Low-cost large-scale production process for high-mesh sulfur-free expanded graphite

A technology of expanded graphite and production process, which is applied in the low-cost mass production process of high-mesh sulfur-free expanded graphite, which can solve the problems of high residual sulfur in worms, toxic pollutants, and inability to apply high-end applications sensitive to sulfur content. Achieve the effect of high mesh number and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

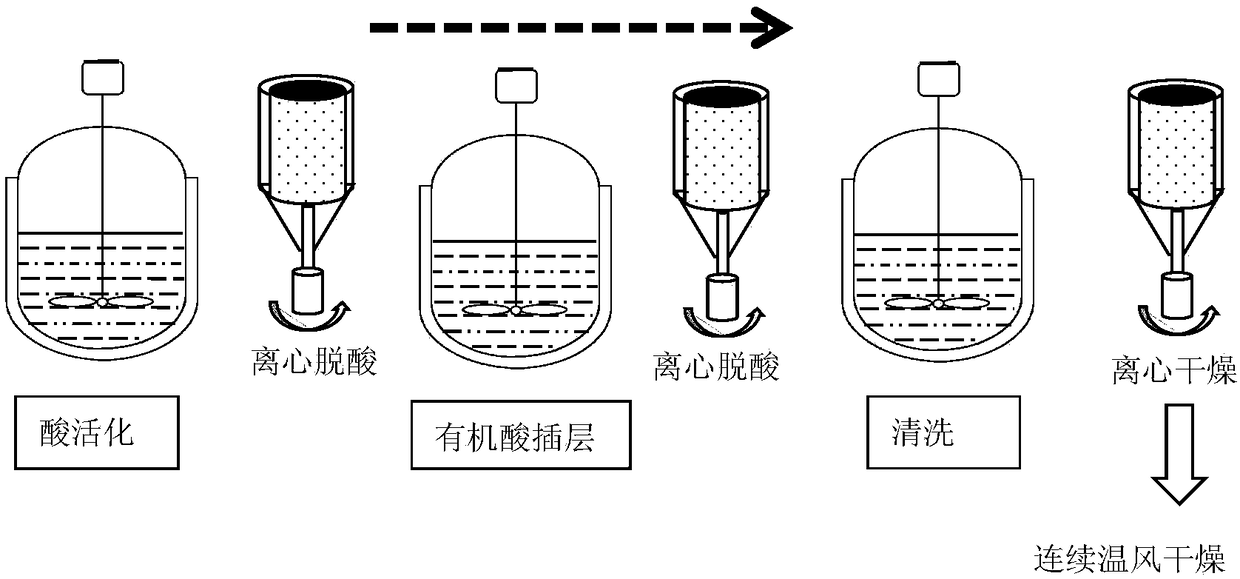

Method used

Image

Examples

Embodiment 1

[0045] 1) Acid activation of graphite: Put 1 part of 150-mesh flake graphite powder dried at 60°C with a carbon content greater than 99% into a heated and cooled enamel jacketed reactor, cool to 5°C, and then add the same 5°C Mix 0.25 parts of 30% hydrogen peroxide evenly, and then add 2.1 parts of 65% nitric acid at the same concentration of 5°C and mix evenly. After mixing for 30 minutes, raise the temperature to 35°C and keep for 60 minutes, then move the slurry to a centrifuge at a high speed of more than 50g Spin deacidification.

[0046]2) Organic acid intercalation: Put the graphite wet powder treated by acid oxidation activation back into the same reaction kettle, add 2.5 parts of mixed acid (the weight ratio of formic acid is 50%, acetic acid 45%, citric acid 5%), and mix well , heated up to 40°C and maintained for 90 minutes, cooled to room temperature, moved the slurry to a high-speed centrifuge, and deacidified by centrifuging at a high speed of more than 50g.

[...

Embodiment 2

[0049] 1) Acid activation of graphite: Put 1 part of 150-mesh flake graphite powder dried at 60°C with a carbon content greater than 99% into a heated and cooled enamel jacketed reactor, cool to 3°C, and then add the same 3°C 50% hydrogen peroxide 0.2 and mix evenly, then add 1.75 parts of 85% nitric acid with the same low concentration of 3°C and mix evenly, after mixing for 30 minutes, raise to 35°C and keep for 60 minutes, then move the slurry to a centrifuge, at a high speed of more than 50g Spin deacidification.

[0050] 2) Organic acid intercalation: Put the graphite wet powder treated by acid oxidation activation back into the same reaction kettle and add 3 parts of mixed acid solution (the weight ratio of formic acid is 40%, acetic acid 57%, citric acid 3%), mix Evenly, heat up to 30°C and keep for 20 minutes, continue to heat up to 50°C and keep for 90 minutes, then cool to room temperature, move the slurry to a high-speed centrifuge, and deacidify by centrifuging at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com