Patents

Literature

49results about How to "Guaranteed continuous feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

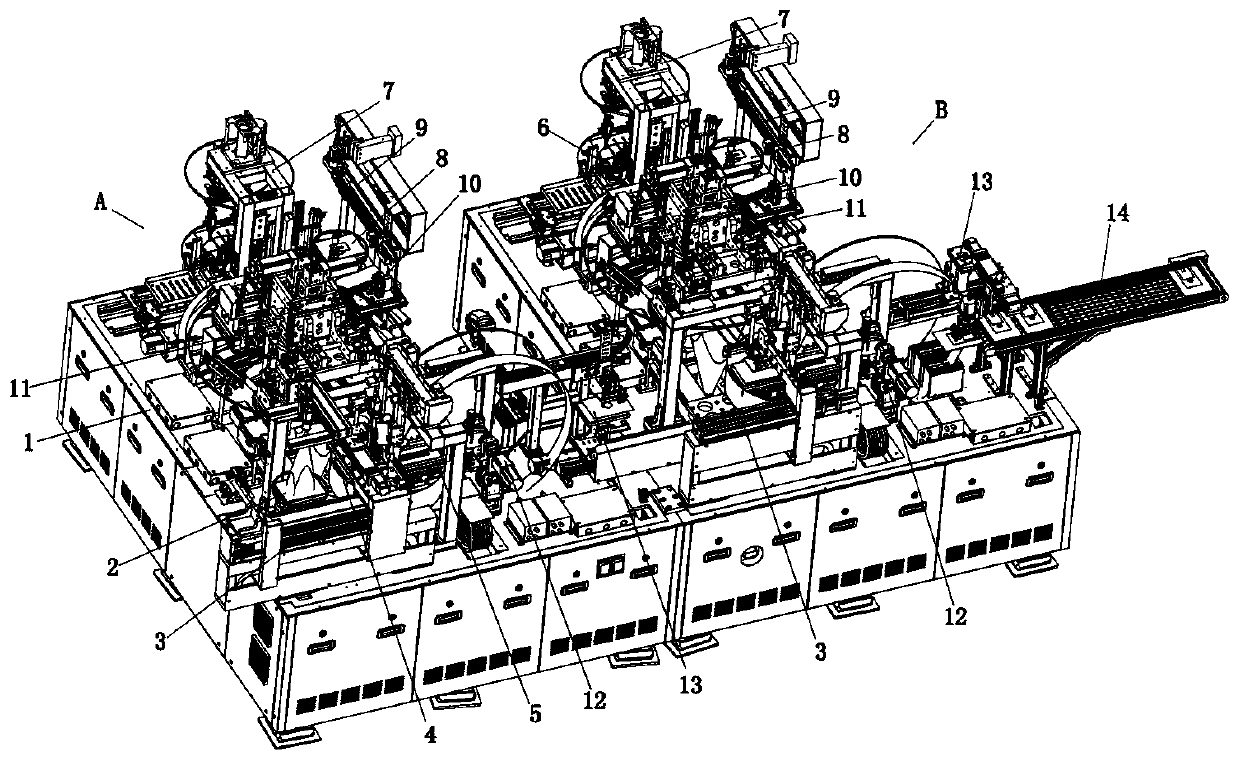

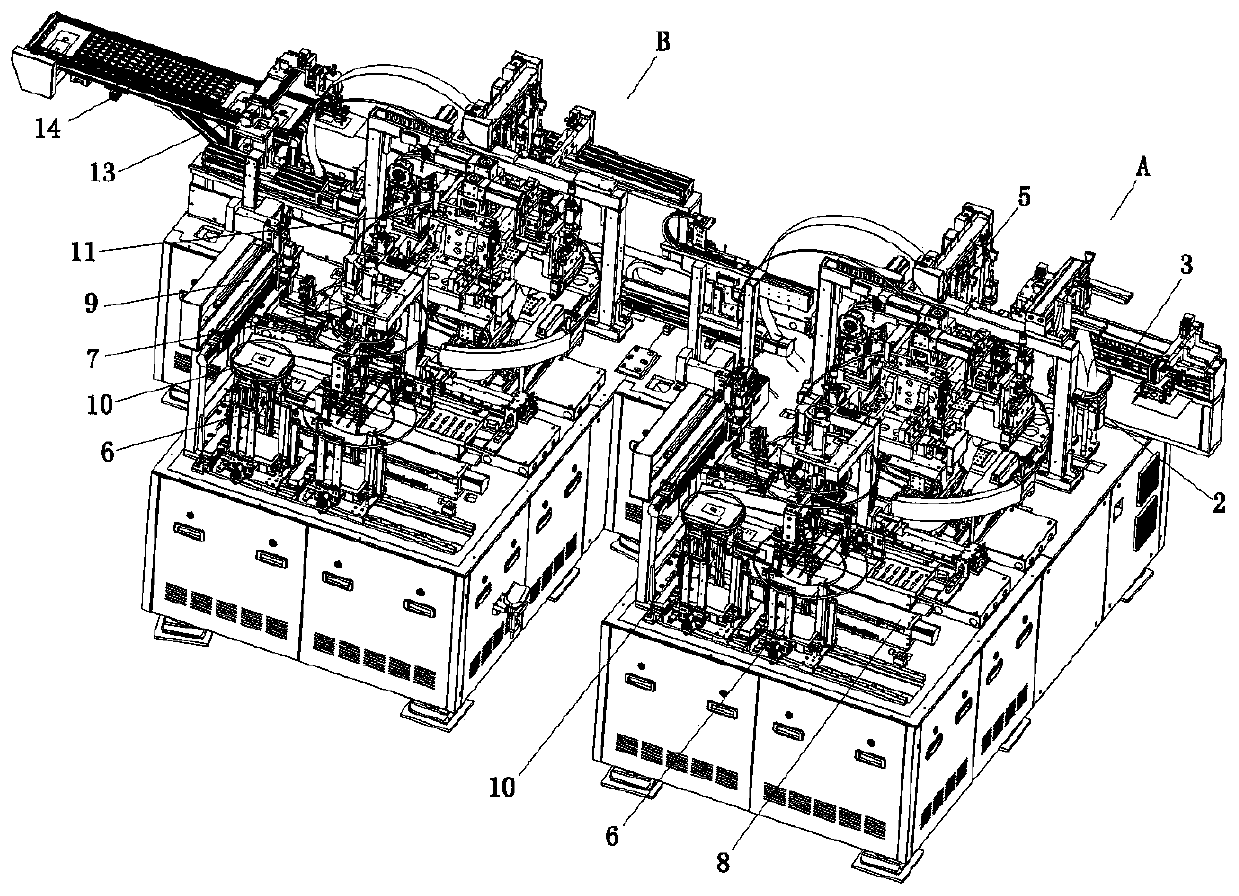

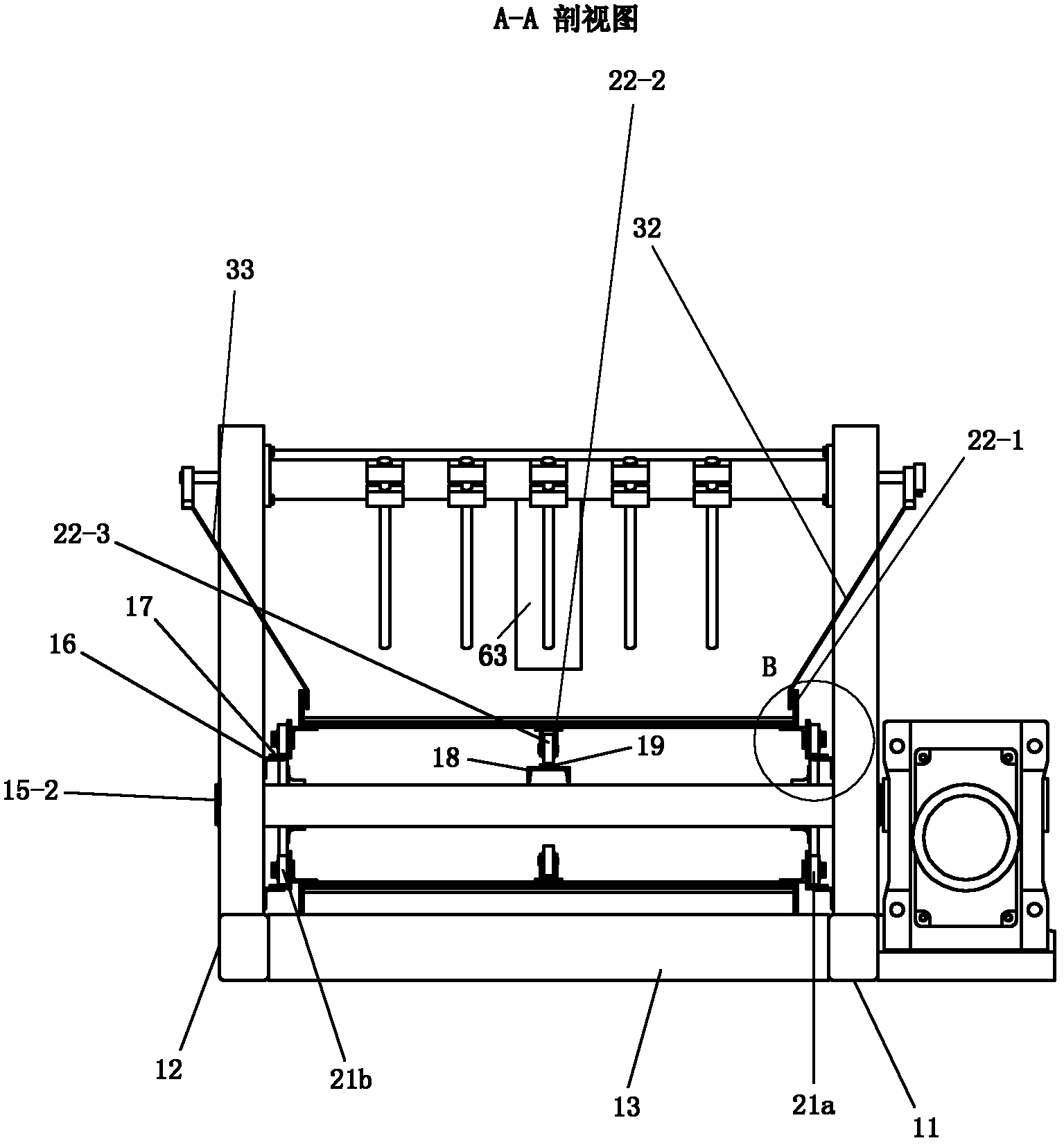

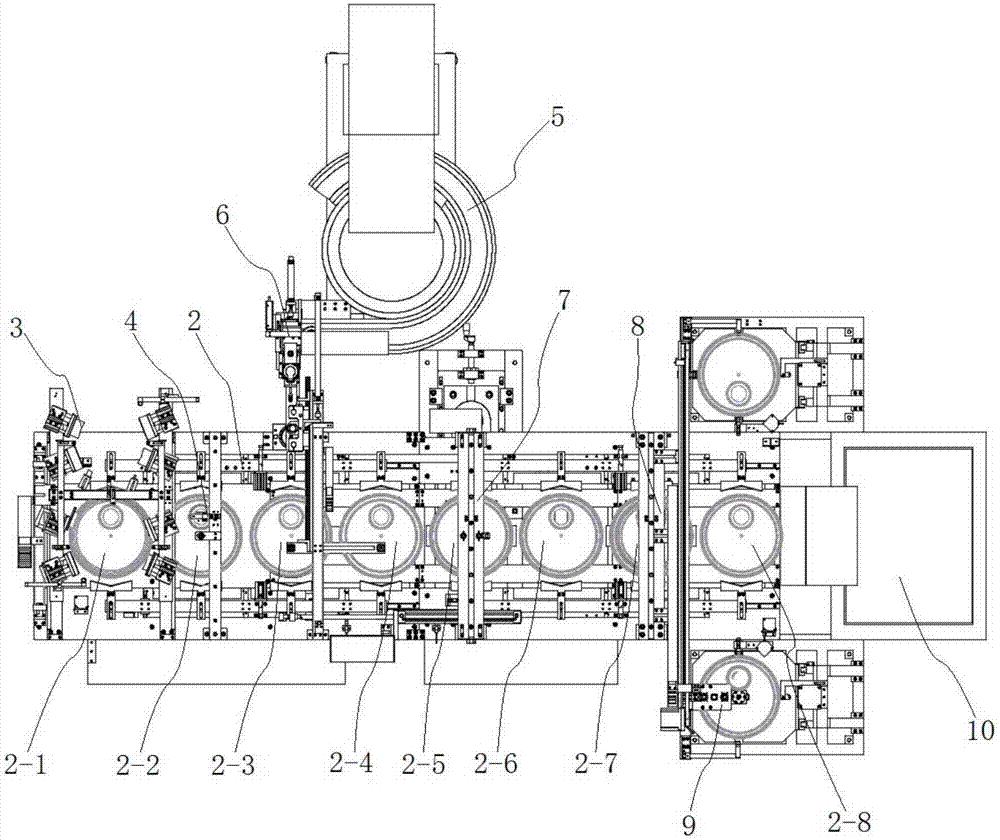

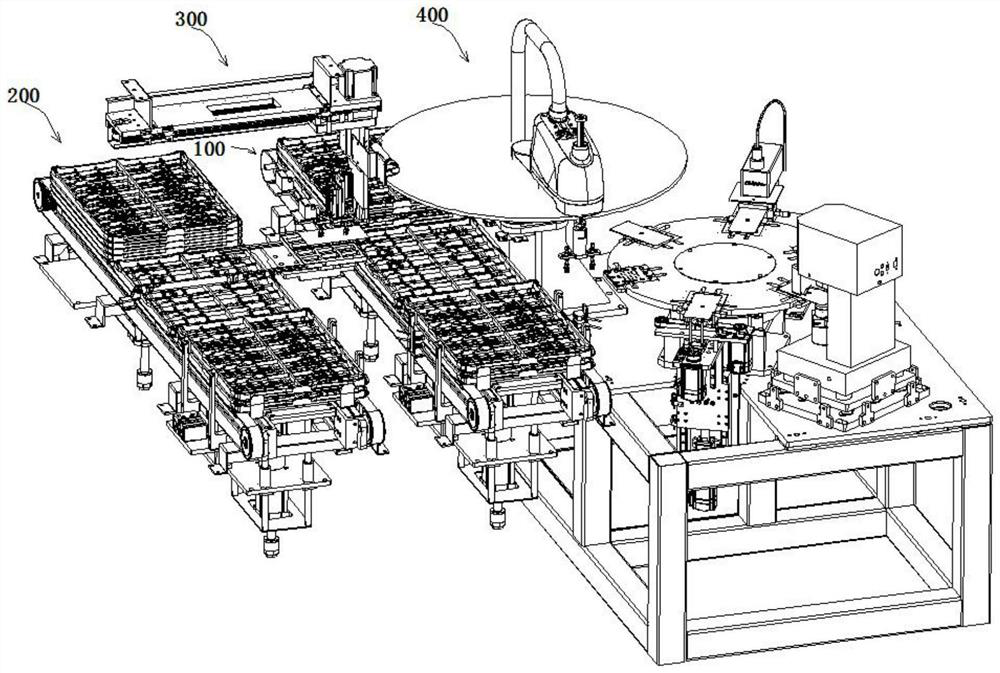

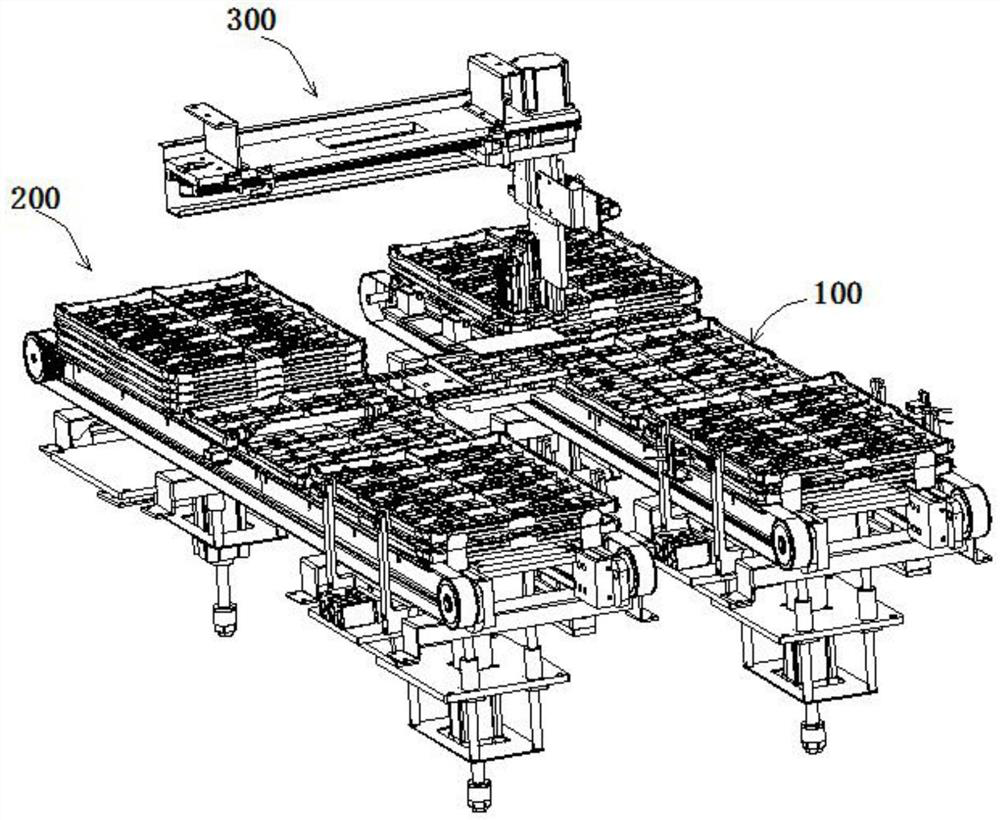

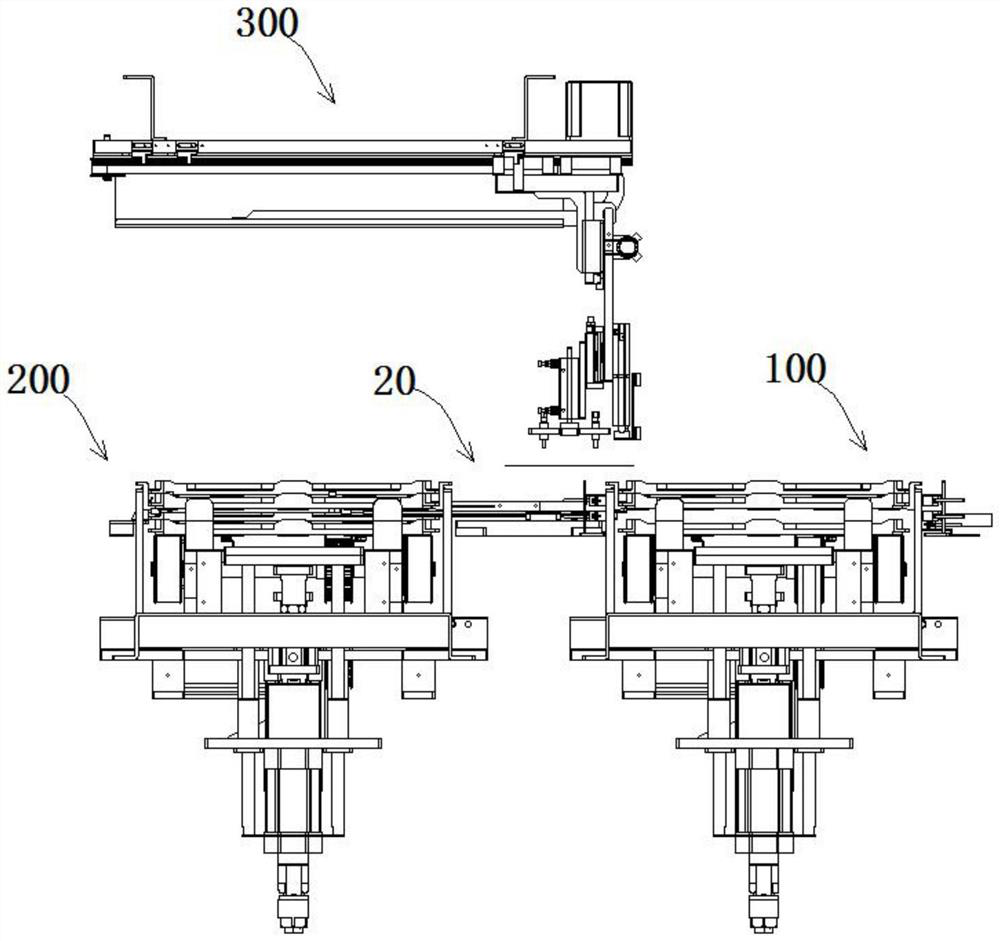

Full-automatic screen double-sided chip mounter and chip mounting technology thereof

PendingCN110174715ARealize automatic and efficient connectionReduce the presence of air bubblesNon-linear opticsOptical elementsEngineeringPolarizer

The invention discloses a full-automatic screen double-sided chip mounter and a chip mounting technology thereof. The full-automatic screen double-sided chip mounter comprises a first mounting part, aturnover mechanism, a second mounting part and a discharging belt which are arranged at intervals in sequence. After one side surface of a to-be-mounted glass sheet is subjected to chip mounting at the first mounting part, the glass sheet is moved to the turnover mechanism; after the glass sheet is turned over by the turnover mechanism, the other side surface of the glass sheet is subjected to chip mounting at the second mounting part; and the glass sheet is exported and discharged through the discharging belt. According to the chip mounter and the chip mounting technology, automatic and efficient connection of double-sided and single-sided mounting devices is effectively realized; automatic mounting of double polarizers is completed; the functions of alternate film tearing, alternating chip mounting, alternate discharging after chip mounting, and the like are realized; the material waiting time of each process gap is effectively utilized; the chip mounting time is shortened; the chipmounting productivity is effectively improved; the polarizers are adhered by adopting a flexible chip mounting adhesive tape; the attachment of the polarizers is completed by single-sided rolling attachment of a rolling attachment assembly; chip mounting air bubbles are effectively reduced; and the chip mounting quality is improved.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

Tea-leaf boxing machine

ActiveCN103183140AGuaranteed success rateEliminate the problem of inaccurate positioningIndividual articlesDrive shaftPulp and paper industry

A tea-leaf boxing machine comprises a rack, as well as a paper box bin component, an air suction mechanism, a paper box forming module component, a paper box pressure block component, a paper box lug folding mechanism, a feeding mechanism, a material incoming and box outgoing push mechanism, a box gluing mechanism, a paper box shaping mechanism and an intermittent indexing drive device which are mounted on the rack, wherein the paper box bin component comprises a paper box bin and a paper box pressure block which are located on the same straight line, and the paper box pressure block is located above paper box forming modules; the air suction mechanism is arranged below the paper box bin component, and connected with a first rocker arm of a main transmission shaft; and the paper box forming module component comprises the paper box forming modules and a synchronous belt, the paper box forming modules are uniformly distributed on the synchronous belt, and the synchronous belt is connected with the intermittent indexing drive device. The invention provides the tea-leaf boxing machine which can perform mechanization packing, reduce the cost, and improve the efficiency.

Owner:浙江武义浩伟机械有限公司

Automatic flat plate box boxing machine

InactiveCN104058132AGuaranteed success rateEliminate the problem of inaccurate positioningPackaging automatic controlCartonEngineering

An automatic flat plate box boxing machine comprises a rack, wherein a feeding mechanism, a mechanism of pushing feed into and pushing boxes out of bins, a carton feed bin, a carton formation mechanism, a lug folding mechanism, an edge folding and tongue folding mechanism, a glue box mechanism, a side wing edge folding device and a transmission mechanism for ejected boxes are arranged on the rack; a carton briquetting component includes a carton briquetting which is arranged right above a groove of a carton formation module; the lug folding mechanism is positioned in front of the carton briquetting component; the edge folding and tongue folding mechanism is arranged in front of the lug folding mechanism; the glue box mechanism is arranged on the box ejecting side of a synchronous belt of the carton formation module; the side wing edge folding device is arranged on one side of a box outlet of the glue box mechanism; the transmission mechanism for ejected boxes is arranged on one side of a box outlet of the side wing edge folding device. The automatic flat plate box boxing machine, provided by the invention, is suitable for a plurality of inclusions, and has higher stability when the boxes are sealed, and higher qualified rate.

Owner:傅会武

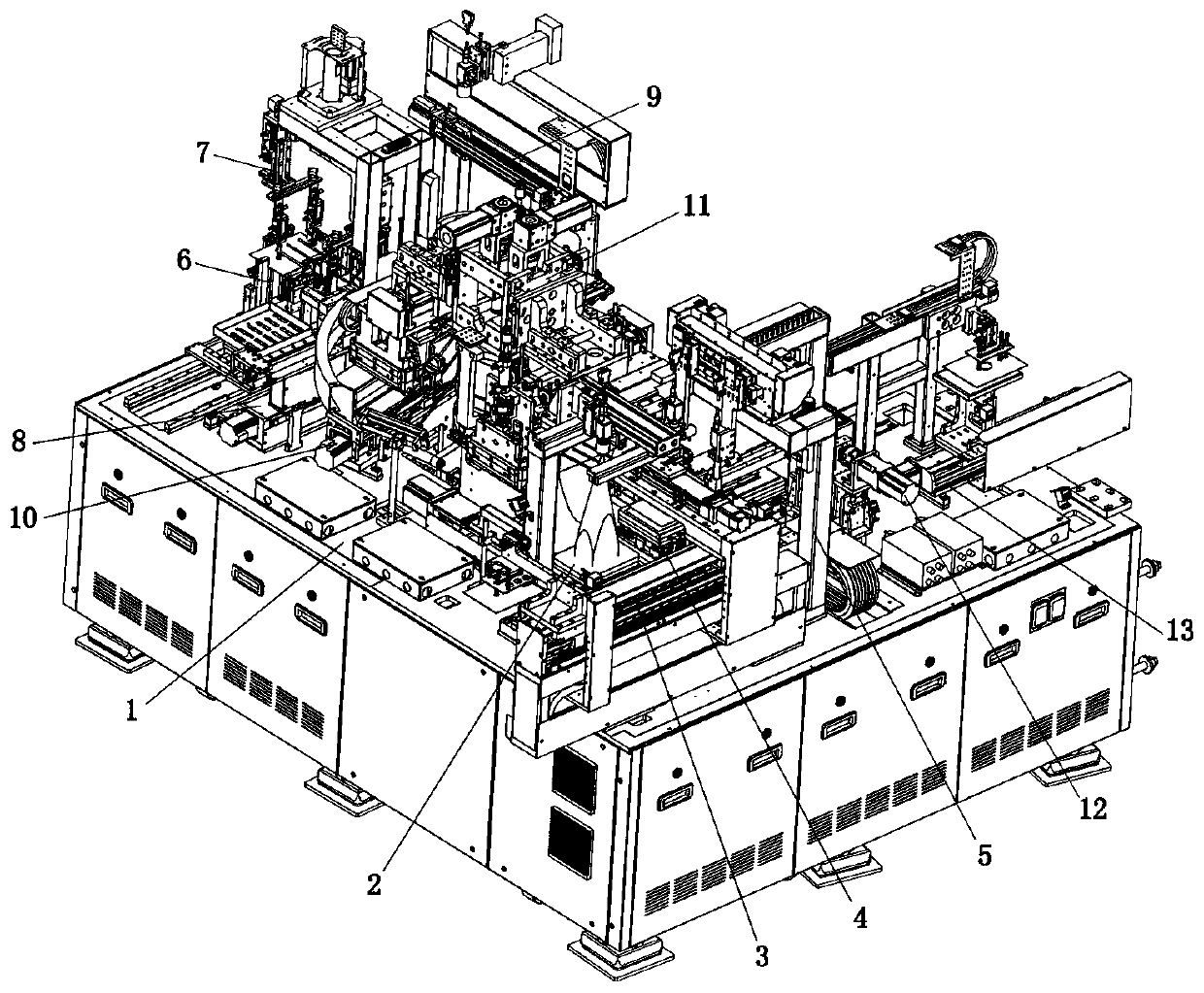

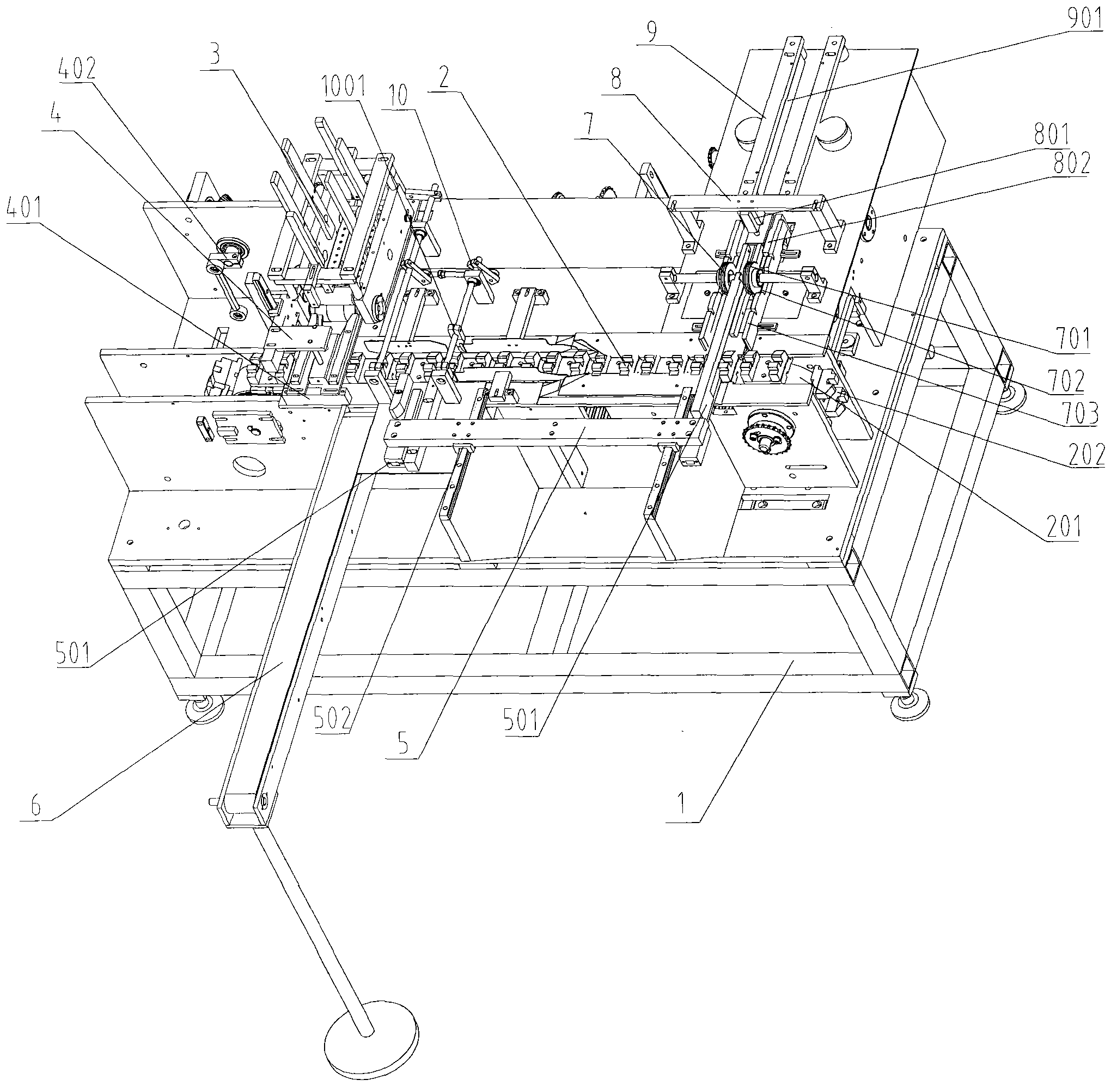

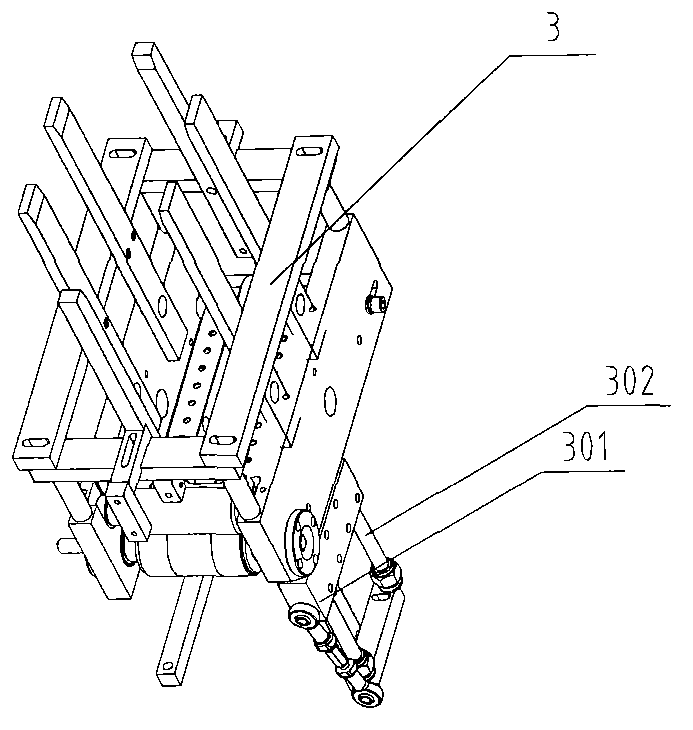

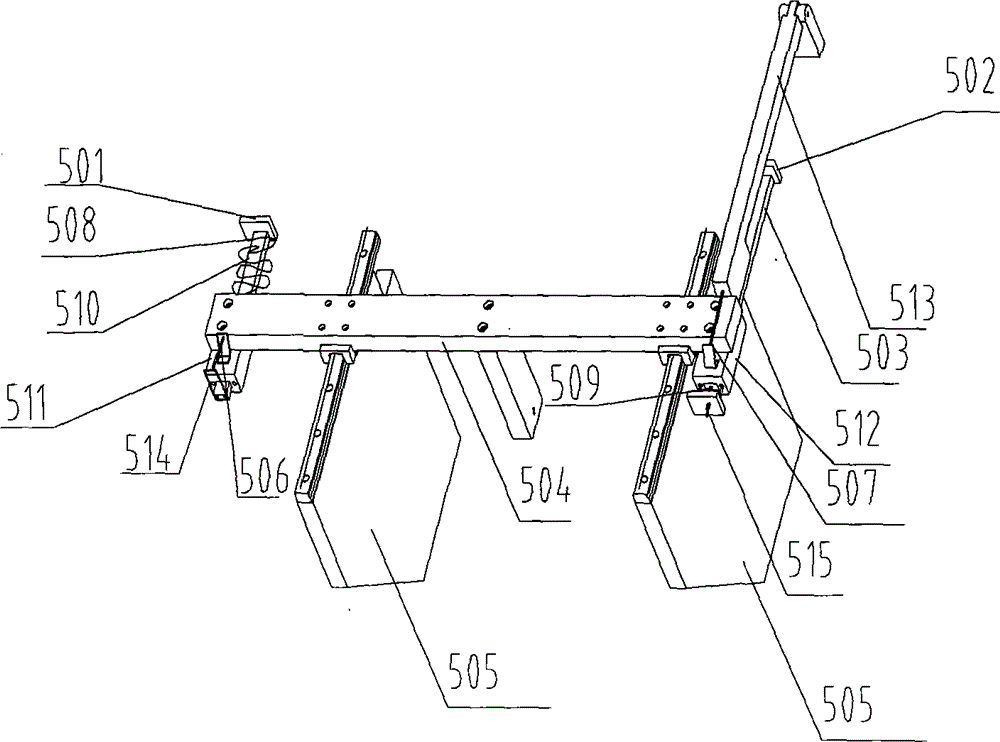

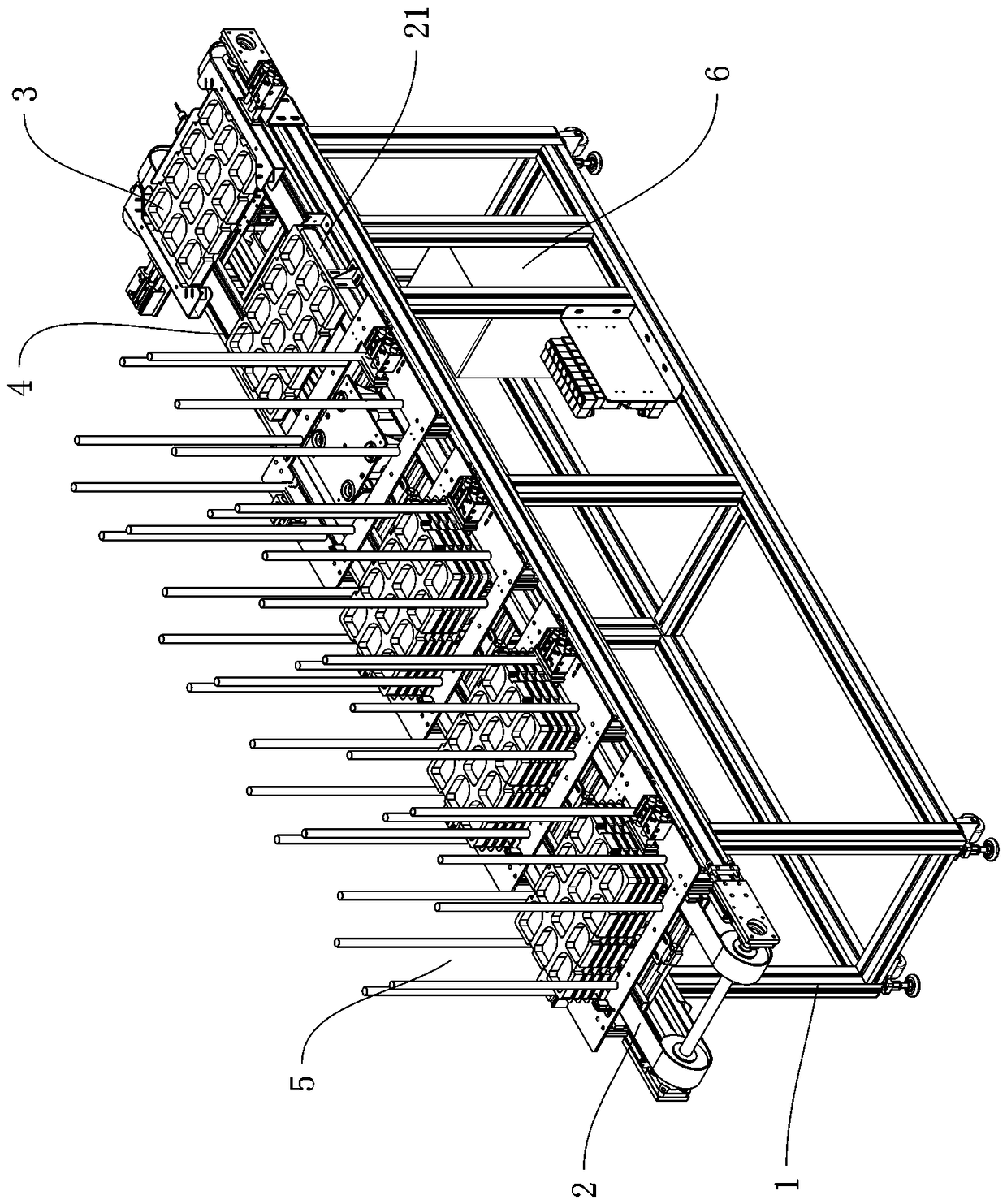

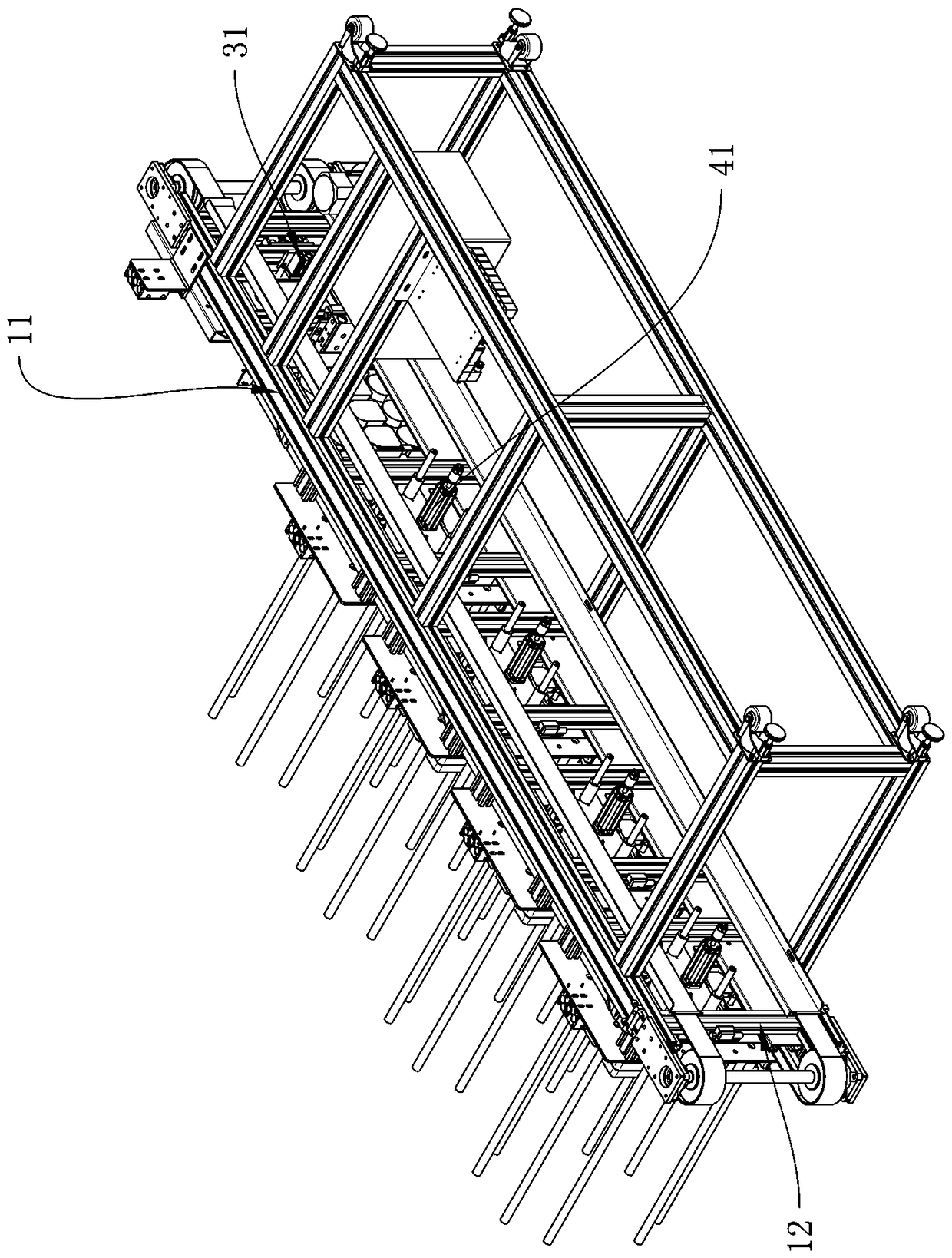

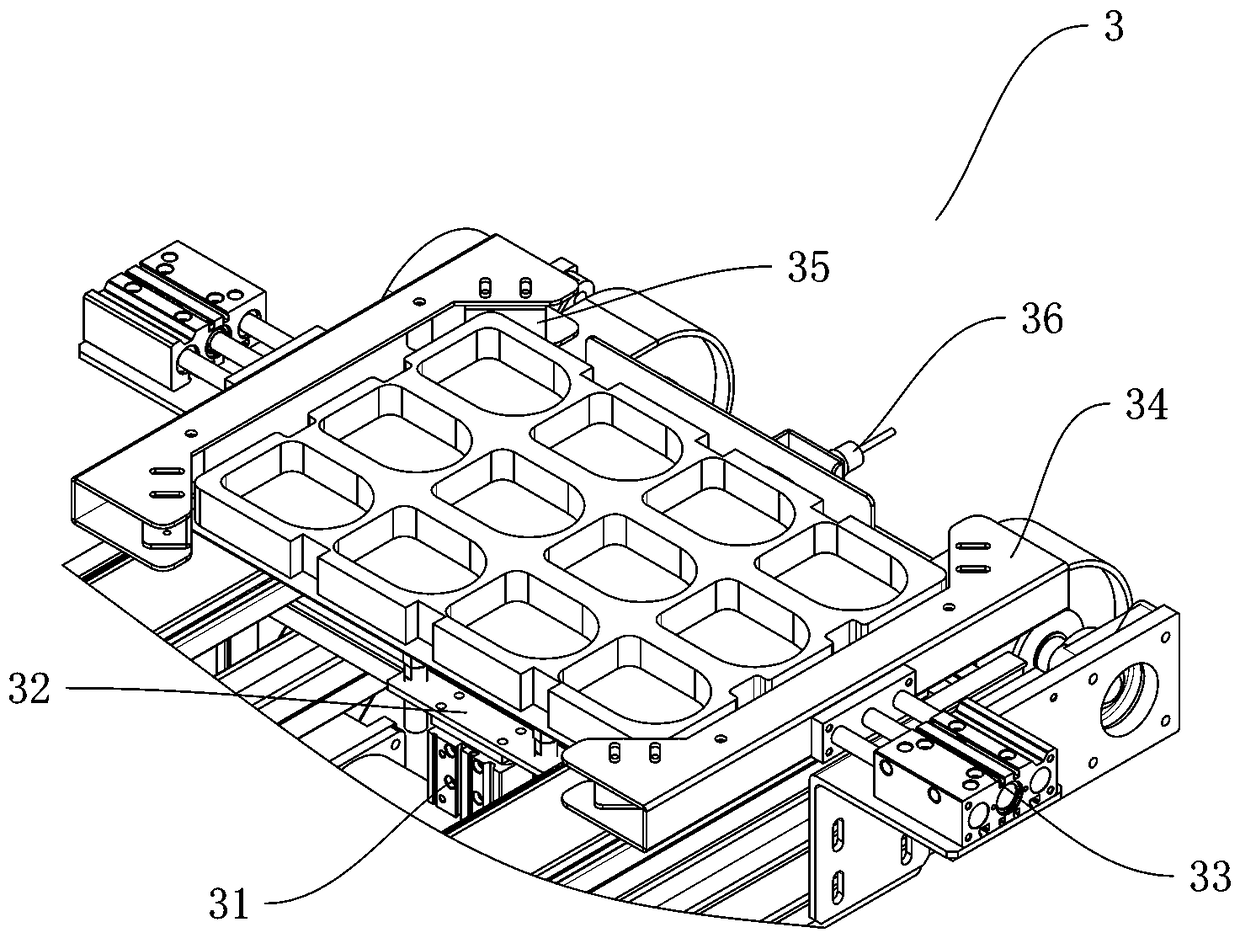

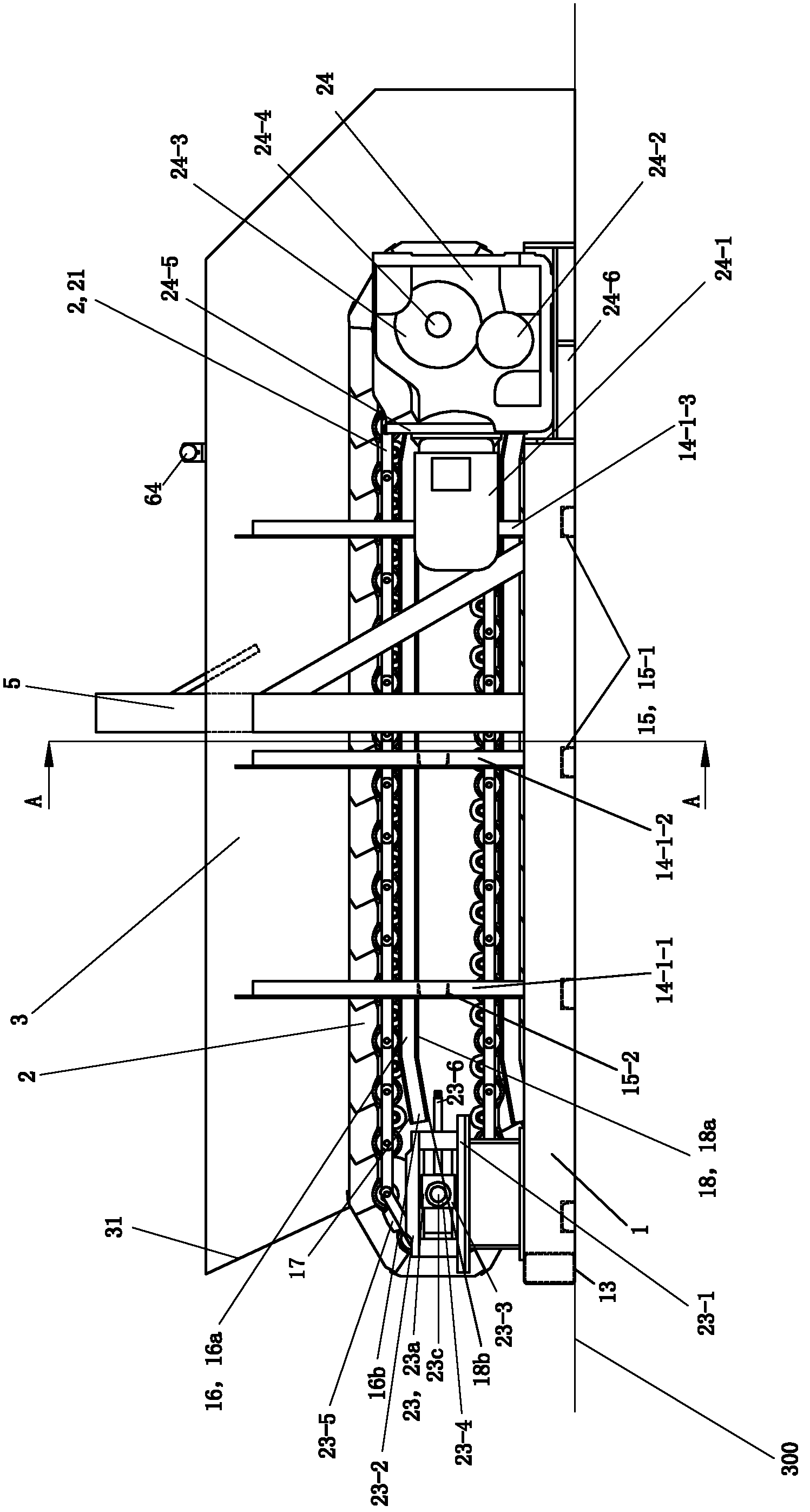

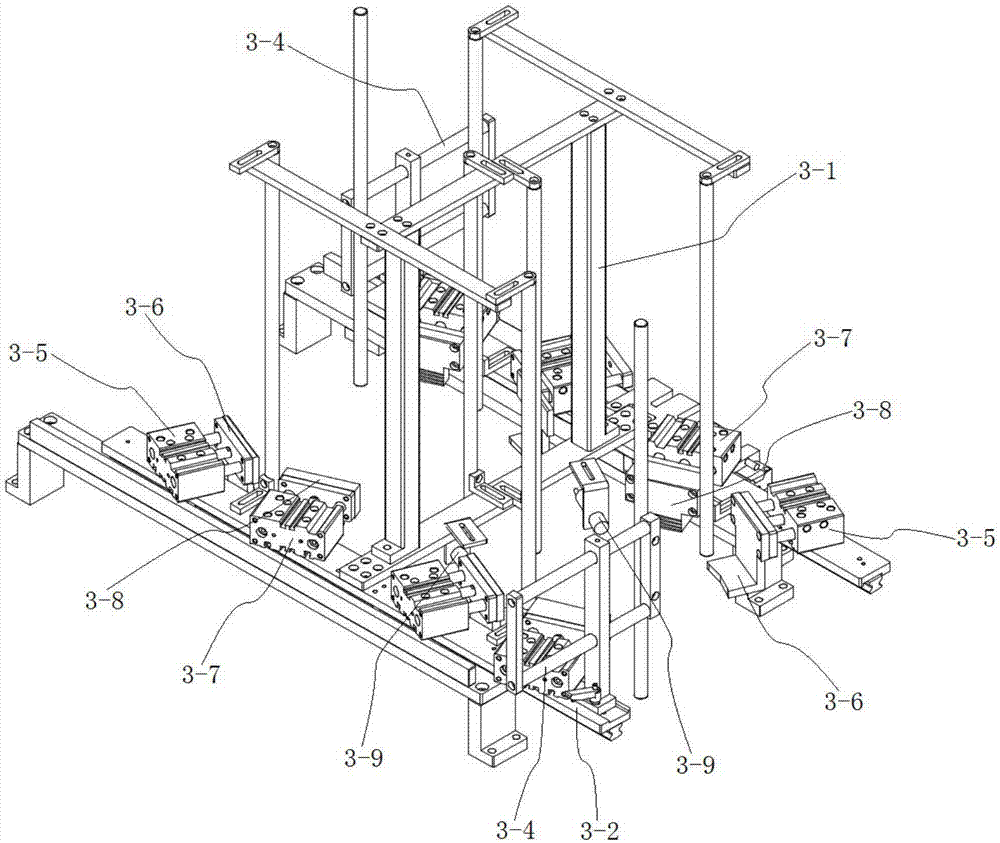

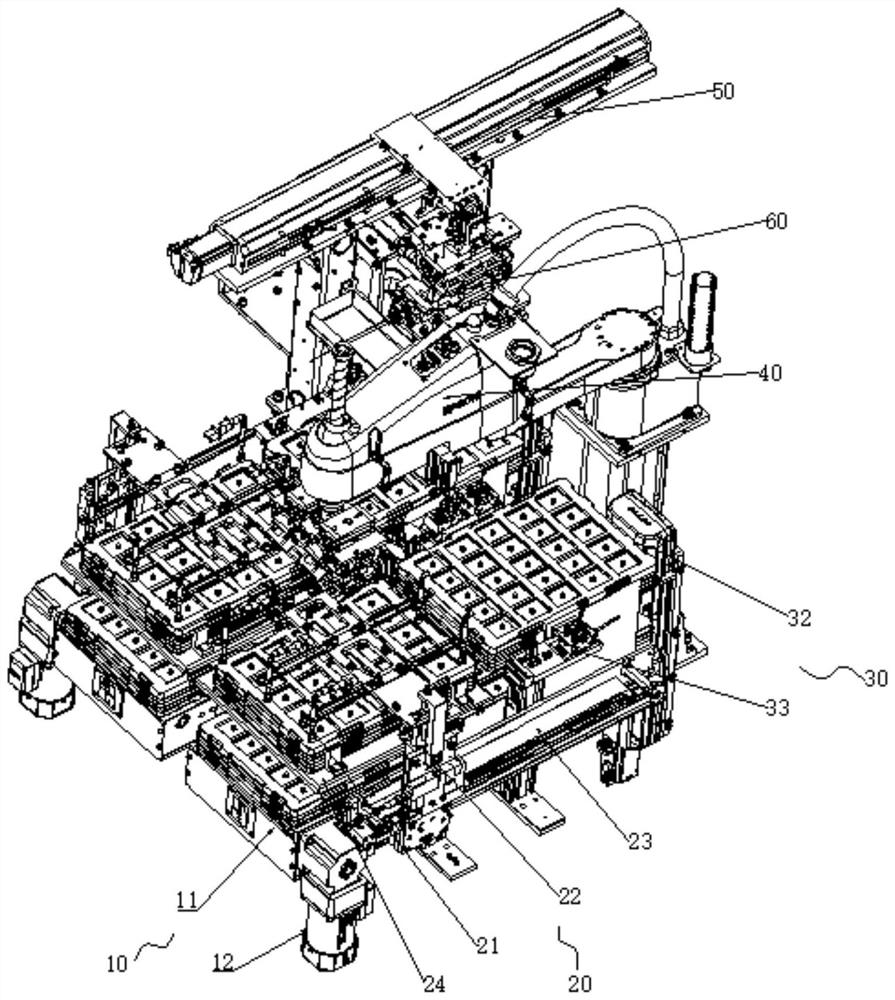

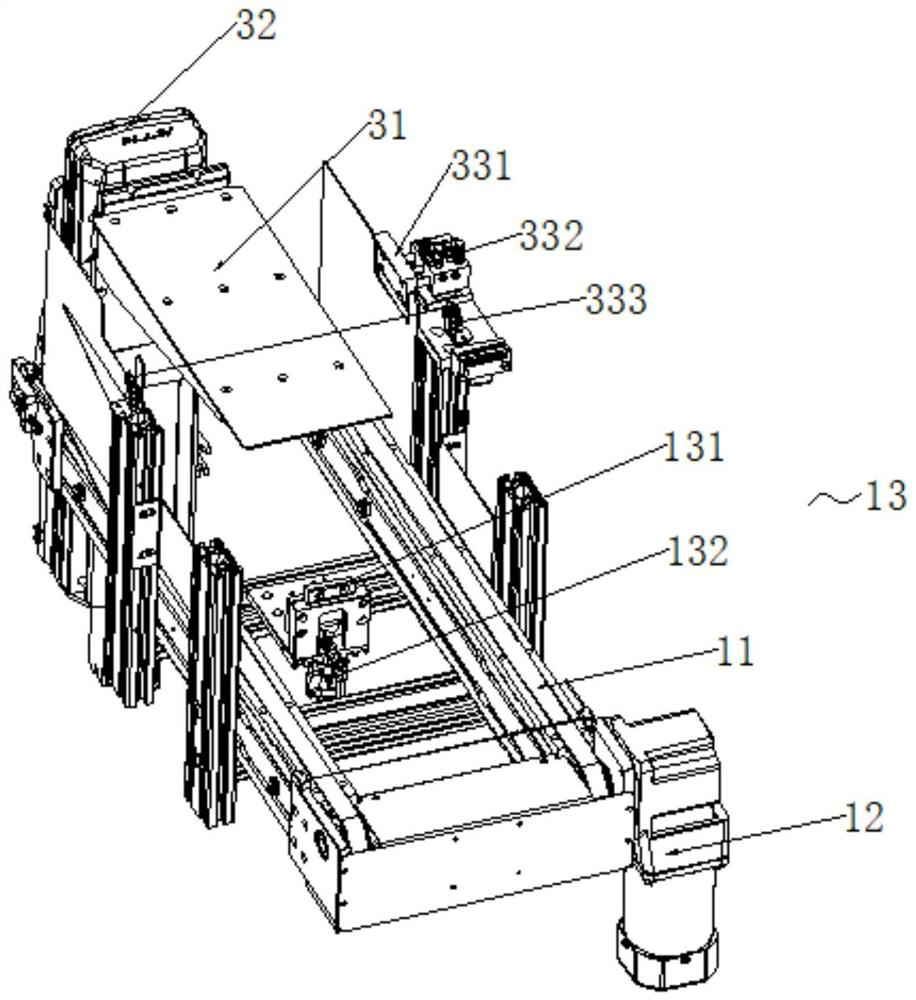

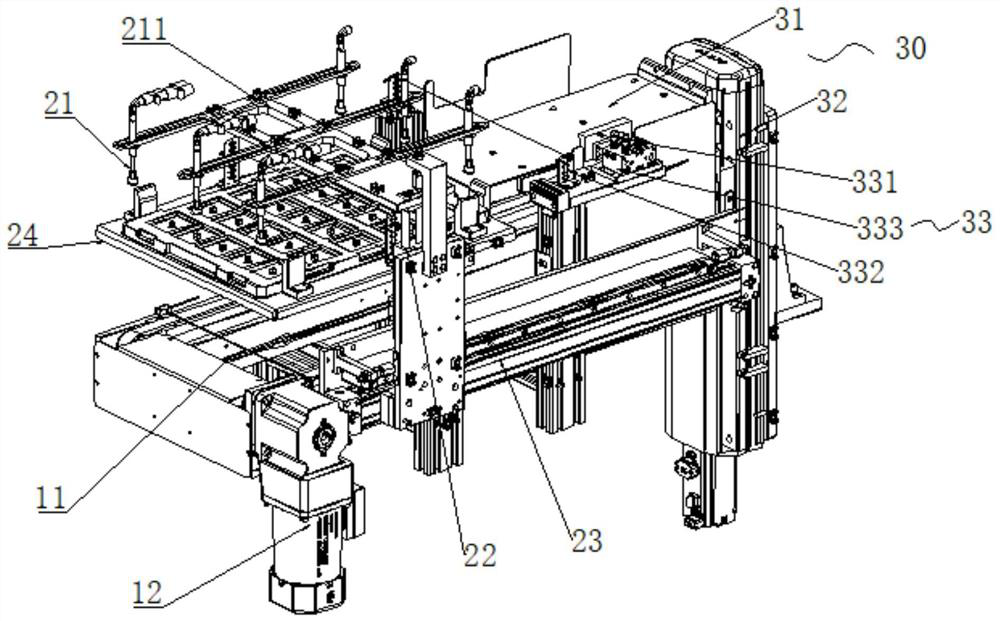

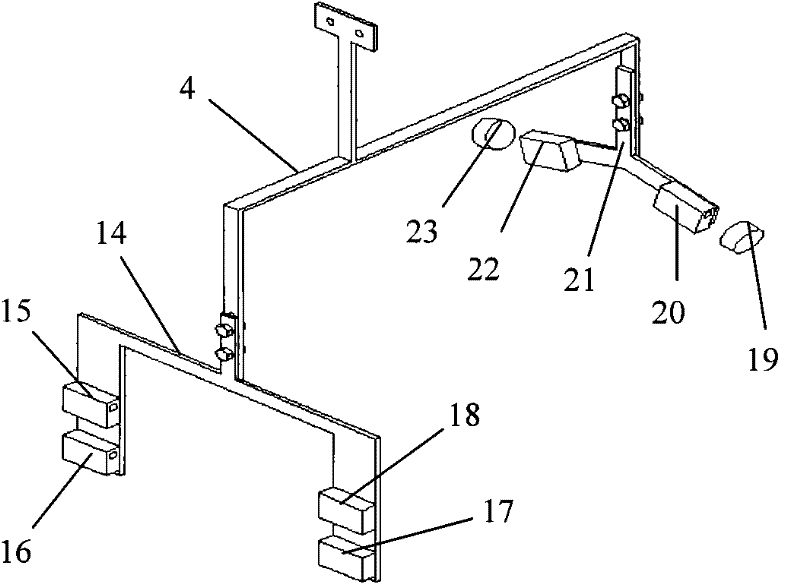

Automatic charging tray feeding system

PendingCN109484821AHigh precisionGuaranteed continuous feedingConveyorsControl devices for conveyorsEngineeringElectric control

The invention discloses an automatic charging tray feeding system. The system comprises a rack, a conveying belt, an assembling positioning mechanism, a material waiting position, a stock bin and an electric control box, the stock bin, the material waiting position, and the assembling positioning mechanism are arranged from back to front sequentially in the conveying direction, the assembling positioning mechanism comprises a lifting air cylinder, a lifting plate, a positioning air cylinder and positioning clamping claws, a piston rod of the lifting air cylinder is connected with the lifting plate, a charging tray is lifted to the positioning face, the two positioning clamping claws limit the charging tray to the position over the conveying belt, the stock bin comprises a discharging frame, a lifting mechanism and a dividing clamping claw, the lifting mechanism lifts the bottom charging tray to the conveying belt, and the dividing clamping jaw lifts remaining charging trays. Continuousfeeding can be ensured, the feeding position precision is greatly improved, the correcting rate of the next procedure can be ensured, the whole structure is ingenious and fine, in combination with sensors of mechanisms, the feeding process automation is achieved through a PLC, the labor intensity of a worker is greatly reduced, production cost is reduced, and production efficiency and productionprecision are improved.

Owner:XIAMEN BANGZHONG TECH

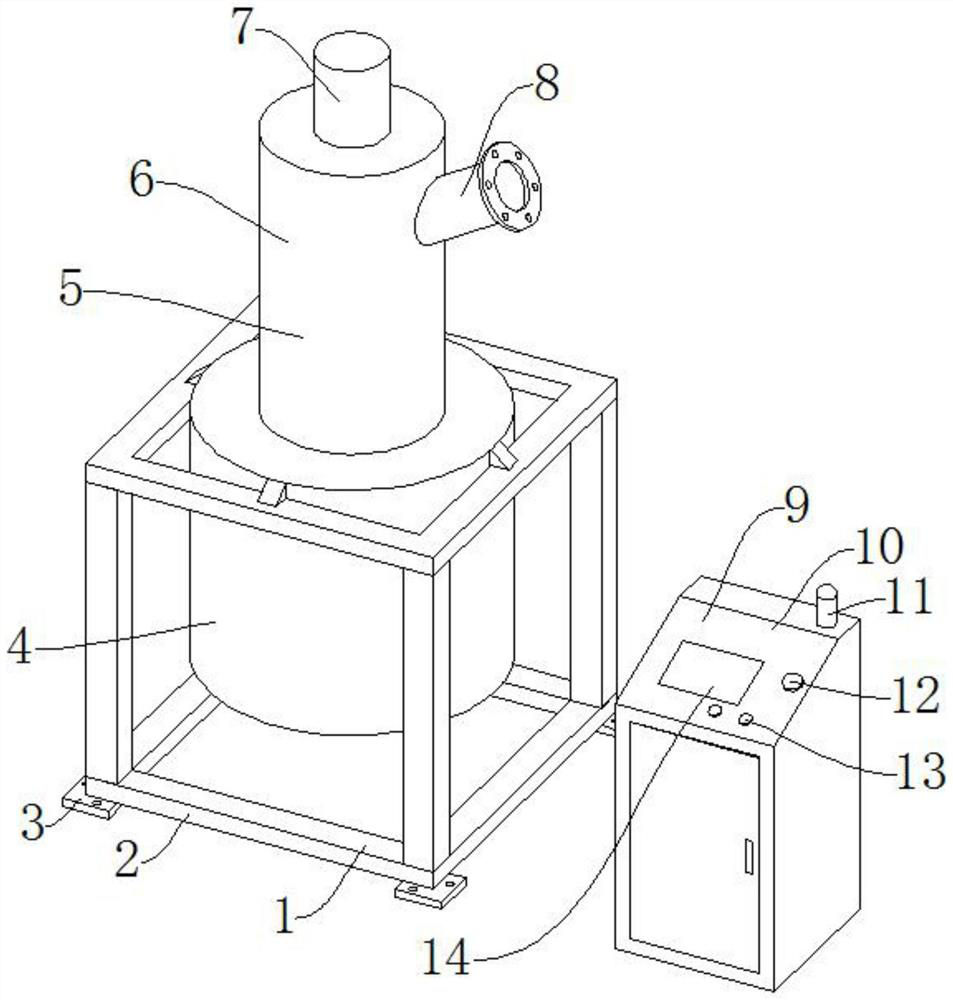

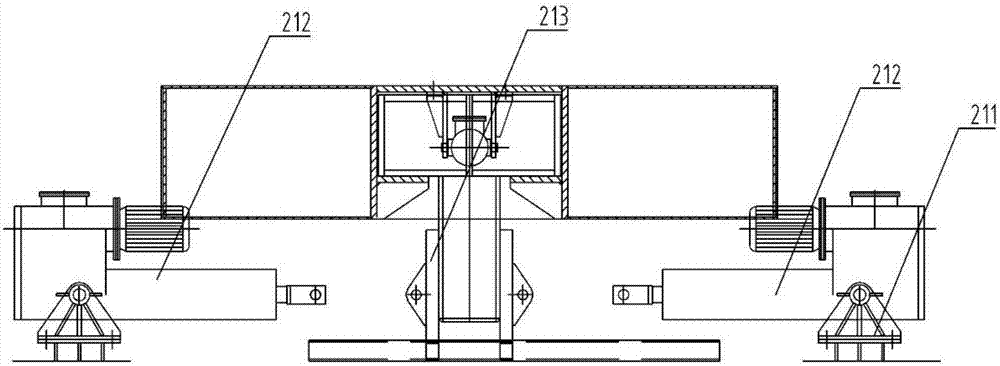

Garbage feeder

InactiveCN102491056AGuaranteed continuous feedingGuaranteed thicknessConveyorsControl devices for conveyorsEngineeringMechanical engineering

The invention discloses a garbage feeder, which comprises a machine frame, a conveying device and a guiding tank, wherein the conveying device is arranged on the machine frame; and the guiding tank is fixed on the machine frame and positioned above and on the right side of the conveying device. The garbage feeder is characterized by also comprising a blending device and a feed level feedback device. The machine frame comprises supporting posts, a connecting cross beam and supporting wheel bearers, wherein 1 to 3 supporting wheel bearers are used. Each feeding plate of the conveying device hasa roller support, the number of the roller supports is the same as that of the supporting wheel bearers, and each roller support is rotationally connected with a corresponding supporting roller. The supporting roller of each corresponding feeding plate is contacted with a supporting wheel bearer in a rolling manner. The blending device comprises a main frame body and comb teeth. The comb teeth are arranged on the main frame body. The blending device is arranged in the middle of the left and right direction of the machine frame. The comb teeth are positioned above the conveying device. The feed level feedback device is transversely spun over the guiding tank from the front to the back and is positioned above the part, which is on the right side of the blending device, of the conveying device.

Owner:江苏金陵环保科技有限公司

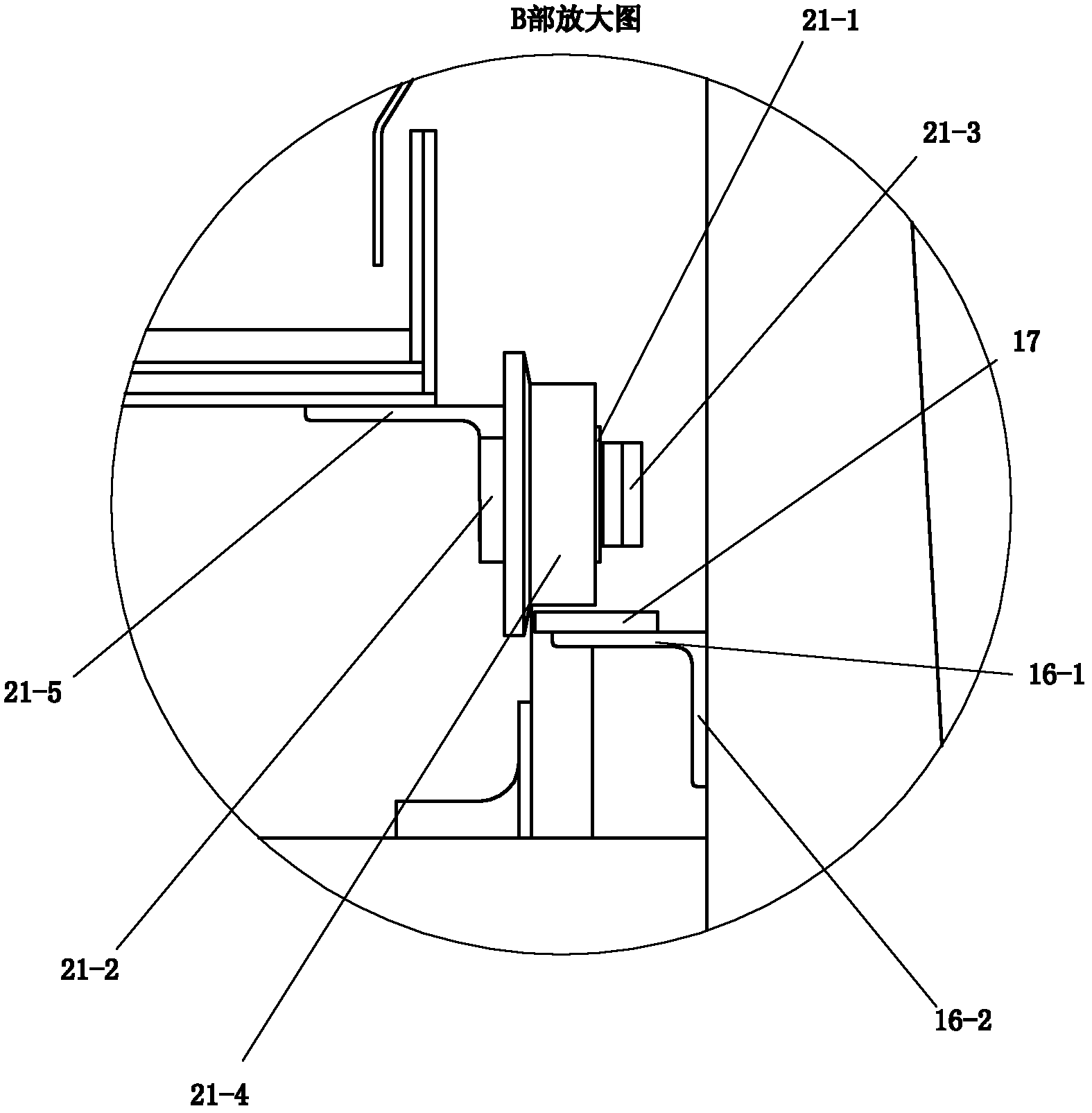

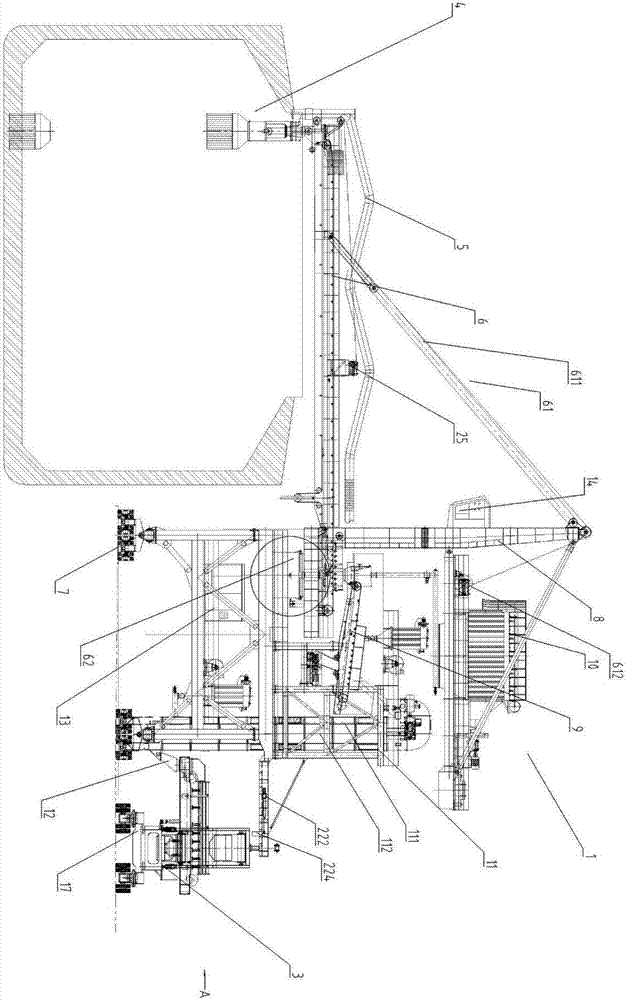

Tire type tail car conveying ship loader

InactiveCN106966195ATo achieve synchronous operationGuaranteed continuous feedingLoading/unloadingBogieEngineering

The invention provides a tire type tail car conveying ship loading machine, its tail car belt conveyor and mobile ship loading machine all adopt tire walking mechanism and are connected through an automatic docking system; Rack belt conveyors, intermediate transition belt conveyors, elevator systems and feeders. The ship loader provided by the present invention uses the tail car belt conveyor to feed the ship loader. When the ship loader moves, the tail car of the conveyor moves together, realizing the synchronous operation of the two sets of moving devices and ensuring continuous material supply; The automatic docking system is designed to connect the mobile ship loader and the tail car belt conveyor, and the twisted shaft is controlled by three sets of oil cylinders to realize fast docking and separation; when the ship loading operation is not in progress, the tail car belt conveyor and the mobile ship loader can be moved out Wharf, improve the operating capacity of the wharf; the hoist system can lift materials to a higher height in the narrow space of the wharf, meeting the loading needs of large ships; the system is equipped with dust-proof and dust-removing devices to achieve environmentally friendly shipping.

Owner:JIANGSU WANBAO MACHINERY

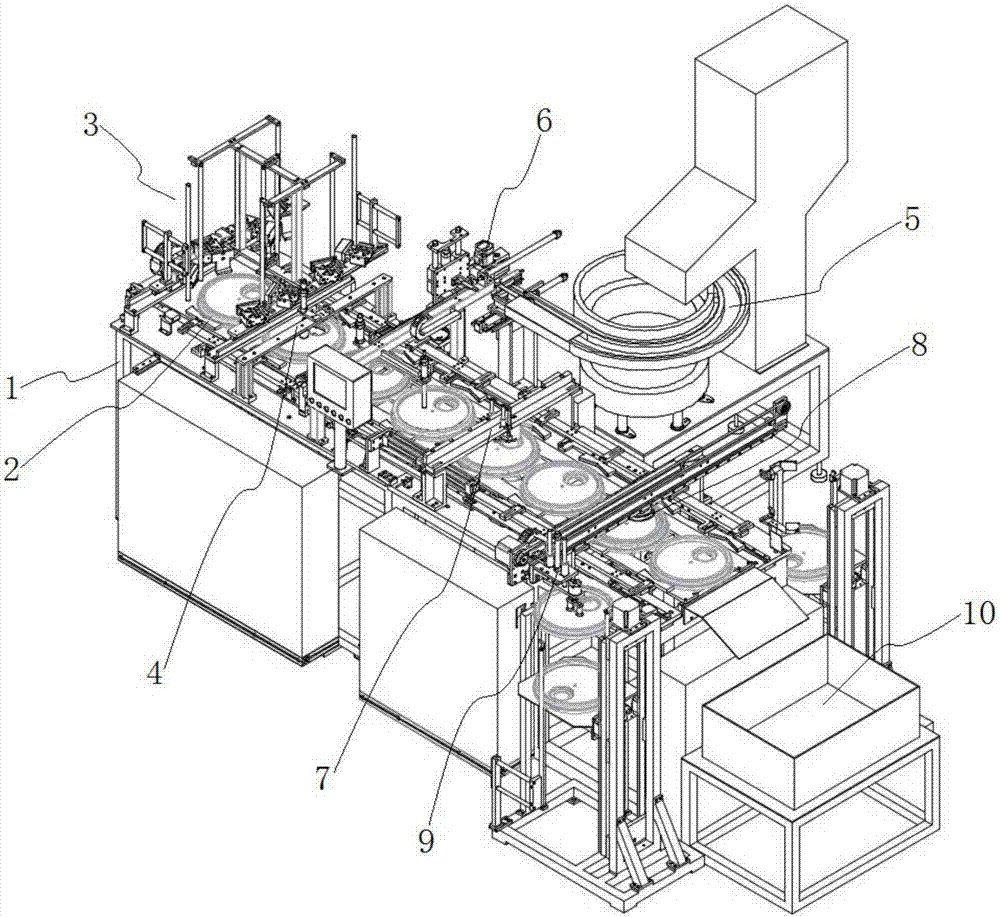

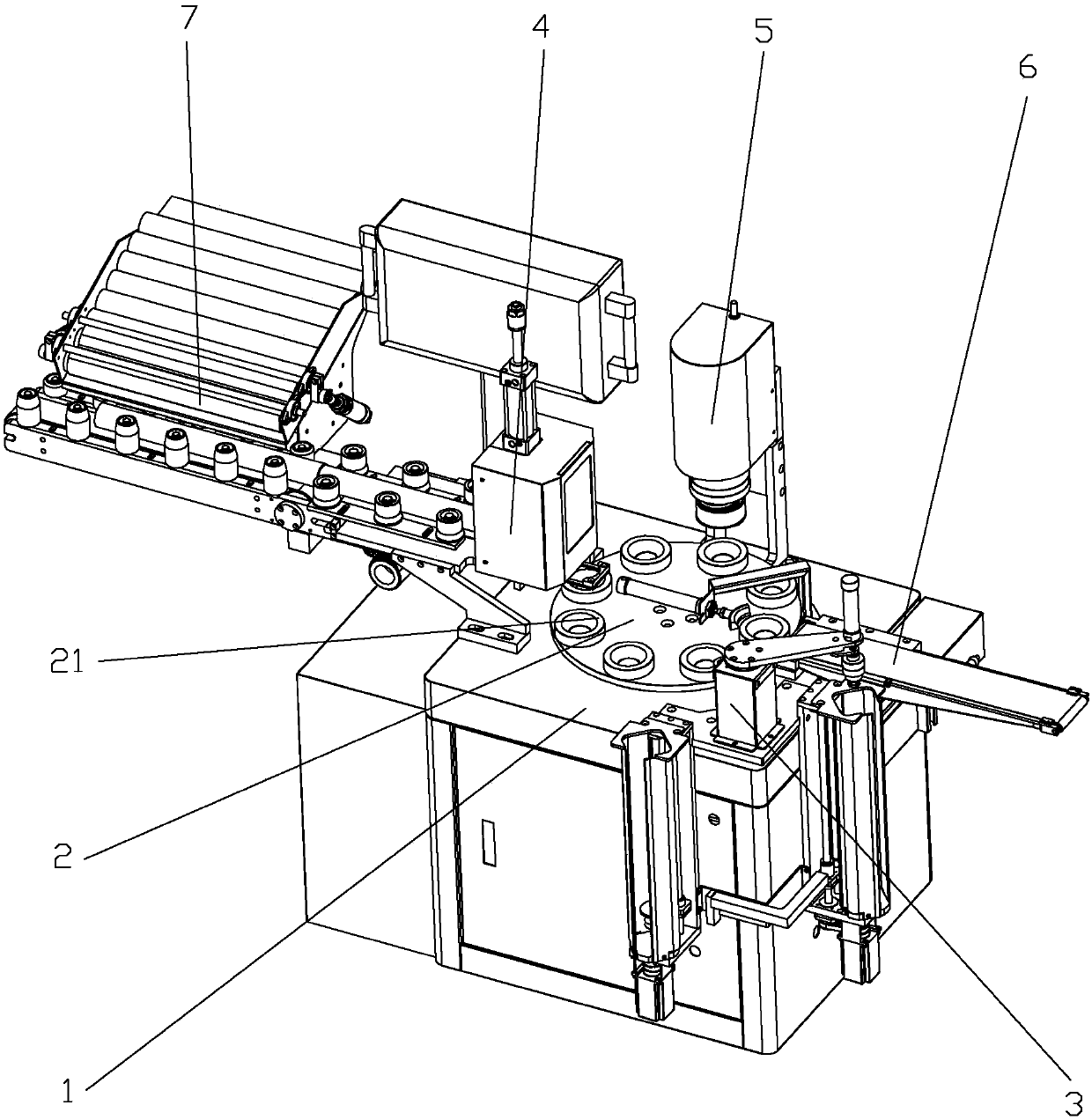

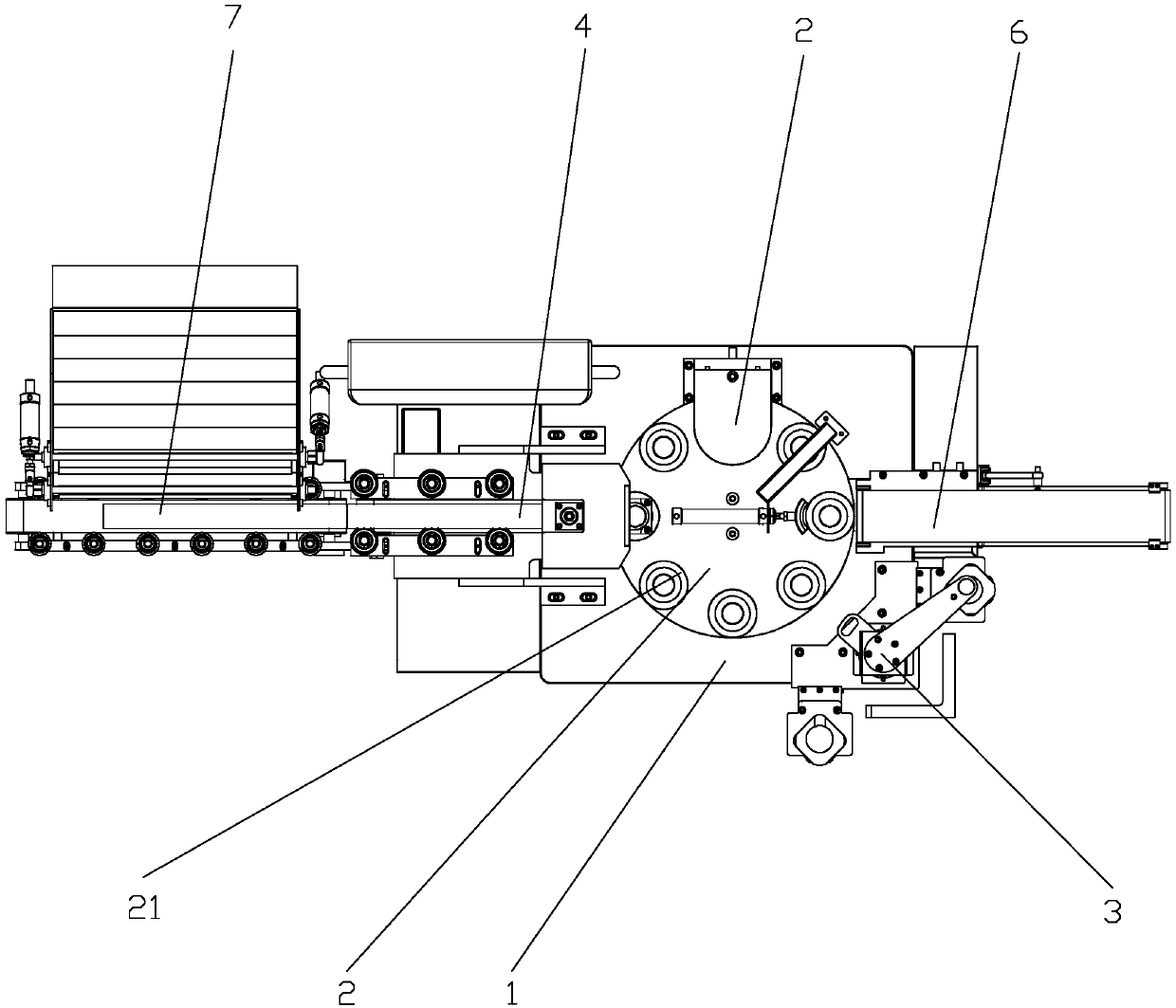

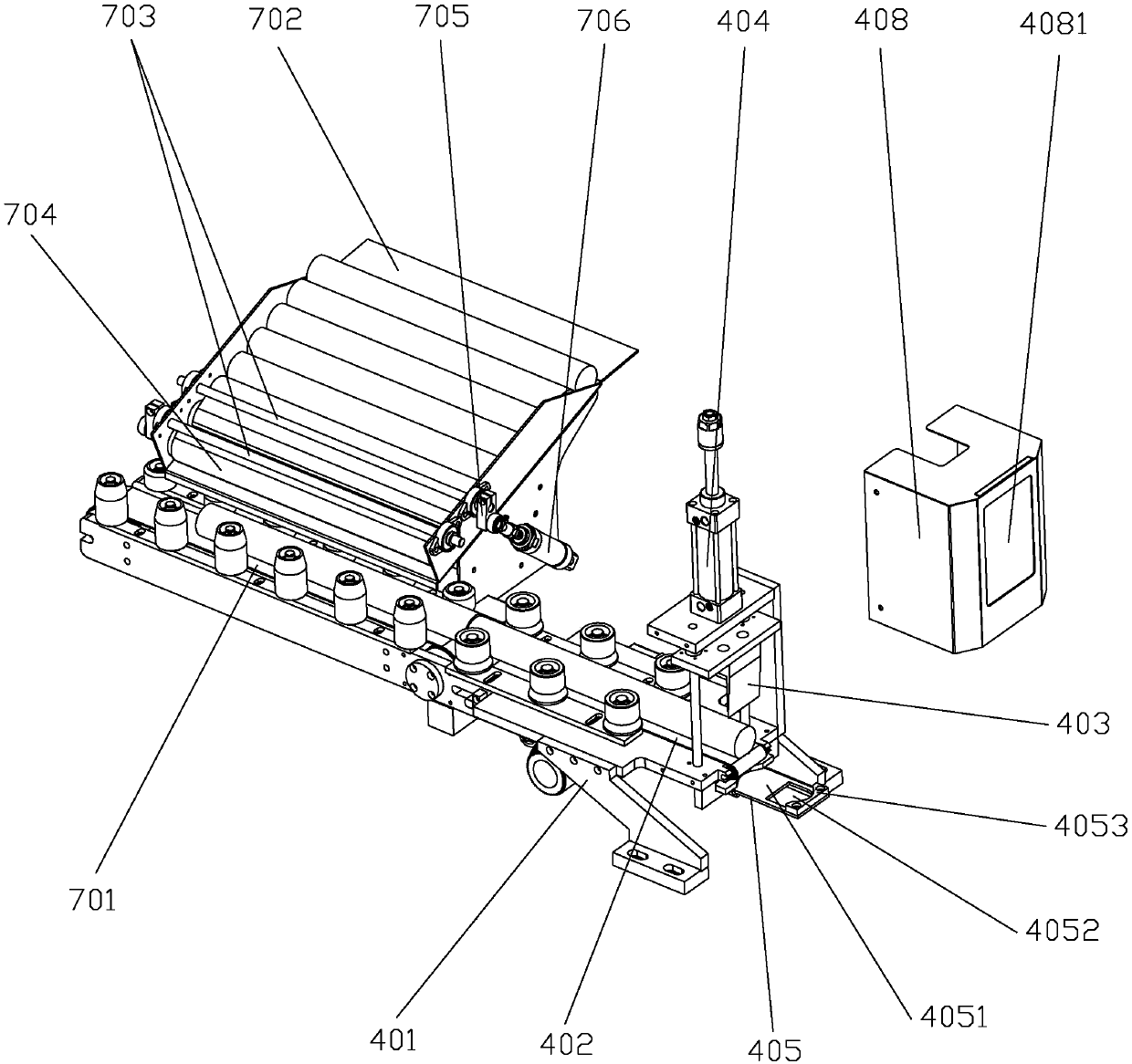

Automatic welding equipment for plastic barrel cover and oil nozzle

ActiveCN107139488ARealize continuous automatic welding productionCompact structureStacking articlesDe-stacking articlesUltrasonic weldingStructural engineering

The invention discloses automatic welding equipment for a plastic barrel cover and an oil nozzle and belongs to the field of automatic equipment. The automatic welding equipment disclosed by the invention comprises a frame and a barrel cover clamping and conveying device; a barrel cover feeding station, a barrel cover positioning station, an oil nozzle mounting station, a welding station, a detecting station and a discharging station are arranged in sequence on the barrel cover clamping and conveying device and along a rectilinear direction; a barrel cover feeding device is arranged at the barrel cover feeding station; a barrel cover rotary positioning device is arranged at the barrel cover positioning station; an oil nozzle positioning and mounting device is arranged at the oil nozzle mounting station; an ultrasonic welding device is arranged at the welding station; an air tightness detecting device is arranged at the detecting station; and a discharged material stacking device and an inferior-quality product recycling device are arranged at the discharging station. The automatic welding equipment disclosed by the invention can sequentially automatically accomplish the work of barrel cover feeding, barrel cover positioning, oil nozzle positioning and mounting, welding, air tightness detection and discharged material stacking, and is simple and compact in structure, stable and reliable in operation, flexible and convenient to control, high in production efficiency and good in welding quality.

Owner:CHANGZHOU CENTRWAY PLASTICS

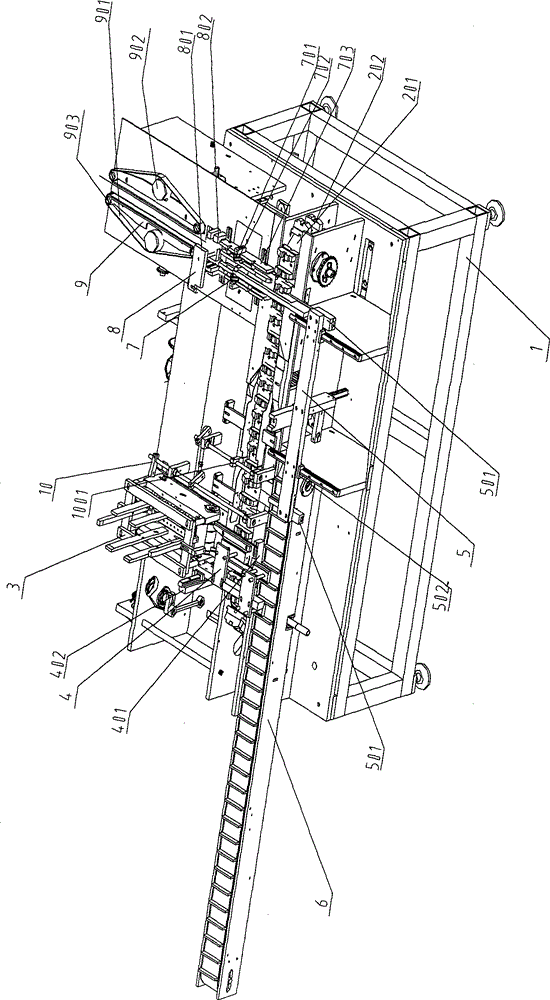

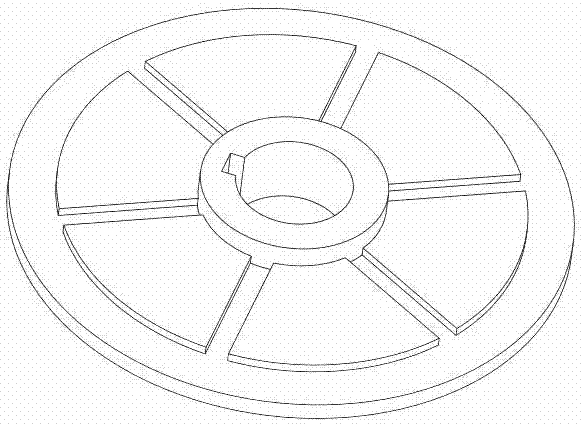

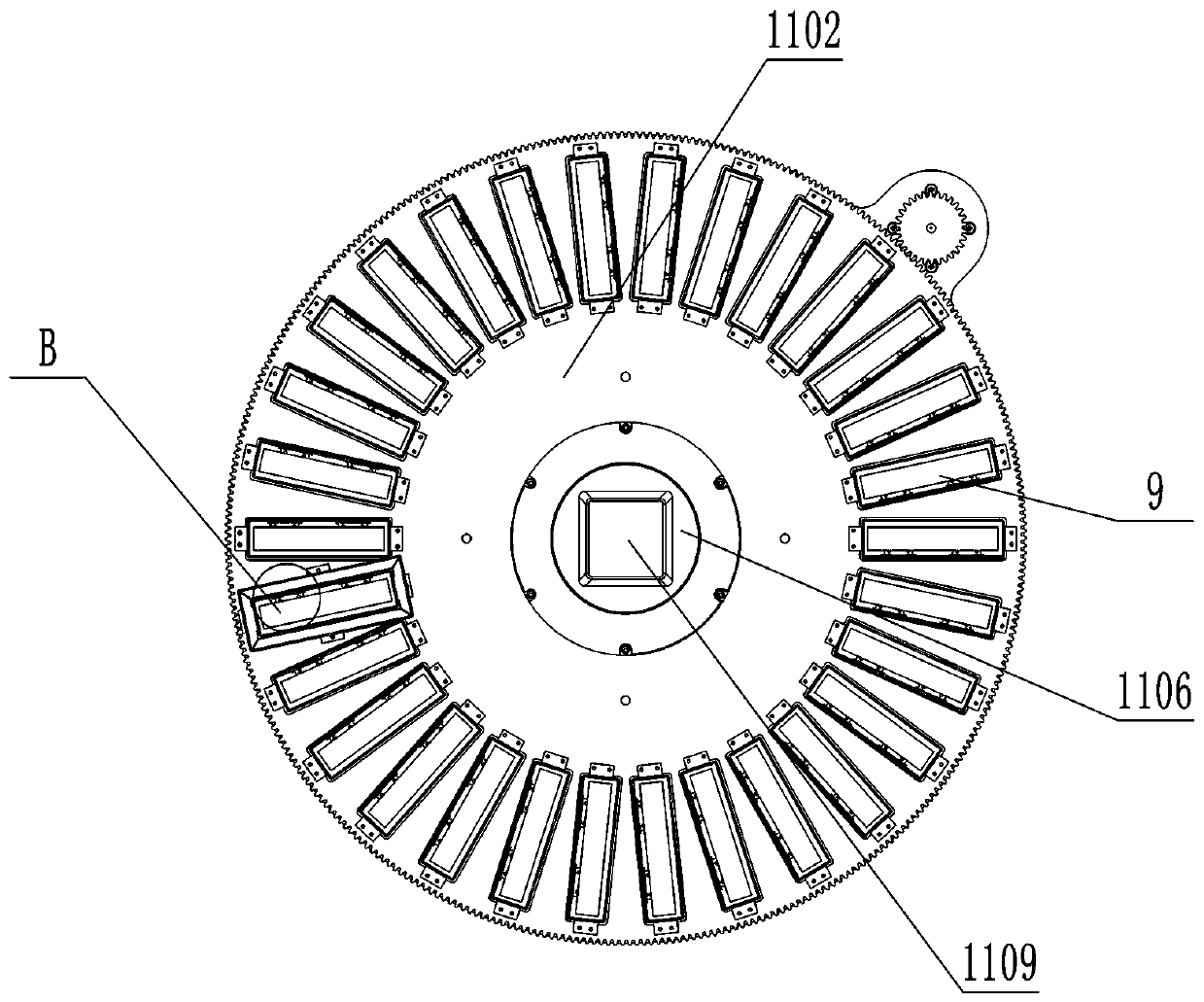

Double-station egg tart tin paper cup loading system

InactiveCN107840119AGuaranteed continuous feedingImprove efficiencyConveyor partsRotary conveyorsPulp and paper industryEngineering

The invention discloses a double-station egg tart tin paper cup loading system. The double-station egg tart tin paper cup loading system comprises a main frame; a turntable is arranged on the main frame, and is provided with multiple cup supports uniformly distributed in the peripheral direction; the cup supports are provided with cavities for placing tin paper cups; the main frame is connected with a power device for driving the turntable to rotate; the main frame is connected with a tin paper cup loading device positioned beside the turntable; the tin paper cup loading device comprises cup cylinders for stacking the tin paper cups, and a transfer mechanism; the cup cylinders are vertically arranged, and are provided with inner holes matched with the tin paper cups; the transfer mechanismtransfers the tin paper cups from the cup cylinders to the cup supports; and two cup cylinders are provided, and are separately positioned on two sides of the transfer mechanism.

Owner:江门市神川自动化设备有限公司

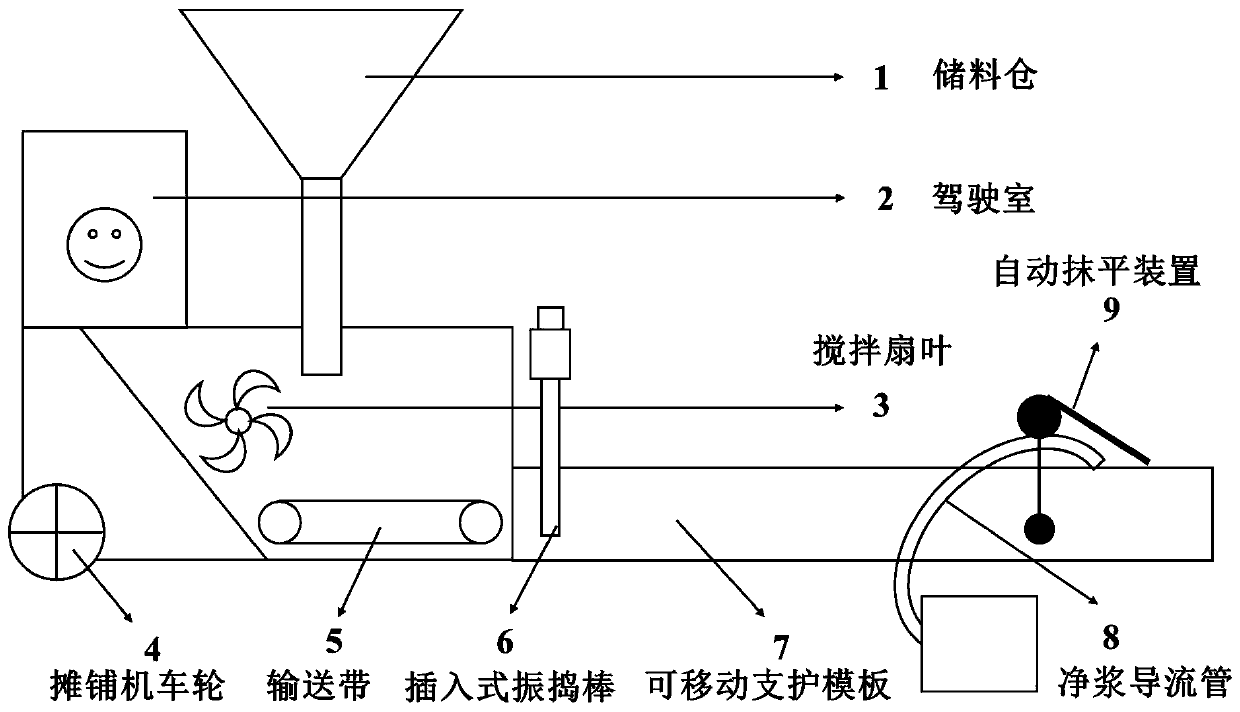

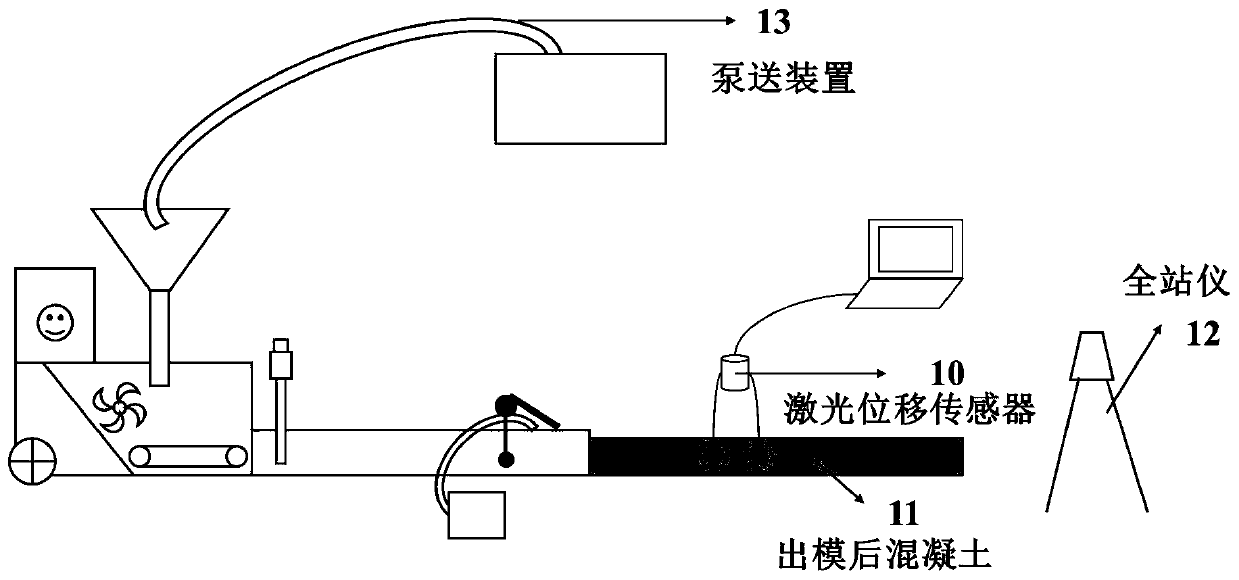

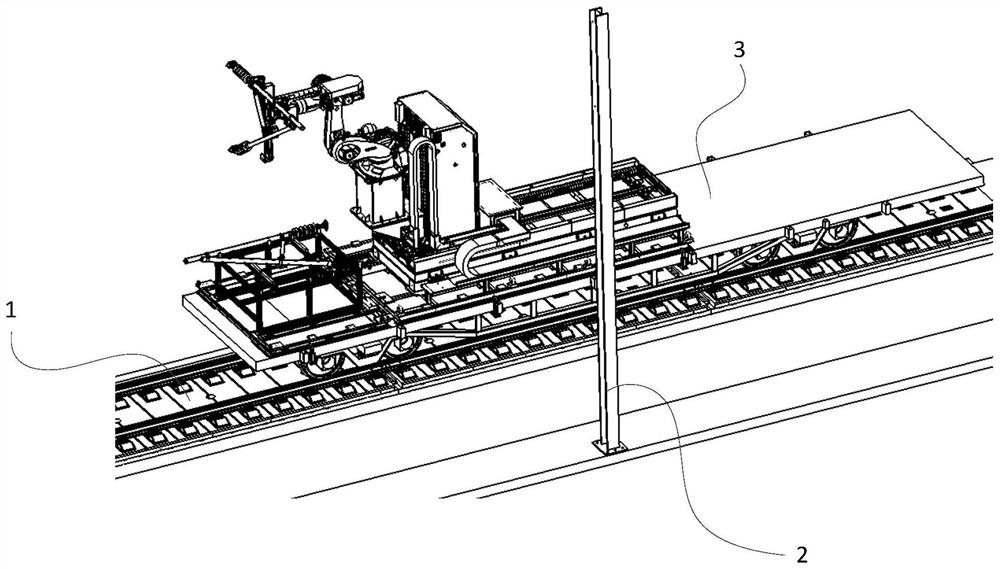

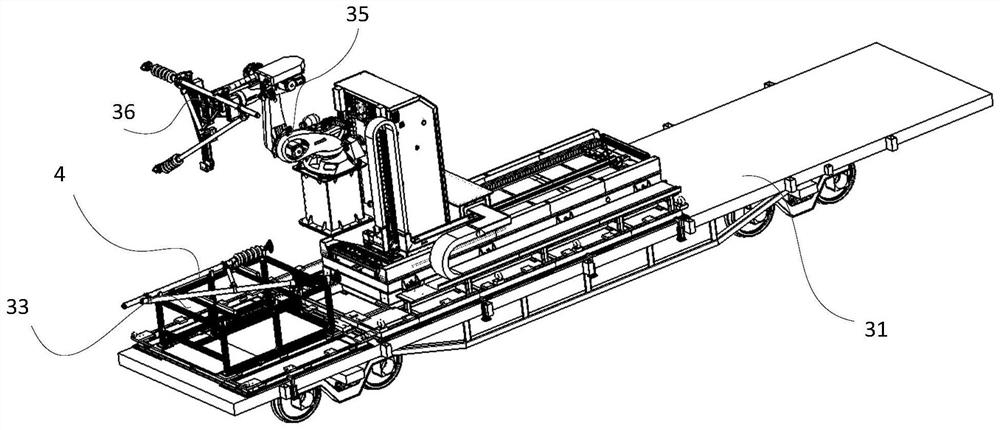

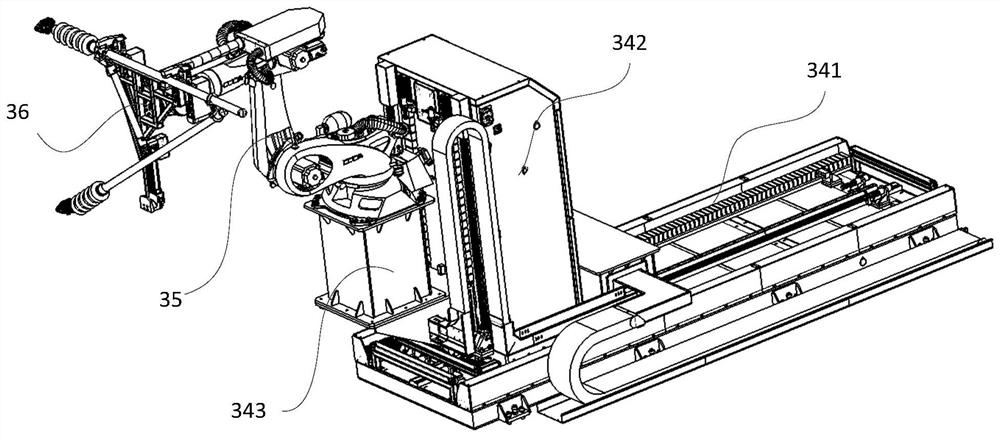

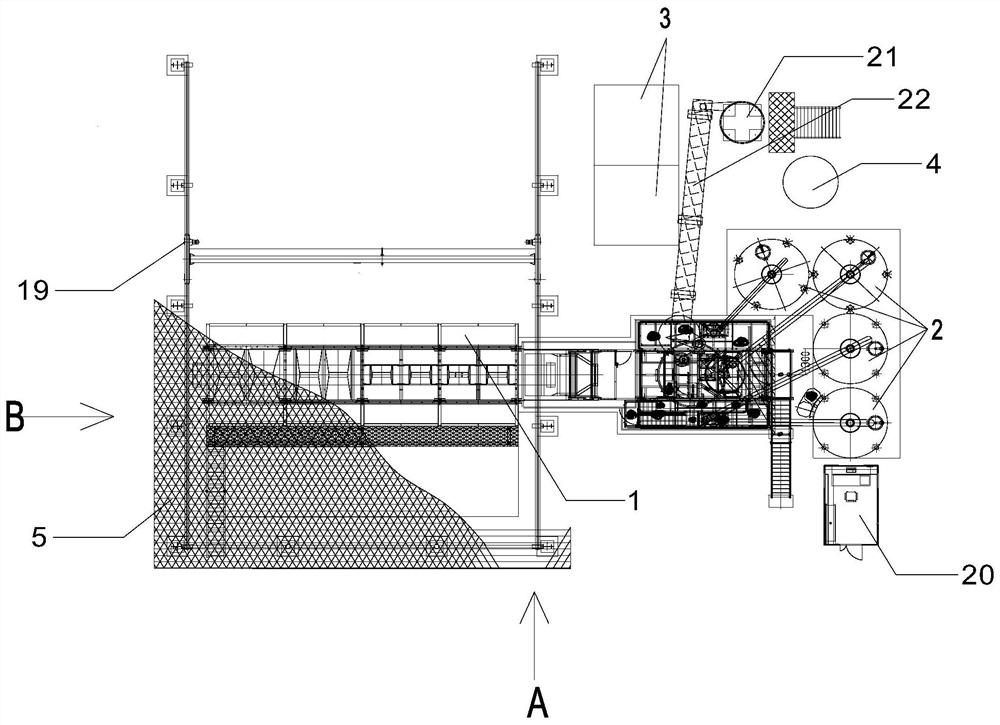

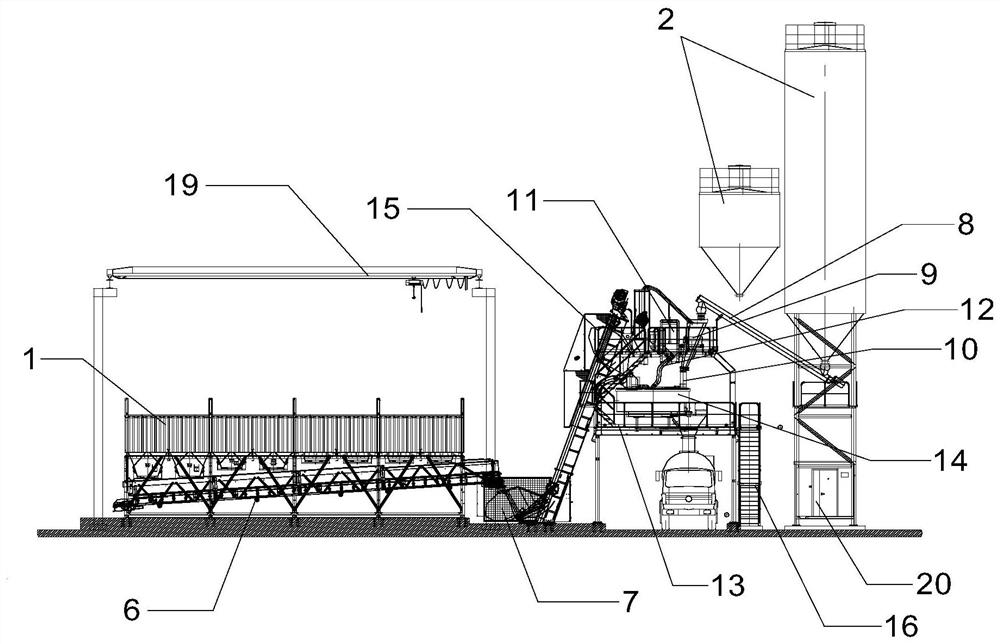

Slip form construction method of large-fluidity paving concrete for subway rail base

The invention discloses a slip form construction method of large-fluidity paving concrete for subway rail base. The large-fluidity paving concrete and a slip form paving machine which is adaptive to the performance of the concrete are applied. The method comprises the following steps that, (1) the slip form paving machine for the subway rail base concrete is in position and debugged; (2) the large-fluidity paving concrete is prepared and transported; (3) the concrete is loaded into a material storage bin, and the slip form paving machine is tested to carry out the slip form; (4) the slip formpaving machine is operated, and the linear shape and flatness of the concrete base are detected; and (5) the surface of the base concrete is finished and maintained. According to the slip form construction method for subway base concrete, the method is low in energy consumption, low in noise pollution and capable of continuously constructing, the automation degree of the construction process is improved, the consumption of manpower and material resources is remarkably reduced, and the method has extremely high popularization and application values.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST +2

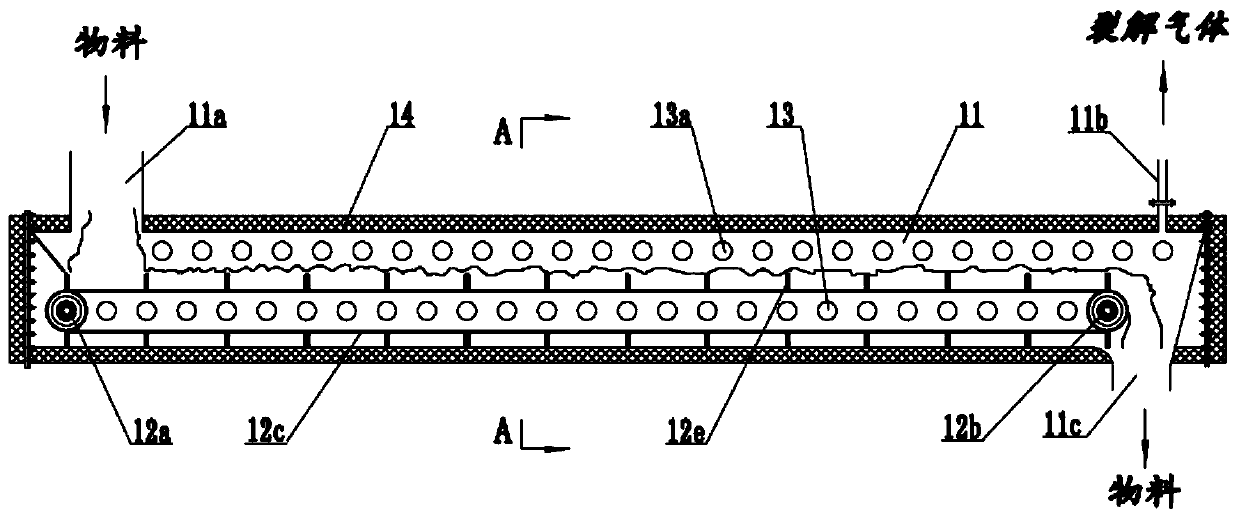

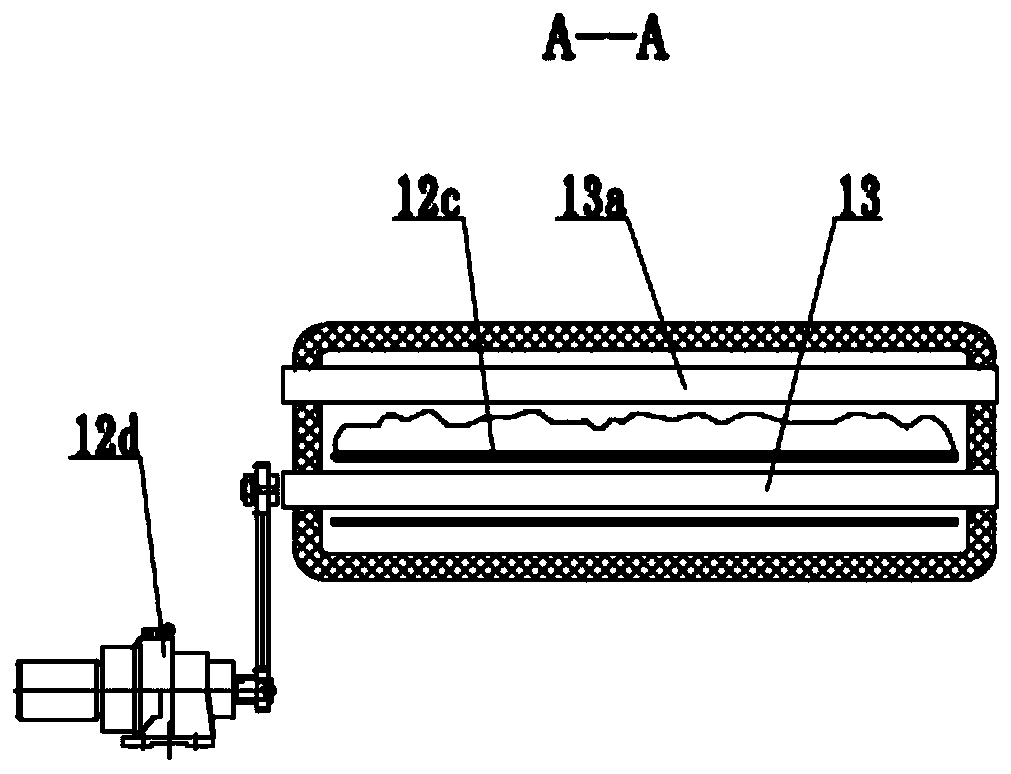

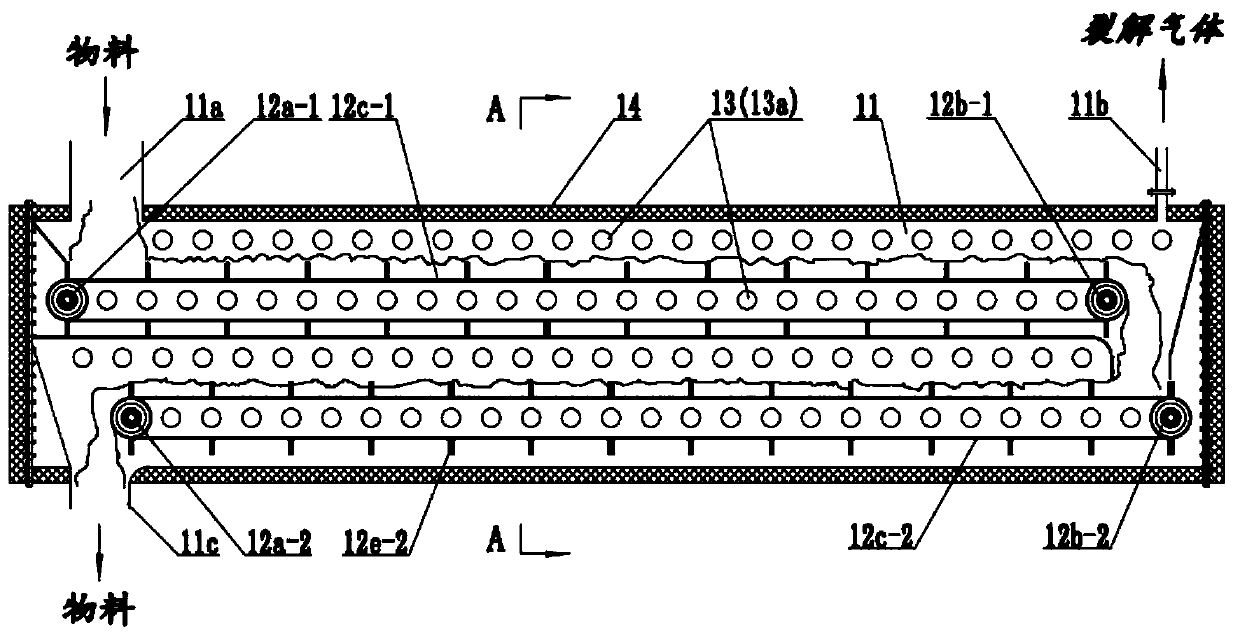

Material treatment device and material treatment system

PendingCN109824228AImprove cracking performanceGuarantee the predetermined temperatureSludge treatment by pyrolysisElectric heatingSprocket

The invention relates to a material treatment device for oil sludge cracking and a material treatment system for oil sludge treatment. The material treatment device comprises a shell, a conveying mechanism and a heating device. The shell comprises an upper wall with a feeding port and an exhaust port and a lower wall with a discharging port. The conveying mechanism comprises a driving chain wheel,a driven chain wheel and a conveying belt engaged with the driving chain wheel and the driven chain wheel, and the conveying belt is configured to receive and convey materials to be treated. The heating device comprises multiple electric heating tubes. The electric heating tubes are evenly arranged in parallel to the conveying belt at preset intervals, the feeding port corresponds to the feedingend of the conveying mechanism, and the discharging port corresponds to the discharging end of the conveying mechanism.

Owner:SHAN DONG HI LINK ELECTRICITY

Feeding device for electronic protective film processing

The invention belongs to the technical field of electronic protective film processing, and particularly relates to a feeding device for electronic protective film processing. The feeding device comprises a feeding module and a mounting frame; and two semicircular grooves are symmetrically formed in one side of the top of the mounting frame. According to the feeding device, the angle of a rotatingrod is adjusted through a crank, a round rod sleeved with an electronic protective film winding drum is conveniently adjusted to be located at the top of the mounting frame, the two ends of the roundrod are fixed through semicircular fixing clamps, a driven gear is engaged with a driving gear, and a second motor drives a linkage belt to rotate, so that the round rod rotates, an electronic protective film can be conveniently released, and when the electronic protective film is released, a worker can conveniently take the other electronic protective film winding drum to be connected with one round rod under the round rod in a sleeving manner, continuous feeding of the electronic protective films can be guaranteed, the electronic protective films can be conveniently replaced, the number of workers can be reduced, and the working efficiency can be improved.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

Film gluing device

InactiveCN107262327AFacilitate the realization of compactionAchieve compactionLiquid surface applicatorsCoatingsConductor CoilMachining

The invention provides a film gluing device, and belongs to the technical field of film machining. The film gluing device comprises a film winding mechanism and a gluing mechanism; a guide roller of the film winding mechanism is rotationally arranged on a left bracket; a left support roller is rotationally arranged on the left bracket; a right support roller is rotationally arranged on a right bracket; the left support roller and the right support roller are positioned on the same horizontal height; a pressing roller is rotationally arranged on the right bracket, and is near and not contacted with the right support roller; a gluing support jaw of the gluing mechanism is hinged to a gluing bracket through an upper pin shaft; a support jaw is hinged to the gluing bracket through a lower pin shaft; a gluing roller is rotationally arranged at one end of the gluing support jaw; a support roller is rotationally arranged at one end of the support jaw; the upper and lower ends of a gluing tension spring are respectively connected with an upper pull rod and a lower pull rod; a top plate is mounted at one end of a piston rod; and a glue nozzle is mounted on a nozzle bracket. The film gluing device not only can quickly realize the film gluing, but also can quickly realize adjustment of the gluing position.

Owner:浙江耀阳新材料科技有限公司

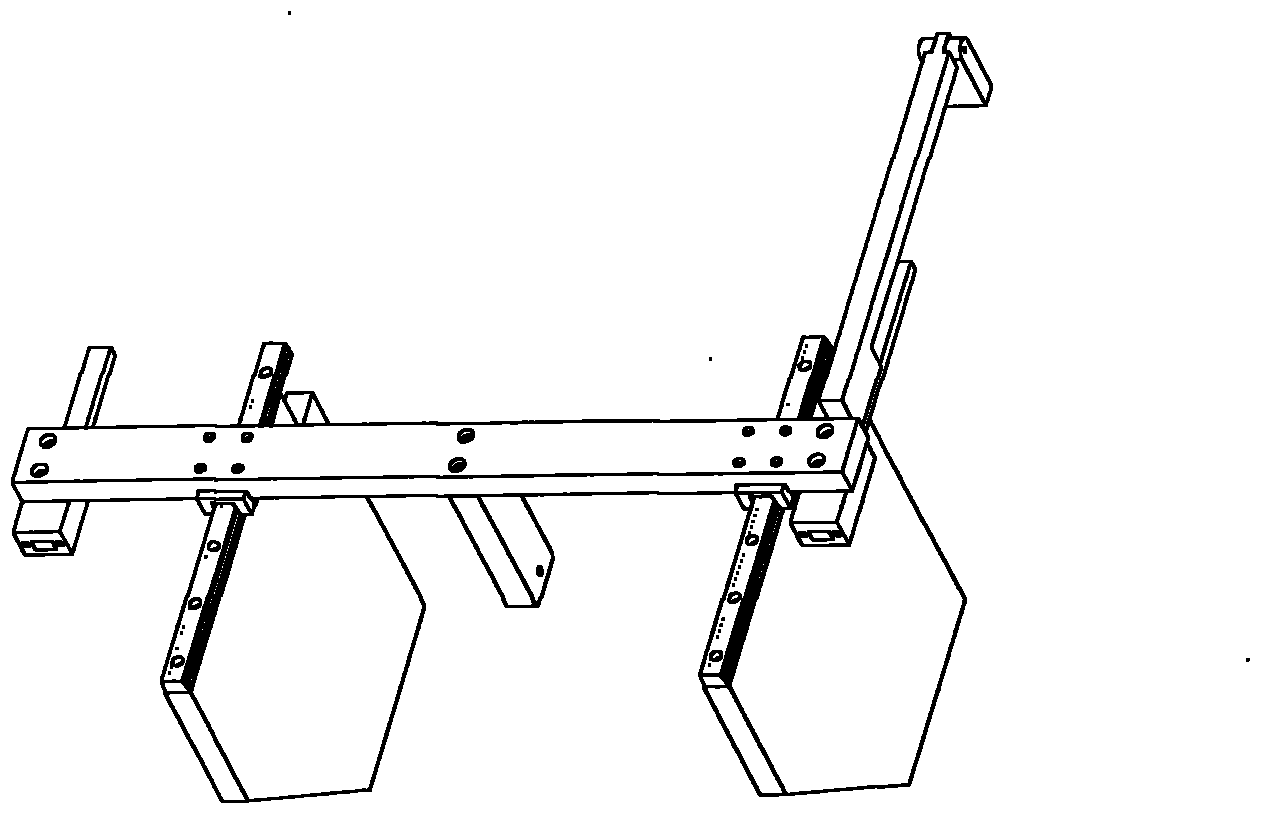

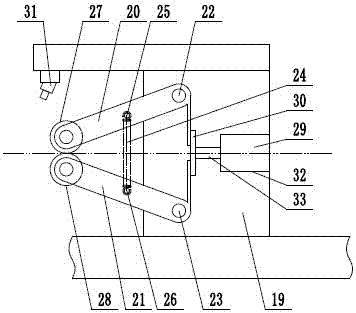

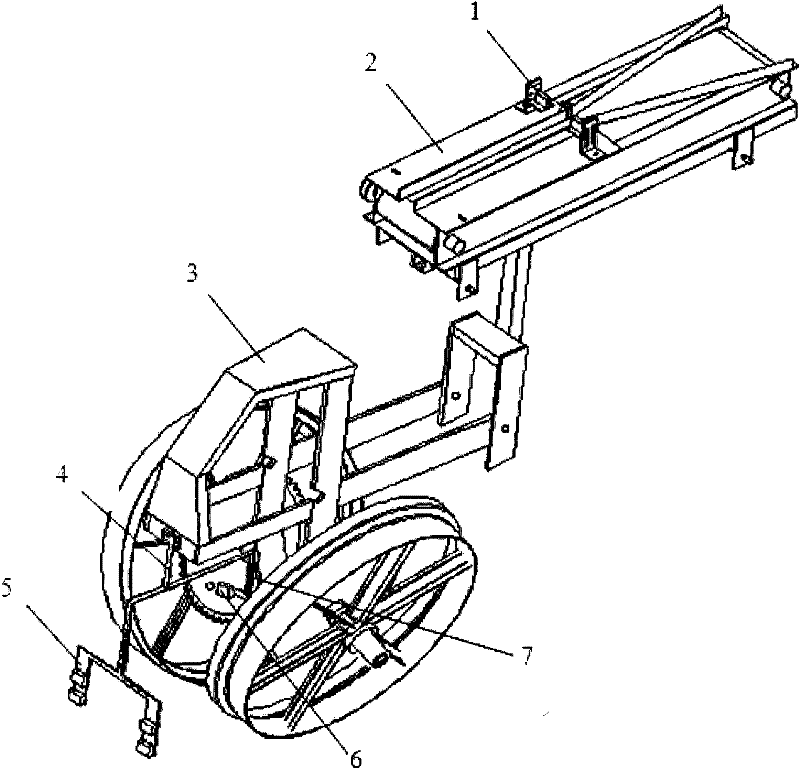

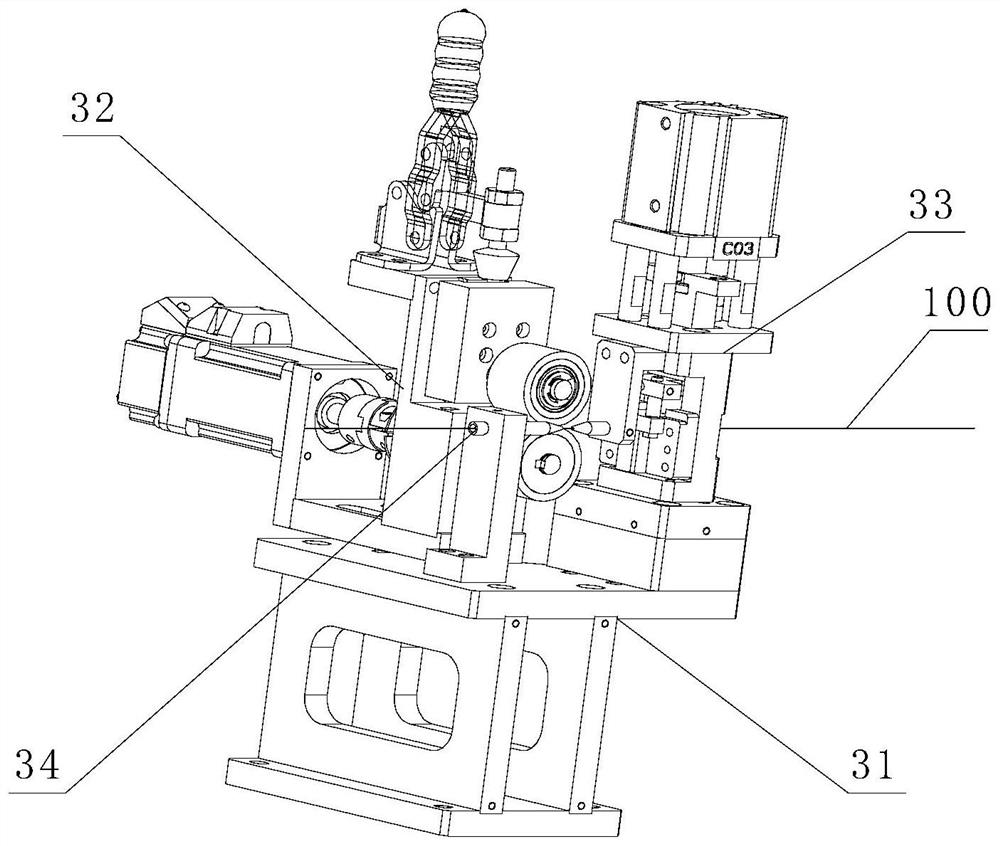

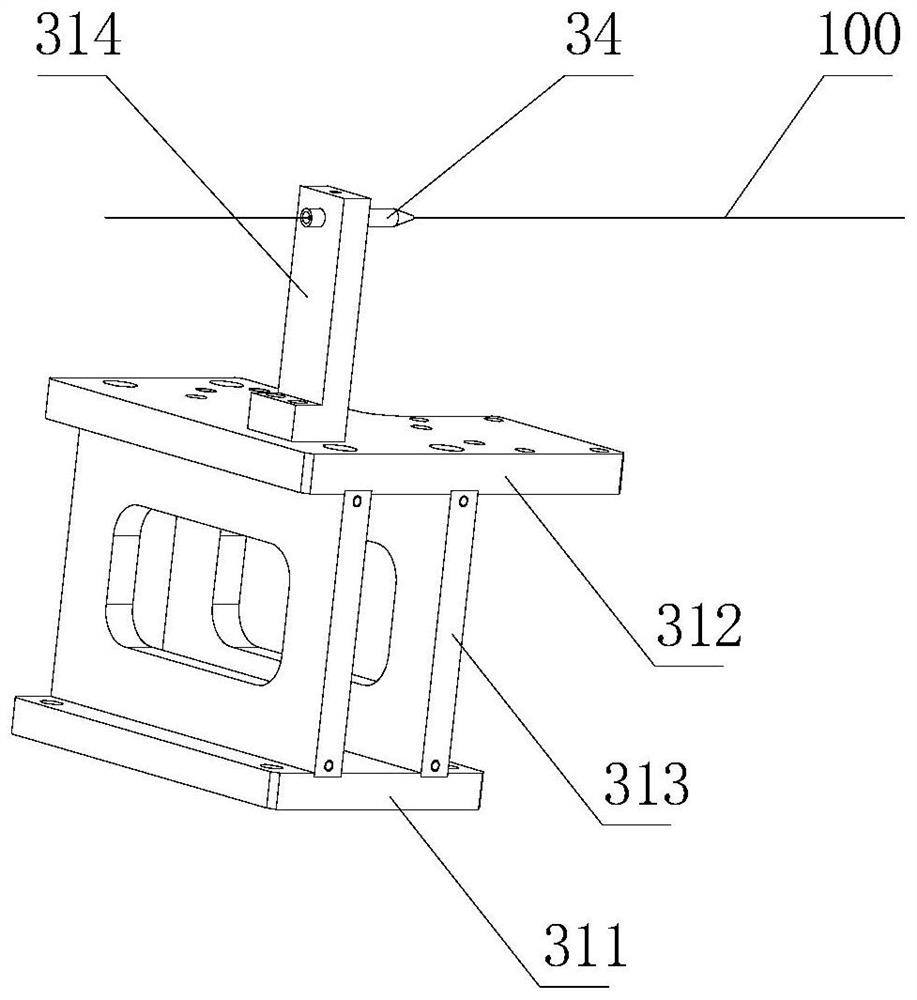

Cantilever grabbing mechanical arm of railway cantilever mounting robot

The invention discloses a cantilever grabbing mechanical arm of a railway cantilever mounting robot. The cantilever grabbing mechanical arm comprises a mechanical arm body and a grabbing mechanism which is arranged at the front end of the mechanical arm body, is jointly driven by the mechanical arm body and a mechanical arm lifting mechanism to grab a cantilever on a cantilever bracket and hoiststhe cantilever to the mounting position of an overhead contact system mast, wherein the grabbing mechanism comprises a triangular cantilever grabbing rack, a left grabbing mechanism, a right grabbingmechanism and a lower grabbing mechanism; and the middle part of the cantilever grabbing rack is connected with the mechanical arm body, the left grabbing mechanism and the right grabbing mechanism are arranged on the cantilever grabbing rack in a one-to-one correspondence mode in the horizontal direction and are of the same structure, and the lower grabbing mechanism is arranged at the lower endof the cantilever grabbing rack. By means of the scheme, the cantilever grabbing mechanical arm of the railway cantilever mounting robot has the advantages of reliable action, high hoisting efficiency, wide application range and the like.

Owner:成都圭目机器人有限公司

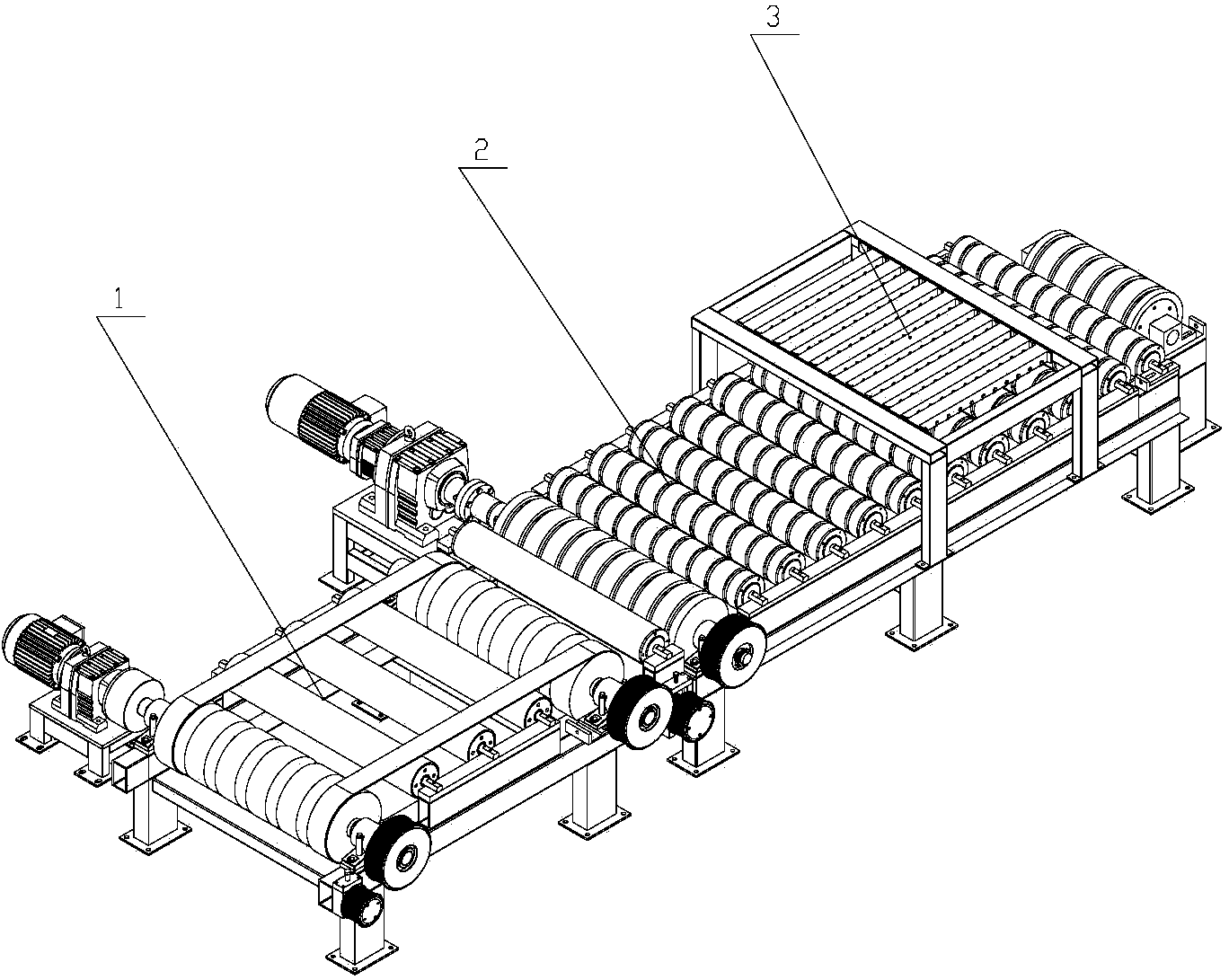

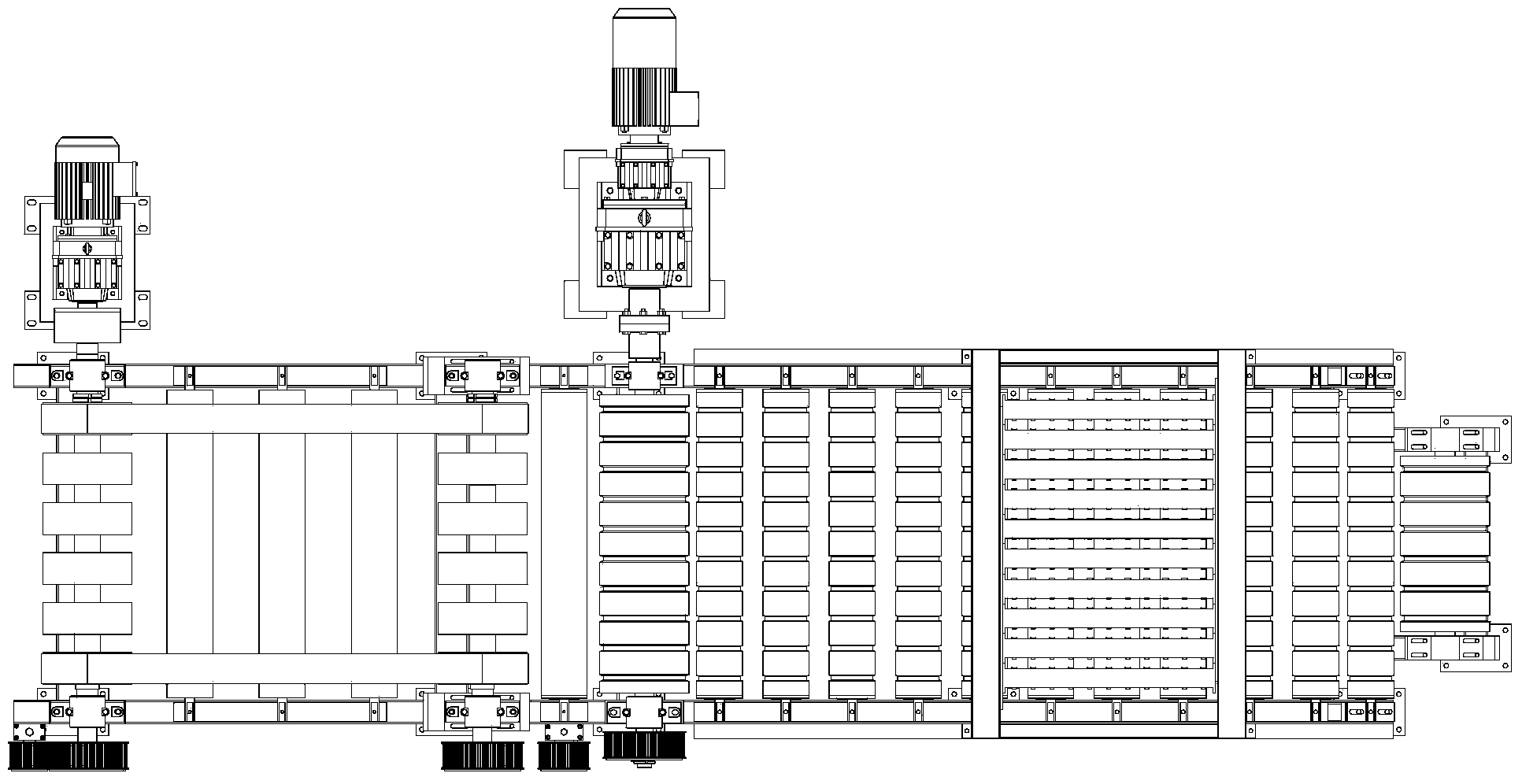

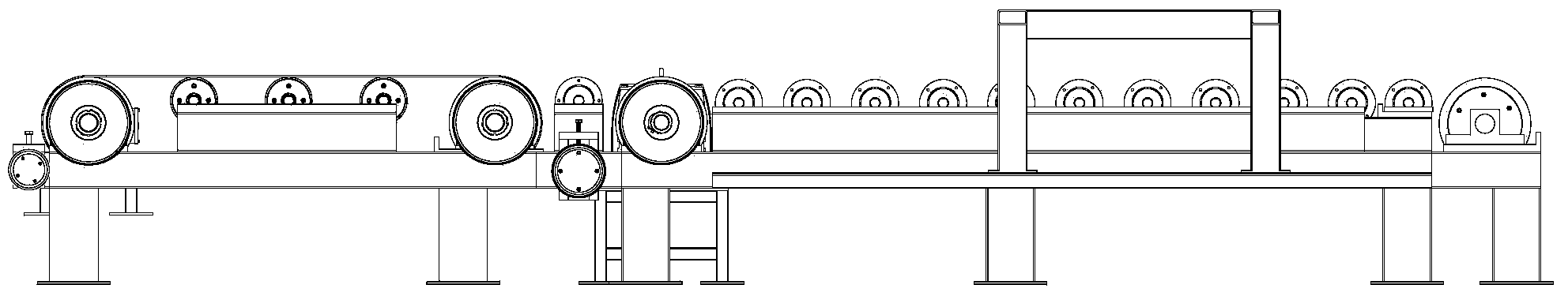

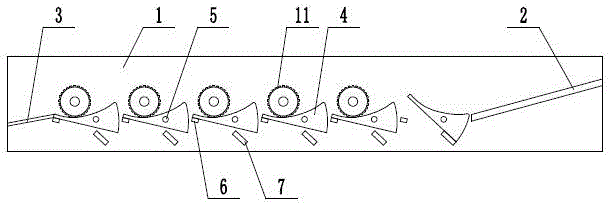

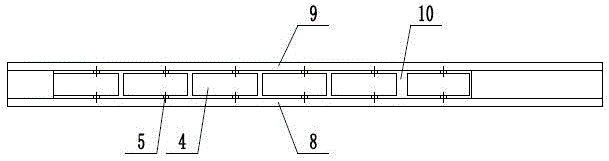

Building block cutting, feeding and conveying mechanism

ActiveCN103878873AGuaranteed to liftExpand the scope of useCeramic shaping apparatusRoller-waysFixed frameEngineering

The invention discloses a building block cutting, feeding and conveying mechanism which comprises a conveying mechanism, a feeding mechanism and a first compressing mechanism. The tail end of the conveying mechanism is fixed to the front end of the feeding mechanism; the first compressing mechanism is mounted above the feeding mechanism; the conveying mechanism comprises a conveying mechanism frame, a conveying motor fixing frame, a gear motor, a first roller and a first synchronous belt pulley, the feeding mechanism comprises a motor fixing frame, a motor, a transitional roller, a driving roller, a second compressing mechanism, a feeding mechanism frame, a first tension roller and a second tension roller, the second tension roller is arranged at the tail end of the feeding mechanism frame, the first compressing mechanism comprises compressing wheel fixing plates, compressing wheel frames and compressing wheels, and the bottoms of the compressing wheel frames are mounted on supporting steel angles of the feeding mechanism frame; the compressing wheels are connected onto the compressing wheel fixing plates by shafts, and rolling surfaces of the compressing wheels are positioned above first supporting rollers. The building block cutting, feeding and conveying mechanism has the advantages that by the aid of the building block cutting, feeding and conveying mechanism, building blocks can be continuously and stably cut, can be assuredly thoroughly cut and can be quickly conveyed after being cut, accordingly, the efficiency can be improved, and the labor intensity of staffs can be relieved.

Owner:湖州优研知识产权服务有限公司

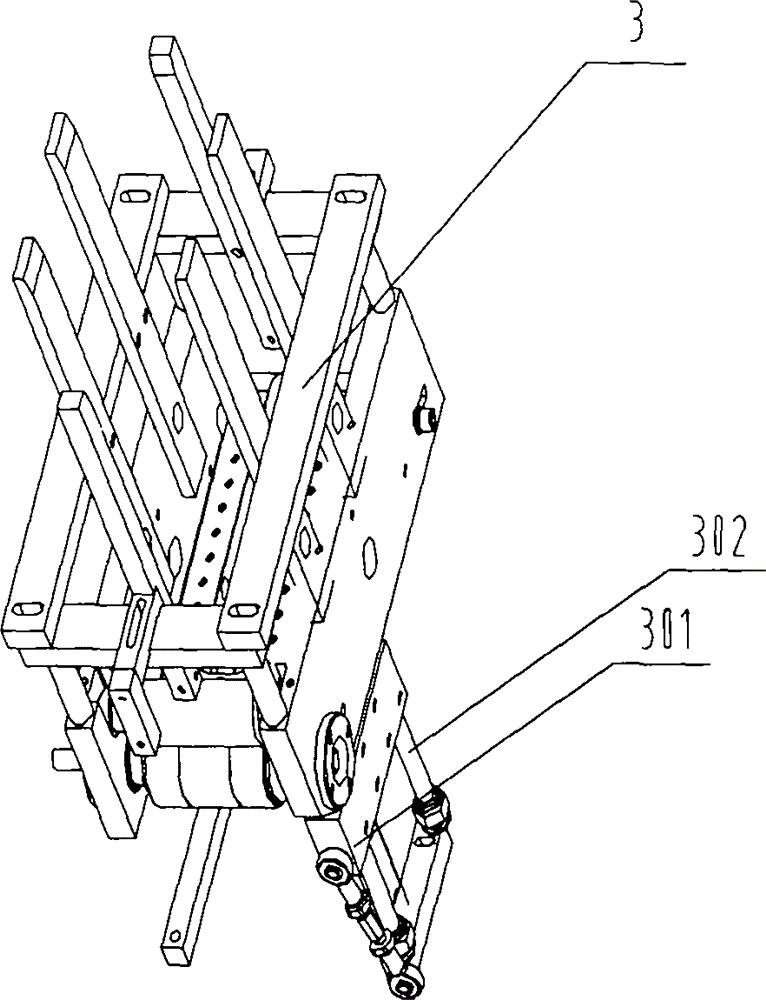

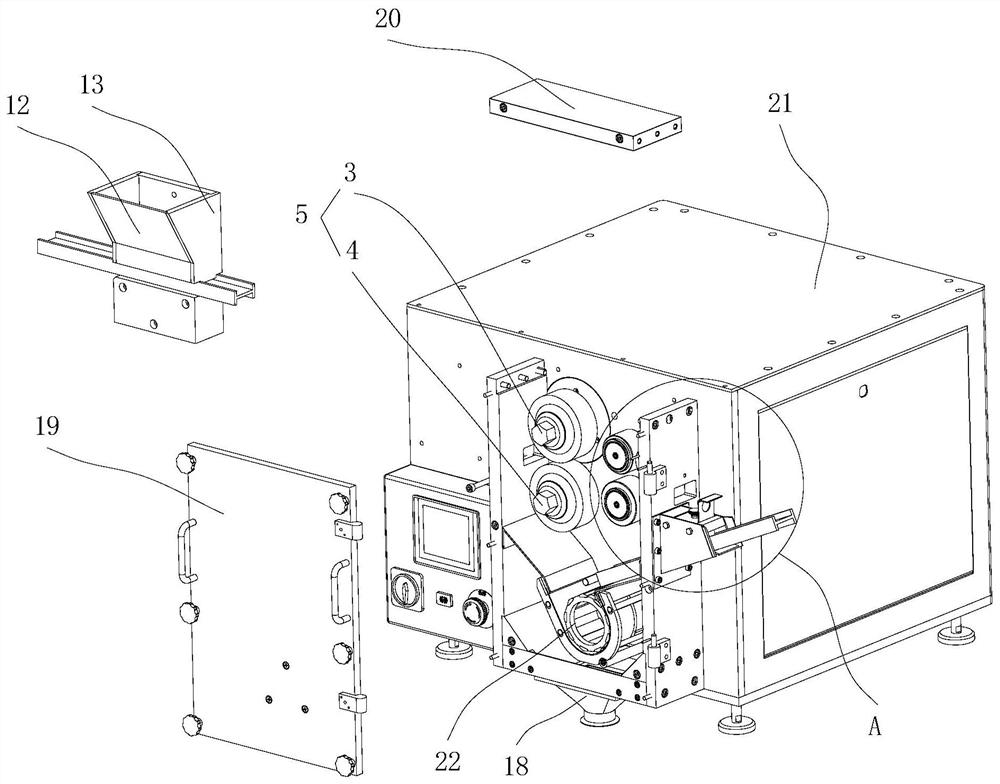

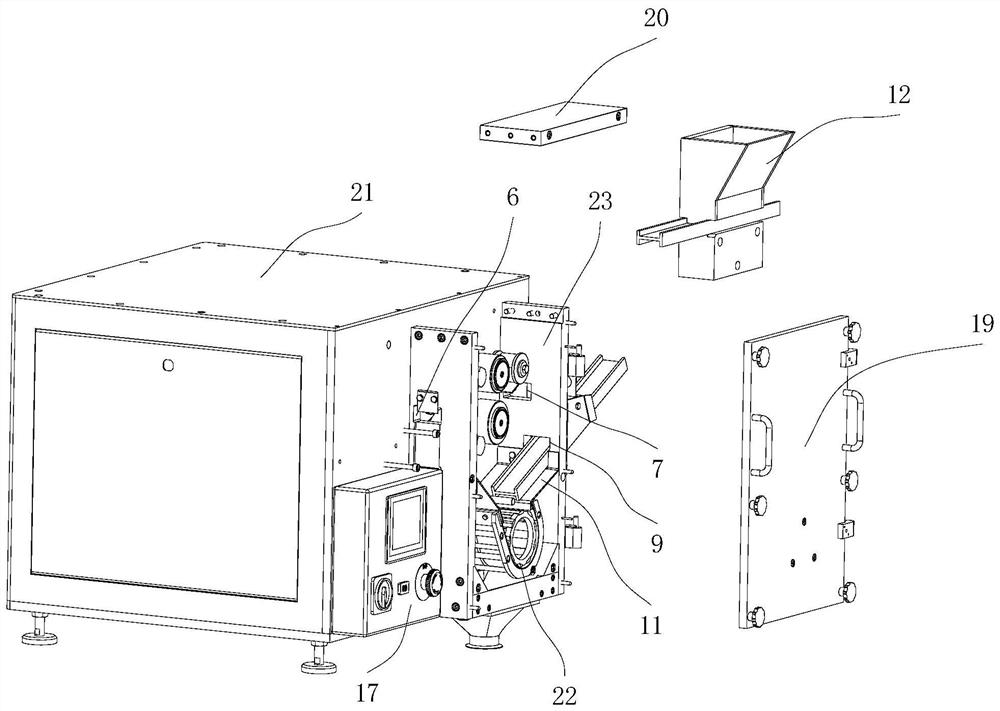

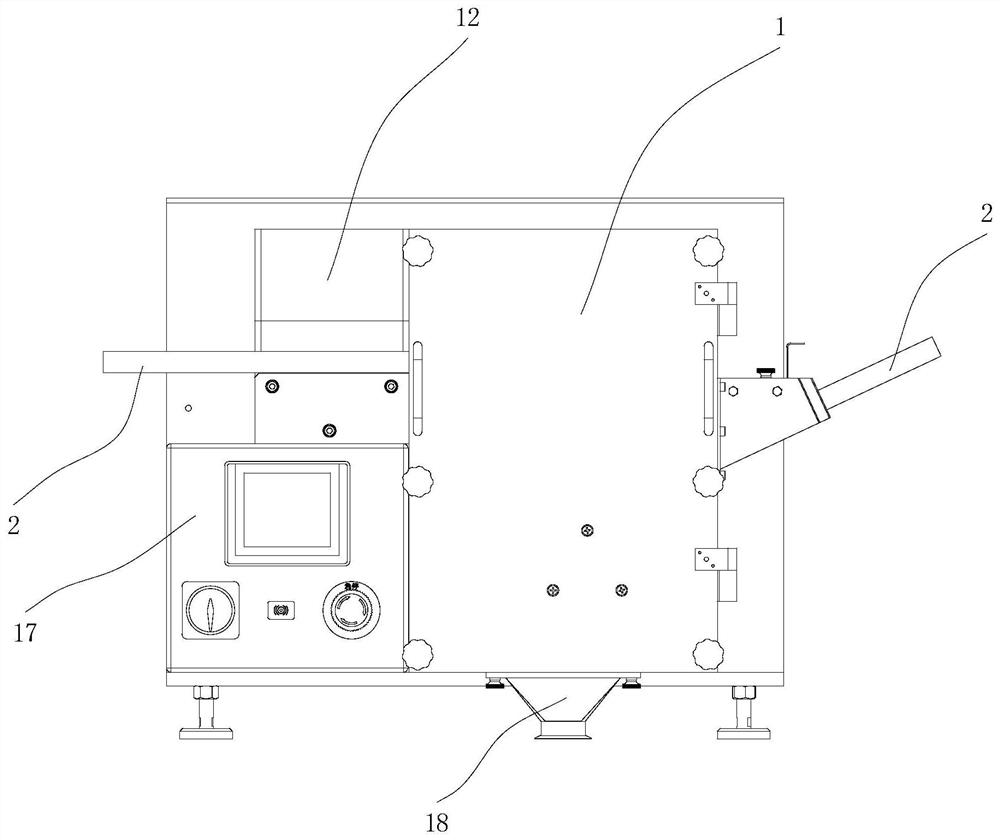

Connecting piece feeding equipment

PendingCN113666115AGuaranteed feeding efficiencyGuaranteed continuous feedingDe-stacking articlesConveyor partsTransfer mechanismManufacturing engineering

The invention relates to the technical field of feeding equipment, in particular to connecting piece feeding equipment which comprises a conveying mechanism, a transferring mechanism, a lifting mechanism and a carrying mechanism, the lifting mechanism is used for lifting trays, the carrying mechanism sucks connecting pieces in the tray on the uppermost layer, and then the connecting pieces are fed; and after the connecting pieces in the tray on the uppermost layer on the lifting mechanism are fed, the empty tray on the lifting mechanism is transferred away through the transferring mechanism, then the lifting mechanism continues to lift the tray on the lower layer, it is guaranteed that the connecting pieces are fed continuously, the trays do not need to be replaced manually, and the feeding efficiency of the connecting pieces is guaranteed. The conveying mechanism conveys the connecting pieces made of two materials, so that the two kinds of connecting pieces are paired and fed, the two kinds of connecting pieces are fed at the same time through one device, the feeding efficiency of the connecting pieces is greatly improved, the problem that a plurality of production lines need to be arranged is solved, the occupied area of a production area is reduced, meanwhile, the production cost is greatly reduced, and the feeding accuracy and the assembling efficiency are guaranteed.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

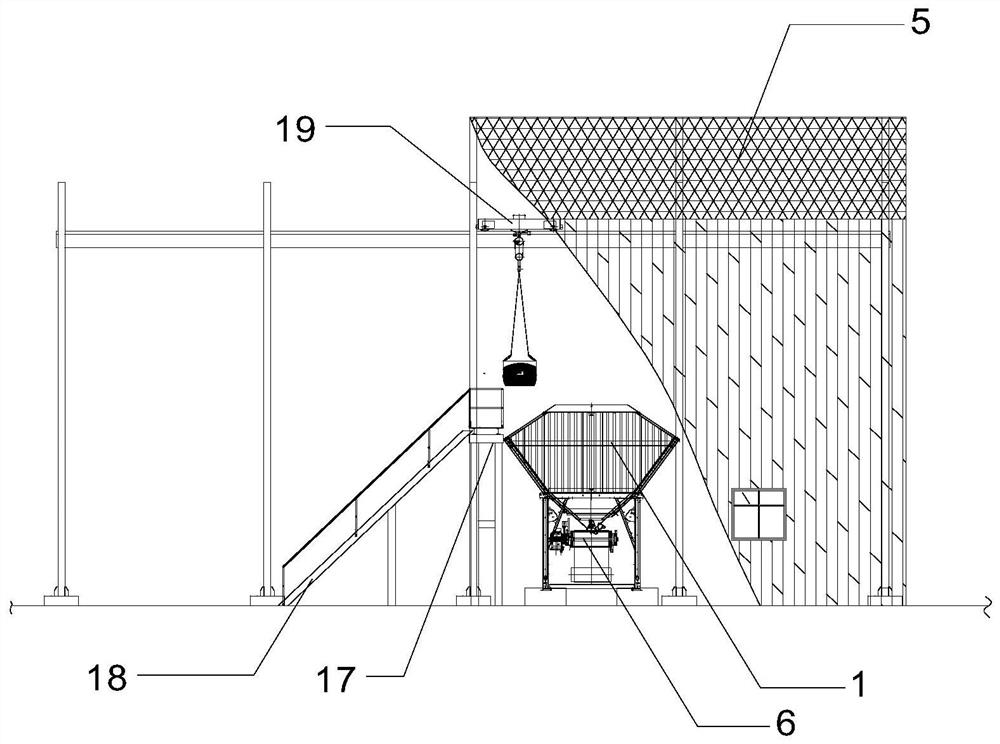

UHPC industrial production stirring process

InactiveCN113386256ALower the outlet temperatureGuaranteed uniformityMixing operation control apparatusCement mixing apparatusTemperature controlProcess engineering

The invention discloses an UHPC industrial production stirring process. The UHPC industrial production stirring process comprises the following steps that firstly, the components are mounted and debugged, raw materials are fed into a site, quality detection is carried out on the raw materials, and the raw materials are fed into storage bin stations after the raw materials are detected to be qualified; before stirring operation, temperature control is carried out on the storage bin stations of the raw materials; the raw materials are weighed and proportioned correspondingly, and then a stirring device is started; the raw materials are sequentially conveyed, dumped and discharged into the stirring device, the stirring state is observed, and the next disc of raw materials is weighed while stirring; and when the stirring state meets the requirement, discharging is carried out, and meanwhile, the next disc of the raw materials is put into the stirring device. According to the UHPC industrial production stirring process, the whole process is high in working continuity and high in automation degree; and continuous stirring can be carried out during production, so that continuous feeding is guaranteed, and the engineering project requirements that the single-time pouring volume is large and the pouring time is long can be met.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG +2

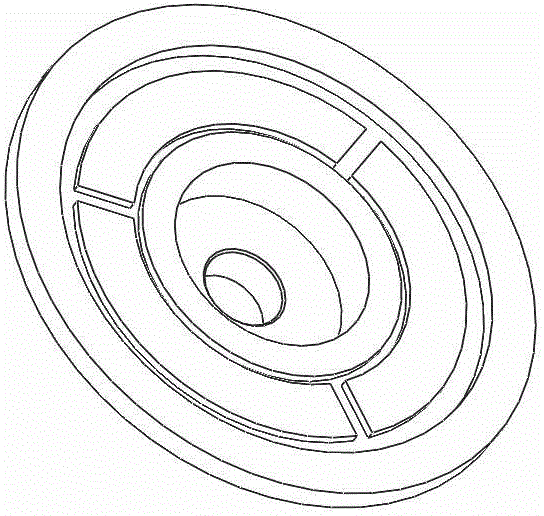

Continuous flow upright type planar liquid-phase shearing method

ActiveCN107522192AReduce fluid volumeSolve power consumptionGrapheneMolybdenum sulfidesHydraulic pumpEngineering

The invention discloses a continuous flow upright type planar liquid-phase shearing method which comprises the following steps: mixing a processed laminar precursor material with a liquid, injecting into a device from a feeding hole, and feeding into a part between an upper disc and a lower disc; when the lower disc is rotated, enabling the fluid between the upper disc and the lower disc to flow in a laminar manner and a turbulent manner simultaneously; and feeding a liquid material into a liquid cavity after one round of liquid-phase shearing processing, feeding back to the part between the upper disc and the lower disc by using a hydraulic pump through a tube connector, a backflow tube and a three-way tube connector, performing liquid-phase shearing processing for another time, and circulating the liquid for multiple times till processing requirements are met completely. The method is excellent in working property.

Owner:NANTONG UNIVERSITY

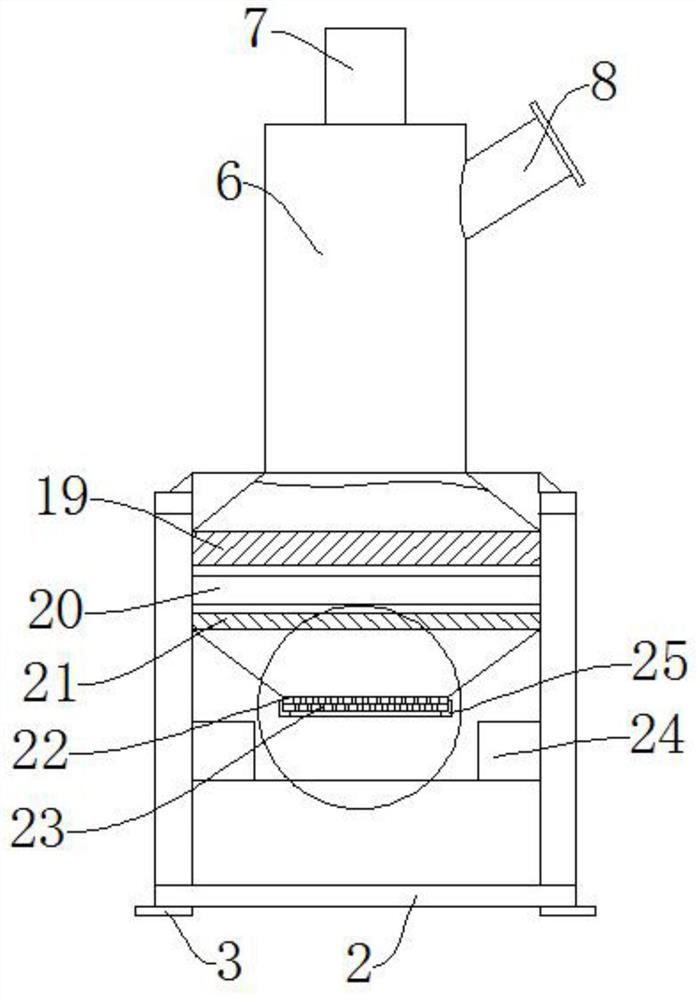

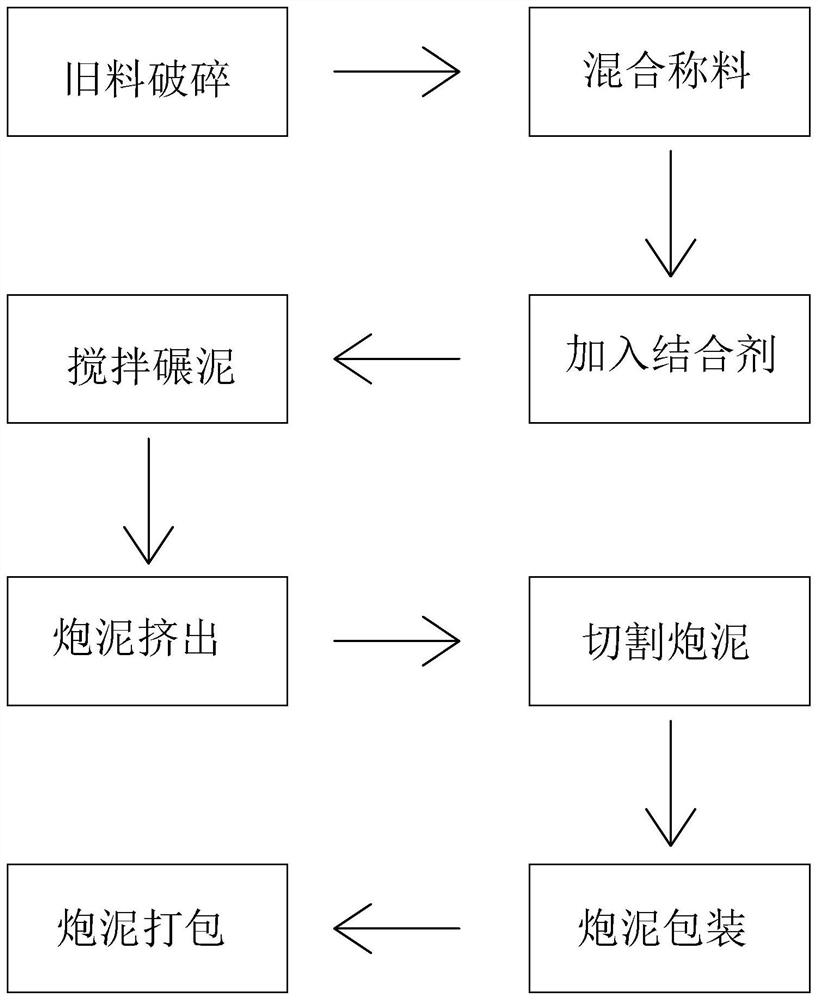

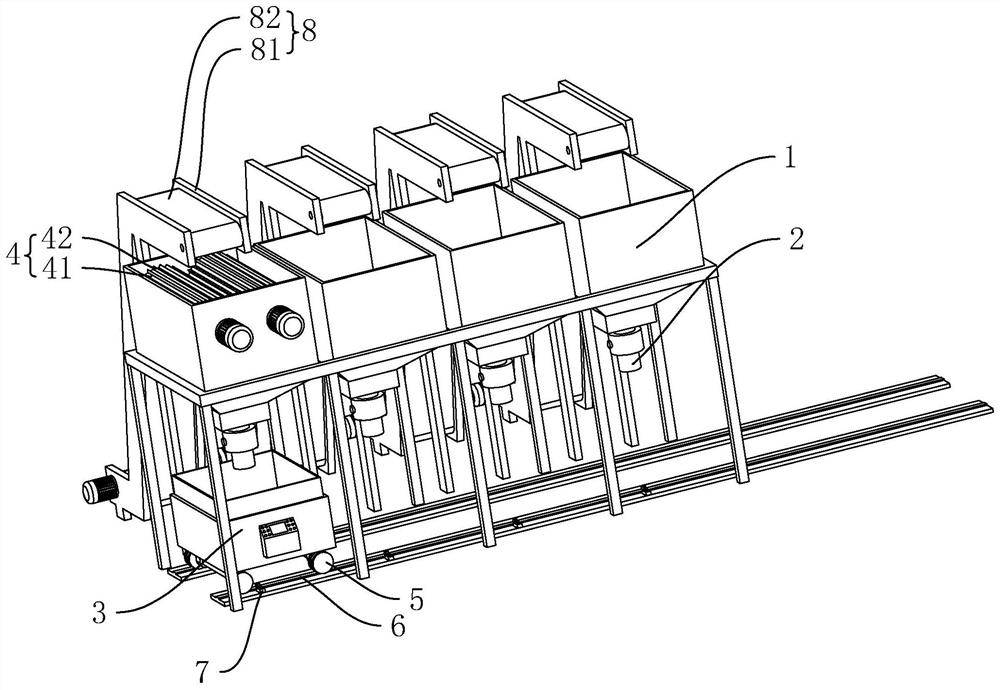

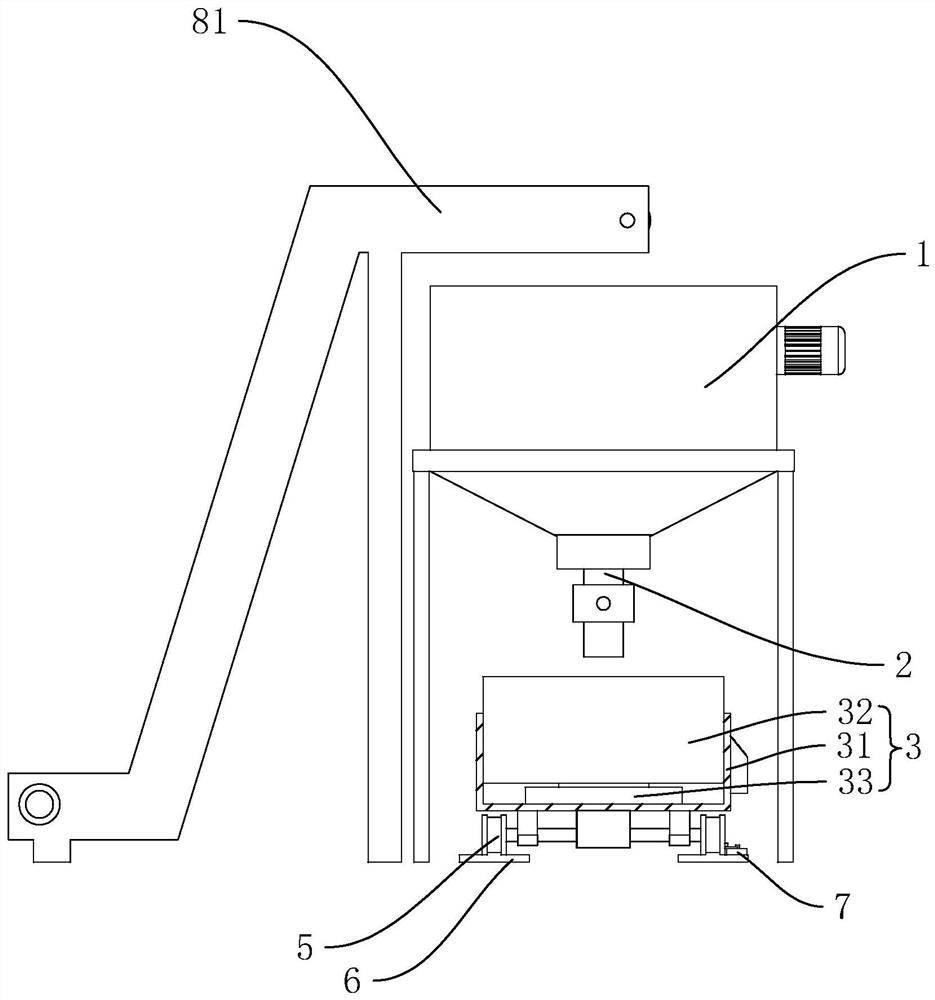

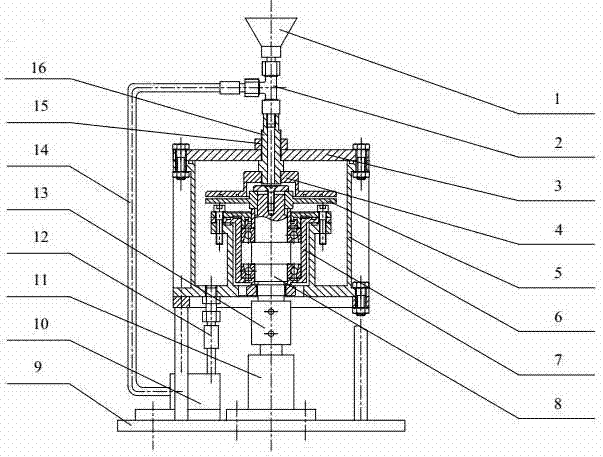

New and old mixed stemming manufacturing process and equipment applied to process

InactiveCN112519168ASave resourcesQuality improvementGrain treatmentsShaping pressProcess engineeringMixed materials

The invention relates to a new and old mixed stemming manufacturing process. The process comprises the following steps of 1, crushing old materials, namely crushing dried stemming until the stemming is crushed into powder; 2, performing mixing and weighing, namely weighing and proportioning the crushed stemming and stemming raw materials in proportion and performing mixing; 3, adding a binding agent, and adding the binding agent while stirring the mixed material; 4, stirring and grinding the stemming, namely grinding and stirring the stemming by adopting an edge runner mill; 5, extruding the stemming, namely putting the stemming obtained after grinding and stirring into a stemming extruder to be extruded; 6, cutting the stemming, namely cutting the the stemming obtained after extrusion; 7,packaging the stemming, namely packaging the cut stemming; and 8, bailing the stemming, namely bailing the packaged stemming. The process has the advantages that the dried stemming is crushed and mixed with new materials for new stemming manufacturing, the dried stemming can be reused, and resources are saved.

Owner:山东恒信力众新型材料有限公司

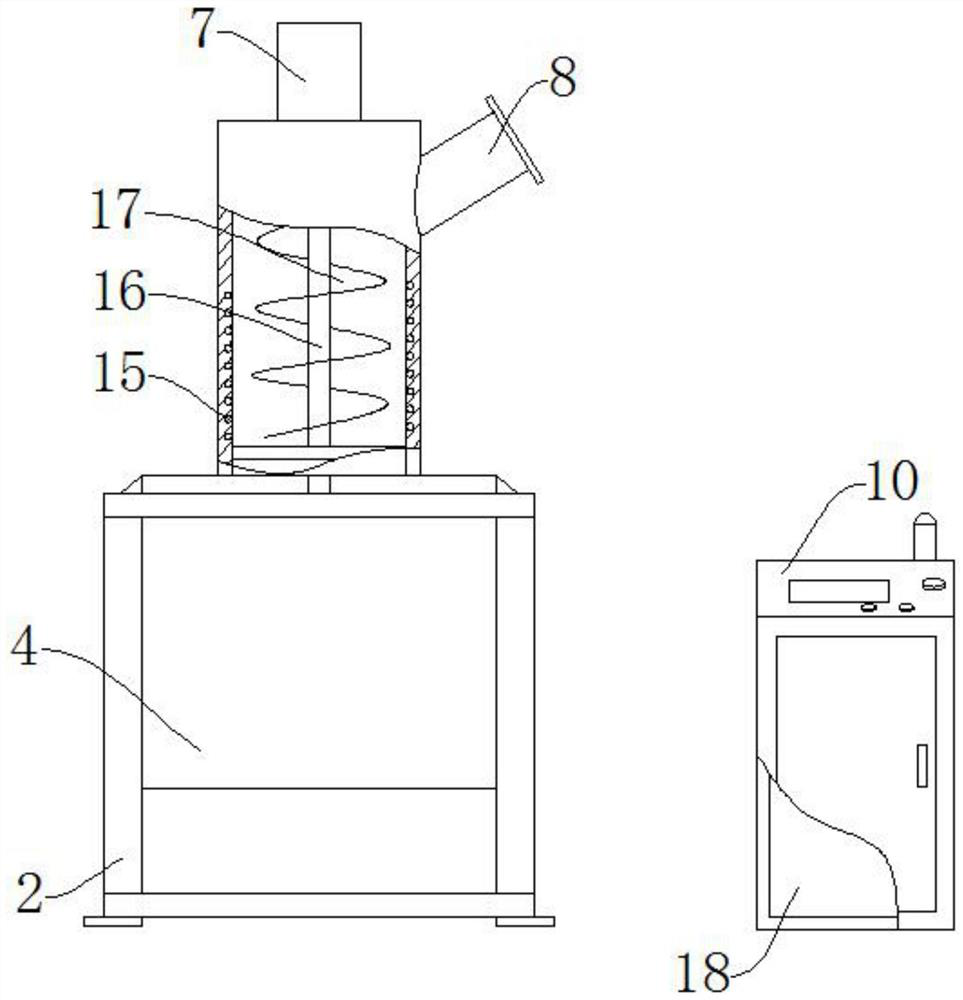

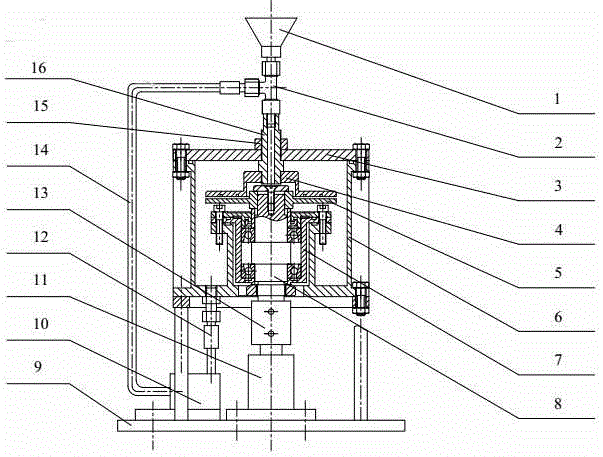

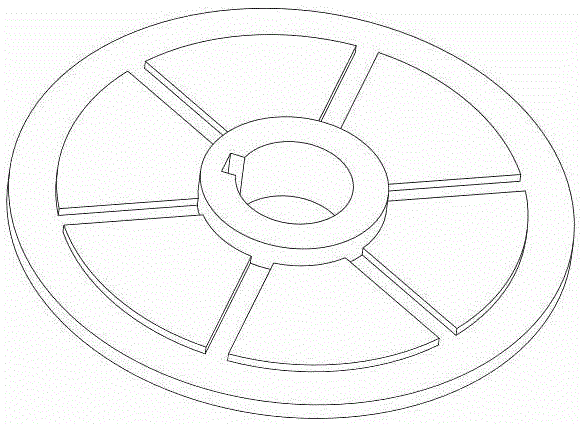

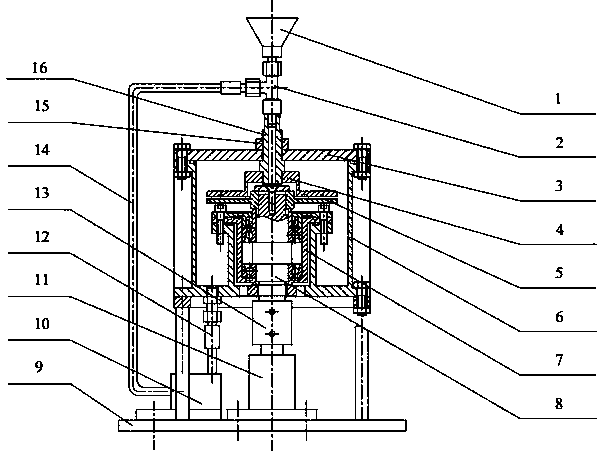

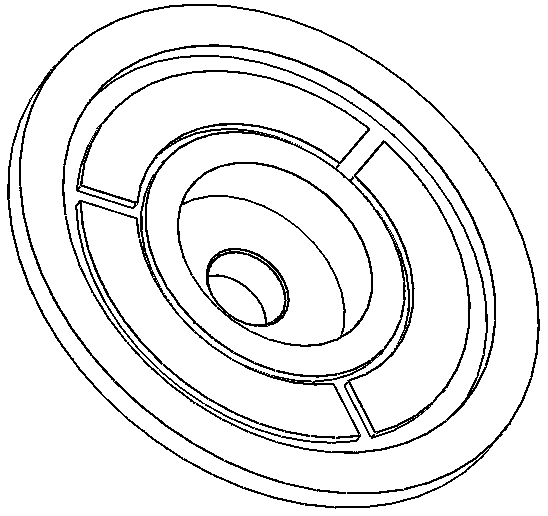

Continuous flow vertical planar liquid phase shearing device

ActiveCN107364849AReduce fluid volumeSolve power consumptionGrapheneMolybdenum sulfidesCouplingAgricultural engineering

The invention discloses a continuous flow vertical planar liquid phase shearing device. The device comprises a base, a vertical motor is installed on the base, the vertical motor is connected to a lower shaft in a liquid chamber through a coupler, the lower shaft is connected to a lower disc, an upper disc in the liquid chamber is arranged above the lower disc, the upper disc is connected to an upper shaft provided with a material path, the upper shaft passes through the liquid chamber and is connected to one end of a t-branch pipe joint, other two ends of a t-branch pipe are respectively connected to a feeding inlet and a material returning pipe, the material returning pipe is connected to a hydraulic pump, the hydraulic pump is connected to the liquid chamber through the pipe joint, the liquid chamber comprises a chamber body, the upper end of the chamber body is provided with an upper cover plate and the lower end of the chamber body is connected to a stand column fixed to the base. The device has a reasonable structure and good working performances.

Owner:NANTONG UNIVERSITY

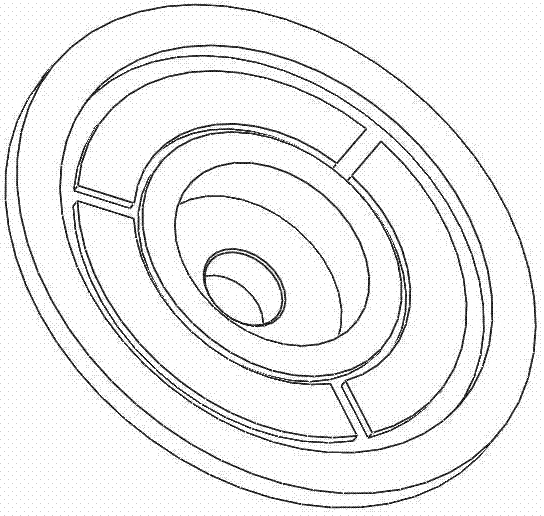

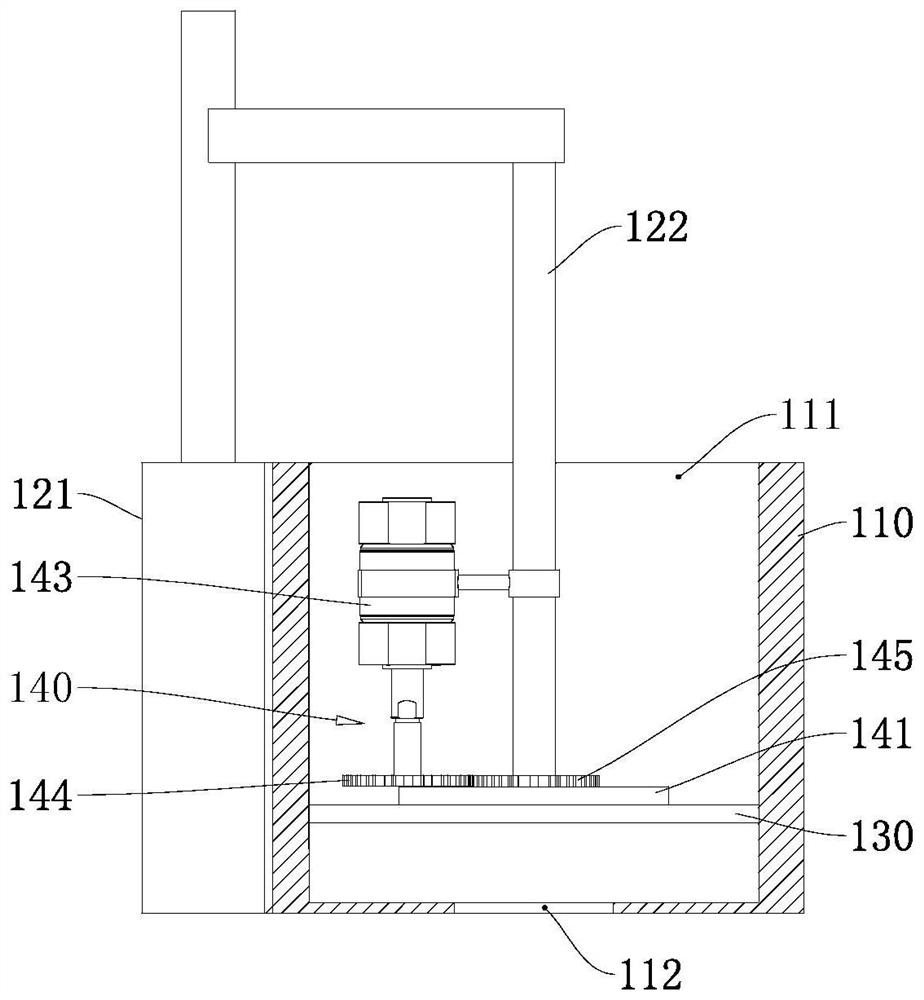

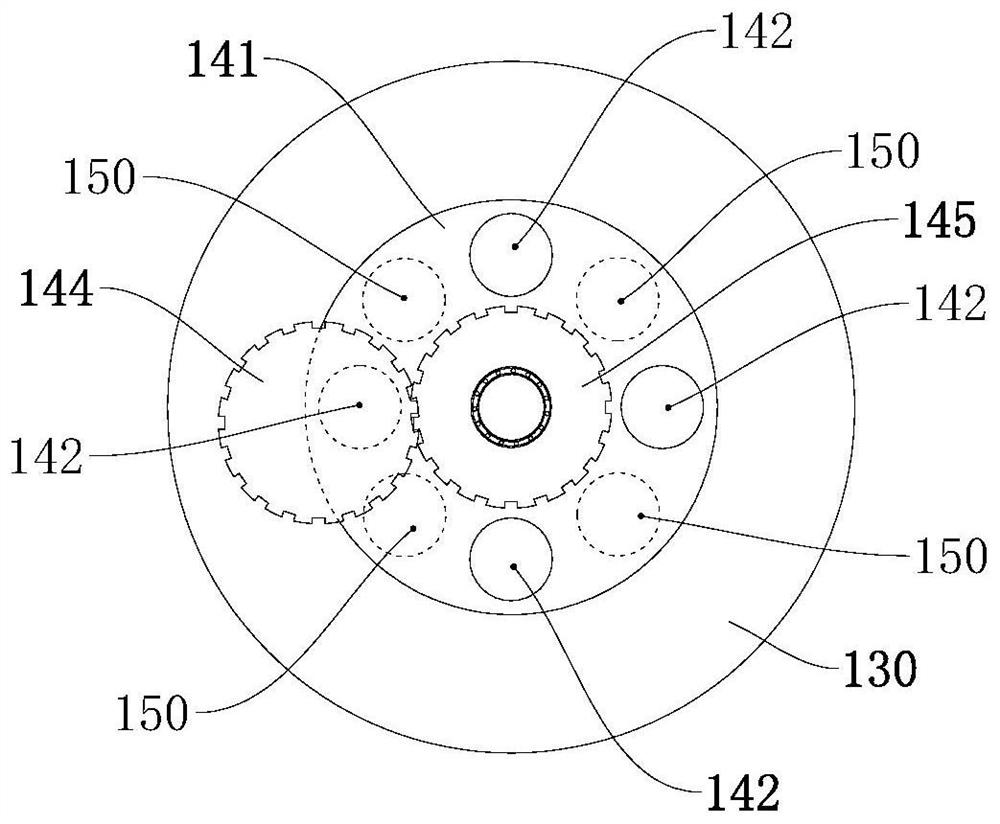

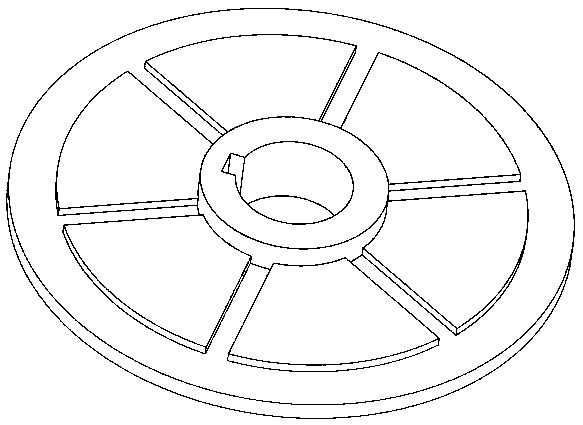

Feeding device for metal nano-powder production

PendingCN110027925AGuaranteed continuityGuaranteed continuous feedingLoading/unloadingDrive motorEngineering

The invention discloses a feeding device for metal nano-powder production, and relates to the field of metal nano-powder production equipment. The feeding device comprises a box body, a box cover is hinged to the top of the box body, a material storage mechanism is arranged in the box body, a discharge pipe is arranged at the bottom of the box body, the upper end of the discharge pipe extends intothe box body and is connected with a material storage mechanism, the material storage mechanism comprises a plurality of disc-shaped storage devices which are vertically stacked in the box body, thedisc-shaped storage device comprises a tray, a connecting shaft is coaxially arranged in the middle of the tray, a bulge is arranged at the upper end of the connecting shaft, a clamping groove matchedwith the bulge is formed in the bottom of the connecting shaft, a rotating gear disc is coaxially arranged on the connecting shaft, a driving motor is arranged on the tray, a driving motor is connected with the driving gear, leakage holes are uniformly formed in the upper end surface of the rotating gear disc around the shaft, a hopper is arranged at the position, corresponding to the material leaking hole, of the rotating gear disc, a baffle is hinged to the bottom of the hopper, a leaking plate hole is formed in the position, corresponding to the baffle, of the tray, leaking plate hole is communicated with the top of the discharging pipe, and has the advantages of being capable of continuously feeding materials and high in production efficiency.

Owner:纳华(宁波)新材料科技有限公司

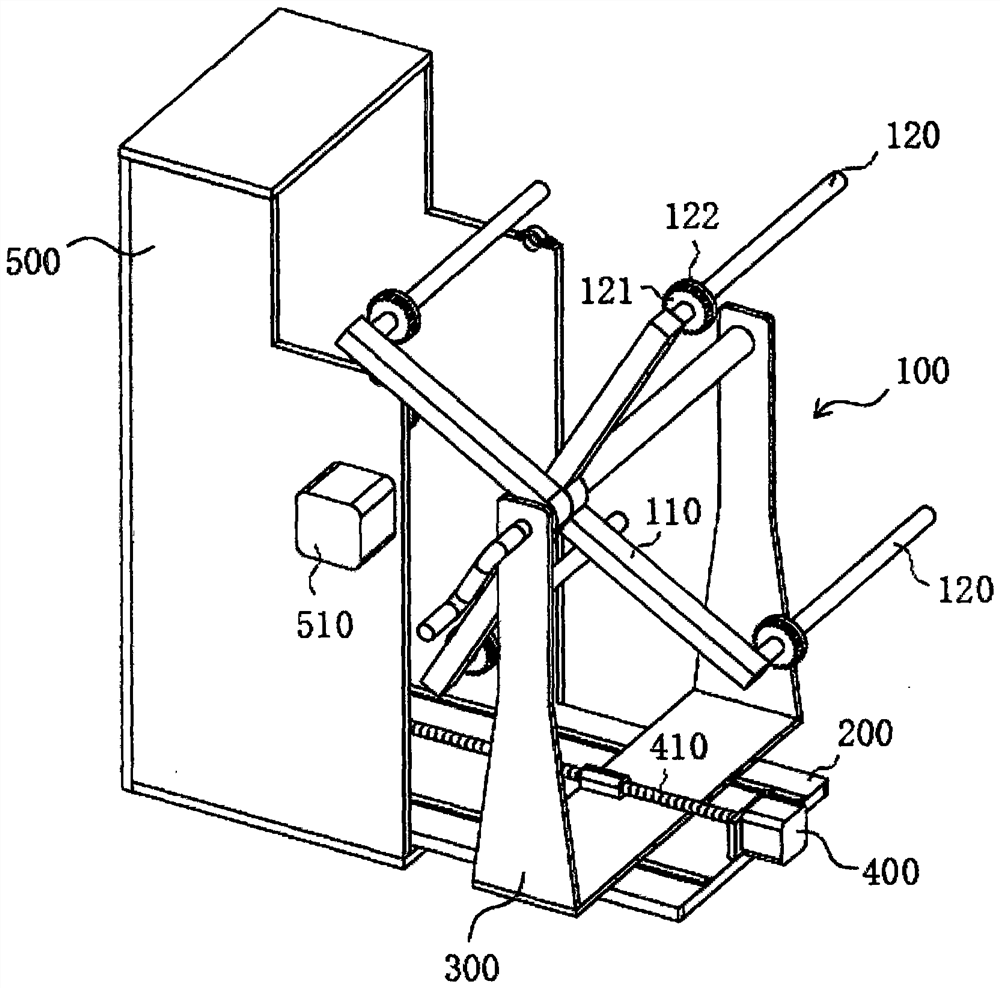

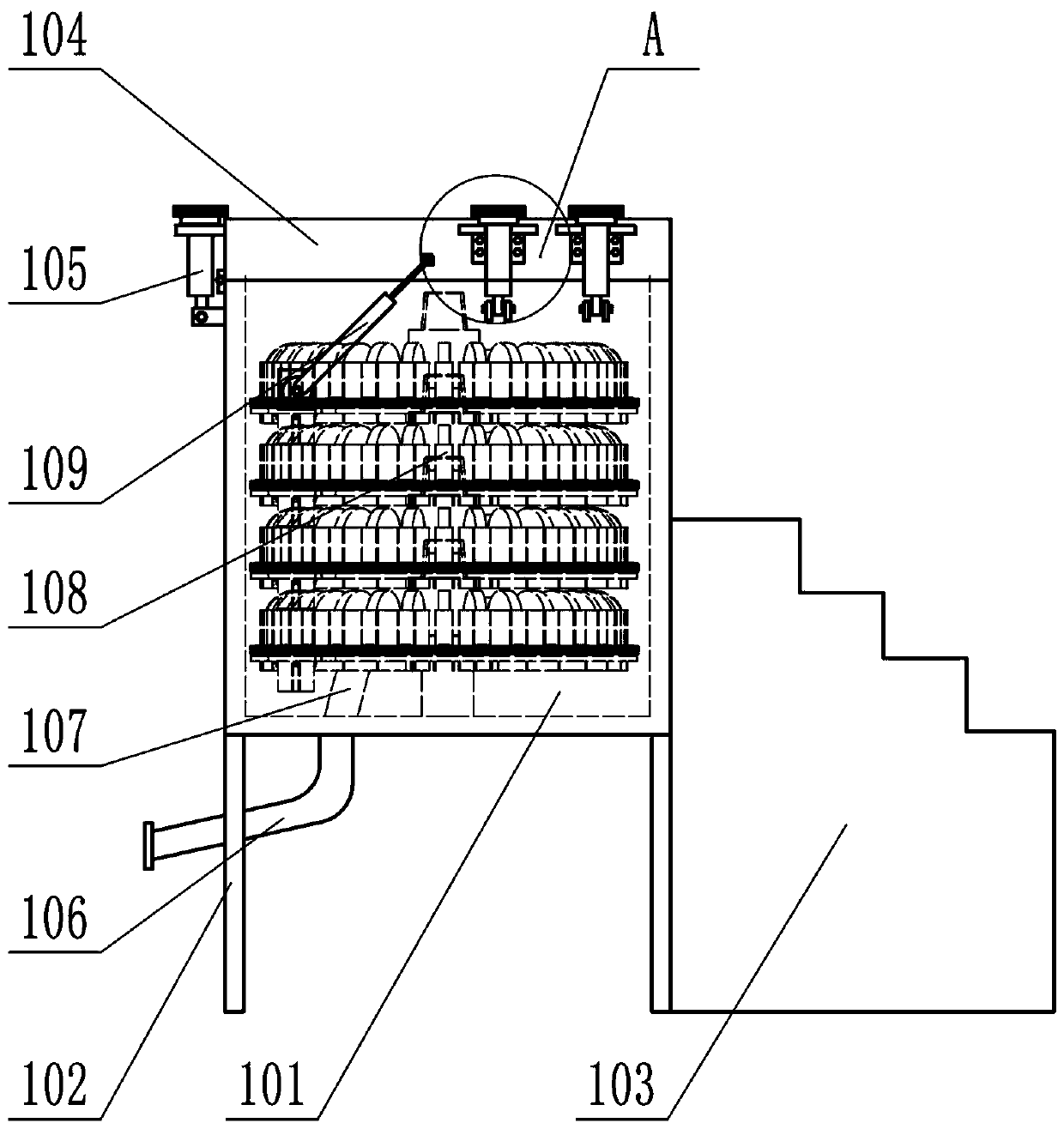

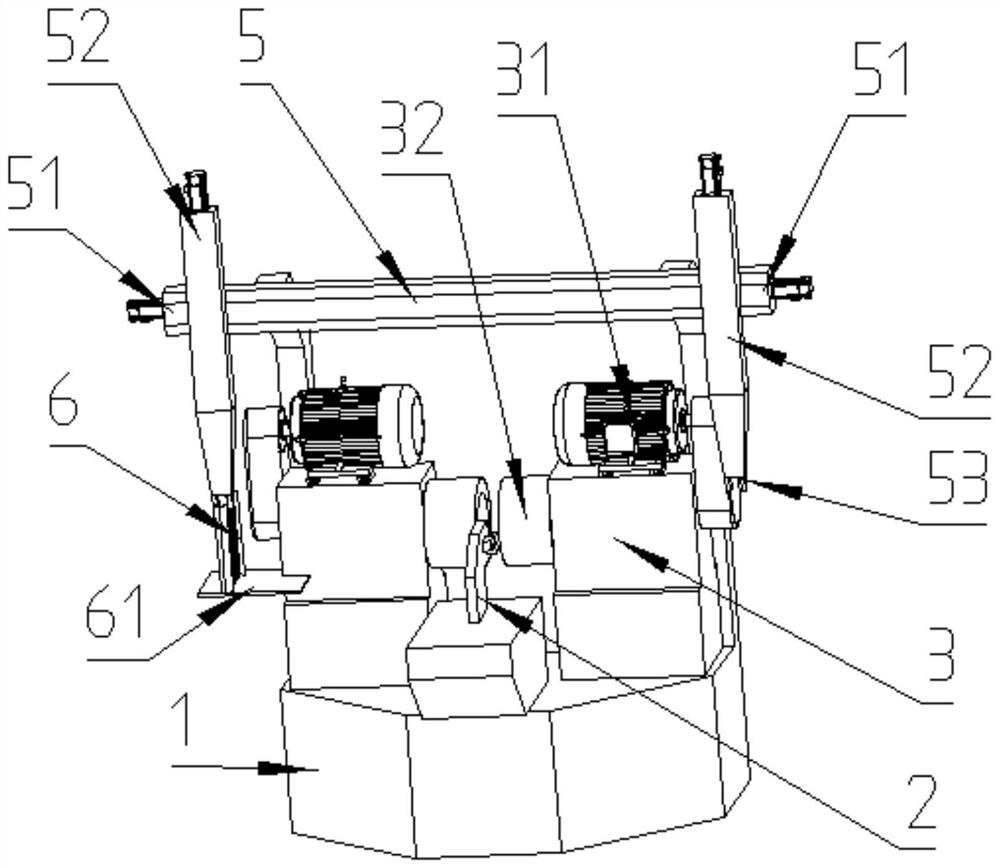

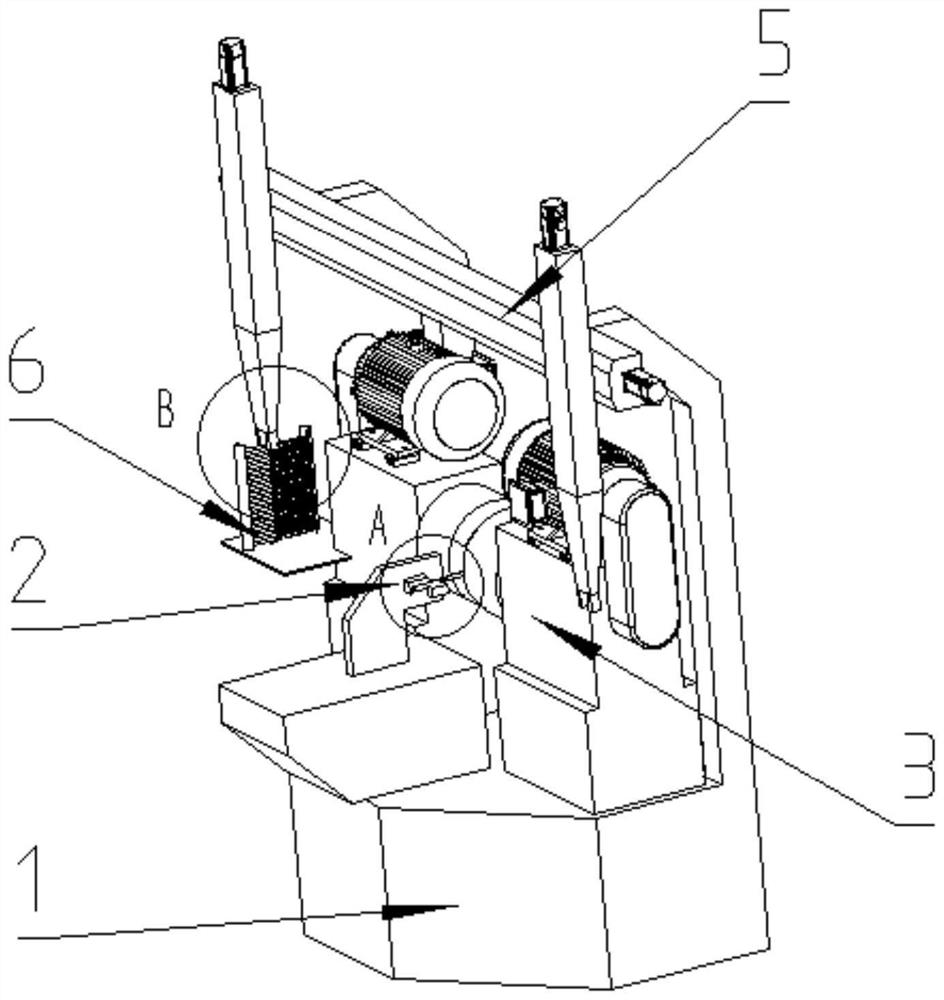

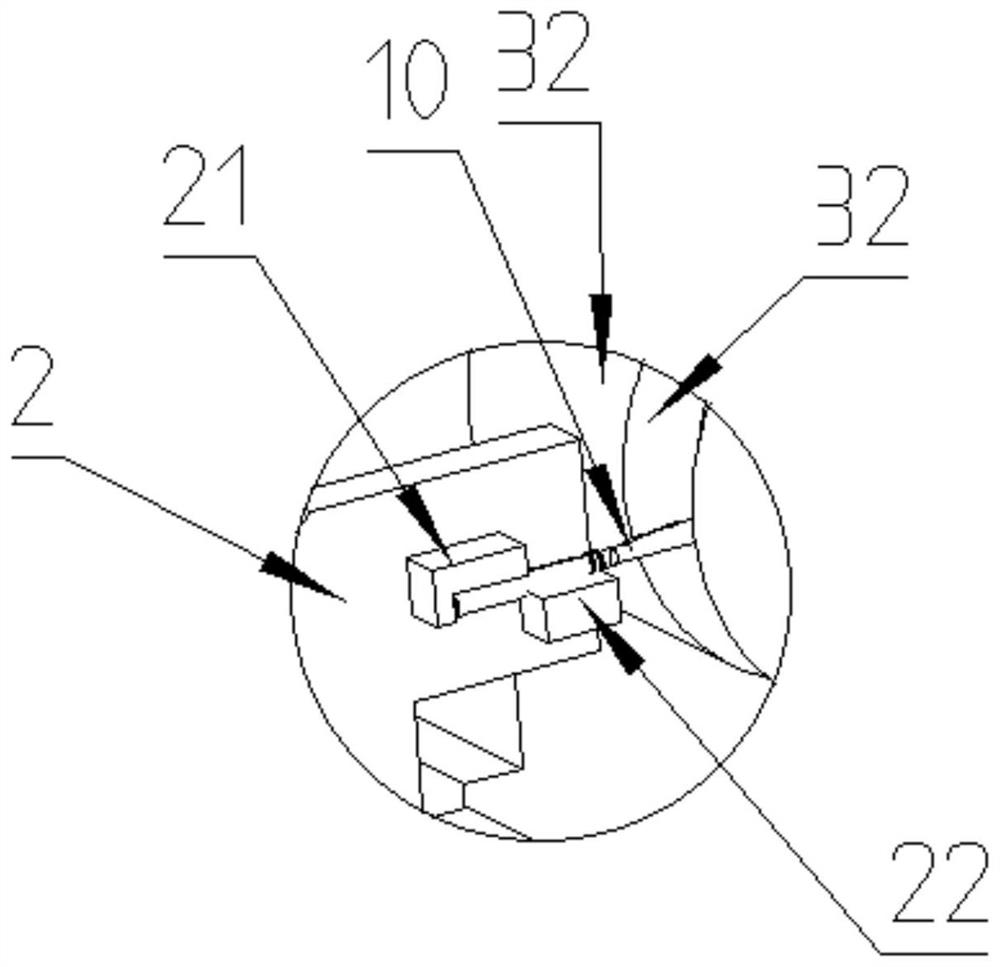

Automatic feeding and grinding equipment for table knives

PendingCN112676931AGuaranteed continuous feedingImprove work efficiencyGrinding drivesOther manufacturing equipments/toolsKnife holderEngineering

The invention provides automatic feeding and grinding equipment for table knives, and belongs to the field of tableware processing equipment. The automatic feeding and grinding equipment comprises a knife rest, a knife grinding assembly, a feeding assembly and a clamping assembly; the knife grinding assembly is of an axially symmetrical structure and comprises grinding discs, and the knife rest is arranged between the two symmetrical grinding discs; the knife rest is used for fixing handles of the table knives, the other ends of the table knives extend to the position between the two grinding discs, and the grinding discs move along the axes of the grinding discs to clamp and grind the table knives; the feeding assembly is arranged on one side of the knife rest, and is used for positioning the plurality of table knives which are overlapped up and down; and the clamping assembly comprises a feeding clamping piece and a discharging clamping piece, the feeding clamping piece transfers the table knives to the knife rest from the feeding assembly, and the discharging clamping piece transfers the table knives to a discharging position from the knife rest. According to the automatic feeding and grinding equipment for the table knives, continuous feeding, automatic grinding and automatic discharging of the table knives can be achieved, so that the grinding efficiency is greatly improved, the precision is high, the labor intensity is reduced, and manpower is saved.

Owner:TIANJIN TTX GROUP

Mobile phone glass detection equipment

PendingCN114308700AAchieve high precision machiningGuaranteed continuous feedingSortingGlass chipManipulator

The mobile phone glass detection equipment comprises a first material supplementing conveying line, the first material supplementing conveying line is sequentially provided with an unstacking area, a feeding area and a stacking area in the conveying direction, and an unstacking jacking mechanism and a stacking jacking mechanism are arranged at the positions, corresponding to the unstacking area and the stacking area, of the bottom of the first material supplementing conveying line correspondingly; the station turntable mechanism comprises a rotary table, and jigs for fixing glass sheets are arranged on the corresponding stations of the rotary table; the manipulator is used for transferring the glass sheets in the feeding area to the jig and transferring the glass sheets on the jig to the feeding area; the positioning mechanism is arranged at the lower end of the rotary worktable and is used for adjusting the position of the glass sheet on the jig before detection; the first detection mechanism is arranged at the next rotating station of the positioning mechanism and is used for carrying out defect detection on the glass sheet on the jig; the invention provides mobile phone glass detection equipment, and aims to improve the production efficiency and realize the automation of mobile phone glass processing.

Owner:深圳市粤源智造科技有限公司

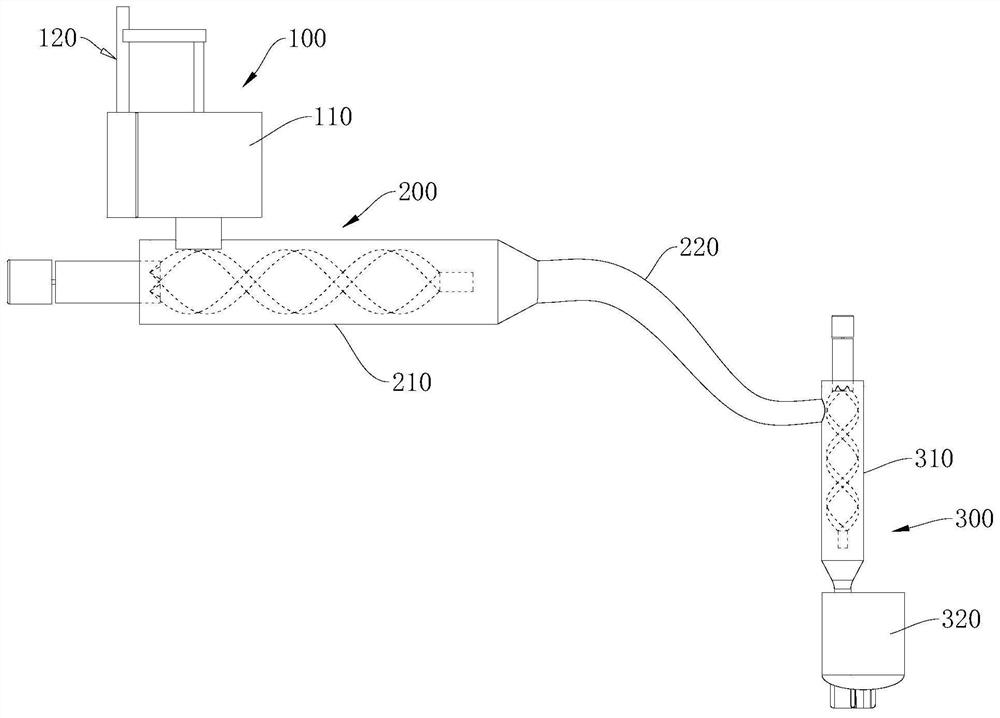

3d printing equipment

ActiveCN113400438BImprove firmnessReduce airAdditive manufacturing apparatusFeeding arrangmentsEngineeringMaterial storage

The invention provides a 3D printing device, comprising a material storage device, a conveying device and an extrusion device connected in sequence; the material storage device includes a material storage barrel, a lifting mechanism, an extrusion structure and an adjustment mechanism; an inlet is formed on the top of the material storage barrel , an outlet is formed at the bottom, and the outlet is connected to the conveying device; the lifting mechanism has a lifting end that can enter and exit the storage barrel from the inlet; the extrusion structure is set at the lifting end, and the edge of the extrusion structure is slidingly attached to the inner wall of the storage barrel, so as to An extrusion space is formed between the extrusion structure and the material storage barrel, the extrusion space is located below the extrusion structure, and the extrusion structure is provided with a first air hole communicating with the extrusion space; the adjustment mechanism is arranged in the extrusion structure, and the adjustment mechanism It has a first state in which the first air hole is sealed, and a second state in which the first air hole is opened. The 3D printing equipment provided by the present invention can ensure the continuous supply of materials during the printing process, avoid printing interruption, and will not cause the backflow of raw materials.

Owner:保定吉米网络科技有限公司

Continuous flow vertical plane type liquid phase shearing device

ActiveCN107364849BReduce fluid volumeSolve power consumptionGrapheneMolybdenum sulfidesCouplingHydraulic pump

Owner:NANTONG UNIVERSITY

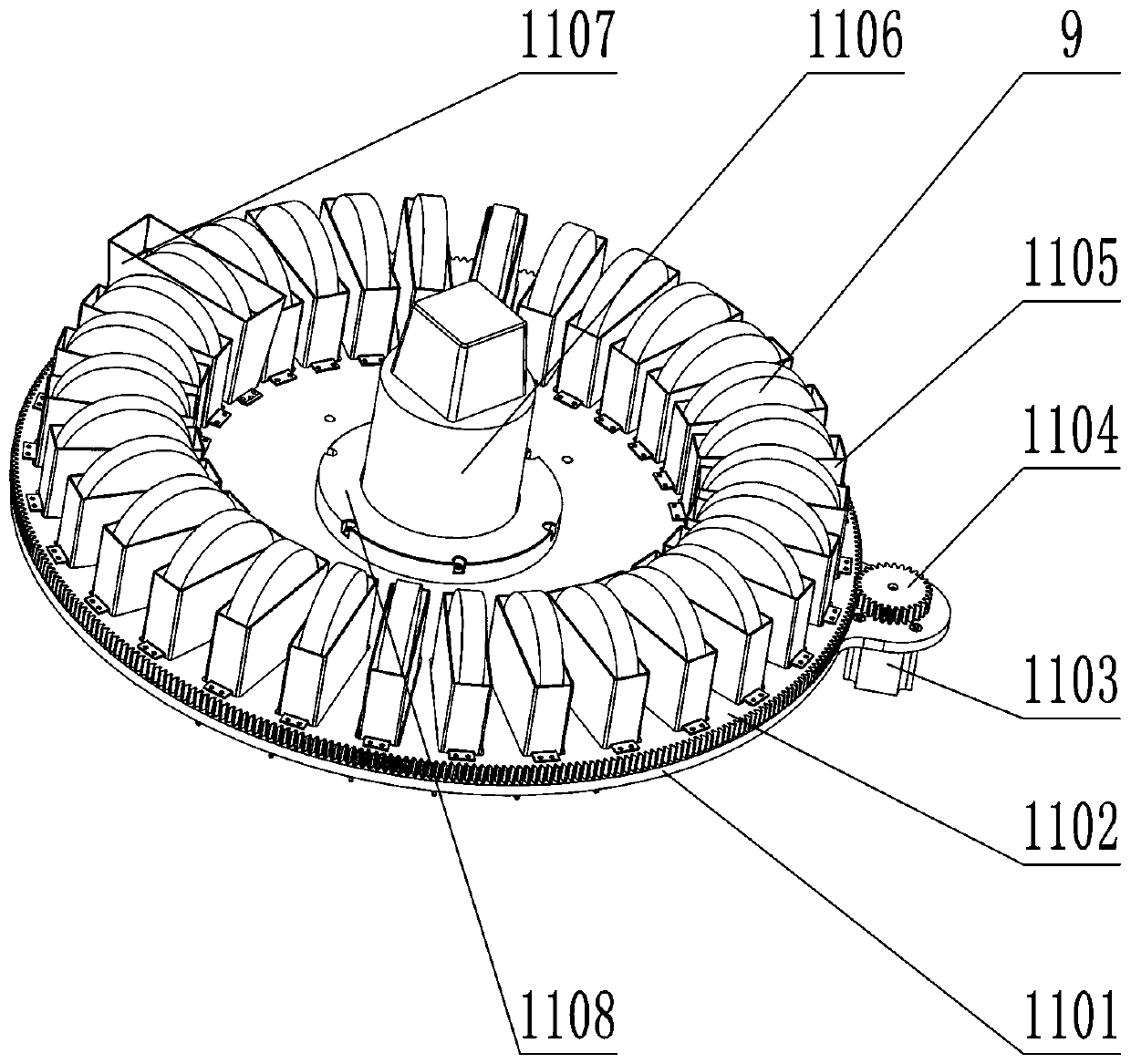

Dry type granulator

InactiveCN112774575AMeet delivery requirementsGuaranteed continuous feedingGranulation by pressingMechanical engineeringPhysics

The invention relates to the technical field of particle preparation, in particular to a dry type granulator which comprises a rolling mechanism, a granulating mechanism and a box body. The rolling mechanism comprises a first driving part and a rolling assembly connected with the first driving piece, and the first driving piece is suitable for driving the rolling assembly to act. The granulating mechanism comprises a second driving piece and a granulating assembly connected with the second driving piece, and the second driving piece is suitable for driving the granulating assembly to act. The rolling assembly and the granulating assembly are arranged in the box body, and the first driving piece and the second driving piece are arranged outside the box body. The dry type granulator further comprises a feeding mechanism which is arranged on one side of the box body and comprises a material bearing piece and a feeding structure, the material bearing piece is used for bearing materials, and a feeding channel is formed between the feeding structure and the material bearing piece. The dry type granulator is compact in structure and small in occupied space, two working procedures of rolling and granulating can be completed on one device during operation, the operation is convenient, and the granulating efficiency is improved.

Owner:北京新龙立自动化技术有限公司

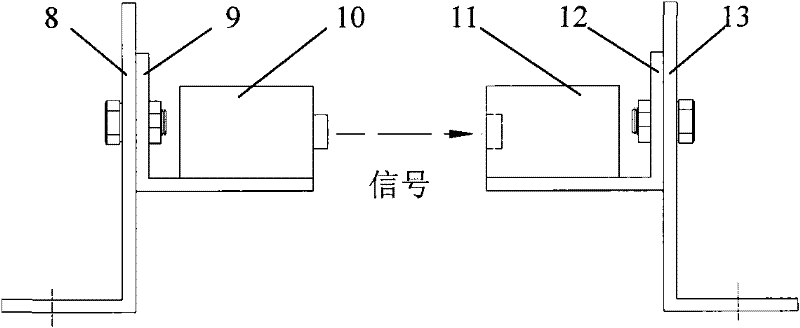

Combined device and method for early seedling continuously feeding failure warning and monitoring seedling planting quality

ActiveCN101828457BGuaranteed continuous feedingReduce seedling leakage rateTransplantingDevices using electric/magnetic meansBiologyContinuous feeding

The invention discloses a combined device for early seedling continuous feeding failure warning and monitoring seedling planting quality, which is used for detecting and early warning for continuous feeding and monitoring seedling planting quality and comprises a seedling feeding detector, a mounting bracket, a seedling planting quality monitor and a speed detector, wherein the seedling feeding detector is fixedly arranged at a parallel inlet of a conveyer belt baffle plate and is used for detecting and warning for continuous feeding; the mounting bracket is fixedly arranged on a machine frame; the seedling planting quality monitor is fixedly arranged on the bracket, is used for monitoring the vertical degree qualification rate and seedling leaking rate of the seedling planting and can measure planting row spacing when combined with the advancing speed detector; and the speed detector is used for detecting the advancing speed of a machine. The invention also provides a method for early seedling continuous feeding failure warning and monitoring the seedling planting quality. The adoption of the combined device for early seedling continuous feeding failure warning and monitoring theseedling planting quality in a planting process can realize early warning high-speed seedling continuous feeding and the monitoring of the planting quality. The combined device is simple in structureand convenient in operation.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

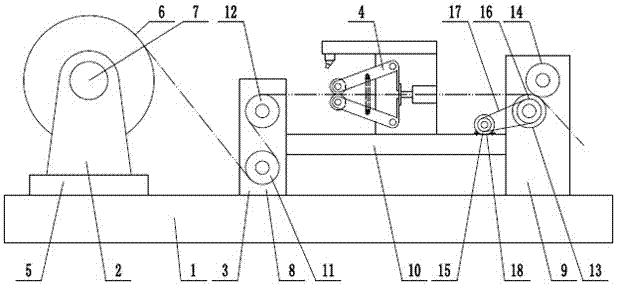

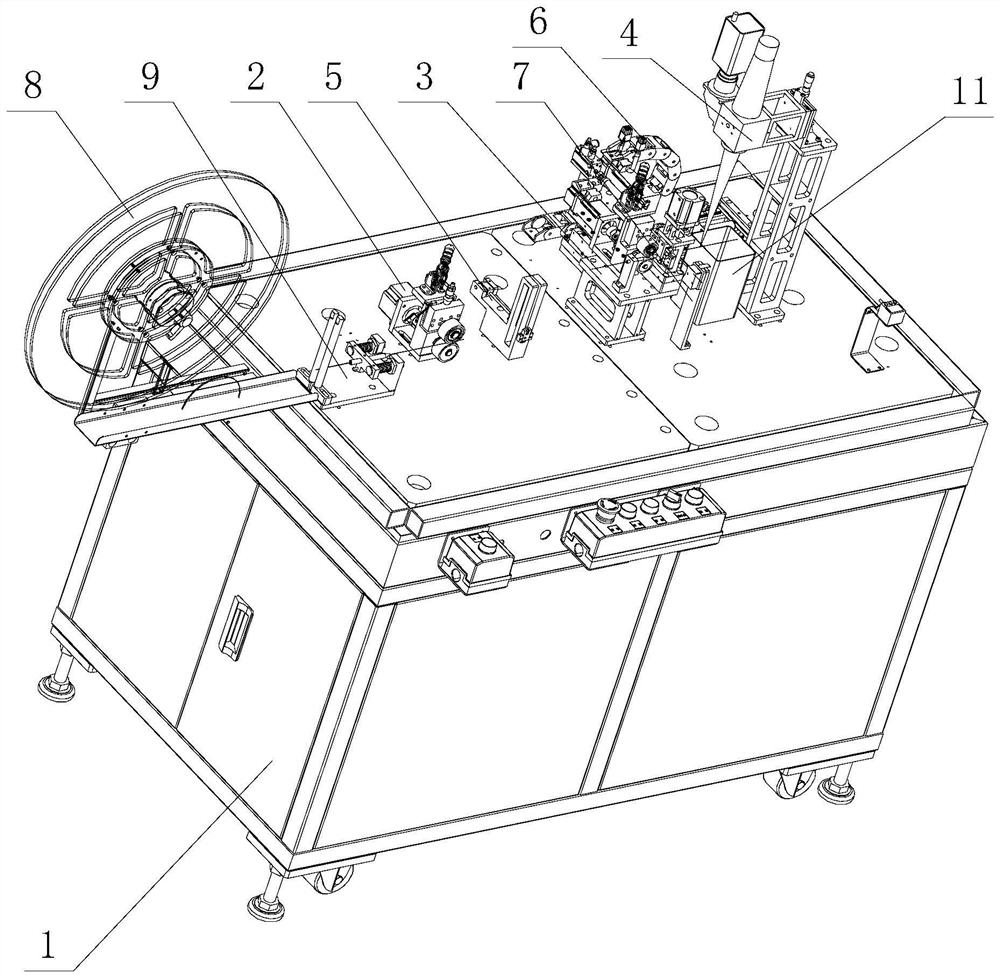

Stranded wire contact pin cutting and spot welding device

PendingCN114824992AQuick spot weldingRealize automatic feedingContact member manufacturingSpot weldingMechanical engineering

The invention relates to a stranded wire contact pin cutting and spot welding device which comprises a rack, a feeding module, a cutting module and a welding module, a carrying module and a stranded wire contact pin sensing optical fiber module are arranged on the rack, the carrying module is arranged between the cutting module and the welding module, and the carrying module comprises a moving mechanism and a rotary clamping mechanism. The stranded wire pin wire cut by the cutting module is clamped by the rotary clamping mechanism and then moved to the position below the welding module through the moving mechanism, and spot welding of the two ends of the stranded wire pin wire is achieved through rotation of the rotary clamping mechanism during welding; the device has the advantages that the stranded wire contact pin wire is fed into the cutting module through the feeding module to be cut, and the carrying module is arranged between the cutting module and the welding module, so that the stranded wire contact pin wire cut by the cutting module can be sent out from the cutting module, the welding process and the cutting process form two mutually independent processes, and the welding efficiency is improved. And the two are not interfered, so that the overall production efficiency is improved.

Owner:杭州航天电子技术有限公司

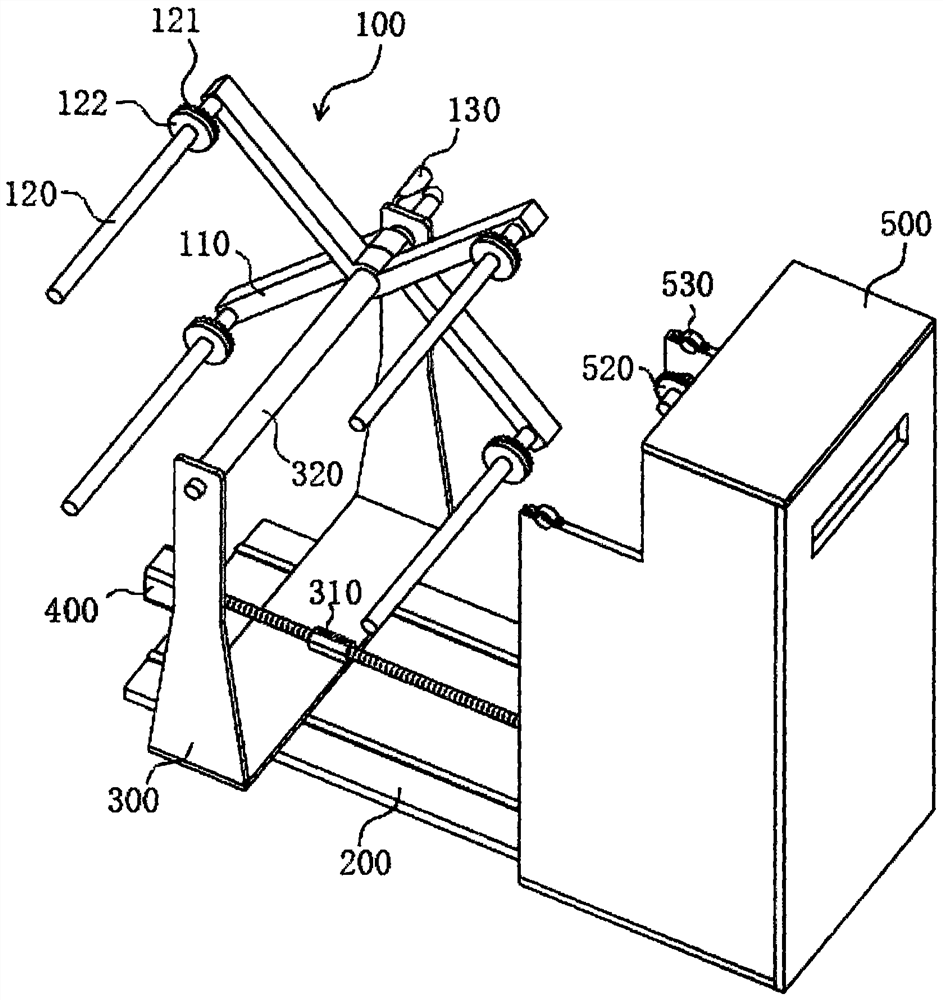

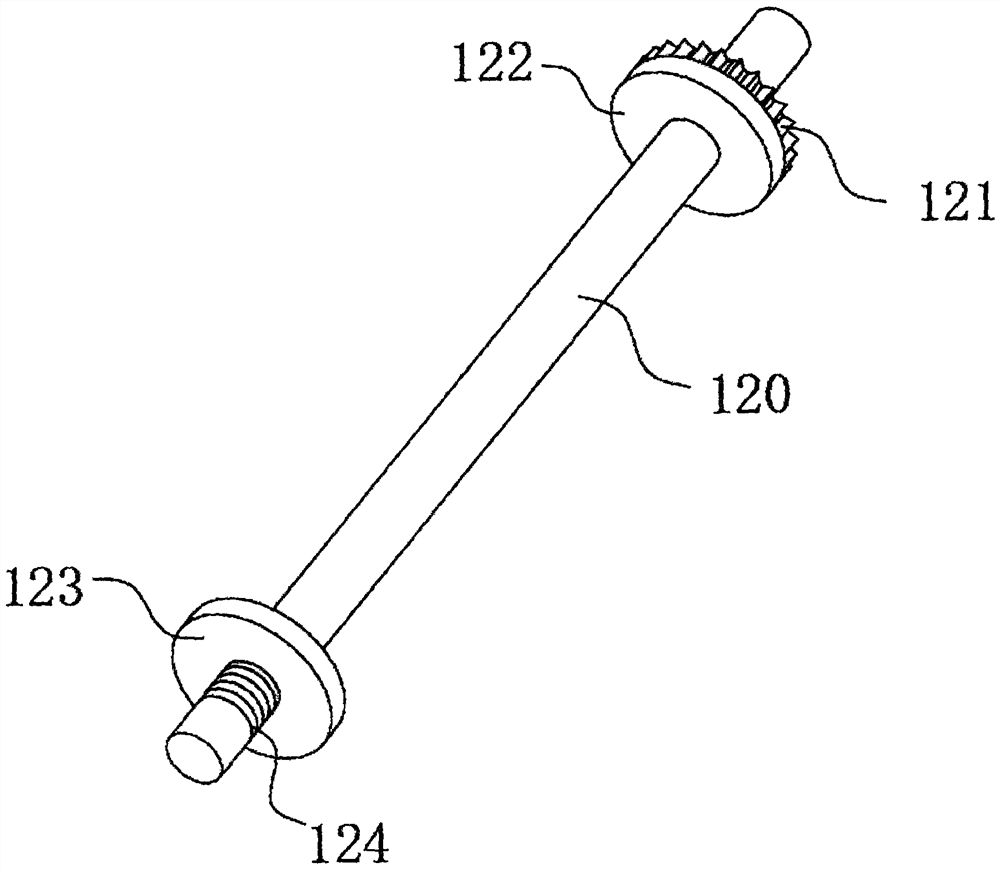

Gear feeding device

ActiveCN106081577AReasonable structureGood spacing effectConveyor partsMechanical conveyorsMaterial supplyEngineering

The invention provides a gear feeding device and belongs to the technical field of machining. The gear feeding device comprises a feeding support, a feeding guide plate, a material supply guide plate, sector-shaped support plates, supporting pin shafts, first baffles and second baffles, wherein the feeding support comprises a front support plate, a rear support plate and a support bottom plate; the front support plate is parallel to the rear support plate; the lower end of the front support plate and the lower end of the rear support plate are connected by virtue of the support bottom plate; the feeding guide plate is obliquely arranged at the right end of the feeding support; the material supply guide plate is obliquely arranged at the left end of the feeding support; the sector-shaped supporting plates are swingably arranged on the feeding support by virtue of the supporting pin shafts and positioned between the feeding guide plate and the material supply guide plate; the gravity centers of the sector-shaped supporting plates are positioned on the right side of the supporting pin shafts; the first baffles are arranged at the lower sides of the left ends of the sector-shaped supporting plates, and the second baffles are arranged at the lower sides of the right ends of the sector-shaped supporting plates. The gear feeding device is capable of realizing certain-interval continuous feeding of gears, and is high in automation degree and good in reliability.

Owner:江苏兴利达齿轮有限公司

Continuous preparation system and method of 3-[N-(2-aminoethyl)]aminopropyl alkoxy silane

The invention discloses a continuous preparation system and method of 3-[N-(2-aminoethyl)]aminopropyl alkoxy silane and belongs to the field of chemical engineering. For solving the problems of poor reaction continuity, high temperature and high pressure demands, servere reaction environment requirements, low cost and unremarkable yield existing in the prior art, the continuous preparation systemof the 3-[N-(2-aminoethyl)]aminopropyl alkoxy silane comprises a distillation tank, wherein the distillation tank form a circular reaction pipeline through a heater, a filling tower and a U-shaped reaction tube which are connected in sequence, and the bottom of the distillation tank is connected with a receiver. By adopting the methods of circular reaction and continuous material supply, product preparation is performed, work under ordinary pressure can be achieved, the environmental requirements are, and the efficiency and yield are high.

Owner:GBXF SILICONES CO LTD

Spinning device for producing chemical fibers and using method of spinning device

InactiveCN112111796AImprove performanceFully filteredSpinning solution de-aeratingSpinnerette packsLiquid storage tankEngineering

The invention discloses a spinning device for producing chemical fibers and a using method of the spinning device. The spinning device comprises a supporting device and a control device, wherein a spinning mechanism is arranged above the supporting device, the control device is arranged on one side of the supporting device, the spinning mechanism comprises a spinning tank, a liquid storage tank isarranged at the upper end of the spinning tank, a servo motor is arranged at the upper end of the liquid storage tank, a liquid inlet pipe is arranged on the side, close to the servo motor, of the liquid storage tank, a rotating shaft is arranged in the liquid storage tank, and auger blades are arranged on the rotating shaft. Through the arrangement of a heating pipe and the auger blades, a chemical fiber solution keeps the optimal performance before spinning, meanwhile, slag in the chemical fiber solution is fully filtered through double filtering of a first filtering frame and a second filtering frame, and thus spinning quality of chemical fiber filaments is improved; Through the corresponding arrangement of a distribution plate and a spinneret plate, the chemical fiber solution firstlyfills liquid storage holes and then enters spinneret holes again, continuous feeding of the chemical fiber solution in a chemical fiber spinning process is guaranteed, and production efficiency and quality of the chemical fibers are improved.

Owner:浙江长兴天盛化纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Continuous preparation system and method of 3-[N-(2-aminoethyl)]aminopropyl alkoxy silane Continuous preparation system and method of 3-[N-(2-aminoethyl)]aminopropyl alkoxy silane](https://images-eureka.patsnap.com/patent_img/2e1d2b85-fc3f-4502-ab63-30a19e903807/HDA0001427048520000011.png)