Conductive silver paste for ceramic filter and preparation method thereof

A ceramic filter, conductive silver paste technology, applied in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem that the overall performance is not as good as ethyl cellulose, and the process temperature required for sintering is high. , poor stability of silver paste, etc., to achieve the effect of not easy infiltration, low ash content, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

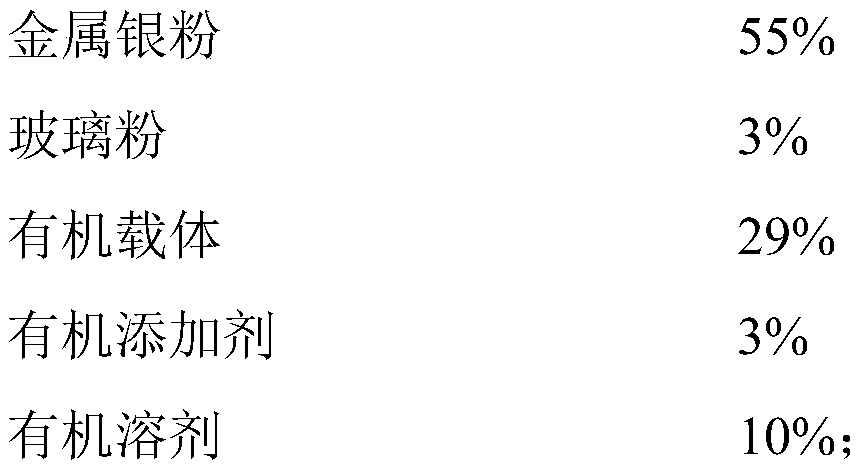

[0031] In the present embodiment, a conductive silver paste for a ceramic filter, the conductive silver paste comprises the following components and weight percentage content: 55% of metallic silver powder, 3% of glass powder, 29% of organic vehicle, 3% of organic additive and 10% of organic solvent %.

[0032] Among them, the metallic silver powder is spherical silver powder with a particle size of 0.95 μm and a tap density of 2.2 g / ml. The glass powder is lead-free glass powder with a thermal expansion coefficient of 115×10 -7 / °C, the sintering temperature is 650°C, the glass powder includes the following components and weight percentages: Bi 2o 3 79%, ZnO 8%, B 2 o 3 7%, SiO 2 3%, Na 2 O 2%, TiO 2 0.5% and Al 2 o 3 0.5%.

[0033] The organic carrier is made by mixing ethyl cellulose and terpineol. The specific preparation method is: according to the mass ratio of ethyl cellulose and terpineol as 1:4, add ethyl cellulose to terpineol, heat Raise the temperat...

Embodiment 2

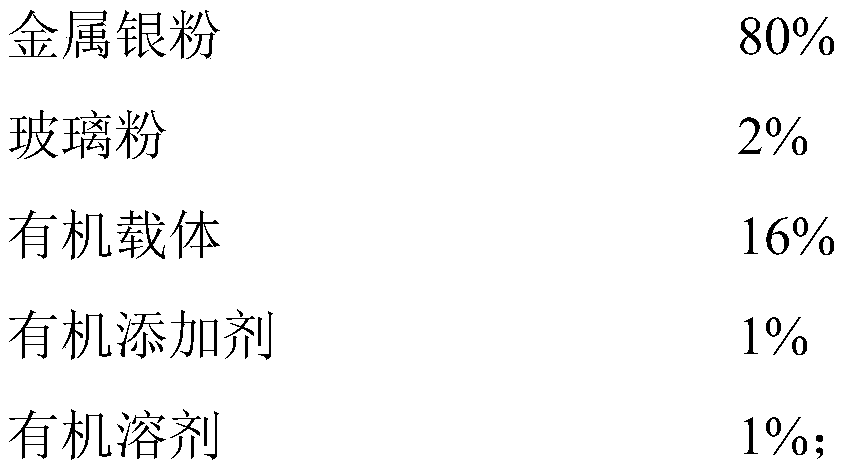

[0042] In the present embodiment, a conductive silver paste for a ceramic filter, the conductive silver paste includes the following components and weight percentage content: 80% of metallic silver powder, 2% of glass powder, 16% of organic vehicle, 1% of organic additive and 1% of organic solvent %.

[0043] Wherein, the metallic silver powder is spherical silver powder with a particle size of 1.2 μm and a tap density of 2.5 g / ml. The glass powder is lead-free glass powder with a thermal expansion coefficient of 110×10 -7 / °C, the sintering temperature is 550°C, the glass powder includes the following components and weight percentages: Bi 2 o 3 81%, ZnO 6.5%, B 2 o 3 6.5%, SiO 2 2%, Na 2 O 3%, TiO 2 0.5% and Al 2 o 3 0.5%.

[0044] The organic carrier is made by mixing nitrocellulose and tripropylene glycol monomethyl ether. The specific preparation method is: according to the mass ratio of nitrocellulose and tripropylene glycol monomethyl ether is 1:4, add nit...

Embodiment 3

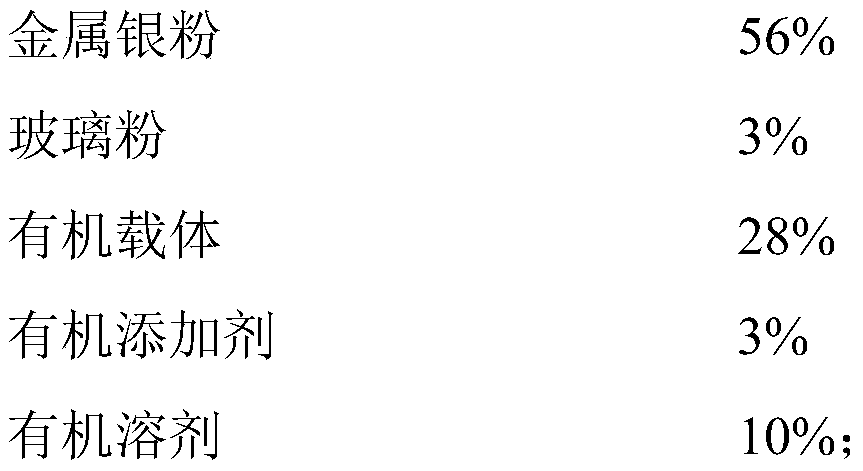

[0053] In the present embodiment, a conductive silver paste for a ceramic filter, the conductive silver paste includes the following components and weight percentage content: 56% of metallic silver powder, 3% of glass powder, 28% of organic vehicle, 3% of organic additive and 10% of organic solvent %.

[0054] Wherein, the metallic silver powder is spherical silver powder with a particle size of 0.5 μm and a tap density of 2.0 g / ml. The glass powder is lead-free glass powder with a thermal expansion coefficient of 115×10 -7 / °C, the sintering temperature is 700°C, the glass powder includes the following components and weight percentages: Bi 2 o 3 85%, ZnO 5%, B 2 o 3 3%, SiO 2 1%, Na 2 O 1%, TiO 2 3% and Al 2 o 3 2%.

[0055] The organic carrier is made by mixing ethyl hydroxyethyl cellulose and butyl carbitol acetate. The specific preparation method is: the mass ratio of ethyl hydroxyethyl cellulose and butyl carbitol acetate is 1:4 , add ethyl hydroxyethyl ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com