Servo motion control integrated machine system for flying saw machine

A servo motion, flying saw machine technology, applied in the control system, vector control system, control generator and other directions, can solve the problems of large installation space, affecting equipment reliability and accuracy requirements, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The detailed structure of the present invention is described in conjunction with specific embodiments.

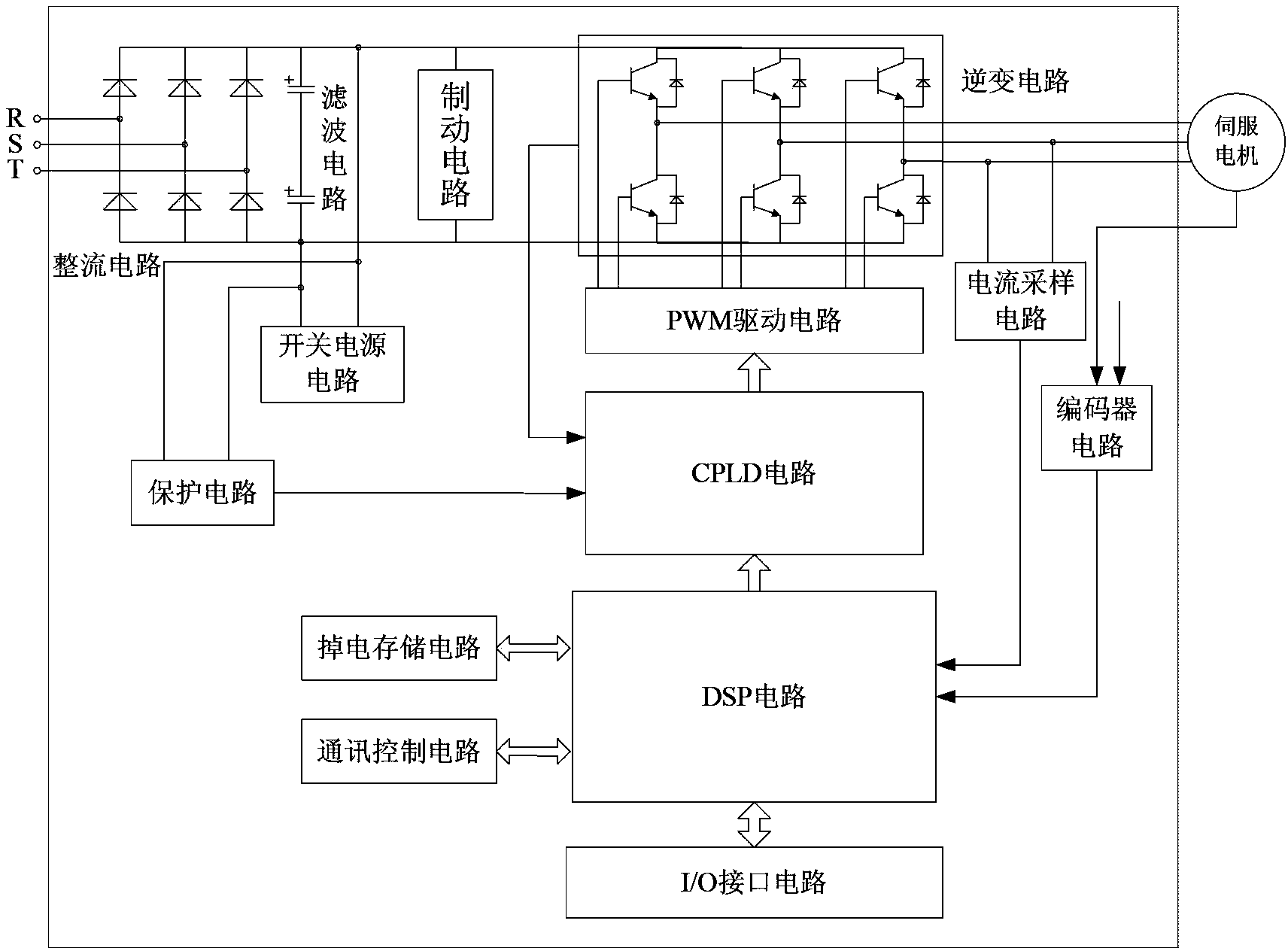

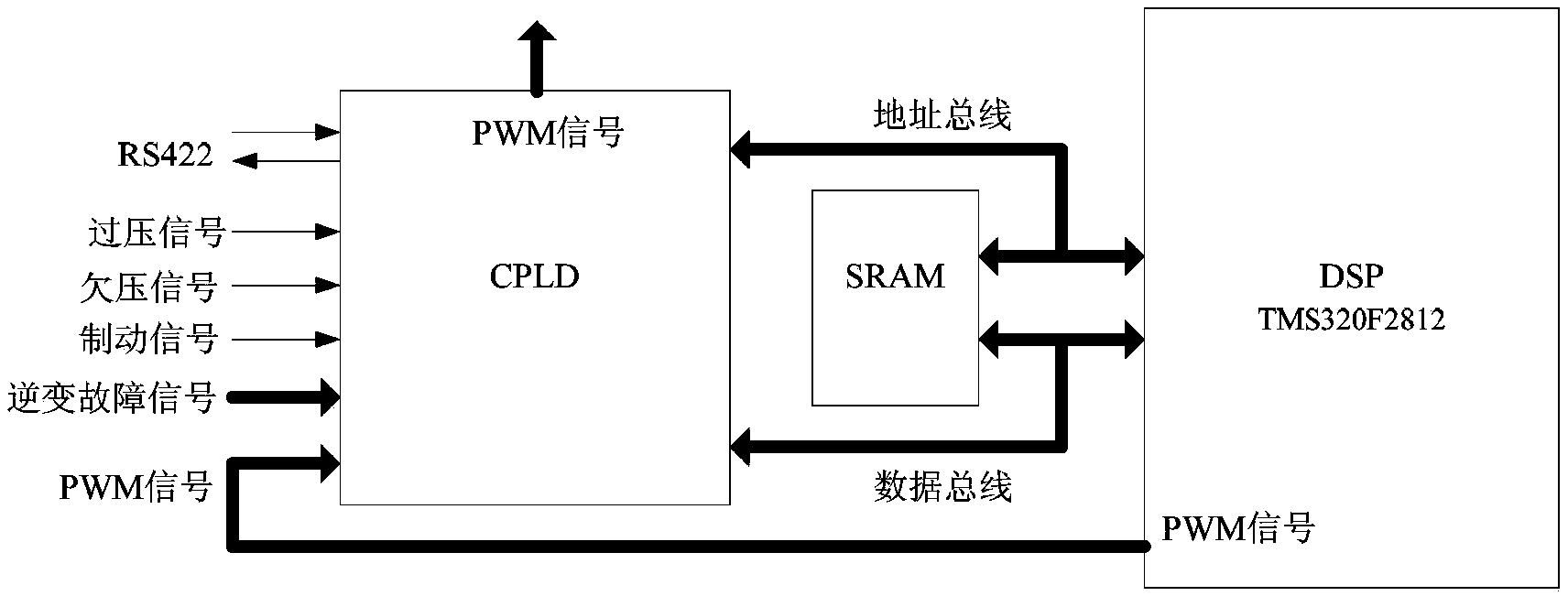

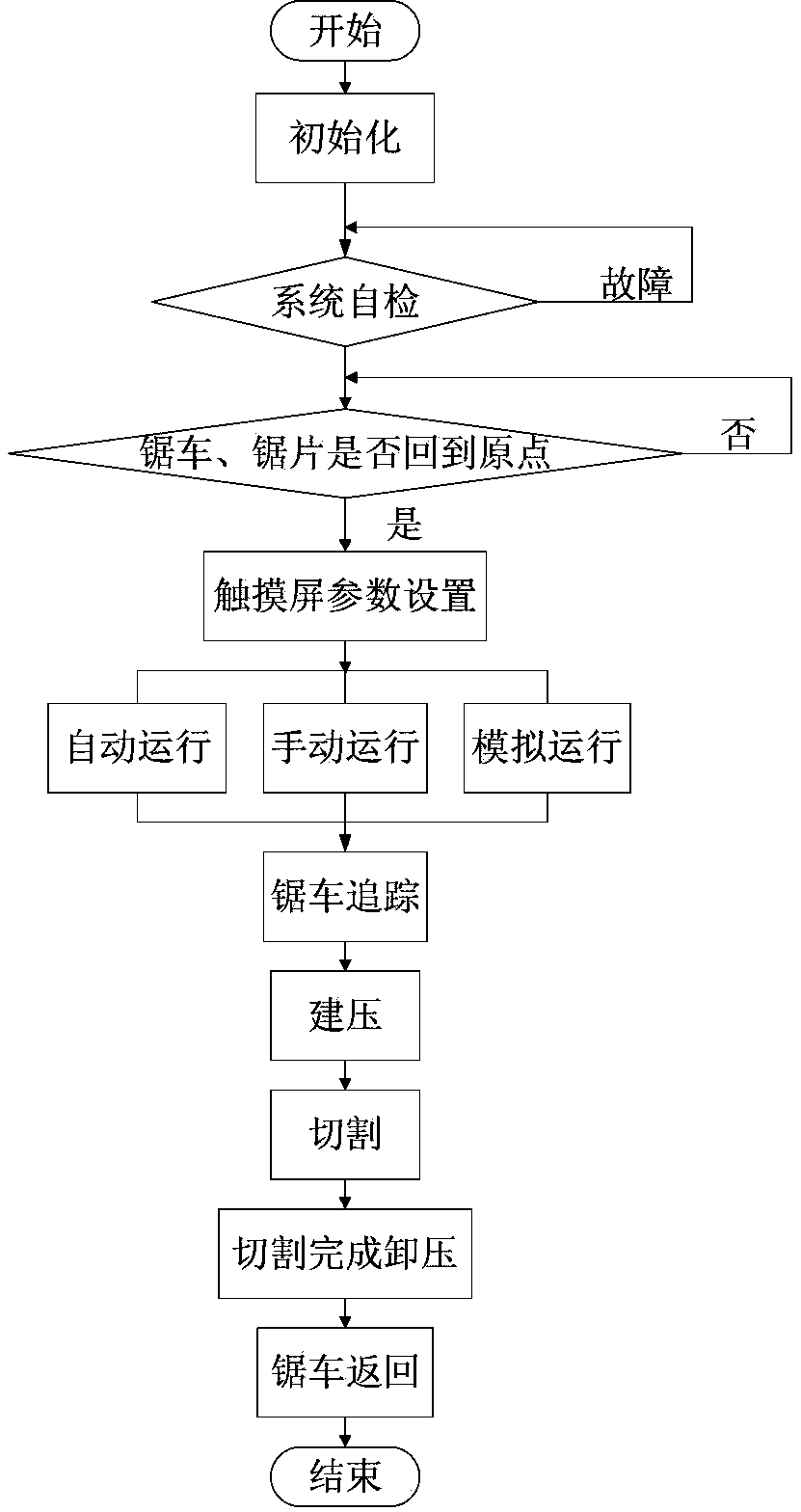

[0080] A servo motion control all-in-one system for flying saws, such as figure 1 with 2 As shown, including rectifier circuit, filter circuit, brake circuit, switching power supply circuit, protection circuit, inverter circuit, current sampling circuit, encoder circuit, PWM drive circuit, CPLD circuit, DSP circuit, power-down storage circuit, communication control circuit and I / O interface circuit.

[0081] In this embodiment, the DSP circuit chip adopts the TMS320F2812 digital signal processor of TI Company, the CPLD circuit adopts the EPM1270 chip of Altera Company, the power-down storage circuit adopts the FM24CL16 chip, the rectifier circuit adopts the MDS-100-16 module, and the Ximenkang The SKM150GB173D model IGBT module builds the inverter circuit and the braking circuit. The current sensor uses the LA100-P model sensor of LEM, and the 400V4700μF capacitor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com