Feeding device for metal nano-powder production

A technology of metal nano-powder and metal block, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of low efficiency of nano-metal powder, slow feeding speed and unable to guarantee automatic production, etc., to reduce oxygen content and improve feeding Efficiency, the effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

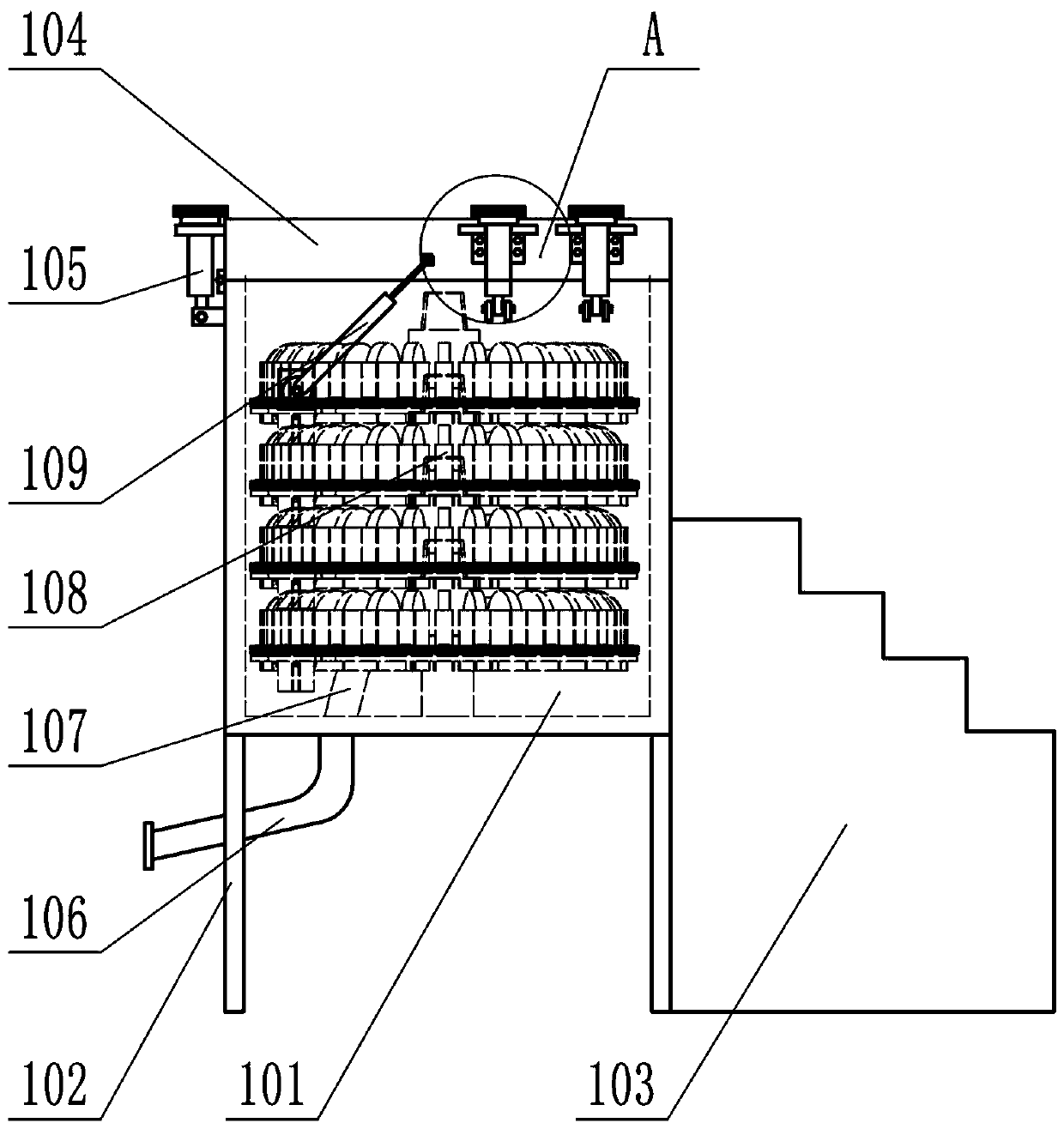

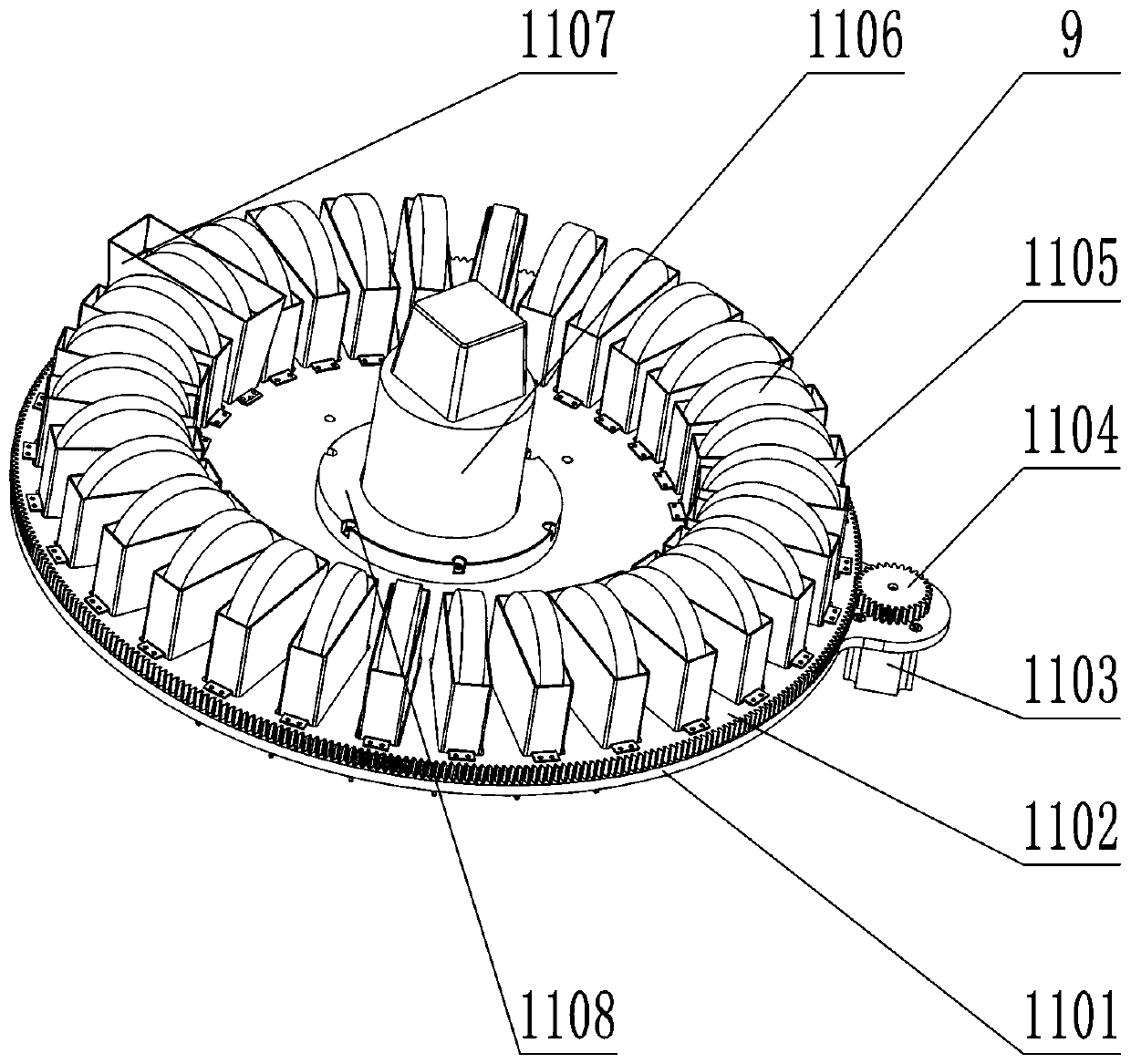

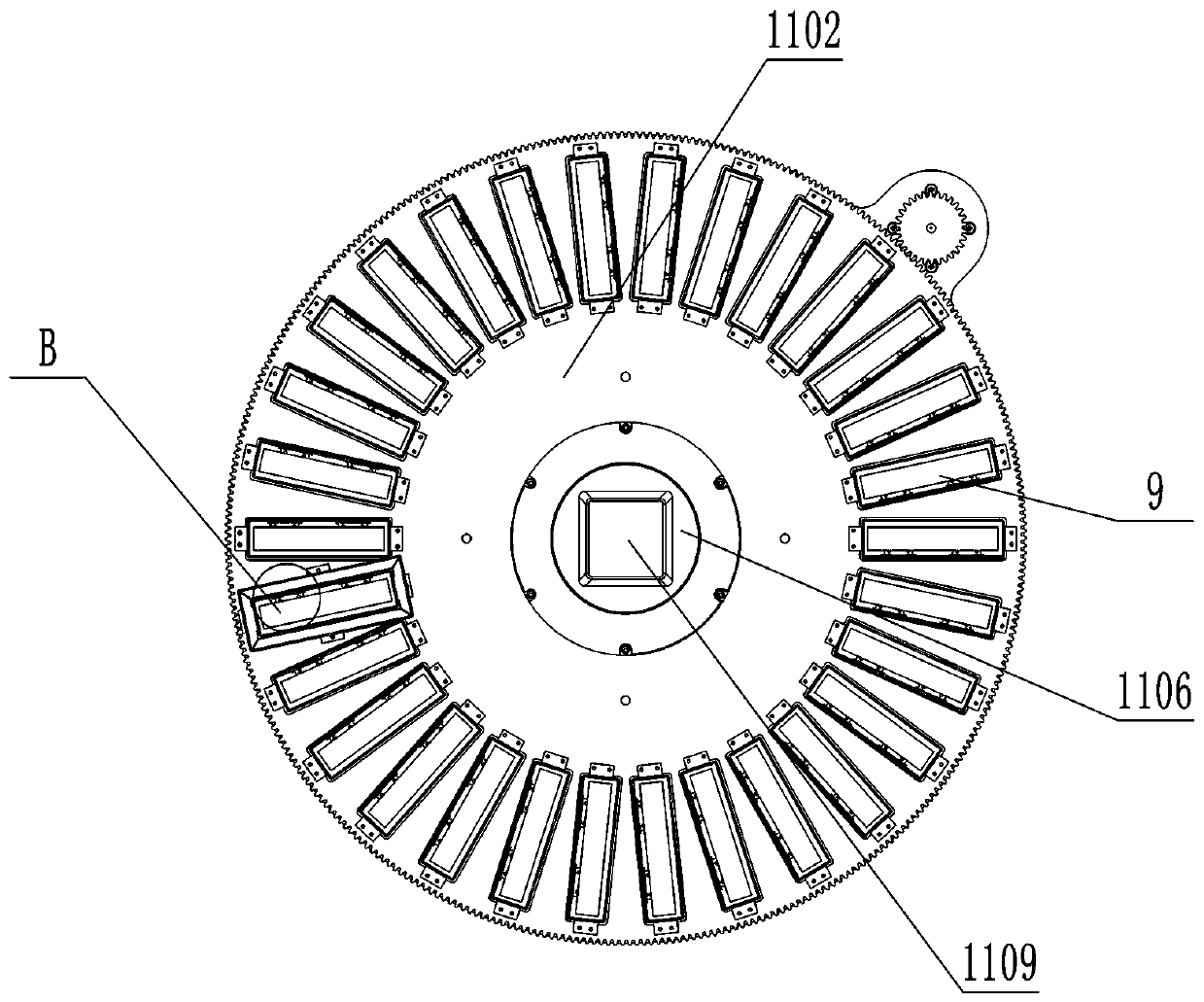

[0030] Such as Figure 1-8 As shown, a feeding device for metal nano powder production includes a box body 101, the top of the box body 101 is hinged and sealed with a box cover 104, the back of the box cover 104 is hinged with the box body 101 through a hinge, and the left and right sides of the box cover are symmetrical. A drive cylinder 109 for opening the box cover is installed, one end of the drive cylinder 109 is hingedly installed on the outer wall of the box body, and the other end of the drive cylinder 109 is hingedly installed on the outer side wall of the box cover, and the drive cylinder is used to drive the box cover and the box body , can reduce the labor intensity of the operator, and at the same time ensure the safety during the opening process of the box cover. The operator can supplement the production raw materials in the box through the openable and closed box cover. One side of the hinged end of the box cover is equipped with a feeding step ladder 103. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com