Method of preparing g-C3N4/silicon carbon cathode material of lithium ion battery by electrostatic spinning and application thereof

A lithium-ion battery, electrospinning technology, applied in electrospinning, battery electrodes, secondary batteries, etc., can solve the problems of reducing the electrochemical activity of electrode materials, increasing the impedance of cycle performance materials, etc., to improve ion transmission speed, High specific capacity, reducing the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

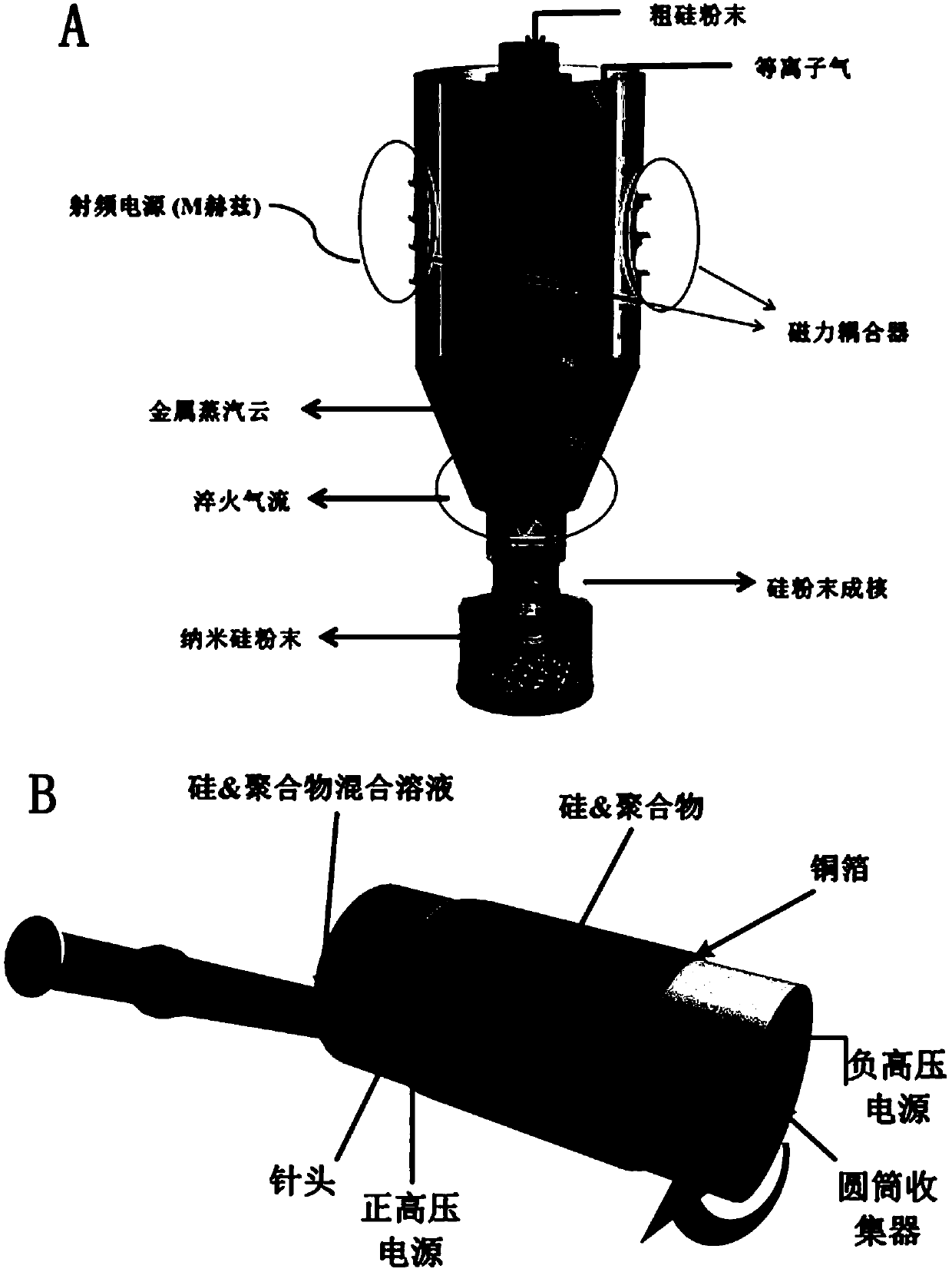

[0067] (1) Take the radio frequency plasma equipment to make nano-silicon particles

[0068] Put 10 g of commercially available coarse silicon powder (particle size: 200 mesh, 74 μm) into a radio frequency plasma system ( figure 1 A, 15KWInduction plasma system, Tekna Plasma Systems Co., Canada), and adjust the radio frequency current to 5.8A, and simultaneously turn on the inductively coupled plasma beam for argon, so that the cavity temperature reaches 9000°C, and the rough Silicon is gasified to obtain gaseous silicon, and then the steam valve of gaseous silicon is opened to introduce gaseous silicon into the liquid nitrogen cooling chamber (rapidly solidified through the condensation zone), and the cooling rate is 250°C / min to obtain cooled and condensed nano-silicon powder, nano-silicon The particle size is about 50-80nm.

[0069] (2) Measure 10ml of N,N-dimethylformamide (purity ≥ 99.9%), and then add 0.6g of polyvinylpyrrolidone (molecular weight: 1.3 million) into N,N...

Embodiment 2

[0078] (1) Take the radio frequency plasma equipment to make nano-silicon particles

[0079] Put 10 g of commercial coarse silicon powder (particle size: 200 mesh, 74 μm) into the ultra-high temperature inductive plasma system ( figure 1 A, 15KW Induction plasma system), and adjust the radio frequency current to 6.2A, synchronously turn on the inductively coupled plasma beam, make the cavity temperature to 11000°C, gasify the crude silicon to obtain gaseous silicon, and then turn on the gaseous silicon The steam valve introduces the gaseous silicon into the liquid nitrogen cooling chamber, (through the condensation zone is rapid solidification), the cooling rate is 350°C / min, and the cooled and condensed nano-silicon powder is obtained. The particle size of the nano-silicon is about 40-60nm.

[0080] (2) Measure 10ml of N,N-dimethylformamide (purity ≥ 99.9%), and then add 0.6g of polyvinylpyrrolidone (molecular weight: 1.3 million) into N,N-dimethylformamide, The mixture was ...

Embodiment 3

[0087] (1) Take the radio frequency plasma equipment to make nano-silicon particles

[0088] Put 10 g of commercial coarse silicon powder (particle size: 200 mesh, 74 μm) into the ultra-high temperature inductive plasma system ( figure 1 A, 15KW Induction plasma system), and adjust the radio frequency current to 7.3A, synchronously turn on the inductively coupled plasma beam, make the cavity temperature to 12000°C, gasify the crude silicon to obtain gaseous silicon, and then turn on the gaseous silicon The steam valve introduces the gaseous silicon into the liquid nitrogen cooling chamber (rapidly solidified through the condensation zone), and the cooling rate is 500°C / min to obtain the cooled and condensed nano-silicon powder. The particle size of the nano-silicon is about 30-50nm.

[0089] (2) Measure 10ml of N,N-dimethylformamide (purity ≥ 99.9%), and then add 0.6g of polyvinylpyrrolidone (molecular weight: 1.3 million) into N,N-dimethylformamide, Stir at 60°C for 3 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com