Compound type stair filter material and forming method and application thereof

A filter material and molding method technology, applied in the field of separation, can solve the problems of low filtration efficiency and filtration precision, increased filtration pressure, and easy clogging of the surface layer, so as to reduce product cost, reduce the number of filters, and solve the problem of increased resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

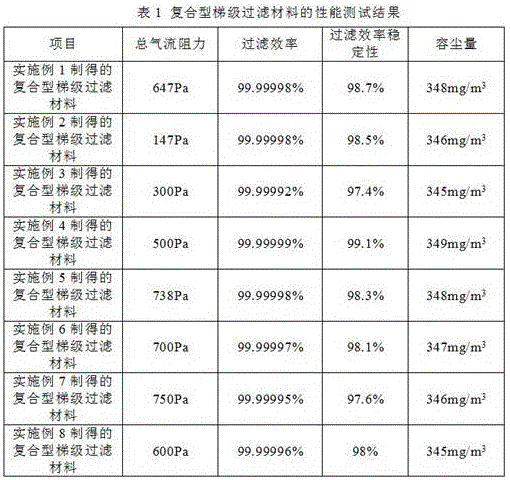

Examples

Embodiment 1

[0024] The utility model relates to a composite stepped filter material, which includes a surface layer filter material and an inner layer filter material, and is made into a two-stage stepped filter material.

[0025] The surface filter material is glass fiber filter material, the quantitative is 70g / m 2 , the filtration accuracy is 35μm, and the air permeability is 5000L / m 2 / S, the air resistance is 100Pa when the wind speed is 5.33cm / s, and the filtration efficiency is 90% when the test particle is 0.3μm and the wind speed is 5.33cm / s. Among them, the glass fiber is formed by wet method.

[0026] The inner filter material is glass fiber filter material, the quantitative is 90g / m 2 , the filtration accuracy is 1.5μm, and the air permeability is 70L / m 2 / S, the air resistance is 540Pa at a wind speed of 5.33cm / s, and the filtration efficiency is 99.99995% at a test particle size of 0.3μm and a wind speed of 5.33cm / s. Among them, the glass fiber is formed by wet method. ...

Embodiment 2

[0029] The utility model relates to a composite stepped filter material, which includes a surface layer filter material and an inner layer filter material, and is made into a two-stage stepped filter material.

[0030] The surface filter material is glass fiber filter material, the quantitative is 70g / m 2 , the filtration accuracy is 60μm, and the air permeability is 5100L / m 2 / S, the air resistance is 110Pa when the wind speed is 5.33cm / s, and the filtration efficiency is 92% when the test particle is 0.3μm and the wind speed is 5.33cm / s. Among them, the glass fiber is formed by wet method.

[0031] The inner filter material is polyethylene melt-blown fiber filter material, the weight is 25g / m 2 , the filtration accuracy is 5μm, and the air permeability is 80L / m 2 / S, the air resistance is 30Pa when the wind speed is 5.33cm / s, and the filtration efficiency is 99.9997% when the test particle is 0.3μm and the wind speed is 5.33cm / s.

[0032] Use a hot-melt glue machine to s...

Embodiment 3

[0034] The utility model relates to a composite stepped filter material, which includes a surface layer filter material and an inner layer filter material, and is made into a two-stage stepped filter material.

[0035] The surface filter material is glass fiber filter material, the quantitative is 20g / m 2 , the filtration accuracy is 40μm, and the air permeability is 5500L / m 2 / S, the air resistance is 5Pa when the wind speed is 5.33cm / s, and the filtration efficiency is 70% when the test particles are 0.3μm and the wind speed is 5.33cm / s. Among them, the glass fiber is formed by wet method.

[0036] The inner filter material is poly-p-phenylene terephthalamide electrostatic cotton filter material, the quantitative is 110g / m 2 , the filtration accuracy is 3μm, and the air permeability is 90L / m 2 / S, the air resistance is 290Pa at a wind speed of 5.33cm / s, and the filtration efficiency is 99.99% at a test particle size of 0.3μm and a wind speed of 5.33cm / s.

[0037] Use a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wind resistance | aaaaa | aaaaa |

| wind resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com