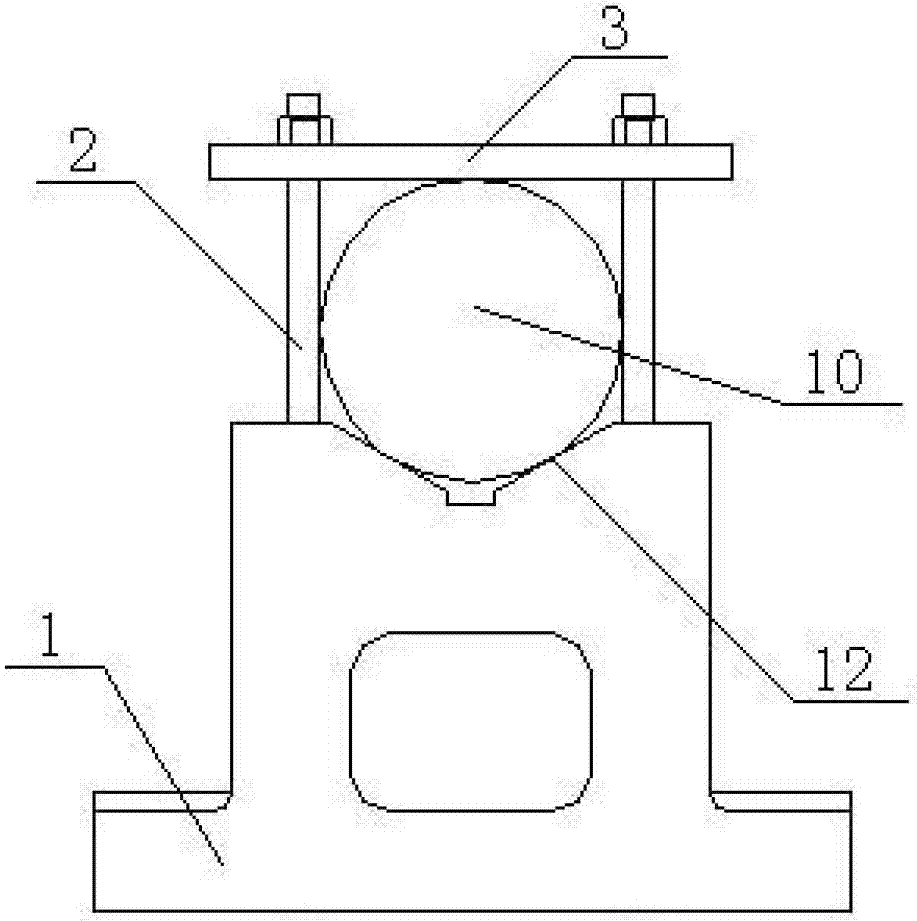

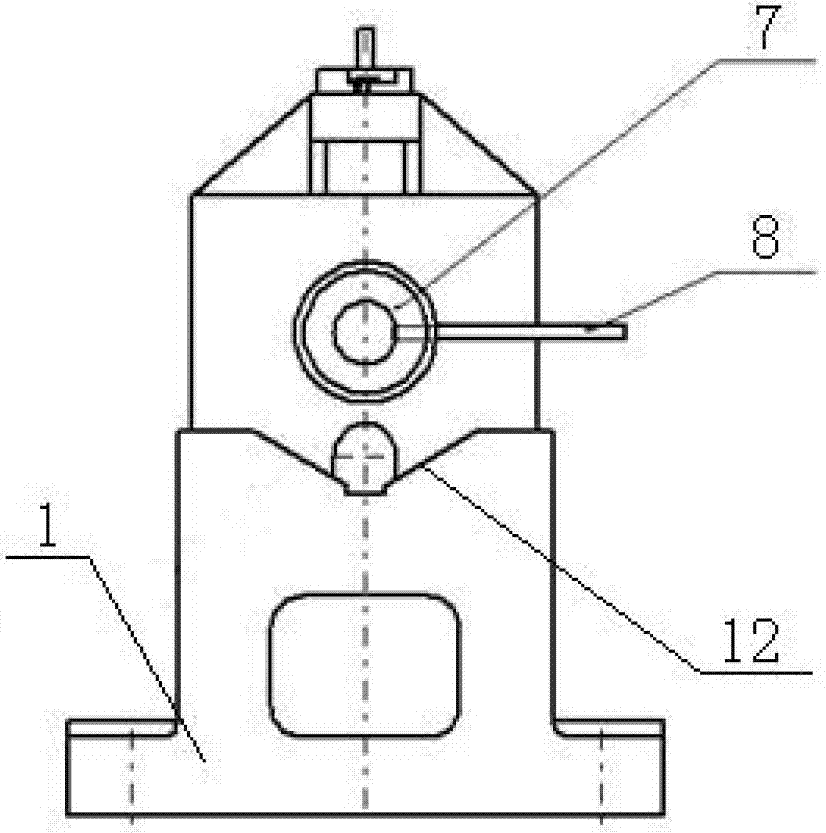

Curvature detection device and method for drill rod

InactiveCN103868470APrevent rotationStructural scienceUsing optical meansMicrocontrollerMicrocomputer

The invention relates to a curvature detection device and method for a drill rod. The device comprises a drill rod clamping part, a sensor transmission part and a control and operation part, wherein a three-jaw chuck, a V-shaped block and a stepping motor A are arranged on the drill rod clamping part; the three-jaw chuck is used for clamping one end of the drill rod, and the other end of the drill rod is placed on the V-shaped block; a 2D (two-dimensional) laser sensor and a stepping motor B are arranged on the sensor transmission part; the control and operation part comprises a single-chip microcomputer and a host. The detection method comprises the following steps: acquiring the three-dimensional coordinate information of hemi-profile data points of a plurality of sections of the drill rod by using the 2D laser sensor; processing and calculating a section central point through the host, and fitting the central lines of n sections; determining the maximum curvature and coordinate value of a maximum bending point, comparing with the curvature limit value of the drill rod, judging whether the curvature of the drill rod is qualified or not, and providing a judgment result for a user. The device is scientific in structure, the detection method is simple, the curvature information of the drill rod can be obtained efficiently and accurately, and technical support is provided for the increase of the production accuracy of the drill rod.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

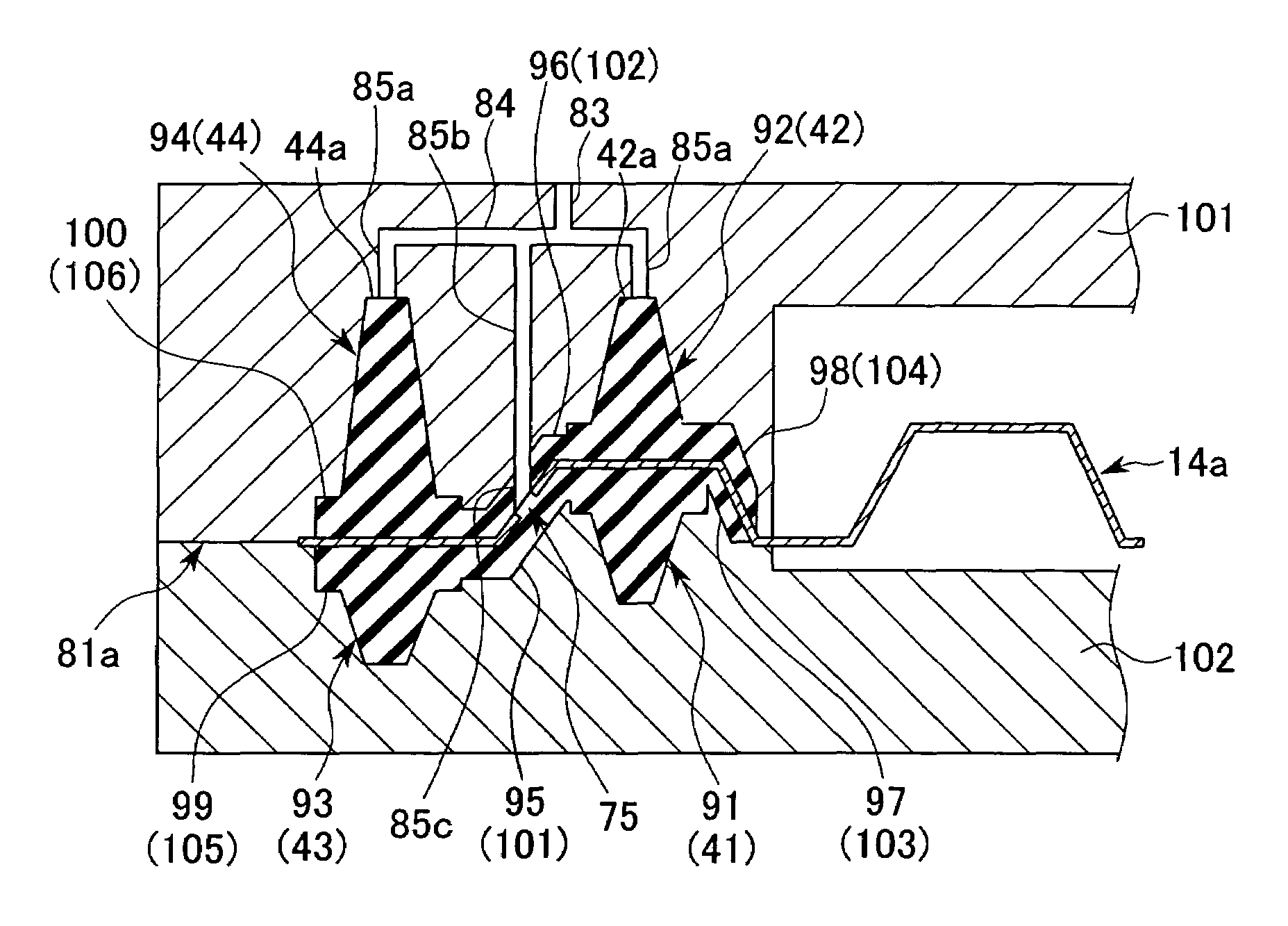

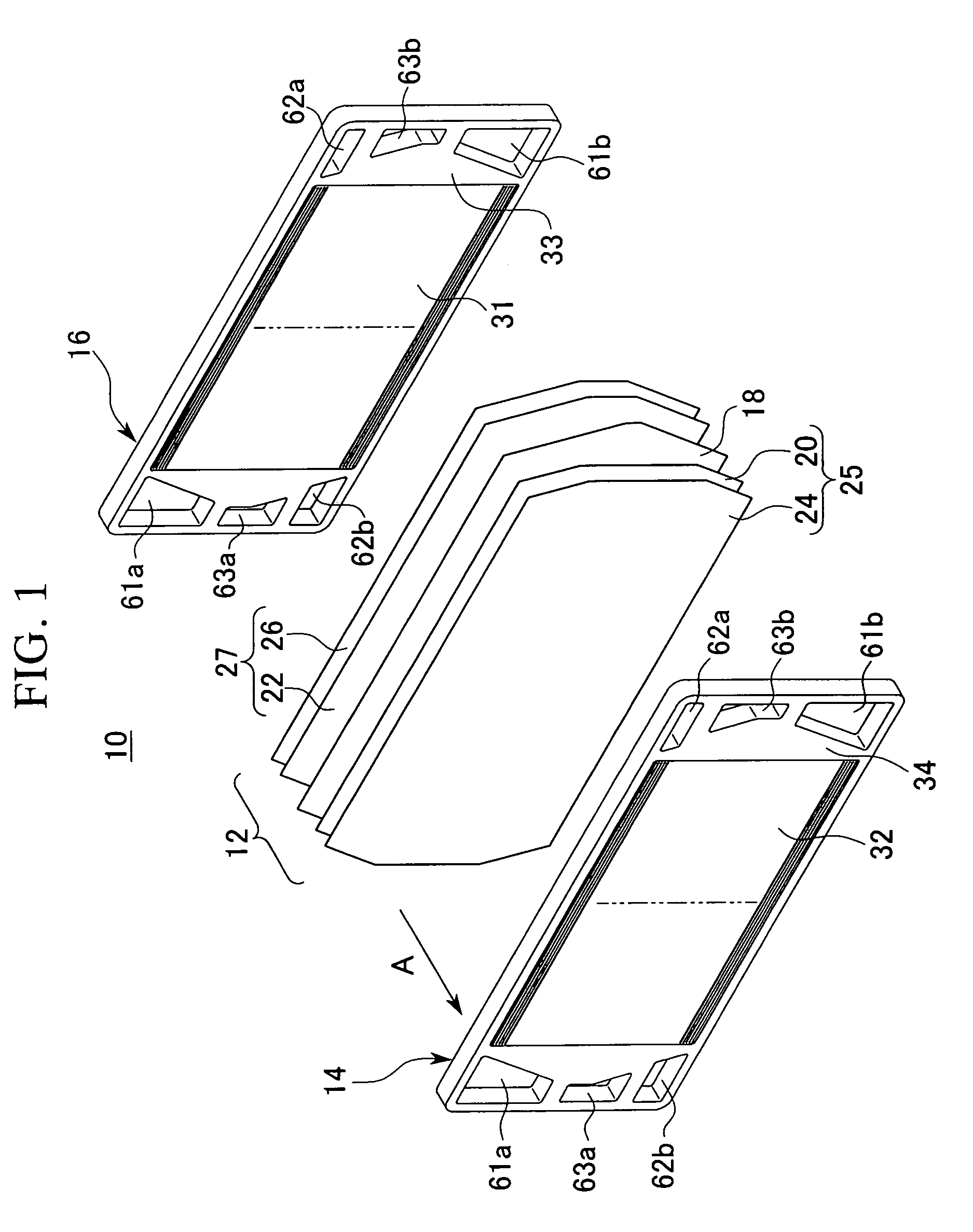

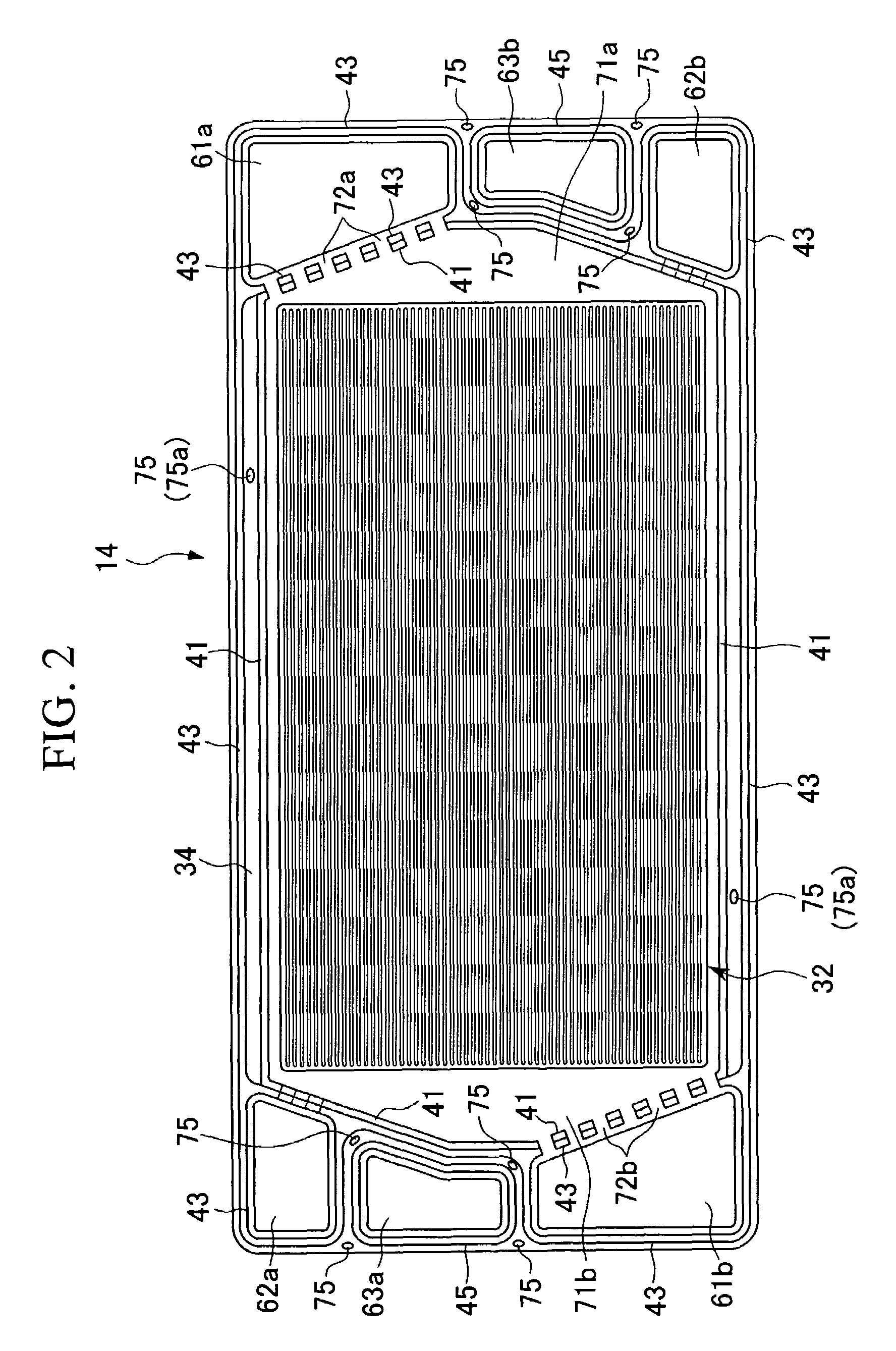

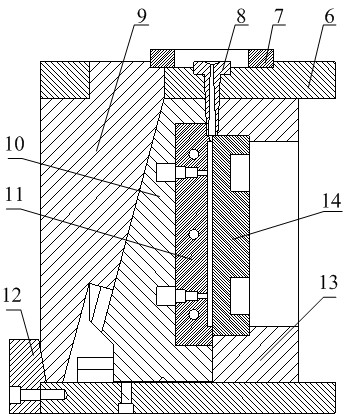

Method for fabricating a seal-integrated separator

InactiveUS7008584B2Shorten molding timeReduced durabilityButtonsFinal product manufactureFuel cellsEngineering

A method for fabricating a seal-integrated separator for a fuel cell is presented, with which seals can be accurately positioned and the assembling time for the fuel cell units may be greatly reduced. The method comprises the steps of: forming a through hole in the separator body; providing a first mold having grooves respectively positioned corresponding to the inner and outer seals disposed on one side of the separator body, a connecting cavity for forming a seal bridge at least partially connecting the inner and outer seals to each other at a position corresponding to the through hole, and at least one gate communicating with each of the grooves, and a second mold having grooves respectively positioned corresponding to the inner and outer seals disposed on the other side of the separator body, and a connecting cavity for forming a seal bridge at least partially connecting the inner and outer seals to each other at a position corresponding to the through hole; holding the separator body between the first mold and the second mold; and injecting melted seal material to form the seals into each of the grooves in the first mold by supplying the melted seal material into the gate and injecting a portion of the melted seal material into each of the grooves in the second mold via the through hole. Through this method, a seal-integrated separator having first to fourth seals which are integrated on both sides of the separator body is fabricated.

Owner:HONDA MOTOR CO LTD

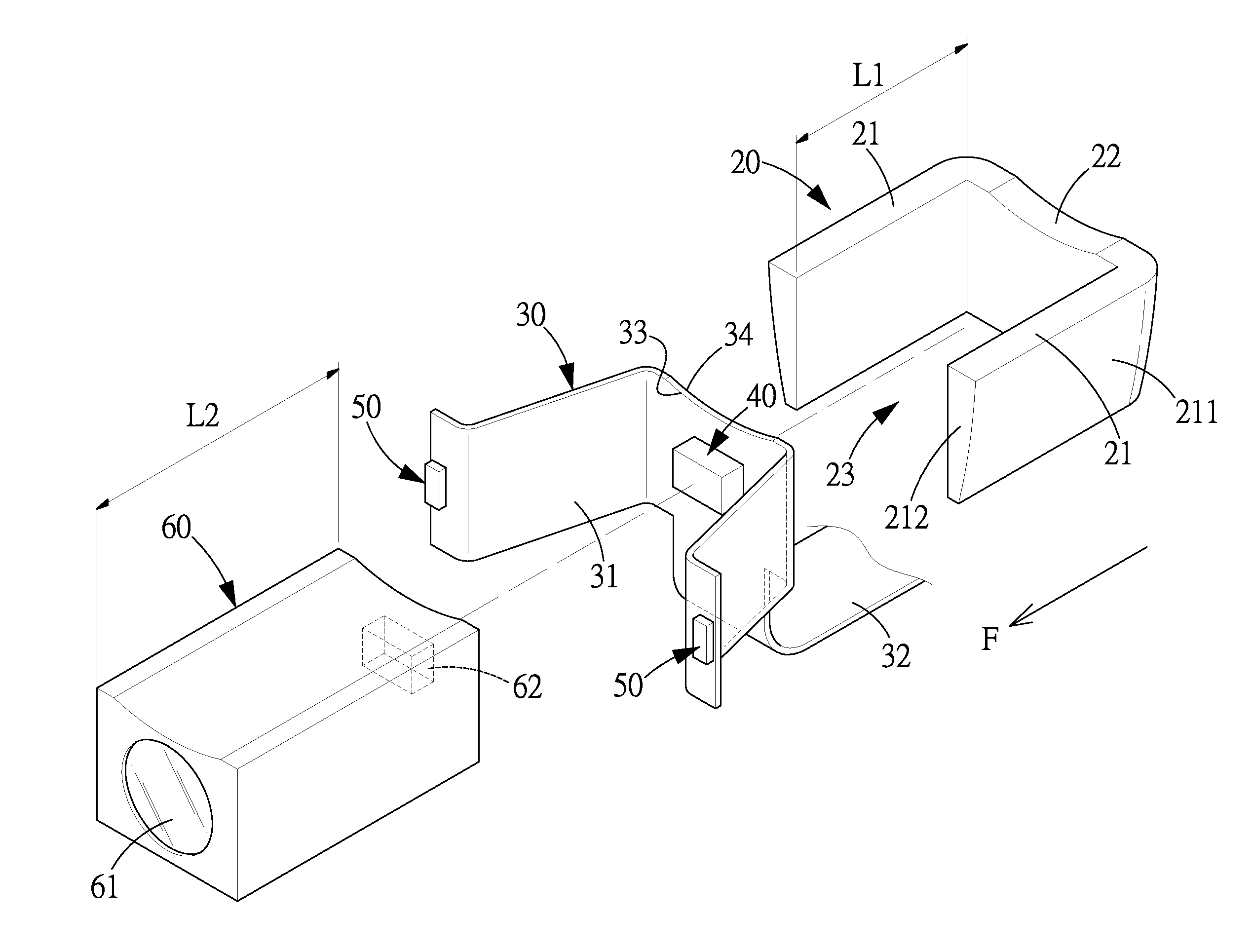

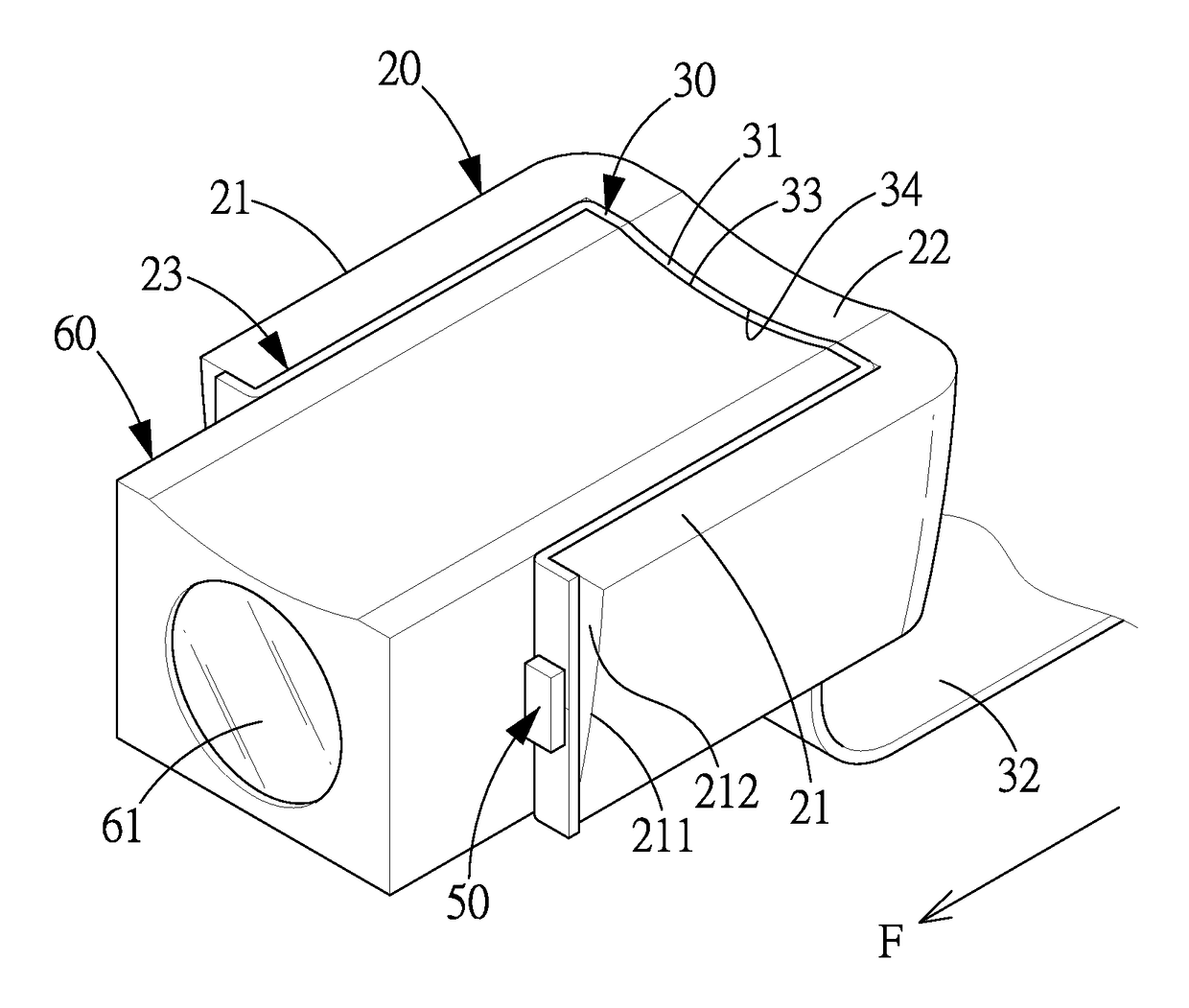

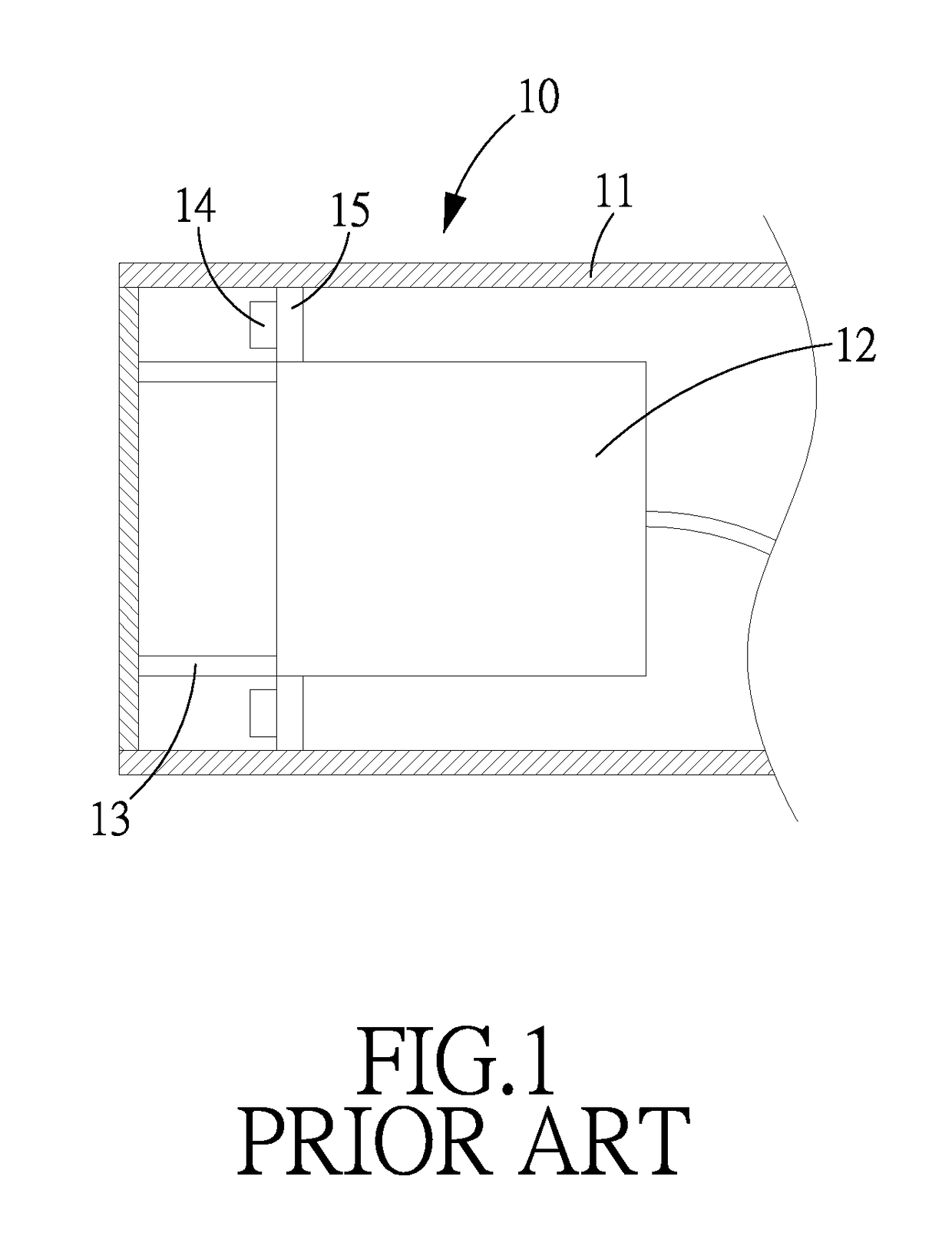

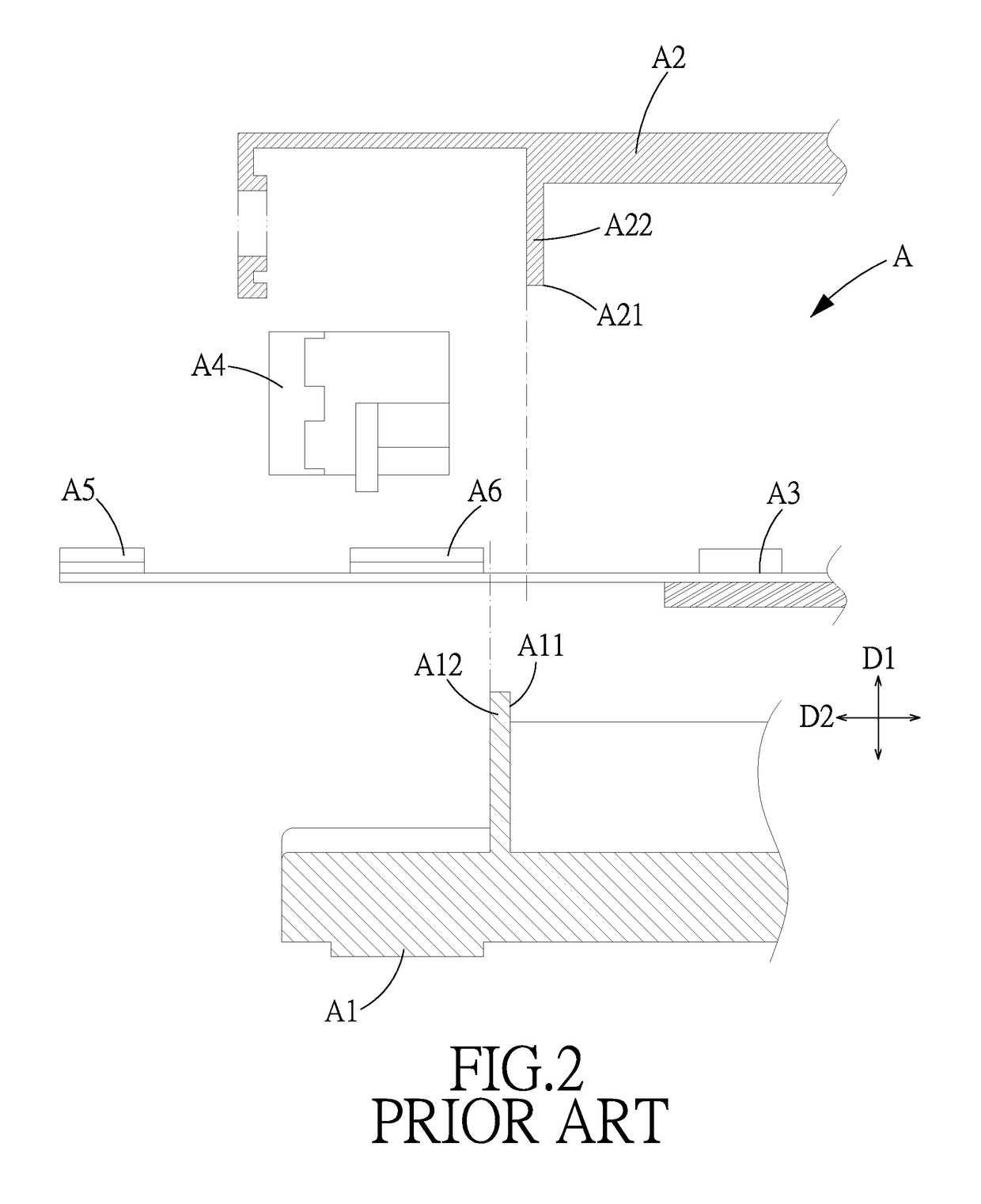

Endoscope with a t-shaped flexible circuit board

An endoscope with a T-shaped flexible circuit board includes: a base mounting frame, a flexible circuit, a photosensitive element, two light emitting elements and a camera. The photosensitive element, the two light emitting elements and the camera are mounted onto the T-shaped flexible circuit board, then the flexible circuit board deforms to fit in the base mounting frame. During assembly, the photosensitive element, the two light emitting elements and the camera are maintained in the same orientation, and the T-shaped flexible circuit can be pushed into the base mounting frame simply by applying a force in a single direction parallel to the orientation direction of the photosensitive element, the two light emitting elements and the camera.

Owner:AMBU AS

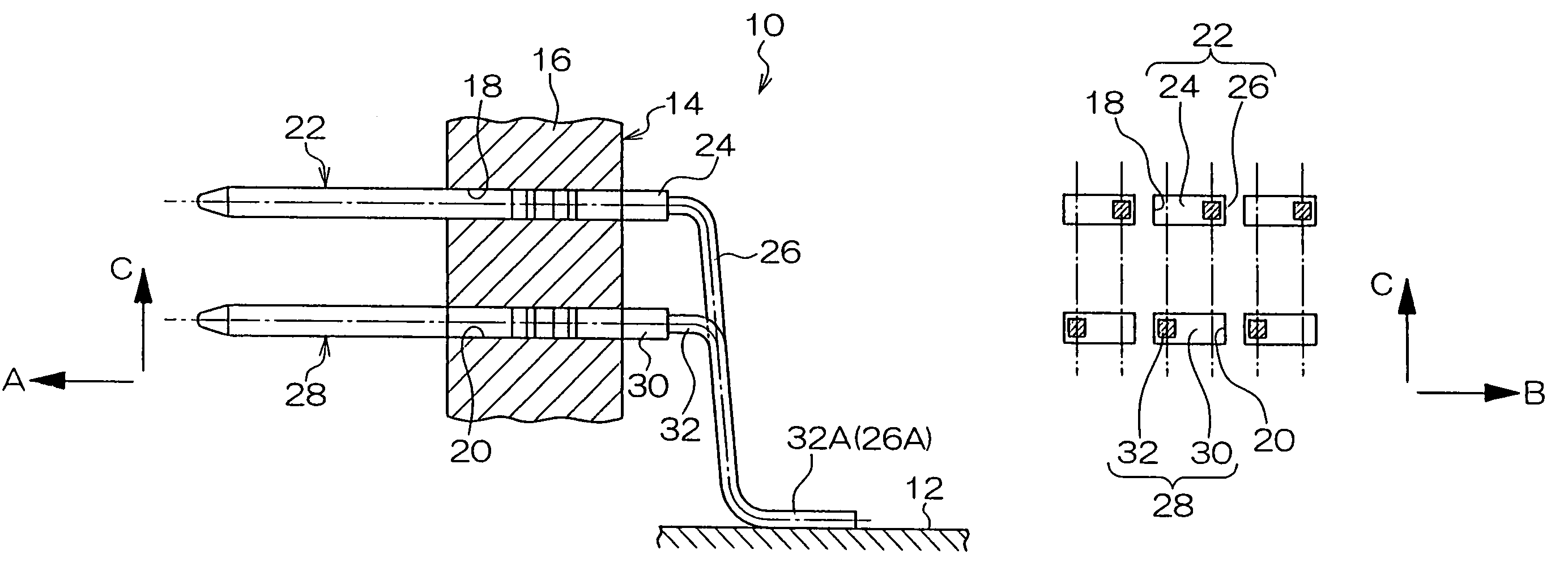

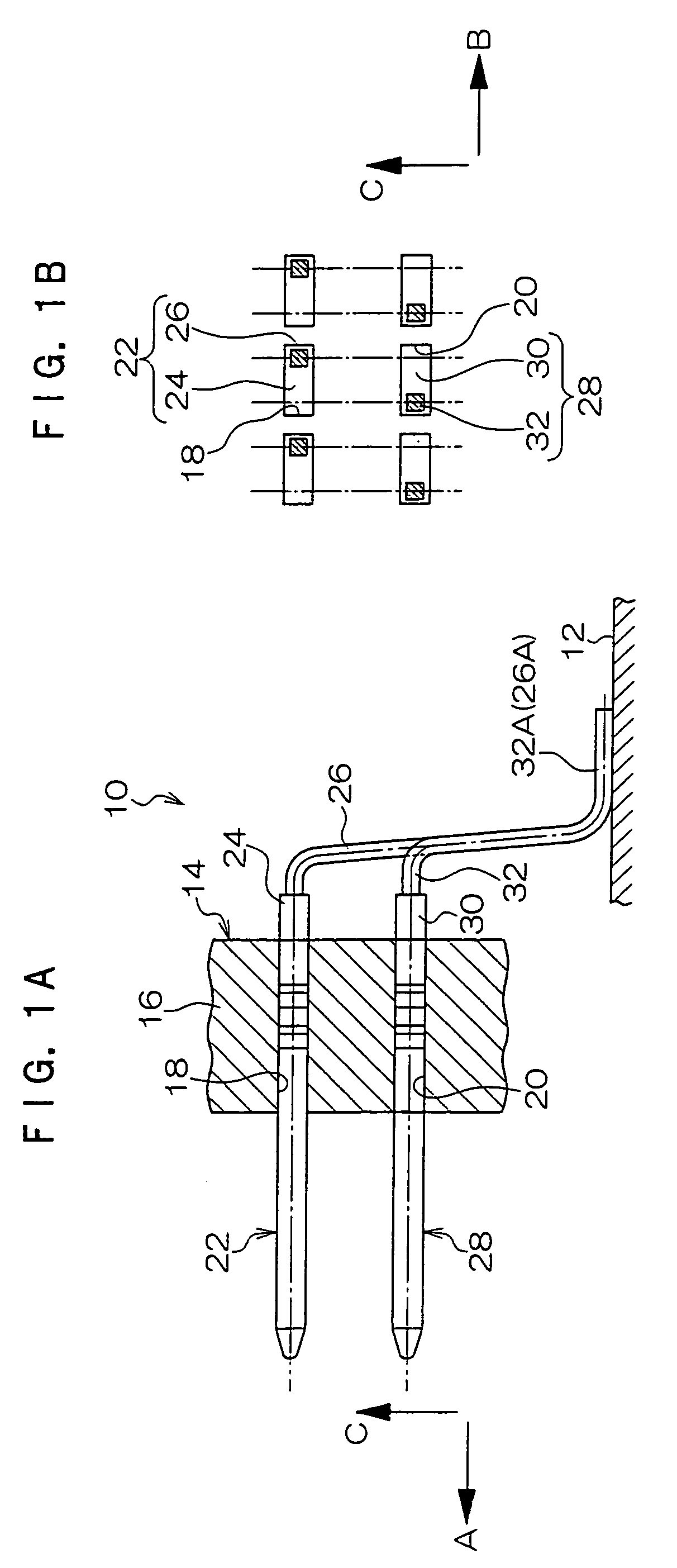

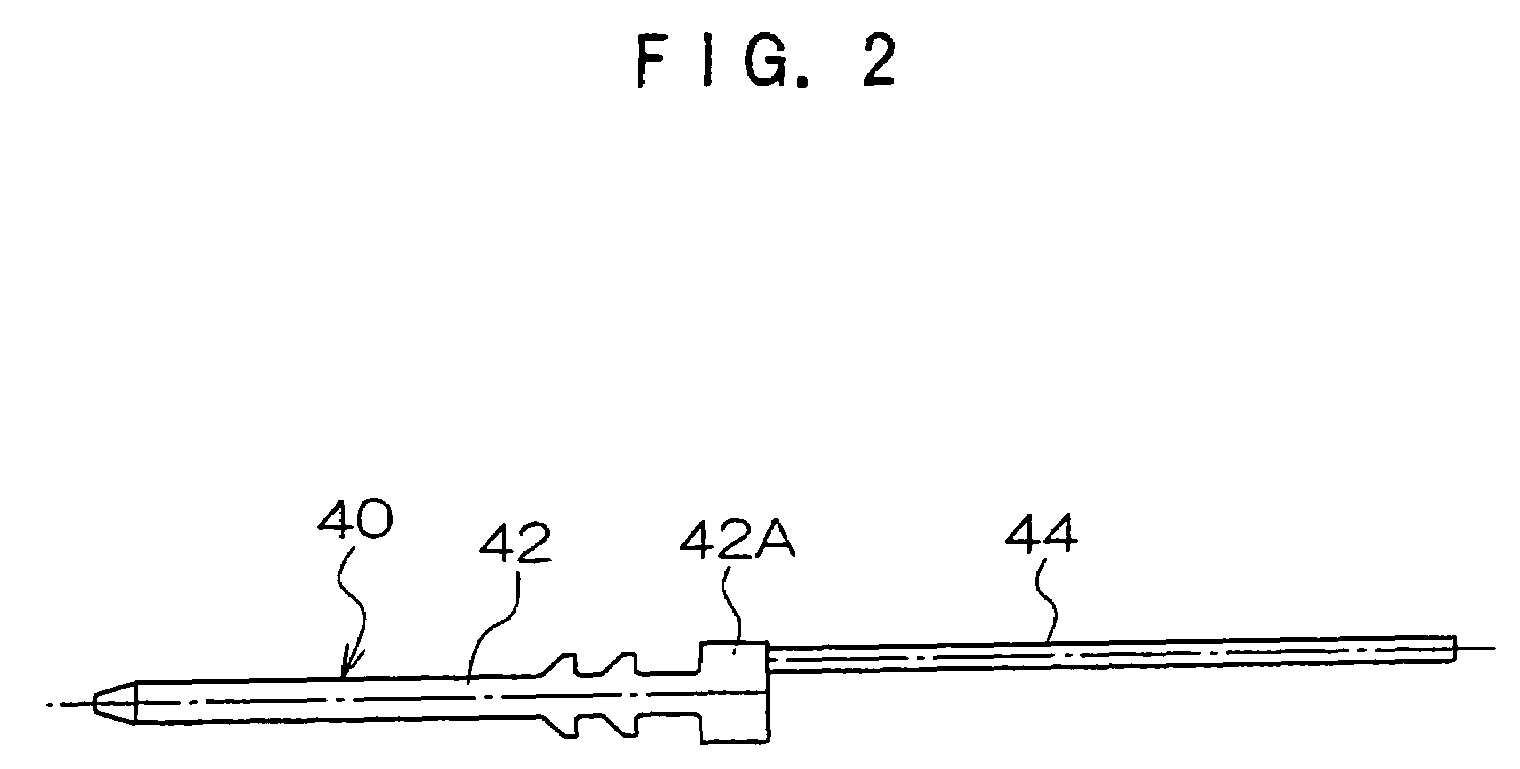

Method of manufacturing terminal

InactiveUS7207809B2Reduce tooling costsImprove production accuracyContact member manufacturingCoupling device detailsEngineeringMechanical engineering

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

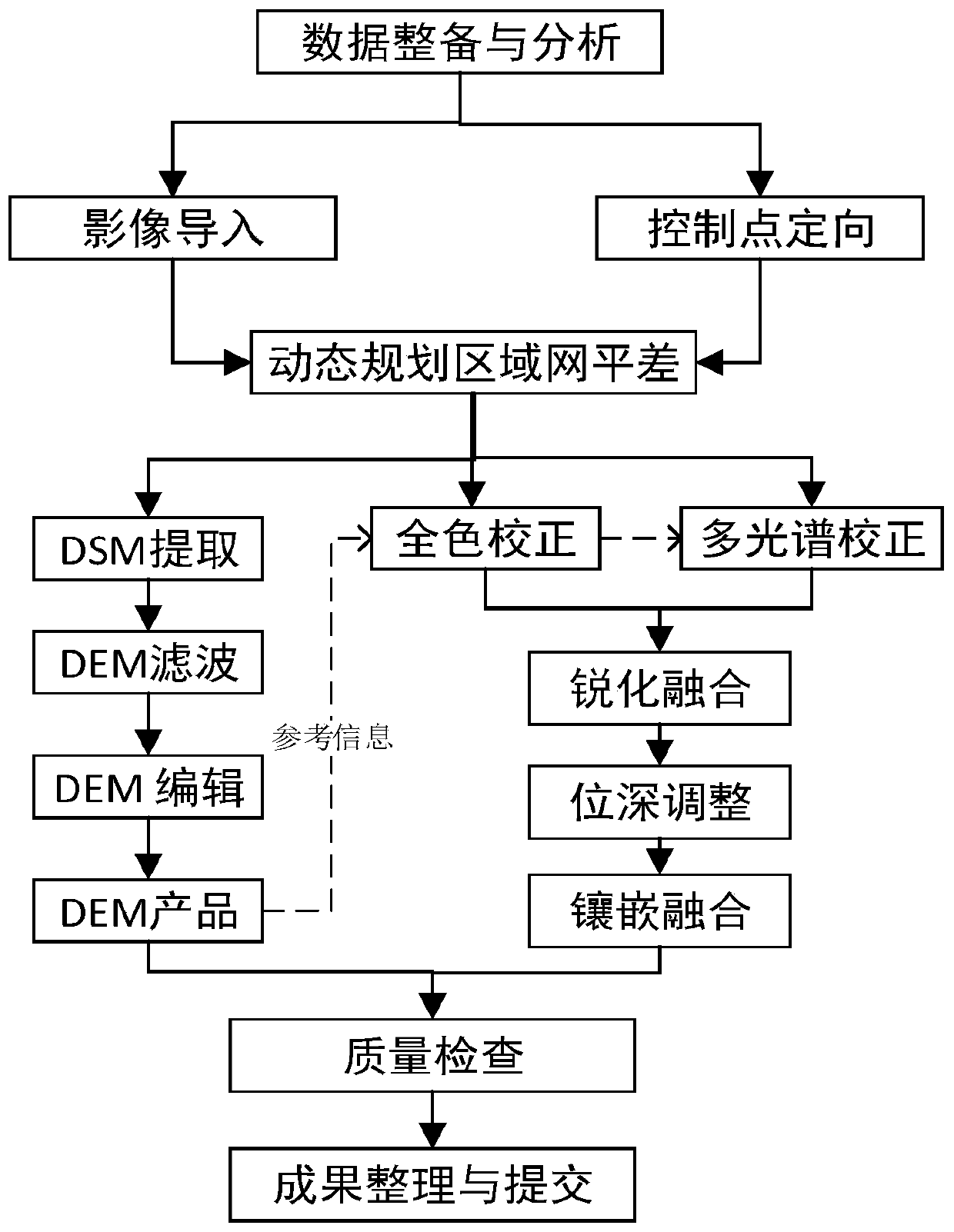

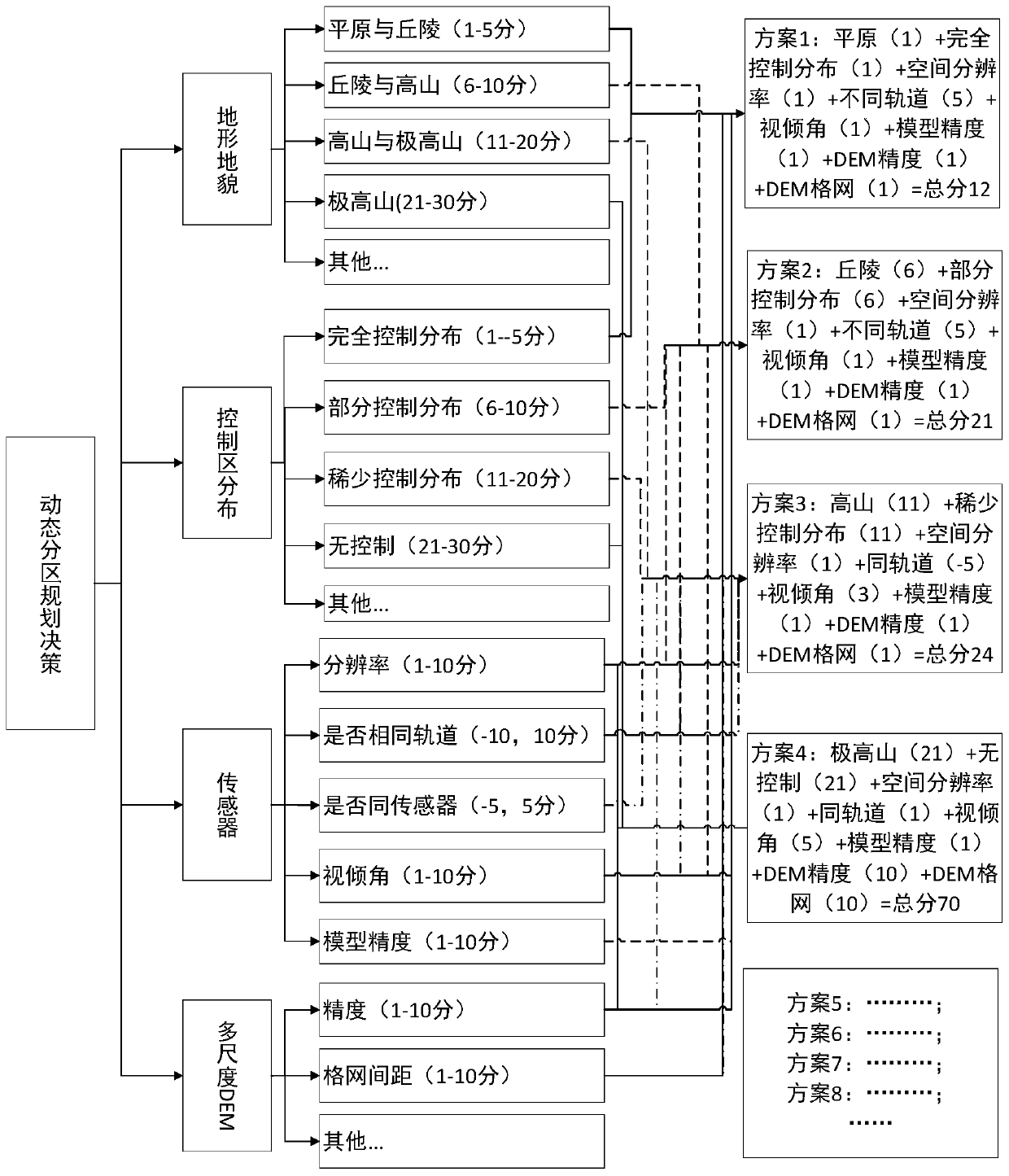

Method for generating ortho-photo map of narrow and long region of border by digital photogrammetry system

InactiveCN110763205AImprove production accuracyIncrease productivityImage enhancementImage analysisData ingestionDigital surface

The invention discloses a method for generating an ortho-photo map of a narrow and long region of a border by a digital photogrammetry system. The method comprises the following steps of (1) preparingand analyzing data; (2) dynamically planning block adjustment; (3) extracting digital surface model data; (4) generating digital elevation model data; (5) performing quality inspection; (6) generating a digital orthoimage; and (7) evaluating the quality of a digital orthoimage product, and generating digital orthoimage product regulations with processes conforming to the national and industry standards. By adopting the method, the precision of the generated digital orthoimage can meet the precision requirements of level-3 products with the scales of 1:10,000 in the national standards minimally, a high-precision, efficient and high-universality digital orthoimage production process is realized, and an innovative technical method is provided for digital mapping work of the narrow and long region of the uncontrolled or less-controlled border.

Owner:新疆维吾尔自治区测绘科学研究院

Method for predicating productivity of nonhomogeneity ancient karst carbonate reservoir

InactiveCN104047598AImprove quantitative calculation accuracyAccurate calculationBorehole/well accessoriesUltrasound attenuationGeomorphology

The invention discloses a method for predicating productivity of nonhomogeneity ancient karst carbonate reservoir. The method includes the steps of firstly clarifying the reservoir through reservoir parameter processing and conducting the reservoir thickness statistics according to the clarified reservoir, secondly determining key parameters related to the productivity, such as matrix porosity, stoneley wave energy attenuation, the surface hole rate and the reservoir thickness, thirdly working out the comprehensive evaluation index RQ of reservoir quality according to the determined key parameters, establishing a productivity predicating model according to the comprehensive evaluation index RQ of the reservoir quality, and finally conducting productivity predication of the nonhomogeneity ancient karst carbonate reservoir according to the established productivity predicating model. By means of the method, the fine depicting and representing of the nonhomogeneity ancient karst reservoir are achieved, the problem of permeability of the nonhomogeneity ancient karst reservoir is solved, the main control factor problem of the productivity of the nonhomogeneity ancient karst reservoir is solved, and quantitative calculation of the main control factor is achieved, so that accurate productivity prediction can be achieved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

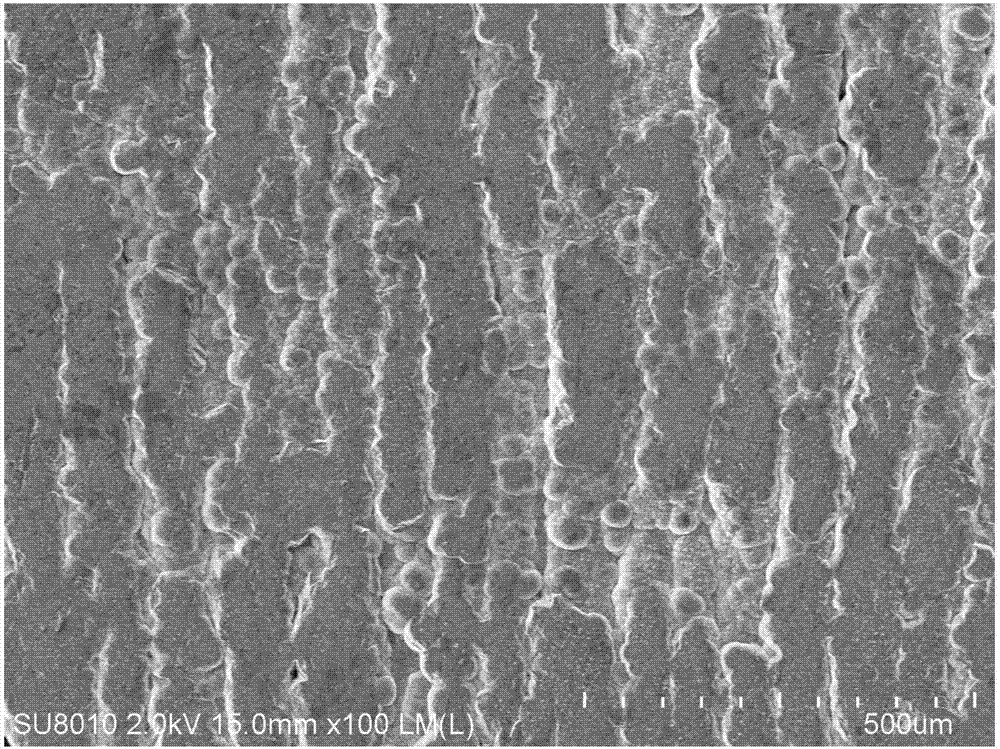

Production process of large-caliber thin-walled seamless stainless steel pipe

ActiveCN101862763AHigh quality and precisionImprove production accuracyMetal rolling arrangementsSolution treatmentElectric arc furnace

The invention relates to a production process of a large-caliber thin-walled seamless stainless steel pipe, which comprises the following production steps: (a) firstly, preparing 0Cr18Ni10Ti stainless steel pipe bloom made by an arc furnace and electroslag remelting or vacuum induction and electroslag remelting; (b) after pickling and solution treatment, carrying out first cold-rolled processing for the stainless steel pipe bloom to make a coarse steel pipe; (c) after degreasing and solution treatment, carrying out the crude steel pipe by cold-drawing and caliber-enlarging processing for the coarse steel pipe to make a large-caliber steel pipe; (d) after degreasing and solution treatment, carrying out second cold-rolled processing for the stainless steel pipe to make a refined steel pipe;and (e) after degreasing and solution treatment, straightening, pipe cutting, pickling and inspection, the refined steel pipe being made into a large-caliber thin-walled seamless stainless steel pipefinished product. With the process of the invention, the length of the steel pipe can reach or exceed 6000mm, and the steel pipe does not produce twisting and spinning amboss phenomenon and the like.

Owner:常州市联谊特种不锈钢管有限公司

Manufacturing method of directionally organized ceramic matrix composite spare part

ActiveCN107032824AImprove production accuracyGood surface qualityCeramic shaping apparatusClay mixing apparatusSolventPyrolysis

The invention relates to a manufacturing method of a directionally organized ceramic matrix composite spare part. The manufacturing method includes steps of firstly manufacturing a spare part resin shell with two opened ends; preparing suspending slurry by monomer, crosslinking agent and ceramic powder, and pouring the suspending slurry in the spare part resin shell; cooling, solidifying and directionally crystalizing solvent in the suspending slurry along the direction of temperature gradient by arranging a temperate field; vacuum-freezing and drying the suspending slurry after being solidified completely, then preserving temperature at 900-1200 DEG; removing organic matters to obtain a ceramic spare part porous body; depositing a SiC interface on the inner fiber surface of the ceramic spare part porous body by a CVD / CVI method; applying precursor infiltration and pyrolysis to densify the ceramic spare part porous body deposited with the SiC interface to obtain the directionally organized ceramic matrix composite spare part. Through controlling solvent crystal under low temperature, and rapid shaping, fiber enhancement, precursor infiltration and pyrolysis and other technical steps, the directional organization is formed; the reinforcement and toughening can be realized effectively.

Owner:XI AN JIAOTONG UNIV

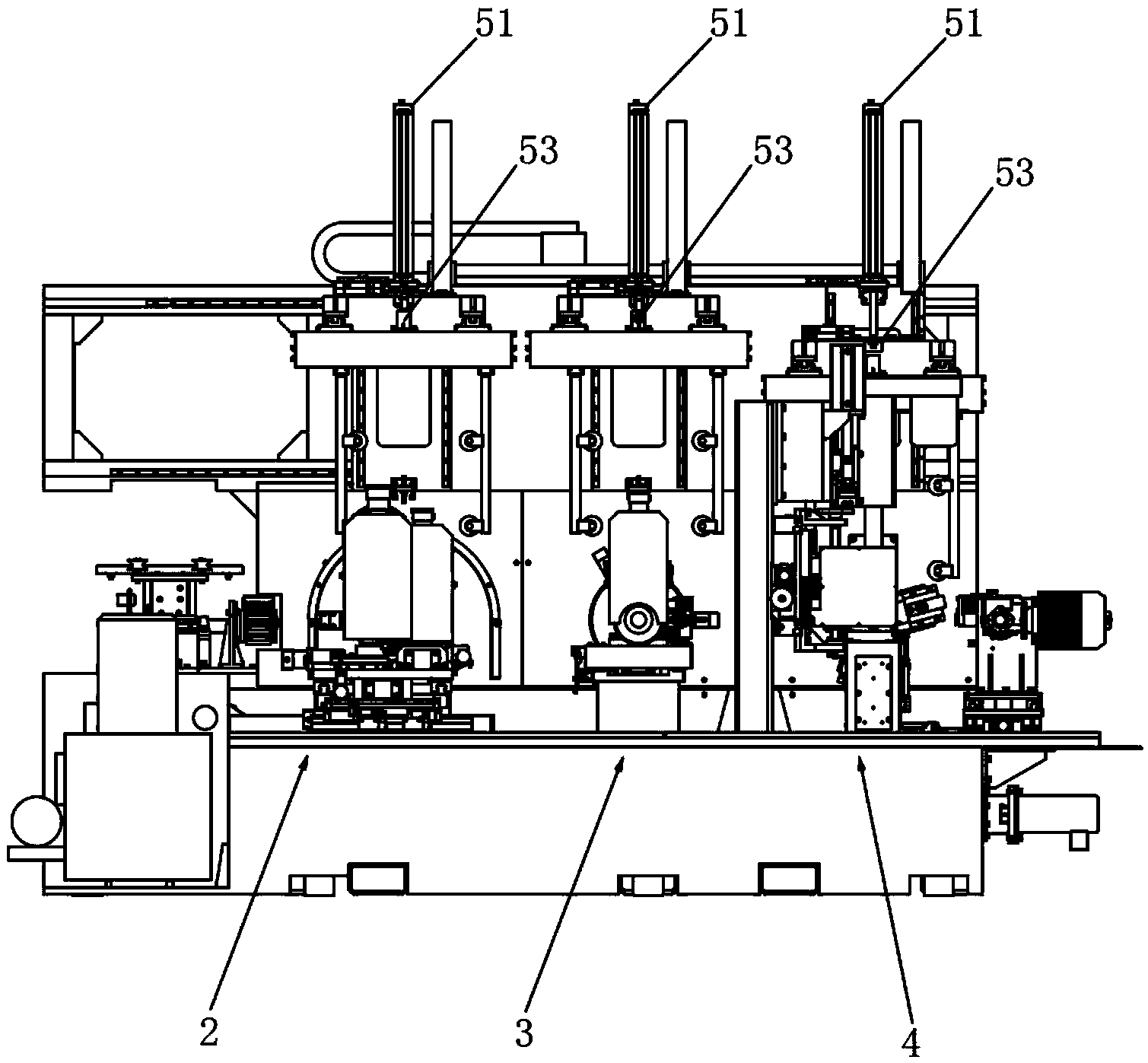

Full-automatic rough machining method and system for motorcycle wheel

ActiveCN104015054AIncrease productivityImprove production accuracyWork clamping meansOther manufacturing equipments/toolsEngineeringAssembly line

The invention discloses a full-automatic rough machining method and system for a motorcycle wheel. A machine tool is sequentially provided with a dead head and sprue cutting station, a center hole drilling station and a valve core hole drilling station in the feeding direction. The dead head and sprue cutting station, the center hole drilling station and the valve core hole drilling station in the feeding direction are respectively provided with a claw disc for three-station synchronous working. Each claw disc is provided with three synchronous pneumatic claws for clamping a hub. The synchronous pneumatic claws sequentially convey hub workblanks to the dead head sprue cutting station, the center hole drilling station and the valve core hole drilling station for continuous machining. A dead head and sprue cutting device at the dead head and sprue cutting station completes dead head cutting and sprue cutting of the third hub workblank at the same time, center hole drilling and valve core hole drilling are completed on the first and second hub workblanks conveyed to the center hole drilling station and the valve core hole drilling station respectively at the same time at the center hole drilling station and the valve core hole drilling station, and the machined hub workblanks are conveyed to a discharging assembly line. According to the full-automatic rough machining method and system for the motorcycle wheel, production efficiency and production precision can be greatly improved, and the production cost is reduced.

Owner:ZHEJIANG WANFENG TECH DEV CO LTD

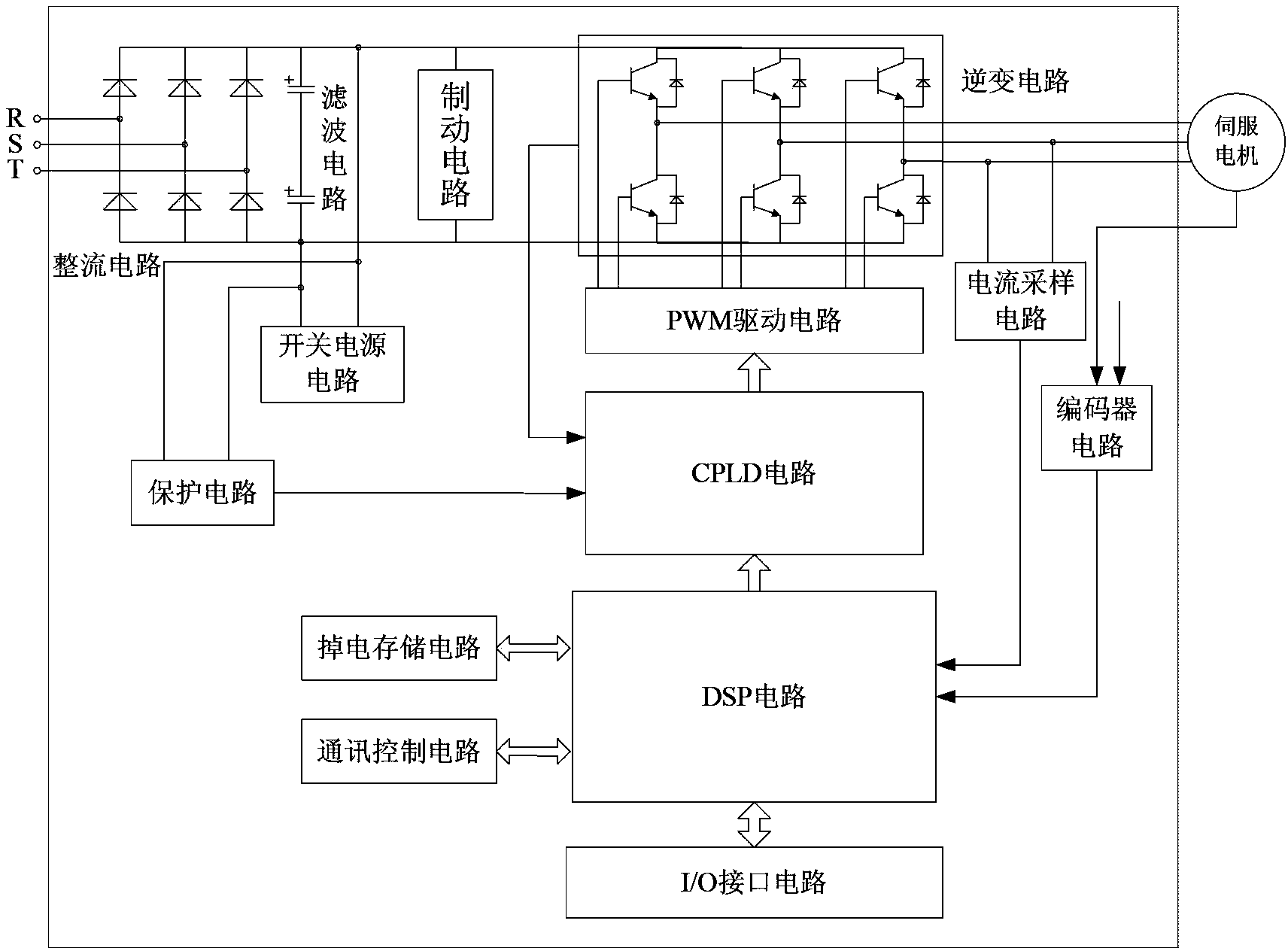

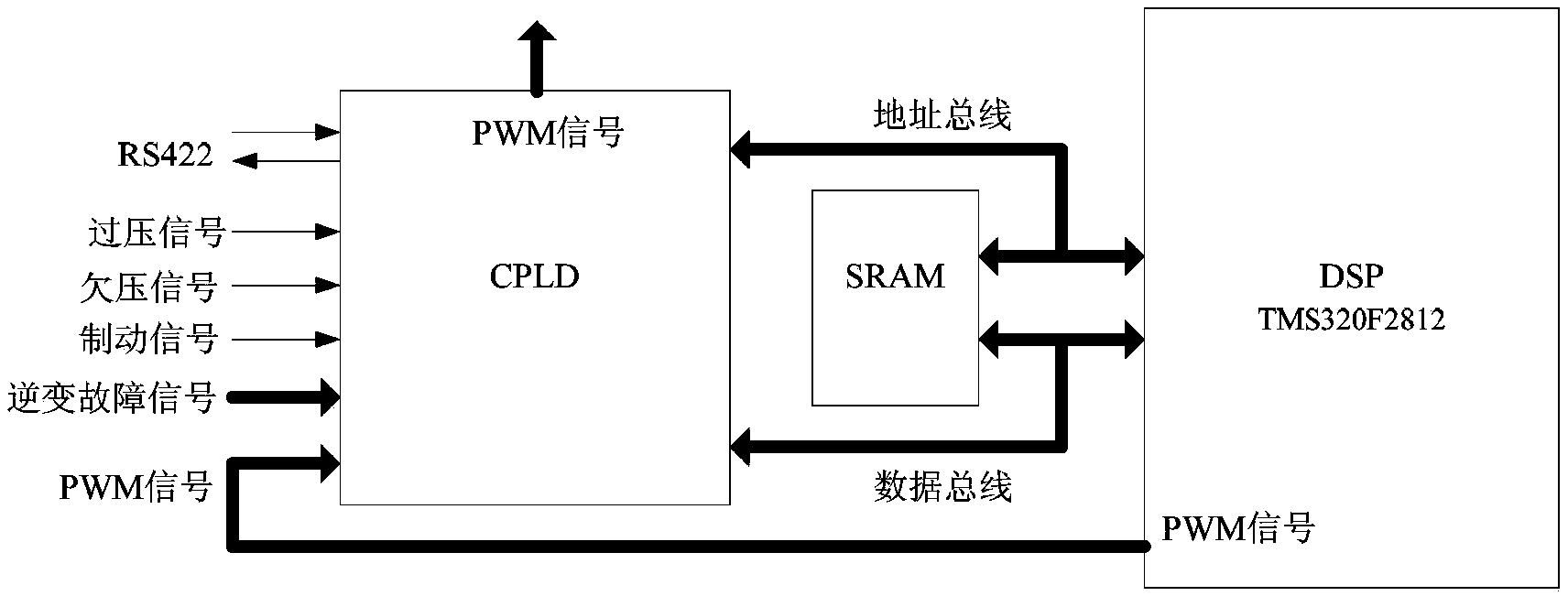

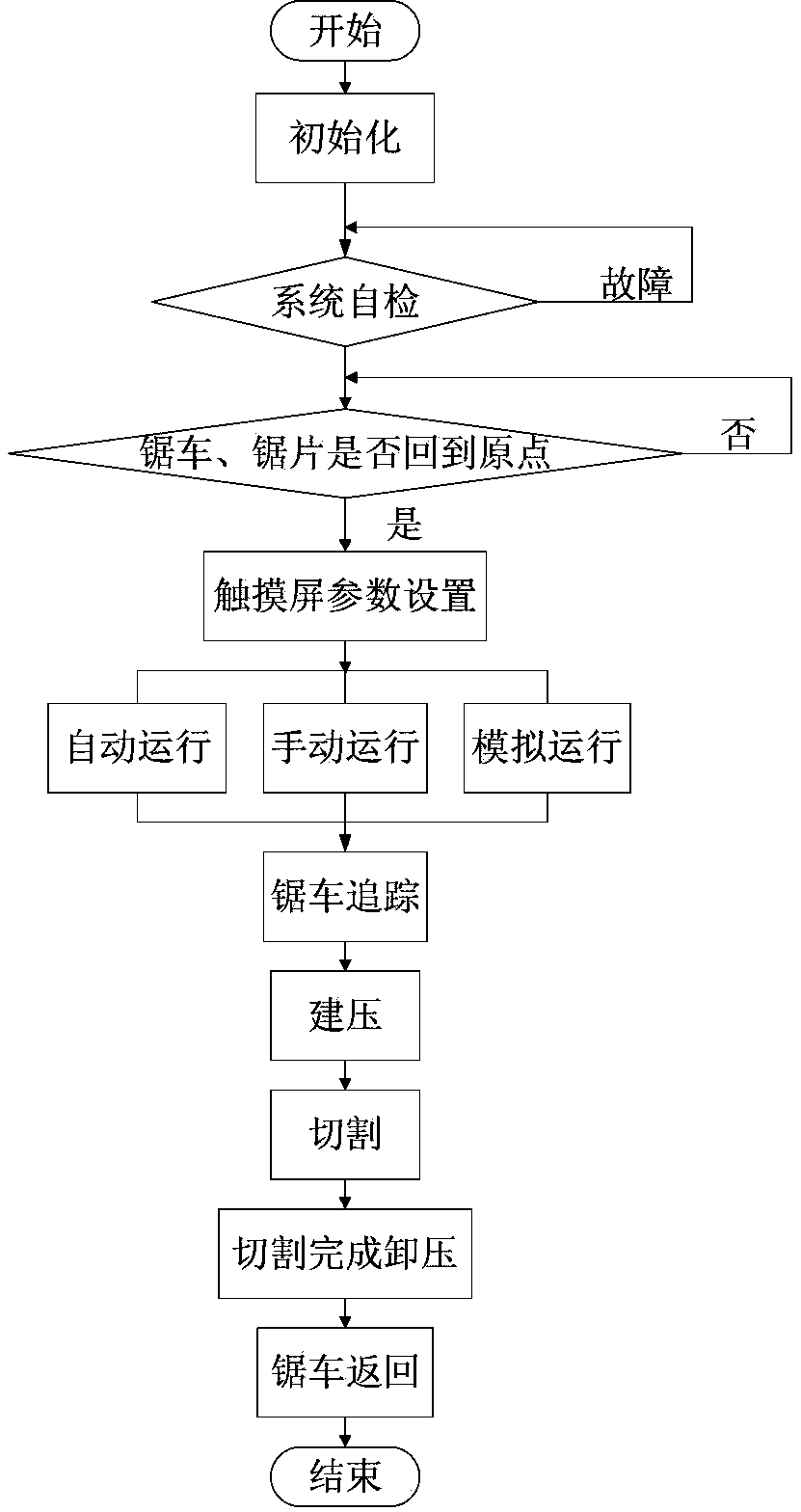

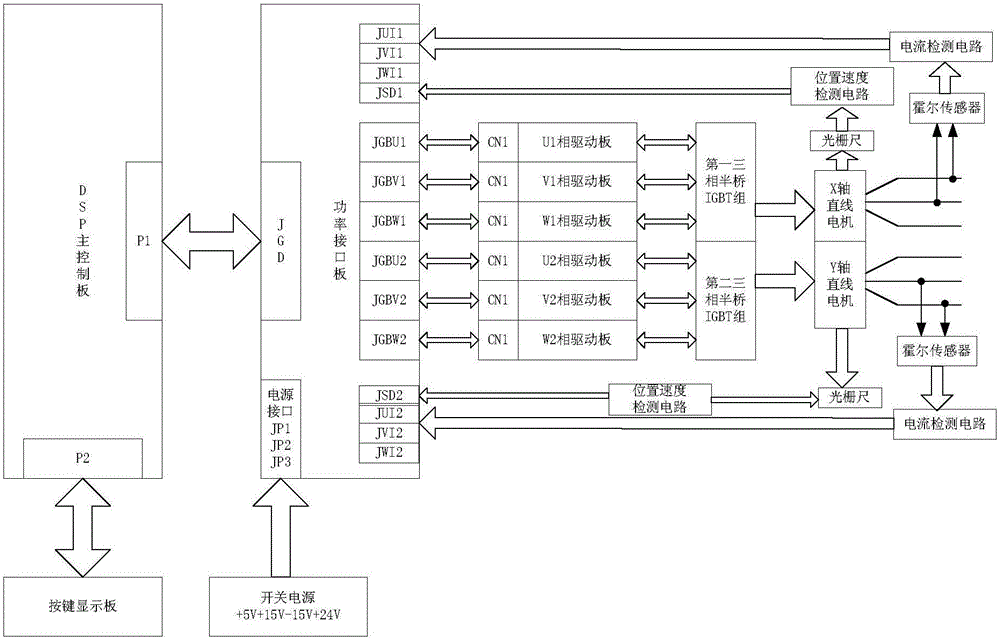

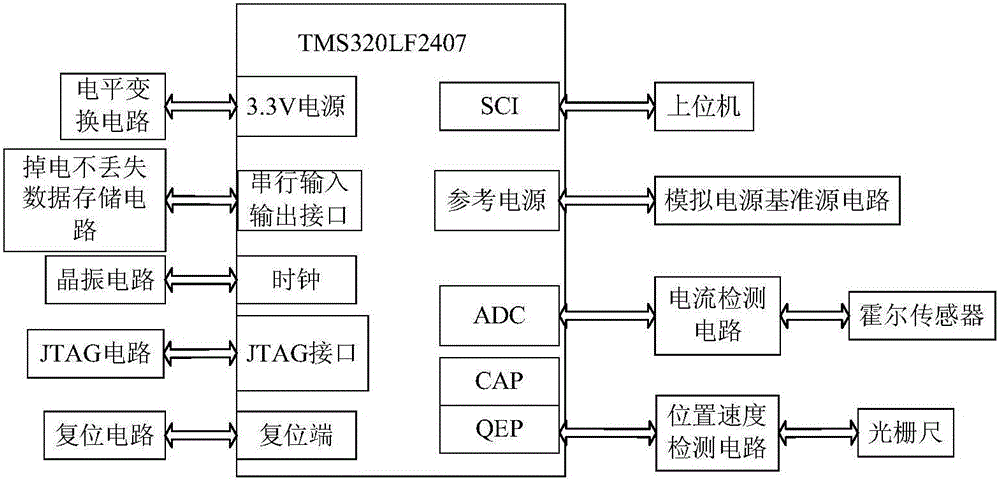

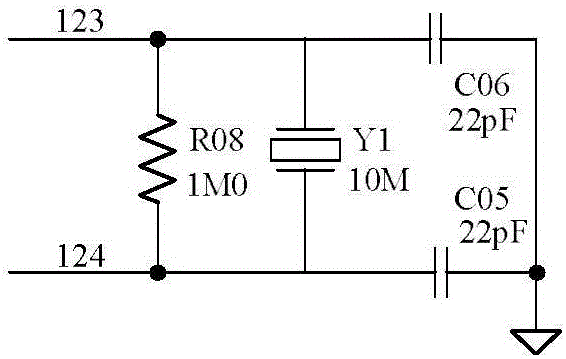

Servo motion control integrated machine system for flying saw machine

InactiveCN103414431AAddressing vulnerability to distractionsReduce occupancyElectronic commutation motor controlAC motor controlAutomatic controlControl signal

The invention provides a servo motion control integrated machine system for a flying saw machine, belonging to the technical field of automatic control. The system comprises a rectifier circuit, a filter circuit, a brake circuit, a switch power supply circuit, a protection circuit, an inverter circuit, a current sampling circuit, an encoder circuit, a PWM drive circuit, a CPLD circuit, a DSP circuit, a power down memory circuit, a communication control circuit and an I / O interface circuit. The system has the advantages that the problems of oscillation, instability and even out of control of a flying saw actuator which is a servo motor caused by control signal introduction interference caused by different ground potentials of two devices are solved. The production precision is improved. The reliability is enhanced, and the response speed is improved.

Owner:SHENYANG CONTOR MACHINE & ELECTRIC EQUIP

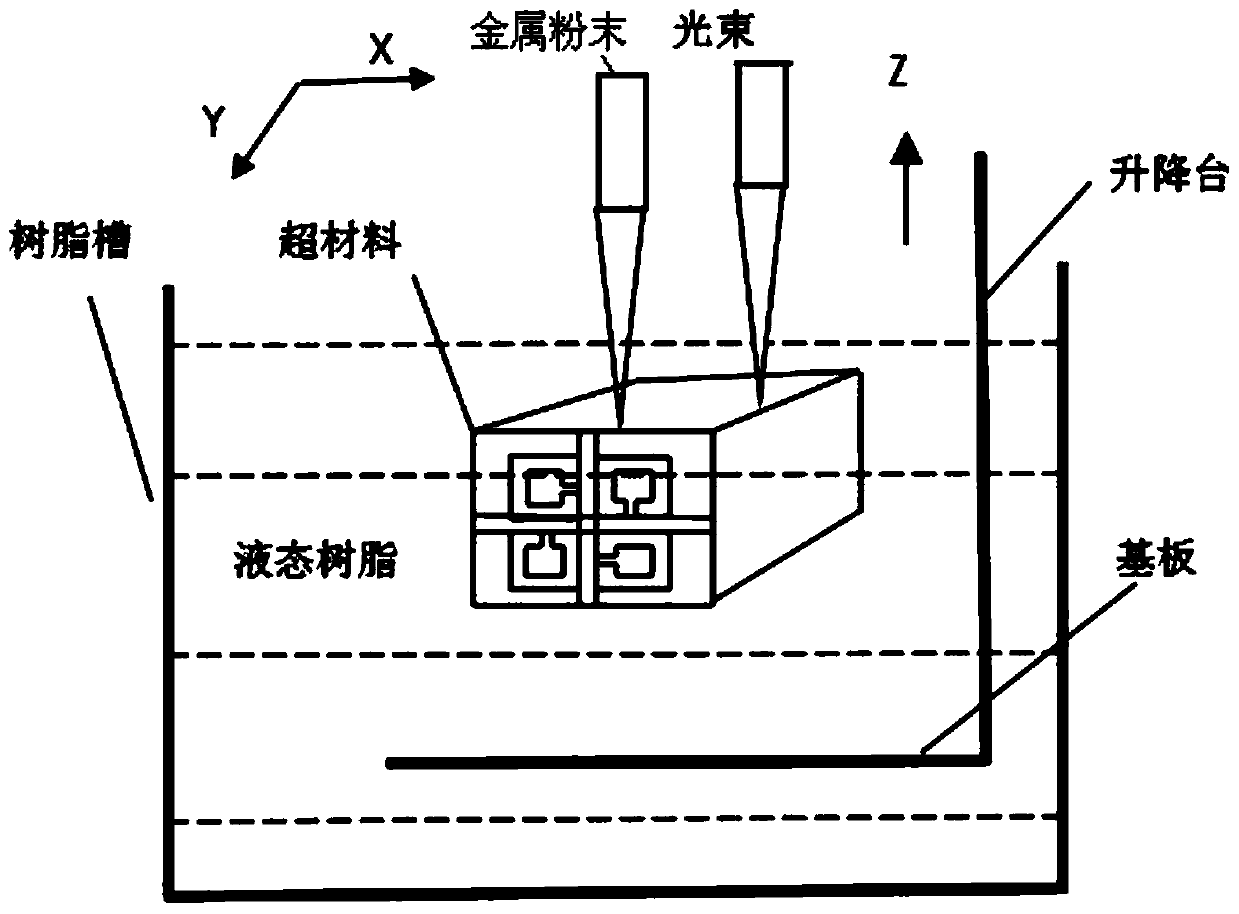

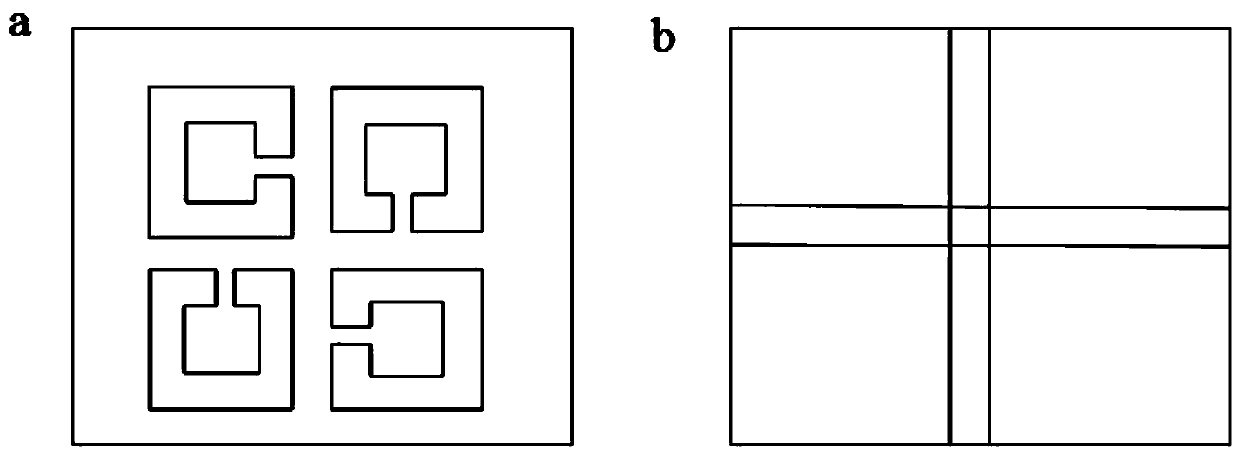

Method for manufacturing three-dimensional periodic structure metamaterial by utilizing three-dimensional printing technology

ActiveCN103692654AImprove production accuracyConvenient speedTurbinesOther manufacturing equipments/toolsPhysicsComputer Aided Design

The invention discloses a method for manufacturing a three-dimensional periodic structure metamaterial by utilizing the three-dimensional printing technology and belongs to the field of micro machining and microwave technology, aiming at solving the technical problems of poor accuracy and long time consumption in an existing method for manufacturing the metamaterial. The method comprises the following steps: establishing a three-dimensional CAD (computer aided design) model of a metal material structure and a three-dimensional CAD model of a resin material structure of the metamaterial respectively by utilizing three-dimensional modeling software; converting the three-dimensional CAD models into STL (standard template library) formatted files; inputting the STL formatted files into a double-material three-dimensional printer; and printing the metal material structure and the resin material structure of the metamaterial simultaneously by adopting different materials to obtain the three-dimensional periodic structure metamaterial. By utilizing the method, the metamaterial with any three-dimensional periodic units and any facial forms can be manufactured, the manufacturing accuracy is high, the speed is high, and the process is simple.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

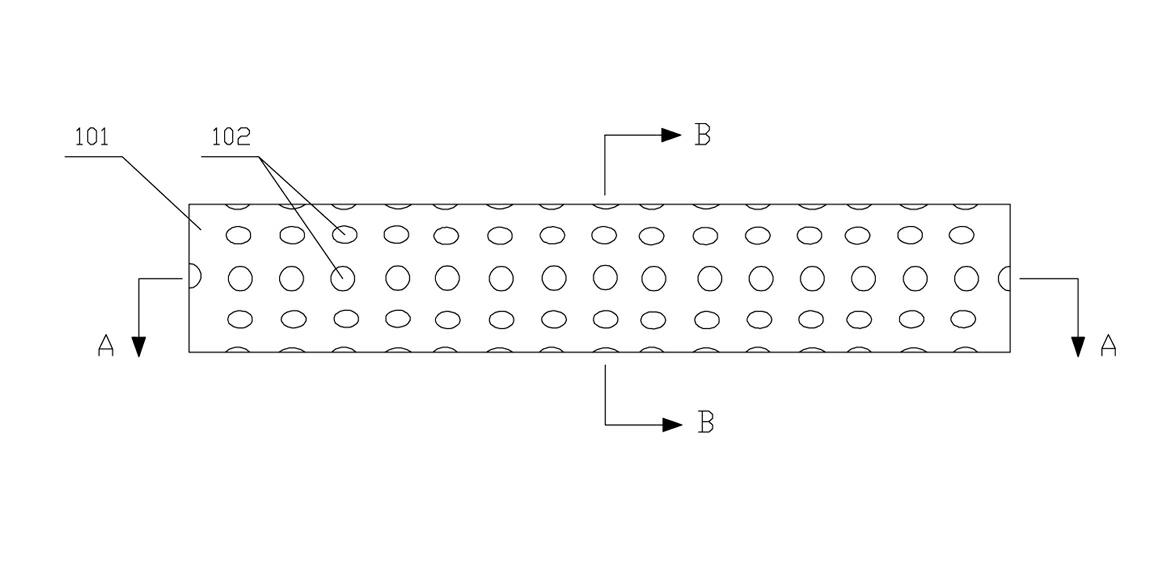

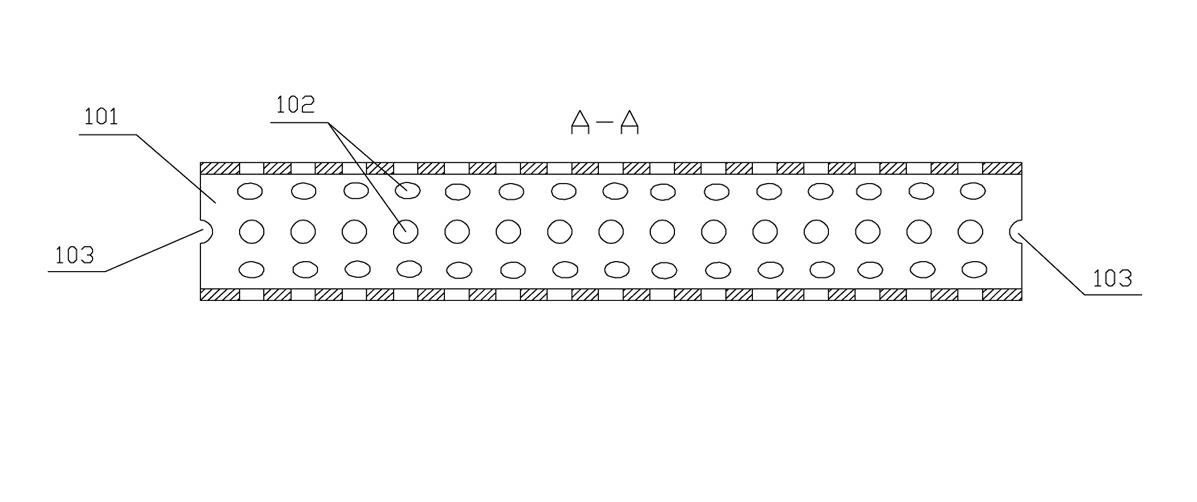

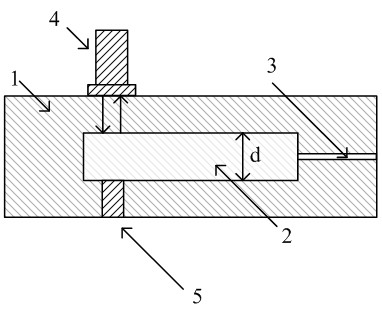

Punching die for drainage holes of stainless steel tubes

InactiveCN102615173AImprove work efficiencyImprove production accuracyShaping toolsPerforating toolsPunchingEngineering

The invention relates to a punching die for drainage holes of stainless steel tubes, which is characterized by comprising an upper die and a lower die. The upper die comprises a die handle (201), an upper die plate (202), a cushion plate (203), a fixed plate (207) and a plurality of abreast punching heads (205). The lower die comprises a product location device (301), a left location plate (320), a right location plate (303), a lower fixing plate (317) and a bottom plate (316), wherein the lower fixing plate (317) is arranged at the upper end face of the bottom plate (316), the left location plate (320) is positioned on the left side of the lower fixing plate (317), the right location plate (303) is installed on the right side of the lower fixing plate (317), the product location device (301) is arranged on the left side of the left location plate (320), and stainless steel tube insertion holes are arranged on the right location plate (303). The punching die for drainage holes of stainless steel tubes is small in manual operation and high in production efficiency.

Owner:宁海县雁苍山电力建设有限公司 +4

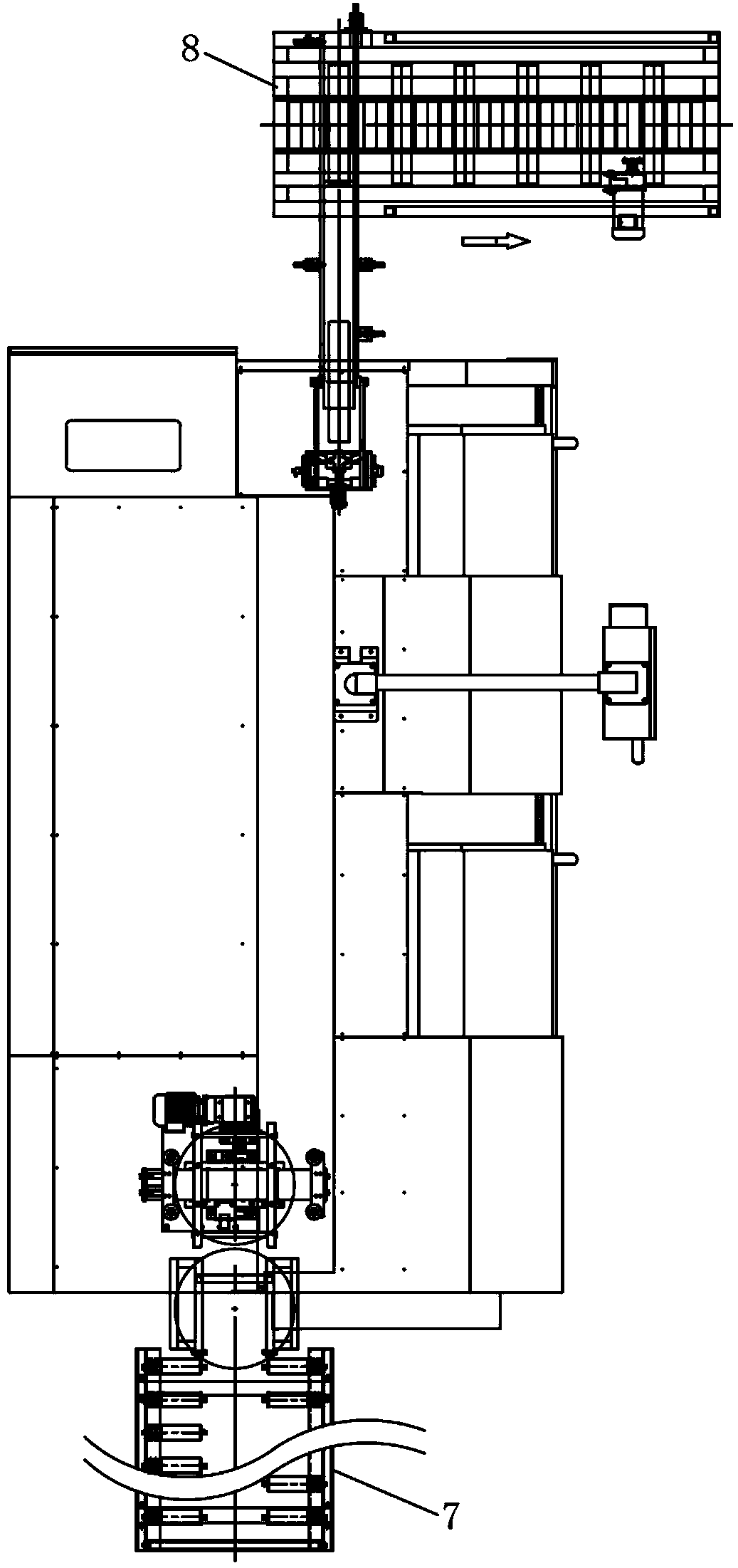

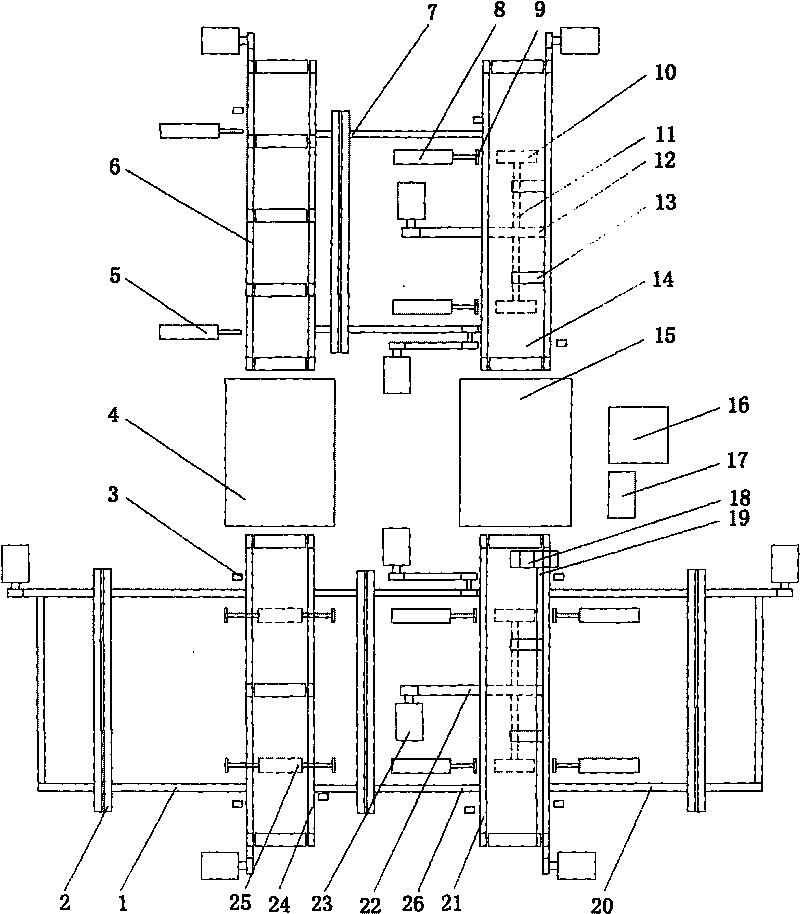

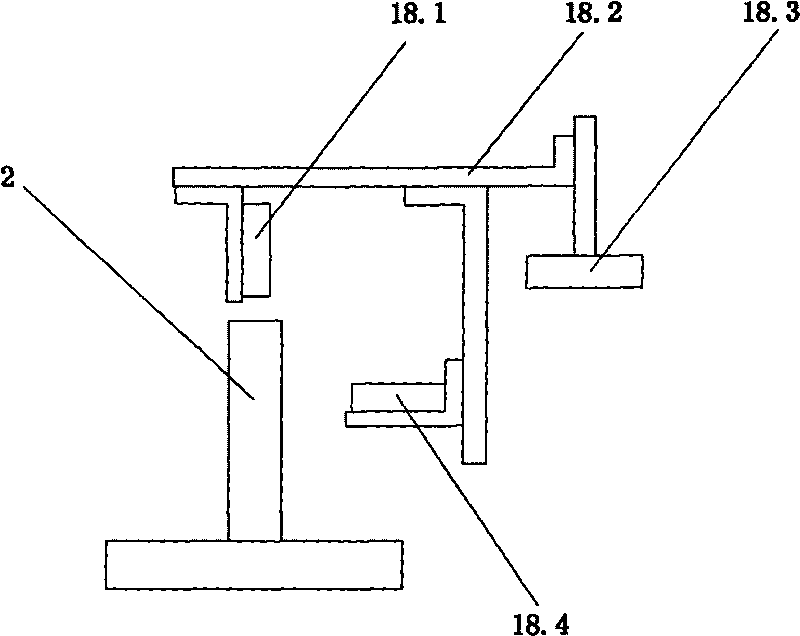

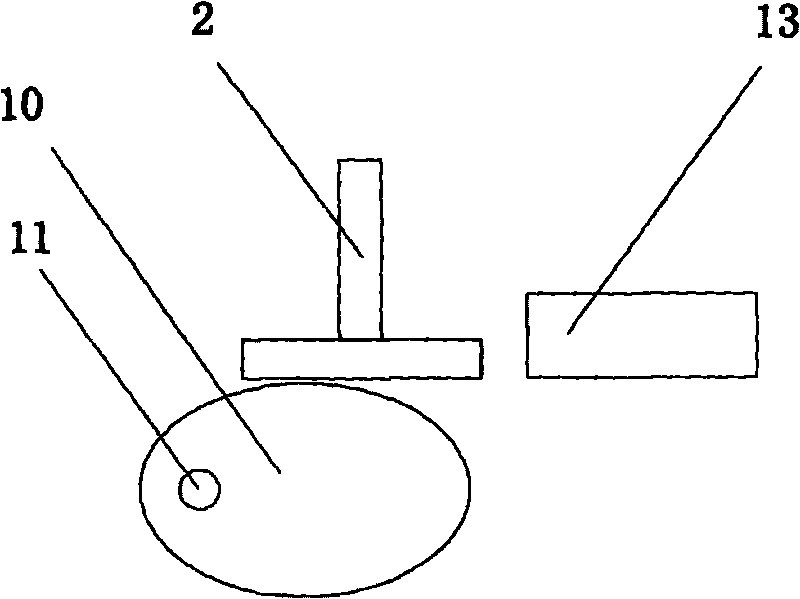

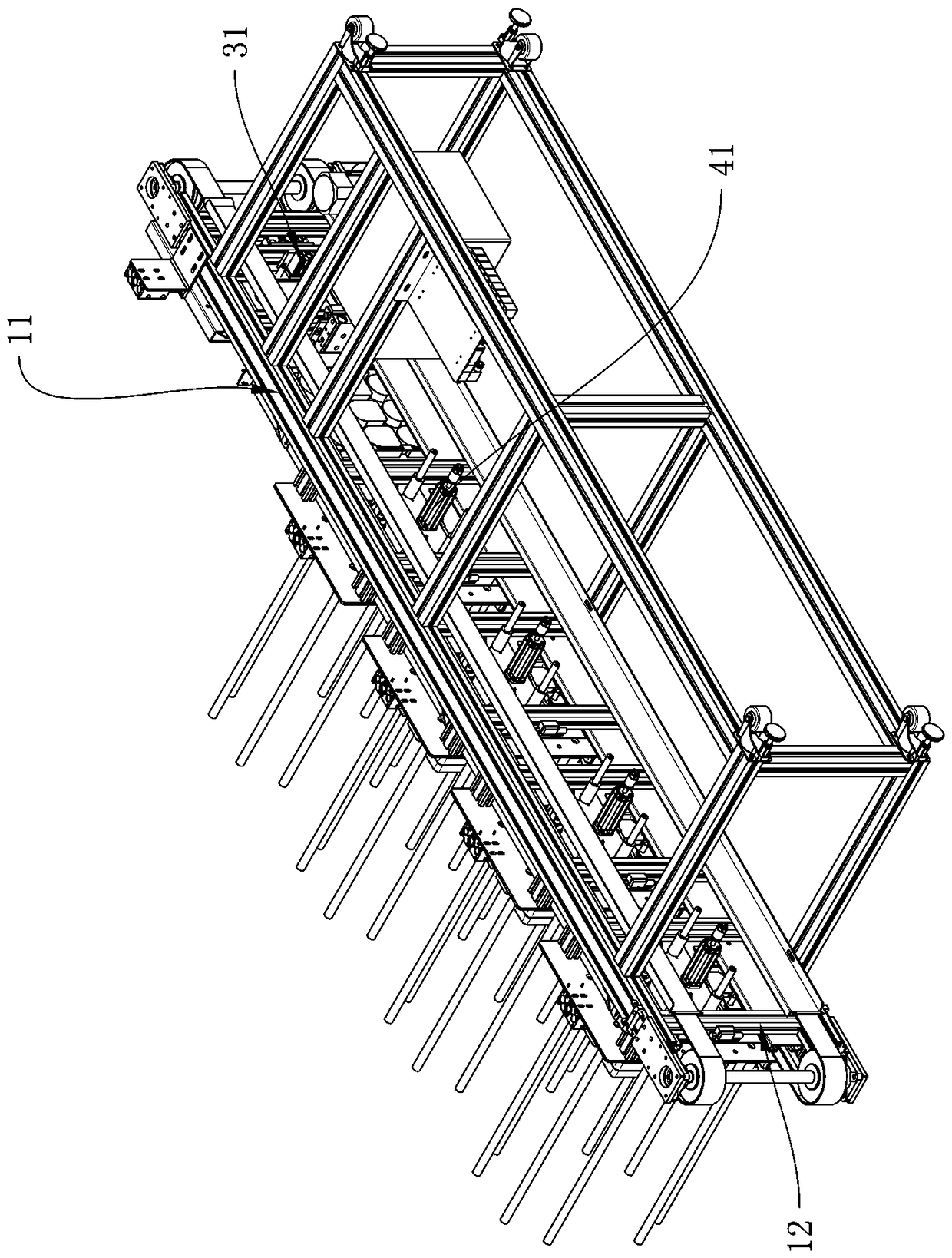

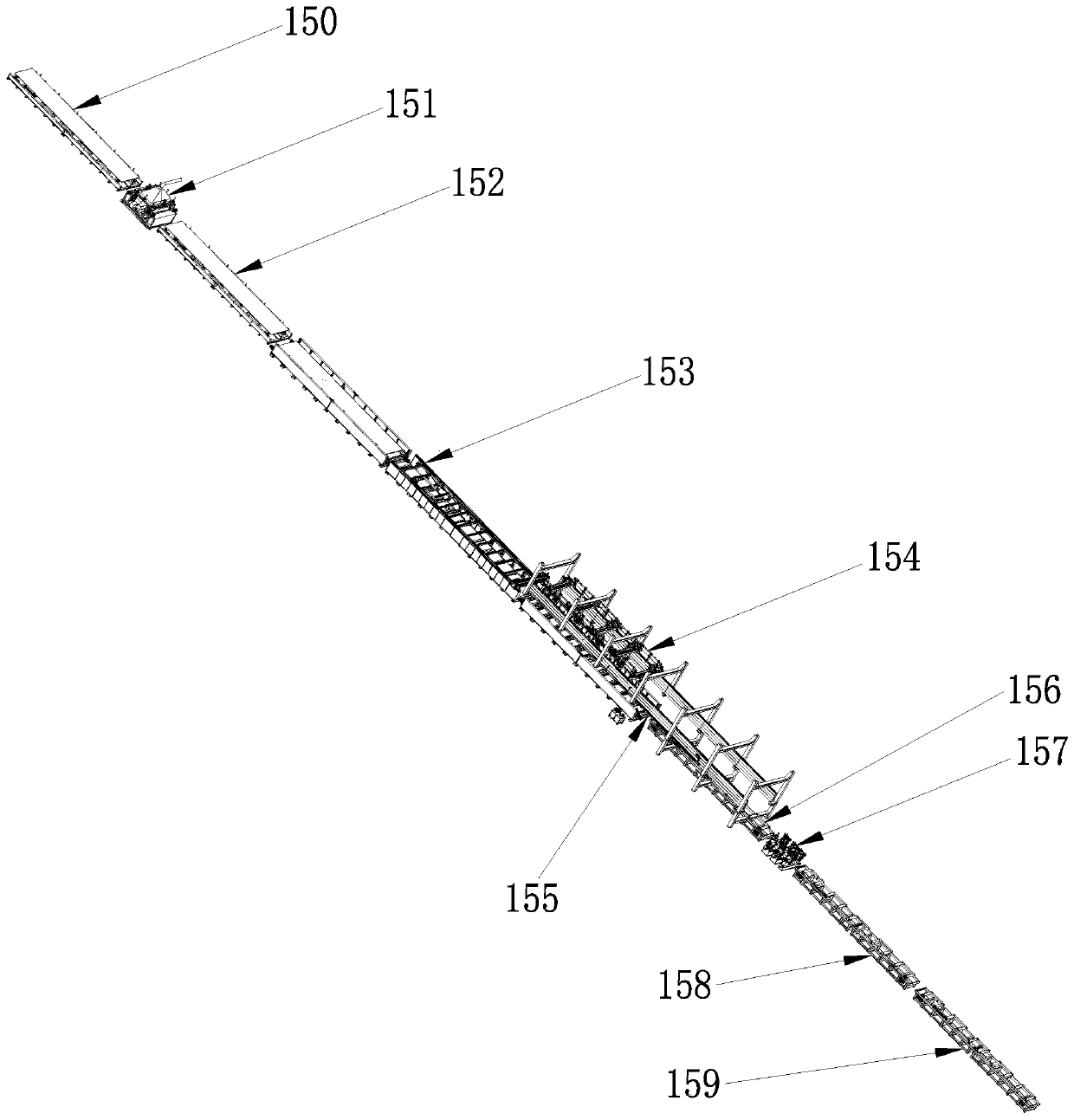

Automatic straightening production line of T-shaped guide rail

The invention discloses an automatic straightening production line of a T-shaped guide rail. The inlet ends and the outlet ends of a side automatic straightening machine and a top automatic straightening machine which are distributed in parallel are axially provided with a first rolling way, a second rolling way, a third rolling way and a fourth rolling way respectively, wherein a second chain transmission frame is arranged between the first rolling way and the third rolling way; a first chain transmission frame is arranged between the second rolling way and the fourth rolling way; the sides of the first rolling way and the third rolling way, which are opposite to the second chain transmission frame, are respectively provided with a chain transmission feeding frame and a chain transmission discharge frame; a turning mechanism is arranged below the third rolling way and the fourth rolling way; a two-way cylinder with a baffle sheet is arranged below the first rolling way; one sides of the second rolling way and the fourth rolling way in the direction of the chain transmission feeding frame are respectively provided with a cylinder and a one-way cylinder with a baffle sheet; one side of the fourth rolling way is provided with an idler wheel; a linear motor with a measuring device is arranged above one side of the third rolling way, and the production line is controlled by a programmable controller and a computer. The invention greatly saves labor and occupied space and simultaneously improves the production precision and efficiency.

Owner:ZHEJIANG UNIV

Endoscope with a T-shaped flexible circuit board

Owner:AMBU AS

Biaxial motion platform positioning and dynamic locus tracking control device and method

InactiveCN105159227AReduce transient overshootImprove stabilityNumerical controlSelf adaptiveSliding mode control

The invention relates to a biaxial motion platform positioning and dynamic locus tracking control device and method and belongs to the technical field of multi-axis motion control. The method comprises steps of: setting a position coordinate according to a shape of an instruction motion locus and enabling two linear motors to motion when receiving the same instruction signal; determining the actually-measured position and actual speed of each linear motor; computing the position tracking error and the rotating speed deviation of each linear motor; performing variable-speed switching control if a positioning instruction is executed; in a dynamic locus tracking control process executed in real time, preliminarily designing an inversion sliding-mode control law, namely the control current of a permanent-magnetic synchronous linear motor, by selecting a Lyapunov function, correcting the control law in real time in combination with an adaptive method, and feeding the corrected control law, namely the corrected input current, back to the system. The device and the method may achieve smooth platform positioning speed transition, improve platform positioning precision, suppress disturbance existing in the platform system, and achieve precision tracking control of a dynamic locus.

Owner:BOHAI UNIV

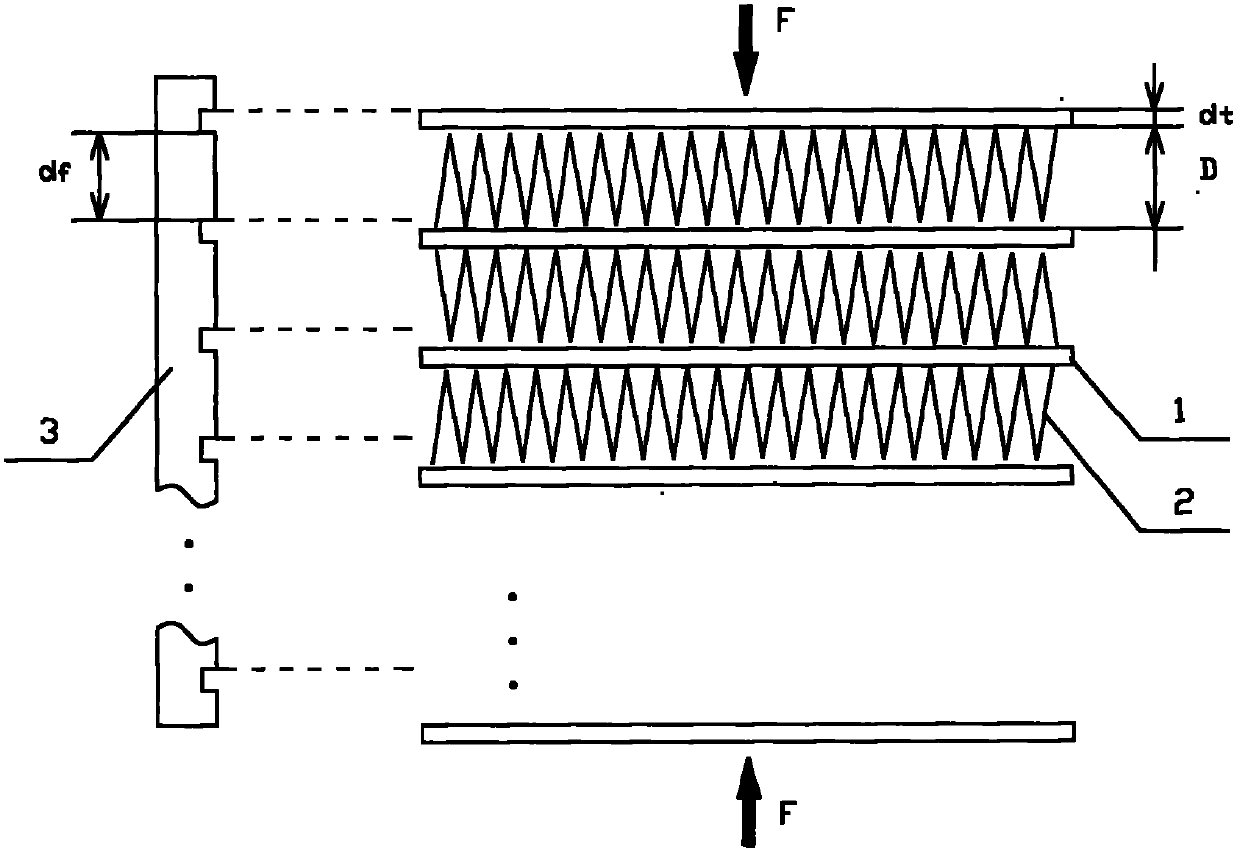

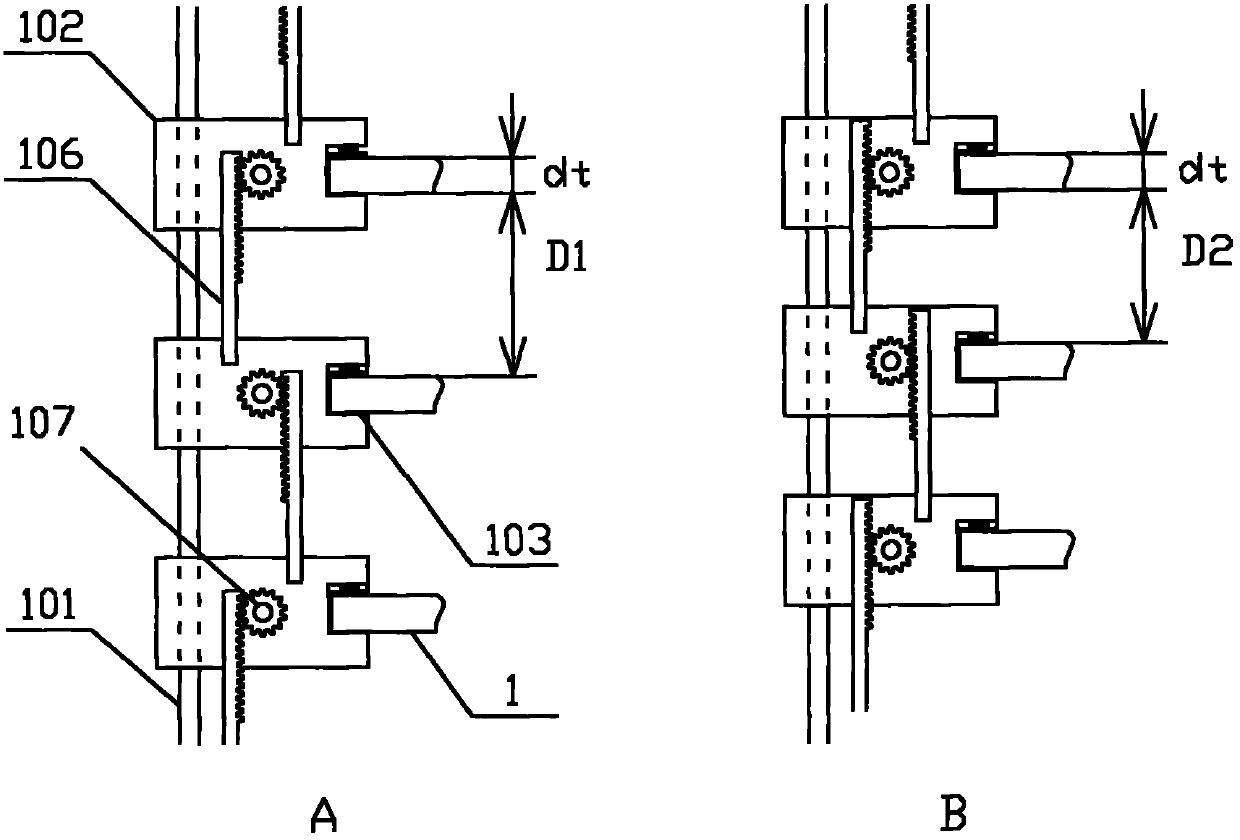

Finned tube locating fixture and assembly method of heat exchanger

InactiveCN102886666ASimple structural designEven by forceWork holdersMetal working apparatusEngineeringDislocation

The invention relates to a finned tube assembly technique method for manufacturing heat exchangers, provides a finned tube locating fixture of a heat exchanger, and aims to solve the problems that the operation efficiency is low, and dislocation is easy to occur when a group of finned flat tube bundles is tightened and assembled to a collecting tube. The finned tube locating fixture comprises a bracket, a driving mechanism and a group of tube fixators, wherein each tube fixator is provided with at least two locating points; and the tube fixators can be driven to move between a first locating point and a second locating point through the driving mechanism so as to drive each flat tube to reach the position corresponding to the slot of the collecting tube. Each flat tube and fin in the front and back directions are uniformly stressed and tightened through the finned tube locating fixture; the group of finned flat tube bundles is tightened at a set distance and position quickly, accurately and uniformly; the finned tube locating fixture is simple and reasonable in structure; and the production efficiency and precision of a finned tube locating assembly process are improved.

Owner:WESTERNHOUSE AUTOMATION CHANGZHOU

Thin-walled workpiece machining method

The invention discloses a thin-walled workpiece machining method, and relates to the field of machining. The thin-walled workpiece machining method includes the following steps that a forge piece is prepared, and a clamping process end is reserved on the forge piece; rough turning on the forge piece is carried out; semi-finish turning is carried out on the outer circle of the workpiece; carburizing treatment is carried out; a carbon layer is turned; quenching is carried out; semi-finish turning is carried out on an inner hole, the process end of the workpiece is clamped, the end face and the inner hole are turned, the allowance being 0.5 mm is reserved, and a ring slot is machined until the required size is obtained; cutting is carried out, wherein wire-electrode cutting is carried out, the turned end face serves as a standard face, and the allowance of the end face is 0.5 mm; finish turning is carried out, wherein the workpiece is turned round, the end face of the turned workpiece is attracted through a lathe sucker, alignment with a meter is carried out to enable the allowance of the outer circle to range from 0.05 mm to 0.10 mm, and finish turning is carried out on the end face, the inner hole and the outer circle through a ceramic tip or a cubic boron nitride blade until required sizes are obtained; burrs are removed; and washing and packaging are carried out. The machining process is simple, the production efficiency and the product machining accuracy can be effectively improved, and the production cost is reduced.

Owner:SHAANXI QIYUAN TECH DEV

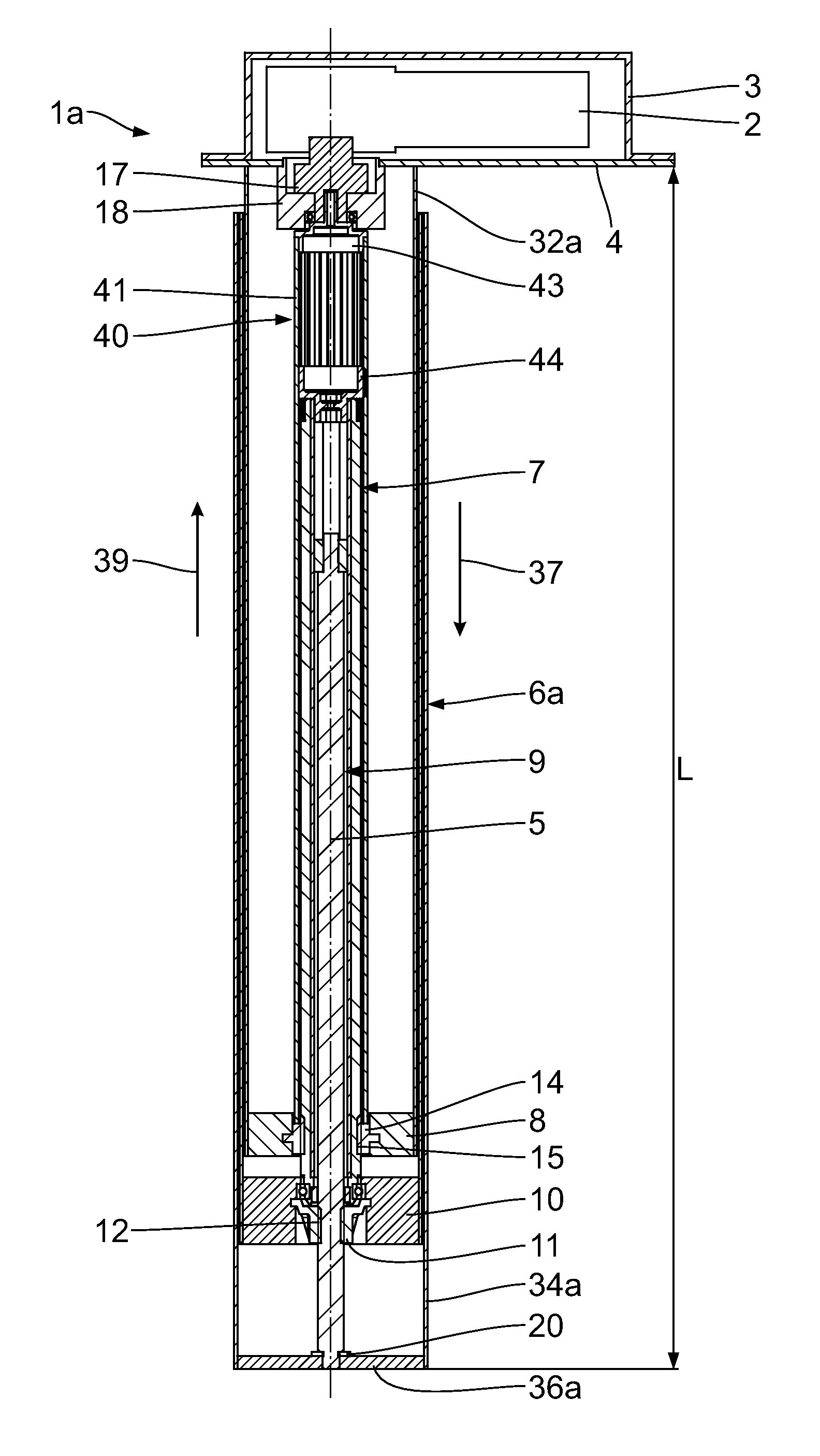

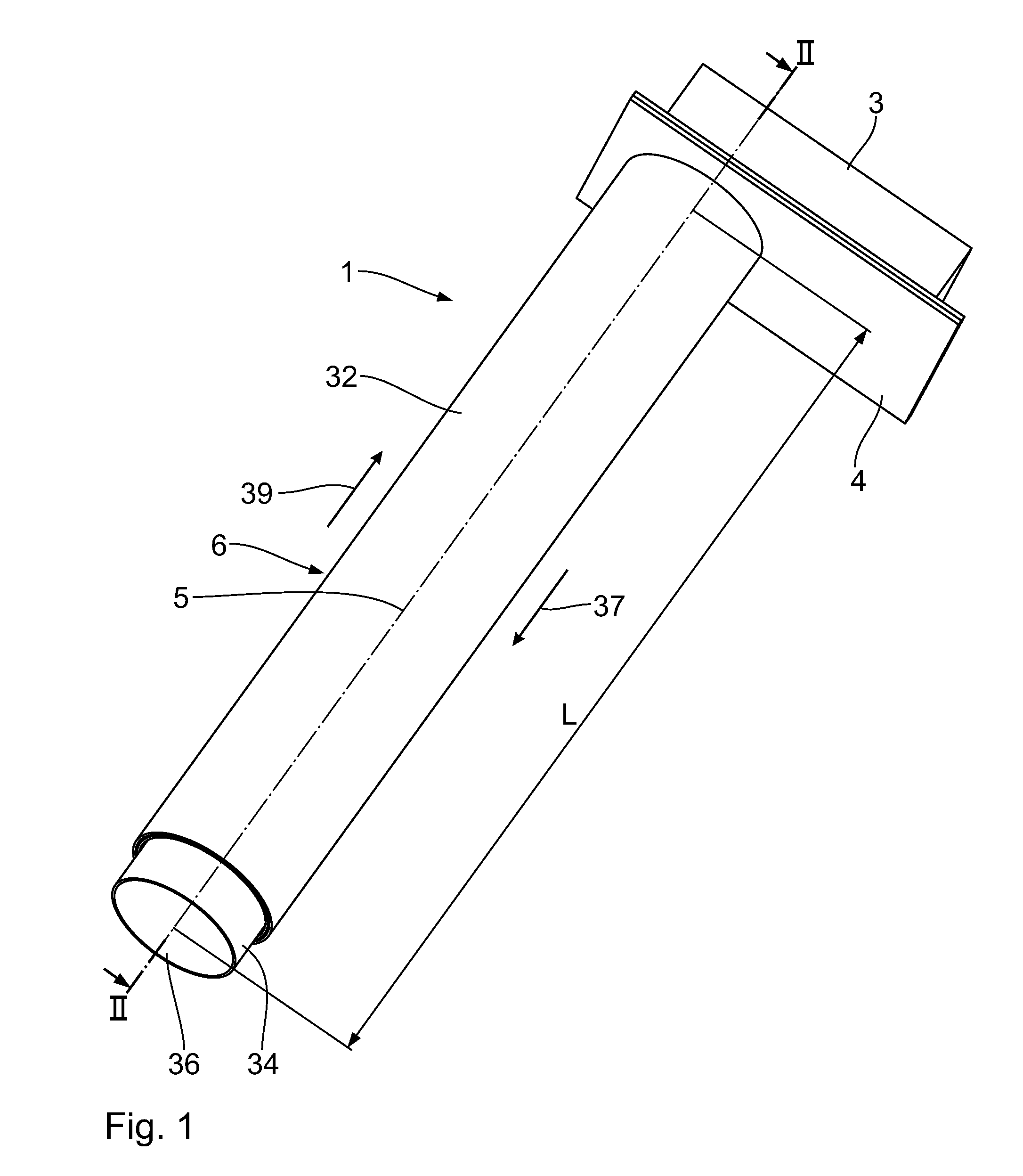

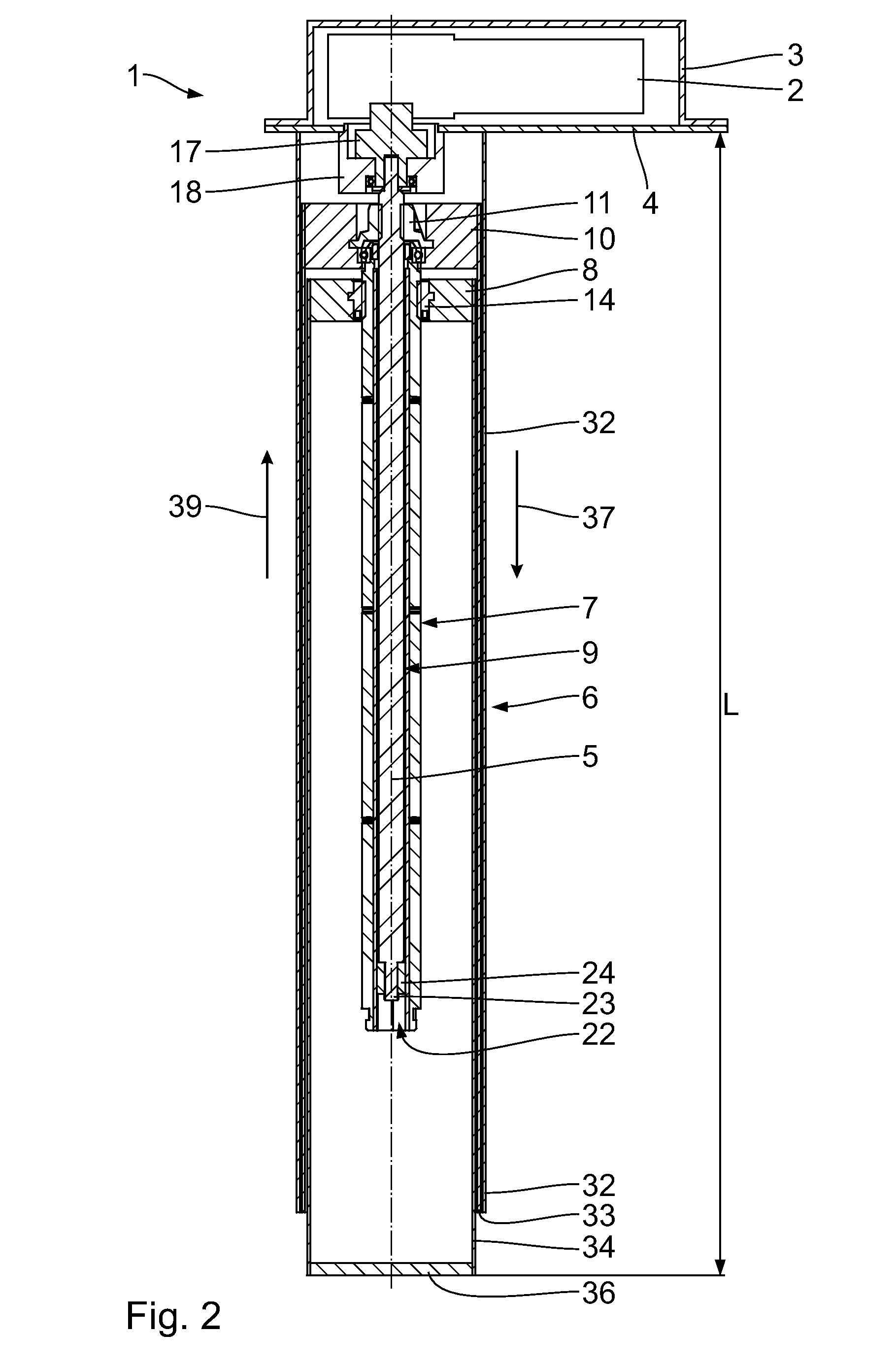

Height-adjustable actuation device

InactiveUS20110174101A1Easy constructionImprove production accuracyGearingVariable height tablesEngineeringMechanical engineering

Owner:SUSPA

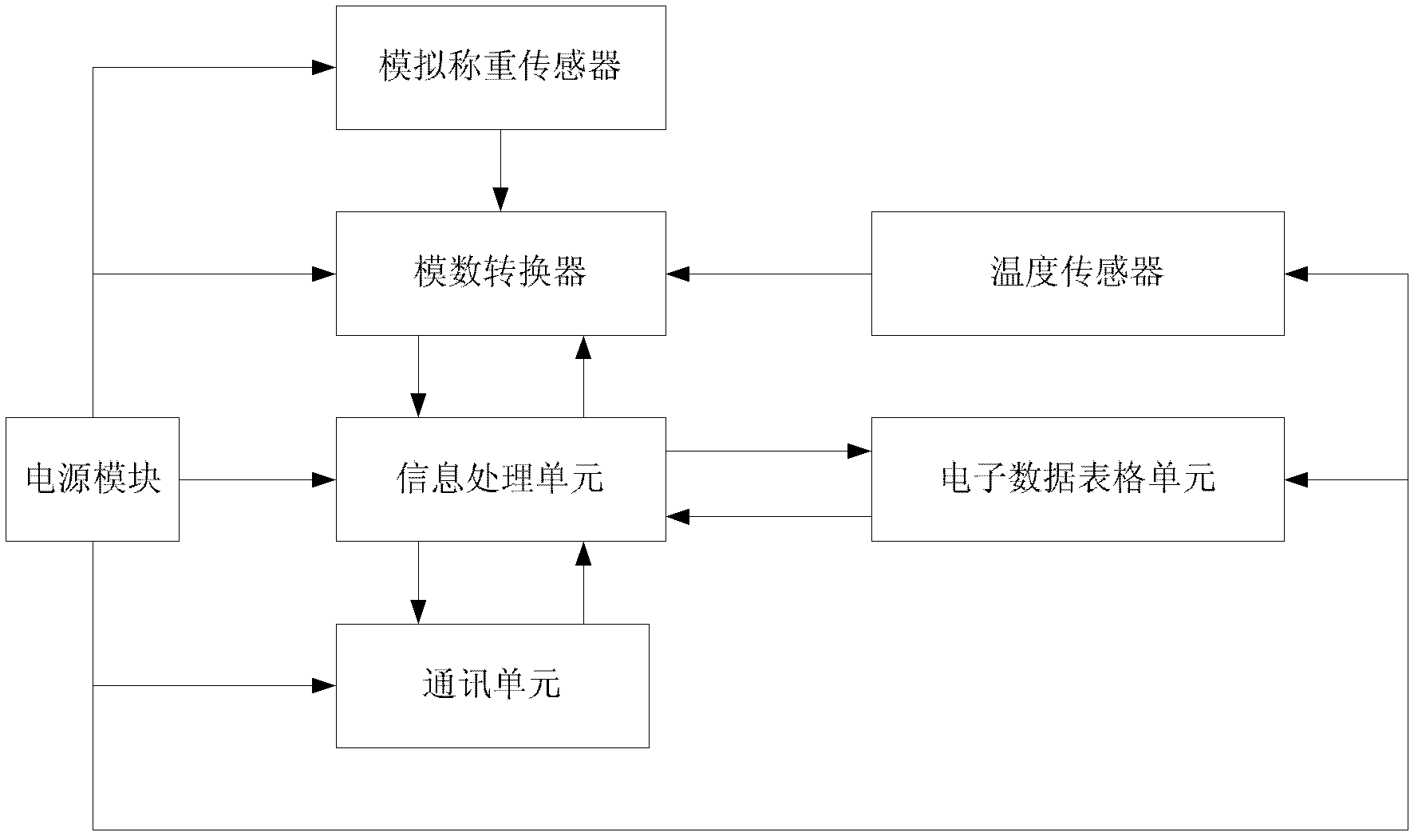

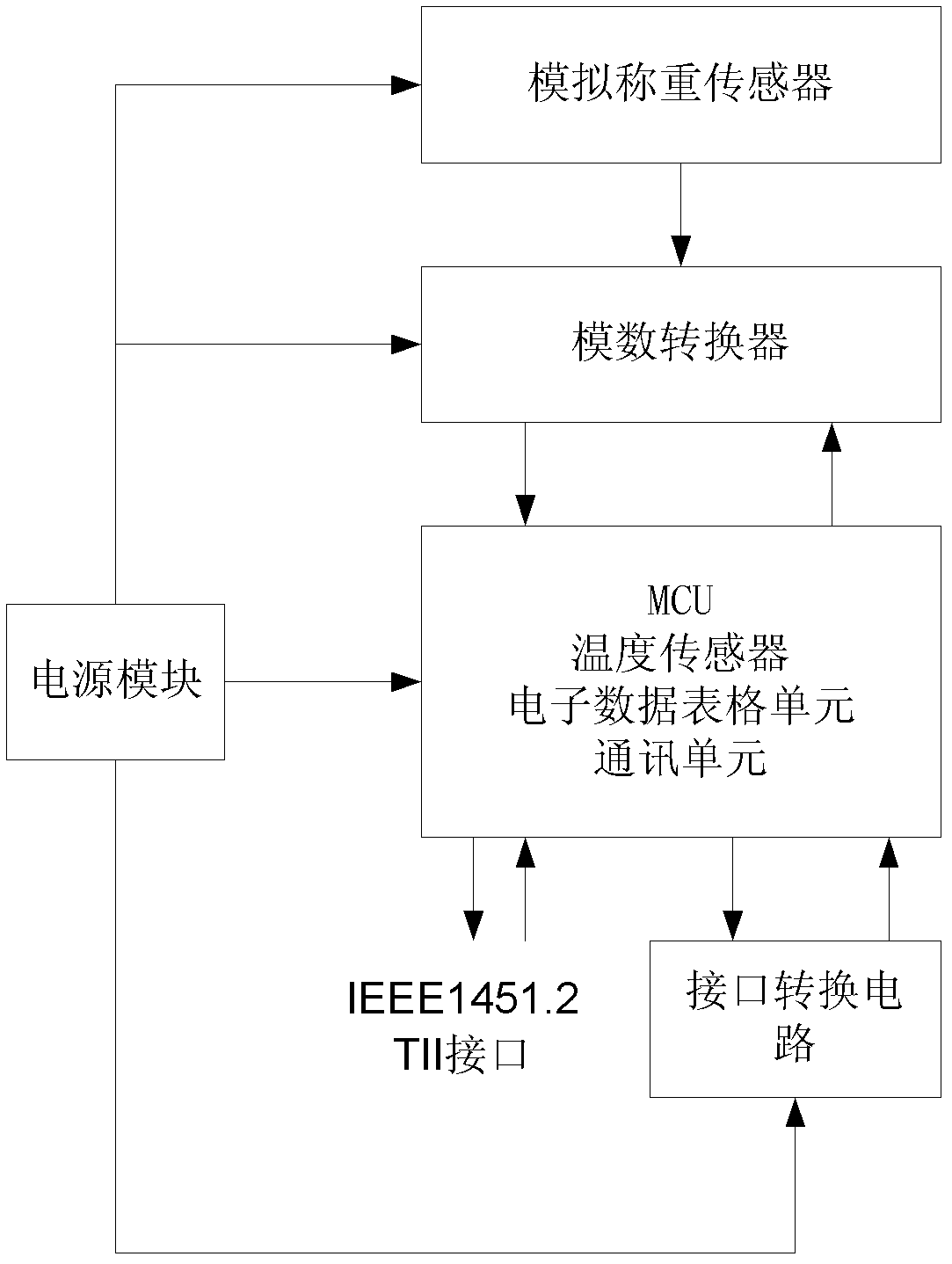

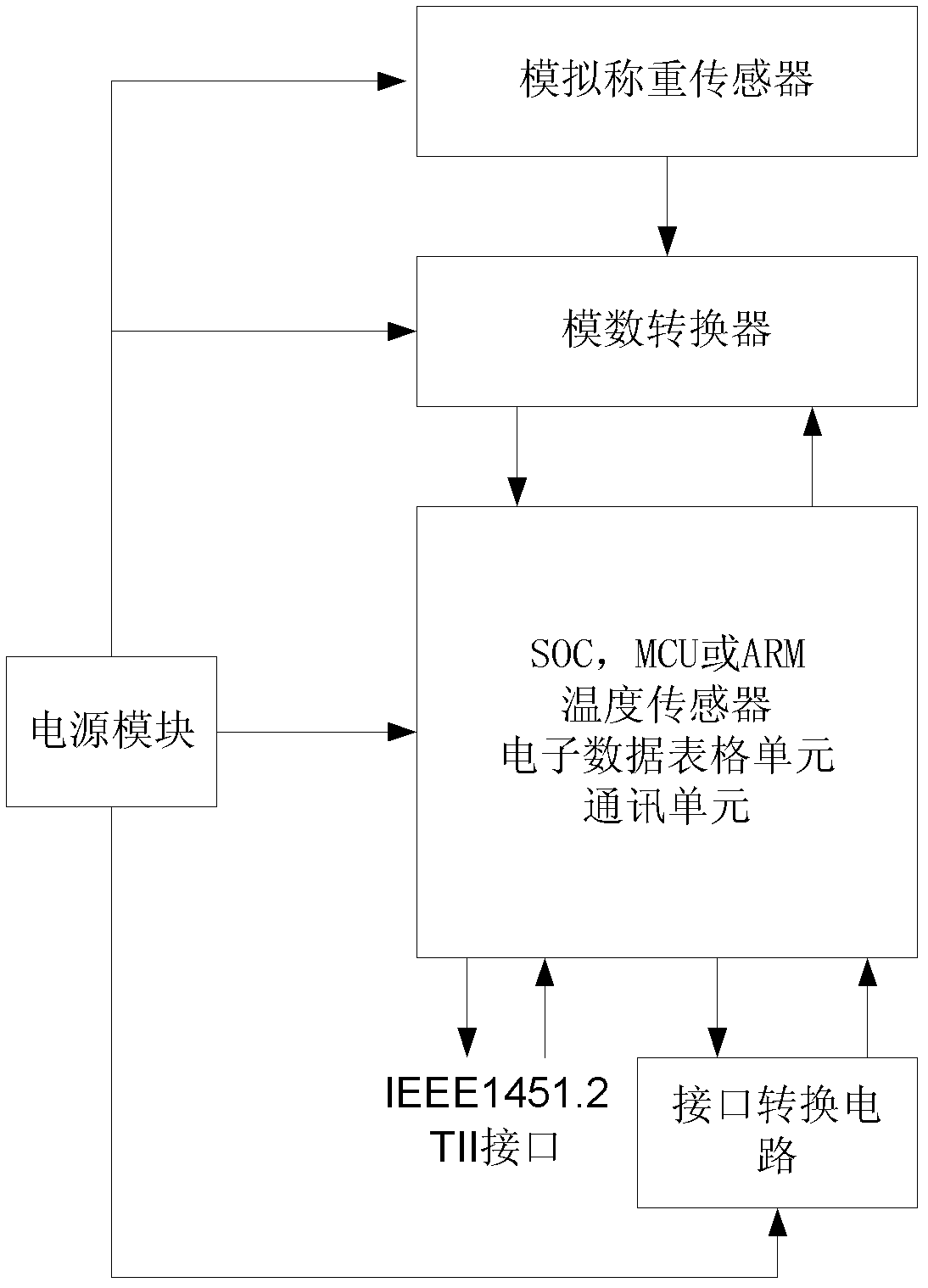

Networking intelligent digital weighing sensor

InactiveCN102538918AMeets the requirements of the Independent Interface (TII)Easy to addWeighing apparatus using elastically-deformable membersWeighing auxillary devicesSmart transducerImage resolution

The invention discloses a networking intelligent digital weighing sensor, which comprises a simulation weighing sensor, a temperature sensor, an analog-to-digital converter, an electronic data table unit, an information processing unit, a communication unit and a power supply module, wherein the electronic data table unit conforms to IEEE1415.2 standards, the simulation weighing sensor is used for collecting weight data, the temperature sensor is used for collecting real-time temperature data, the analog-to-digital converter is used for converting the weight data and the real-time temperature data into corresponding digital signals, the information processing unit is used for outputting weight data after compensation calibration, and the communication unit is provided with a universal serial interface and a communication interface compatible with IEEE1415.2. The technical scheme conforms to requirements of the IEEE1415.2 standards on an independent interface of the intelligent sensor and simultaneously solves the problems that in the sensor manufacture process, the precision is difficult to improve, the production efficiency is low, the finished product rate is low and the like, and in addition, the digital weighing sensors with the same resolution ratio can be produced in batches.

Owner:CHIPSEA TECH SHENZHEN CO LTD

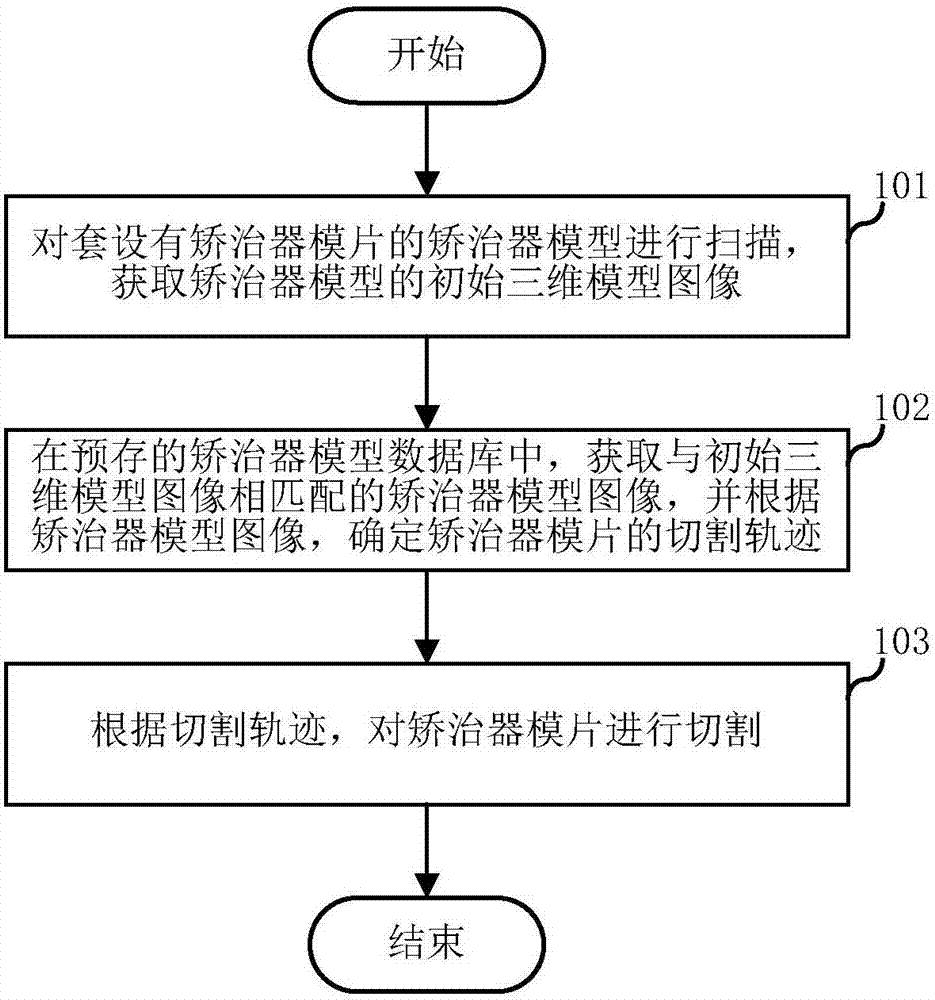

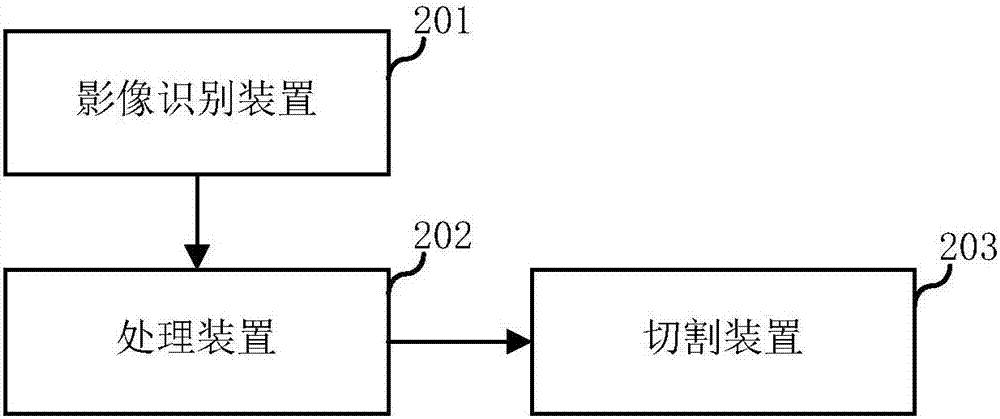

Correction appliance machining method and correction appliance machining system

InactiveCN107049529ARealize automatic identificationHigh precisionOthrodonticsMetal working apparatusMachining systemComputer science

The invention relates to the technical field of medical treatment, and discloses a correction appliance machining method and a correction appliance machining system. In an execution mode of the invention, the correction appliance machining method comprises the following steps: scanning a correction appliance model on which a correction appliance template in a sleeving way, and acquiring a three-dimensional model image of the correction appliance model; acquiring a correction appliance model image matched with the three-dimensional model image from a prestored correction appliance model database, and determining a cutting trace of the correction appliance template according to the correction appliance model image; cutting the correction appliance template according to the cutting trace. By adopting the execution mode of the invention, automatic cutting of the system for machining the correction appliance on the correction appliance template is realized, the intelligent degree is higher, the phenomenon of more tailoring, more grinding or less tailoring when the correction appliance template is manually tailored according to experience can be effectively avoided, and the reject ratio and the labor cost of product production are reduced.

Owner:TIANJIN ZHENGLI TECH CO LTD

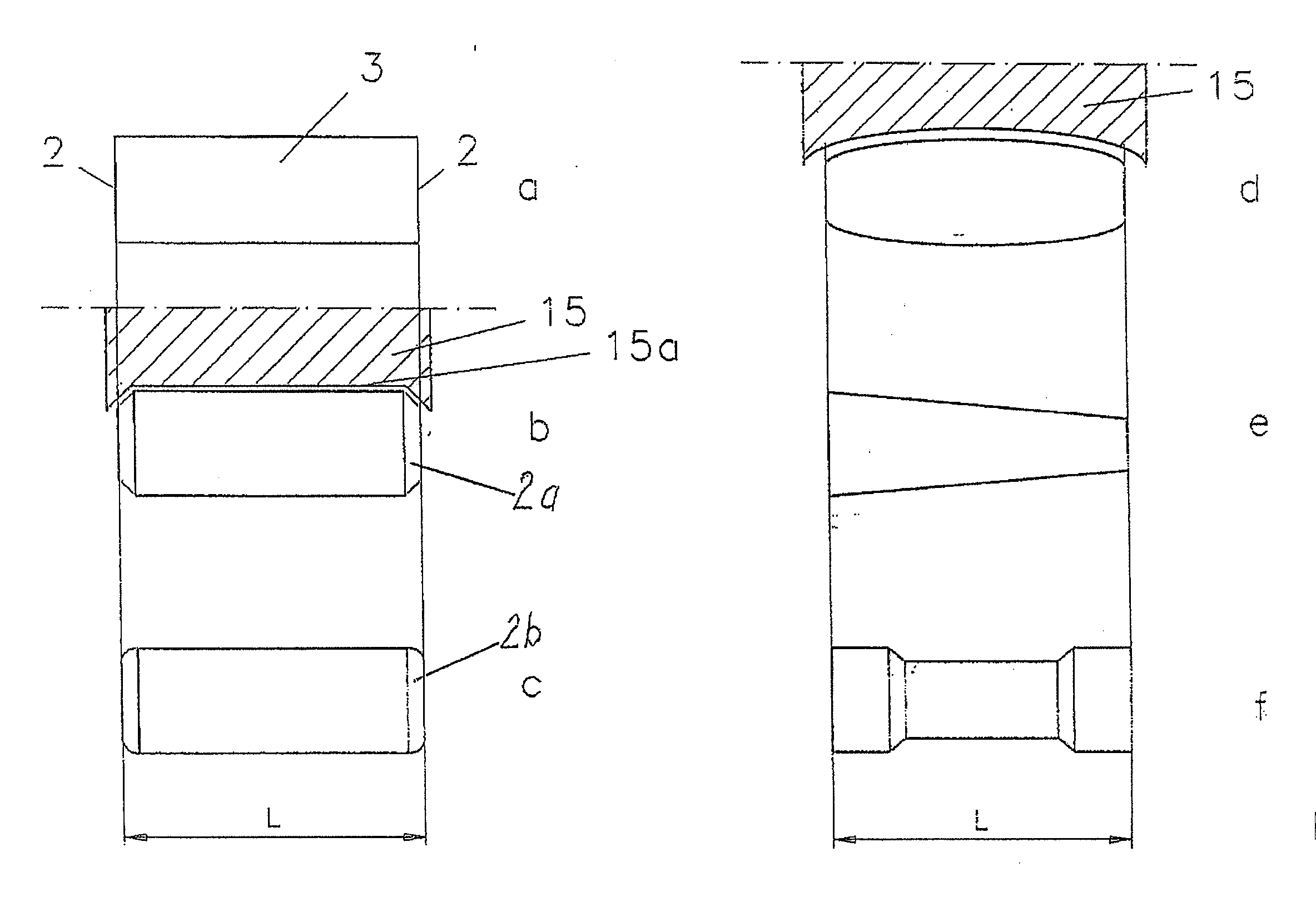

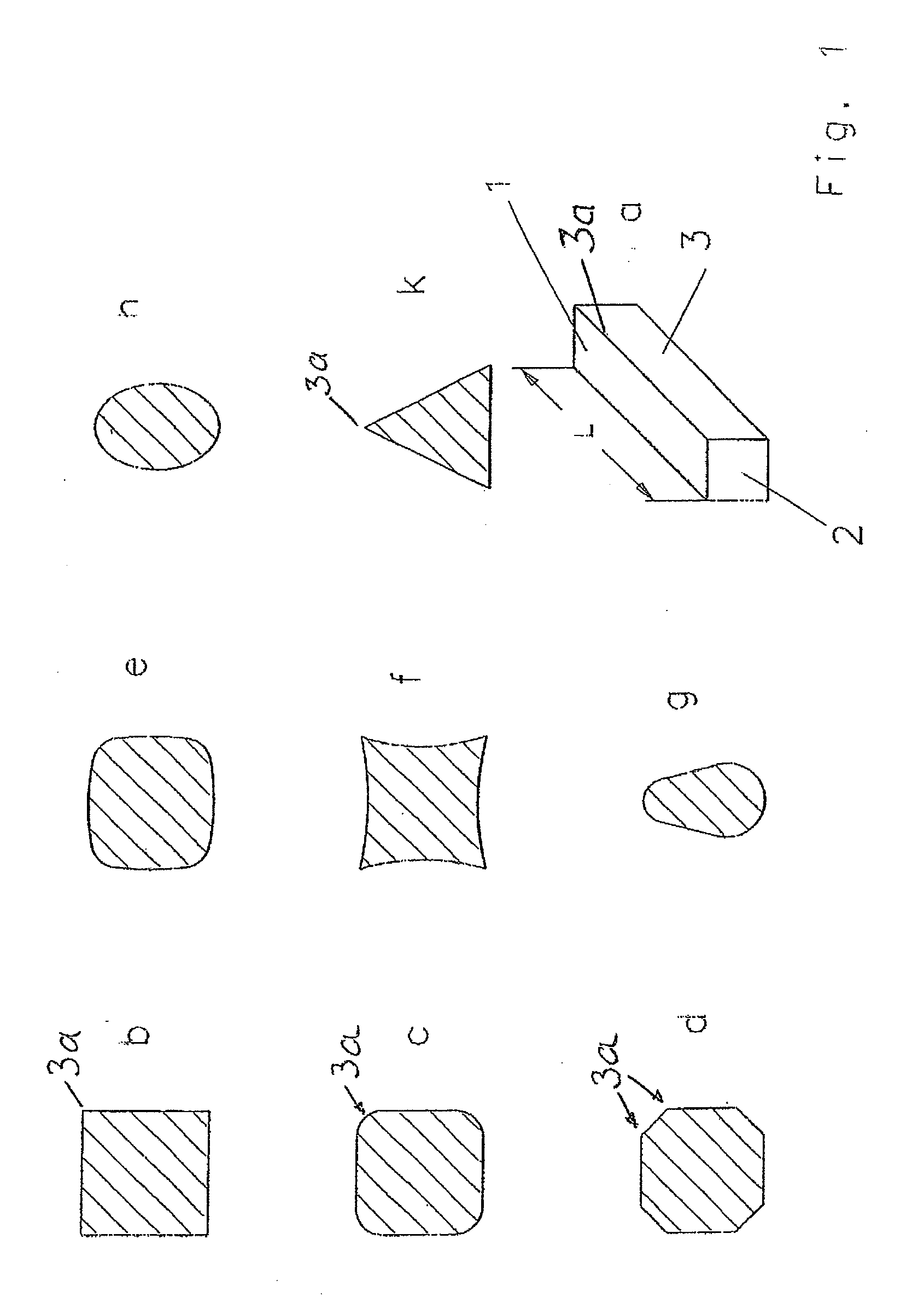

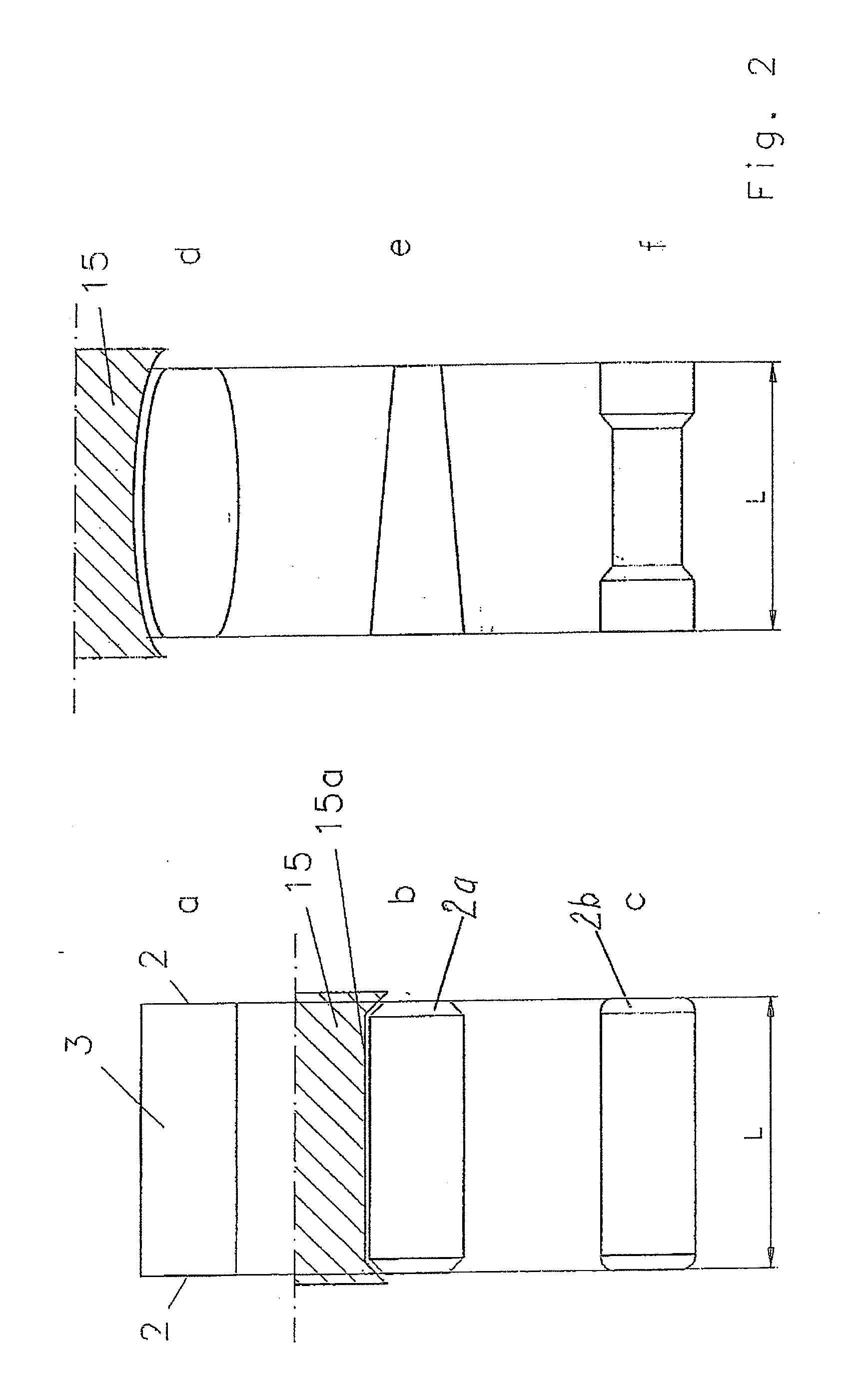

Method and grinding machine for the complete grinding of short and/or rod-shaped workpieces

ActiveUS20110195635A1Improve production accuracyIncrease speedEdge grinding machinesRevolution surface grinding machinesRotational axisEngineering

Short and / or rod-shaped workpieces are completely machined by grinding two parallel end faces and the longitudinal sides of the workpiece with very short cycle times. The grinding machine includes two grinding spindles that are arranged in a tandem arrangement with parallel rotational axes on a shared grinding headstock and that are jointly moved in the X direction. In cooperation with a special holding and transport device for the workpieces, two workpieces are each ground, at least partly concurrently, the end faces of the one workpiece being ground in one machining position and the final non-circular grinding of the exterior contour of a second workpiece occurring in a second machining station, the end faces of the second workpiece having already been ground.

Owner:ERWIN JUNKER MASCHNINENFAB

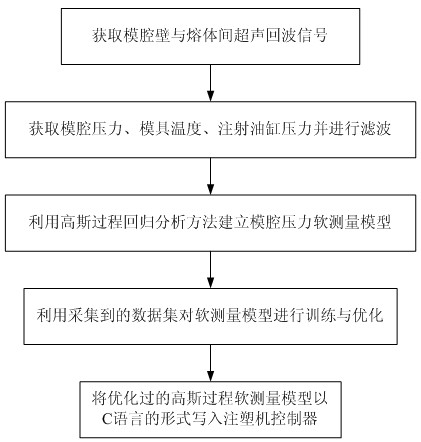

Method for detecting die cavity pressure in injection molding process based on ultrasonic signals

The invention discloses a method for detecting die cavity pressure in an injection molding process based on ultrasonic signals. The method includes the steps: firstly, acquiring ultrasonic echo signals, die temperature and injection cylinder pressure between the wall of a die cavity and a melt interface in the injection molding process; secondly, building a Gaussian process measuring model based on the Bayesian information criterion, using data acquired in the first step as training data, inputting the ultrasonic echo signals, the die temperature and the injection cylinder pressure to the model, outputting melt pressure in the die cavity from the model and optimizing the model by the aid of a minimal negative boundary likelihood function logarithm method after building the model; and finally, writing the optimized Gaussian process measuring model into an injection molding equipment controller in the form of C language and realizing real-time online soft measuring for the die cavity pressure. The method can be used for realizing online soft measuring for the melt pressure in the die cavity in the injection molding process, and has the advantages of low cost and convenience in use.

Owner:ZHEJIANG UNIV

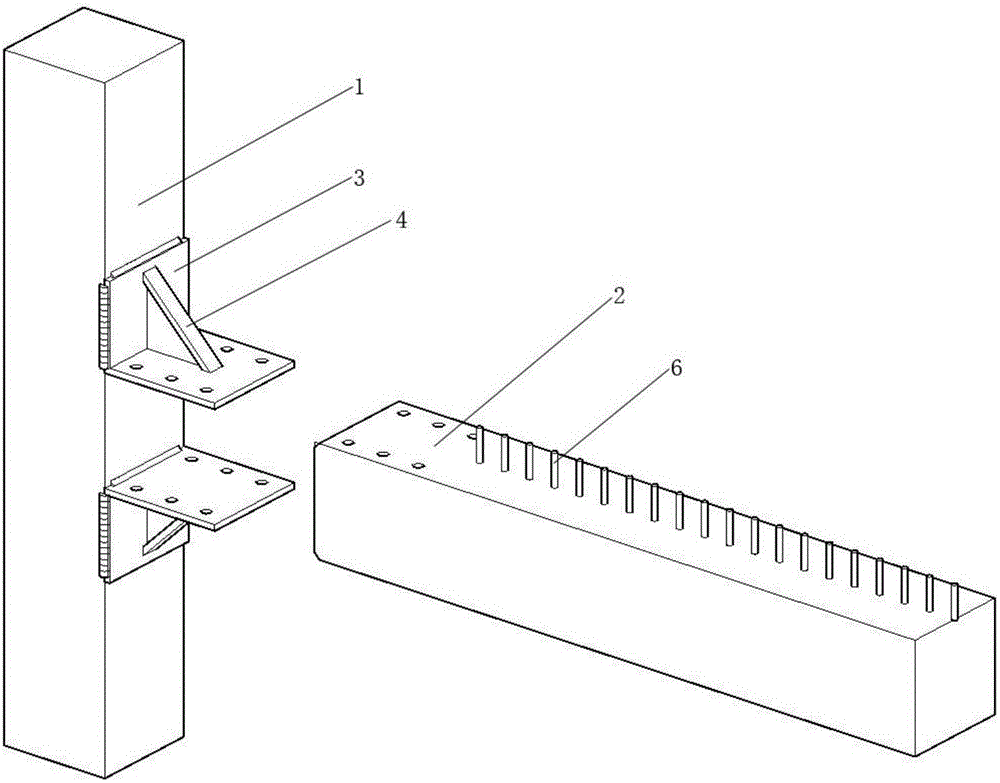

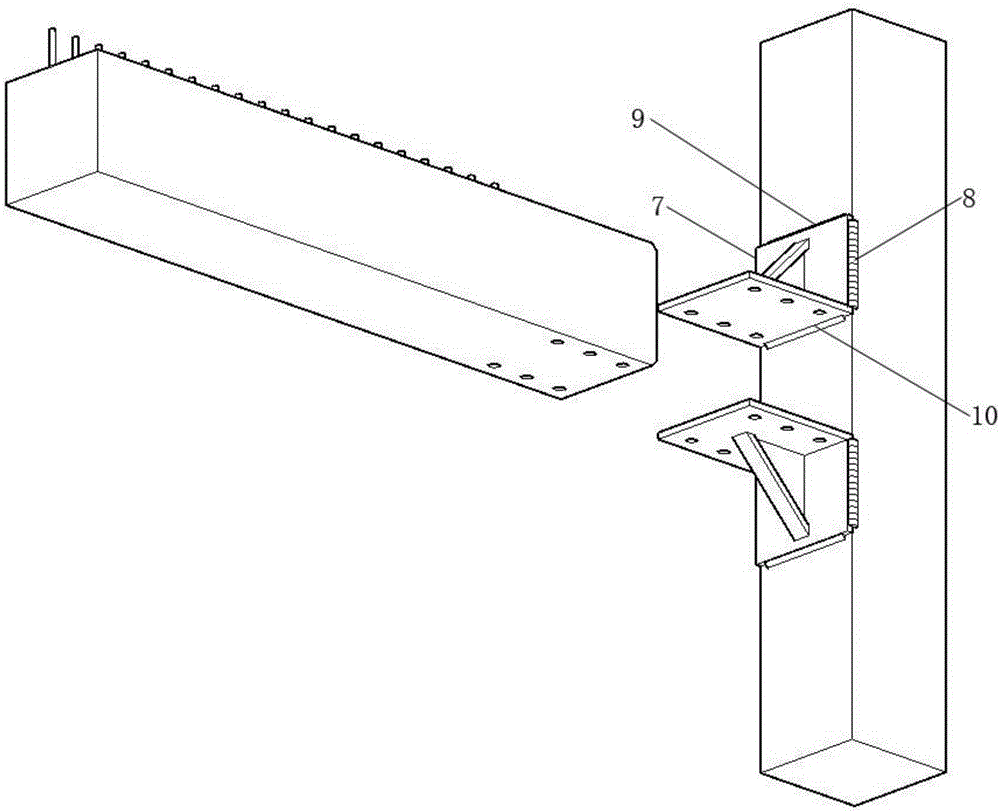

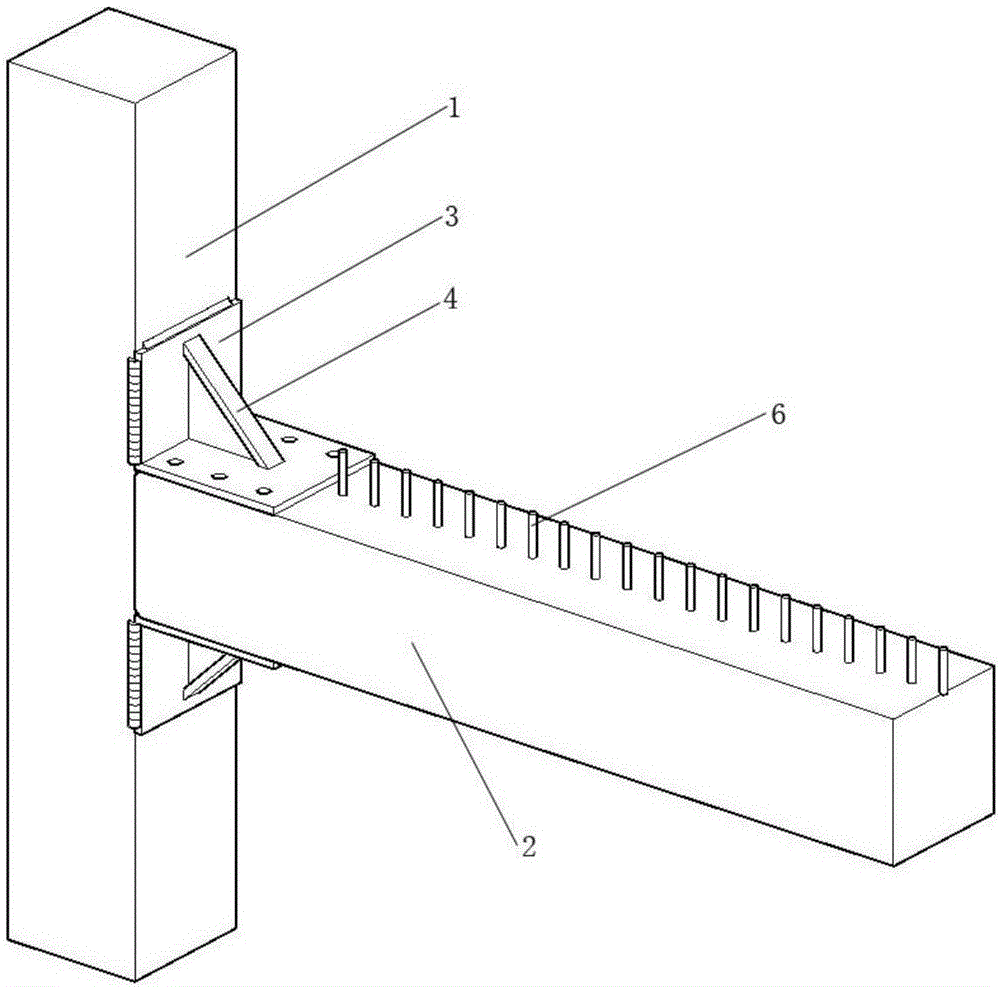

Connection node construction of concrete-filled square steel tube column and rectangular section steel beam

InactiveCN106703184ANode structure is simpleFlexible layoutBuilding constructionsLocal failureArchitectural engineering

The invention discloses a connection node construction of a concrete-filled square steel tube column and a rectangular section steel beam. The connection node construction is formed by the concrete-filled square steel tube column, the rectangular section steel beam, a right-angle connecting plate, a T-shaped triangle rib plate, a high-strength bolt, and a toggle pin on the top face of the steel beam. The connection node construction is simple, and the stress is clear. The amount of the steel for the connection node construction is less, and the connection node construction is only installed at one side of the column provided with the beam, so the composite cost is lower. The design of the beam column connection node is the ductile failure mode that the beam end is damaged by the tension, the obvious symptom and the duration time are existent before the damage, and the whole structure cannot be collapsed by the local failure. The connection of the steel beam and the concrete-filled steel tube column is firm, the integrality is good, the node rigidity is large, the assembly is simple and the construction period is short. New building rubbishes are not generated, and the requirements of housing industrialization and environmental protection are satisfied. The connection node construction is a novel node connection mode suitable for the connection of the current lower-layer and multi-layer light steel frame housing construction beam columns.

Owner:BEIJING UNIV OF TECH

Universal clamp for machining pin holes of ball-head screws

InactiveCN102729078AAvoid wear and tearAvoid chippingPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a universal clamp for machining pin holes of ball-head screws. The universal clamp comprises a drilling die bracket arranged on the right end surface of a V-shaped base, wherein a drilling sleeve is embedded into a hole on the drilling die bracket; a drilling die is arranged in a hole of the drilling sleeve; the right end surface of the V-shaped base is provided with a key groove which is internally provided with a guide key by a fixed bolt; the center line of the key groove is consistent to the center of a V-shaped surface; the right end surface of the V-shaped base is also provided with a ball bowl which is provided with a handle; the ball surface of the ball bowl is matched with the ball surfaces of the top ends of the ball-head screws, and the other surface of the ball bowl is matched with the inner side surface of the drilling die bracket; the center of the drilling die bracket is provided with a vertical U-shaped through groove which is matched with the guide key. The universal clamp disclosed by the invention has the advantages that the pin holes of the ball-head screws with different specifications are conveniently machined, the production accuracy is improved, the production cost is reduced, the production efficiency is improved, the phenomena of wearing, chip falling and burning in use of the ball-head screws are effectively avoided, and the production need is met.

Owner:JIANGSU XUZHOU METALFORMING MACHINE GROUP

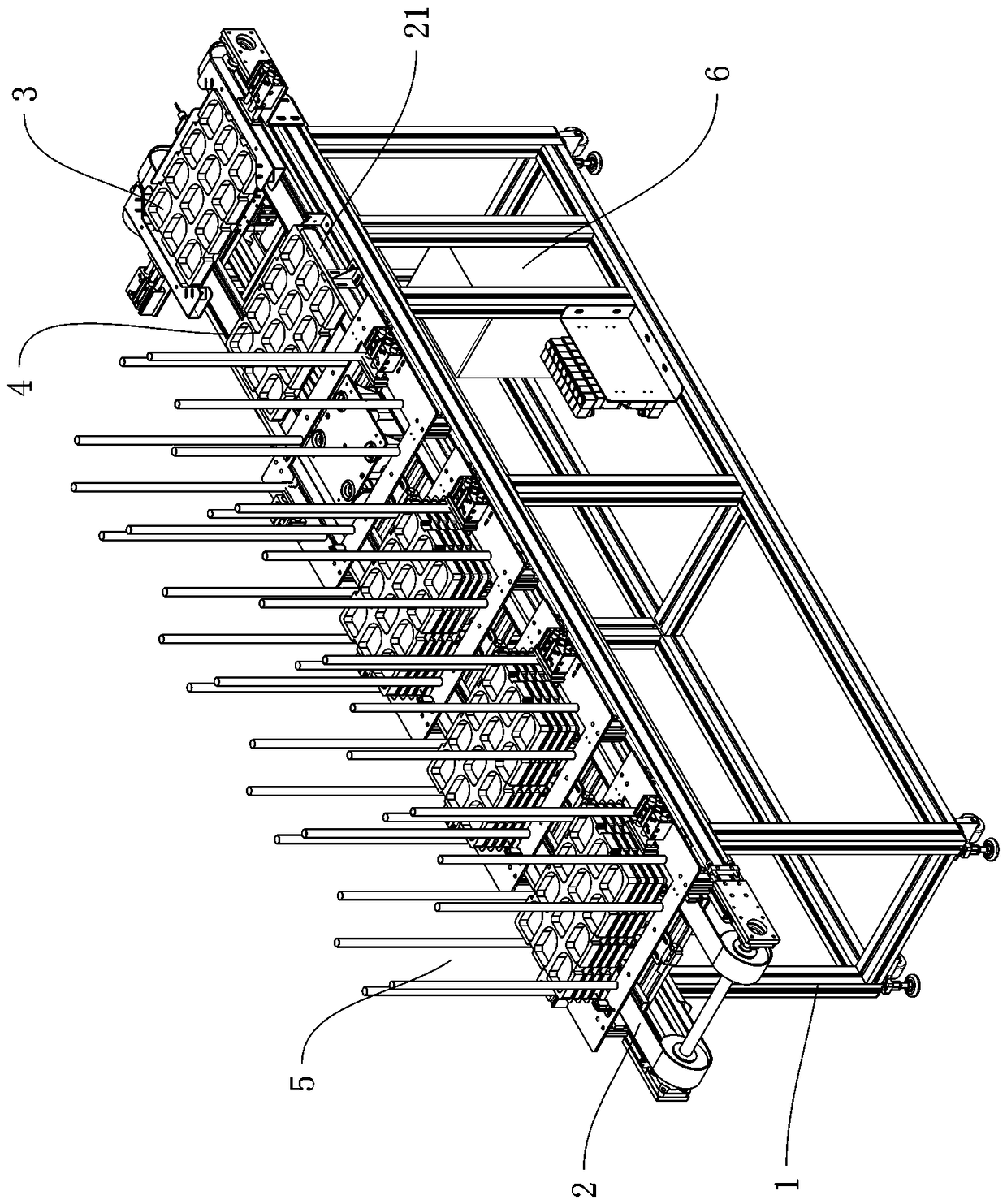

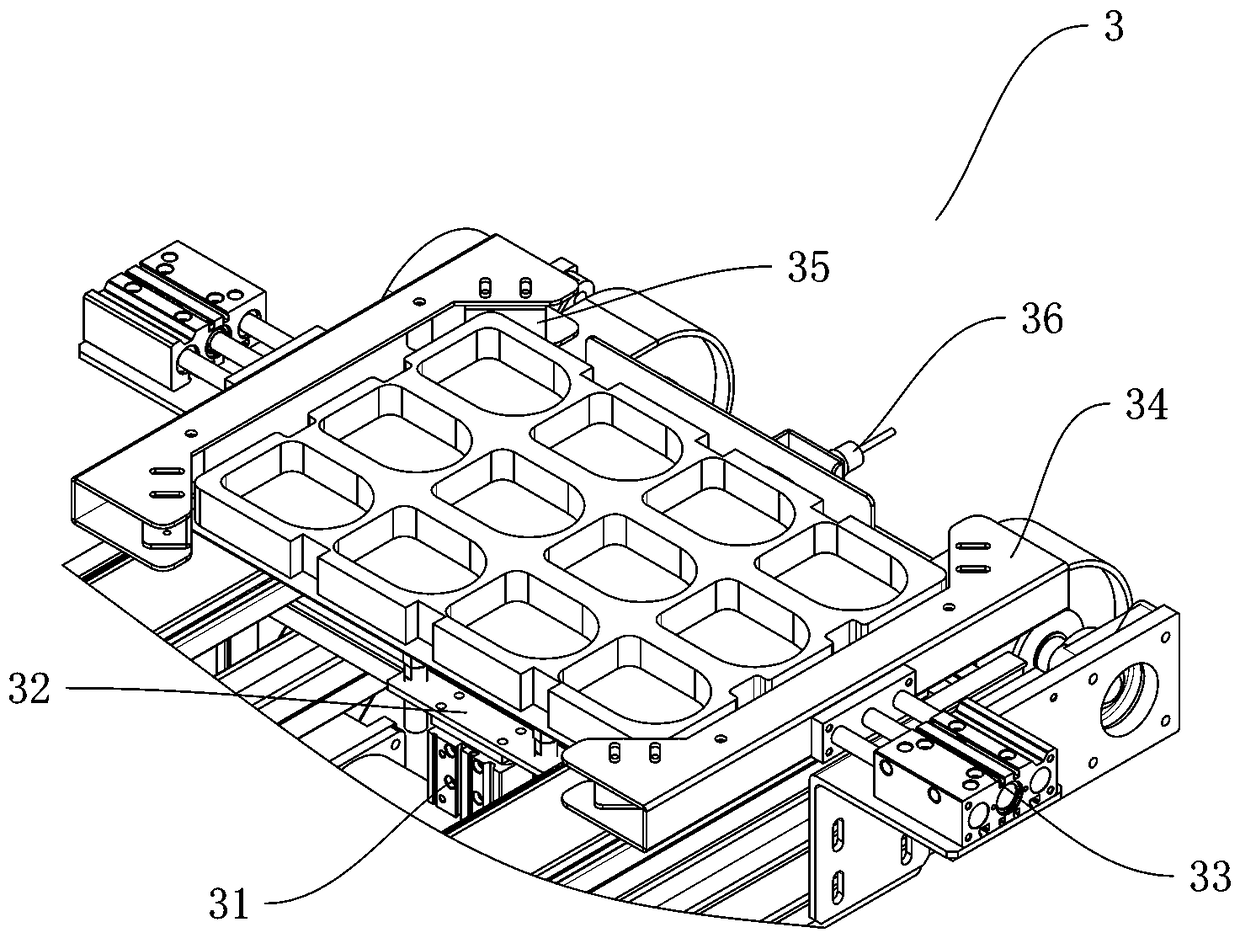

Automatic charging tray feeding system

PendingCN109484821AHigh precisionGuaranteed continuous feedingConveyorsControl devices for conveyorsEngineeringElectric control

The invention discloses an automatic charging tray feeding system. The system comprises a rack, a conveying belt, an assembling positioning mechanism, a material waiting position, a stock bin and an electric control box, the stock bin, the material waiting position, and the assembling positioning mechanism are arranged from back to front sequentially in the conveying direction, the assembling positioning mechanism comprises a lifting air cylinder, a lifting plate, a positioning air cylinder and positioning clamping claws, a piston rod of the lifting air cylinder is connected with the lifting plate, a charging tray is lifted to the positioning face, the two positioning clamping claws limit the charging tray to the position over the conveying belt, the stock bin comprises a discharging frame, a lifting mechanism and a dividing clamping claw, the lifting mechanism lifts the bottom charging tray to the conveying belt, and the dividing clamping jaw lifts remaining charging trays. Continuousfeeding can be ensured, the feeding position precision is greatly improved, the correcting rate of the next procedure can be ensured, the whole structure is ingenious and fine, in combination with sensors of mechanisms, the feeding process automation is achieved through a PLC, the labor intensity of a worker is greatly reduced, production cost is reduced, and production efficiency and productionprecision are improved.

Owner:XIAMEN BANGZHONG TECH

Intelligent steel plate production device

ActiveCN110814764ASimple structureUnique designOther manufacturing equipments/toolsRobot handMachine

The invention relates to an intelligent steel plate production device which comprises a derusting machine feeding roller way, a steel plate derusting mechanism, a derusting machine receiving roller way, a three-station automatic exchange workbench, a truss type mechanical hand, a temporary storage material station, a chamfering machine feeding roller way, a bilateral double-sided edge milling machine, a chamfering machine receiving roller way and a blanking temporary storage platform which are sequentially arranged. The intelligent steel plate production device is simple in structure, unique in design and convenient to operate, original manual operation is changed into the existing automatic operation, the production efficiency is greatly improved, the production precision is high, the production cost is reduced, and the defective rate is reduced.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

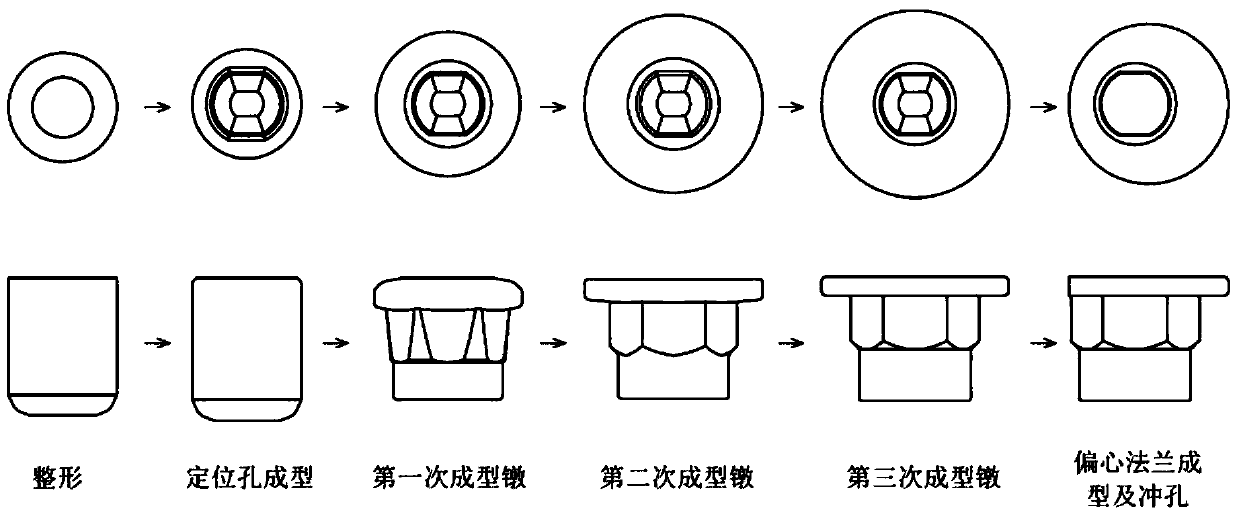

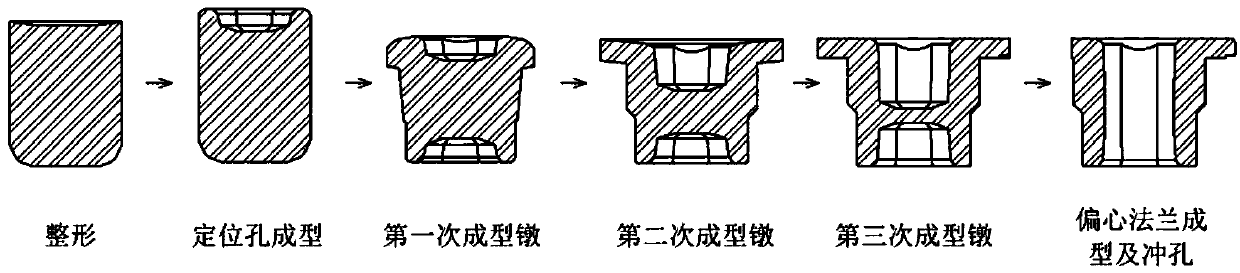

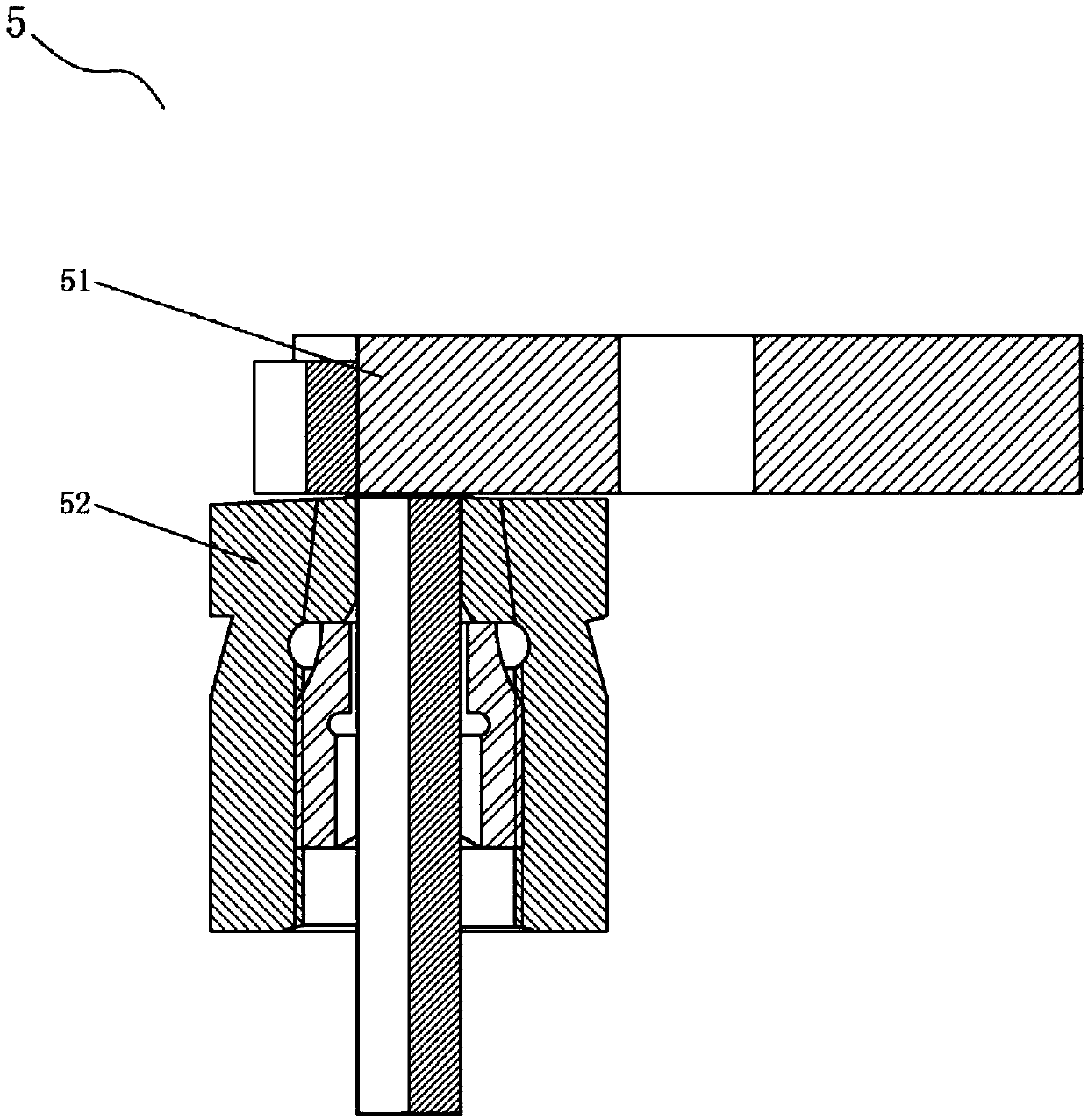

Cold heading forming technology of eccentric flange nut with bosses and combined mold applied to cold heading forming technology

PendingCN109622872AA large forceExtended service lifeNutsForging/hammering/pressing machinesPunchingEngineering

The invention discloses a cold heading forming technology of an eccentric flange nut with bosses and a combined mold applied to the cold heading forming technology. The cold heading forming technologyof the eccentric flange nut with the bosses comprises the steps of a blanking process, a shaping process, a punching process, and three heading forming processes and an eccentric flange forming process sequentially following the shaping process; in the three heading forming processes, a forward flange section, a hexagonal prism section, and a boss section are sequentially formed in a blank threetimes, kidney-shaped counterbores with sequentially increased depths are formed in the blank three times, and kidney-shaped locating holes with sequentially increased depths are formed in the blank three times; the forward flange section is coaxial with the hexagonal prism section and the boss section; and in the eccentric flange forming process, the blanking process is conducted on the forward flange in the axial direction to form the desired eccentric flange section. The cold heading forming technology of the eccentric flange nut with the bosses has the advantages that the technology is simple, the production efficiency is greatly improved, the production process is stable, the stripping is convenient, the service life of the mold is prolonged, the flange face of the formed eccentric flange nut is uniform and attractive, and the product precision is high.

Owner:厦门恒耀金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com