Patents

Literature

76results about How to "Excellent high magnification performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

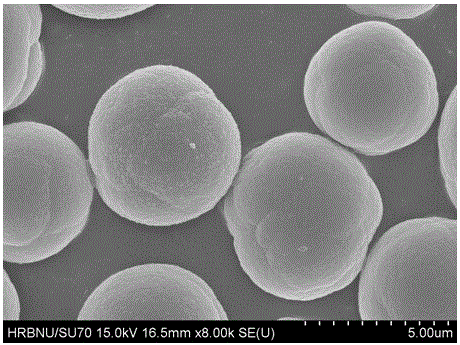

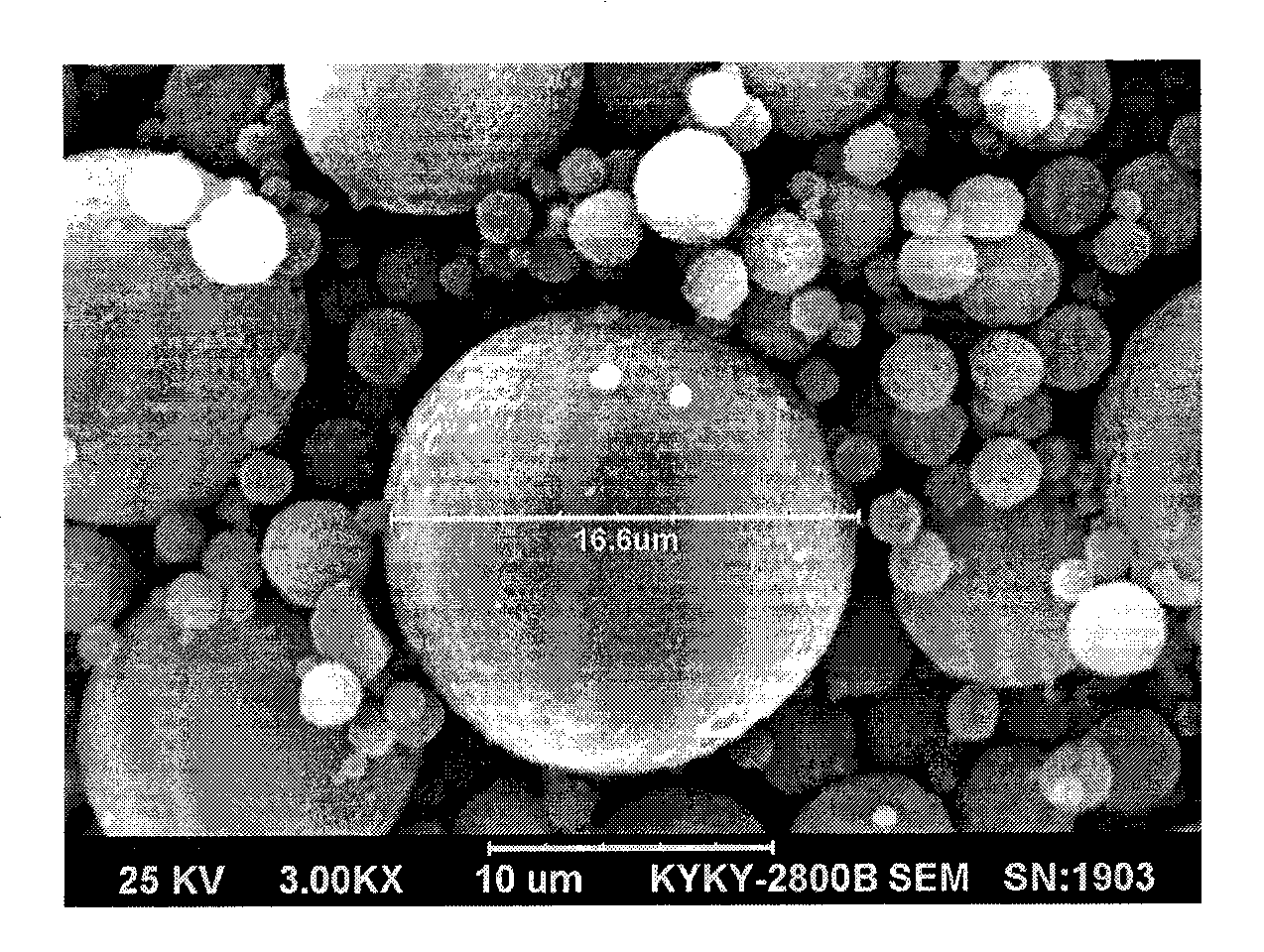

Titanium-series cathode active material and preparation method thereof, titanium-series lithium ion power battery

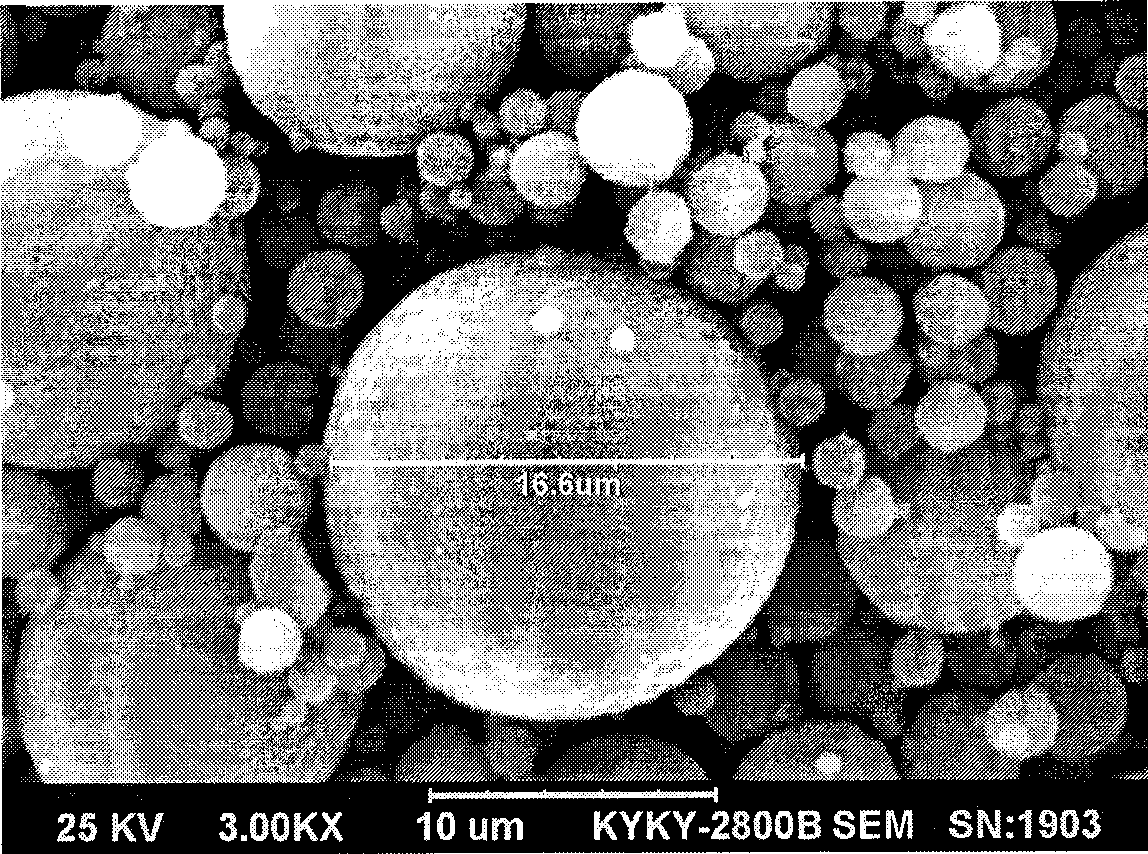

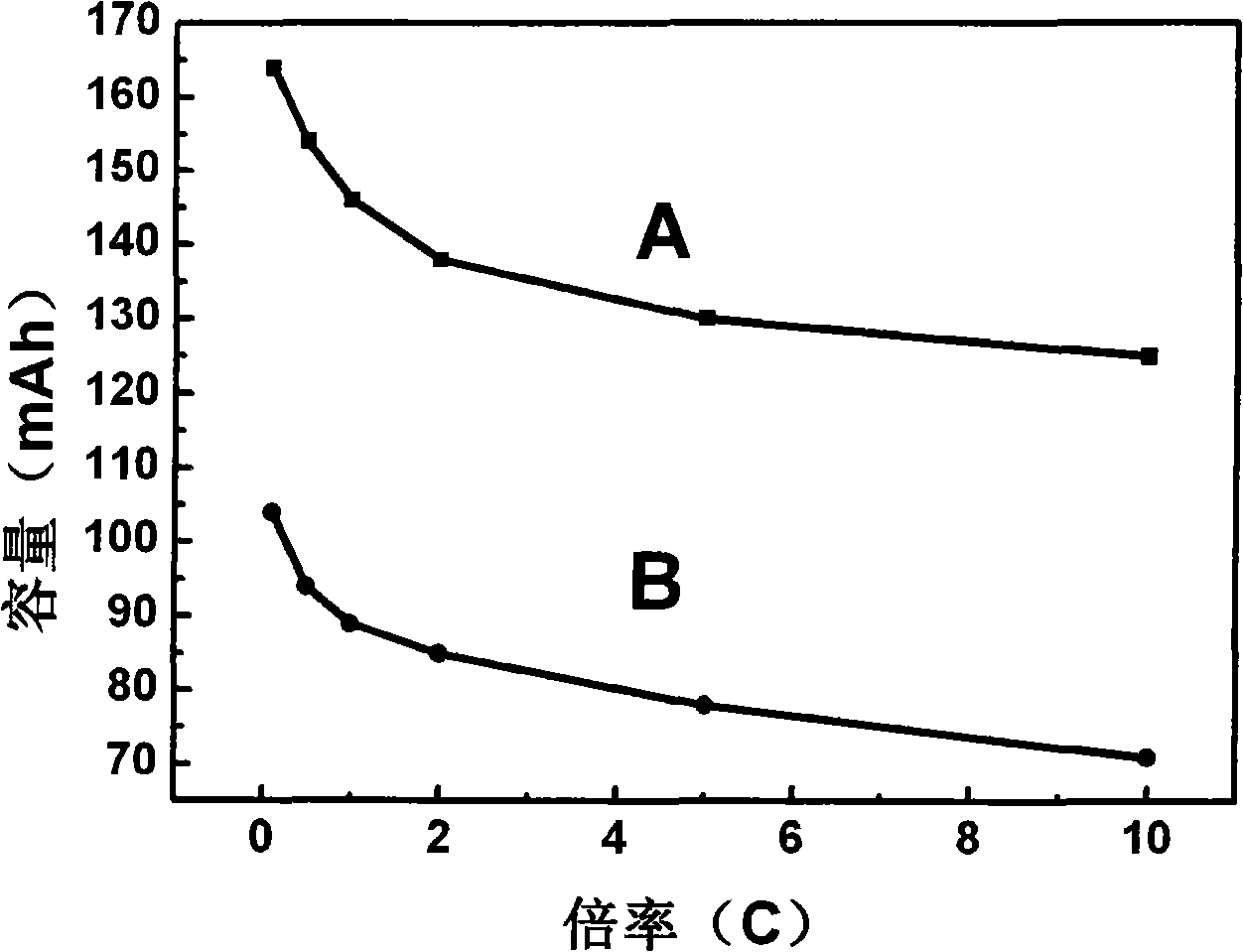

ActiveCN101373829AIncrease capacityHigh bulk densityElectrode manufacturing processesLi-accumulatorsHigh rateLithium titanate

The invention discloses a titanium cathode active substance, a preparation method thereof and a titanium lithium ion power battery, and aims to solve the technical problem of enhancing the rate performance of a lithium ion power battery. The formula of the titanium cathode active substance is Li4Ti5O12 / Mx, wherein Li4Ti5O12 is spinel lithium titanate, M is a dopant such as a metal simple substance, a metal compound, a nonmetallic simple substance or a nonmetallic compound; the elements or the ions contained in the dopant enter the Li4Ti5O12 crystal lattice or are compounded with the Li4Ti5O12 crystal lattice; and the preparation method comprises the following steps: the precursor mixture of compound lithium titanate is prepared, and spray drying and heat treatment are performed. The cathode of the titanium lithium ion power battery adopts Li4Ti5O12 / Mx. Compared with the prior art, the titanium cathode active substance has the advantages of high capacity, high bulk density, high volume specific capacity, good high-rate performance, good product uniformity, good battery processability, low possibility of air bulking of the battery, and low cost.

Owner:BTR NEW MATERIAL GRP CO LTD

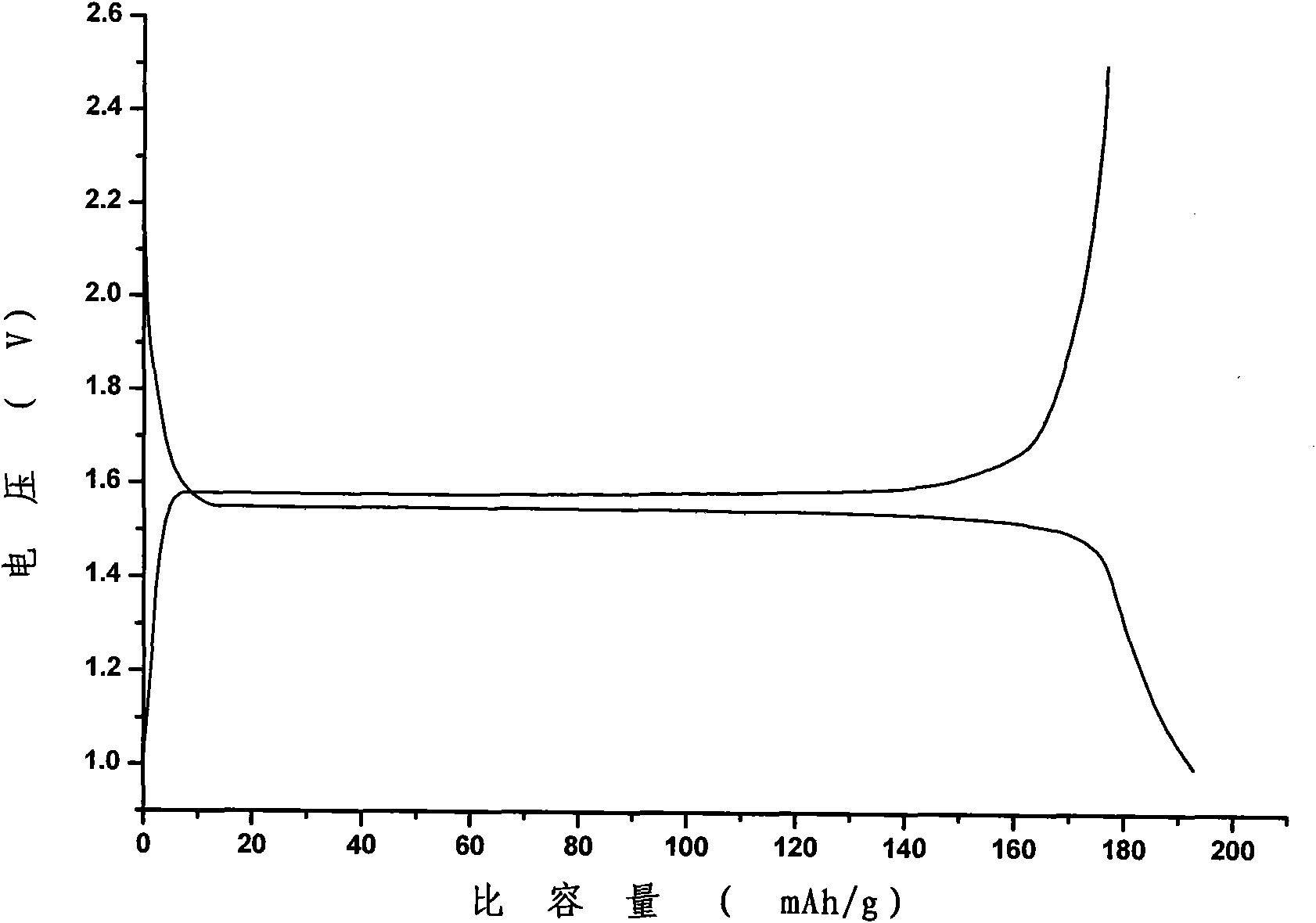

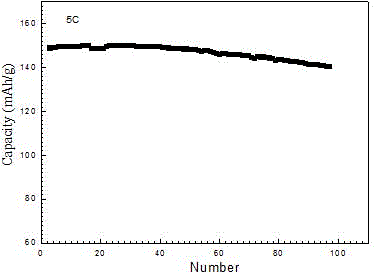

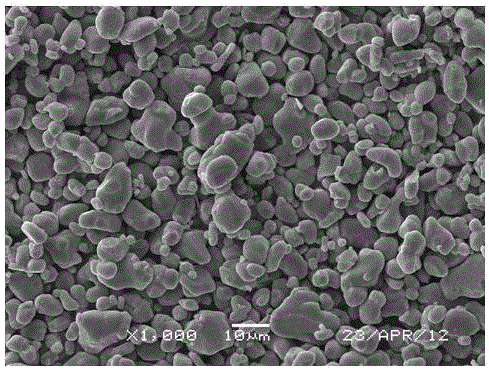

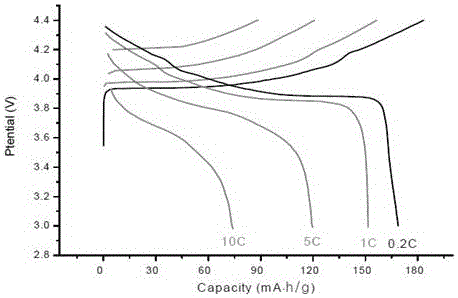

Preparation method of lithium titanate-graphene combination electrode material

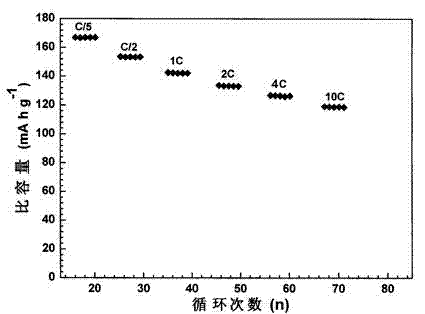

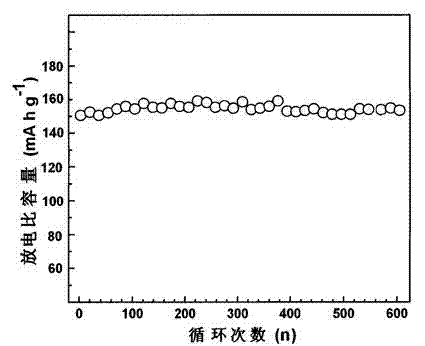

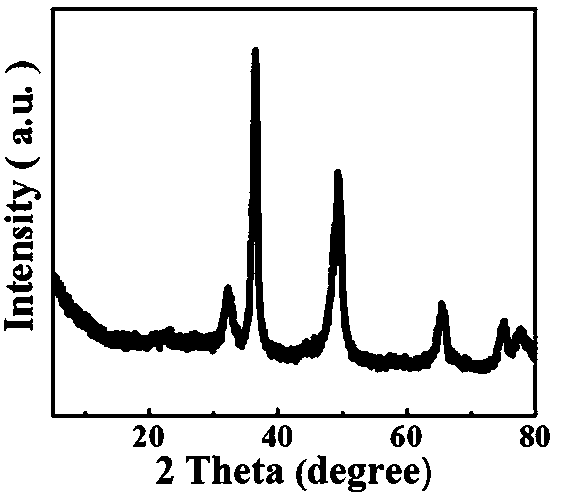

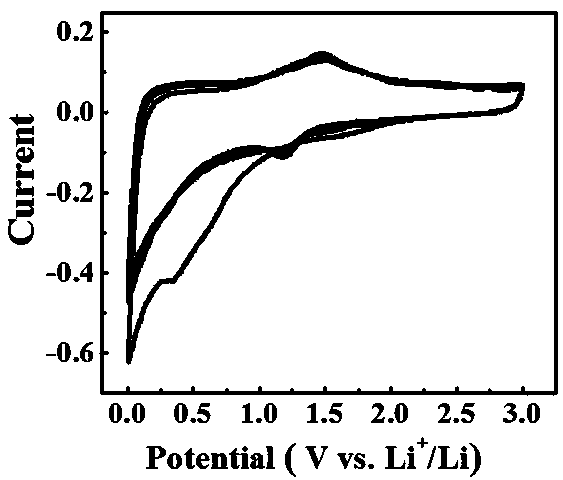

InactiveCN101877405APerformance is not affectedExcellent high magnification performanceCell electrodesCvd grapheneLithium electrode

The invention relates to a preparation method of lithium titanate-graphene combination electrode material, belonging to the field of electrochemical power source; in the invention, the lithium titanate and graphite oxide are mixed and are prepared into titanate-graphene combination electrode material by heating under inert atmosphere; in the synthesized lithium titanate-graphene combination electrode material, metallic lithium is used as the cathode for preparing a battery, and the first charging and discharging capacity exceeds 186mAh / g when 10C charging and discharging is carried out; after 100 circles of the charging and discharging are carried out, the discharging capacity is higher than 116mAh / g. the method in the invention has low cost, and simple and flexible preparation procedures, and is suitable for industrial large-scale production. High multiplying power of the prepared titanate-graphene combination electrode material has good performance, and the combination electrode material has high specific capacity and can be widely applied to lithium ion batteries of various kinds of potable electronic equipment and various electric motors.

Owner:SOUTH CHINA UNIV OF TECH

Manganese phosphate lithium and carbon nanometer pipe situ compounding anode material and preparation method thereof

ActiveCN102412398AStable structureImprove conductivityMaterial nanotechnologyCell electrodesPtru catalystPhysical chemistry

The invention provides a manganese phosphate lithium and carbon nanometer pipe situ compounding anode material and a preparation method thereof. The chemical formula of the material is Li ( Mn 1-xMx) PO4, wherein the x is 0-0.1, M is a transition metal Fe, Co or Ni; a carbon nanometer pipe is uniformly distributed in manganese phosphate lithium grains in a synthetic process of the manganese phosphate lithium; a transition metal compound is adopted as a catalyzer and an alloying element so as to catalyze pyrolytic hydrocarbon gas and prepare a situ carbon nanometer pipe compound manganese phosphate lithium material; the preparation method provided by the invention has the advantages that the preparation method is simple, the cost is cheap, the manganese phosphate material purity is high, a structure is full, the conductivity is high, and the electrochemistry performance is excellent.

Owner:DONGFANG ELECTRIC CORP LTD

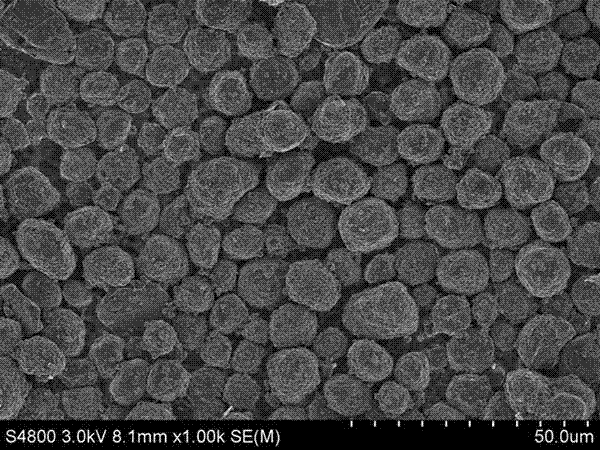

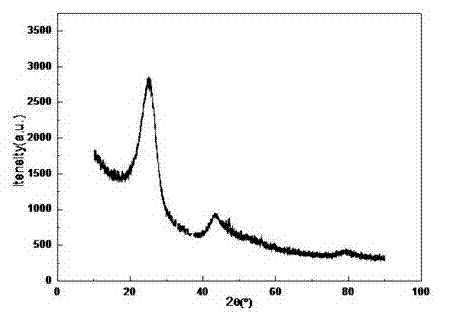

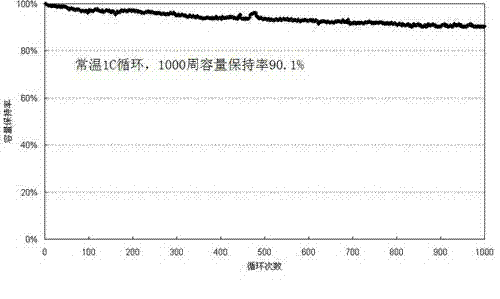

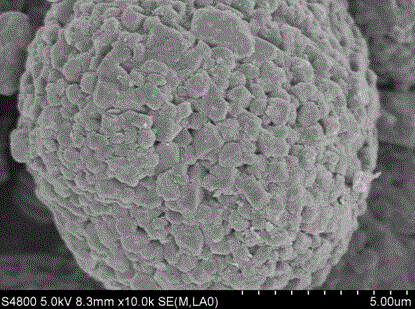

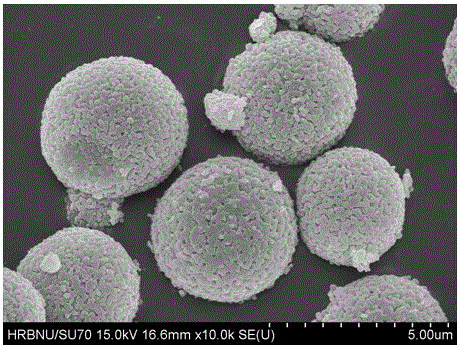

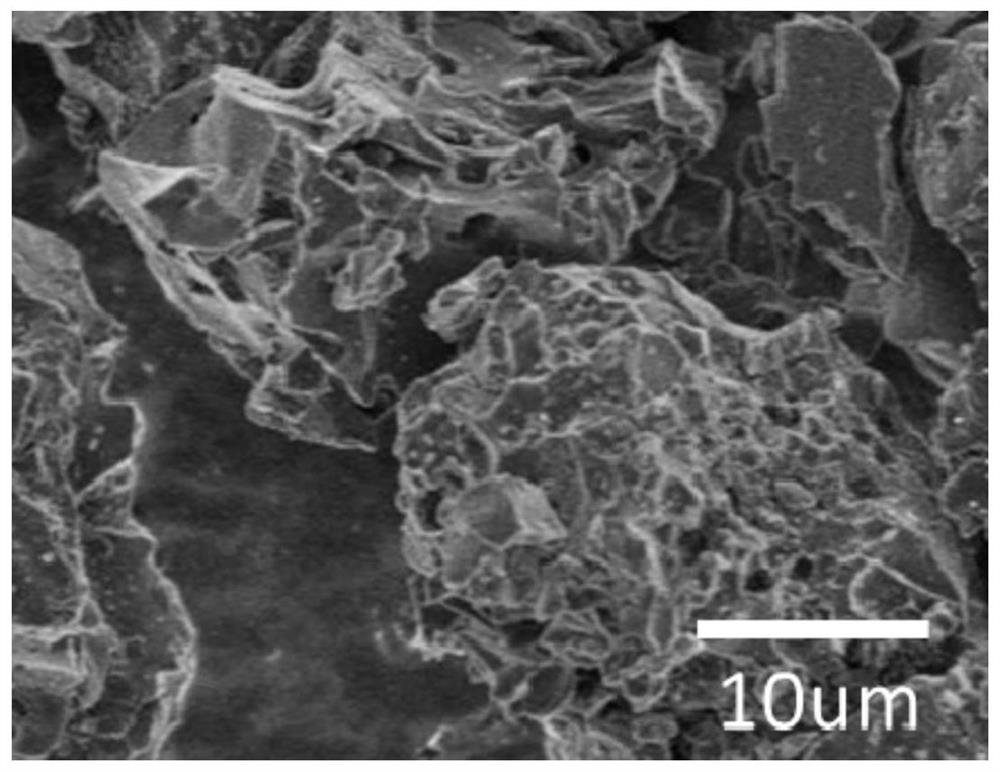

Lithium ion battery cathode material as well as preparation method and applications thereof

ActiveCN103050663AImprove lithium storage performanceImproved magnification performanceCell electrodesCarbon preparation/purificationPower batteryChemical physics

The invention relates to a lithium ion battery cathode material as well as a preparation method and applications of the lithium ion battery cathode material. The cathode material is an intermediate-phase carbon microsphere after low-temperature carbonization treatment, impregnation doping treatment and low-temperature sintering treatment, and are spherical or similar spherical with the ratio of long diameter to short diameter less than 2; and micro crystal structures in the cathode material are in unordered arrangement. The battery cathode material provided by the method provided by the invention has the advantages of rapid electric charge and discharge with large current, high lithium storage capability, high capacity, excellent high-rate performance and low-temperature performance and the like; and the discharge capacity under 25 DEG C can reach 412mAh / g, the discharge capacity under -20 DEG C can reach 328mAh / g, the rate performance is favorable, and the specific capacity under 20C current test in circulation for 100 times is not less than 340mAh / g, thus the high requirements on rate performance and circulation performance by a power battery can be met well.

Owner:天津市贝特瑞新能源科技有限公司

Nickel cobalt lithium manganate composite anode material of lithium ion battery and preparation method of nickel cobalt lithium manganate composite anode material

ActiveCN104835955AImproved magnification performanceImprove cycle performanceCell electrodesManganateConductive materials

The invention relates to a nickel cobalt lithium manganate composite anode material of a lithium ion battery and a preparation method of the nickel cobalt lithium manganate composite anode material, and belongs to the technical field of anode materials of lithium ion batteries. The composite anode material comprises nickel cobalt lithium manganate and lithium lanthanum titanate wrapping the surface of the nickel cobalt lithium manganate. The chemical formula of the composite anode material is LiNixCoyMn(1-x-y) O2 / LizLa (2-z) / 3TiO3, x is greater than 1 and smaller than 1, y is greater than 0 and smaller than 1, (x+y) is greater than 1 and smaller than 1, z is greater than or equal to 0.5 and smaller than or equal to 1.5, and the mass percent of the lithium lanthanum titanate is 0.5-1.5%wt. A layer of stable conductive materials which are the lithium lanthanum titanate wraps the surface of the nickel cobalt lithium manganate composite anode material. On one hand, the structure of the nickel cobalt lithium manganate composite anode material is quite stable; and on the other hand, the ionic conductivity of the nickel cobalt lithium manganate material is quite high, so that dissolution of the nickel cobalt lithium manganate material is restrained, the conductivity is improved, and the rate capability and the recycling performance of the material are greatly improved.

Owner:中国东方电气集团有限公司

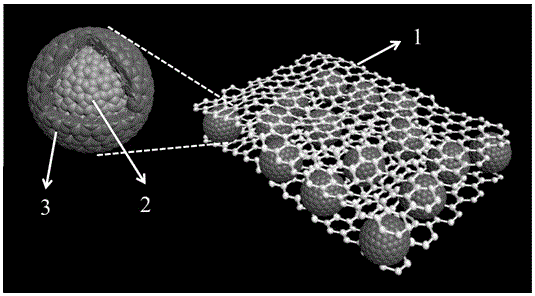

Sandwich core-shell structured lithium-rich manganese base, spinel and graphene flexible composite positive electrode and production method thereof

ActiveCN106558682AIncrease energy densityImprove flexibilityCell electrodesSecondary cellsComposite filmFiltration

The invention discloses a sandwich core-shell structured lithium-rich manganese base, spinel and graphene flexible composite positive electrode and a production method thereof, and belongs to the field of material synthesis. The chemical formula of a lithium-rich manganese base positive electrode material is aLi2MnO3.(1-a)LiMO2, and the chemical formula of a spinel material is LiMn2-xMxO4, wherein x is not less than 0.1 and is less than 1, M = Mn1-x-yNixCoy, x is not less than 0 and not more than 0.5, and y is not less than 0 and not more than 0.5. The production method comprises the following steps: carrying out a coprecipitation technology to obtain a manganese nickel cobalt carbonate spherical precursor, uniformly mixing the precursor with a lithium salt compound, calcining the obtained mixture to obtain the spherical lithium-rich manganese base positive electrode material, mixing the positive electrode material with a graphene oxide dispersion, carrying out a vacuum suction filtration technology to produce a sandwich structured lithium-rich manganese base and graphene oxide composite film, and carrying out high-temperature in-situ carbothermal reduction to produce the sandwich core-shell structured lithium-rich manganese base, spinel and graphene flexible composite positive electrode. The production method has the advantages of simple process and low production cost; and the sandwich core-shell structured lithium-rich manganese base, spinel and graphene flexible composite positive electrode has the advantages of obviously improved and reliable performances, large specific capacity, excellent rate and excellent cycle performances.

Owner:黑龙江瑞霭科技有限公司

Cathode material of battery with high rate performance and preparation method thereof

InactiveCN101794876AEasy to makeExcellent high magnification performanceElectrolytic capacitorsHybrid capacitor electrodesCapacitanceCarbon composites

The invention relates to a preparation method of a spinel lithium titanate / carbon composite material as an electrode material of a novel accumulator and a cathode material of a supercapacitor or lithium ion battery accumulator. A lithium titanate / carbon nanometer composite material is prepared by using inorganic lithium salt and tetrabutyl titanate as materials, and conductive carbon black as a carbon source and a reaction precursor and adopting a sol-gel method. The lithium titanate / carbon composite material prepared by using the method has small particles and evenly distributed granularity and presents excellent high rate performance and cycle performance when used as cathodes of supercapacitors and lithium ion batteries, thereby having wide application potential in high-powered hybrid supercapacitors and lithium ion batteries.

Owner:JIANGSU TENGFANG NEW ENERGY TECH

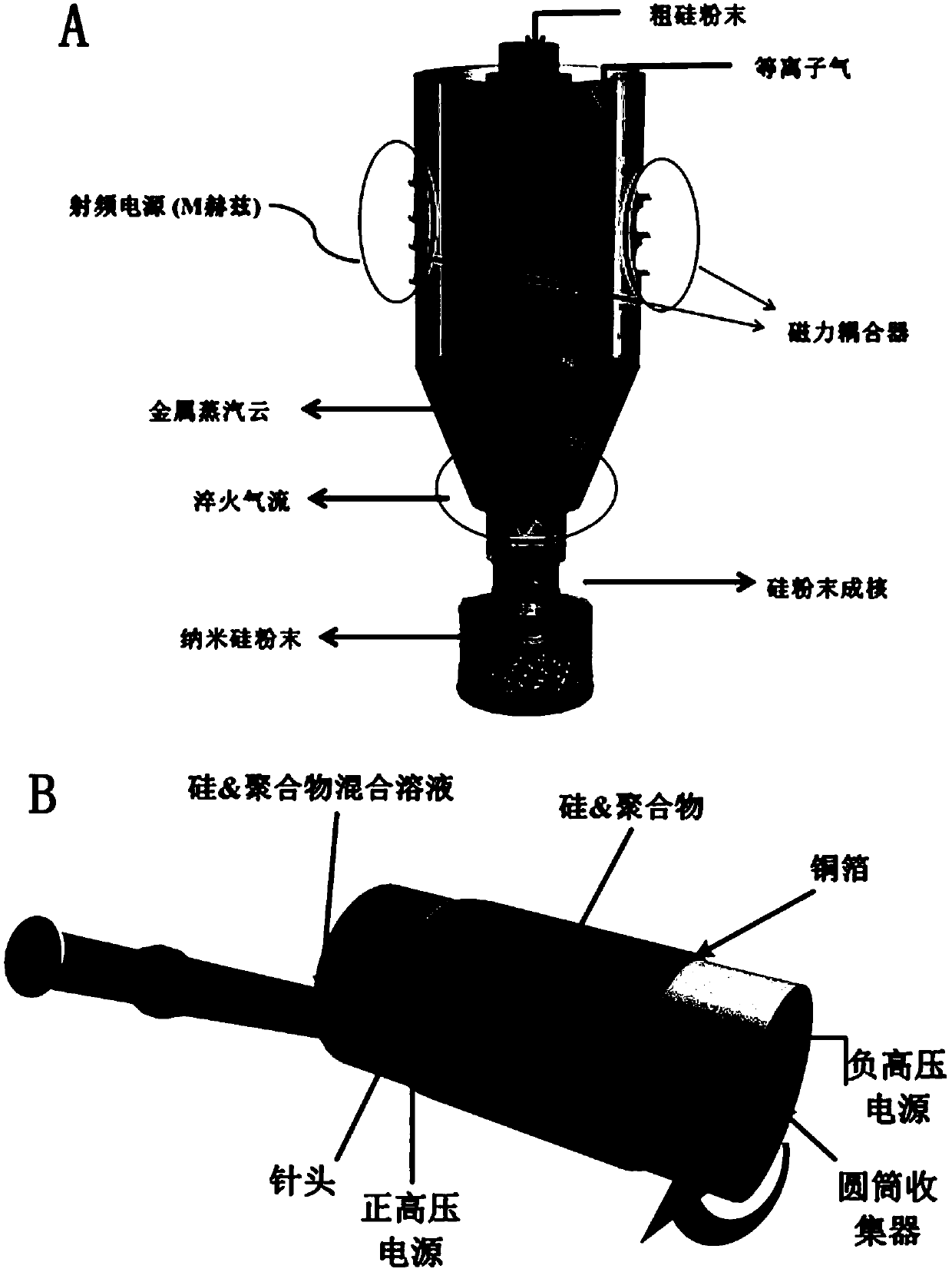

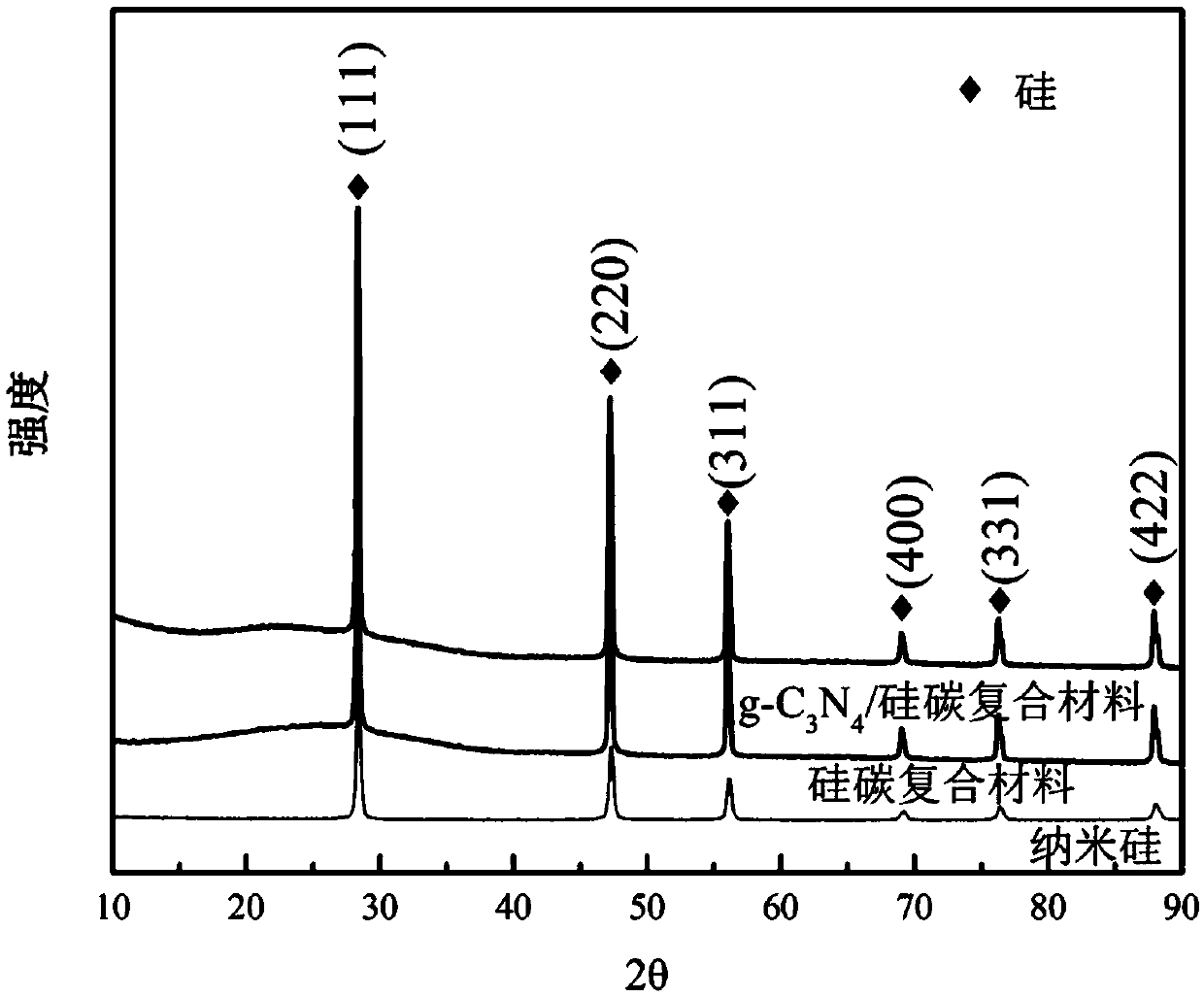

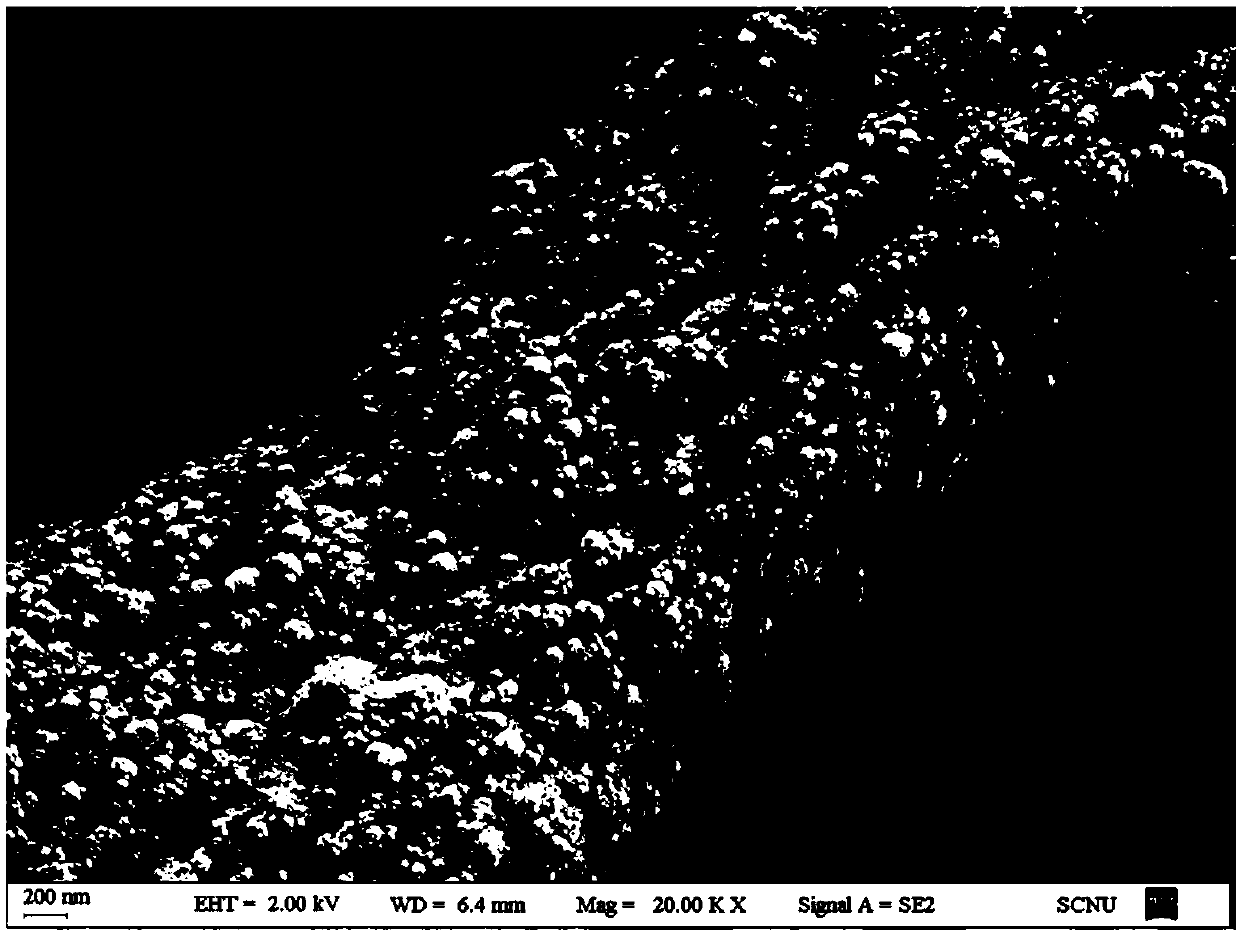

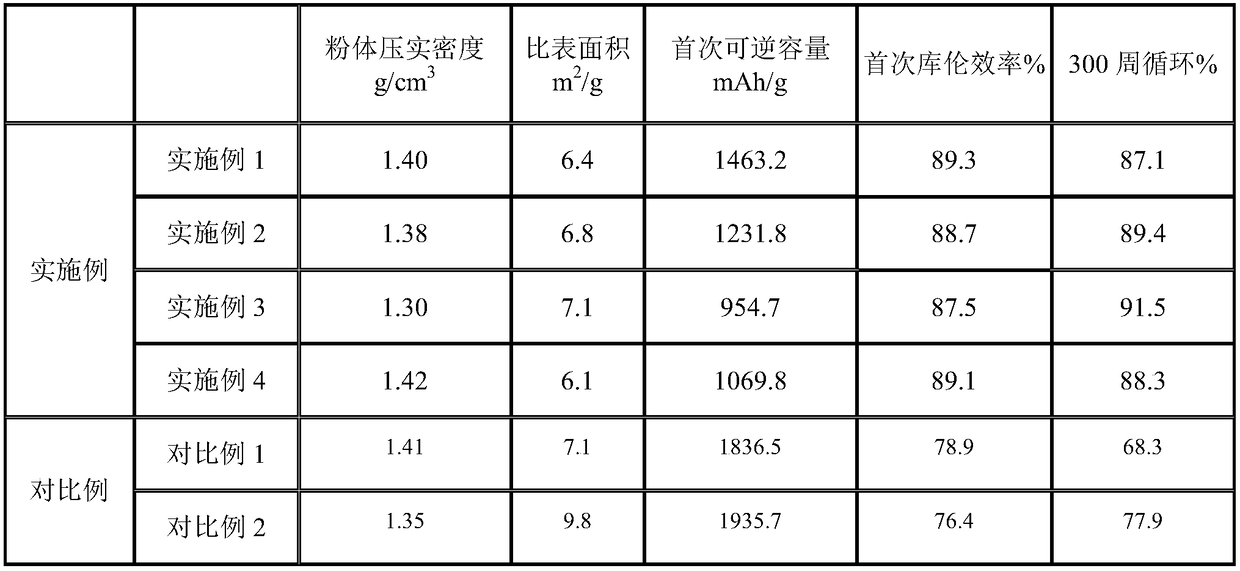

Method of preparing g-C3N4/silicon carbon cathode material of lithium ion battery by electrostatic spinning and application thereof

ActiveCN109524639AReduce reunionAlleviate volume expansionCell electrodesSecondary cellsN dimethylformamideSodium-ion battery

The invention discloses a method of preparing a g-C3N4 / silicon carbon cathode material of a lithium ion battery by electrostatic spinning and an application thereof. The method comprises the followingsteps: (1) adding polyvinylpyrrolidone into N,N-dimethylformamide to obtain a polyvinylpyrrolidone solution; (2) adding nano silicon into the polyvinylpyrrolidone solution to obtain a mixed solutionA; (3) adding urea into the mixed solution A to obtain a mixed solution B; (4) carrying out electrostatic spinning on the mixed solution B to obtain a silicon polymer composite material; and (5) putting the silicon polymer composite material in an inert gas environment, heating the material to 200-400 DEG C, keeping the temperature constantly for 3-6 hours, and heating the material to 500-700 DEGC and keeping the temperature constantly for 3-6 hours to obtain the g-C3N4 / silicon carbon cathode material of the lithium ion battery. The g-C3N4 / silicon carbon cathode material of the lithium ion battery has the advantages of being high in specific capacity, stable to recycle, good in rate performance and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Hollow-structure carbon and silicon negative pole material used for lithium ion battery, and preparation method of hollow-structure carbon and silicon negative pole material

ActiveCN108258230AImprove volume expansionImprove performanceNegative electrodesSecondary cellsCarbon coatingTransmission channel

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a hollow-structure carbon and silicon negative pole material used for a lithium ion battery. The inner side of the negative pole material is of a hollow structure, and a wall layer of the negative pole material comprises an inner wall and an outer wall; the inner wall is subjected to homogeneous phase compounding by nanometer silicon and a low carbon residue carbon source; the outer wall is a carbon coating layer formed by an original pyrolysis carbon source; the particle size of the nanometer silicon is 5-300nm; the softening point of the low carbon residue carbon source is less than 200DEG C, and a carbon residue rate is less than 40%; the thickness of the outer wall is 0.1-10 microns; thethickness of the inner wall is 1-8 microns. The invention designs the large hollow-structure carbon and silicon negative pole material used for the lithium ion battery, a large hollow part is reservedfor the volume expansion of silicon, the volume expansion problem of a silicon negative pole can be obviously solved, the formation of the large hollow structure is guaranteed by the low carbon residue carbon source, meanwhile, the nanometer silicon is subjected to homogeneous phase dispersion, a transmission channel and rate of electrons and lithium ions can be guaranteed, and the carbon coatinglayer coats the outmost layer so as to form a protection shell for isolating electrolyte.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD

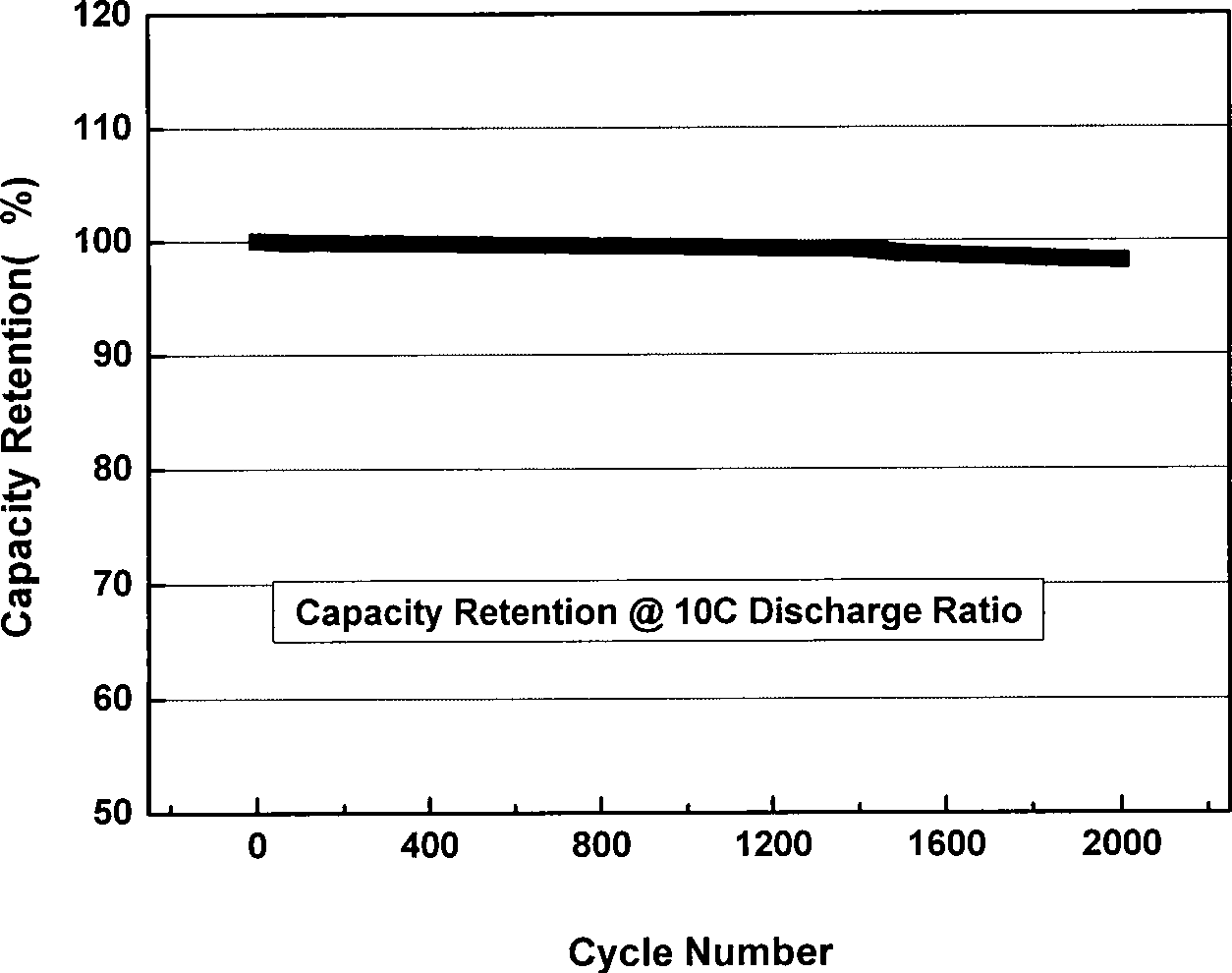

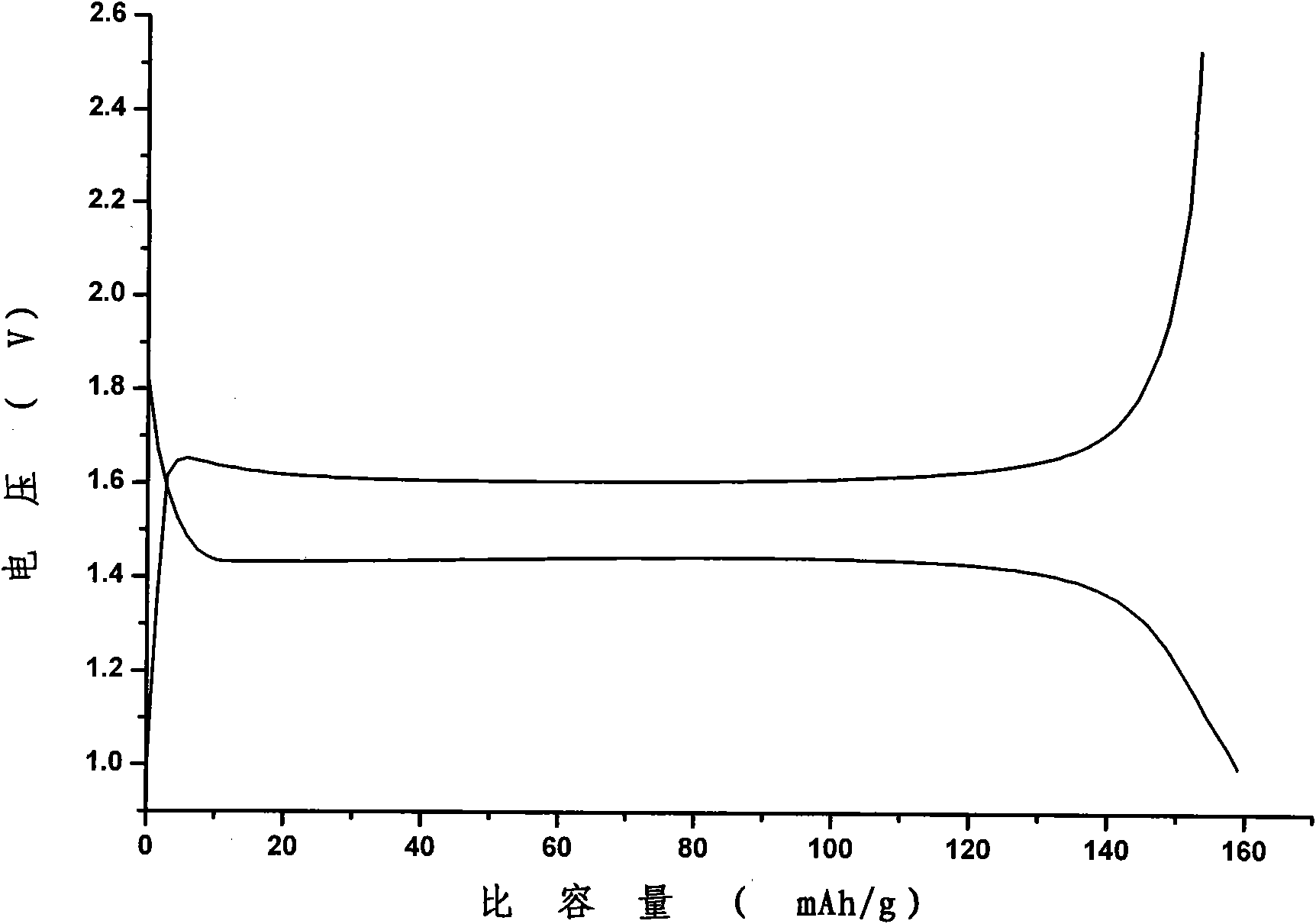

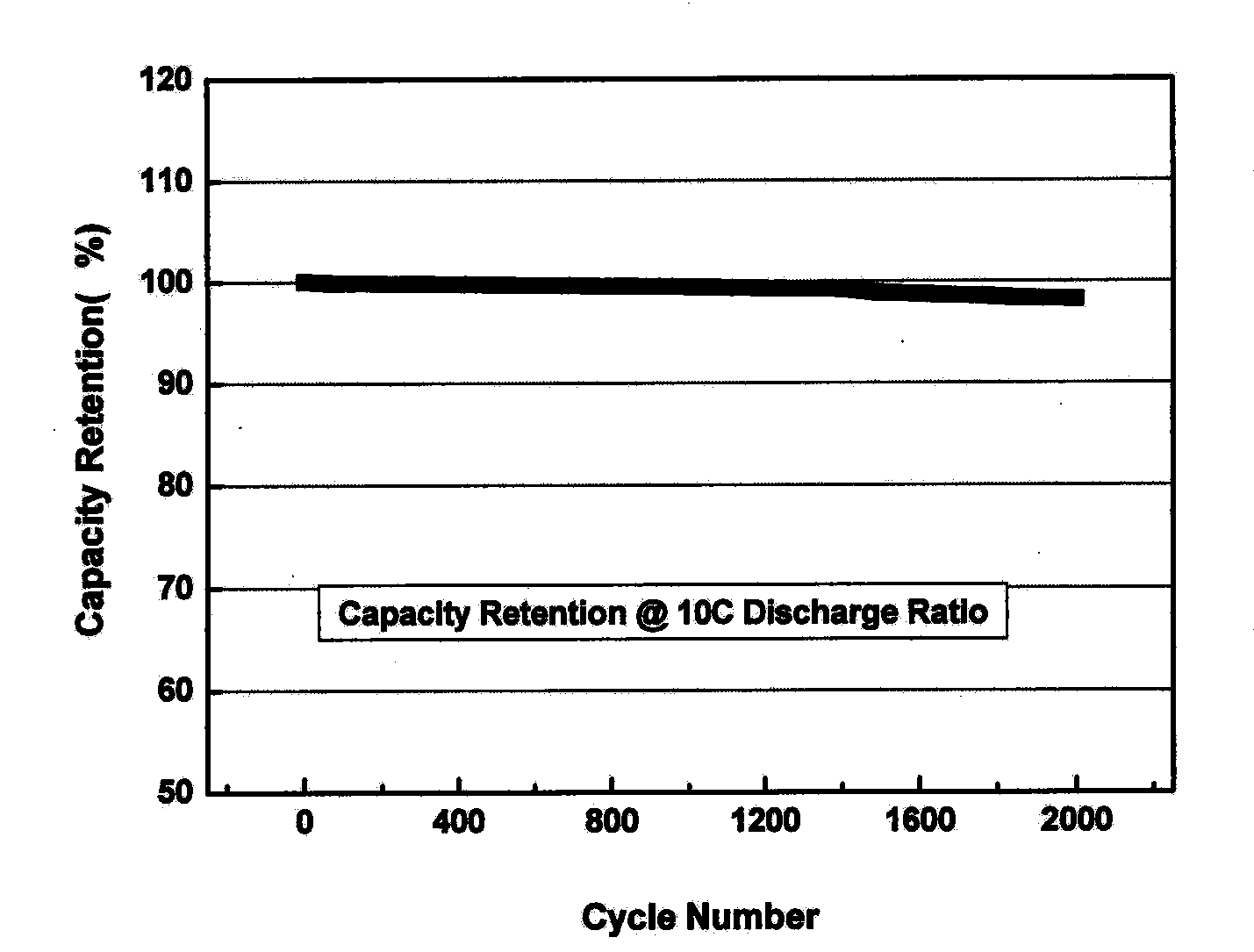

Lithium-ion battery cathode material with long service life and high power as well as preparation method thereof

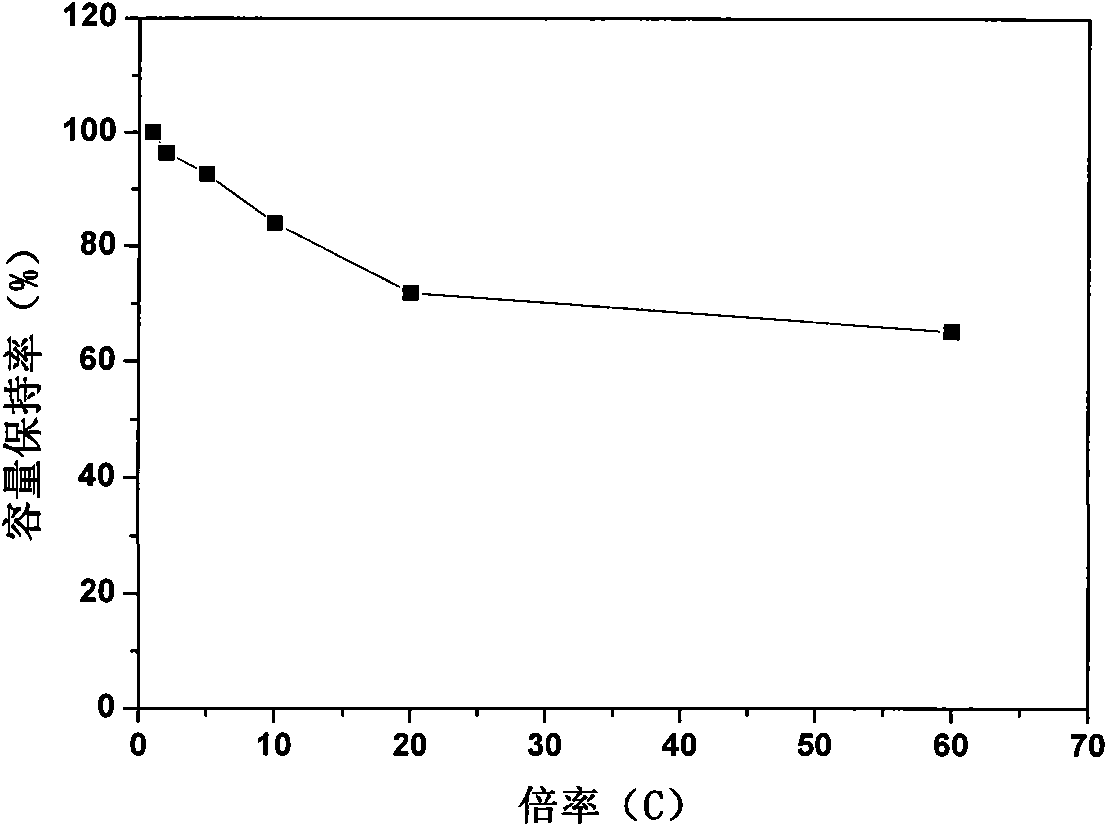

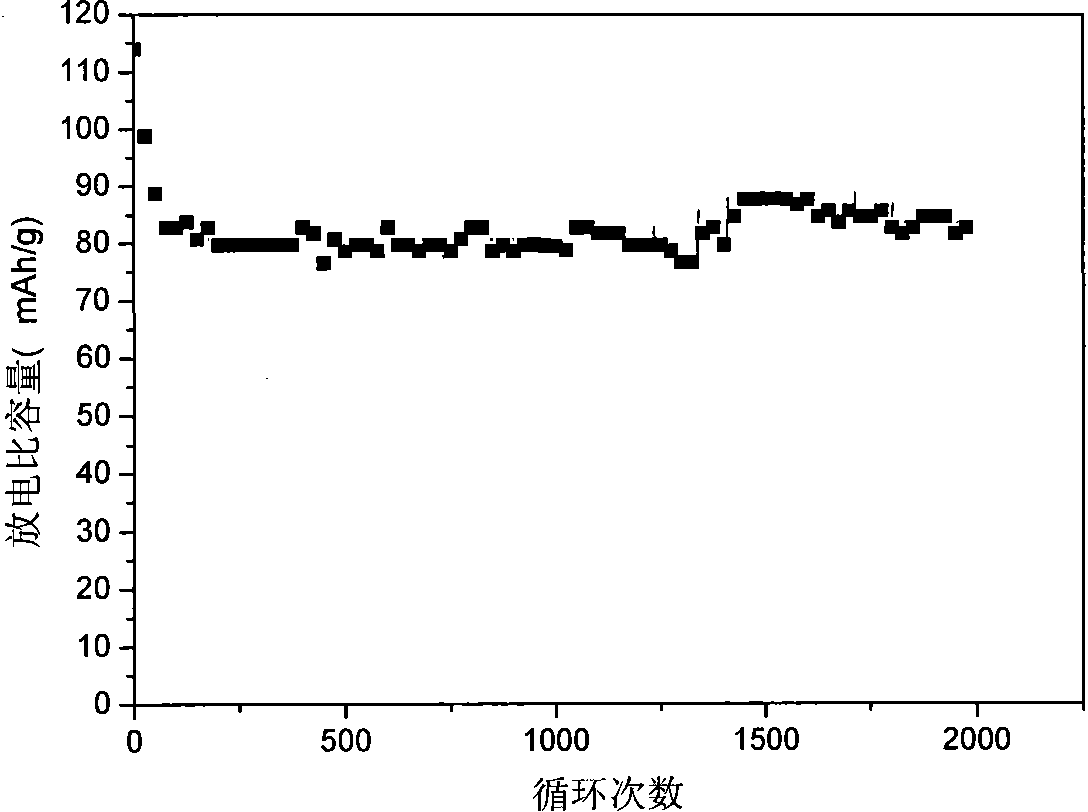

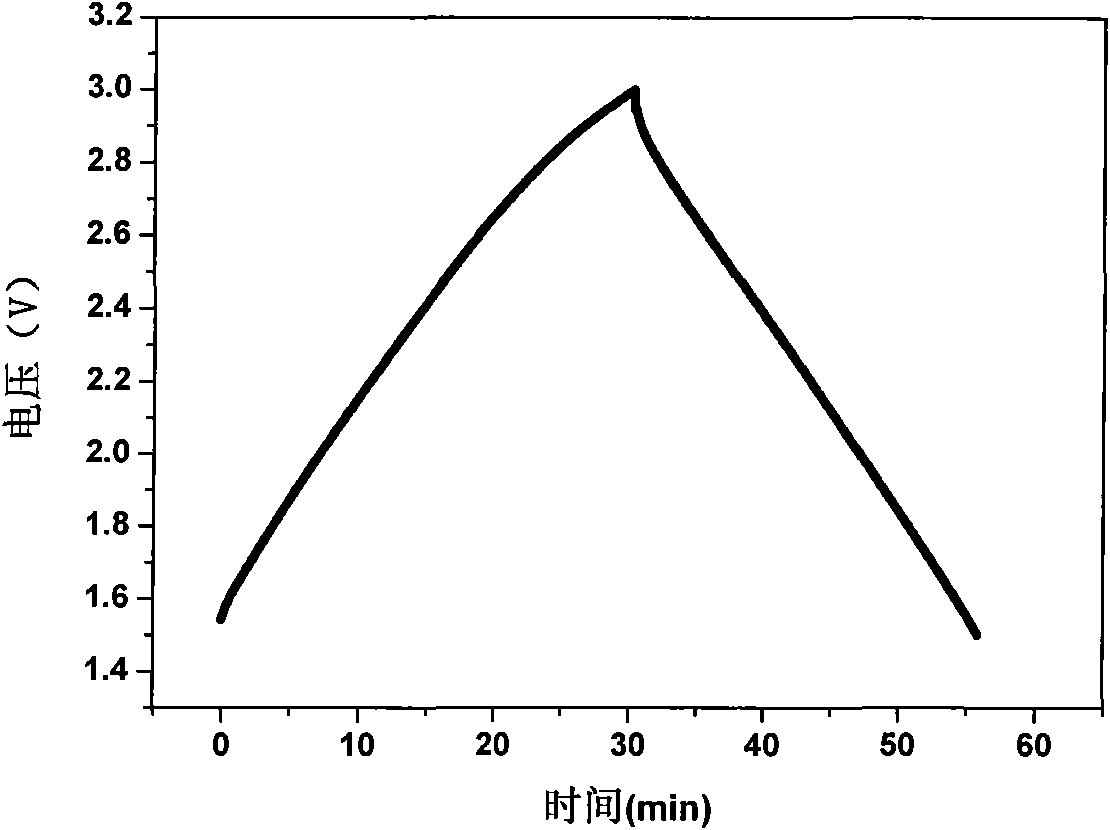

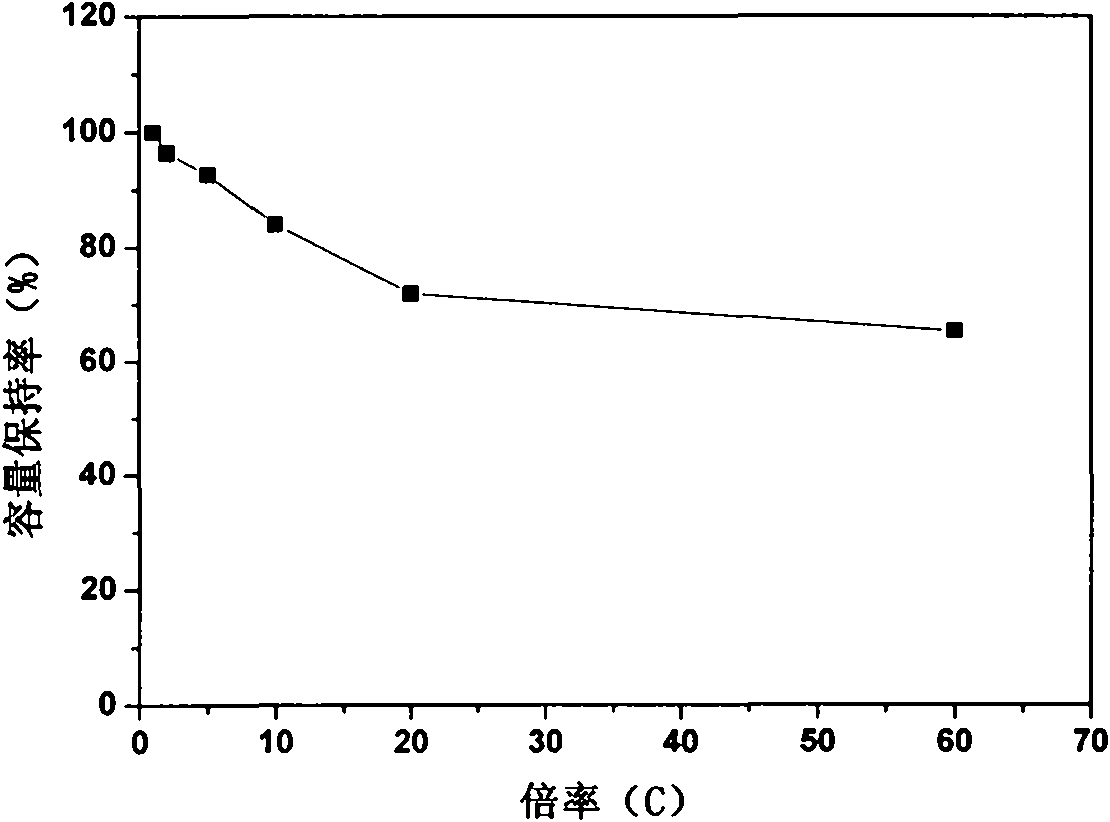

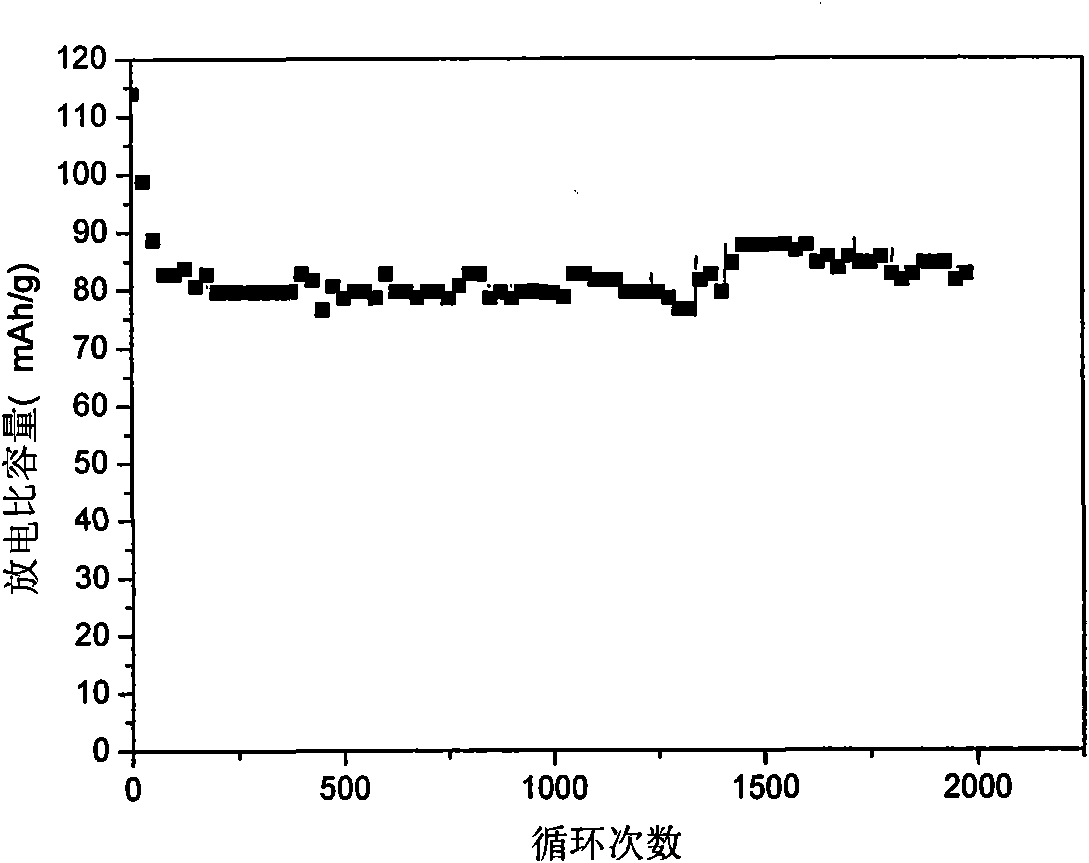

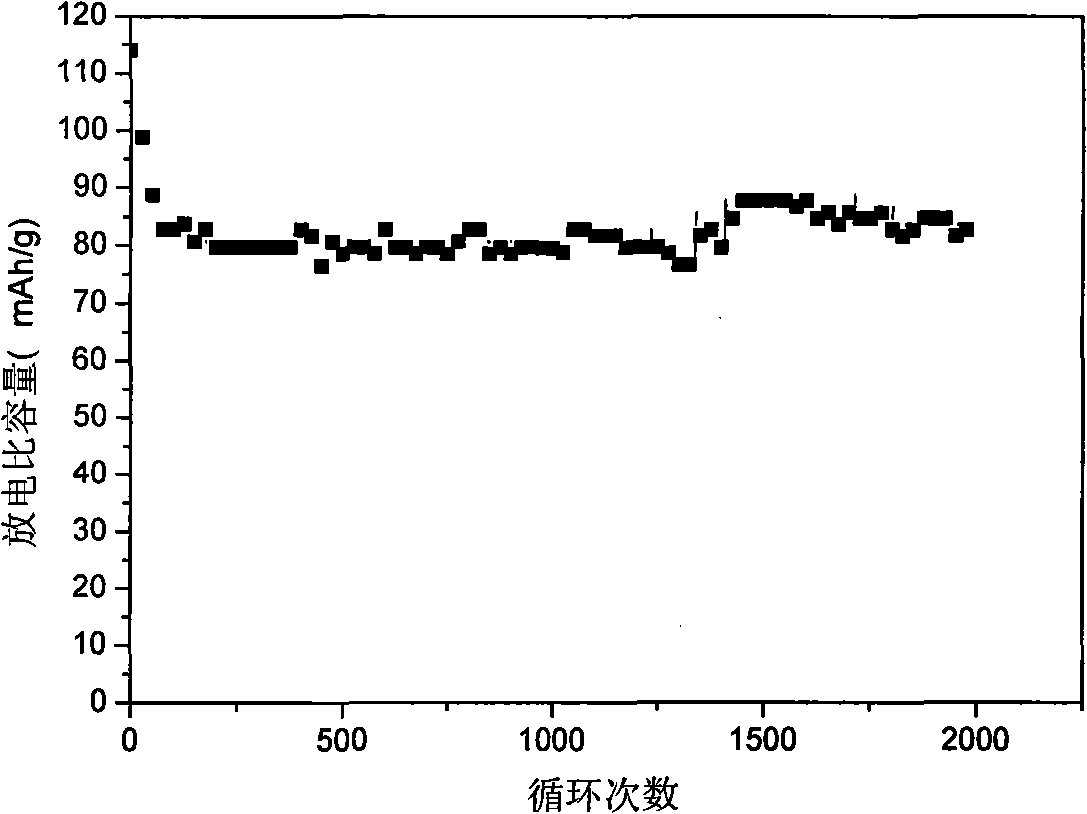

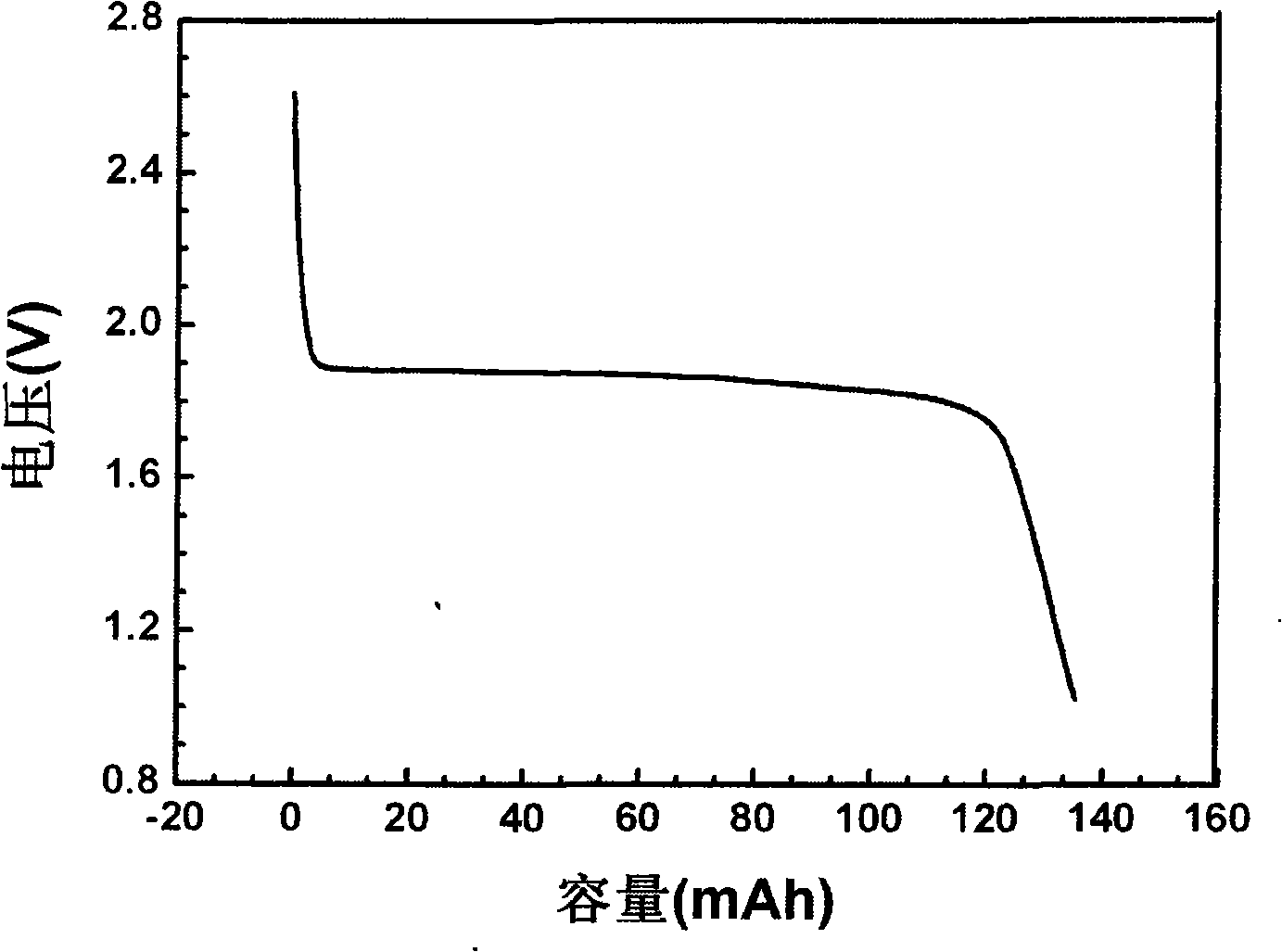

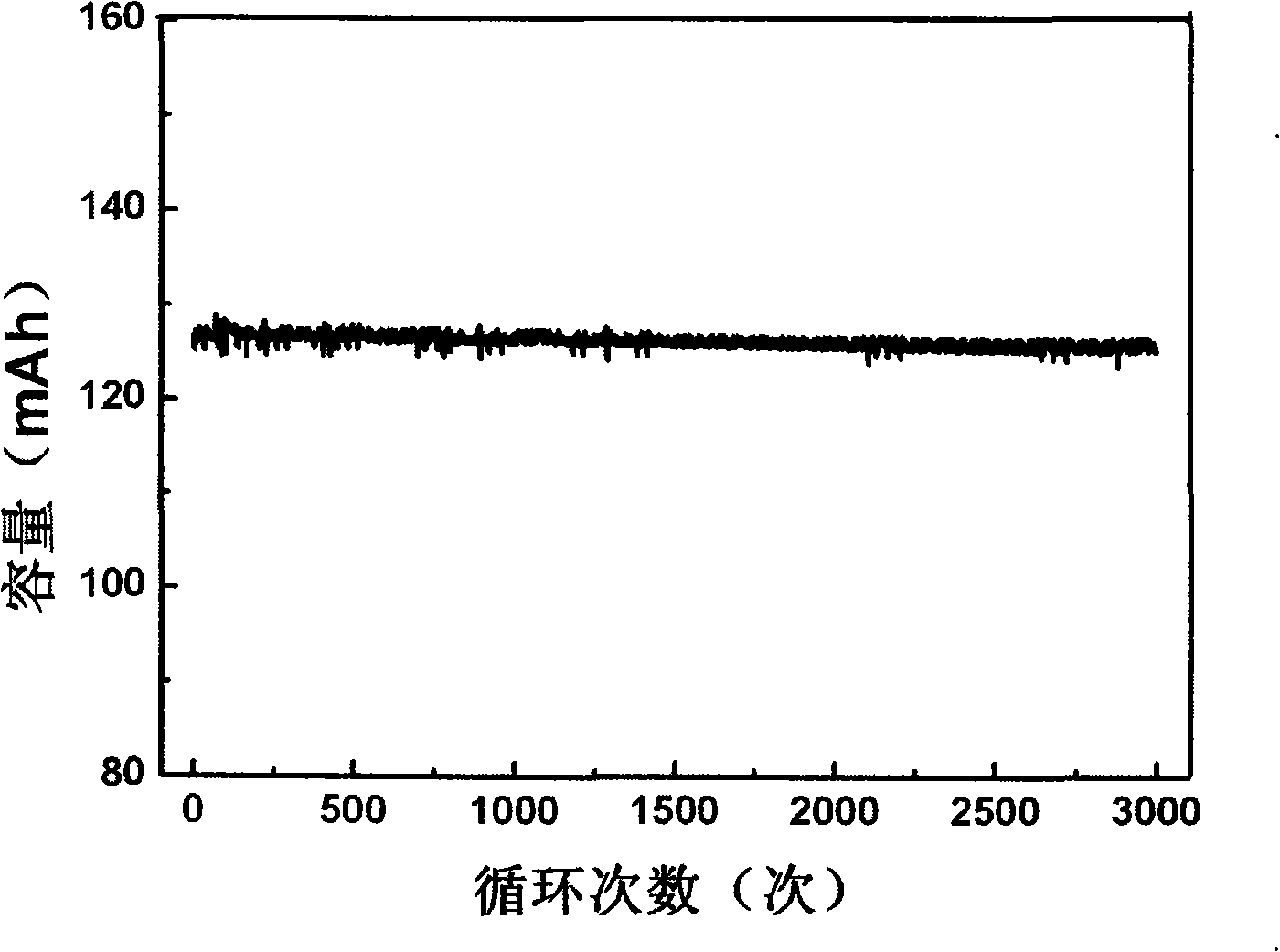

InactiveCN101867036AEasy to makeExcellent high magnification performanceNon-aqueous electrolyte accumulator electrodesMetallic lithiumCarbon composites

The invention relates to a novel energy storage device and a preparation method of a spinel lithium titanate / carbon composite material of a lithium-ion battery cathode material with long service life and high power. The lithium titanate / carbon composite material is prepared by adopting a sol-gel method and taking inorganic lithium salts and tetrabutyl titanate as materials and carbon black as a carbon source. The prepared lithium titanate / carbon composite material has small particles and even particle size distribution and shows excellent large-rate capability and cycling performance as the cathode of a lithium-ion battery with long service life and high power. When the lithium titanate / carbon composite material and metallic lithium form a half-cell, the first specific capacity of the half-cell can still reach 108.9mAh / g in the 60C discharging process, and the capacity retention ratio of the half-cell after 2000 cycles is 75.9 percent. When the lithium titanate / carbon composite material and spinel lithium manganite form the lithium-ion battery and the current density reaches 1A / g (about 60C multiplying power), the discharge capacity can still reach 85 percent of discharge capacity when the current density reaches 60mA / g. Therefore, the invention has wide application potential in the lithium-ion battery with long service life and high power.

Owner:CSI CELLS CO LTD

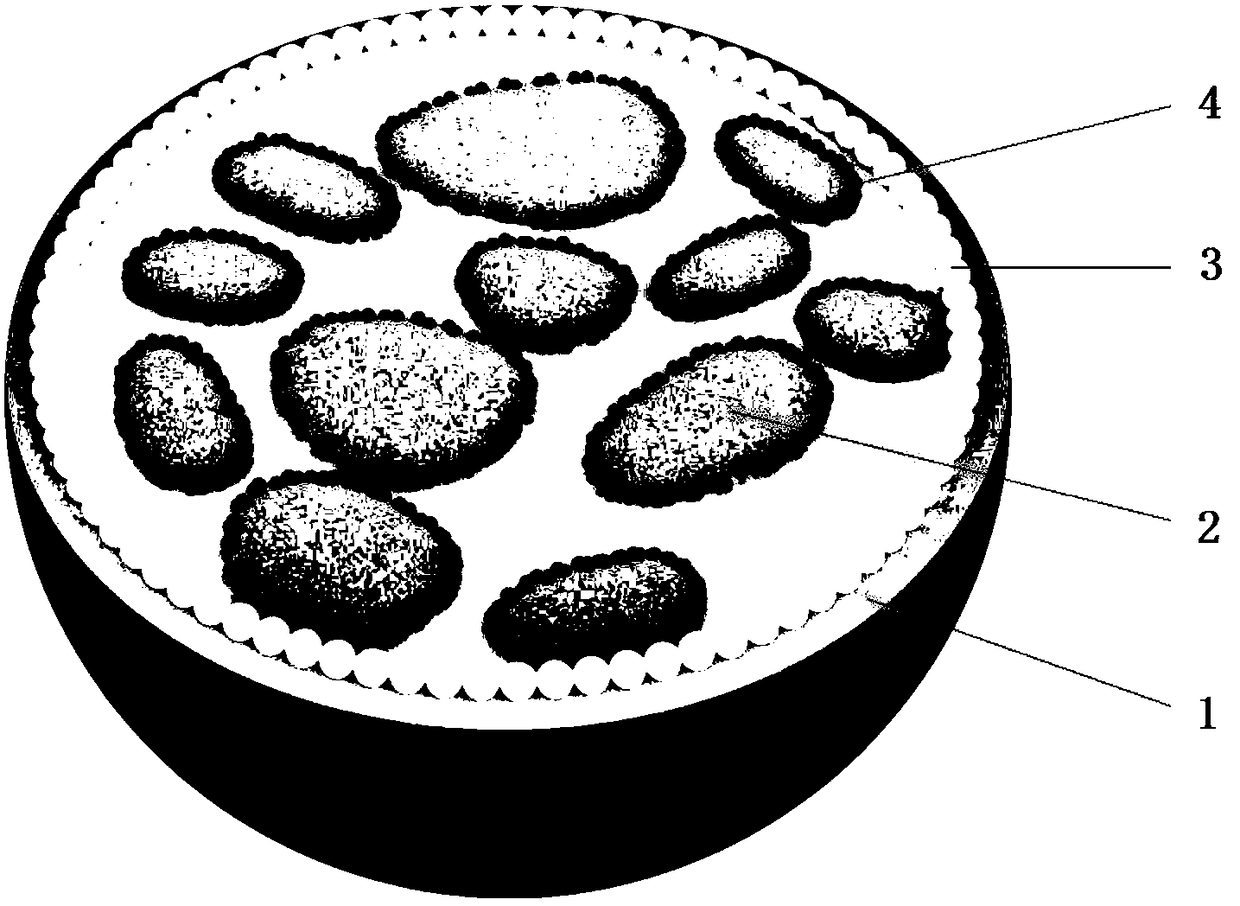

A double-layer coated core-shell negative electrode material for lithium ion battery and a preparation method thereof

InactiveCN109119618AHigh magnificationExcellent long cycle performanceMaterial nanotechnologyCell electrodesHigh rateSodium-ion battery

The invention discloses a double-layer coated core-shell negative electrode material for lithium ion battery and a preparation method thereof. A CVD deposition method is used for depositing nano silicon on that graphite particle to obtain a precursor of a negative electrode material; The titanium dioxide, the lithium carbonate and the organic pyrolysis carbon source are dispersed in an organic solvent to prepare a gel; the precursor of anode material was added into the gel, and the core-shell structure anode material was prepared by low temperature treatment, homogeneous dispersion and high temperature reaction. The core of double-layer coated core-shell negative electrode material for the lithium ion battery is nano silicon and graphite, the nano silicon is deposited on the surface of graphite particles, the outer shell is an organic pyrolytic carbon layer, and the inner shell is formed by attaching lithium titanate to the inner wall of the organic pyrolytic carbon layer. The core-shell negative electrode material has high capacity, high rate and excellent cycling performance, and the preparation process is simple, green and pollution-free, suitable for large-scale production.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD

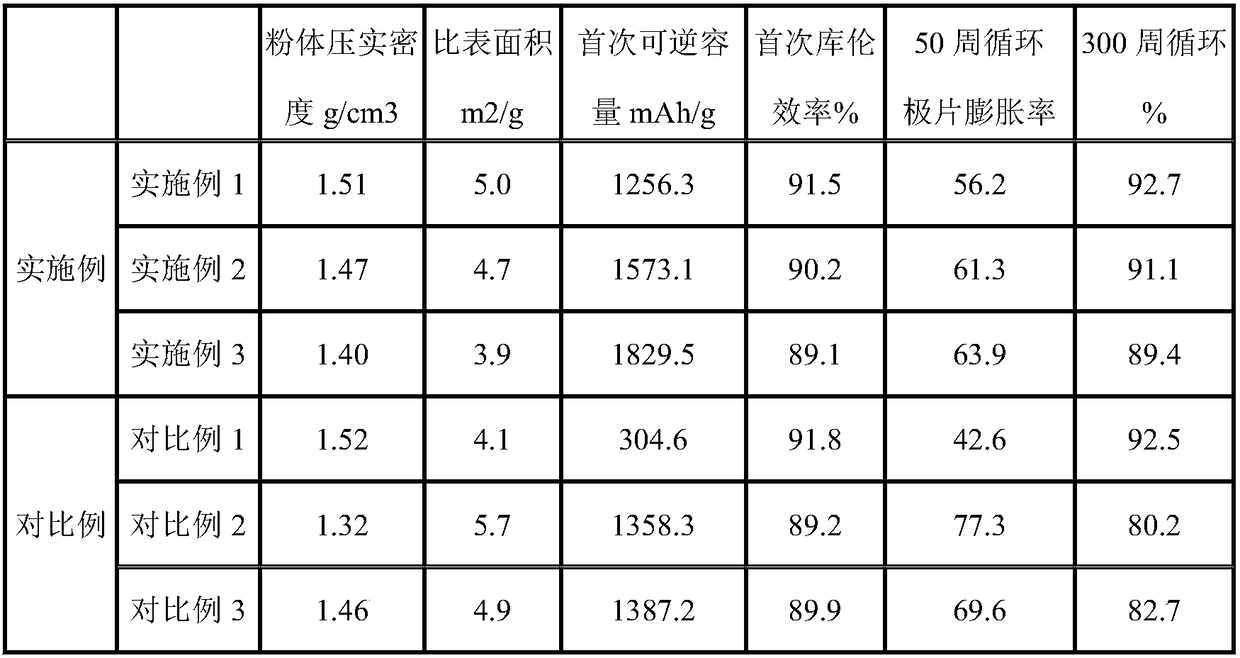

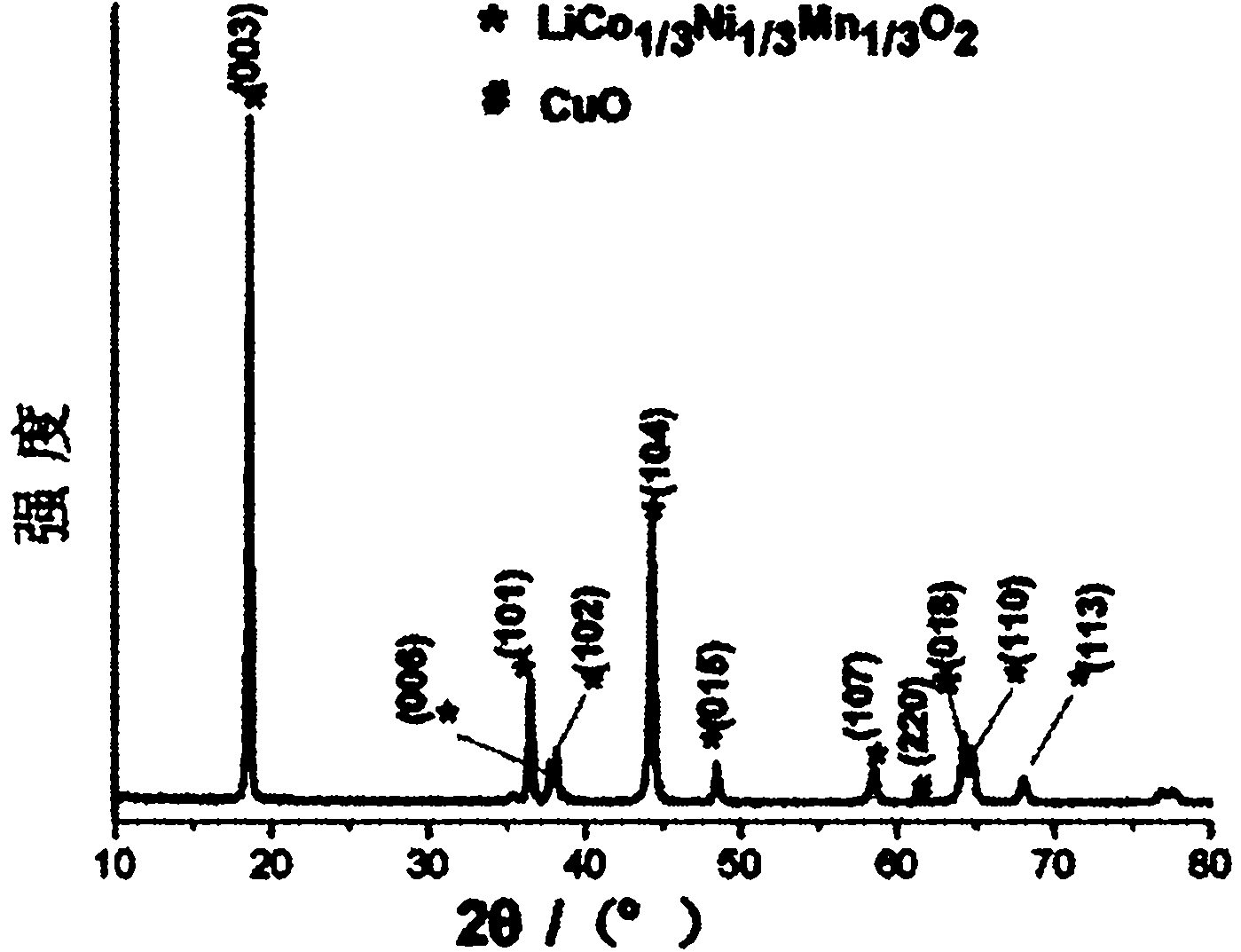

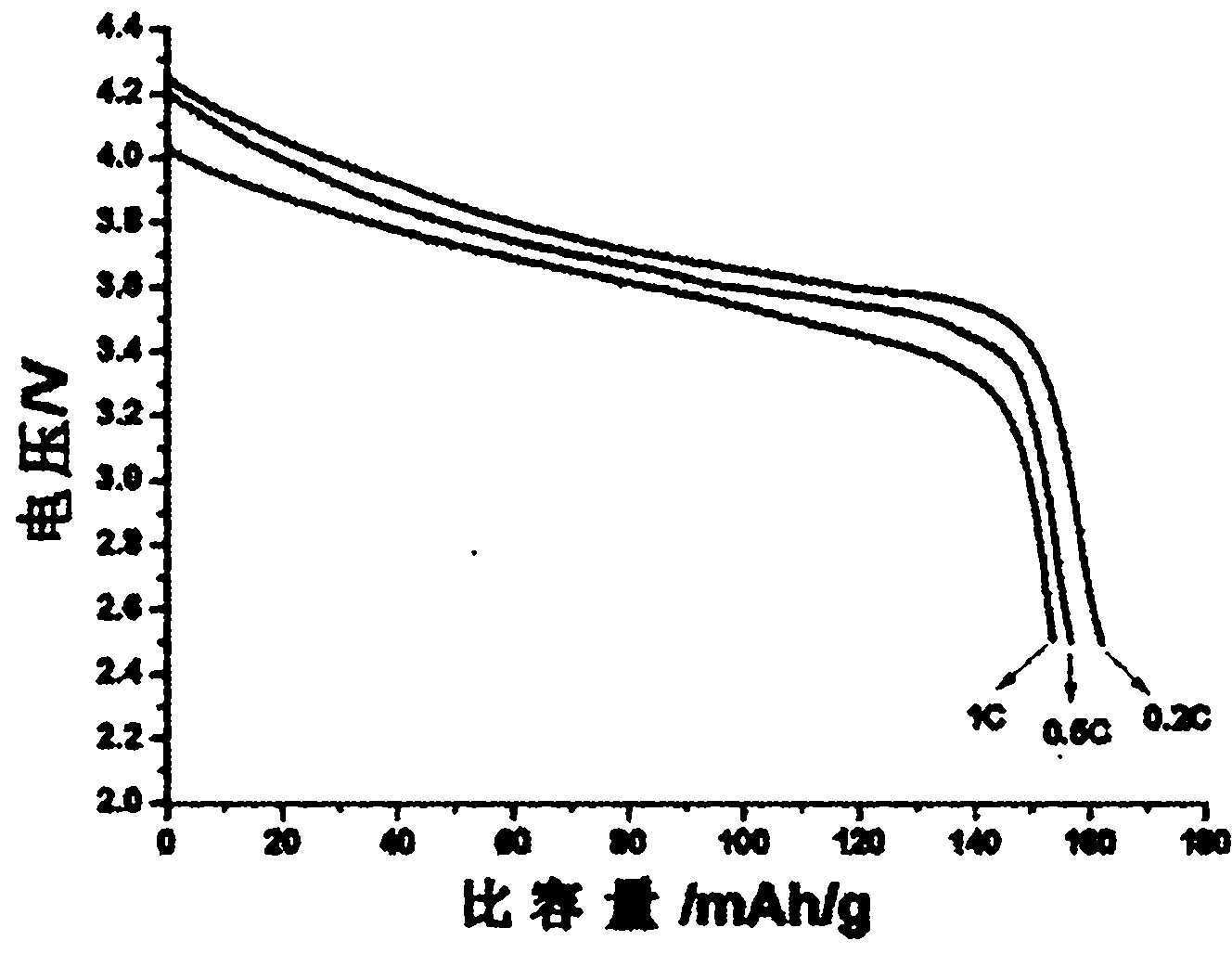

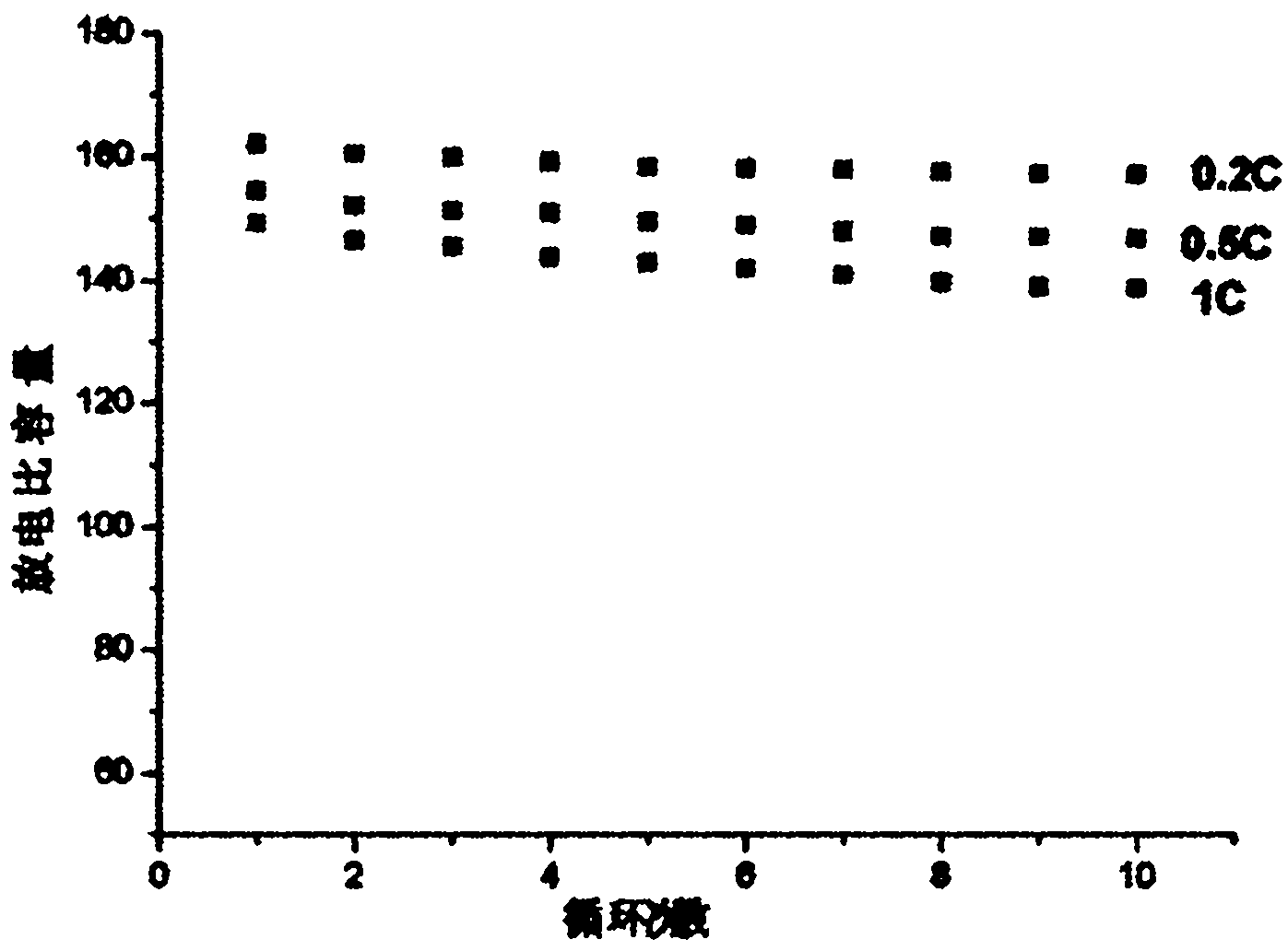

Cobalt nickel manganese lithium oxide-cooper oxide compound positive material for lithium ion battery and preparation method thereof

InactiveCN102163709AGood cycle stabilityExcellent high magnification performanceCell electrodesNickelLithium electrode

The invention discloses a cobalt nickel manganese lithium oxide-cooper oxide compound positive material for a lithium ion battery and a preparation method thereof. The compound positive material is obtained by coating cooper oxide on the surface of cobalt nickel manganese lithium oxide; and the chemical general formula of the compound positive material is LiCoxNiMn(1-x-y)O2 / CuO, wherein x is large than or equal to 0.2 and less than or equal to 0.4, and y is more than or equal to 0.3 and less than or equal to 0.7. The preparation method comprises the following steps: preparing cobalt nickel manganese lithium oxide ternary compound oxide lithium salt by a high temperature solid method; and then coating the copper oxide on the surface of the cobalt nickel manganese lithium oxide through high-temperature sintering so as to obtain the cobalt nickel manganese lithium oxide-cooper oxide compound positive material for the lithium ion battery. The material provided by the invention has the advantages of high specific capacity, good circulation characteristic, short production period and the like, is suitable for industrial production, and can be applied to the fields of electromobiles, energy storing equipment, electric power tools and the like.

Owner:HEFEI UNIV OF TECH

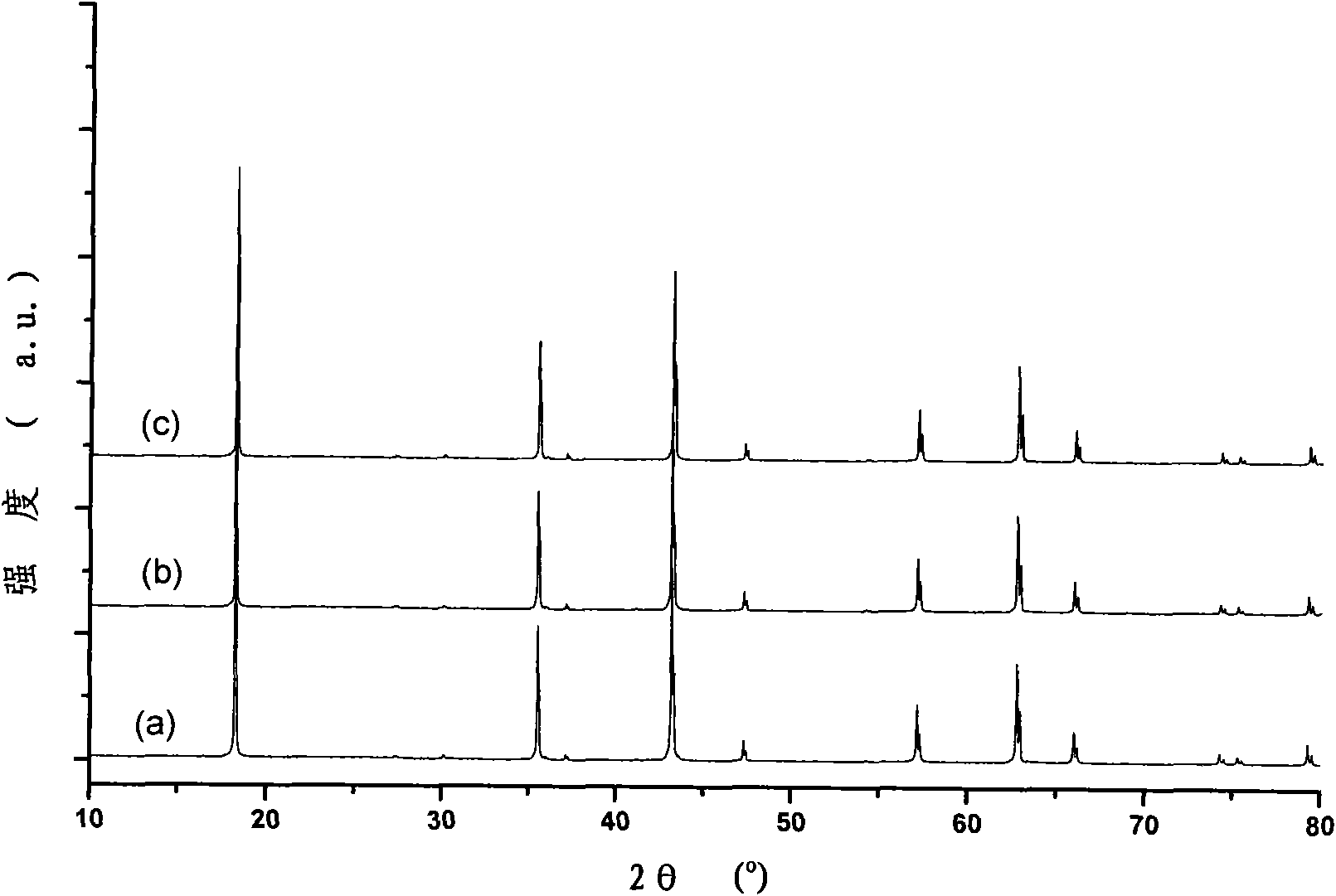

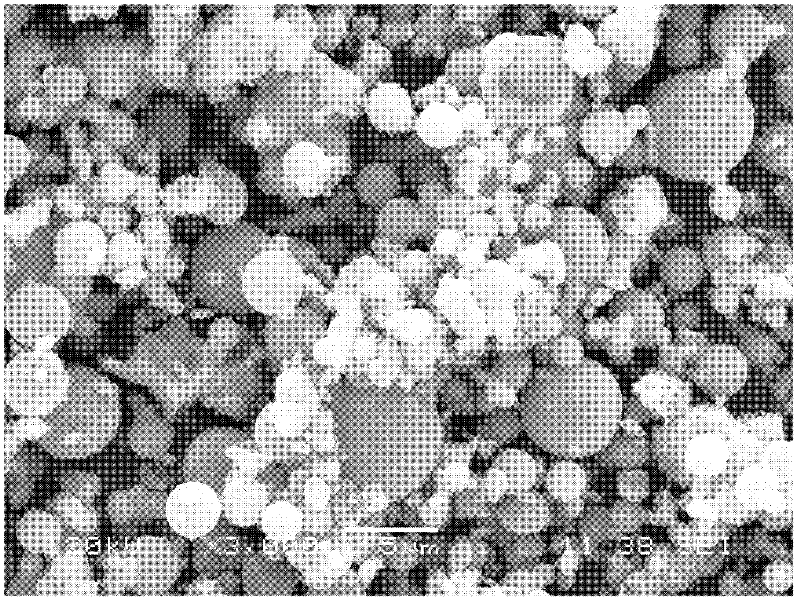

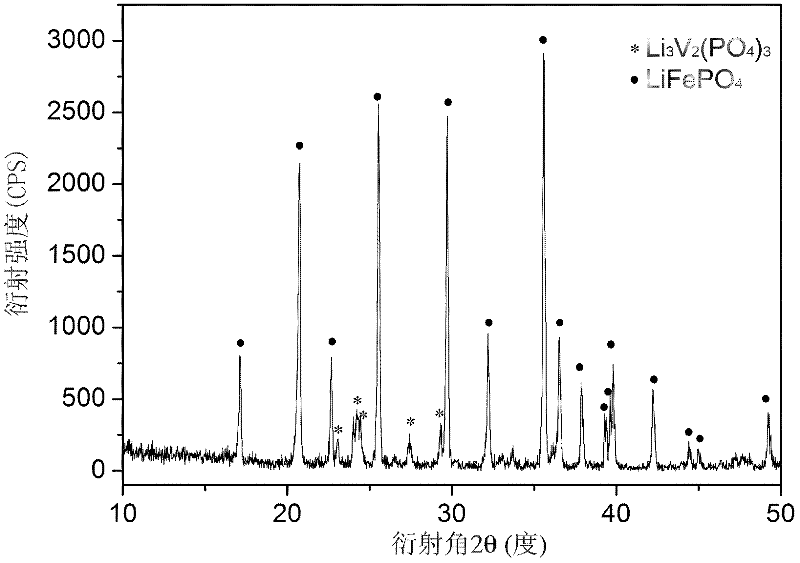

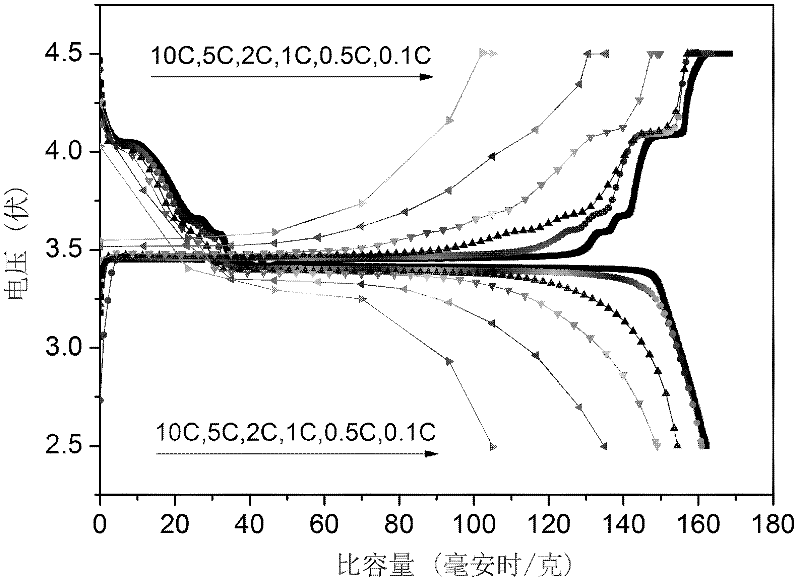

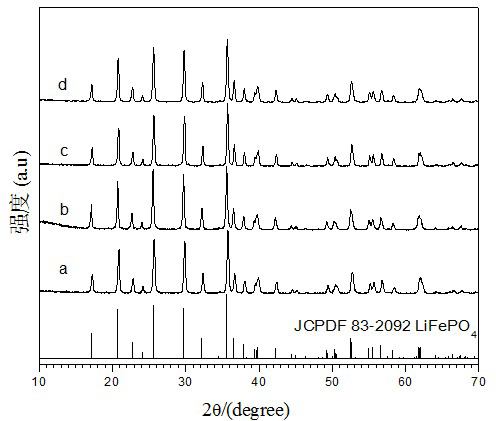

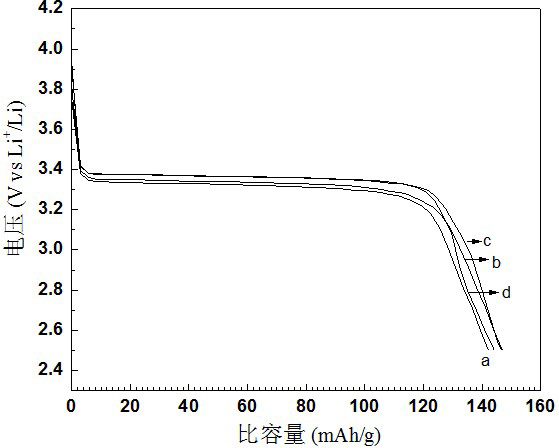

Method for improving tap density of composite anode material xLiFePO4.yLi3V2(PO4)3 of lithium ion battery

ActiveCN102244244AImprove electrochemical performanceHigh tap densityCell electrodesPhosphoric acidSodium-ion battery

The invention discloses a method for improving the tap density of a composite anode material xLiFePO4.yLi3V2(PO4)3 of a lithium ion battery. A combined sol gel-spray drying-carbon thermal reduction method is adopted to prepare the composite anode material xLiFePO4.yLi3V2(PO4)3 of the lithium ion battery, comprising the following concrete steps: mixing a lithium source, an iron source and a vanadium source with phosphate groups in a stoichiometric ratio; adding a solvent and a coordinating agent containing carbon to stir to form sols; carrying out spray drying on the sols; and roasting the obtained powder for 2-24 hours in an argon or nitrogen atmosphere at the temperature of 500-850 DEG C to obtain the composite anode material xLiFePO4.yLi3V2(PO4)3. The tap density of the prepared composite material is 1.50-2.00g / cm<3> and the electrochemical performance of the prepared composite material is good.

Owner:CENT SOUTH UNIV

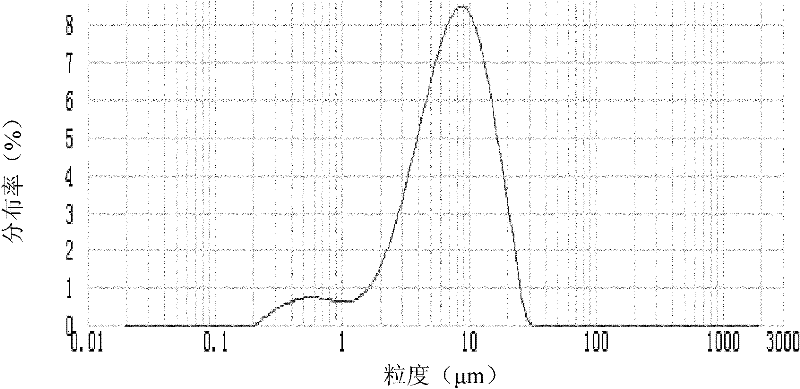

A kind of multi-component doped lithium phosphate cathode material and preparation method thereof, and lithium ion power battery

ActiveCN102290576AShorten the transmission distanceEasy to processCell electrodesSecondary cellsPower batteryPhysical chemistry

The invention relates to a multi-doped lithium phosphate anode material for a lithium ion power cell, LiFe1 minus x minus y Ti0.5x Mn0.1 minus y PO4 as base material is clad by a carbon material particle layer, the base material and the carbon material particle layer are combined to form composite particles, the composite particles are evenly dispersed in the conductive network of carbon materialparticles, wherein x / 2 plus y is larger than or equal to 0.03 and less than or equal to 0.10, x is larger than or equal to 0.02 and less than or equal to y, y is less than or equal to 0.08, organic carbon source compound is decomposed to produce C, and the added amount of the organic carbon source compound is 1 to 10 percent of the total weight of the base material; the average grain size of the composite particles is between 0.5Mu m and 5Mu m, and the diameter of the carbon material particle is between 5nm and 50nm; and the specific surface area of the composite particle is 12m<2> / g to 35m<2> / g. The anode material has the advantages of good high-rate performance, good product consistency and good cell processability, and the power cell adopting the material as anode material has the advantages of high safety performance, high rate performance and high cycle performance.

Owner:FIRST NEW ENERGY GRP CO LTD

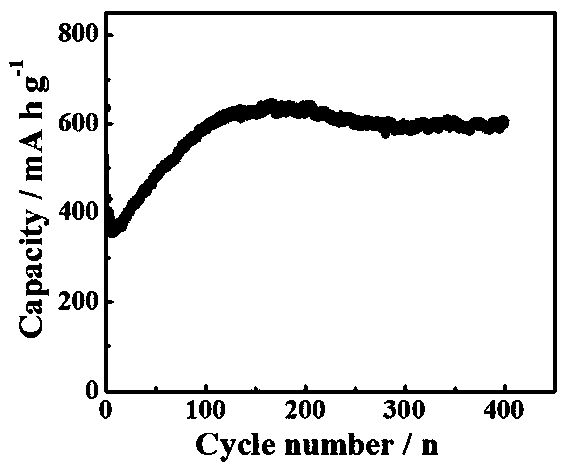

Carbon-supported porous spherical MoN formed by nanosheets, and application of porous spherical MoN as negative material in lithium batteries

ActiveCN108777294AGood cycle stabilityExcellent high magnification performanceCell electrodesSecondary cellsTube furnaceLithium electrode

The invention relates to a carbon-supported porous spherical MoN lithium battery negative material formed by nanosheets. A preparation method of the material comprises the following steps: adding 0.1gof MoO2(acac)2, 0.2g of CH4N2S and 0.1g of glucose into 20ml of H2O and stirring for 1h, then placing in an oven at 200 DEG C for 12h, then taking out, centrifuging the product when the product is cooled to the room temperature, washing with ethanol and deionized water for a plurality of times, and placing in the oven at 70 DEG C to obtain a precursor of MoN; then, placing the obtained precursorin a tube furnace, and calcining for 4h at 800 DEG C in an ammonia atmosphere to obtain the carbon-supported porous spherical MoN material formed by the nanosheets. The prepared spherical MoN nanosheets having sizes of 500nm have good cycle stability and high rate performance as negative electrodes of lithium ion batteries, and has a specific capacity of 600mAh / g after 400 cycles of charge and discharge when the current density is 1A.

Owner:FUZHOU UNIVERSITY

SiO2-coated lithium ion battery positive electrode precursor material and preparation method thereof

InactiveCN110880591AHigh metal content per unitLarge specific surface areaCell electrodesFinal product manufactureElectrical batteryLithium-ion battery

The invention provides a SiO2-coated lithium ion battery positive electrode precursor material and a preparation method thereof, the SiO2-coated lithium ion battery positive electrode precursor material comprises a core and a SiO2 coating layer at least partially coating the surface of the core,a chemical structural formula of the core is NixCoyM1-x-yO, and M is selected from Mn or Al. The SiO2-coated lithium ion battery positive electrode precursor material has the advantages of higher unit metal content, larger specific surface area and the like, so that the lithium mixing effect in the sintering process of the material is better. The prepared positive electrode material is a compound lithium ion positive electrode material with more uniform morphology and better consistency, and is morebeneficial to the long cycle performance and high rate performance of the positive electrode material. The SiO2 coating layer improves the stability of the material, reduces the anisotropic volume change caused by phase change in the cycle process of the battery, and avoids the rupture of the internal structure of secondary particles.

Owner:CNGR ADVANCED MATERIAL CO LTD

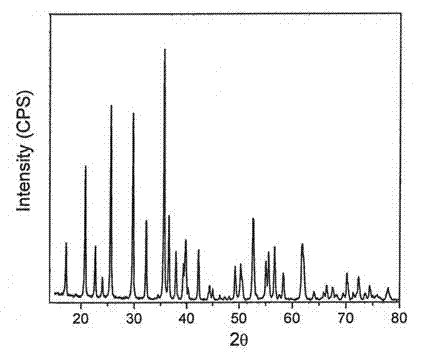

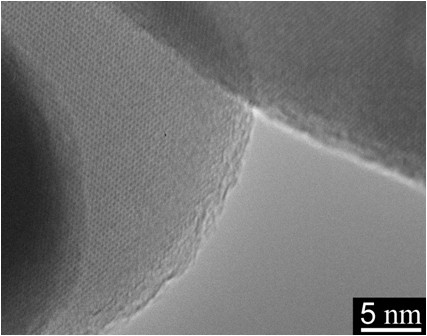

High-conductivity ferrous phosphate lithium cathode material for lithium ion battery and preparation method thereof

The invention provides a high-conductivity ferrous phosphate lithium cathode material for a lithium ion battery and a preparation method thereof. The material is made from a lithium compound, an iron compound, a phosphorous compound, a carbon compound, and a transition metal compound which serves as a graphite catalyst and a doped element, and has a chemical formula of Li(Fe1-xMx)PO4, wherein x is 0 to 0.1; and M may be a transition metal element Fe, Cr, Ni, Co, Mo or Mn. A clad carbon material is catalyzed by adopting the transition metal compound to increase the graphitizing grade of a high-carbon film, thereby improving the conductivity of the material; and the transition metal element can serve as the doped element at the same time to further improve the intrinsic conductivity of the material.

Owner:中国东方电气集团有限公司

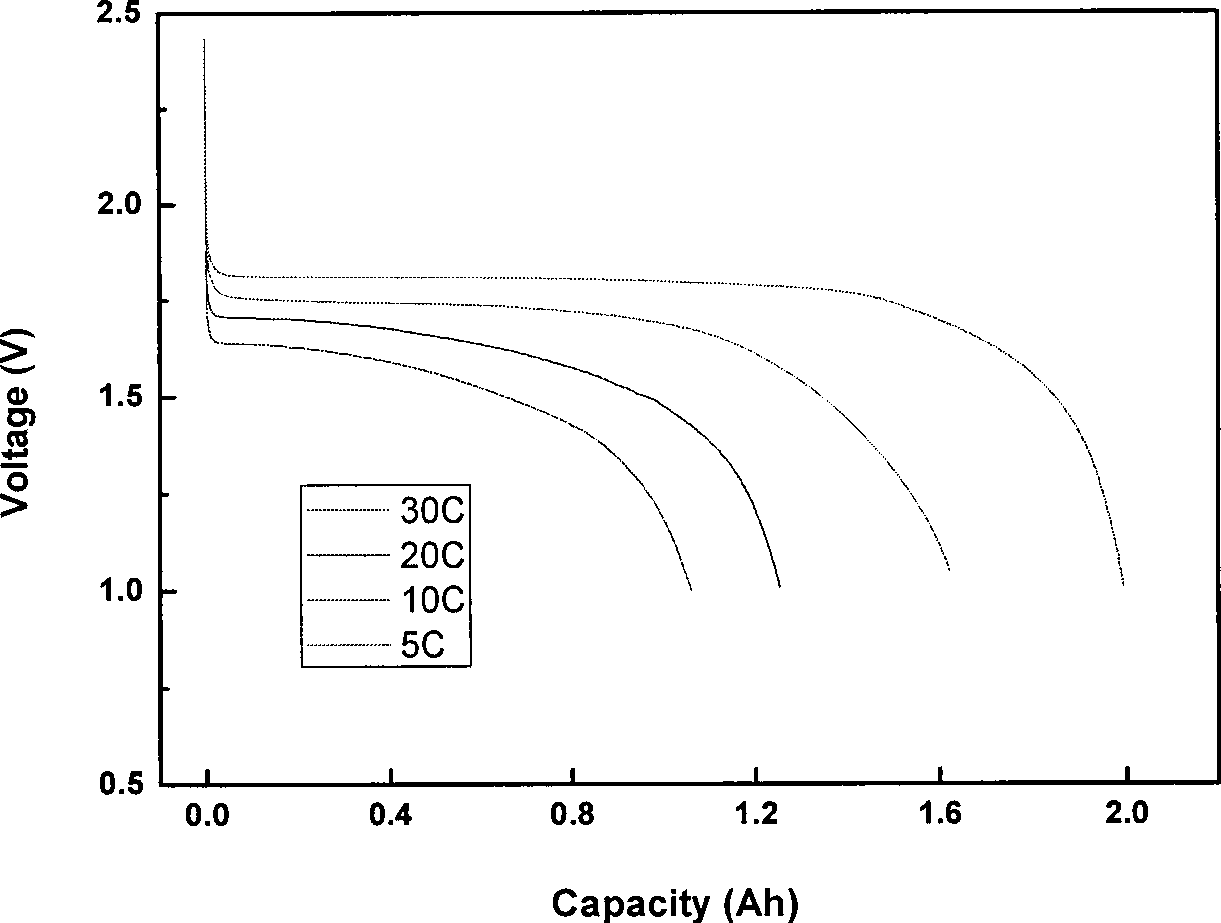

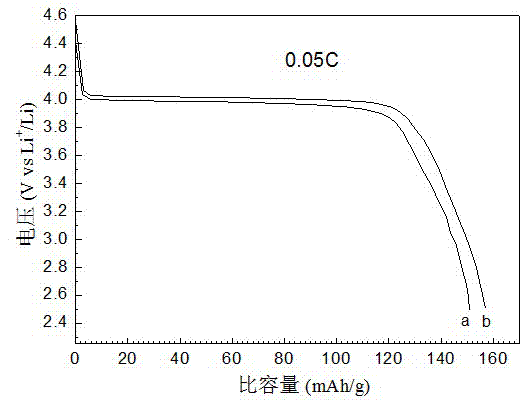

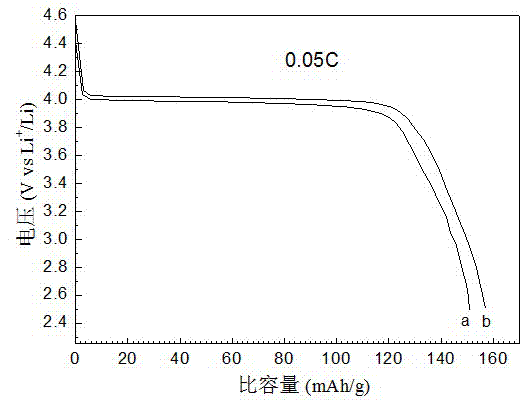

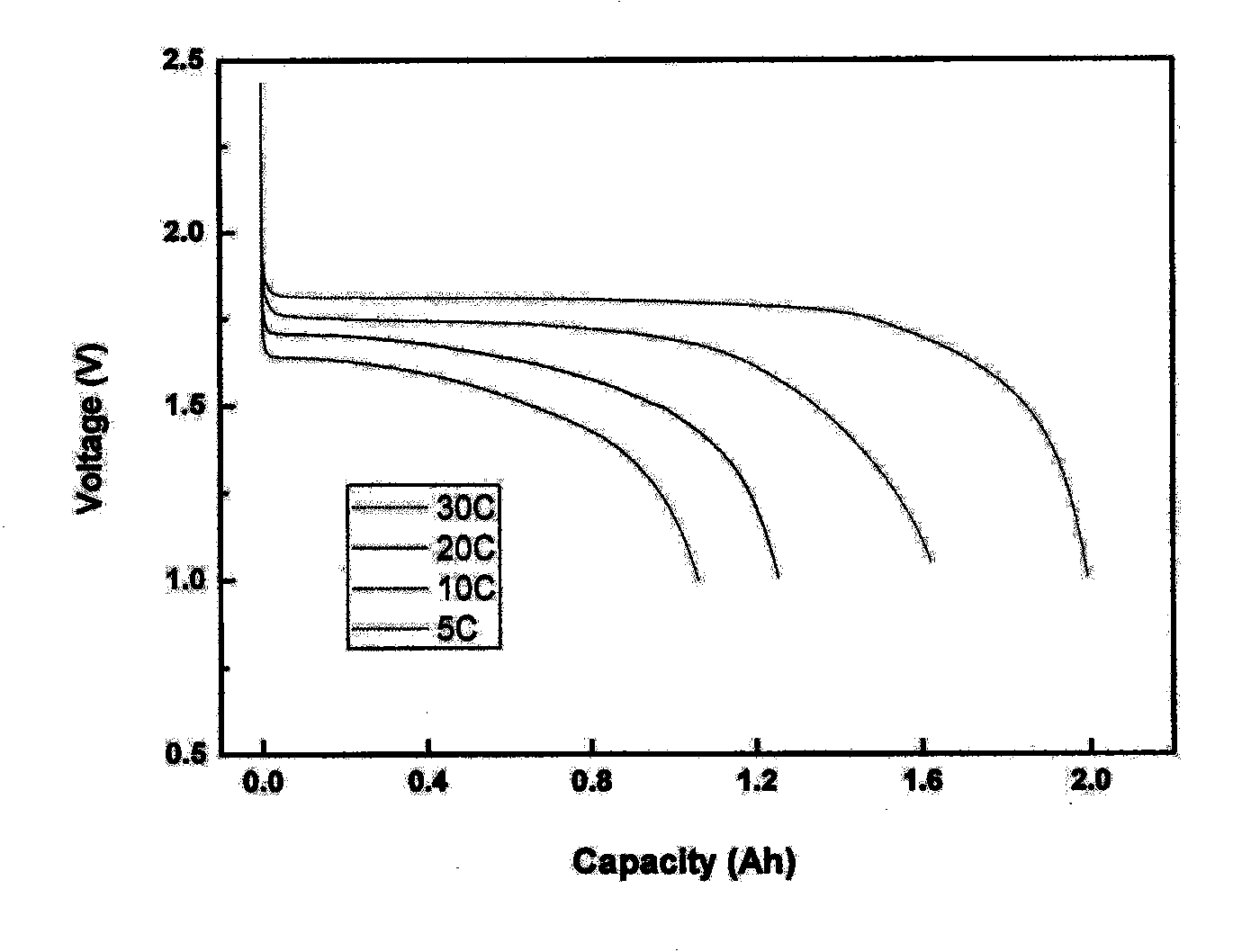

Power lithium ion battery

InactiveCN101527370AFacilitated DiffusionShorten Diffusion TimeCell electrodesSecondary cellsLithium–air batterySolvent

The invention relates to a lithium ion battery, more particularly to a power lithium ion battery. The inventive power lithium ion battery comprises an anode, a cathode, and a membrane between the anode and the cathode and organic electrolyte, wherein, the active material of the anode is nanometer LiFePO4 / C which accounts for 85-95% (by mass) of the mixed powders of the anode; the active material of the cathode is nanometer Li4Ti5O12 / C which accounts for 85-95% (by mass) of the mixed powders of the cathode; the organic electrolyte takes LiPF6 as an electrolyte and takes EC and DEC as solvents. Compared with the existing lithium ion battery which serves as the power source of electric vehicle, the inventive power lithium ion battery is good in conductivity, high in safety, stable in discharging, long in cycle life and excellent in high-current charging and discharging; the invention is extremely suitable for the power source of the electric vehicle.

Owner:GUILIN JIUYI NEW ENERGY SCI & TECH CORP

Preparation method of composite lithium iron phosphate material

A preparation method of a composite lithium iron phosphate material relates to a lithium ion battery cathode material. The method comprises the following steps: feeding main raw materials of Fe(NO)3, LiH2PO4, oxide doped with metal ions, and a polymer organic carbon source into an autoclave according to a stoichiometric ratio, adding water and argon to allow the raw materials to react and to be mixed well so as to obtain a slurry; cooling the slurry, drying and sieving; sintering the materials in argon atmosphere to obtain primary sintered materials; sieving the primary sintered materials, continuing to sinter the materials in argon atmosphere, cooling to obtain a composite lithium iron phosphate material. The prepared composite lithium iron phosphate material has high conductivity and excellent electrochemical performance, and the process is stable and simple, is easy for industrial production.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

Lithium iron phosphate/titanium diboride composite cathode material for lithium ion battery and preparation method of lithium iron phosphate/titanium diboride composite cathode material

InactiveCN102623697AHigh tap densityExcellent high magnification performanceCell electrodesBoron carbideNitrogen gas

The invention discloses a preparation method for a lithium iron phosphate / titanium diboride composite cathode material for a lithium ion battery. The preparation method comprises the following steps of: (1) sufficiently and uniformly mixing lithium carbonate, iron phosphate, a titanium source, boron carbide and carbon powder according to a molar ratio of (0.51-0.60): 1.0: (0.005-0.05): (0.025-0.25): (0.075-0.10); (2) roasting the obtained mixture for 10-16 hours at 650-900 DEG C under the protection of nitrogen; and (3) cooling an obtained product after roasting, and then ball-milling and smashing the product to an appointed granularity. The composite cathode material prepared by the preparation method has the advantages of high tap density, good processability and good cycle performance.

Owner:TIANJIN B&M SCI & TECH

Metal doped and Mxene coated double modified lithium iron phosphate composite material, and preparationmethodand application

ActiveCN110589793AImprove uniformityLarge specific surface areaMaterial nanotechnologySecondary cellsIron saltsPhosphoric acid

The invention discloses a preparation method of a metal doped and Mxene coated double modified lithium iron phosphate composite material. The preparationmethod comprises the following steps that S1, alithium iron phosphate / Mxene precursor is prepared, specifically, an iron salt solution, a phosphoric acid or a salt solution thereof and a lithium salt solution are sequentially placed in a reactionkettle, the Mxene is added after stirring evenly, the pH of a solution is adjusted to 7-10, after protective gas is introduced for reaction, cooling is conducted to the room temperature, and a precursor product is obtained by centrifugal separation and drying; and S2, the precursor product of the step 1 is placed in a high-temperature furnace, sintering is conducted at high temperature in an inert atmosphere, and cooling is conducted to the room temperature to obtain the metal doped and Mxene coated double modified lithium iron phosphate composite material. Double modifying is conducted on the lithium iron phosphate through doping and Mxene surface coating, the conductivity of an electrode material is effectively improved, and the prepared composite material shows excellent large-rate performance and cycle performance.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

B and N co-doped graphene coated silicon nano negative electrode material and preparation method thereof

ActiveCN111048757AImprove lithium storage performanceExcellent high magnification performanceMaterial nanotechnologyCell electrodesDoped grapheneFreeze-drying

The invention discloses a B and N co-doped graphene coated silicon nano negative electrode material and a preparation method thereof. The negative electrode material is prepared from B and N co-dopedgraphene coated silicon nano particles. The preparation method comprises the following steps: (1) adding graphene oxide powder into water, and carrying out ultrasonic dispersion to obtain a graphene oxide aqueous dispersion; (2) adding silicon nanoparticles and a nitrogen source into the graphene oxide aqueous dispersion, carrying out primary ultrasonic dispersion, adding a boron source, carryingout secondary ultrasonic dispersion, and carrying out freeze drying to obtain a B and N-containing graphene oxide coated silicon nano composite material; and (3) in an inert atmosphere, carrying out heat treatment on the B and N-containing graphene oxide coated silicon nano composite material, washing with water, and drying to obtain the material. The battery assembled by the negative electrode material well solves the problem that the volume of the silicon negative electrode material is sharply expanded in the charging and discharging process and is good in cycle performance and high-rate electrochemical performance and low in cost; and the method is simple in process and suitable for industrial production.

Owner:CENT SOUTH UNIV

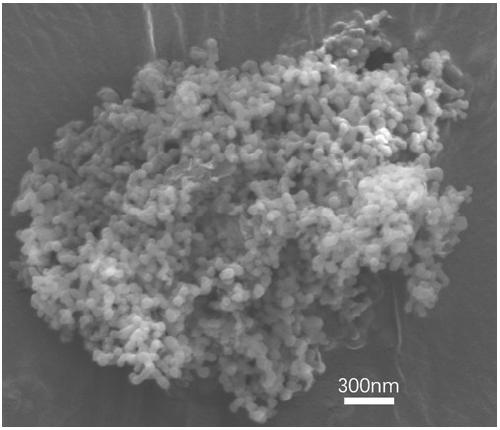

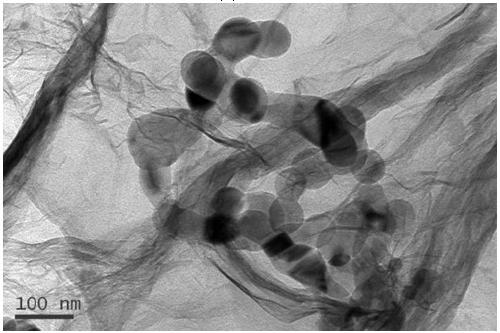

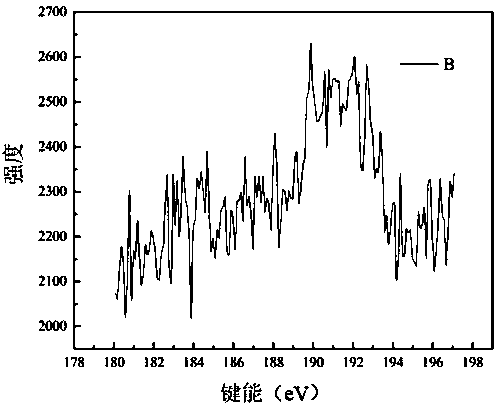

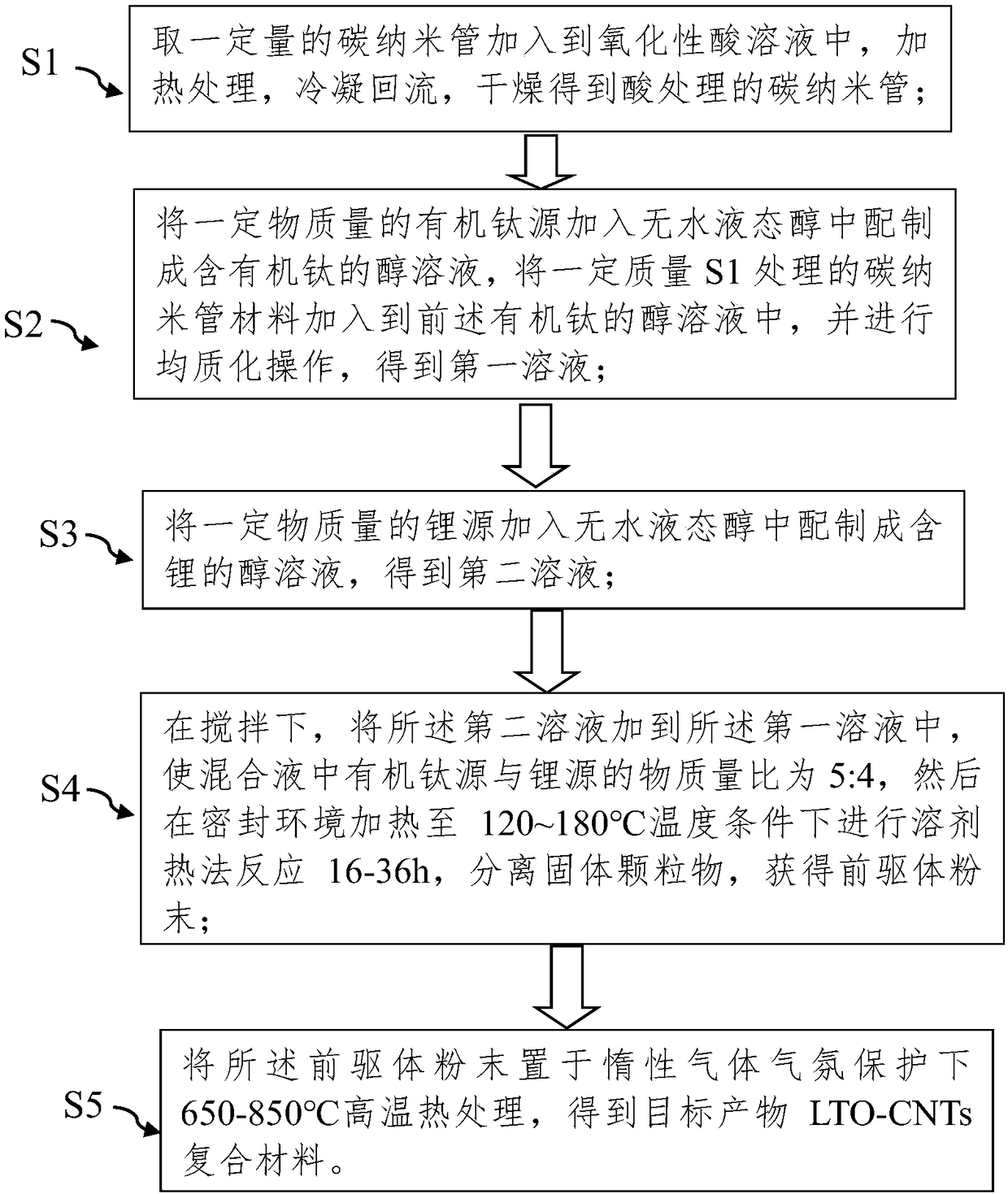

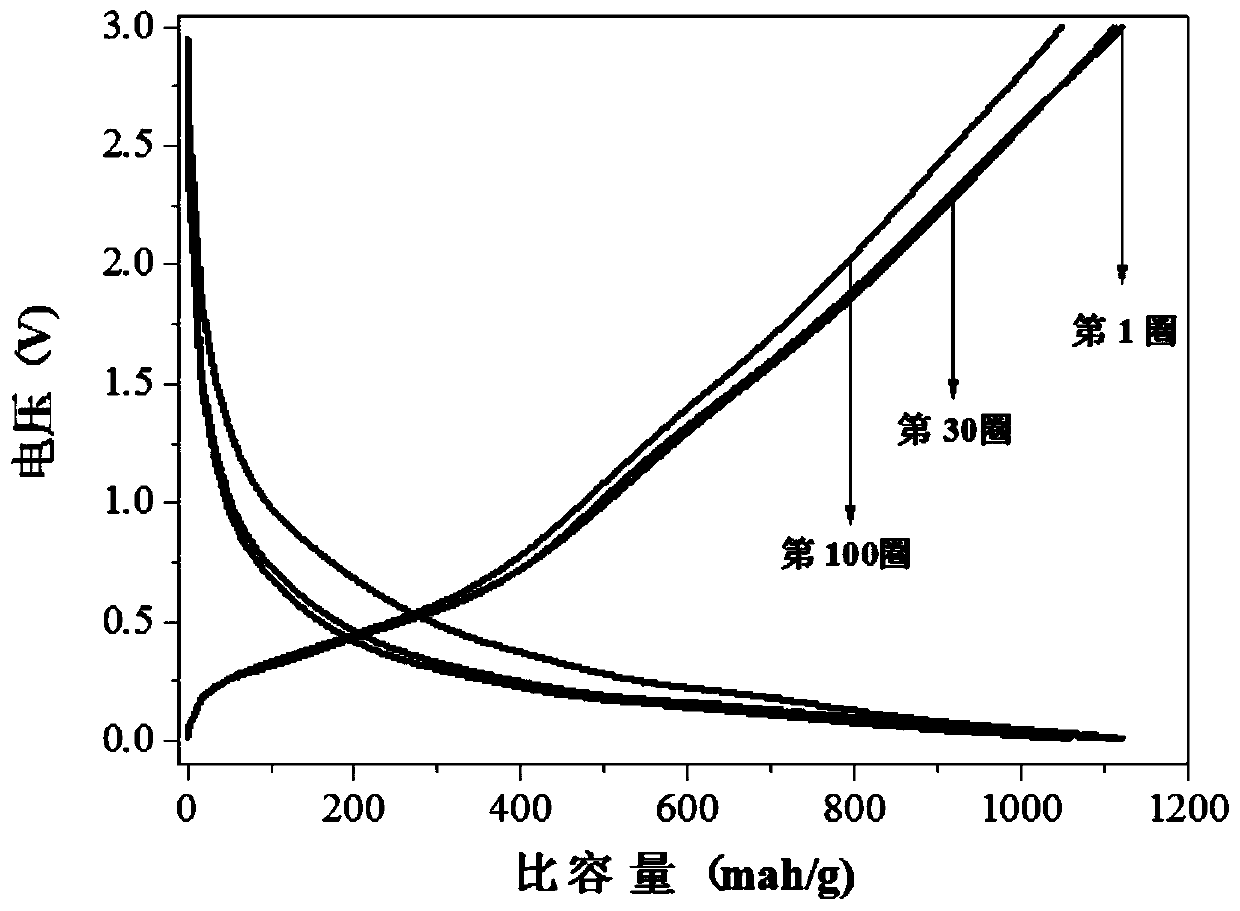

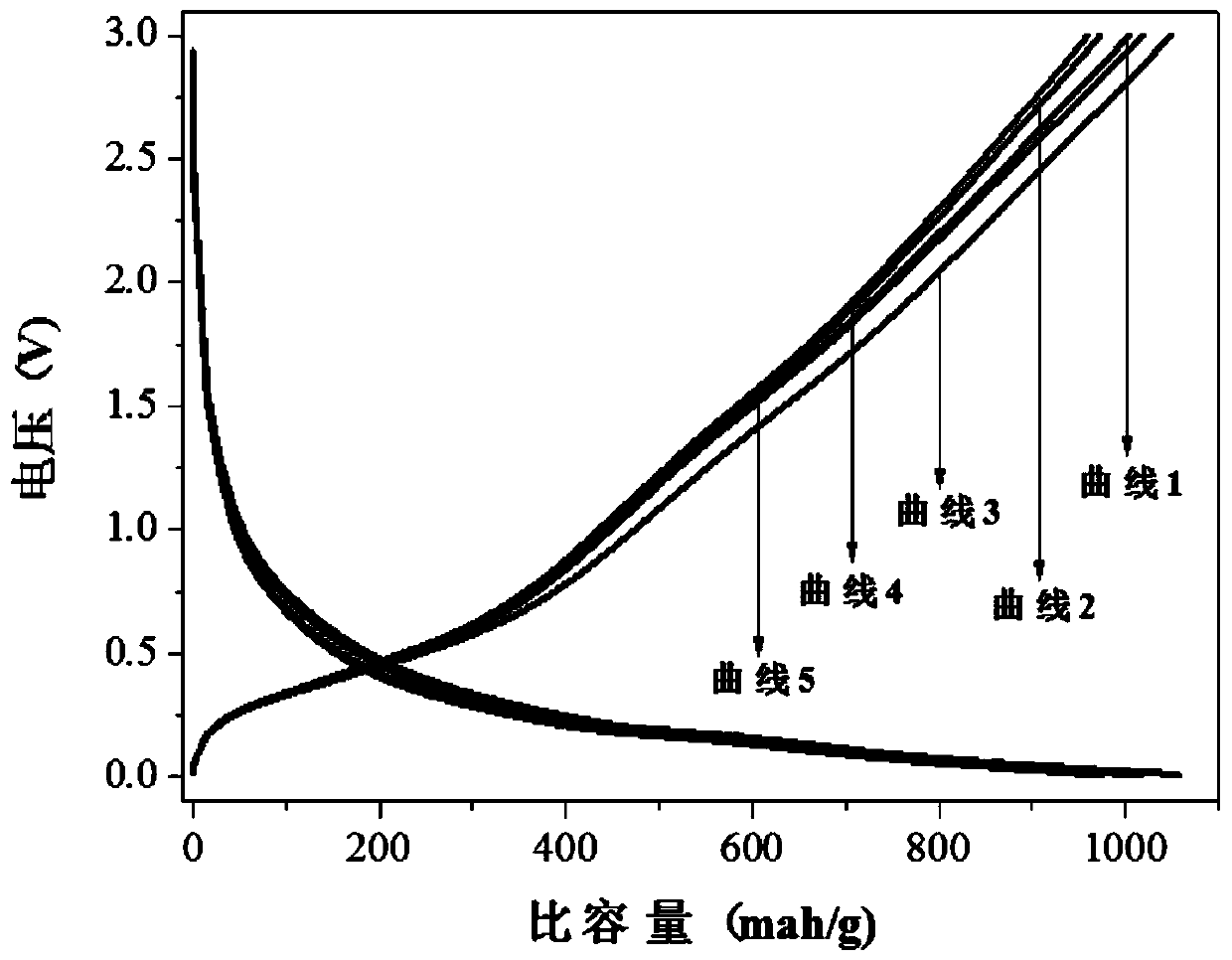

Lithium titanate-carbon nanotube composite material, preparation method thereof and lithium ion battery

InactiveCN108448085AEasy to bondWeak protonation abilityMaterial nanotechnologyCell electrodesCarbon nanotubeTitanium

The invention relates to a preparation method of a lithium titanate-carbon nanotube composite material. The preparation method comprises the steps of precursor preparation, in which a carbon nanotube,an organic titanium source and a lithium source are placed in a solvent system with hydroalcohol for reaction to obtain the precursor of the lithium titanate-carbon nanotube composite material; and calcination, in which the precursor is calcinated to obtain the lithium titanate-carbon nanotube composite material. In the composite material prepared by the method, lithium titanate is a in uniform particle shape, the lithium titanate-carbon nanotube composite material is better in combination uniformity, small in lithium titanate particle and is used as a lithium ion battery negative electrode material, the material conductivity can be obviously improved, and excellent large-rate conductivity and electrochemical cycle stability are shown. The invention also provides the lithium titanate-carbon nanotube composite material and a lithium battery fabricated by employing the material.

Owner:桑德新能源技术开发有限公司 +1

Titanium-series cathode active material and preparation method thereof, titanium-series lithium ion power battery

ActiveCN101373829BIncrease capacityHigh bulk densityElectrode manufacturing processesLi-accumulatorsHigh rateLithium titanate

The invention discloses a titanium cathode active substance, a preparation method thereof and a titanium lithium ion power battery, which solves the technical problem of enhancing the rate performance of a lithium ion power battery. The formula of the titanium cathode active substance is Li4Ti5O12 / Mx, wherein Li4Ti5O12 is spinel lithium titanate, M is a dopant such as a metal simple substance, a metal compound, a nonmetallic simple substance or a nonmetallic compound; the elements or the ions contained in the dopant enter the Li4Ti5O12 crystal lattice or are compounded with the Li4Ti5O12 crystal lattice; and the preparation method comprises the following steps: the precursor mixture of compound lithium titanate is prepared, and spray drying and heat treatment are performed. The cathode of the titanium lithium ion power battery adopts Li4Ti5O12 / Mx. Compared with the prior art, the titanium cathode active substance has the advantages of high capacity, high bulk density, high volume specific capacity, good high-rate performance, good product uniformity, good battery processability, low possibility of air bulking of the battery, and low cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Amorphous carbon negative electrode material as well as preparation method and application thereof

PendingCN112531160AHigher quality than capacityImprove electronic conductivityCell electrodesSecondary cellsCarbon particleElectrode material

The invention provides an amorphous carbon negative electrode material as well as a preparation method and application thereof. The amorphous carbon negative electrode material comprises a foam type carbon skeleton and carbon particles embedded in the foam type carbon skeleton, wherein the surface of the amorphous carbon negative electrode material comprises macropores and ultramicropores. The preparation method comprises the following steps: (1) subjecting carbon particles to reacting with an organic complex so as to obtain sol; (2) adding a curing and expanding agent into the sol, and conducting reacting to obtain a composite material; and (3) sintering the composite material to obtain the amorphous carbon negative electrode material. The material has a concave-convex structure similar to the surface of a lotus leaf, and the special structure can resist adsorption and provide a rapid diffusion channel for reaction ions, and shows excellent high-rate long-cycle performance in energy storage application.

Owner:BTR NEW MATERIAL GRP CO LTD

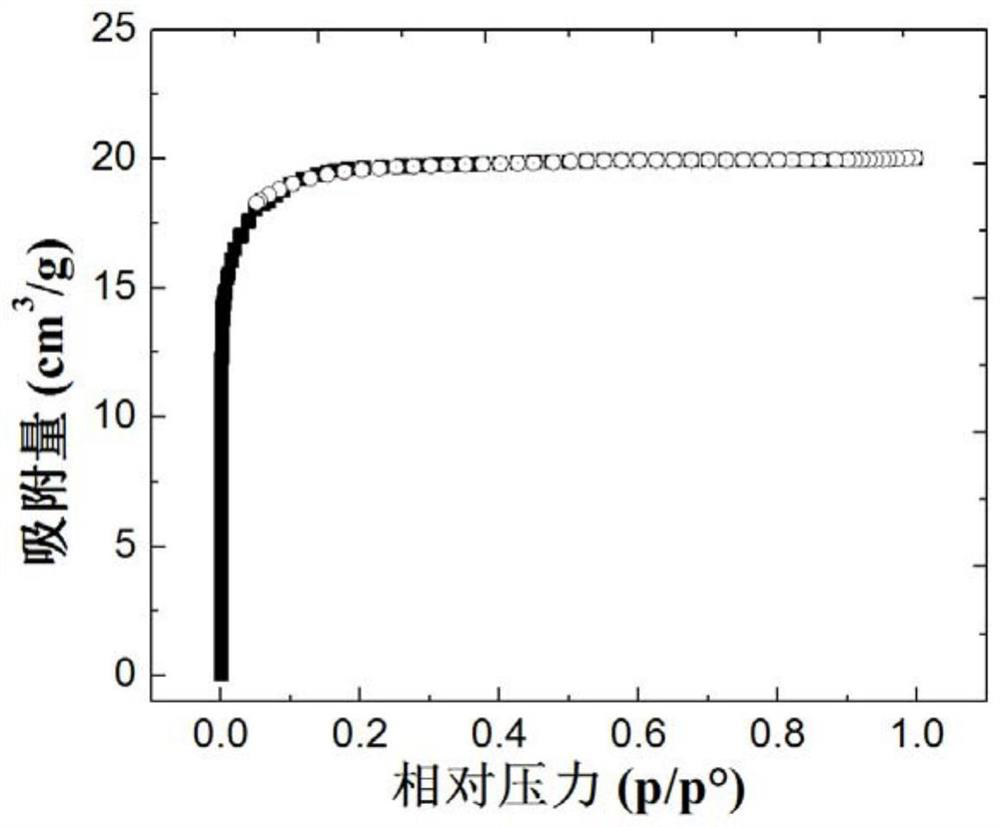

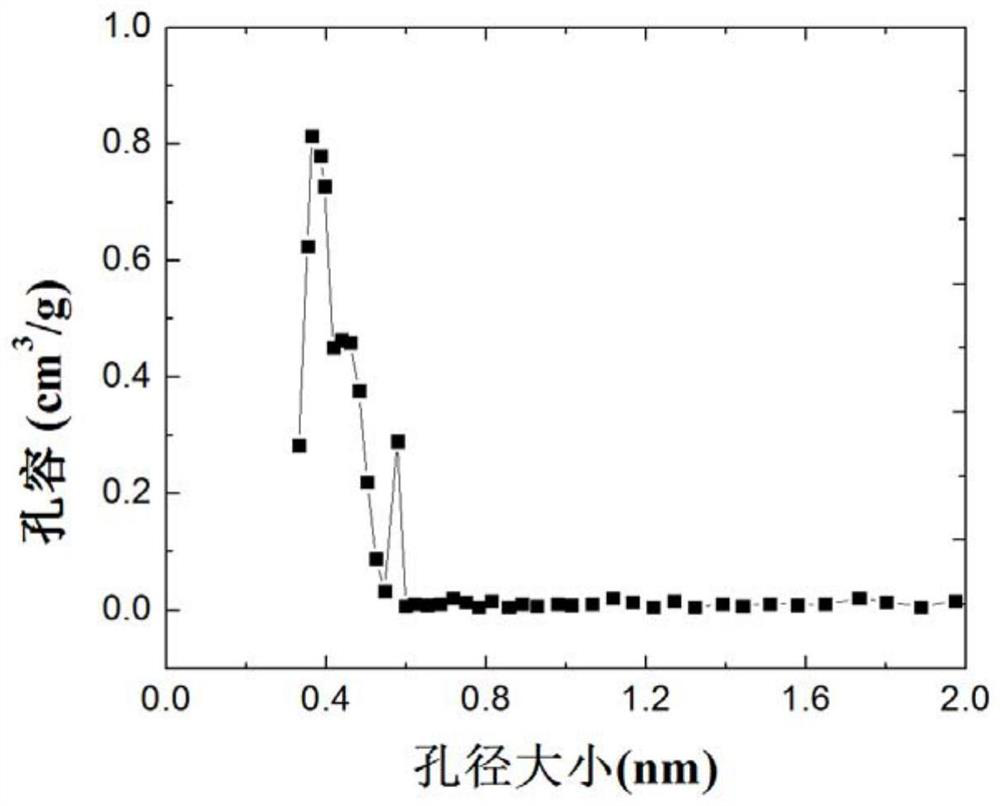

Method for preparing porous carbon through zeolite ore template

InactiveCN104649249AExcellent high magnification performanceGood scan curvePorous carbonPore diameter

The invention relates to the technical field of functional material application and preparation and particularly relates to a method for preparing a porous carbon through a zeolite template. The method for preparing the porous carbon through the zeolite template comprises the following steps: preparing a carbon / template compound from the zeolite; and preparing the porous carbon from the carbon / template compound. A mesopore and macropore template carbon with wide pore size distribution can be prepared by taking a natural zeolite as the template. The specific surface area of the template carbon is 411m<2> / g, and the mesopore rate is 66%. In the H2SO4 medium, the template carbon has excellent high-rate capability. When the scanning speed is 1mV / s, the specific capacity is 185F / g; when the scanning speed is increased to 500mV / s, the specific capacity is 133F / g, and the capacity retention ratio is 72%, and a good scanning curve can be kept.

Owner:徐玉磊

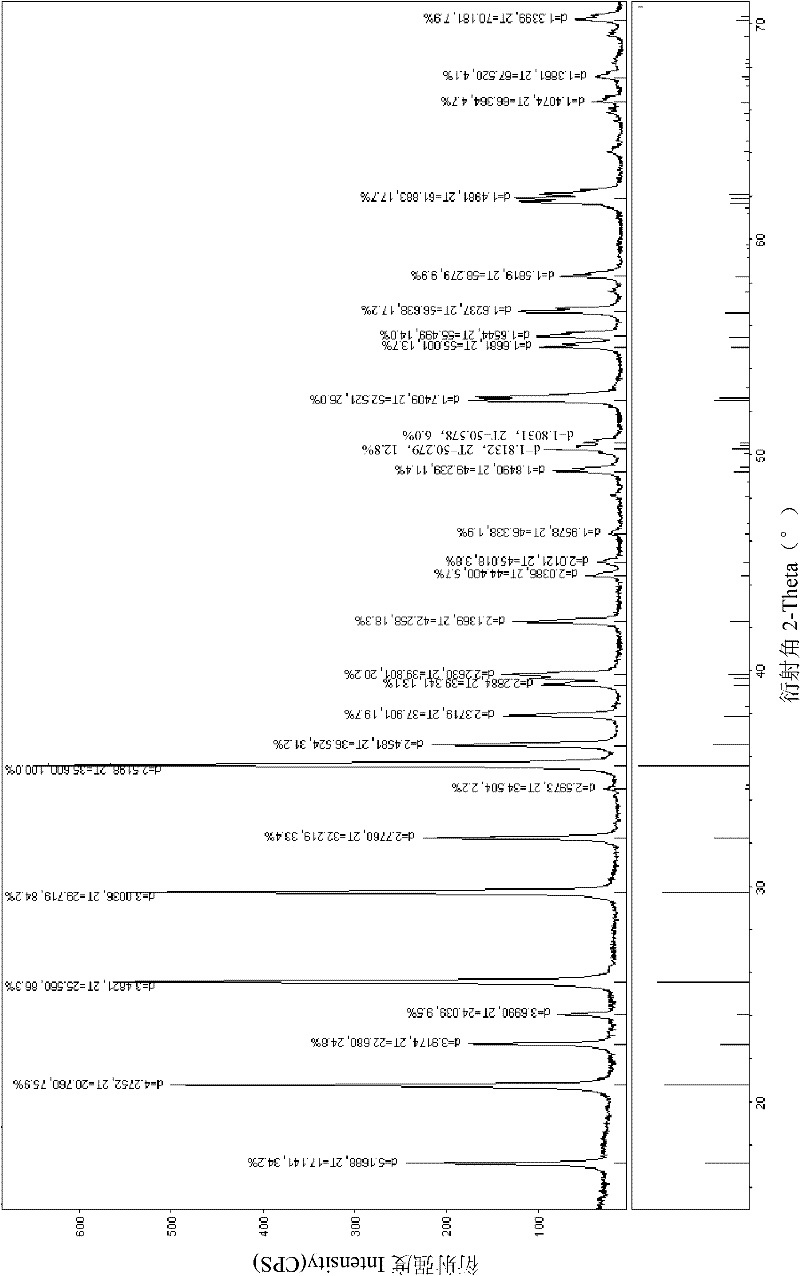

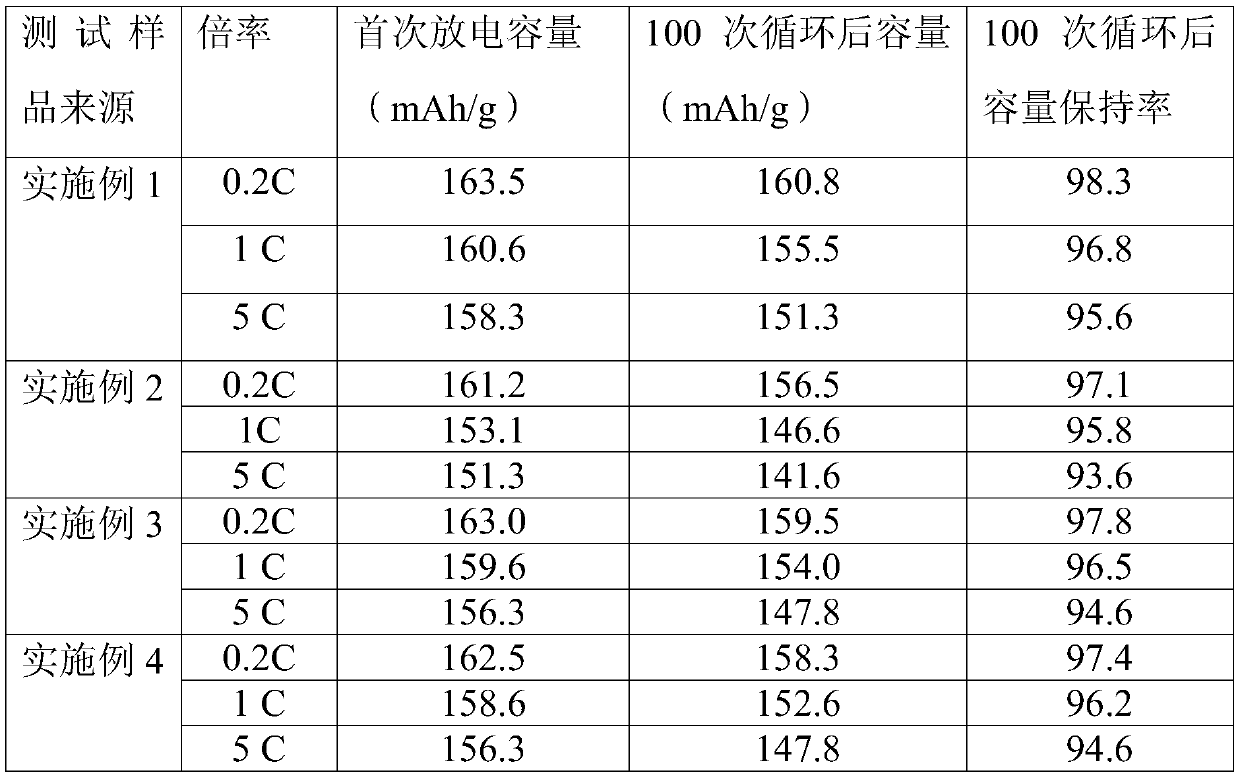

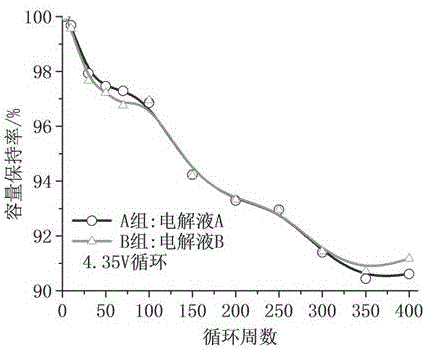

Preparation method for improving potential of lithium ion battery positive electrode material LiCoO2

InactiveCN106299330AIncrease compaction densityExcellent high magnification performanceCell electrodesSecondary cellsLithium electrodeTest material

The invention discloses a preparation method for improving the potential of a lithium ion battery positive electrode material LiCoO2. The method comprises the following steps: mixing cobaltosic oxide with a lithium salt, adding an additive T1, preprocessing above mixed materials, carrying out high-temperature primary sintering on the above obtained preprocessed uniformly-mixed materials, carrying out surface treatment on the obtained sintered material, carrying out secondary mixing after the treatment ends, preprocessing the secondary mixed material, carrying out low-temperature secondary sintering, and carrying out surface treatment to obtain a product. Lithium cobaltate produced through the preparation method for improving the potential of the lithium ion battery positive electrode material has original properties, and also realize 4.4 v charge and discharge; the material is processed to form a final battery undergoing test, the test current rate is 0.2 C, the discharge voltage range is 3.0-4.35 V, the specific capacity of the tested material is greater than 160 mAh / g, and the capacity retention ratio is 99.5% or above after cycling 1 C charge / 1 C discharge 10 times; and the preparation method has good economic and social benefits, and is suitable for being promoted and used.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

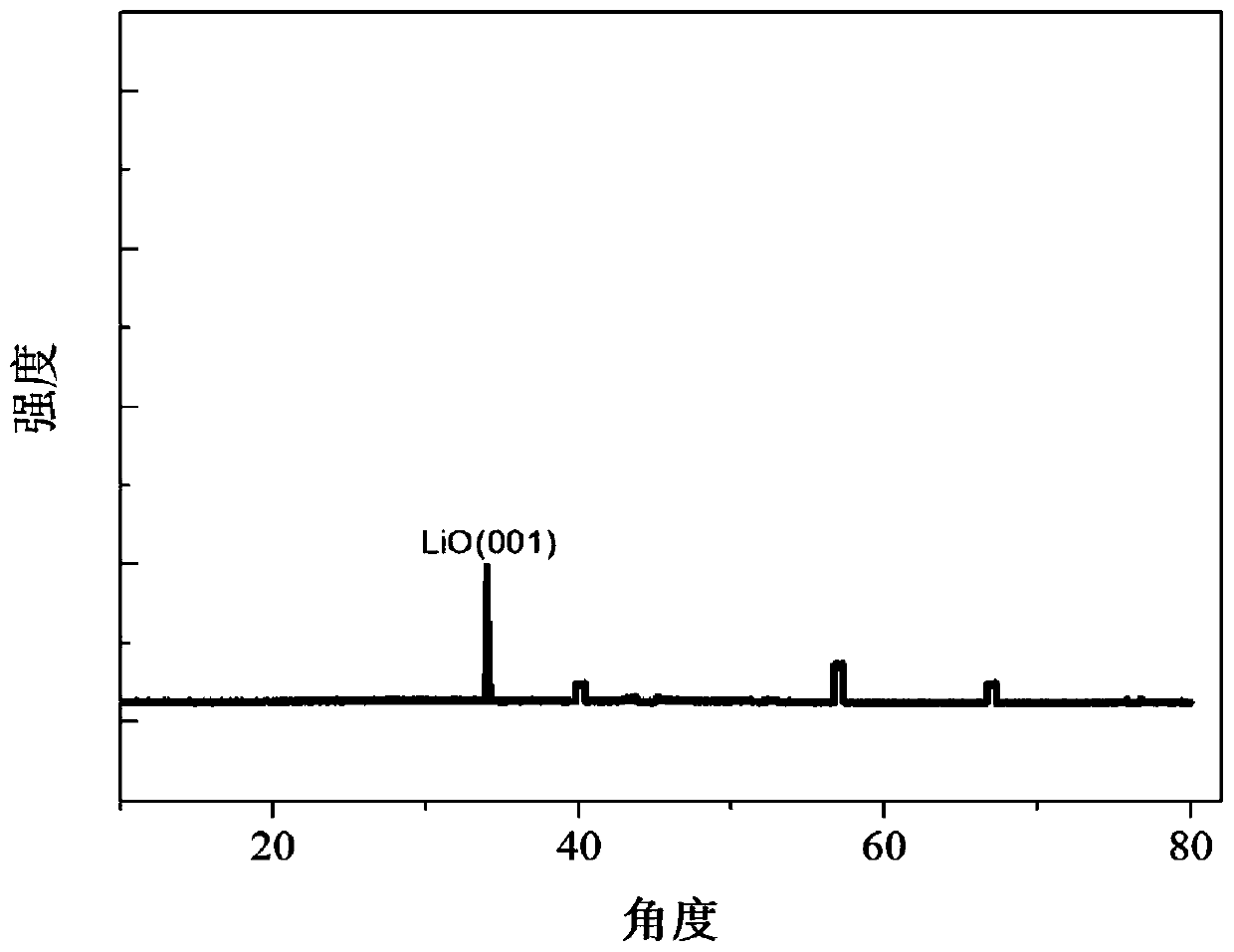

Composite lithium oxide film and preparation method and application thereof

ActiveCN110190240AReduce interface resistanceStable chemical propertiesHybrid capacitor electrodesVacuum evaporation coatingLithium oxideInterfacial resistance

The invention provides a composite lithium oxide film and a preparation method and an application thereof. The preparation method of the composite lithium oxide film comprises the step of performing co-sputtering treatment on a lithium oxide target material and an energy density contribution main element target material in an inert atmosphere so as to grow a composite lithium oxide film on a substrate. According to the preparation method of the composite lithium oxide film, the lithium oxide target material and the energy density contribution main element target material are directly depositedby adopting the co-sputtering method. The grown composite lithium oxide film is enabled to have the characteristic of low interfacial resistance. In addition, the generation of a solid electrolyte interface (SEI) film can be reduced, the stress of periodic volume change is relieved, and the structural stability of lithium ions in the embedding / disembedding process is maintained. Furthermore, thepreparation method effectively ensures that the grown composite lithium oxide film is stable in chemical performance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method of using zeolite template to prepare porous carbon

InactiveCN107804835AExcellent high magnification performanceGood scan curveHybrid capacitor electrodesCarbon preparation/purificationHigh rateCompound s

The invention relates to the technical field of application and preparation of functional materials, in particular to a method of using a zeolite template to prepare porous carbon, comprising the steps of preparing a carbon / template composite with zeolite; preparing porous carbon with the prepared carbon / template composite. A template is made with natural zeolite to prepare medium- and large-poretemplate carbon with wide particle size distribution. The template carbon has specific surface area of 41 lm<2> / g and medium-pore rate of 66%; in H2SO4 medium, the template carbon has good high-rate performance; in case of scanning speed of 1 mV / s, the template carbon has specific capacity of 185 F / g; when the scanning speed is increased to 500 mV / s, the specific capacity is still 133 F / g, the capacity retention ratio is 72%, and a good scanning curve is maintained.

Owner:SHAANXI SHENGMAI PETROLEUM

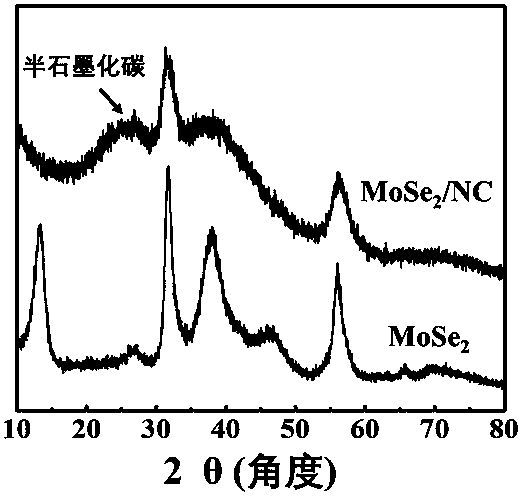

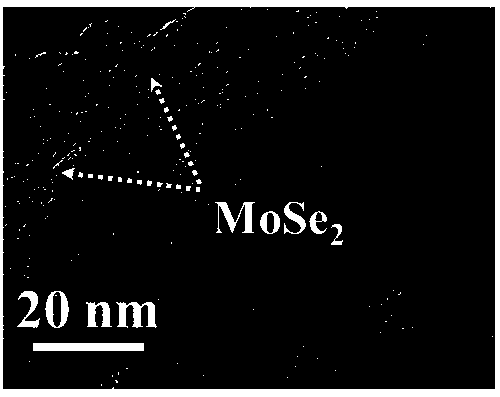

Double-ion battery based on molybdenum selenide-graphite and preparation method thereof

ActiveCN110635112AExtended working voltage rangeImprove cycle stabilityGraphiteCell electrodesPhosphomolybdic acidHigh rate

The invention discloses a double-ion battery based on molybdenum selenide-graphite and a preparation method of the double-ion battery. The gel containing phosphomolybdic acid is obtained through a simple sol-gel method. The preparation method comprises steps of calcining to synthesize the molybdenum selenide / nitrogen-doped carbon (MoSe2 / NC) compound, and designing the molybdenum selenide-graphite-based dual-ion battery by taking the MoSe2 / NC compound as a negative electrode material of the dual-ion battery and taking graphite as a positive electrode material. The method is advantaged in that the battery designed by the method is low in cost, the working voltage range of the assembled dual-ion battery is as high as 2-5V, and the assembled dual-ion battery is good in cycling stability, relatively high in reversible capacity and good in high-rate performance, the capacity is 86 mA h / g after 100 times of circulation under 2C multiplying power, and the 76 mA h / g reversible capacity can still be provided after circulation under 20 C super-large multiplying power.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com