B and N co-doped graphene coated silicon nano negative electrode material and preparation method thereof

A graphene-coated, negative-electrode material technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of not being able to adapt to large current charging and discharging, and not fundamentally inhibiting the volume expansion of silicon particles and other issues, to achieve the effects of stable structure, high rate performance, and good lithium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 B, N co-doped graphene-coated silicon nano-anode material

[0043] The negative electrode material is made of B and N co-doped graphene coated with silicon nanoparticles at a mass ratio of 1:1; the doping amounts of B and N in the B and N co-doped graphene are 7.37% respectively , 5.9%; the average particle size of the silicon nanoparticles is 30nm.

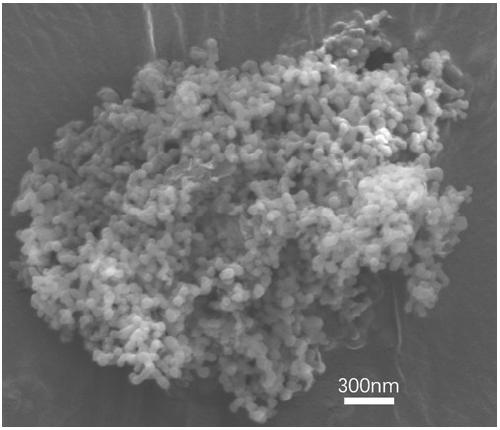

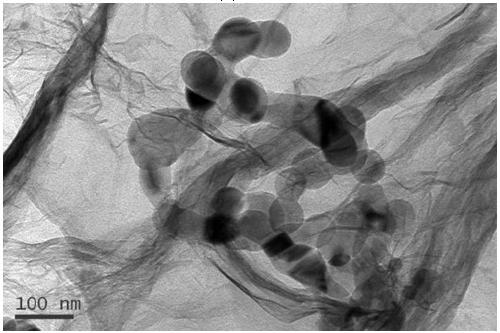

[0044] Such as figure 1 , 2 As shown, the average particle size of the silicon nanoparticles is 30nm, and graphene is coated on the surface of the silicon nanoparticles.

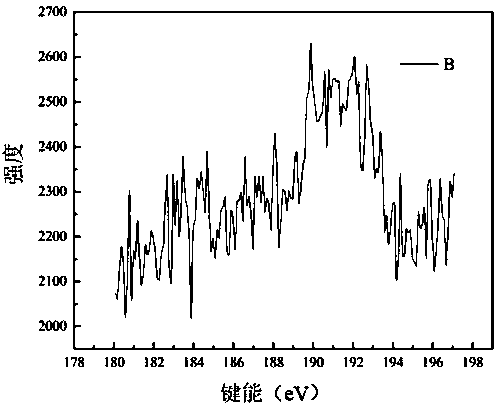

[0045] Such as image 3 , 4 As shown, XPS has clearly detected the energy spectrum peaks of B and N, indicating that boron and nitrogen atoms are successfully doped in the embodiment of the present invention B and N co-doped graphene-coated silicon nano-anode materials, and B, N are obtained by calculation. The doping amounts of N are 7.37% and 5.9%, respectively.

[0046] Embodiment 1 B, the preparation method of N co-doped graphene-coat...

Embodiment 2

[0053] Example 2 B, N co-doped graphene-coated silicon nano-anode material

[0054] The negative electrode material is made of B and N co-doped graphene coated with silicon nanoparticles at a mass ratio of 1.5:1; the doping amounts of B and N in the B and N co-doped graphene are 2.64% respectively , 7.6%; the average particle size of the silicon nanoparticles is 60nm.

[0055] After testing, the average particle size of the silicon nanoparticles is 60nm, and the graphene is coated on the surface of the silicon nanoparticles.

[0056] After testing, XPS has clearly detected the energy spectrum peaks of B and N, indicating that the boron and nitrogen atoms in the B and N co-doped graphene-coated silicon nano negative electrode materials of the embodiment of the present invention are successfully doped, and B, N are obtained by calculation. The doping amounts of N are 2.64% and 7.6%, respectively.

[0057] Example 2 B, the preparation method of N co-doped graphene-coated silico...

Embodiment 3

[0064] Example 3 B, N co-doped graphene-coated silicon nano-anode material

[0065] The negative electrode material is made of B and N co-doped graphene coated with silicon nanoparticles at a mass ratio of 0.6:1; the doping amounts of B and N in the B and N co-doped graphene are 9.3% respectively , 3.2%; the average particle size of the silicon nanoparticles is 20nm.

[0066] After testing, the average particle size of the silicon nanoparticles is 20nm, and the graphene is coated on the surface of the silicon nanoparticles.

[0067] After testing, XPS has clearly detected the energy spectrum peaks of B and N, indicating that the boron and nitrogen atoms in the B and N co-doped graphene-coated silicon nano negative electrode materials of the embodiment of the present invention are successfully doped, and B, N are obtained by calculation. The doping amounts of N are 9.3% and 3.2%, respectively.

[0068] Example 3 B, the preparation method of N co-doped graphene-coated silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com