Patents

Literature

322results about How to "Dense surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

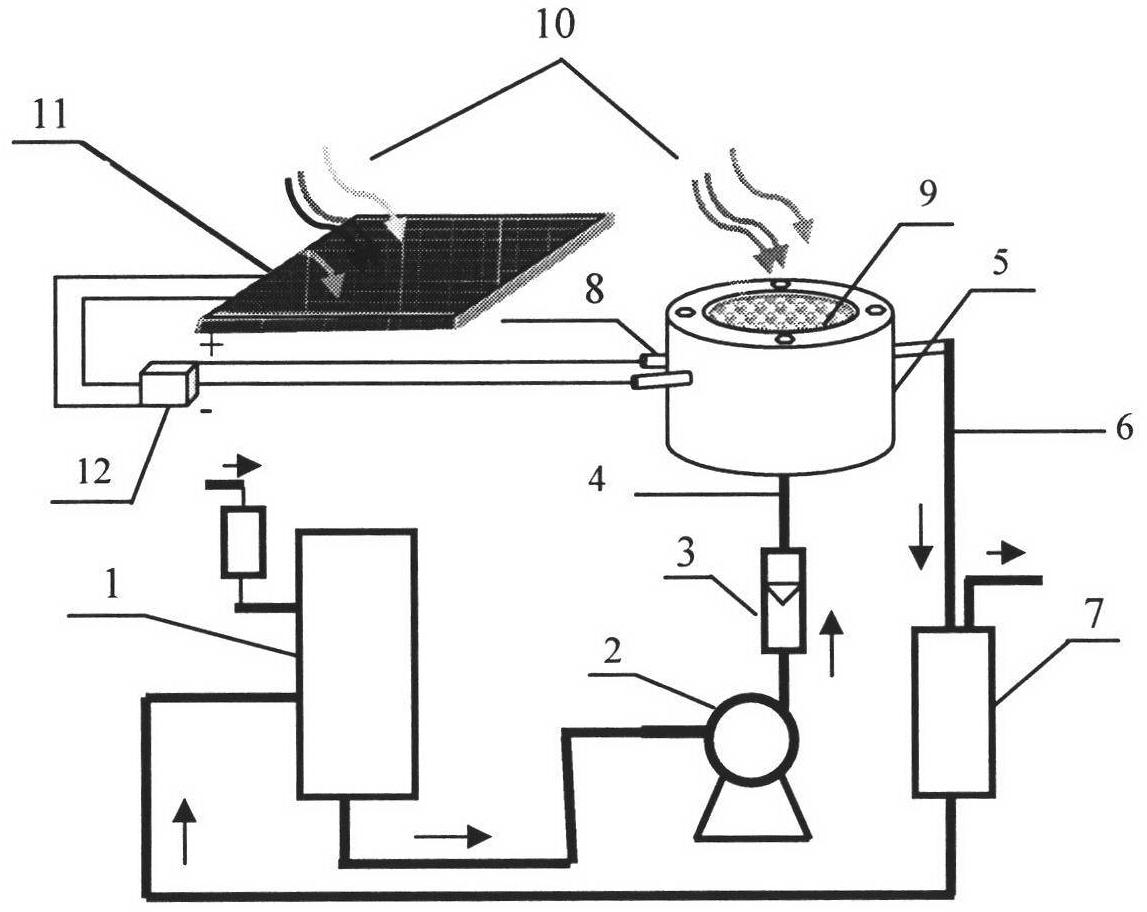

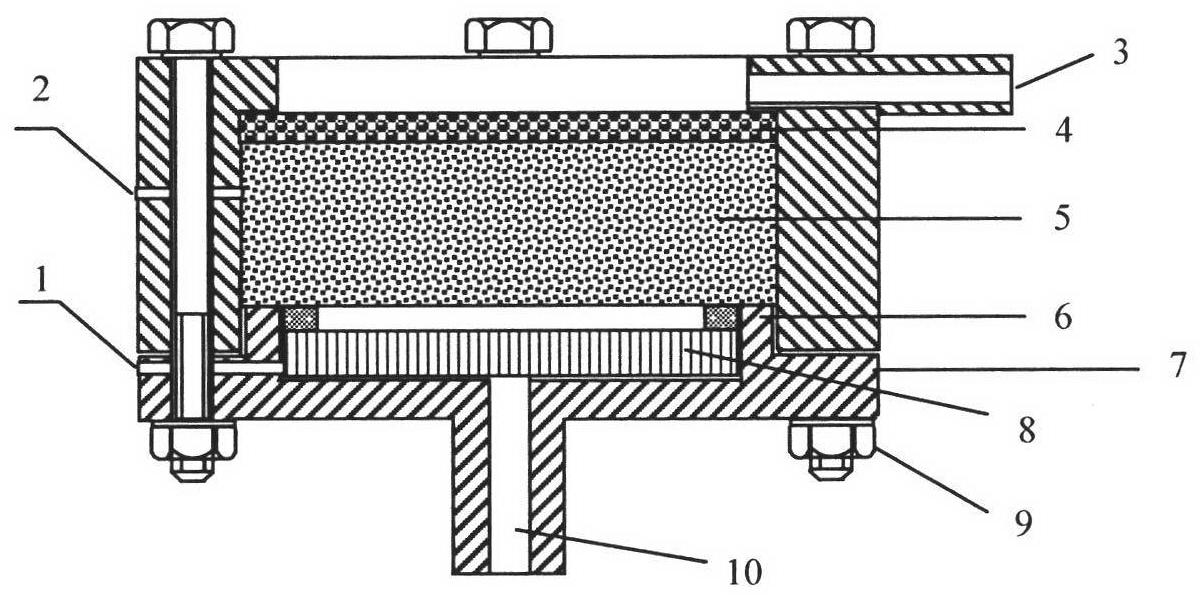

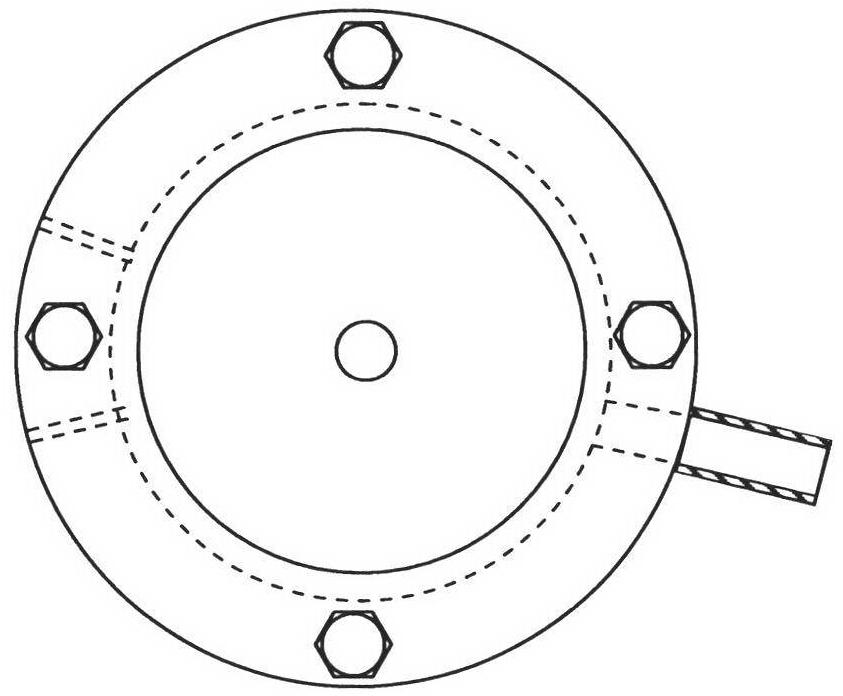

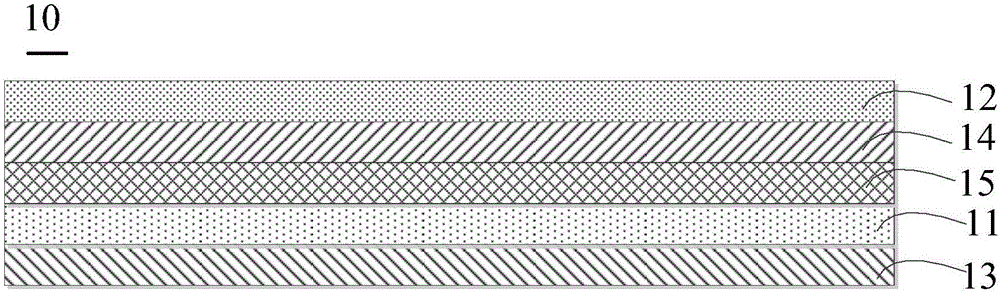

Organic wastewater treatment film reactor utilizing sunlight-assisted electro-catalysis

InactiveCN102603037AAccelerated adsorption/desorption rateThe actual user interface increasesWater/sewage treatment by irradiationEnergy based wastewater treatmentPhoto assistedPorous channel

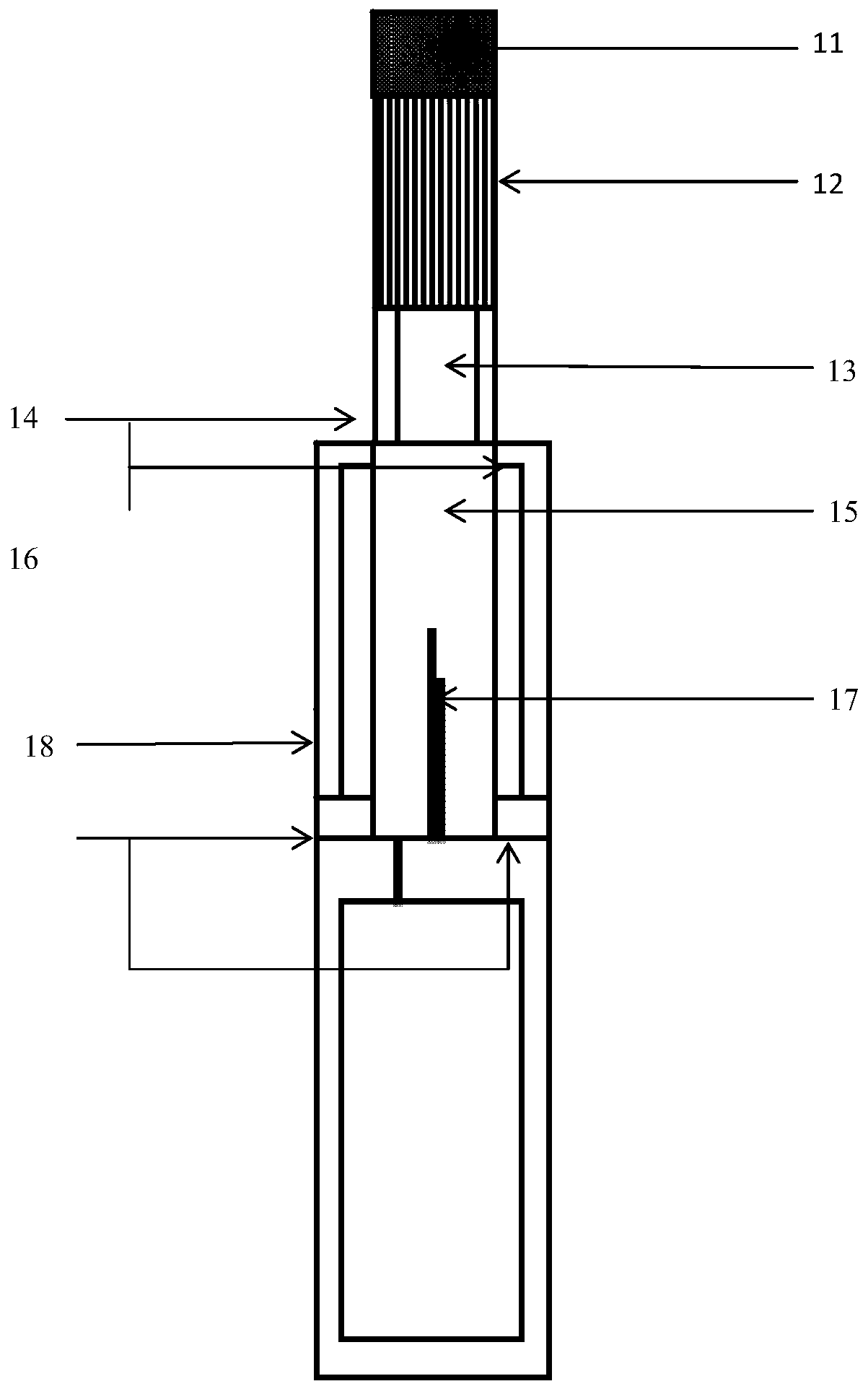

The invention relates to an organic wastewater treatment film reactor utilizing solar energy photo-assisted electro-catalysis, which comprises a storage tank of water to be processed, a flow controllable constant flow pump, a photoelectric chemical reactor, a clear water storage tank and a solar battery component, wherein a photo anode and a cathode are correspondingly arranged in the reactor; the photo anode takes a porous metal membrane as a base body, and a TiO2 nano tube or a TiO2 mesoporous membrane is formed on the surface of a porous titanium membrane (net) by an electrochemical anisotropic etching technology; a porous channel film is used as the base body; a metal oxide coating electrode with high electrochemical catalytic activity and high electrical conductivity is prepared by a dipping film-forming method, simultaneously, by doping and modifying operations, the electrode material has photo catalytic activity and the reaction efficiency is improved. The reactor integrates electrochemistry, photocatalysis and film separation technologies; the three technologies are coupled to enhance a synergistic effect; the wastewater treatment efficiency can be improved; a solar component is adopted as a power supply; the clean solar energy is utilized to the maximal degree, and the organic wastewater treatment film reactor has social benefits of reducing environment load and economic benefits of reducing cost.

Owner:NANJING UNIV OF TECH

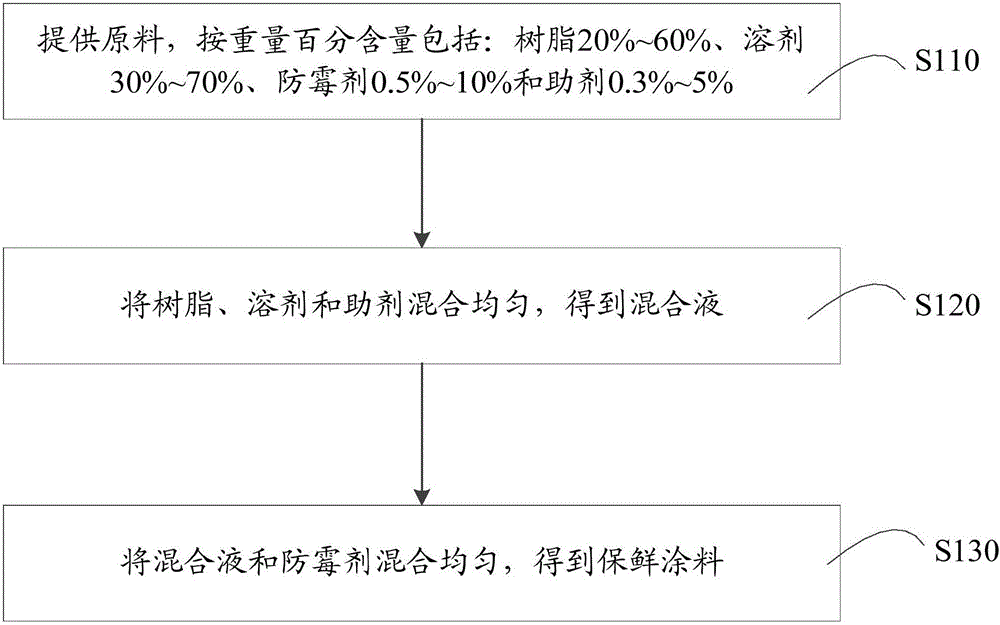

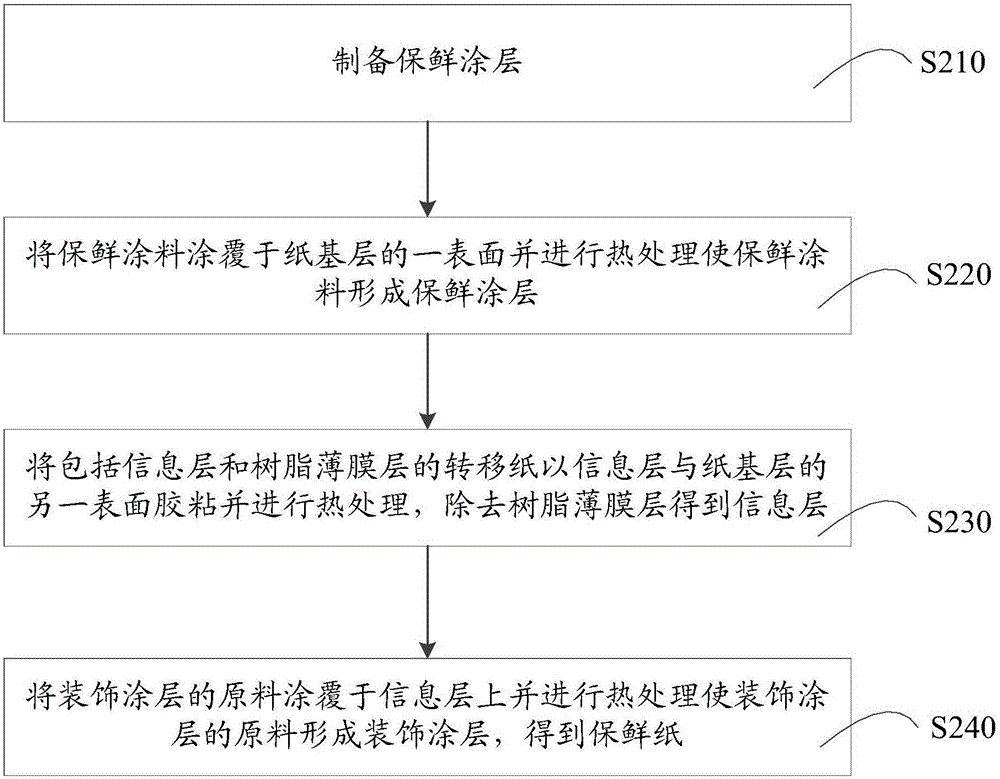

Mildew-proof preservative paper and preparation method and preparation device thereof

InactiveCN106638157AEasy to prepareGood reproducibilityFlexible coversWrappersCarvacryl acetateSolvent

The invention provides a mildew-proof preservative paper and a preparation method and a preparation device thereof. The preparation device comprises a paper-based layer, a decorative coating and a mildew-proof preservative coating, wherein the mildew-proof preservative coating is arranged one surface of the paper-based layer, the decorative coating is arranged on the other surface of the paper-based layer, the mildew-proof preservative coating is made from a mildew-proof preservative coating raw material and is prepared from, by weight, 20%-60% of resin, 30%-70% of solvent, 0.5%-10% of mildew preventive and 0.3%-5% of additive, the resin is at least one of polyurethane resin, acrylic ester copolymer, polyvinyl alcohol, polyvinylidene chloride, modified polyethylene vinylidene chloride, vinyl-vinyl acetate copolymer, polyvinyl acetate copolymer and vinyl acetate-butyl copolymer, and the solvent is at least one of water and ethanol. The surface of the obtained mildew-proof preservative coating is dense and provided with small pores, the mildew-proof preservative coating has the good effect keeping moisture constant, the mildew preventive is dispersed inside resin, mildewing can be also prevented, and further a good preservation effect is reached.

Owner:CHANGDE JINRUN NEW MATERIAL TECH CO LTD

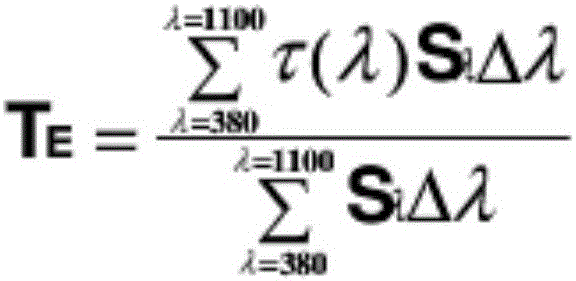

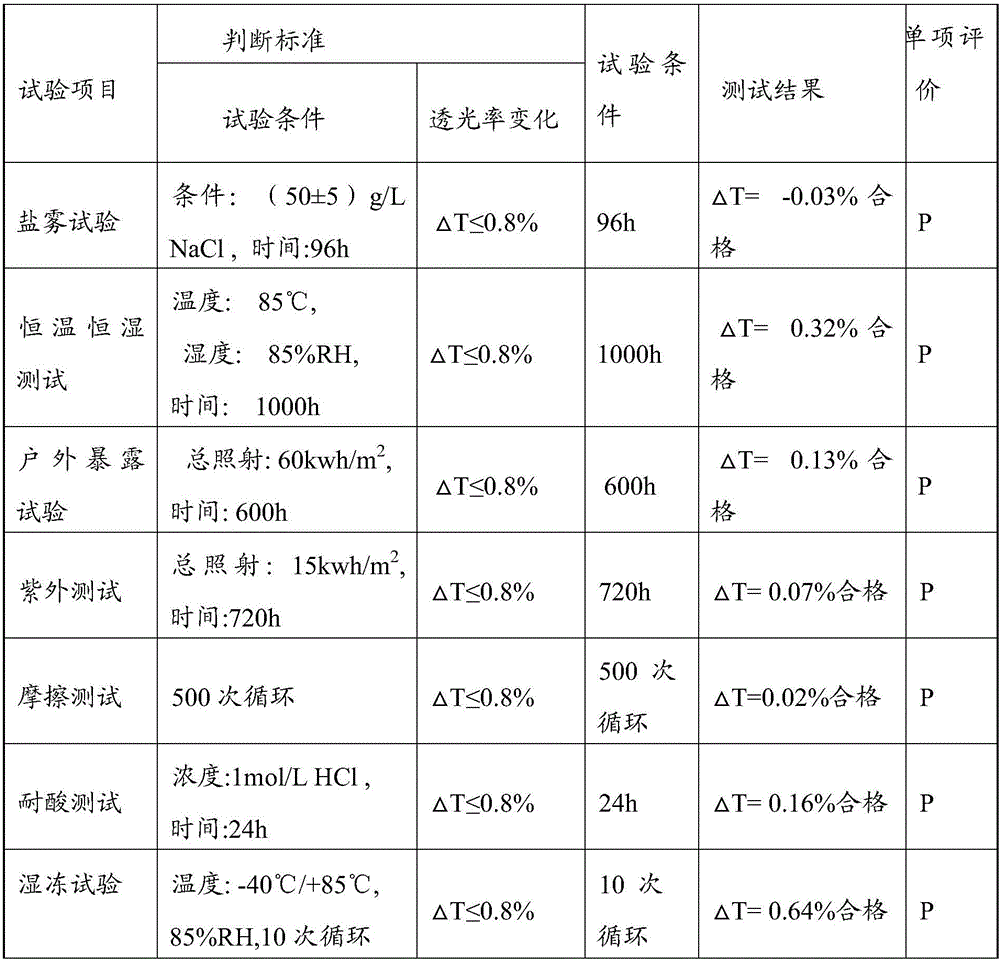

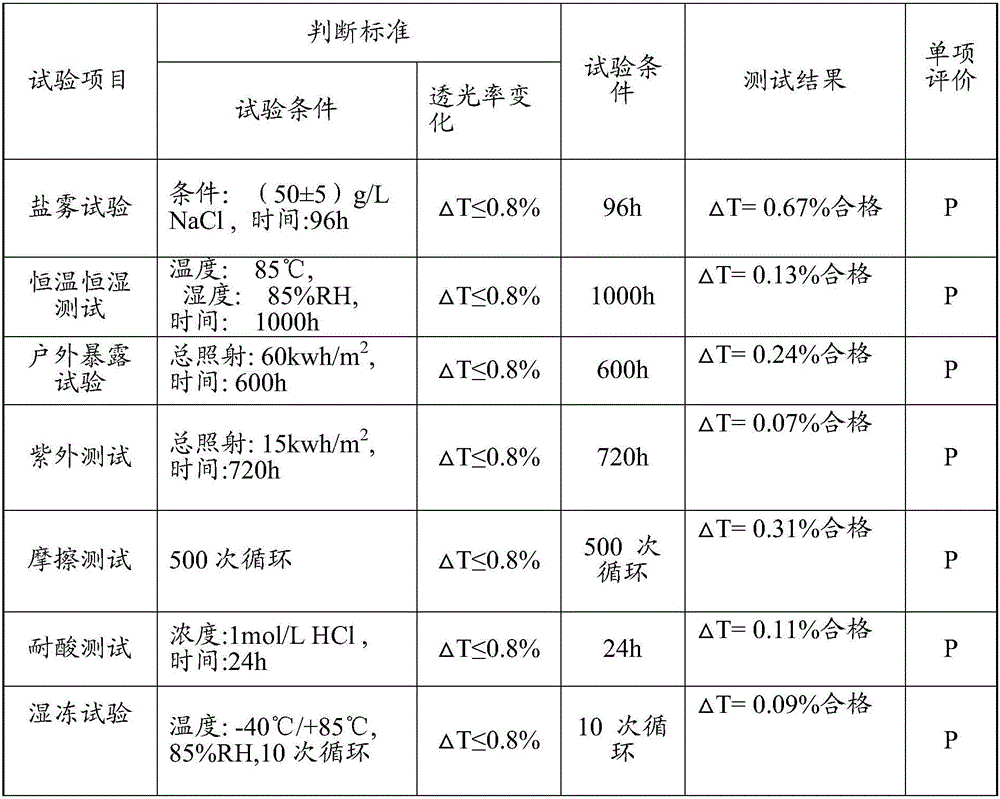

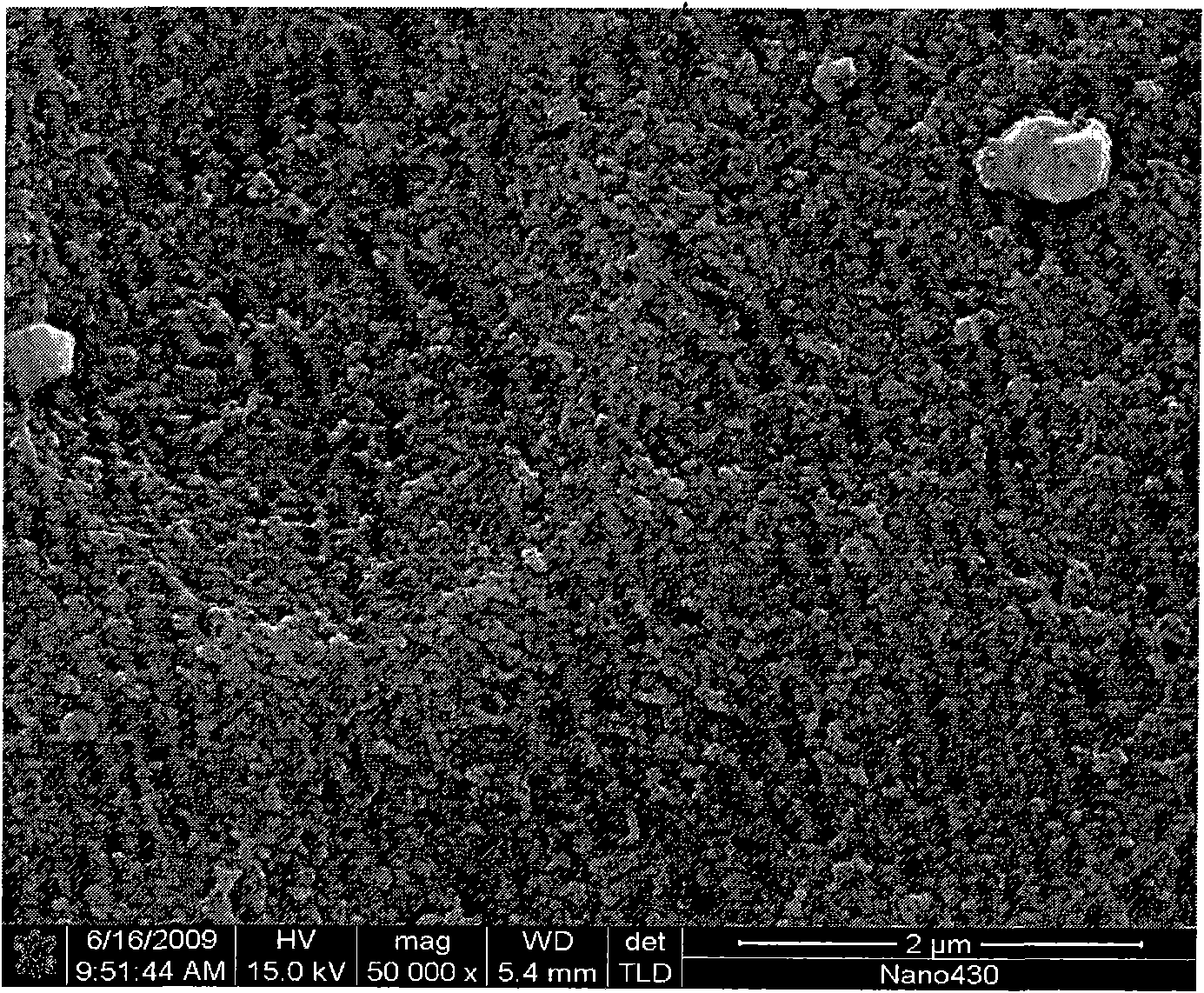

Nanometer core-shell silicon dioxide microsphere as well as preparation and application of antireflection composite coating solution

ActiveCN105964195AHigh light transmittanceHigh mechanical strengthCoatingsMicroballoon preparationPorosityMicrosphere

The invention relates to the field of anti-reflection technology for the surface of glass, and concretely relates to a nanometer core-shell silicon dioxide microsphere and a composite coating solution which is compounded by the nanometer core-shell silicon dioxide microspheres and aluminum silicon sol as well as preparation methods thereof. A cation type polystyrene emulsion is used as a hard template in order to prepare silicon dioxide dispersion liquid with a nanometer core-shell structure, the dispersion liquid and the aluminum silicon sol are compounded in order to prepare the coating solution for an antireflection film, toughening treatment is carried out for the coating solution in order to obtain the antireflection film. The raw materials are easy to obtain, and the antireflection film with a hollow structure is prepared by a simple process; pore spaces are arranged in particles and are not arranged in a silicon dioxide network, so that high light transmittance of the film is guaranteed, the light transmittance reaches 94.5% or above, and the porosity is high; the film has excellent smudginess resisting performance, the antireflection film and a glass substrate can be firmly combined, and the hardness of the film is high; because the surface of the film is compact, the film has good blocking effects for steam erosion, good weatherability, and industrialized application values.

Owner:DONGGUAN CSG SOLAR GLASS +1

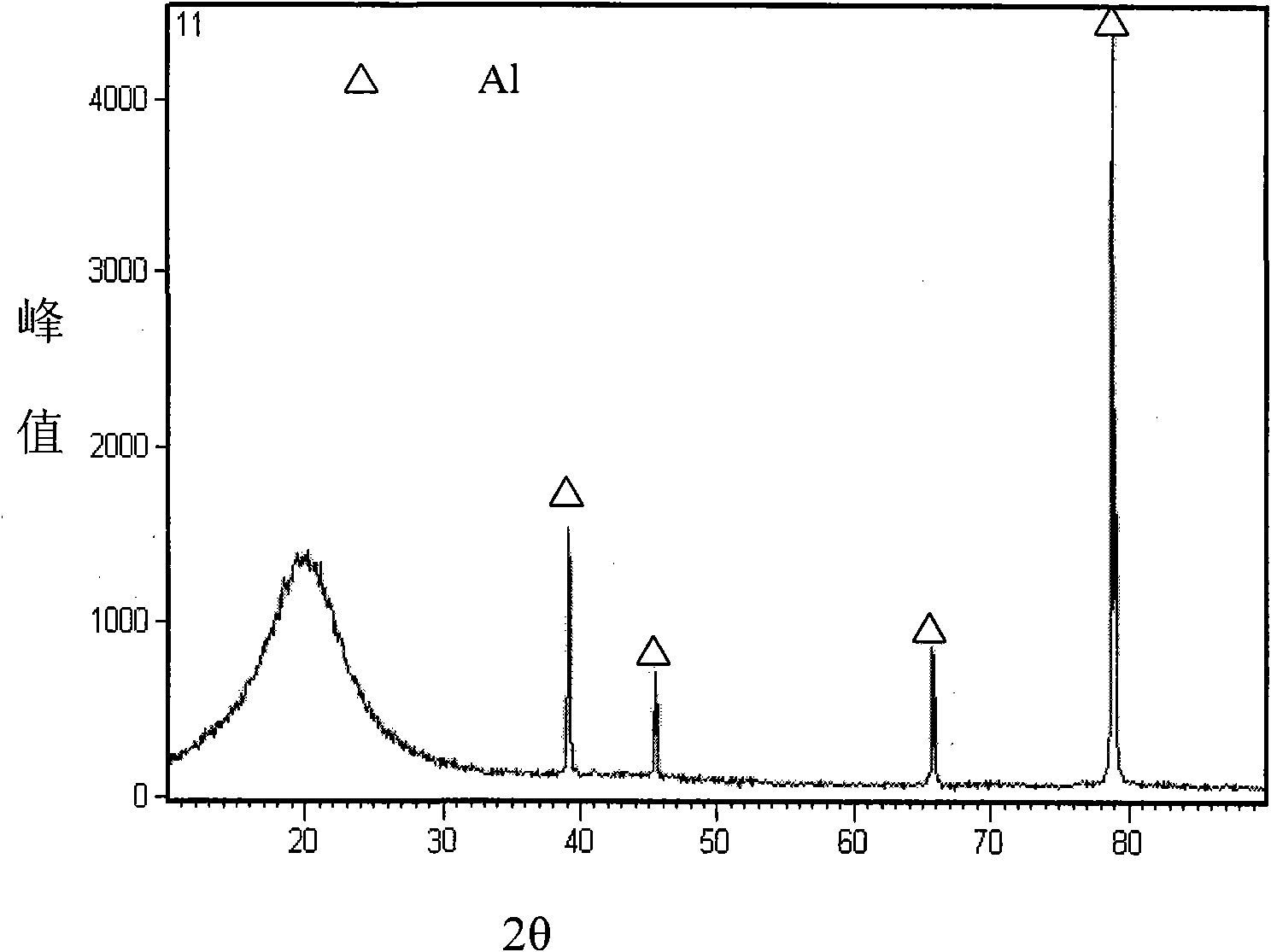

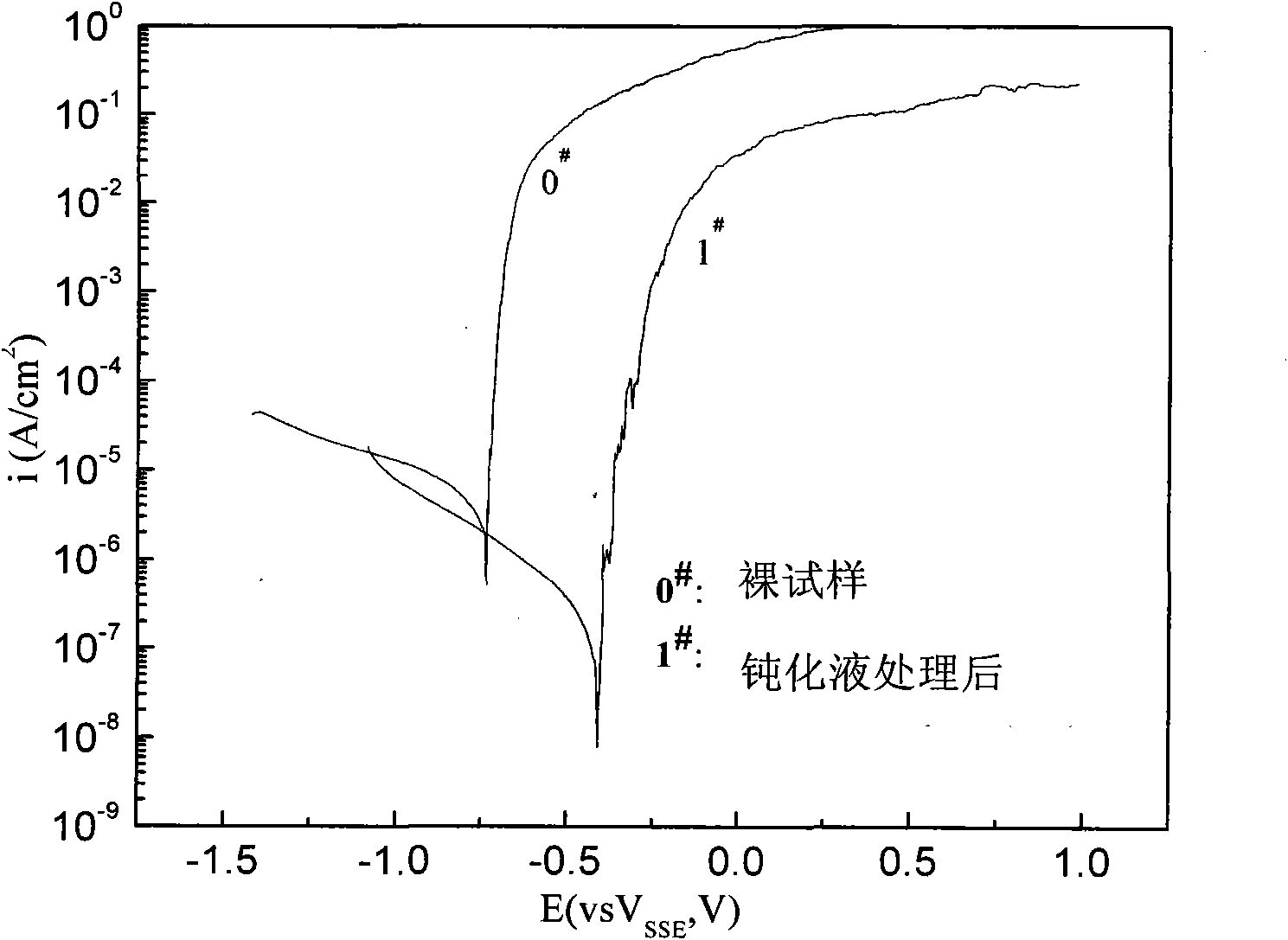

Treatment solution for preparing aluminum alloy surface amorphous composite passivation film, preparation method and application

InactiveCN101892477ASimple recipeSimple processMetallic material coating processesRare earthManganese

The invention discloses treatment solution for preparing an aluminum alloy surface amorphous composite passivation film, a preparation method and application. A formula of the treatment solution comprises 5 to 15g / L of corrosion inhibiting negative ion-containing rare earth salt, 3 to 10g / L of catalyst type composite oxidant, 1 to 3g / L of auxiliary oxidant, 0.1 to 0.5g / L of buffering film-forming accelerator and 0.5 to 1.5g / L of composite stabilizer. The treatment solution does not contain any toxic chromium or organic substances, does not need heating during conversion treatment of 2 to 5 minutes, and can prepare the golden amorphous 'rare earth-manganese' composite passivation film with excellent performance on the aluminum alloy surface. The treatment solution well solves environmental pollution and human harm caused by the present hexavalent chromium treatment, and can overcome the defects that a zirconium titanate series conversion film is colorless and field judgment cannot be realized. The preparation method has the advantages of simple process, simple and convenient operation and low cost, and is easy to realize industrialization.

Owner:SOUTH CHINA UNIV OF TECH

C/SiC composite coating applied to surface of low-density carbon/carbon composite material and preparation process thereof

The invention relates to a C / SiC composite coating applied to the surface of a low-density carbon / carbon composite material and a preparation process thereof. The composite coating consists of an inner hole sealing layer and an outer coating. The inner hole sealing layer is prepared from the raw materials in percentage by weight: 10-60% of silicon carbide powder, 1-25% of silicon powder, 0.05-8% of graphite powder, 1-10% of polyacrylonitrile ground carbon fiber and 40-80% of silica sol. The outer coating is prepared from the raw materials in percentage by weight: 10-30% of silicon carbide powder, 40-60% of resin, 30-70% of diluter and 1-6% of curing agent. The invention further comprises the preparation process of the low density C / SiC composite coating made of the carbon / carbon composite material. The C / SiC composite coating applied to the surface of the low-density carbon / carbon composite material provided by the invention is better in oxidation resistance, better in bonding force with a substrate material, compact in surface, free from crack and free from power fall.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Conductive silver paste for ceramic filter and preparation method thereof

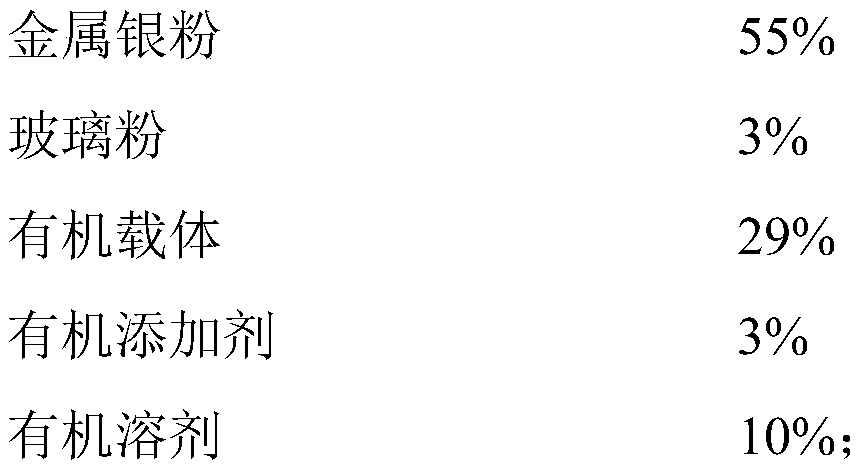

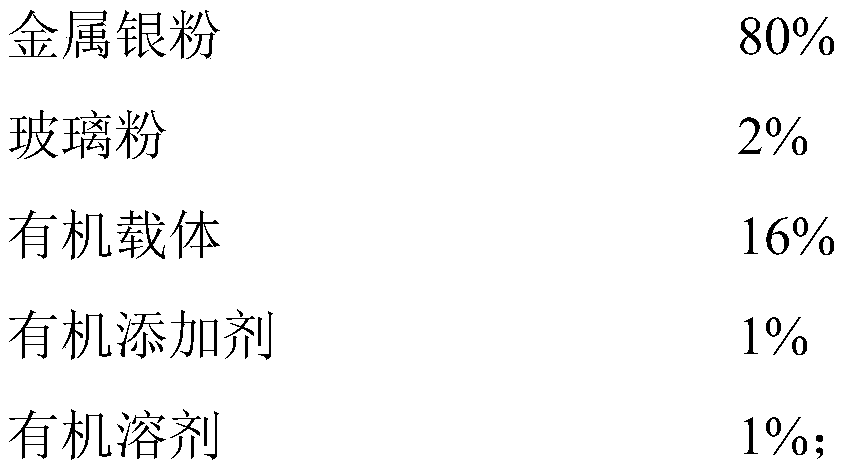

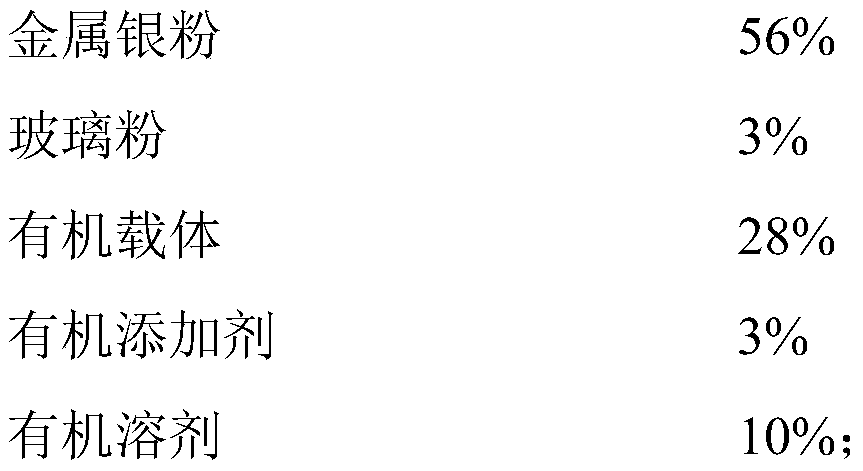

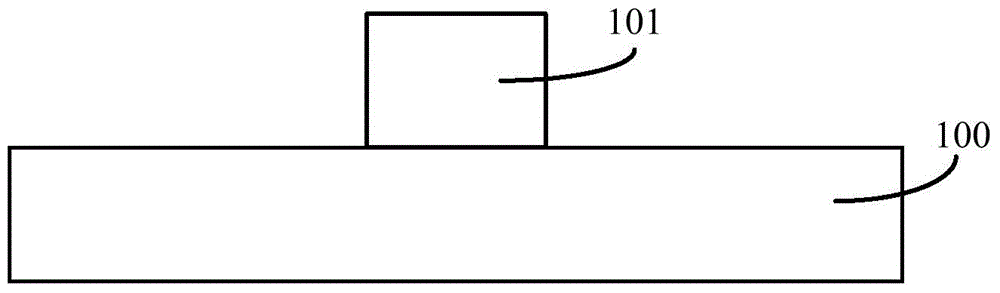

PendingCN111489848ASolve conductivity problemsSolve solder performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteThermal dilatation

The invention relates to conductive silver paste for a ceramic filter and a preparation method of the conductive silver paste. The conductive silver paste comprises the following components in parts by weight: 50-80 parts of metal silver powder, 2-5 parts of glass powder, 10-30 parts of an organic carrier, 1-3 parts of an organic additive and 1-10 parts of an organic solvent, wherein the glass powder is lead-free glass powder, the coefficient of thermal expansion is 110-120*10<-7> / DEG C, and the sintering temperature is 550-750 DEG C. The preparation method comprises the following steps: adding the organic carrier and the organic solvent into a mixer, adding the metal silver powder, the glass powder and the organic additive, fully mixing, transferring a mixture into a high-speed dispersionmachine, and uniformly dispersing at a high speed to obtain a conductive silver paste; and grinding the prepared conductive silver paste in a three-roller mill, and finely adjusting a roller to enable the fineness of the conductive silver paste to be less than 10mu m and the viscosity to be 30-50Pa.S, thereby obtaining the conductive silver paste for the ceramic filter. The conductive silver paste for the filter can form a conductive silver layer which is high in compactness, high in adhesive force, high in conductivity, good in weldability and stable in performance.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

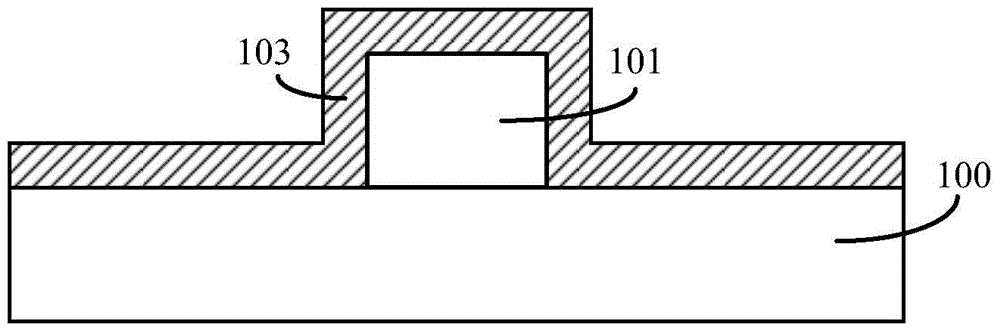

Self-aligning double patterning formation method

ActiveCN104701158AHigh densitySurface Topography Optimization and ImprovementPhotomechanical apparatusSemiconductor/solid-state device manufacturingMask layerElectrical and Electronics engineering

A self-aligning double patterning formation method includes providing a to-be-etched layer, wherein the surface of the to-be-etched layer is provided with a plurality of discrete sacrificial layers; forming mask layers on the surface of the to-be-etched layer and the sidewall and top surfaces of the sacrificial layers; etching back the mask layers until the mask layers expose out of the surface of the to-be-etched layer and the top surfaces of the sacrificial layers, and forming mask spacers on the sidewall surfaces of the sacrificial layers; removing the sacrificial layers after the mask spacers are formed; after the sacrificial layers are removed, subjecting the mask spacers to strengthening treatment to enable the mask spacers to be densified. The masks formed by self-aligning double patterning process are good in shape.

Owner:SEMICON MFG INT (SHANGHAI) CORP

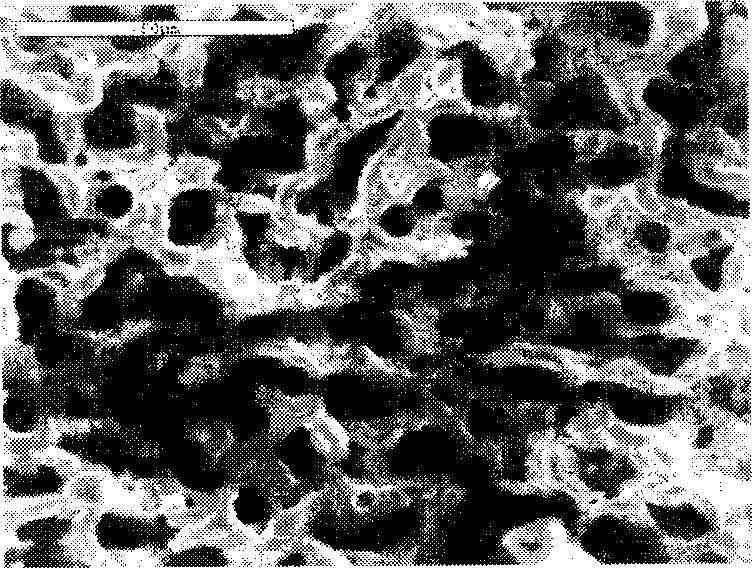

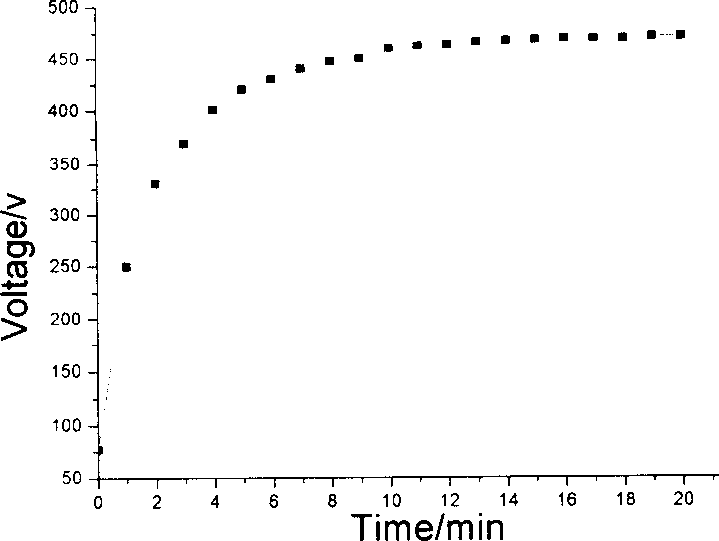

Electrolytic solution for differential arc oxidization surface treatment of magnesium aluminum alloy in aluminates system

InactiveCN1737210ABroad marketHigh electrochemical impedanceAnodisationElectrolysisPlasma electrolytic oxidation

The invention relates to an electrolytic solution used to oxygenize surface of aluminum-magnesium alloy work-piece by differential arc. Said electrolytic solution comprises 4-40g / L of sodium aluminate, 0-10g / L of caustic soda and other assistants. The invention can generate a ceramic film with smooth surface, strong resistance to soiling, corrosion resistance and great mechanical behavior.

Owner:JILIN UNIV

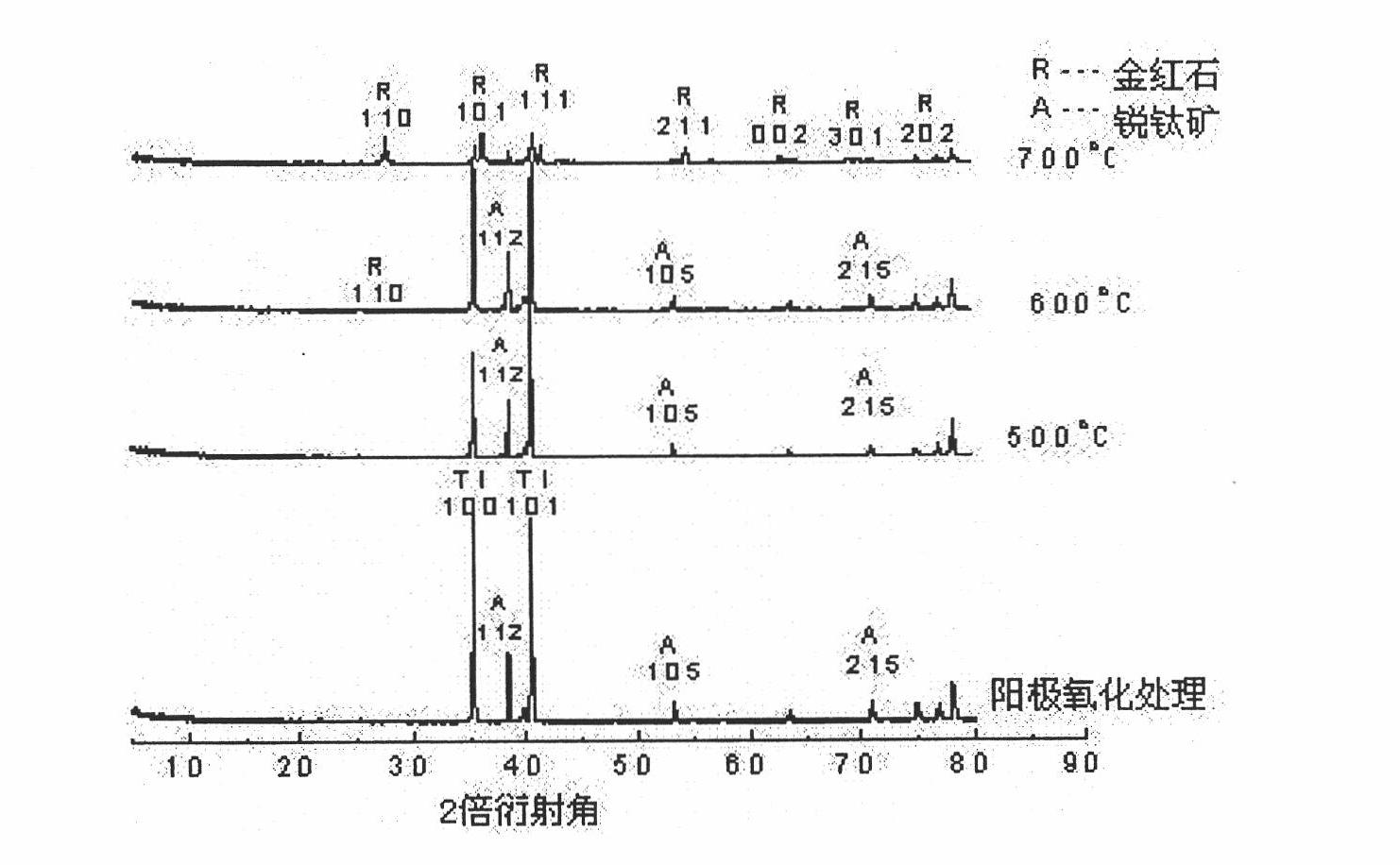

Glass fiber air filter paper repeatedly cleaned and preparation method of glass fiber air filter paper

ActiveCN104213470AHigh strengthDense surfaceSynthetic cellulose/non-cellulose material pulp/paperFiltration separationFilter paperCompounds of carbon

The invention discloses glass fiber air filter paper which can be repeatedly cleaned. The glass fiber air filter paper comprises glass fibers and bonding glue stock, wherein the glass fibers are prepared by mixing 25-45 parts by mass of alkali-free glass fiber cotton with the diameter of 3.5-6.0 microns and 55-75 parts by mass of alkali-free glass fibers with the diameter of 0.4-0.8 micron; the bonding glue stock comprises acrylic resin, macromolecular fluorocarbon, a surfactant and a cross-linking agent; the dry weight of the bonding glue stock accounts for 1-3 percent of the total weight of the glass fiber air filter paper. A method for preparing the glass fiber air filter paper provided by the invention comprises the following steps: dispersing and pulping; conveying pulp to a former for forming, applying glue to the surface of wet paper, and performing suction and dehydration; performing primary drying on the wet paper by an infrared drying device; and finally, drying the wet paper at the temperature of 100-200 DEG C, thereby obtaining the glass fiber air filter paper. According to the invention, the water resistance of the air filter paper can be obviously improved under the condition that other performance of the air filter paper is not influenced, and the air filter paper can be repeatedly used after being cleaned.

Owner:CHONGQING ZAISHENG TECH CORP

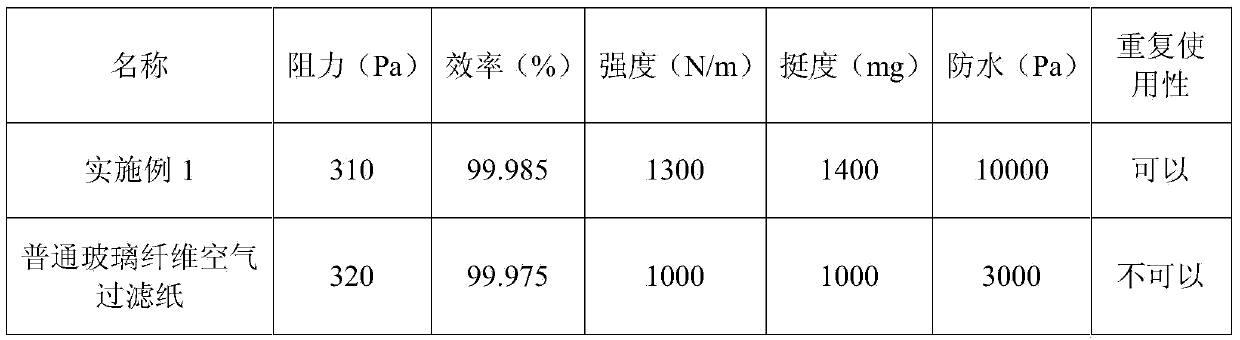

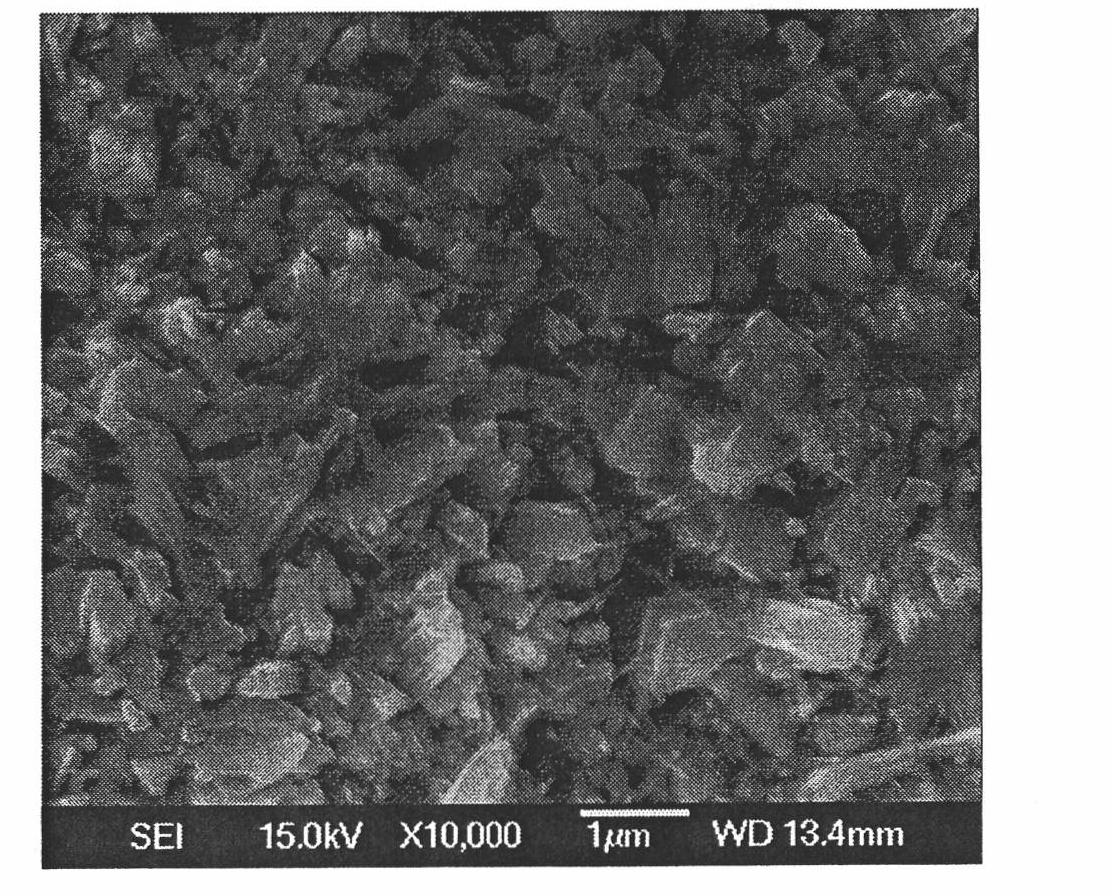

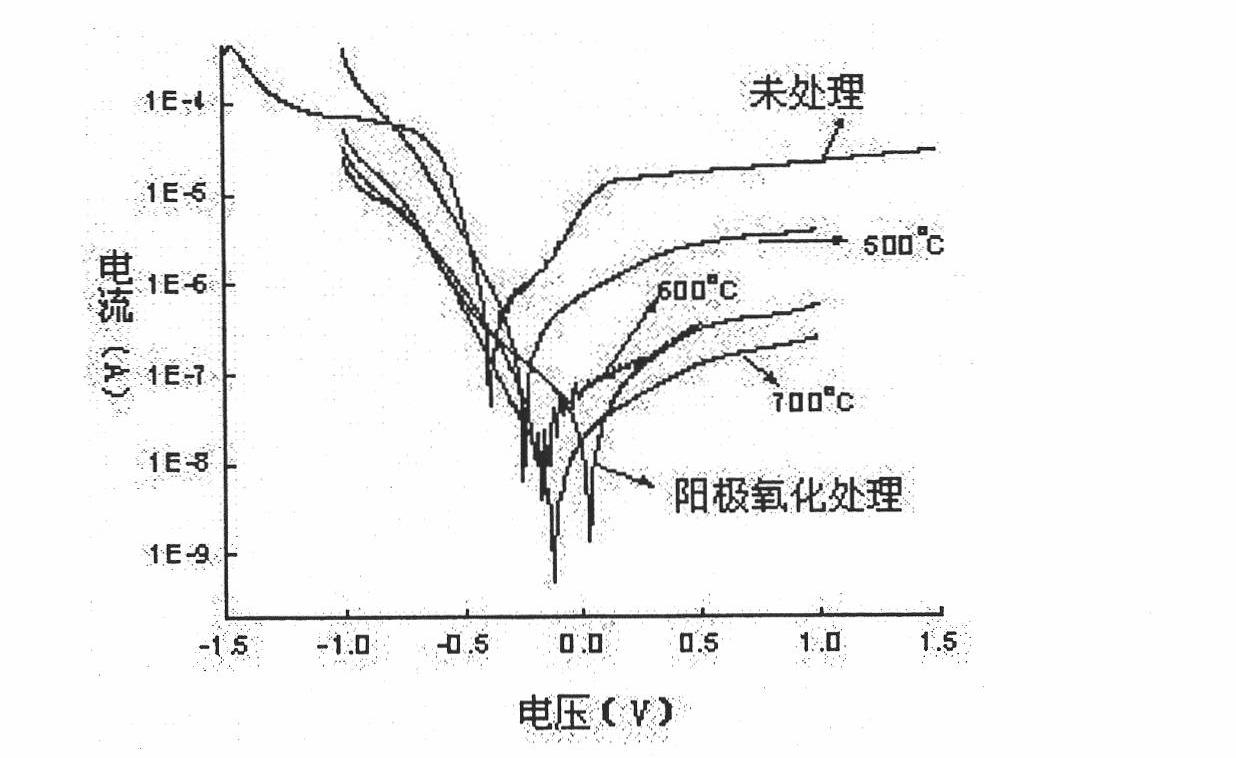

Composite oxidation technology for medicinal titanium alloy

InactiveCN101942688ASimple processLess investmentSurface reaction electrolytic coatingChemical treatmentBiological activation

The invention relates to composite oxidation technology for medicinal titanium alloy, belongs to the technical field of chemical treatment on metal surfaces, and aims to improve the corrosion resistance and abrasion resistance of an oxidation layer on the surface of the medicinal titanium alloy. The method comprises two key processes: 1, anodic oxidation technology on the surface of the titanium alloy; and 2, thermal oxidation technology on the surface of the titanium alloy. The method comprises the following steps of: performing surface finish, alkaline wash and activation on the titanium alloy, and performing anodic oxidation by using mixed solution of ammonium phosphate, ammonium acetate and hydrogen peroxide as electrolyte; drying and performing thermal oxidation in the atmosphere of nitrogen and oxygen according to a certain ratio, and controlling the temperature to be between 500 and 700 DEG C. The provided method has the advantages of simpleness, easy implementation, no damage to mechanical properties of titanium alloy materials, no environmental pollution, application to mass production and great reduction of cost.

Owner:SHANGHAI UNIV

Technique for packaging long stator iron core assembly

The invention is a long stator iron core component packaging process, belonging to electric machine manufacturing technical field, comprising the steps of: a. putting solidified long stator iron core component together with connecting piece into an epoxy resin or unsaturated polyester resin injection mould and heating to 60-200 deg.C, preserving heat for 2-60 min; b. pressurizing the injection mould while vacuumizing and pouring epoxy resin or unsaturated polyester resin and keeping 2-60 min at a pressure of 1-5MPa; c. opening the injection mould and putting injected piece into an oven or baking channel for post-solification and making the long station iron core packaged piece. And the invention has advantages of convenient operating, saving labor and time, simplifying injection device, etc. and the surface of the packaged long stator iron core component is compact, and smooth and birght and clean, and has no air holes and defects, and the invention is especially applied to packaging long stator iron core components for high speed magnetic suspension train and driving motor iron core components for city railway traffic.

Owner:WOLONG ELECTRIC GRP CO LTD

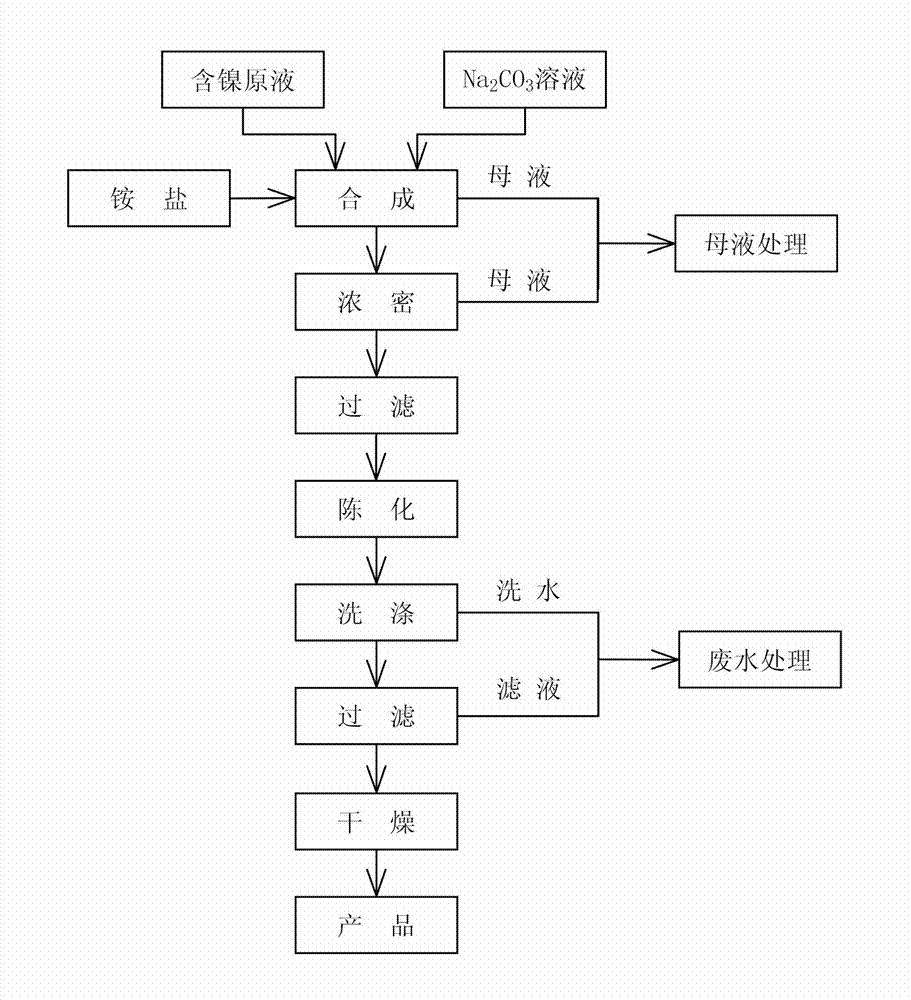

Method for continuously compounding high-purity alkali nickel carbonate

ActiveCN102923794ALow impurity contentFlat surfaceNickel carbonatesTemperature controlReaction temperature

The invention discloses a method for continuously compounding high-purity alkali nickel carbonate. The method comprises the steps as follows: a nickeliferous stock solution, ammonium salt and a precipitant Na2CO3 are continuously conveyed to a multifunctional reactor for carrying out continuous compounding reaction, and resultant slurry is continuously discharged from a material outlet; during the continuous compounding reaction, the reaction temperature is controlled within 50-80 DEG C with a real-time monitoring system, the reaction pH value is controlled within 7.5-8.5, and the average residence time of a reaction system in the multifunctional reactor is controlled within 20 h-30 h; and a reaction discharging is filtered, filter residue is aged, and then the reaction discharging enters into a multi-level washing tower to be washed, when the flow conductance value of the multi-level washing tower bottom is less than 600 ms / cm, a washed product is filtered and dried to obtain the high-purity alkali nickelous carbonate. The invention has the advantages of simple process, low equipment investment, environment protection, complete product structure, good quality and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

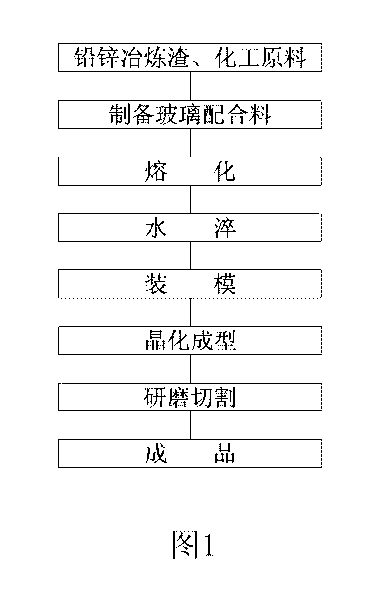

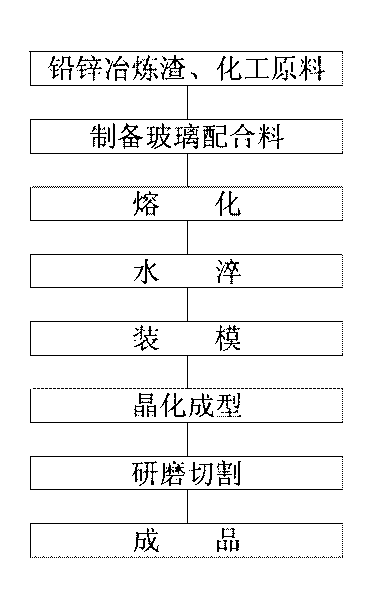

Green glass-ceramic plate made from lead-zinc smelting slag and manufacturing method thereof

The invention relates to a green glass-ceramic plate made from lead-zinc smelting slag and a manufacturing method thereof. The glass raw material is prepared from the following components in parts by weight: 40 to 60 parts of lead-zinc smelting slag, 26 to 38 parts of quartz, 15 to 24 parts of lithium feldspar, 2 to 4 parts of soda ash, 2 to 3 parts of zinc oxide, 2 to 5 parts of barium carbonate, 1 to 3 parts of borax, 2 to 2.5 parts of chromium oxide, 0 to 0.2 part of copper oxide and 0.04 to 0.2 part of carbon powder. The invention is not only in line with the common glass-ceramic produced by completely adopting industrial materials on the aspect of the performance, but also can realize waste utilization, reduce the environmental pollution, the product cost and the melting temperature of glass, improve the melting speed and the melting furnace efficiency of the glass, decrease the energy consumption and can be widely applied to building decoration materials, especially applied in various building decoration engineering, such as inside and outer walls, floors, pillars, table boards of the building, and the like.

Owner:FENGXIAN SANLIAN BUILDING MATERIALS

Environmental-friendly disposable plant fiber tableware and preparation method thereof

The invention discloses an environmental-friendly disposable plant fiber tableware which comprises the following raw materials in parts by weight: 10-18 parts of rice husk, 15-25 parts of corn straw, 10-20 parts of dried straw, 2-4 parts of starch, 8-14 parts of an adhesive, 4-10 parts of processing aids, 2-4 parts of plant albumen glue and 1-3 parts of plant polysaccharide. The disposable tableware disclosed by the invention is non-toxic and harmless, is relatively good in mechanical property, relatively good in mechanical strength and toughness, green and environmental-friendly in raw material, relatively good in degradability, wide in raw material source, safe and reliable in component, harmless to human bodies, low in cost, safe and convenient, simple in preparation process and has relatively high practical values and good application prospects, both resources are saved and environment pollution is reduced, and comprehensive utilization of agricultural wastes is achieved.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Particles capable of lowering temperature of smoke of cigarettes and preparation method and application of particles

ActiveCN109700070AEasy to addDense surfaceTobacco smoke filtersTobacco devicesInorganic particleInorganic particles

The invention belongs to the technical field of cigarette auxiliary materials and relates to particles capable of lowering the temperature of the mainstream smoke of cigarettes and a preparation method and application of the particles. The particles are inactive particles, active particles with outer film layers or inactive particles with outer film layers. The thickness of the outer film layers of the inactive particles is 0-0.2 mm, and the outer film layers account for 0-50% of the total particle mass; the thickness of the outer film layers of the active particles is 001-0.2 mm, and the outer film layers account for 0.001-50% of the total particle mass. The inactive particles are particles which adsorb 3.0 mg / cm<3> or less of nicotine in smoke aerosol; the inactive particles include inorganic particles or organic particles. The preparation method is simple, industrialization is convenient, and the particles are easily added into cigarette filter rods. The surfaces of the particles are dense and have no leakage, and by adding the particles into the cigarette filter rods, the temperature of the smoke of the cigarettes can be greatly lowered.

Owner:NANTONG CELLULOSE FIBERS CO LTD +2

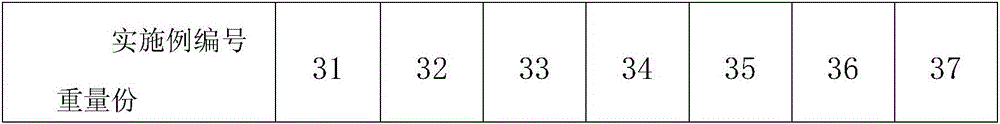

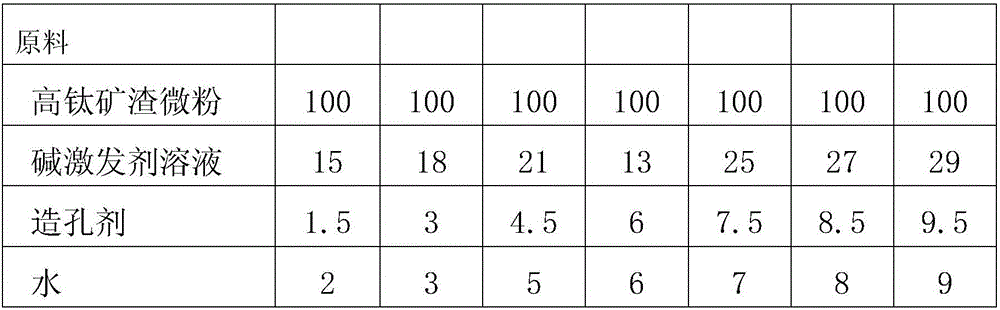

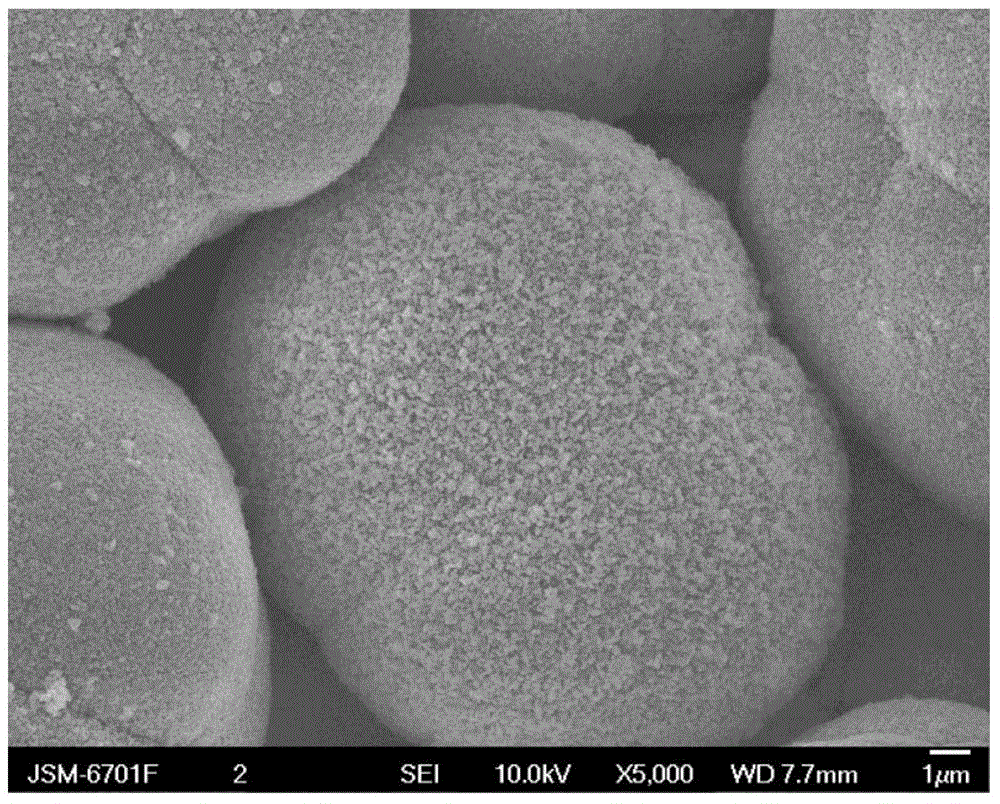

Alkali-activated high-titanium slag baking-free haycite and preparation method thereof

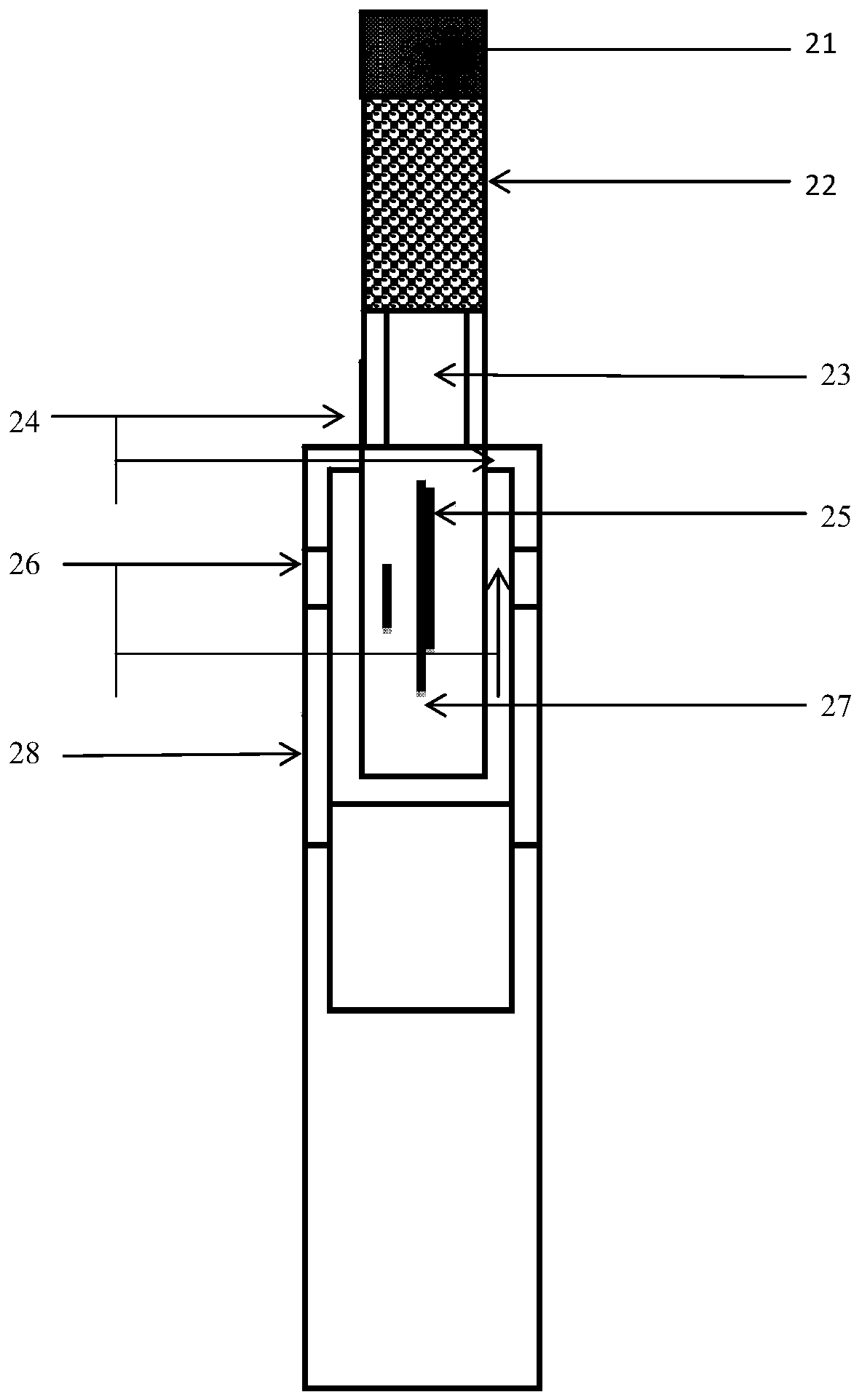

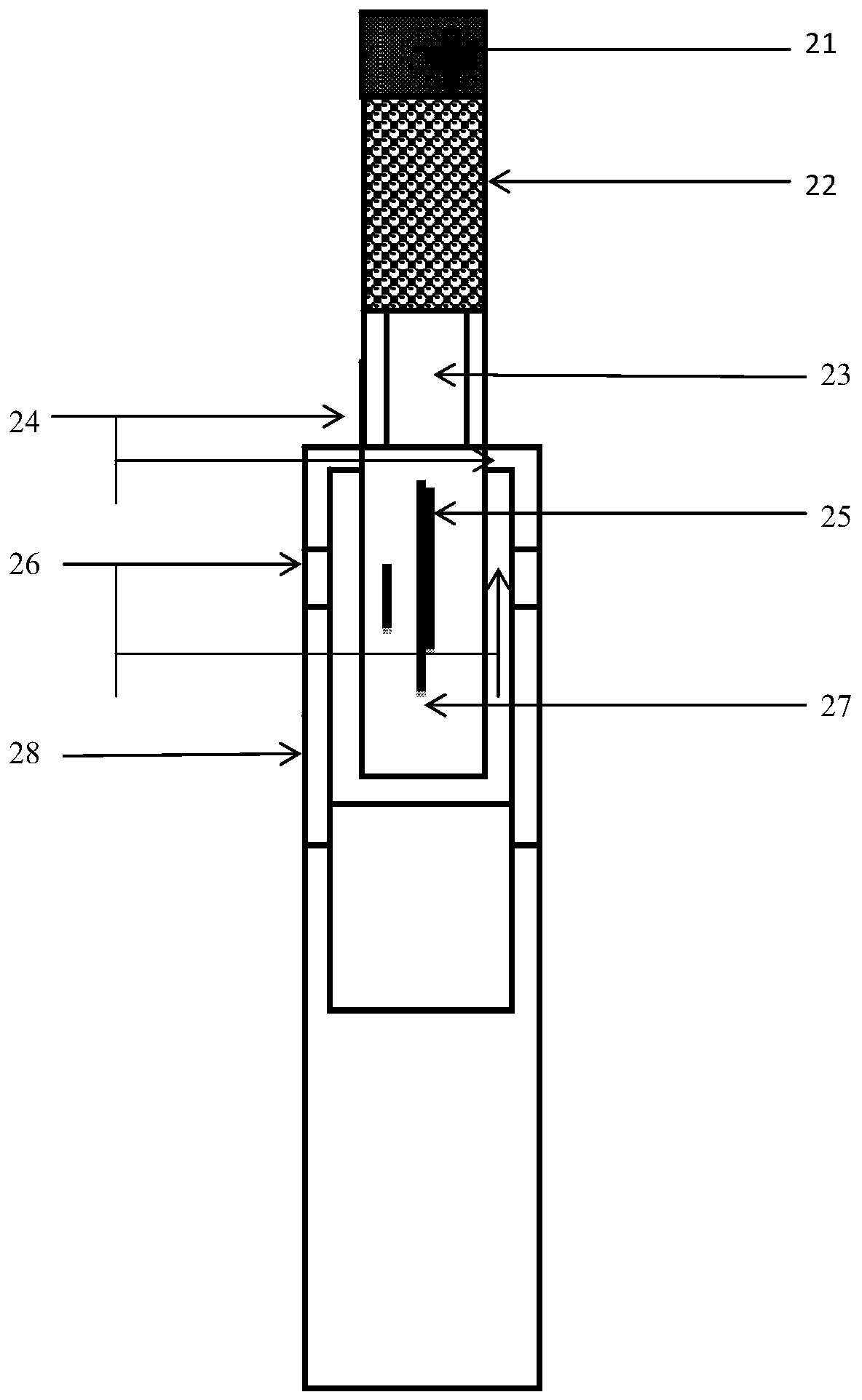

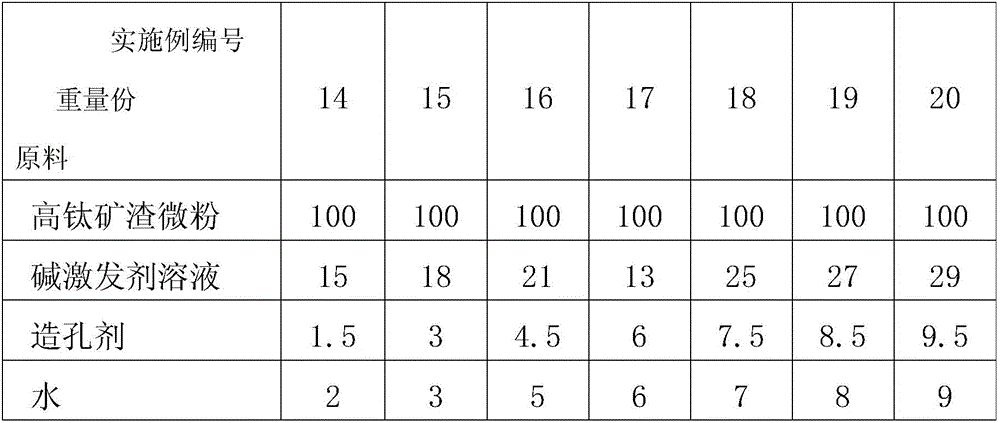

The invention discloses alkali-activated high-titanium slag baking-free haycite which is characterized by being prepared by mixing 100 weight parts of high-titanium slag micro powder, 12.5 to 30 weight parts of an alkali-activator, 0.5 to 10 weight parts of a pore forming substance and 0 to 10 weight parts of water. A preparation method of the alkali-activated high-titanium slag baking-free haycite comprises the following steps: putting the high-titanium slag micro powder into a disk granulator for stirring, so as to form a uniformly dispersed powder body; adding the pore forming substance, the water and the alkali-activator solution in sequence, and performing stirring, granulation and forming to obtain a blank, wherein the alkali-activator solution is water glass; maintaining the blank under a natural environment condition for 28 days, so as to obtain the alkali-activated high-titanium slag baking-free haycite. By the adoption of the preparation method for preparing the alkali-activated high-titanium slag baking-free haycite, high-temperature baking is not needed; a large mixing amount of the high-titanium slag micro powder can be used, so that a product is light in mass and high in strength; the alkali-activated high-titanium slag baking-free haycite has the characteristics of simple process, low cost, energy conservation, low carbon, environment friendliness and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

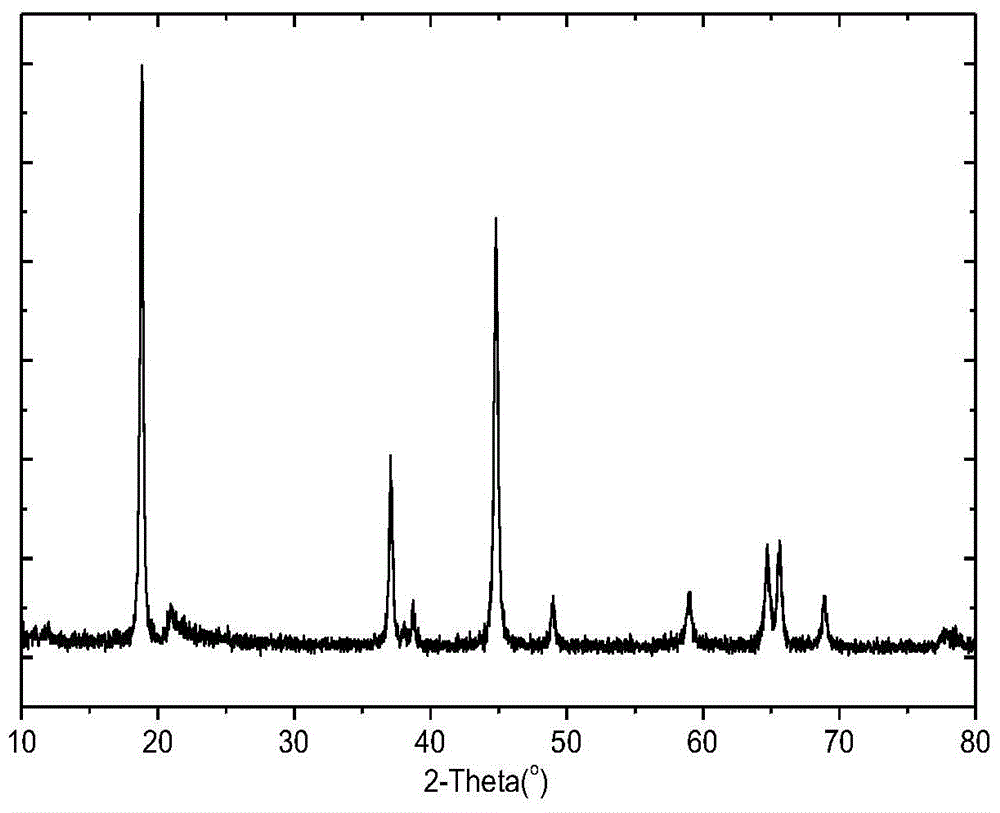

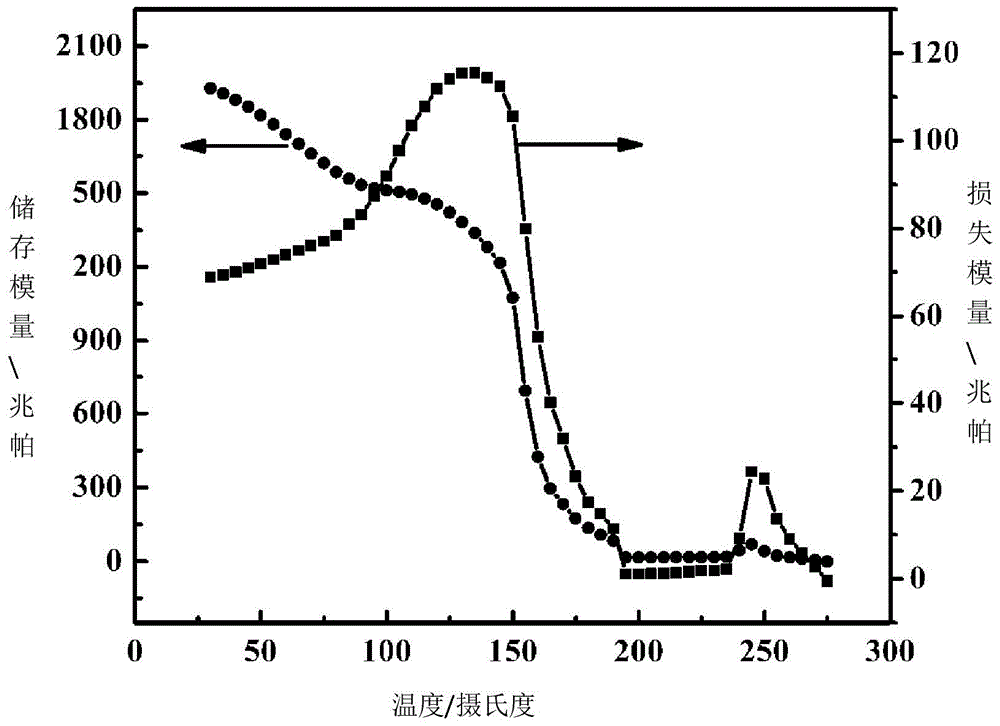

Preparation method of high-capacity lithium-rich anode material

InactiveCN105118987AHigh specific capacityFlat surfacePositive electrodesLithiumAlkaline earth metal

The invention discloses a preparation method of a high-capacity lithium-rich anode material. According to the method, a material precursor, lithium salt and alkali metal or alkaline-earth metal molten salt are calcined at certain temperature according to a certain sequence and ratio, and then the high-capacity lithium-rich anode material is obtained. The obtained lithium-rich anode material is smooth and dense in particle surface and excellent in electrochemical performance, and has the advantages of being high in discharge capacity, low in irreversible capacity, stable in circulation and the like. The method is simple in technological condition, raw materials are cheap, growth of crystal particles of the lithium-rich anode material is controlled through the molten salt, and meanwhile the problem of non-uniform sintering in the sintering process and especially the large-scale sintering process of the material is solved. High practicality is achieved, and the preparation method is suitable for mass production.

Owner:INST OF CHEM CHINESE ACAD OF SCI +2

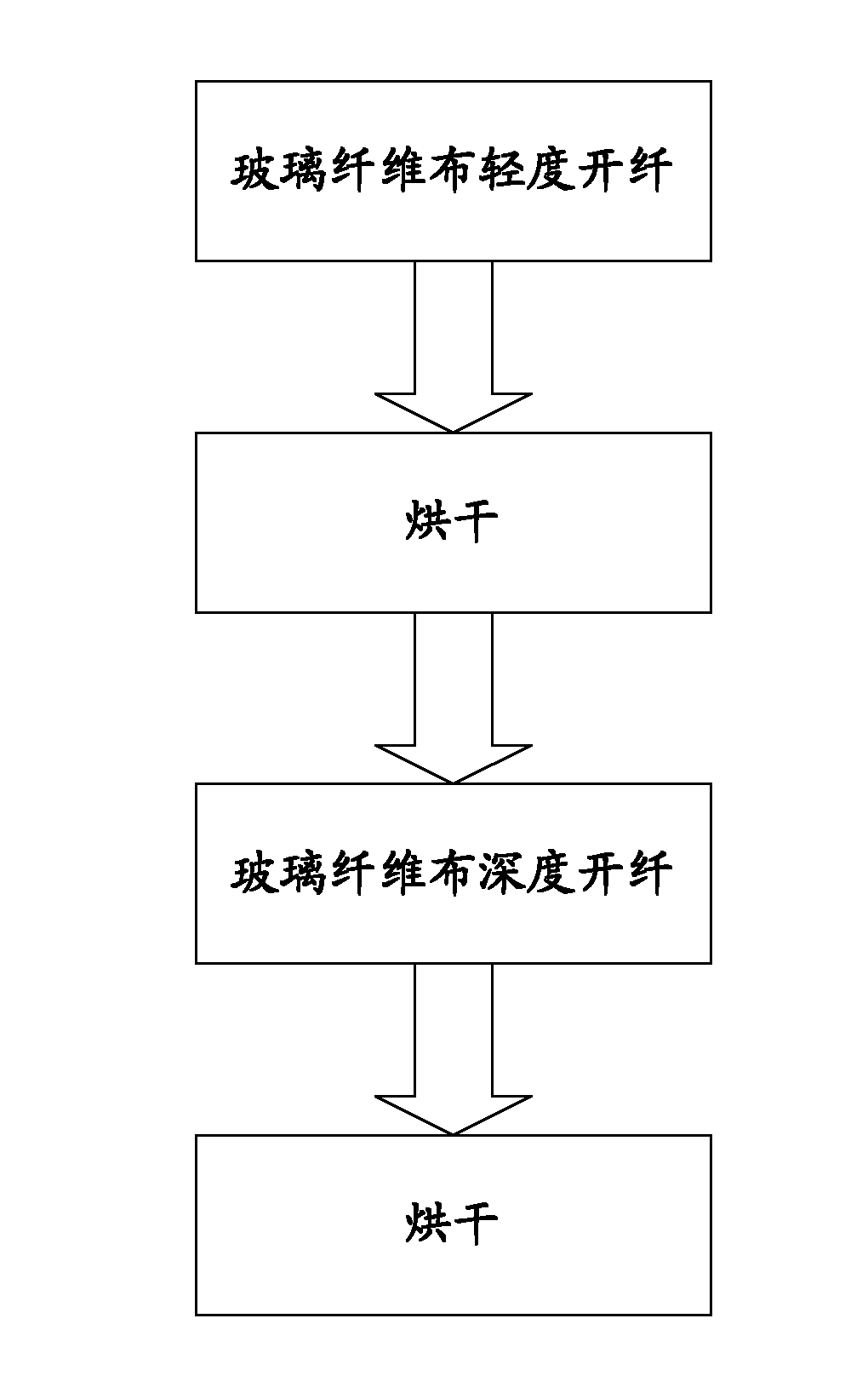

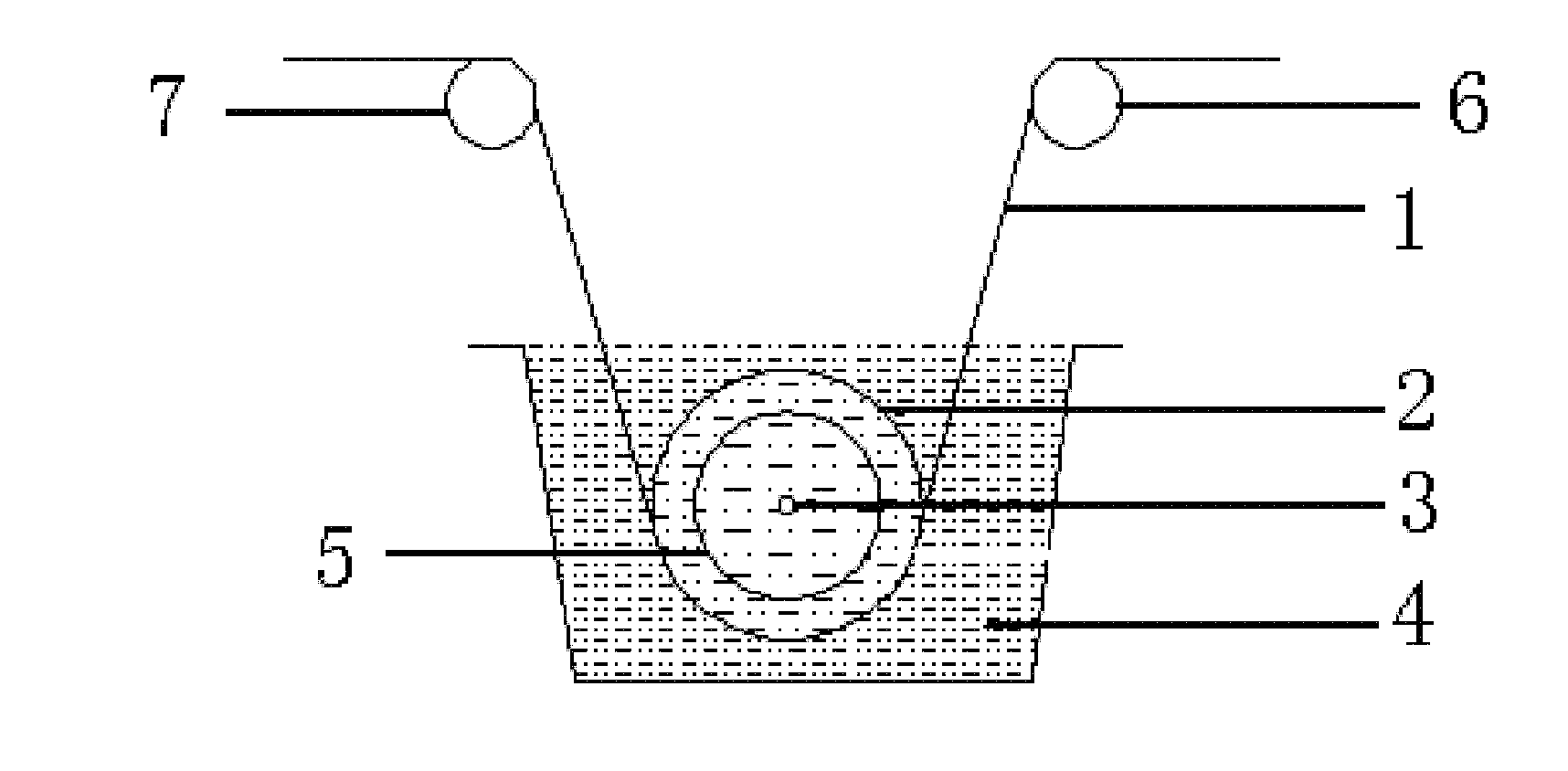

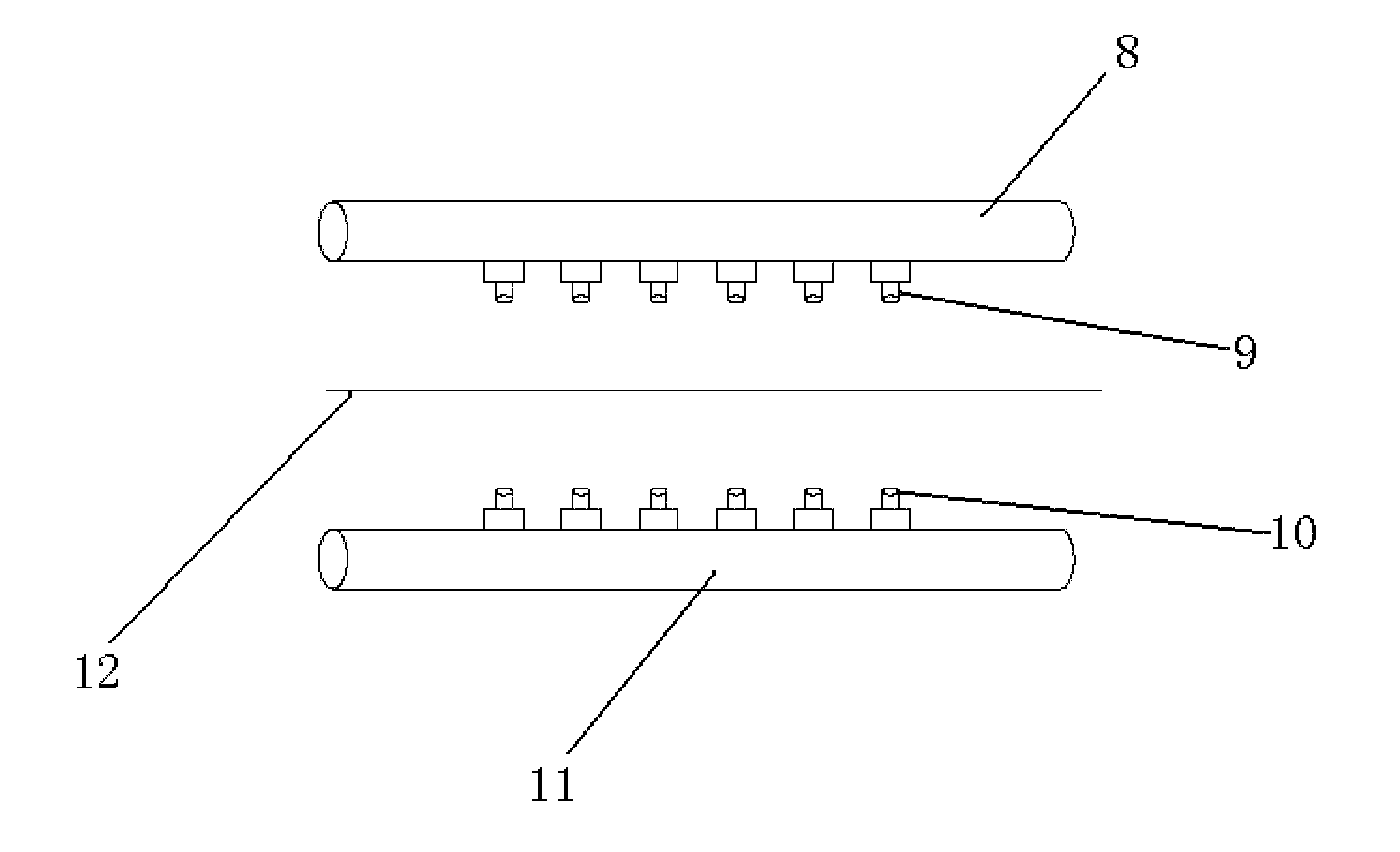

Ultra-high-performance electronic glass fiber cloth production process

ActiveCN102758335ADense surfaceFlat surfaceTextile treatment by spraying/projectingTextile shapingWeft yarnImpact pressure

The invention discloses an ultra-high-performance electronic glass fiber cloth production process which specifically includes the steps: A, slightly splitting electronic glass fiber cloth; B, drying the slightly split electronic glass fiber cloth; C, deeply splitting the dried electronic glass fiber cloth; and D, drying the deeply split electronic glass fiber cloth so that ultra-high-performance electronic glass fiber cloth is obtained. During slight splitting, cloth surfaces are humidified by a water-washing oscillating trough, so that warp and weft yarns are bulked, and fibers are loosened; and during deep splitting, purified water is sprayed from holes of nozzles to be directly jetted to the cloth surfaces, the front and the back of the glass fiber cloth are sprayed by water columns, the warp and weft yarns are broken apart after the cloth surfaces are subjected to impact pressure of the purified water columns, the compactness of the glass fiber cloth is greatly reduced, and gaps among the warp and weft yarns are mostly filled by loose single fibers to be smaller, so that the surfaces of the glass fiber cloth become dense and uniform, and the surfaces of the glass fiber cloth are smoother after splitting.

Owner:建滔(清远)电子材料有限公司

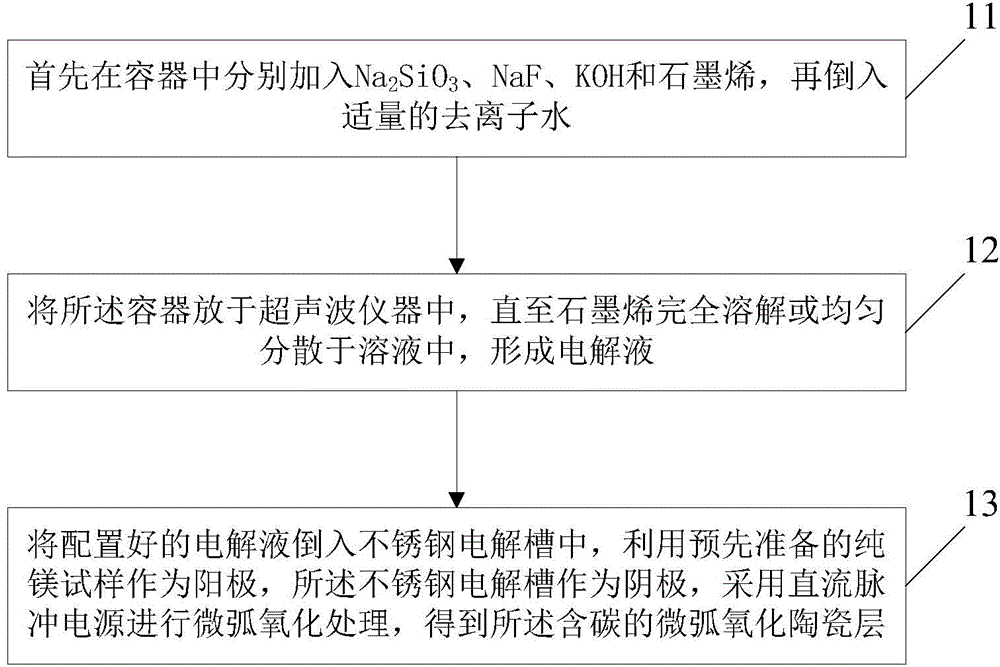

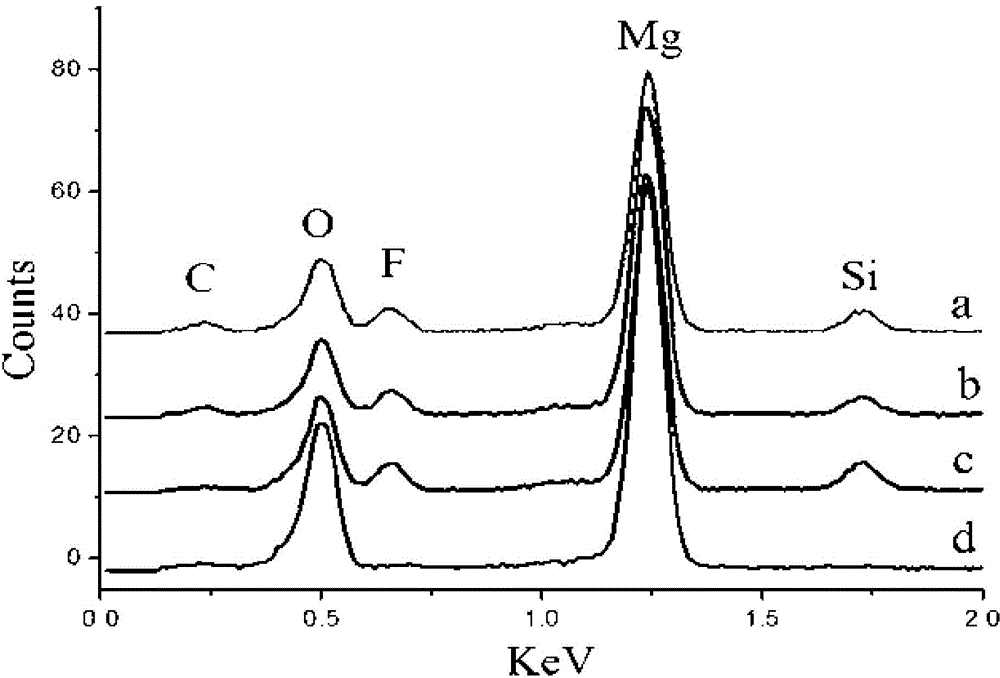

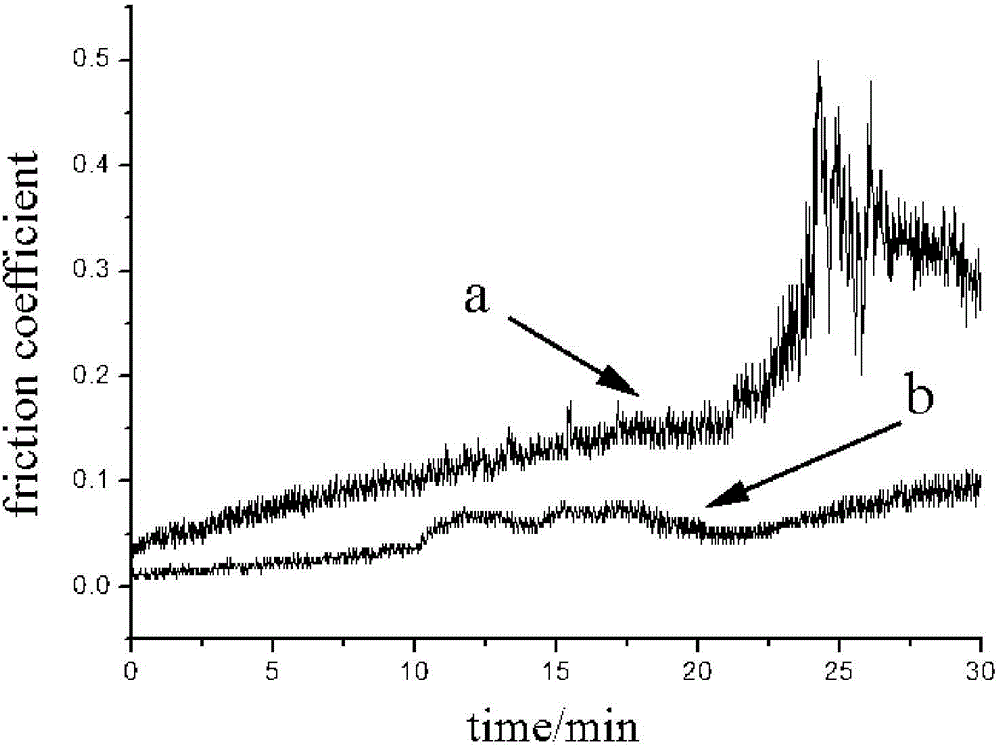

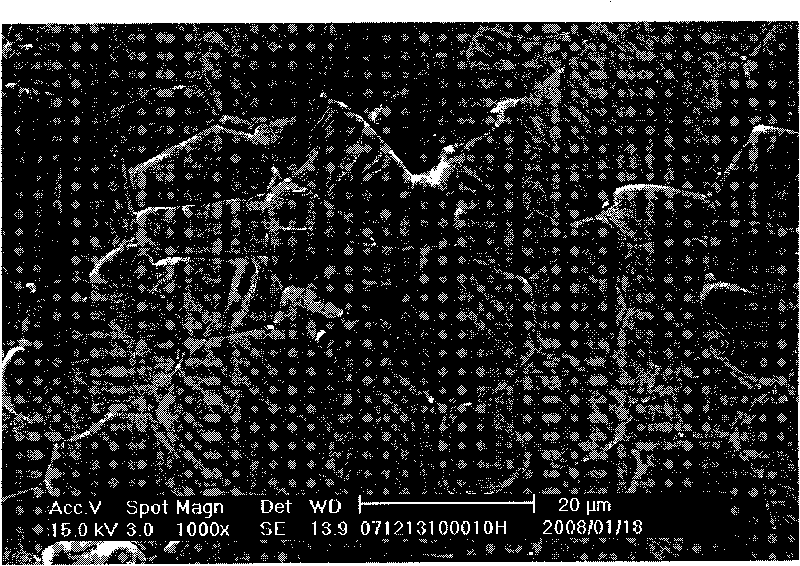

Method for preparing carbon-containing micro-arc oxidation ceramic layer

InactiveCN104562147AFlat surfaceDense surfaceAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for preparing a carbon-containing micro-arc oxidation ceramic layer. The method comprises the following steps: firstly respectively adding Na2SiO3, NaF, KOH and graphene into a container, and pouring a proper amount of deionized water into the container; putting the container into an ultrasonic wave instrument until graphene is completely dissolved or uniformly dispersed in the solution so as to generate electrolyte; pouring the prepared electrolyte into a stainless steel electrolytic cell, carrying out micro-arc oxidation by virtue of a direct-current pulsed power supply by taking a pre-prepared pure magnesium sample as a positive electrode and the stainless steel electrolytic cell as a negative electrode, so as to obtain the carbon-containing micro-arc oxidation ceramic layer. By virtue of the method, the surface of the carbon-containing micro-arc oxidation ceramic layer is relatively smooth and compact, relatively good anti-attrition and wear-resisting effects are achieved, and an energy-efficient preparation process is realized.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

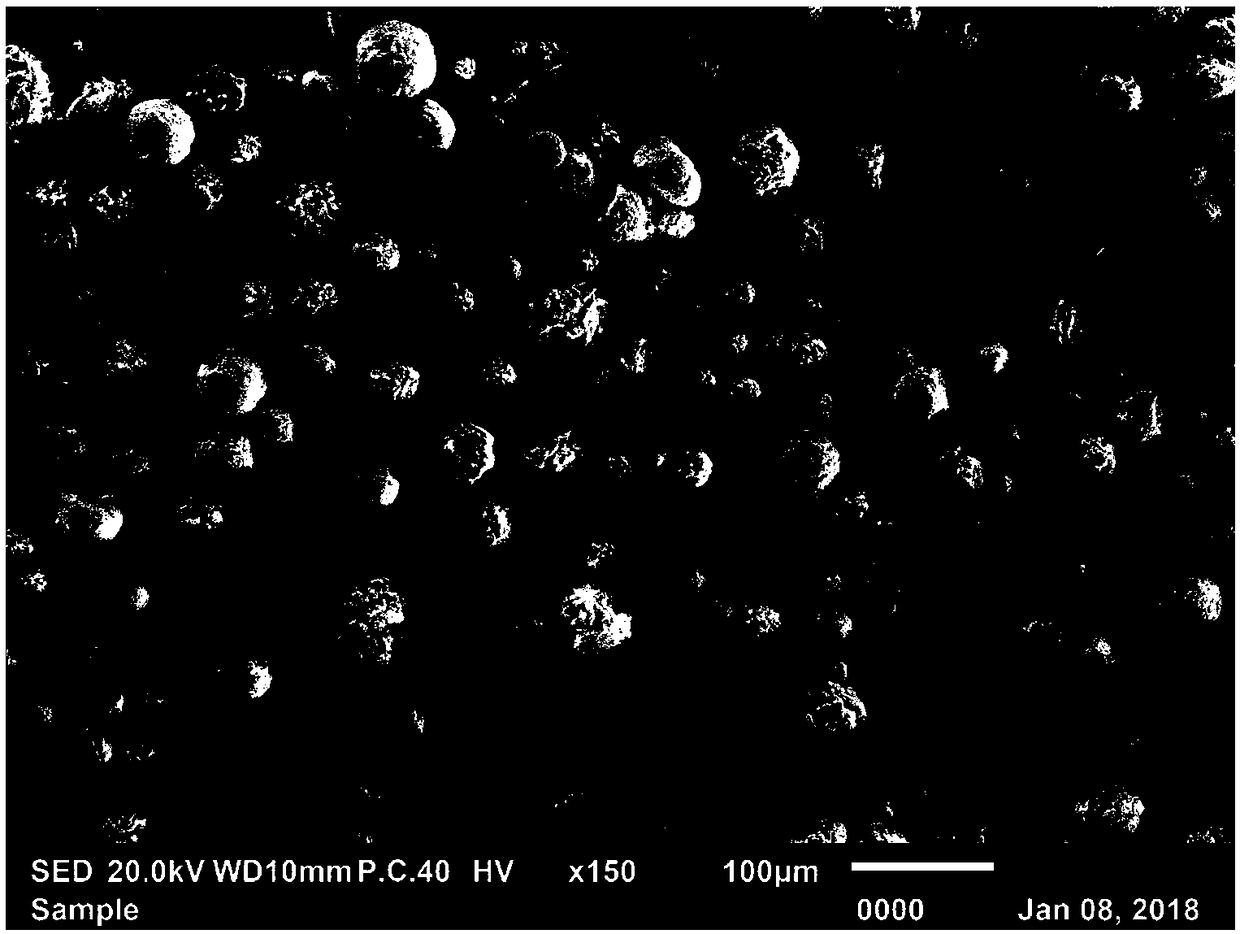

High-sphericility, compact-surface and low-impurity Ni-Co-Mn ternary material precursor and preparation method and application thereof

The invention discloses a high-sphericility, compact-surface and low-impurity Ni-Co-Mn ternary material precursor and preparation method and application thereof, and belongs to the technical field oflithium ion battery preparation. The preparation method comprises the following steps of dissolving a nickel source, a cobalt source and a manganese source compound in deionized water to prepare a solution with certain concentration; mixing the prepared solution and concentrated ammonia water, and combining with a precipitant and an ammonium salt solution to enter a reaction kettle for reaction; washing, re-pulping and re-washing the obtained precursor paste, and adding a certain amount of alkali solution during the re-pulping process; and performing spray drying, thereby obtaining the Ni-Co-Mn ternary material precursor. With the adoption of the method, the prepared Ni-Co-Mn ternary material precursor can be good in crystallinity, high in product sphericility, compact in surface and extremely low in impurity content in a product and can be used for a lithium ion battery positive electrode material-lithium nickel cobalt manganate with more excellent performance.

Owner:安徽同心新材料科技有限公司

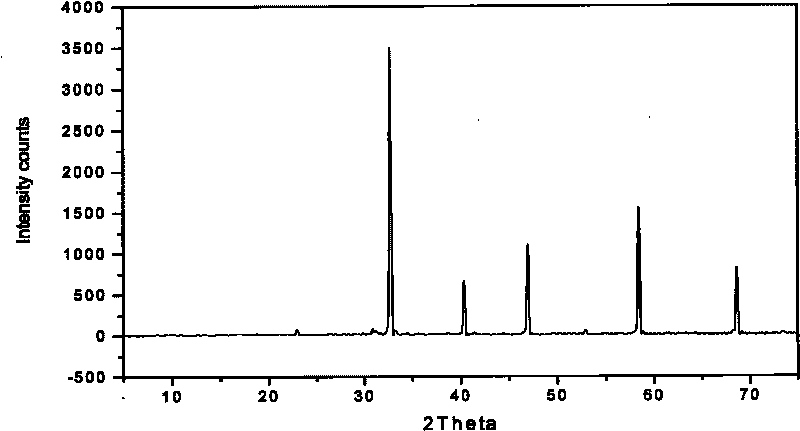

Method for preparing doped perovskite structural material

The invention provides a method for preparing a doped perovskite structural composite oxide, which comprises two steps, namely preparation and sintering of sol-gel. The preparation of the sol-gel comprises the following steps of selecting an element containing Sr or Zr as a group A element and selecting an element containing three elements selected from Ti, Fe, Cu, Pd and Mn as a group B element to prepare perovskite structural composite oxide gel of which the general formula is AB1-x-yB'xB''yO3-epsilon, wherein x and y are more than 0 and less than 0.5; and epsilon is more than -0.5 and less than 0.5 and is an oxygen lattice defect number. The obtained gel is sintered in a muffle furnace of which the temperature can be controlled by a program to obtain a perovskite oxide material which has a high crystallization degree, a single crystal form and a compact surface. The perovskite oxide material can be applied to a piezoelectric material or an electronic apparatus and can also be made into a compact ion conducting oxygen-permeable membrane for oxygen separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

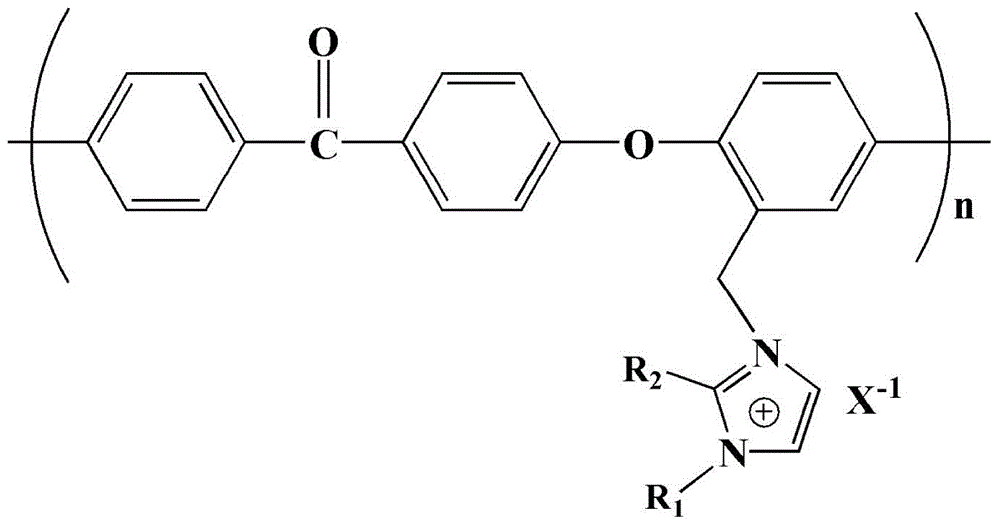

N1 position-substituted imidazole compound and alkaline anion exchange membrane, and preparation methods thereof

InactiveCN105777642ASimple processImprove stabilityOrganic chemistryFinal product manufactureAlkanePhenyl group

In the formula of an N1 position-substituted imidazole compound, R2 is a C1-C10 straight-chain paraffin; and R2 is a C1-C9 chain alkane, or a C3-C6 cycloalkane, or a phenyl group, or a biphenyl group. An alkaline anion exchange membrane comprises a halomethylated high-molecular polymer main chain and an N1 position-substituted imidazole branch chain represented by a molecular formula shown in the description. A preparation method of the alkaline anion exchange membrane comprises the following steps: synthesizing N1 position-substituted imidazole; preparing the halomethylated high-molecular polymer main chain; and preparing the N1 position-substituted imidazole type alkaline anion exchange membrane. The N1 position-substituted imidazole has the advantages of good stability, no toxicity and moderate molecular weight; and the N1 position-substituted imidazole type alkaline anion exchange membrane prepared in the invention has the advantages of uniform and smooth surface, good thermal stability, good mechanical strength, and good application values in alkaline fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

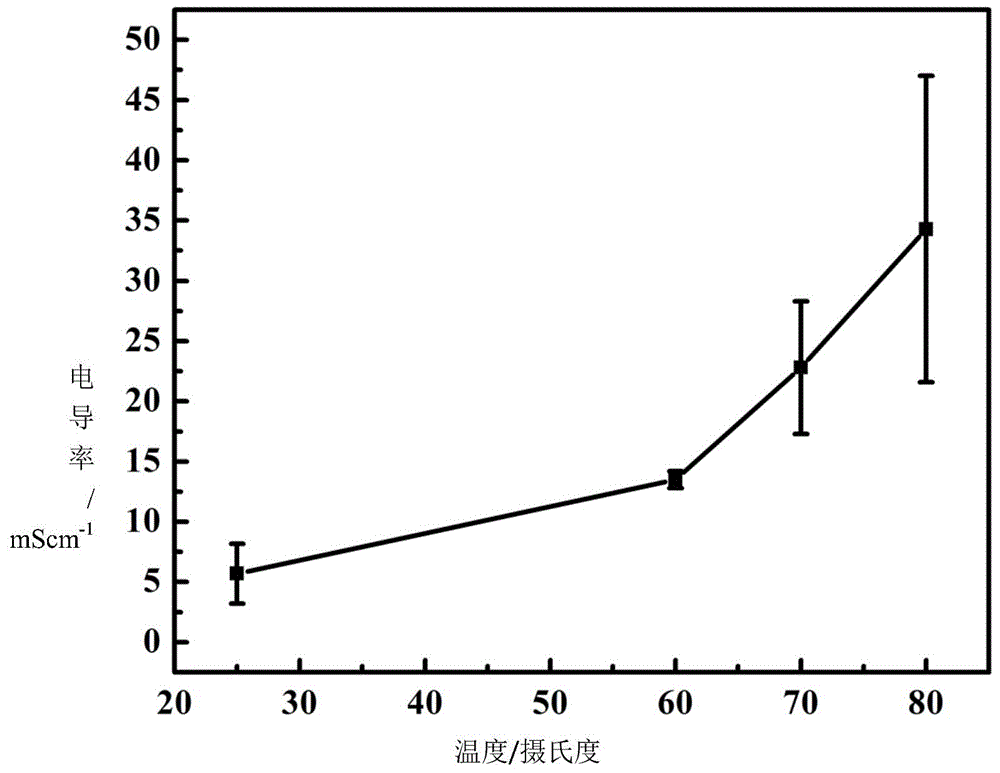

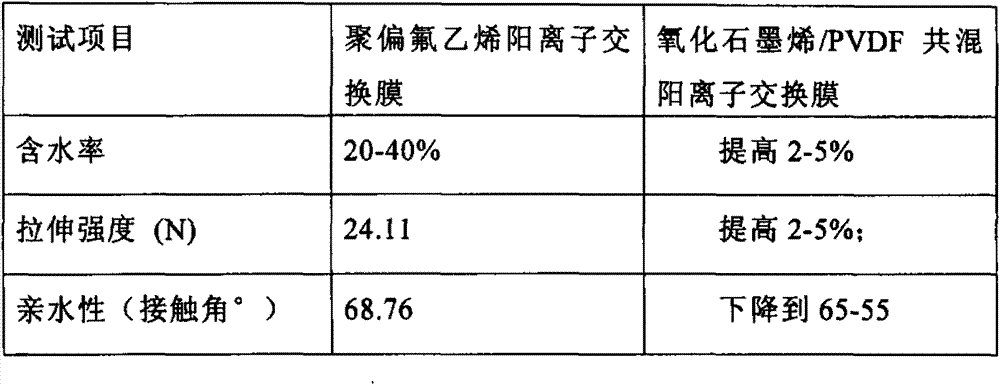

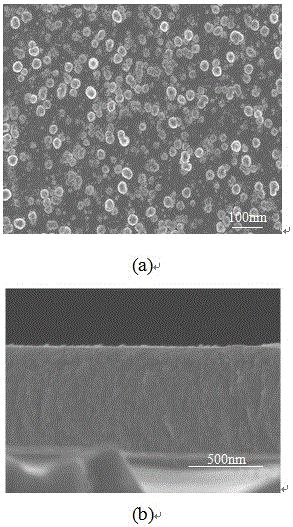

Graphene oxide/PVDF (polyvinylidene fluoride) blended cation exchange membrane and preparation method thereof

InactiveCN103087342AImprove hydrophilicityHigh mechanical strengthSemi-permeable membranesGlycidyl methacrylateBenzoyl peroxide

The invention relates to a graphene oxide / PVDF (polyvinylidene fluoride) blended cation exchange membrane and a preparation method thereof. The cation exchange membrane is prepared from the following components and raw materials in percentage by weight: 5-20% of polyvinylidene fluoride, 0.1-5% of graphene oxide, 50-70% of an organic solvent, 10-20% of divinyl benzene, 6-20% of glycidyl methacrylate, and 0.5-5% of benzoyl peroxide. The preparation method comprises the following steps: preparing membrane casting liquid firstly, preparing the membrane casting liquid into a base membrane by utilizing a tape casting method, cleaning the base membrane, and modifying the base membrane so as to obtain the cation exchange membrane. Compared with the prior art, the graphene oxide / PVDF blended cation exchange membrane prepared by using the method disclosed by the invention has the advantages that not only can the original excellent characteristics of PVDF cation exchange membranes be retained, but also the surface properties of PVDF cation exchange membranes are improved, the hydrophilicity, mechanical strength and acid and alkali resistances of membranes are enhanced, and the anti-pollution capacity of membranes is improved.

Owner:TONGJI UNIV

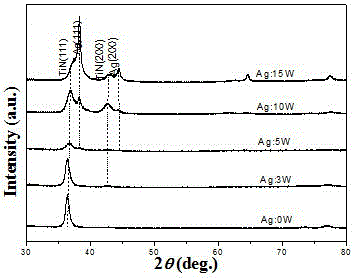

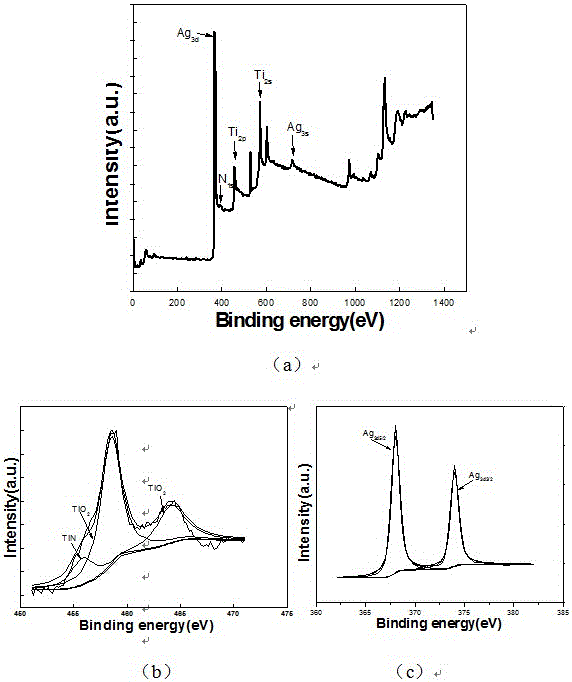

TiN-Ag nano composite coating and preparation and application thereof

InactiveCN105862001AHigh Vickers hardnessEvenly dispersedVacuum evaporation coatingPharmaceutical delivery mechanismComposite filmHardness

The invention discloses a TiN-Ag nano composite coating and a preparation and application thereof. The TiN-Ag nano composite coating is characterized by being a composite film obtained by magnetron co-sputtering deposition; and a certain substrate temperature is kept in the sputtering process, and the obtained thickness is between 0.5[mu] m and 1[mu] m. The negative bias voltage of a substrate in the preparation process is adjusted by experiments; for an obtained TiN-Ag nano composite coating, the hardness of the substrate is remarkably improved; Ag elements are uniformly distributed in a TiN film, so a contact angle of the TiN film is significantly smaller than that of a TiN film in which no Ag is doped, good hydrophilicity is obtained and cell compatibility is improved; and the TiN-Ag nano composite coating is expected to improve application of a titanium alloy in biomedicine. The material formed by the method disclosed by the invention is stable in structure, the method can be repeated, and preparation conditions are controllable.

Owner:TIANJIN NORMAL UNIVERSITY

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

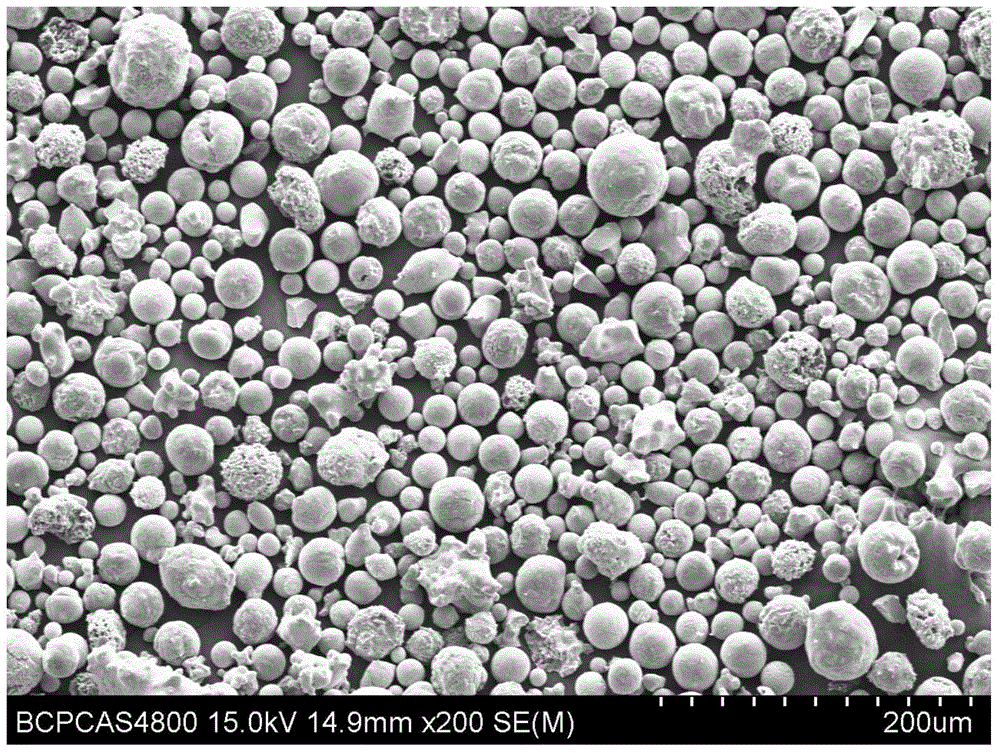

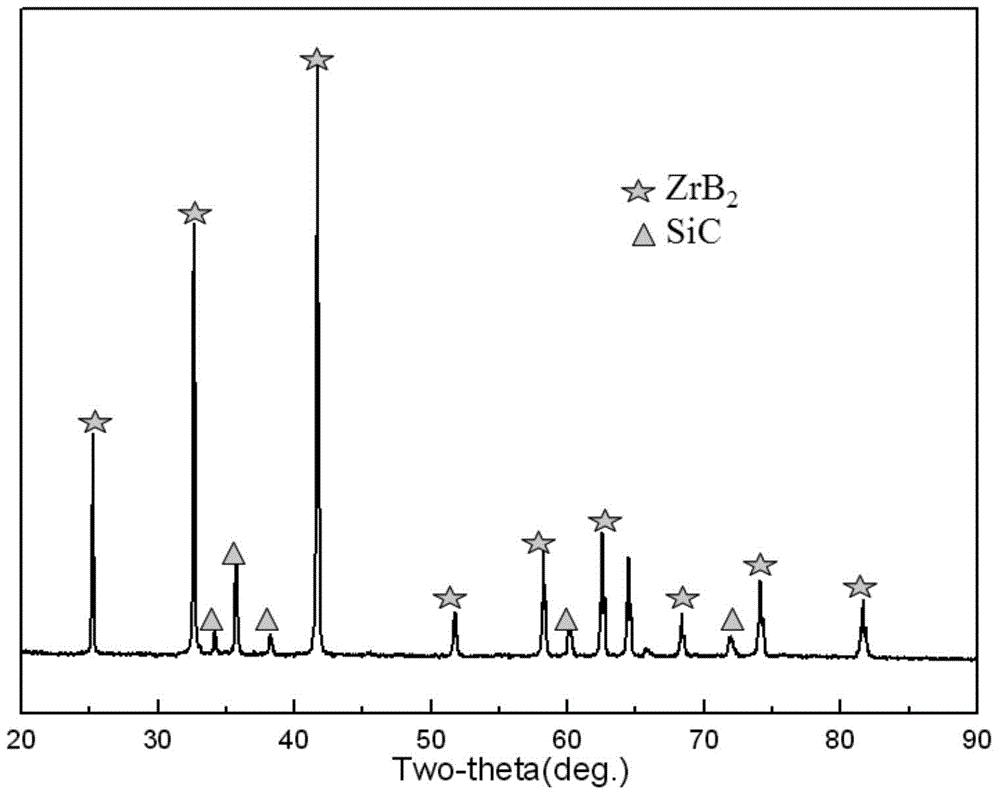

Preparation method of spherical zirconium diboride and silicon carbide aggregate powder

ActiveCN103601192AHigh purityAvoid introducingMetal boridesSilicon carbideAlcoholInduction plasma technology

The invention relates to a preparation method of spherical zirconium diboride and silicon carbide aggregate powder, belonging to the technical field of composite powder materials. The method comprises the following steps: with zirconium diboride and silicon carbide in the mass ratio of (0.5-1):2 as raw materials, preparing a turbid liquid by using the raw materials and absolute ethyl alcohol, and ball-milling and mixing at the speed of 100-400r / min for 2-6h to obtain a precursor, wherein the mass ratio of absolute ethyl alcohol to the raw materials is (1-3):1; adding absolute ethyl alcohol into the precursor, mixing, and placing the mixture into a colloid grinder to grind and emulsify to obtain a mixed turbid liquid of mixed powder and absolute ethyl alcohol, wherein the mass ratio of the raw materials to the sum of absolute ethyl alcohols added twice is 1:(5-8); carrying out agglomeration, nodularization and densification treatment on zirconium diboride and silicon carbide powder in the turbid liquid by using a liquid powder feeder and induction plasma nodulizing equipment to obtain the powder. The method is simple, low in cost, capable of directly preparing the spherical zirconium diboride and silicon carbide aggregate powder from the raw materials, and capable of improving the purity and quality of the spherical zirconium diboride and silicon carbide aggregate powder.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Calcium-based polymer gel material of multicomponent composite powder and preparation method of calcium-based polymer gel material

The invention discloses a calcium-based polymer gel material of multicomponent composite powder and a preparation method of the calcium-based polymer gel material. The calcium-based polymer gel material is prepared by mixing the composite multicomponent powder composed of portland cement, metakaolin, high-calcium fly ash and slag powder, a composite activator composed of liquid sodium silicate andsolid pure sodium hydroxide, and water at a normal temperature, wherein the multicomponent composite powder comprises the following raw materials in parts by weight: 10-30 parts of the portland cement, 20-60 parts of the metakaolin, 15-60 parts of the slag powder and 5-20 parts of the high-calcium fly ash; in the composite activator, the liquid sodium silicate and the solid pure sodium hydroxideaccount for 10-16% of the mass of the composite powder; and the water accounts for 35-45% of the mass of the composite powder. According to the invention, the kaolin, the slag powder and the high-calcium fly ash with wide sources are used as the raw materials, the raw materials are blended with a small amount of the portland cement to obtain the calcium-based polymer gel material, a production process is simple, the energy consumption is low, and energy conservation and environmental protection are achieved; and the obtained calcium-based polymer test piece is compact in surface, high in strength and good in high-temperature resistance and chemical corrosion resistance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

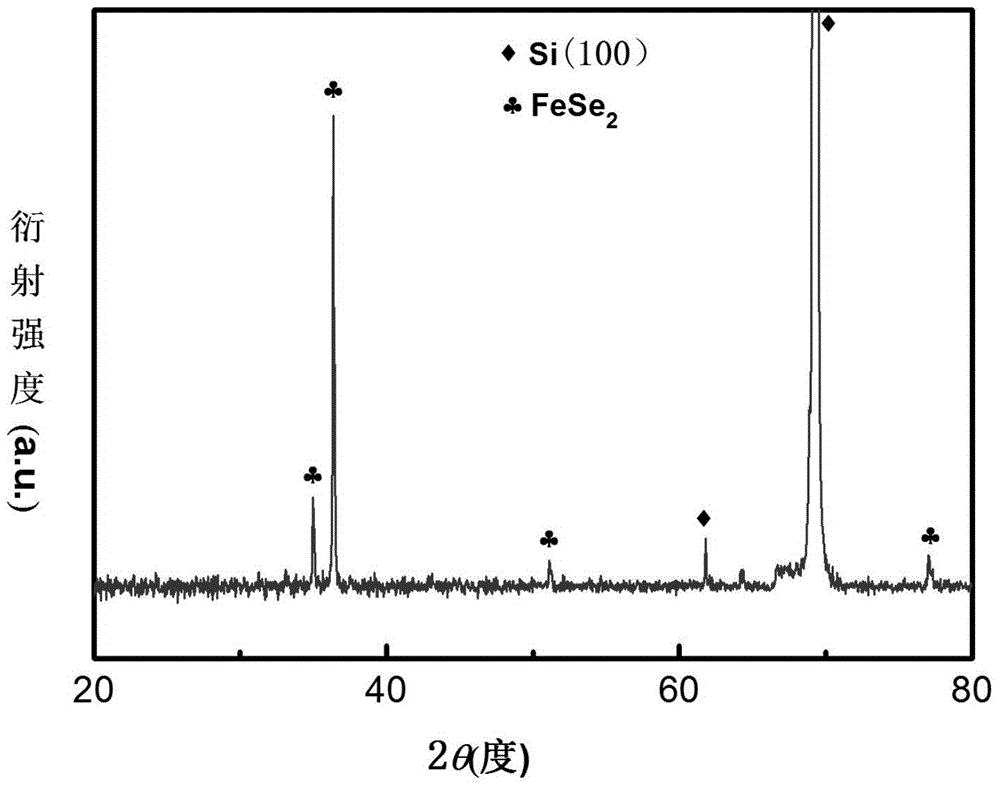

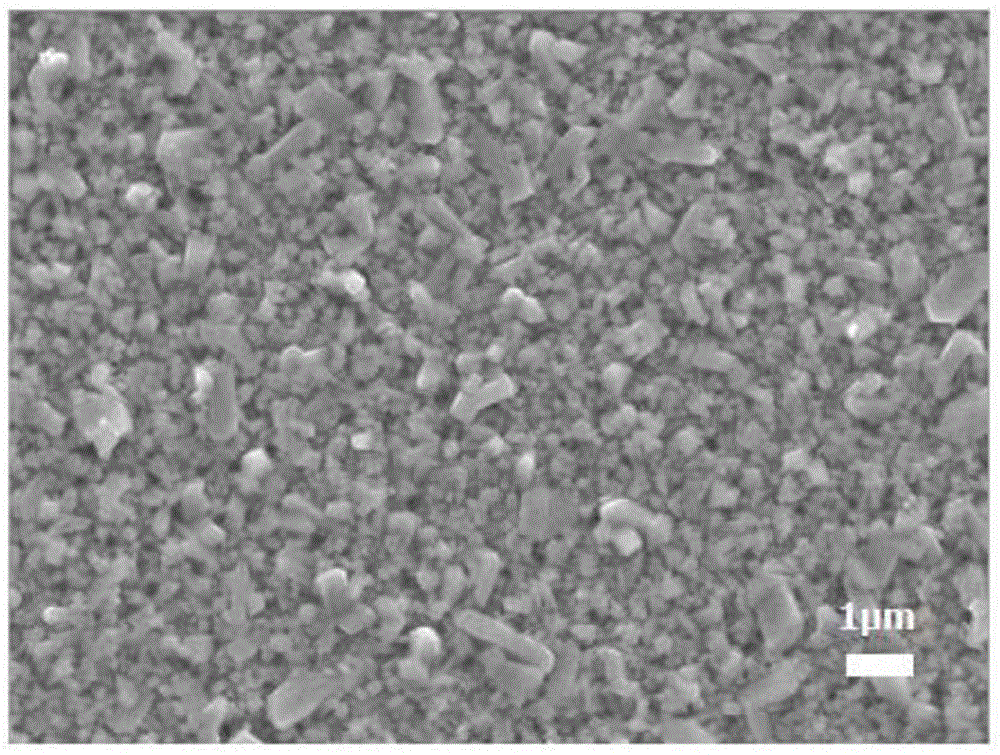

Method for preparing lithium battery electrode material FeSe2 thin film through magnetron sputtering

InactiveCN105112867AHigh efficiency of magnetron sputteringGood repeatabilityVacuum evaporation coatingSputtering coatingTube furnaceSputter deposition

Disclosed is a method for preparing a lithium battery electrode material FeSe2 thin film through magnetron sputtering. The method comprises the steps that a, preparation of sputtering is conducted, a silicon chip selected as a substrate and a FeSe target selected as a sputtering target are installed in a magnetron sputtering chamber, and the distance between the sputtering target and the substrate is adjusted to be 5-7 cm; b, sputtering deposition is conducted, a vacuum chamber is vacuumized until the air pressure is below 2*10-4 Pa, then argon gas is pumped in, the sputtering air pressure, the sputtering power and the temperature of the substrate are adjusted, and a thin film is deposited on the silicon chip after the sputtering is conducted for a certain time; and c, post-annealing treatment is conducted, the silicon chip where the thin film is deposited and a selenium granular ball are sealed in a vacuum quartz tube with the air pressure being smaller than 1*10-2 Pa, then the quartz tube is positioned in a tubular furnace, the post-annealing treatment is conducted under protection of the argon gas, and the FeSe2 thin film is obtained. The method is capable of preparing the FeSe2 thin film with a large area and good properties, simple in preparation process, low in energy consumption, low in cost, high in efficiency, good in repeatability, and suitable for industrialized production.

Owner:SOUTHWEST JIAOTONG UNIV

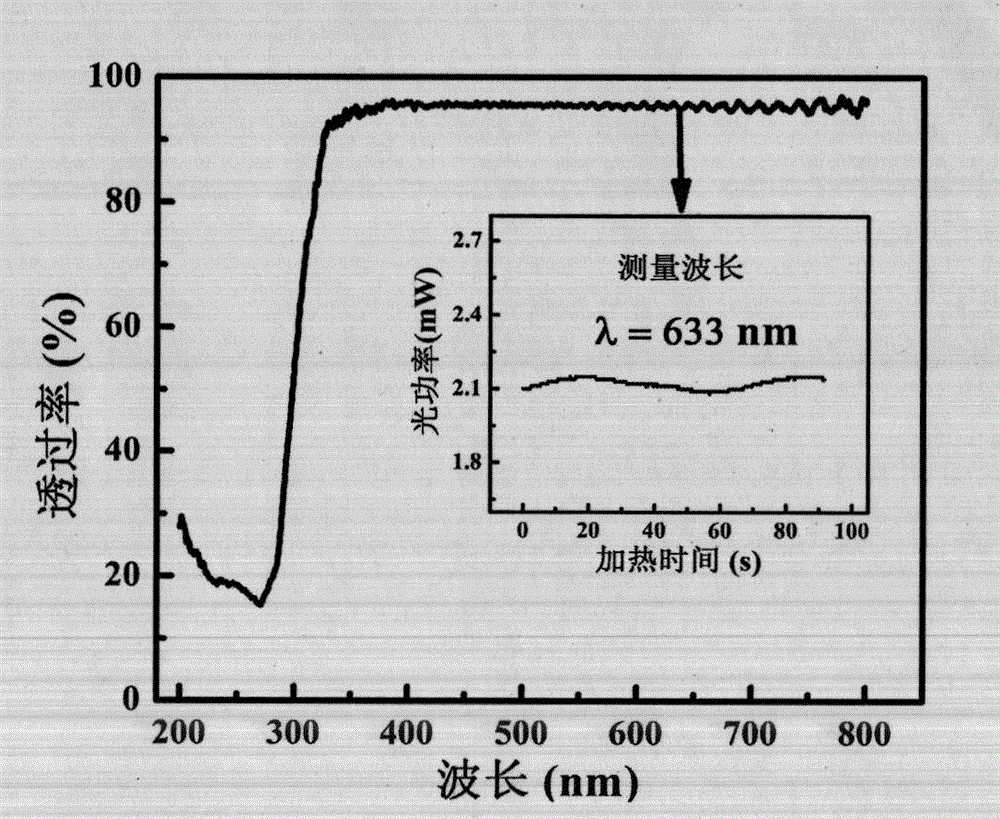

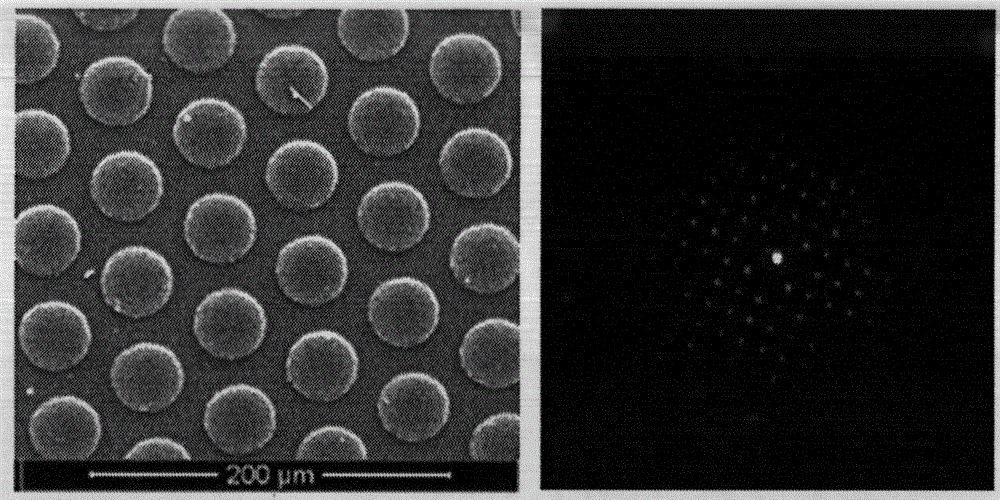

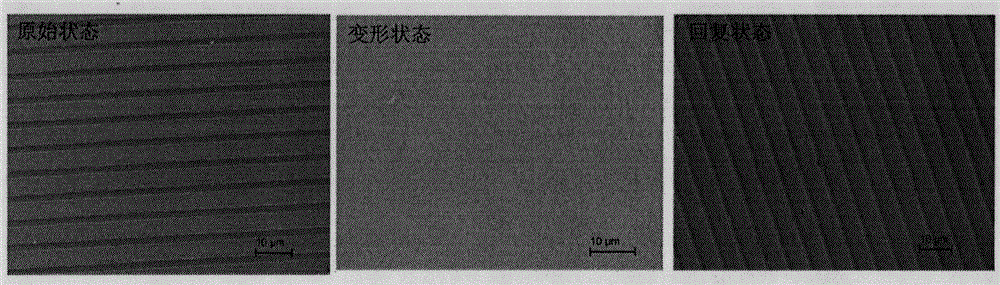

Controllable-optical-property shape-memory polymer film and preparation method thereof

ActiveCN104086791AGood light transmission in visible light bandFlat surfacePolymer scienceOptical property

The invention discloses a controllable-optical-property shape-memory polymer film and a preparation method thereof. Styryl shape-memory polymer solution prepared proportionally is used as the raw material and subjected to a micro photoetching silyl template and spin coating technique to prepare the multiple shape-memory polymer micropattern structure film. The preparation method is simple to operate, and has the advantages of low cost and controllable film thickness; and film surface micro / nano structure can be predesigned according to the application demands, and is applicable to multiple application demands in the field of micro-optics. The styryl shape-memory polymer film has excellent shape memory performance, and can implement the process of quick recovery of the imprinting disappearance on the structural film surface under thermal excitation. By combining the shape-memory characteristic of the material, the method can implement controllable optical properties of the structural film, and has wide application prospects in the fields of tunable micro optical devices, color-control intelligent buildings, display devices, sensors and the like.

Owner:HARBIN INST OF TECH

Method for repairing mechanical shaft kiln lining

The invention discloses a method for repairing a mechanical shaft kiln lining, belonging to the maintenance field of a lime production kiln. The method comprises the following steps: 1. washing a furnace: cleaning a furnace wall with high-pressure water by a high-pressure nozzle driven by a spraying mechanical arm from bottom to top firstly and then from top to bottom; 2. examining for spraying: thoroughly cleaning nodules and residues off from the inner wall of the furnace, cleaning loose floating bricks out of the furnace, digging and repairing seriously collapsing positions in the furnace,installing stainless steel anchorages on a working layer in the furnace, hanging a net, welding a longer anchorage, and hanging a net for spraying; and 3. spraying: integrally spraying the whole lining in a large area and spraying local areas with specific targets to obtain an intact furnace profile. The method has the advantages of short construction period, low cost and good effect.

Owner:TAIYUAN IRON & STEEL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com