Intelligent steel plate production device

An intelligent production and steel plate technology, applied in the field of steel plate processing, can solve problems such as noise pollution, low output, and safety hazards involved in hoisting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

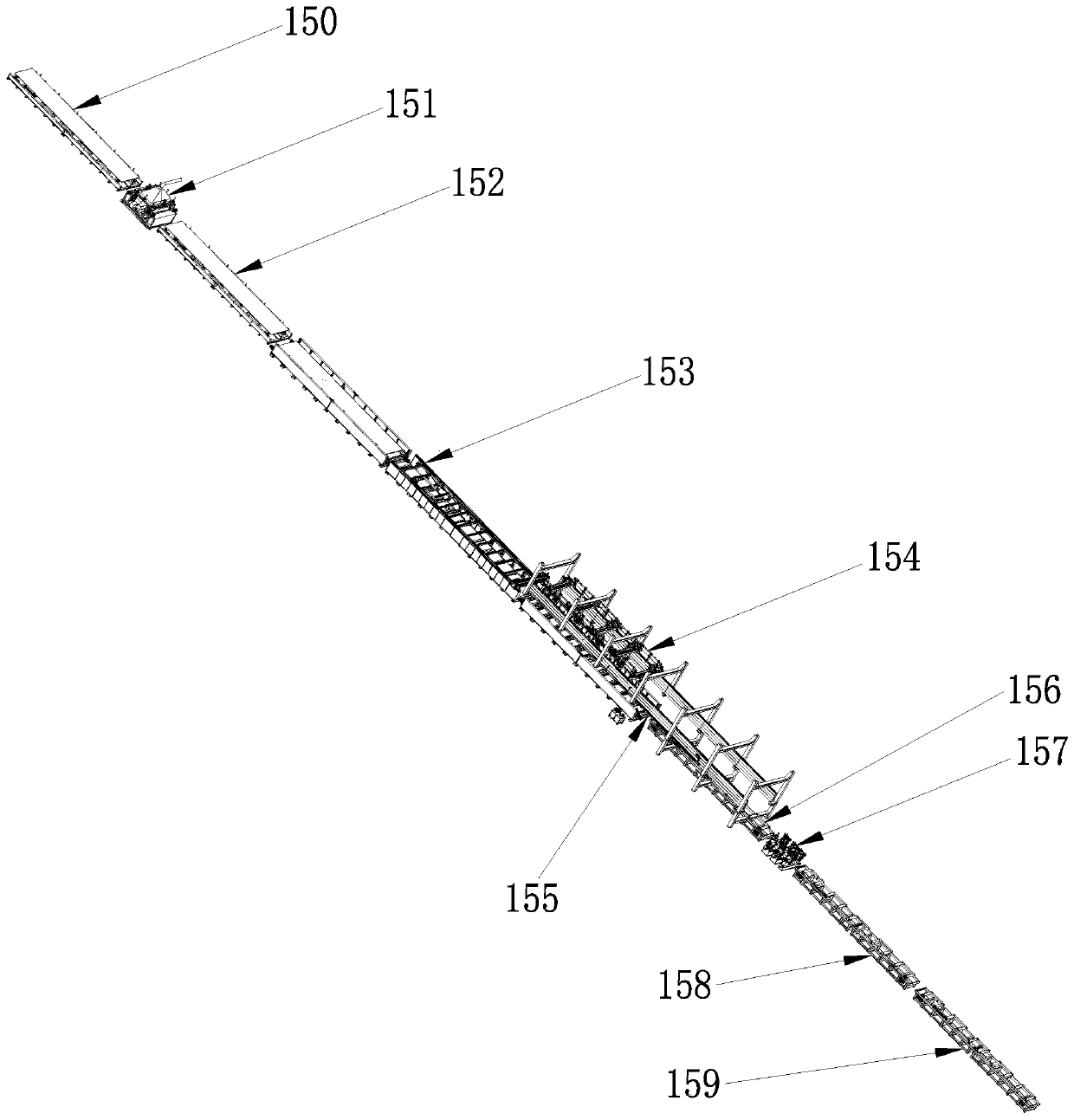

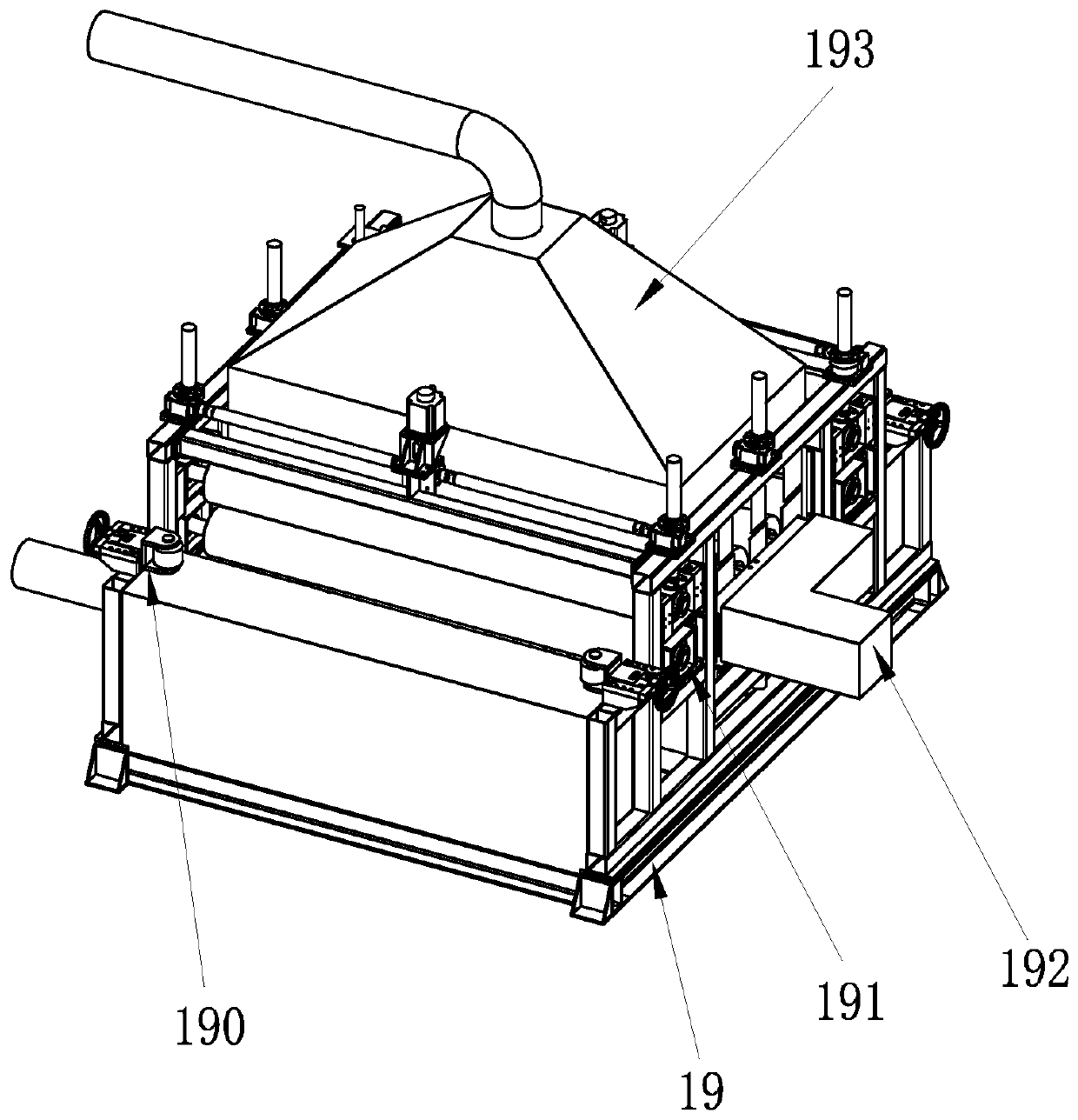

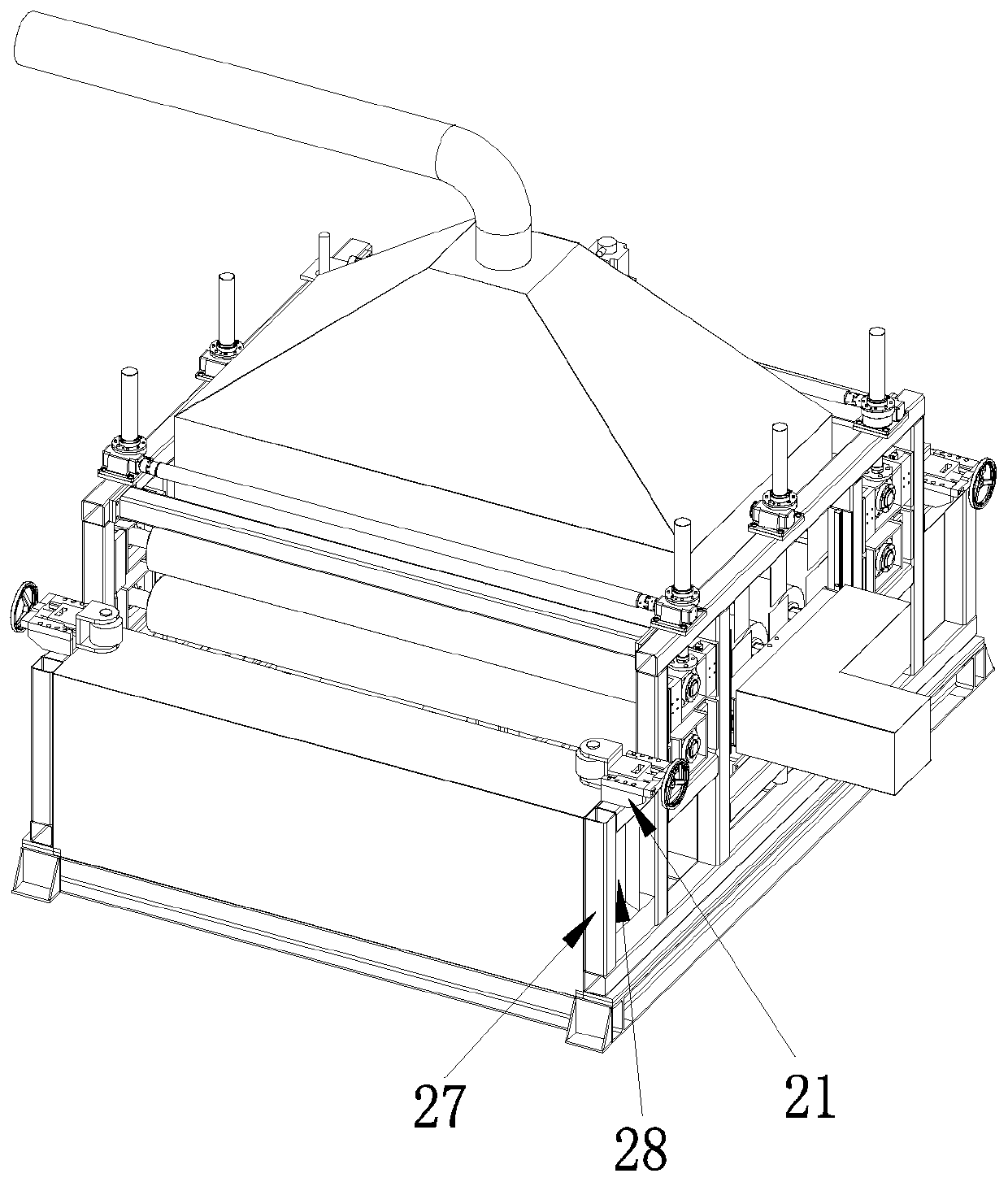

[0055] Example: such as figure 1 As shown, an intelligent steel plate production device includes a descaling machine feeding roller table 150, a steel plate descaling mechanism 151, a descaling machine receiving roller table 152, a three-station automatic exchange workbench 153, and a truss-type manipulator 154 arranged in sequence. , buffer material station 155, chamfering machine loading roller table 156, double-sided double-sided edge milling machine 157, chamfering machine receiving roller table 158 and unloading buffer platform 159; the three-station automatic exchange workbench 153 includes sequential layout The steel plate pre-exchange platform 100, the steel plate cutting platform 101 and the steel plate rear exchange platform 102; the steel plate derusting mechanism 151 includes a fixed platform 19, a steel plate guiding device 190 arranged on the fixed platform 19, a steel plate conveying positioning device 191, Steel plate rust removal device 192 and steel plate rus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com