Furfural residue biological organic fertilizer and preparation method thereof

A bio-organic fertilizer and furfural slag technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as hazardous waste management difficulties, achieve stable product quality, facilitate control, and increase the effect of total nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

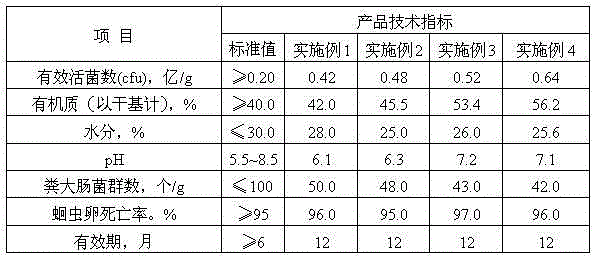

Examples

Embodiment 1

[0043] 1) Take fresh chicken manure for steam sterilization;

[0044] 2) Dry the sterilized chicken manure until the water content is 20%;

[0045] 3) crushing the dried chicken manure to obtain chicken manure treatment;

[0046] 4) Take the streptomycin residue and add methanol for extraction, wherein the volume ratio of methanol and streptomycin residue is 3:1, and extract for 24 hours;

[0047] 5) Filter the mixture obtained in step 4) through a plate frame, and discard the filtrate;

[0048] 6) Repeat three times to collect the filter residue;

[0049] 7) Rinse the filter residue with distilled water, and plate-and-frame filter to obtain a preliminary treatment of streptomycin residue, wherein the volume ratio of distilled water to filter residue is 5:1;

[0050] 8) Drying and pulverizing the preliminary treatment of streptomycin residue obtained in step 7) to obtain the treatment of streptomycin residue;

[0051] 9) Put 50kg of furfural residue into the fermentation t...

Embodiment 2

[0058] 1) Take fresh chicken manure for steam sterilization;

[0059] 2) Dry the sterilized chicken manure until the water content is 25%;

[0060] 3) crushing the dried chicken manure to obtain chicken manure treatment;

[0061] 4) Take the streptomycin residue and add methanol for extraction, wherein the volume ratio of methanol and streptomycin residue is 3:1, and extract for 24 hours;

[0062] 5) Filter the mixture obtained in step 4) through a plate frame, and discard the filtrate;

[0063]6) Repeat three times to collect the filter residue;

[0064] 7) Rinse the filter residue with distilled water, and plate-and-frame filter to obtain a preliminary treatment of streptomycin residue, wherein the volume ratio of distilled water to filter residue is 10:1;

[0065] 8) Drying and pulverizing the preliminary treatment of streptomycin residue obtained in step 7) to obtain the treatment of streptomycin residue;

[0066] 9) Put 55kg of furfural residue into the fermentation t...

Embodiment 3

[0073] 1) Take fresh chicken manure for steam sterilization;

[0074] 2) Dry the sterilized chicken manure until the water content is 30%;

[0075] 3) crushing the dried chicken manure to obtain chicken manure treatment;

[0076] 4) Take the streptomycin residue and add methanol for extraction, wherein the volume ratio of methanol and streptomycin residue is 3:1, and extract for 24 hours;

[0077] 5) Filter the mixture obtained in step 4) through a plate frame, and discard the filtrate;

[0078] 6) Repeat three times to collect the filter residue;

[0079] 7) Rinse the filter residue with distilled water, and plate-and-frame filter to obtain a preliminary treatment of streptomycin residue, wherein the volume ratio of distilled water to filter residue is 8:1;

[0080] 8) Drying and pulverizing the preliminary treatment of streptomycin residue obtained in step 7) to obtain the treatment of streptomycin residue;

[0081] 9) Put 53kg of furfural residue into the fermentation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com