Full-automatic rough machining method and system for motorcycle wheel

A fully automatic and friction wheel technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low processing accuracy, labor and labor, and low production efficiency, so as to improve production accuracy and reduce production cost, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

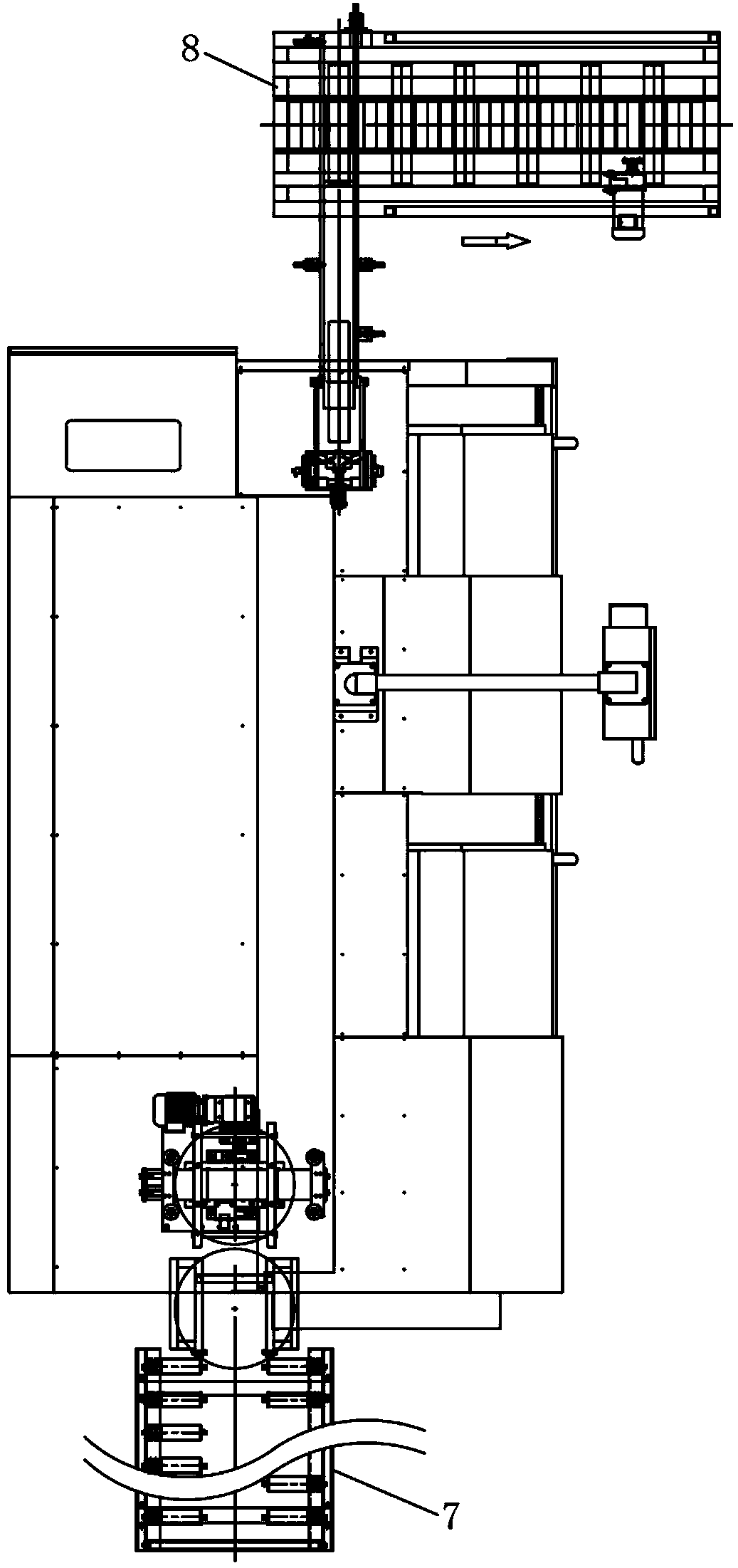

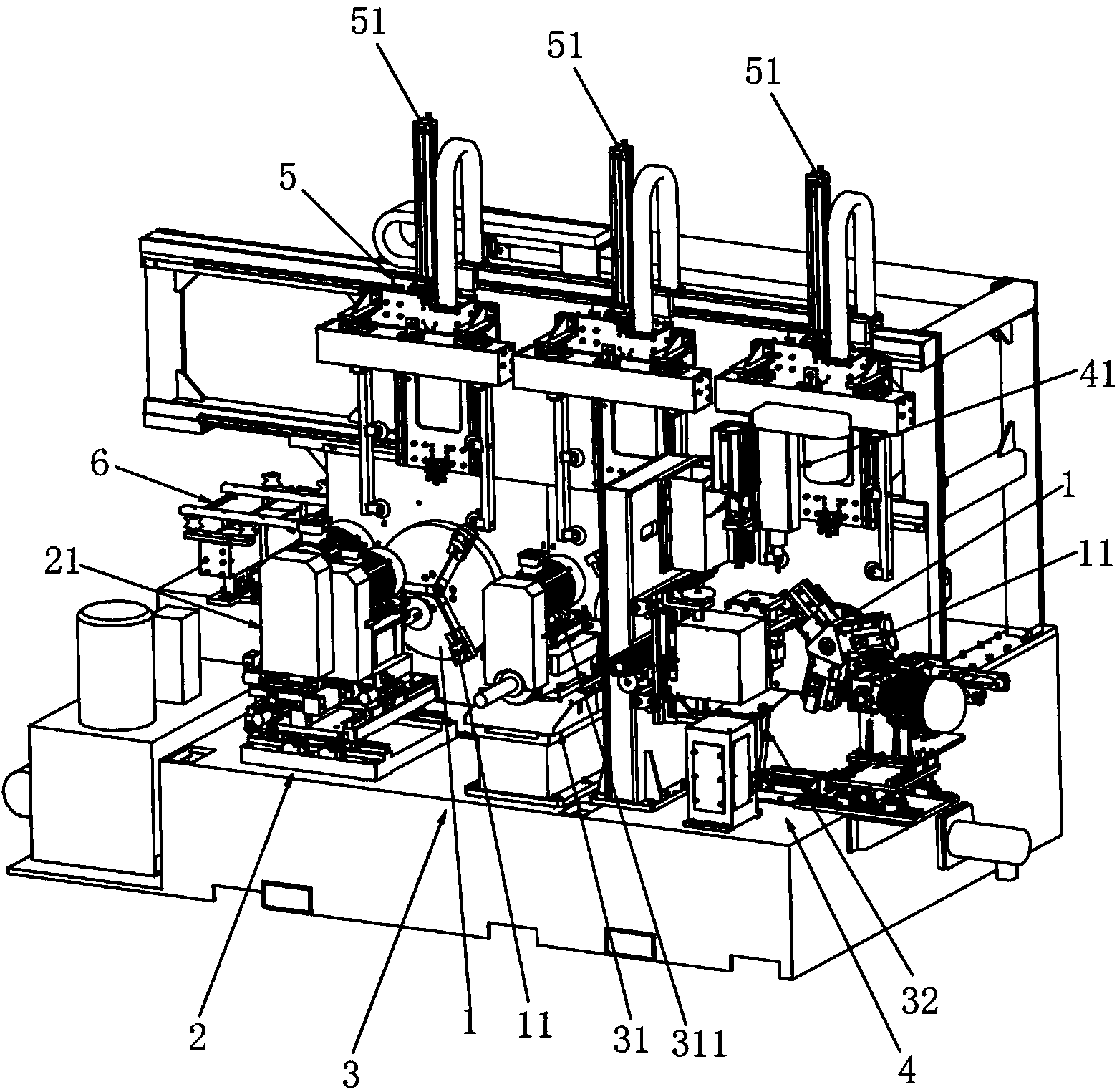

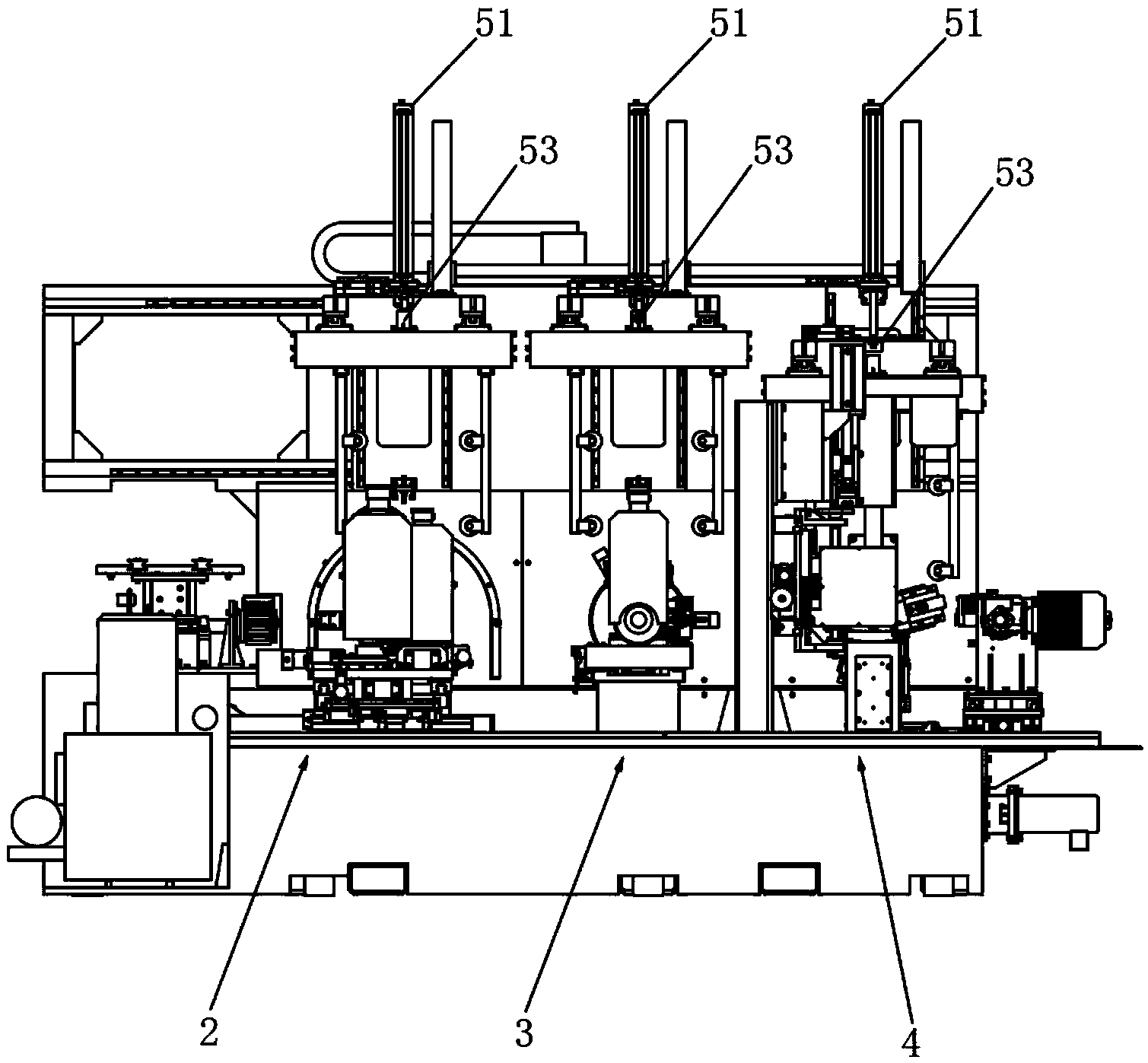

[0035] Examples, see Figure 1 to Figure 6 as shown,

[0036] A method and system for fully automatic rough machining of a friction wheel, including a machine tool. The machine tool is sequentially provided with a cutting riser gate station 2, a drilling center hole station 3, and an air valve core hole drilling station 4 according to the feeding direction. There is a visual identification device for identifying the wheel hub model and an intelligent control system for adjusting the processing program by receiving the signal from the visual identification device. There are three synchronous claw discs 1 for synchronous operation, and the three claw discs 1 are respectively set at cutting riser gate station 2, drilling center hole station 3 and valve core hole drilling station 4, and the machine tool has three se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com