Patents

Literature

160results about How to "Guaranteed vacuuming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

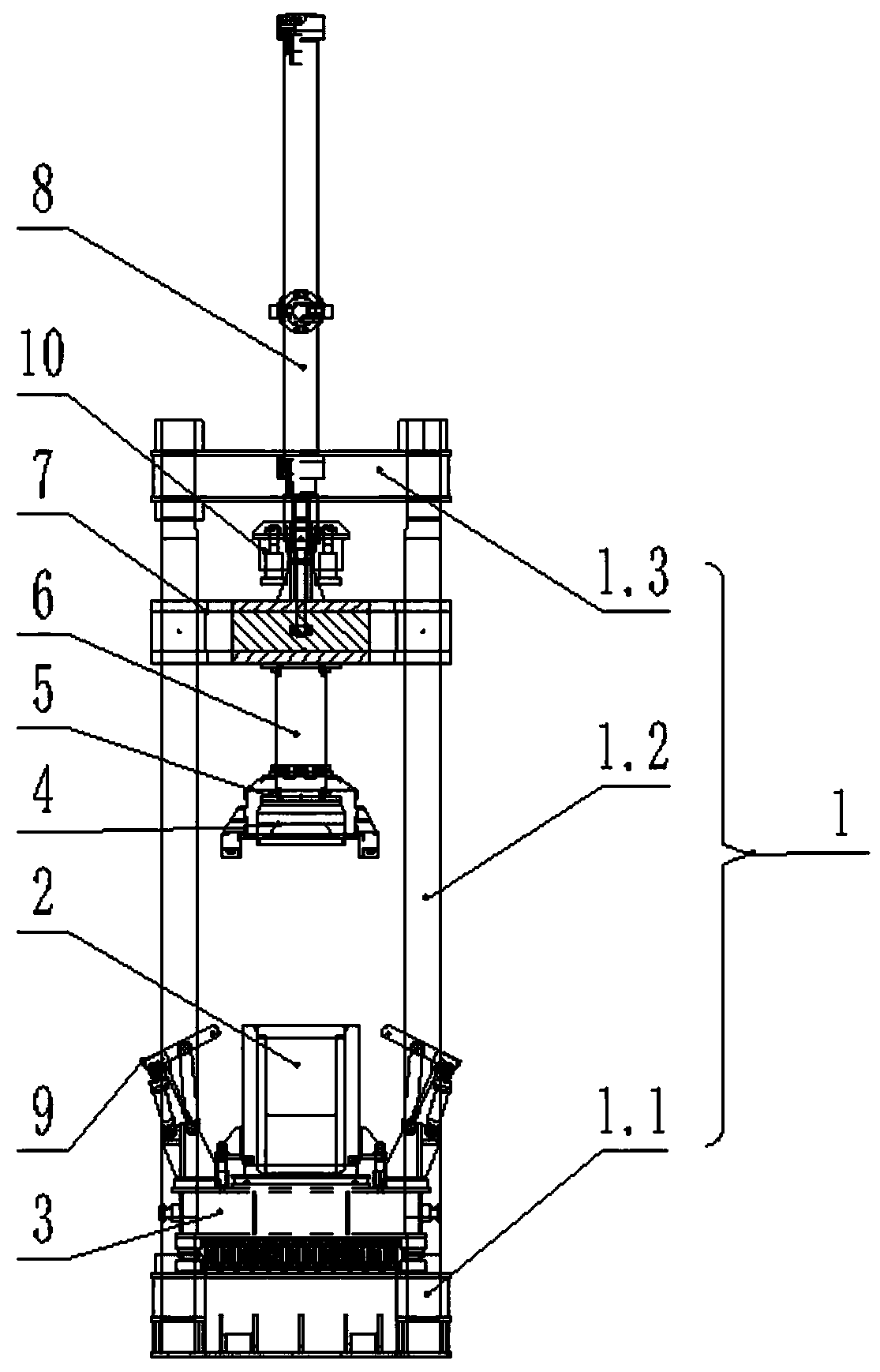

Wall-climbing robot for removing rust on wall surfaces of ships and working method thereof

InactiveCN101704241ARealize high-altitude and heavy-duty operationsImprove adsorption capacityProgramme-controlled manipulatorCleaning using liquidsDrive motorEngineering

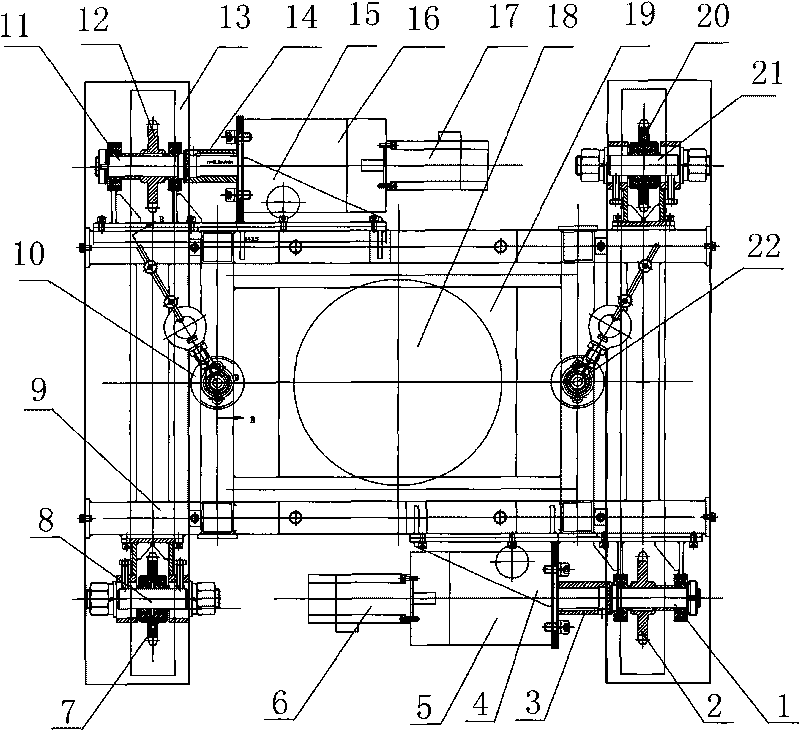

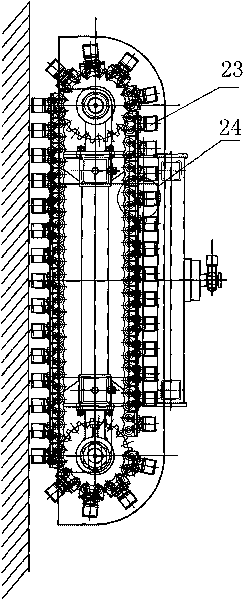

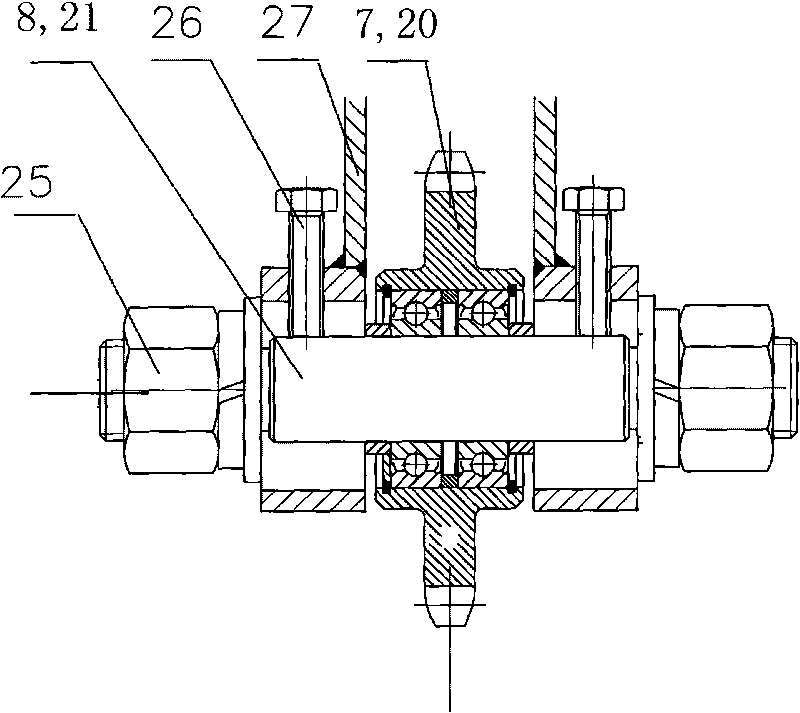

The invention discloses a wall-climbing robot for removing rust on wall surfaces of ships and a working method thereof. The wall-climbing robot comprises a frame, a chain track walking mechanism, a permanent magnetic adsorption unit, a left-upper drive motor, a left-upper decelerator, a right-lower drive motor and a right-lower decelerator, wherein the chain track walking mechanism consists of a left chain track and a right chain track, the permanent magnetic adsorption unit is mounted on the chain track walking mechanism, and an ultrahigh pressure water jet vacuum rust-removing cleaner is externally connected with a vacuum source and the permanent magnetic adsorption unit to form vacuum permanent magnetic mixed adsorption. The method comprises the steps of regulation of the tension of chains, height adjustment and movement control. In the invention, by adopting the vacuum permanent magnetic mixed adsorption mode to design the wall-climbing robot and effectively utilizing and recycling negative pressure of the rust vacuum in combination with permanent magnetic adsorption force, the wall-climbing robot achieves reliable adsorption, safe working and compact adsorption structure and is capable of realizing working with large load at high altitude.

Owner:DALIAN MARITIME UNIVERSITY

Efficient pouring machine and repair method for highway cracks

The invention relates to an efficient pouring machine and a repair method for highway cracks, and belongs to the technical field of pavement repair. The machine comprises a pouring machine body and anasphalt spray gun matched with the pouring machine body for use, wherein an armrest is arranged at the rear end of the pouring machine body; a mounting rack is arranged at the front end of the pouring machine body, and the lower end of the asphalt spray gun extends to the lower part of the mounting rack; the asphalt spray gun comprises a guide pipe and a gun head, a pressure-turning channel shifting group is arranged at the joint of the guide pipe and the gun head, width of the pressure-turning channel shifting group is reduced gradually from front to back, multiple channels are distributed in the pressure-turning channel shifting group, inside dimensions of the channels on the front side are larger than those of the channels on the rear side, and the lower end surface of the pressure-turning channel shifting group is a convex arc surface; a slide plate capable of sliding oppositely to the convex arc surface is mounted at the upper end of the gun head, and the other end of the gun head extends to the lower part of the mounting rack. On the basis that crack width changes irregularly, the cracks with different widths can be filled in a targeted manner by the machine capable of adapting to crack width change.

Owner:HEBEI ROAD & BRIDGE GROUP

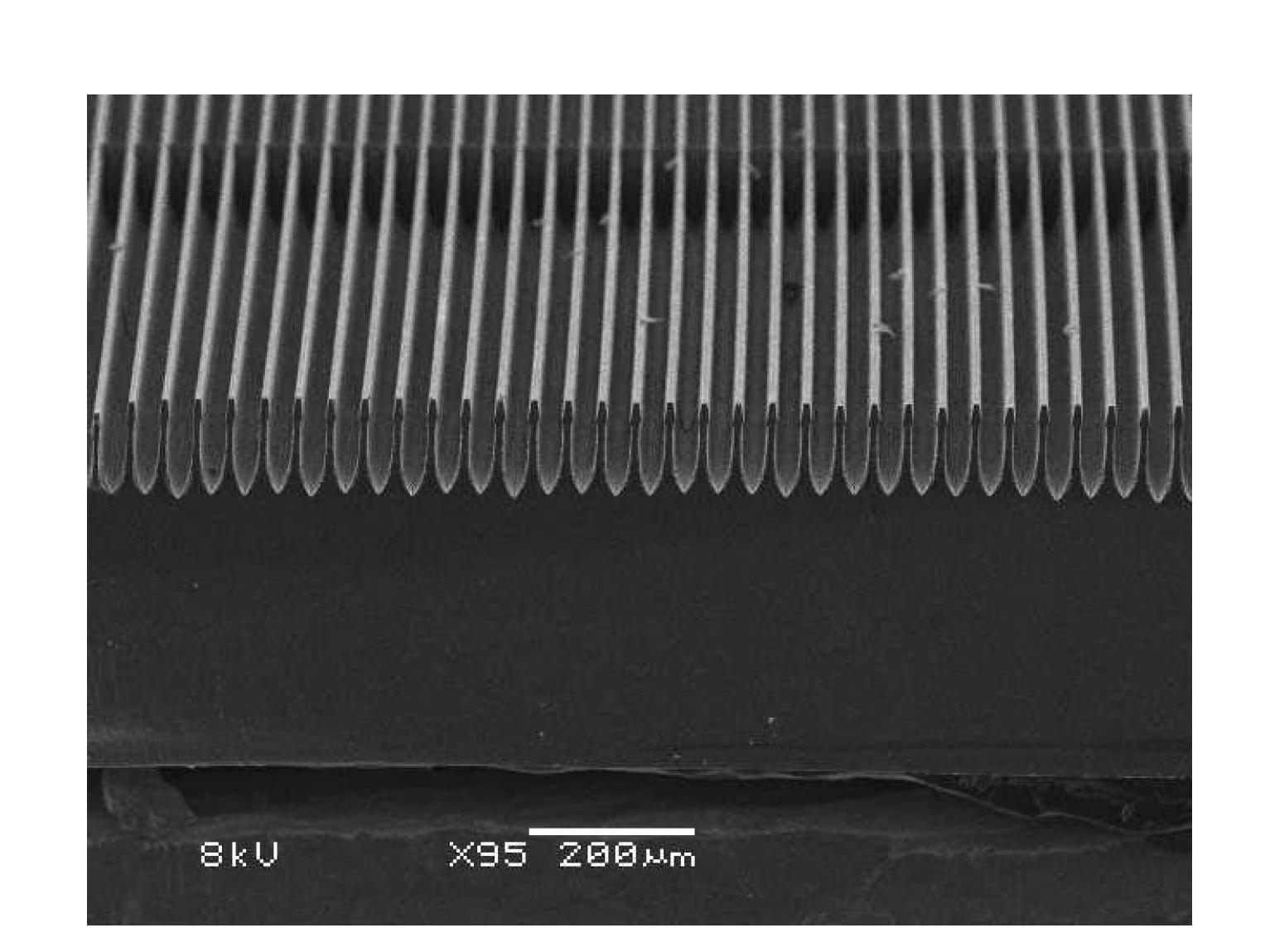

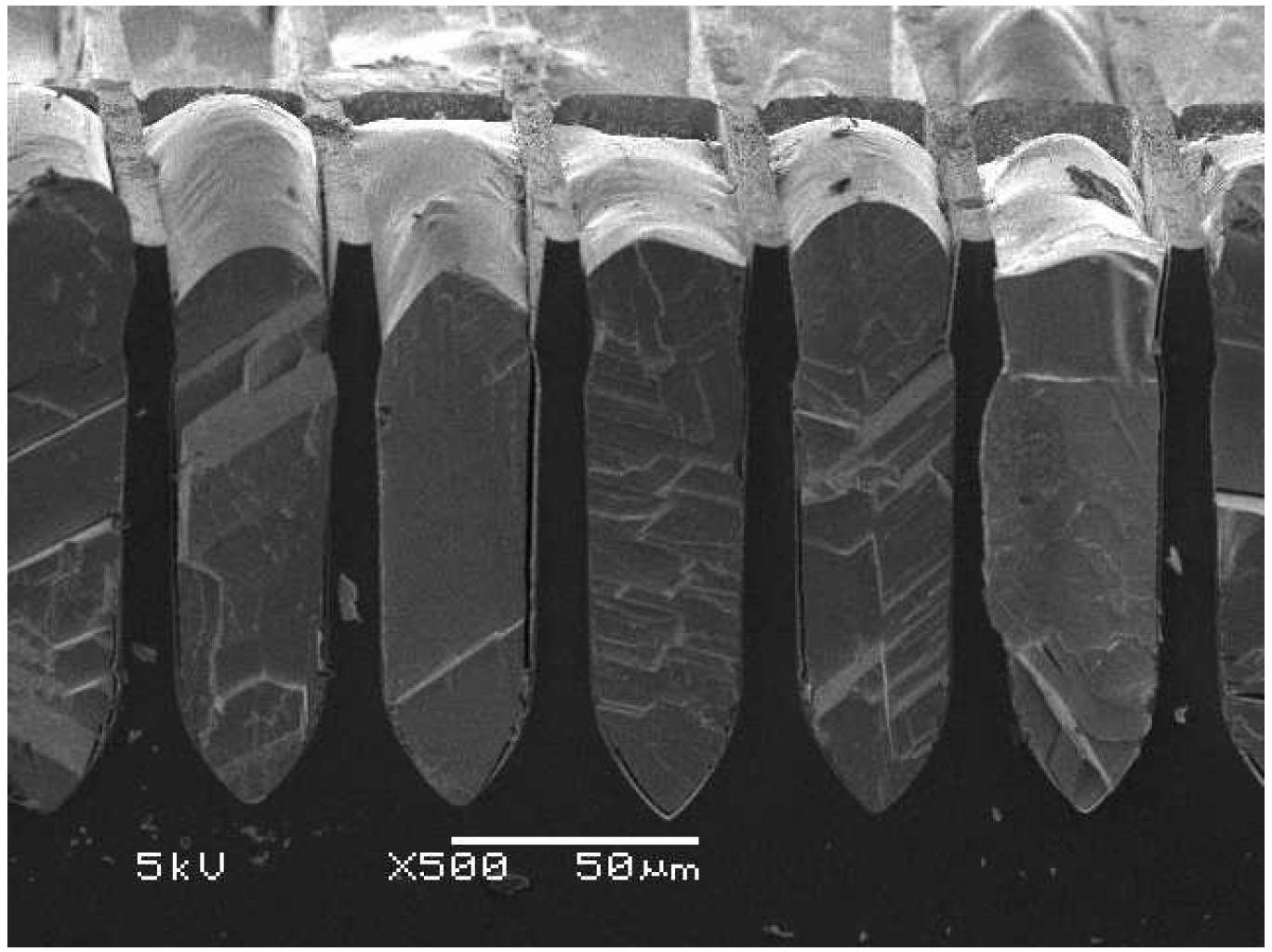

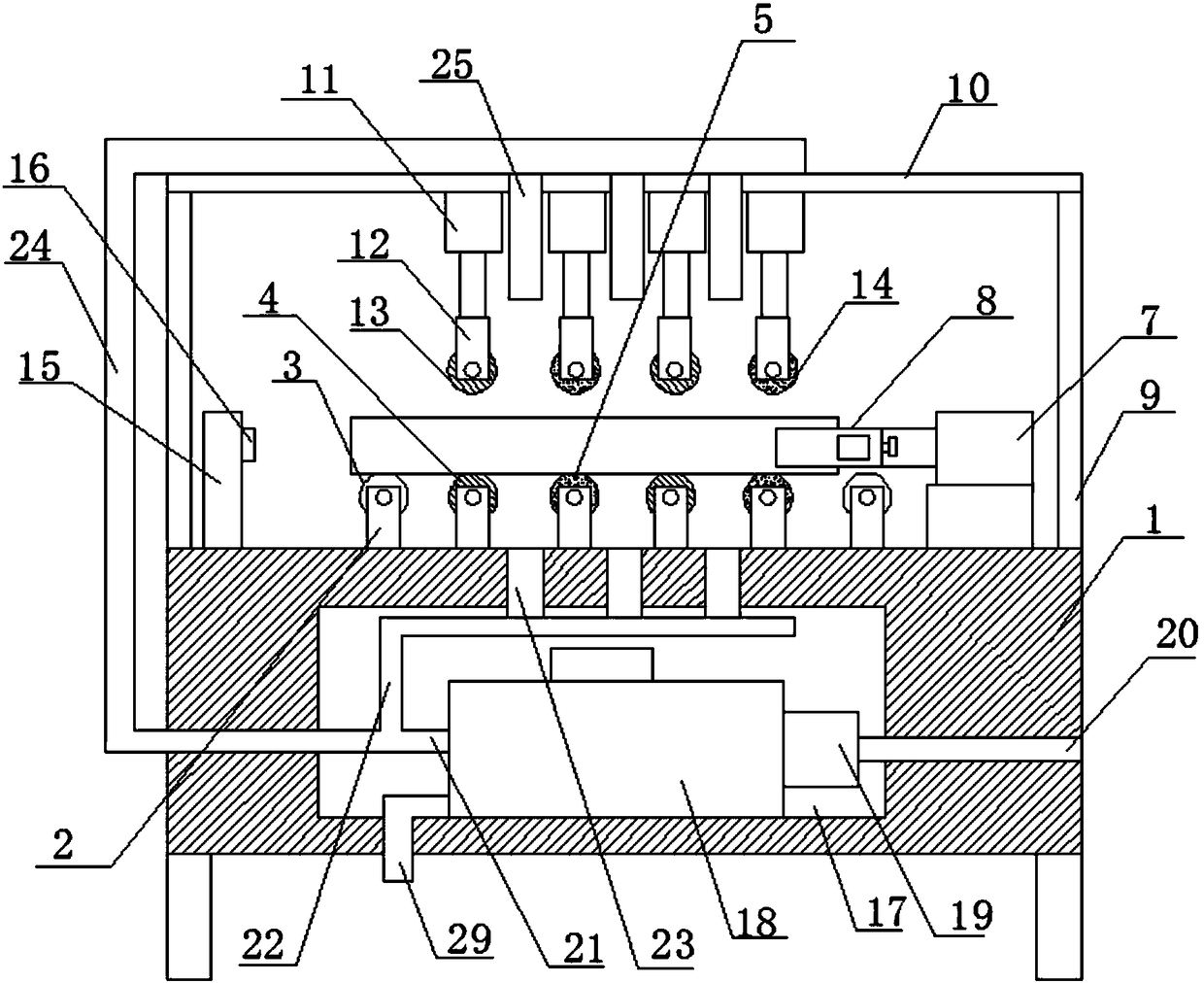

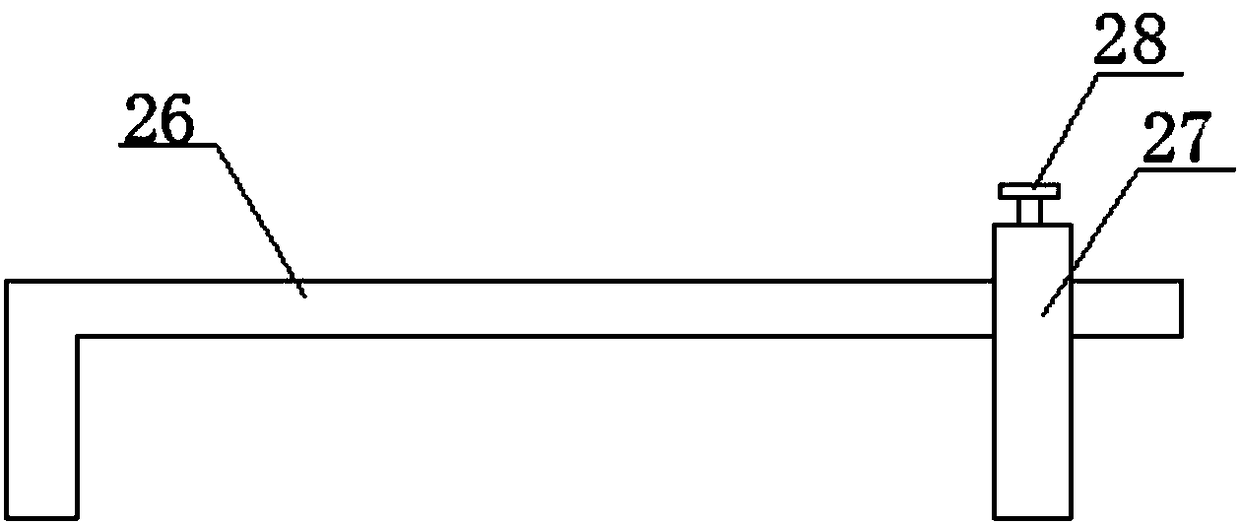

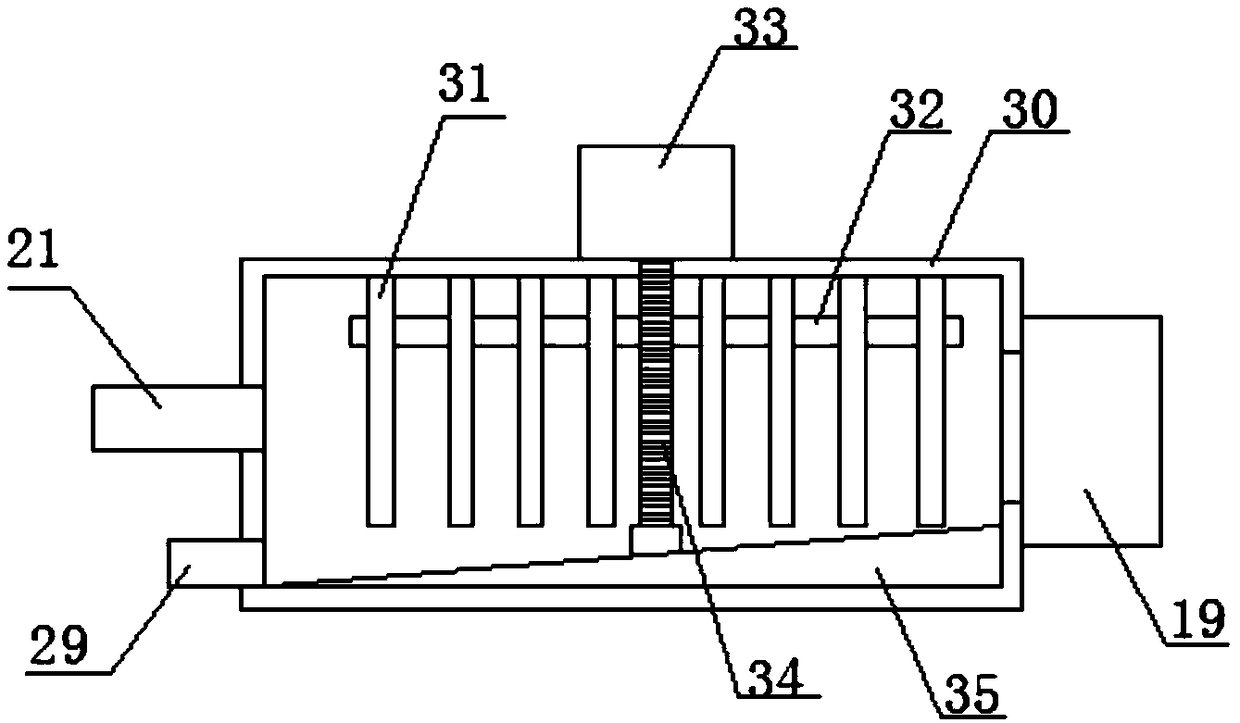

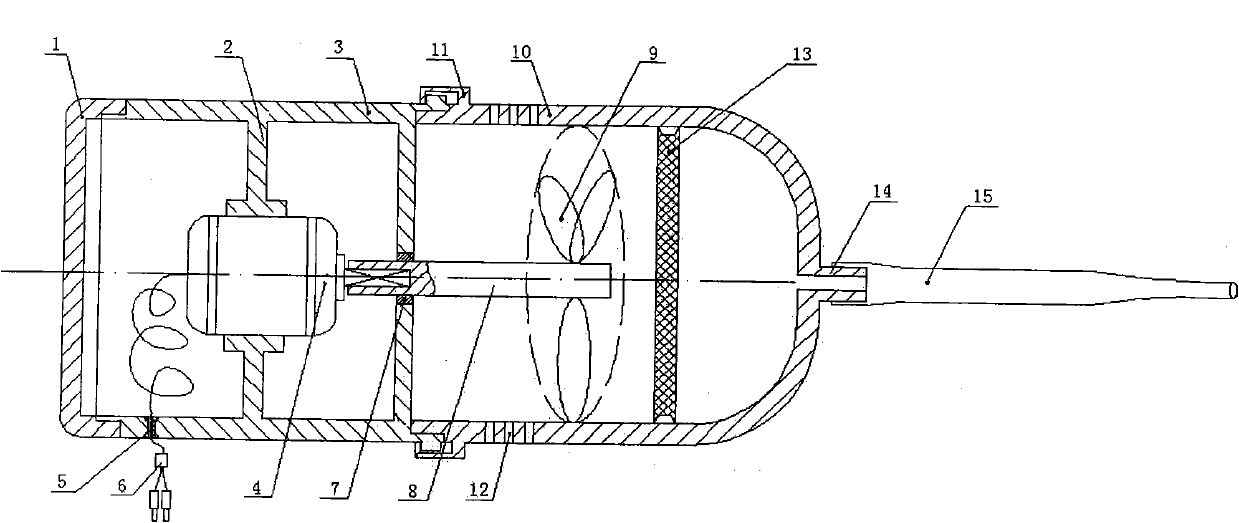

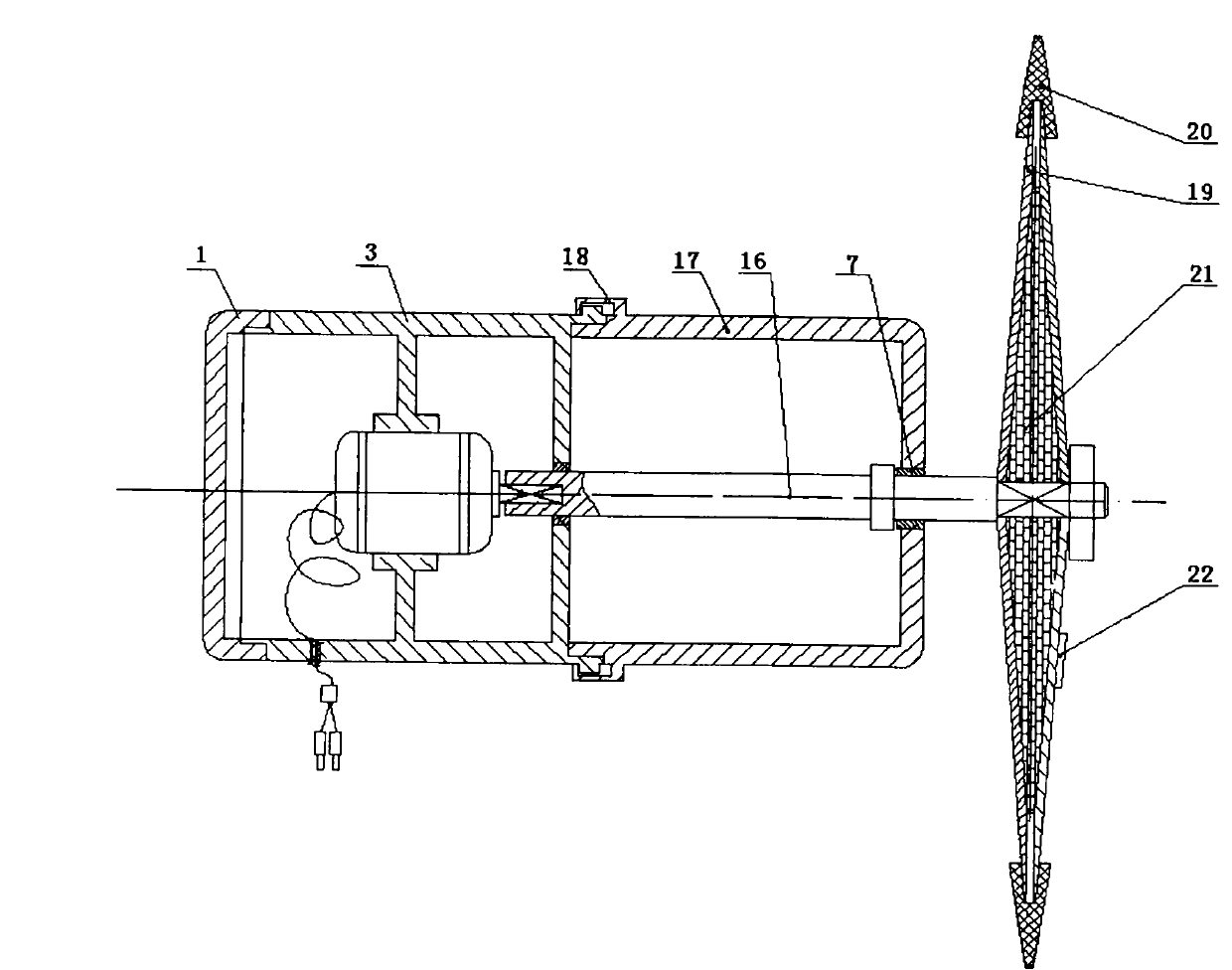

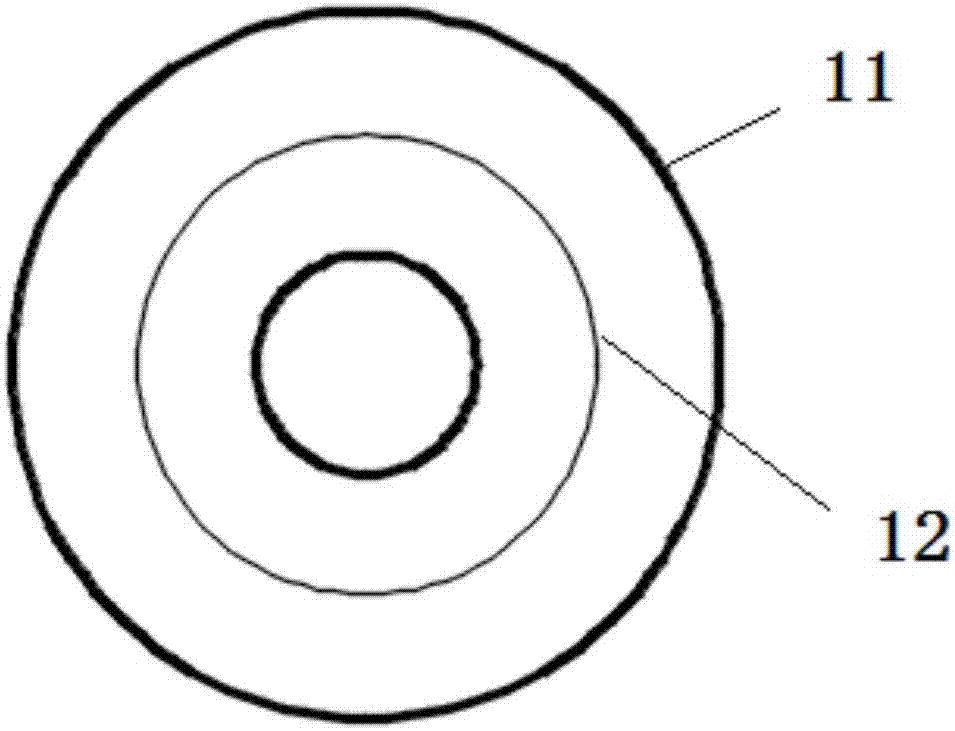

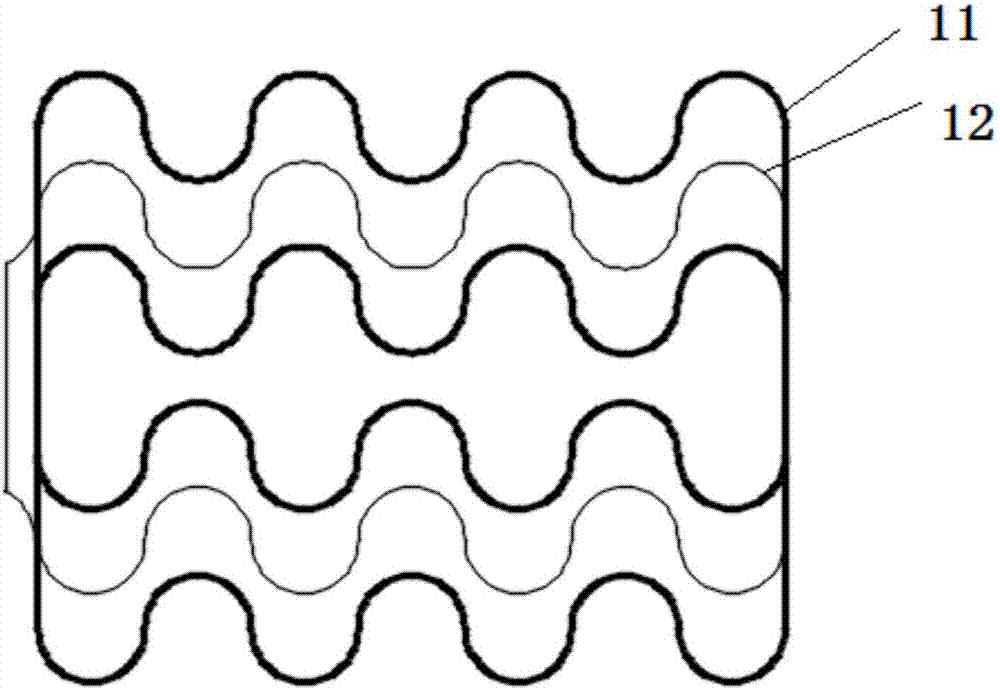

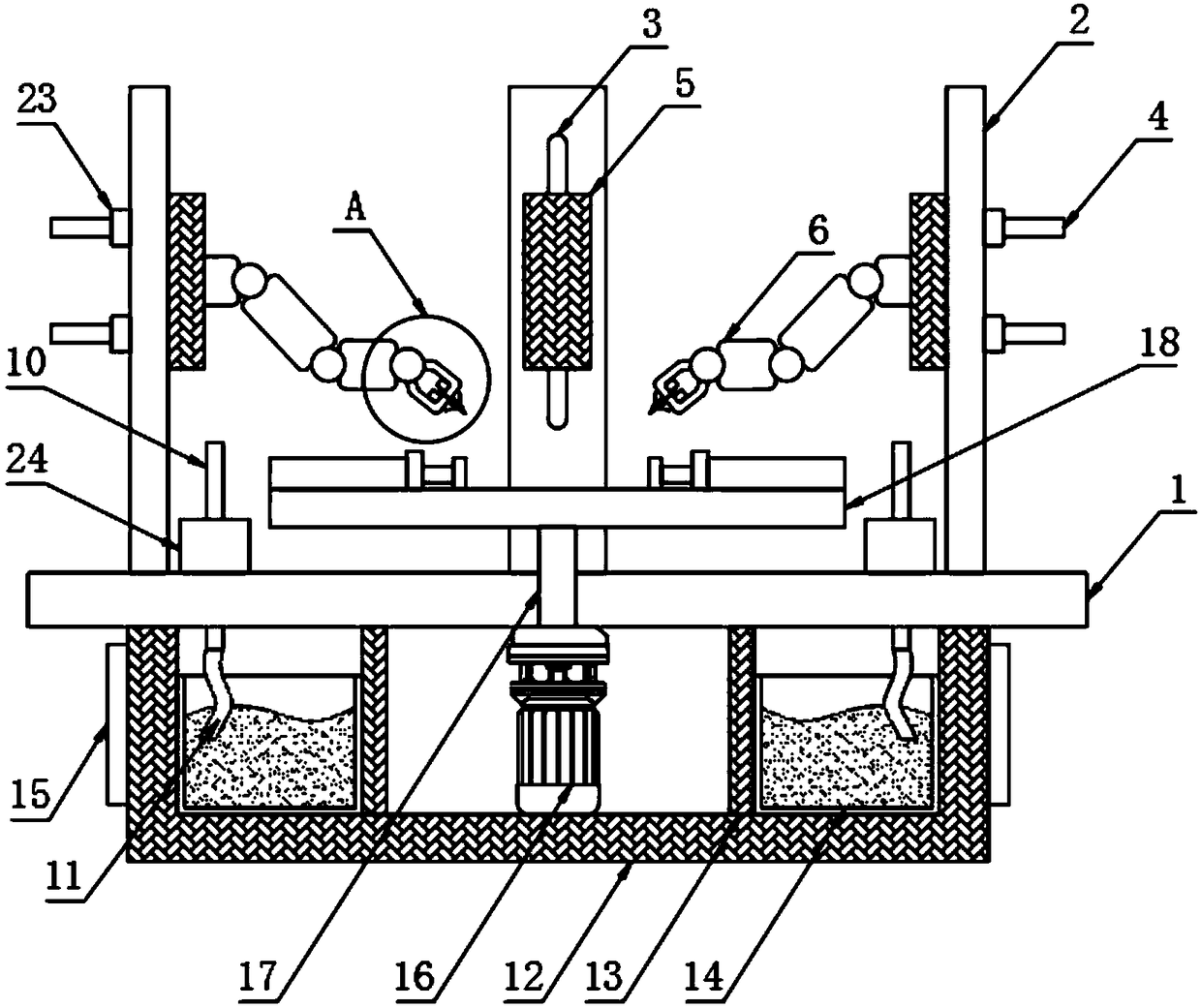

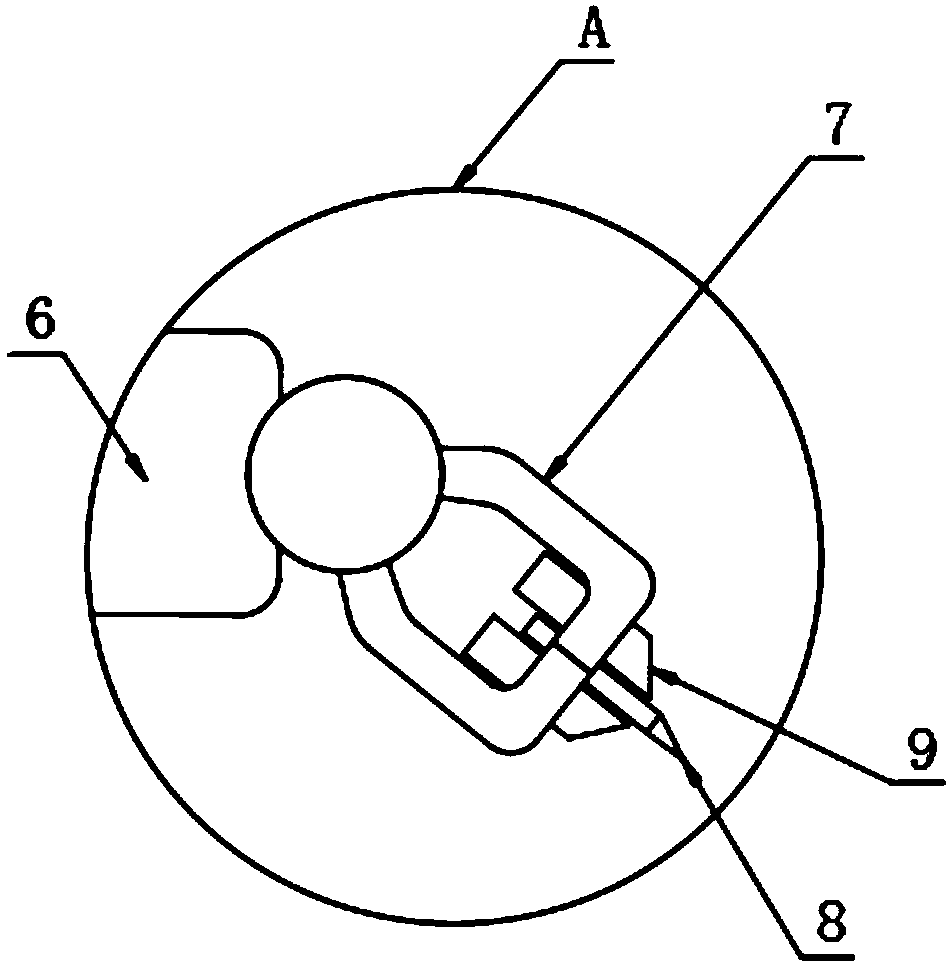

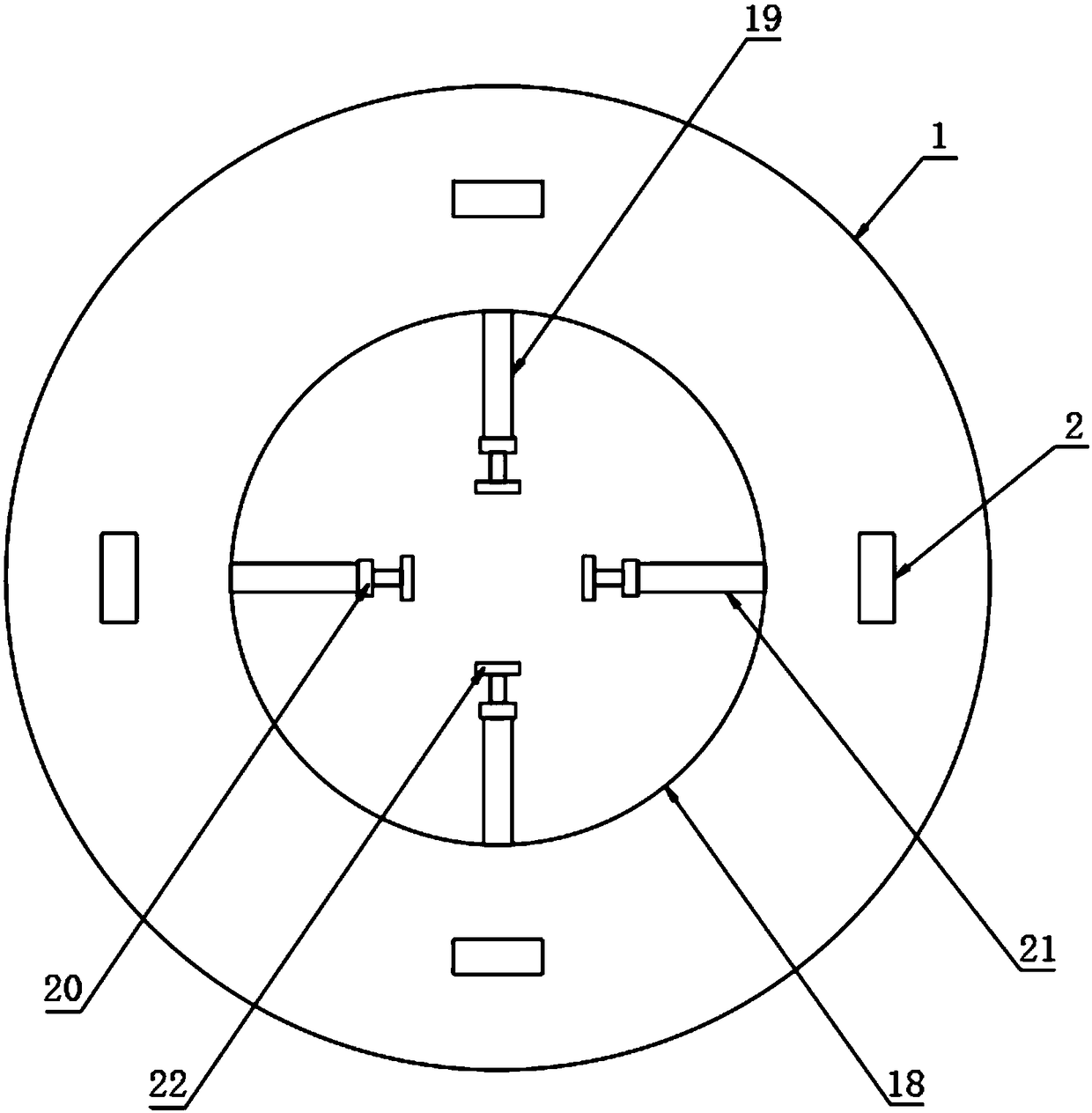

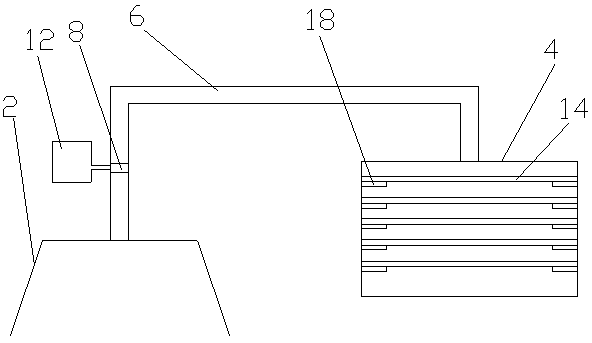

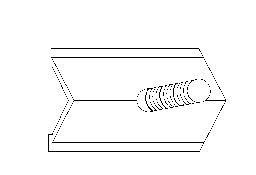

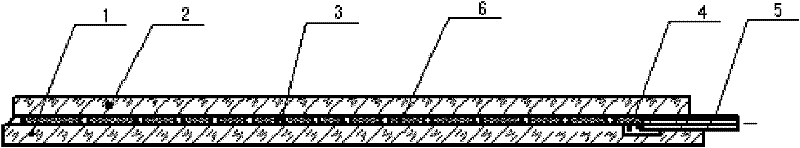

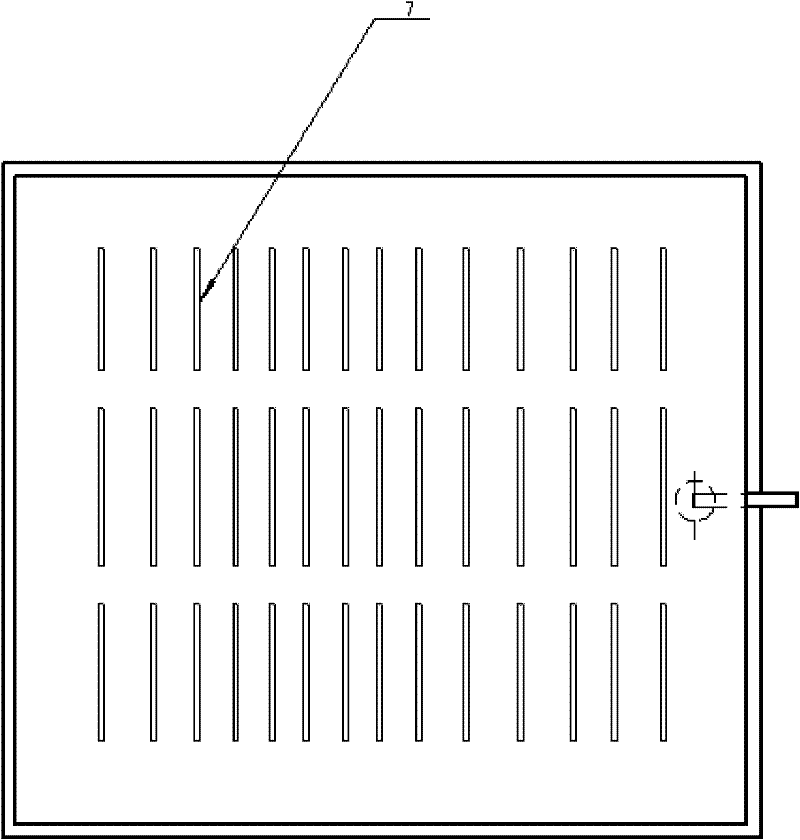

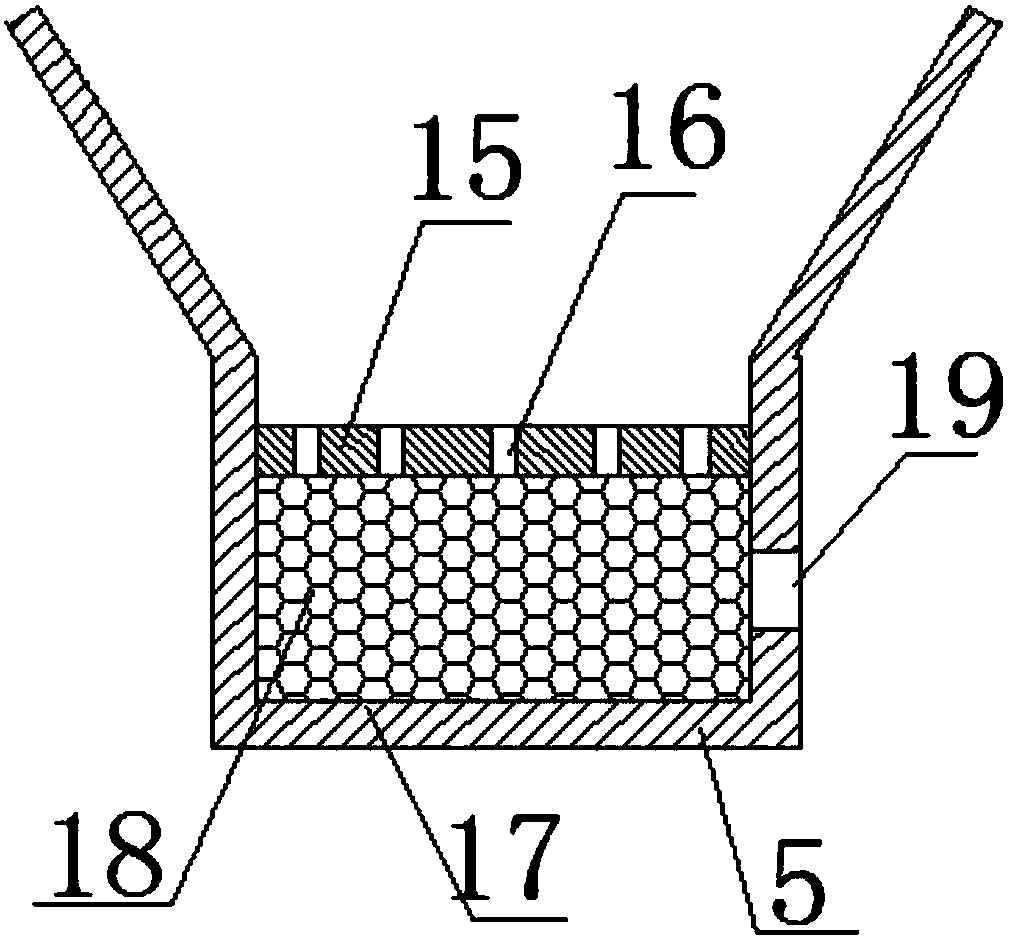

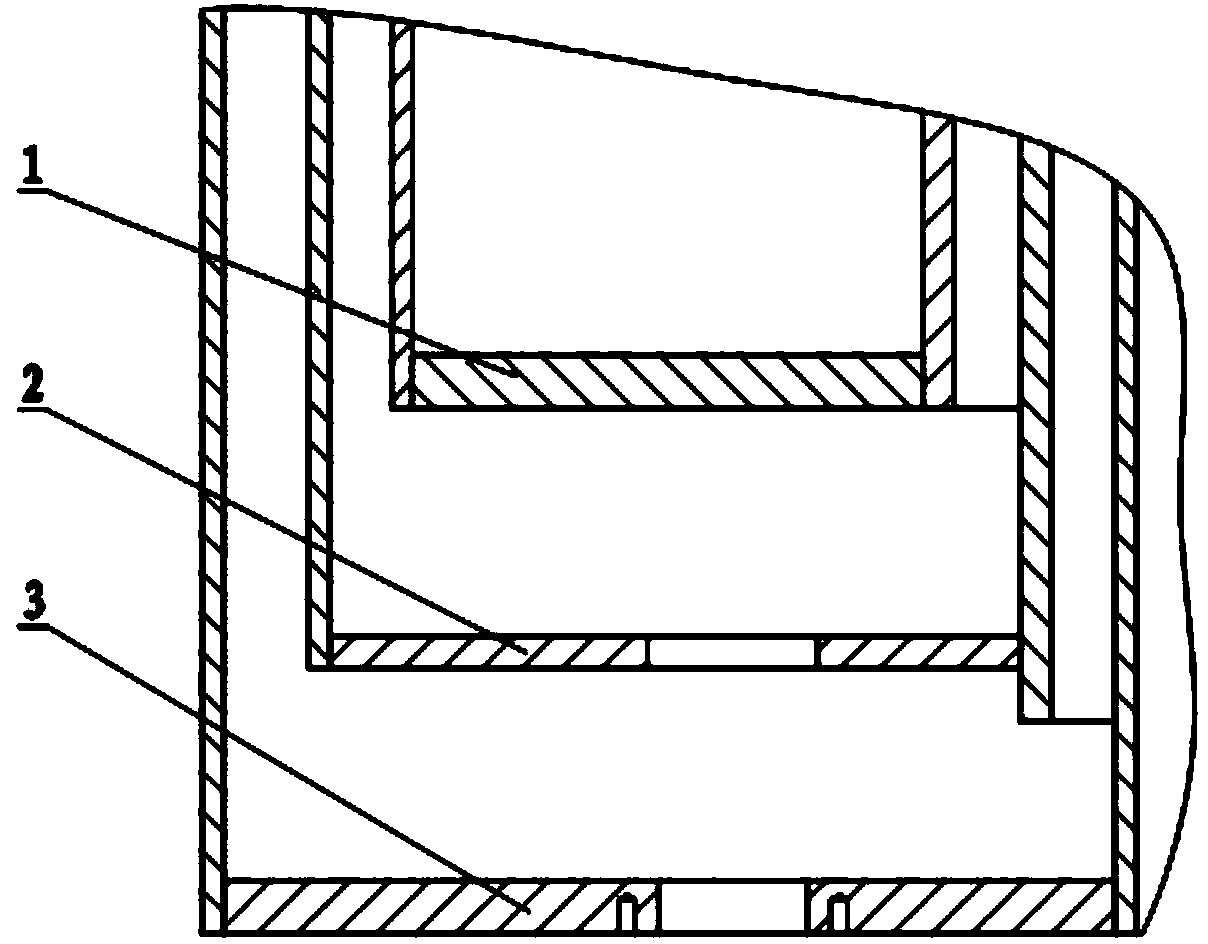

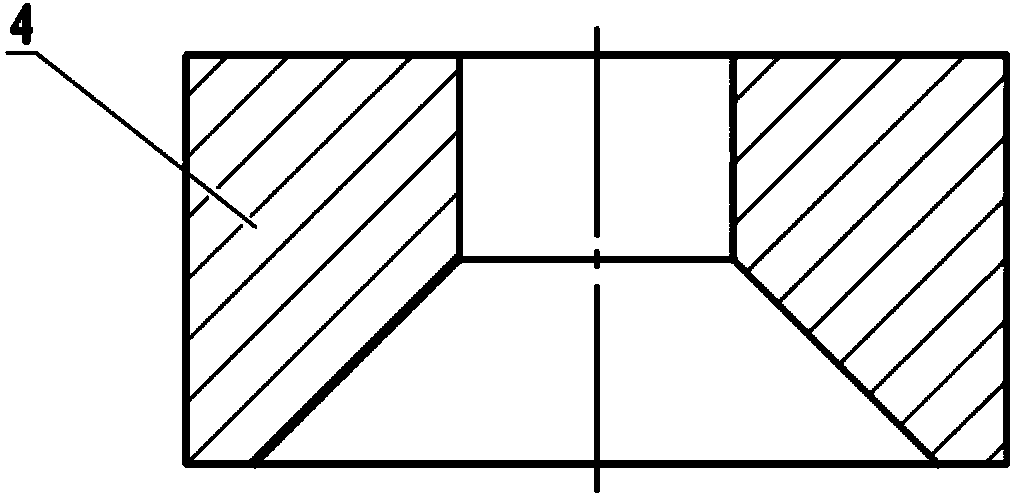

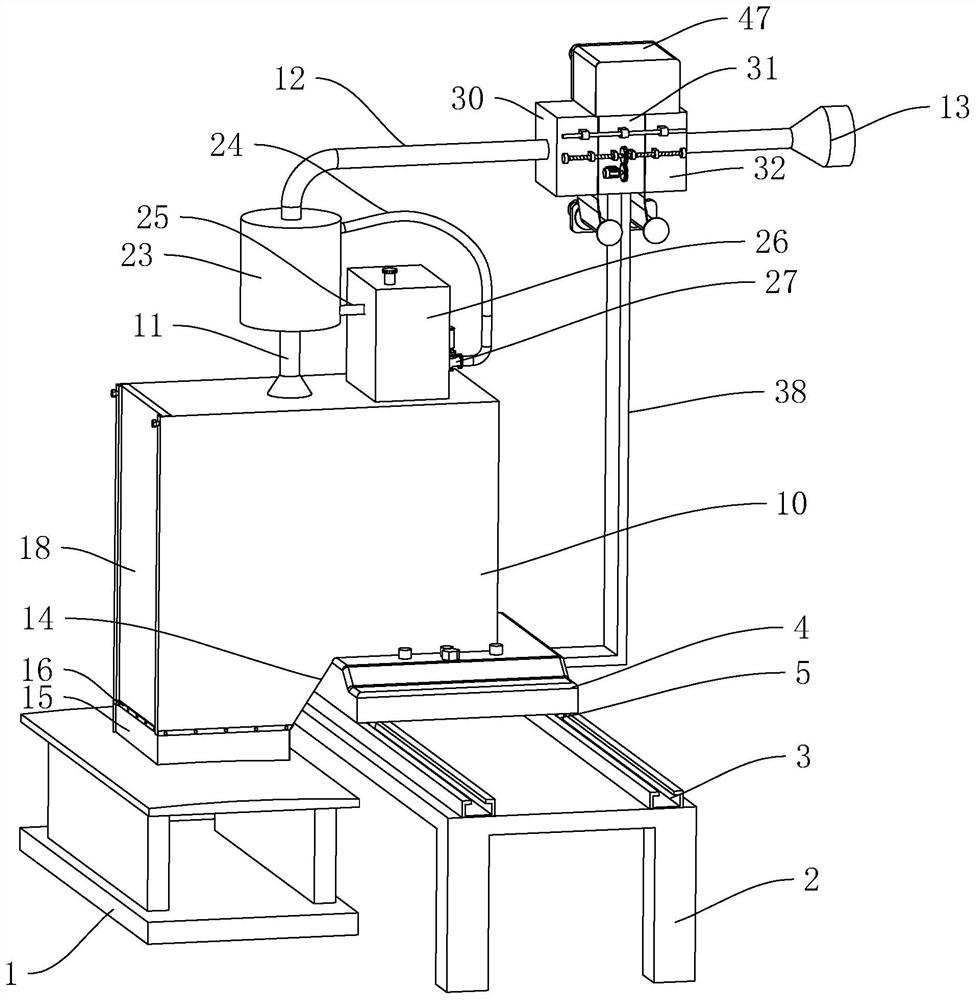

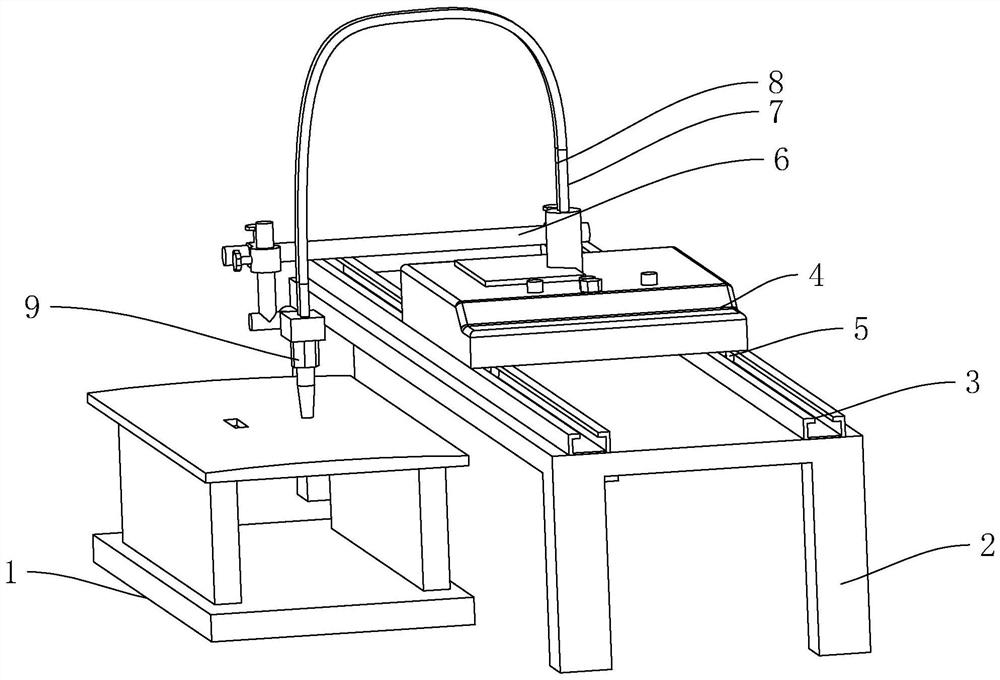

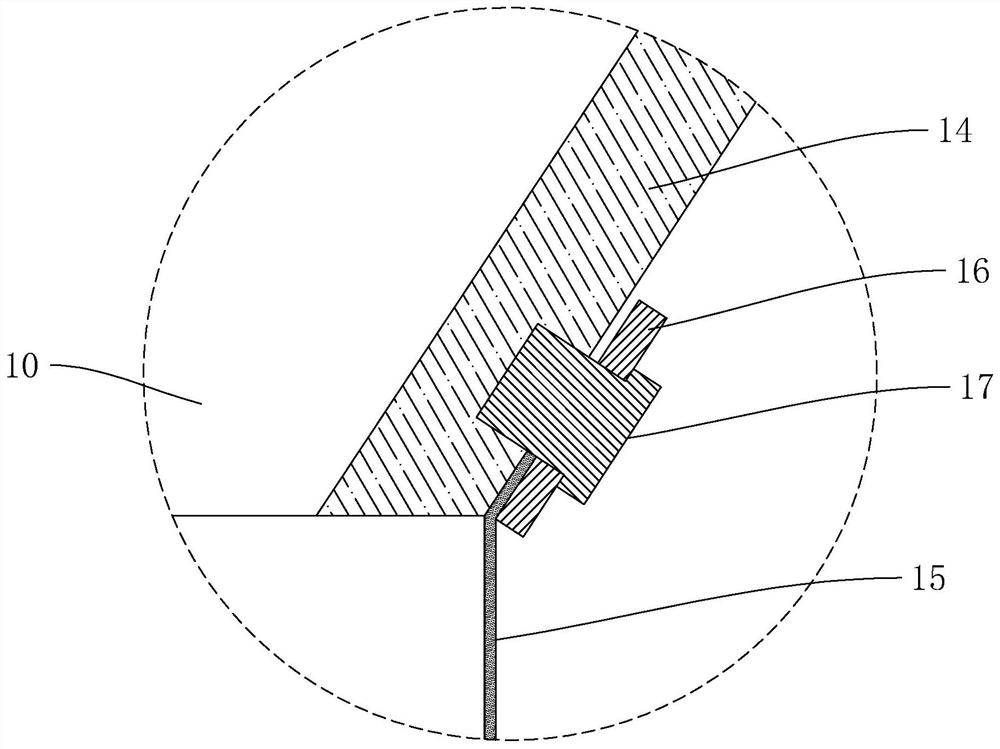

X-ray absorption grate manufacturing method and filling device thereof

InactiveCN102664054AGuaranteed vacuuming effectEvenly filledHandling using diaphragms/collimetersX-rayGas-filled tube

The invention discloses an X-ray absorption grate manufacturing method and a filling device thereof. The manufacturing method comprises the following steps of: firstly depositing and photoetching a Si3N4 film on the surface of a silicon slice, and manufacturing a transparent electrode on the other surface of the silicon slice; protecting the transparent electrode, corroding a silicon substrate to obtain a V-shaped channel; etching a groove with a high aspect ratio abrupt structure; modifying the surface of the silicon substrate and the inner wall surface of the groove; sinking the silicon substrate into molten heavy metal under vacuum for filling to obtain a X-ray absorption grate. The filling device consists of a sealing furnace body, a vacuumizing mechanism and a gas filling mechanism; and the sealing furnace body is internally provided with a filling pool, a heating mechanism, a hoisting mechanism and a supporting mechanism, an exhaust pipe opening is arranged on the sealing furnace body and connected with the vacuumizing mechanism, a gas filling pipe opening and a gas discharging pipe opening are arranged on the sealing furnace body, and the gas filling pipe opening is connected with the gas filling mechanism. According to the invention, the manufacturing method is simple for steps, easy to realize in common laboratory and capable of manufacturing grates of any area, and the filling device can perform high-quality filling on the silicon substrate.

Owner:SHENZHEN UNIV

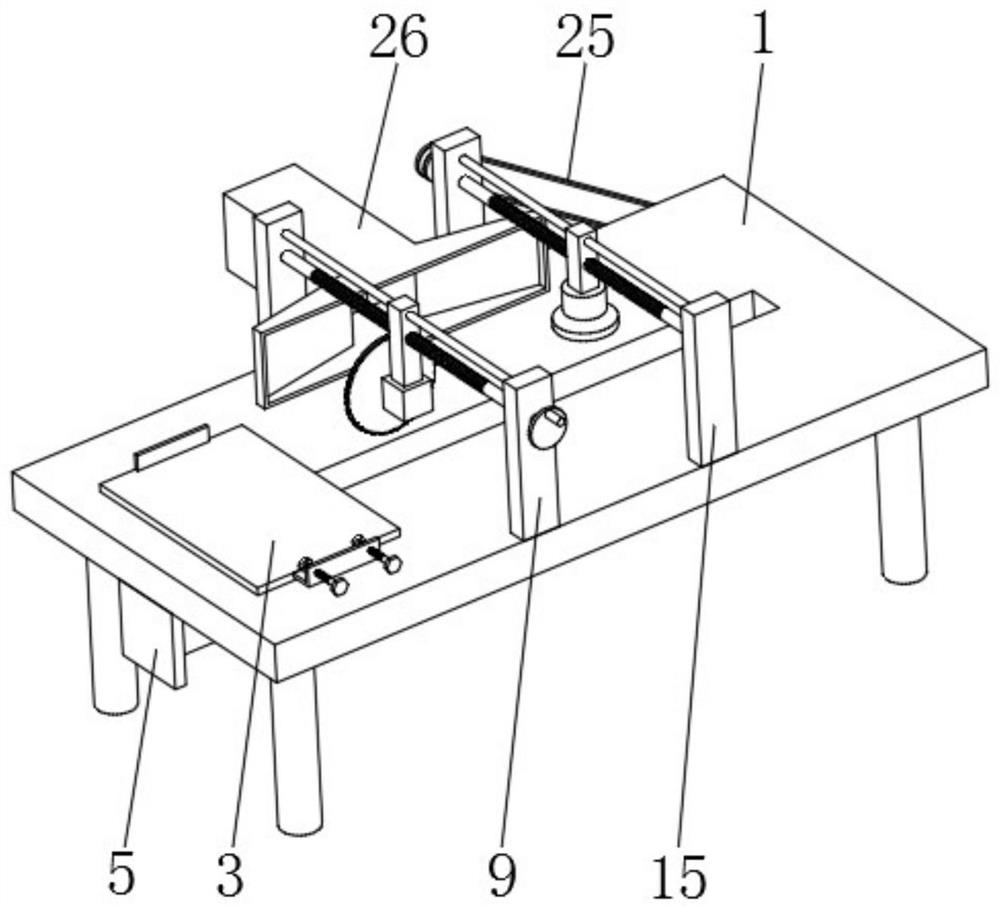

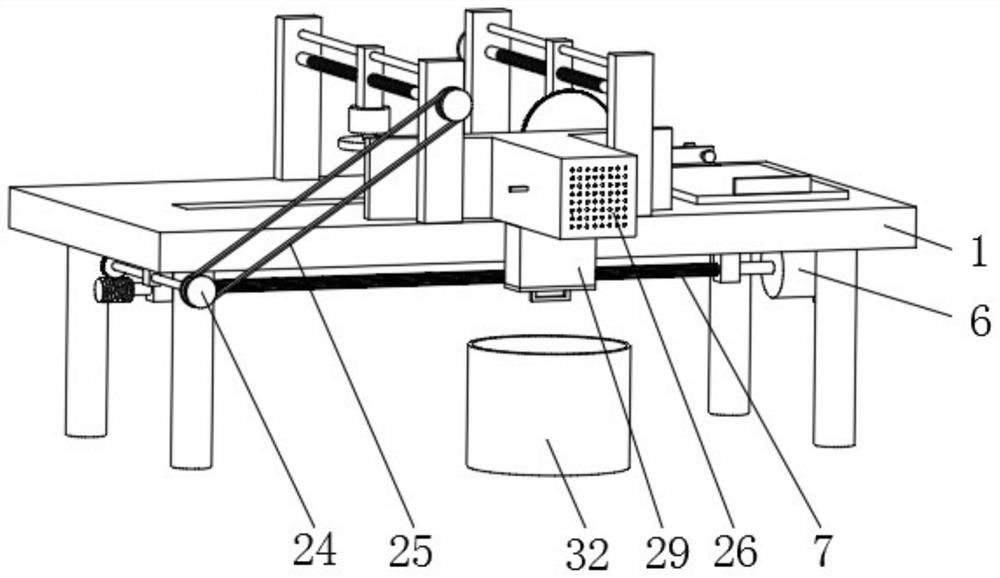

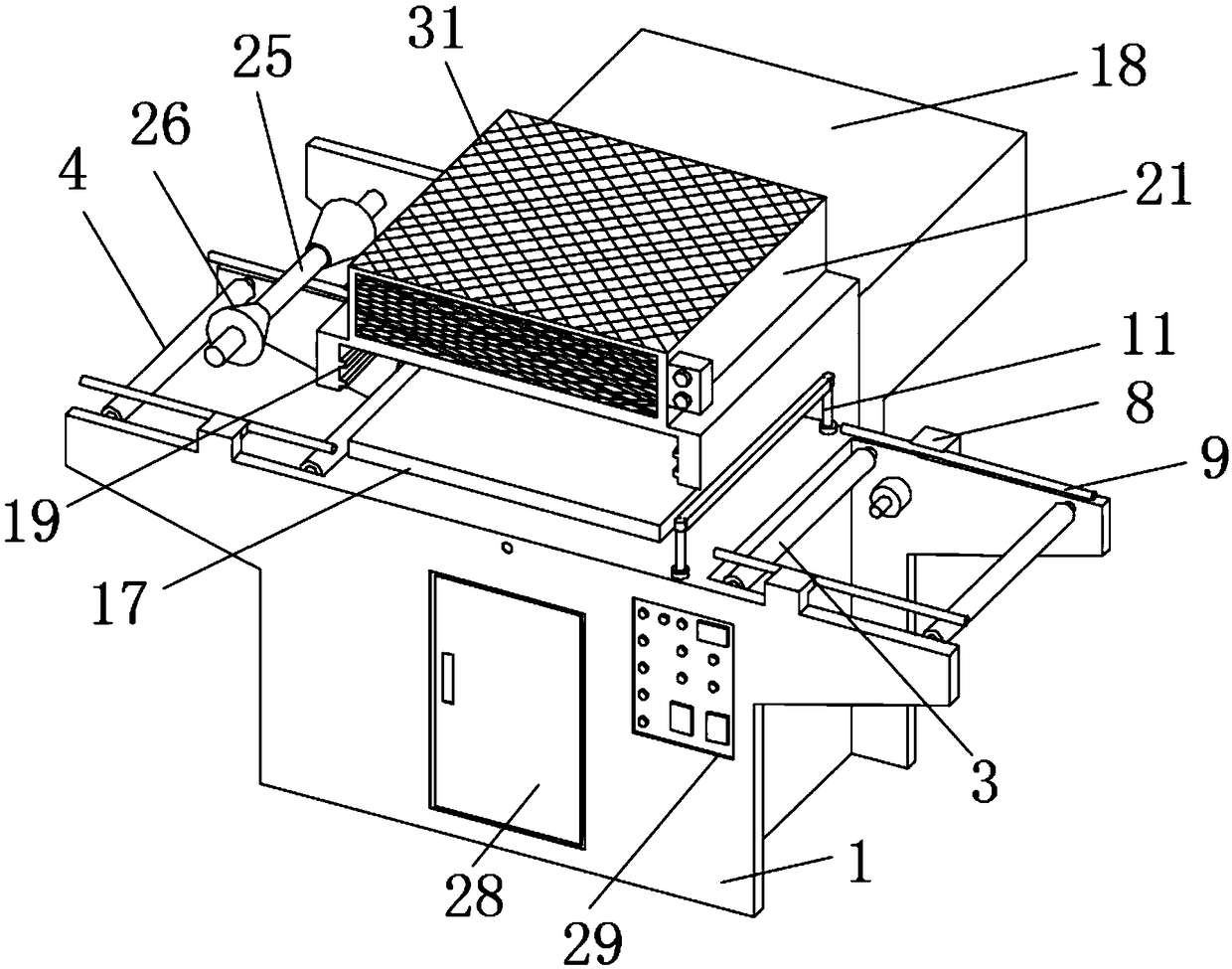

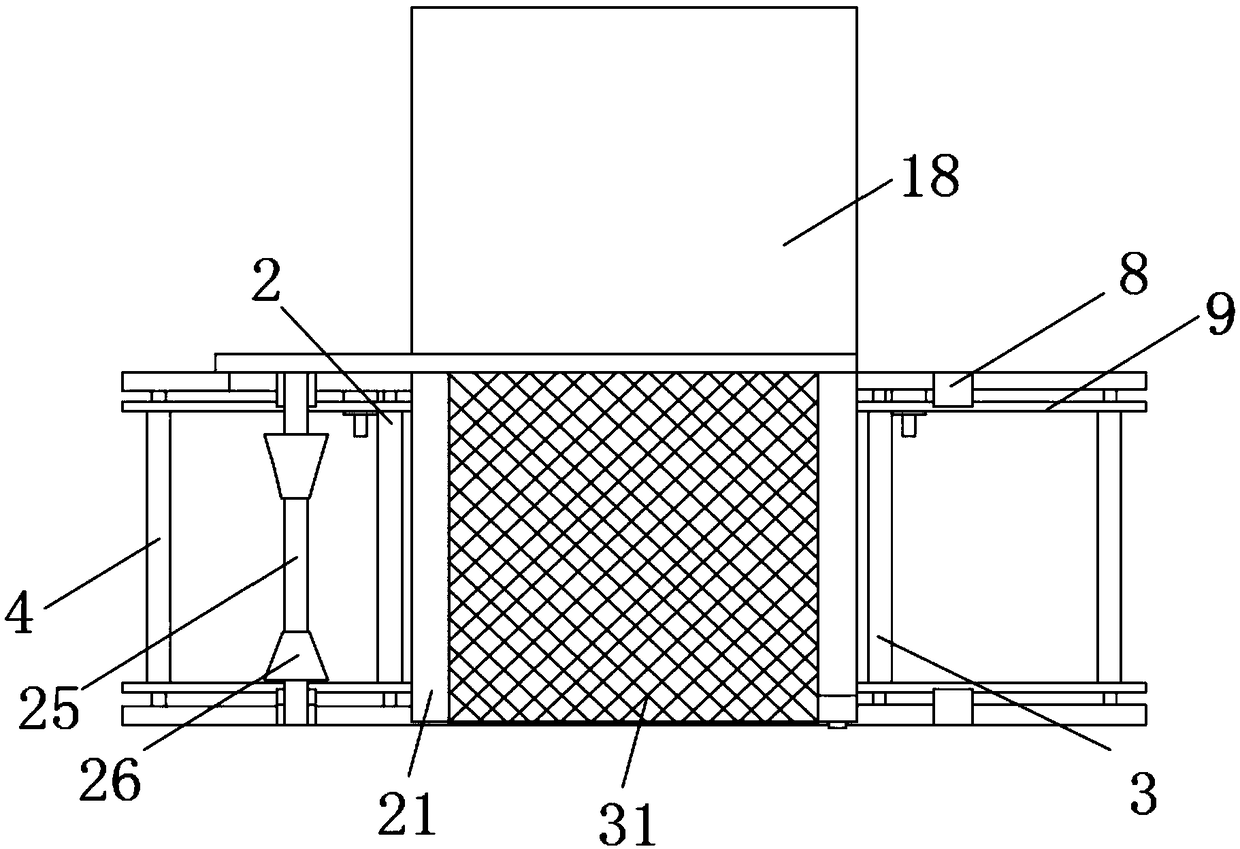

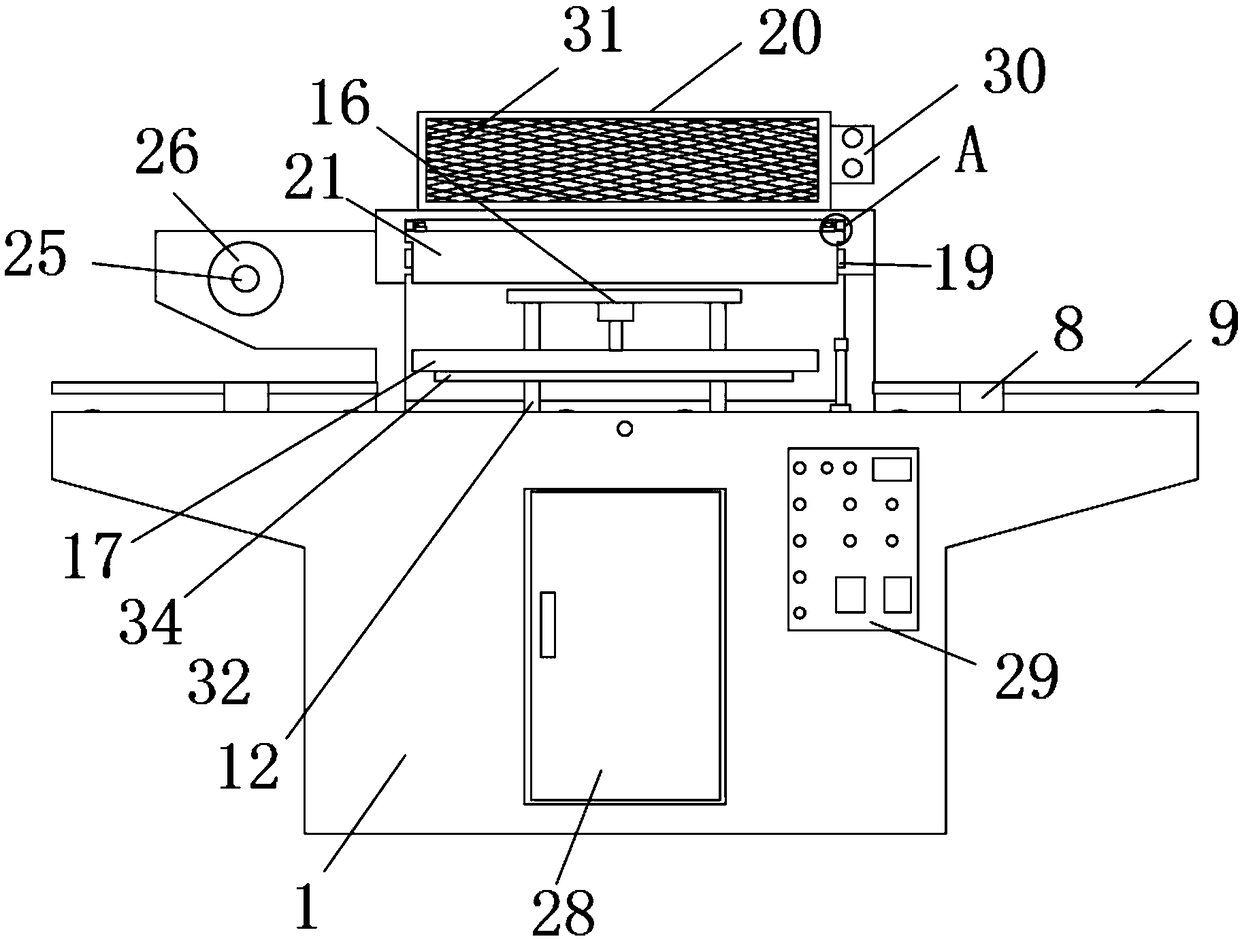

Wood polishing equipment for furniture processing

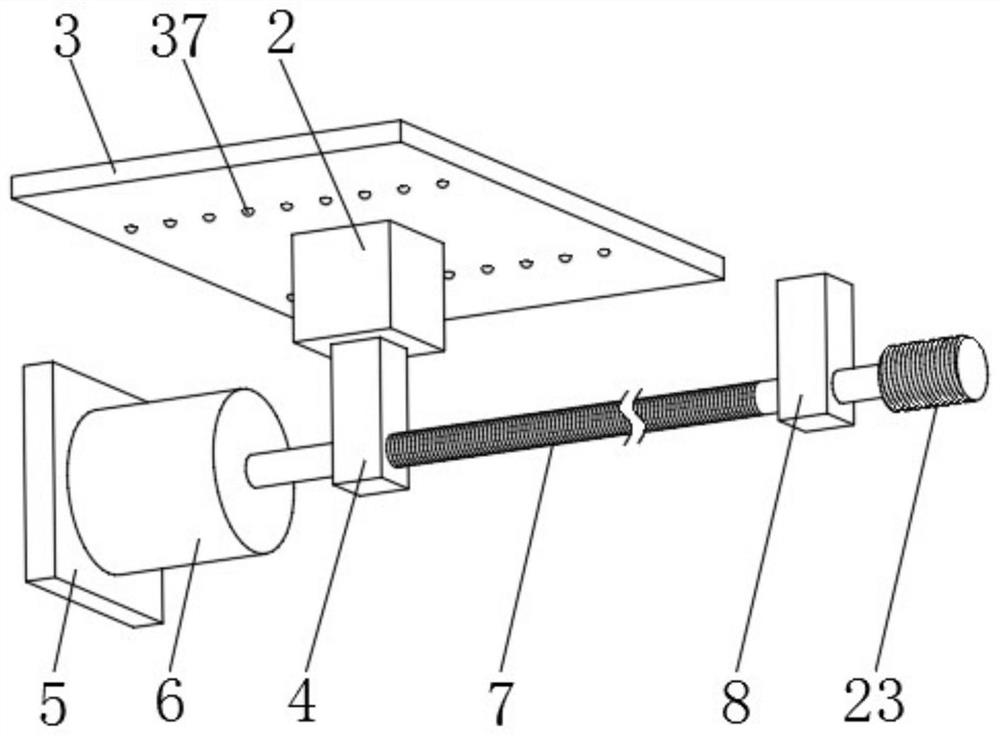

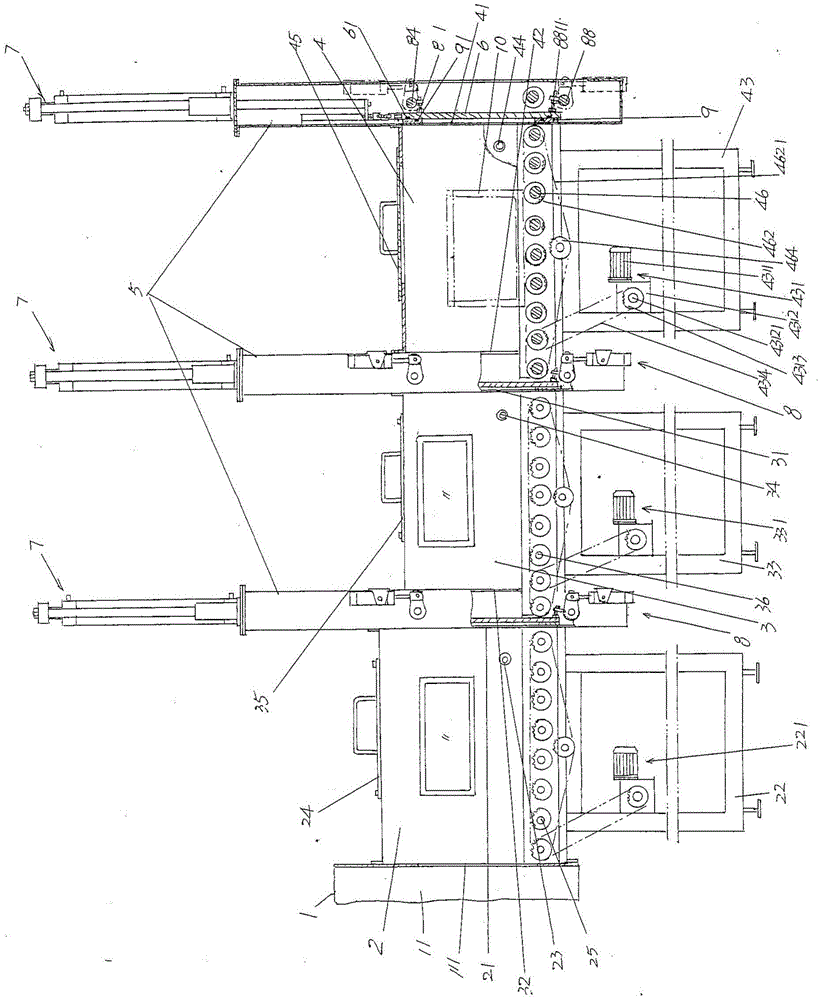

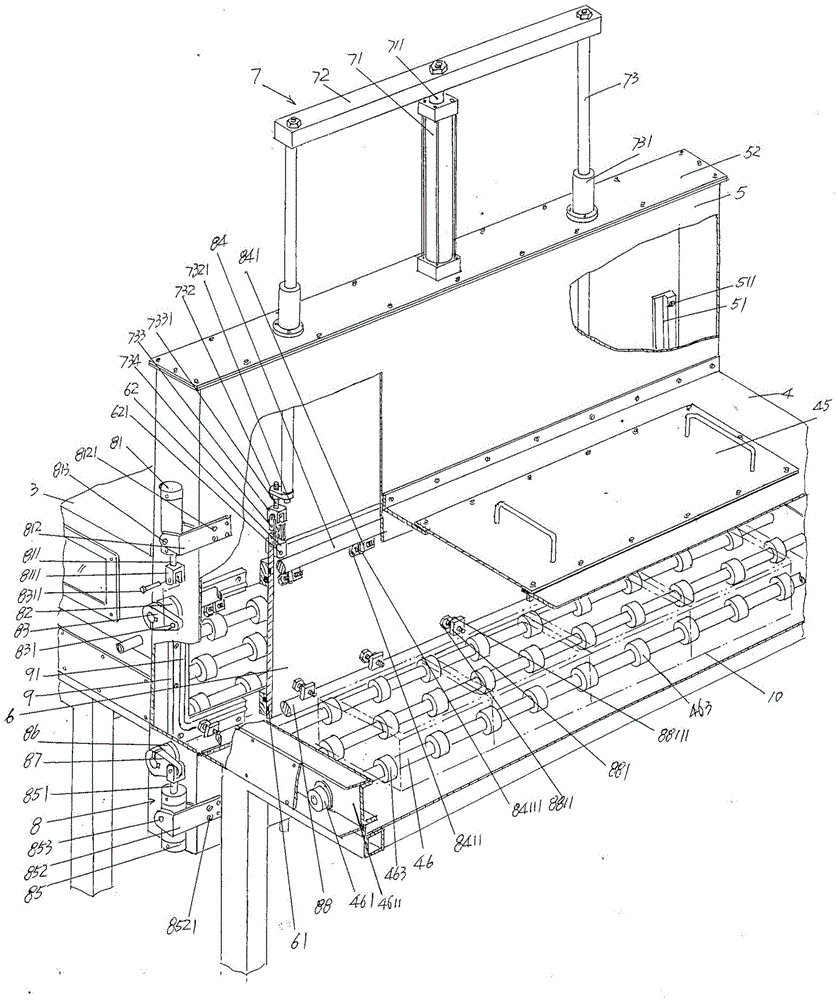

InactiveCN108115487AShorten the timeImprove processing efficiencyGrinding machine componentsPlane surface grinding machinesTouch switchHydraulic cylinder

The invention discloses wood polishing equipment for furniture processing. The wood polishing equipment comprises a workbench, a plurality of groups of lower supporting seats are symmetrically arranged on the upper side of the workbench, the lower supporting seats at two ends are provided with supporting wheels, and lower grinding rollers and lower embossing rollers are arranged on the middle lower supporting seats in a staggered manner. A fixing device is arranged at the left end of a hydraulic cylinder which is arranged at the upper right end of the workbench, the fixing device comprises anL-shaped fixing rod and a moving plate, and the moving plate sleeves the fixing rod. Protective covers are arranged at two upper ends of the workbench, a mounting plate is arranged at the upper ends of the protective covers, a plurality of groups of telescopic air cylinders are arranged on the lower side of the mounting plate, lower ends of the telescopic air cylinders are connected with upper fixing seats, and lower ends of the upper fixing seats are in staggered connection with upper grinding rollers and upper embossing rollers. A supporting column is arranged at the upper left end of the workbench and provided with a touch switch, the workbench is internally provided with a cavity, and an air suction pipe is arranged on the left side of a dust suction box which is arranged in the cavity. The wood polishing equipment has advantages of simple structure, convenience in use and high processing quality.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

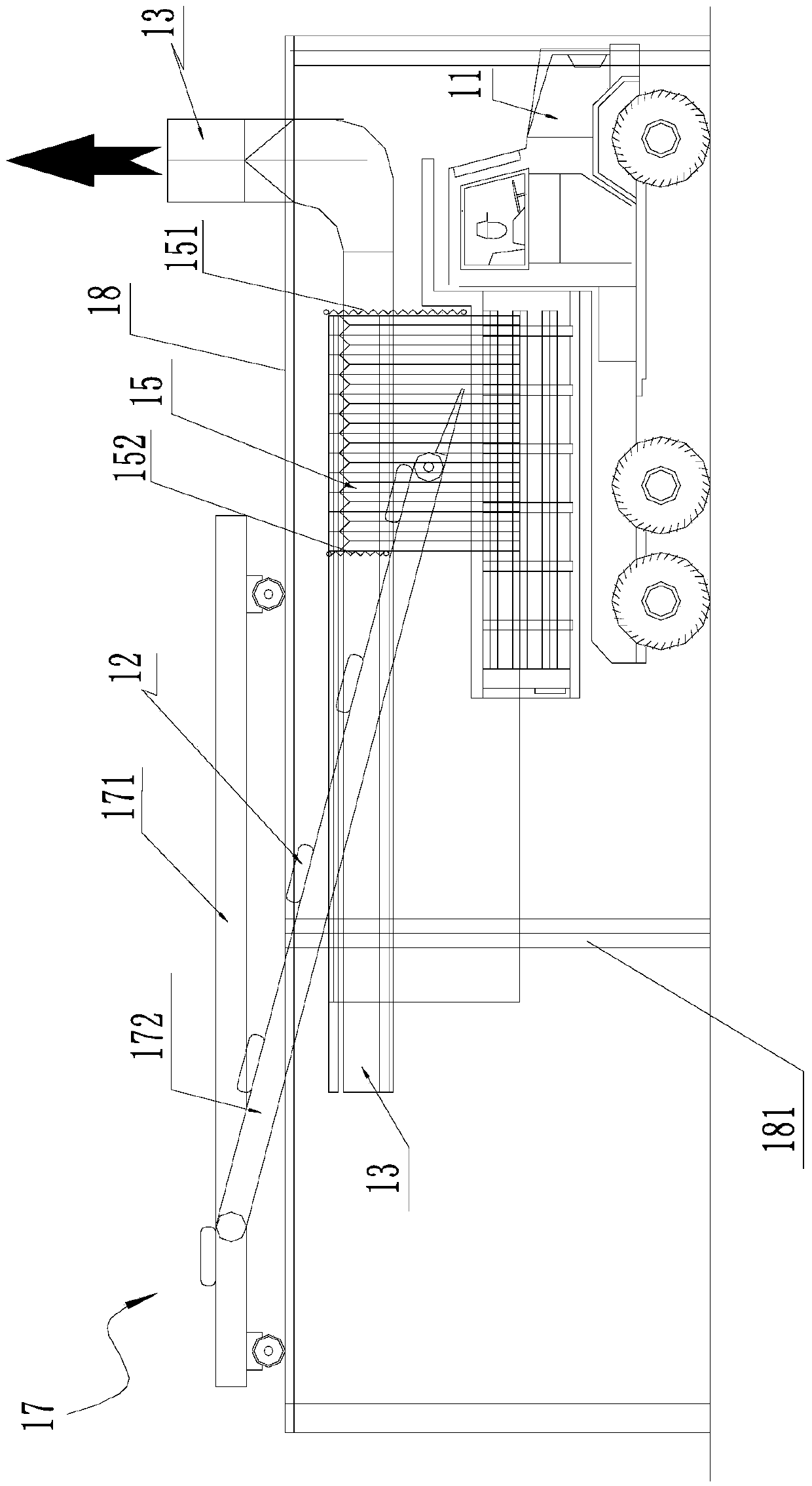

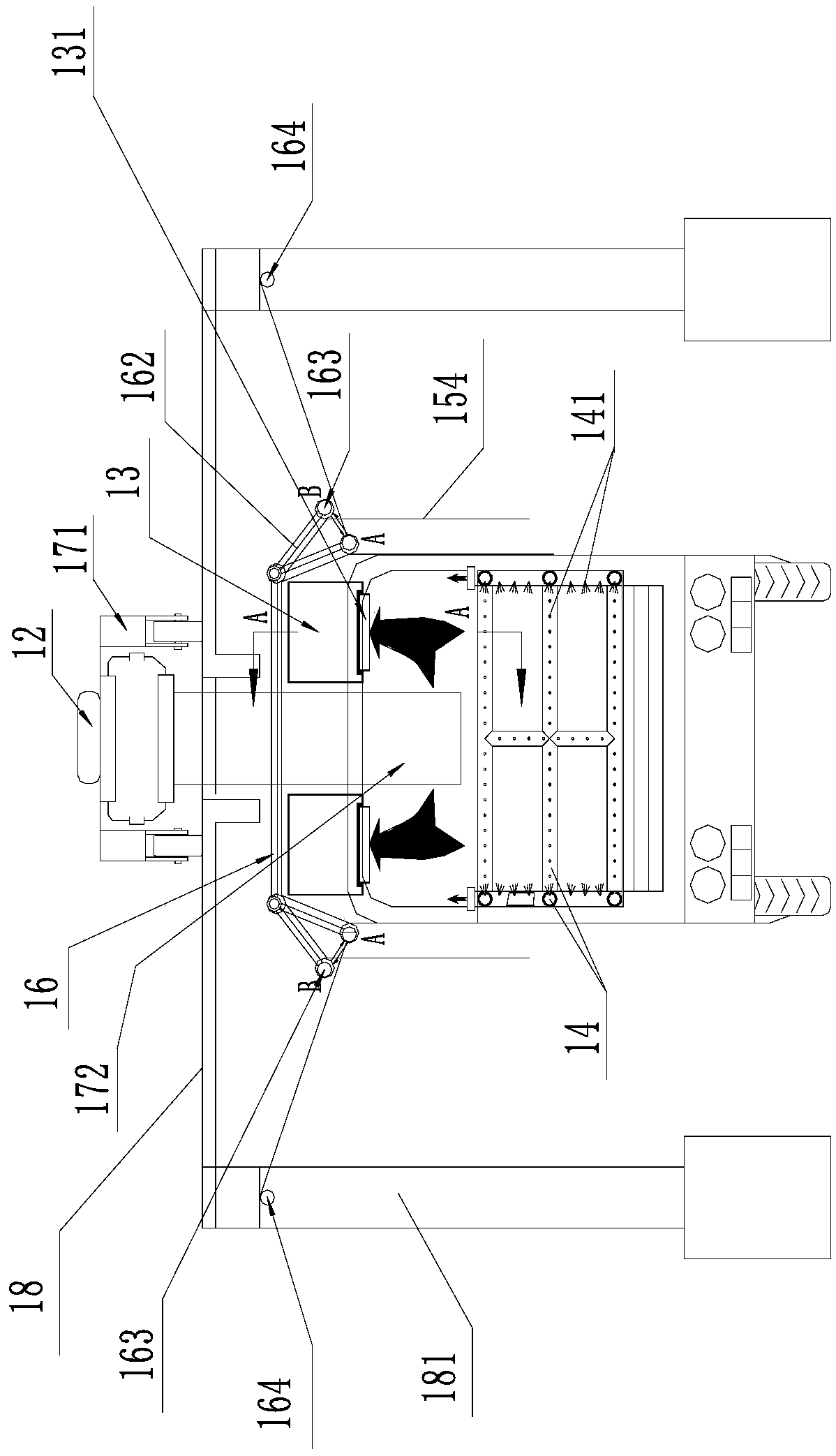

Truck loading dust collecting system

InactiveCN105523398AGuaranteed vacuuming effectPush down easilyLoading/unloadingNational standardEngineering

The invention discloses a truck loading dust collecting system for collecting dust generated by loading dust bags in a loading truck. The truck loading dust collecting system comprises a negative-pressure dust collecting device and a dust sucking pipe, wherein the negative-pressure dust collecting device includes a negative-pressure generator, and a negative-pressure dust collecting pipe connected with the negative-pressure generator; the internal of the negative-pressure dust collecting pipe is in a negative-pressure state; one end of the negative-pressure dust collecting pipe extends above a carriage of the loading truck, and is provided with a dust collecting port towards a carriage; the dust sucking pipe is arranged along the inner wall of the side wall of the carriage of the loading truck, and is communicated with the negative-pressure dust collecting pipe through a joint; and multiple dust sucking ports are formed in one side, towards the dust bags, of the dust sucking pipe. The technical problem to be solved by the invention is to overcome the defect of bad dust pollution around and in the carriage caused by low dust collecting quantity of a traditional truck loading dust collecting device; and the invention provides the truck loading dust collecting system capable of greatly increasing the dust collecting quantity and enabling the content of dust in the truck loading environment to accord with the national standard.

Owner:高玉宗

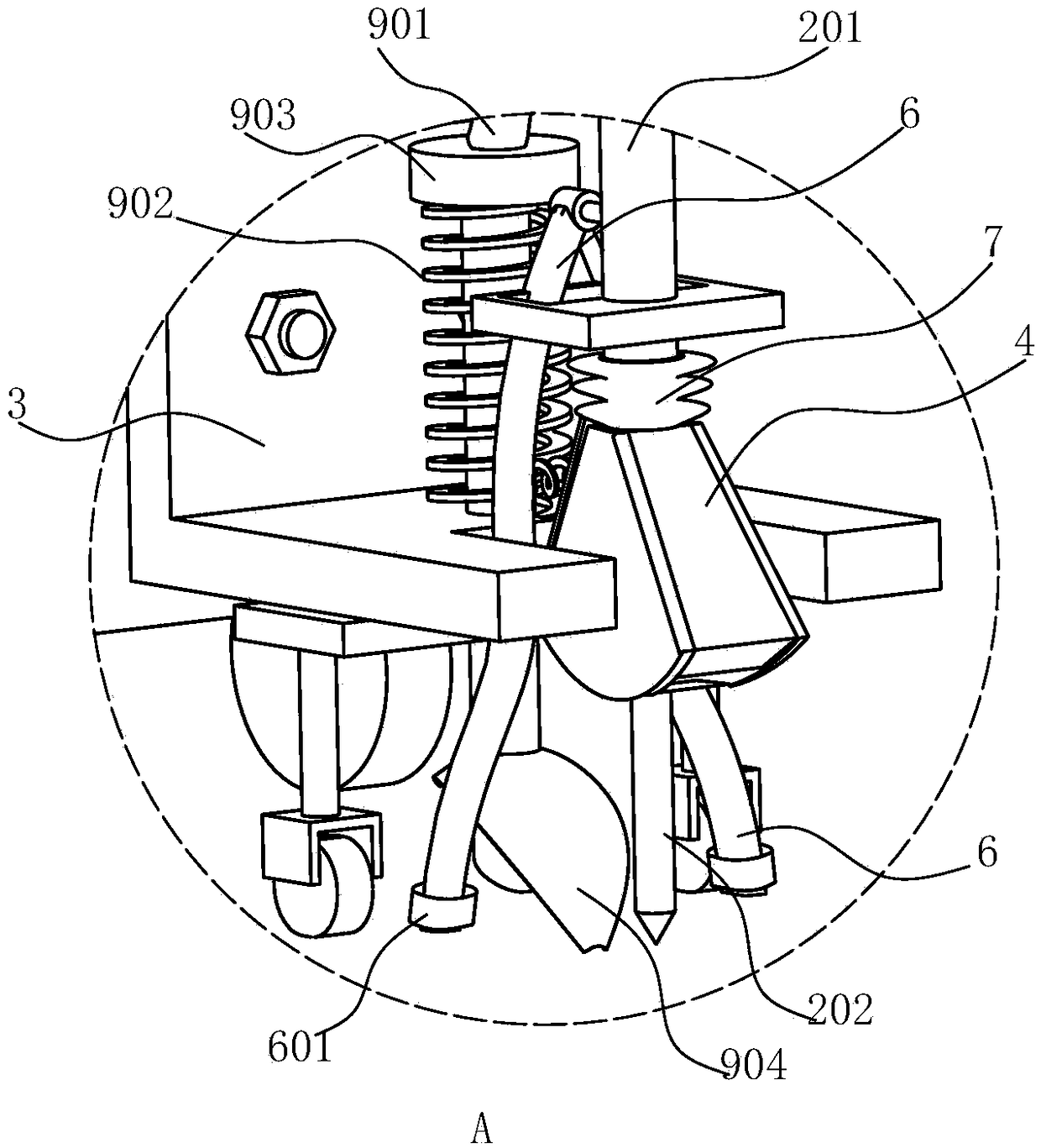

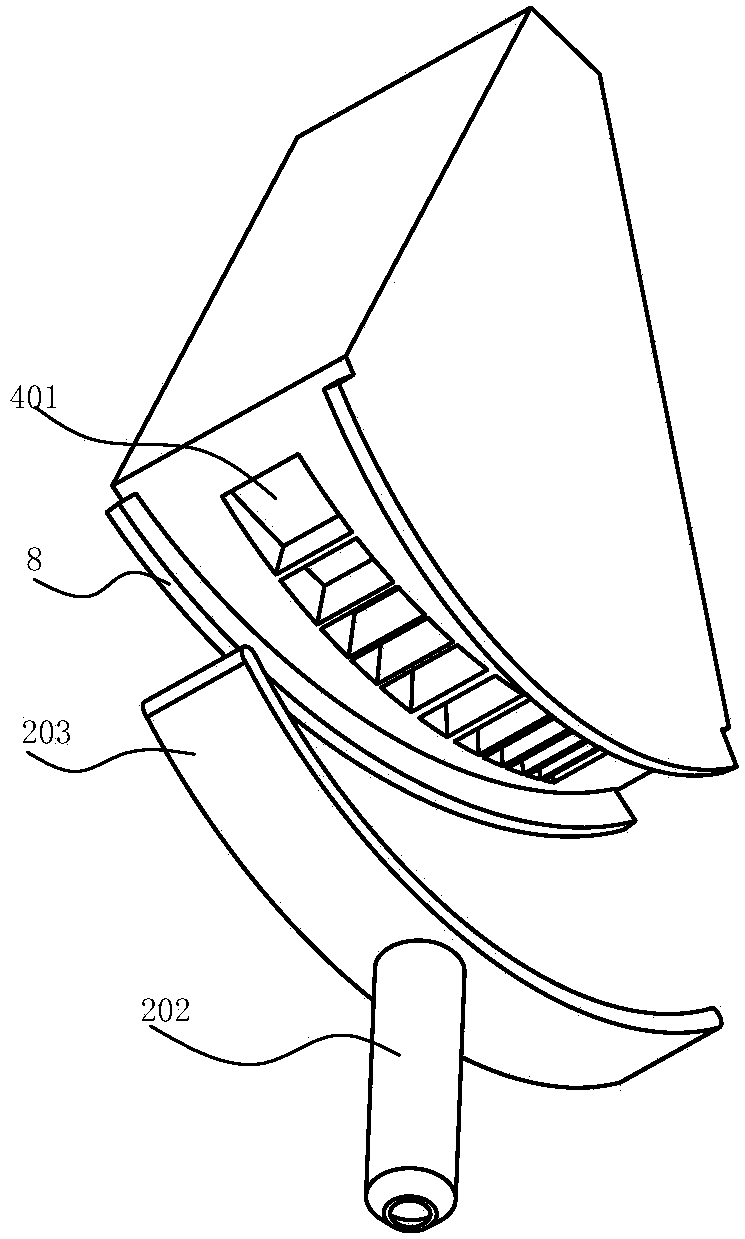

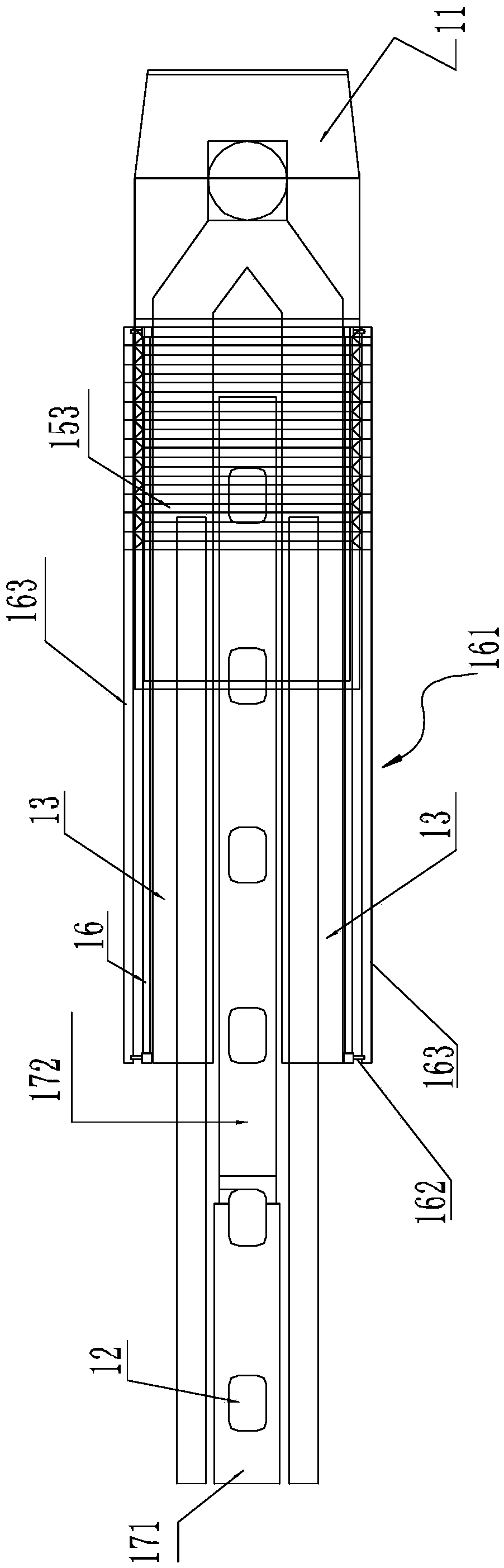

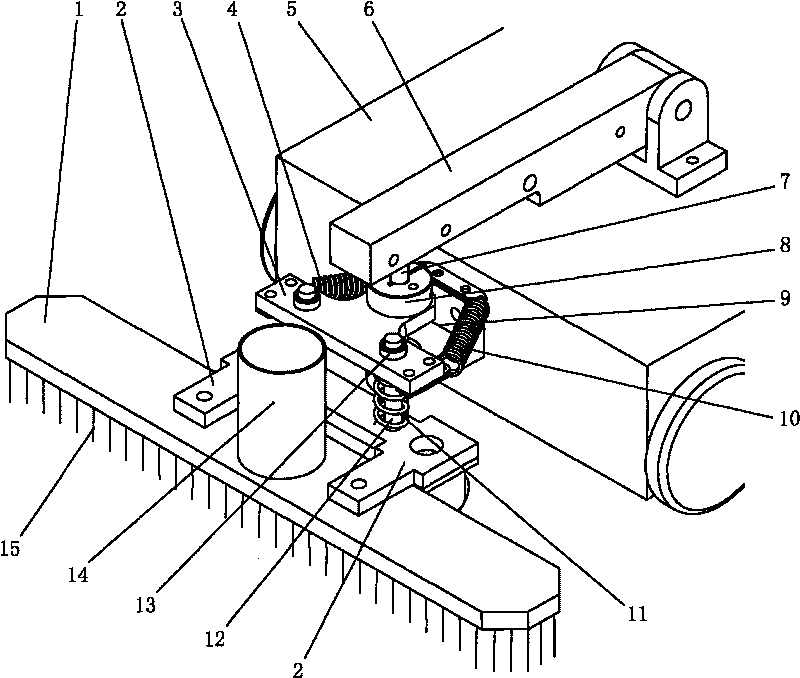

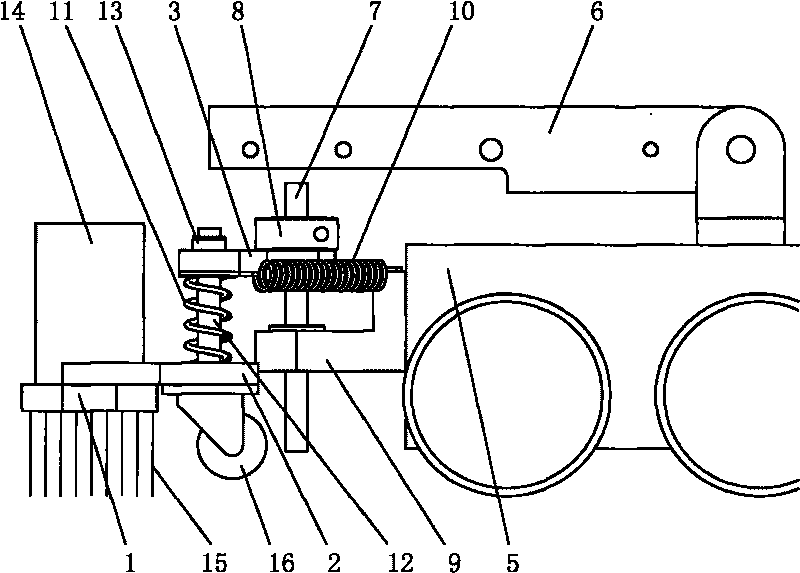

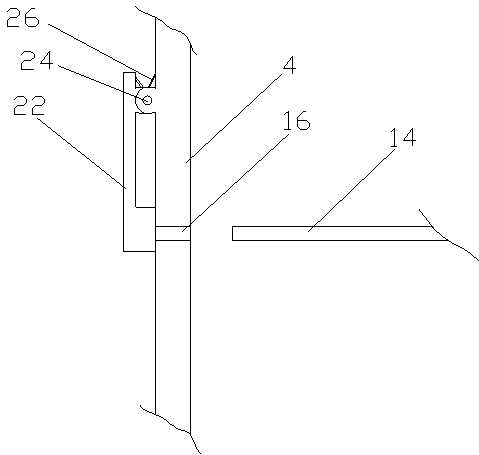

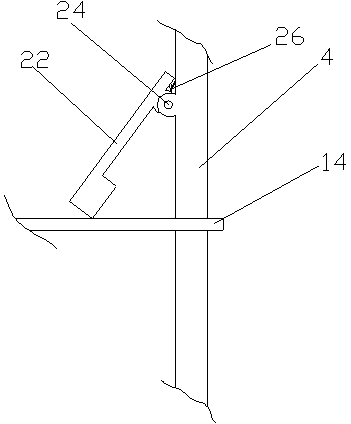

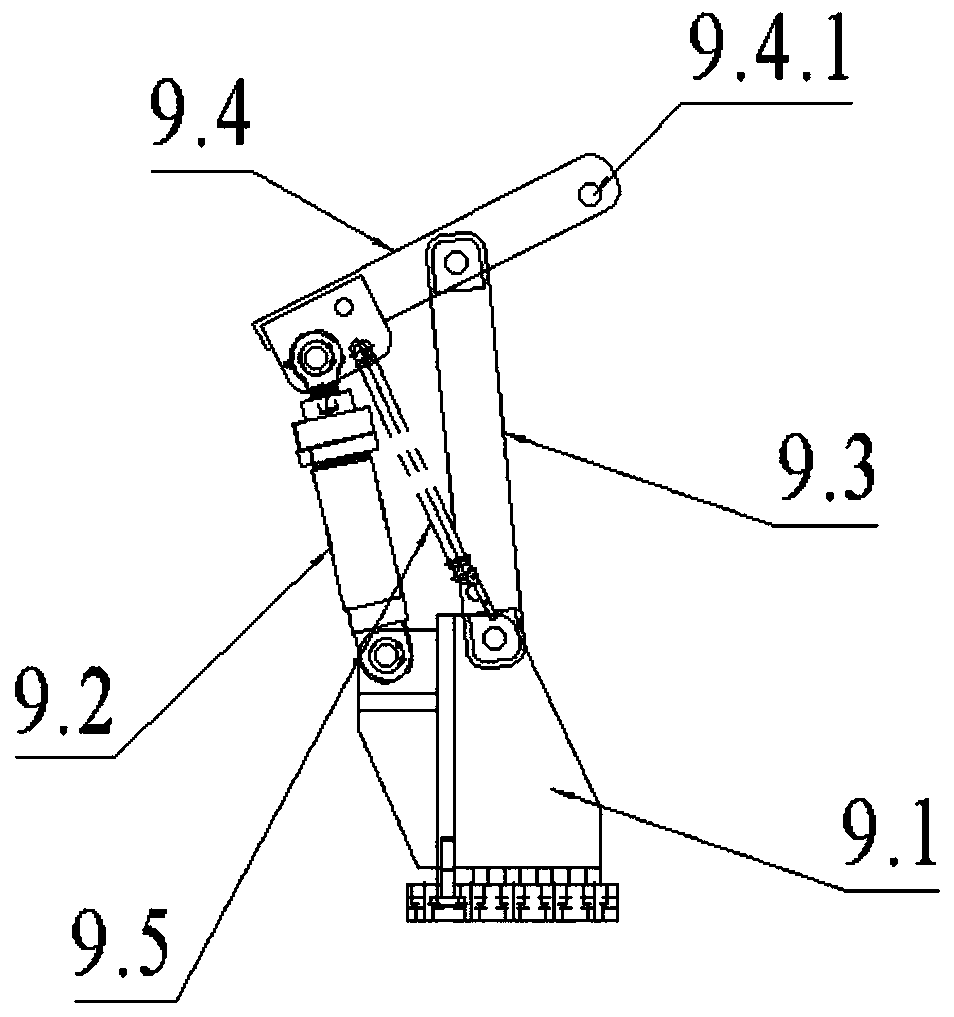

Dust collection mechanism on air duct cleaning robot and air duct cleaning robot

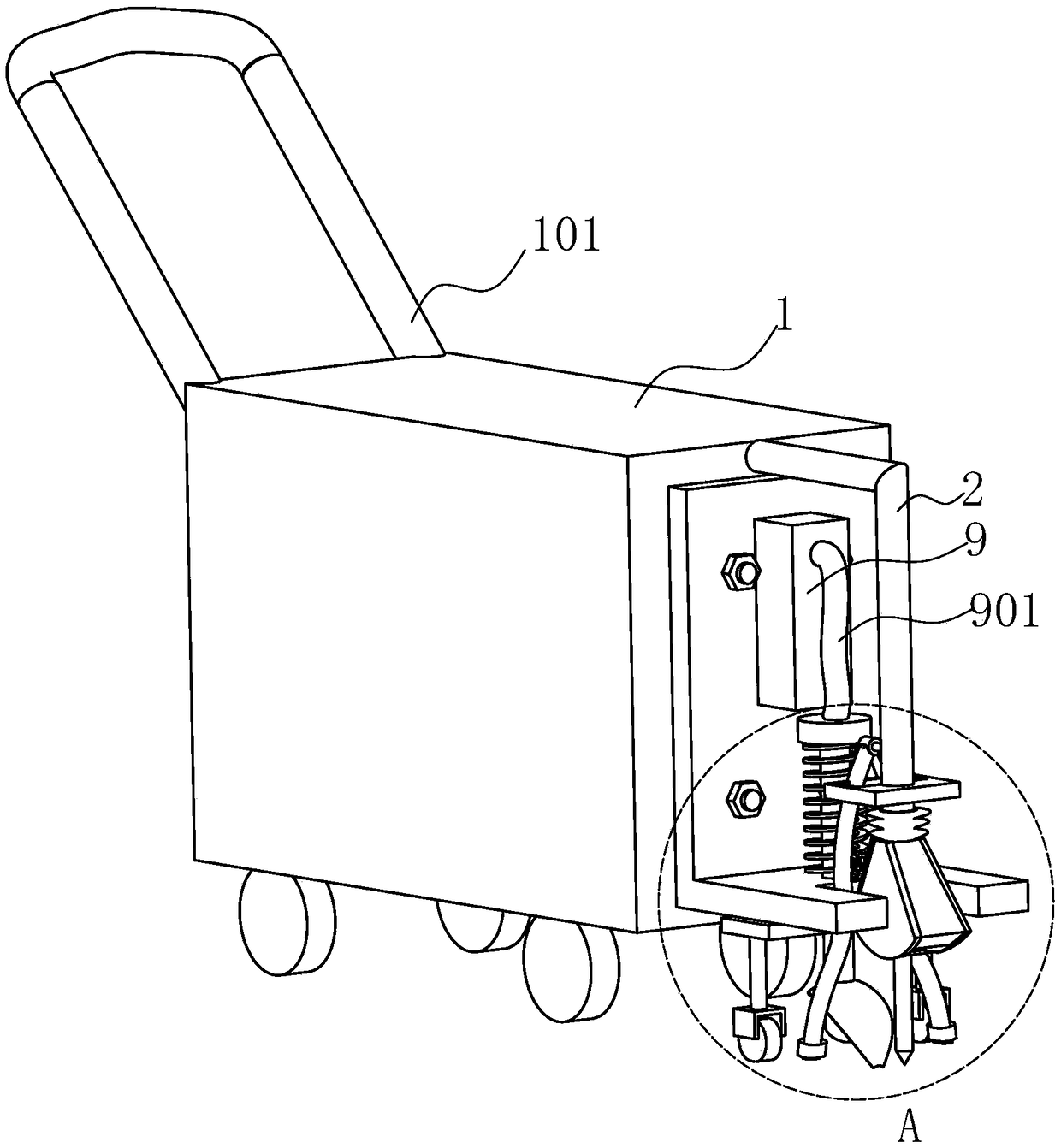

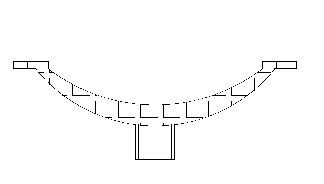

InactiveCN101700522ANo need to adjust the height frequentlySimple structureHollow article cleaningEngineeringSelf adaptive

The invention discloses a dust collection mechanism on an air duct cleaning robot, which comprises a dust collection port and a car body, wherein a rocker arm is hinged on the car body, and the rocker arm is ascended, descended and positioned under the control of a driving mechanism; a connecting base is fixedly arranged in front of the car body, a floating plate is connected on the connecting base through a long guide bar, the floating plate and the connecting base are vertically connected in a sliding manner and can rotate relatively, the rocker arm can impose the downward pressure on the floating plate, and the left side and the right side of the floating plate are connected with the connecting base or the car body through tension springs respectively; and the dust collection port is fixed on a press plate, universal wheels are arranged below the press plate, the press plate and the floating plate are vertically connected in the sliding manner, a compression spring is directly arranged between the press plate and the floating plate, the upper end of the compression spring leans against the floating plate, and the lower end of the compression spring leans against the press plate. The invention further discloses the air duct cleaning robot containing the dust collection mechanism. The technical scheme has a self-adaptive structure, thereby being capable of carrying out self-adjustment according to the complicated situations of elbows, uplifts, depressions and the like in a pipeline of an air duct and further ensuring the good dust collection effect.

Owner:ZHEJIANG UNIV OF TECH

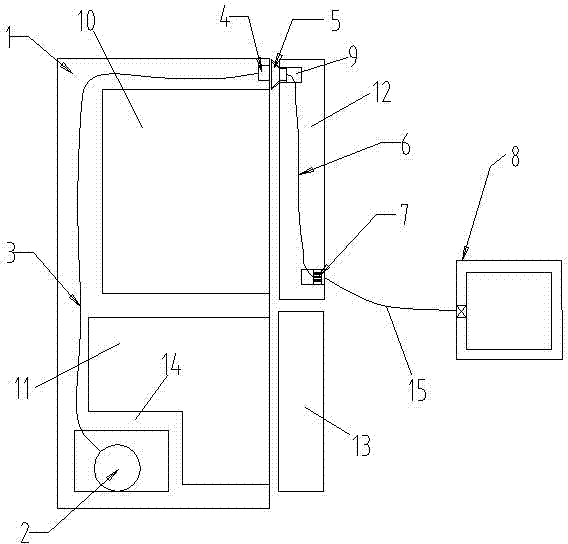

Refrigerator with external vacuum freshness retaining device

ActiveCN104501497AWill not polluteDoes not reduce usable volumeLighting and heating apparatusDomestic refrigeratorsFreezing chamberEngineering

The invention discloses a refrigerator with an external vacuum freshness retaining device. The refrigerator comprises a refrigerator body. A vacuum pump is arranged in a compressor chamber and is connected with a refrigerator body connector by a refrigerator body pipeline, the refrigerator body pipeline is positioned in a refrigerator body wall, and the refrigerator body connector is positioned in a refrigerator body wall which faces a door; a switch of the vacuum pump is positioned on the surface of the refrigerator body or the surface of a door of a refrigerating chamber or the surface of a door of a freezing chamber; a draw-off connector, a door pipeline and a door connector are arranged in the door of the refrigerating chamber, the door pipeline is connected with the draw-off connector, and the door connector is connected with the door pipeline; the draw-off connector is exposed on the outer surface of the door of the refrigerating chamber; the door connector corresponds to the refrigerator body connector; a flexible connector is connected with the door connector or the refrigerator body connector and extends out of the surface of the door or the surface of the refrigerator body. The refrigerator has the advantages that the refrigerator is simple in structure, the door of the refrigerator does not need to be opened in service procedures, various vacuum pumping components do not occupy spaces in the refrigerating chamber and the freezing chamber, accordingly, the refrigerator brings convenience for users during vacuum pumping operation, the door of the refrigerator can be prevented from being frequently opened, and food contamination due to frequent opening of the door of the refrigerator can be prevented.

Owner:HENAN XINFEI ELECTRICAL EQUIP

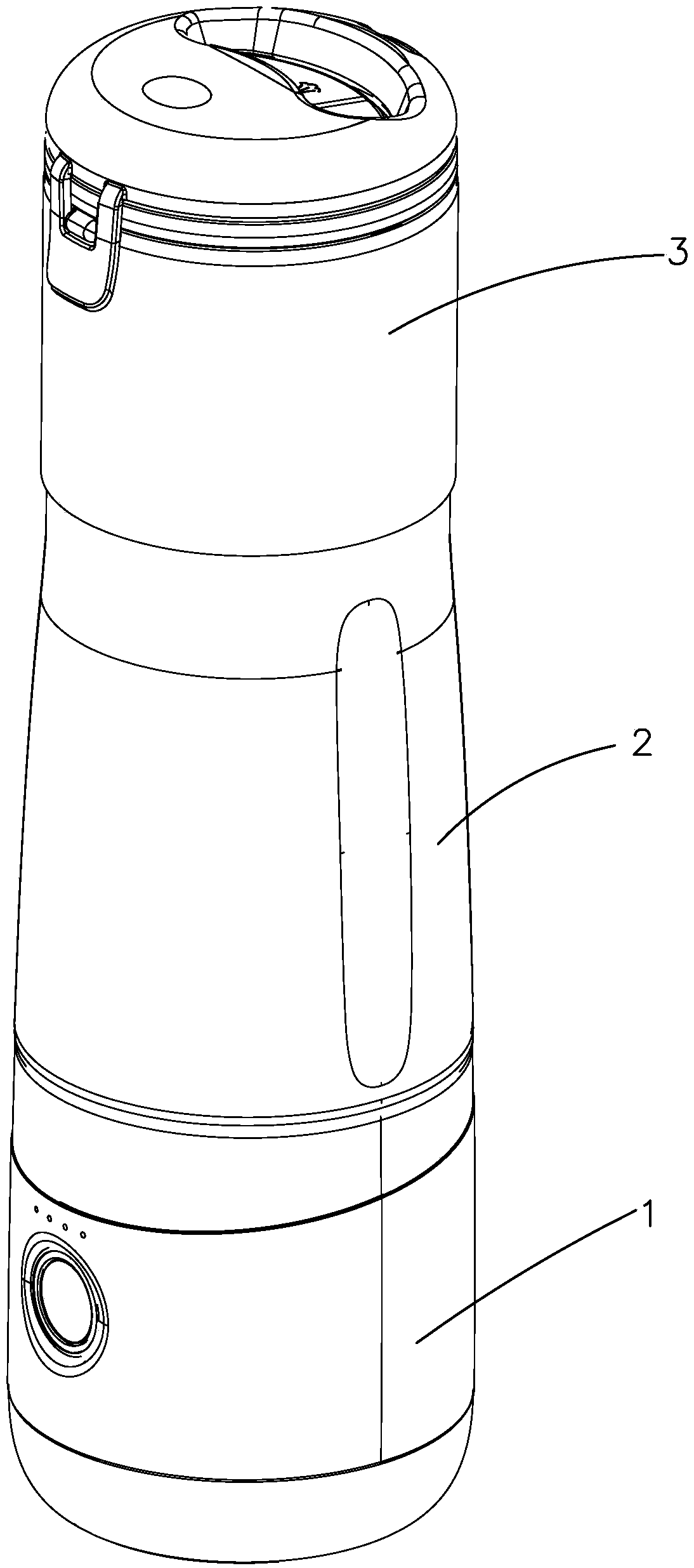

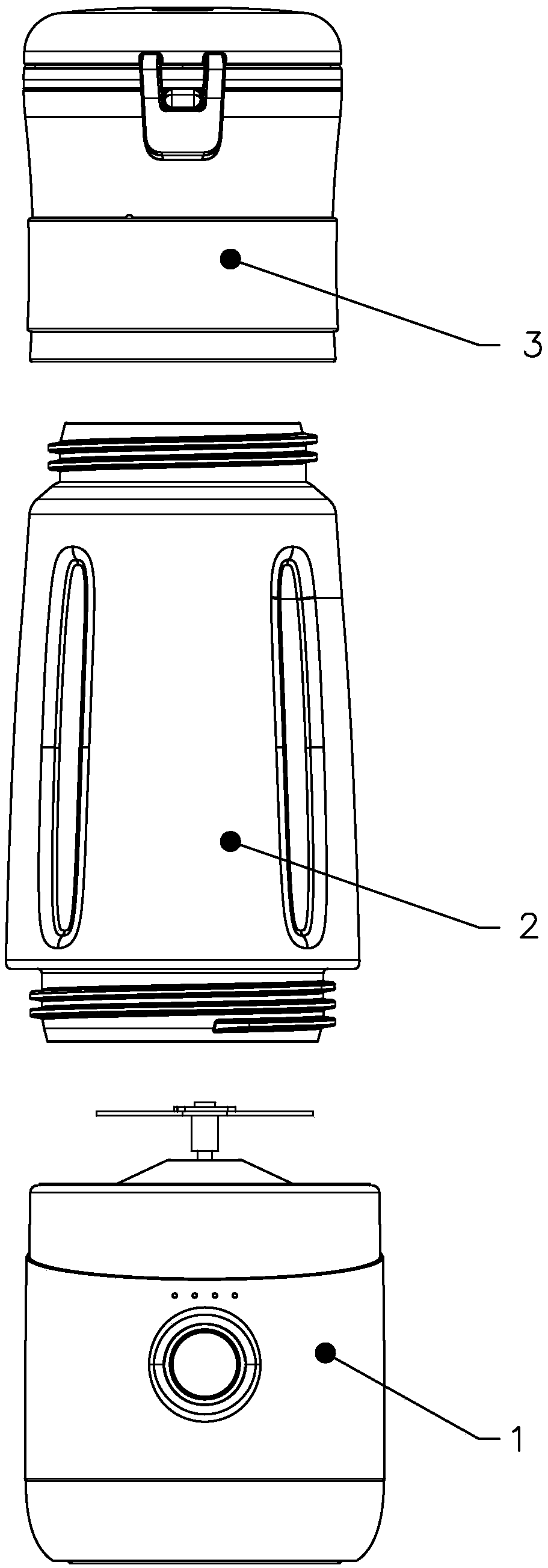

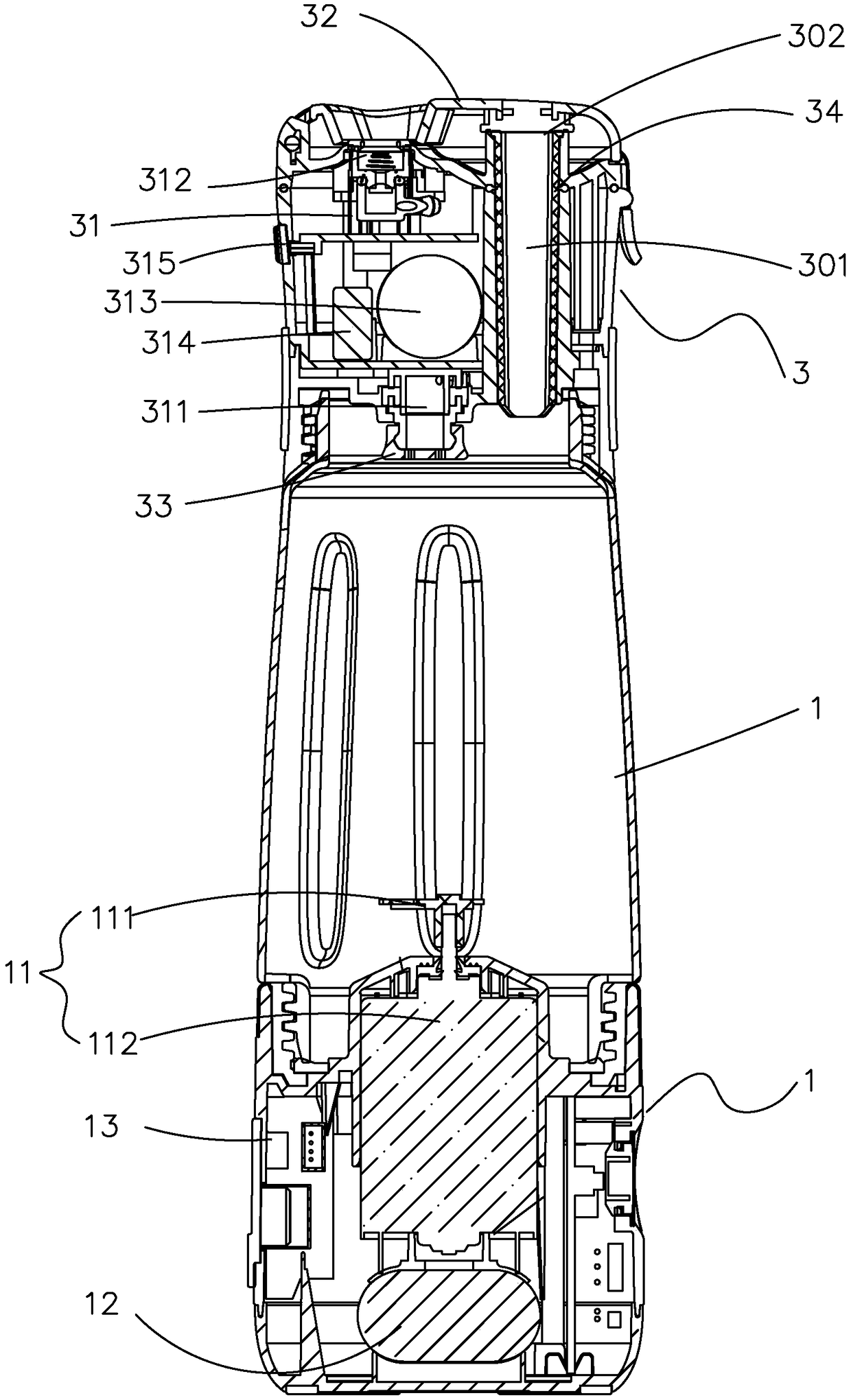

Vacuumizing stirring machine

PendingCN108937638AGuaranteed vacuuming effectGuaranteed freshKitchen equipmentEngineeringFood material

The invention discloses a vacuumizing stirring machine. The vacuumizing stirring machine comprises a machine base, wherein the machine base is provided with a stirring cup and a stirring assembly stirring food materials in the stirring cup, the upper end of the stirring cup is in seal connection with an upper cup seat, the upper cup seat is internally provided with a vacuumizing device vacuumizingthe stirring cup, the upper cup seat is further provided with a liquid outlet channel communicated with the stirring cup, the liquid outlet channel is provided with a liquid outlet for a user to drink directly, and the liquid outlet channel is provided with a seal device used for sealing the liquid outlet channel when the vacuumizing device performs vacuumizing. The vacuumizing stirring machine has the advantages that the upper cup seat is provided with the vacuumizing device so that the stirring cup can be vacuumized before the food materials are stirred or after stirring is completed, the freshness of the food materials in the stirring cup is ensured at any time, the three devices are assembled together, functions are strong, the machine base and the vacuumizing device can be wirelesslyused under the situation of not connecting a power line, drinking can be performed under the situation that the upper cup seat does not need to be disassembled, and the structure is simple.

Owner:中山市小榄镇威的电器有限公司

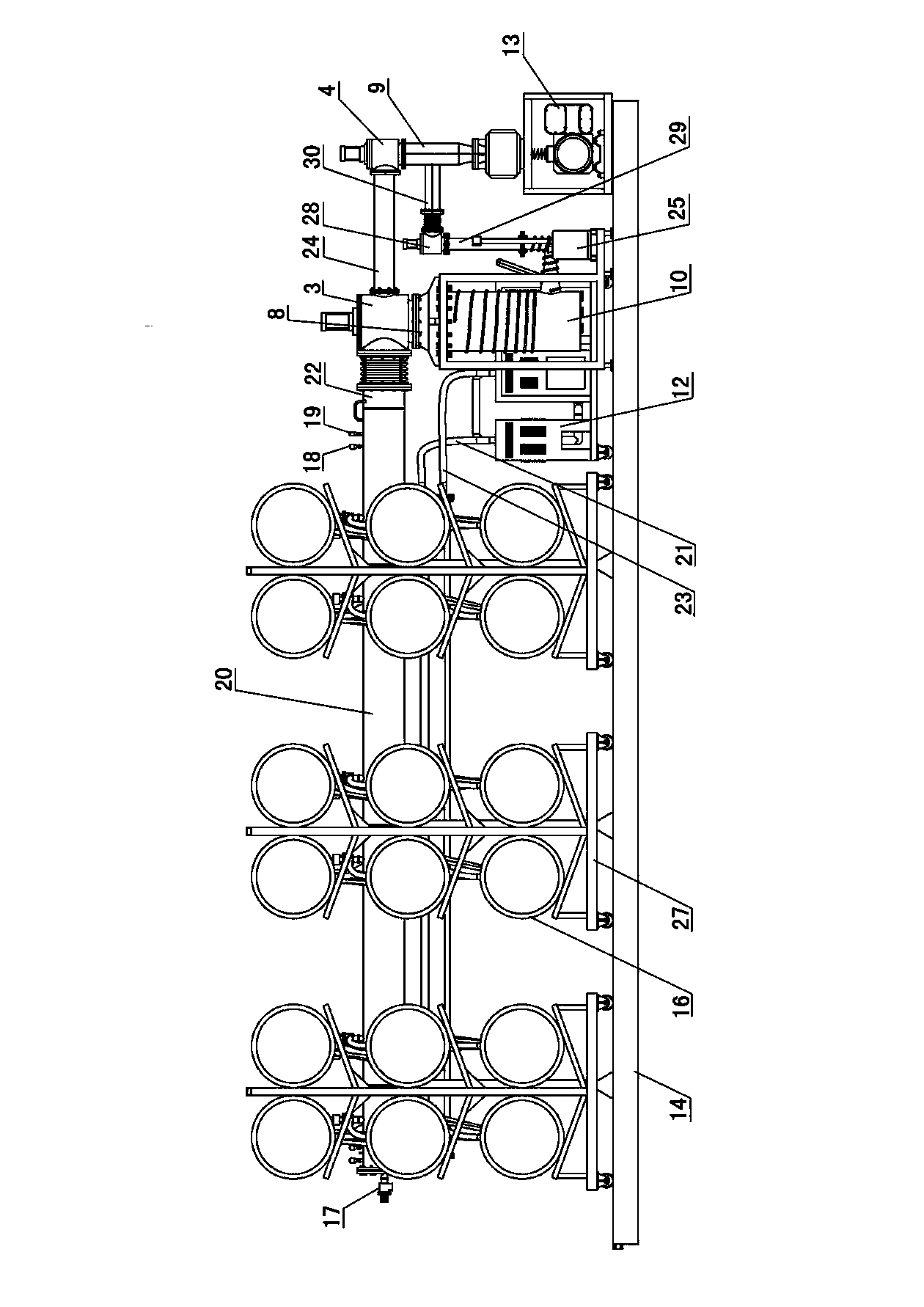

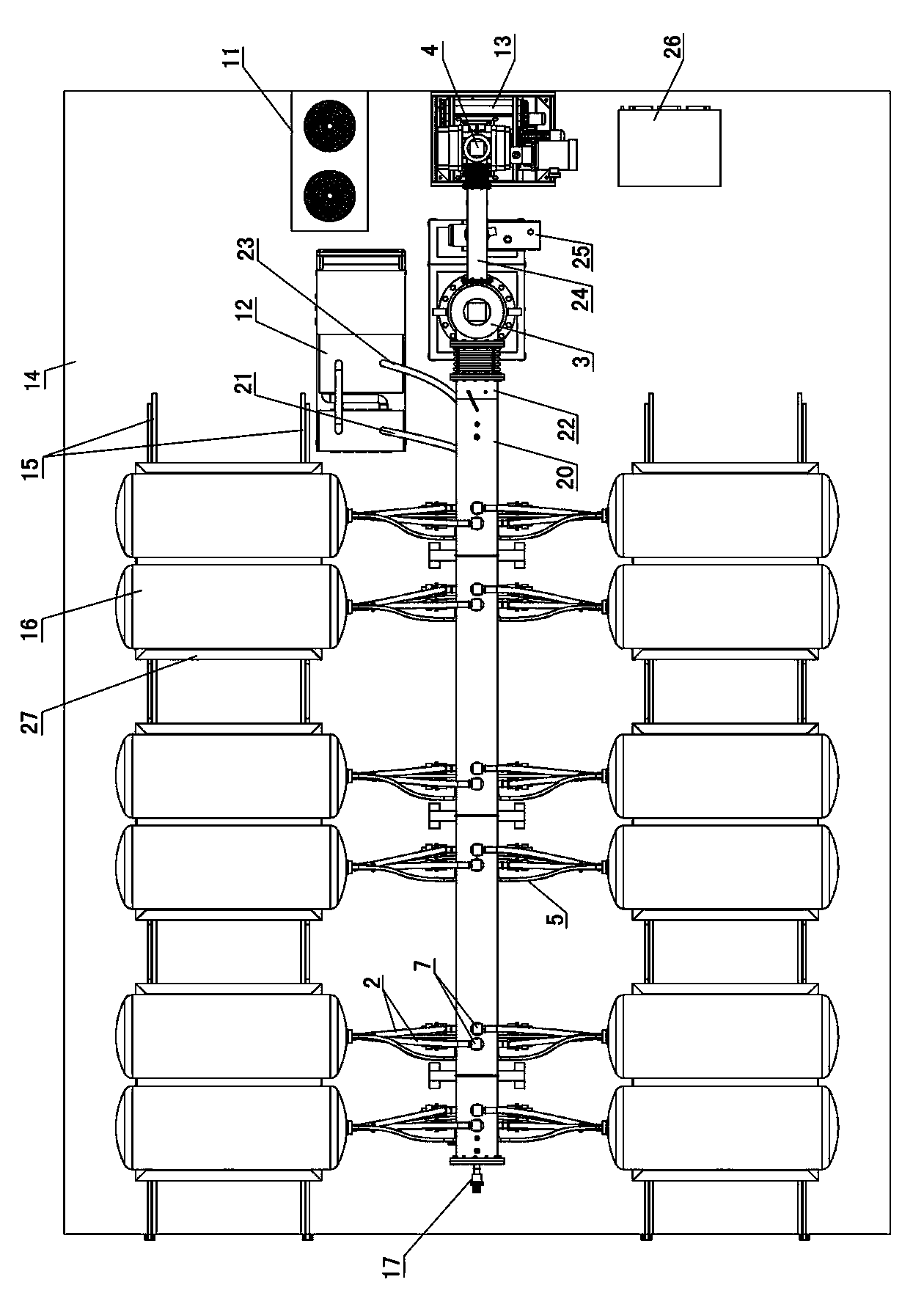

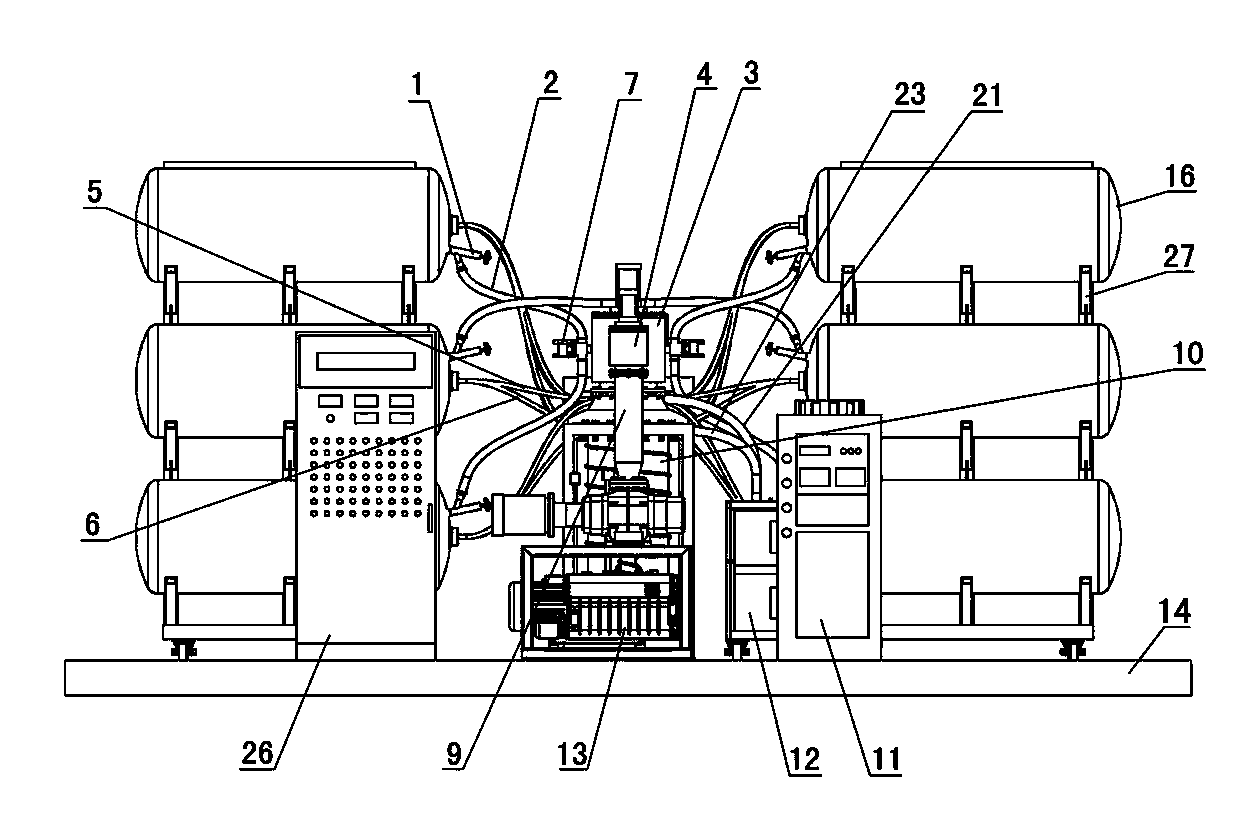

Liquefied natural gas bottle sandwiching vacuum-pumping system and method with function of circularly heating inner container

InactiveCN103822085AGuaranteed vacuuming effectGuaranteed production efficiencyPressure vesselsVacuum pumpingProcess engineering

The invention discloses a liquefied natural gas bottle sandwiching vacuum-pumping system with a function of circularly heating an inner container. The system comprises a vacuum-pumping device, a liquefied natural gas bottle placing device and a liquefied natural gas bottle inner heating device, wherein the liquefied natural gas bottle inner heating device comprises a dry oil-free inner heating circulating fan, a heat inlet main pipe, a heat discharging main pipe, a heat inlet branch pipe and a heat discharging branch pipe; an air outlet of the dry oil-free inner heating circulating fan is communicated with the heat inlet main pipe, the heat inlet main pipe is communicated with the heat inlet branch pipe, and the heat inlet branch pipe is communicated with an air inlet of a to-be-heated liquefied natural gas bottle; an air outlet of the liquefied natural gas bottle is communicated with the heat discharging branch pipe, the heat discharging branch pipe is communicated with the heat discharging main pipe, and the heat discharging main pipe is communicated with an air inlet of the dry oil-free inner heating circulating fan. The system and method disclosed by the invention have the advantages that the vacuum-pumping does not need, meanwhile, a drying room is not utilized to persistently externally heat; the vacuum-pumping effect and production efficiency are guaranteed, and meanwhile, the manufacturing cost and using cost are also saved.

Owner:北京华诚浩达真空空压设备有限公司

Computer keyboard cleaner

InactiveCN101905225AWill not flow out automaticallyWon't flow outCleaning using toolsCleaning using gasesImpellerEngineering

The invention discloses a computer keyboard cleaner, which comprises a dust absorption device and a cleaning device. The dust absorption device comprises a base and a dust absorber. The cleaning device comprises a base and a cleaning head. The dust absorption device and the cleaning device share the same base. Different functions can be realized by replacing different working heads. A motor is arranged in the base. The dust absorber comprises a dust absorbing shell connected to the base; a side wall of the dust absorbing shell is provided with an air vent; a filter screen is arranged in the shell; the front end of the shell is sleeved with a dust absorbing soft tube; an impeller connected to the motor is arranged in the dust absorbing shell; the cleaning head comprises a rotating shaft connected to the motor; a rotating box is arranged on the end of the rotating shaft; the rotating box is provided with a transparent cavity; sponge is filled in the cavity in order to absorb cleaning liquid; an annular brush is sleeved on the edge of the rotating box; a plug seals the cavity of the rotating box; and a liquid adding hole is arranged in the side wall of the rotating box. Through replacing different working heads, the invention can realize the functions of dust absorption and cleaning and the working heads can be conveniently replaced.

Owner:CHINA AGRI UNIV

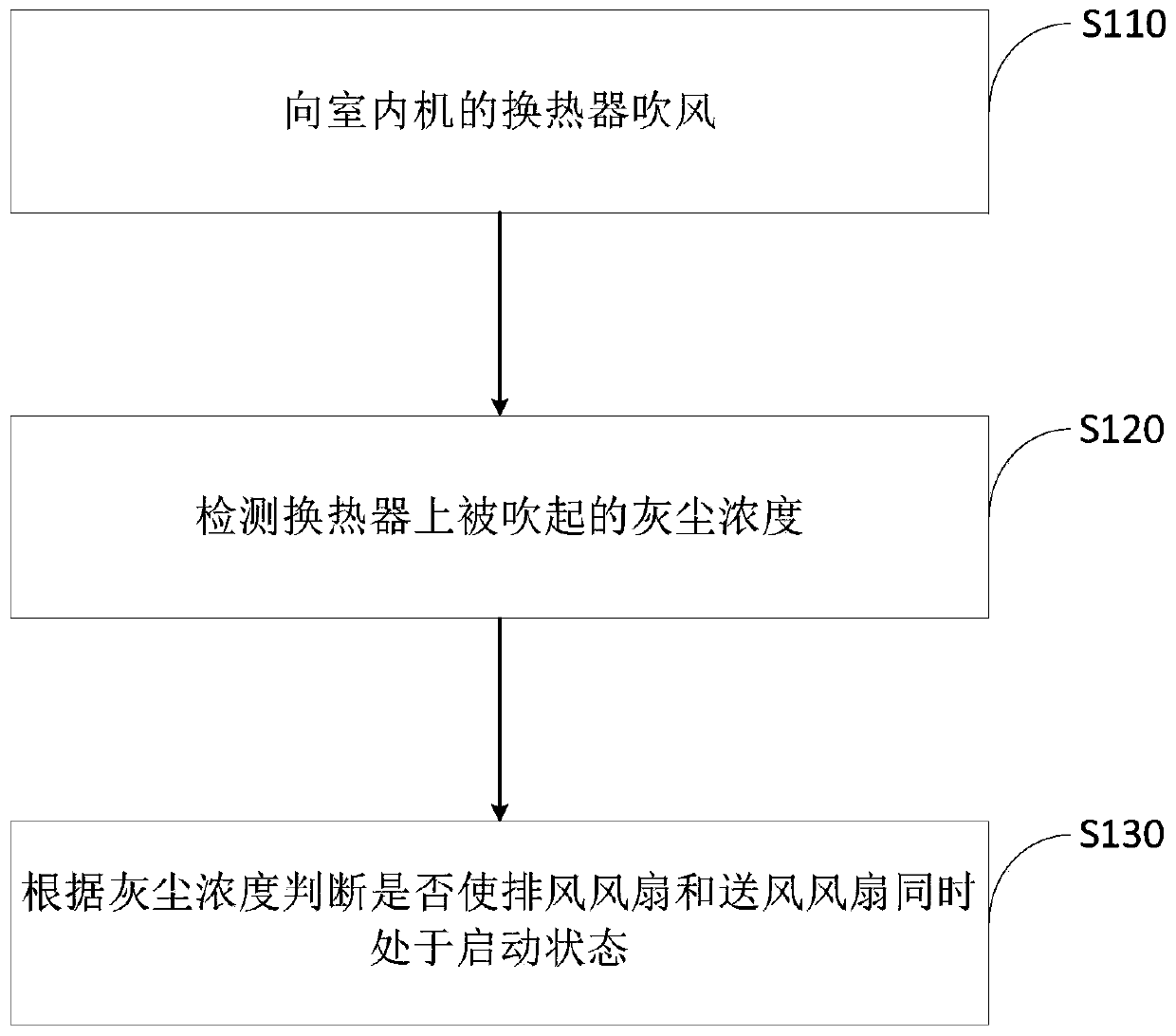

Self-cleaning control method for air conditioner

InactiveCN109916032ADetermine when to vacuumGuaranteed vacuuming effectMechanical apparatusEngineeringHeat exchanger

The invention belongs to the technical field of air conditioners, and particularly provides a self-cleaning control method for an air conditioner. In order to improve the self-cleaning effect of the air conditioner, the air conditioner comprises an indoor unit, an air ejector fan and an air supply fan, the air ejector fan and the air supply fan are arranged on the indoor unit, the air ejector fanis used for extracting dust on a heat exchanger of the indoor unit out of a room, and the air supply fan is used for blowing up dust on the heat exchanger to assist the air ejector fan in extracting dust out of the room. The self-cleaning control method for the air conditioner comprises the steps that air is blown to the heat exchanger of the indoor unit; the concentration of dust blown up from the heat exchanger is detected; and according to the dust concentration, whether the air ejector fan needs to be started or the air supply fan needs to be stopped is judged. Whether the air supply fan and the air ejector fan are made to be in a started state so as to collect dust on the heat exchanger is judged according to the dust degree of the heat exchanger, and therefore the opportunity of dustcollection and cleaning for the heat exchanger is accurately determined.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

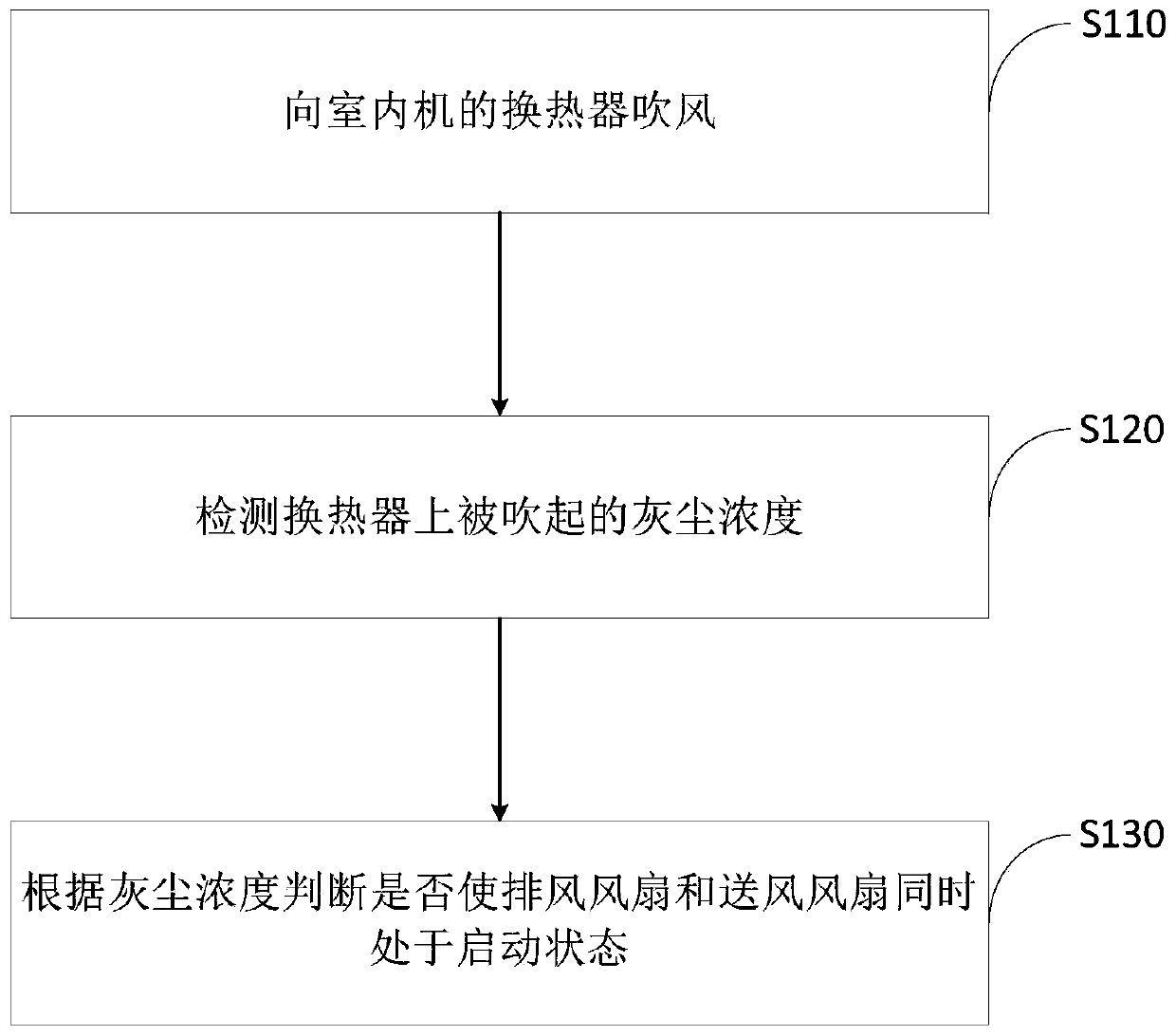

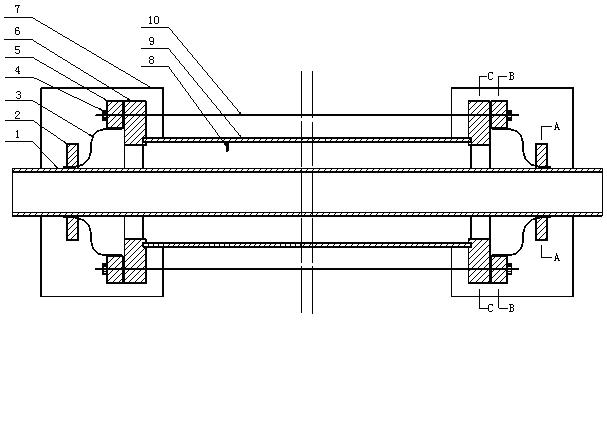

High-temperature glass metal vacuum collector tube

InactiveCN101949604AImprove absorption rateSimple preparation processSolar heating energySolar heat devicesEngineeringTemperature difference

The invention relates to a glass metal vacuum collector tube which comprises a metal inner tube (1), a glass outer tube (9), sealing heads (3), sealing head fixing discs (6) and sealing connecting devices, wherein the metal inner tube (1) is arranged in the glass outer tube (9) in a penetrating way, both ends of the metal inner tube (1) extend and exceed the length of the glass outer tube (9), two sealing heads (3) are respectively arranged at the both ends of the metal inner tube (1), a sealing head fixing disc (6) is connected between each sealing head (3) and the glass outer tube (9), each interface is sealed by the sealing connecting device, and a sealed space is enclosed by the metal inner tube (1), the glass outer tube (9), the sealing heads (3) and the sealing head fixing discs (6) and is vacuumized. The glass metal vacuum collector tube has a structure suitable for a high temperature difference and can resist deforamtion, prolong the service life and enhance the heat collecting efficiency.

Owner:SOUTHEAST UNIV

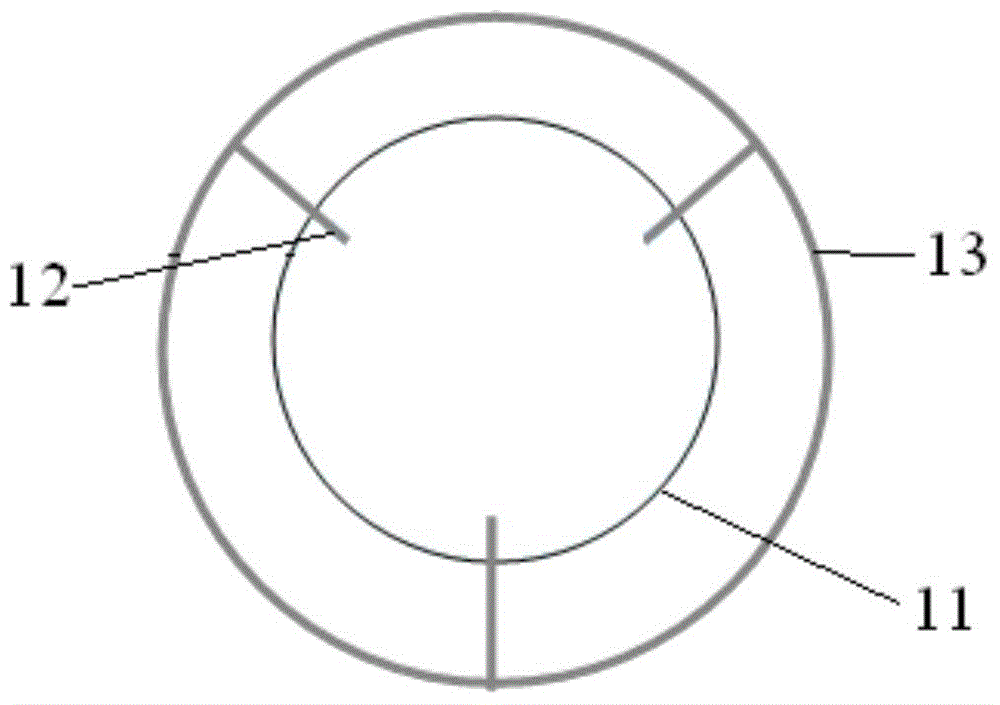

Adsorption device of vacuum interlayer container

ActiveCN105782707AGuaranteed adsorption effectImprove adsorption capacityVessel mounting detailsVessel wallsEngineeringPressure difference

The invention discloses an adsorption device of a vacuum interlayer container. The adsorption device comprises an inner container body and an outer container body; an interlayer is arranged between the inner container body and the outer container body, and the inner container body is connected with an adsorption chamber device; the adsorption chamber device comprises a cavity internally containing an adsorbing agent, an air inlet device and a break-through device, wherein the air inlet device and the break-through device are communicated with the cavity; the air inlet device penetrates the outer container body, and the break-through device is provided with a communication pipe used for communicating the cavity with the interlayer and a sealing component which is located in the interlayer, is used for blocking the communication pipe and can fall apart under the pressure difference effect. The adsorption device is simple in structure, small in size and high in adsorption capacity, has the function of adsorbing leaked gas of the interlayer and supporting the inner container body, and optimizes a bearing structure of the inner container body.

Owner:广东建成机械设备有限公司

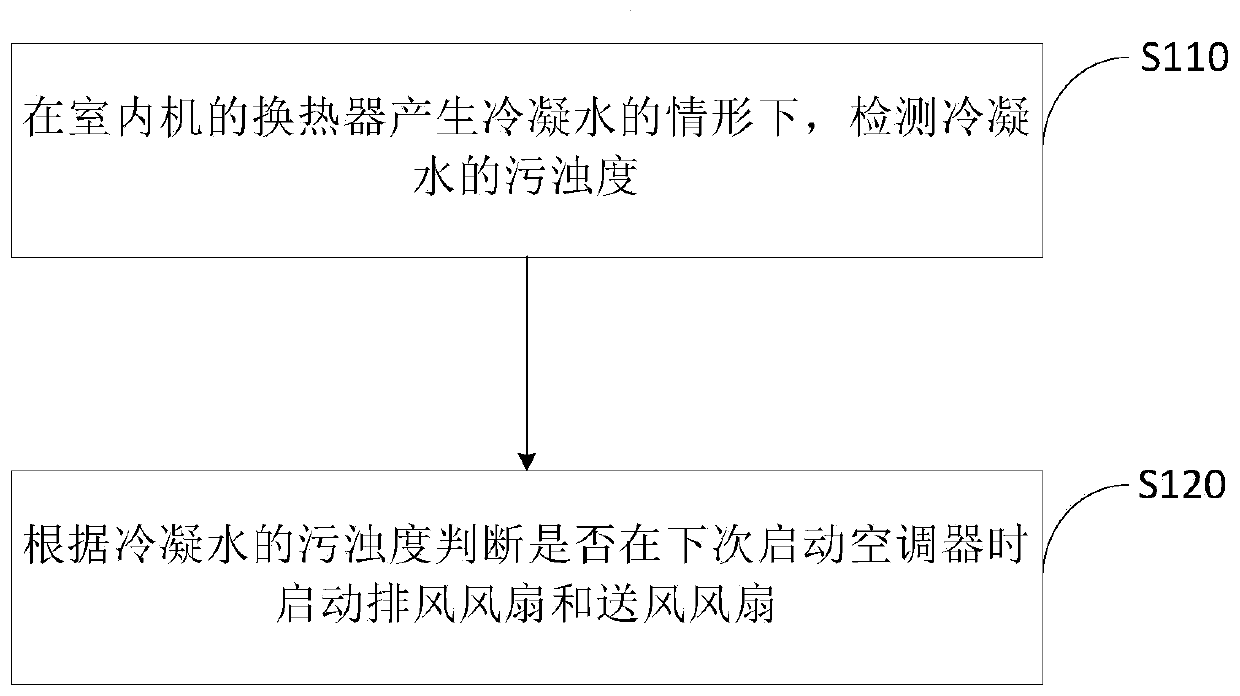

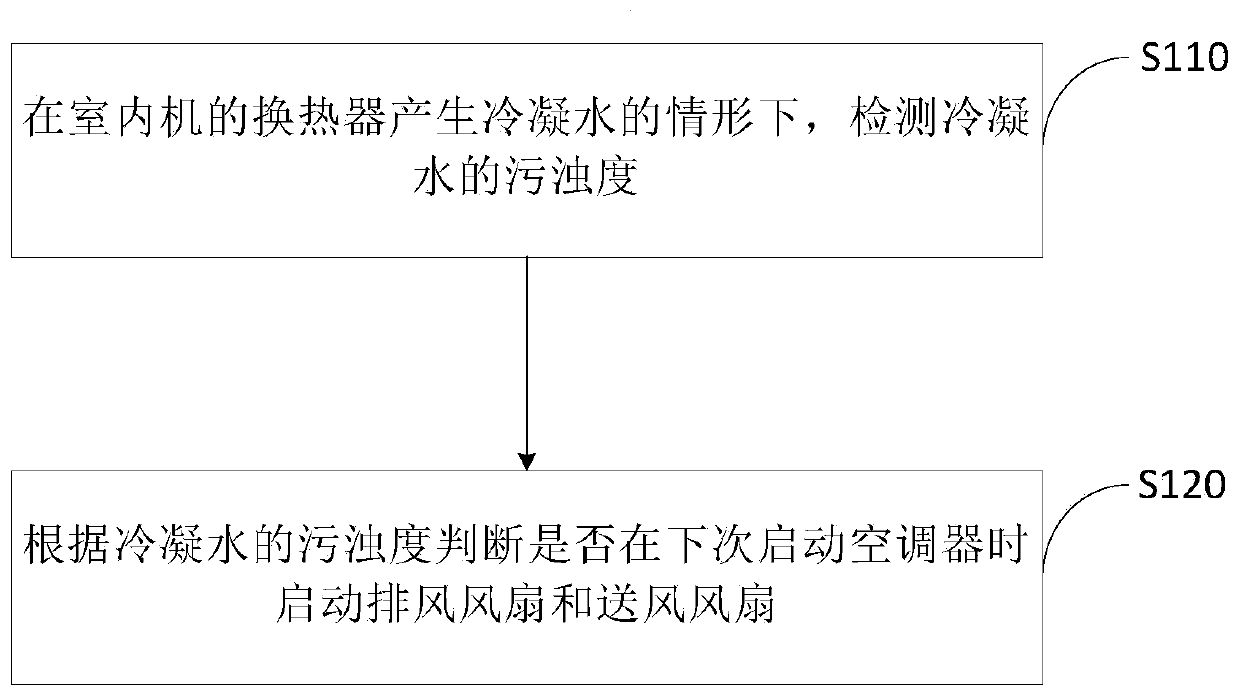

Air conditioner self-cleaning control method

ActiveCN109916037ADetermine when to vacuumGuaranteed vacuuming effectMechanical apparatusExhaust gasEngineering

The invention belongs to the technical field of air conditioners, and particularly provides an air conditioner self-cleaning control method. In order to improve the self-cleaning effect of the air conditioner, the air conditioner comprises an indoor unit, and an exhaust fan and an air supply fan which are arranged on the indoor unit; the exhaust fan is used for sucking dust on a heat exchanger ofthe indoor unit and discharging the dust outdoors; the air supply fan is used for blowing the dust on the heat exchanger for assisting the exhaust fan in sucking and discharging the dust outdoors; theair conditioner self-cleaning control method comprises the steps of detecting the turbidity of condensate water under the condition that the condensate water is generated through the heat exchanger of the indoor unit; and judging whether the exhaust fan and the air supply fan are started or not when the air conditioner is started at next time according to the turbidity of the condensate water. According to the elf-cleaning control method, whether the exhaust fan and the air supply fan are started or not when the air conditioner is started at next time is judged according to the turbidity of the condensate water, so that the dust collection and cleaning time for the heat exchanger is determined accurately.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

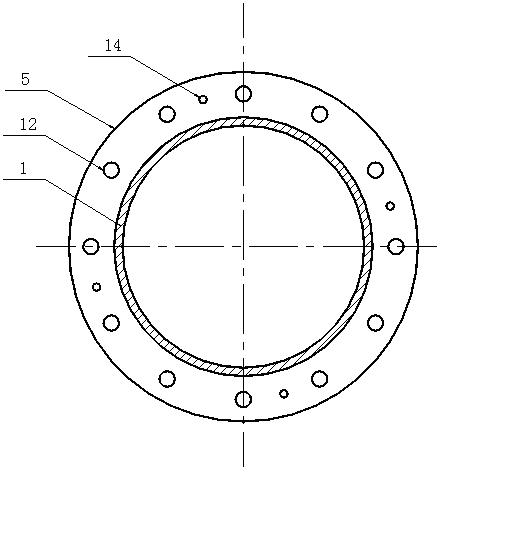

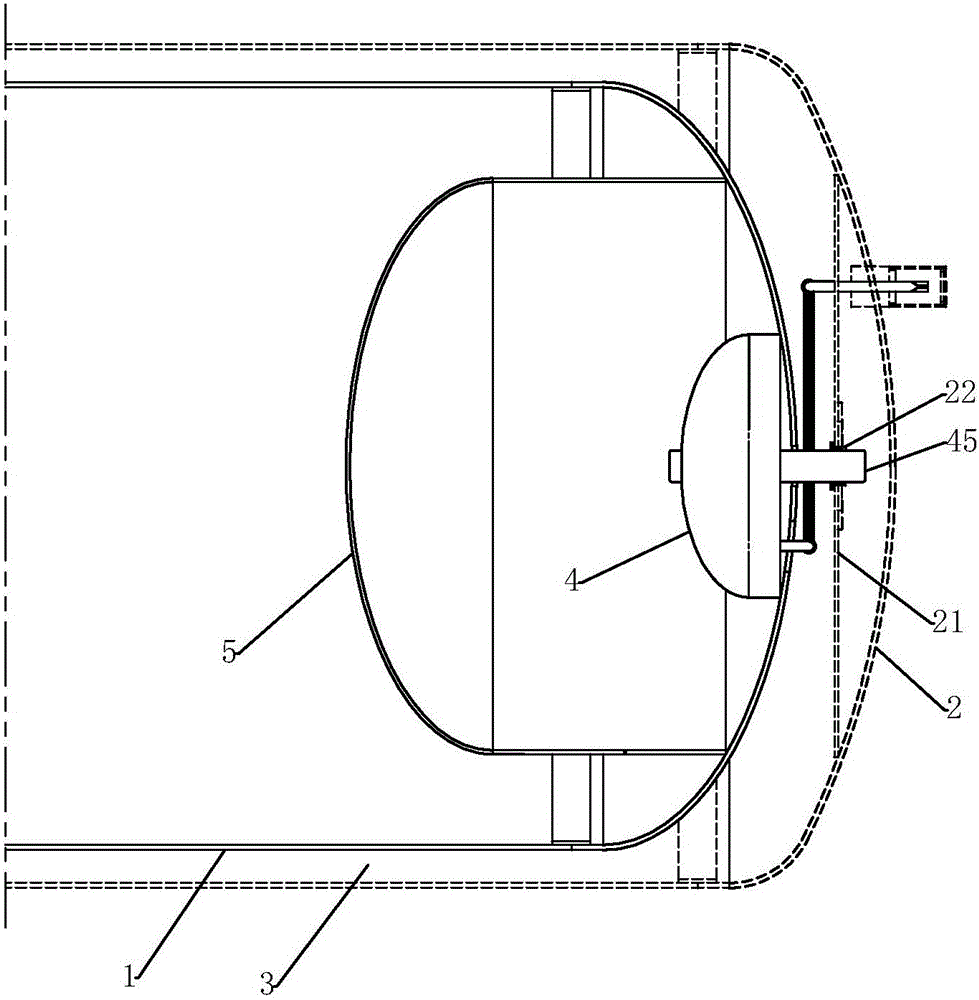

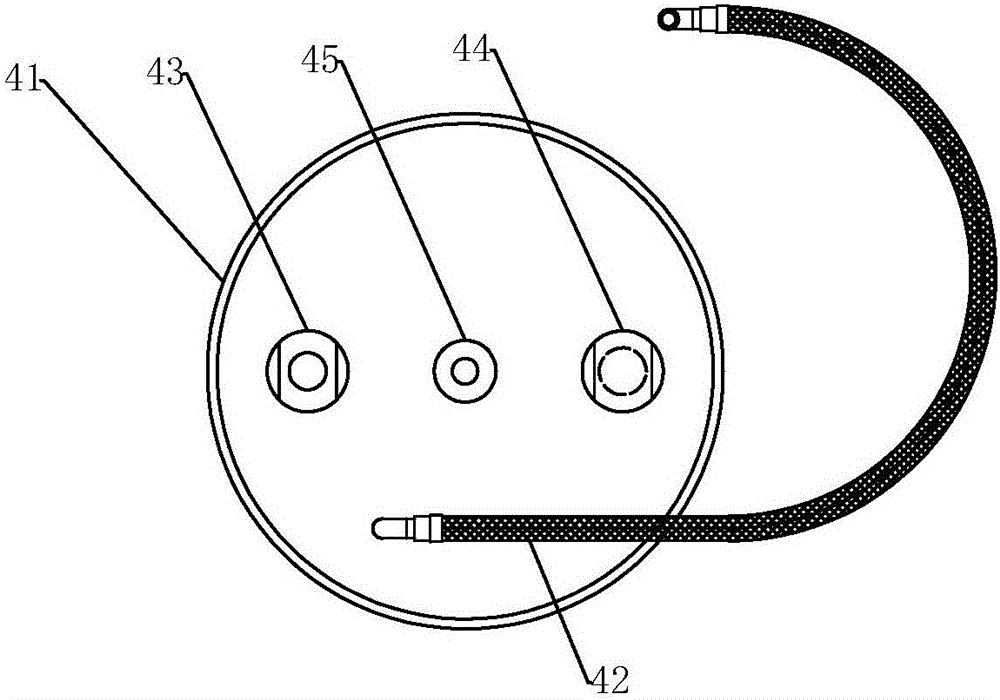

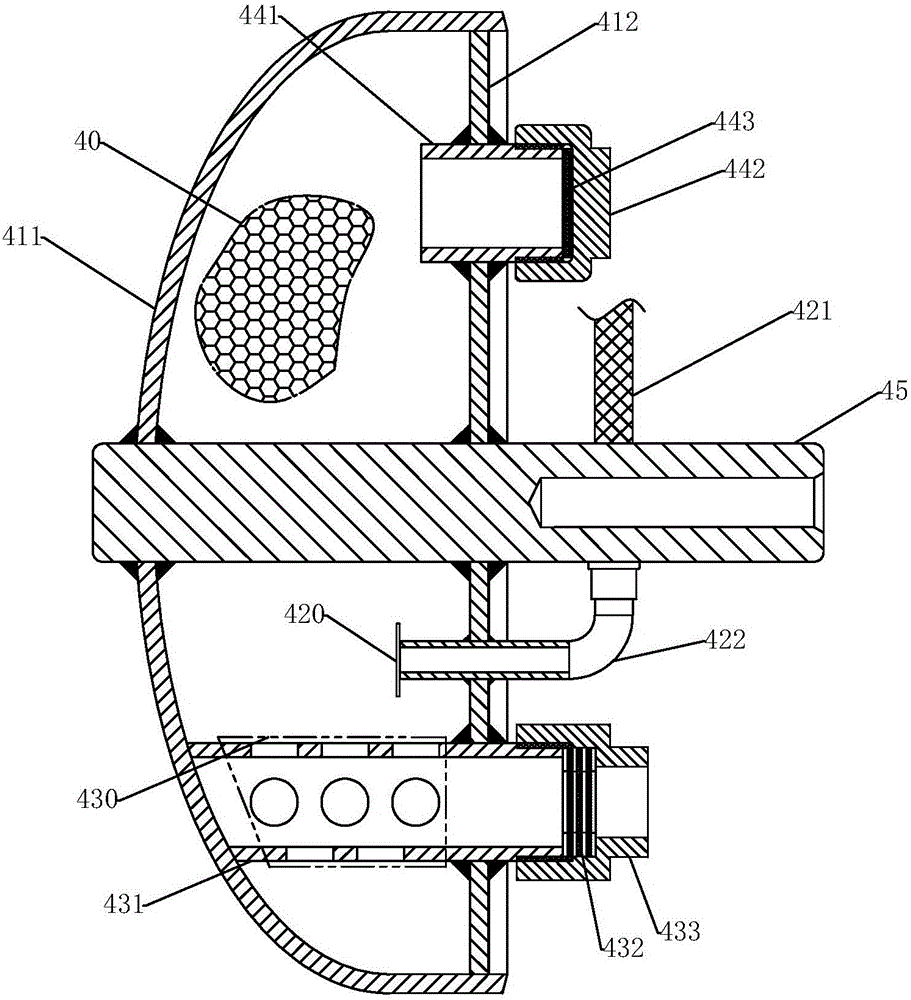

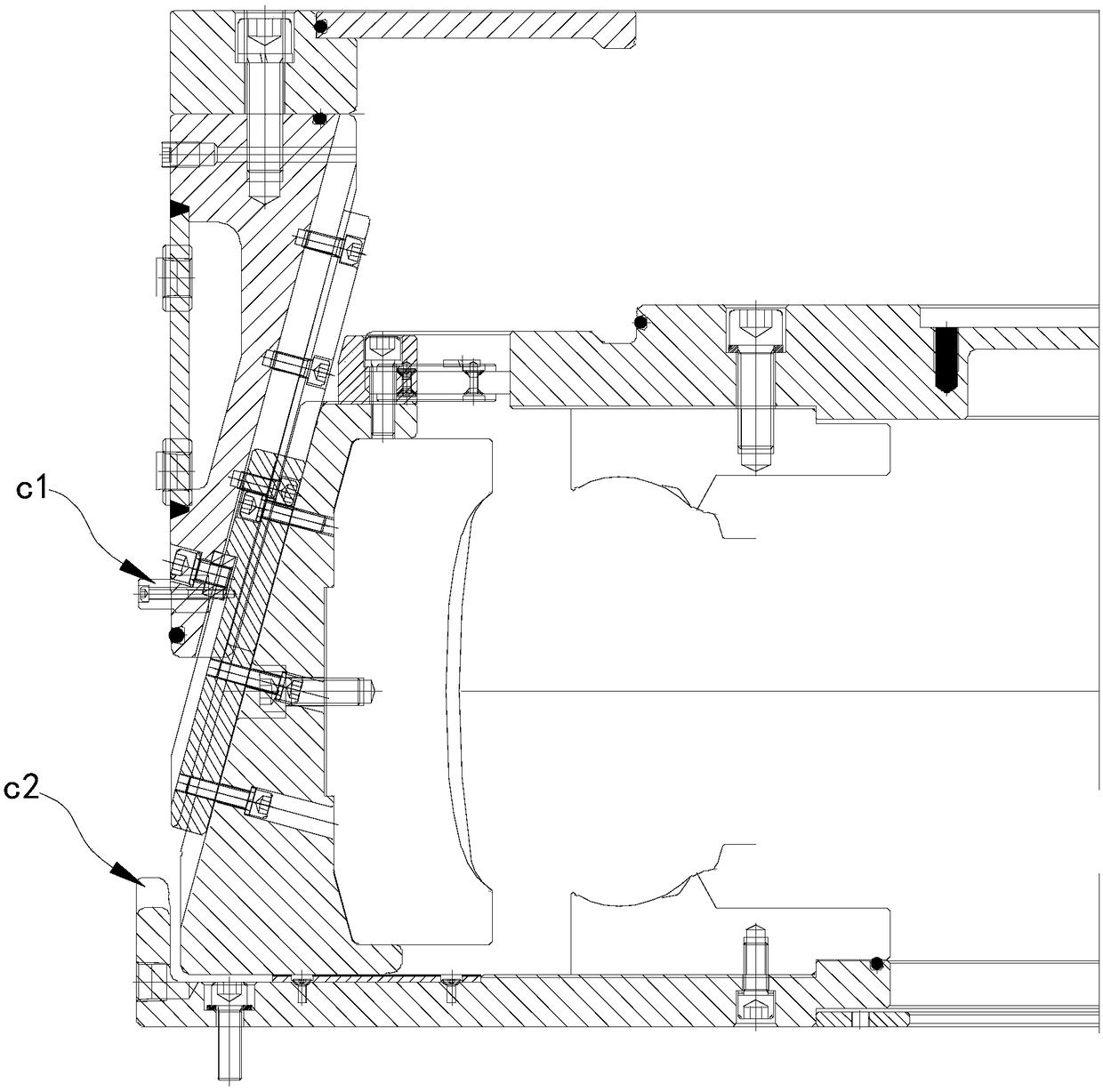

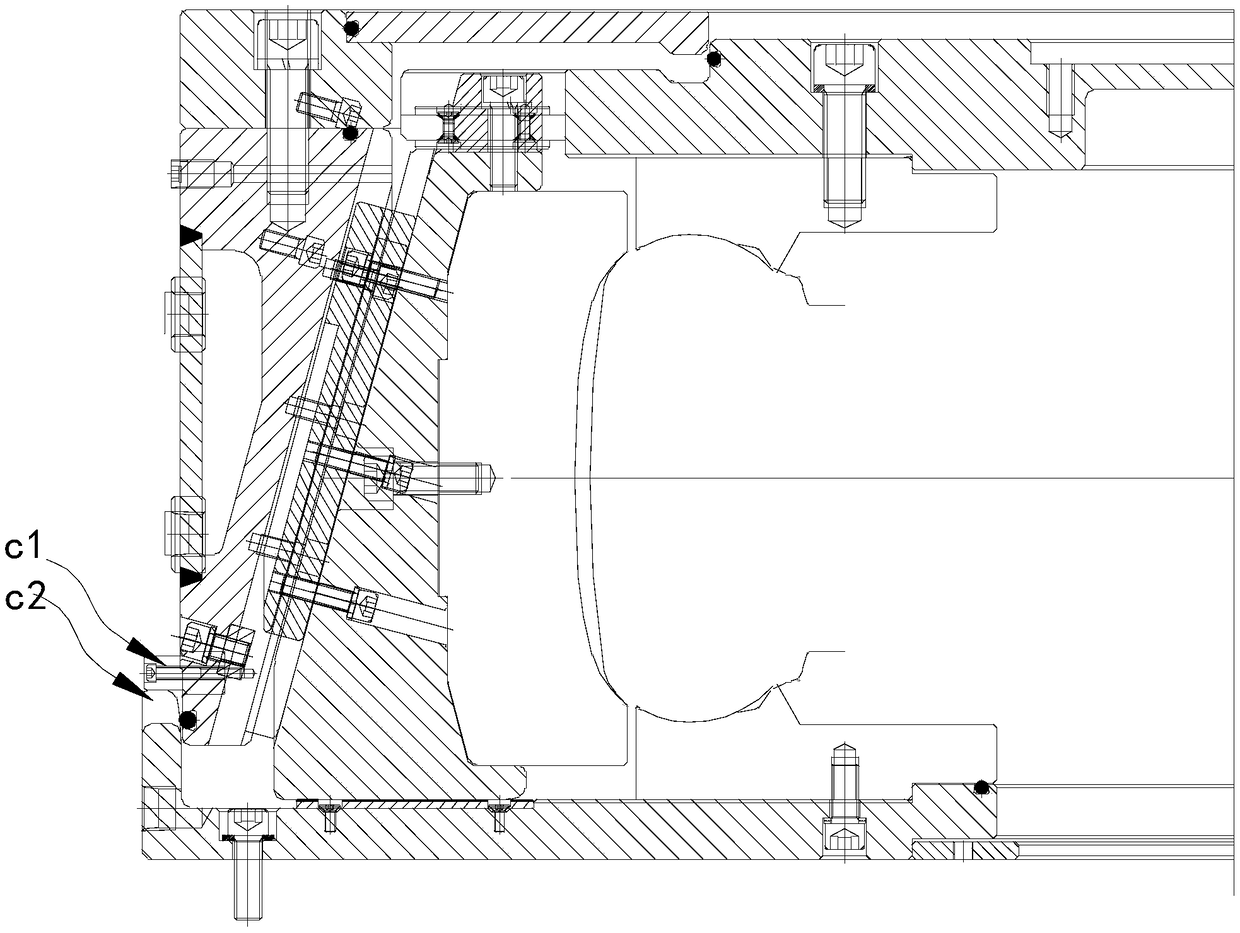

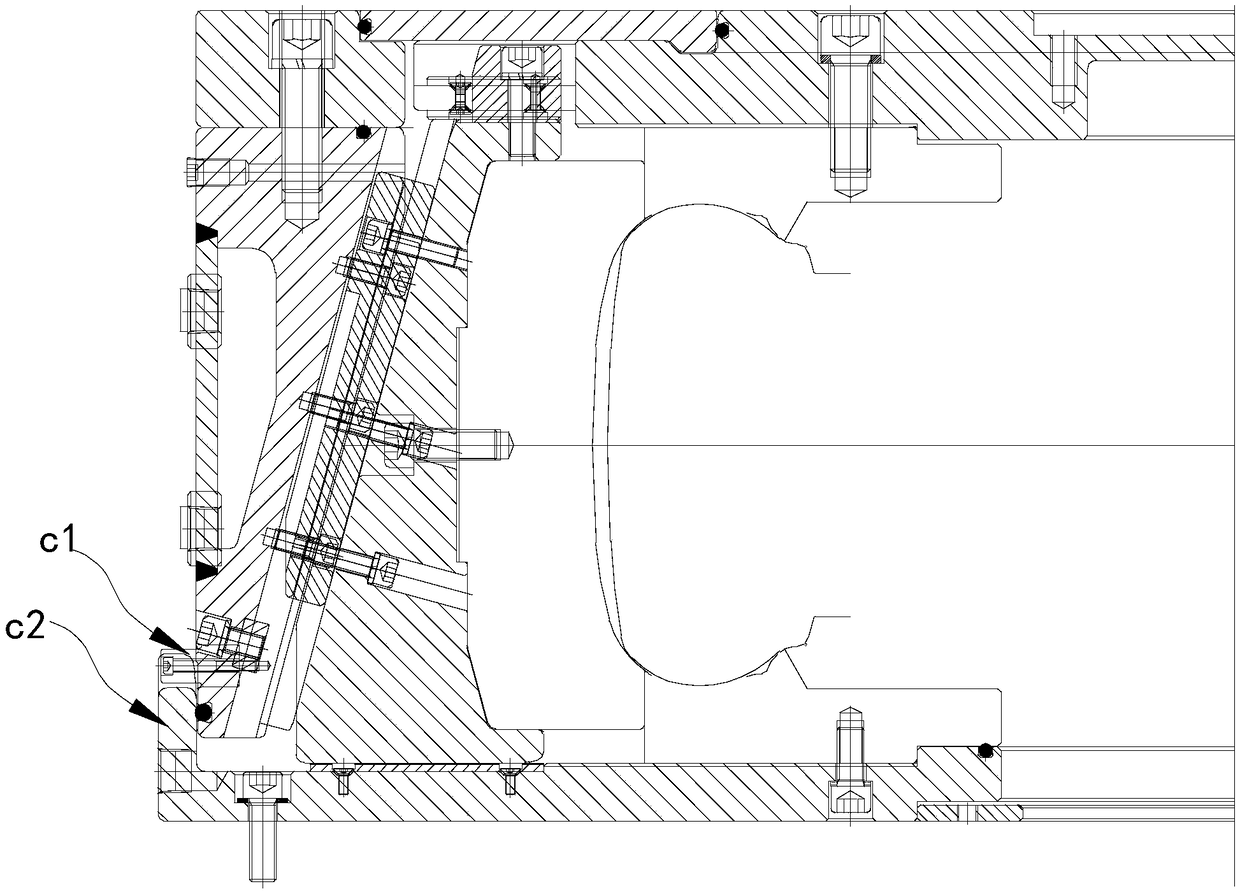

Sealing device and vacuum tire mould

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Oxygen increasing type condensing heat exhaust fresh air ventilator

ActiveCN106871320AReduce the numberGuaranteed vacuuming effectEnergy recovery in ventilation and heatingMechanical apparatusFresh airEngineering

The invention relates to the technical field of machinery and provides an oxygen increasing type condensing heat exhaust fresh air ventilator. The oxygen increasing type condensing heat exhaust fresh air ventilator comprises a fresh air unit, and the fresh air unit comprises a processor system for controlling the fresh air unit to work; the oxygen increasing type condensing heat exhaust fresh air ventilator furthermore comprises an oxygenerator, and the oxygenerator is provided with an air outlet for inputting oxygen into a room; and the processor system is connected with the oxygenerator, and the processor system is furthermore connected with a carbon dioxide sensor for monitoring the indoor carbon dioxide content. The indoor carbon dioxide content is monitored, the switch-on and switch-off conditions of the oxygenerator are adjusted according to the indoor carbon dioxide content, and it is convenient for the oxygenerator to convey oxygen into the room.

Owner:沃姆环境设备启东有限公司

Special carving device for full-automatic ceramic surface machining

ActiveCN108608563AAvoid direct scatterReduce labor intensityCeramic shaping apparatusWorking environmentEngineering

The invention discloses a special carving device for full-automatic ceramic surface machining. The device comprises a worktable; multiple mounting plates are fixedly arranged at the top of the worktable; mechanical arm bases are arranged on the front sides of the mounting plates; mechanical arms are fixedly arranged on one side surfaces of the mechanical arm bases; electric fixtures are arranged at the end parts of the mechanical arms; dust removing pipes are inserted in the electric fixtures, and are fixedly connected with the electric fixtures; carving cutters are clamped on the electric fixtures; the dust removing pipes are arranged on the two sides of the caving cutters; a conveying hard pipe is inserted in the worktable; and an air blower is arranged on the conveying hard pipe. Dust is effectively collected and treated to prevent direct scattering in the working environment, so that the labor intensity of operators is effectively reduced; meanwhile, the multiple mechanical arms can be used for synchronously machining the surfaces of ceramic blanks, so that the machining speed is higher, and the machining efficiency is higher compared with the prior art; and the device is suitable for industrial ceramic production.

Owner:安徽省亚欧陶瓷有限责任公司

Safe and return dust-less dust exhaust apparatus for lapper

InactiveCN102943371AAvoid wastingAvoid secondary pollutionMechanical cleaningPressure cleaningAbsorption effectEngineering

The invention relates to a safe and return dust-less dust exhaust apparatus for a lapper. The dust exhaust apparatus is characterized by comprising a suction hood, a dust filtering device and a dust collecting pipe for connecting the suction hood with the dust filtering device, wherein the dust collecting pipe is internally provided with a suction ventilator, and the dust filtering device comprises a box-shaped housing and at least one of layers of plate-shaped dust filtering cores arranged in the housing. According to the dust exhaust apparatus for the lapper, provided by the invention, the conventional filter bag is replaced by the dust filtering cores in the dust filtering device, and the dust filtering device is better in air permeability and less in return dust, so that the dust exhaust apparatus is better in filtering effect, safer in process, capable of being protected by a hard housing, hard to damage and longer in service life. The suction ventilator can be additively provided with a motor speed adjusting device, and the housing is internally provided with the plurality of layers of detachable dust filtering cores, so that the proper dust filtering intensity can be adjusted according to the dust absorption requirements of different occasions such as the different fabrics, therefore, not only can the energy waste be avoided, but also the dust absorption effect can be guaranteed.

Owner:WUJIANG KESHIDA TEXTILE

Marble building material cutting and grinding integrated equipment with dustproof function

InactiveCN113199638AReasonable structureImprove processing efficiencyGrinding carriagesDispersed particle filtrationArchitectural engineeringStructural engineering

The invention discloses marble building material cutting and grinding integrated equipment with a dustproof function, and relates to the field of marble building material machining equipment. The marble building material cutting and grinding integrated equipment comprises a machining table, wherein a cutting and grinding part, a dust collection part and a conveying assembly are installed on the machining table, and the conveying assembly comprises a sliding groove formed in the top of the machining table; and a sliding block is installed in the sliding groove in a sliding manner. According to the marble building material cutting and grinding device, when a servo motor is started, a placing plate can be driven to move, so that marble building materials are sequentially subjected to cutting treatment through a cutting machine and grinding treatment through a grinding machine, cutting and grinding of the marble building materials can be completed at a time, workers do not need to carry the marble building materials any more, time and labor are saved, and the machining efficiency is improved; and when a suction fan is started, dust generated by cutting and grinding can be sucked into a dust suction pipe, so that it is guaranteed that air in the field working environment is clean, and the situation that because the workers suck the dust for a long time, the health of workers is affected can be effectively avoided.

Owner:杭州勇冠网络科技有限公司

Replacement chamber sealing apparatus for electronic material firing furnace

InactiveCN105546993AShielding gas ensuresImprove firing qualityFurnace componentsElectronic materialsEngineering

The invention relates to a replacement chamber sealing apparatus for an electronic material firing furnace, and belongs to the technical field of an electronic kiln. The electronic material firing furnace comprises a furnace body, an inlet gas chamber box body, a left replacement chamber and a right replacement chamber; the inlet gas chamber box body is connected with the furnace body and is communicated with a hearth; the left replacement chamber is formed corresponding to a position of a cavity port of the inlet gas chamber box body and is communicated with the inlet gas chamber box body; the right replacement chamber is formed corresponding to a position of a left replacement chamber inlet of the left replacement chamber and is communicated with the left replacement chamber; the replacement chamber sealing apparatus comprises a replacement chamber door box; a replacement chamber lifting mechanism is arranged in the replacement chamber door box; and the replacement chamber sealing apparatus is characterized by further comprising a replacement chamber door external force application mechanism which is arranged at the front side or the rear side of the replacement chamber door box and is matched with one side of a replacement chamber door, which is back to a doorframe sealing ring. The replacement chamber sealing apparatus has a good sealing effect, ensures a vacuumizing effect, saves protection gas filled into the inlet gas chamber box body and the left and right replacement chambers and ensures atmosphere balance, and firing quality of an electronic material is improved.

Owner:SUZHOU HUIKE EQUIP CO LTD

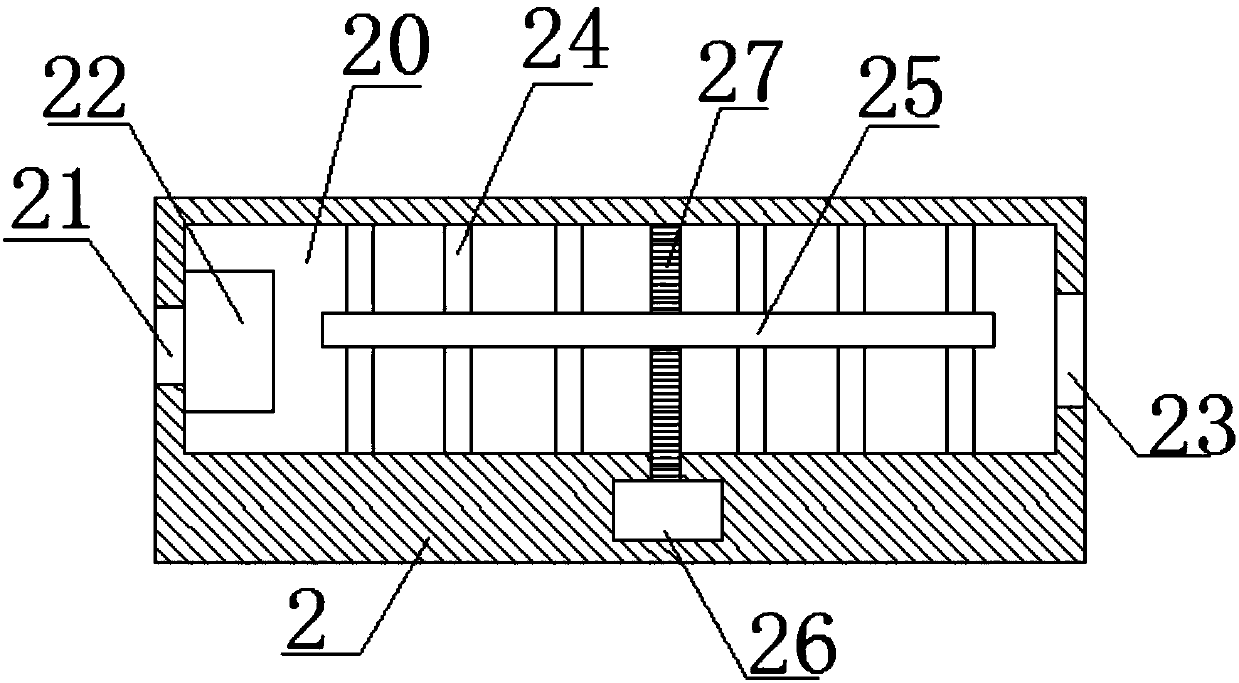

Hydraulic suction seamless repair machine for car shell

A hydraulic suction seamless repair machine for a car shell belongs to the field of car shell repair equipment and particularly relates to a hydraulic suction repair machine for a car shell. The hydraulic suction seamless repair machine is characterized in that a power mechanism comprises a piston rod (5), as well as an upper hydraulic mechanism and a lower hydraulic mechanism which are vertically connected into a whole through a connecting part (6), wherein the piston rod (5) passes through the connecting part (6) to penetrate the upper hydraulic mechanism and the lower hydraulic mechanism; the interior of the upper hydraulic mechanism is divided into a water injection cavity (22) at the upper part and an air cavity (23) at the lower part through a sealing device at the top end of the piston rod (5); one side of the water injection cavity (22) is connected with a water injection mechanism; a circulatory venthole (26) is formed in the hydraulic cylinder wall on one side of the air cavity (25); a sucker (1) is communicated with the water injection cavity (22) through a through hole (23). The hydraulic suction seamless repair machine adopts the evacuating method that water is injected into the sucker at first and then discharged, and the hydraulic power mechanism provides a stable suction force to complete repair, so that the suction force is strong and the repair effect is remarkable.

Owner:张万海

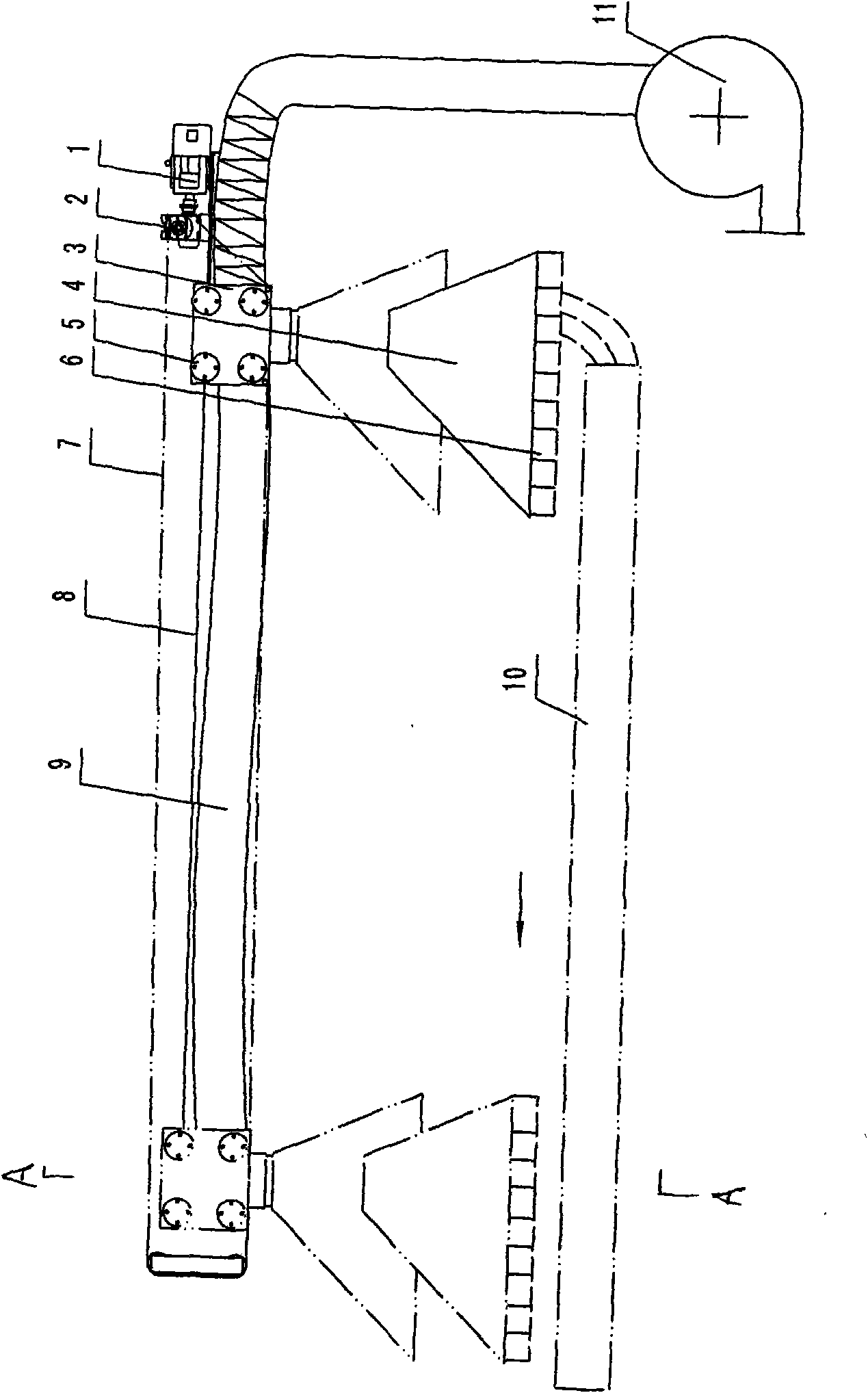

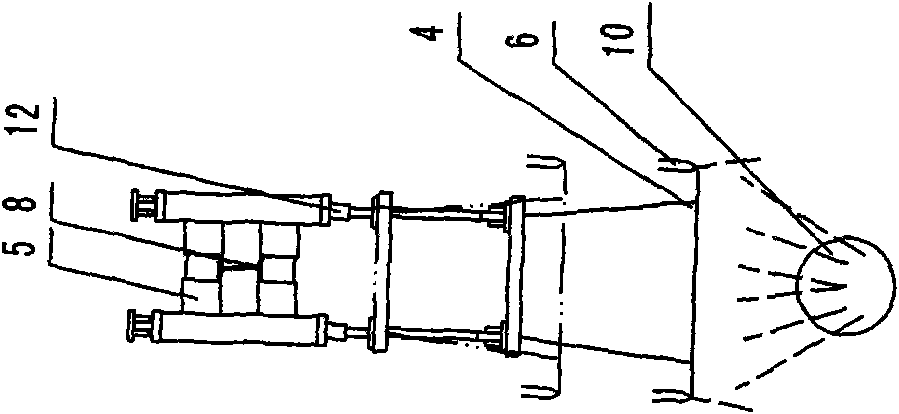

Device for absorbing graphite dust

The invention discloses a device for absorbing graphite dust, comprising a bracket. The bracket is provided with a motor (1), a speed reducer (2) and an I-beam (8). The motor (1) drives the speed reducer (2). The device is characterized in that the I-beam (8) is positioned right above a steel tube (10) made of an expanding pipe, the speed reducer (2) drives a pulley (5) to move along the I-beam (8) through a steel wire (7), the pulley (5) is fixedly connected with a dust absorbing hood (4) arranged below the pulley (5) and the dust absorbing hood (4) is connected with a draught fan (11) through a hose (9). The device ensures that the dust absorbing hood is positioned above the tail of the steel tube at any time by adopting a moving mode and effectively absorbs graphite diffused from a steel tube cavity to the outdoor at any time.

Owner:烟台鲁宝钢管有限责任公司

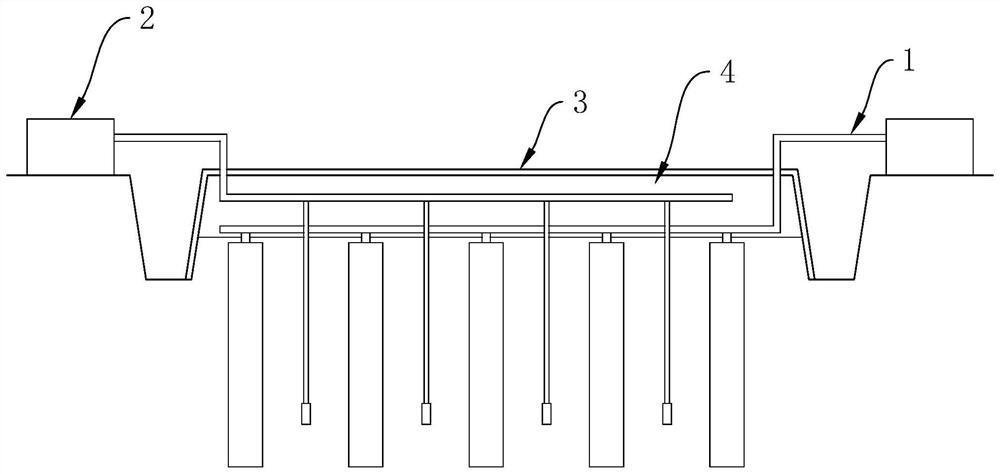

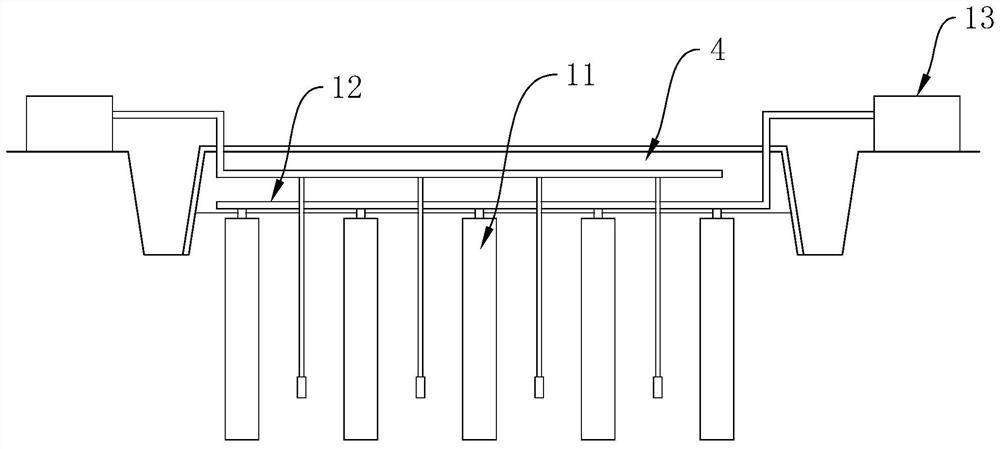

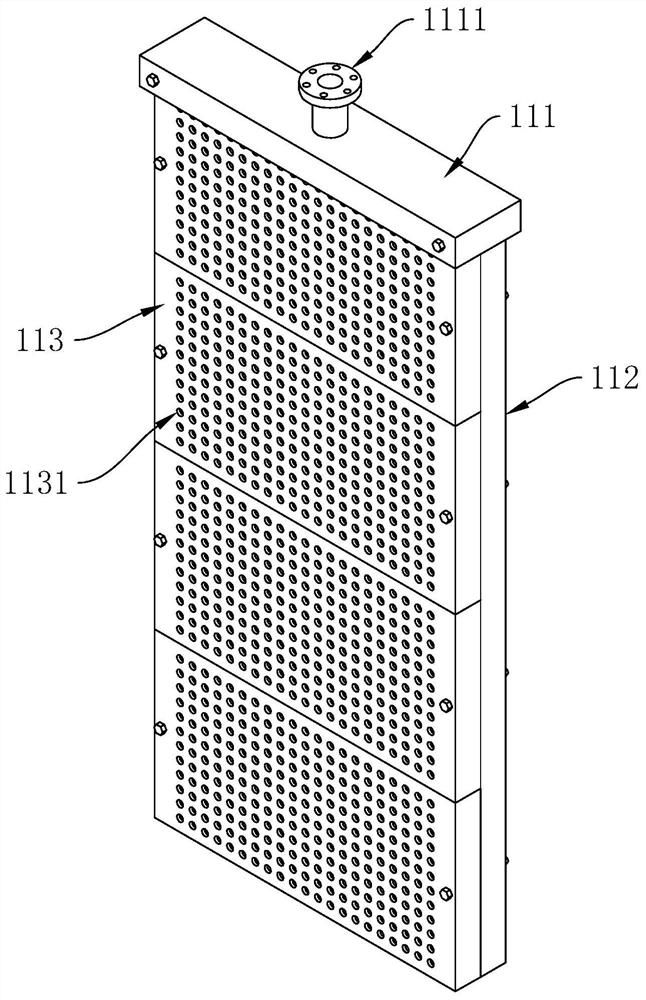

Vacuum preloading treatment system and process

PendingCN112144503AGuaranteed permeabilityGuaranteed vacuumSoil preservationAir compressorPumping vacuum

The invention relates to a vacuum preloading treatment system, and relates to the field of foundation negative pressure hardening technologies. The vacuum preloading treatment system comprises a plurality of vertical drainage plates, a horizontal water suction pipeline, a vacuumizing device and a sealing film, wherein the vertical drainage plates are vertically buried in a foundation, the horizontal water suction pipeline is pre-buried in a sand cushion layer and communicates with the upper ends of the vertical drainage plates, the vacuumizing device communicates with the horizontal water suction pipeline, and the sealing film covers the ground. The vacuum preloading treatment system further comprises a first air compressor, an air supply pipe and a plurality of air injection pipes, wherein the air supply pipe is horizontally buried in the sand cushion layer, the air injection pipes are vertically buried in the foundation, the air injection pipes communicate with the air supply pipe, and the first air compressor communicates with the air supply pipe. The vacuum preloading treatment system has the effect of improving the too low permeability of soil.

Owner:FUJIAN BAICHUAN CONSTR DEV

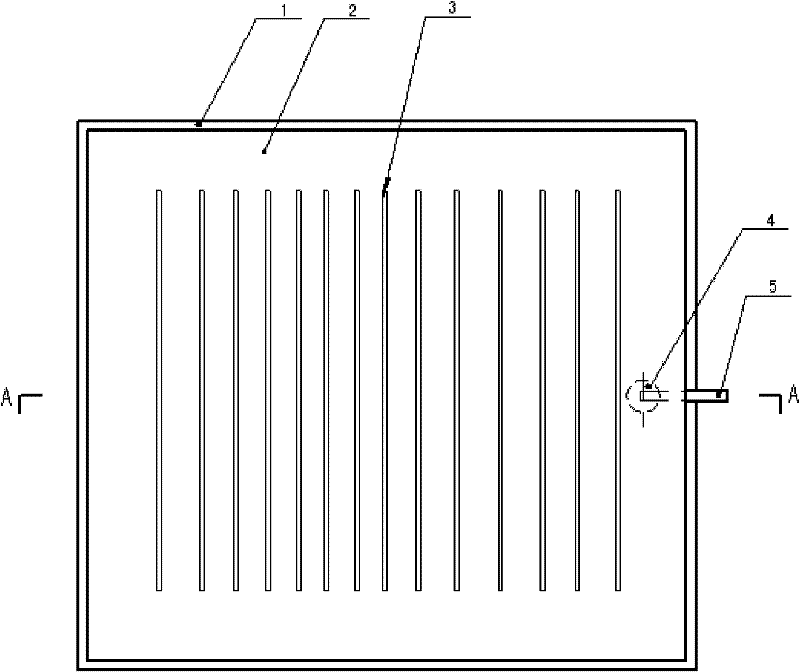

A method for placing a vacuum glass support

The invention relates to a paving method of supports for vacuum glass, and the paving method comprises the steps: (1) tailoring upper glass and substrate glass and forming extraction grooves or holes on the side of the substrate glass or the plane of the upper glass; (2) parallelly and uniformly paving support wires or support rods on the glass substrate by bonding with an adhesive, wherein the distance between the support wires or support rods in the length direction and the edge of the substrate glass is 1-15 cm and the interval between the support wires or support rods is 2-20cm; and (3) placing extraction pipes in the extraction grooves, filling sealing materials at the periphery of the upper glass and substrate glass, introducing the upper glass and glass substrate into a furnace, heating to 100-500 DEG C and vacuumizing to obtain a finished product. Through the paving method provided by the invention, the support wires or support rods are directly bonded onto the substrate glass or directly processed into film layers containing the support wires or support rods, thereby realizing the rapid paving of the supports for the vacuum glass; the paving method is accurate in positioning and high in paving efficiency; and the film layers further enhance the heat-insulation performance of the vacuum glass, thus effectively improving the production efficiency and performance of the vacuum glass.

Owner:左树森

Packaging and film covering device for formed EPS foam board

ActiveCN109130434AImprove lamination efficiencyTimely coolingLamination ancillary operationsLaminationEngineeringVacuum pump

The invention discloses a packaging and film covering device for a formed EPS foam board, and relates to the technical field of foam board processing. The device comprises a machine body; a material feeding roller, a discharging roller and driven rollers are respectively and rotationally connected between opposite inner surfaces of the machine body; a conveying belt is connected to the surfaces ofthe material feeding roller and the discharging roller; vacuum suction holes are formed in one surface of the machine body; the surfaces of the vacuum suction holes communicate with a vacuum pump; one surface of the vacuum pump is fixedly connected with the machine body; one surface of the machine body is fixedly connected with adjustable pipe clamps; and a guide rod is clamped on the inner surfaces of the adjustable pipe clamps. According to the invention, the automatic film covering operation of the film covering device can be realized by the design of the material feeding roller, the discharging roller and material conveying rollers, and the film covering efficiency of the foam board is improved; and through the position design of a cooling box and a heating box, a frame can be cooledin time by a cooling mechanism after a film clamping frame is used, thereby preventing the film clamping frame from affecting the film covering effect.

Owner:丰县建鑫泡沫制品有限公司

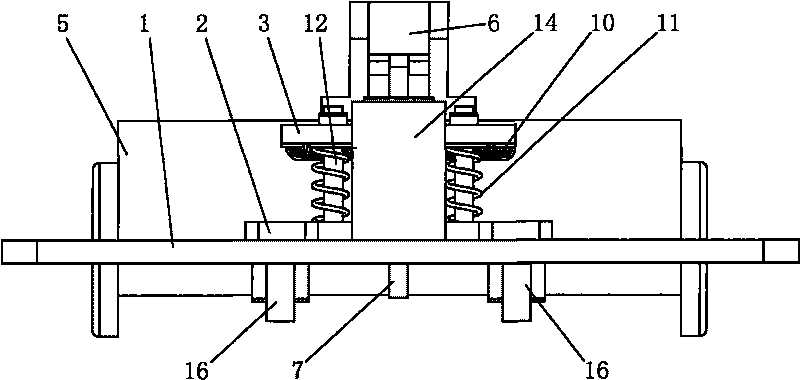

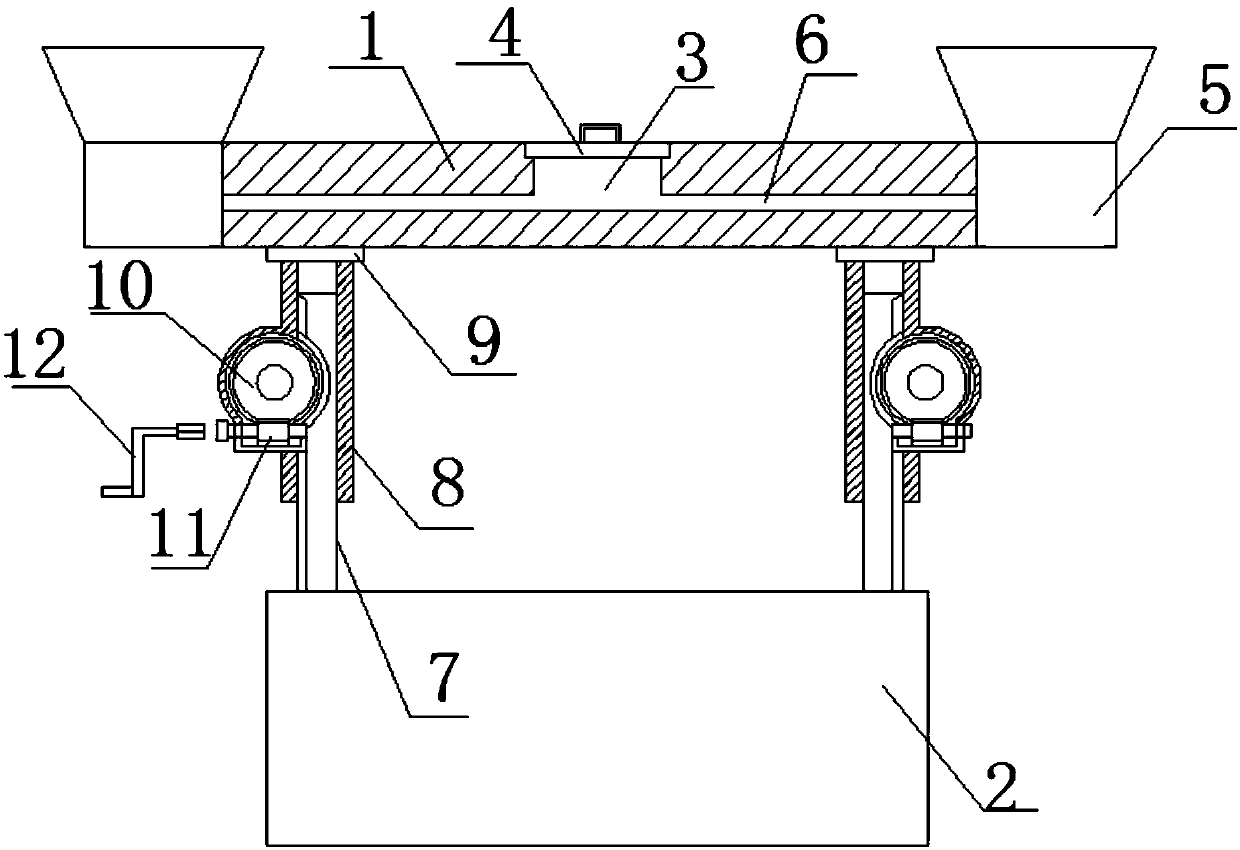

Four-column guide vacuumizing pressurizing vibration forming machine

PendingCN111469480ASolve the problem of exerting pressureGuaranteed vacuuming effectShaping pressMolding machineEngineering

The invention relates to a four-column guide vacuumizing pressurizing vibration forming machine. A rack of the four-column guide vacuumizing pressurizing vibration forming machine comprises four standcolumns, a base and a top mounting base, wherein a weight beam is mounted on the stand columns; a connecting column is mounted below the weight beam; a vacuum cover is mounted on the connecting column in a sleeving manner; a pressing head is fixedly mounted at the bottom of the connecting column; a vibration platform is mounted above the base; a mold box is mounted above the vibration platform; locking mechanisms are mounted on the vibration platform and positioned on the two sides of the mold box; each locking mechanism comprises a pressing rod, wherein the pressing rod can be buckled and pressed on the vacuum cover; a vacuum cover clamping jaw matched with the pressing rods of the locking mechanisms is arranged on the side wall of the vacuum cover; each vacuum cover clamping jaw comprises a clamping jaw side plate, wherein the clamping jaw side plate is welded to the side wall of the vacuum cover, a pin shaft clamping block is arranged on the clamping jaw side plate, and a pin shaftgroove is formed in the pin shaft clamping block; and a clamping and fixing pin mounting pin hole is formed in the end of each pressing rod, and a clamping and fixing pin rod is mounted in each clamping and fixing pin mounting pin hole. The four-column guide vacuumizing pressurizing vibration forming machine has the beneficial effects of being good in sealing performance, safe and stable.

Owner:山东华鹏重工有限公司

Tea table capable of removing dust

InactiveCN107836844AEliminate potential hazardsEasy to handleFurniture partsServing tablesWater storageEngineering

The invention discloses a tea table capable of removing dust. The tea table comprises a crank, a table plate and a pedestal; a connecting plate is installed at a lower side of the table plate; a support housing is installed at a lower side of the connecting plate; a gear shaft is installed inside the support housing; the pedestal is installed at a lower end of the gear shaft; a turbine is installed in the middle of the support housing; a worm is installed at a lower end of the turbine; a hexagonal sleeve is installed at a left end of the worm; an inner hexagon socket is installed on the crank;a water chamber is opened in the middle at an upper side of the table plate; flower pots are installed at the left end and the right end of the table plate; a mud separating plate is installed insidethe flower pot; a water storage chamber is installed between a lower side of the mud separating plate and a flower pot; the water storage chamber is provided with water absorbing sponge; water pipesare installed at a left end and a right end of the water chamber; the water storage chamber is provided with a water inlet which is connected with the water pipes; a purifying chamber is opened insidethe pedestal. The invention has a simple structure and high comfortableness and is convenient to use; tea water can be utilize and the air is purified.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

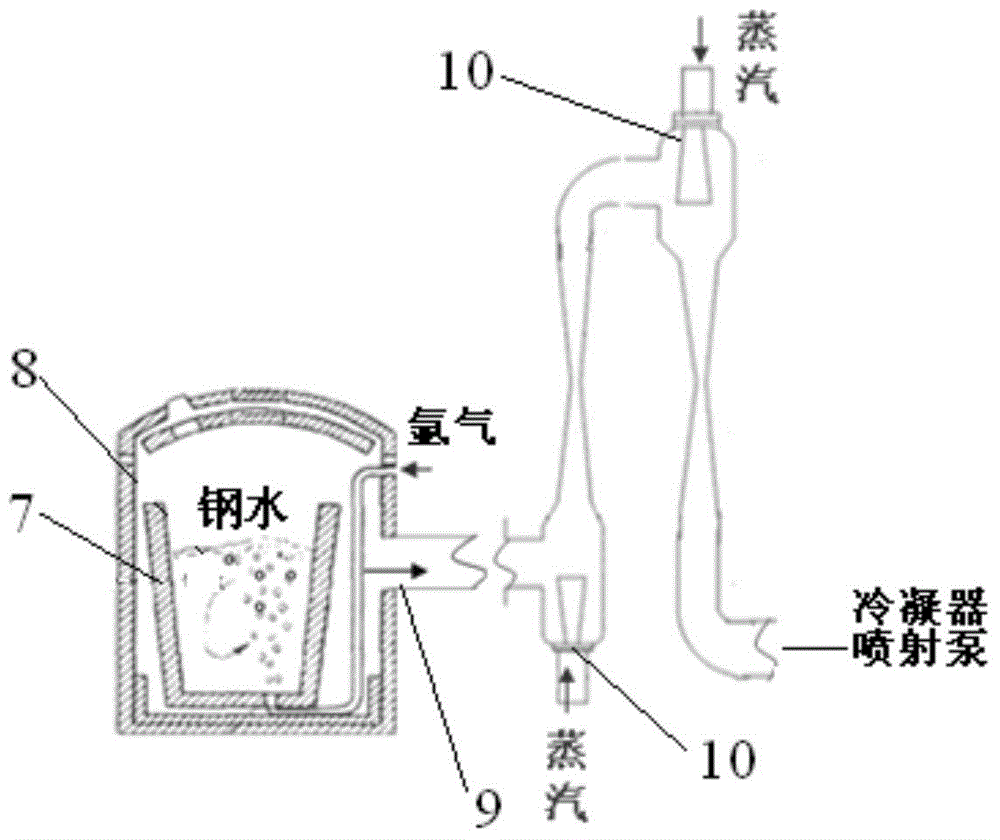

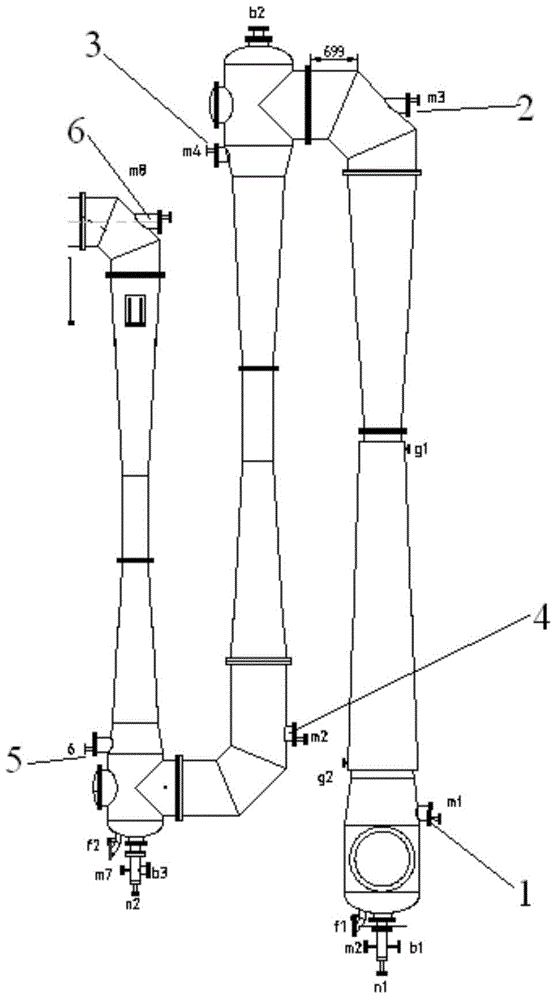

Inner wall cleaning device for steam jet pump

InactiveCN104314883AReduce labor intensityGuaranteed vacuum effectHollow article cleaningJet pumpsInjection pumpEngineering

The invention discloses an inner wall cleaning device for a steam jet pump. The jet pump is arranged in a molten steel vacuum processor; the molten steel vacuum processor is communicated with an exhaust hole of a vacuum tank by a vacuum pipeline; along the vacuum exhaust direction, the jet pump comprises a first level jet pump, a second level jet pump and a third level jet pump; the pipeline of the motel steel vacuum processor is provided with a cleaning spraying mechanism. By adopting the technical scheme, under the condition of a limited site position, the invention provides the cleaning device for accumulated dust on the inner wall of the steam jet pump and solves the difficulties in the prior art; each cleaning point is controlled to start spraying and cleaning according to solenoid valves, an automatic water gun sprays water to clean a pipeline wall, the worker labor intensity is relieved, and the vacuum effect of molten steel is ensured; a nozzle positioned under a pump body is enabled not to be blocked; sewage generated by spraying and cleaning is drained as an drain pipe is arranged under the pump body.

Owner:WUHU XINXING DUCTILE IRON PIPES

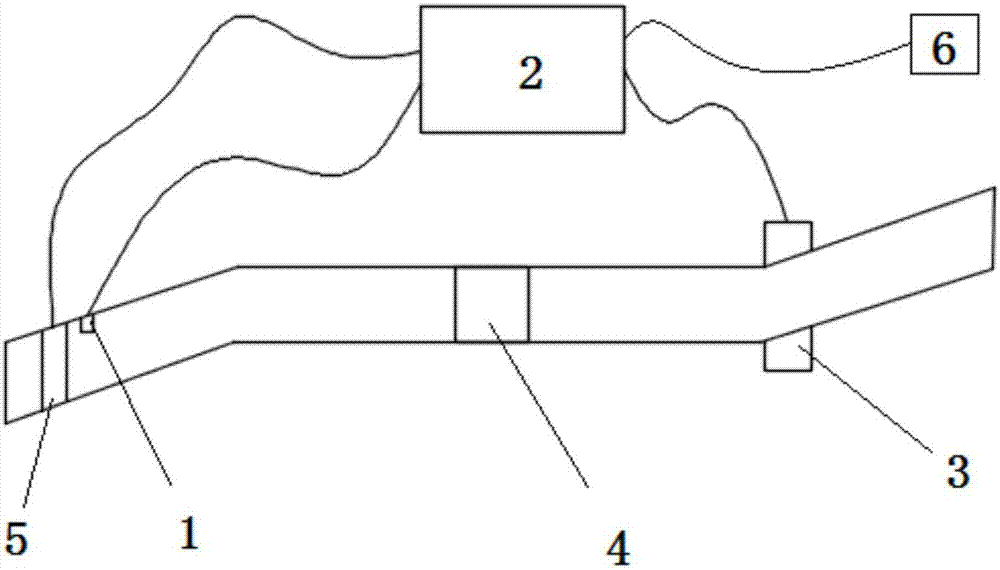

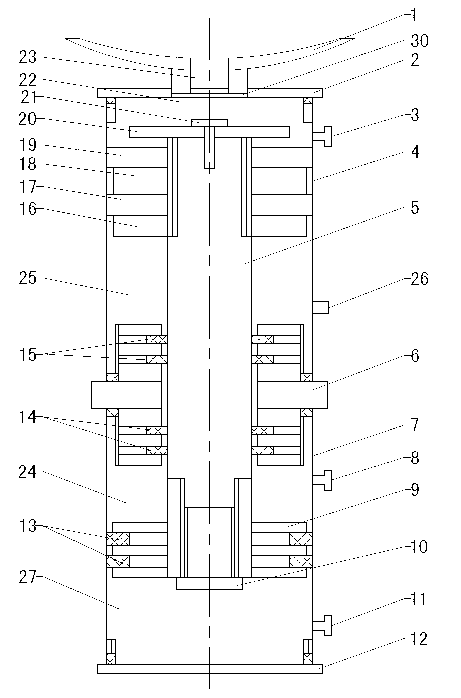

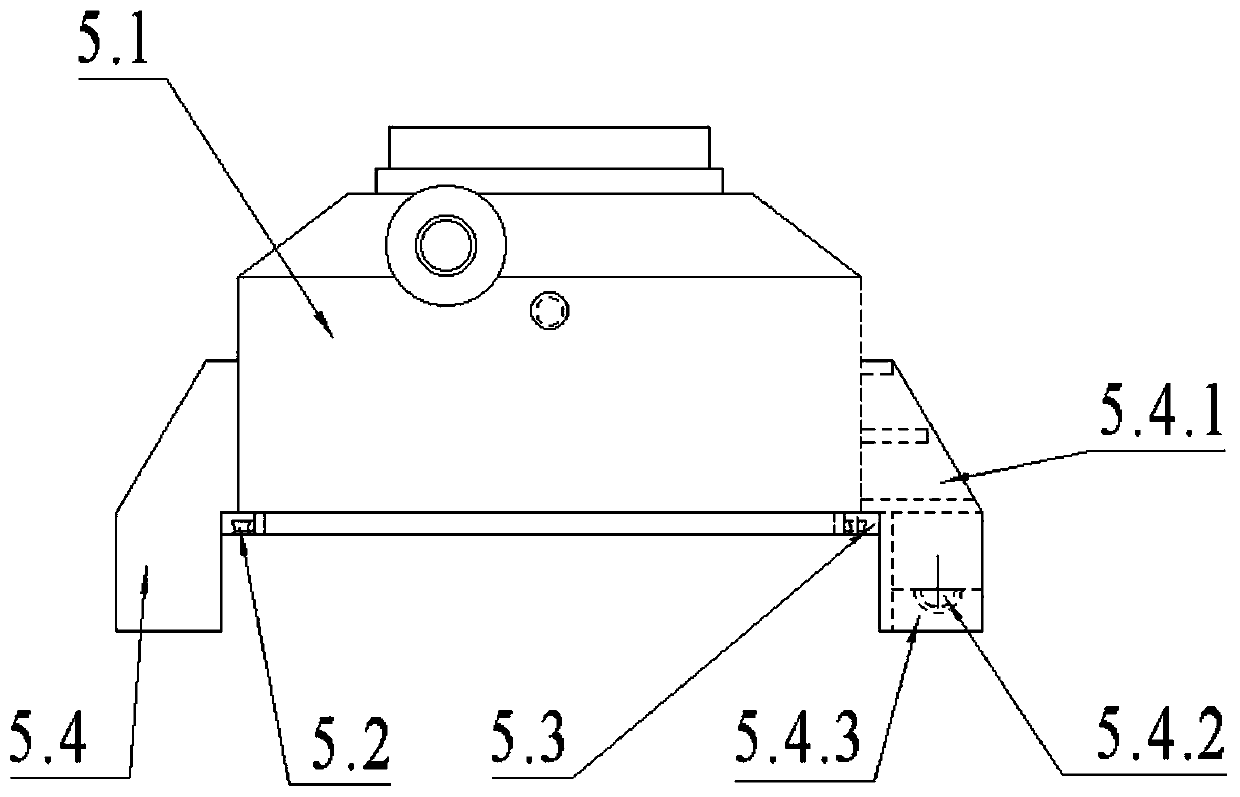

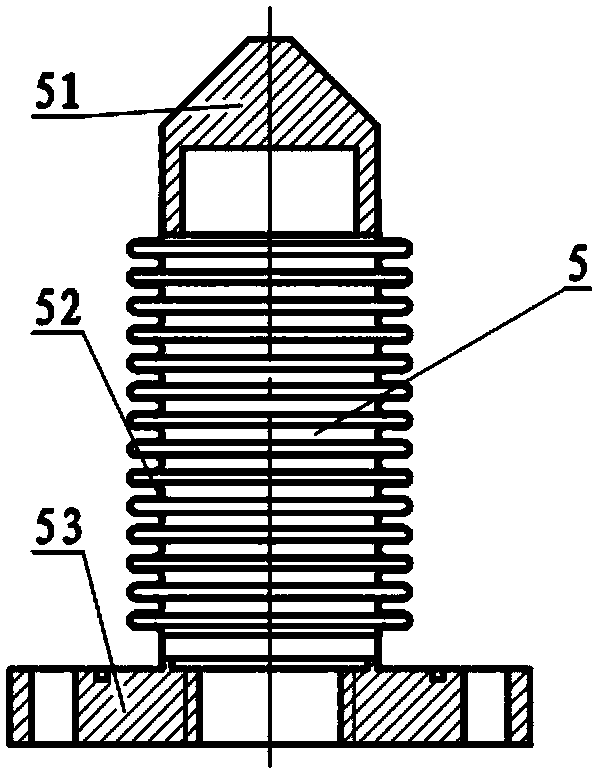

Superconducting magnet low-temperature container conveying and supporting device

ActiveCN104029899ARealize transportation supportGuaranteed vacuuming effectExternal fittingsSuperconducting CoilsEngineering

A superconducting magnet low-temperature container conveying and supporting device comprises an inner container conveying support (4), a corrugated pipe sealing base (5) and an ejector rod (6). A taper hole is formed in the lower end of an inner cavity of the inner container conveying support (4). The corrugated pipe sealing base (5) comprises a tapered base (51), a corrugated pipe (52) and a sealing flange (53). The tapered base (51) is divided into a tapered section and a circular section. A taper angle of the taper section is the same as a taper angle of the taper hole of the inner cavity of the inner container conveying support (4). A circular hole is formed in the bottom of the circular section and used for containing the ejector rod. The inner container conveying support (4) is welded to an inner container bottom plate (1). The corrugated pipe sealing base (5) is fixed to a vacuum container bottom plate (3) through the sealing flange (53). The ejector rod (6) is rotationally inserted into the tapered base (51) and pushes the corrugated pipe sealing base (5) to move until the tapered base (51) is inserted into the taper hole in the inner cavity of the inner container conveying support (4) to make close contact with the taper hole.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Dismantling equipment and dismantling process for scrapped automobiles

ActiveCN111515491BAvoid emissionsProtect your healthVehicle dissasembly recoveryDispersed particle filtrationConvertersAutomobile air conditioning

The invention discloses a scrapped automobile dismantling equipment and a dismantling process, and relates to the technical field of scrapped automobile dismantling. Its technical gist is: a scrapped car dismantling process, including the following steps: inspection and registration, checking and registering the information of scrapped cars; pretreatment, removing batteries, removing and detonating airbags, removing waste capacitors containing PCBs and tail gas purification catalyst, empty and collect the waste liquid in the car, and recycle the automobile air-conditioning refrigerant; dismantle, use the scrapped car dismantling equipment to cut and disassemble the car body, and then remove the fuel tank, oil filter, Glass, parts containing toxic substances, converters and mufflers, tires, copper and aluminum parts, plastic parts, rubber parts, assemblies and parts; storage and management, sorted storage of parts, materials and waste after disassembly and logo. The invention has the advantage of protecting workers' health.

Owner:陕西欣辉报废汽车回收拆解有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com