Patents

Literature

233results about How to "Guaranteed Filtration Quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing terylene POY filament in scale by recycling PET bottle sheet material

ActiveCN101435113ASolve the problem of water content inconsistencyHigh meshSolid waste disposalMelt spinning methodsEngineeringBottle

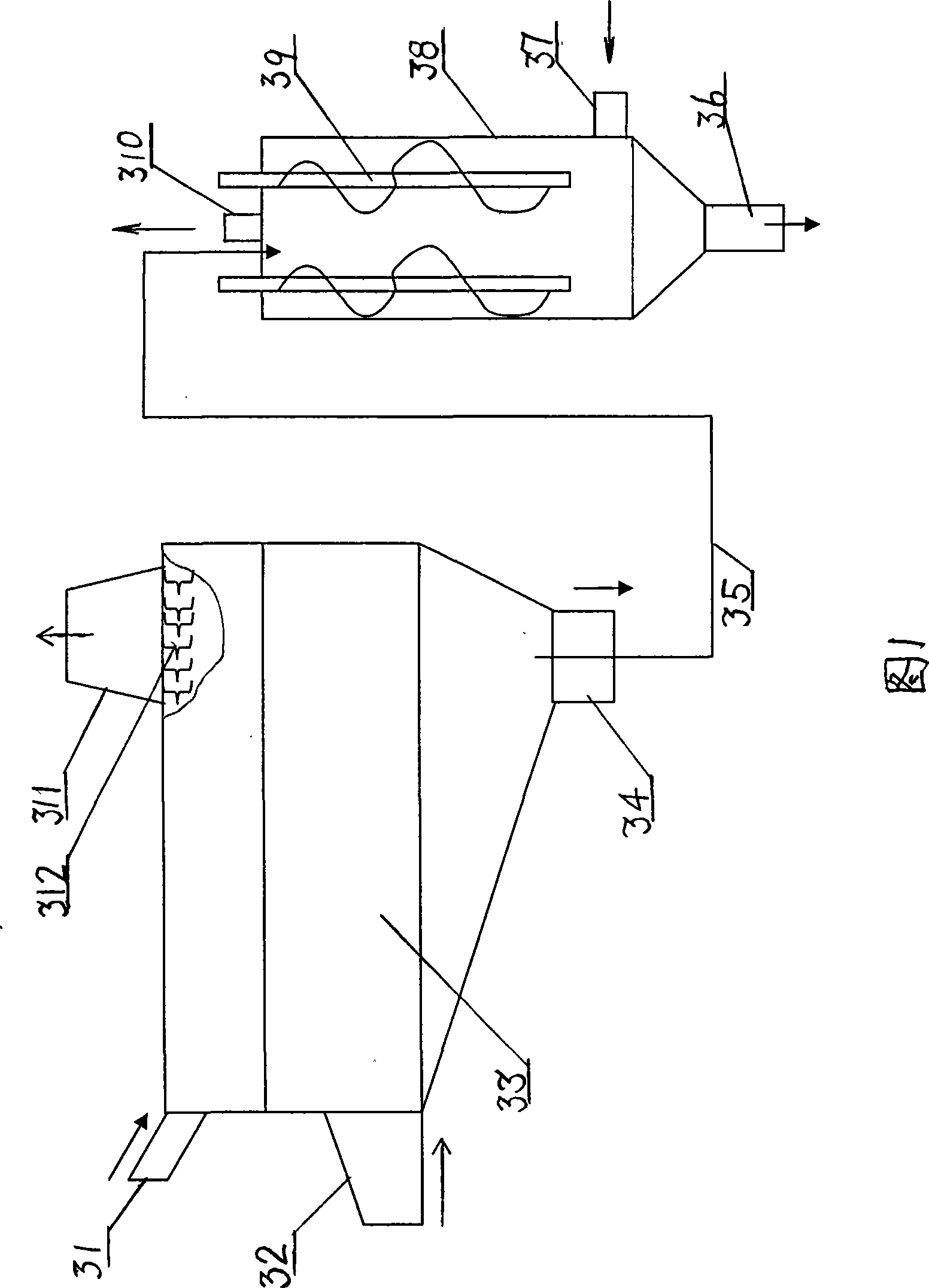

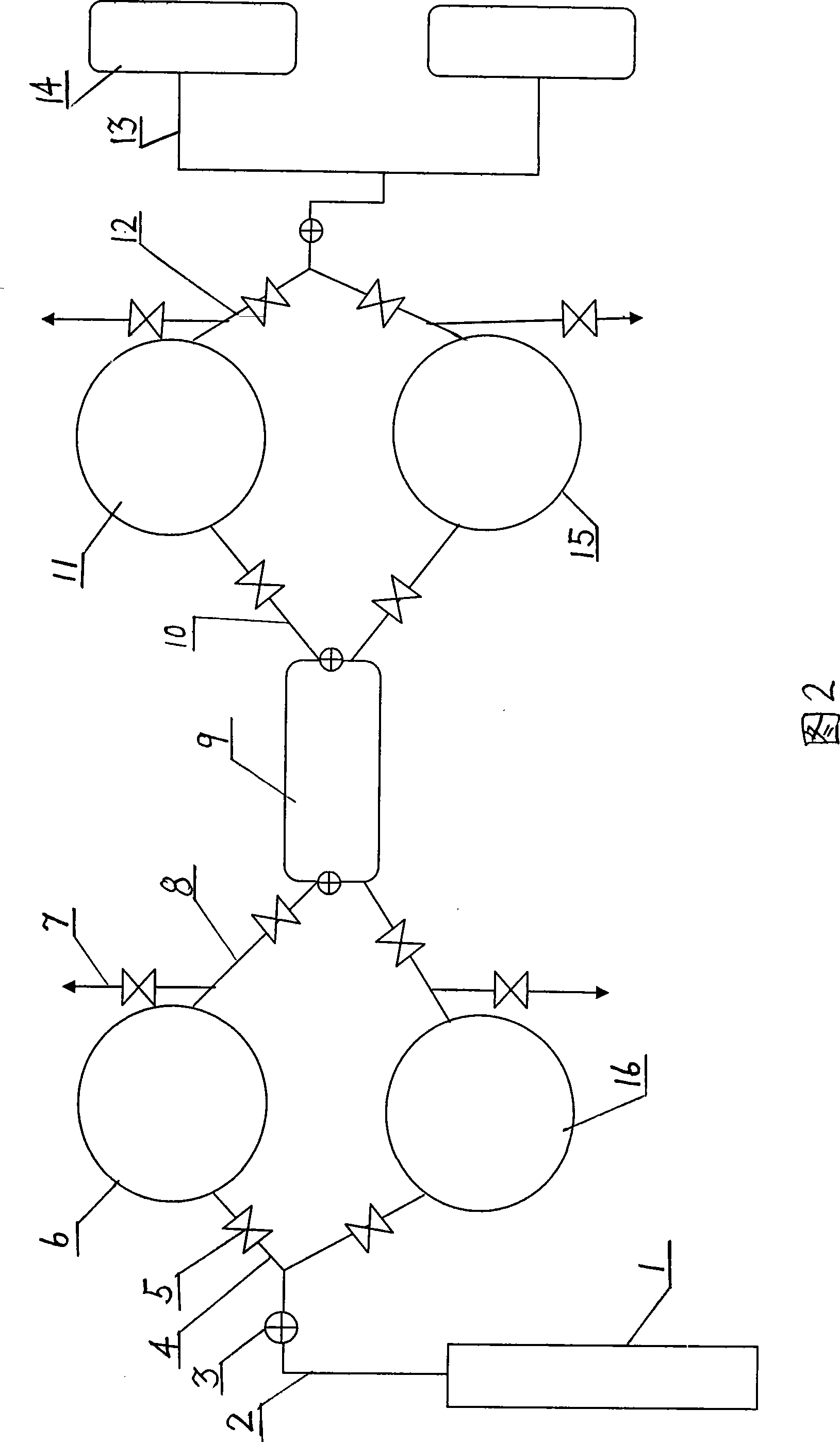

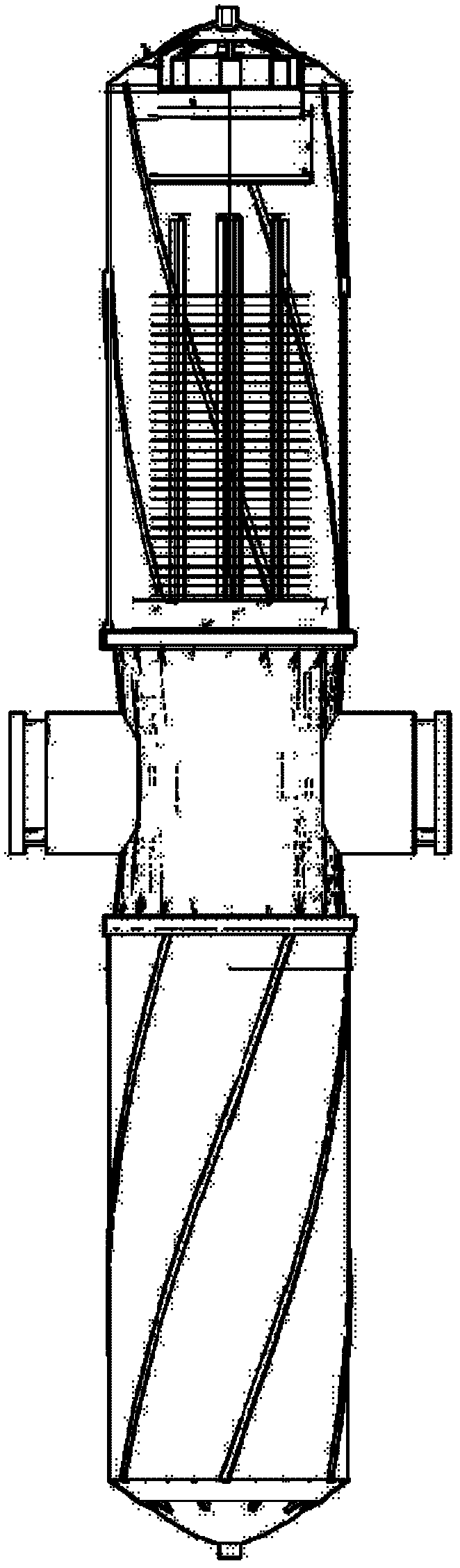

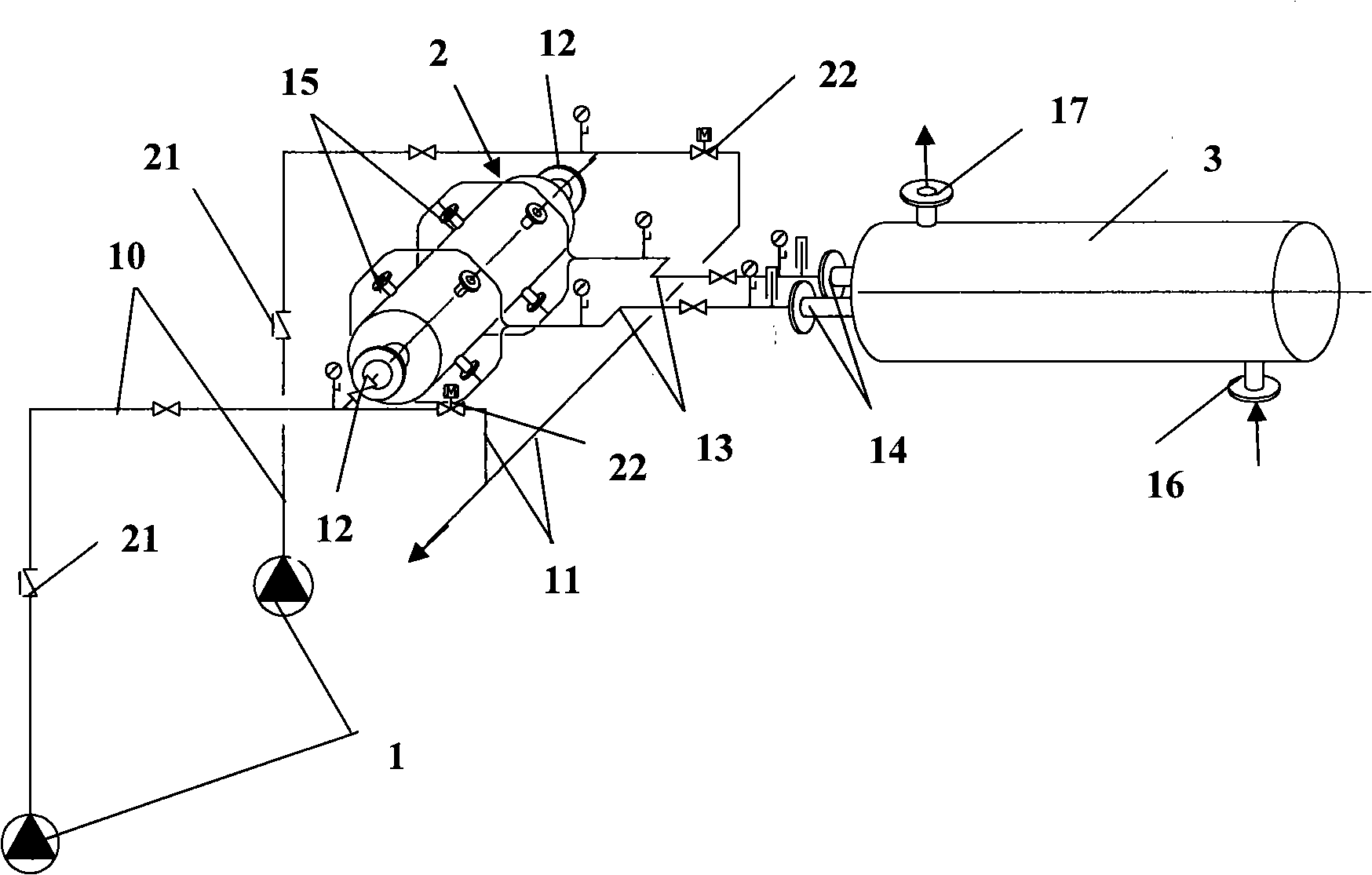

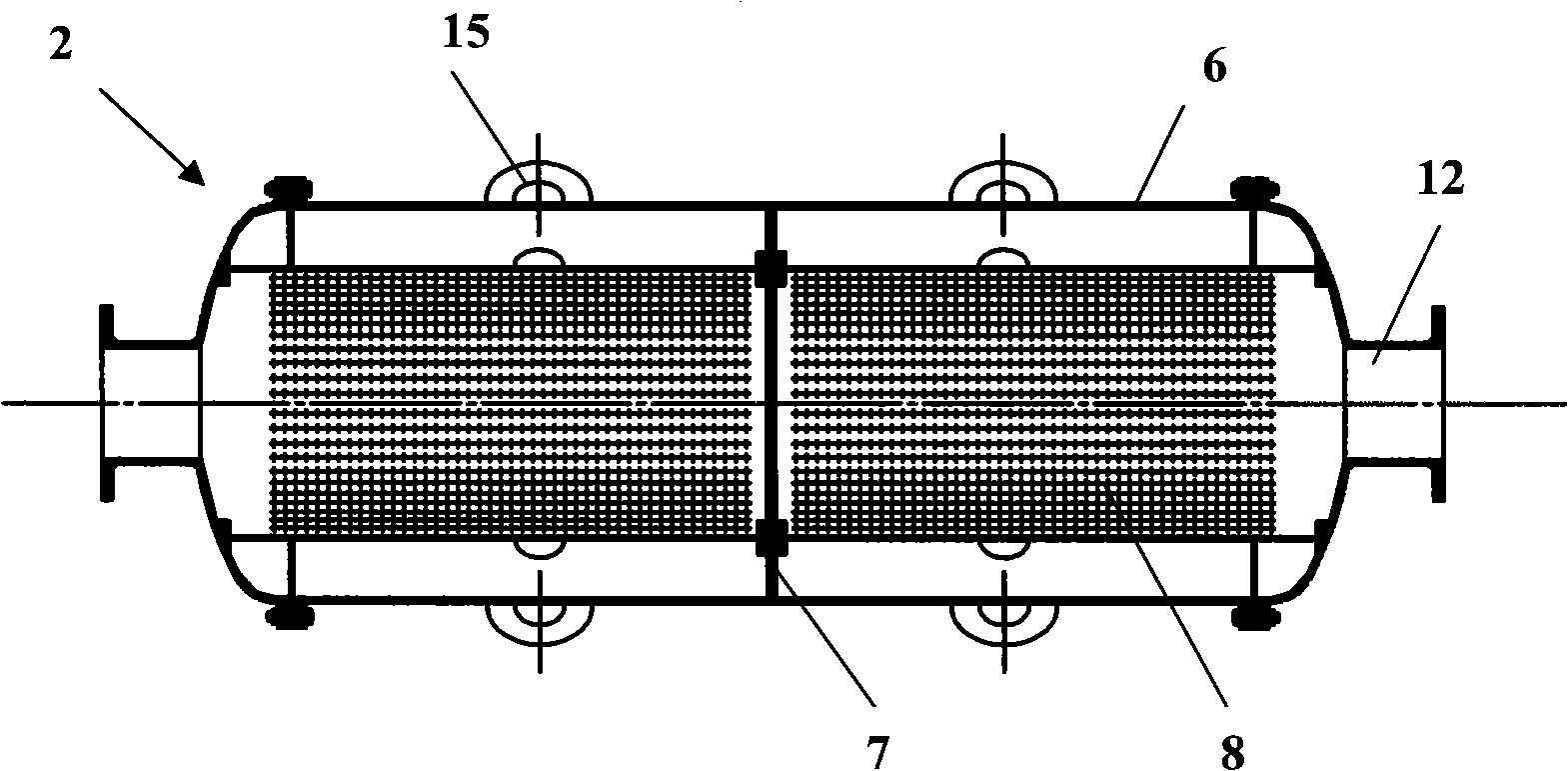

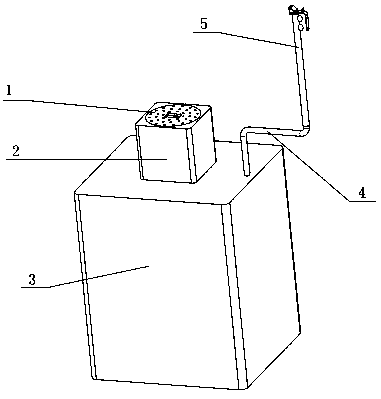

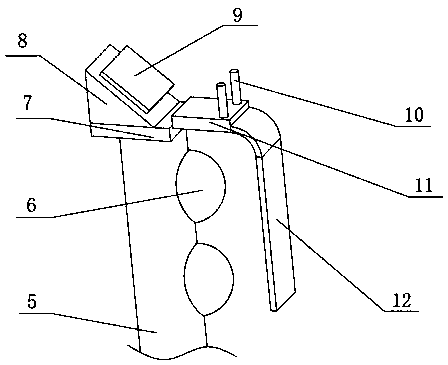

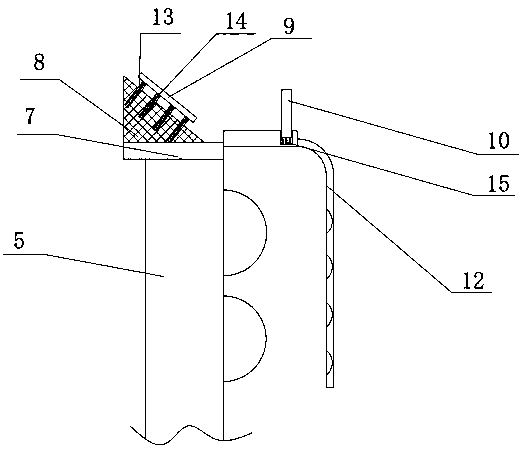

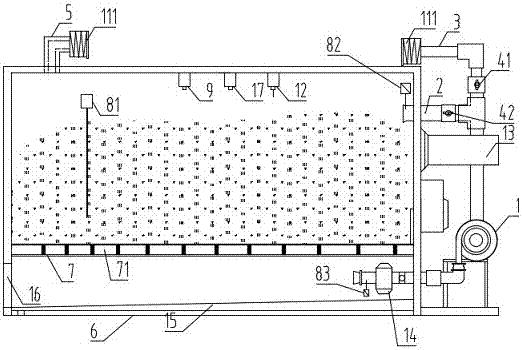

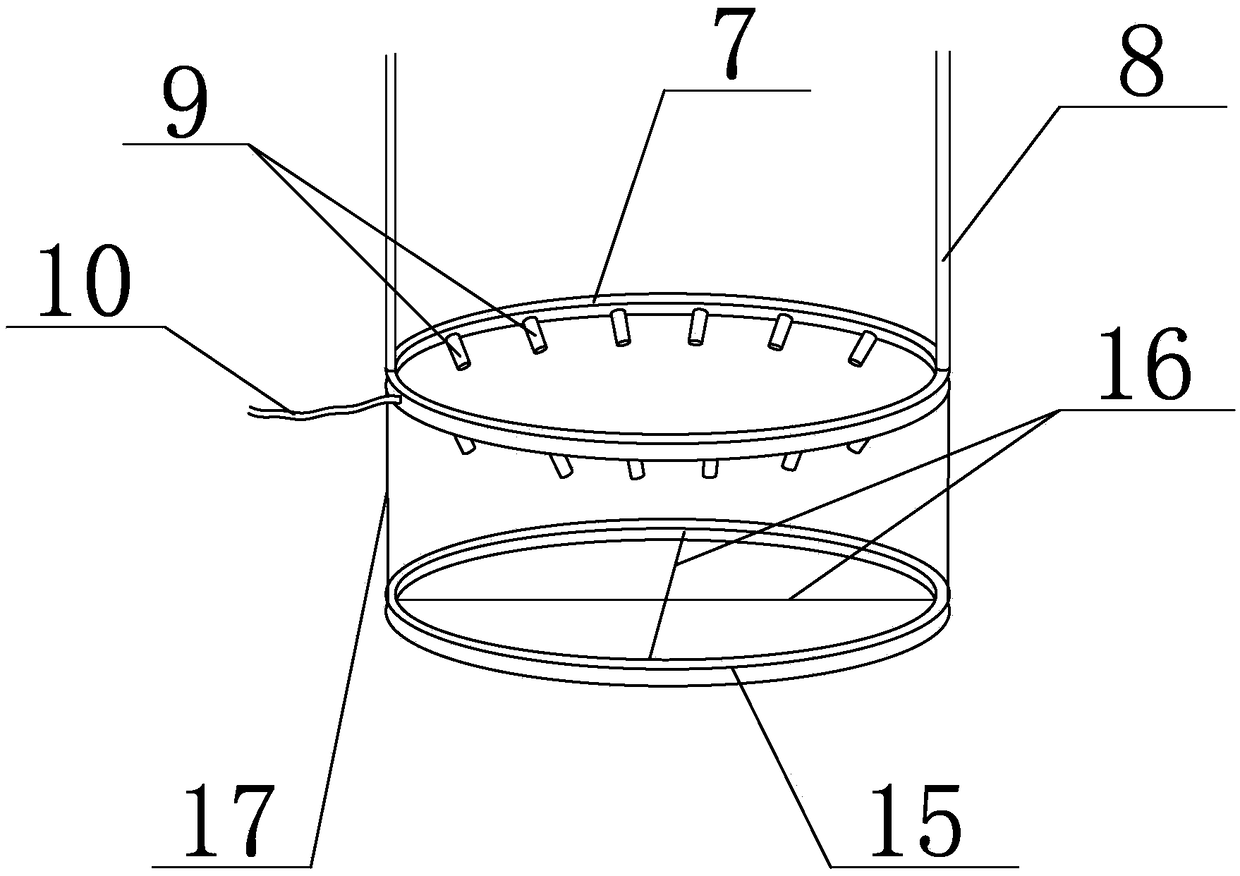

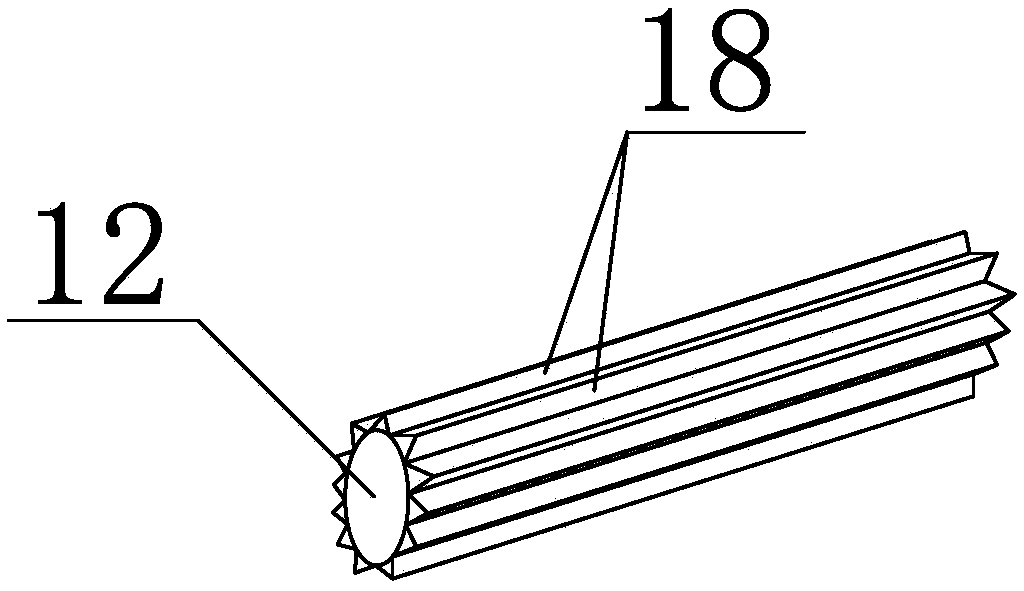

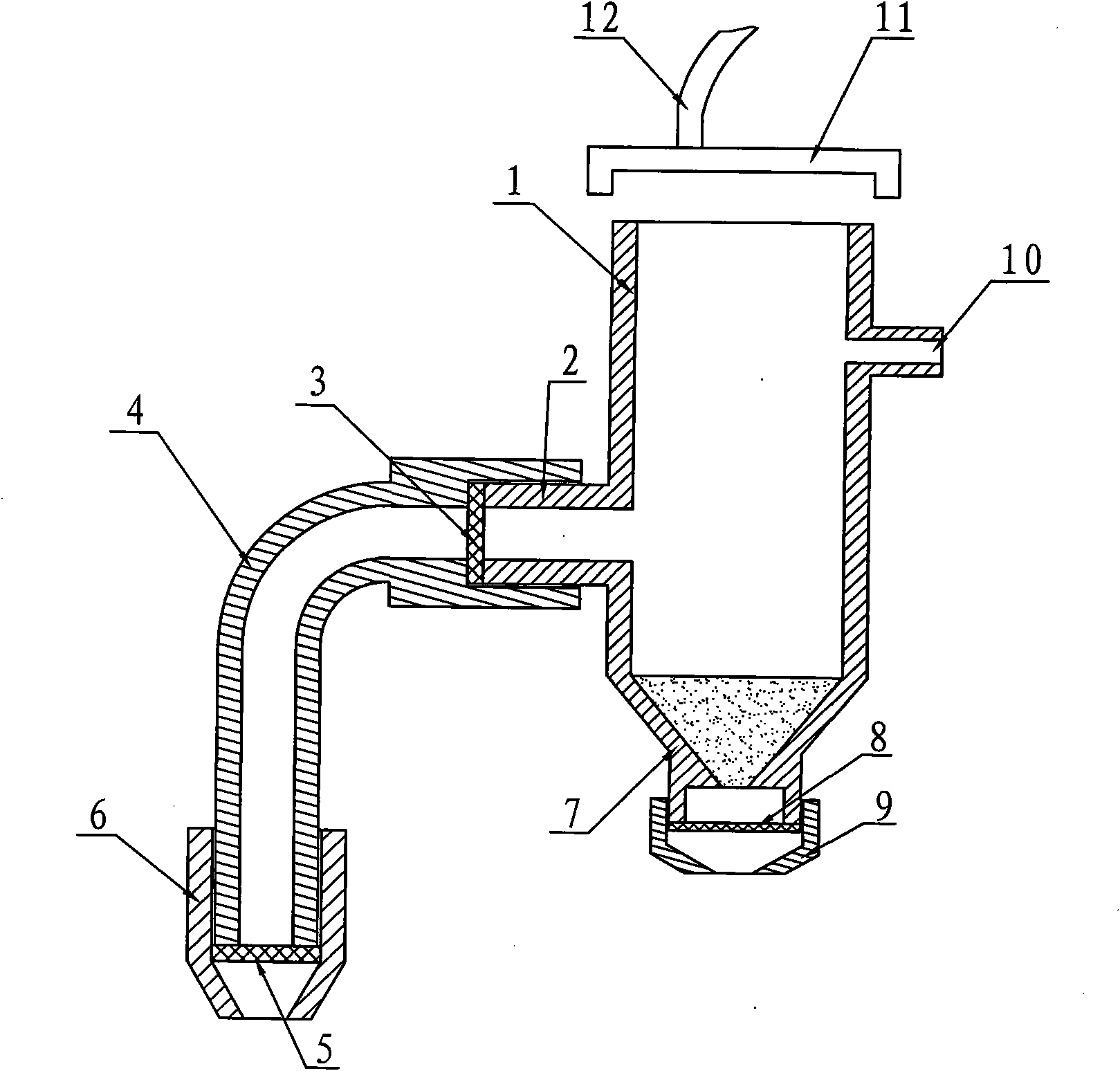

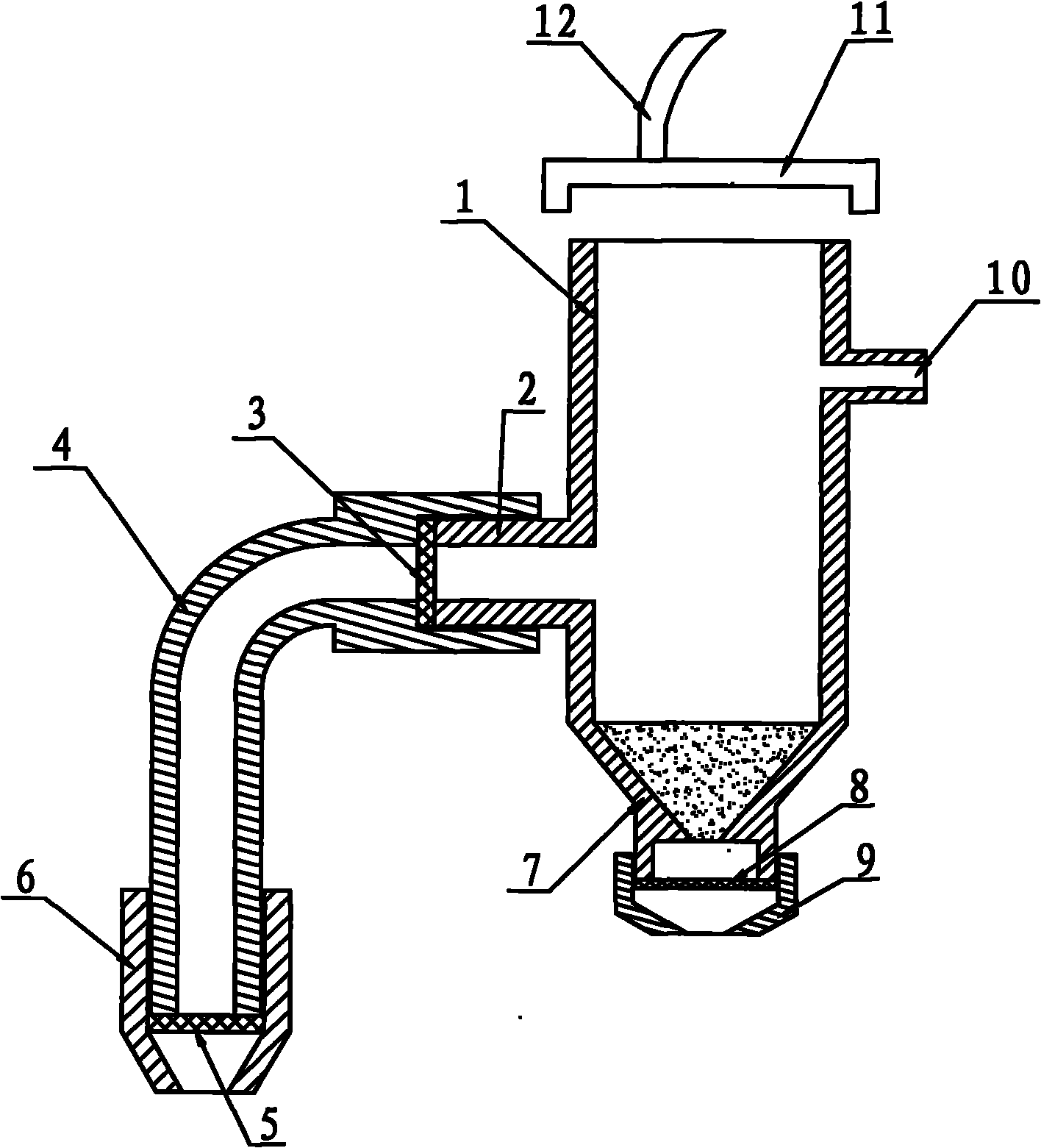

The invention provides a method for producing polyester POY filament in scale by recycling PET bottle chip. Recycled waste PET bottles are crushed into flaky bottle chip, dried after cleaning, and then sent into a crystallizing bed body; under the action of hot air entering the crystallizing bed body, crystallization is carried out, a crystallizing layer is formed on the bottle chip surface, and then the bottle chip is sent into a drying tower for drying; the dried bottle chip enters a screw extruder for melt extrusion, and the obtained melt is sent into a two-stage filtering device for filtering and then enters a spinning box; and a high-speed spinning process is adopted for spinning to produce the polyester POY filament. The method for producing the polyester POY filament adopts a filling type drying mode, the drying is even and the operating cost is low; a screw mixer is arranged in the drying tower, which solves the problem of 'arching' that happens to the recycled PET bottle chip during the drying process; and the two-stage filtering device is adopted, which ensures the filtering quality. Therefore, the high-end product-polyester POY filament can be continuously produced in large scale.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

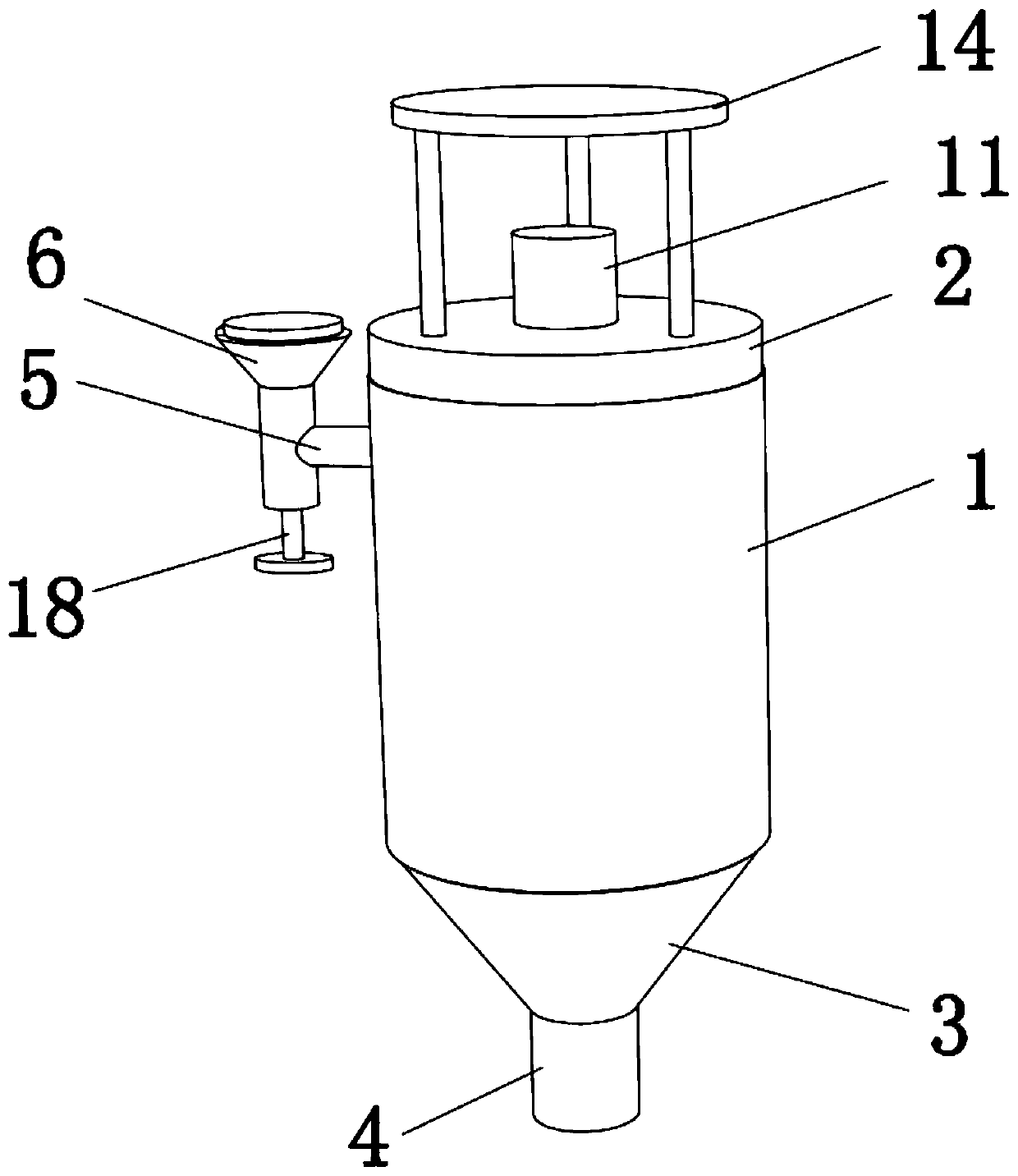

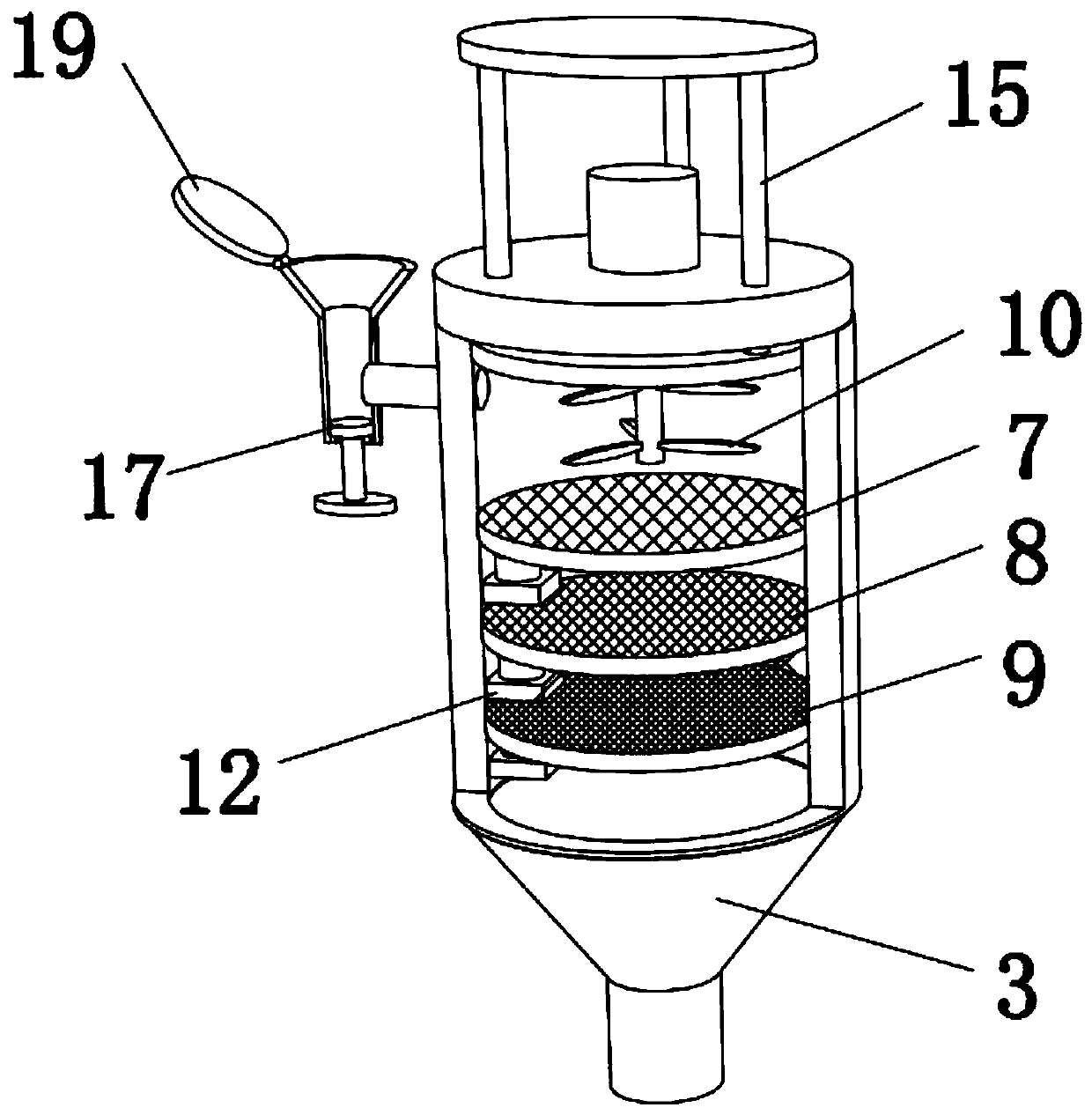

Method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on scale

ActiveCN102605454ASolve the problem of water content inconsistencyGuaranteed Filtration QualityFilament forming substance formingMonocomponent polyesters artificial filamentPolyesterPolyethylene terephthalate

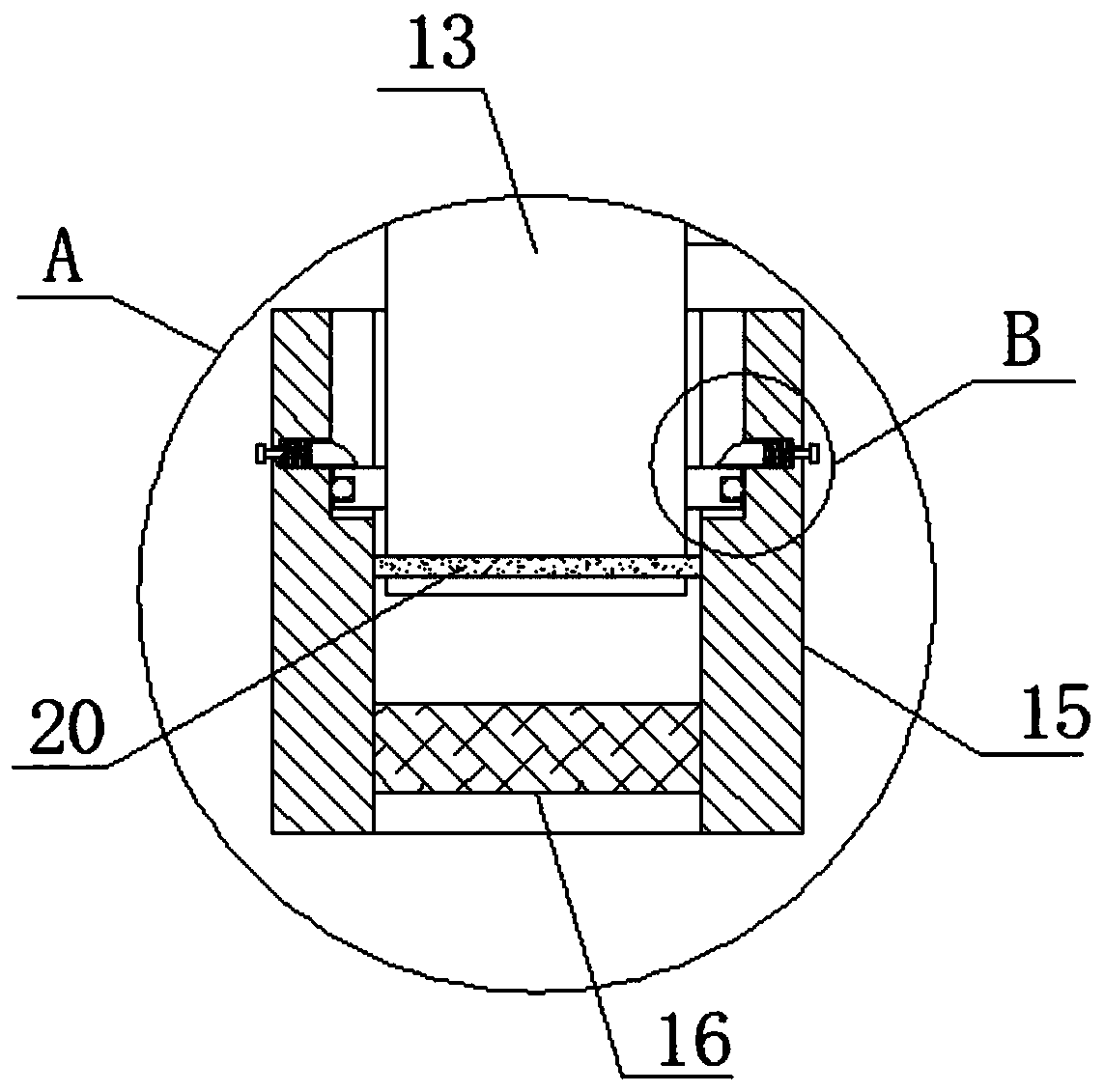

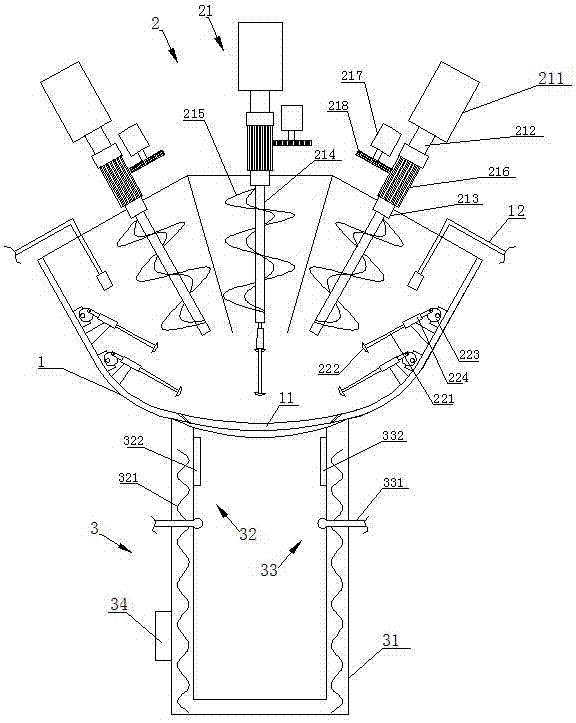

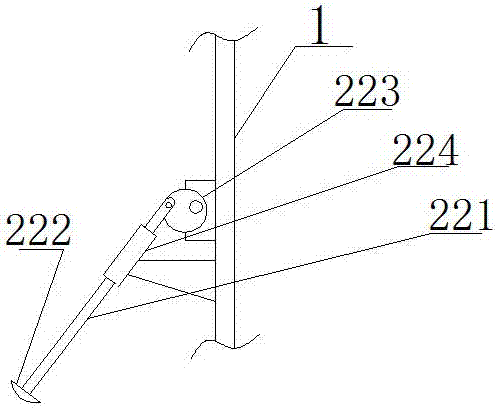

The invention provides a method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on a scale. The method comprises the steps of crushing the recycled PET bottles into chips, washing and drying, sending into a crystallization bed body for crystallization, forming crystallization layers on the surfaces of the bottle chips, sending the crystallizedbottle chips into a drying tower which is provided with a pair of spiral agitators, leading the dried bottle chips to enter a screw extruder for melting and extrusion, sending the obtained melt into a two-stage filtration device consisting of a coarse filter, a fine filter and a pressure pump between the coarse filter and the fine filter for filtration, leading the melt which is filtrated by two stages to enter a liquid phase tackifying kettle, conducting polycondensation reaction in the liquid phase tackifying kettle, leading the melt after being subjected to liquid phase tackifying to entera spinning box, and spinning by adopting a high-speed spinning process, thus obtaining the industrial polyester filament. In the method for producing the industrial polyester filament, the liquid phase tackifying step is added in the production process, so that the problems of low viscosity and poor stability of the PET bottle chip melts are solved.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

Emulsion mixing stirrer for preparing nano new material

InactiveCN110124559AWell mixedAvoid stickingTransportation and packagingRotary stirring mixersEmulsionEngineering

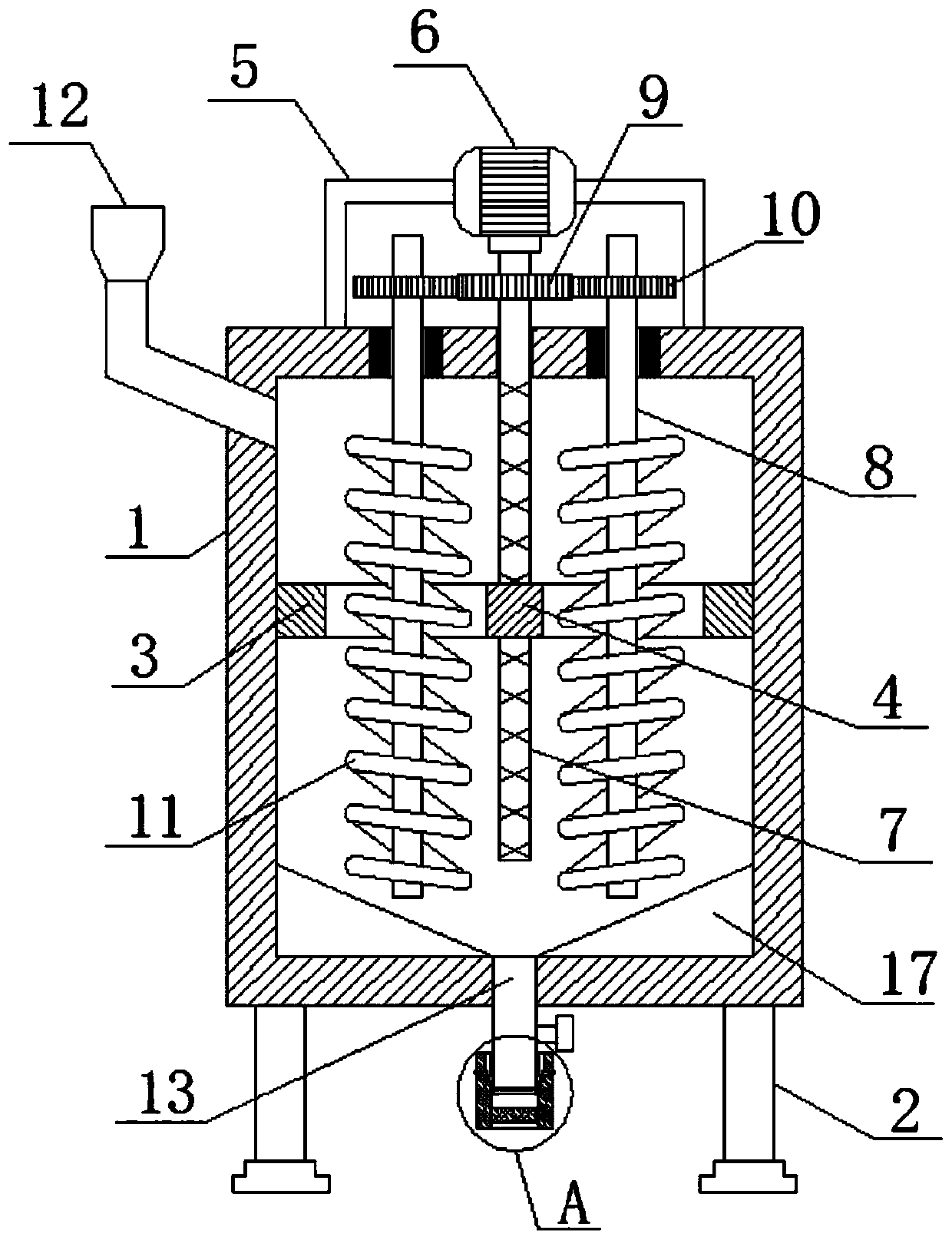

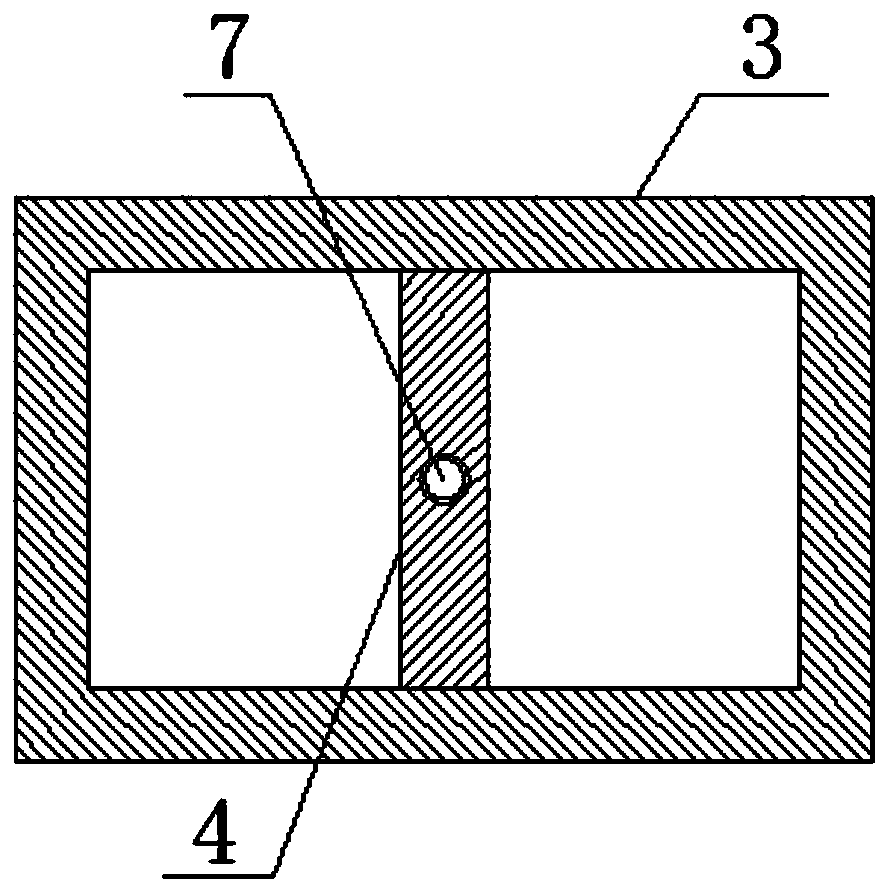

The invention relates to the technical field of stirring equipment, and discloses an emulsion mixing stirrer for preparing a nano new material. The emulsion mixing stirrer comprises a stirring box; supporting legs are fixedly connected to four corners of the bottom of the stirring box; a matched scraping frame is slidably connected in the stirring box; a fixing plate is fixedly connected in the scraping frame; the top of the stirring box is fixedly connected with a driving motor through a support; the output end of the driving motor is fixedly connected with a reciprocating screw rod through acoupler; the other end of the reciprocating screw rod sequentially penetrates through the top of the stirring box and the fixing plate extends downwards; the reciprocating screw rod is rotationally connected with the top of the stirring box; the reciprocating screw rod is in threaded connection with the fixing plate; two rotating rods which are symmetrical relative to the position of the reciprocating screw rod are arranged in the stirring box; and the top end of each rotating rod penetrates through the top of the stirring box and extends upwards. According to the invention, mixing and stirring by the emulsion mixing stirrer for preparing the nano new material are more uniform, and the emulsion attached to the inner wall of the stirring box is convenient to clean.

Owner:马鞍山久特新材料科技有限公司

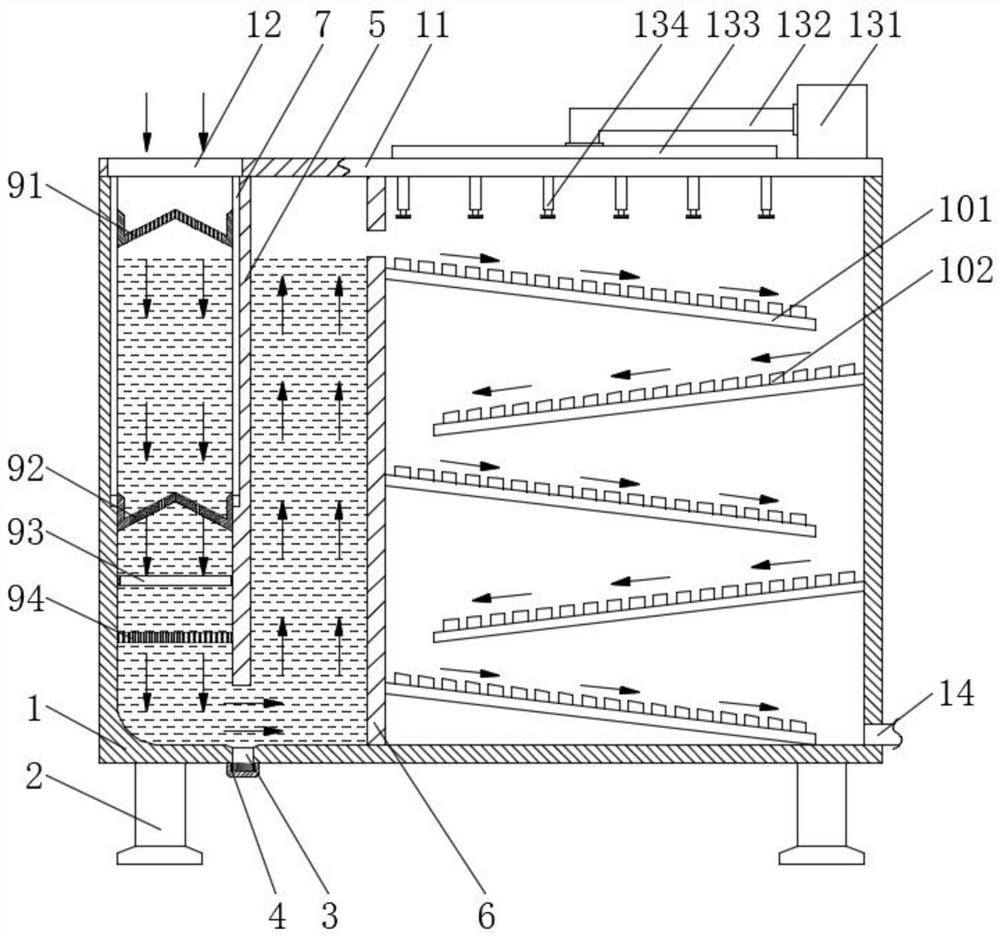

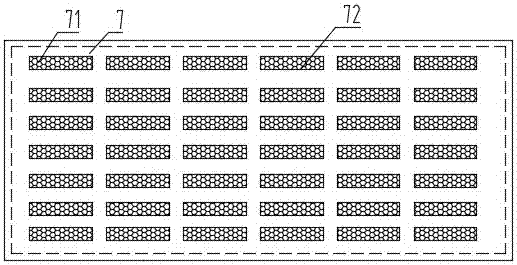

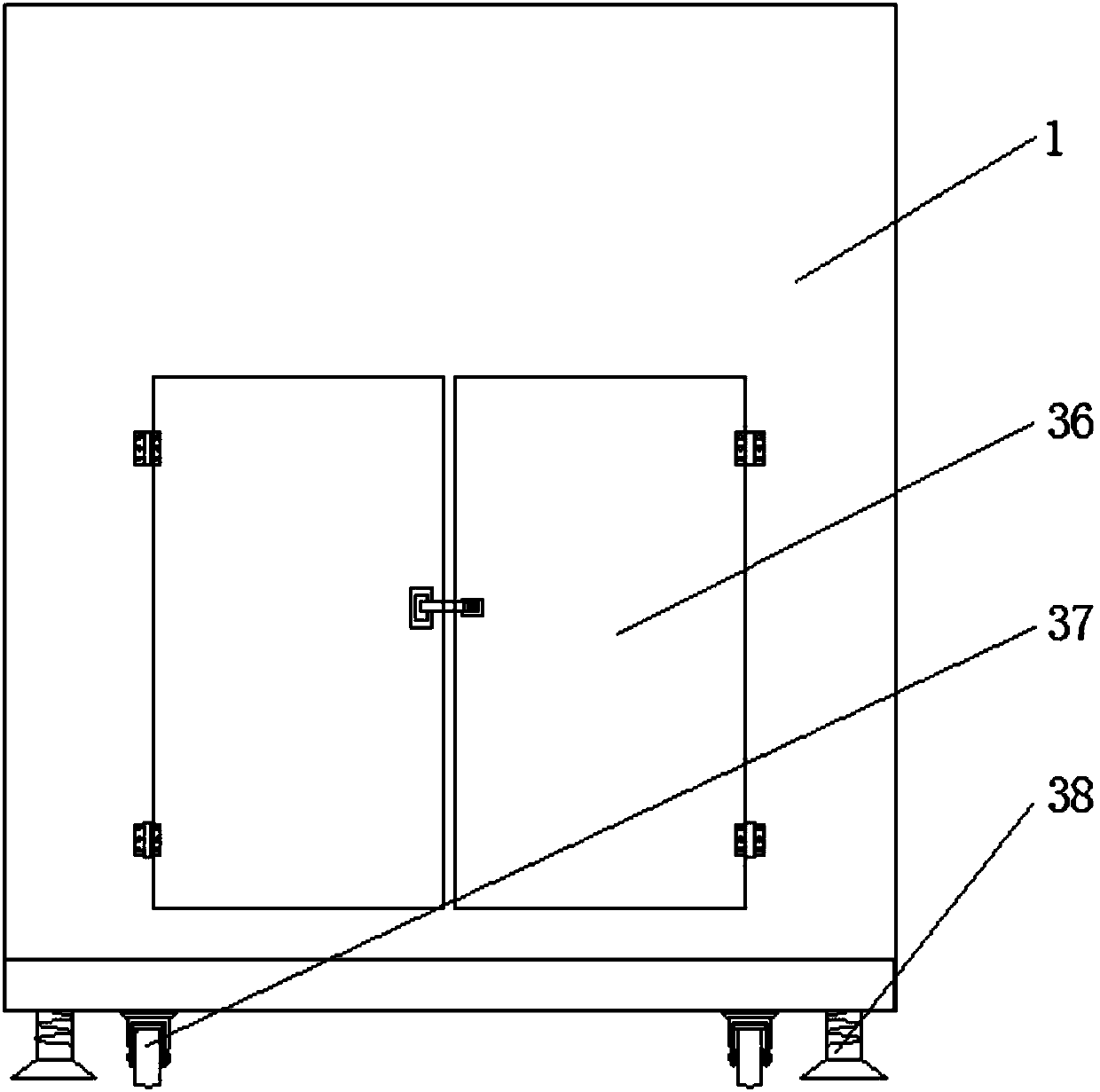

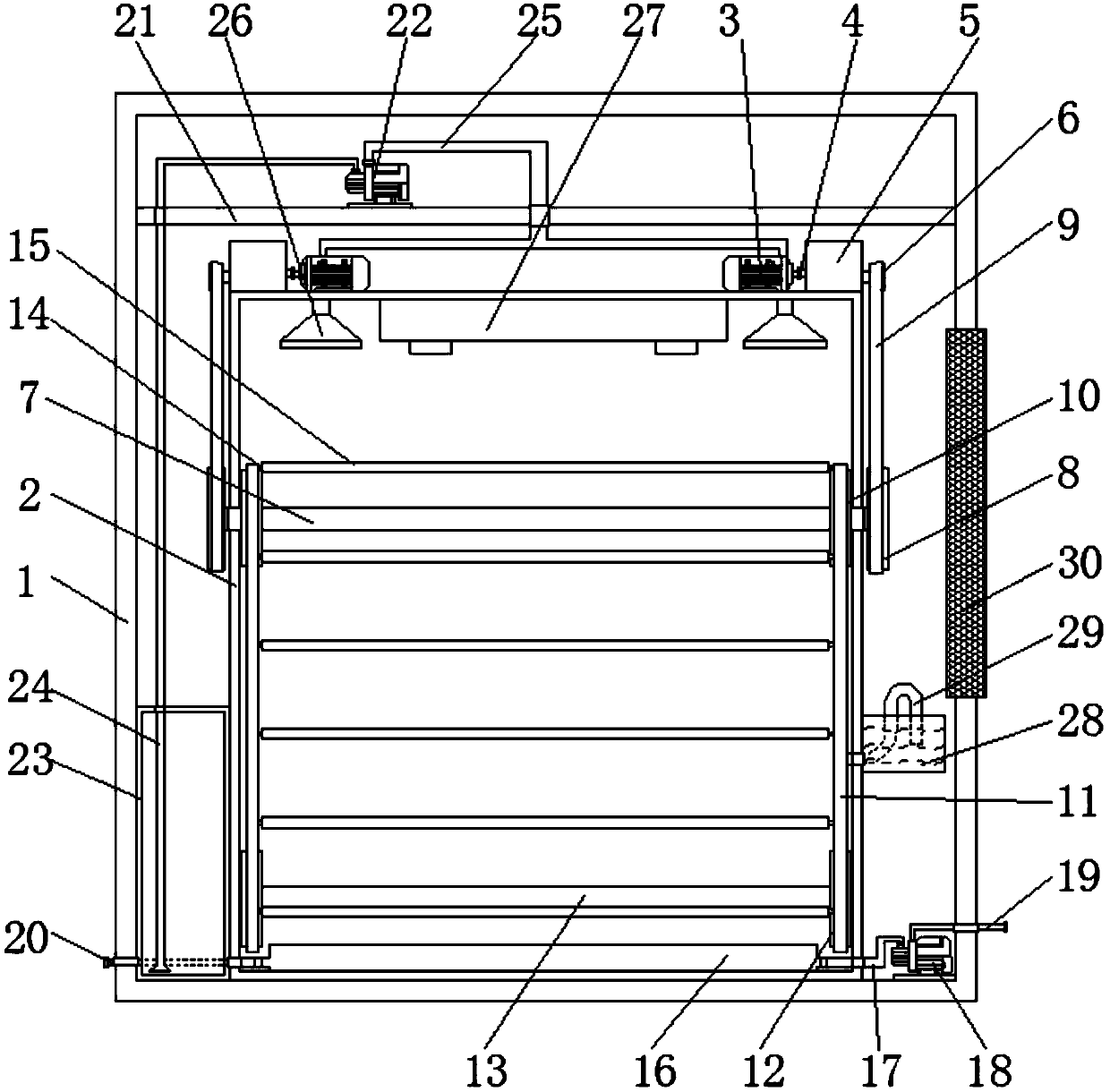

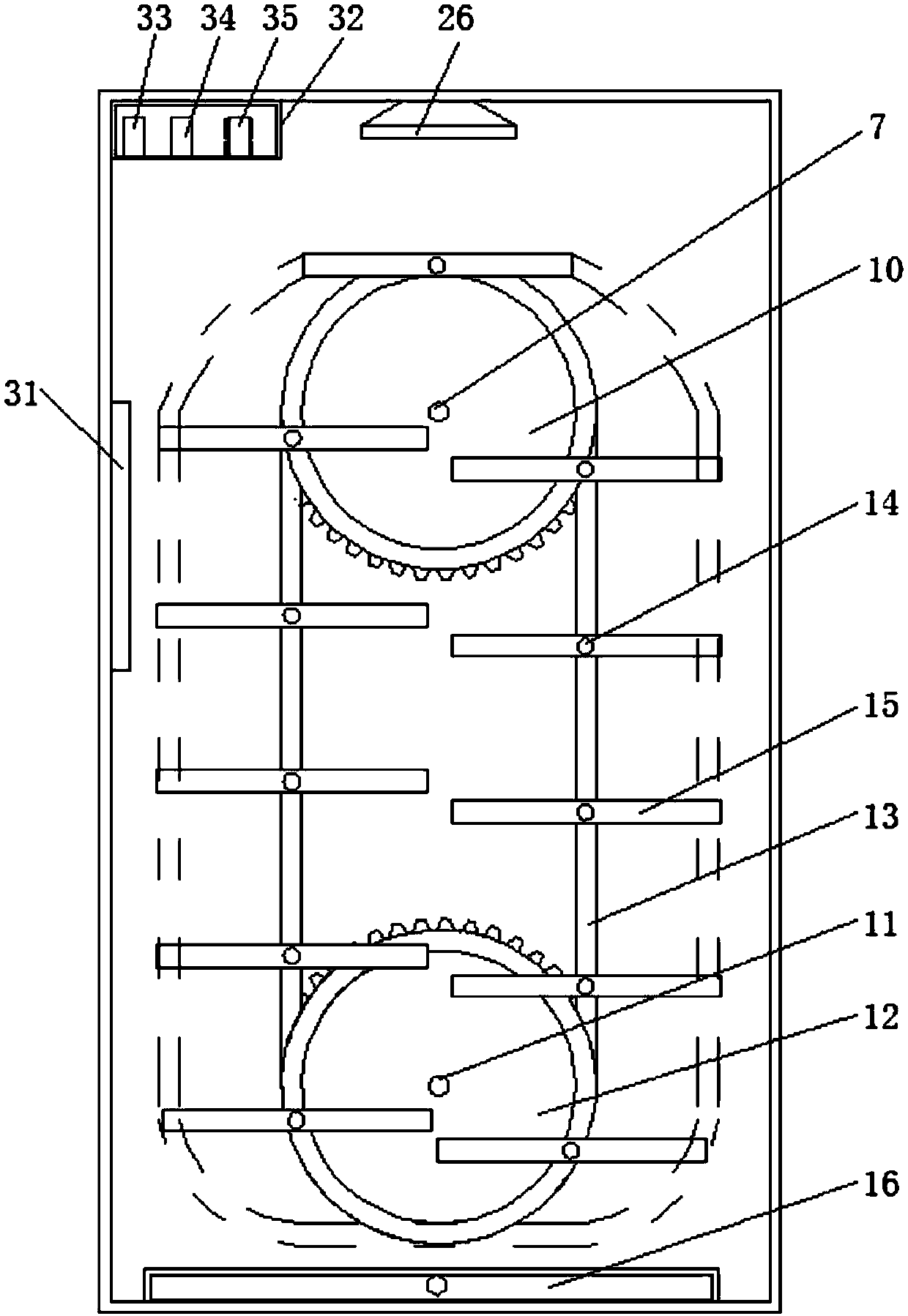

Tea leaf fermentation device and fermentation method thereof

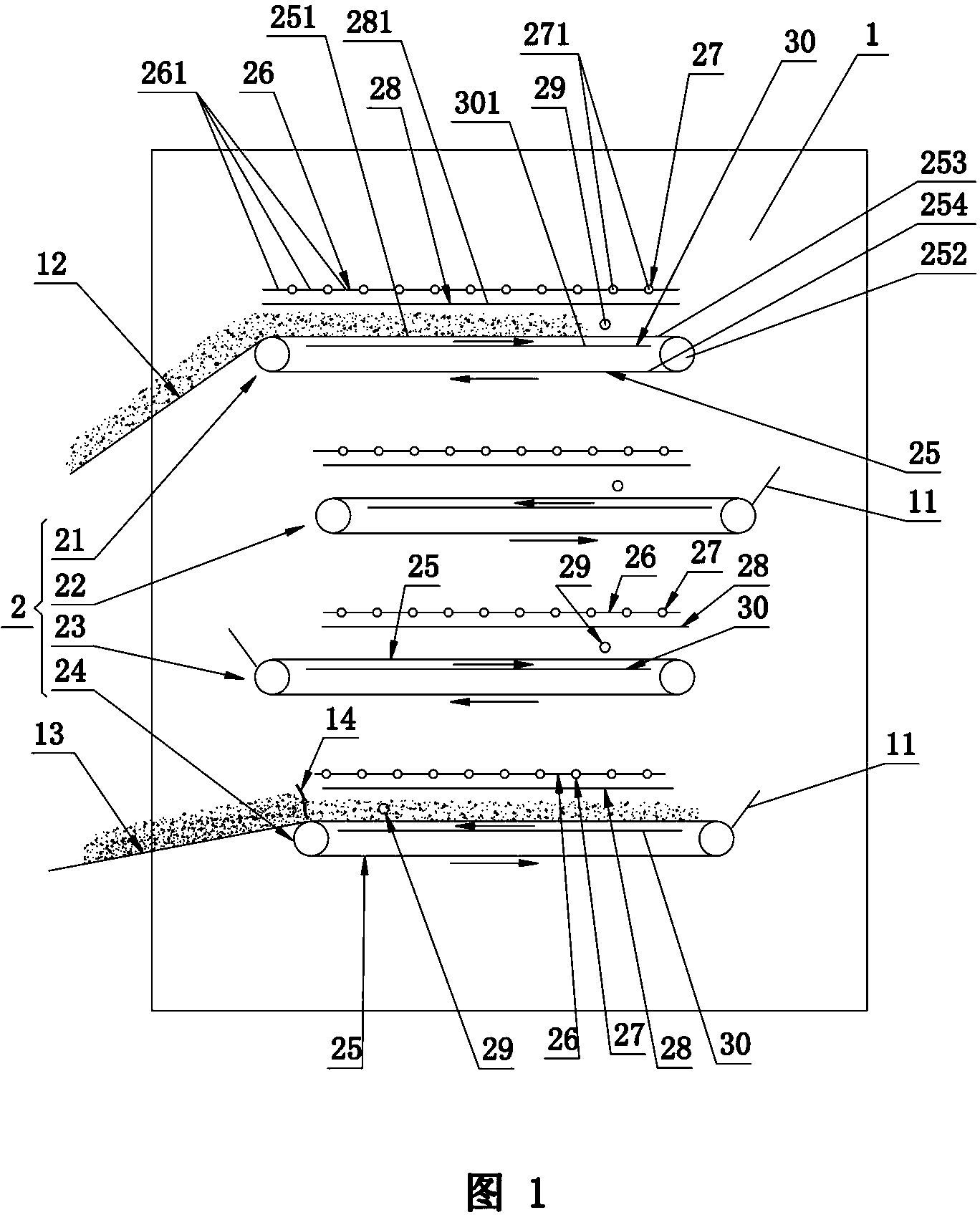

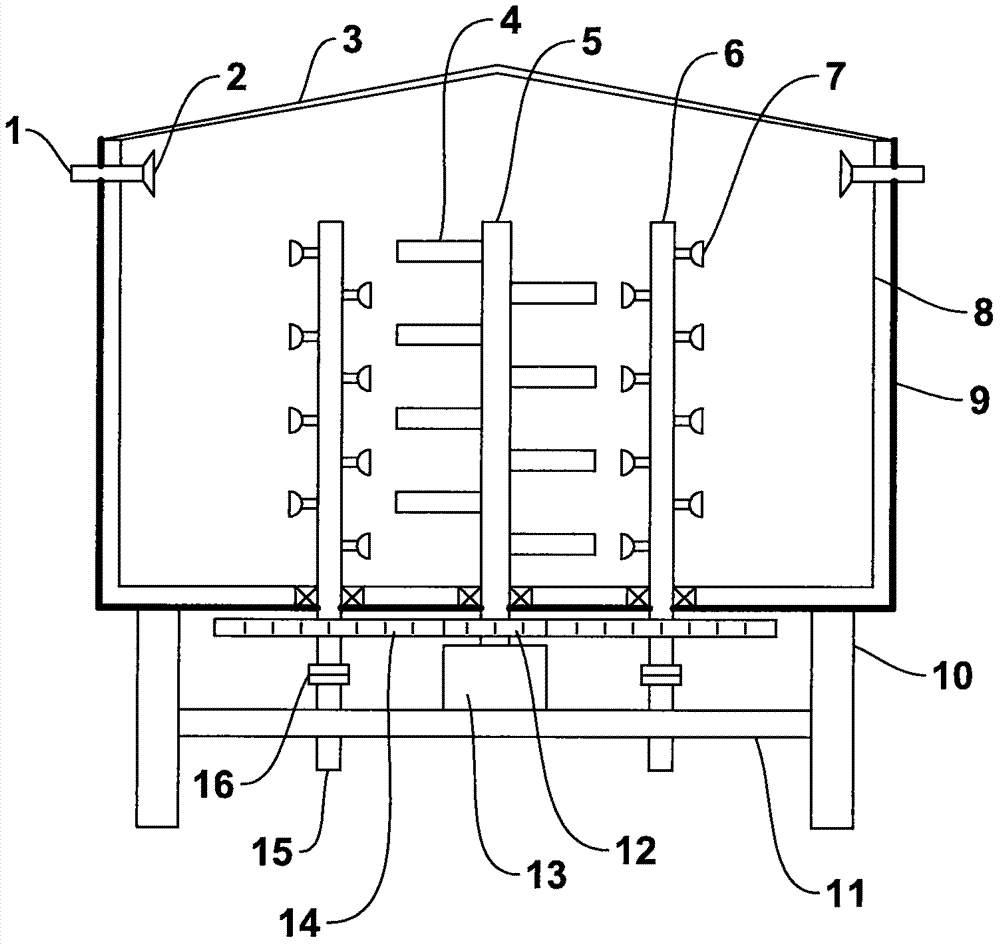

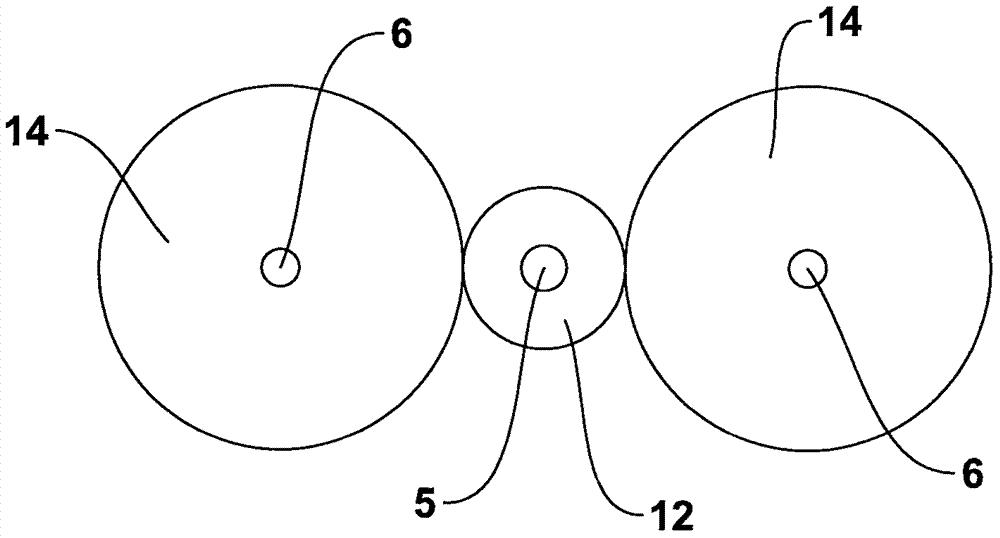

InactiveCN103238688ARealize automated fermentationGuaranteed Filtration QualityPre-extraction tea treatmentAutomatic controlBiology

The invention relates to a tea leaf fermentation device and a fermentation method. The tea leaf fermentation device comprises a fermentation chamber, a control mechanism and at least one fermentation group which is assembled in the fermentation chamber, wherein the fermentation group comprises a conveying mechanism, a first heating mechanism, an air mist mechanism, a cover cloth mechanism and a temperature and humidity detector which are respectively linked with the control mechanism; and the first heating mechanism and the air mist mechanism are arranged above the conveying mechanism, and the cover cloth mechanism is arranged between the conveying mechanism and the first heating mechanism. The tea leaf fermentation device disclosed by the invention can complete automatic pile-turning, automatic cloth covering, automatic control of temperature and humidity and other operations of tea leaves and realize automatic fermentation of the tea leaves; furthermore, the fermentation process is very close to a traditional fermentation technology, the manual intervention is less, and the fermentation efficiency is effectively improved; in addition, by using the tea leaf fermentation device disclosed by the invention to perform fermentation on the tea leaves, the fermentation quality of the tea leaves can be effectively ensured; and furthermore, the energy consumption is low, energy conservation and environmental friendliness are realized, and the fermentation cost is also effectively reduced.

Owner:林清矫

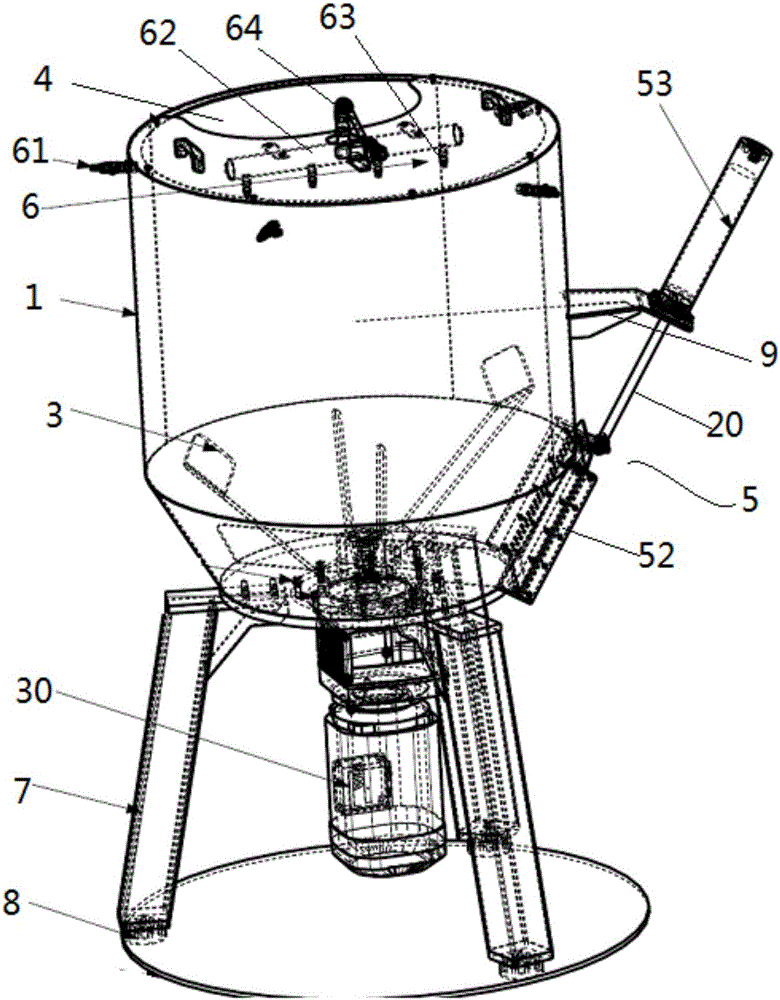

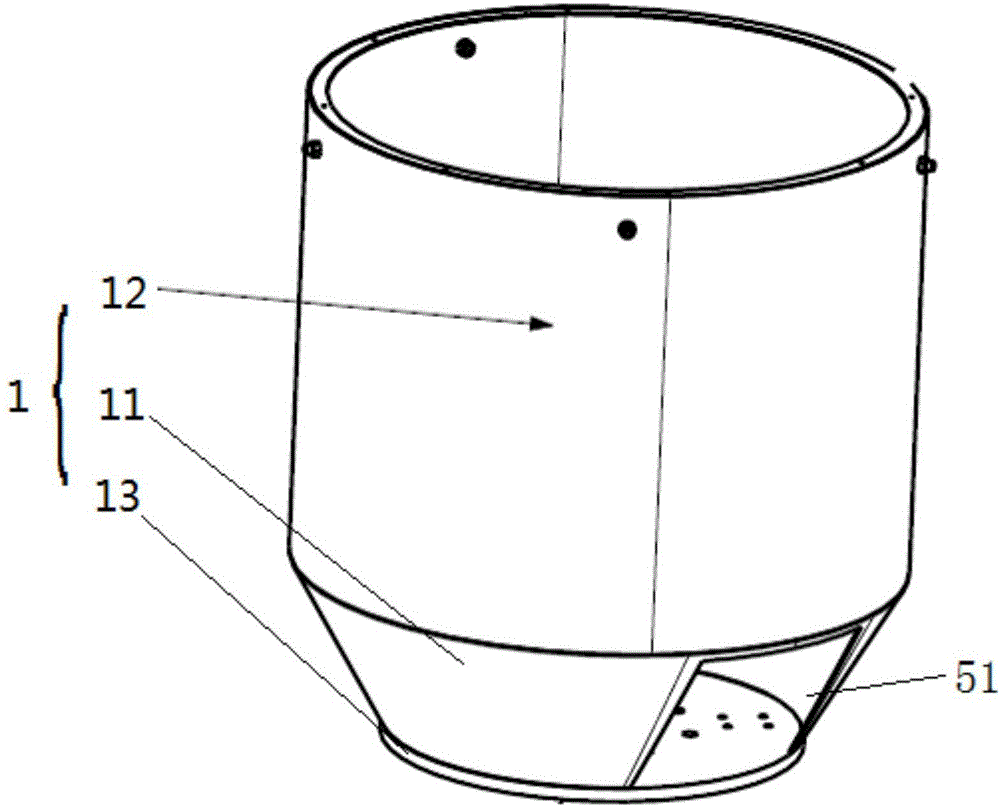

Mixed aeration type organic fertilizer fermenting equipment

InactiveCN106927877AIncreased fermentation activityFully fermentedBio-organic fraction processingIrradiation based treatmentOrganic manurePulp and paper industry

The invention discloses mixed aeration type organic fertilizer fermenting equipment, which comprises a fermenting tank. A sun shed is fixedly installed at the top of the fermenting tank. The upper part of the sidewall of the fermenting tank is provided with multiple water supplement pipes. Water spray heads are arranged at the ends of the water supplement pipes at the inner side of the fermenting tank. A mixer shaft is arranged in the middle of the inner side of the fermenting tank, and aerator pipes are arranged at left and right sides of the mixer shaft. Multiple stirring paddles are arranged on the mixer shaft at the inner side of the fermenting tank. Multiple jet heads are arranged on the aerator pipes at the inner side of the fermenting tank. A driving gear is arranged on the mixer shaft at the lower side of the fermenting tank. The lower end of the mixer shaft is provided with a motor. A driven gear is arranged on each aerator pipe at the lower side of the fermenting tank. The lower end of each aerator pipe is connected to an oxygen pipe through a rotating joint. By the use of the equipment, organic fertilizers can be enshrined, fermentation activity is enhanced, fermentation period is shortened, and fermentation quality is guaranteed.

Owner:刘海明

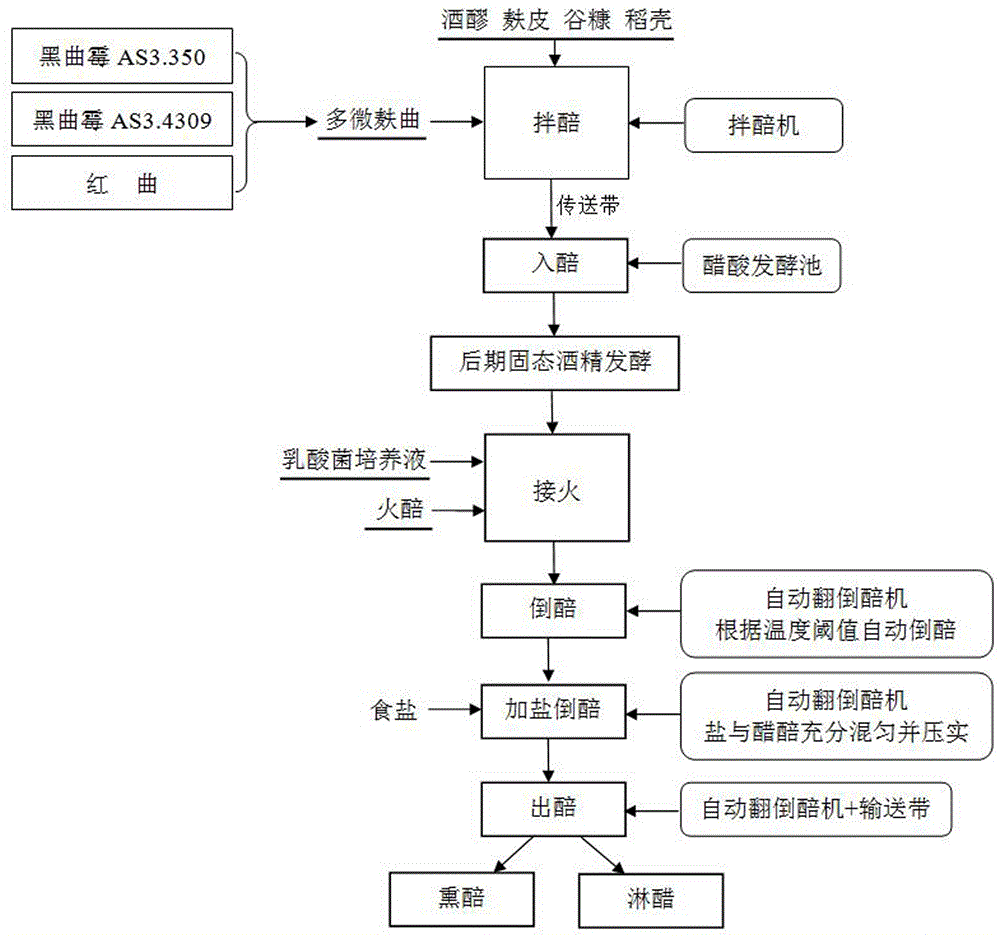

Mechanized production technique for mature vinegar by solid-state acetic acid fermentation

ActiveCN106635735AIncrease enzyme activityLess irritatingMicroorganism based processesVinegar preparationFlavorAcetic acid

The invention provides a mechanized production technique for mature vinegar by solid-state acetic acid fermentation. A machine for stirring fermented grains is used to mix wine mash obtained after an thick mash alcoholic fermentation is ended, accessories and multi-microbe mouldy bran; a conveyor belt conveys materials into a stainless steel long-strip-shaped acetic acid fermentation vat for performing later solid-state alcoholic fermentation; then fire-fermented grains mixed with lactic acid bacteria is added for performing multi-microbe acetic acid fermentation; a temperature control type machine for automatically stirring and pouring the fermented grains is used to replace manpower for stirring and tank pouring of the fermented grains. The prepared multi-microbe mouldy bran and the lactic acid bacteria are added in a preparation process, so the physical appearance and flavor of a product are improved.

Owner:SHANXI ZILIN VINEGAR

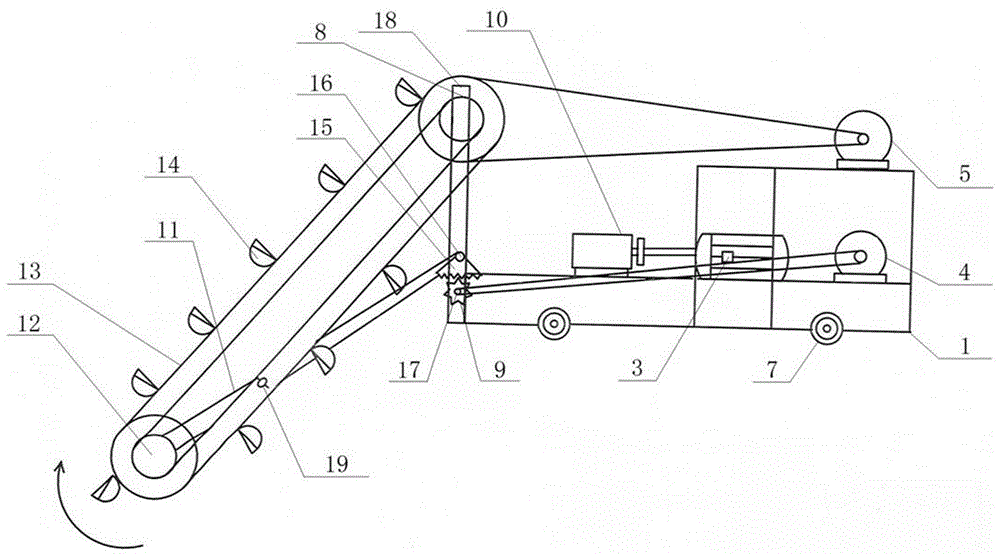

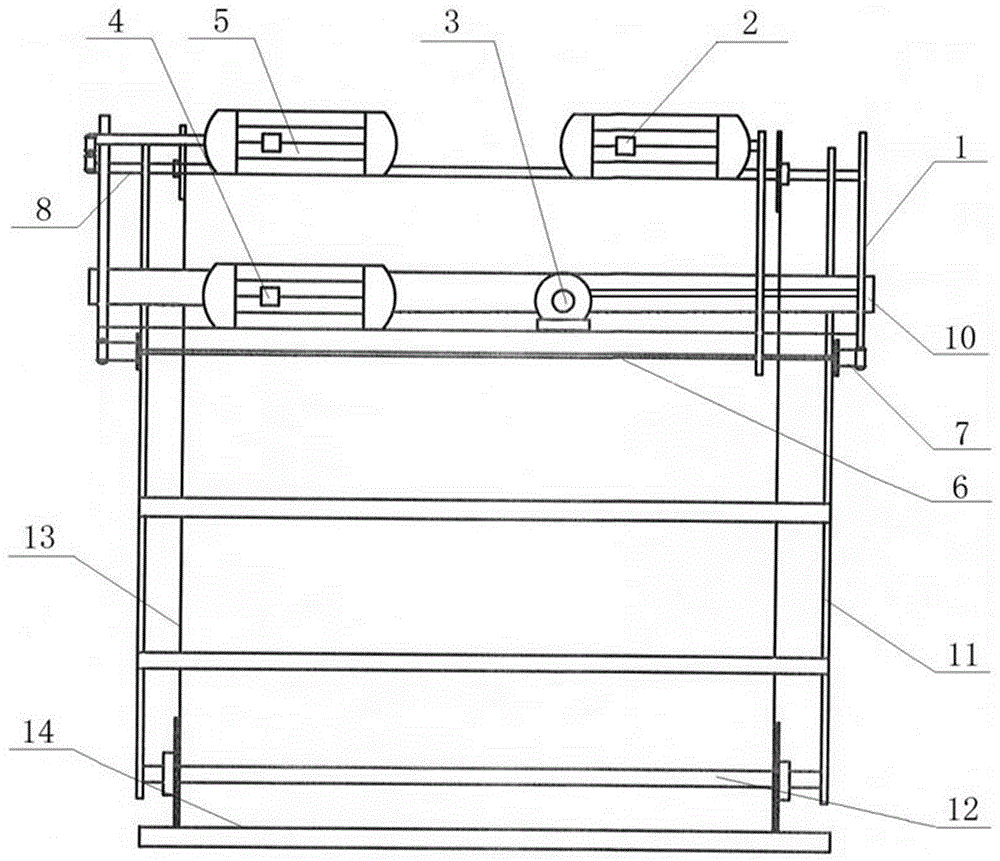

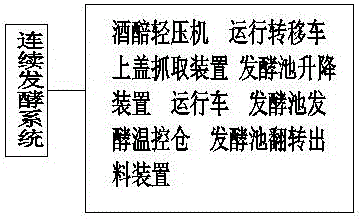

Intelligent continuous fermentation system for solid-state Baijiu

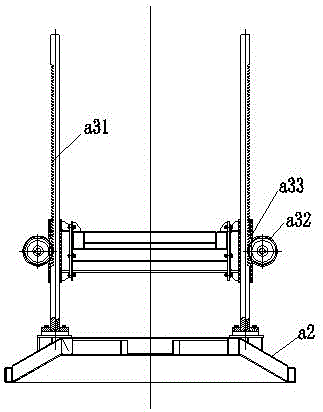

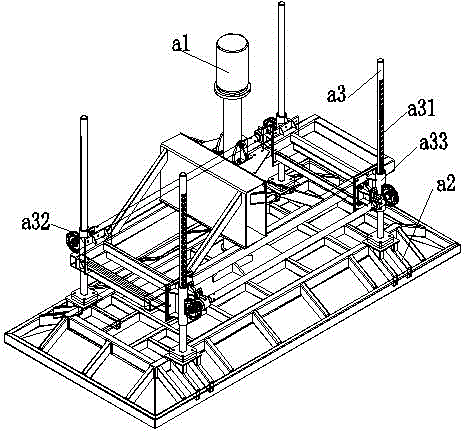

PendingCN106479815AAchieve continuous fermentationHigh yieldAlcoholic beverage preparationContinuous fermentationTemperature control

The invention relates to an intelligent continuous fermentation system for solid-state Baijiu. The intelligent continuous fermentation system comprises a fermented-grain mild compression machine, an operation transfer vehicle, an upper cover grabbing device, a fermentation tank lifting device, an operation vehicle, a fermentation tank, a fermentation temperature control bin and a turnover discharge device. Fermented grains are fed into the fermentation tank, the fermentation tank is stopped below the fermented-grain mild compression machine, and the fermented-grain mild compression machine performs compaction by an electric-hydraulic pusher pushing down a compression panel; after the compaction, the fermentation tank is transferred to the fermentation tank lifting device through the operation vehicle and just stopped above the upper cover grabbing device in a position-limited manner, and the upper cover grabbing device stably places an upper cover on the fermentation tank through lifting and unhooking; the fermentation tank is placed into the fermentation temperature control bin, the fermentation tank is moved through the operation transfer vehicle, the fermentation tank is moved out of the temperature control bin after the fermentation, and discharging is performed through the turnover discharge device to complete the whole fermentation process. The intelligent continuous fermentation system for the solid-state Baijiu is reasonable in structure and capable of achieving mechanical brewing.

Owner:YANGZHOU XIANYE GRP

Filtering apparatus for lubricating oil production

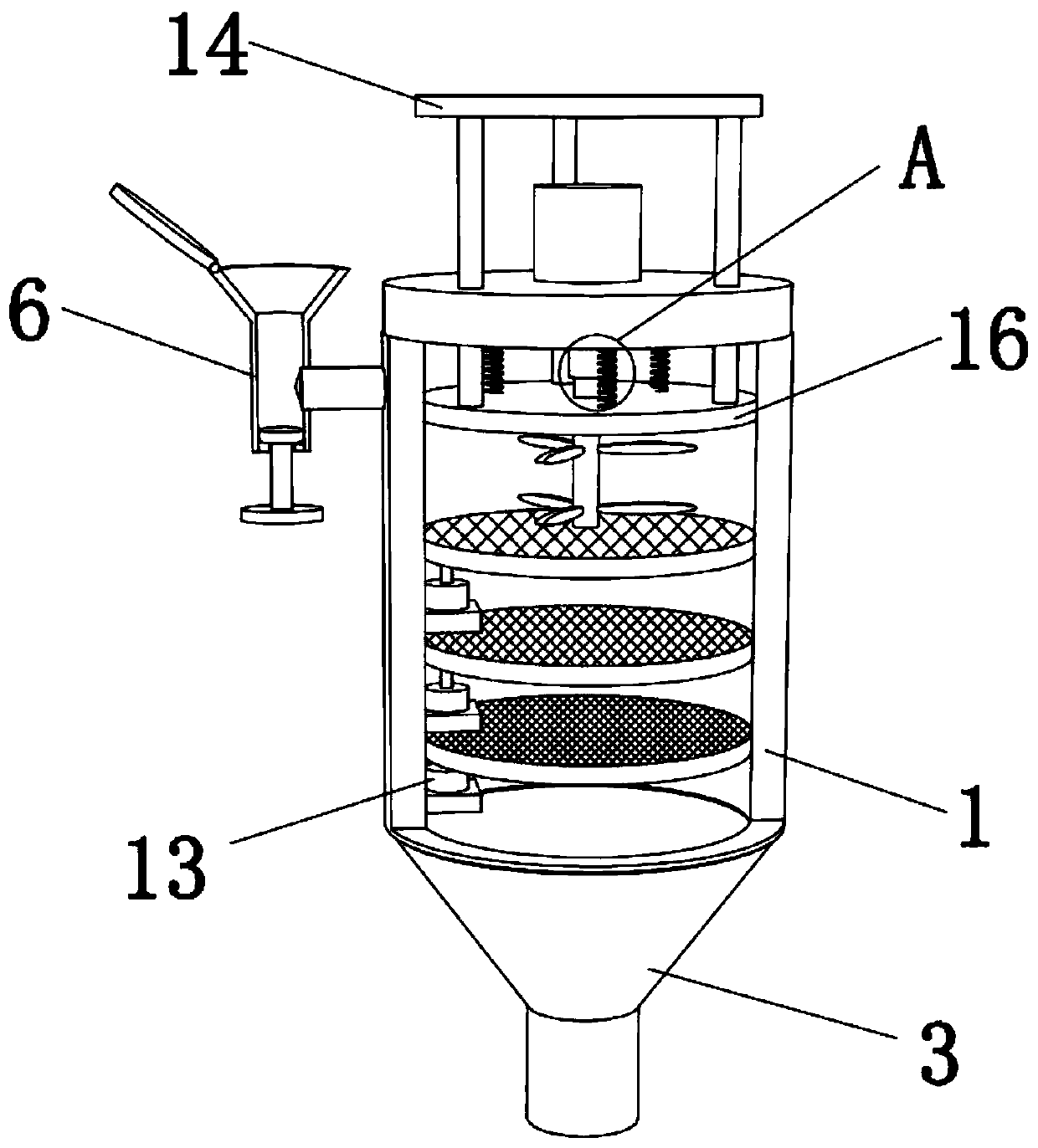

PendingCN110975394AFilter evenlyLeaked smoothlyMoving filtering element filtersPhysicsOil production

The invention discloses a filtering apparatus for lubricating oil production. The apparatus comprises a filter box, a first filter screen, a second filter screen and a third filter screen are sequentially connected to the inner side of the filter box from top to bottom, the side end of the filter box is connected with an oil guide tube, a dredging type feeding device is connected to one end, awayfrom the filtering box body, of the oil guide tube, the upper end of the filtering box is connected with a sealing cover, the upper end of the sealing cover is connected with a stirring driving device, a through hole is formed in the center of the sealing cover, the power output end of the stirring driving device penetrates through the through hole and is connected with a rotating shaft, the sideend of the rotating shaft is connected with a plurality of stirring blades, a dredging mechanism is arranged at the top end in the filtering box body, an auxiliary funnel is connected to the lower endof the filtering box body, an oil outlet tube is connected to the lower end of the auxiliary funnel, the rotating shaft and the stirring blades are magnetic blocks, the magnetic blocks can effectively adsorb iron impurities in lubricating oil, and the stirring driving device drives the magnetic blocks to rotate in order to achieve a good adsorption effect. The apparatus has a simple structure, and improves the lubricating oil filtering efficiency while ensuring the lubricating oil filtering quality.

Owner:杭州新灵峰润滑油有限公司

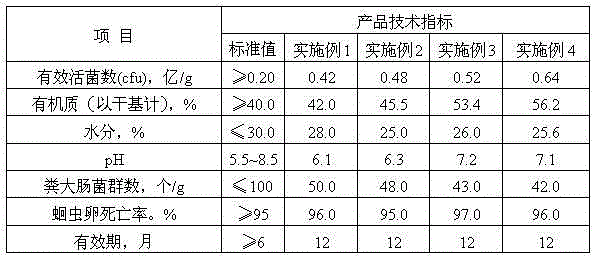

Furfural residue biological organic fertilizer and preparation method thereof

InactiveCN105294267AGuaranteed K and CGuaranteed elements such as K and CFertilizer mixturesBiotechnologyFurfural

The invention relates to a furfural residue biological organic fertilizer which comprises, by weight parts, 30-35 parts of chicken manure treatment substance, 50-55 parts of furfural residue, 2-3 parts of ammonia water, 3-4 parts of phosphate rock powder, 3-4 parts of plant ash, 2-4 parts of streptomycin fungi residue treatment substance, 0.05 part of zymophyte and 0.04 part of functional bacteria. The invention further relates to a method for preparing the organic fertilizer. According to the method, furfural residue and antibiotic fungi residue can be utilized effectively to be used for preparing the biological organic fertilizer.

Owner:GENLIDUO BIO TECH CO LTD

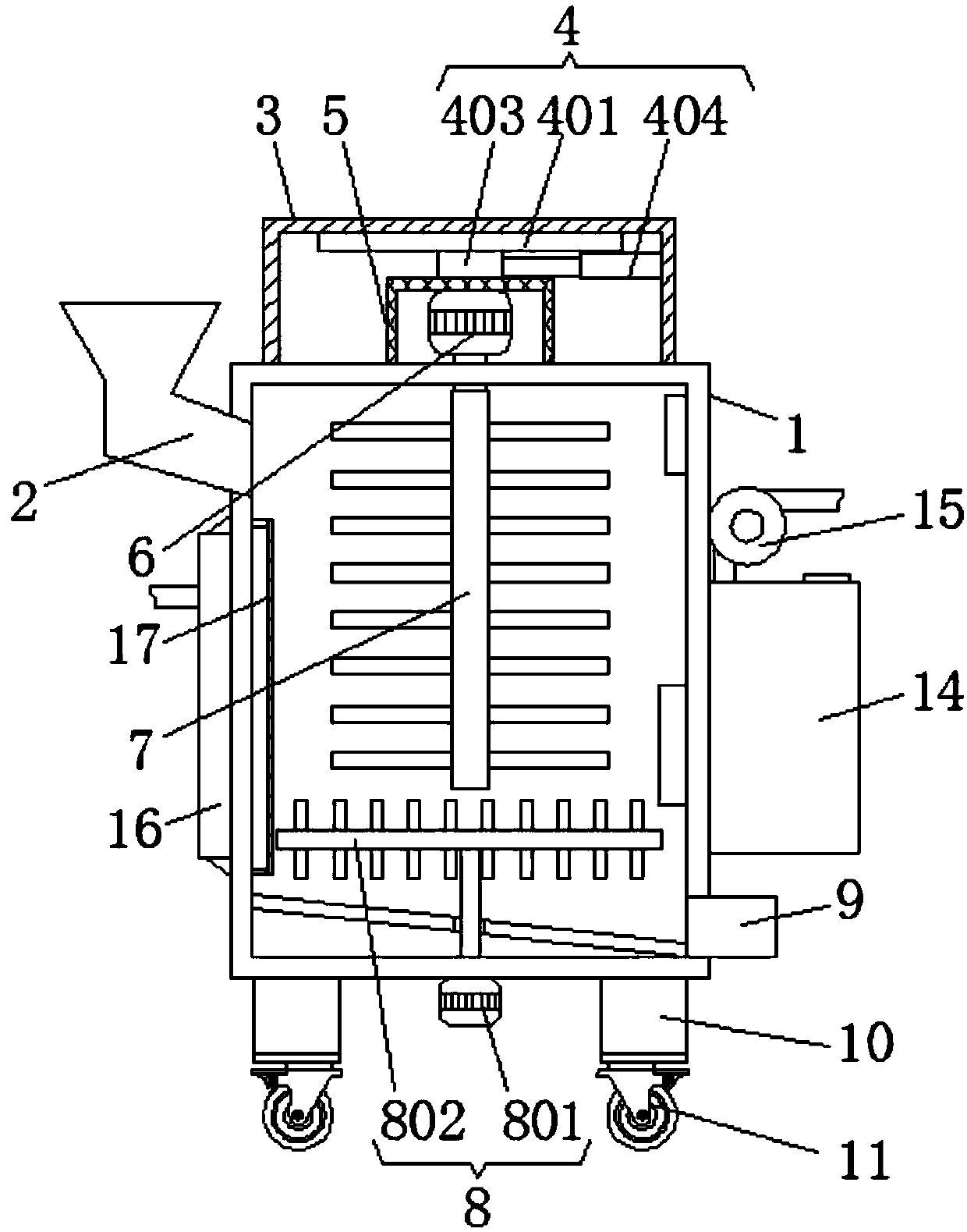

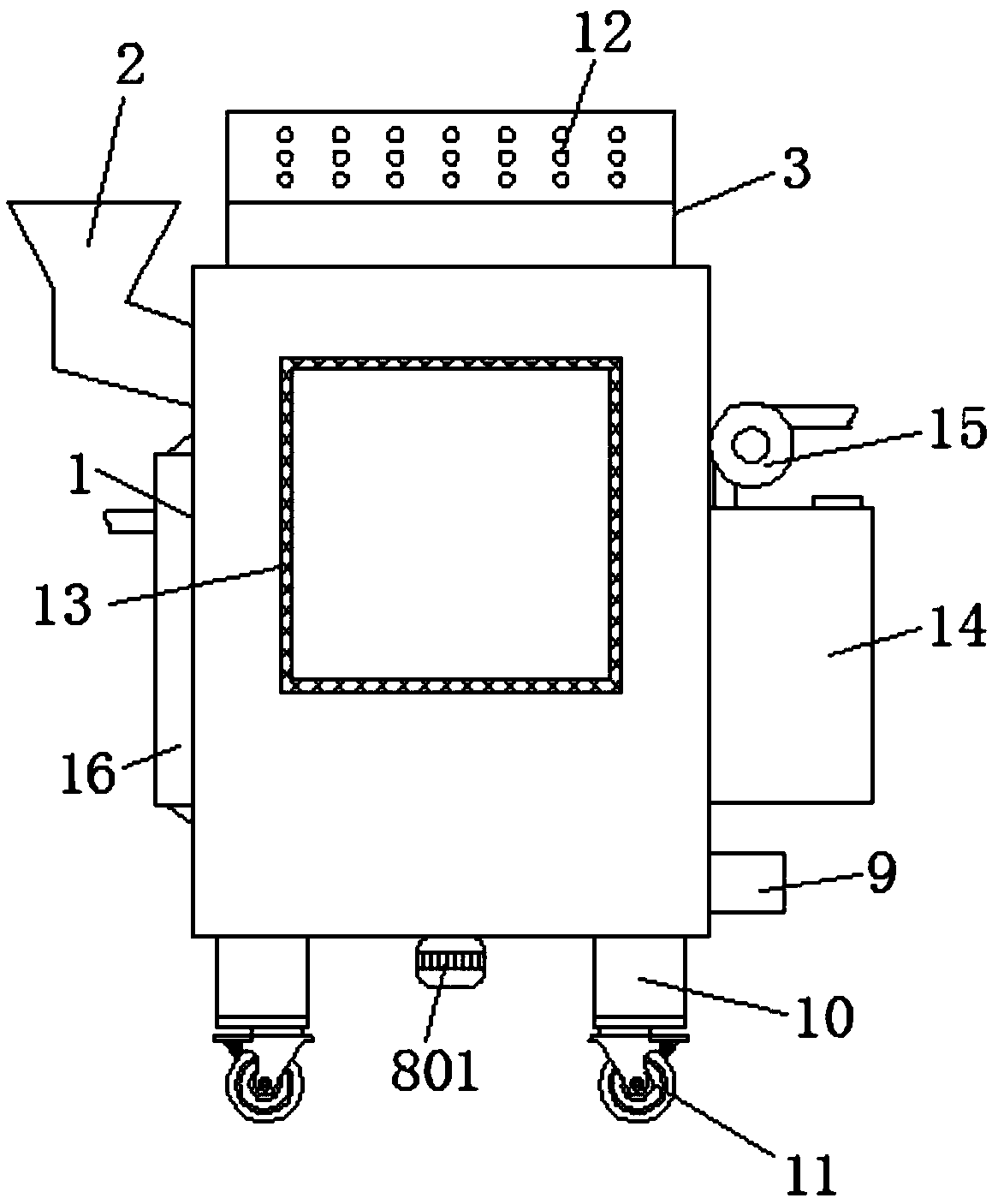

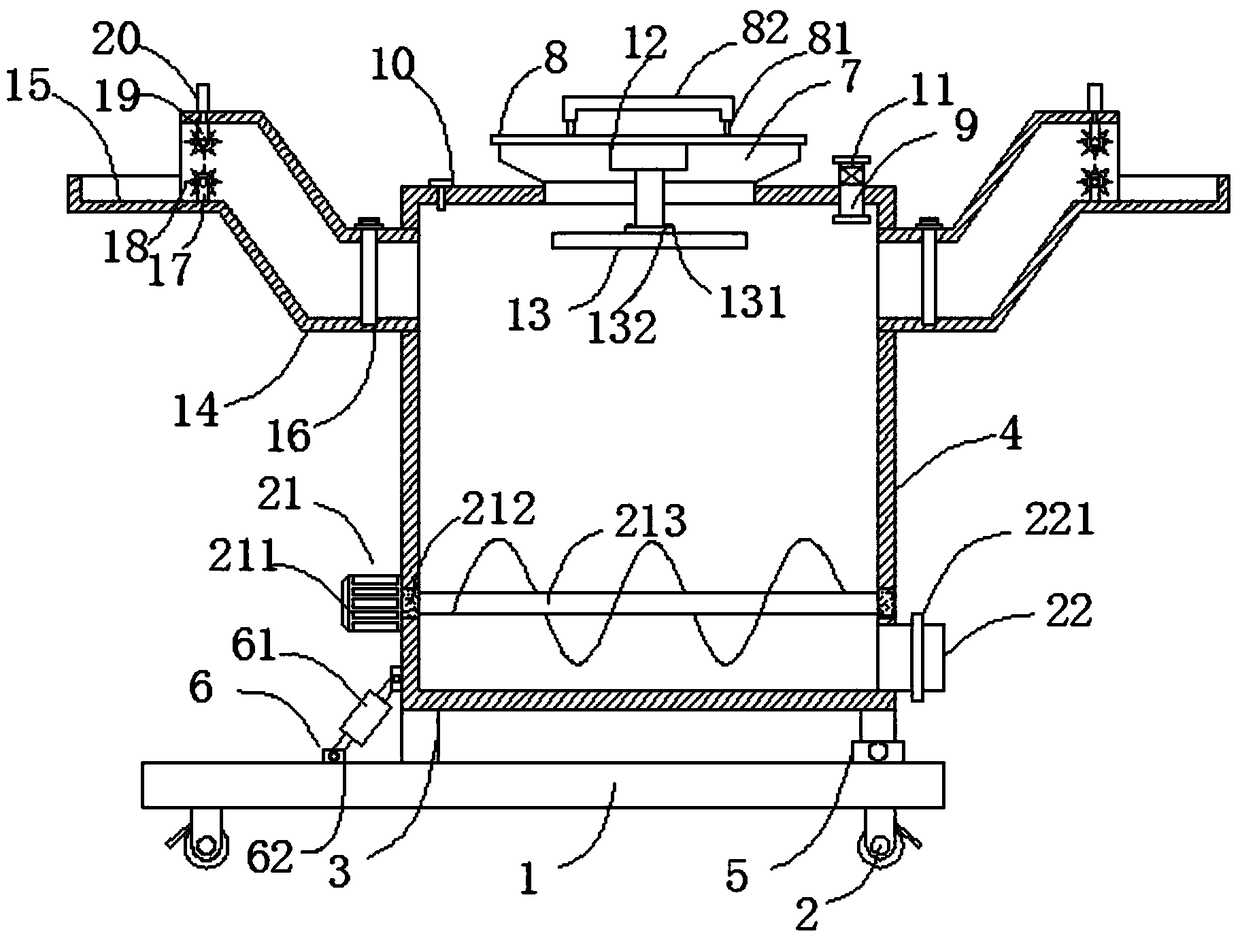

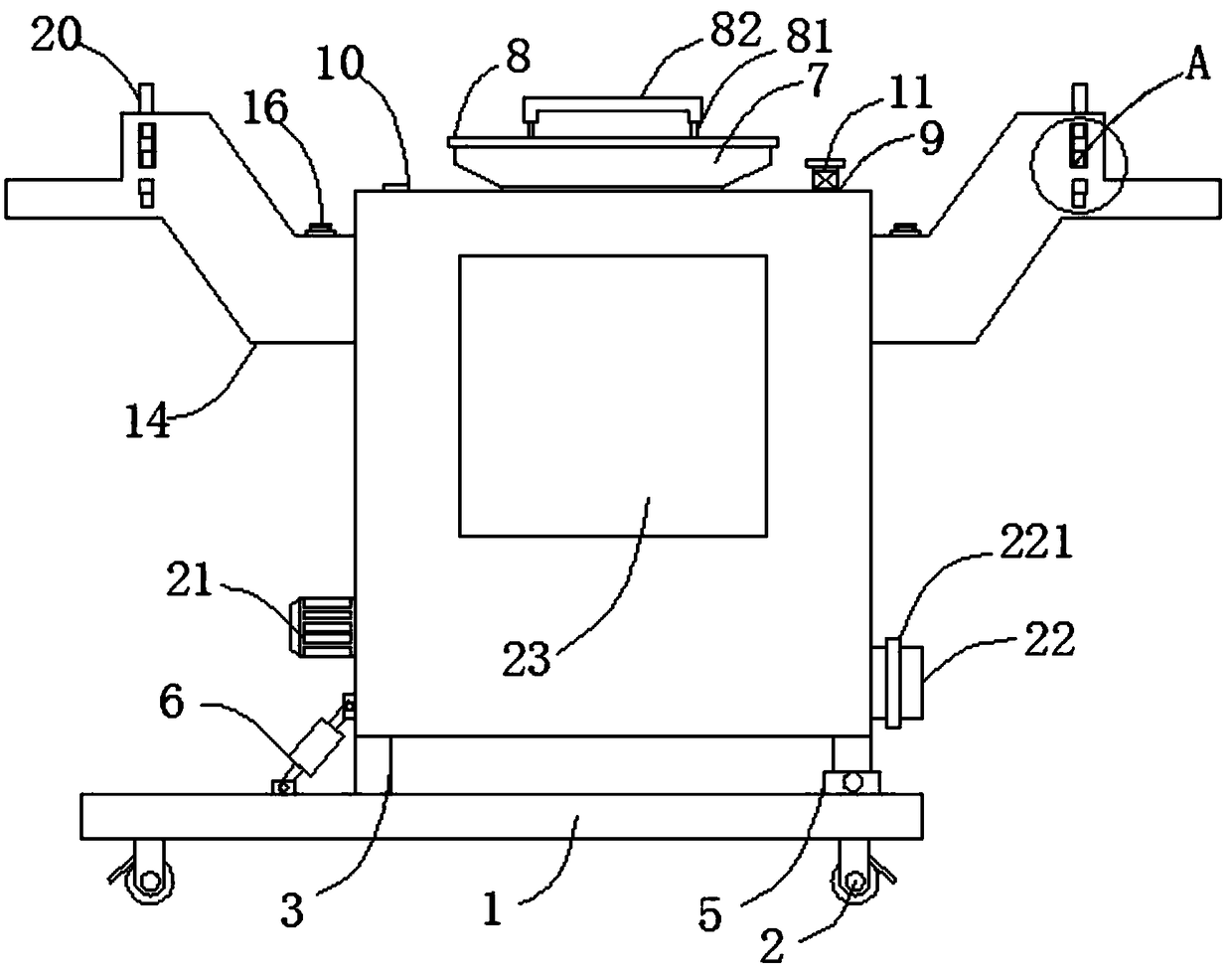

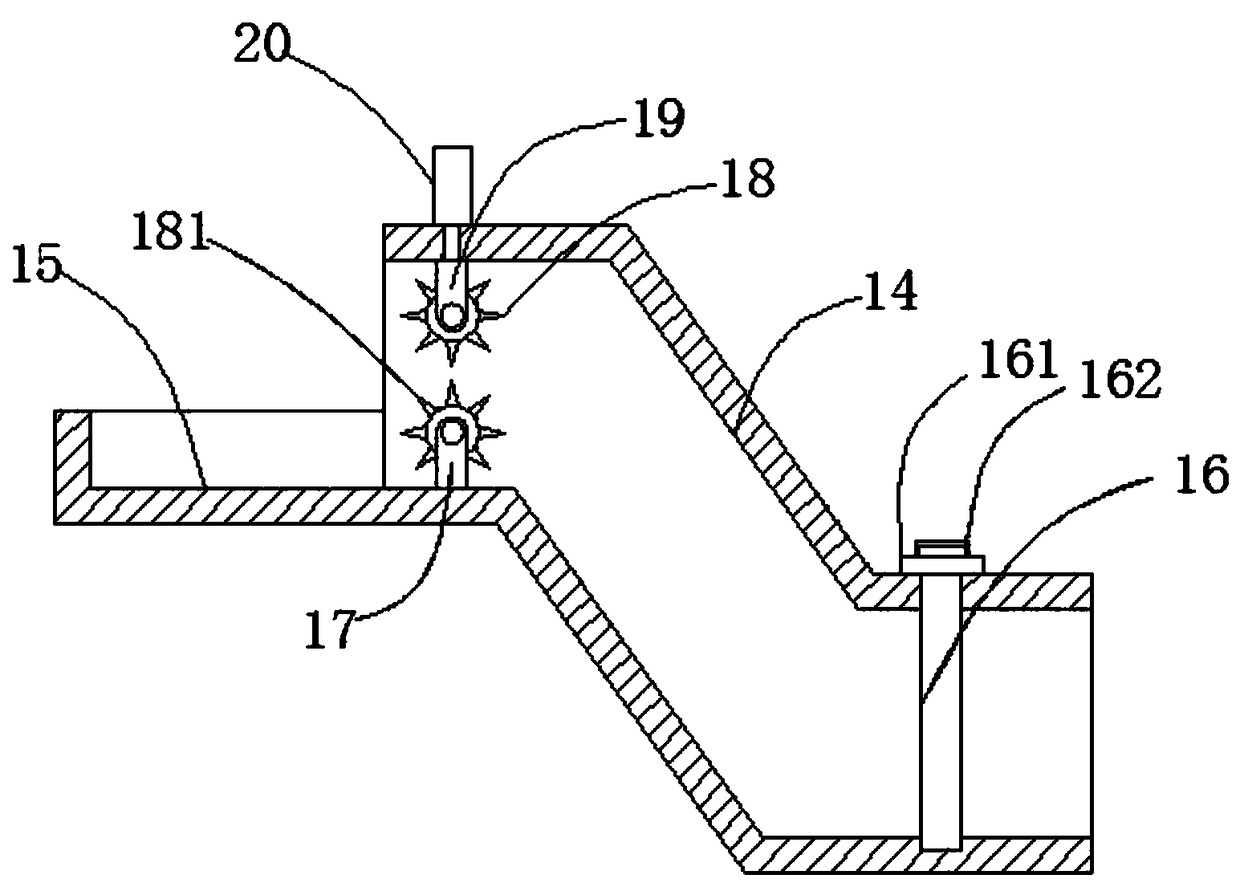

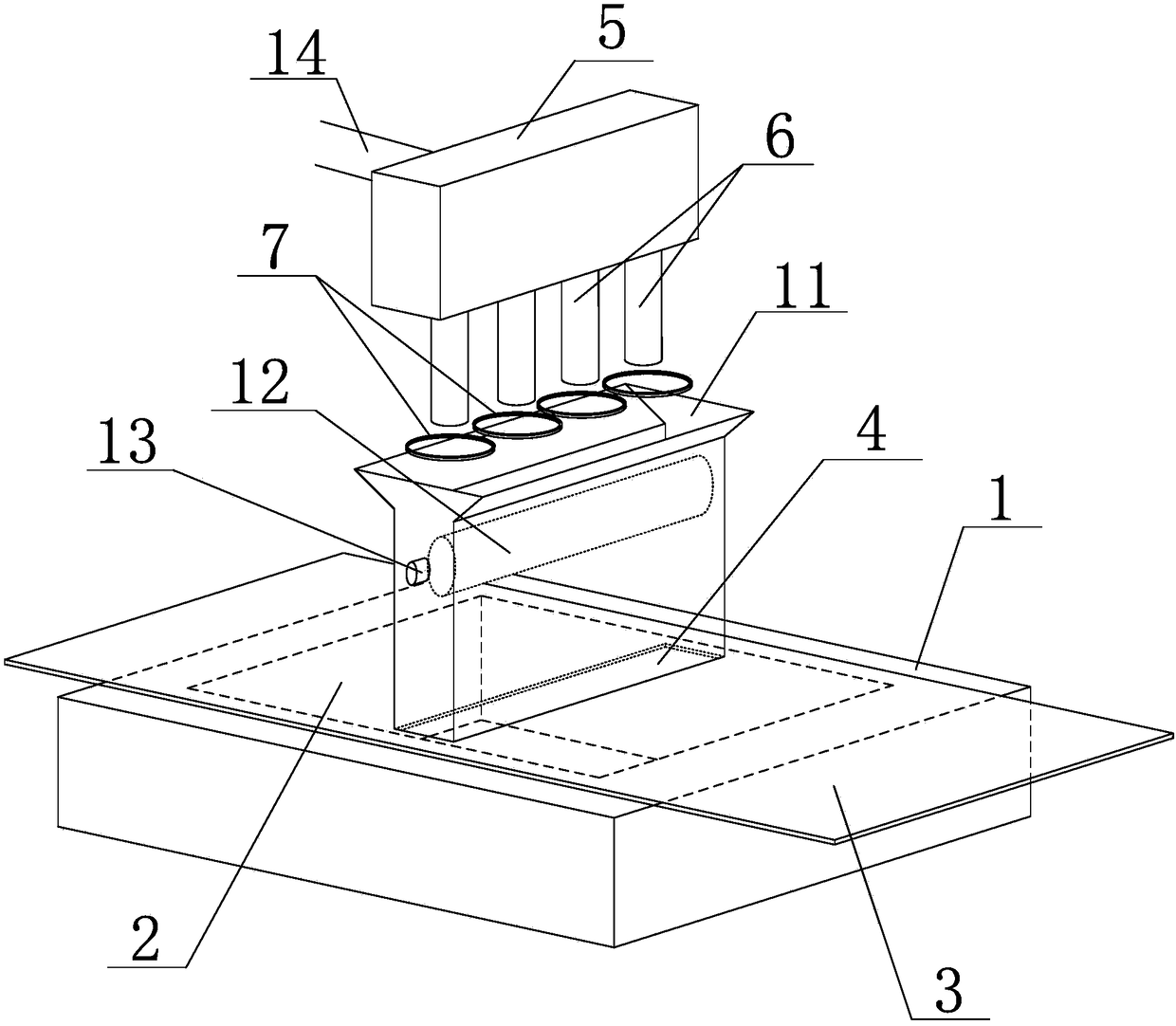

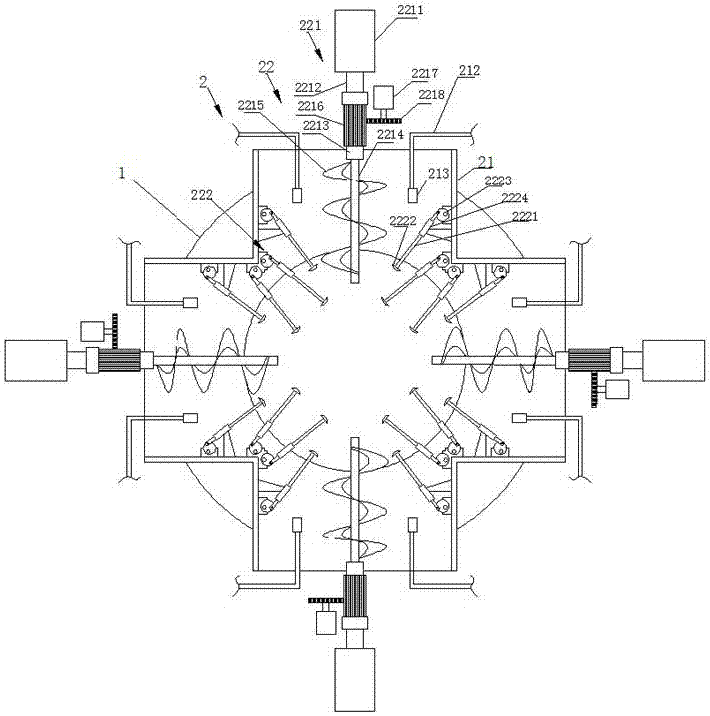

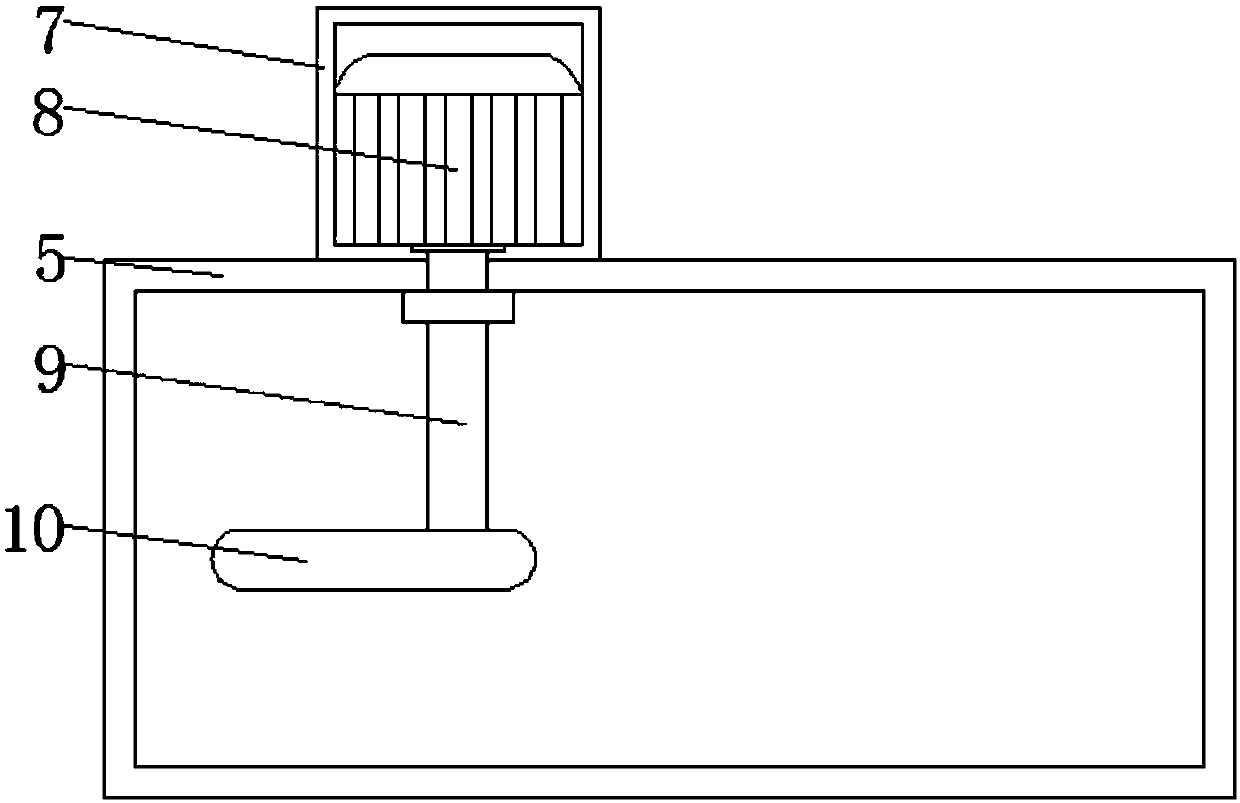

Automatic microbial fermented feed mixing device

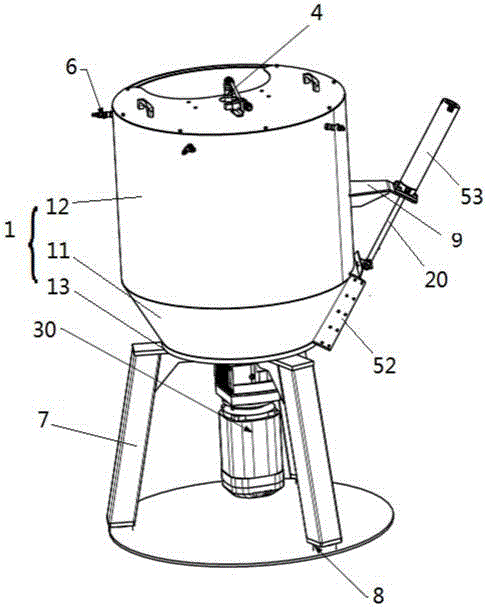

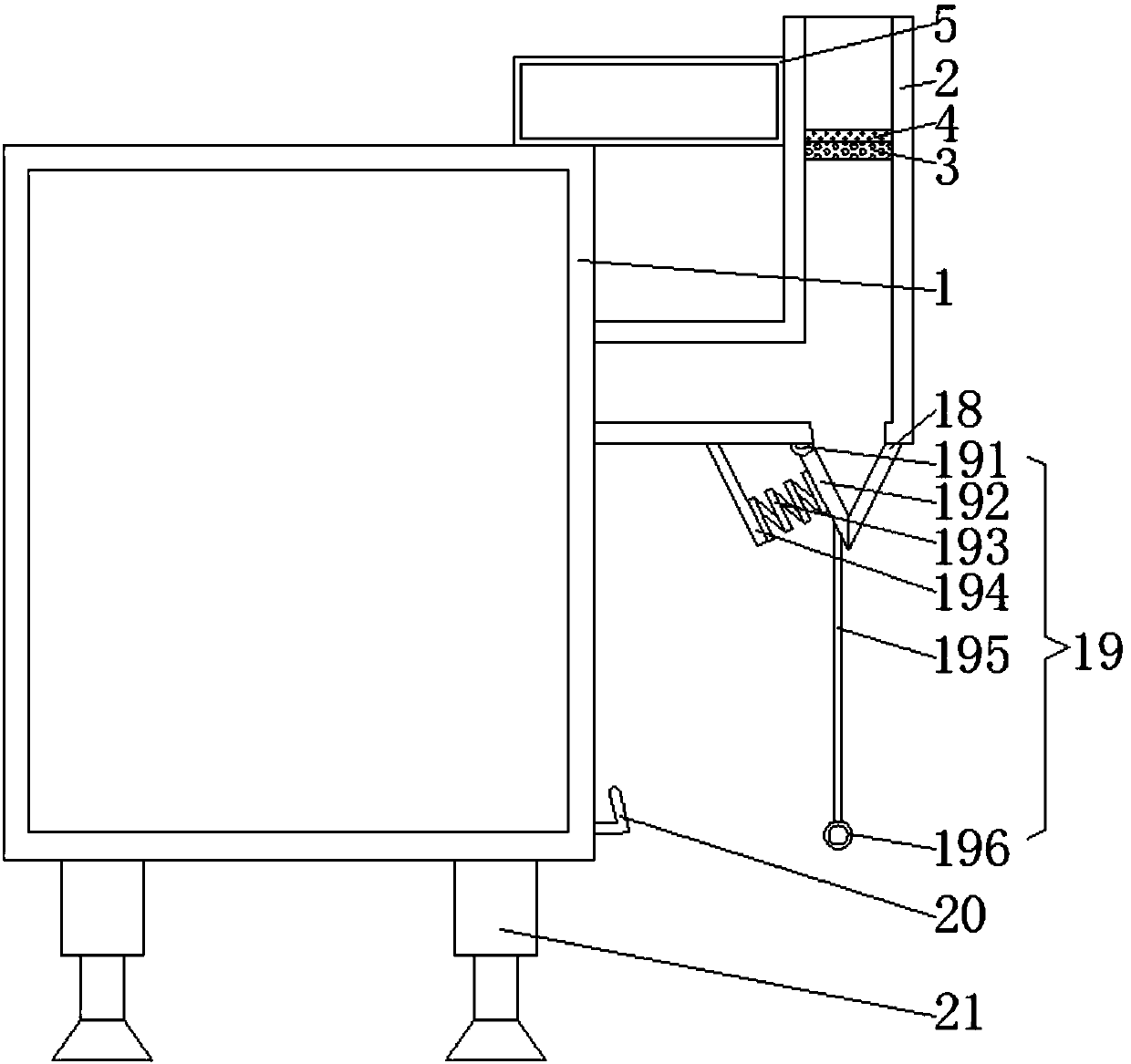

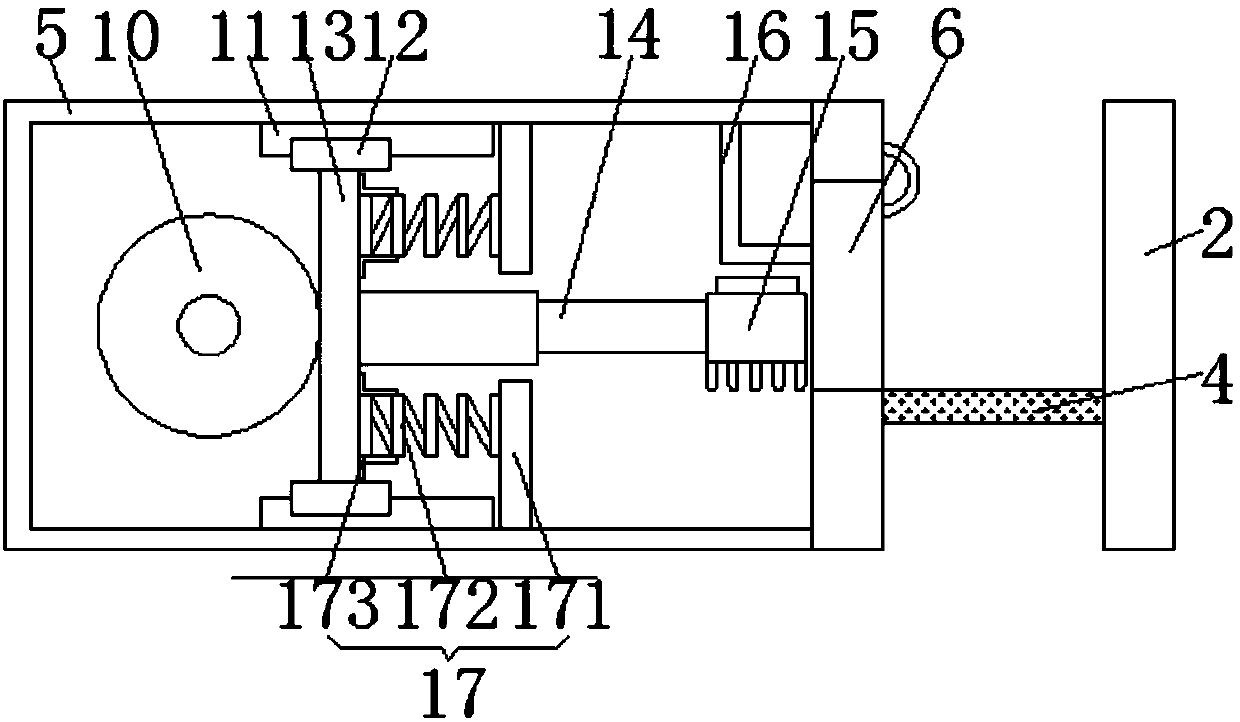

InactiveCN111117868AWell mixedGuaranteed Filtration QualityBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismElectric machinery

The invention discloses an automatic microbial fermented feed mixing device. The mixing device includes a fermentation tank; the left side of the fermentation tank communicates with a feeding pipe; aninstallation rack is fixedly installed on the top of the fermentation tank; a moving device is arranged in the installation rack; a protective cover is horizontally and slidingly connected to the internal, located at the upper part of the fermentation tank, of the installation rack; a first motor is fixedly installed on the top of the inner cavity of the protective cover; and a rotating shaft isfixedly installed on the part, penetrating the internal of the fermentation tank, of the output shaft of the first motor. Through the arrangement of the fermentation tank, the feeding pipe, the installation rack, the moving device, the protective cover, the first motor, the rotating shaft, a driving device and a discharging pipe, feed can be uniformly stirred and mixed, so that the fermentation quality of the feed can be guaranteed, and fermentation efficiency can be enhanced; and the problems, that the stirring efficiency of general fermentation tanks during the mixing of the feed is low andmicrobial fermentation quality is affected by incomplete feed fermentation due to non-uniform mixing, can be solved.

Owner:JIANGSU UNISON BIOTECH DEV

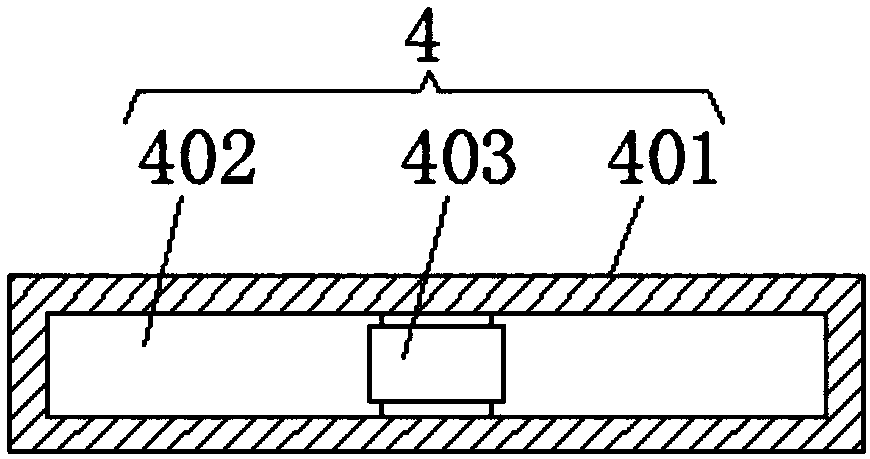

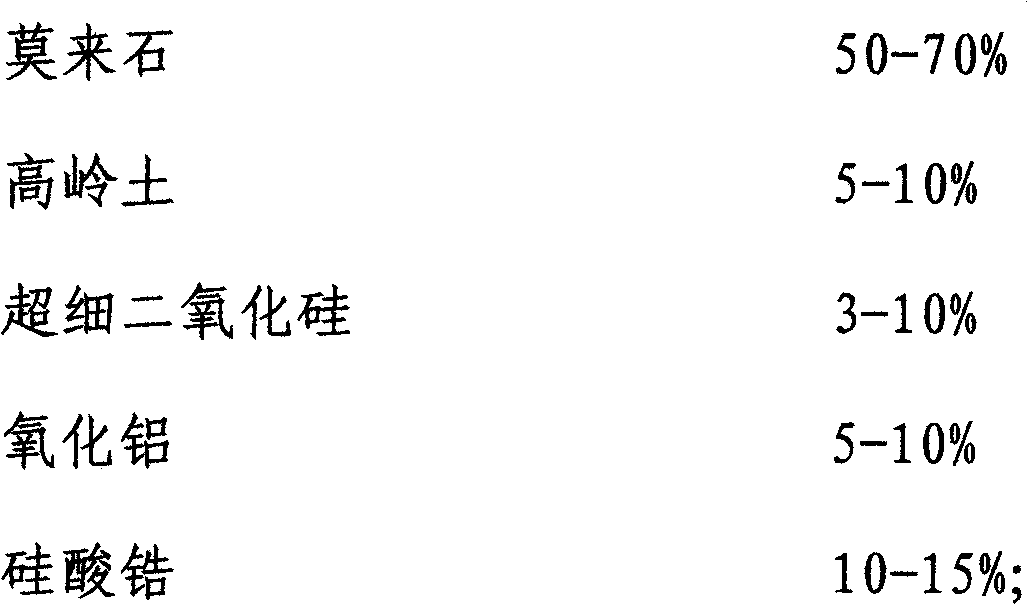

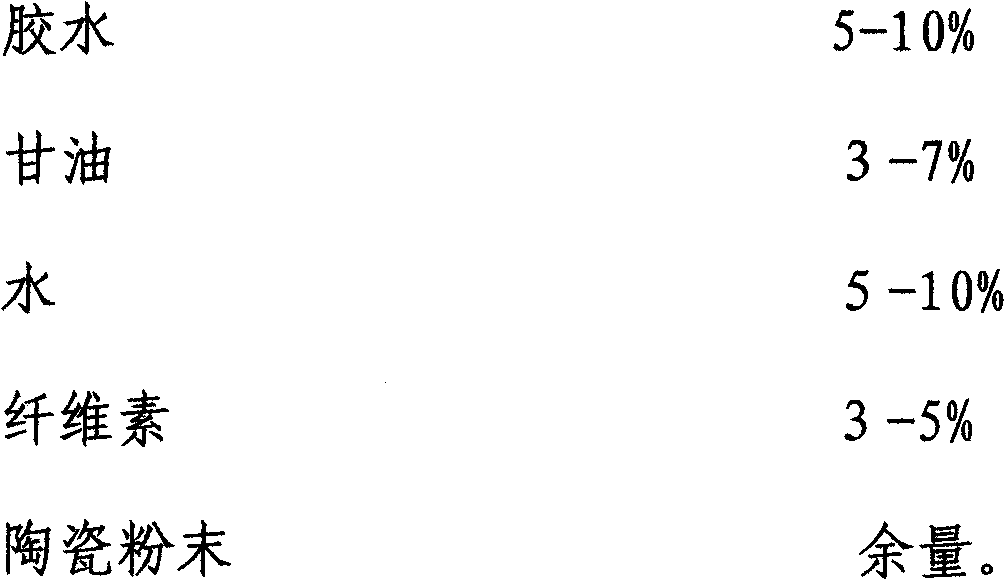

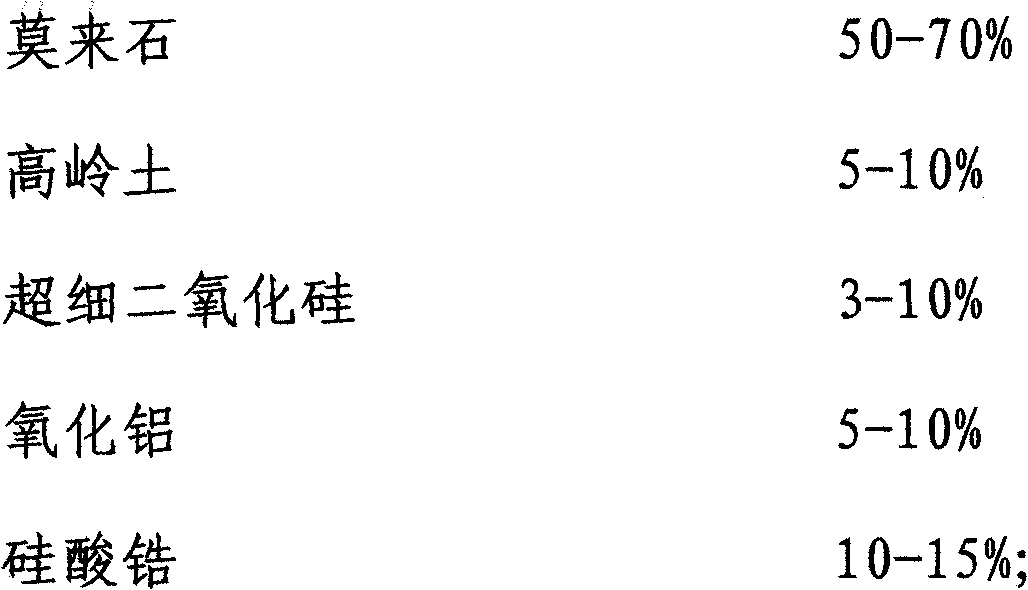

Honeycomb ceramic filter and preparation method thereof

The invention discloses a honeycomb ceramic filter and a preparation method thereof, and belongs to the field of inorganic nonmetal. The honeycomb ceramic filter is obtained after ceramic powder and plastic pug are sequentially subjected to ball milling, mixing, decaying, vacuum pugging and extrusion forming, dry cutting and sintering, wherein the ceramic powder is prepared by mixing mullite, kaolin, ultrafine silicon dioxide, aluminum oxide and zirconium silicate according to the proportion, and the plastic pug is prepared by mixing auxiliary materials composed of a glue, glycerol and hydrate cellulose. The honeycomb ceramic filter has good high-temperature strength and good thermal shock resistance. The method has the characteristics of low cost and simplicity in operation and is suitable for industrial production.

Owner:晋城市富基新材料股份有限公司

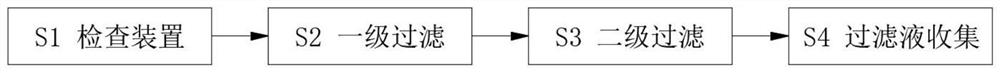

Recycling method for machining cutting fluid

InactiveCN112025394AIncrease flow resistanceReduce flow rateMagnetic separationMaintainance and safety accessoriesFiltrationCommunicating vessels

The invention relates to a recycling method for machining cutting fluid. The recycling method for the machining cutting fluid adopts the following cutting fluid recycling device; the cutting fluid recycling device comprises a box body and supporting legs; the supporting legs are fixedly installed at the lower surface of the box body; a bottom liquid outlet is fixedly installed at the bottom end ofthe left side of the box body; a U-shaped communicating vessel structure is arranged at one end of the left side of the device, so that large-particle impurities in the device are filtered out through a first filter plate and a second filter plate which are arranged in the device; afterwards, through a first turbulent flow plate and a second turbulent flow plate, the preliminarily filtered liquidreaches a laminar-flow-like state, and the flow resistance of the cutting fluid in the liquid is increased, so that the flow speed of the cutting fluid at the bottom of the U-shaped communicating vessel structure is reduced, and then impurities can be settled again in a slow flowing process of the waste cutting fluid; and thus, relatively large impurities in the cutting fluid are removed to guarantee the subsequent filtration quality of the cutting fluid.

Owner:许翠英

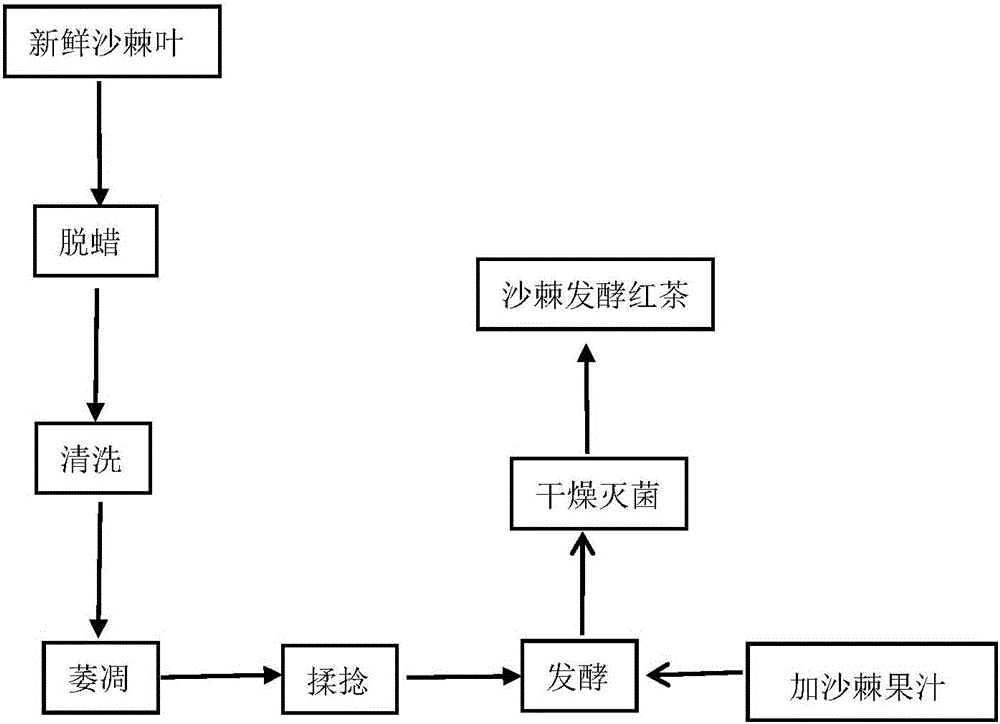

Hippophae rhamnoides black tea and preparation method thereof

The invention discloses a preparation method of hippophae rhamnoides black tea. The preparation method comprises the following steps of (1) picking hippophae rhamnoides leaves; (2) performing dewaxing treatment on the pickled hippophae rhamnoides leaves, wherein dewaxing means removing tissue having protection effects on surfaces of the hippophae rhamnoides leaves through a specific reagent; (3) performing withering; (4) performing rolling; (5) performing fermentation; and (6) performing drying and sterilization. The black tea not only has color, aroma and taste of tea and pleasure sense when the black tea is drunk, but also has certain health-care functions.

Owner:内蒙古宇航人高技术产业有限责任公司

Laminated filter unit

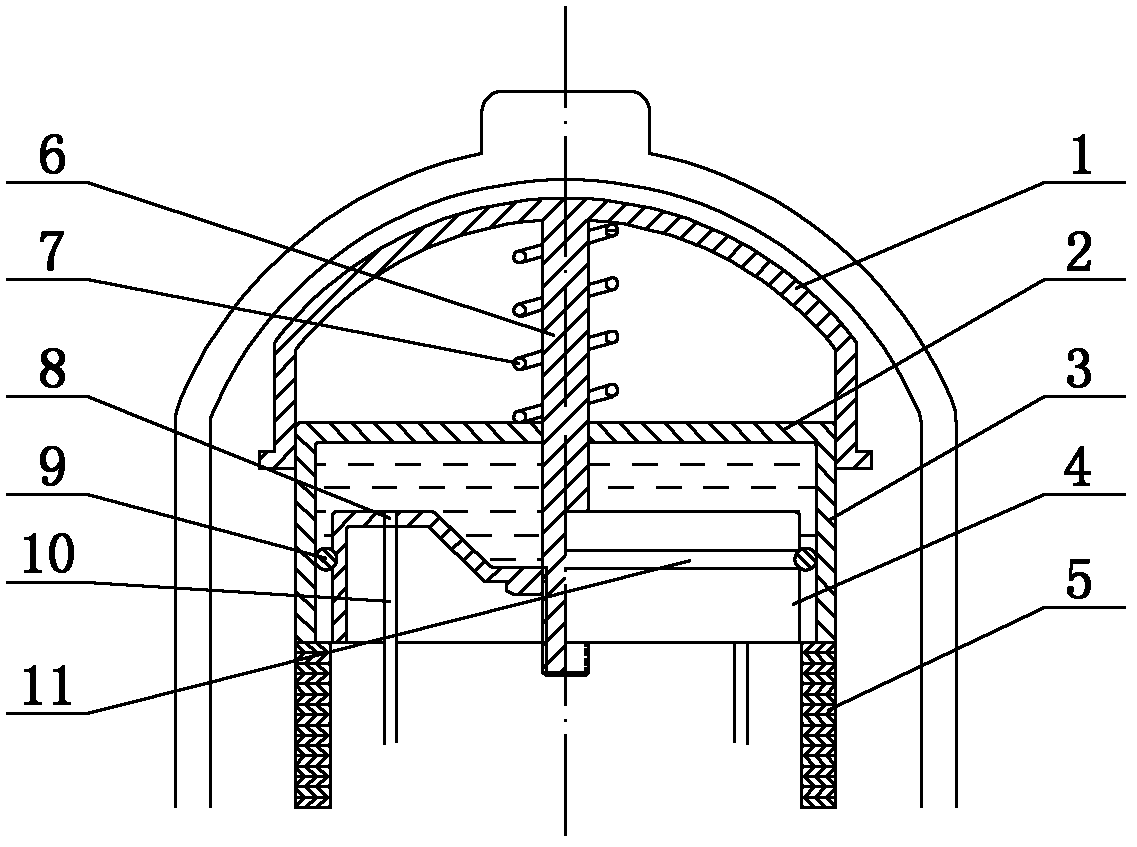

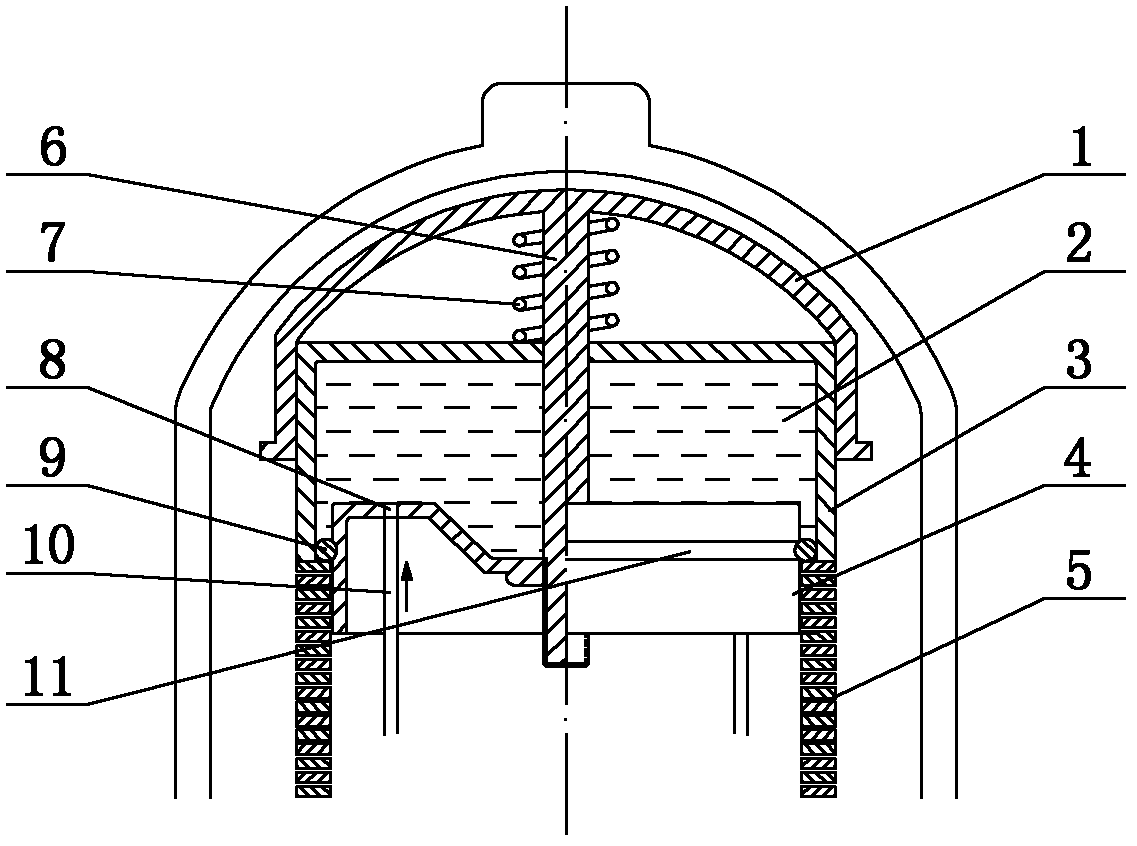

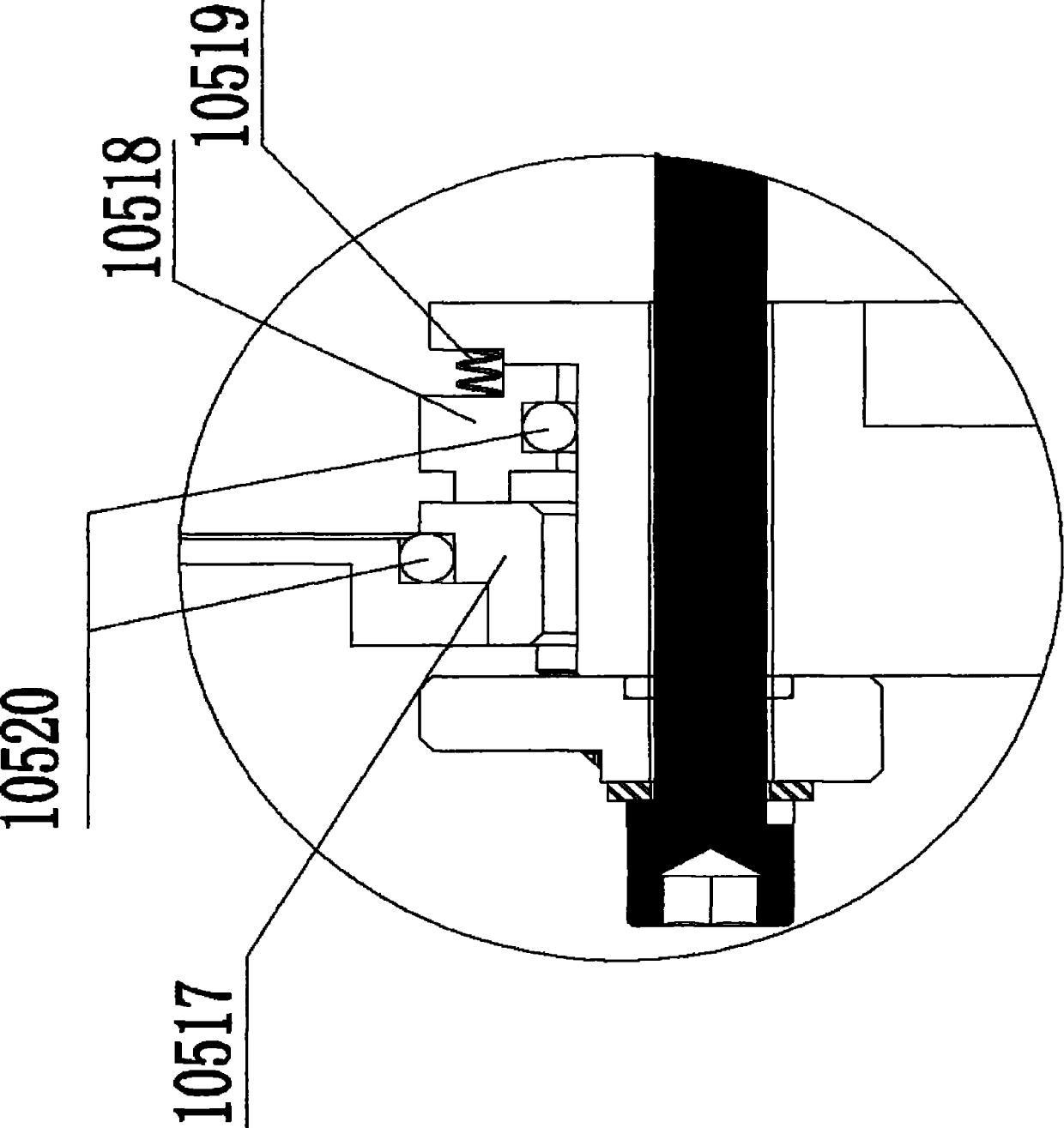

InactiveCN102430281AGuaranteed filtration accuracyGuaranteed Filtration QualityFiltration circuitsStationary filtering element filtersWater flowEngineering

The invention relates to a laminated filter unit, which belongs to a component of a laminated filter. The filter unit comprises a shell, wherein the shell is provided with an inlet and an outlet; a piston, a piston sleeve and a piston seat are arranged in the shell; the side wall of the piston sleeve is arranged on a lamination assembly; the lower part of the lamination assembly is provided with centrifugal flow guide blades; and a check valve is arranged between the centrifugal flow guide blades and the outlet. Impurities in liquid get away from the lamination assembly and move upwards by centrifugal force produced by the liquid rotating at a high speed and are finally centralized at the top end of the laminated filter unit, so that the back wash frequency of a product is greatly reduced. In a back wash state, after a high-pressure clean water flow is gathered to a flow guide pipe in a reverse direction, the water flow enters a piston chamber through a piston hole at the top end of the flow guide pipe, and the piston sleeve overcomes outward movement of the spring pressure on the top so as to release the pressure applied to the lamination assembly; and by now, the lamination assembly is loose, and the cleaning water flow can extremely easily pass through each lamination to clean impurities inside and outside a laminated filter tank.

Owner:乌鲁木齐瑞拓环保设备制造有限公司

Loose tea Eurotium cristatum growth technology

ActiveCN106417724AGuaranteed oxygen supplyPrevent backflowPre-extraction tea treatmentMicroorganismEngineering

The invention belongs to the fields of microbes and food biotechnologies, and concretely discloses a loose tea Eurotium cristatum fermentation technology. The technology comprises the following steps: 1, rehydrating gross tea by a rehydrating machine to make the water content reach 16-35 wt%; 2, adding the rehydrated gross tea to a rotary bottling machine to make the rehydrated gross tea be packaged in charging bottles, stacking the bottles, placing the charging bottles to a high-temperature and high-pressure sterilizer, sterilizing the charging bottles, adding the sterilized charging bottles into a cooling room, cooling the charging bottles to 30-80 DEG C, placing the cooled charging bottles into an inoculation room, and carrying out inoculation; 3, adding the inoculated charging bottles into a fermentation room, and carrying out fermentation at 20-40 DEG C under a humidity of 30-75% for 6-10 d; and 4, adding the fermented tea leaves to an automatic discharging machine, taking out the tea leaves from the charging bottles, placing the tea leaves in a drying disc, and drying the tea leaves until the water content is 5-12 wt%. The technology has the advantages of uniform Eurotium cristatum growth, high Eurotium cristatum growth capacity, obvious Eurotium cristatum, simplicity and high standardization degree, so the product quality is safe and controllable, the health effects of the product are further enhanced, and the product quality is excellent.

Owner:CHINA TEA CO LTD

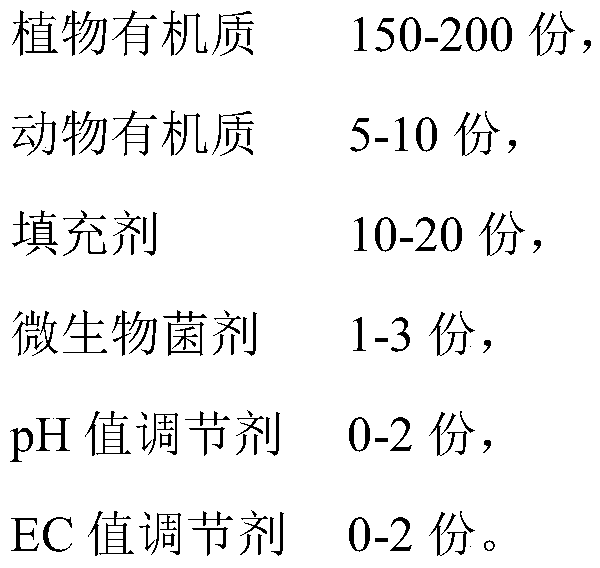

Organic substrate for cultivated crops and preparation method of substrate

InactiveCN110169333AImprove breathabilityImprove water retentionGrowth substratesCulture mediaMonsoonBiology

The invention discloses an organic substrate for cultivated crops and a preparation method of the substrate. The organic substrate for cultivated crops comprises the following components in parts by weight: 150-200 parts of plant organic matters, 5-10 parts of animal organic matters, 10-20 parts of fillers, 1-3 parts of microbial inoculums, 0-2 parts of pH regulators and 0-2 parts of EC regulators. The organic substrate for cultivating crops is obtained through high-temperature fermentation, can effectively remove germs, eggs and weed seeds, has rich nutrient components, can enhance the immunity of crops, and improve the quality and yield of the crops, thereby meeting the requirements of urban agriculture on shallow soil cultivation, simple configuration and convenient planting and maintenance, and particularly can effectively solve the problem of low yield caused by insufficient air permeability, water retention and colonization of the substrate when high temperatures and monsoons occur in summer in southern cities.

Owner:江门市城市绿苑科技有限公司

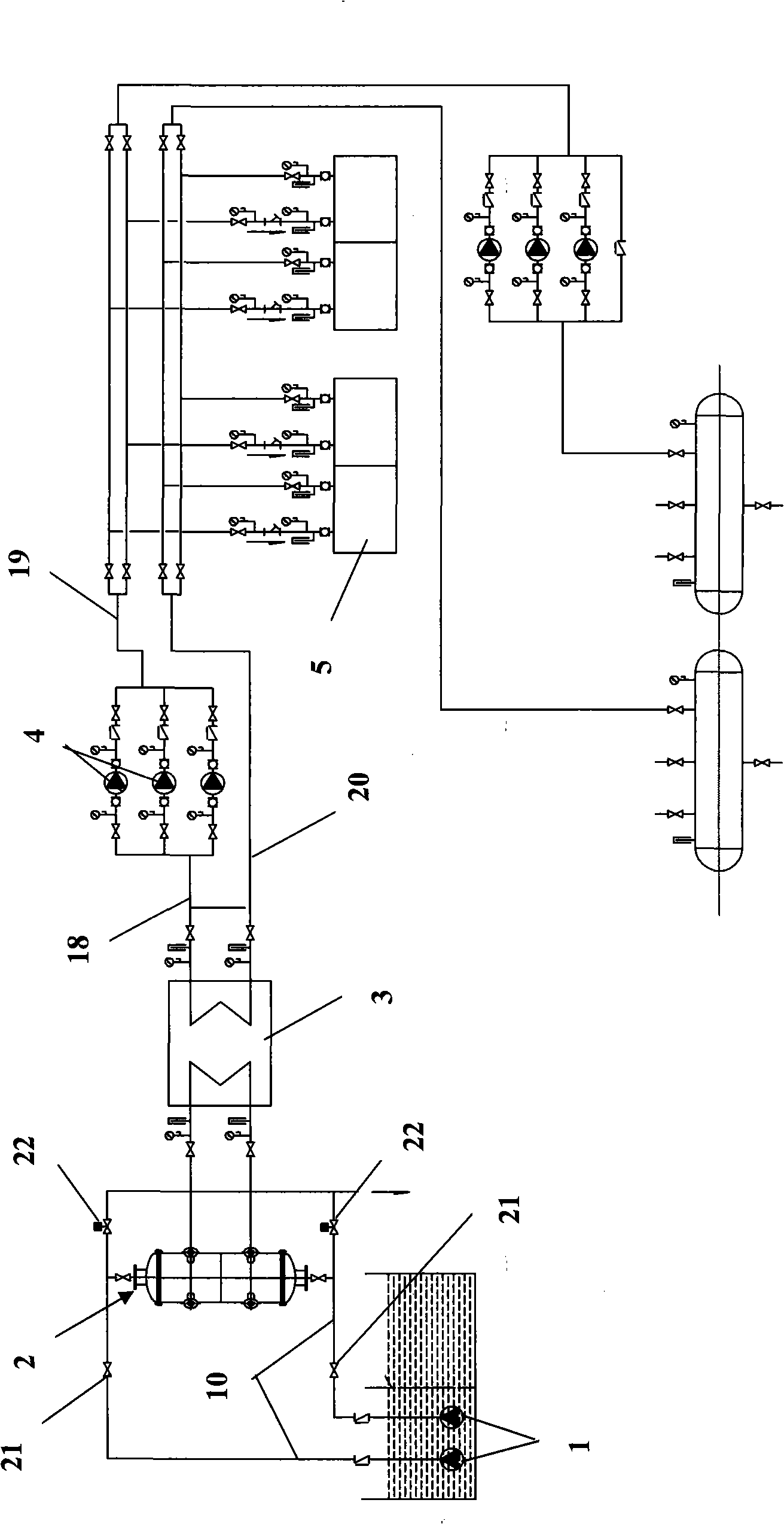

Native sewage water heat pump air conditioning system

InactiveCN101280985ARestore filter capacityReduce processing requirementsHeat pumpsWater/sewage treatmentWater cyclingSewage

An untreated sewage heat pump air adjusting system is disclosed, mainly comprising two diving sewage pumps that are interconnected though a pipeline, an untreated sewage filter, a shell pipe type heat exchanger, a plurality of medium water circulation water pump and a plurality of heat pump units. The untreated sewage heat pump air adjusting system provided by the invention utilizes two diving sewage pumps in an alternative working way to enable a steel plate filter net in the untreated sewage filter to filter the untreated sewage, meanwhile, to perform back washing to another steel plate filter net in order to recover filter ability of the filter and guarantee the filter quality, therefore the untreated sewage filter does not need power in the process of running the system and the energy consumption of the system can be reduced. In addition, as the untreated sewage filter is a fixing device, the processing requirements, cost and running expenditure are low.

Owner:天津美意机电设备工程有限公司

Spray irrigation device used for park and garden construction

InactiveCN111264353ABig impactExpand the spraying rangeGeneral water supply conservationWatering devicesWater flowEnvironmental engineering

The invention belongs to the technical field of park and garden construction, and particularly relates to a spray irrigation device used for park and garden construction. According to the following scheme, the spray irrigation device used for park and garden construction comprises a storage shell, wherein a filtering shell is installed on an outer wall of the top of the storage shell, a water pumpis installed on an inner wall of the bottom of the storage shell, a water outlet pipe is installed at an output end of the water pump, a connection pipe is installed at the other end of the water outlet pipe, a circulation groove is formed in the joint of the filtering shell and the storage shell, and two spray heads are installed on an outer wall on one side of the connection pipe. In the sprayirrigation device used for park and garden construction, by arranging an arc baffle, during work, water flows sprayed by the spray heads can make impacts on the arc baffle, the arc baffle rises, at the time, vertical rods hit a push board, under the action of first connection springs and second connection springs, the arc baffle fast bounces back to the power portion, then water sprayed by the spray heads is blocked, and thus the water splashes in all directions so that the spray heads not only can spray water to remote plants, but also can spray water to plants nearby, that is to say, a spraying range is extended.

Owner:王聪燕

Container type edible fungi base material fermenting device and method

InactiveCN107125022ALabor savingLower cleaning costsBio-organic fraction processingFertiliser treatment heating/coolingSteel platesProcess engineering

The invention relates to a container type edible fungi base material fermenting device and method. The device comprises a steel plate mechanism, wherein the steel plate mechanism is arranged at the lower end of the inside of a container body; ventilating openings are uniformly distributed in the steel plate mechanism; the steel plate mechanism and the bottom of the container body curve a ventilating channel; the ventilating channel is connected with an air outlet of a fan; an oxygen sensor, a temperature sensor group, a carbon dioxide sensor and a humidity sensor are arranged in the container body; a control system which respectively controls an air valve controller, the temperature sensor group, the oxygen sensor, the carbon dioxide sensor and the humidity sensor is arranged on the outer side of the container body; and a temperature regulator and a humidity regulator are arranged at an air inlet and an air outlet of the fan. By the fermenting device and method, a base material is ventilated uniformly, two-time and three-time fermentation is realized, the fermentation period is shortened, and the labor cost and the manufacturing cost are greatly saved; and the device is flexible to use and is placed in a close distance. State-sponsored quality and efficiency improvement spirit of the featured agriculture is realized.

Owner:山东世纪智慧农业科技有限公司 +1

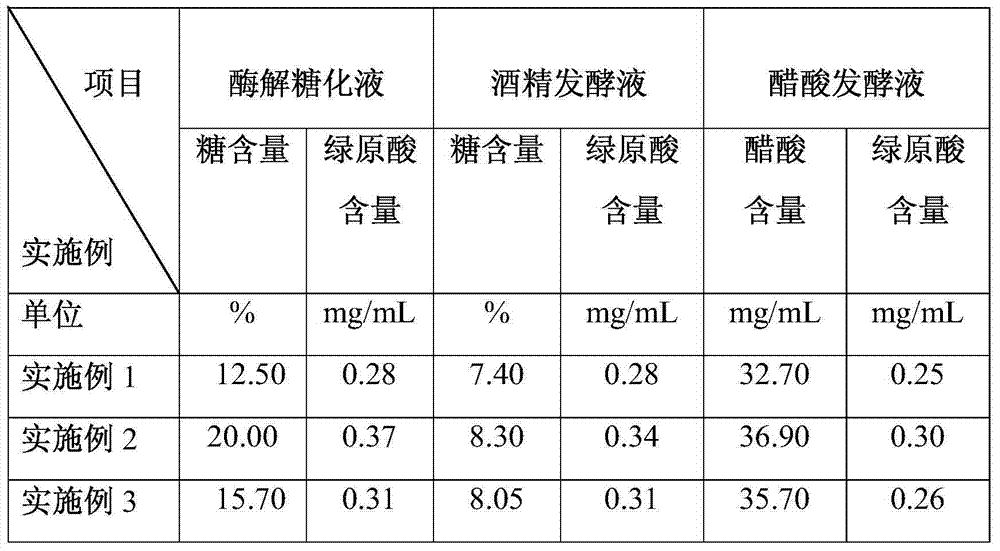

Brewing process of purple sweet potato vinegar

InactiveCN103540516AGuaranteed chlorogenic acid contentGuaranteed Filtration QualityVinegar preparationAcetic acidFlavor

The invention relates to the technical field of deep processing of agricultural products, and particularly relates to a brewing process of purple sweet potato vinegar. The brewing process is characterized by comprising the following steps: material treatment, enzymolysis saccharification, alcoholic fermentation, acetic acid fermentation, vinegar pour, and preparation of finished product sweet potato vinegar by pasteurization. The brewing process disclosed by the invention has the beneficial effect that production device investment adopted for the purple sweet potato vinegar brewing process is a little, production conditions are easy to control; and an obtained finished product has the characteristics of being clear and free from precipitates, free from suspended matters, bright in color, high in acetic acid content, and strong in acid flavor, and is a table vinegar product integrating seasoning and healthcare.

Owner:BAODING UNIV

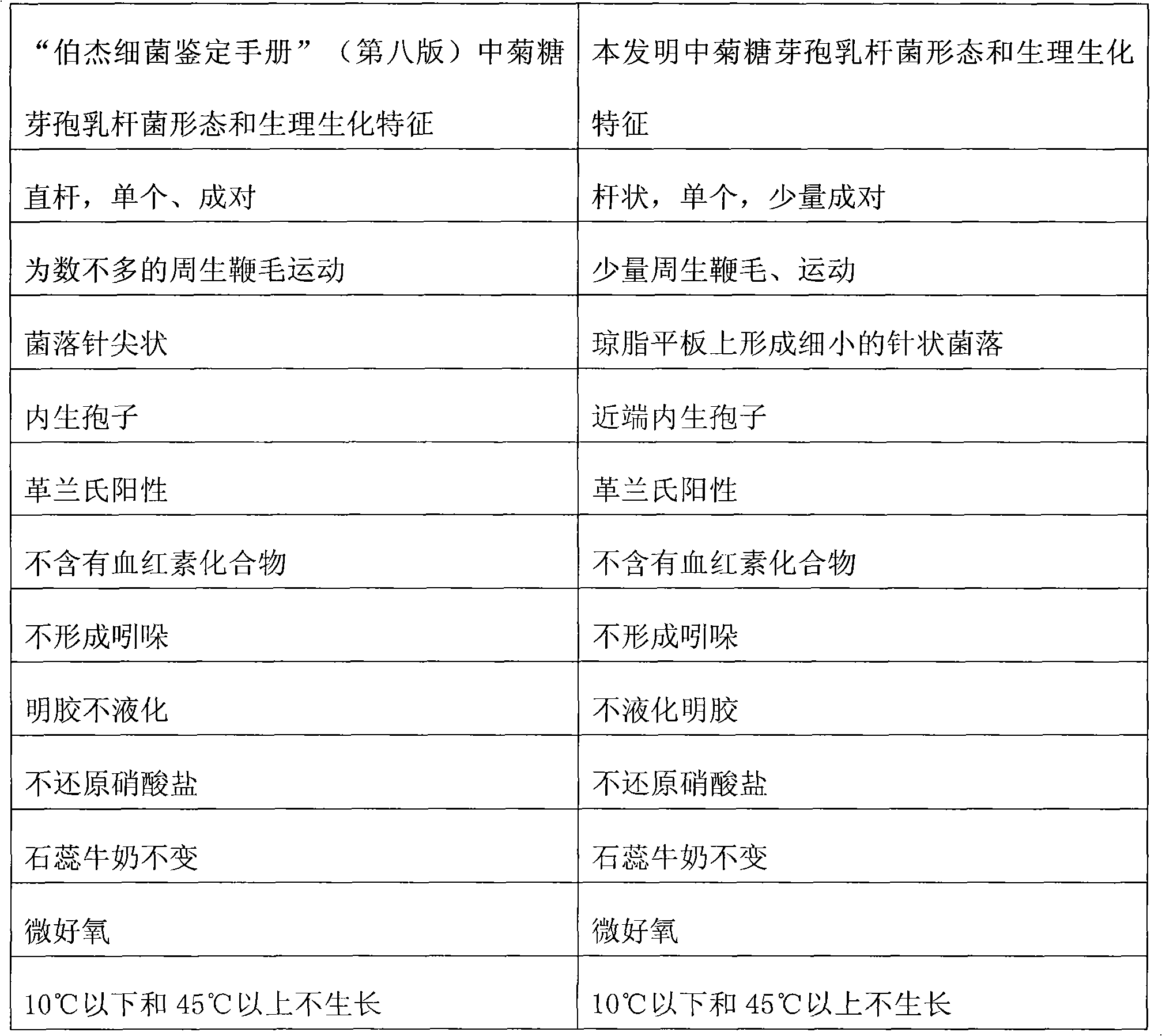

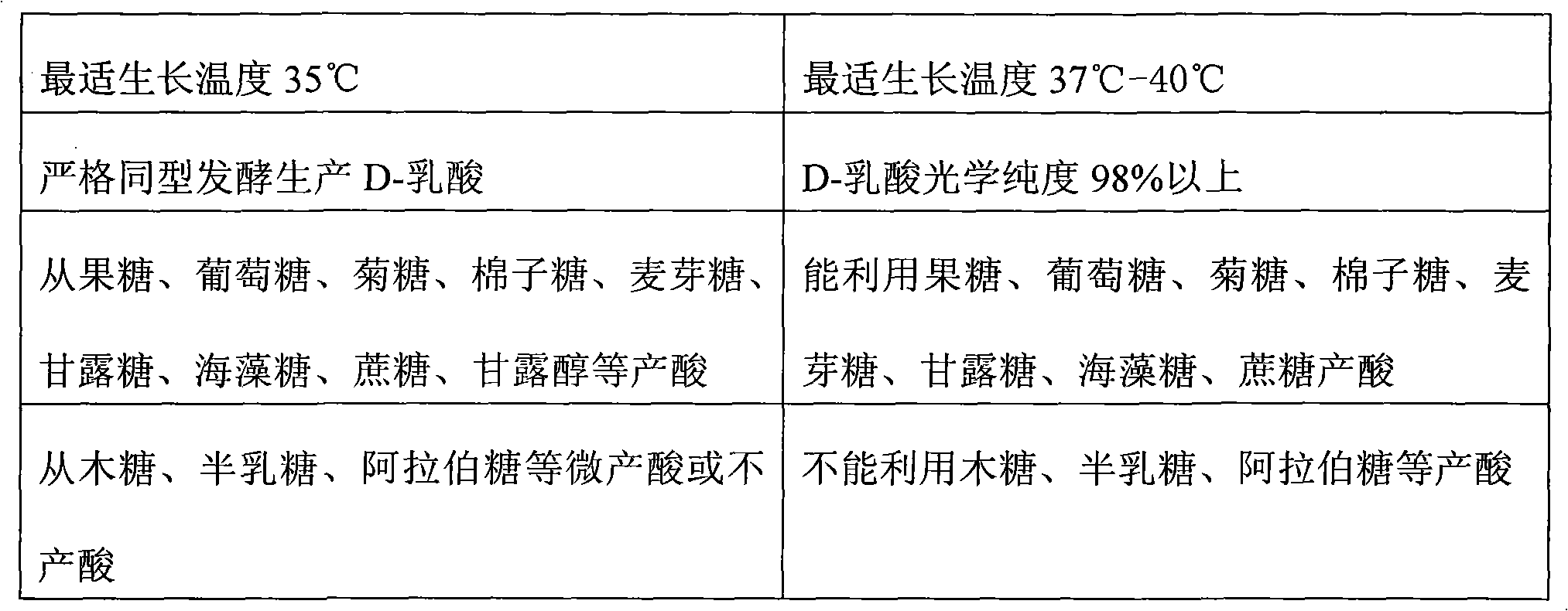

Sporolactobacillus inulinus and method for preparing D-lactic acid by fermenting strains of sporolactobacillus inulinus

ActiveCN101974447AIncrease production capacityHigh optical purityBacteriaMutant preparationBiotechnologyMembrane technology

The invention provides a sporolactobacillus inulinus and a method for preparing D-lactic acid by fermenting strains of sporolactobacillus inulinus (CGMCC No. 3997). The method comprises the steps of (1) cultivating seeds for fermentation; (2) fermenting the obtained strains to prepare D-lactic acid; and (3) extracting and refining the D-lactic acid. The strains in the invention have the characteristics of stable high-yield performance and high optical purity as well as wide source of fermentation formula and low cost, wherein the fermentation state is between the anaerobic state and the microaerophilic state, the fermentation period of the strains is 40 to 50 hours, the acidogenic rate by fermentation is 12 to 14 percent, the conversion rate of sugar to acid is 92 to 94 percent, and the optical purity of fermentation is 98 to 99 percent. In the invention, a series of currently advanced membrane technologies and short-path distillation technologies are adopted in the aspects of extraction and purification, thereby ensuring the quality of products and the extraction yield.

Owner:北京朗净汇明生物科技有限公司 +1

Agricultural straw and weed smashing and fixed fermentation device

InactiveCN109089570AGood crushing effectImprove mixing efficiencyFeeding-stuffCuttersAgricultural engineeringAgriculture

The invention discloses an agricultural straw and weed smashing and fixed fermentation device, which comprises a supporting seat and universal wheels. The universal wheels are mounted on two sides ofthe bottom of the supporting seat through supporting rods respectively. A fermentation tank is mounted at the top of the supporting seat through supporting legs. One side of the supporting seat is movably connected to the fermentation tank through a movably-mounted pushing mechanism. The top of the fermentation tank is provided with a top port, a liquid inlet and a temperature gauge. A pressure plate is connected to the bottom of a seal cover plate through a piston rod at the end of a hydraulic cylinder. Two sides of the fermentation tank are provided with smashed material inlets respectively.Smashing rollers are mounted on one side of each guide chutes through a fixed support and a movable support. Each of the fixed supports and the movable supports is in transmission connection with a smashing motor corresponding to the penetration position of a corresponding smashing roller shaft, and a mixing mechanism is penetratingly arranged at the bottom of the fermentation tank. The device isgreat in smashing effect and thorough in material mixing, mixing efficiency is improved, material fermentation quality is guaranteed, convenience in feeding and discharging is achieved, and internalresidual waste is avoided.

Owner:李俊

Food fermenting device convenient to operate

The invention discloses a food fermenting device convenient to operate. The food fermenting device comprises a tank body, wherein a fermenting tank is fixedly connected to the bottom of the inner wallof the tank body; first motors are respectively and fixedly connected to two sides of the top of the fermenting tank; the output shaft end of each first motor in driving connection with a driving rotary disc through a gearbox and a belt; the surface of each driving rotary disc is in driving connection with a driven rotary disc through a conveying chain; a moving plate is rotationally connected toone side of the driving chain through rotating pins; a water cooling plate is fixedly connected to the bottom of the inner wall of the fermenting tank; an atomizer is fixedly connected between two opposite sides of the inner wall of the tank body; atomizing spray heads communicate to the water outlet ends of the atomizer through an atomizing pipe; and a heating device is fixedly connected to thetop of the inner wall of the fermenting tank. The invention relates to the technical field of food processing. The food fermenting device has the advantages that the problems of instable control overtemperature and poor exhaust in a traditional machine are solved, the fermenting quality is ensured, convenience in taking and putting is brought to workers, and the production efficiency is improved.

Owner:六安市胜缘食品有限公司

Production device capable of raising utilization rate of feed and production method thereof

ActiveCN109497598AFully dispersedImprove mixing uniformityBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyLiquid jet

The invention discloses a production device capable of raising utilization rate of a feed and a production method thereof. The production device comprises a fermentation platform, on which a fermentation tank is arranged. The opening of the fermentation tank is covered with a sealing cover plate, which is provided with a bar-shaped feeding hole. Two undersides of the sealing cover plate and the surface of the fermentation platform are slidingly connected. A storage splitting box is arranged above the opening of the fermentation tank. The bottom of the storage splitting box is connected with multiple discharge pipes, below which a fermented liquid jet ring is arranged. Jet pipes are uniformly distributed on the inner wall of the fermented liquid jet ring. A middle passing barrel is vertically connected to the opening above the bar-shaped feeding hole. A dispersing roller is horizontally arranged in the middle passing barrel. By the feed production device, the raw material and a bacteriasolution are mixed while feeding such that the bacteria solution can be fully dispersed in the raw material. The mixing uniformity of the bacteria solution and the raw material is increased. Meanwhile, the materials can be relatively sealed timely, inactivation of a strain in the bacteria solution is avoided, and the fermentation quality is guaranteed.

Owner:乐山恒峰华邦生物科技有限公司

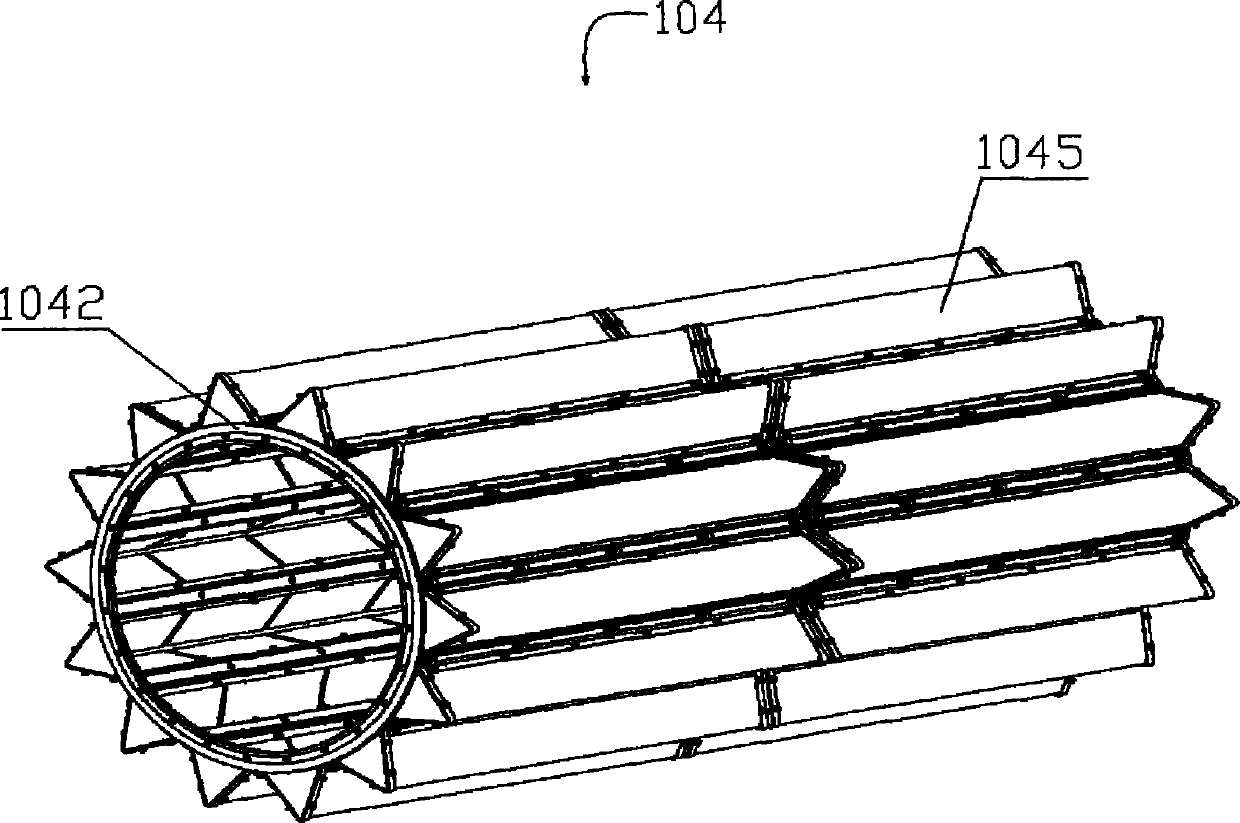

Micro-filter equipment for tertiary treatment of sewage

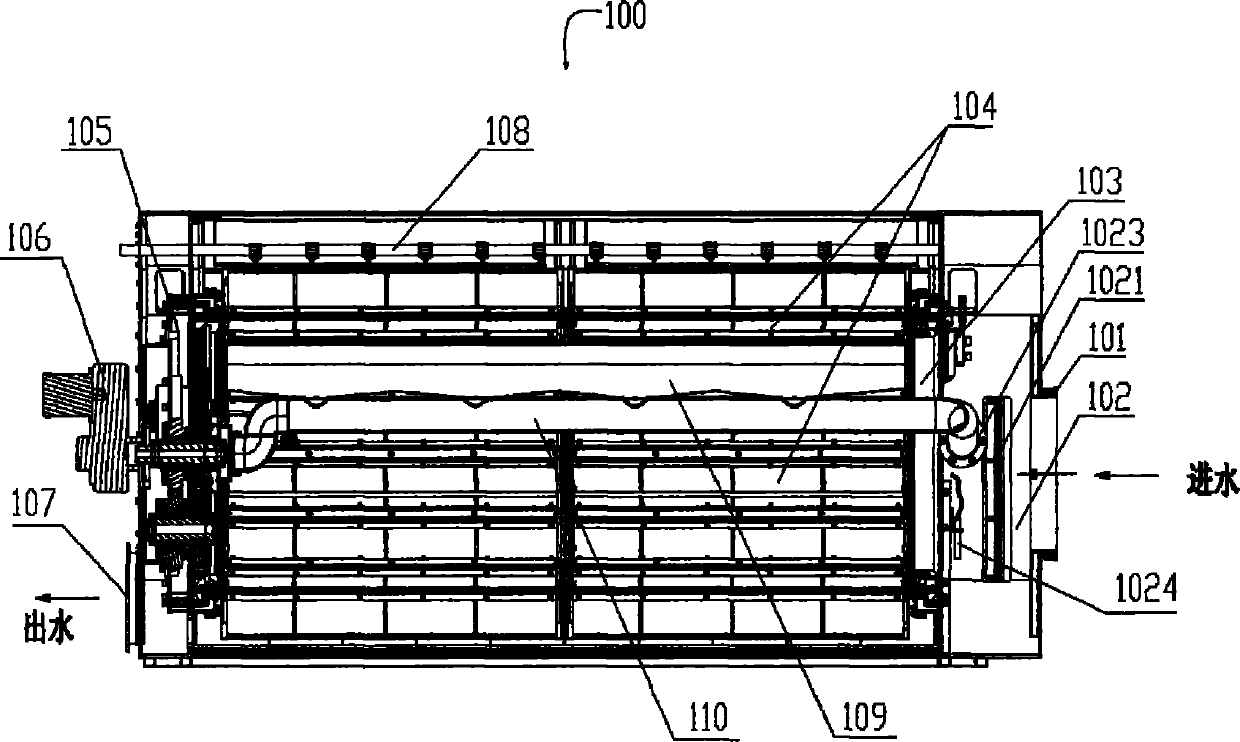

InactiveCN103127761AEasy to replace and overhaulGuaranteed Filtration QualityMoving filtering element filtersTriangular prismSewage

The invention discloses micro-filter equipment for tertiary treatment of sewage. The micro-filter equipment for the tertiary treatment of the sewage comprises a water inlet, an inlet-water buffer tank and a filter rotating drum connected with the inlet-water buffer tank, wherein the filter rotating drum comprises a cylindrical filter rotating drum frame body, a first rotating drum connecting tray, a second rotating drum connecting tray and a rotating drum middle connecting piece are respectively mounted at two ends and in the middle of the cylindrical filter rotating drum frame body, and the outer surface of the cylindrical filter rotating drum frame body is tightly connected with at least one triangular prism filter unit body through a sealing pressing part. According to the micro-filter equipment for the tertiary treatment of the sewage, the relative filter area of filter equipment is large, the standardization and universalization of maintenance and replacement of a filter are realized, the flow speed of a filter inlet is adjustable, and the driving life of the filter is long.

Owner:中和荣华环保科技(北京)有限公司

Method for producing dacron FDY (Fully Drawn Yarn) filaments in large scale by utilizing recycled PET (Poly Ethylene Terephthalate) bottle chips

ActiveCN102605455ASolve the problem of water content inconsistencyImprove stabilityFilament forming substance formingMonocomponent polyesters artificial filamentEngineeringBottle

The invention provides a method for producing dacron FDY (Fully Drawn Yarn) filaments in large scale by utilizing recycled PET (Poly Ethylene Terephthalate) bottle chips. The method comprises the following steps: crushing recycled PET bottles into chips; cleaning and then drying; feeding the chips into a crystallizing bed so as to crystallize, and then drying; pouring the dried bottle chips into a screw extruder for performing fusion extrusion; causing the filtered flux to enter into a homogenizing kettle and performing condensation polymerization for 1.4-1.5 hours, thereby homogenizing the flux in the homogenizing kettle; causing the homogenized flux to enter into a spinning box; and spinning according to a high-speed spinning technology, thereby obtaining the dacron FDY filaments. A homogenizing step is added in the producing method, so that the problems of big viscosity fluctuation and inferior stability of the flux of the PET bottle chips are solved, and the continuous and large-scale production of the FDY filament products by taking the recycled PET bottle chips as raw materials is realized.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

Method for producing dacron FDY (Fully Drawn Yarn) filaments in large scale by utilizing recycled PET (Poly Ethylene Terephthalate) bottle chips

ActiveCN102605455BSolve the problem of water content inconsistencyImprove stabilityFilament forming substance formingMonocomponent polyesters artificial filamentEngineeringBottle

The invention provides a method for producing dacron FDY (Fully Drawn Yarn) filaments in large scale by utilizing recycled PET (Poly Ethylene Terephthalate) bottle chips. The method comprises the following steps: crushing recycled PET bottles into chips; cleaning and then drying; feeding the chips into a crystallizing bed so as to crystallize, and then drying; pouring the dried bottle chips into a screw extruder for performing fusion extrusion; causing the filtered flux to enter into a homogenizing kettle and performing condensation polymerization for 1.4-1.5 hours, thereby homogenizing the flux in the homogenizing kettle; causing the homogenized flux to enter into a spinning box; and spinning according to a high-speed spinning technology, thereby obtaining the dacron FDY filaments. A homogenizing step is added in the producing method, so that the problems of big viscosity fluctuation and inferior stability of the flux of the PET bottle chips are solved, and the continuous and large-scale production of the FDY filament products by taking the recycled PET bottle chips as raw materials is realized.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

Liquid lubricating oil filtering device

ActiveCN101954206AImprove filtering effectEffective filteringSettling tanks feed/dischargeSedimentation settling tanksImpurityOil filter

The invention discloses a liquid lubricating oil filtering device. The filtering device comprises a filtering barrel body, a side face oil outlet joint, a first filter screen, an oil outlet elbow, a second filter screen, an oil outlet nozzle, an impurity deposition cone, a waste oil filter screen and a waste oil nozzle, wherein the impurity deposition cone is arranged at the lower end of the filtering barrel body; the side face oil outlet joint is arranged on the lower section side face of the filtering barrel body and positioned above the impurity deposition cone; the first and second filter screens are arranged in an oil outlet pipeline; and the waste oil filter screen is arranged in a waste oil outlet path. Impurity-containing liquid lubricating oil is deposited and filtered by the first and second filter screens and then flows out of the oil outlet nozzle, so that the liquid lubricating oil has low impurity content and can meet the requirement; impurities positioned in the impurity deposition cone can be conveniently discharged; and a pressurizing port is used for making pressure between a barrel cover and the filtering barrel body better facilitate filtering the liquid lubricating oil. The filtering device has the advantages of reasonable structure, difficult blocking of filter screen meshes, high filtering speed and guaranteed filtering quality.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Rapid flour kneading machine

InactiveCN106982879AIncrease elasticityUniform elasticityMixing/kneading structural elementsMixing/kneading with inclined rotationEngineeringMotor shaft

The invention relates to a fast flour kneading machine, comprising a basin body and a plurality of kneading noodle kneading devices arranged obliquely on the basin body; The kneading device in the body; the telescopic water inlet pipe facing the basin is arranged in the cylinder; the end of the telescopic water inlet pipe is a cylindrical self-rotating nozzle; the kneading device includes a stirring device that can be lifted and inserted into the basin along the cylinder and striking devices evenly distributed on the inner periphery of the cylinder; the striking devices include a plurality of striking rods facing the basin; one end of the striking rods facing the basin is provided with a hemispherical hammer, and the other end is hinged on the outer periphery of a turntable above; the turntable is driven and rotated by a first motor, and the shaft of the motor is set eccentrically on the turntable; the middle part of the striker is slidably set in a limit sleeve; the bottom of the basin is provided with an opening and closing port; the A fermentation device is arranged below the opening and closing opening.

Owner:林娜娜

Environment-friendly rubbish incineration device

InactiveCN107869720AEmission reductionGuaranteed living environmentIncinerator apparatusActivated carbonElectricity

The invention discloses an environment-friendly incineration device for rubbish, which comprises an incinerator, an air outlet pipe is fixedly connected to the gas outlet on one side of the incinerator, a casing is fixedly installed on one side of the top of the incinerator, and an electrical outlet is fixedly installed on the rear side of the casing. Chassis, the inside of the motor box is fixed with a rotating motor. One end of the rotating shaft of the rotating motor is connected to the main shaft through a coupling. One end of the main shaft extends to the inside of the housing and is fixedly connected with a circular plate. Both sides of the inner wall of the housing are fixed A slide rail is installed, one side of the slide rail is slidingly connected with a slider, and a movable rod is welded between the two sliders, and an electric push rod is welded on the other side of the movable rod, and one end of the electric push rod is fixedly connected with a cleaning brush , the other two sides on the inner wall of the shell are fixedly installed with a reset mechanism. The environment-friendly waste incineration device is provided with a rotating motor, a main shaft, a circular plate and a reset mechanism, so that the cleaning brush can automatically clean the activated carbon adsorption layer and the filter screen.

Owner:SHAOXING KEQIAO JINGLIANG MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com