Vacuum preloading treatment system and process

A processing system and preloading technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problem of low soil permeability and achieve the effects of reducing the time of vacuuming, ensuring permeability, and ensuring vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

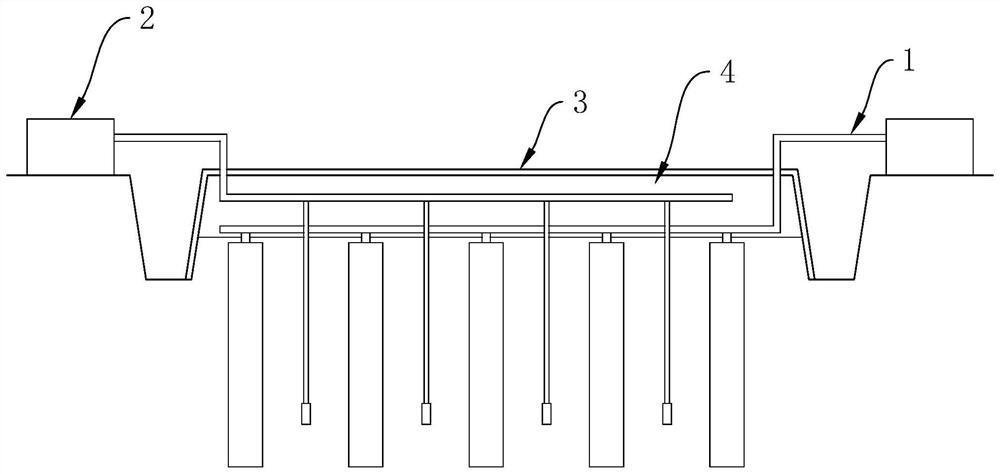

[0044] The embodiment of the present application discloses a vacuum pre-pressing treatment system. refer to figure 1, the vacuum preloading treatment system includes a drainage assembly 1, a micro-splitting assembly 2, a sealing assembly 3, and vibration equipment (not shown in the figure), the drainage system is used to vacuum the foundation to achieve the effect of drainage, and the micro-splitting The cracking system is used to split the foundation soil to achieve the effect of improving the soil permeability, the sealing component 3 is used to seal the surface of the foundation to ensure the vacuum effect of the drainage component 1, and the vibration equipment is used to clean the foundation Densification is performed to speed up the consolidation efficiency of the foundation; among them, in this technical solution, the vibratory equipment adopts a vibratory road roller.

[0045] Among them, before installing the vacuum components, bulldozers were used to push away the s...

Embodiment 2

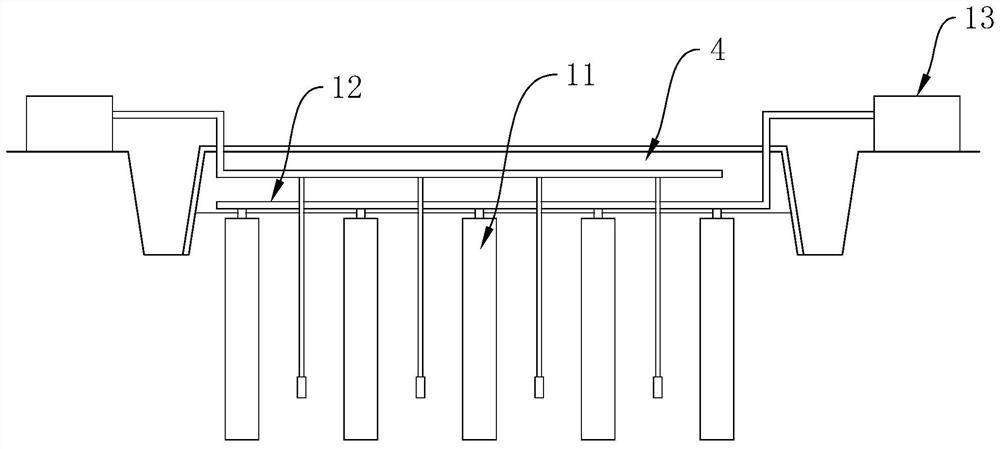

[0059] refer to Figure 7 , The difference between this embodiment and Embodiment 1 is that the drainage assembly 1 includes a vertical drainage board 11, a horizontal water suction pipeline 12, a horizontal gas delivery pipeline 14, a vacuum device 13 and a second air compressor 15, and the vacuum device 13 It communicates with the horizontal water suction pipeline 12, and the second air compressor 15 communicates with the horizontal gas delivery pipeline 14.

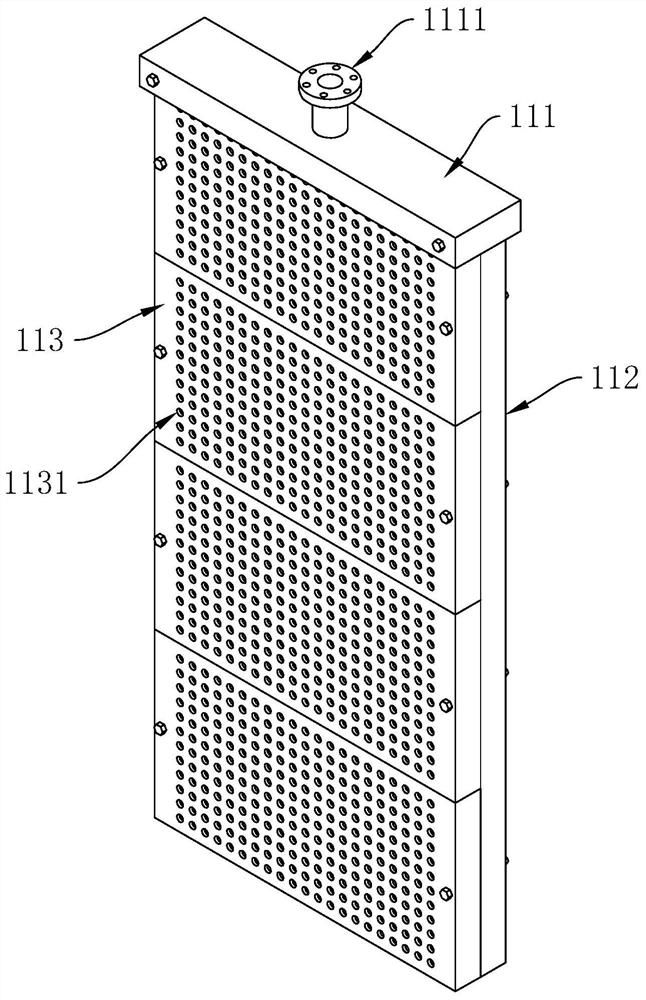

[0060] Among them, refer to Figure 8 , the vertical drainage plate 11 includes a main body 115, a drain pipe 116, an air supply pipe 117 and a plurality of rectangular plate frames 113, the main body 115 is used to connect the drain pipe 116, the air supply pipe 117 and each rectangular plate frame 113, and the rectangular plate frame 113 is used for Drainage chambers 1133 are formed in the main body 115 . Drainage pipes 116 are used to communicate each drainage chamber 1133 with the horizontal water suction pipe 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com