Patents

Literature

96results about How to "Guaranteed filtration accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

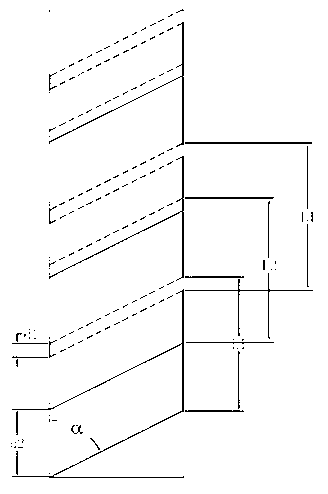

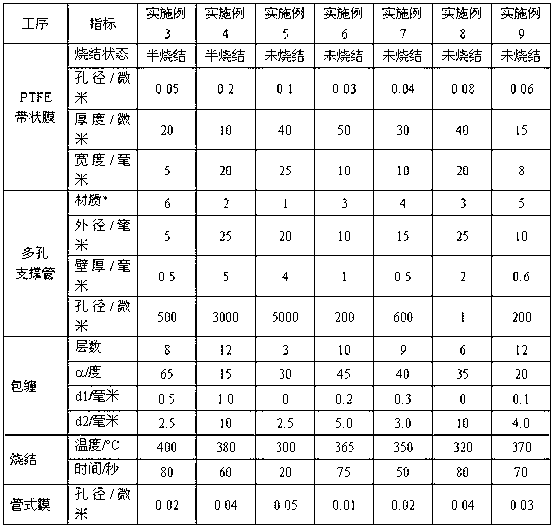

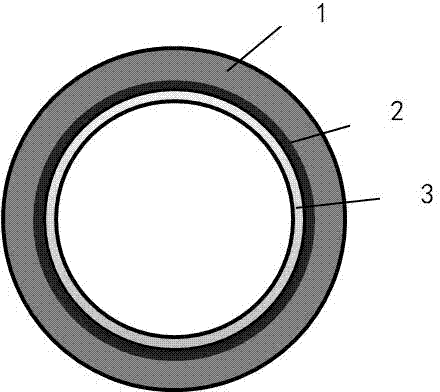

Preparation method of wrapped polytetrafluoroethylene ultra-micro filter tube membrane

ActiveCN103007788AAvoid layeringUniform filtering effectSemi-permeable membranesPorosityOrganic solvent

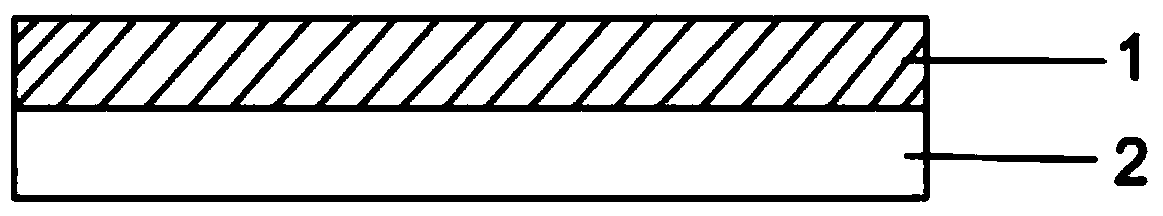

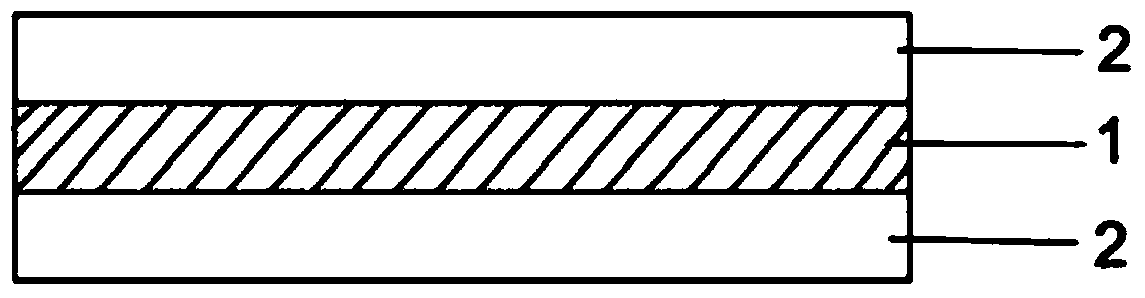

The invention discloses a preparation method of a wrapped polytetrafluoroethylene ultra-micro filter tube membrane. A sintered or unsintered drown polytetrafluoroethylene membrane of which the aperture is 0.03-0.3micon and the thickness is 10-50micon is cut into polytetrafluoroethylene strip-shaped membranes which are 5-25mm in width; the membranes are wrapped on a porous support tube which resists a temperature of 300-500 DEG C and is corrosion resistant and organic solvent resistant; and the support tube wrapped with the prepared polytetrafluoroethylene membranes is sintered for 20-80s at the temperature of 300-400 DEG C so as to prepare the wrapped polytetrafluoroethylene ultra-micro filter tube membrane of which the aperture of a filtering layer is 0.01-0.05micon. The wrapped polytetrafluoroethylene ultra-micro filter tube membrane has the advantages of high porosity, small aperture, uniformity in filtering layer, blocking resistance, internal and external pressure resistance, capability of back washing and the like, and can be used in solid-liquid and gas-liquid separation with high viscosity, high solid content and high pollution in food concentration, waste penetration liquid treatment, oil-water separation, membrane biologic reactor and the like.

Owner:ZHEJIANG SCI-TECH UNIV

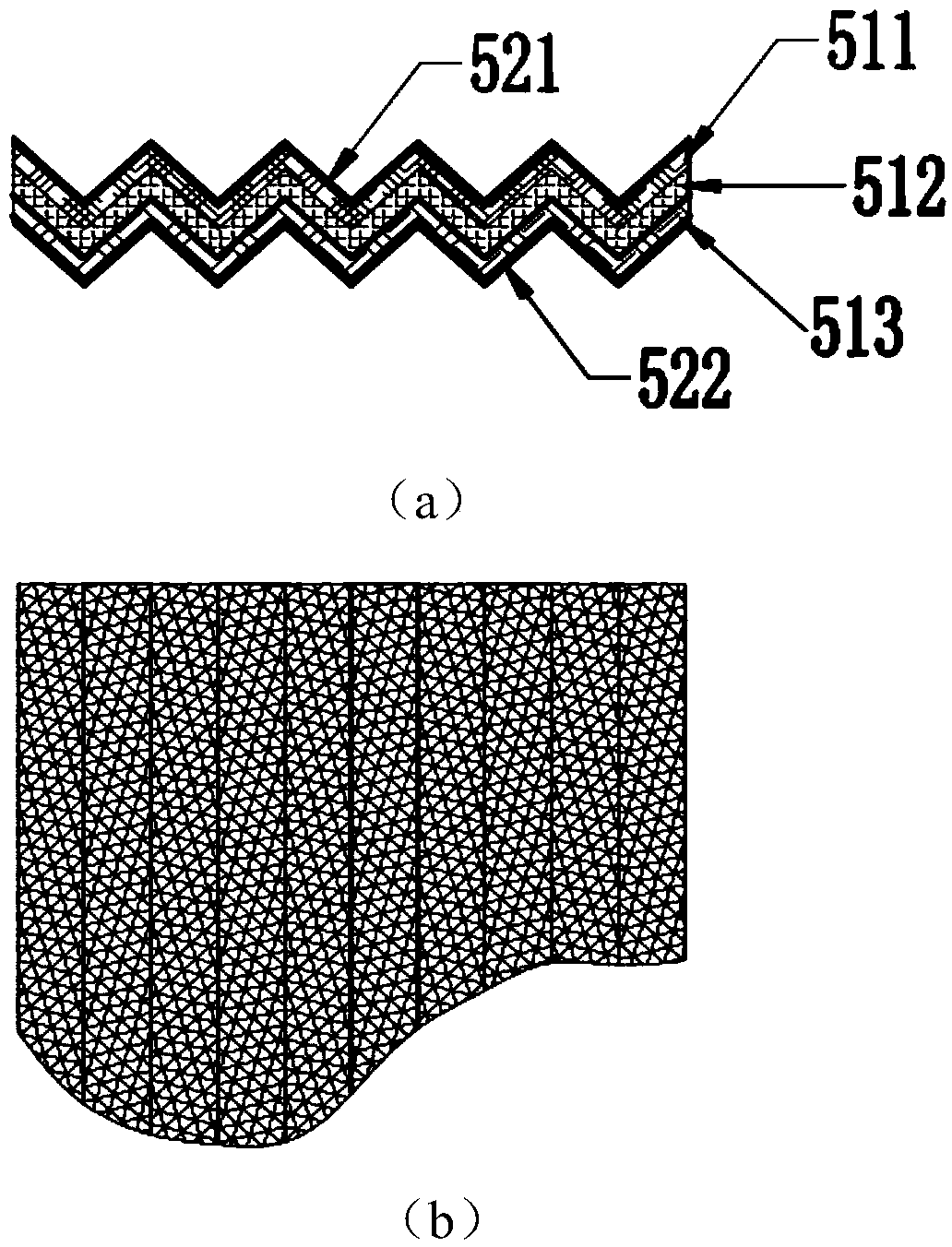

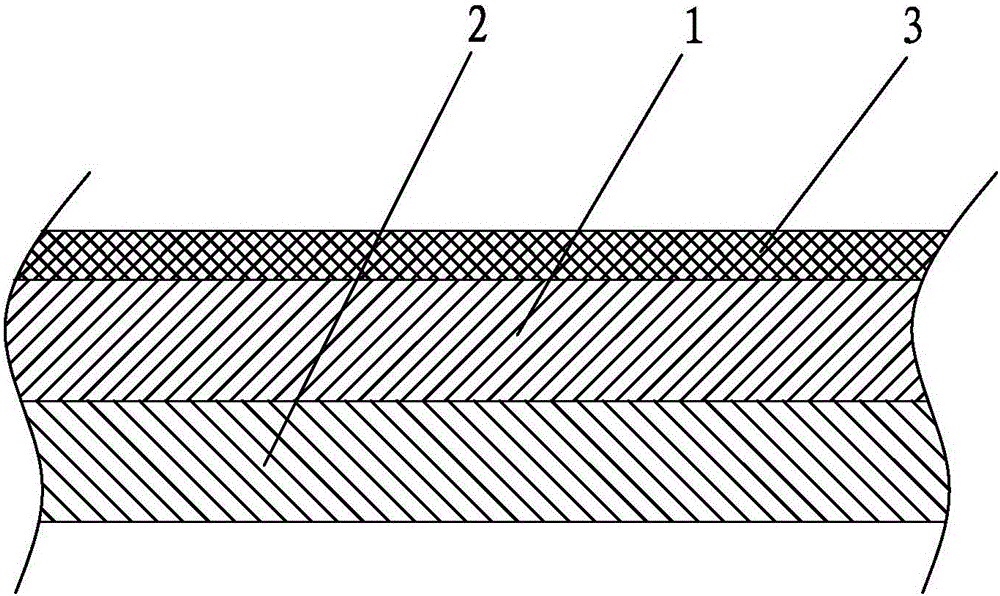

Composite filter material for heat-setting-free pleated filter cartridge and processing method of composite filter material

InactiveCN103908837AGood mechanical foldabilityImprove stiffnessSynthetic resin layered productsFiltration separationGlass fiberPolymer science

The invention discloses a composite filter material for a heat-setting-free pleated filter cartridge and a processing method of the composite filter material. The composite filter material is prepared by taking paper made of plant fibers, synthetic fibers and glass fibers as a base material, and compounding the base material and a polypropylene (PP) or polytetrafluoroethylene (PTFE) synthetic fiber filter film by adopting hot melt adhesive, liquid glue or an ultrasonic composite method. The paper made of the plant fibers, synthetic fiber materials and glass fibers serves as the base material, and the prepared material is a novel composite filter material which is low in airflow resistance, high in tensile strength, diversified in varieties, convenient to fold, wide in application range and excellent in overall performance.

Owner:重庆造纸工业研究设计院有限责任公司

Quantitative filter paper and preparing method and application thereof

InactiveCN104878642AGuaranteed Filtration SpeedFast filtrationPaper/cardboardChemical/chemomechanical pulpFilter paperFiber

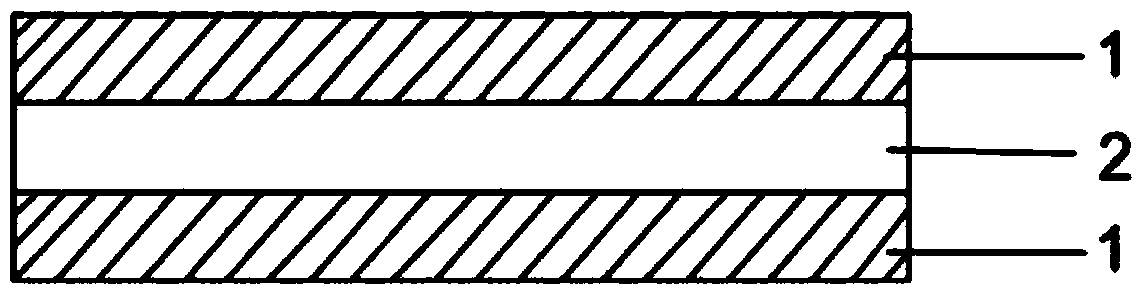

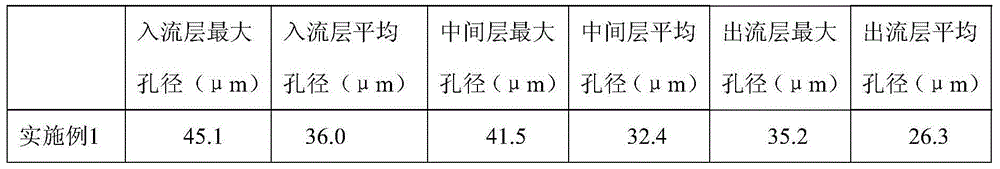

The invention discloses quantitative filter paper, comprising an inflow layer, a middle layer and an outflow layer. The inflow layer is made by forming, pressing and drying slurry 14 DEG SR to 17 DEG SR in beating degree; the middle layer is made by forming, pressing and drying pulp 19 DEG SR to 21 DEG SR in beating degree; the outflow layer is made by forming, pressing and drying pulp 23 DEG SR to 25 DEG SR; the inflow layer, the middle layer and the outflow layer are made of the pulp of same material. The invention further discloses a preparing method of and application of the quantitative filter paper. The layers have different beating degrees of the pulp, the different void distributions of the insides are ensured, and high filtering speed, high precision and high stability are integrated; the preparing method ensures that the fibers in the layers are tightly tangled together, no evident interface occurs, the three-layer composite filter payer manufactured with the pulp is in a complete structure, and smoothness of the separating process is ensured.

Owner:杭州特种纸业有限公司

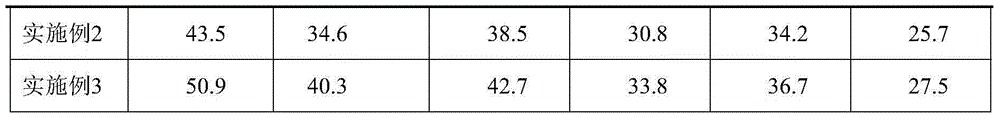

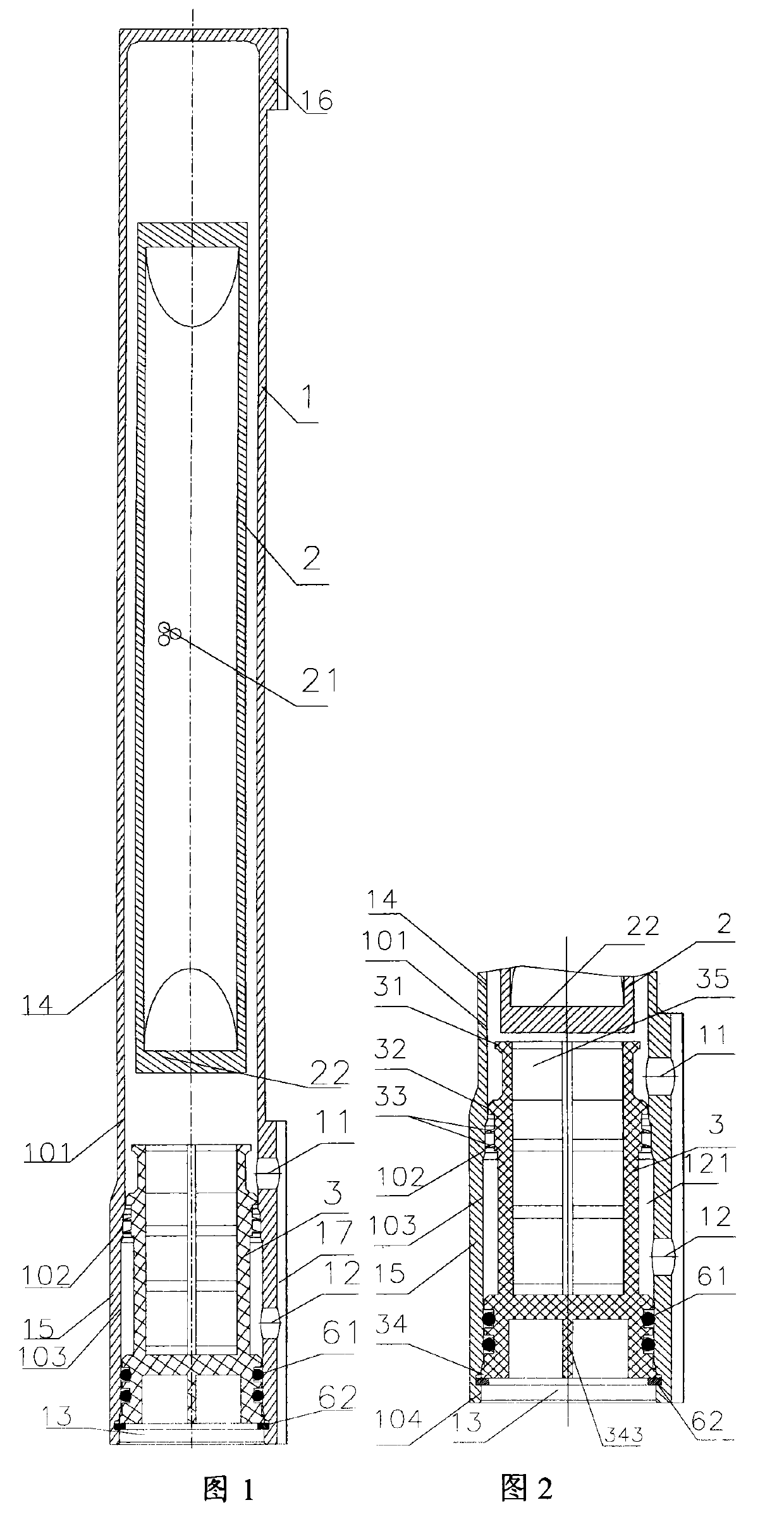

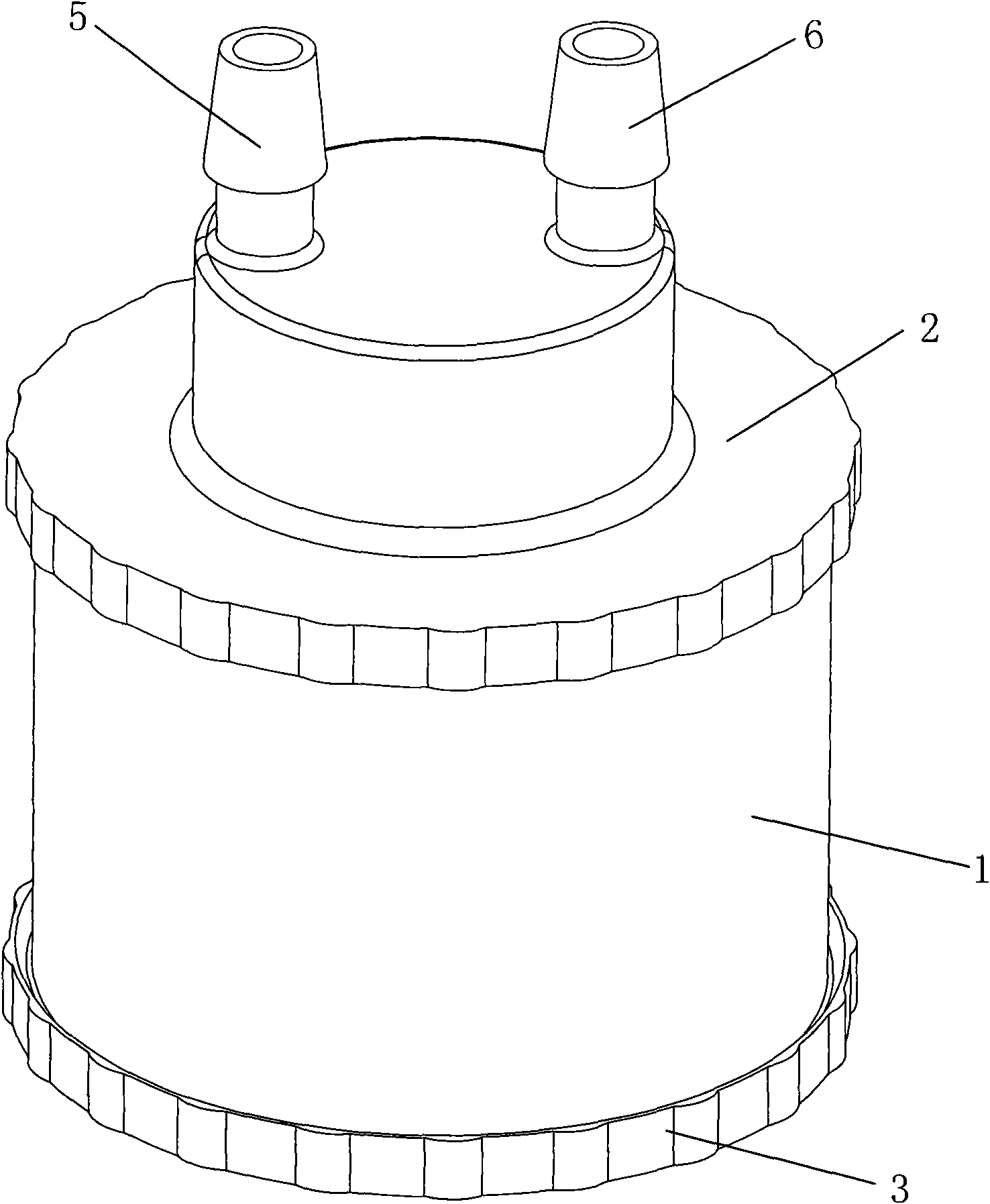

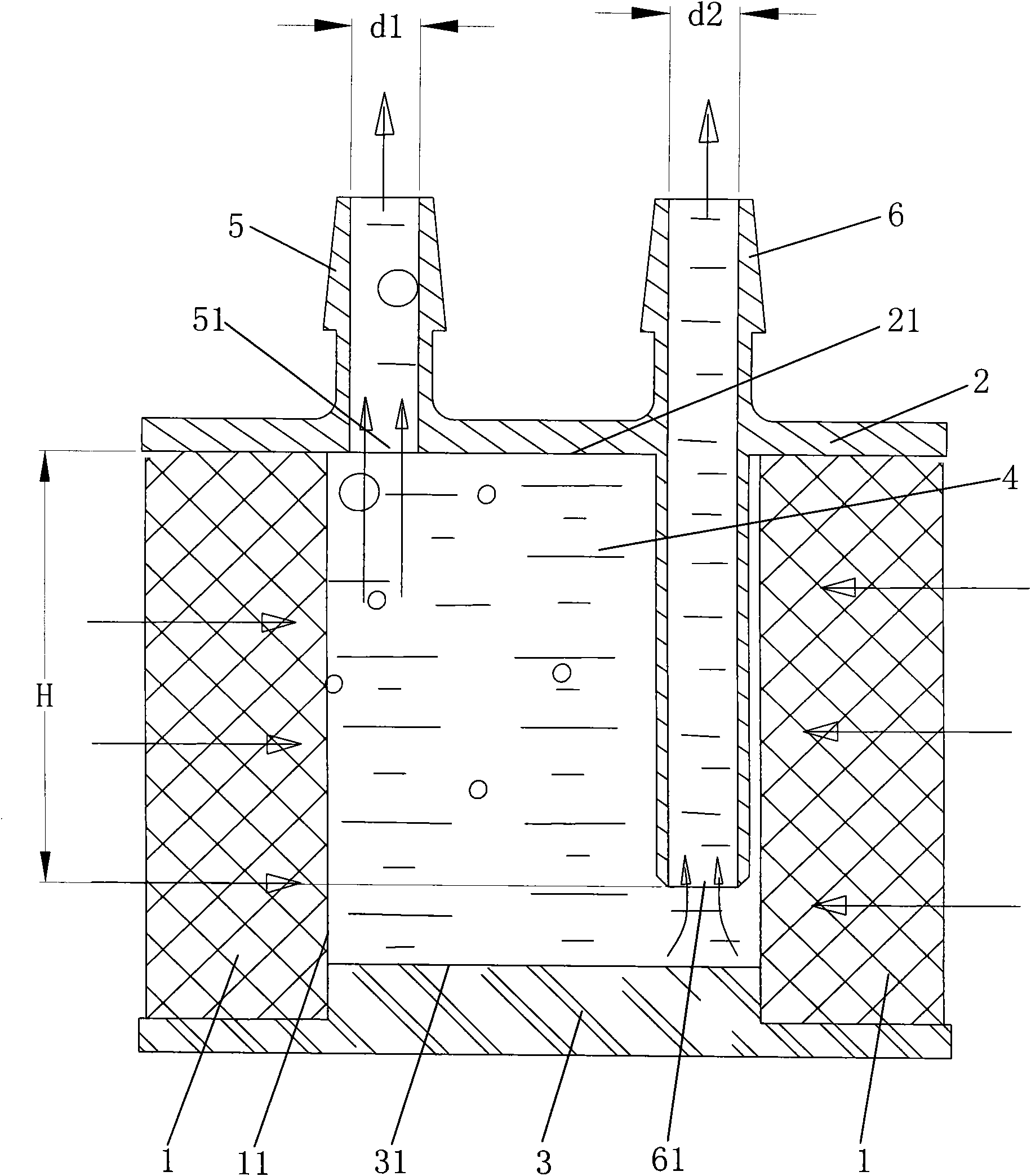

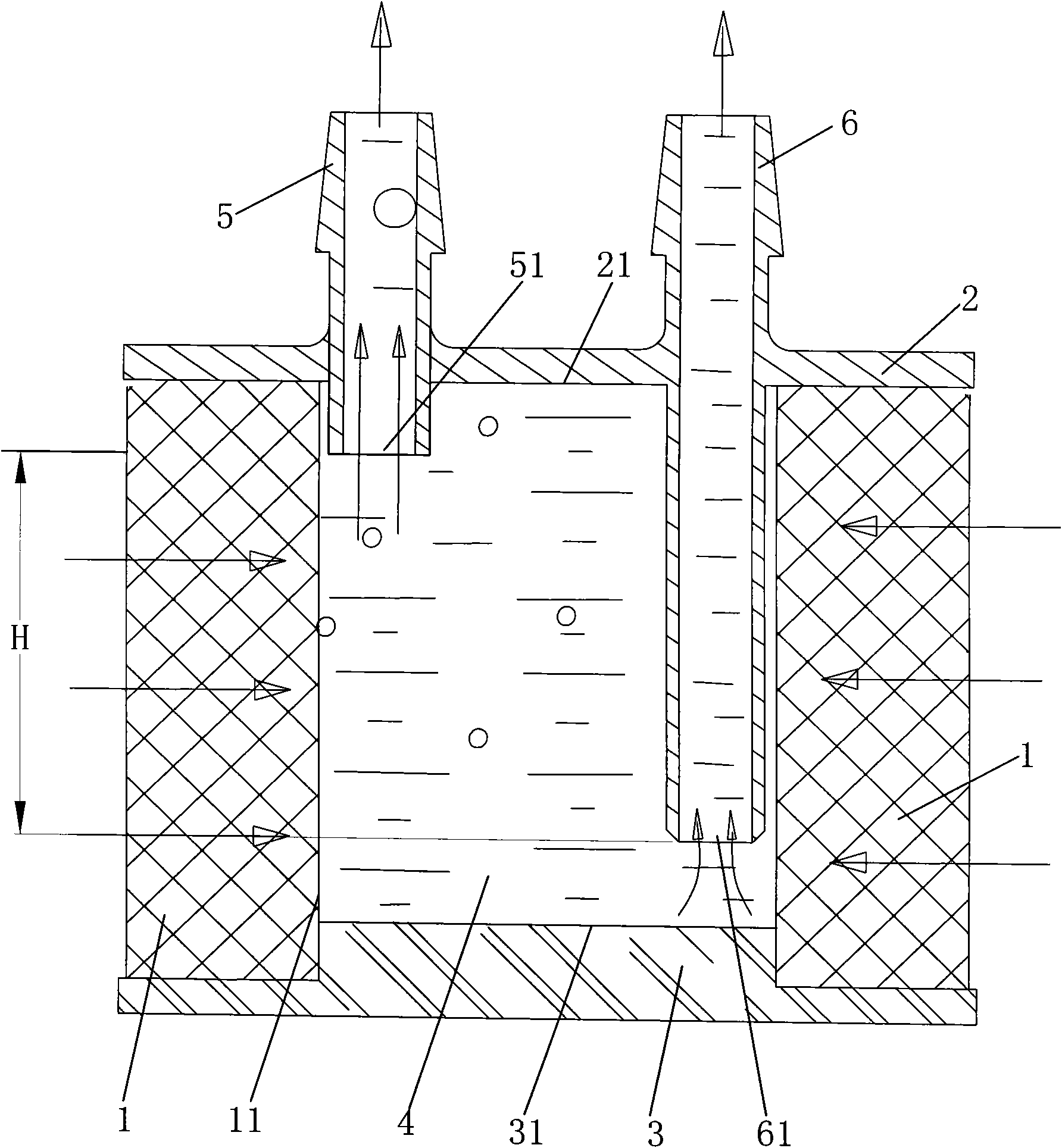

Air conditioner refrigeration system and liquid reservoir thereof

ActiveCN102538323AGuaranteed filtration accuracySolve the disadvantages of large flow resistanceSolid sorbent liquid separationMembrane filtersEngineeringFilter material

The invention discloses a liquid reservoir which comprises a lower reservoir body and a filter barrel, wherein a refrigerant inlet and a refrigerant outlet are formed at the lower end of the lower reservoir body; the filter barrel is matched with the inner wall of the lower reservoir body to form a liquid flow cavity; the filter barrel comprises a barrel wall made of a filter material, an upper liquid flow barrel and a lower liquid flow barrel; the upper liquid flow barrel and the lower liquid flow barrel are arranged at two ends of the barrel wall and communicated with each other; the lower liquid flow barrel and the liquid flow cavity are communicated with the refrigerant inlet and the refrigerant outlet respectively; and a refrigerant is at least filtered once in a process of flowing from the refrigerant inlet to the refrigerant outlet. The invention also discloses an air conditioner refrigeration system with the liquid reservoir. The refrigerant flows into the liquid flow cavity from the refrigerant inlet, further flows through the filter barrel and flows out from the refrigerant outlet, thus impurities in the refrigerant are stopped in the liquid reservoir, and an aim of filtering the refrigerant is achieved. According to the liquid reservoir, the filter barrel, instead of a non-woven cloth, is utilized as a filter part for the refrigerant, so that the own filter precision of the liquid reservoir is guaranteed, and simultaneously the flow resistance is reduced.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

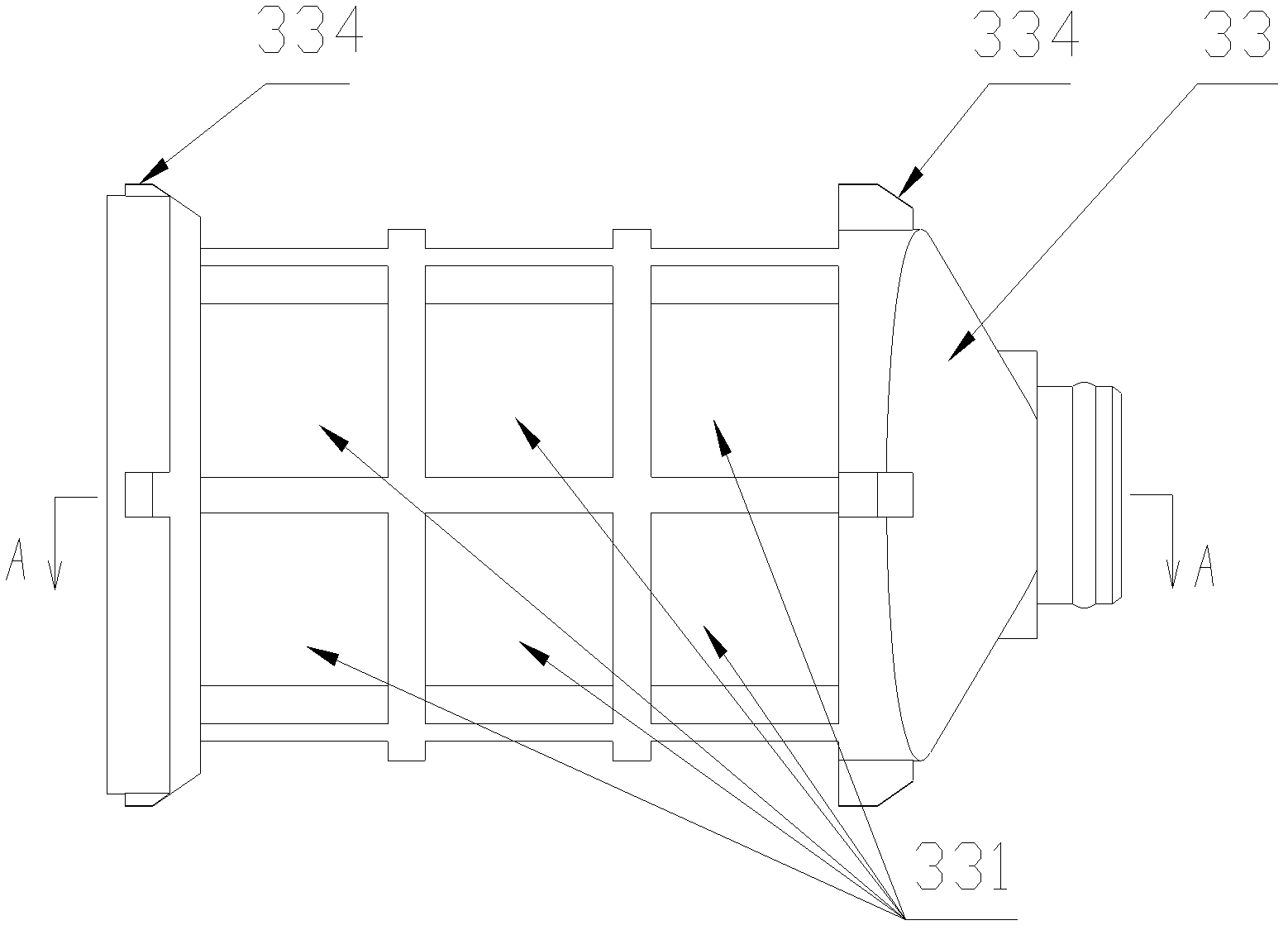

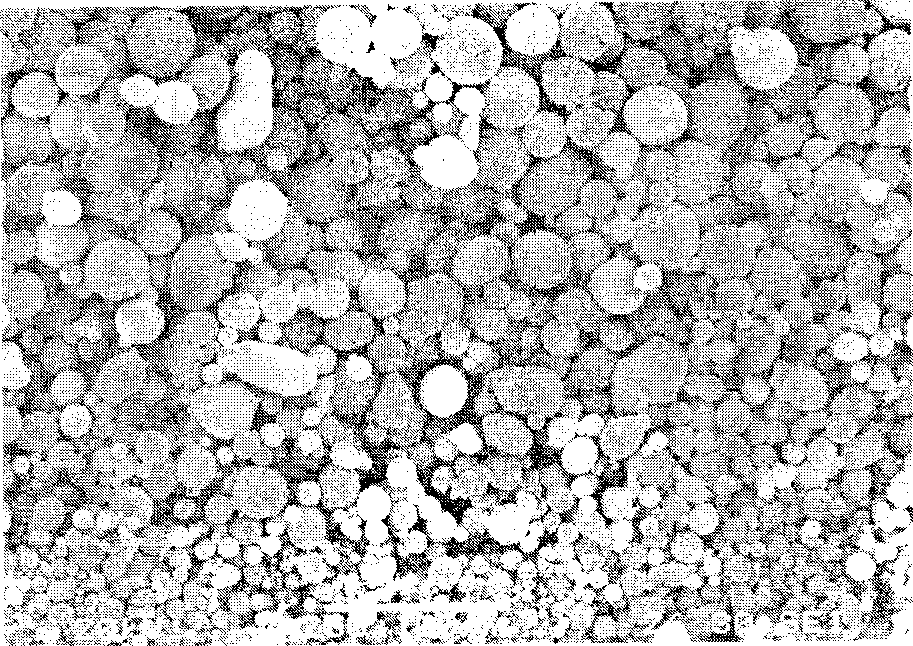

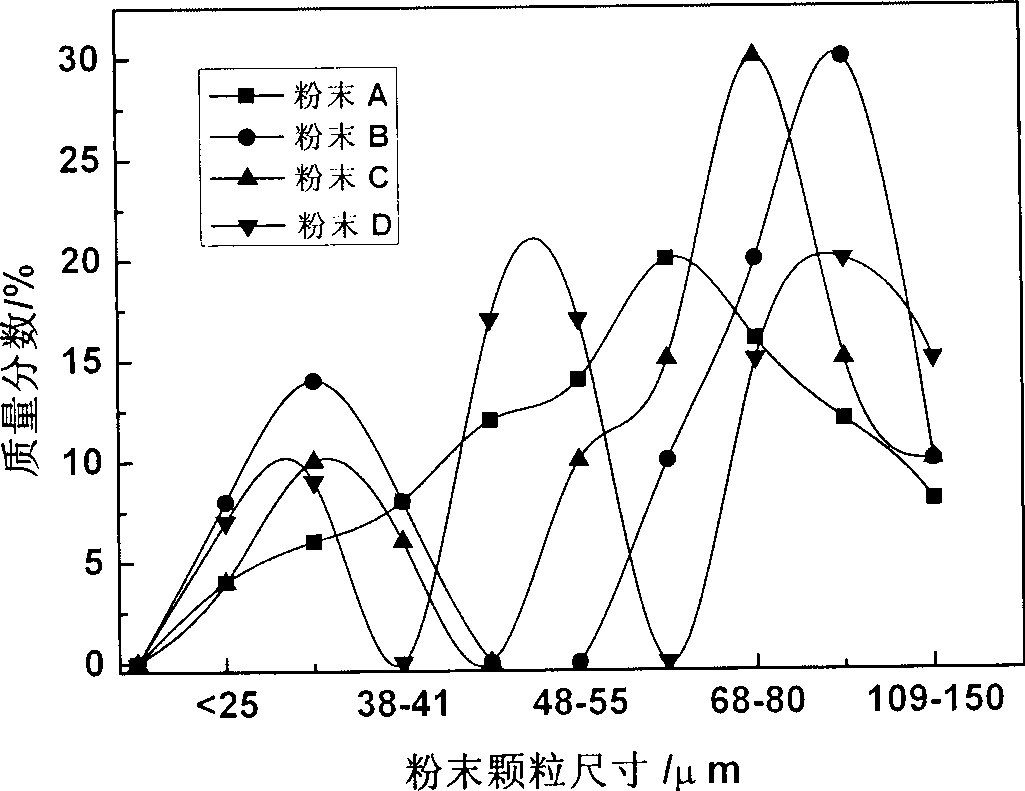

Method of manufacturing gradual-change bore diameter stainless steel antipriming pipe

ActiveCN101428346AImprove breathabilityGuaranteed filtration accuracyFiltration separationPolyvinyl alcoholSS - Stainless steel

The invention provides a preparation method for a stainless steel perforated pipe with gradually-varied aperture, the invention adopts the preparation process that stainless steel powder is mixed with a certain polyvinyl alcohol solution to prepare stainless steel powder suspension, and getter is added into the suspension and poured into a two-piece-type opening and closing rigid pipe die made of stainless steel after even stirring, which centrifugally takes shape on a centrifuge, thereby preparing a green body of the stainless steel perforated pipe with gradually-varied aperture grads; the green body is dried in a blast-type baking oven, and then the demoulding is performed; the green body of the stainless steel perforated pipe after drying is sintered in a vacuum stove, the sintering atmosphere adopts vacuum, and the stainless steel perforated pipe with gradually-varied aperture grads is prepared after cooling. The invention has the advantages that the demoulding attainment rate of the green body of the stainless steel perforated pipe with gradually-varied aperture is greatly enhanced, and the filtering precision of the perforated pipe is ensured; meanwhile, the air transmission coefficient of the stainless steel perforated pipe with gradually-varied aperture is enhanced, and the preparation method solves the phenomenon of the reciprocal relationship between the filtering precision of the stainless steel perforated pipe and the transmission performance in the filtration, separation and application process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

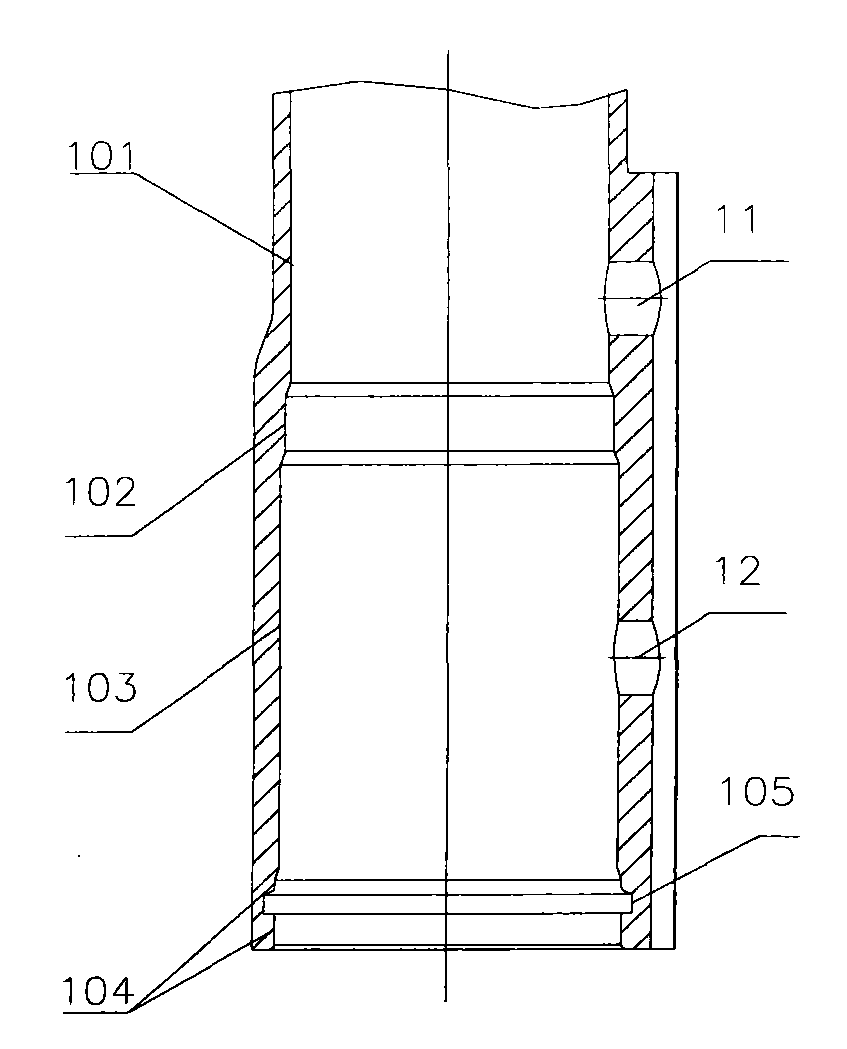

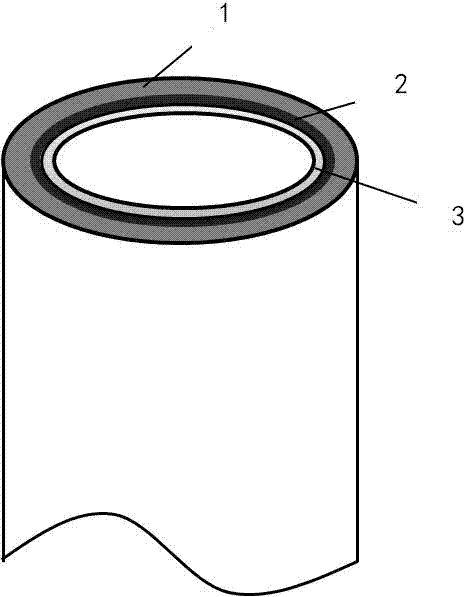

Liquid receiver and manufacturing method thereof

ActiveCN103968624AGuaranteed filtration accuracySolve the disadvantages of large flow resistanceRefrigeration componentsNormal filterControl theory

A liquid receiver comprises a shell with an opening at one end, a filter cap and a drying bag. The filter cap is arranged the open end of the shell, the drying bag is arranged in a cavity formed by the filter cap and the shell, the shell is provided with a first connection port and a second connection port, the filter cap comprises a filter portion and a seal cap portion close to the open end of the shell, the seal cap portion is in seal fit with the inner wall of the shell, the filter portion is of a cylindrical surface structure, the second connection port is communicated with space between the inner wall portion of the shell and the filter portion, the first connection port is communicated with internal space of the filter portion, the filter cap is provided with a matched seal structure close to one end of the drying bag and the inner wall portion of the shell, and refrigerant is filtered via the filter portion in the process of flowing between the first connection port and the second connection port. The liquid receiver further comprises a limiting structure for preventing the drying bag from falling into the filter cap, so that normal filter capacity of the filter cap is guaranteed.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

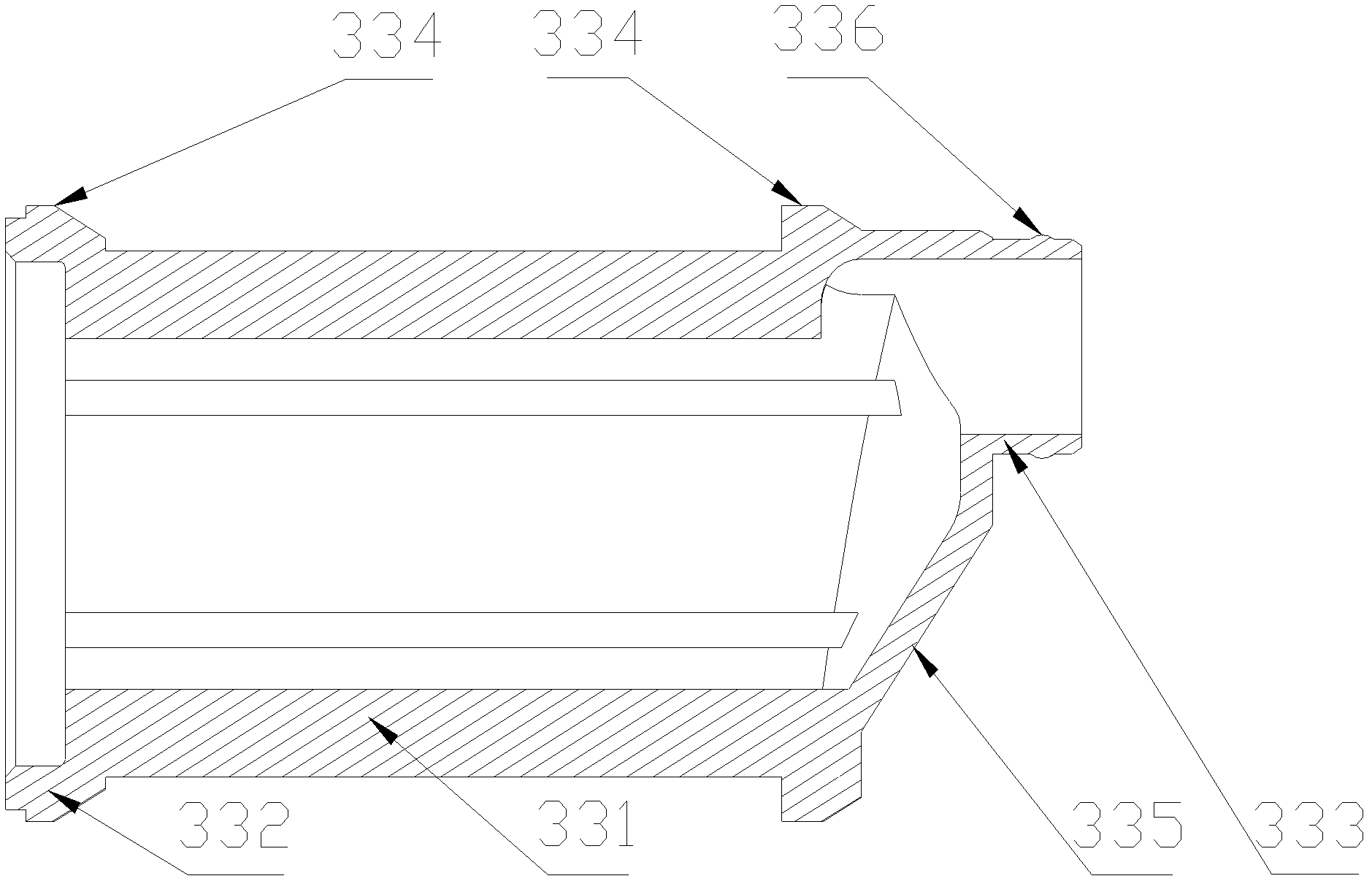

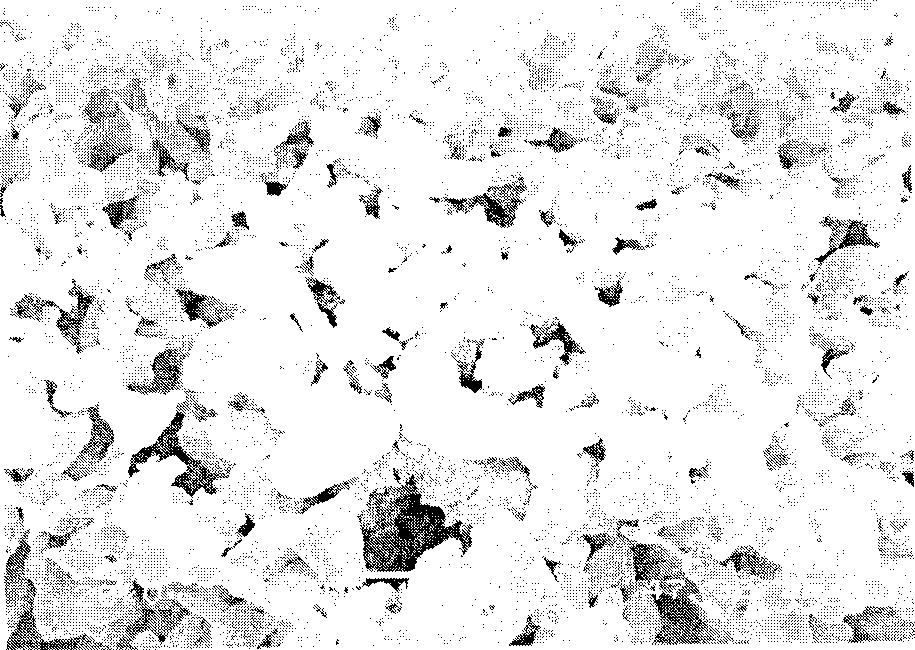

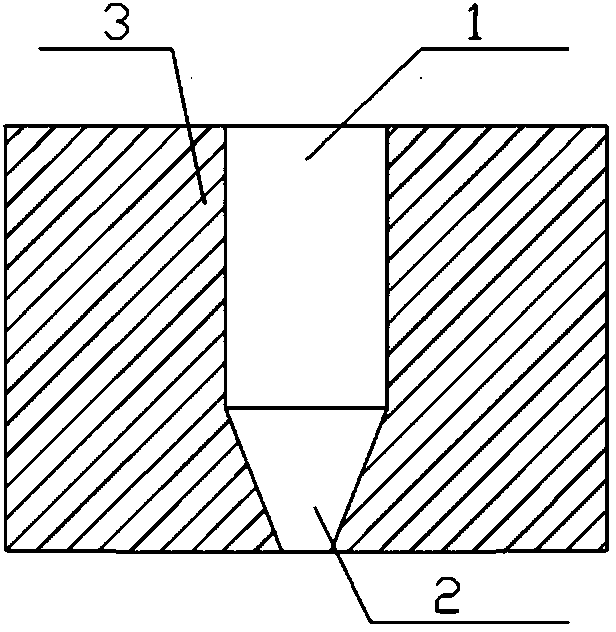

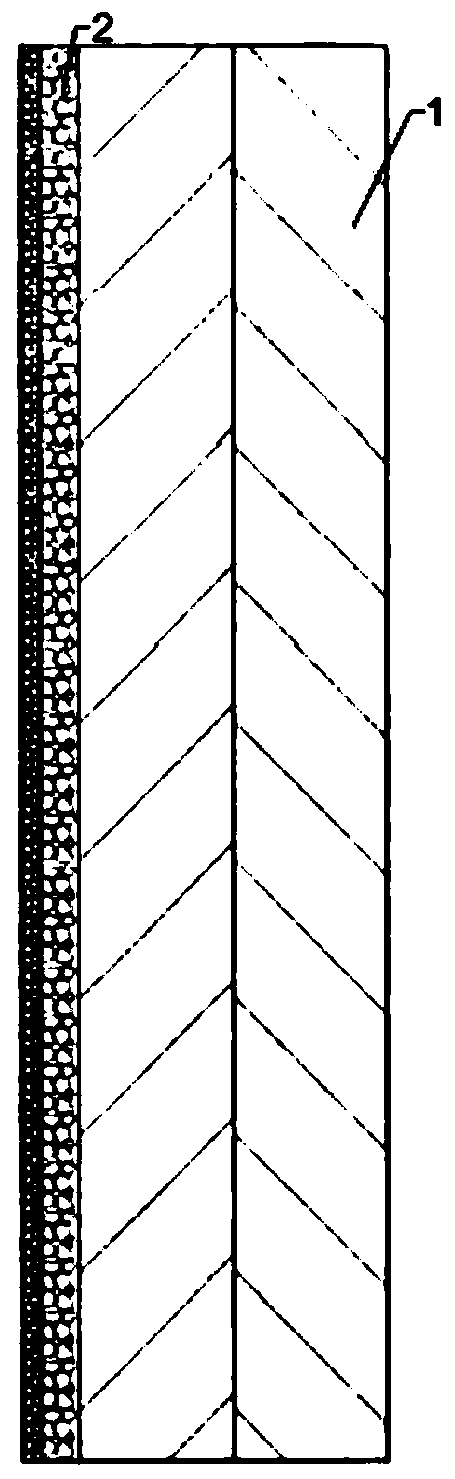

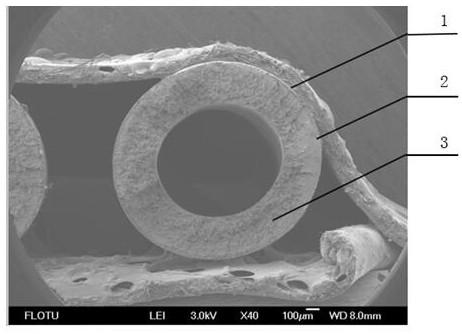

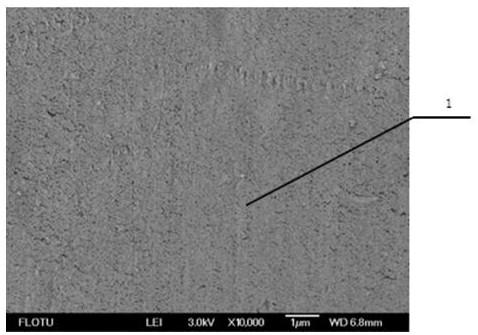

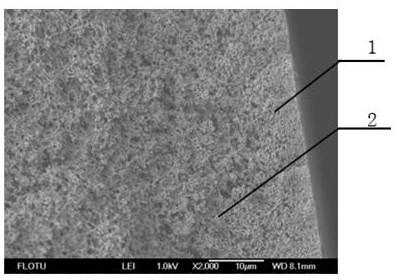

Asymmetrical stainless steel filter membrane tube and production method thereof

ActiveCN102962464AGuaranteed filtration accuracyImprove air permeabilityMetal layered productsComposite materialStainless steel fiber

The invention provides an asymmetrical stainless steel filter membrane tube and a production method thereof. The asymmetrical stainless steel filter membrane tube produced by the production method for the asymmetrical stainless steel filter membrane tube comprises a support layer and a control layer and is characterized by further comprising stainless steel fiber felts between the support layer and the control layer. According to the asymmetrical stainless steel filter membrane tube disclosed by the invention, the stainless steel fiber felts are additionally arranged among different powder layers, so that the filtering precision and the filtering performance of the filtering tube in performance are ensured; and meanwhile, the problems of cracking, peeling and the like of the stainless steel filter membrane with mutant fluctuant gradient in the sintering process are solved to the great degree.

Owner:江苏云才材料有限公司

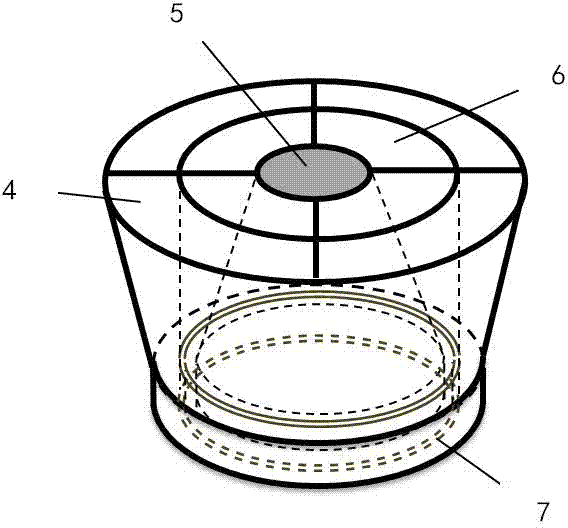

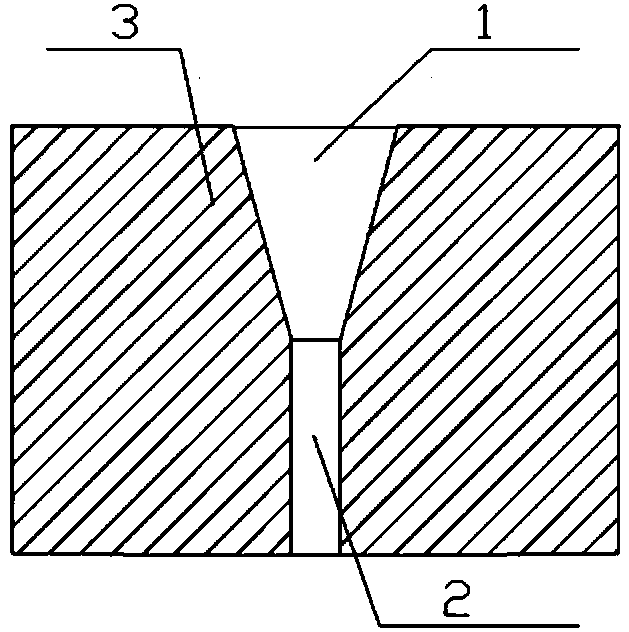

Nuclear pore filter membrane with compound pore passage and preparation method of nuclear pore filter membrane

ActiveCN103933876APrecise size controlSpeed up filteringSemi-permeable membranesFiltrationHigh energy

The invention relates to a preparation method of a nuclear pore filter membrane and particularly relates to a nuclear pore filter membrane with a pore passage structure combined by a cone-shaped pore passage and a columnar pore passage. A preparation method of the nuclear pore filter membrane with tthe compound pore passage structure mainly comprises the following steps: radiating a polymer film by virtue of high-energy heavy ions, so as to form a latent trace; respectively etching the same surface of the radiated polymer film by virtue of two etching solutions with different track etching speeds, so as to form the novel cone / column compound pore passage structure. The cone / column compound pore passage structure has the obvious structural characteristics that the pore passage is formed by the linkage of an upper part and a lower part, and specifically comprises the cone-shaped pore passage and the columnar pore passage; the columnar pore passage is etched and machined by virtue of liquid with high track etching speed; the cone-shaped pore passage is etched and machined by virtue of liquid with the lower track etching speed. By utilizing the novel pore passage design, the technical problem of low filtration flux of the small-aperture nuclear pore filter membrane can be beneficially solved, and the technical problems of single-layer filtration and repeated cleaning are further beneficially solved.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

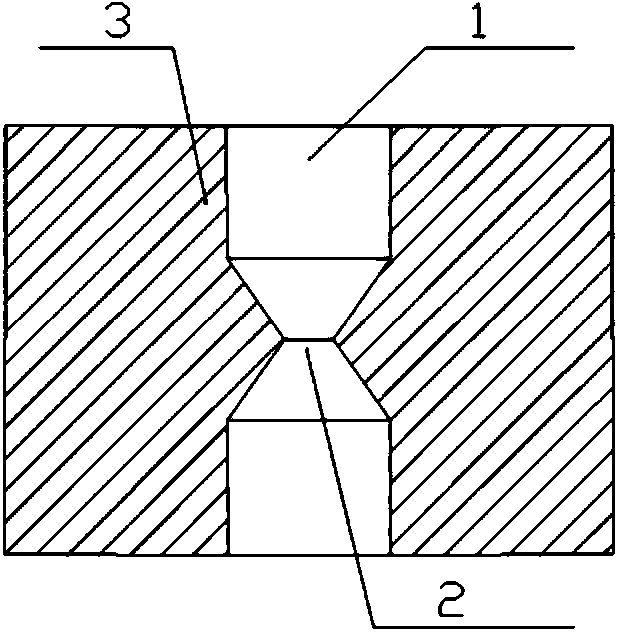

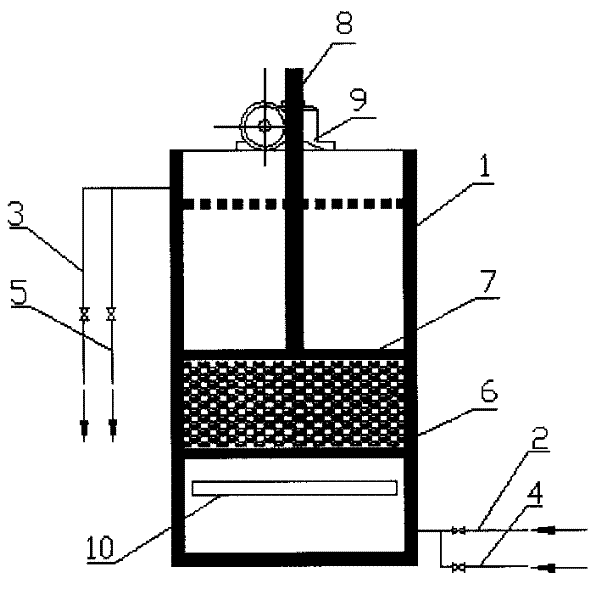

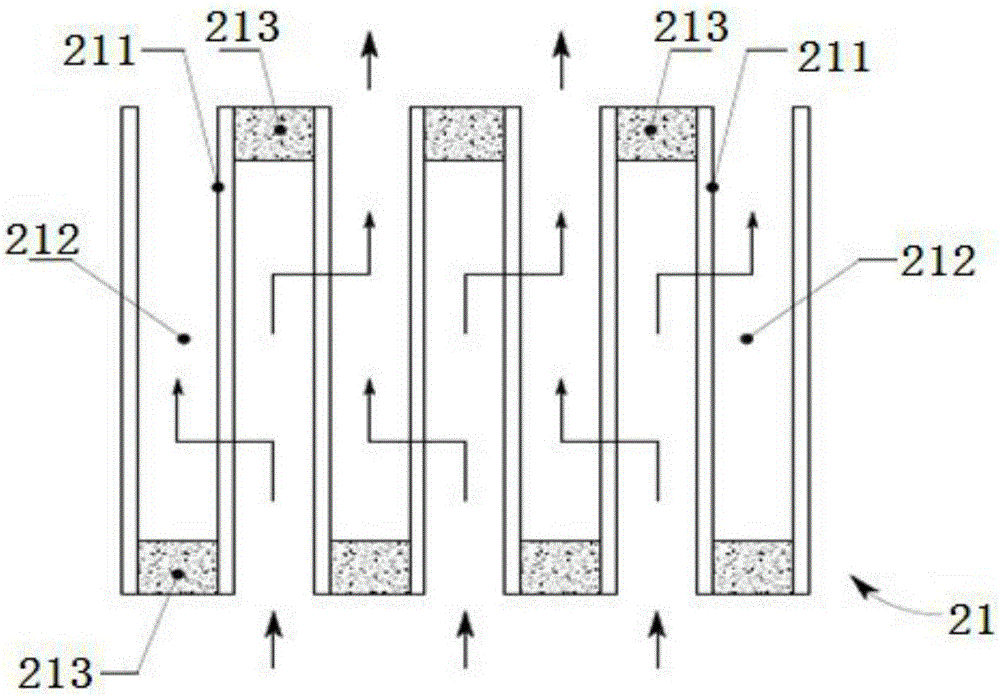

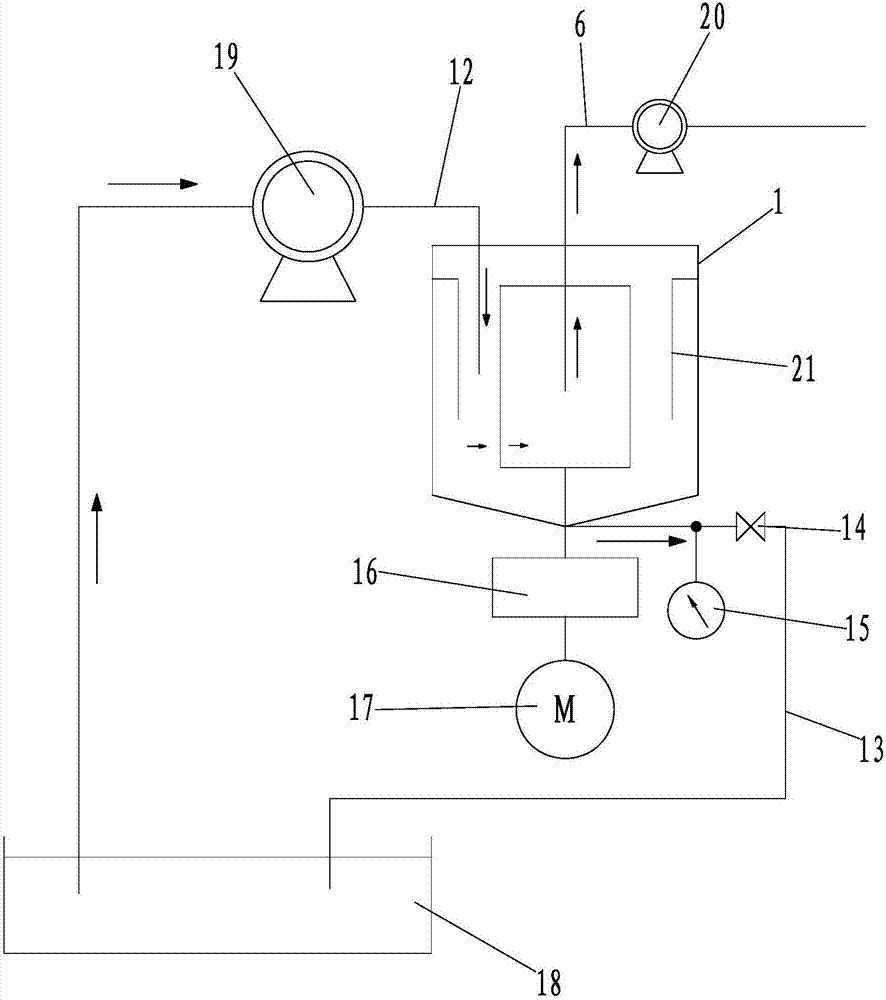

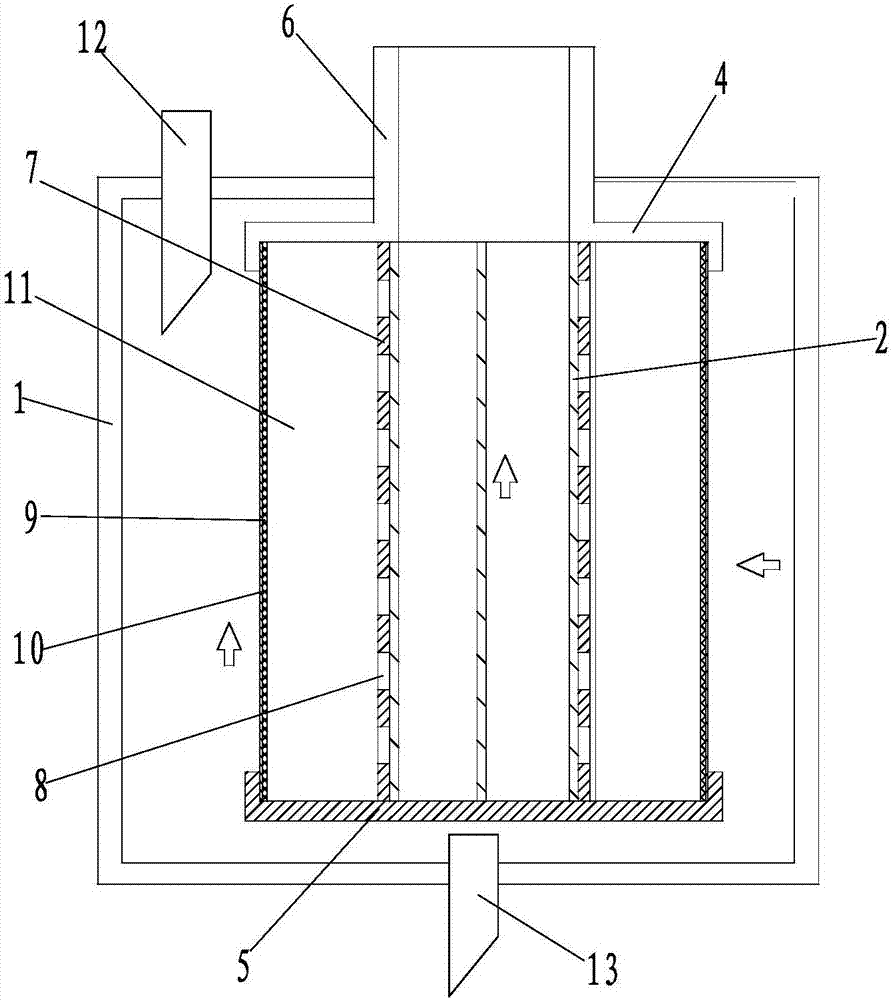

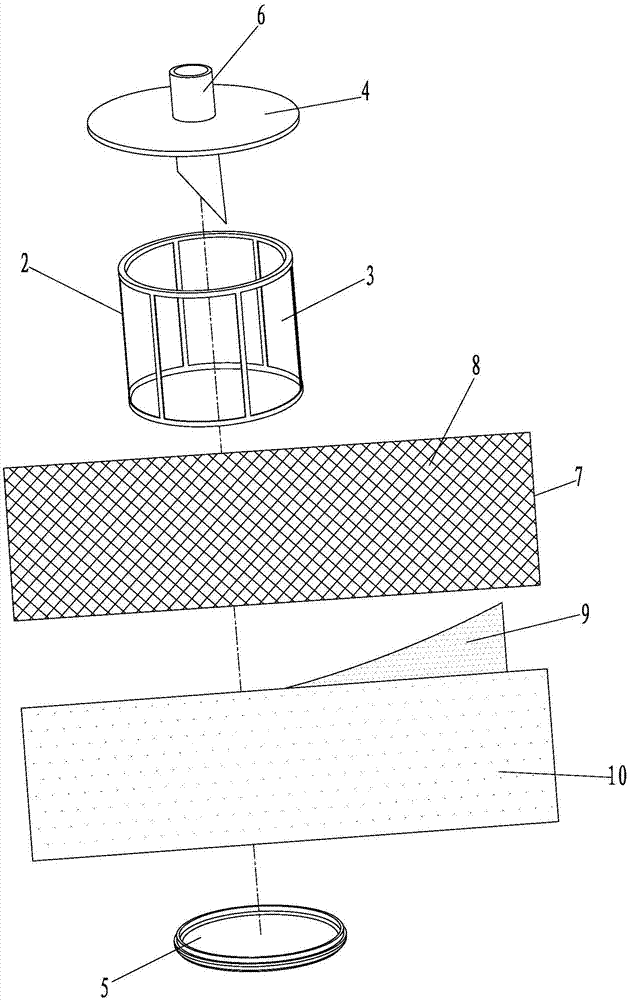

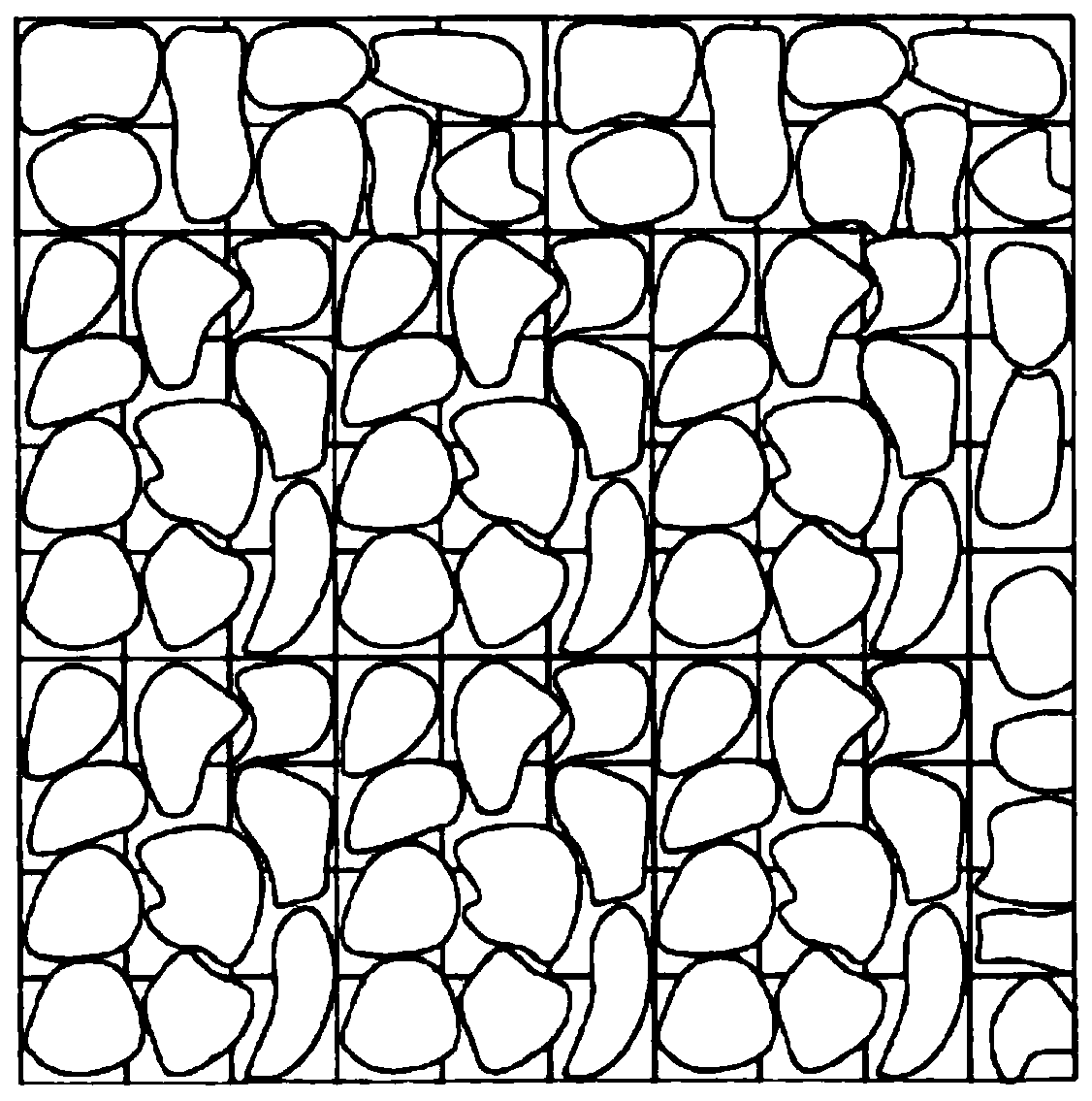

Upflowing and compressable filtration system

InactiveCN1565698AGuaranteed filtration accuracySpeed up filteringLoose filtering material filtersGravity filtersFiberFiltration

A reverse flow compressible filtering system, especially a filtering device using flexible filter material such as fibrous globule relates to the field of water treatment. In the course of filtering, the water flows from bottom to top and the filtering speed is over 80 m / h. The filtering system provided by the invention can replace micro-filter membrane filtering system because of the high water output in unit filtering area.

Owner:TONGFANG ENVIRONMENT

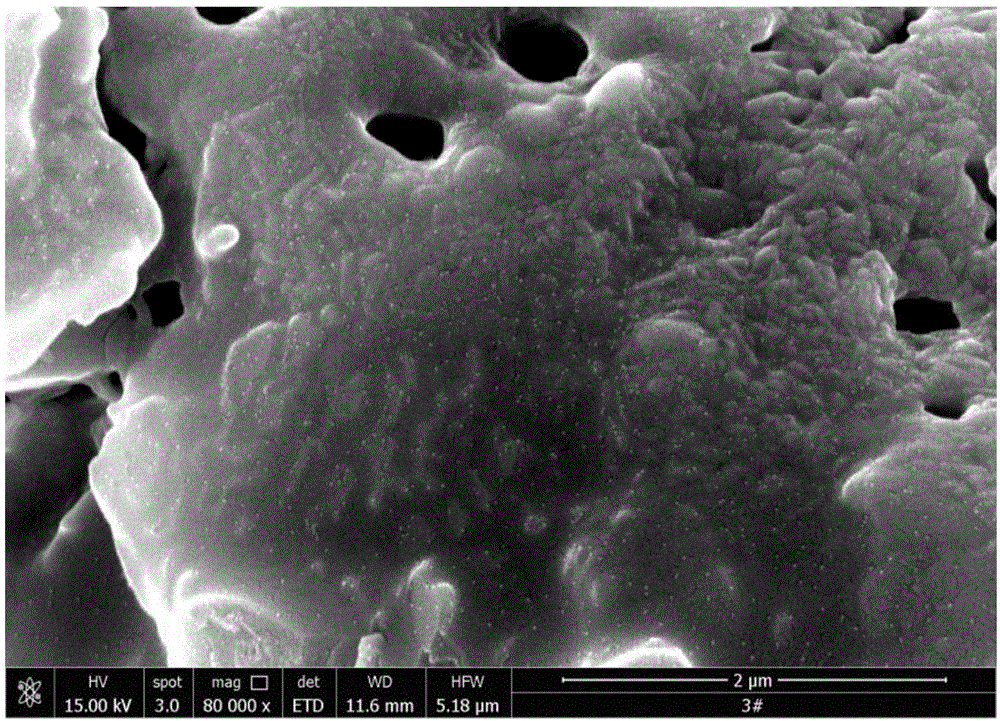

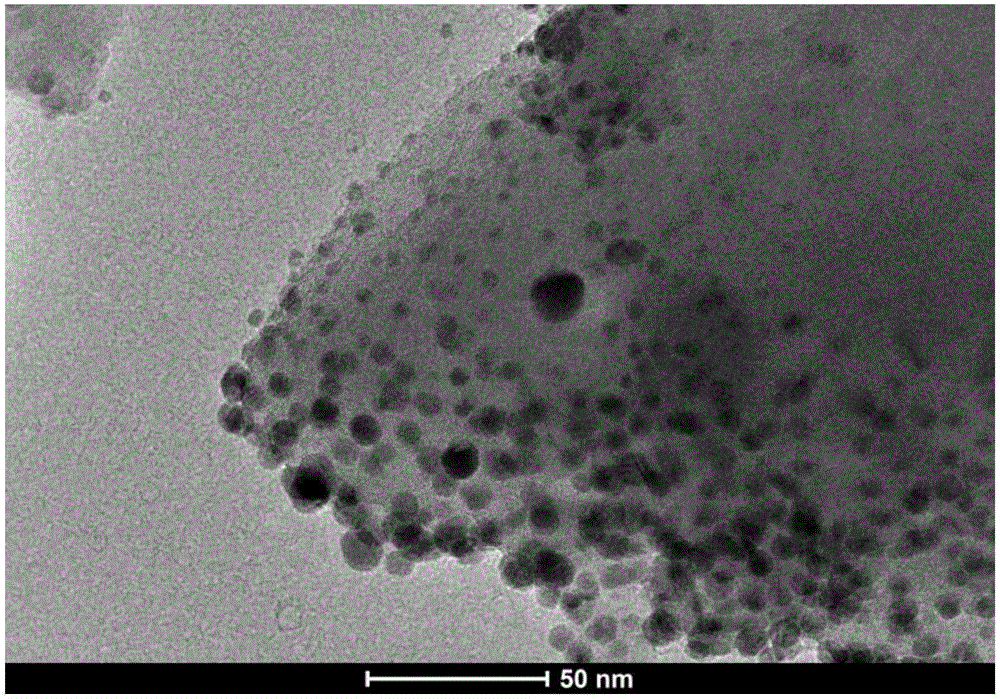

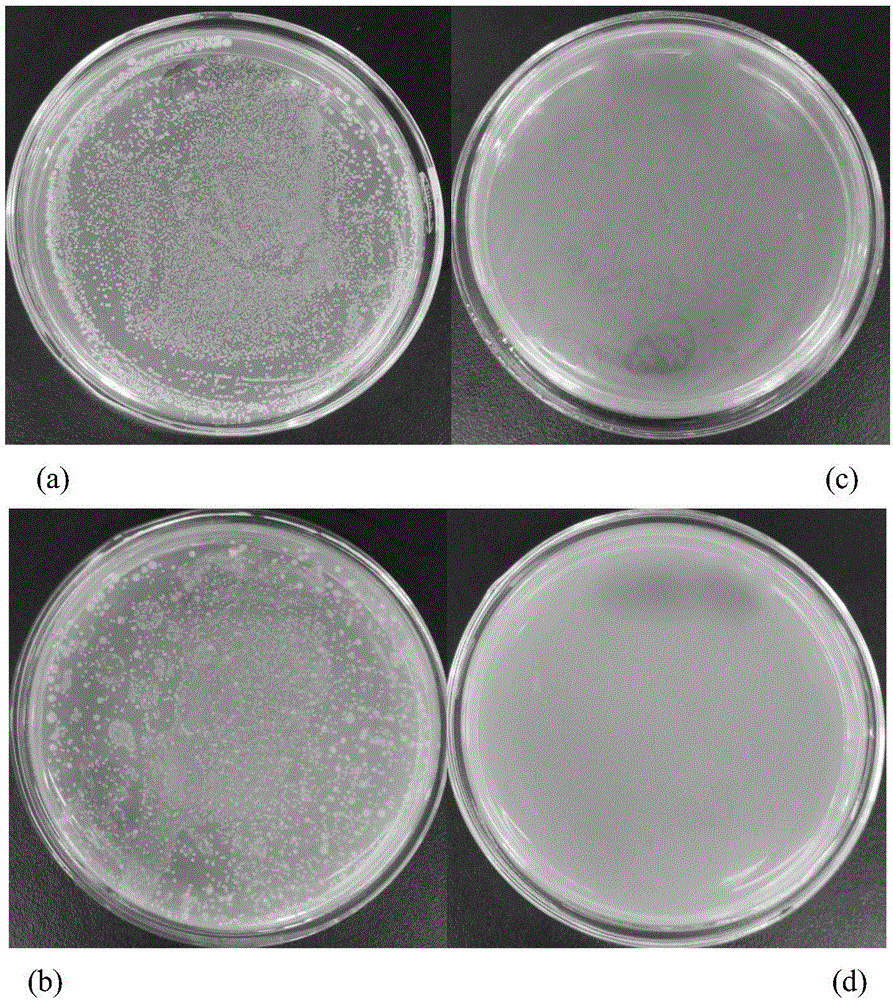

In-situ composite antibacterial filtering ceramic as well as preparation method and application thereof

InactiveCN106518006AImprove antibacterial propertiesGood dispersionTreatment involving filtrationMembrane filtersMicroorganismAdhesive

The invention relates to antibacterial filtering ceramic, in particular to in-situ composite antibacterial filtering ceramic as well as a preparation method and application thereof. The composite antibacterial filtering ceramic is prepared from the following components in percentage by mass: 60 to 75 percent of kieselguhr, 10 to 20 percent of hydroxyapatite, 10 to 30 percent of purple sand, 0.1 to 2 percent of silver and 1 to 5 percent of an adhesive, and the mass percentage sum of the five components is 100 percent. The diameter of the silver is 3 to 20 nm, and the silver is located on the surface and in gaps of the kieselguhr. According to the in-situ composite antibacterial filtering ceramic, combination of nano silveer and porous kieselguhr, combination of the silver and the hydroxyapatite and combination of silver-carried hydroxyapatite and the porous kieselguhr are realized under a hydrothermal condition, so that the dispersivity of the silver and the binding force of the silver and a material are improved. The material is high in filtering performance, antibacterial property and antibacterial endurance, can effectively filter out microorganisms, impurity particles and organic matters from water, and can be widely applied to the field of water treatment and relevant industries.

Owner:JIANGXI UNIV OF SCI & TECH

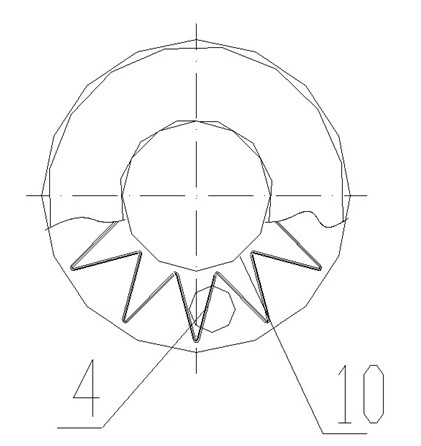

Laminated filter unit

InactiveCN102430281AGuaranteed filtration accuracyGuaranteed Filtration QualityFiltration circuitsStationary filtering element filtersWater flowEngineering

The invention relates to a laminated filter unit, which belongs to a component of a laminated filter. The filter unit comprises a shell, wherein the shell is provided with an inlet and an outlet; a piston, a piston sleeve and a piston seat are arranged in the shell; the side wall of the piston sleeve is arranged on a lamination assembly; the lower part of the lamination assembly is provided with centrifugal flow guide blades; and a check valve is arranged between the centrifugal flow guide blades and the outlet. Impurities in liquid get away from the lamination assembly and move upwards by centrifugal force produced by the liquid rotating at a high speed and are finally centralized at the top end of the laminated filter unit, so that the back wash frequency of a product is greatly reduced. In a back wash state, after a high-pressure clean water flow is gathered to a flow guide pipe in a reverse direction, the water flow enters a piston chamber through a piston hole at the top end of the flow guide pipe, and the piston sleeve overcomes outward movement of the spring pressure on the top so as to release the pressure applied to the lamination assembly; and by now, the lamination assembly is loose, and the cleaning water flow can extremely easily pass through each lamination to clean impurities inside and outside a laminated filter tank.

Owner:乌鲁木齐瑞拓环保设备制造有限公司

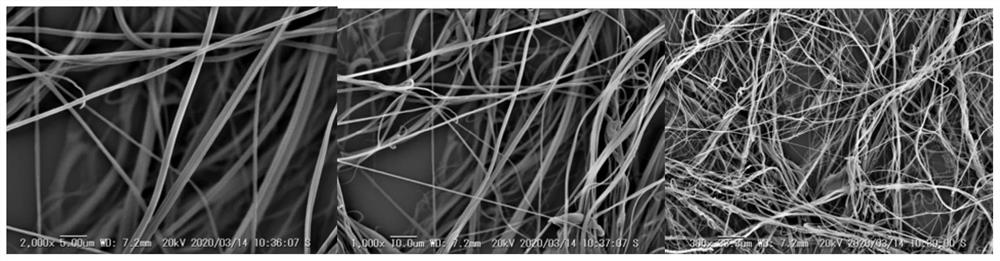

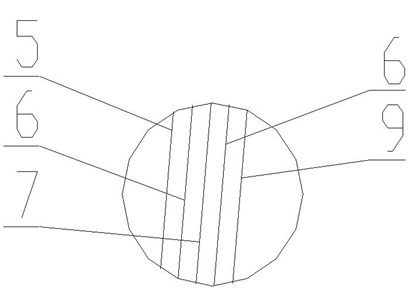

Deep filter element with crude and fine fiber mixed structure and preparation method of deep filter element

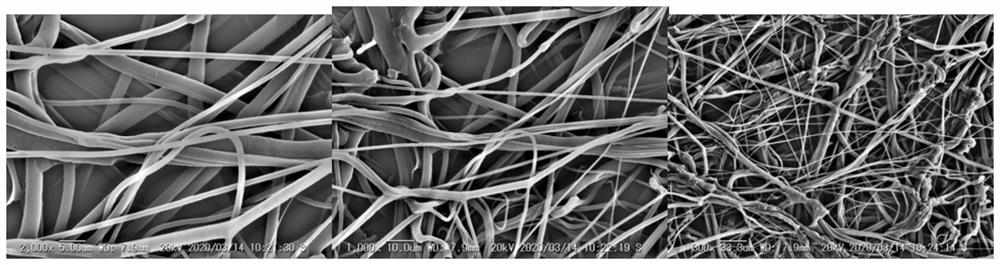

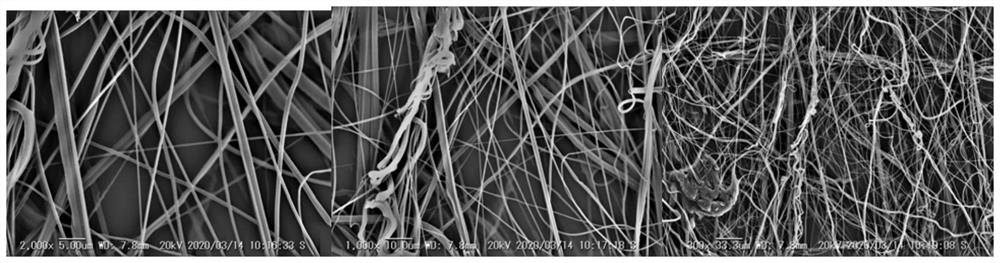

PendingCN111603846AEnsure structural stabilityDoes not increase filter resistanceMembrane filtersMelt spinning methodsCrude fibreFiber diameter

The invention discloses a deep filter element with a crude and fine fiber mixed structure. The deep filter element at least comprises two filtering layers; each filtering layer comprises a crude fiberset and a fine fiber set which are interwoven with each other; the average diameter of the crude fiber set of each filtering layer is reduced from the outer side to the inner side; the average diameter of the fine fiber set of each filtering layer is reduced from the outer side to the inner side; the fiber diameter of the fine fiber set of the innermost filtering layer is not larger than 1 micrometer; the fiber diameter of the crude fiber set of the outermost filtering layer is not smaller than 5 micrometers. The invention further discloses a preparation method of the deep filter element withthe crude and fine fiber mixed structure. The preparation method comprises the following steps of: 1) melt spinning; and 2) receiving a finished screen. The crude coarse fiber sets play a role in bonding the fine fiber sets and play a role in supporting, and therefore, the filter element is prevented from being compressed in a using process, and a dirt containing amount is increased, the fine fiber sets play a role in filtering and intercepting, so that filtering precision is improved, and the filter element has the functions of high filtering precision, high dirt containing capacity and longservice life and is good in filtering effect.

Owner:HANGZHOU COBETTER TECH CO LTD

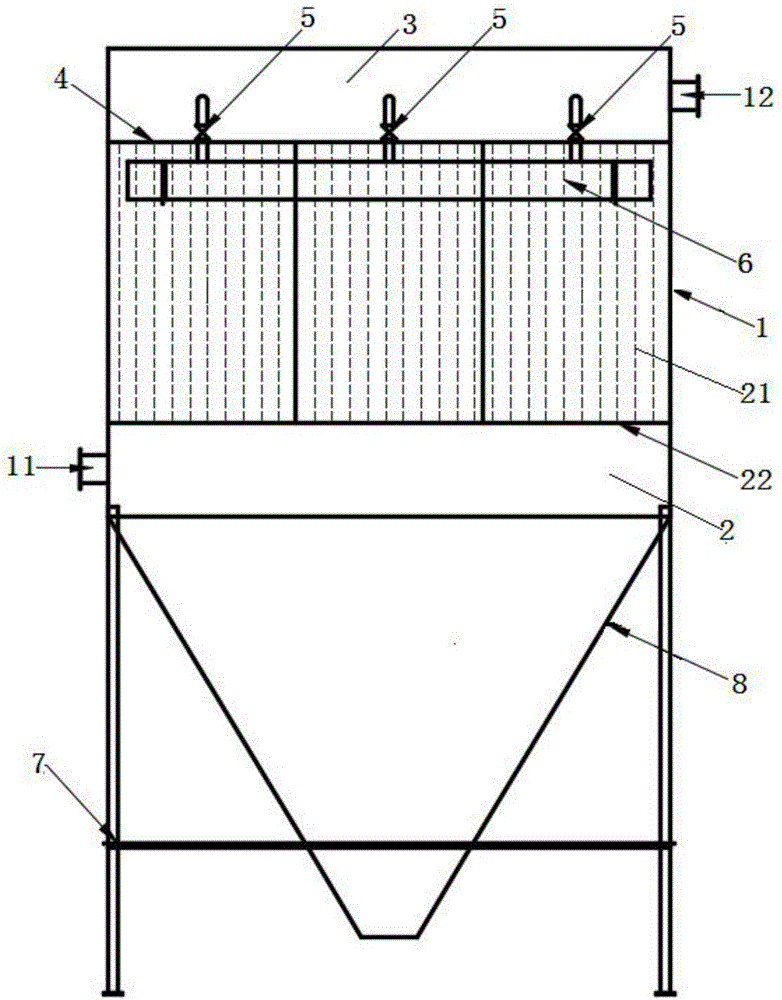

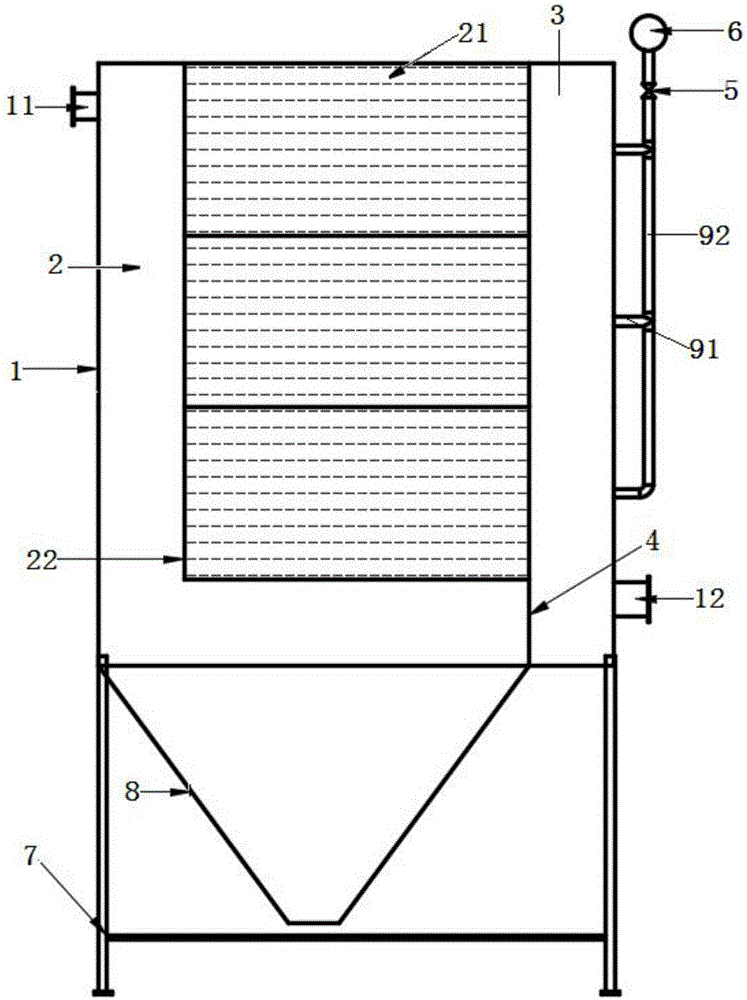

Dust removing and filtering device based on honeycomb ceramic filter elements

InactiveCN105944469ANo damage such as corrosionEasy to useHuman health protectionDispersed particle filtrationEngineeringControl valves

The invention provides a dust removing and filtering device based on honeycomb ceramic filter elements. The dust removing and filtering device comprises a shell, a dust cavity, a clean cavity, a dust removal fan and a compressed air cylinder, wherein a waste gas inlet is formed in one side of the shell, and a purified gas outlet is formed in the other side of the shell; the dust cavity is formed inside the shell and is communicated with one end of the waste gas inlet, and at least one ceramic filter body is arranged inside the dust cavity; the clean cavity is formed inside the shell, a cavity partition plate is mounted between the clean cavity and the dust cavity and is connected with one end of the purified gas outlet; the dust removal fan is connected with the other end of the purified gas outlet; the compressed air cylinder is connected with the clean cavity through a pipeline, and a pulse inverse blow control valve is arranged on the pipeline. A dust removing and filtering device body adopts the ceramic filter body to filter dust, and the structural strength and the material strength of the dust removing and filtering device body are strong, so that the filter body cannot generate breakage, deformation, corrosion and other damages; as the pulse inverse blow control valve is adopted for controlling compressed air to flow out from the air cylinder so as to blow the dust on the ceramic filter body, the dust removing and filtering device provided by the invention has excellent dust down performance.

Owner:德州奥深节能环保技术有限公司

Precise liquid filtering apparatus

InactiveCN107158781AHigh hole densityUniform pore sizeMoving filtering element filtersPorous membranePollutant

The invention discloses a precise liquid filtering apparatus. The apparatus comprises a rotatable filter cylinder device, the rotatable filter cylinder device is provided with an ultrasonic wave or air explosion cleaning device, the filter cylinder device is connected with a liquid inlet tube, a liquid outlet tube and a waste discharging tube, the filter cylinder device communicates with a filter stock solution through the liquid inlet tube, the liquid inlet tube is provided with a circulating pump, the water outlet tube is provided with a vacuum pump, a filtered filtrate is pumped out by the vacuum pump, and the waste discharge tube communicates with the filter stock solution. The apparatus adopts a nuclear porous membrane or an effective compound of the nuclear porous membrane and other filter materials as a filter material reserves the filtration characteristics of a traditional filter material and the fine filtration effect of the nuclear porous membrane, and the apparatus adopting a cross flow filtration manner keeps pollutants on the surface of the filter membrane at a small level, alleviates the obstruction of filter pores, improves the filtering efficiency and prolongs the service life of the filter membrane.

Owner:上海谷奇核孔膜科技股份有限公司

Combined polypropylene thermal spray fiber membrane folding type filter element

InactiveCN101590337ALarge amount of dirtImprove stain resistanceStationary filtering element filtersLiquid productFilter media

The invention relates to a combined polypropylene thermal spray fiber membrane folding type filter element which comprises a filtering medium layer, an inner supporting barrel and an outer supporting barrel, wherein the filtering medium layer is folded into fins and then wound on the outer circumference of the inner supporting barrel, the outer supporting barrel is sleeved at the outer side of a barrel formed by the filtering medium layer, the filtering medium layer is formed by overlapping three layers of polypropylene thermal spray fiber membranes and two protective layers, wherein the three layers of the polypropylene thermal spray fiber membranes are adjacently connected in sequence, the protective layers are respectively arranged at the upstream side and the downstream side of the polypropylene thermal spray fiber membrane, and the adjacent fins are in welding connection. Since the three layers of polypropylene thermal spray fiber membranes are arranged in the filtering medium layer of the folding type filter element, the fiber membranes are protected by using the long-fiber nonwoven fabrics at both sides of the folding type filter element, the dirt holding capacity of the filter element is increased, particles are gradually intercepted from the large size to the small size, the pollution resistibility of the filter element is improved, and the filtering precision and the efficiency of the filter element are ensured, thus the service life of the filter element is greatly prolonged, and the quality of a filtered liquid product is guaranteed to be stable.

Owner:SHANGHAI FILTER

Efficient backwash-free high-precision filter

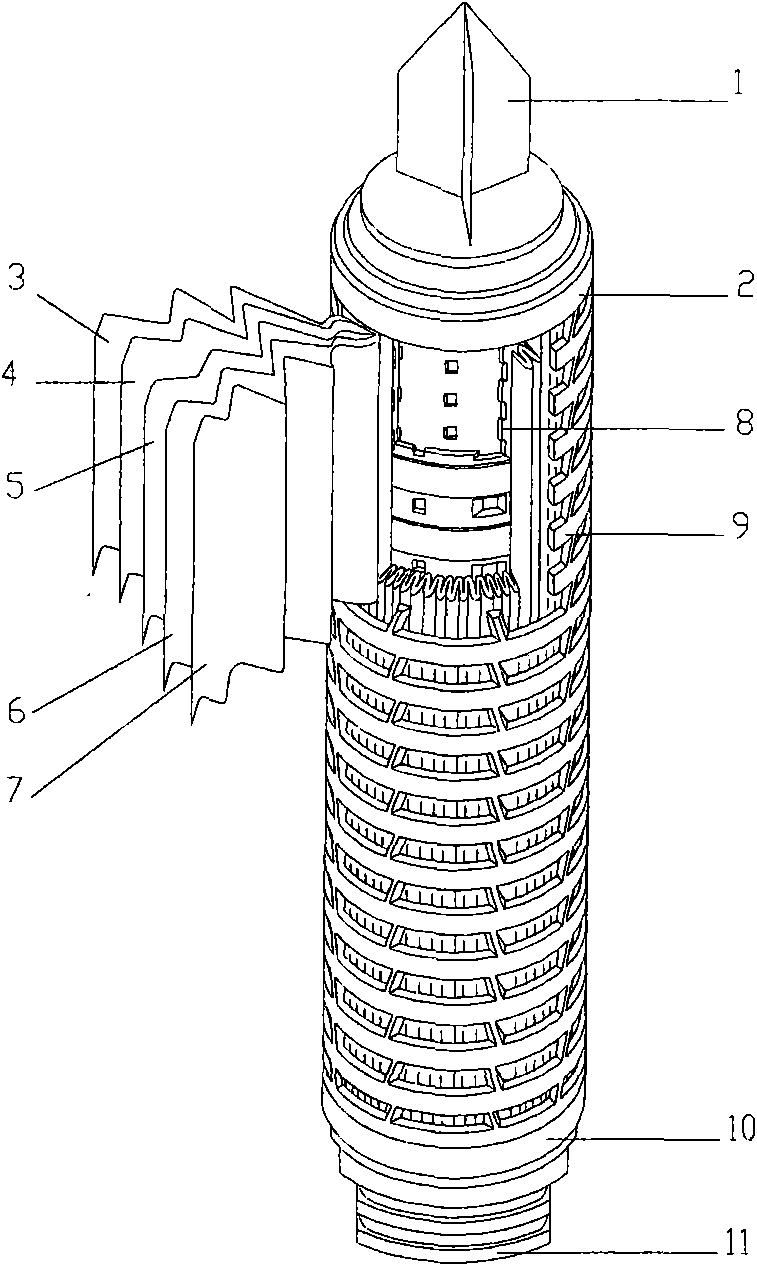

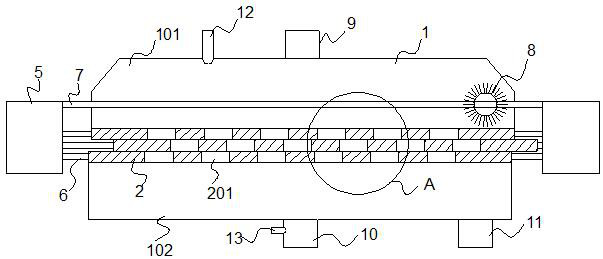

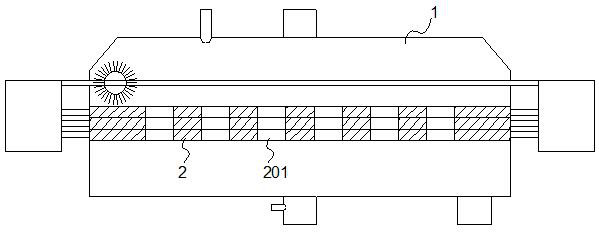

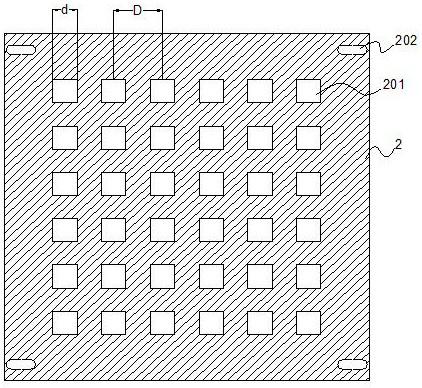

ActiveCN112023470AAdjustable filterHigh precisionSustainable biological treatmentStationary filtering element filtersParticulatesEngineering

The invention discloses an efficient backwash-free high-precision filter, which belongs to the technical field of high-precision filters, and is characterized in that a filtering mechanism comprises more than three layers of laminated perforated plates, and the perforated plates are uniformly provided with filtering holes of which the hole diameters are greater than the diameter of the maximum particulate matters to be filtered, the distance D between the centers of the adjacent filtering holes is larger than or equal to two times of the diameter d of the filtering holes, pre-pressing mechanisms are arranged on the perforated plates, the adjacent perforated plates are tightly connected in a sliding mode through the pre-pressing mechanisms, and the adjacent perforated plates move relativelyin a staggered mode. More than two filtrate holes with different hole diameters are formed between every two adjacent filter holes in a staggered manner, the hole diameters of the filtrate holes aregradually reduced from top to bottom, and the filtrate holes are communicated to form a filtrate channel. The filter has high-precision filtering capacity, is convenient to clean and does not need tobe backwashed.

Owner:深圳市正达环境工程实业有限公司

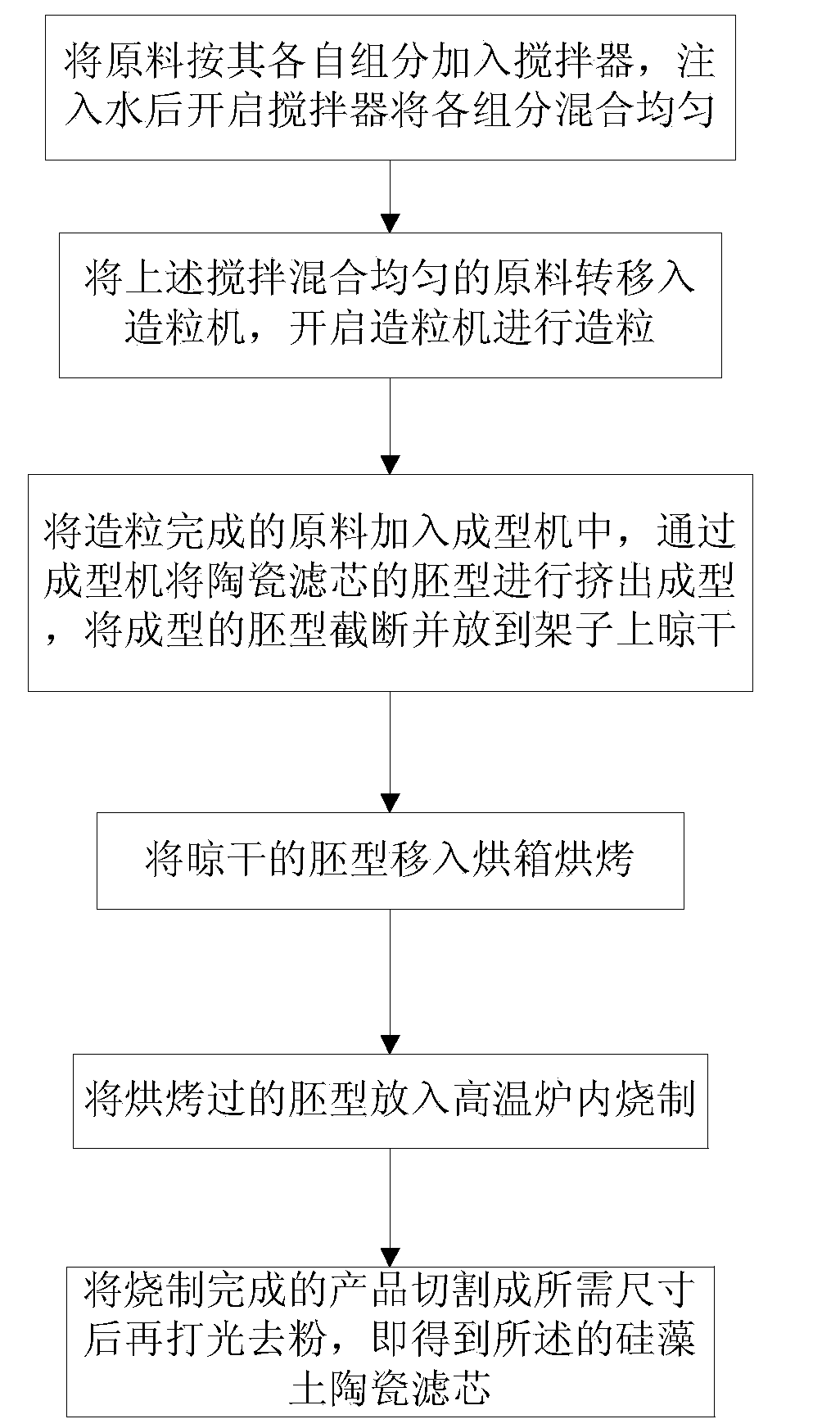

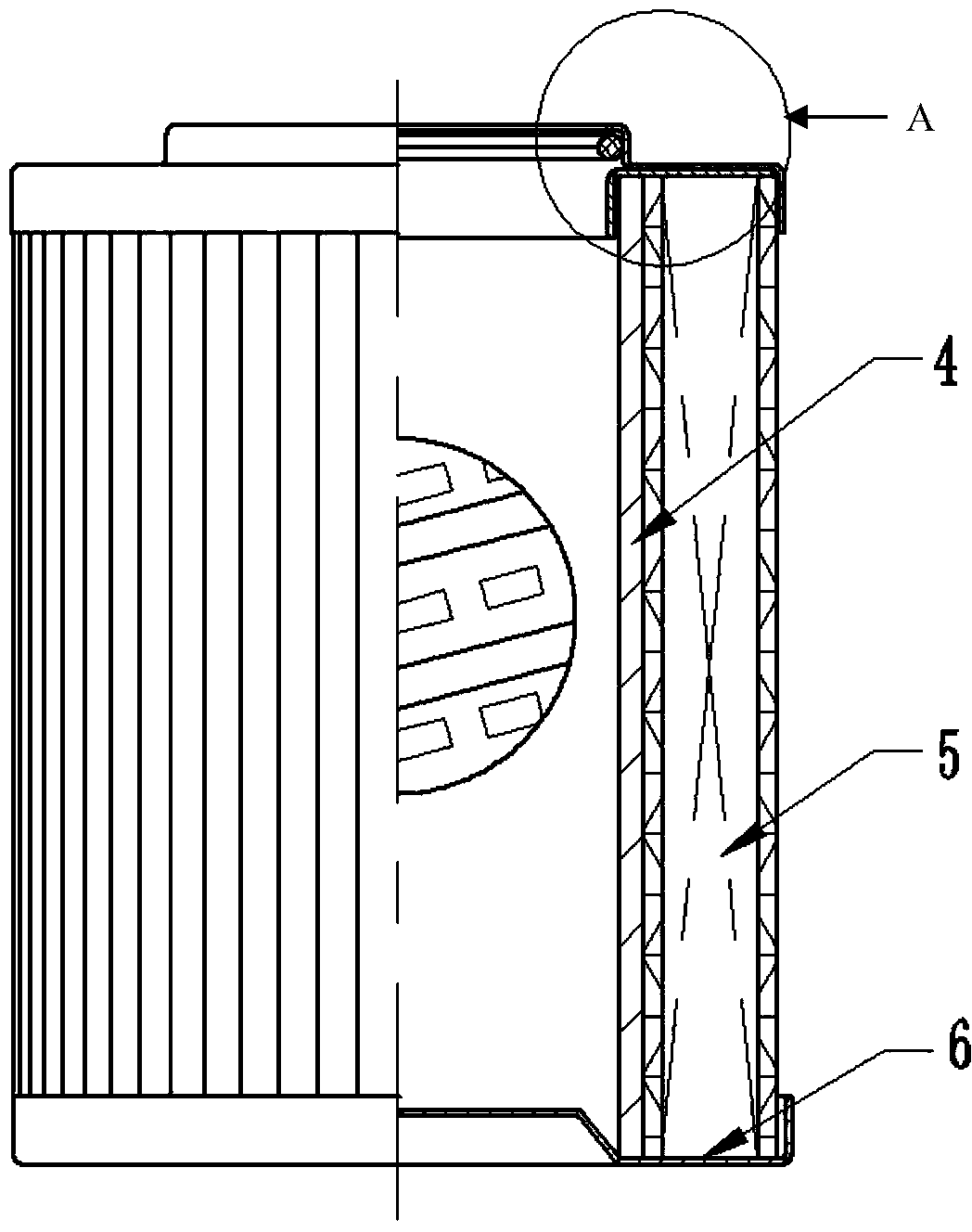

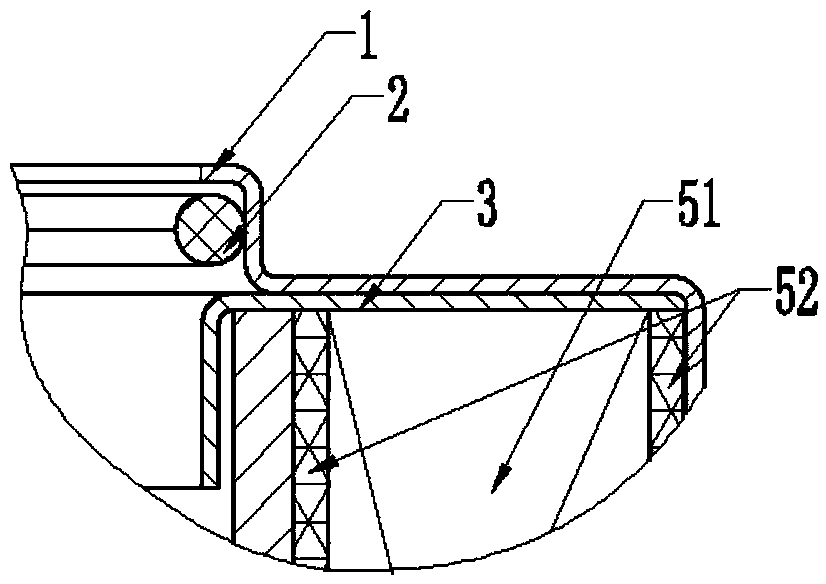

Preparation method of kieselguhr ceramic filter cartridge

ActiveCN103467075AGuaranteed filtration accuracyAvoid infringementFiltration separationCeramicwareCharoiteAdhesive

The invention relates to a preparation method of a kieselguhr ceramic filter cartridge. The method comprises the following steps of (1) weighing the following raw materials by mass percent: 93% to 97% of kieselguhr, 1% to 5% of fluxing pore-enlarging agent, 1% to 5% of adhesive and 0.1% to 1% of embryonic body enhancer and putting the raw materials into a stirrer to be mixed evenly by adding water after the starting of the stirrer; (2) pelleting the raw materials; (3) performing extrusion molding on an embryonic model of the ceramic filter cartridge by using a molding machine and drying the embryonic model in the air; (4) roasting; (5) firing; and (6) polishing and removing powder. Other minerals are not contained in the raw materials for preparing the kieselguhr ceramic filter cartridge, so that the injury to a human body, caused by harmful chemical elements, is avoided. In addition, the filtration precision of the kieselguhr ceramic filter cartridge is high, so that a good filtration effect is obtained. The preparation method is in the extrusion molding manner, so that the trouble caused by manufacturing the models in different shapes is avoided, which is favorable for a manufacturer to improve the production efficiency. The preparation method is short in time spending. As a result, the market competitiveness of the kieselguhr ceramic filter cartridge is further improved.

Owner:宁波杜康陶瓷有限公司

High-strength high-performance filter element

InactiveCN104190133AIncrease stiffnessEasy to processStationary filtering element filtersFinenessSteel belt

The invention belongs to the technical field of filter devices and discloses a high-strength high-performance filter element. The high-strength high-performance filter element comprises upper end covers, lower end covers, a central pipe and a filter cartridge arranged at the periphery of the central pipe; the upper end covers and the lower end covers are arranged on the upper and lower ends of the filter cartridge and the center pipe respectively; the filter cartridge comprises a waved filter layer and waved metal nets which are arranged on the inner and outer sides of the waved filter layer; the filter layer is formed by orderly stacking a glass fiber felt layer, a glass fiber filter paper layer and a non-woven cloth layer; the non-woven cloth layer is close to the central pipe; the body of the central pipe is formed by narrow steel strips which are spirally coiled in a staggered manner, wherein the narrow steel strip of the upper layer is fixedly connected with the narrow steel strip of the lower layer, and a squeezing hole is formed in the length direction of the narrow strips. The high-strength high-performance filter element is reasonable in design and simple in structure; the filter element has high strength and safety, and therefore, the filtering fineness of a filter is guaranteed, and moreover, the filtering efficiency of the filter is well improved and the service life of the filter is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

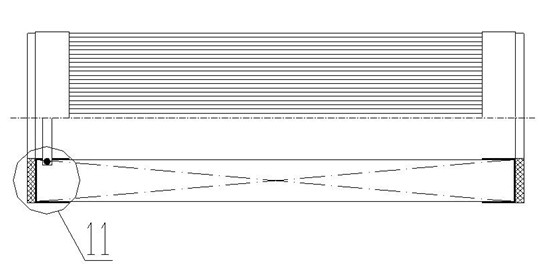

Natural gas filter element and manufacturing method thereof

ActiveCN102151450AExtended service lifeImprove and ensure filtration accuracyDispersed particle filtrationPolyesterGlass fiber

The invention discloses a natural gas filter element with high precision and high flow and a manufacturing method of the natural gas filter element. The natural gas filter element adopts a multilayer composite structure; a stainless steel dense screen on the outer layer forms a first surface filtration layer and simultaneously plays an anti-scouring role; a non-woven fabric protection layer formsdeep filtration; a middle layer of a polyester or glass fiber filtration membrane forms a second surface filtration layer; a coarse-grain silk screen on the inner layer plays a supporting role; and an axial sealing and radial sealing structure is adopted at the end part of the filter element. Through a multilayer composite and combined sealing structure, the overall filtering precision, the service life and the performance reliability of the filter element are ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

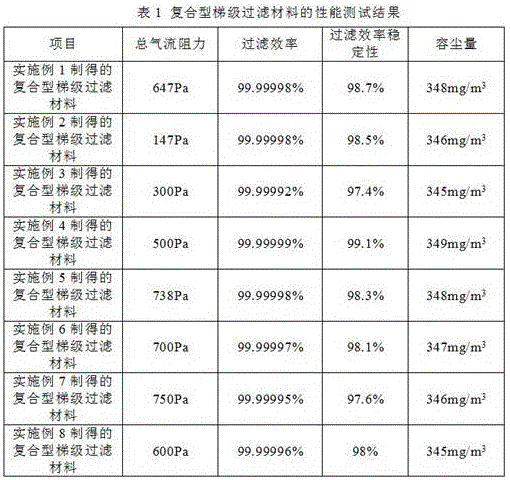

Compound type stair filter material and forming method and application thereof

InactiveCN106512555AReduce in quantityIncrease dust holding capacityMembrane filtersFiltration separationFiberGlass fiber

The invention discloses a compound type stair filter material and a forming method and application thereof. A surface-layer filter material and an inner-layer filter material, or a surface-layer filter material, at least one middle-layer filter material and an inner-layer filter material are compositely formed by adopting at least two filter materials with different filtering precision in a filtering precision gradient decreasing mode; the filtering precision is 3.5 mu m to 65 mu m; the filter material comprises one or more of a glass fiber filter material, a plant fiber filter material, a meltblown fiber filter material, and an electrostatic cotton filter material; the total air flow resistance of a compound type stair filter material is less than or equal to 750Pa, the filtering efficiency is 99.99992% to 99.99999%; a hot melt adhesive is sprayed between the filter material layers by utilizing a hot melt adhesive machine, and adhesive filaments are formed, and then press-fitting to form the compound type stair filter material. The compound type stair filter material prepared by the invention has the advantages of obviously improving the filtering effect, simplifying filtering equipment and prolonging the service life of the filtering equipment.

Owner:DSP TECH DEV WENZHOU CO LTD

Nanofiber composite air filter paper and production method thereof

ActiveCN106012652AImprove water resistanceExtended service lifeNon-macromolecular organic additionPaper coatingWeather resistanceFilter paper

The invention discloses a nanofiber composite air filter paper and a production method thereof. The nanofiber composite air filter paper comprises an upper filter layer, a lower filter layer and a nanocellulose composite coating layer arranged on the upper surface of the upper filter layer; a composite slurry comprises nanocellulose, titanium dioxide aerogel nanoparticles, phenolic resin, dimethylformamide and water; raw materials of the upper filter layer comprise mercerized fibers, sisal fiber, akund fibers, ethylene glycol diglycidyl ether, a dispersant and water; and raw materials of the lower filter layer comprise broadleaf wood fibers, titanium dioxide aerogel particles, beta-cyclodextrin, carboxymethylcellulose, ethylene glycol diglycidyl ether and water. The filter layer of the nanofiber composite air filter paper is provided with a high-air permeability and good-water resistance nanofiber composite coating layer, so the water resistance, the weather resistance and the bursting strength of the filter paper are improved on the premise of guaranteeing the air permeability and the filtering efficiency of the filter paper.

Owner:杭州特种纸业有限公司

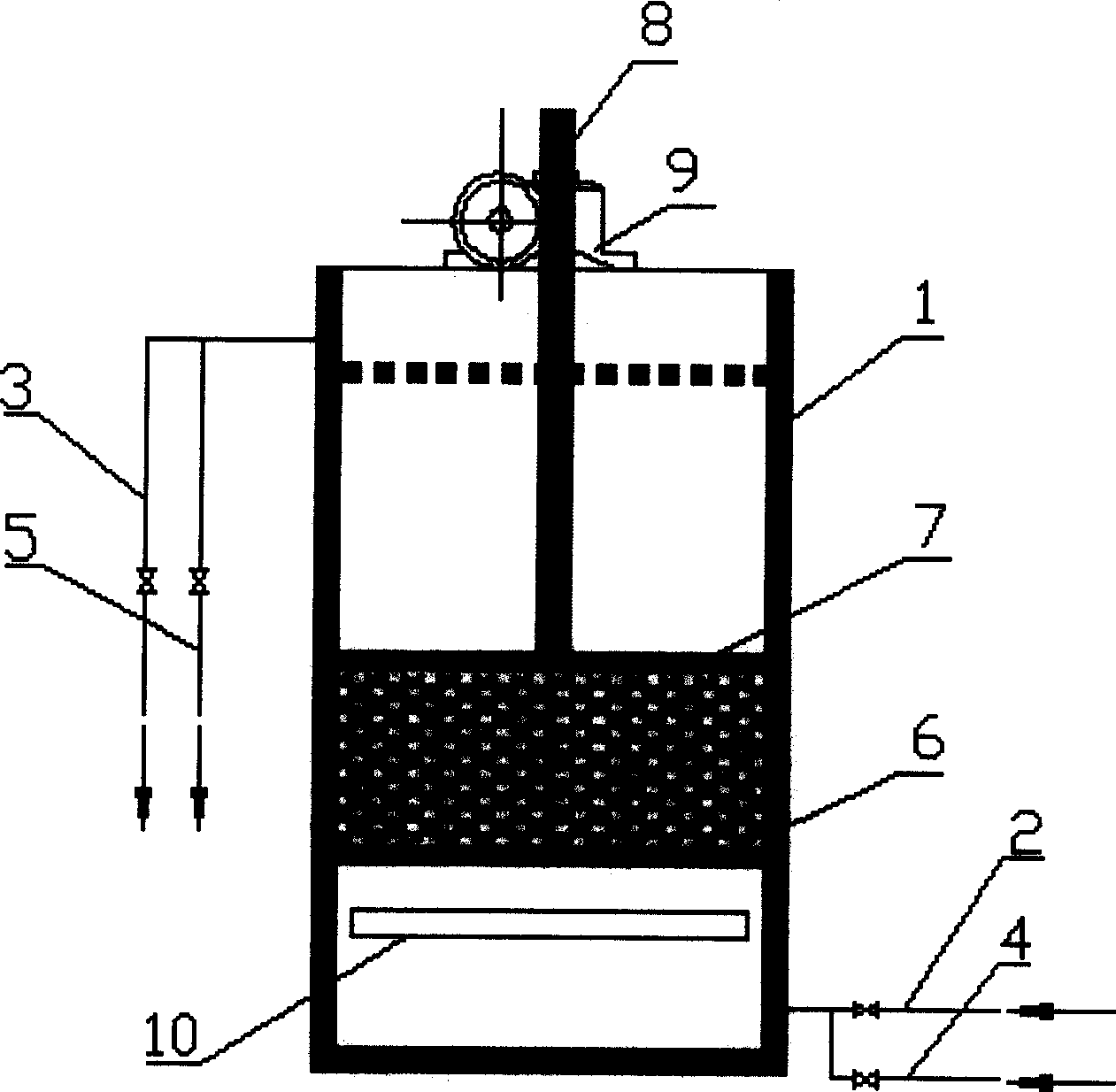

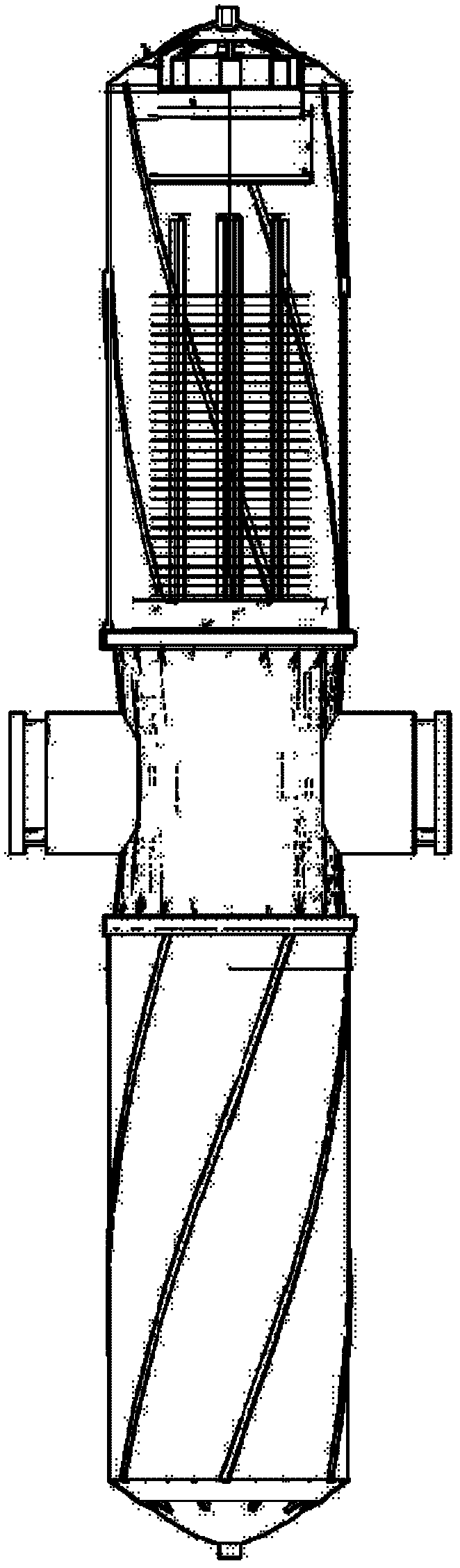

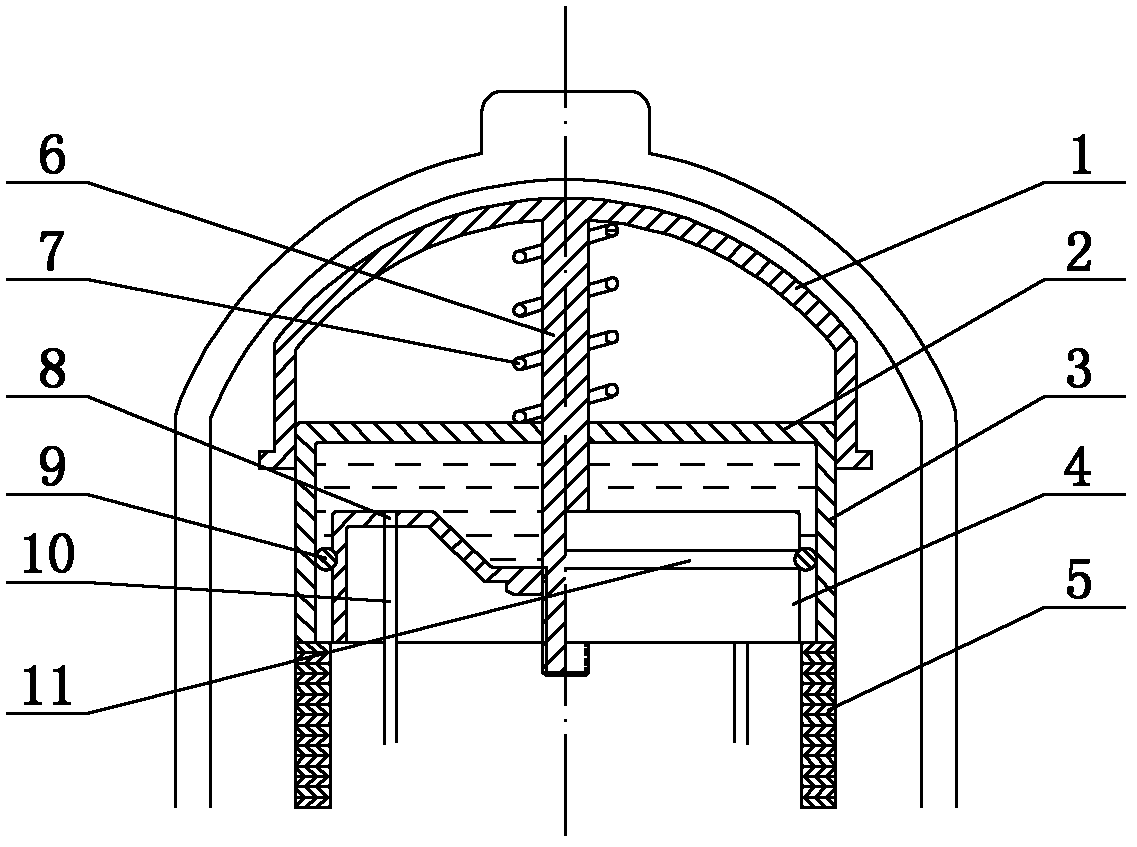

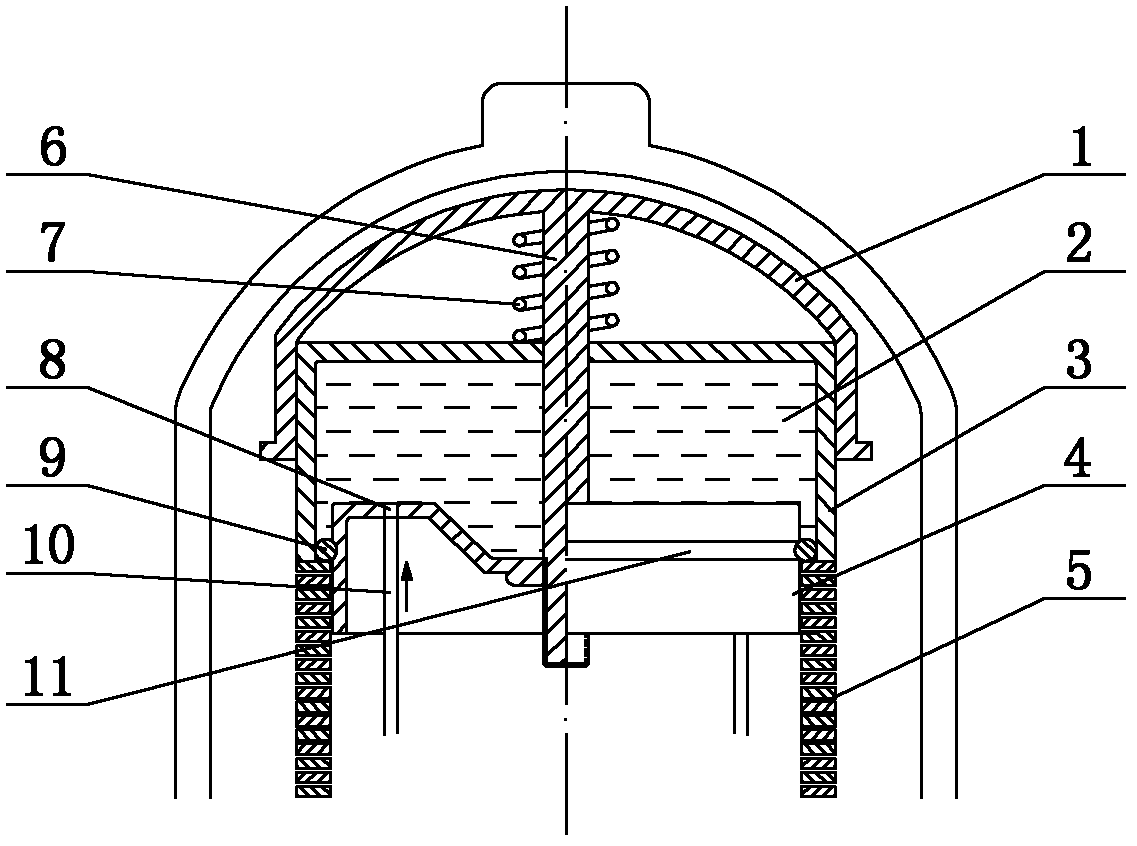

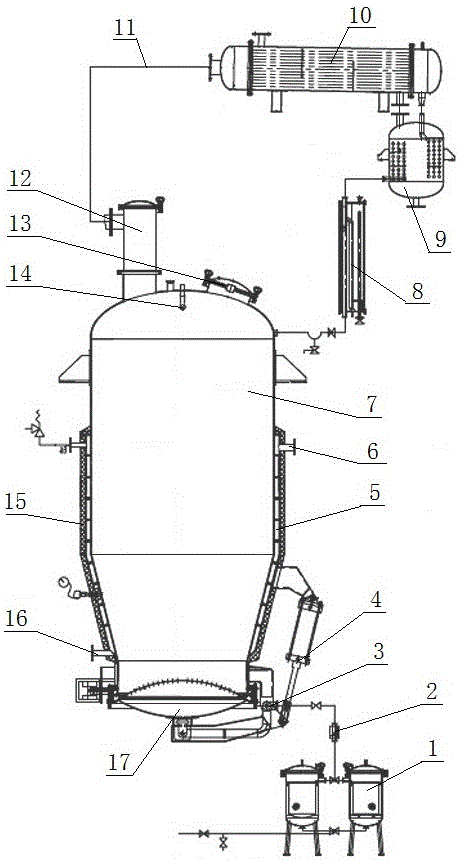

Multifunctional extraction tank

InactiveCN105107225AUniform temperatureImprove extraction efficiencySolid solvent extractionInsulation layerOil–water separator

The invention discloses a multifunctional extraction tank and relates to the technical field of manufacturing of pharmaceutical equipment. The multifunctional extraction tank comprises a main tank having a liquid outgoing pipe at its bottom and a gas outlet at its top. The gas outlet of the main tank is connected sequentially with a condenser, a cooler and an oil-water separator through a pipeline. The oil-water separator is provided with a reflow pipe connected with an upper portion of the main tank. A jacket is provided outside the main tank. A condensate drain pipe is mounted at the bottom of the jacket. Two steam incoming pipes opposite to each other are arranged on an upper portion of the jacket. The outer surface of the jacket is covered with an insulation layer. An applicator is mounted at the gas outlet of the main tank. Compared with the prior art, the tank has the advantages that steam entering the jacket has a uniform temperature, the main tank is heated in a balanced manner, liquor is extracted more efficiently, froth produced in an extraction process enters the condenser with the steam, and condensing effect is good.

Owner:GUANGXI XINLONG PHARMA

Preparation process of metal filter layer and filter element

ActiveCN111228877AImprove yieldHigh bonding strengthLamination ancillary operationsLaminationCompression moldingFluid phase

The invention provides a preparation process of a metal filter layer, which comprises the following steps: B, sintering a metal net, flattening the metal net to a set thickness, and preparing the metal net into a predetermined shape to obtain a support layer; C, coating the supporting layer with metal powder slurry which comprises metal powder, a liquid phase carrier and a binder, and sintering toan integrated structure to obtain the metal filter layer. According to the preparation process of the metal filter layer, the manufacturing process of a traditional process is changed, the sintered metal net is made into a preset shape and then coated with the metal powder slurry, then the sintered metal net and the metal powder slurry are sintered into a whole to form the metal filter layer, themetal filter layer is protected from being rolled or bent or subjected to compression molding and other procedures, and the yield is high.

Owner:格锐德过滤科技(浙江)有限公司

Double-layer composite filter paper and preparation method thereof

InactiveCN110424176AImprove filtration efficiencyGuaranteed filtration accuracyNatural cellulose pulp/paperPaper coatingFiberFiltration

The invention provides a double-layer composite filter paper and a preparation method thereof. The double-layer composite filter paper comprises an outflow layer and an inflow layer which are combinedtogether, wherein the outflow layer and the inflow layer are impregnated with a resin material; the slurry of each of the outflow layer and the inflow layer consists of hardwood pulp, dried softwoodpulp and softwood pulp; the average pore size of the outflow layer is 15.1-18.5 [mu]m; and the average pore size of the inflow layer is 18.8-23.8 [mu]m. The double-layer composite filter paper has high filtration precision, high filtration efficiency, and good mechanical properties and high temperature resistance; and raw materials used for the preparation of the paper are all wood fibers, and arecheap and easily available.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

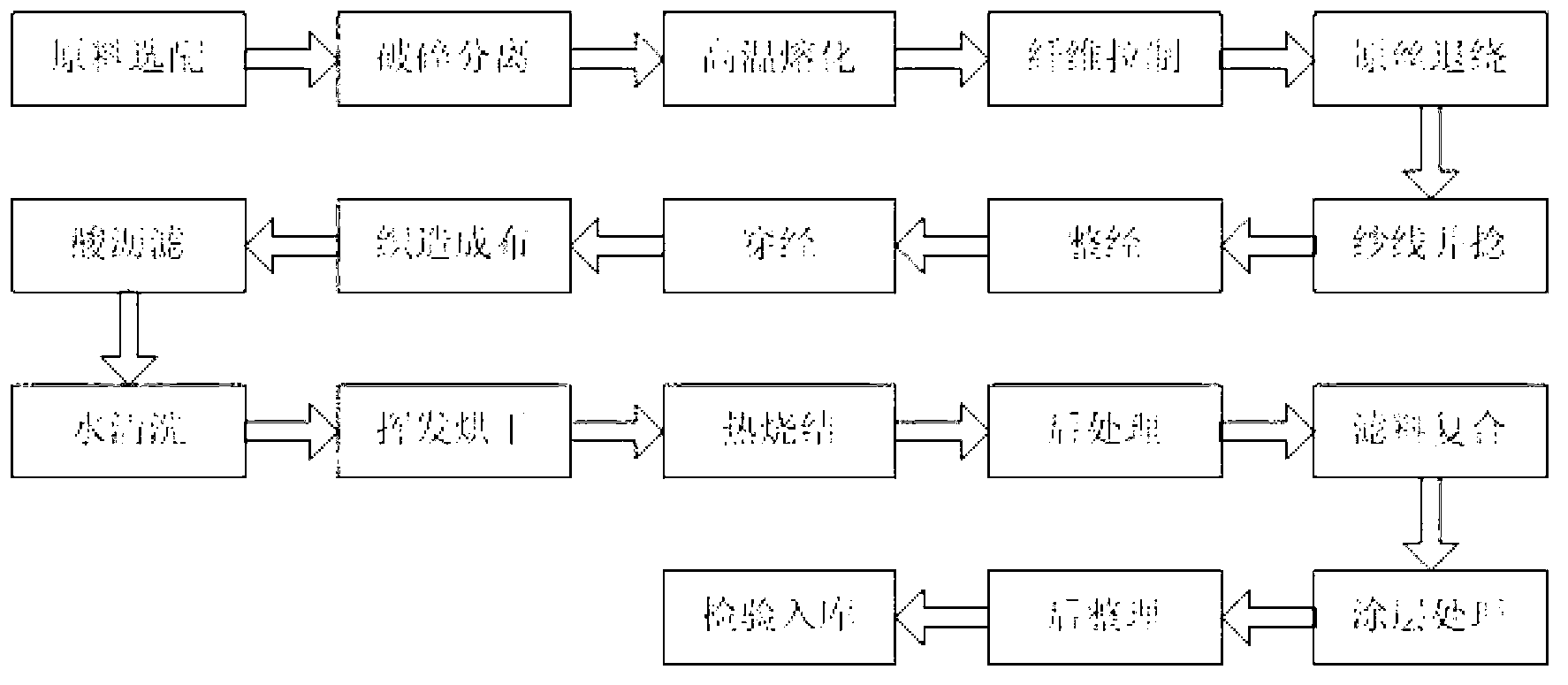

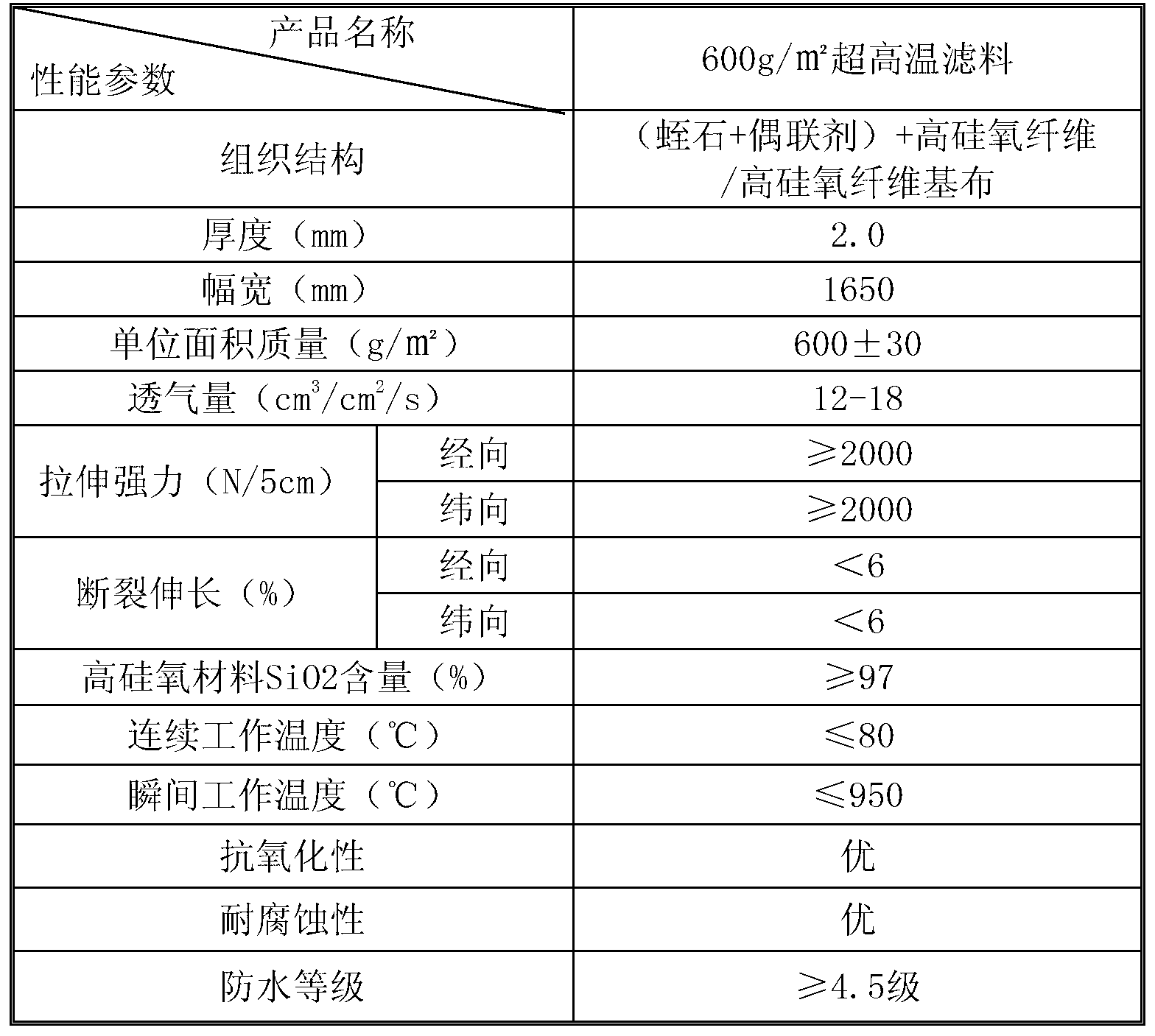

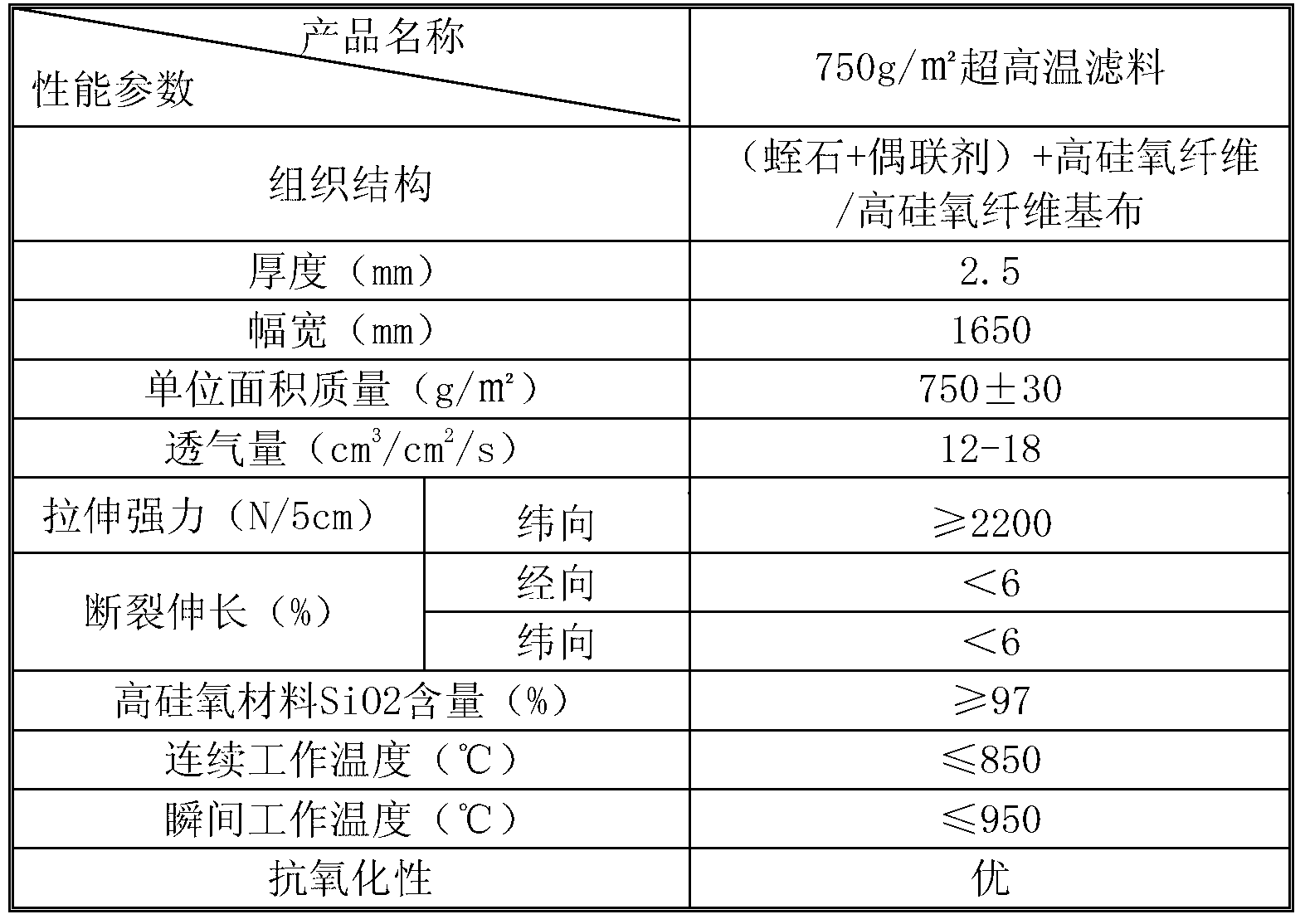

Preparation method of superhigh temperature filter material

InactiveCN103230709AImprove high temperature resistanceGood chemical resistanceFiltration separationNon-woven fabricsFiberYarn

The invention provides a preparation method of a superhigh temperature filter material. The preparation method comprises the steps of melting glass fiber raw materials at high temperature, and then, drawing the molten glass fiber raw materials to produce high silica fiber; weaving the fiber into a high silica fiber woven fabric; carrying out acid leaching treatment on the high silica fiber and the high silica fiber woven fabric; washing, volatilizing, drying and carrying out high-temperature sintering on a glass fiber product subjected to acid leaching; making the prepared high silica chopped fiber into a felt by taking the high silica fiber woven fabric as a base fabric by using a conventional needling or spunlacing process, wherein the diameter of a monofilament of the prepared high silica chopped fiber is over 6mum; needling or spunlacing high silica chopped yarn on one side of the prepared felt, wherein the diameter of a monofilament of the prepared high silica chopped yarn is smaller than 5mum; and finally, coating a vermiculite and coupling agent high-temperature resistant coating on the surface of a finished spun yarn. The superhigh temperature filter material prepared by using the preparation method can achieve the continuous working temperature of 650-850 DEG C and bear the instant high temperature of 950 DEG C and also has the physiochemical indexes such as high temperature resistance, chemical resistance, stable structure and remarkable filtering property.

Owner:昆山万瑞达工业纺织品有限公司

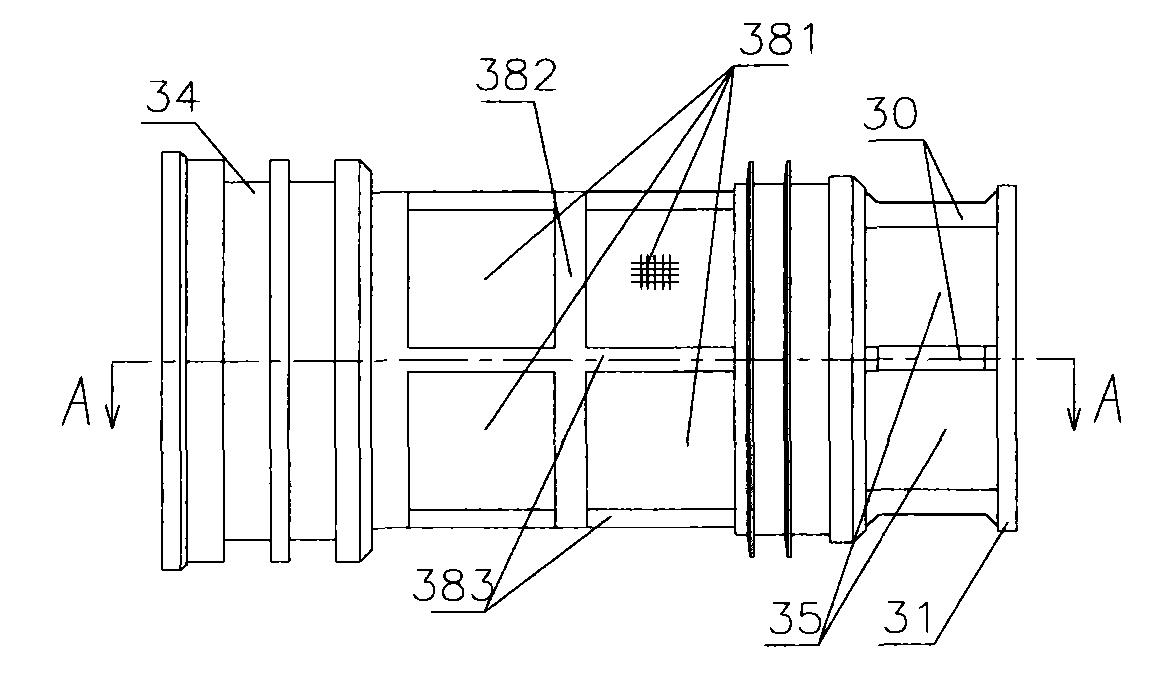

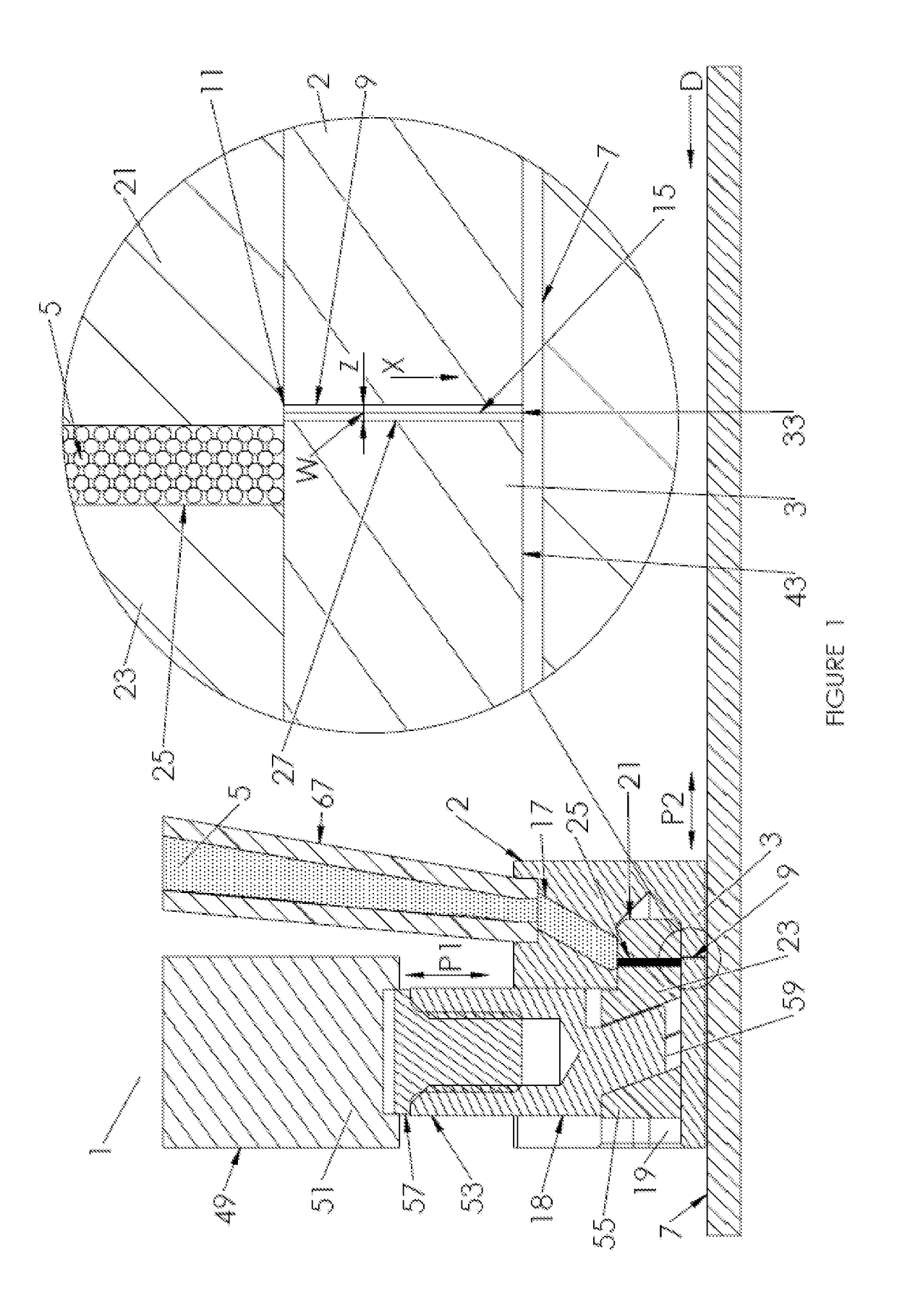

A Three Dimensional Printing Apparatus, a Material Dispensing Unit Therefor and a Method

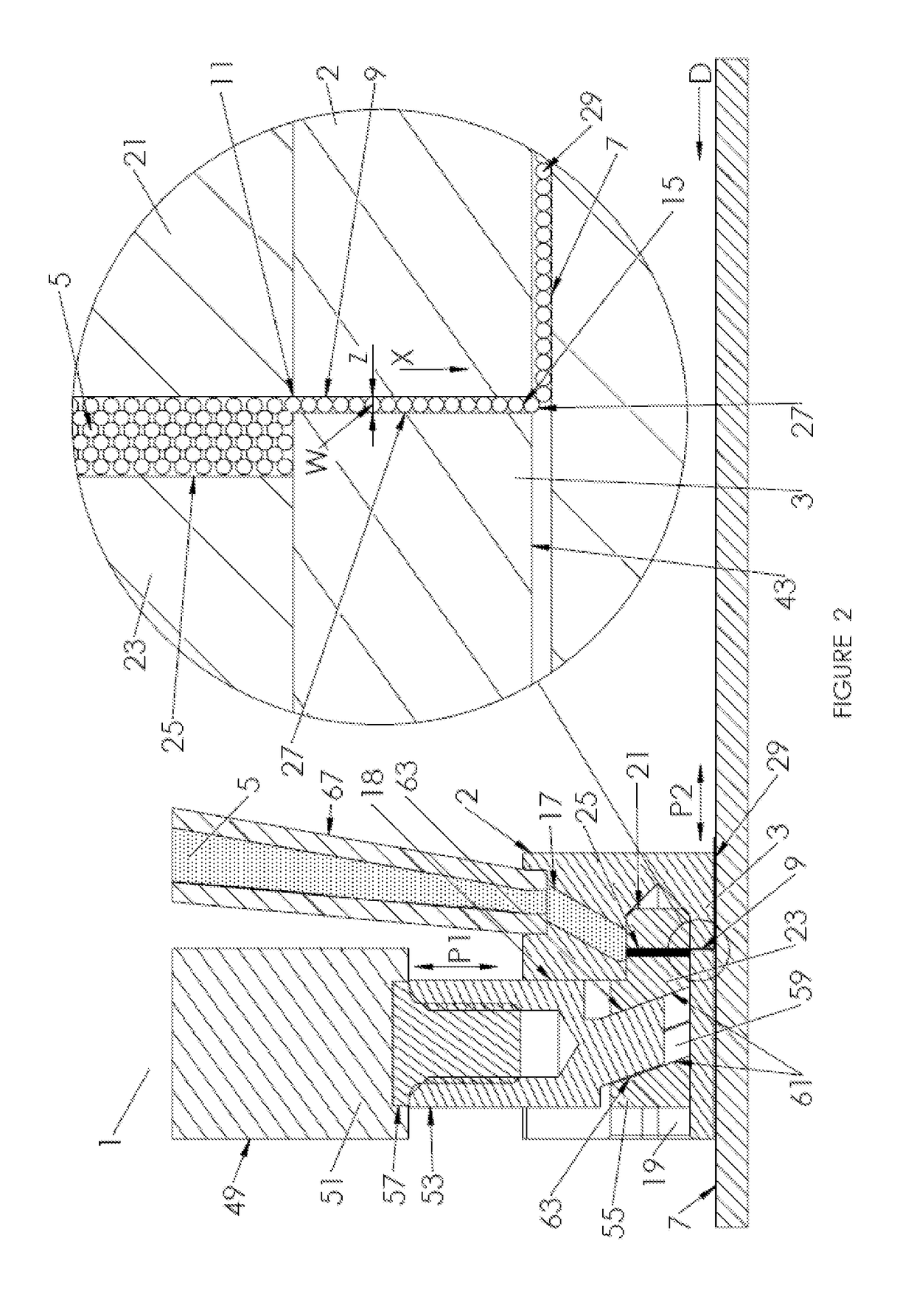

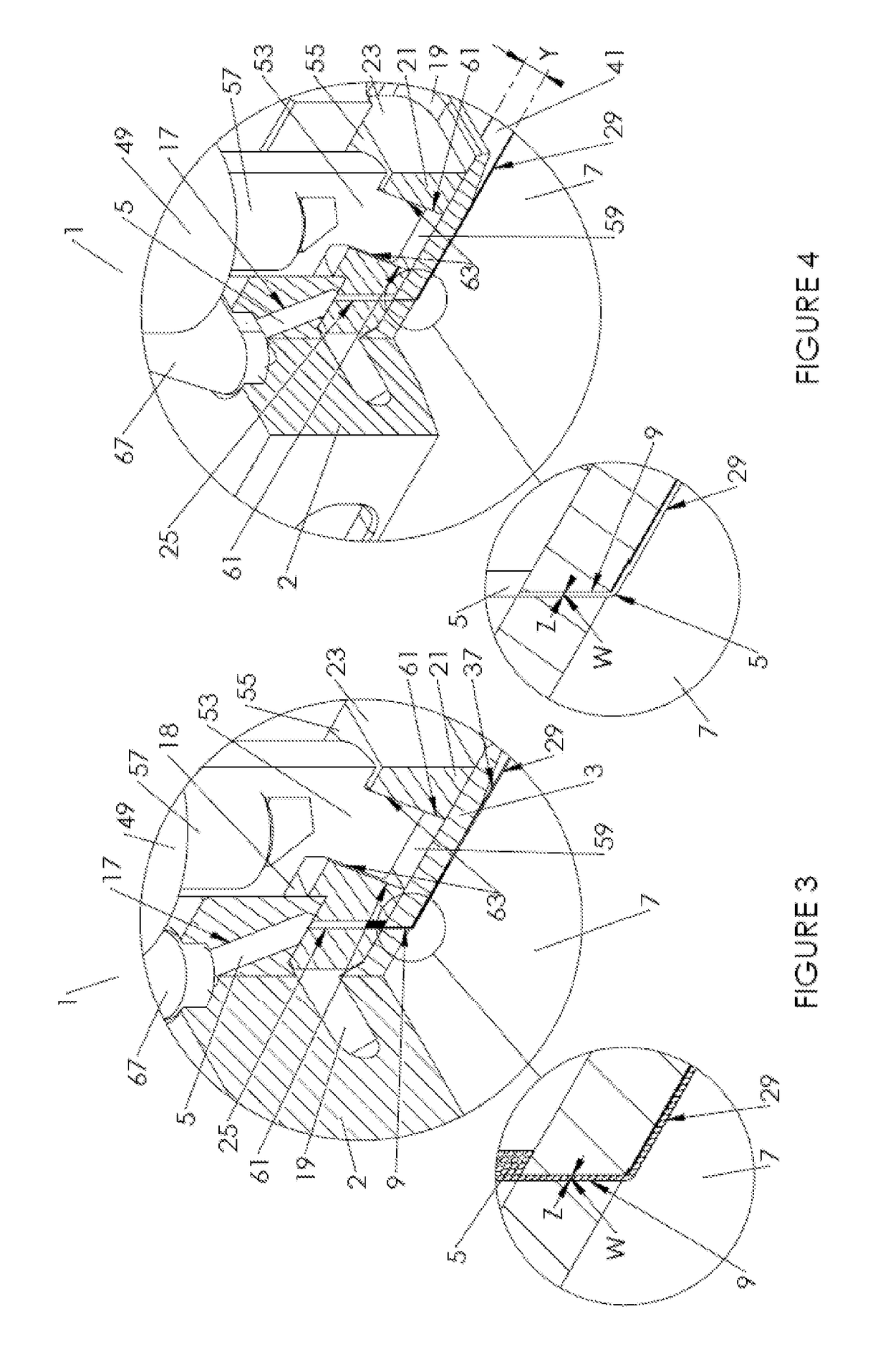

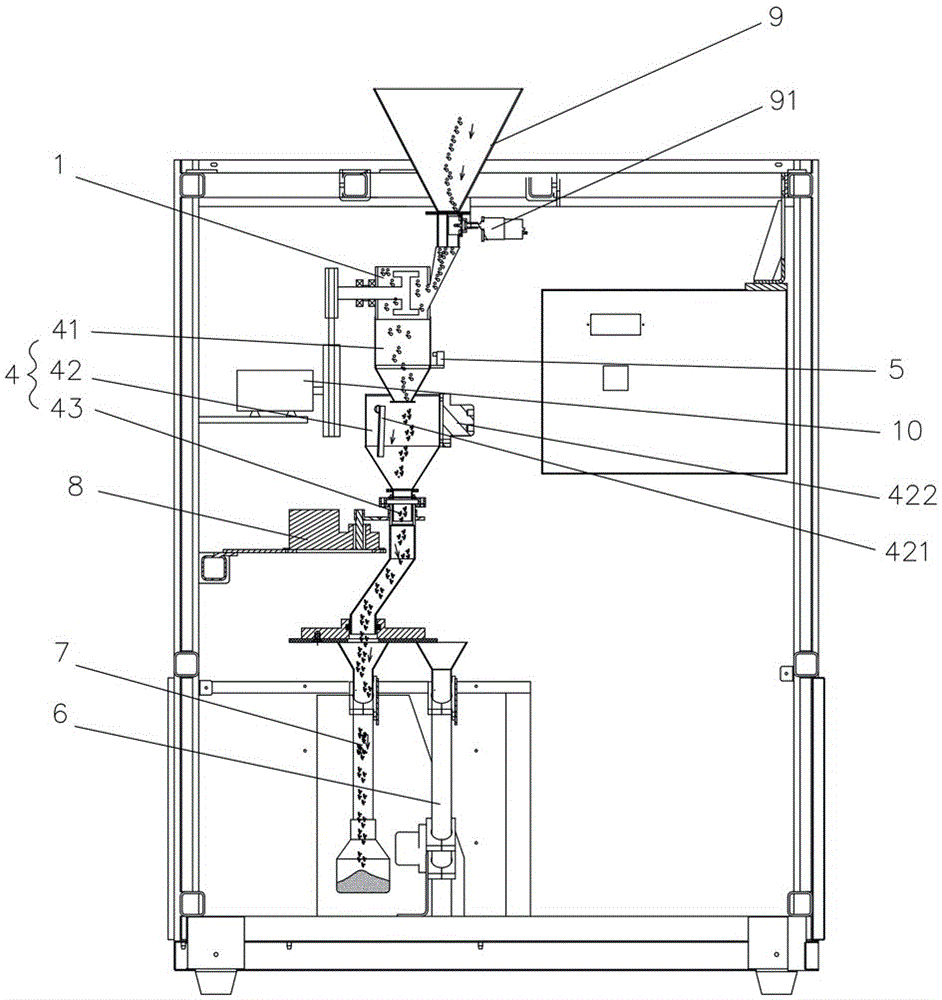

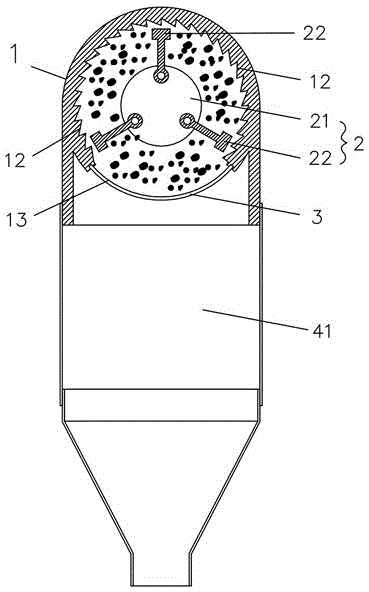

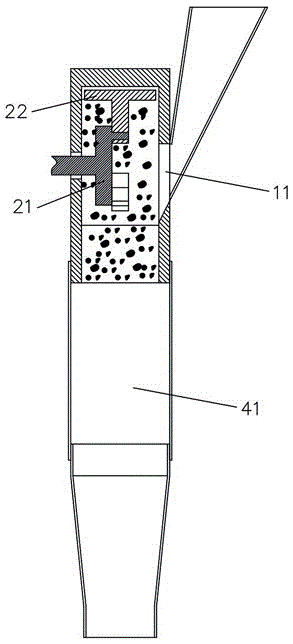

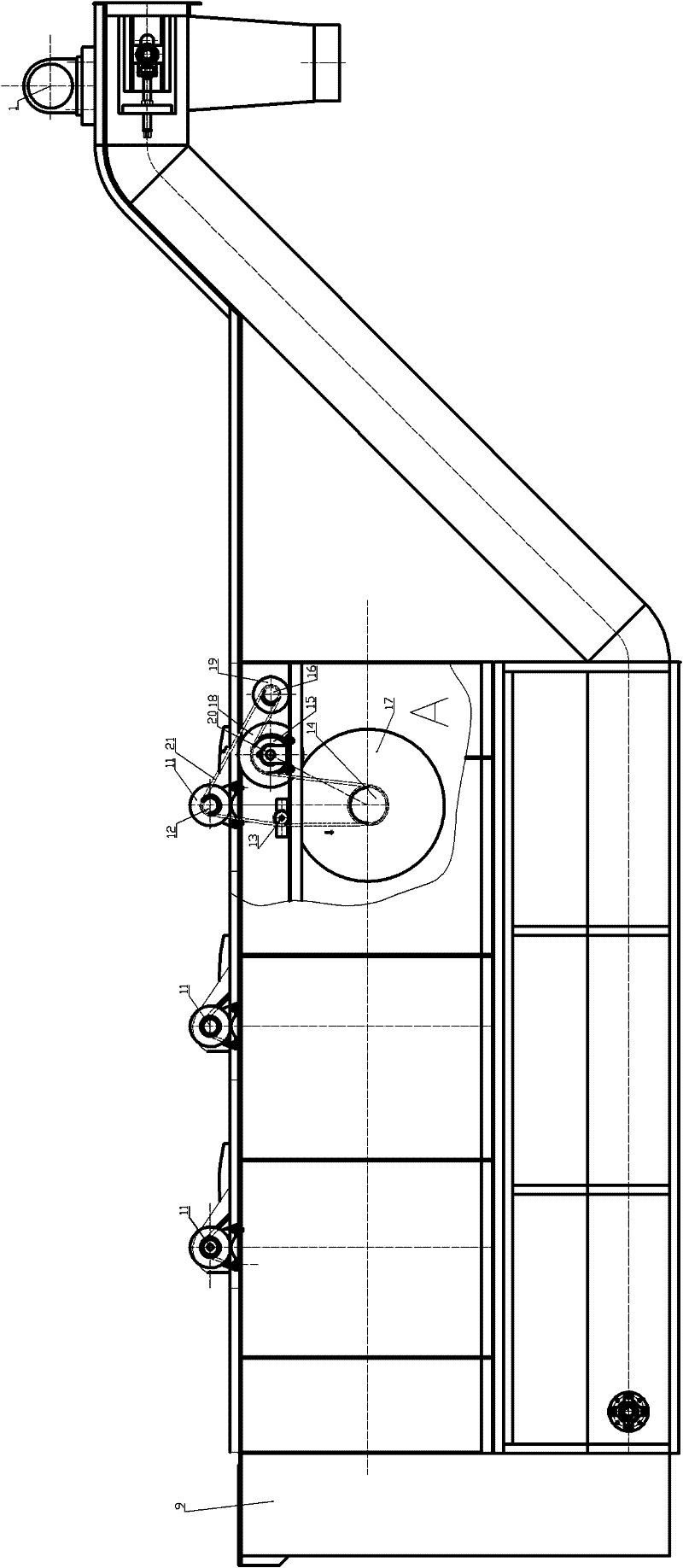

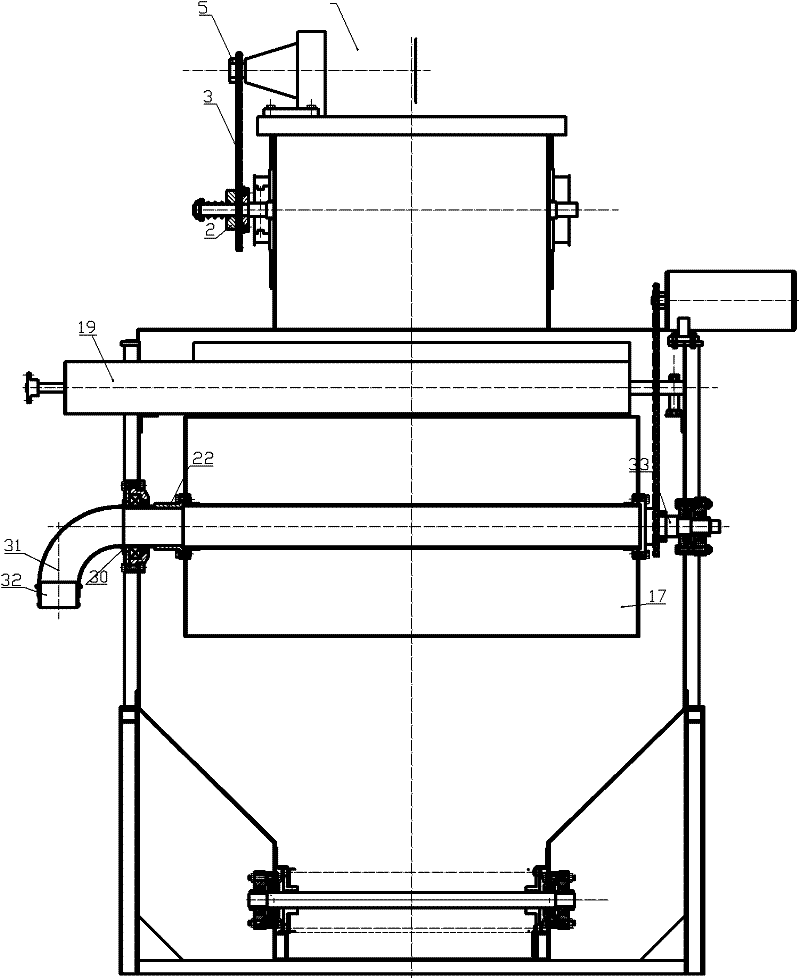

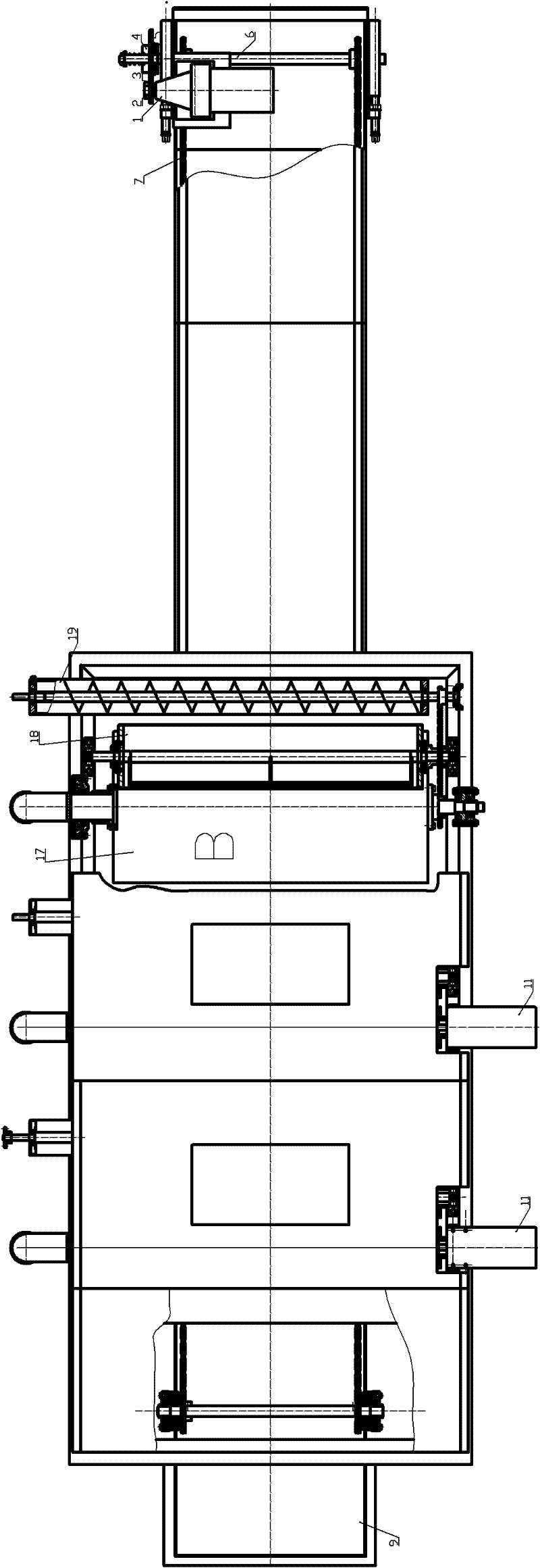

InactiveUS20180361663A1Uniform thicknessQuick buildManufacturing enclosuresManufacturing heating elementsControl flowEngineering

A material dispensing unit (1; 10) for a three dimensional printing apparatus (100; 200) has a nozzle (3) for depositing particulate material (5; 220a, 220b; 224; 226) on a build surface (7), where the nozzle defines a through passage (9) for the material. The through passage has an inlet end (11) for receiving the material and an outlet end (15) for dispensing the material. A valve (21) is provided at least one of at, within or in fluid communication with the through passage for controlling flow of the material via the through passage, the valve being operable between open and closed positions. Flow of said material into the through passage is blocked when in the closed position and, when in the open position, flow of the material into the through passage is allowed. A method of forming a three dimensional object (31) is also disclosed, as is a three dimensional printing apparatus (200) comprising one or more dispensing units (la; b) for dispensing particulate material (220a, 220b; 224; 226), an enclosure (137) for containing the material dispensed by the one or more dispensing units and one or more heating elements (210, 212) for heating the material contained in the enclosure to a first predetermined temperature.

Owner:BURT MAXIMILIAN BARCLAY

Flour mill for collecting and preparing samples

ActiveCN105833964AReduce wearExtended service lifePreparing sample for investigationGrain treatmentsEngineeringSieve

The invention discloses a flour mill for collecting and preparing samples. The flour mill comprises a flour milling cavity, wherein a feeding opening is formed in the flour milling cavity; a rotary flour-milling rotating blade assembly is arranged inside the flour milling cavity; an annular crushing area used for crushing samples and an annular sieve net area used for filtering samples are formed in the inner annular surface of the rotating circumference of the flour-milling rotating blade assembly in the flour milling cavity; the flour-milling rotating blade assembly rotates at high speed in the flour milling cavity and cooperates with the annular crushing area to collide and crush the samples and then discharge the samples through the annular sieve net. The flour mill has the advantages that the structure is simple and compact, the crushing and sample-preparing accuracy can be further improved, and the service life of the flour mill is prolonged.

Owner:HUNAN SUNDY SCI & TECH DEV

An industrial coolant purification device

The invention discloses a device for purification industrial cooling liquid, comprising a buffering water inlet tank, a plurality of groups of filtering devices and a scraper chain deslagging device, wherein each filtering device comprises a rolling cage filtering device, a magnetic rolling adsorption device and an auger-type deslagging device; liquid waste grinded by a machine tool group is introduced to the buffering water inlet tank through a liquid waste pipeline; and a plurality of circular cage-type rotating filtering cylinders are installed in the buffering water inlet tank. After being filtered by a fine stainless steel filtering screen on the circular cage-type rotating filtering cylinders, waste cooling liquid is introduced to a built-in hollow transmission main shaft and drained into a liquid-purifying box through a water outlet sleeve for recycling. A powerful magnetic roller is installed above each circular cage-type rotating filtering cylinder and used for adsorbing iron impurities by utilizing strong magnetism and connected with the auger-type deslagging device through a scraper board, and slag is discharged outside the buffering water inlet tank through auger rotation. The invention has the characteristics of low manufacturing cost, favorable use effect, strong environmental conservation, simple and practical structure, recycling of the cooling liquid and the like and is particularly suitable for grinding and machining the machine tool group in a large scale, has large filtering flow rate, is recycled and has remarkable energy-saving effect.

Owner:DALIAN KAIHONG SCI & TECH

High-flux virus-removing polyvinylidene fluoride hollow fiber microporous membrane and preparation method thereof

ActiveCN111530304AExpand the effective filtration areaIncreased pure water fluxSemi-permeable membranesPolyvinylidene fluorideHollow fibre

The invention relates to a high-flux virus-removing polyvinylidene fluoride hollow fiber microporous membrane with a multi-layer filtering structure and a preparation method thereof. In order to improve the virus interception performance and the pure water flux of the hollow fiber microporous membrane, the polyvinylidene fluoride hollow fiber microporous membrane disclosed by the invention has theadvantages that the outer diameter of membrane filaments is 1.1-1.4 mm, the inner diameter is 0.6-0.8 mm, and the wall thickness is 0.2-0.4 mm, obvious holes are formed in the outer surfaces of the membrane filaments, and a three-layer film pore structure layer with a remarkable boundary is formed from outside to inside. The preparation method comprises the following steps: preparing a membrane casting solution, extruding a hollow fiber membrane, spraying a solvent on the outer layer and exchanging to form a film, performing low-temperature split-phase film forming on the middle layer, carrying out inner-layer low-temperature split-phase film formation and carrying out extraction. The method is based on a thermally induced phase separation membrane preparation method, technologies such asshallow solvent-non-solvent rapid exchange film formation and graded temperature gradient split-phase pore formation are combined, the hollow fiber membrane with the three-layer pore structure, whichhas obvious different boundaries, is prepared by using the method disclosed by the invention, on the premise of ensuring large filtration flux, efficient multi-layer filtration can be formed on pathogenic microorganisms such as viruses, the interception performance reaches 99.99%, and the average interception rate detected by a third party reaches 99.999%.

Owner:BEIJING SCINO MEMBRANCE TECH

Filter

ActiveCN101637678AAchieve separationGuaranteed filtration accuracyLiquid degasificationWithdrawing sample devicesEngineeringExhaust pipe

The invention discloses a filter. The filter comprises a filter core, a top cover, a bottom cover, at least one first exhaust pipe and at least one second exhaust pipe, wherein the filter core is provided with a gap for passing through fluid to be filtered; the top cover and the bottom cover are respectively fixed to the upper part and the lower part of the filter core; the inner wall surface of the filter core, the inner wall surface of the top cover and the inner wall surface of the bottom cover enclose a filter cavity; the first exhaust pipe is communicated with the filter cavity and is arranged on the top cover; the first exhaust pipe is provided with at least one first inlet for fluid flowing in; the second exhaust pipe is communicated with the filter cavity and is arranged on the topcover or the bottom cover; the second exhaust pipe is provided with at least one second inlet for fluid flowing in; and the first inlets are all positioned above the second inlets in a direction of gravity. The filter not only can ensure filter accuracy, but also can separate two kinds of fluid.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com