Multilayer screening machine

A technology of screening machine and sieve plate, which is applied in the direction of sieving, solid separation, grille, etc., can solve the problems of easy blockage of the sieve plate, high equipment cost, and many required equipment, so as to achieve low use cost and high efficiency. Quality of work, effect on reducing downtime incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

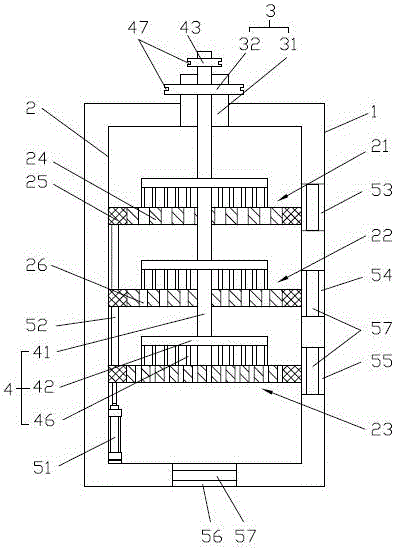

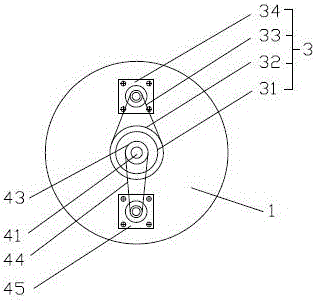

[0019] Such as Figure 1-2 Shown, be a kind of multi-layer screening machine of the present invention, comprise the first box 1, the second box 2, the first sieve plate 21, the second sieve plate 22 and the third sieve plate 23, the second box body 2 Located inside the first box body 1, the second box body 2 is connected to the first rotating device 3, the first rotating device 3 is composed of a fixed frame 31, a first transmission wheel 32, a first transmission chain 33 and a first motor 34, One end of the fixed mount 31 is connected with the second casing 2, and the other end of the fixed mount 31 passes through the first casing 1 and is connected with the first transmission wheel 32. The first motor 34 is positioned at the top of the first casing 1, and the first motor 34 is connected with the first transmission wheel 32 through the first transmission chain 33. The first motor 34 starts, and the motor shaft of the first motor 34 drives the first transmission wheel 32 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com