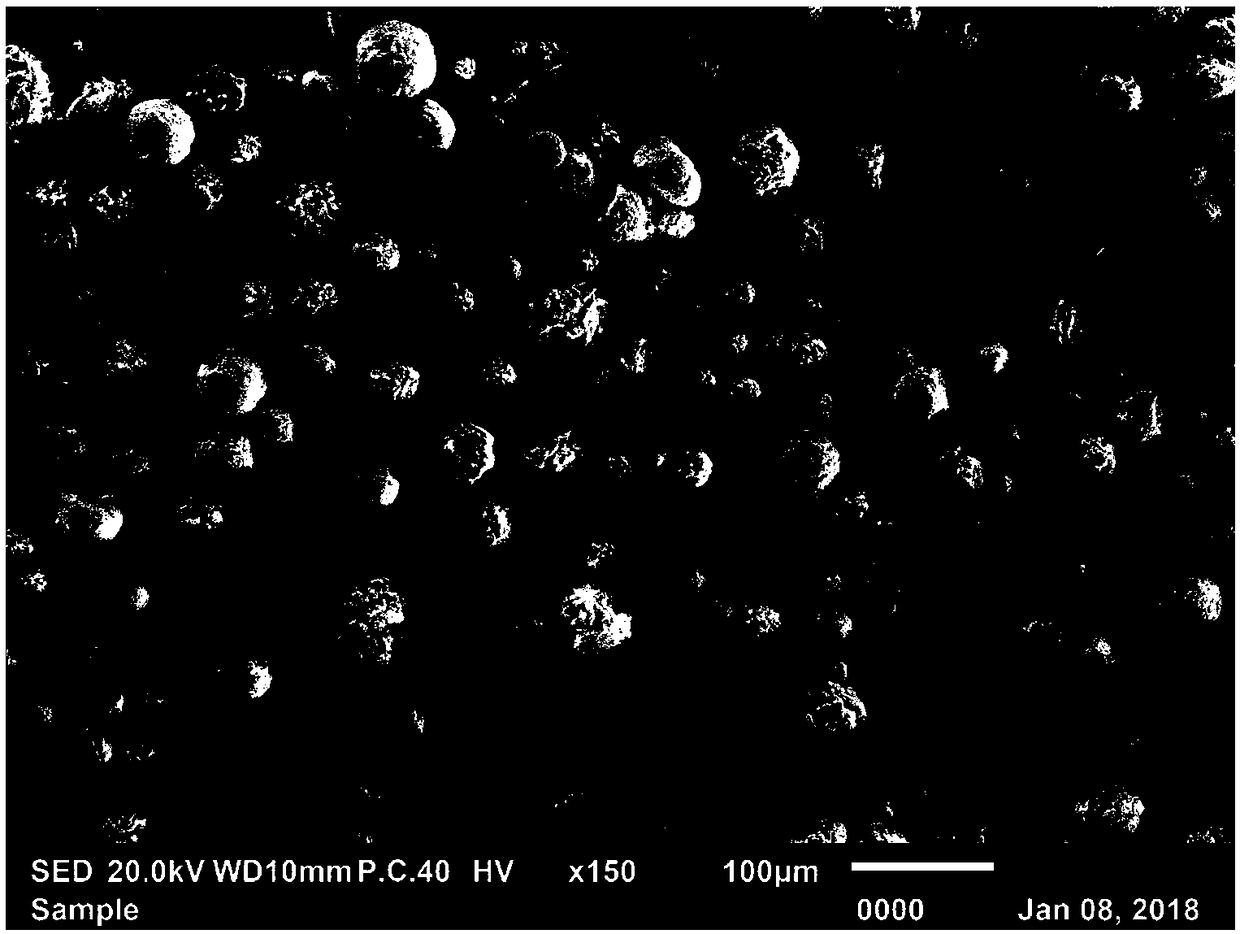

High-sphericility, compact-surface and low-impurity Ni-Co-Mn ternary material precursor and preparation method and application thereof

A technology of ternary materials and precursors, which is applied in the field of high-nickel nickel-cobalt-manganese ternary materials with high surface density, can solve the problem of high sulfur content, achieve low impurity content, good surface compactness, and particle size distribution narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The molar ratio Ni / Co / Mn is 80:10:10 and takes by weighing 150.0g of nickel chloride, 17.8g of cobalt chloride, and 9.9g of manganese chloride, and dissolves nickel chloride, cobalt chloride, and manganese chloride in the Prepare a mixed solution with a total metal ion concentration of 1.8mol / L in ionized water; 4 + The molar ratio is 1.0, and 59.1mL of concentrated ammonia water with a mass fraction of 25% is added to the mixed solution; the temperature of the reaction system is controlled at 65°C, and the prepared solution and the prepared precipitant 6mol / L NaOH solution, 2.0mol / L The ammonium chloride solution of L (contain normal hexane in the ammonium salt solution used, and the total content of normal hexane is 1% of the total mass of the ammonium salt solution added) and flow into the reactor under agitation, the reactor will The pH value of the reaction system is controlled at 11.5; after the pH value of the reaction system is stable, the reaction is continued...

Embodiment 2

[0043] The molar ratio Ni / Co / Mn is 60:20:20 and takes by weighing 150.0g of nickel chloride, 50.1g of cobalt chloride, and 26.5g of manganese chloride, and dissolves nickel chloride, cobalt chloride, and manganese chloride in the Prepare a mixed solution with a total metal ion concentration of 2mol / L in ionized water; 4 + The molar ratio is 1.0, and 78.76mL of ammonia water with a mass fraction of 25% is added to the mixed solution; the temperature of the reaction system is controlled at 70°C, and the prepared solution and the prepared precipitant 6mol / L KOH solution, 3.0mol / L Ammonium chloride solution (containing toluene in the ammonium salt solution used, and the total content of toluene in the ammonium salt solution is 0.5% of the total mass of the ammonium salt solution added) and flows into the reactor under stirring, and the reactor The pH value in the solution was controlled at 11.4; after the pH value of the reaction system was stable, the reaction was continued for ...

Embodiment 3

[0045] Weigh 150.0g of nickel nitrate, 18.8g of cobalt nitrate, and 8.7g of manganese nitrate with a molar ratio of Ni / Co / Mn of 80:10:10, and dissolve nickel nitrate, cobalt nitrate, and manganese nitrate in deionized water to prepare a total metal A mixed solution with an ion concentration of 1.5mol / L; according to the sum of moles of metal elements and NH 4 + The molar ratio is 2.0, and 24.1mL of ammonia water with a mass fraction of 25% is added to the mixed solution; the temperature of the reaction system is controlled at 62°C, and the prepared solution and the prepared precipitant 6mol / L NaOH solution, 2.5mol / L Ammonium nitrate solution (containing ethylbenzene in the ammonium salt solution used, and the total content of ethylbenzene in the ammonium salt solution is 0.01% of the total mass of the ammonium salt solution added) and flows into the reactor under stirring, and the reaction The pH value in the kettle is controlled at 11.2; after the pH value of the reaction sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com