Amorphous tetratin triphosphate/phosphorus/few-layer graphene negative material for lithium ion batteries and preparation method and application thereof

A few-layer graphene, lithium-ion battery technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of long preparation process, insufficient capacity and cycle stability of tin phosphide negative electrode, and achieve high efficiency The effect of peeling, low cost, and improved rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the amorphous tetratin phosphide / phosphorus / small-layer graphene negative electrode material in this embodiment is as follows:

[0043] The first step is ball milling: mixing tin powder and phosphor powder in a molar ratio of 1:3, ball-to-battery ratio of 50:1, ball milling in an argon atmosphere to obtain the ball-milled tin triphosphide. Among them, the ball milling method is planetary ball milling, the ball milling speed is 500 rpm, and the ball milling time is 10 hours.

[0044] The second step of ball milling: the product obtained from the first step of ball milling is mixed with expanded graphite for ball milling with a ball-to-material ratio of 50:1 to obtain an amorphous tetratin phosphide / phosphorus / small-layer graphene negative electrode material. Among them, the mass percentage of expanded graphite in the negative electrode material is 20%, and the ball milling time is 2h.

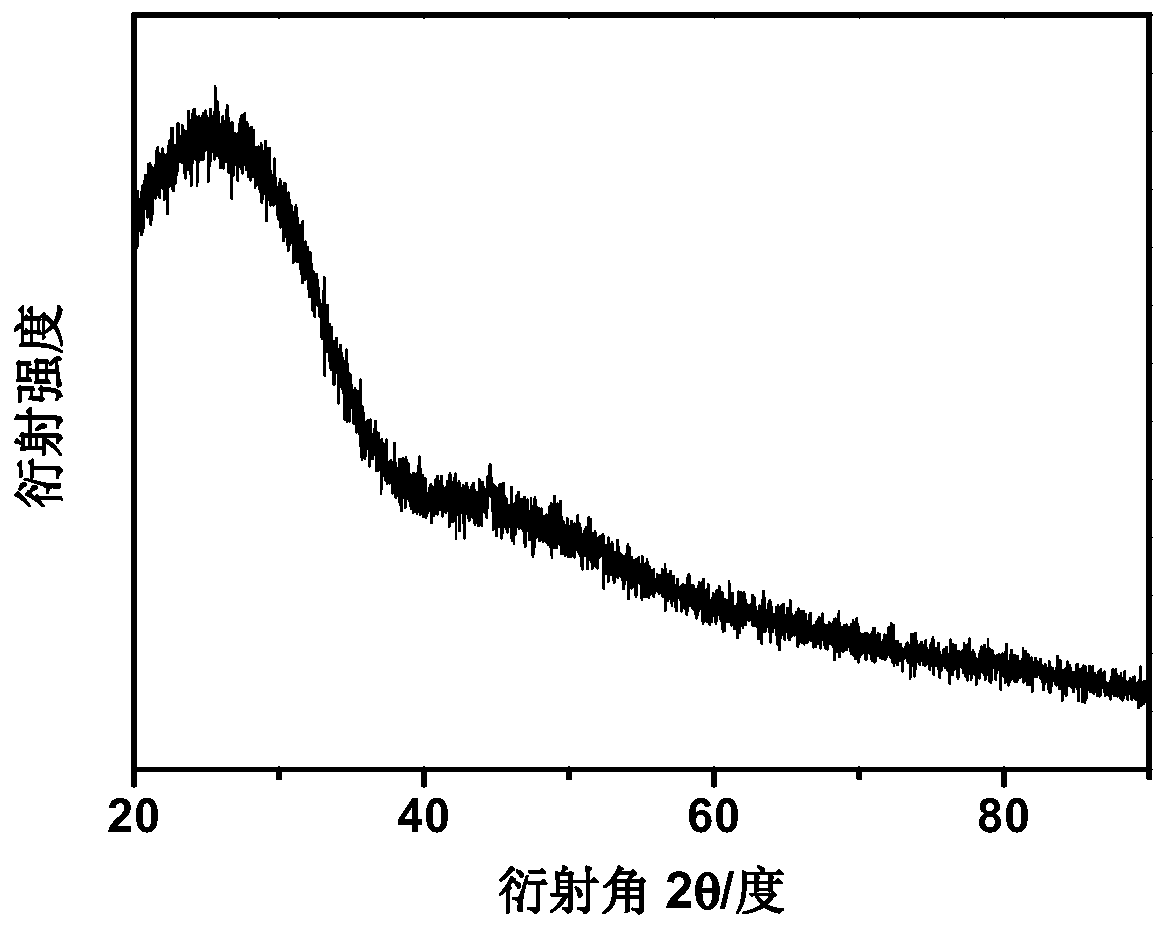

[0045] The XRD pattern of the amorphous tetratin phosphide / phosph...

Embodiment 2

[0050] In the preparation method of the amorphous tetratin phosphide / phosphorus / small-layer graphene negative electrode material in this embodiment, the other parameters are the same as those in the first embodiment except that the mass percentage of expanded graphite in the negative electrode material is 10%.

[0051] When the negative electrode material prepared in this example is used in the performance test of a lithium ion half-cell, at a current density of 1A / g, the first reversible specific capacity is 1310.2mAh / g, and the first coulombic efficiency is 88.7%. After 100 cycles, it is reversible. The specific capacity can be maintained at 1091.1mAh / g.

Embodiment 3

[0053] In the preparation method of the amorphous tetratin phosphide / phosphorus / small-layer graphene negative electrode material in this embodiment, the other parameters are the same as those in the first embodiment except that the mass percentage of expanded graphite in the negative electrode material is 30%.

[0054] When the negative electrode material prepared in this example is used in the performance test of a lithium-ion half-cell, at a current density of 1A / g, the first reversible specific capacity is 1162.1mAh / g, and the first coulombic efficiency is 88.7%. After 400 cycles, it is reversible. The specific capacity can be maintained at 1101.1mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com