Patents

Literature

52results about How to "High mesh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing terylene POY filament in scale by recycling PET bottle sheet material

ActiveCN101435113ASolve the problem of water content inconsistencyHigh meshSolid waste disposalMelt spinning methodsEngineeringBottle

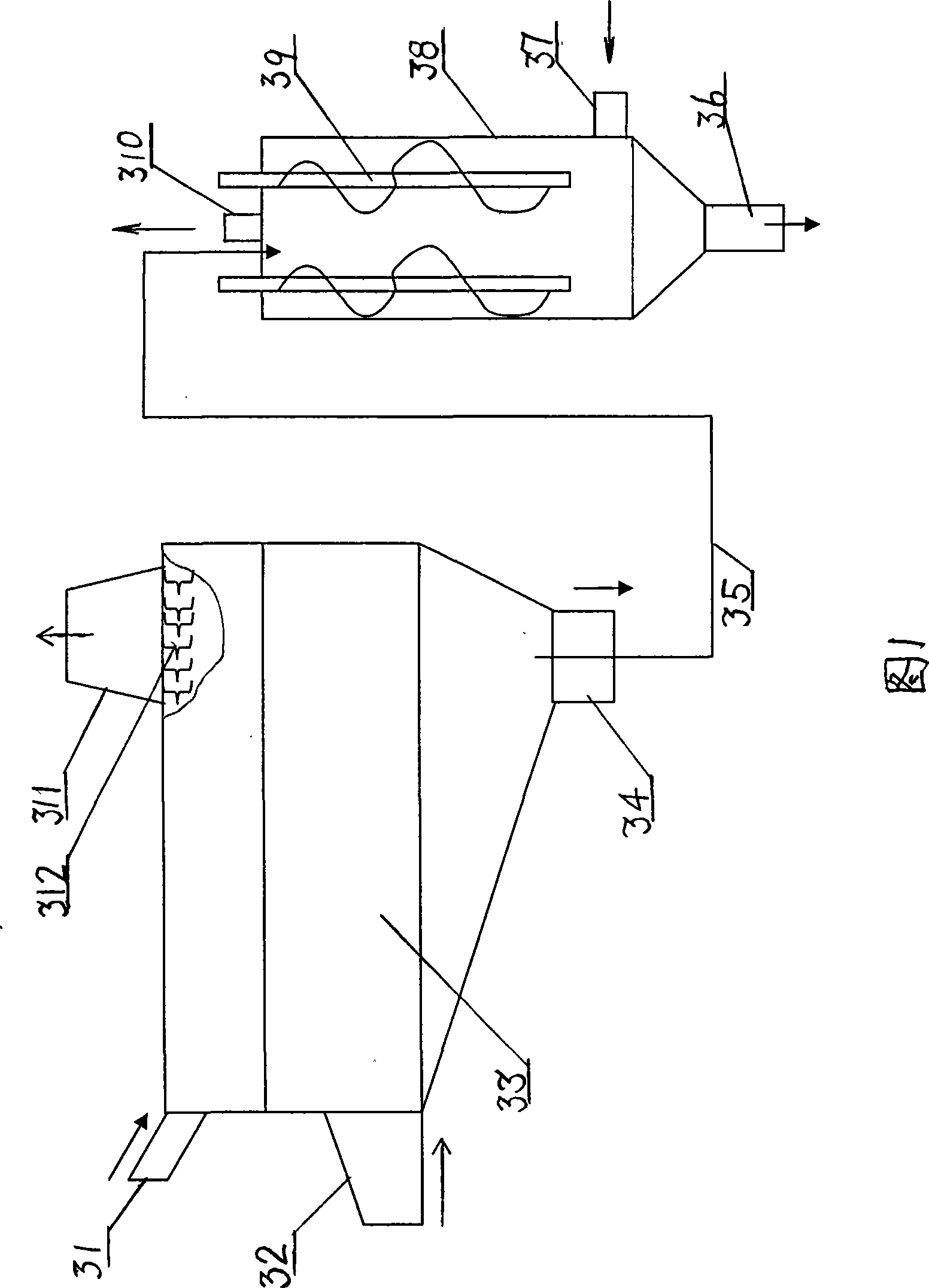

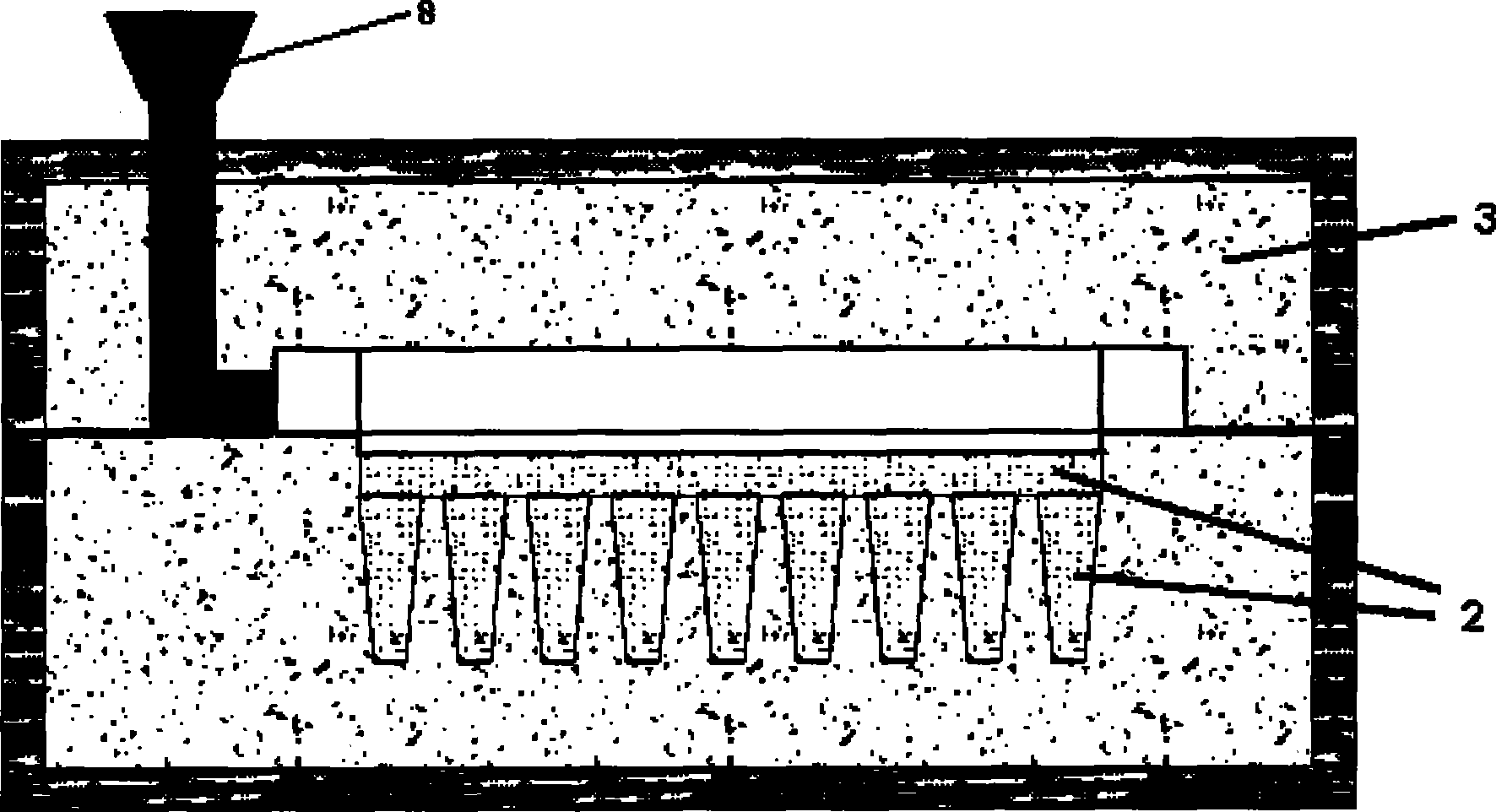

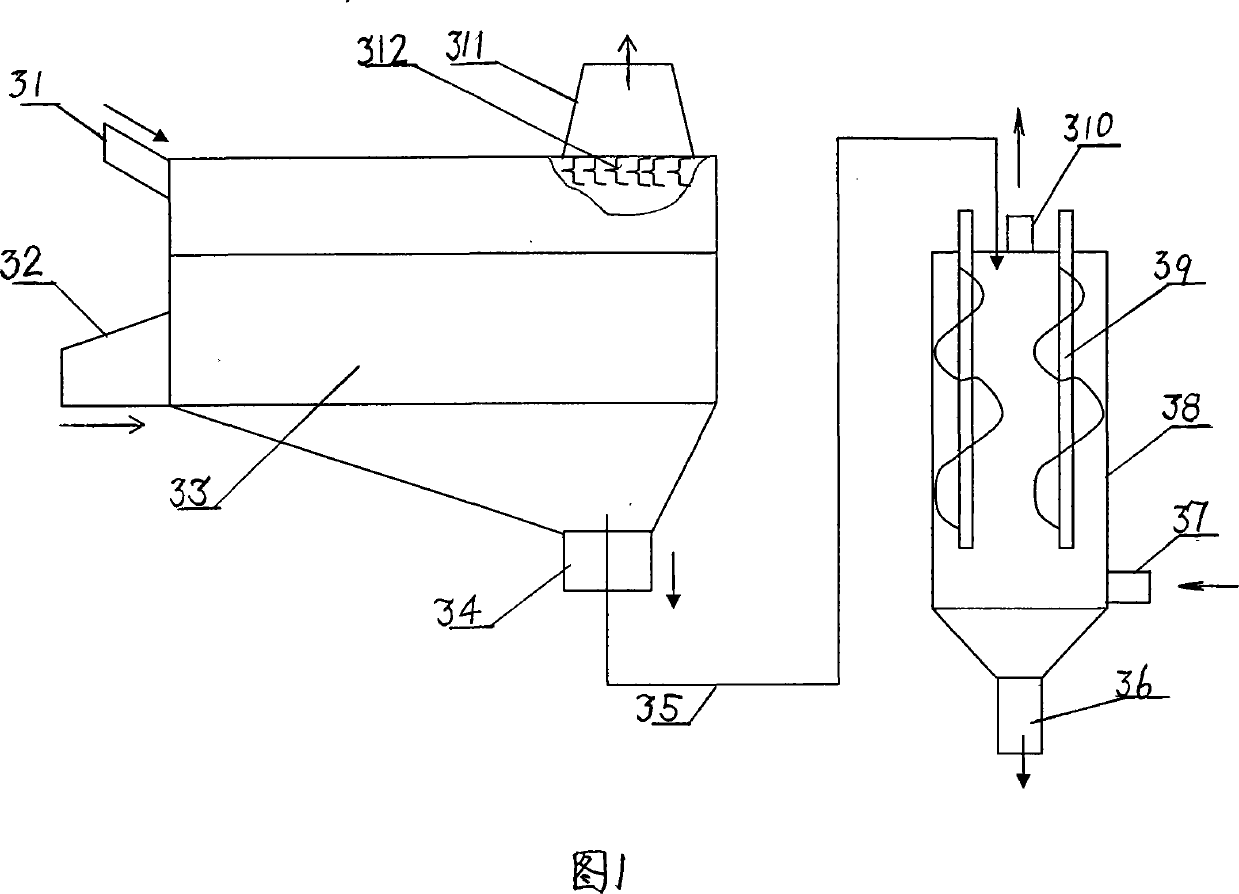

The invention provides a method for producing polyester POY filament in scale by recycling PET bottle chip. Recycled waste PET bottles are crushed into flaky bottle chip, dried after cleaning, and then sent into a crystallizing bed body; under the action of hot air entering the crystallizing bed body, crystallization is carried out, a crystallizing layer is formed on the bottle chip surface, and then the bottle chip is sent into a drying tower for drying; the dried bottle chip enters a screw extruder for melt extrusion, and the obtained melt is sent into a two-stage filtering device for filtering and then enters a spinning box; and a high-speed spinning process is adopted for spinning to produce the polyester POY filament. The method for producing the polyester POY filament adopts a filling type drying mode, the drying is even and the operating cost is low; a screw mixer is arranged in the drying tower, which solves the problem of 'arching' that happens to the recycled PET bottle chip during the drying process; and the two-stage filtering device is adopted, which ensures the filtering quality. Therefore, the high-end product-polyester POY filament can be continuously produced in large scale.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

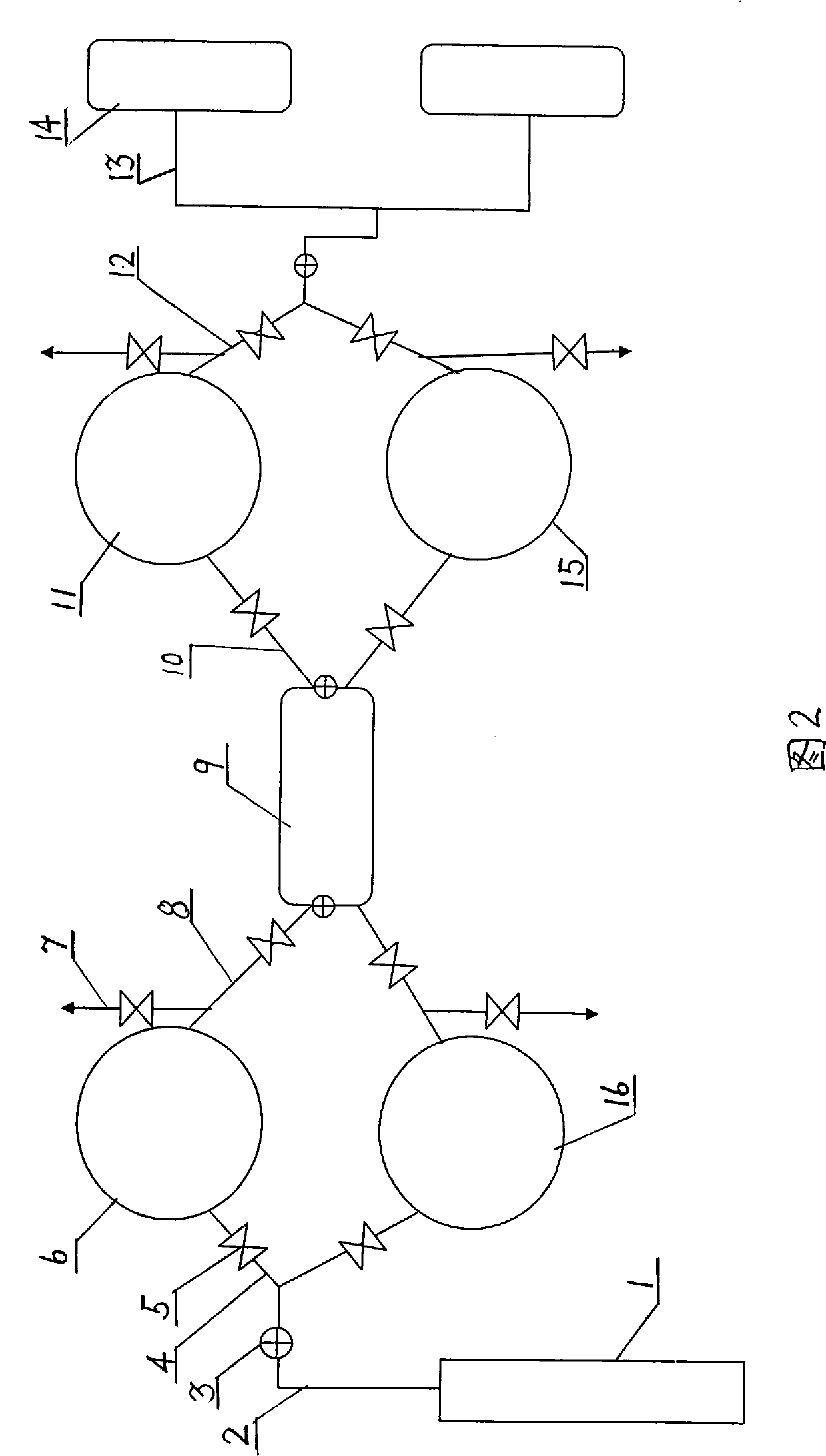

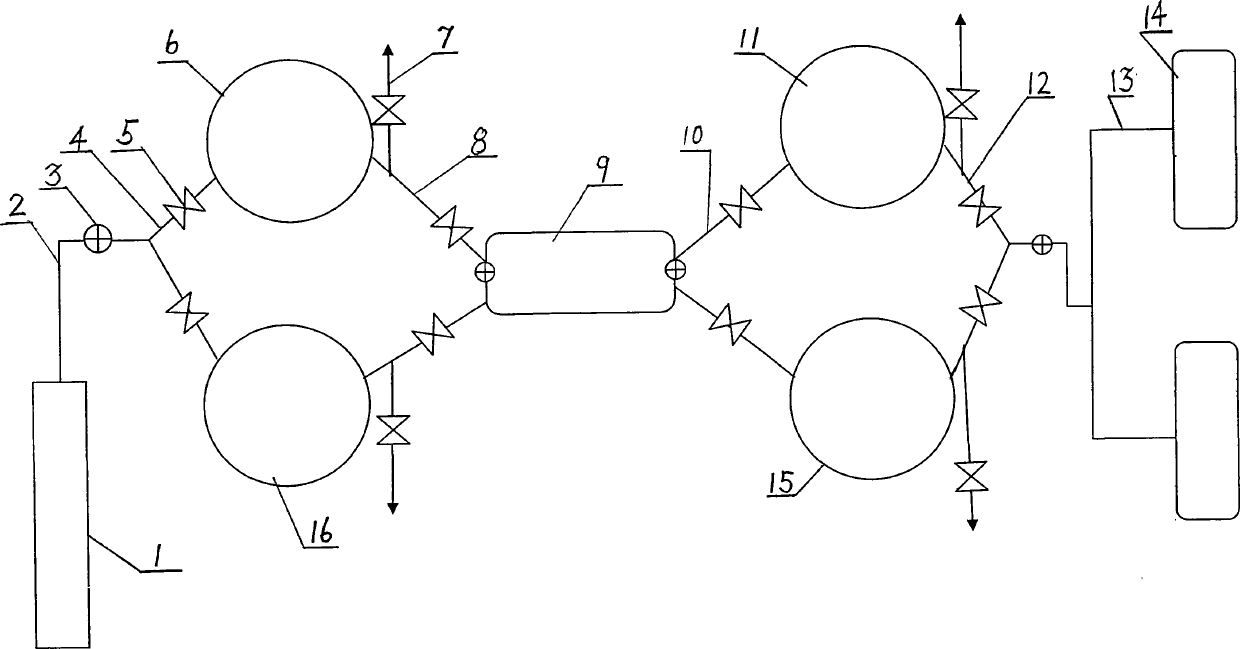

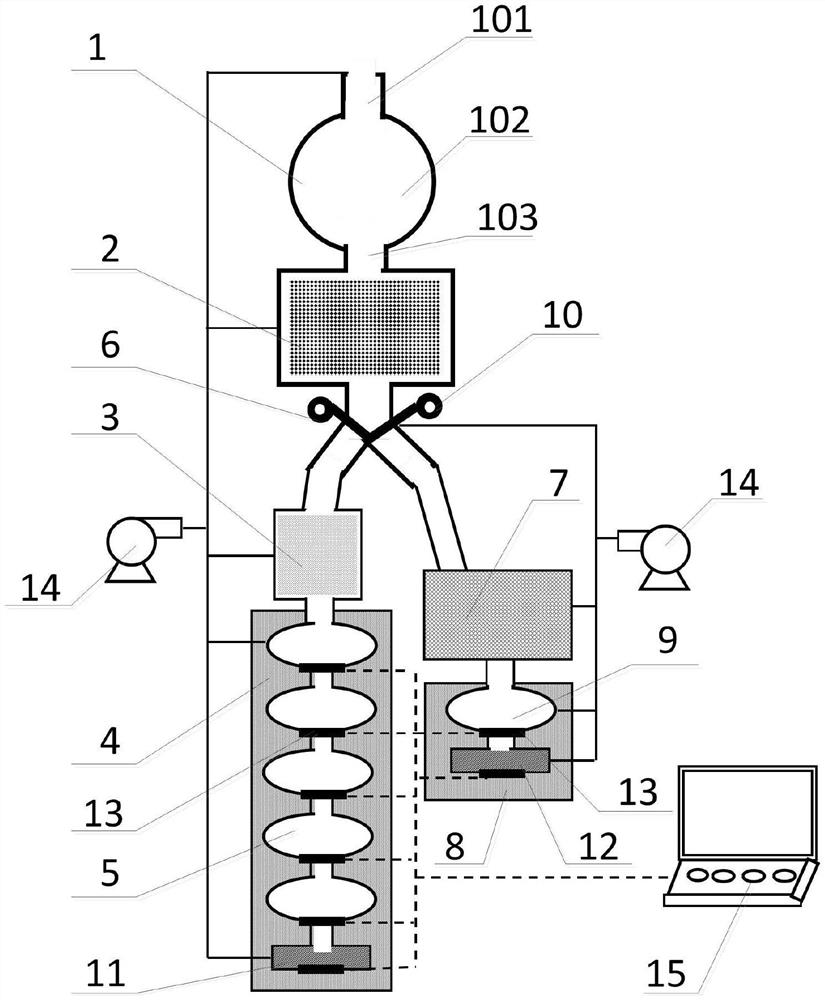

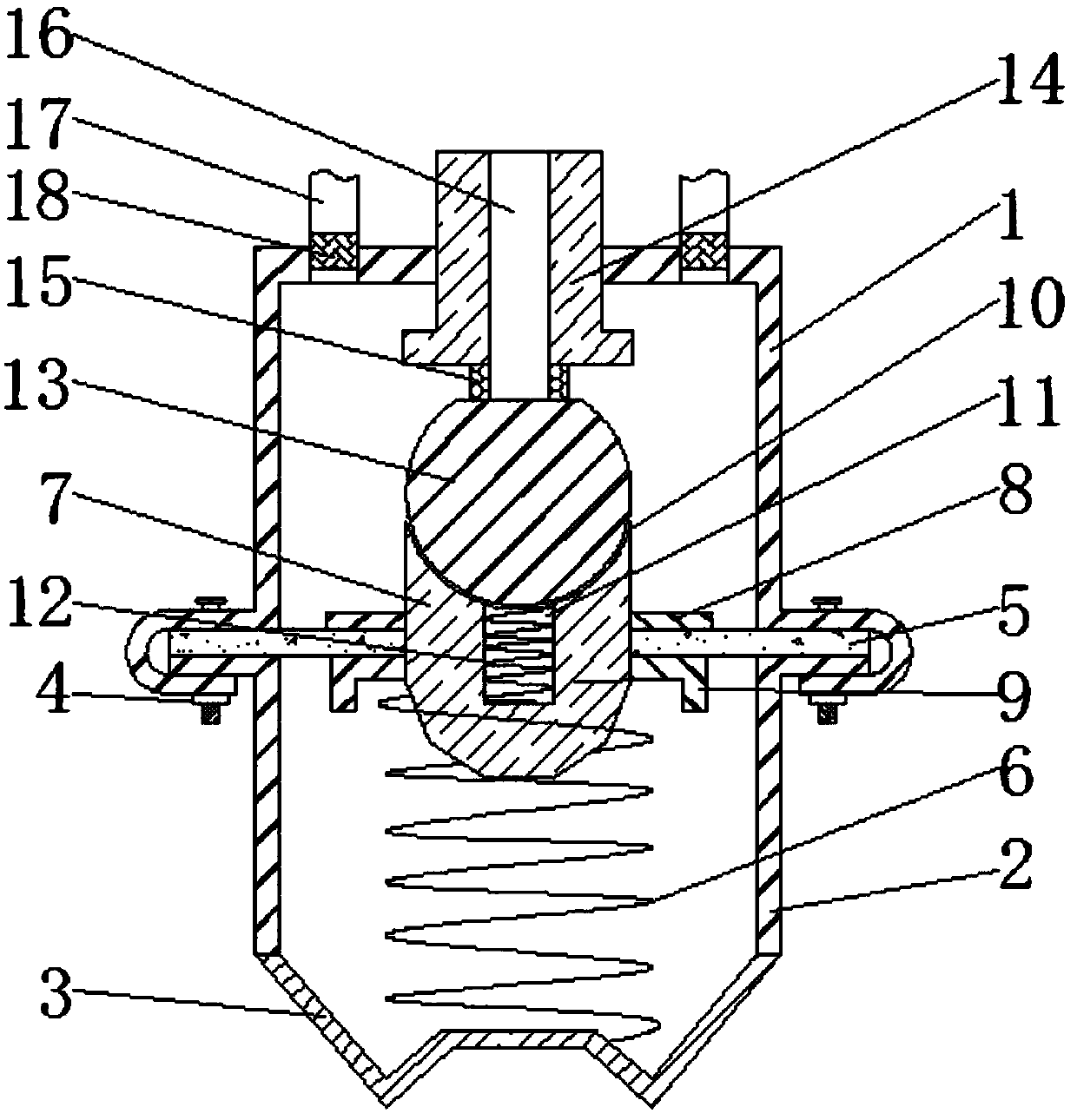

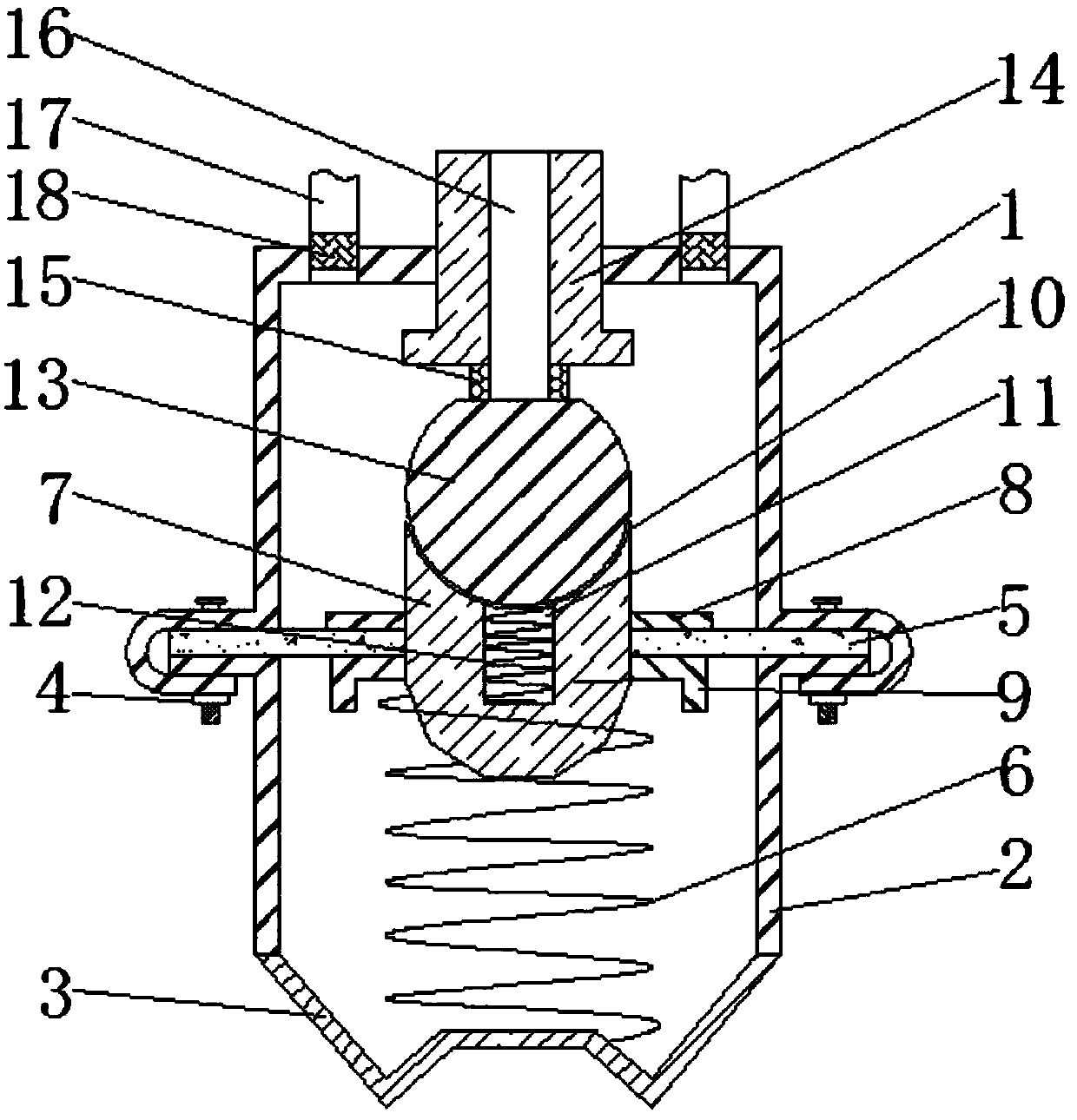

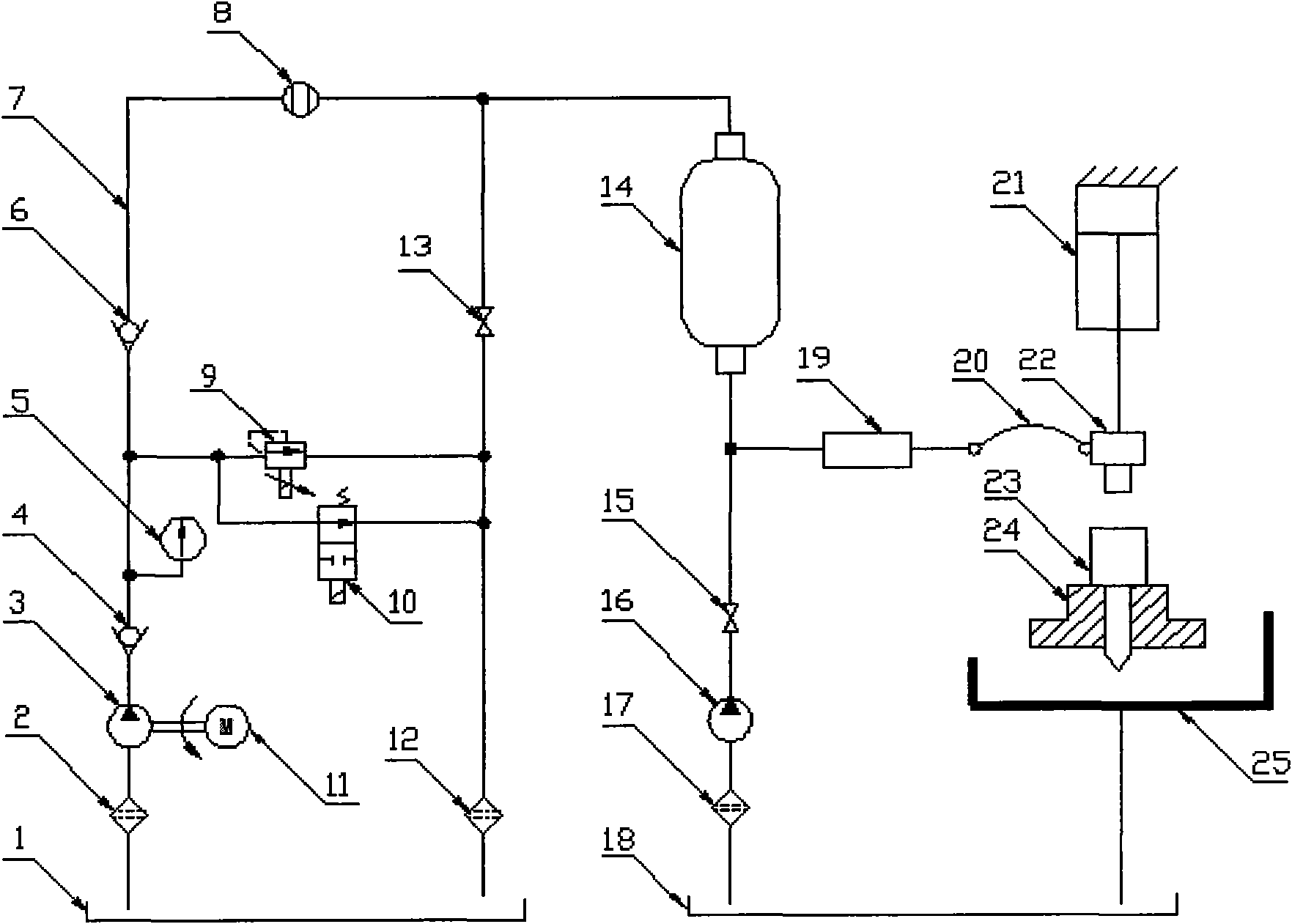

Equipment for processing abrasive slurry water-jet microporous nozzle internal runner and method for detecting and controlling real-time flux

InactiveCN101564831AIncrease the flow rate coefficientTraffic real-time detectionAbrasive feedersRelative volume flow measurementsControl signalFuel tank

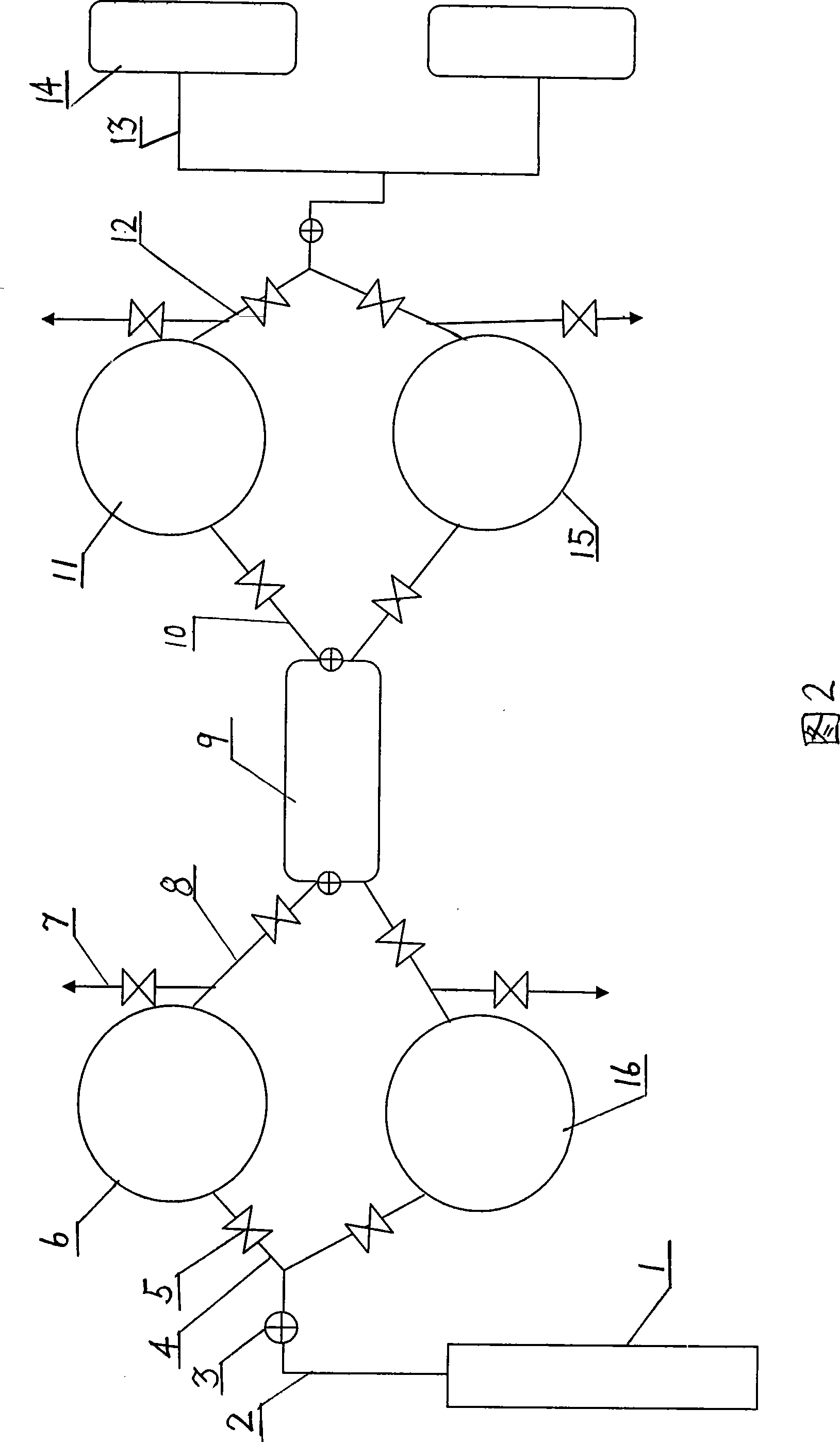

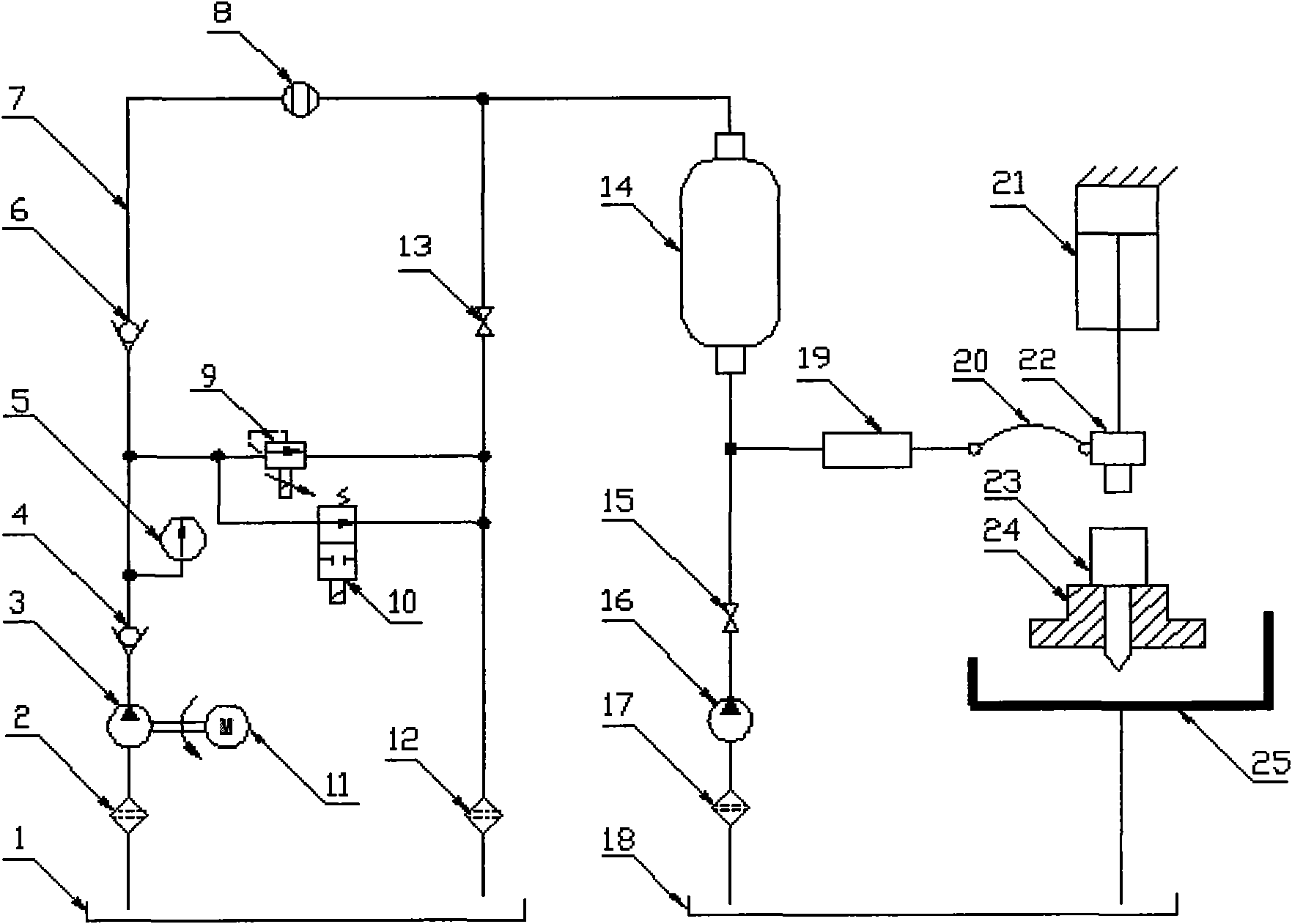

The invention relates to an equipment for processing abrasive slurry water-jet microporous nozzle internal runner and a method for detecting and controlling real-time flux. The equipment comprises an oil tank, a slurry box and a high-pressure material tank; a high-pressure pipeline and an oil returning pipeline are communicated with the oil inlet of the high-pressure material tank and the oil tank; a material inlet pipe and a material supply pipe are communicated with the material inlet of the high-pressure material tank and the slurry box; the oil inlet of the high-pressure material tank is provided with a high-precision flowmeter; a processed microporous nozzle is communicated with a material supply interface; the inlet of the material supply joint is provided with a check valve; the material supply joint is arranged on a clamping device; the real-time oil inlet quantity of the high-pressure material tank, namely the real-time flux of the processing microporous nozzle, is measured by the high-precision flowmeter; the real-time slurry flux detection data is input to a controller; when the slurry flux reaches a given value, the controller outputs a control signal to close the check valve, thus stop processing. The equipment has high grinding efficiency and high precision.

Owner:SHANGHAI UNIV +2

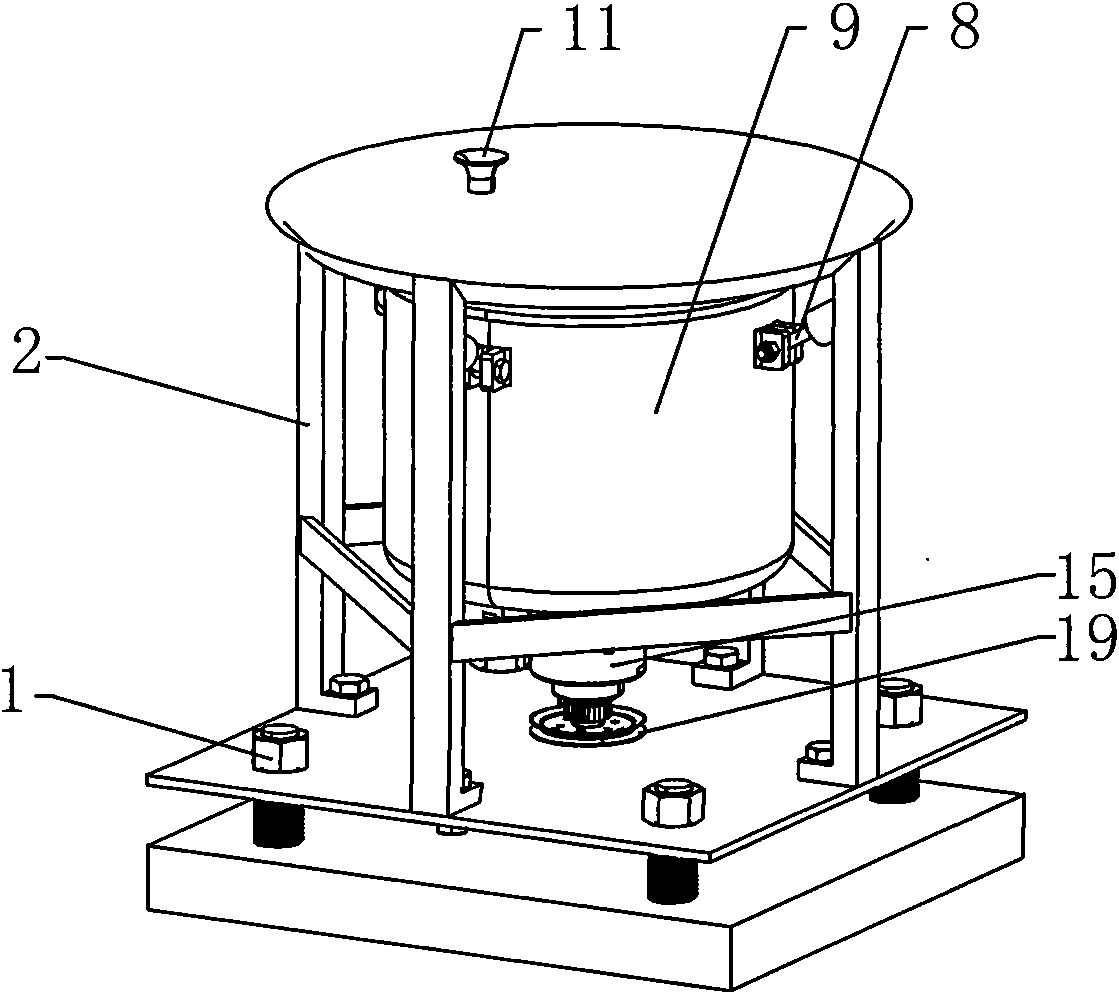

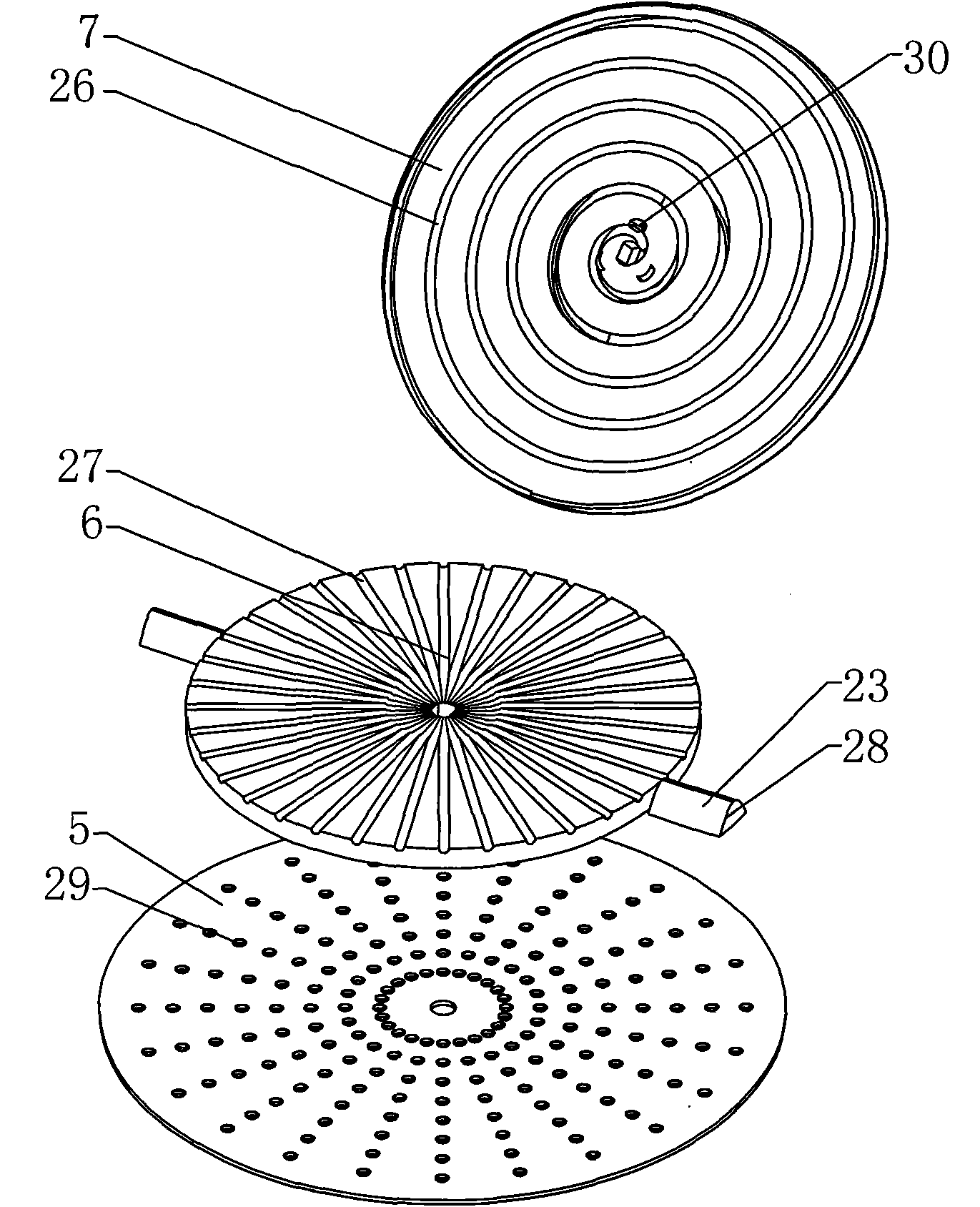

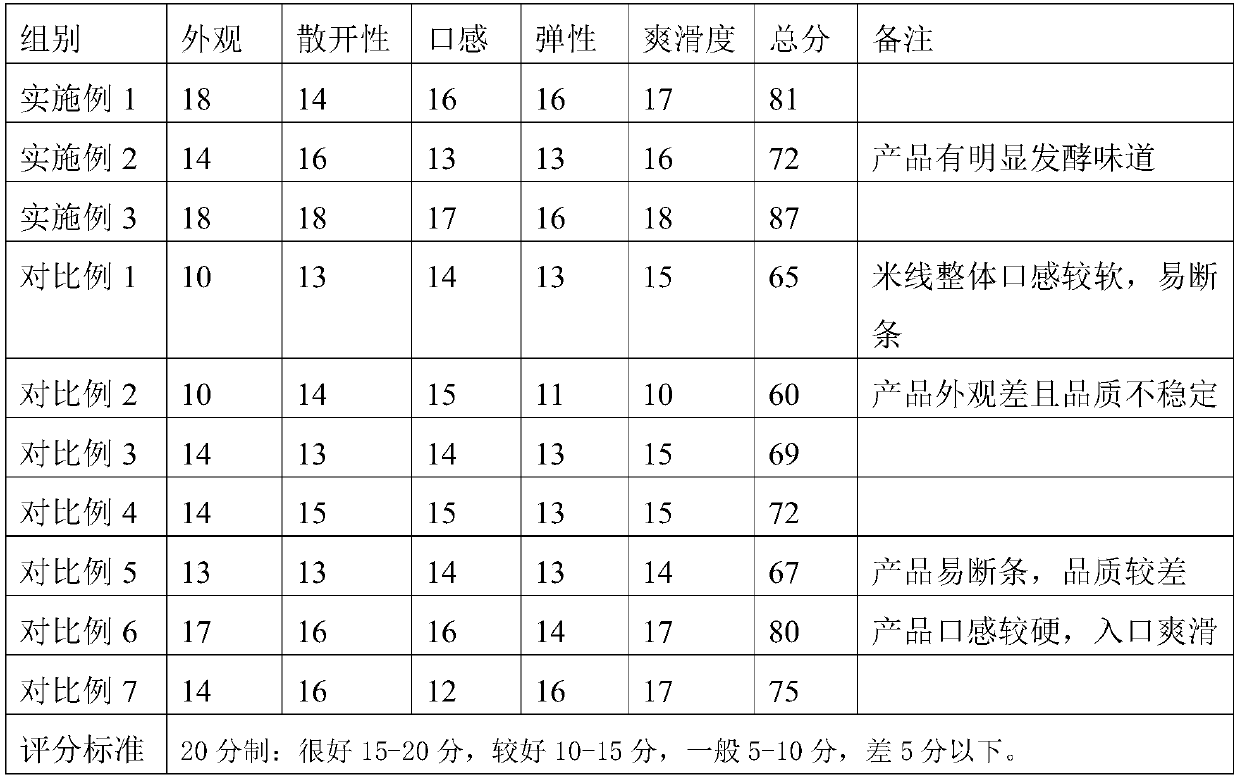

All-in-one machine for crushing, stirring and screening

InactiveCN101829626AMaintain pharmacological propertiesEfficient and uniform crushingCocoaGrain treatmentsLow speedEngineering

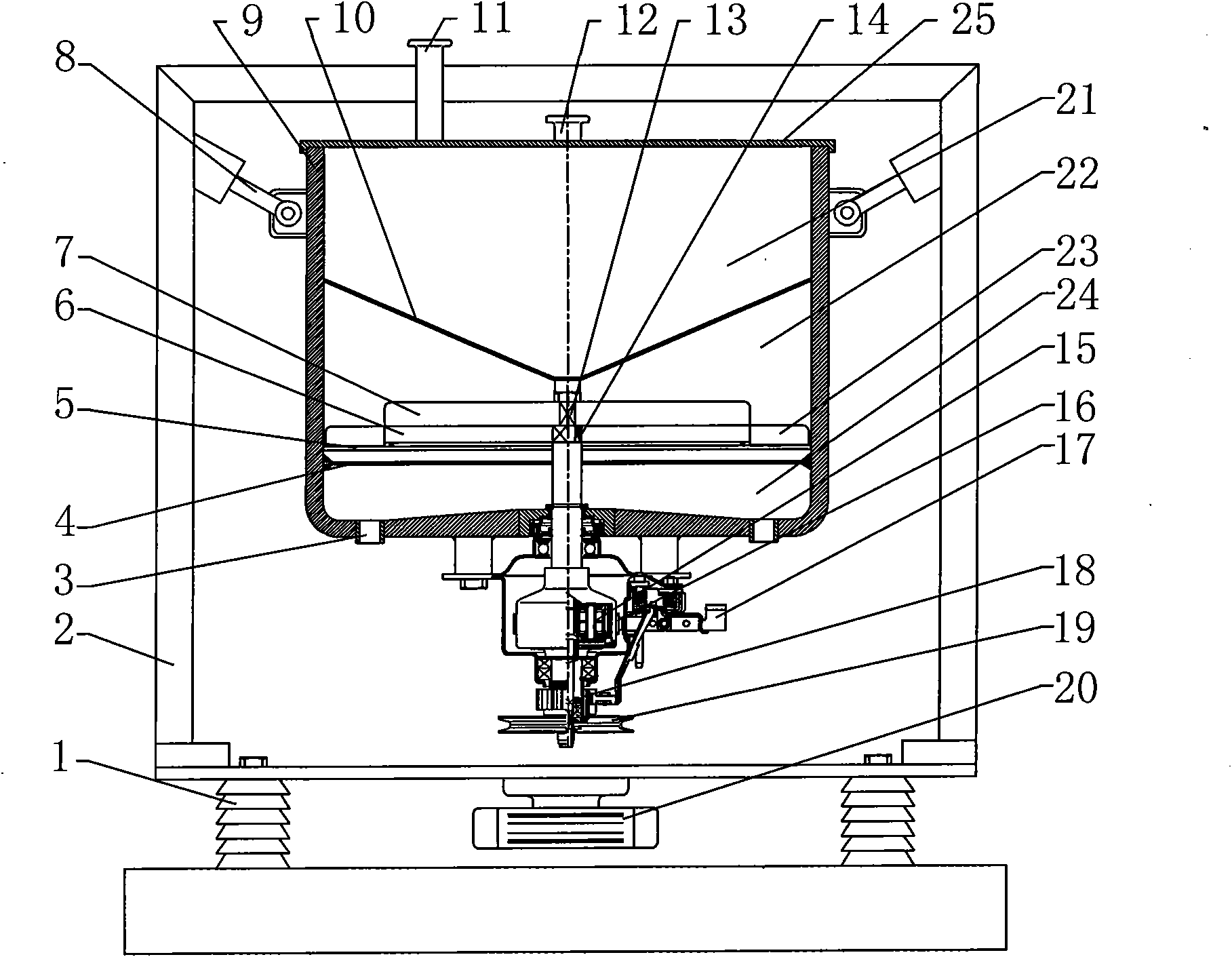

The invention relates to an all-in-one machine for crushing, stirring and screening. A cylinder is hung on a vibration platform, and the inside of the cylinder is partitioned into a feeding chamber, a crushing chamber and a storage chamber. The crushing chamber is internally provided with a crushing disk and a stirring disk which are stacked up, and the outer edge of the stirring disk is provided with a stirring arm. A shifting clutch assembly is fixed at the bottom of the cylinder, the low-speed shaft end of the shifting clutch assembly is connected to the crushing disk, and the high-speed shaft end of the shifting clutch assembly is connected to the stirring disk. In the invention, traditional Chinese medicine materials are crushed, stirred and screened effectively in single equipment with high quality, and safety and sanitation are ensured, thereby the requirement of large-scale and industrial production is satisfied.

Owner:JIANGNAN UNIV

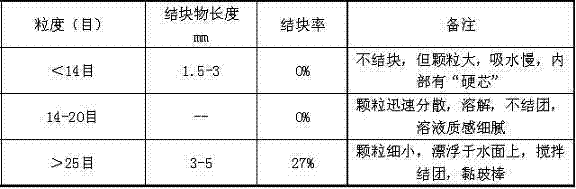

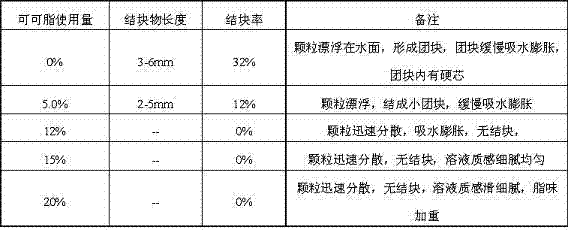

Mixed product comprising beta-glucan and preparation method of mixed product

ActiveCN102919964AUnited will notImprove function and effectFood preparationBiotechnologyButter cocoa

The invention relates to a mixed product comprising beta-glucan, which is prepared by the following raw materials in ratio by weight: 7.5-80% of beta-glucan, 6-20% of cocoa butter, 0-30% of supermicro carrot powder, 0-30% of supermicro highland barley, and 0-40% of erythritol. Meanwhile, the invention further discloses a preparation method of the product. In the mixed product, beta-glucan can be quickly dissolved in daily drinking water. The mixed product has a certain healthcare effect, is convenient to have and good in taste, and can meet the recommended dose of beta-glucan to reach the health keeping effect.

Owner:TIBET TIANMAILI HEALTH PROD CO LTD

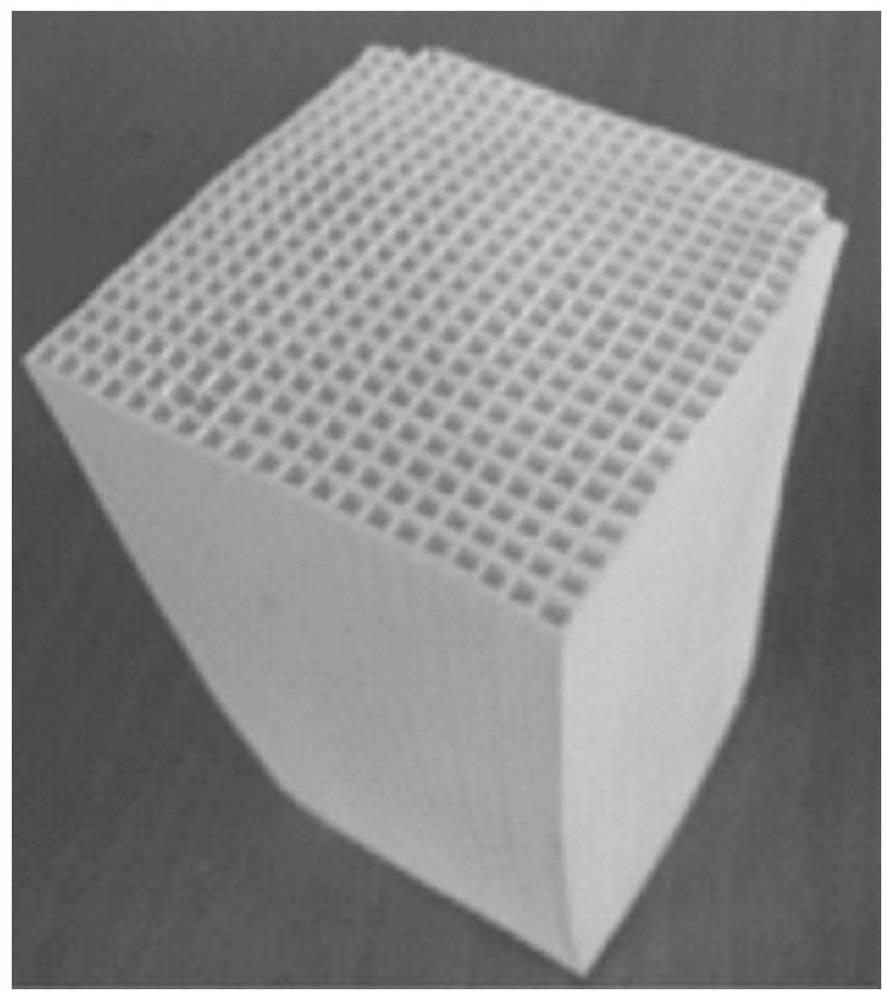

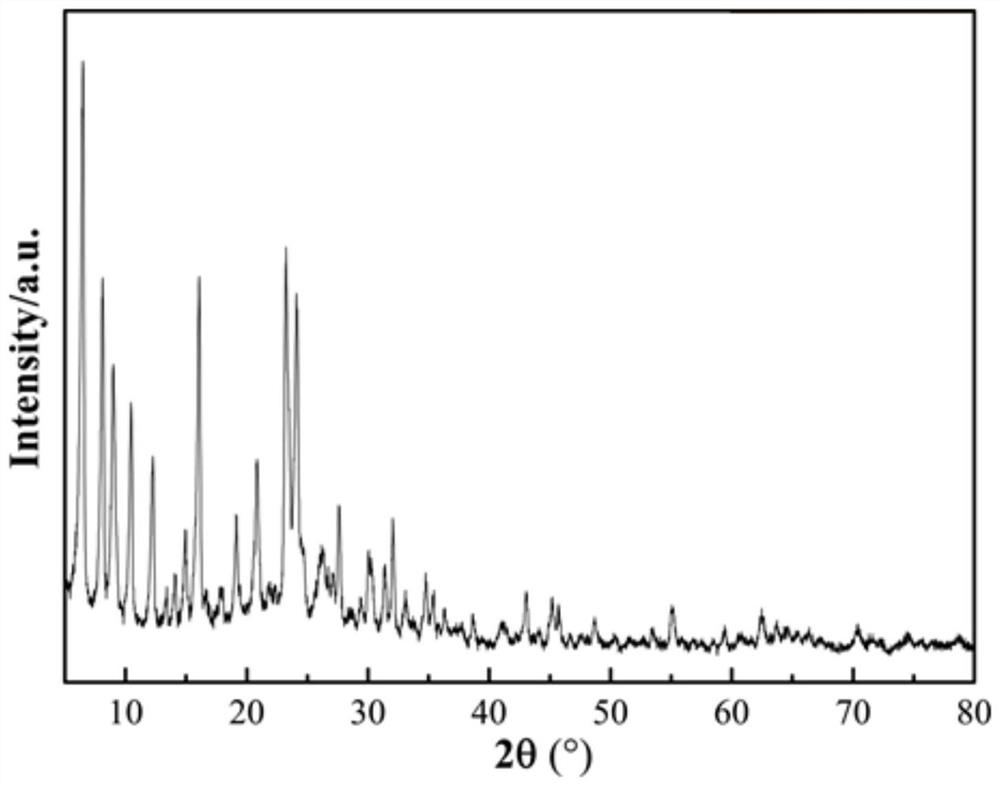

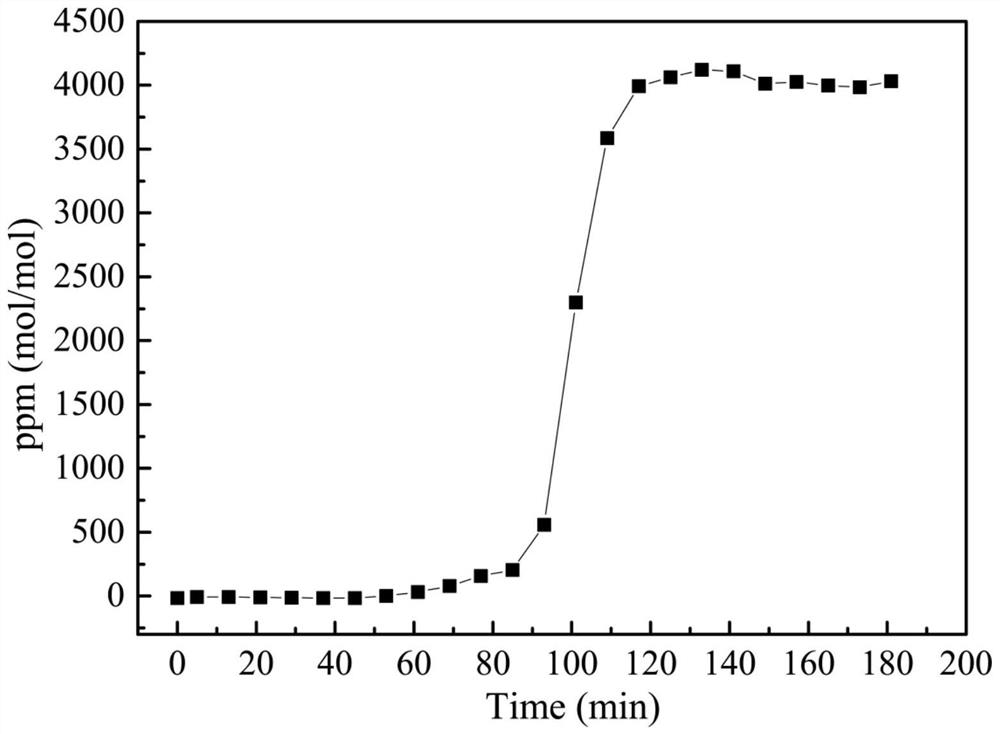

Integral honeycomb molecular sieve for purifying VOCs in zeolite adsorption runner and preparation

PendingCN112246217AGood removal effectImprove adsorption capacityGas treatmentOther chemical processesMolecular sievePlasticizer

The invention relates to an integral honeycomb molecular sieve for purifying VOCs in zeolite adsorption runner and preparation, the preparation method comprises the following steps: 1) powder pre-granulation: mixing a molecular sieve, an inorganic filler, an inorganic binder A and water to prepare slurry, and then carrying out granulation and high-temperature roasting to obtain particle powder; 2)mixing and pugging: uniformly mixing the particle powder, an inorganic reinforcing agent, an organic binder, a pore-forming agent, a plasticizer and a dispersing agent, adding a lubricant, an inorganic binder B and water, and kneading and pugging to obtain pug; and 3) extrusion molding and high-temperature roasting: carrying out vacuum extrusion molding on the pug, and then carrying out drying and high-temperature roasting. Compared with the prior art, the integral honeycomb molecular sieve with the pore density of more than or equal to 300 meshes and the wall thickness of less than or equalto 0.25 mm, which is suitable for purifying VOCs in a zeolite adsorption rotating wheel, is prepared, and when the integral honeycomb molecular sieve is applied to purification of low-concentration VOCs-containing waste gas, the filling volume is small, the adsorption rate and the desorption rate are high, and the thermal regeneration temperature is low.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Solid material grinding method and solid material grinding machine

The invention relates to a solid material grinding method and a grinding machine. Solid materials enter a grinding body of a grinding room after being subjected to primary air classification, and are thrown onto a lining plate along the radial direction to be broken due to collision under the centrifugal effect of the grinding body in high-speed rotation; after rebounding from the lining plate, the broken materials oppositely collide newly-added materials to be broken; large-particle materials drop under the gravity effect and upwards enter a working cabin through a guide pipe after being subjected to high-speed hammering; the working bin has the functions of feeding and wind mixing elutriation; the materials subjected to wind mixing elutriation enter a classifier to be classified; finished material products achieving the granularity requirements are collected by a spiral collector and a bag-type dust remover and then are discharged from a finished product discharging device; and materials not achieving the granularity requirements are returned to the grinding room to be reground. The grinding machine has the beneficial effects that the grinding granularity is small, the grinding efficiency is high, the fine powder collecting effect is good, the equipment is compact in structure, the maintenance cost is low, powder bodies with the granularity in a range of 80-1,500 meshes can be produced, and the grinding machine has the advantages of high yield ad stable quality particularly when producing ultrafine powder with the granularity being greater than 800 meshes and materials with higher rigidity.

Owner:蔡昌荣

Cactus powder and method for preparing same

The present invention discloses a cactus powder and its preparation method. It is characterized by that said cactus powder is made up by using Mexican mibangta edible cactus, its grain size is powder with 80-100 meshes. Its preparation method includes the following steps: cleaning raw material edible cactus, slicing, drying by airing, vacuum moisture-absorbing drying or low-temp. drying by airing at 25 deg.C-28 deg.C, and pulvering to make its grain size be reached to 80-100 meshes. The invented product can be added to food, and can be made into various health-care foods with the functions of supplementing spleen, for tifying stomach, raising immunity of human body and prolonging life, etc.

Owner:TAIFENG PLANTING & CULTIVATION SCI & TECH YANTAI CITY

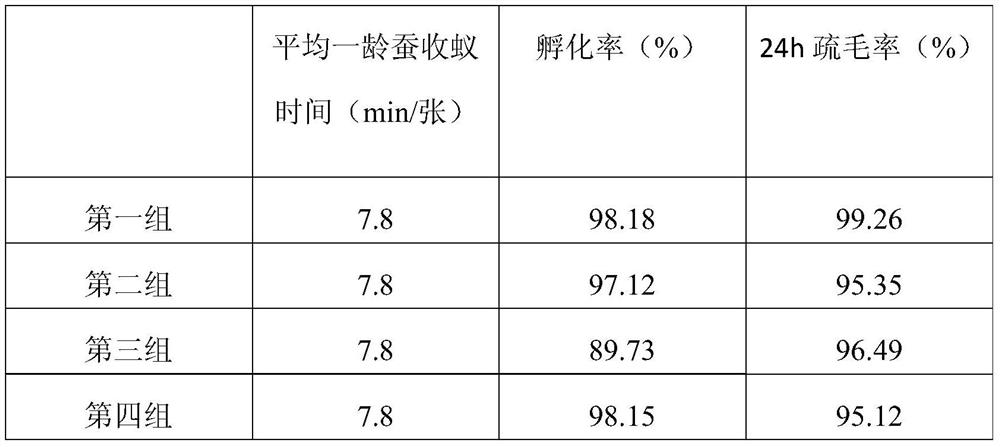

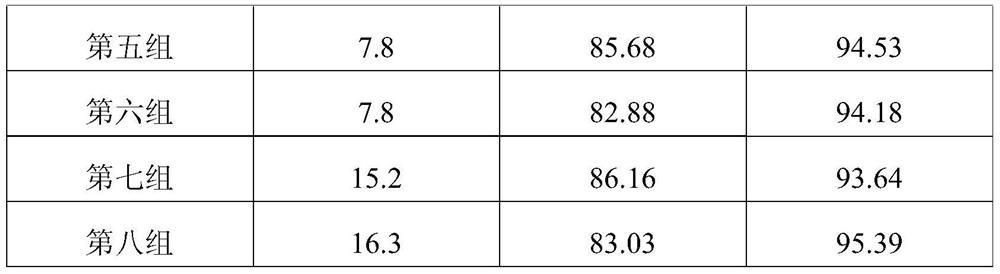

Simple newly-hatched silkworm brushing off method for silkworm artificial feed breeding

ActiveCN112273339AAnt fastAvoid damageAnimal feeding stuffAccessory food factorsAnimal scienceFishery

The invention relates to the technical field of home textiles, in particular to a simple newly-hatched silkworm brushing off method for silkworm artificial feed breeding. The simple newly-hatched silkworm brushing off method for silkworm artificial feed breeding comprises the following steps of (1) silkworm egg incubation; (2) silkworm egg scattering and disinfecting; (3) egg amount weighing and zoning; (4) feed treatment; (5), light sensing for newly-hatched silkworm brushing off; and (6) light supplementing and temperatuer rising. On the basis of feed breeding, starting from each technical link of newly-hatched silkworm brushing off according to physiological development characteristics of silkworms, by combining manners of optimizing temperature and humidity control, feed pretreatment,light supplement and temperature supplement in each stage of loose egg incubation, directly scattering loose eggs on the feed during artificial feed breeding, irradiating with an LED yellow warm lightlamp and the like, the method achieves the effects of one-time quick, labor-saving and efficient newly-hatched silkworm brushing off, is suitable for mechanical newly-hatched silkworm brushing off, and provides technical support for large-scale young silkworm artificial feed breeding.

Owner:来宾市农业科学院

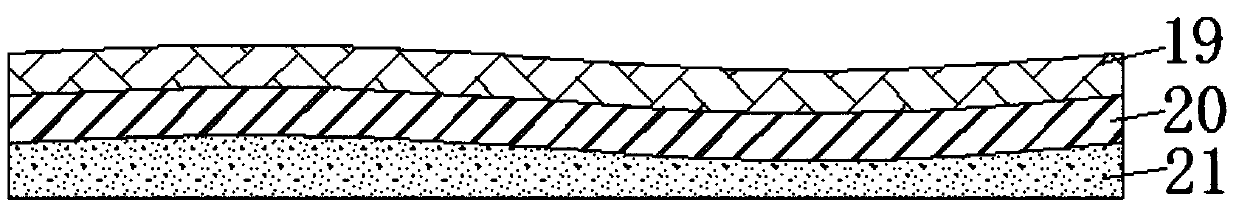

Method for producing radiation-proof multifunctional casual blanket

InactiveCN101851824AGood radiation protection functionGood comfortWoven fabricsYarnWeather resistanceWool

The invention discloses a method for producing a radiation-proof multifunctional casual blanket. The method for producing the radiation-proof multifunctional casual blanket comprises the steps of material proportioning preparation, spinning, weaving and after finishing of a product and is characterized in that the radiation-proof multifunctional casual blanket adopts a double-layer structure; a surface layer is silk, wool, cotton or bamboo fibers; an inner layer is formed from blending metal fibers with cotton; the diameter of the metal fibers is between 6.5 and 7mum; the blending ratio of the metal fibers with the length of 40 to 50mm to the cotton is 30 percent of metal fibers and 70 percent of cotton fibers; and in the step of after finishing of the product, the surface layer is subjected to emerizing, grabbing and shearing and lustre finishing repeatedly and the inner layer is raised lightly and is not subjected to grabbing and shearing. The radiation-proof multifunctional casual blanket of the invention has the advantages of wide application, wide radiation-proof frequency, high shielding effectiveness, strong function of resisting electromagnetic wave, good flexibility, capability of being washed randomly, good weather resistance and difficult damage.

Owner:嘉兴市锦帛尔家居用品有限公司

Method for preparing column shaped horniness phase composite wear-resistant jaw plate

InactiveCN101412101AImprove wear resistanceHigh tensile strengthGrain treatmentsCompound aWear resistant

The invention discloses a method for preparing a composite crushing plate with a columnar hard phase. A gear rack of the composite crushing plate with the columnar hard phase prepared by the method is formed by compounding a high hardness columnar hard phase and a high tenacity base metal. The method comprises the following steps: weaving alloy powder core materials into an alloy powder core material framework according to the shape of the gear rack on the crushing plate; fixing the framework on the crushing plate through binding or welding; through a casting method, performing in situ reaction on the alloy powder core materials to generate the columnar hard phase by using the high temperature of melted base molten metal; and performing the metallurgical combination of the hard phase and a base metal interface to form a high wear resistant high tenacity composite material on the gear rack of the crushing plate. The composite crushing plate prepared by the method has the advantages of high wear resistance, high tenacity, high tensile strength, high compression strength and the like. The method has the characteristics of small equipment input, low cost, simple operation and the like, and can be widely applied to various jaw type crushers.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

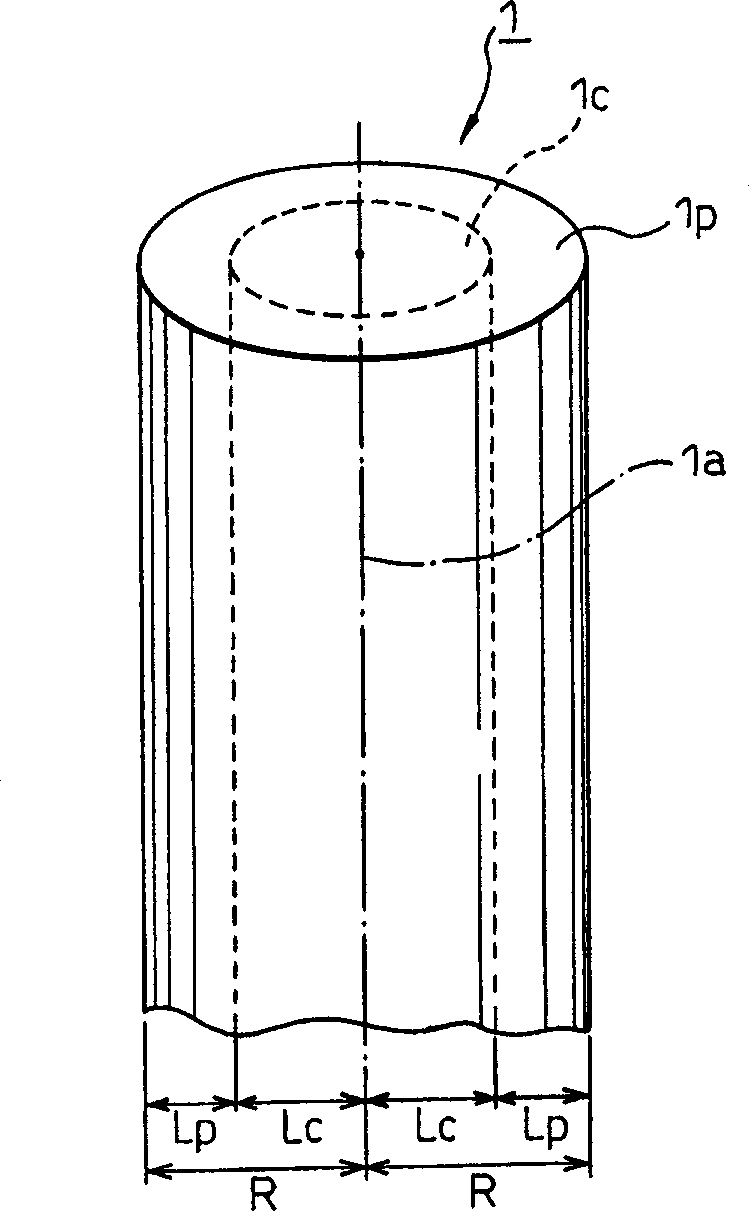

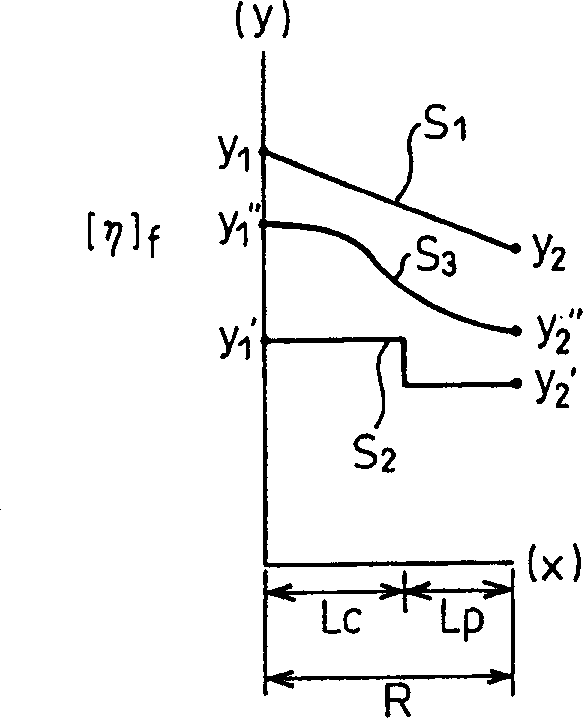

Non-crimping polyester monofilament and process for producing same

InactiveCN1321206AHigh mechanical strengthHigh modulusFilament/thread formingConductive pattern formationFiberPolyester resin

A non-crimping polyester monofilament having an excellent resistance to abrasion and satisfactory mechanical strength and modulus has an intrinsic viscosity distribution such that the farther the location of a part of the monofilament from the longitudinal axis of the monofilament, the lower the intrinsic viscosity of a portion of polyester resin located in the part of the monofilament, wherein a peripheral part of the monofilament formed from a portion of the polyester resin having a lowest average intrinsic viscosity of 0.6 to 1.1 and concentrically surrounds a center part of the monofilament formed from another portion of the polyester resin having a highest average intrinsic viscosity, and the intrinsic viscosities the polyester resin portions for the peripheral and center parts of the monofilament is controlled by controlling the heat history of each of the portions of the polyester resin in a melt spinneret for producing the monofilament.

Owner:TEIJIN LTD

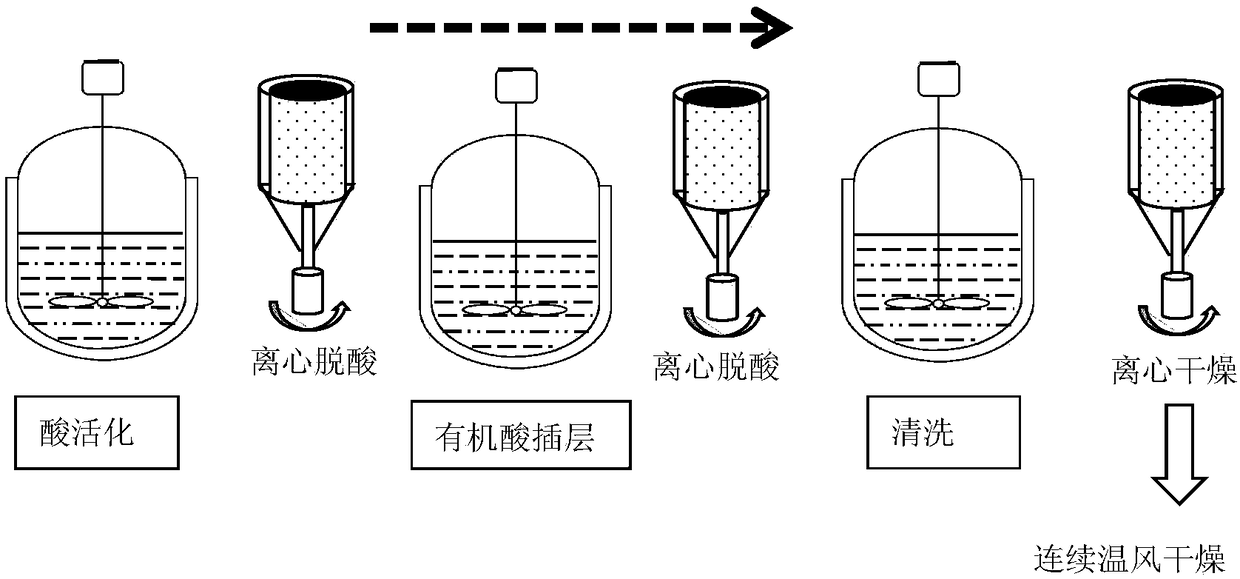

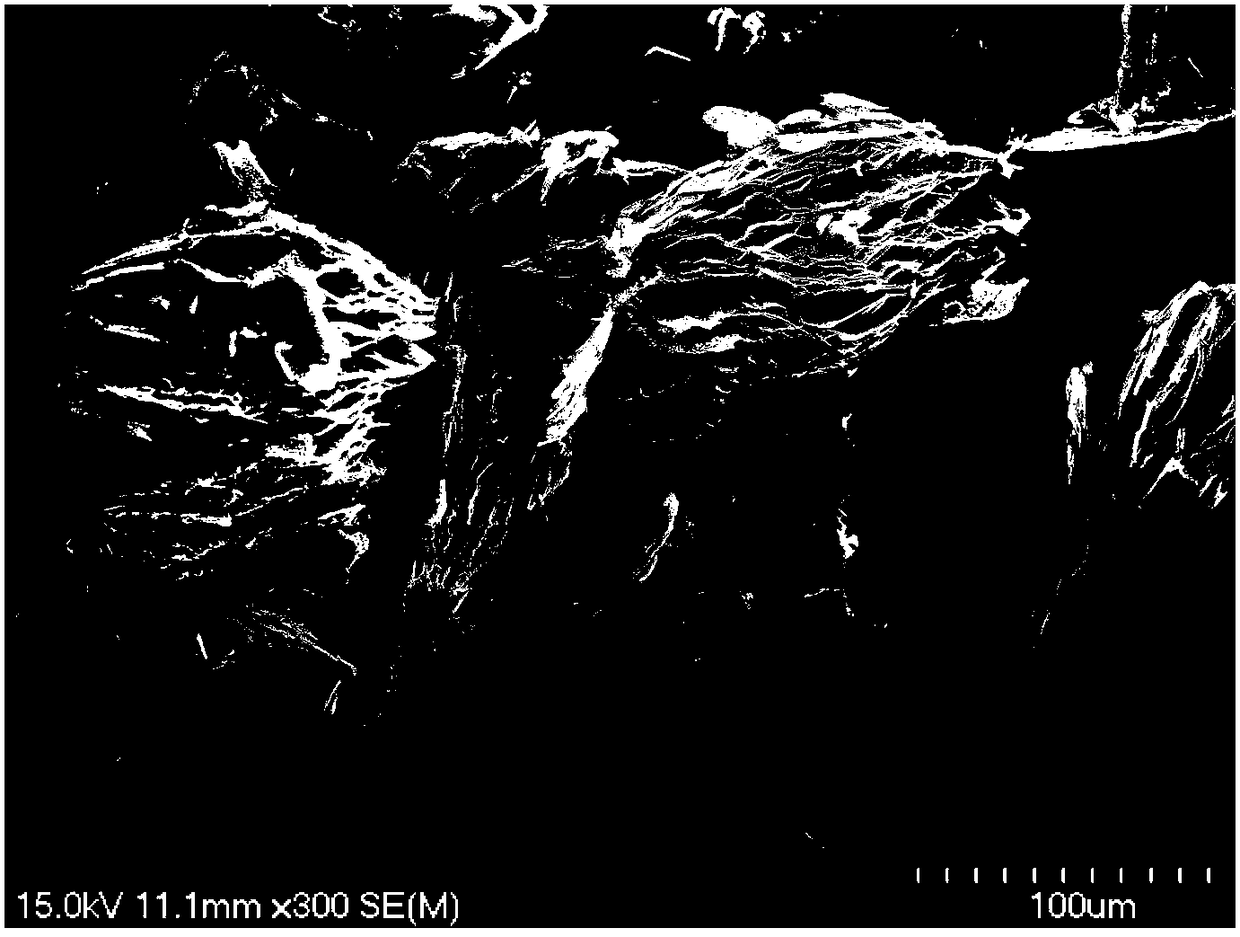

Low-cost large-scale production process for high-mesh sulfur-free expanded graphite

The invention relates to the technical field of preparation of expanded graphite, in particular to a low-cost large-scale production process for high-mesh sulfur-free expanded graphite. The low-cost large-scale production process for high-mesh sulfur-free expanded graphite particularly comprises the following steps: (1) acid activation of graphite: fully oxidizing high-mesh flake graphite powder with hydrogen peroxide and concentrated nitric acid in a kettle at the temperature lower than 15 DEG C, and deacidifying to obtain acidized graphite; (2) organic acid intercalation: adding organic acidin the acidized graphite, carrying out intercalation reaction, and deacidifying; and (3) cleaning and drying: adding cleanout fluid, and after cleaning, removing the cleanout fluid; feeding graphitewet powder into continuous drying equipment and drying to obtain the product. The expanded graphite prepared by the method is high in expansion times, does not contain sulfur, is low in preparation cost, and can be applied to large-scale production.

Owner:苏州鼎烯聚材纳米科技有限公司

Preparation method of crude fiber mixed flour by taking corn as main raw materials

The invention provides a preparation method of crude fiber mixed flour by taking corn as main raw materials, relating to the field of grain processing. The crude fiber mixed flour comprises the following raw materials in parts by weight: 80-120 parts of corn kernels, 3-7 parts of wheat bran, 3-7 parts of yellow soybean meal powder, 3-7 parts of soybean curd residue skins, 200-250 parts of drinking water and 0.015-0.019 part of lactobacillus powder; the preparation method comprises the following steps: respectively drying wheat bran and corn kernels through grain dryer so as to obtain dry wheat bran and dry corn kernels, respectively grinding the dry wheat bran and corn kernels to 40-70 meshes so as to obtain whole corn powder and wheat bran powder, stirring the whole corn powder, wheat bran powder, yellow soybean meal powder, soybean curd residue skins, drinking water and lactobacillus powder for 20-24 hours in the tank at 25-38DEG C to obtain crude flour paste, finely grinding the crude flour paste to 60-80 meshes so as to obtain fine flour paste, and dehydrating and drying the fine flour paste to obtain the finished crude fiber mixed flour, cooling the finished crude fiber mixed flour and packaging and storing into a warehouse.

Owner:张子飚

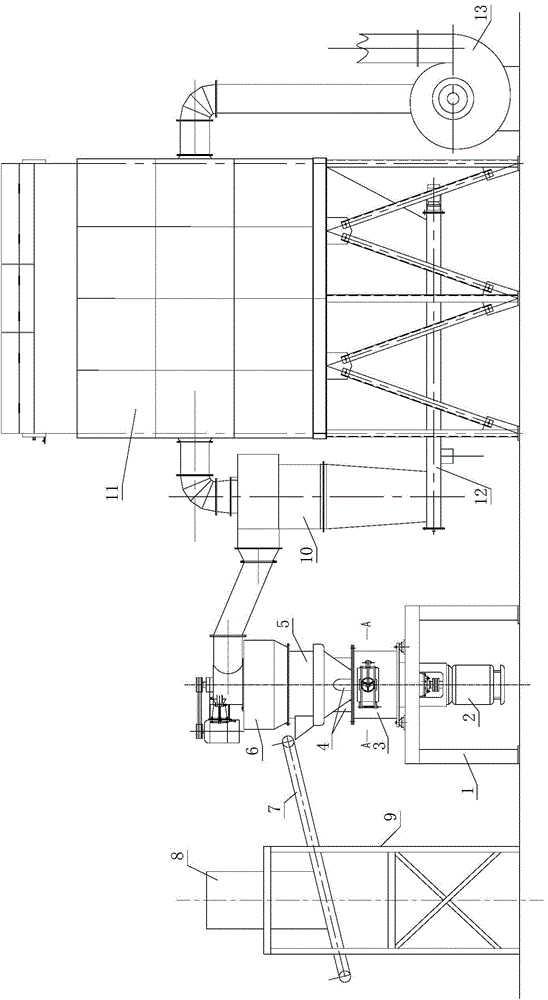

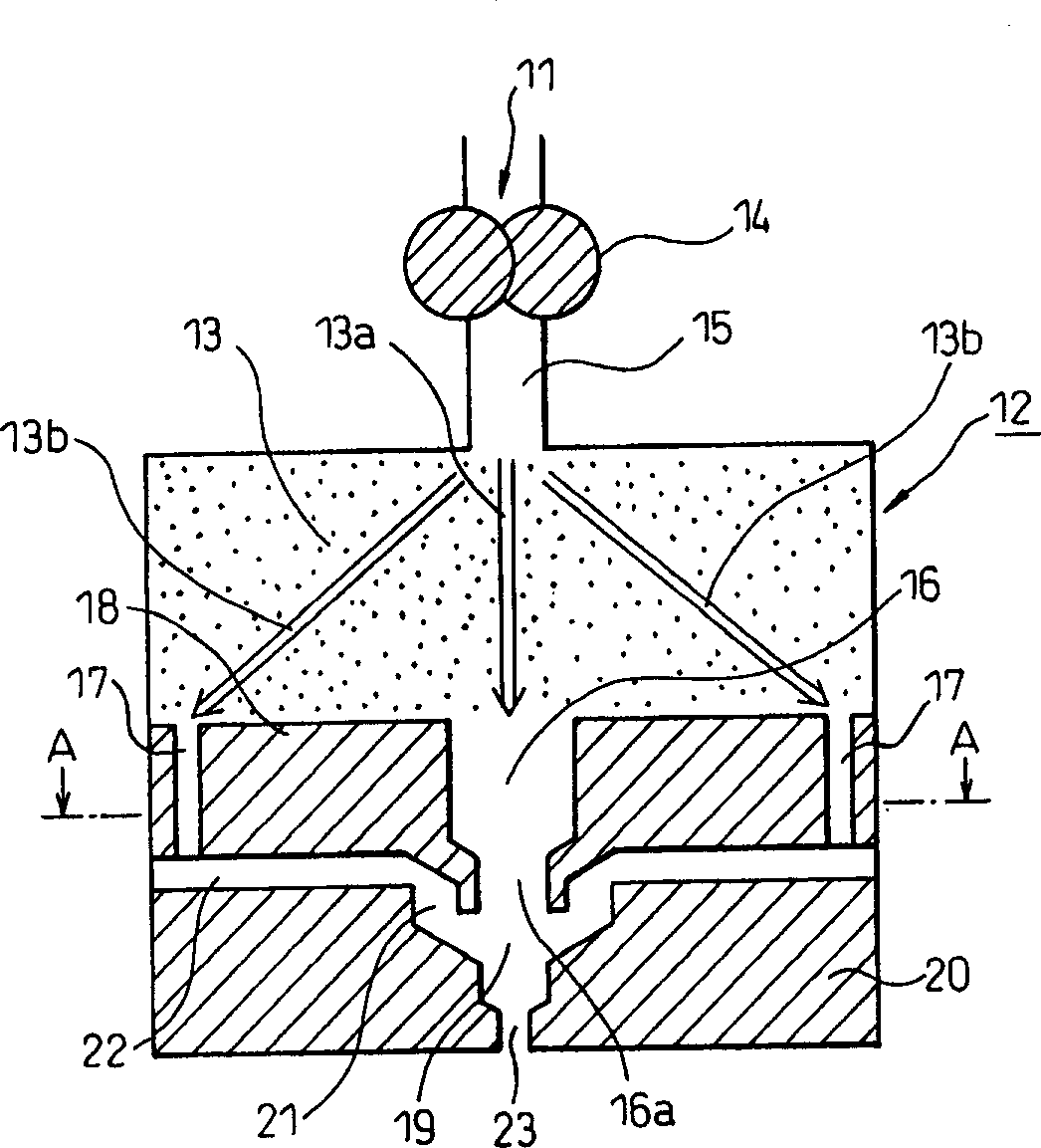

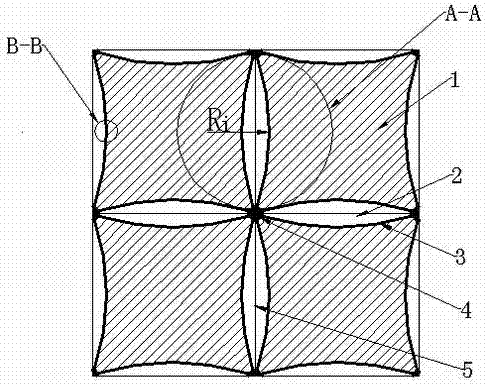

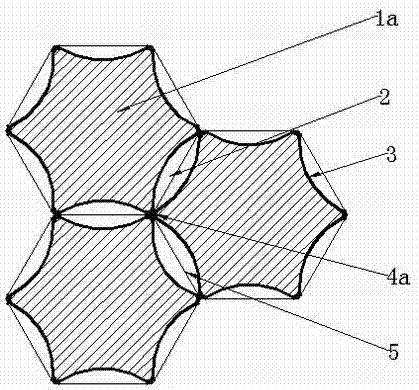

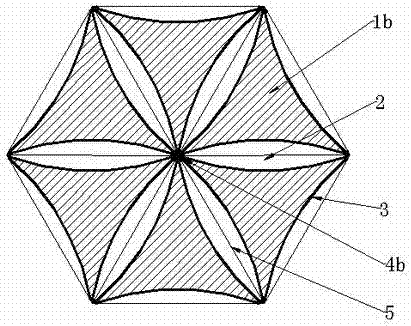

Novel asymmetrical hole-channel structure of filter body of particulate trap

InactiveCN106870071AHigh meshExtended service lifeExhaust apparatusSilencing apparatusParticulatesEngineering

The invention discloses a novel asymmetrical hole-channel structure of a filter body of a particulate trap and belongs to the field of purification of internal combustion engine exhaust gas. According to traditional symmetrical hole channels, the pressure drop rising rate is reduced by increasing the number of the hole channels, but an upper limit exists for increase of the number, and therefore it is needed to adopt the asymmetrical hole-channel structure with the gas outlet hole channel volume smaller than the gas inlet hole channel volume to increase the number of gas inlet hole channels, increase the wall face area of the gas inlet hole channels and further reduce the pressure drop rising rate. The novel asymmetrical hole-channel structure is achieved through the following manner that the cross sections of gas outlet hole channels are designed into a long and narrow shape, the wall faces of the gas outlet hole channels are curved faces, the center lines of the cross sections of the gas outlet hole channels define a polygon, the middle portion defined by the hole channel wall faces serve as the gas inlet hole channels, and the asymmetrical hole-channel structure with a large surface-to-volume ratio is formed. The number of the gas inlet hole channels of the filter body structure is increased by nearly once, the effective filtering area is increased by 2.2 times, and the pressure drop rising rate is reduced by 50 %.

Owner:DALIAN UNIV OF TECH

Method for producing terylene POY filament in scale by recycling PET bottle sheet material

ActiveCN101435113BSolve the problem of water content inconsistencyHigh meshSolid waste disposalMelt spinning methodsEngineeringTower

The invention provides a method for producing polyester POY filament in scale by recycling PET bottle chip. Recycled waste PET bottles are crushed into flaky bottle chip, dried after cleaning, and then sent into a crystallizing bed body; under the action of hot air entering the crystallizing bed body, crystallization is carried out, a crystallizing layer is formed on the bottle chip surface, and then the bottle chip is sent into a drying tower for drying; the dried bottle chip enters a screw extruder for melt extrusion, and the obtained melt is sent into a two-stage filtering device for filtering and then enters a spinning box; and a high-speed spinning process is adopted for spinning to produce the polyester POY filament. The method for producing the polyester POY filament adopts a filling type drying mode, the drying is even and the operating cost is low; a screw mixer is arranged in the drying tower, which solves the problem of 'arching' that happens to the recycled PET bottle chipduring the drying process; and the two-stage filtering device is adopted, which ensures the filtering quality. Therefore, the high-end product-polyester POY filament can be continuously produced in large scale.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

Method for producing polyvinyl chloride fibers for artificial hair through ultrahigh pressure spinning

ActiveCN102560715AHigh viscosityImprove liquidityArtificial filament heat treatmentMelt spinning methodsUltra high pressureResin matrix

The invention relates to the technical field of manufacturing artificial filaments and analogues through polyvinyl chloride resin, in particular to a method for producing polyvinyl chloride fibers for artificial hair through ultrahigh pressure spinning, wherein the ultrahigh pressure spinning is adopted to convert cohesive energy of melts into system friction heat; material in a system is prompted to be heated uniformly; the utilization of heat resistant chlorinated vinyl chloride resin and heat stabilizers is reduced at the same time; the spinning fluidity is improved; the method chooses and utilizes the ultrahigh pressure melt spinning technology to prepare the polyvinyl chloride fibers, and the spinning pressure can reach 800 to 1000 kg / cm<2>; the application of the ultrahigh pressure spinning technology can improve the situations that the viscosity of vinyl chloride series resin is high and the fluidity is not good to a great extent; meanwhile, additives such as compatible chlorinated vinyl chloride resin matrix heat resistant chlorinated vinyl chloride resin can be omitted; in addition, the method enables the spinning process to be simplified and can improve the efficiency, and finished products have excellent performances.

Owner:HENAN REBECCA HAIR PRODS TNC

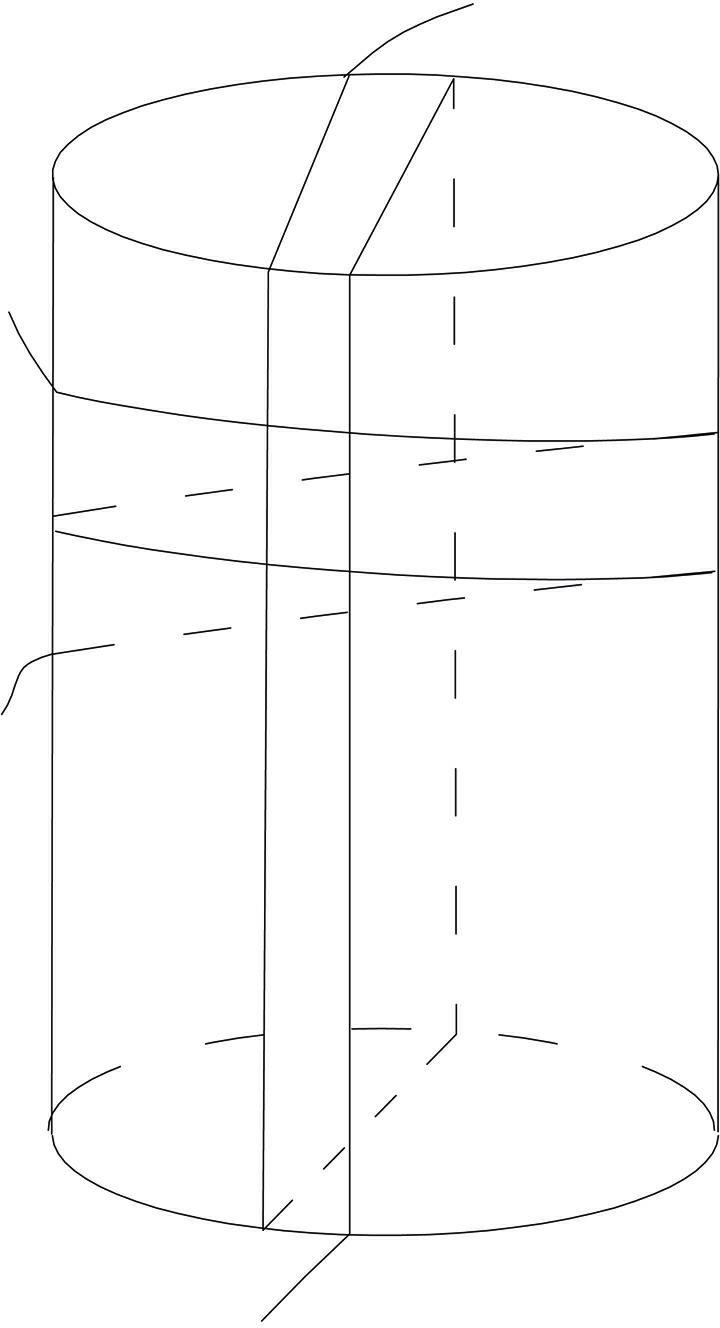

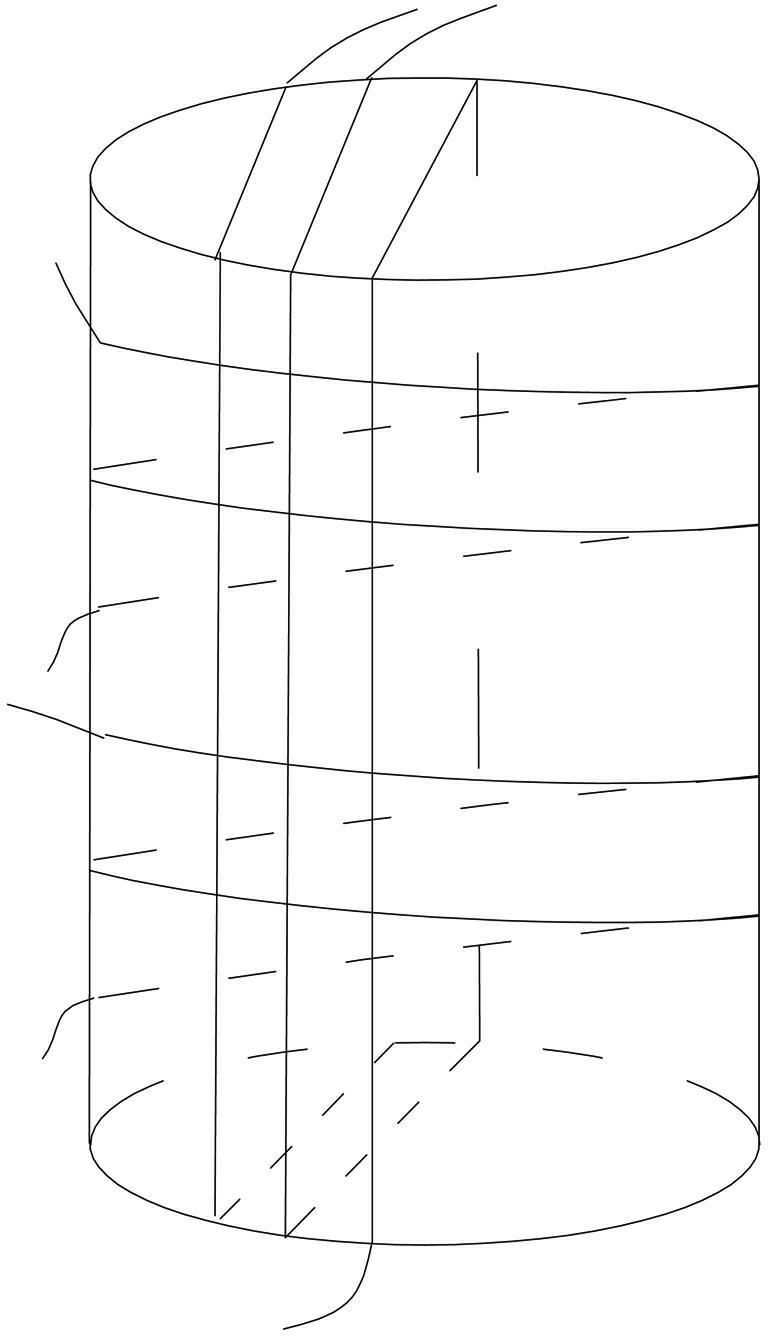

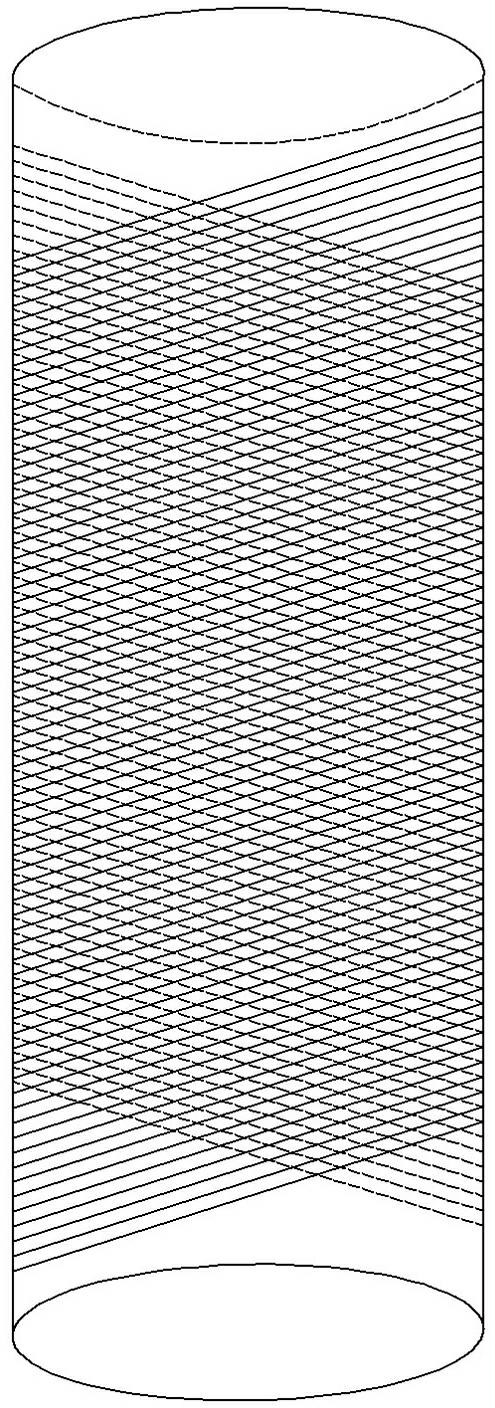

Manufacturing method for printing rotary screen

A manufacturing method for a rotary printing screen comprises the steps as follows: 1, metal microfilaments or metallized nonmetal fibers are wound around on a roll at intervals in the warp and weft directions to form a metal microfilament or nonmetal fiber rotary screen; on the circumferential surface of the roll, one or more filaments are wound to form a framework in the weft direction, another one or more filaments are wound to form a framework in the warp direction, and the sequences of weaving the frameworks in the warp and weft directions can be interchanged; the frameworks in the warp and weft directions cannot in interpenetration and form a non-weaved printing rotary screen; or the frameworks in the warp and weft directions incline in the weft direction and are sequentially intertwined to and fro so as to form a crossed mesh shape; 2, the metal microfilament rotary screen or the nonmetal fiber rotary screen is treated preliminarily; and 3, the electroplating or the chemical plating, the water washing, the mesh separating, the drying and the cutting are conducted as required. The frameworks have high tensile strength and good toughness, thereby avoiding easy breakage. The percentage of opening is high, and through the use of the nonmetal fibers, the cost can be lowered. The rotary screen has a large mesh size and high high permeability. The printing rotary screen shaped like double loudspeakers is plated once through the method while twice in the prior art, therefore, the method has the advantages that the process is saved.

Owner:SHENYANG LIGONG UNIV

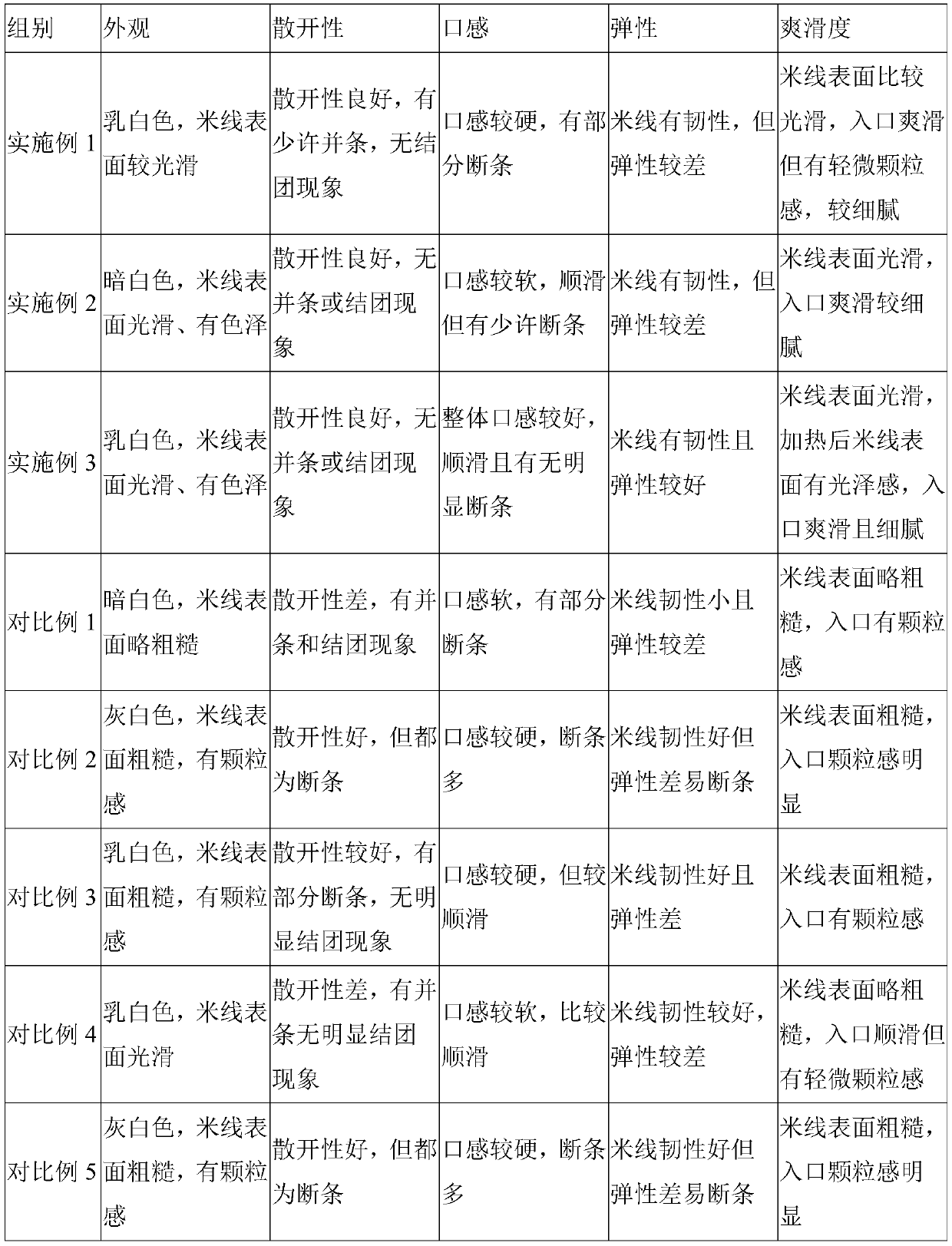

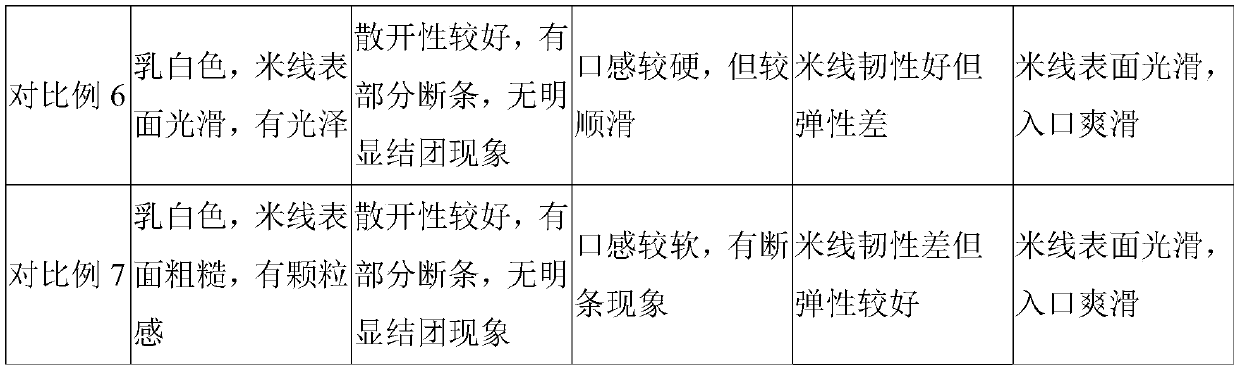

Convenient wet rice-flour noodle and preparation method thereof

The invention relates to the field of foods, in particular to a convenient wet rice-flour noodle and a preparation method thereof. The preparation method comprises the steps of fermenting first polished long-grained non-glutinous rice to obtain a fermentation product, and performing first refining treatment on the fermentation product to obtain a rice syrup; grinding second polished long-grained non-glutinous rice to obtain dry rice flour, mixing the dry rice flour and the rice slurry, and performing second refining treatment to obtain a mixed rice syrup; pre-gelatinizing the mixed rice syrupto obtain a pre-gelatinized product; making the gelatinized product be subjected to anti-aging treatment, gelatinization treatment, water washing treatment and immersion treatment to obtain the convenient rice-flour noodle. The convenient wet rice-flour noodle prepared by the method has lustre and delicate mouth feelings.

Owner:北京金田麦国际食品有限公司

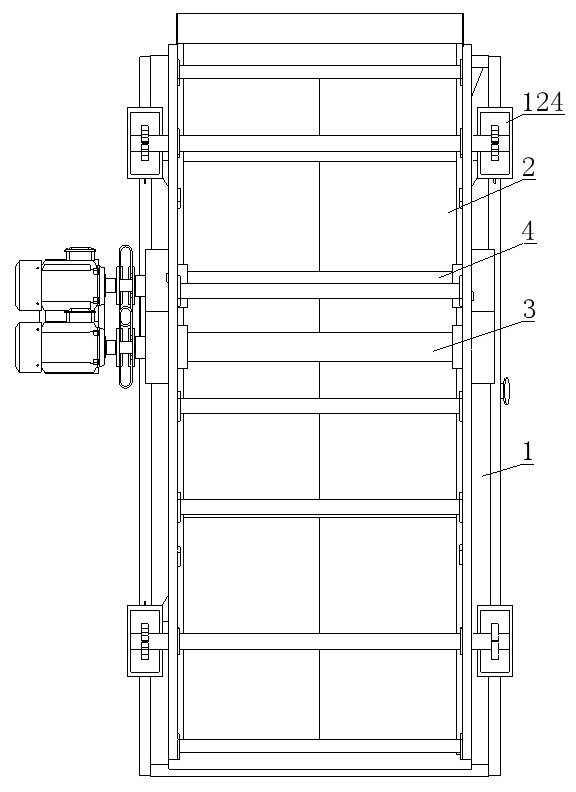

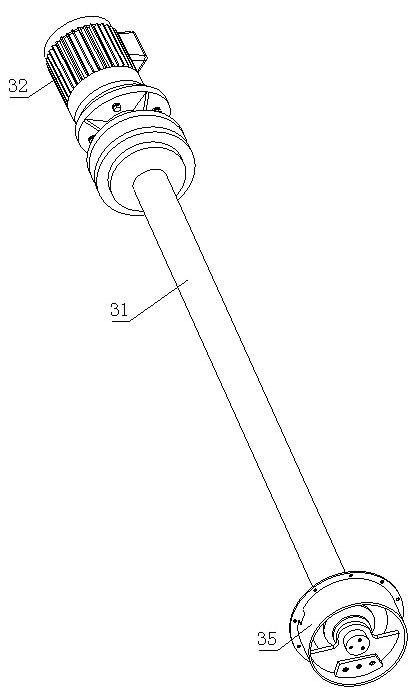

Sand washing boat dual-shaft dewatering screen and method

PendingCN111672752AIncrease the amplitude of up and down vibrationSmall sizeSievingScreeningDrive shaftElectric machinery

The invention discloses a sand washing boat dual-shaft dewatering screen and a method, and belongs to the technical field of dewatering screens. The dewatering screen comprises a dewatering screen shelf, a dewatering screen mesh, a first driving shaft assembly, a second driving shaft assembly and a water tank; the dewatering screen mesh is installed on the middle part of the dewatering screen shelf; the water tank is arranged at the lower end of the dewatering screen mesh; the first driving shaft assembly and the second driving shaft assembly are arranged above the dewatering screen mesh; thefirst driving shaft assembly comprises a main shaft, a driving motor, an eccentric wheel, an eccentric block, a sleeve and an installation plate; one end of the main shaft is connected with a motor shaft of the driving motor via a coupler and the other end is fixedly connected with the eccentric wheel which is in a semicircular shape; and the eccentric block is connected with the eccentric wheel in a fastening mode via a bolt. Vibration is realized by centrifugal force generated by rotation of the eccentric wheel, the vibration amplitude is large, operation is stable, noises are low, screeningefficiency is improved, and the filtering area is large.

Owner:湖南湘德夏工机械设备制造有限公司

Processing technology of faint-scent white tea

InactiveCN106689515AIncrease aromaEasy to soak outPre-extraction tea treatmentFood preservationOsmanthusFood processing

The invention relates to the field of food processing, and in particular relates to a processing technology of a faint-scent white tea. The processing technology of the faint-scent white tea is prepared by the following steps of (1) preparing unsifted tea; (2) harvesting sweet osmanthus; (3) collecting jujuba; (4) drying the jujuba; (5) drying the sweet osmanthus and white tea; (6) carrying out pore treatment; (7) crushing jujuba; (8) mixing; and (9) packaging. According to the processing method, the problems that the white tea is simple in faint scent and the fragrance is not obvious are solved.

Owner:贵州省凤冈县永田露茶业有限公司

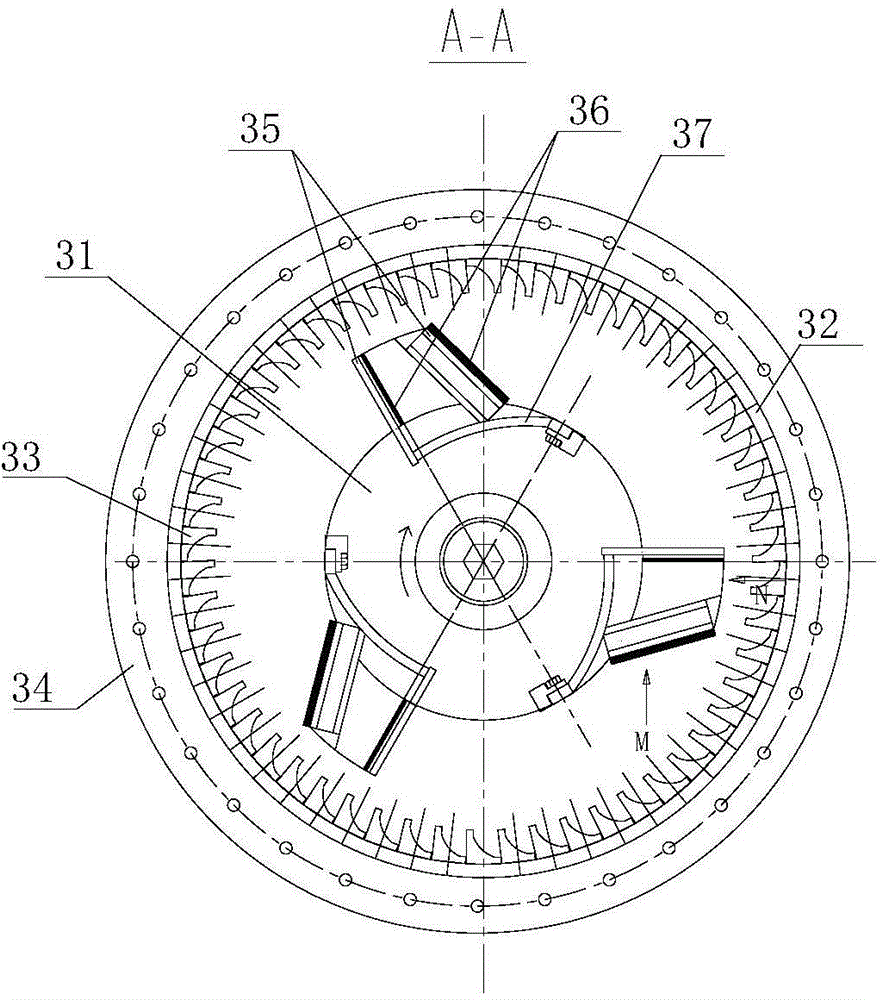

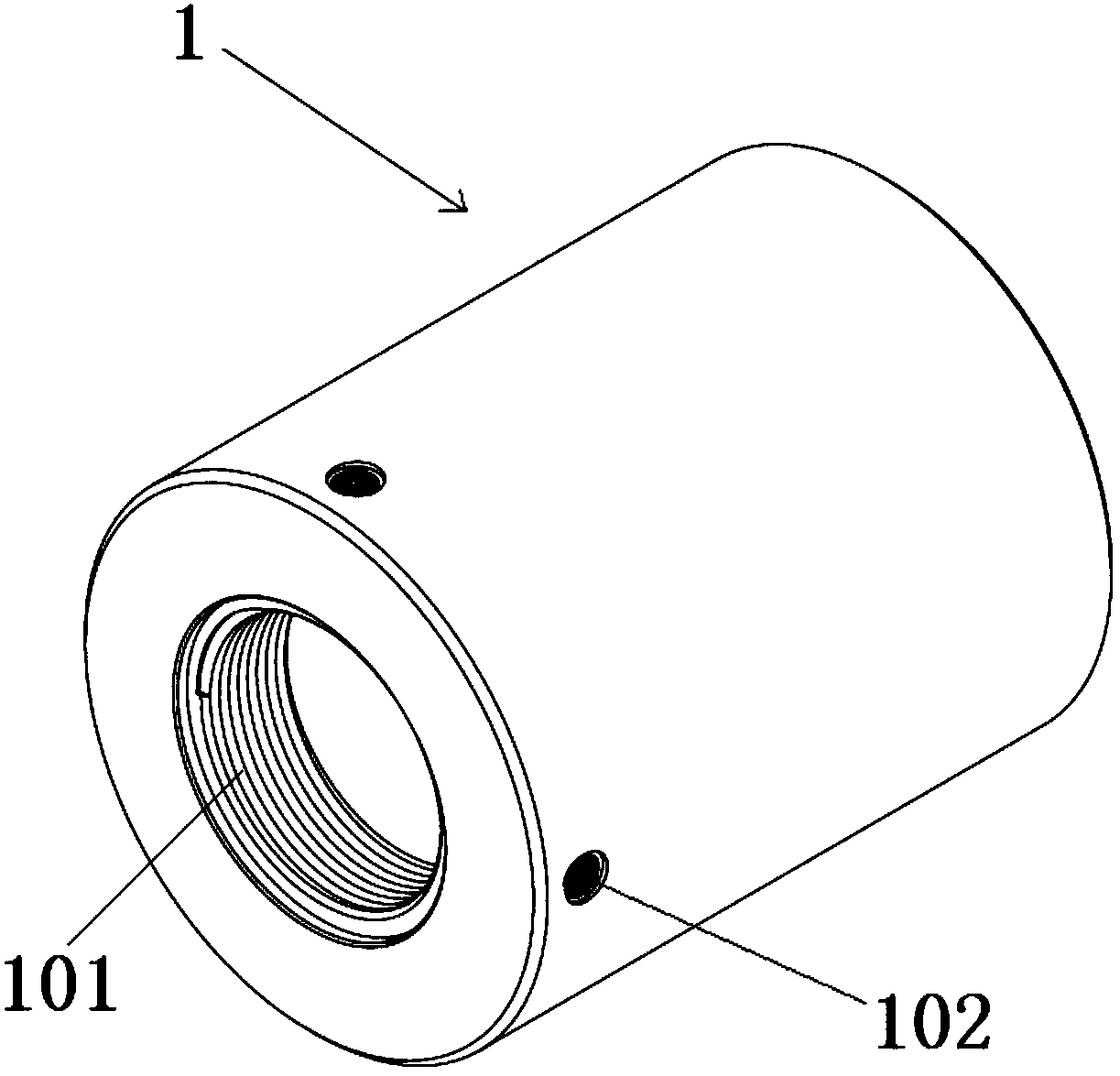

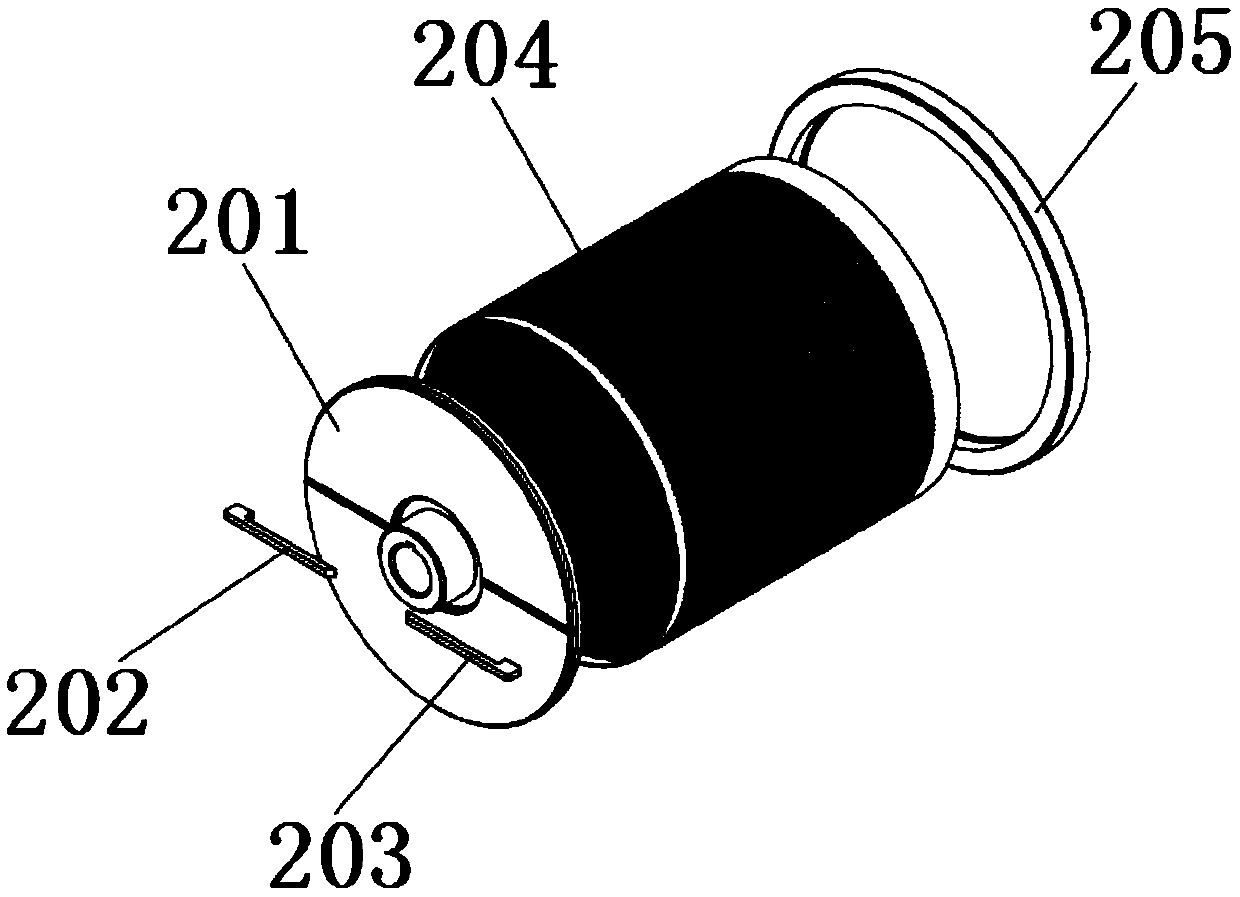

Rotor screen preparing device

ActiveCN110860853ASmooth rotationImprove the efficiency of separation and demouldingSievingScreeningEngineeringScrew thread

The invention discloses a rotor screen preparing device. The rotor screen preparing device comprises a positioning core mold, a welding locking mechanism, a turning mechanism, a pulling-out demouldingmechanism, and a clamping device, wherein the positioning core mold is used for being sleeved with a rotor screen assembly, and the rotor screen assembly is composed of a rotary disc flange, left andright scraper plates, a screen body and a screen upper flange; the welding locking mechanism is used for locking the positioning core mold and the rotor screen assembly before welding; the turning mechanism is used for turning the rotor screen assembly after welding; the pulling-out demoulding mechanism is used for separating and demoulding the rotor screen assembly and the positioning core moldafter turning; and the clamping device is used for fixing the rotor screen assembly during separating and demoulding, the positioning core mold is of a hollow structure, a large thread hole and a small thread hole are formed in the two end surfaces of the positioning core mold correspondingly, and a step positioning hole matched with a spindle chuck of the turning processing mechanism is formed inthe large thread hole. By means of the rotor screen preparing device, the machining accuracy can be improved, the number of the holes and is increased, the hole diameter is reduced, the mesh number of a rotor screen is increased, and the crushed whole particles are finer accordingly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

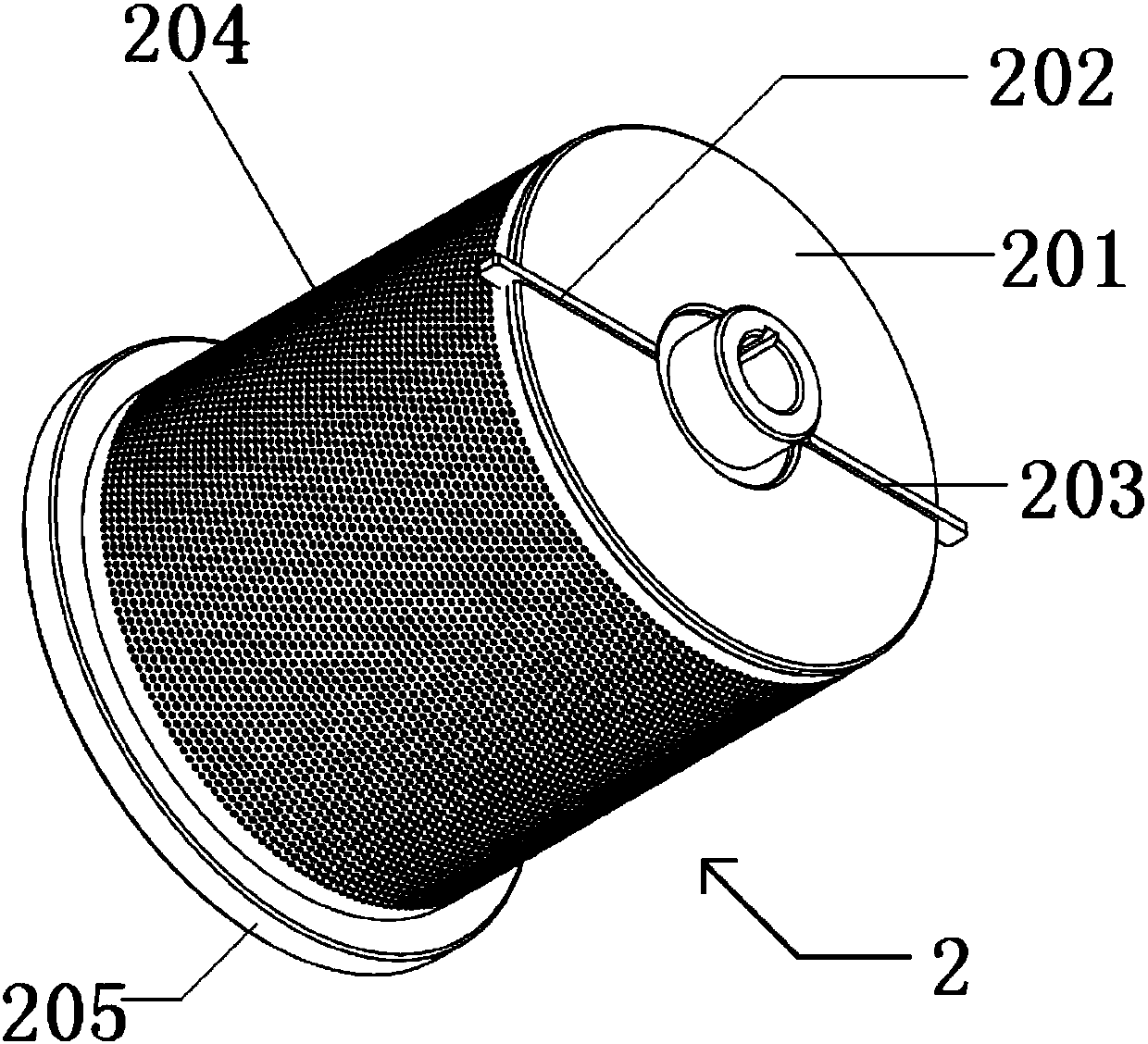

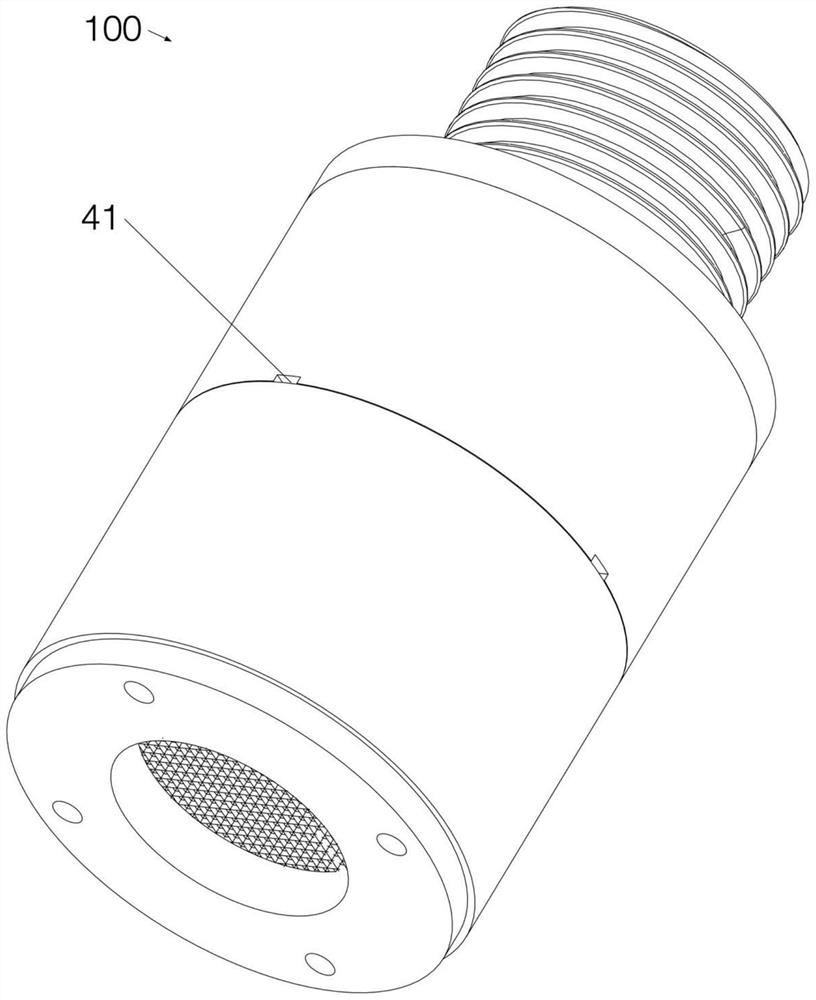

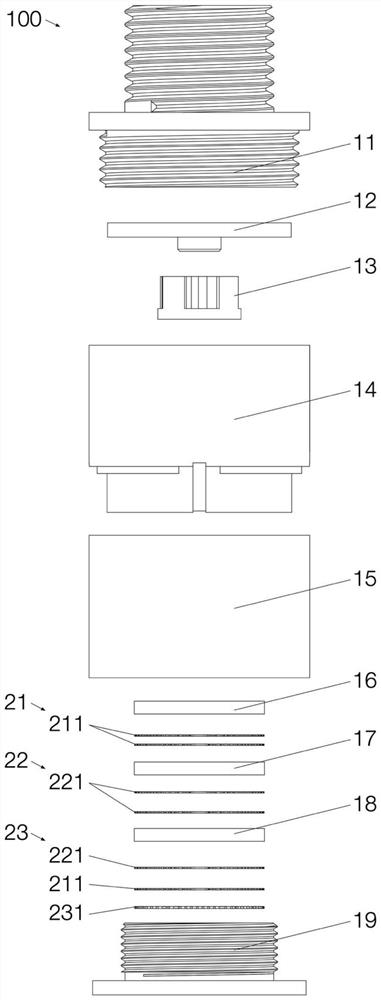

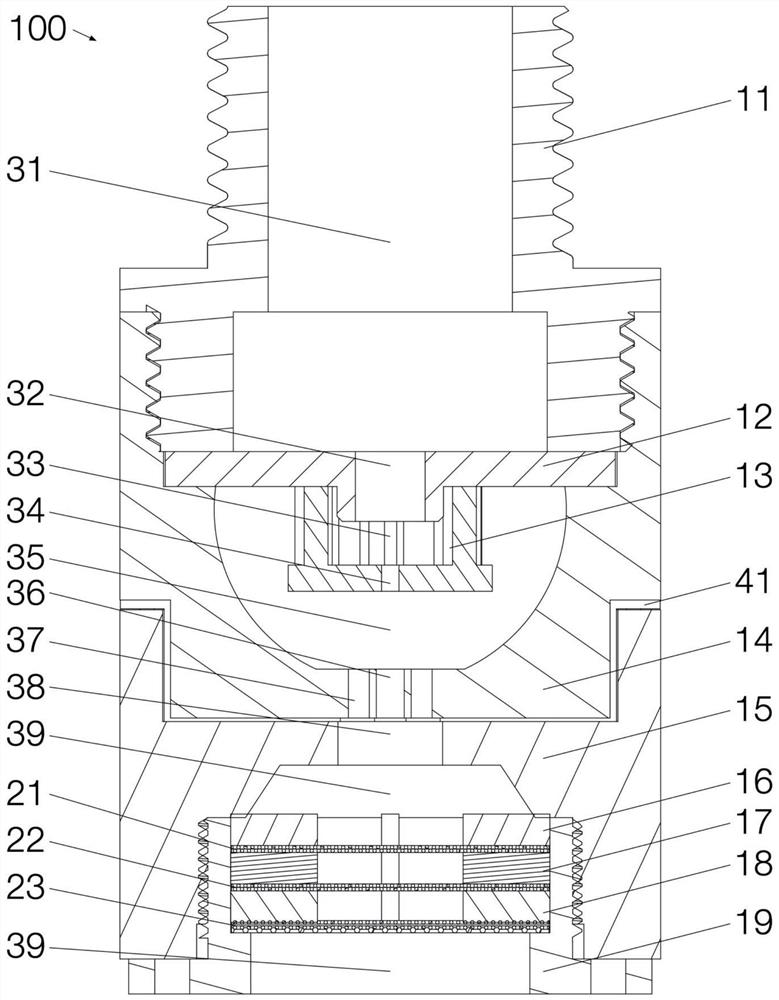

Water outlet device

PendingCN112177107AGet stableGuaranteed water flowDomestic plumbingWater flowEnvironmental engineering

The invention discloses a water outlet device. The water outlet device is provided with a water outlet flow channel, and the water outlet flow channel is provided with a vortex cavity and an air-watermixing cavity in the water outlet direction; the air-water mixing cavity communicates with the atmosphere through a bypass air passage; and the vortex cavity communicates with the air-water mixing cavity through a center hole and at least two first holes evenly distributed around the center hole in the circumferential direction. By the adoption of the structure, compared with the prior art, air can be stably sucked, flocculation and bounce are not prone to happening, and therefore stable sparkling water is output.

Owner:JOMOO KITCHEN & BATHROOM

Process method capable of improving breaking limit of permanent magnetic ferrite magnetic shoe device

ActiveCN112645705AReduce chance of abnormal growthReduce expansion rateBreaking strengthFerrite (magnet)

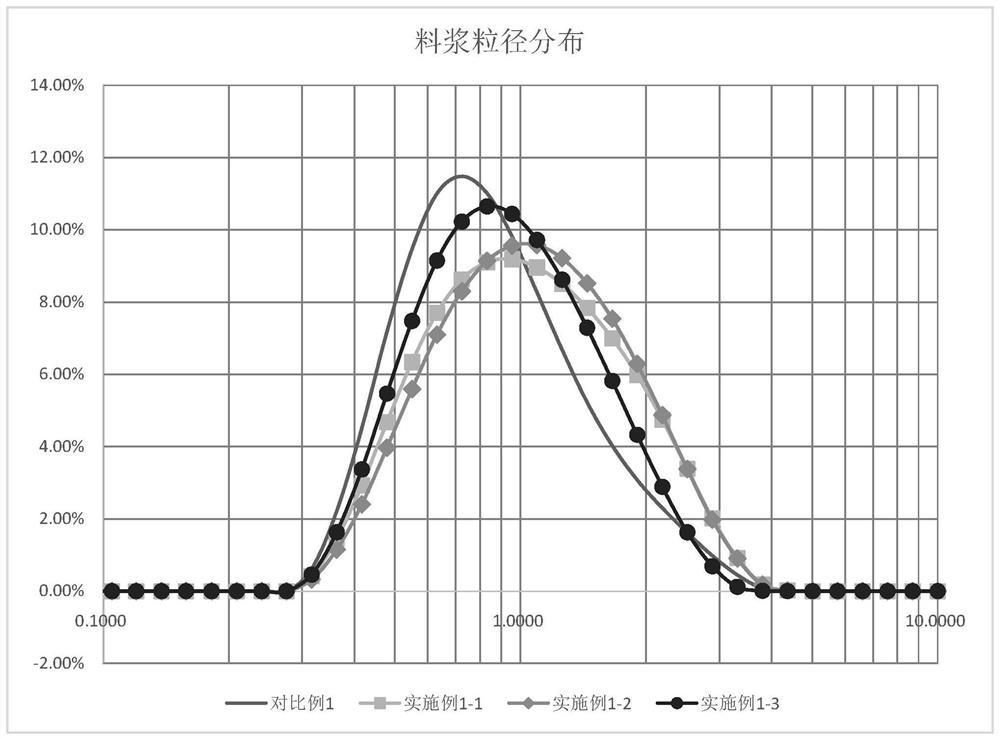

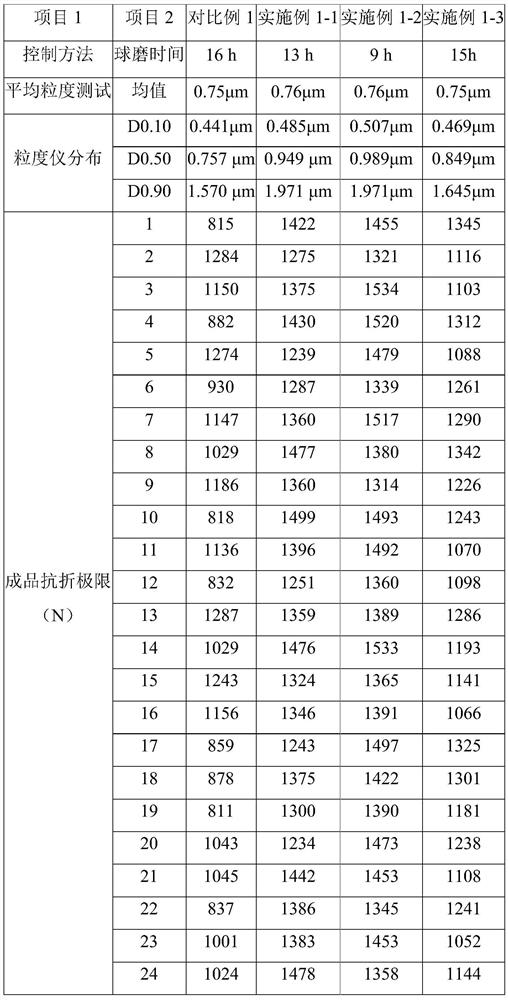

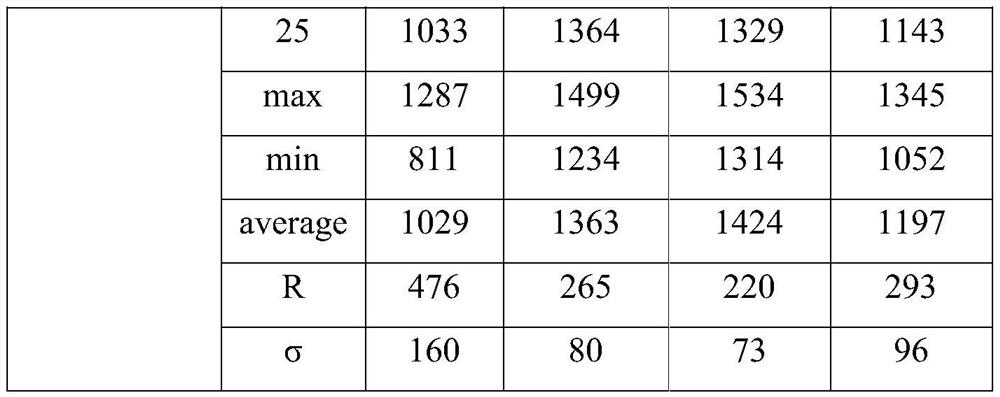

The invention discloses a process method capable of improving the breaking limit of a permanent magnetic ferrite magnetic shoe device, and belongs to the technical field of permanent magnetic ferrites. The method comprises the steps of ball milling, pressing, sintering and grinding of raw materials, wherein the particle size distribution of the ball-milled raw materials is controlled to be D0.10:(0.4-0.6) mu m, D0.50: (0.8-1.0) mu m and D0.90: (1.9-2.0) mu m; a mold is adopted for pressing, and the single-cavity grouting flow rate of the mold is 15-40 mm / s; and in the grinding process, the mesh number of the adopted grinding wheel is 150-400. According to the invention, the breaking strength is improved while the magnetic performance of the ferrite is not damaged.

Owner:SINOSTEEL TIANYUAN MAANSHAN TONGLI MAGNETIC MATERIAL

Anti-digital discharge printing process

InactiveCN107227642ALower post-costSave slurryDyeing processLiquid/gas/vapor textile treatmentDyeingSteaming

The invention discloses an anti-digital discharge printing process, which comprises the following steps of grey fabric preparation, dyeing, primary shaping, pattern printing, ventilation, steaming, water washing, drying, shaping by smoothening agents and finished product rolling. The pattern printing step comprises the steps of screen making, pulping and pattern printing on a machine; the screen making mode comprises the processes of buying pattern form software and making the screen according to the patterns of the pattern software, wherein the mesh number is 200 to 250 meshes. Compared with ordinary discharge printing, the anti-digital discharge printing process disclosed by the invention has the advantages that the pattern software is used for making 4-color / 8-color patterns so as to laminate different colors. The process has the characteristics that the later stage cost is reduced; the pulp is saved. Correspondingly, the screen making mesh number is increased; the precision and the fineness of the product printing are improved.

Owner:SHAOXING GAOFENG PRINTING & DYEING CO LTD

Rock crushing system

The invention discloses a rock crushing system which comprises a sample introduction channel and a first crusher, the sample introduction channel is communicated with an inlet of the first crusher, an outlet of the first crusher is connected with a first crushing unit and a second crushing unit, the first crushing unit comprises a second crusher and a first vibration machine, and a plurality of layers of first ore sample sieves are arranged in the first vibration machine; the second crushing unit comprises a third crusher and a second vibration machine; and a second ore sample sieve is arranged in the second vibration machine. During working, blocky rock samples enter the first crusher through the sample introduction channel to be primarily crushed, then the first crushing unit or the second crushing unit is selected according to a crushing target, the rock samples with different granularities are screened in the first ore sample sieve or the second ore sample sieve with different mesh numbers after further crushing, and thus the rock samples with different granularities are separated to obtain rock samples with small granularities. The rock crushing system is easy and convenient to operate, and the rock samples with different granularities can be efficiently crushed and separated.

Owner:PEKING UNIV

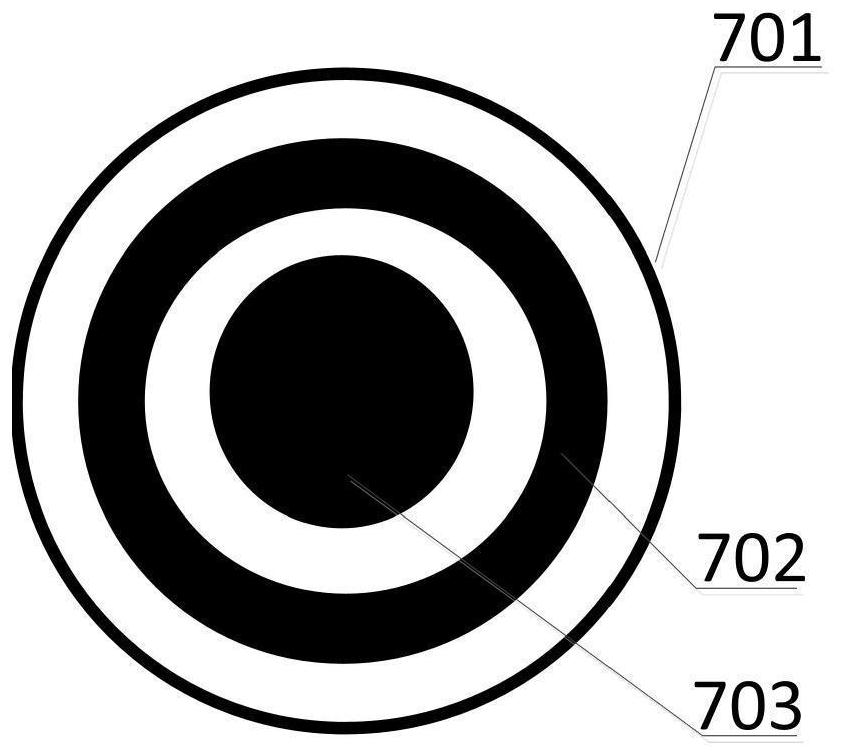

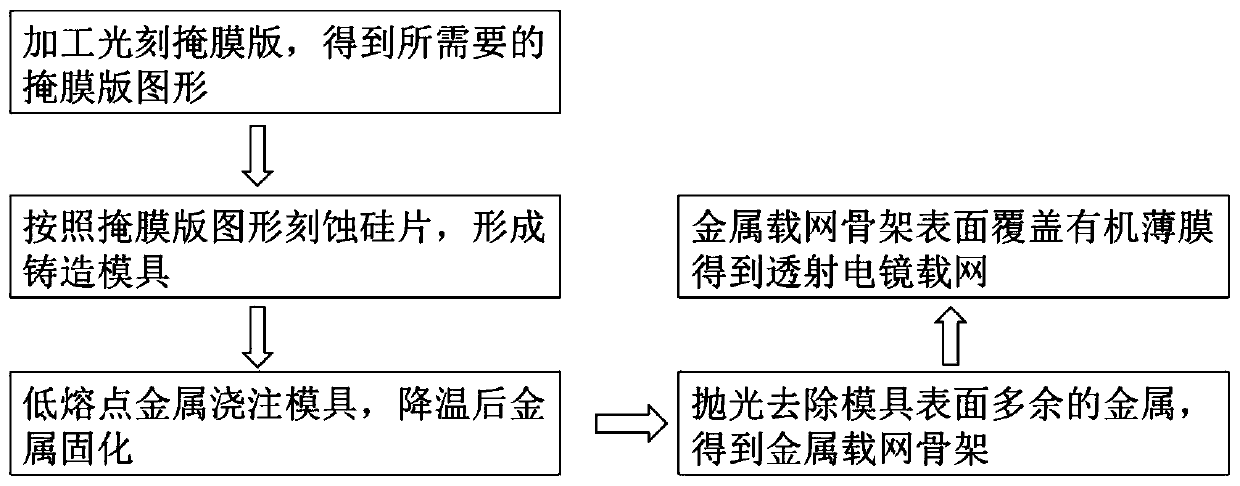

Transmission electron microscope carrier net capable of being produced in batches and preparation method of transmission electron microscope carrier net

ActiveCN110739196AFlexible solutionFlexible designElectric discharge tubesFoundry mouldsOrganic filmLithography process

The invention discloses a transmission electron microscope carrier net of being produced in batches and a preparation method of the transmission electron microscope carrier net. The preparation methodof the transmission electron microscope carrier net comprises the following steps that: 1) a photoetching mask is designed and processed according to the requirements of the transmission electron microscope carrier net, so that a required mask pattern is obtained; 2) the mask pattern is transferred to a silicon wafer through a photoetching process, and the mask pattern is etched into the siliconwafer through an etching process, so that a casting mold can be formed; (3) the casting mold is heated, low-melting-point metal is molten and poured into the mold, and the metal is solidified after the temperature of the metal is reduced to room temperature; (4) redundant metal on the upper surface of the casting mold filled with the metal is removed, and then a casted metal carrier net frameworkis taken out from the mold; and (5) the metal carrier net framework is covered with an organic thin-film, so that the transmission electron microscope carrier net can be formed. According to the method, on the basis of a micro-nano machining technology and the excellent characteristics of the low-melting-point metal, the electron microscope metal carrier net with 200 to 3000 meshes can be manufactured in batches. With the transmission electron microscope carrier net and the preparation method thereof of the invention adopted, a more flexible electron microscope carrier net solution can be provided for the field of electron microscope characterization.

Owner:SOUTHEAST UNIV

Impurity filtering device of diesel oil delivery pump

InactiveCN109989906AImprove filtering effectGood filtering effectPositive displacement pump componentsFlexible member pumpsEngineeringDiesel fuel

The invention relates to the technical field of oil delivery pumps. The invention further discloses an impurity filtering device of a diesel oil delivery pump. The impurity filtering device comprisesan upper pump cover and a lower pump cover, a diaphragm is fixedly connected between the upper pump cover and the lower pump cover, a spring seat is fixedly connected to the bottom of the lower pump cover, a large spring is arranged at the top of the spring seat, a pump core seat is movably connected to the top of the large spring, an upper connecting lug and a lower connecting lug are fixedly connected to two sides of the pump core seat respectively, a groove is formed in the top of the pump core seat, and a spring groove is formed in the bottom of the groove. According to the invention, an end filter screen is arranged on the inner wall of an oil inlet pipe, diesel oil flowing into the oil delivery pump is filtered, the end filter screen is designed to be wavy to enable the surface areaof the end filter screen to be large, under the condition of the same oil inlet amount, the mesh number of the filter screens can be increased, the filtering effect is improved, the filtering effect of the device is better, the service life of an engine is prolonged, and the large spring can provide required pipeline pressure for a system.

Owner:JIANGSU JINHU FUEL FEED PUMP

Equipment for processing abrasive slurry water-jet microporous nozzle internal runner and method for detecting and controlling real-time flux

InactiveCN101564831BIncrease the flow rate coefficientTraffic real-time detectionAbrasive feedersRelative volume flow measurementsControl signalFuel tank

The invention relates to an equipment for processing abrasive slurry water-jet microporous nozzle internal runner and a method for detecting and controlling real-time flux. The equipment comprises an oil tank, a slurry box and a high-pressure material tank; a high-pressure pipeline and an oil returning pipeline are communicated with the oil inlet of the high-pressure material tank and the oil tank; a material inlet pipe and a material supply pipe are communicated with the material inlet of the high-pressure material tank and the slurry box; the oil inlet of the high-pressure material tank is provided with a high-precision flowmeter; a processed microporous nozzle is communicated with a material supply interface; the inlet of the material supply joint is provided with a check valve; the material supply joint is arranged on a clamping device; the real-time oil inlet quantity of the high-pressure material tank, namely the real-time flux of the processing microporous nozzle, is measured bythe high-precision flowmeter; the real-time slurry flux detection data is input to a controller; when the slurry flux reaches a given value, the controller outputs a control signal to close the checkvalve, thus stop processing. The equipment has high grinding efficiency and high precision.

Owner:SHANGHAI UNIV +2

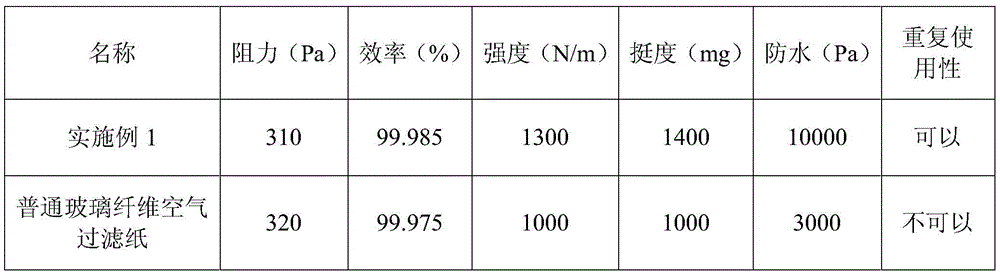

A kind of rewashable glass fiber air filter paper and preparation method thereof

ActiveCN104213470BHigh strengthDense surfaceSynthetic cellulose/non-cellulose material pulp/paperFiltration separationFiberCross-link

The invention discloses glass fiber air filter paper which can be repeatedly cleaned. The glass fiber air filter paper comprises glass fibers and bonding glue stock, wherein the glass fibers are prepared by mixing 25-45 parts by mass of alkali-free glass fiber cotton with the diameter of 3.5-6.0 microns and 55-75 parts by mass of alkali-free glass fibers with the diameter of 0.4-0.8 micron; the bonding glue stock comprises acrylic resin, macromolecular fluorocarbon, a surfactant and a cross-linking agent; the dry weight of the bonding glue stock accounts for 1-3 percent of the total weight of the glass fiber air filter paper. A method for preparing the glass fiber air filter paper provided by the invention comprises the following steps: dispersing and pulping; conveying pulp to a former for forming, applying glue to the surface of wet paper, and performing suction and dehydration; performing primary drying on the wet paper by an infrared drying device; and finally, drying the wet paper at the temperature of 100-200 DEG C, thereby obtaining the glass fiber air filter paper. According to the invention, the water resistance of the air filter paper can be obviously improved under the condition that other performance of the air filter paper is not influenced, and the air filter paper can be repeatedly used after being cleaned.

Owner:CHONGQING ZAISHENG TECH CORP

Processing process for preparing refrigerator vacuum heat-insulating plate by new drying method

ActiveCN110822219AReduce production linksHigh purityThermal insulationDomestic cooling apparatusCalcium hydroxideSorbent

The invention discloses a processing process for preparing a refrigerator vacuum heat-insulating plate by a new drying method. According to the process, a high-efficiency adsorbent material is added,and the residual water after vacuumizing is absorbed by a chemical adsorption mode; meanwhile, the vacuumizing mode and the environment of the process are controlled, so that the aim of not drying a core material in advance is fulfilled; and the material used by the invention adopts the adsorbent which takes calcium oxide and calcium hydroxide as raw materials, and in the calcium oxide obtained through pretreatment and high-temperature calcination, the purity is higher, the mesh number is larger, the specific surface area can reach to more than 20 m<2> / g, and the water-absorbing rate of the adsorbent is 4 to 5 times higher than that of the ordinary adsorbent. After the vacuum heat-insulating plate is manufactured, the residual water inside can be absorbed rapidly through the high-speed water-absorbing capability of the adsorbent, so that the production links of the vacuum heat-insulating plate are reduced and efficiency is improved.

Owner:CHUZHOU YINXING NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com