Method for producing terylene POY filament in scale by recycling PET bottle sheet material

A technology for bottle flakes and polyester, which is applied in filament forming treatment, single-component polyester artificial filament, melt spinning, etc., and can solve problems such as bridging, good filtering effect, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is further described below.

[0009] The polyester POY filaments are polyester pre-oriented filaments.

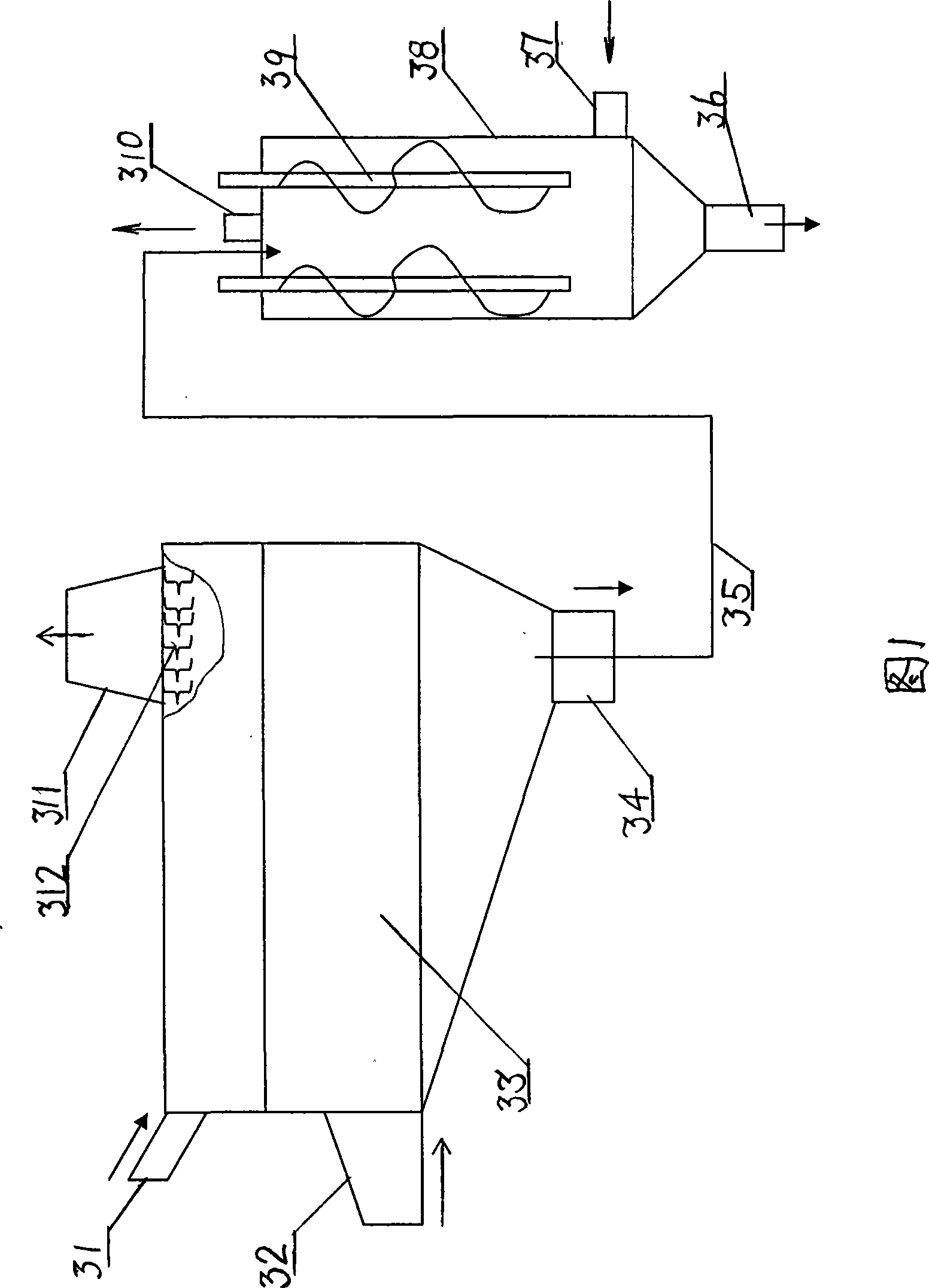

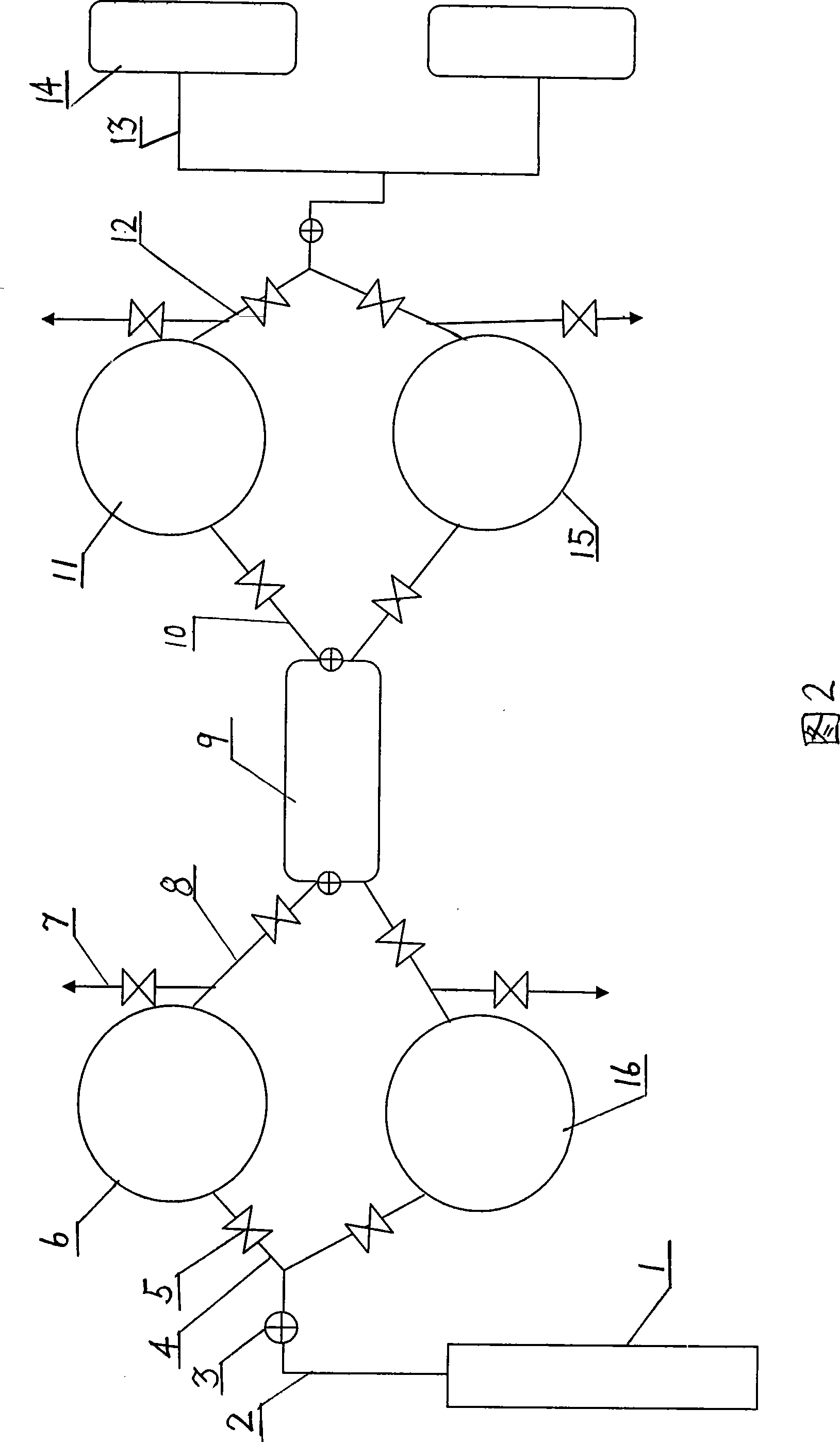

[0010] The bottle flakes are sent into the crystallization bed, and under the action of the hot air entering the crystallization bed, the crystallization temperature is 170-175°C during crystallization. When sent to the drying tower for drying, the drying temperature is 165-168°C. When the dried bottle flakes enter the screw extruder for melt extrusion, the temperature in the cooling zone of the screw extruder is ≤50°C, and the temperature in the first zone to the sixth zone is 278-289°C, increasing zone by zone. When the obtained melt is sent to a two-stage filter device consisting of a coarse filter, a fine filter and a booster pump between the two for filtration, the filtration accuracy of the coarse filter is 50 μm, and the filtration accuracy of the fine filter is 30μm, coarse filtration first, and then fine filtration. The temperature w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com