Patents

Literature

513results about How to "Alleviate volume changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

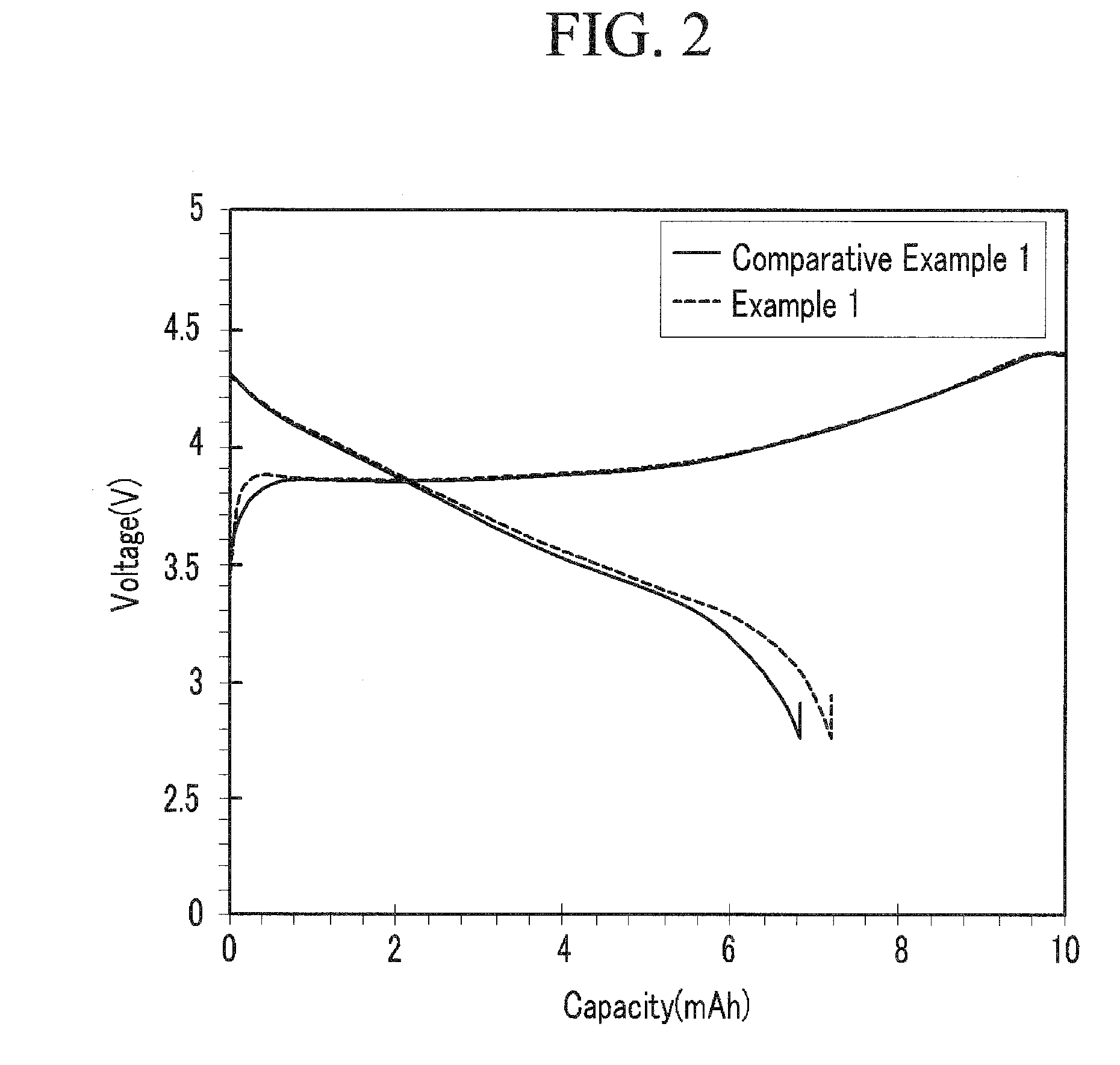

Non-aqueous electrolyte secondary battery, negative electrode material, and making method

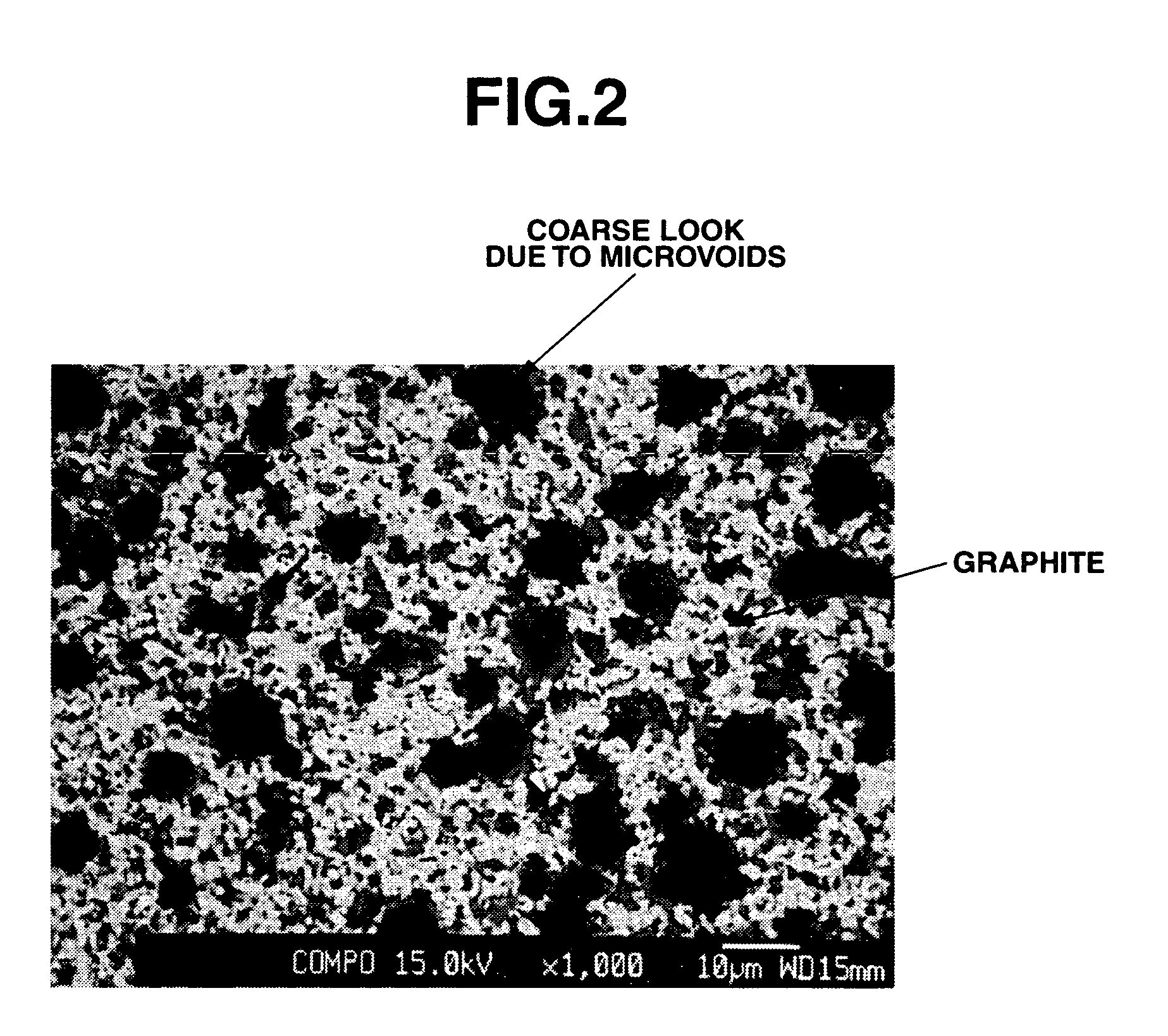

ActiveUS20090239151A1Improve cycle performanceImprove efficiencyNon-aqueous electrolyte accumulatorsActive material electrodesSilicon oxideSilicon particle

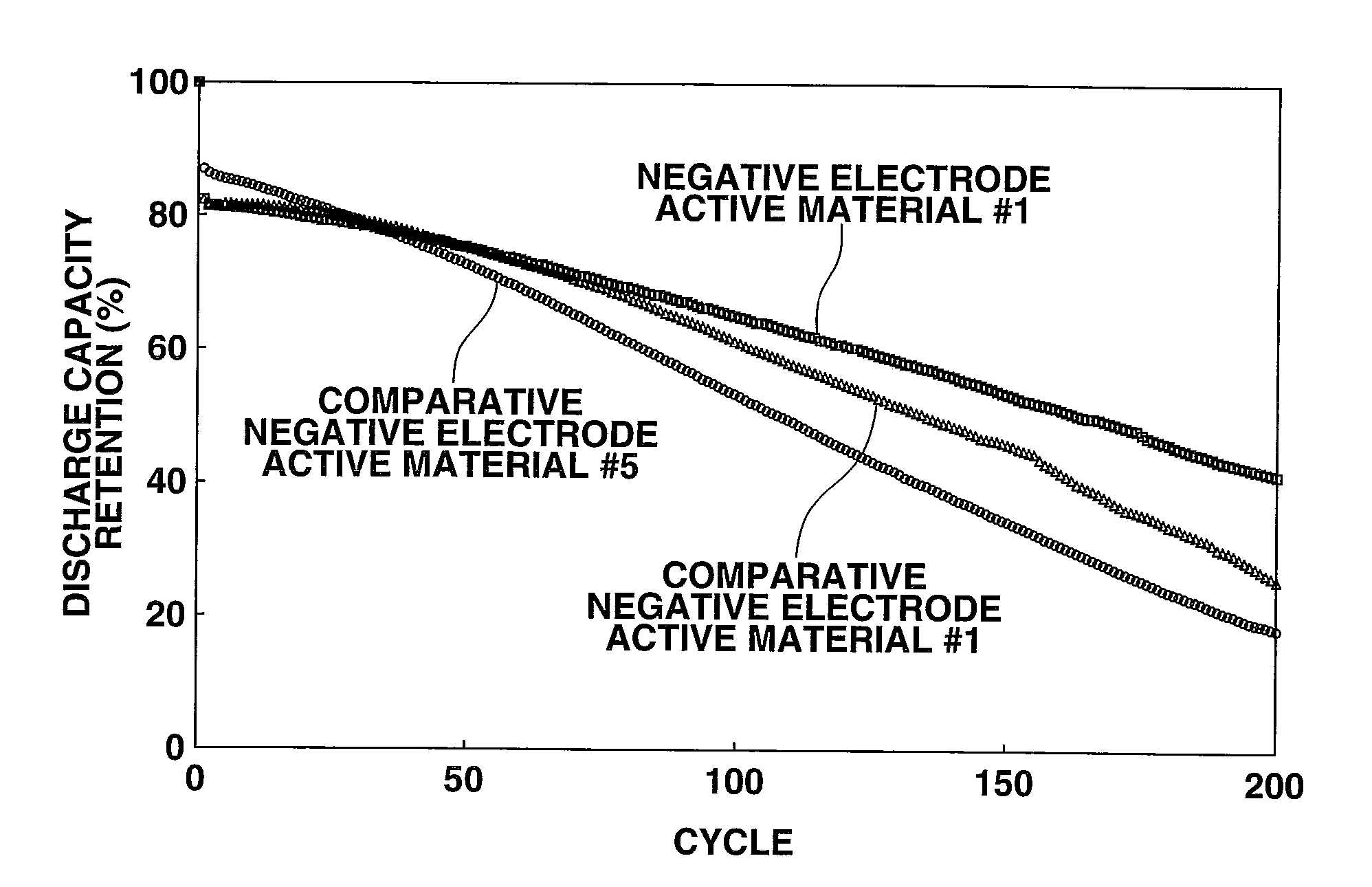

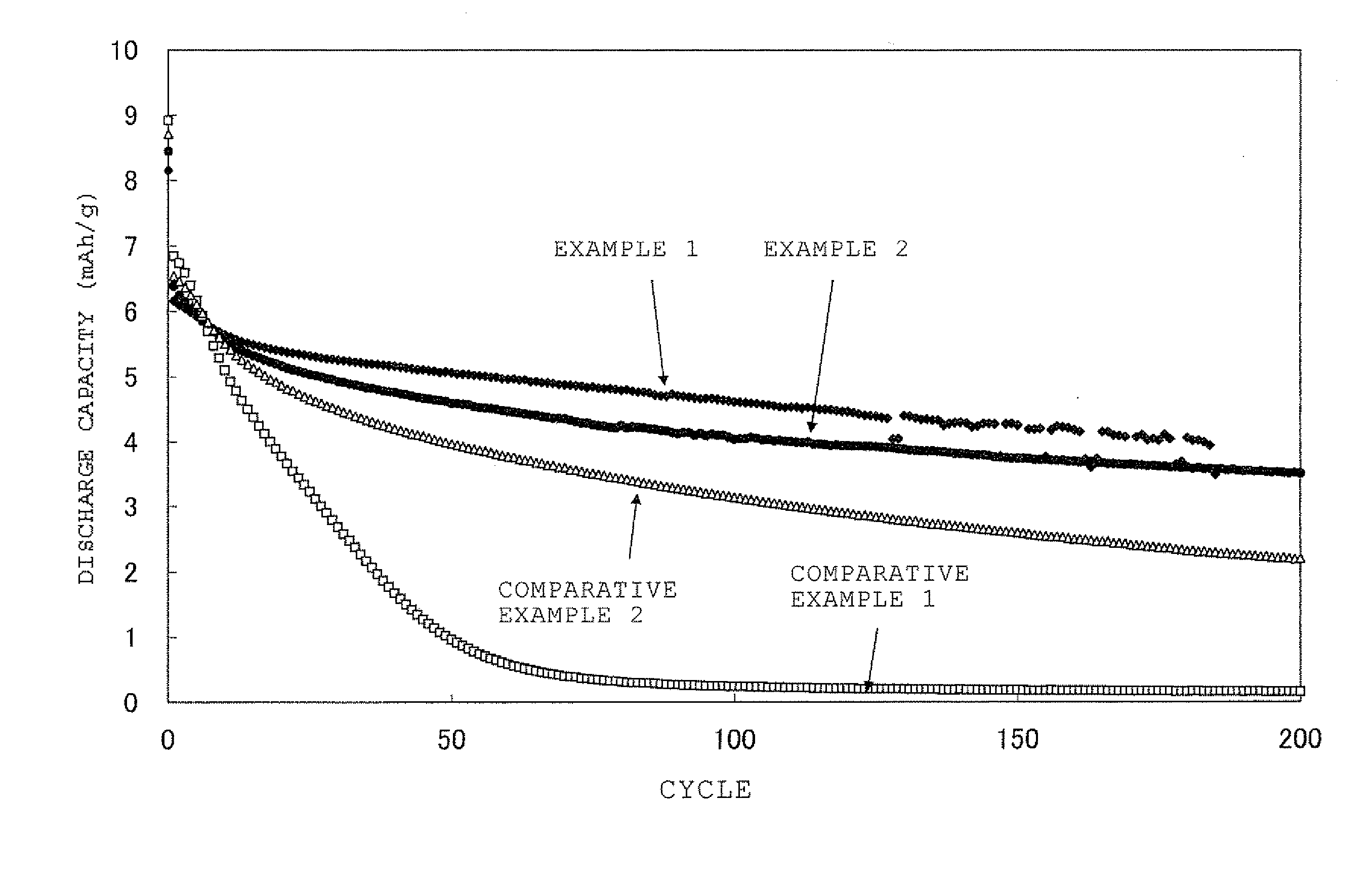

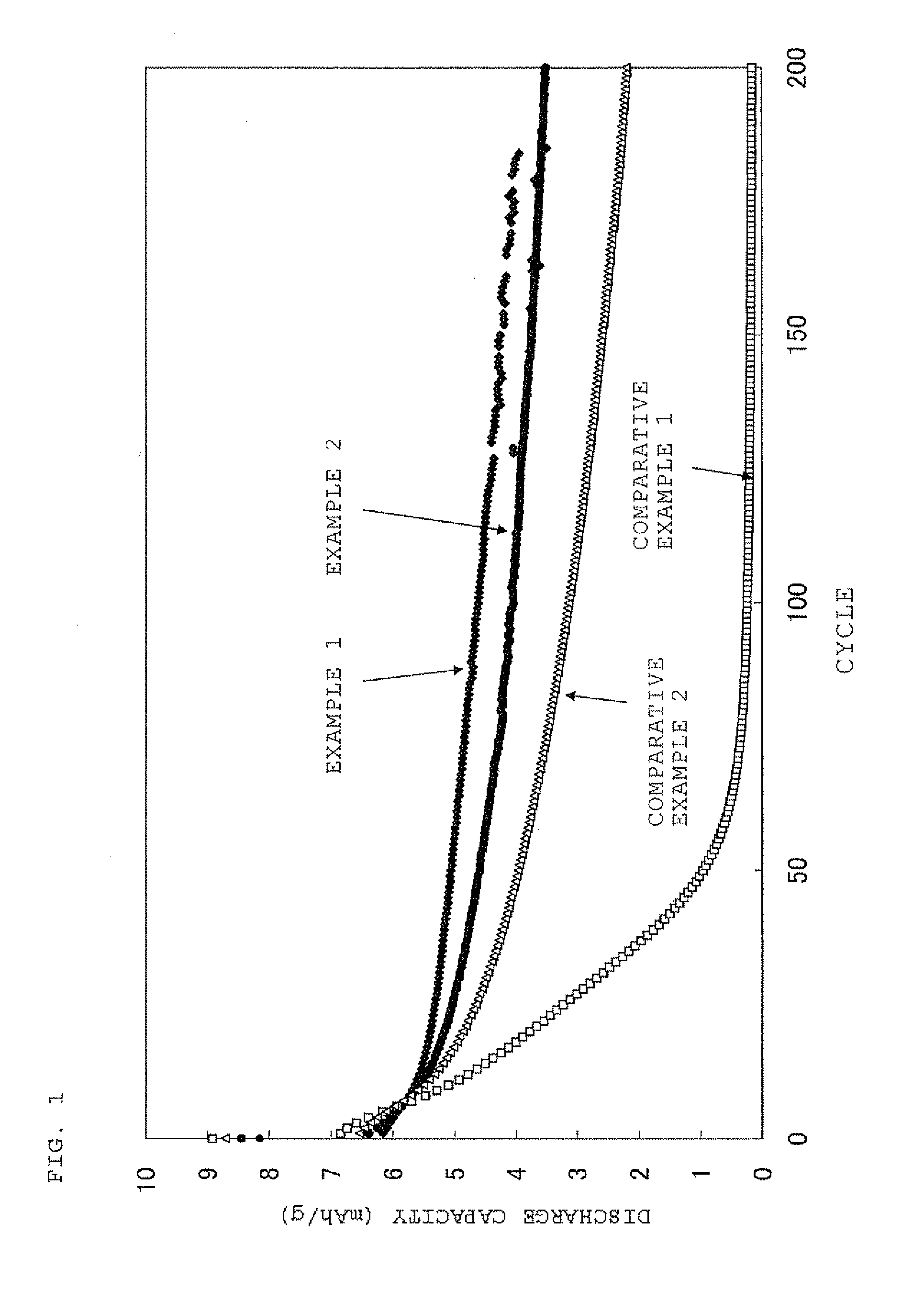

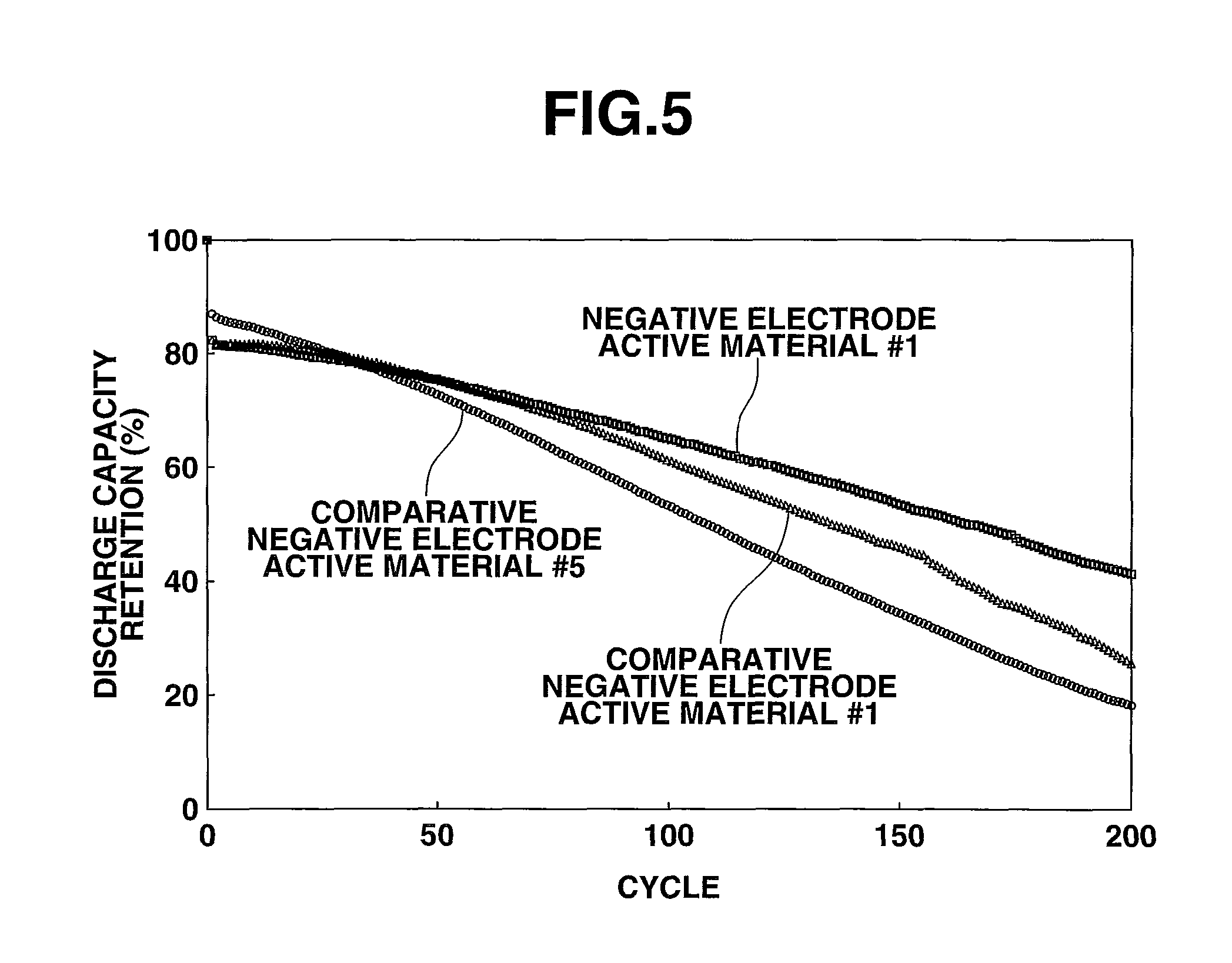

A negative electrode material comprising an active material and 1-20 wt % of a polyimide resin binder is suitable for use in non-aqueous electrolyte secondary batteries. The active material comprises silicon oxide particles and 1-50 wt % of silicon particles. The negative electrode exhibits improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide. The non-aqueous electrolyte secondary battery has a high initial efficiency and maintains improved performance and efficiency over repeated charge / discharge cycles by virtue of mitigated volumetric changes during charge / discharge cycles.

Owner:SHIN ETSU CHEM IND CO LTD

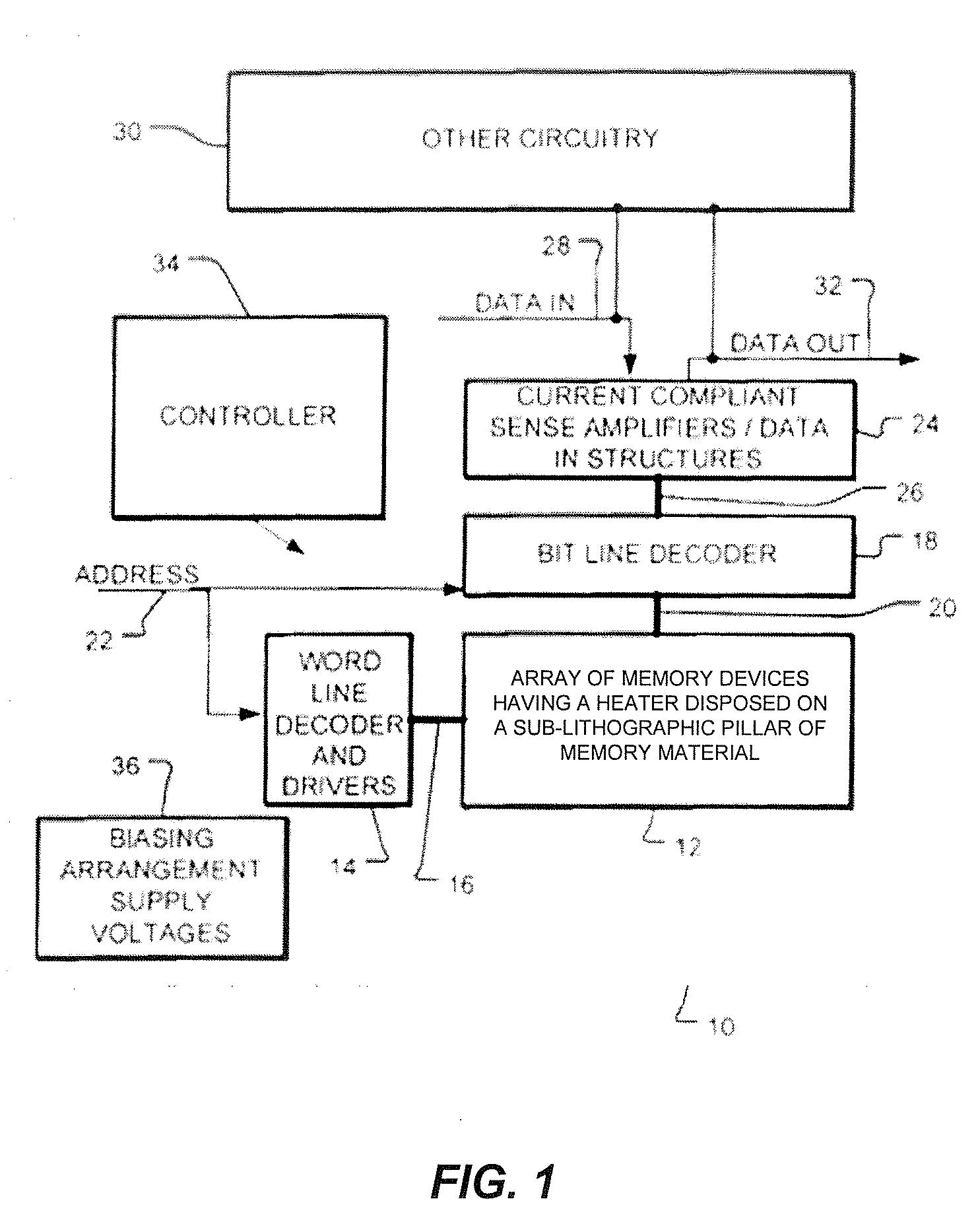

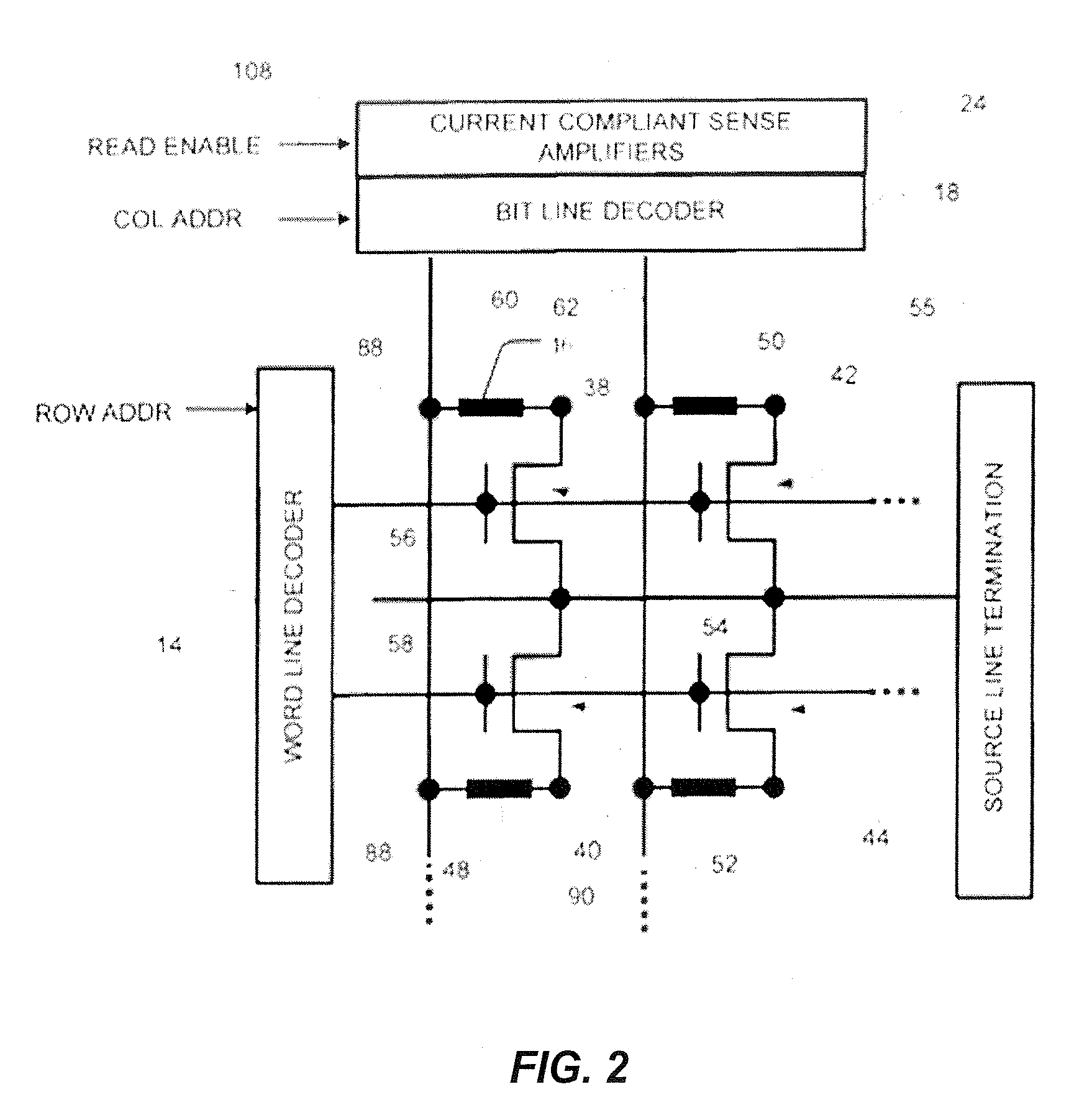

Phase Change Memory Cell with Heater and Method for Fabricating the Same

ActiveUS20080197334A1Total current dropAlleviate volume changesSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryElectrical and Electronics engineering

A memory device with a thin heater forms a programmable resistive change region in a sub-lithographic pillar of programmable resistive change material (“memory material”), where the heater is formed within the pillar between the top electrode and the programmable material. The device includes a dielectric material layer and vertically separated top and bottom electrodes having mutually opposed contact surfaces. A sub-lithographic pillar of memory material, which in a particular embodiment is a chalcogenide, is encased within the dielectric material layer. A heater between the pillar of programmable resistive material and the top electrode forms an active region, or programmable resistive change region, next to the heater when the memory device is programmed or reset.

Owner:MACRONIX INT CO LTD

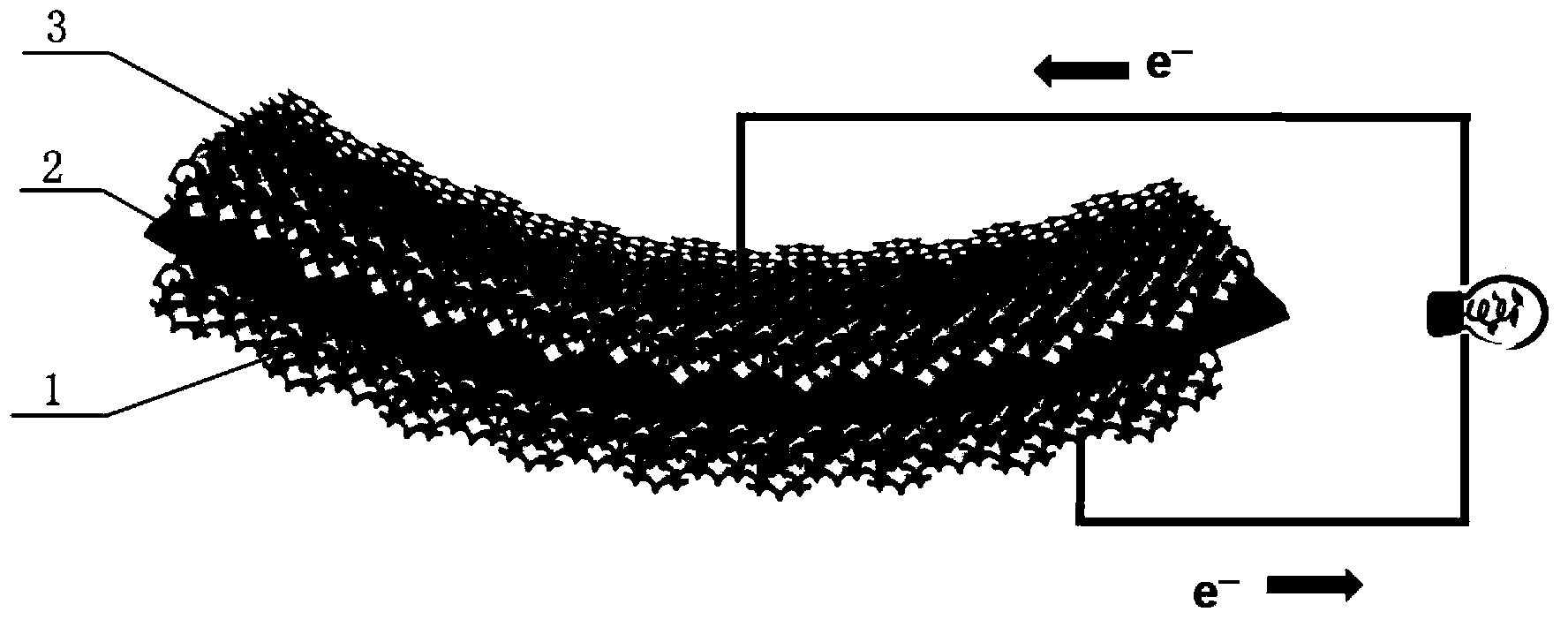

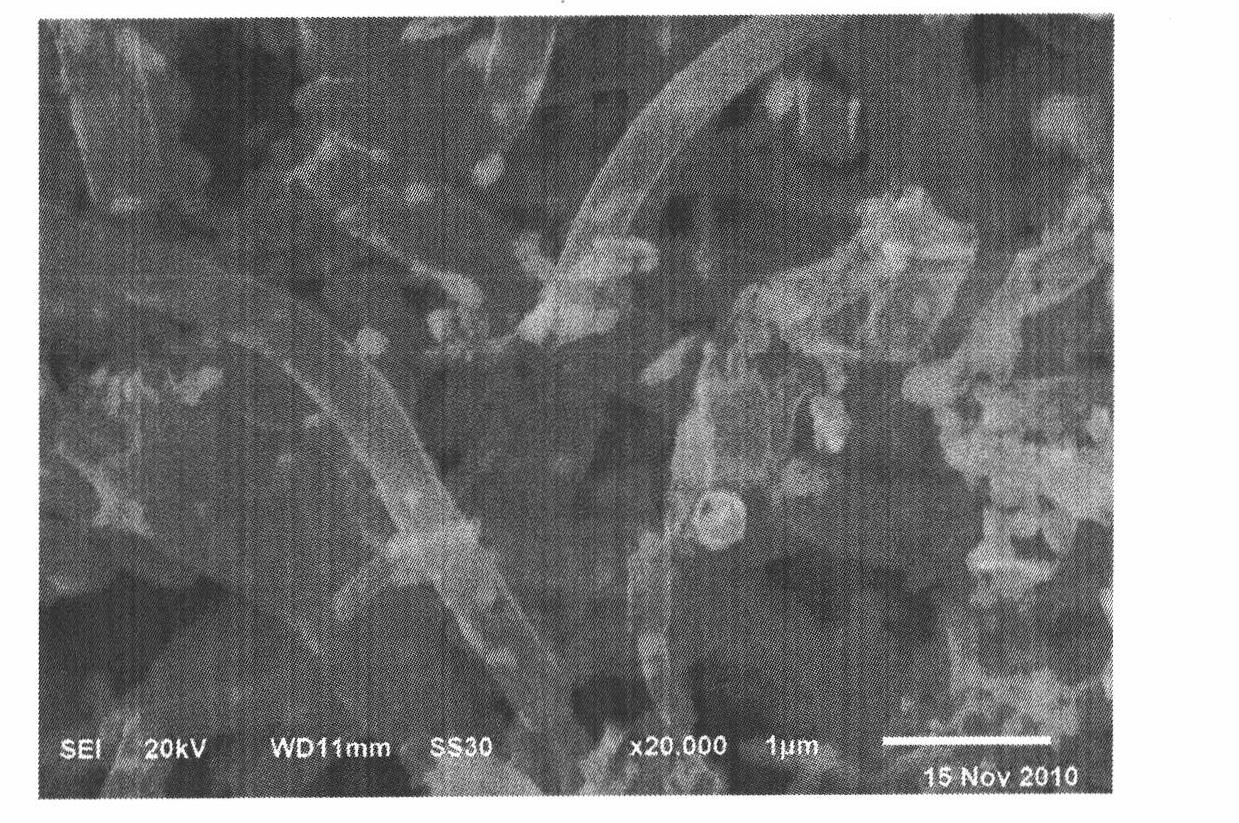

Rapidly charged flexible lithium ion battery and preparation method of electrodes of rapidly charged flexible lithium ion battery

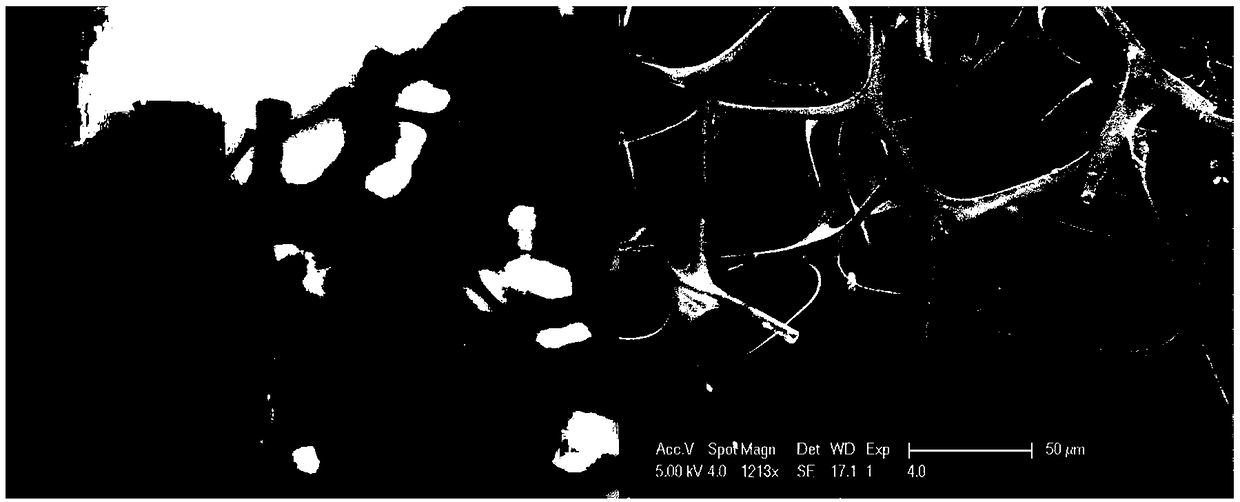

InactiveCN103682368AReduce electrode massImproved magnification performanceElectrode carriers/collectorsSecondary cellsElectrical batteryGraphene foam

The invention discloses a rapidly charged flexible lithium ion battery and a preparation method of electrodes of the rapidly charged flexible lithium ion battery, belonging to the technical field of lithium ion batteries. The electrodes of the lithium ion battery are integrally designed by a current collector and active substances. An ultralight and flexible three-dimensional graphene communicating network structure (short for graphene foams) is used as a current collector, the active substances are embedded on the surface of the three-dimensional graphene foams, the integrated active substances and the current collector can be obtained through hydrothermal, pulp filling and impregnation processes, and the content of the active substances can be regulated as required. The electrodes of the battery are not required for a metal current collector, a binder and a conductive agent, the ultrahigh conductivity and porous structure of the three-dimensional graphene network provide rapid diffusion channels for lithium ions and electrons. The lithium ion battery consisting of a positive electrode and a negative electrode can be rapidly charged, is bendable and has no capacity loss. The method disclosed by the invention is low in product production cost, ultralight and ultrathin, and capable of realizing large-batch production, and has high practical application values.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

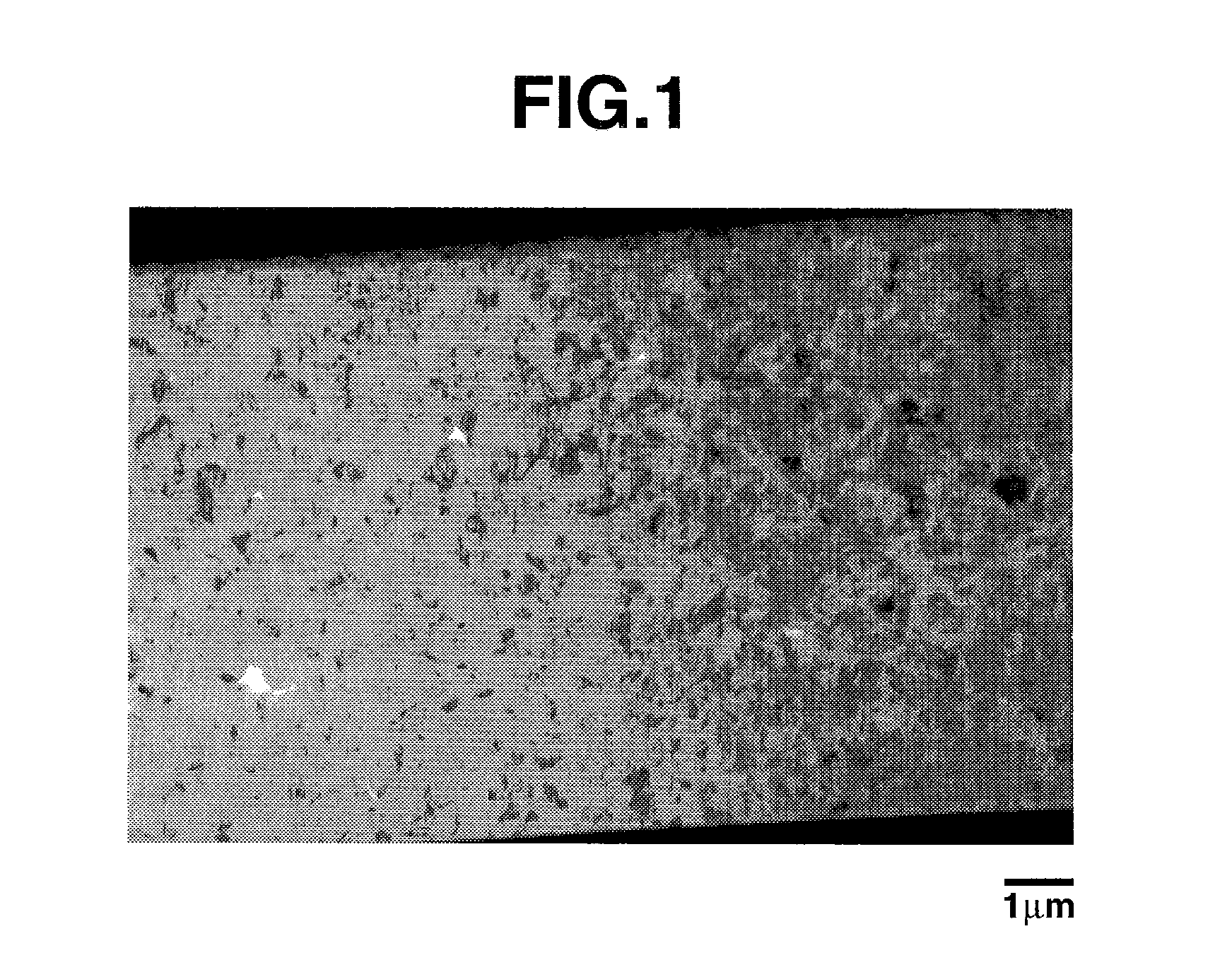

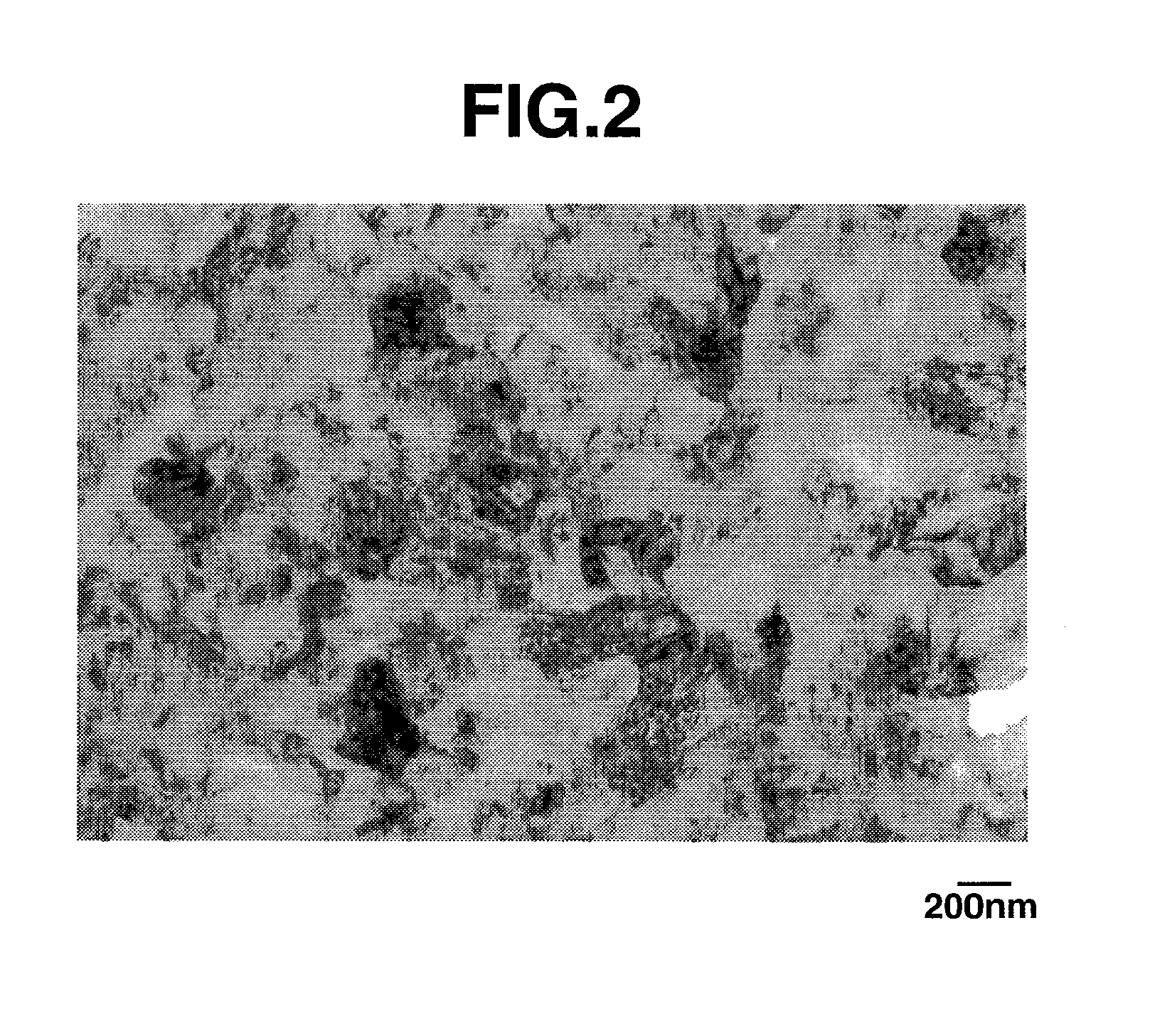

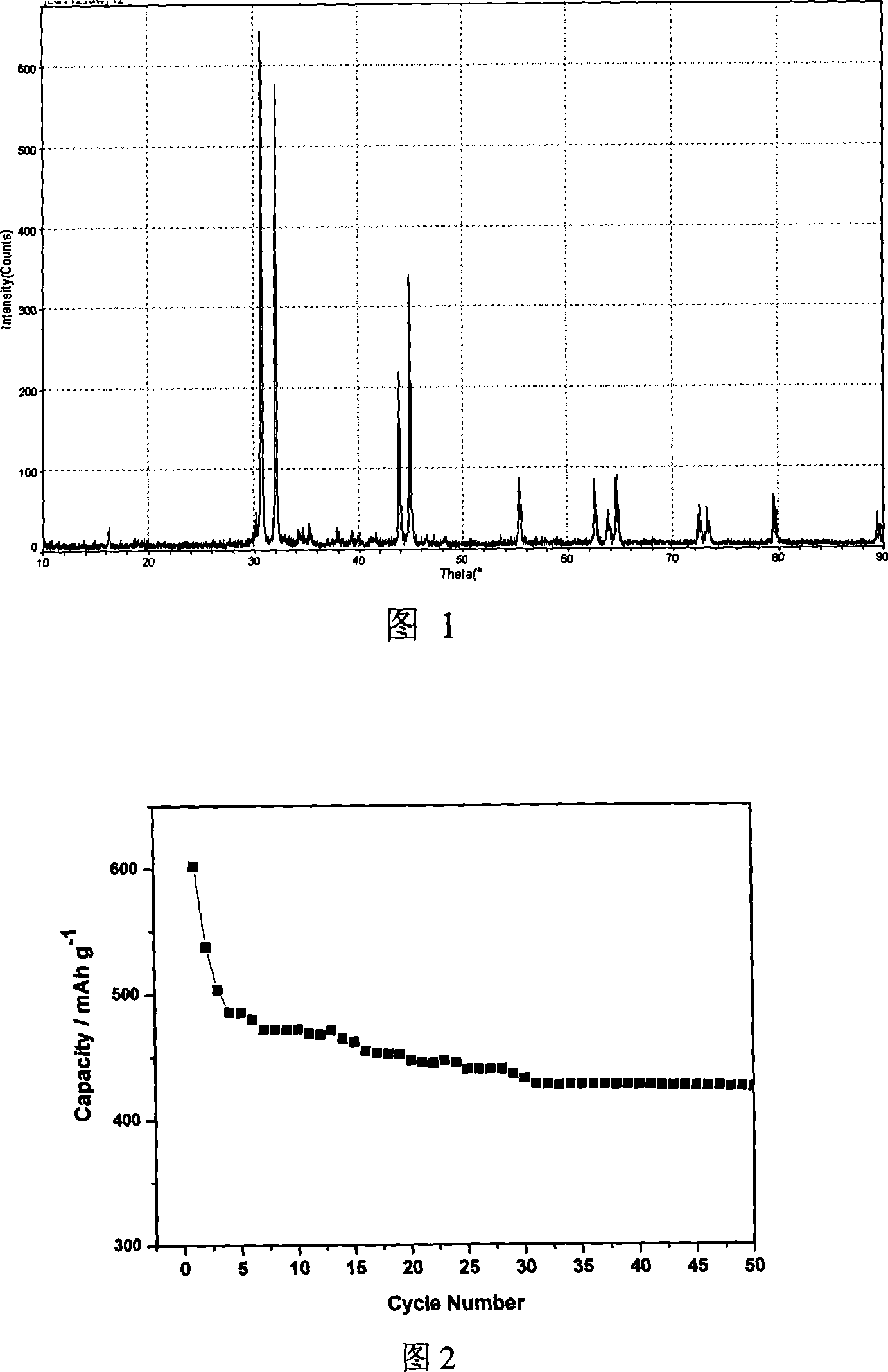

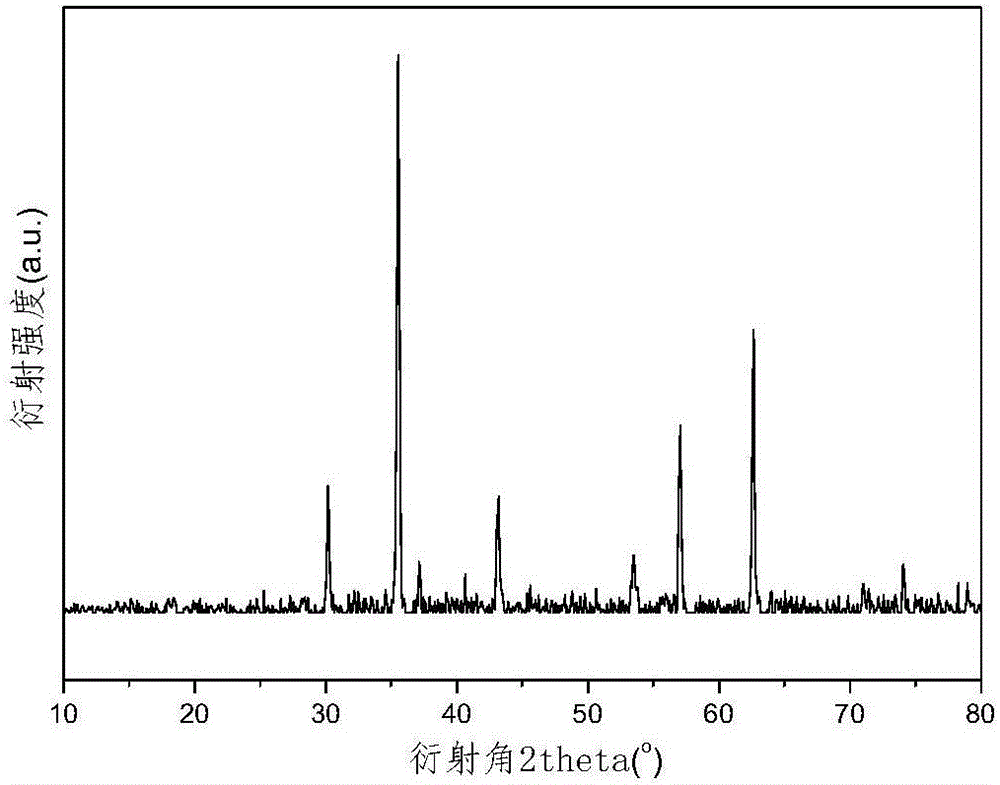

Negative electrode material for rechargeable battery with nonaqueous electrolyte, negative electrode for rechargeable battery with nonaqueous electrolyte, rechargeable battery with nonaqueous electrolyte, and process for producing polycrystalline silicon particles for active material for negative electrode material for rechargeable battery with nonaqueous electrolyte

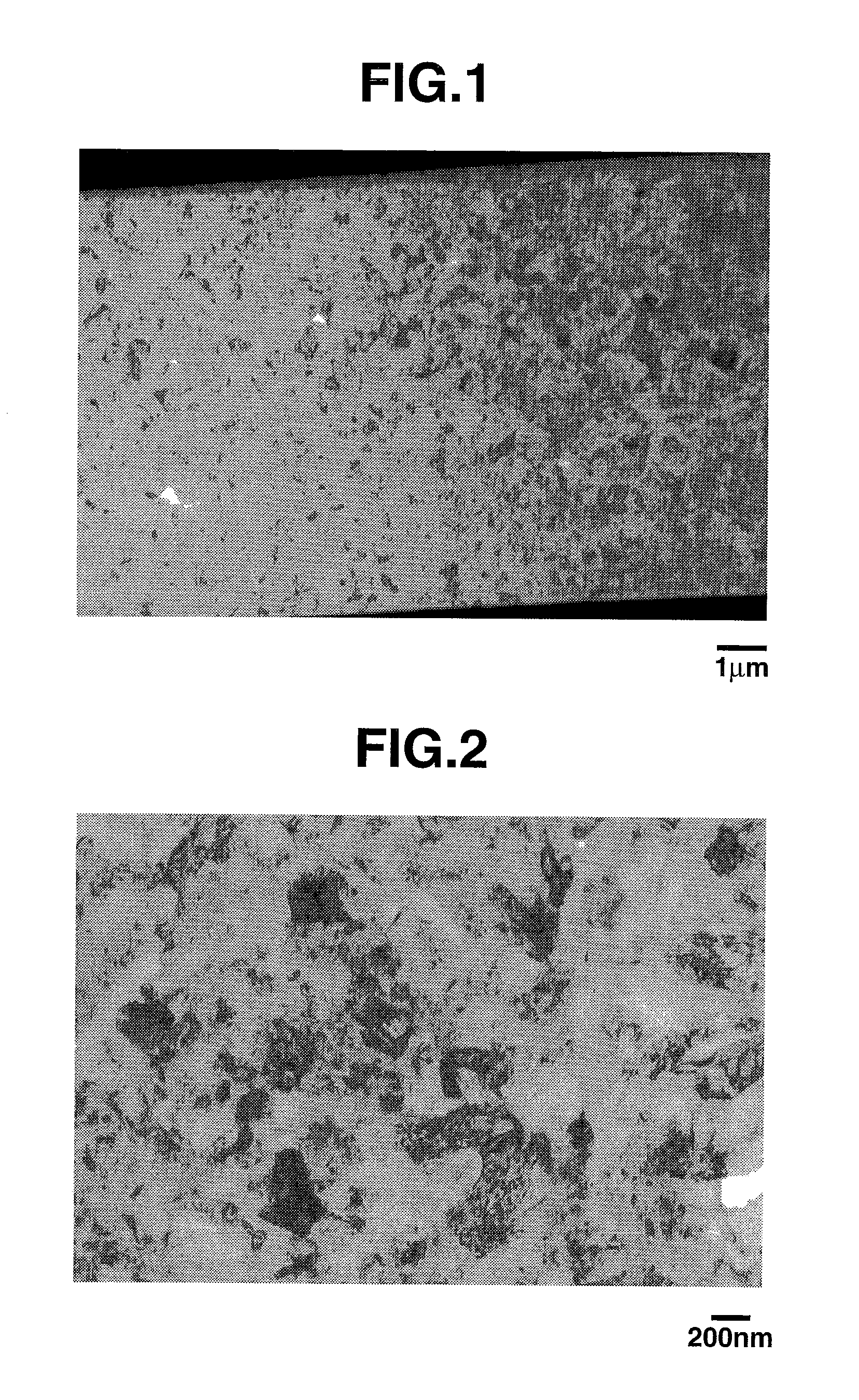

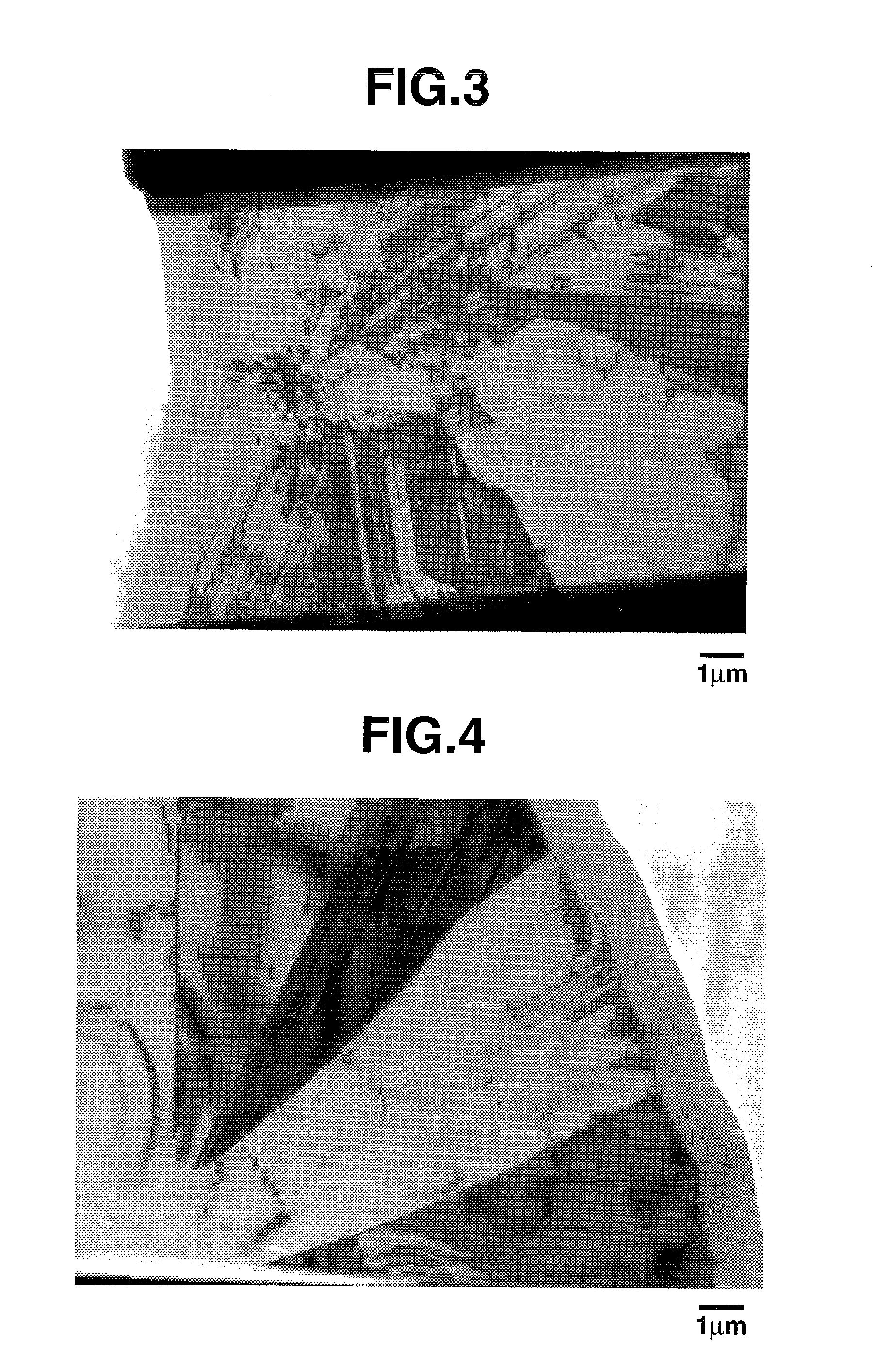

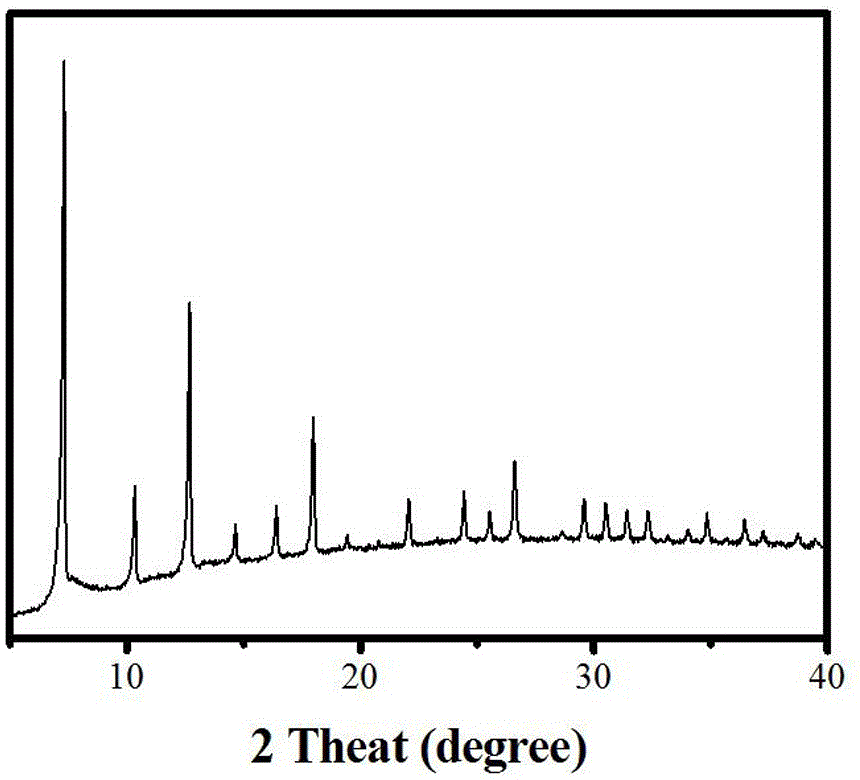

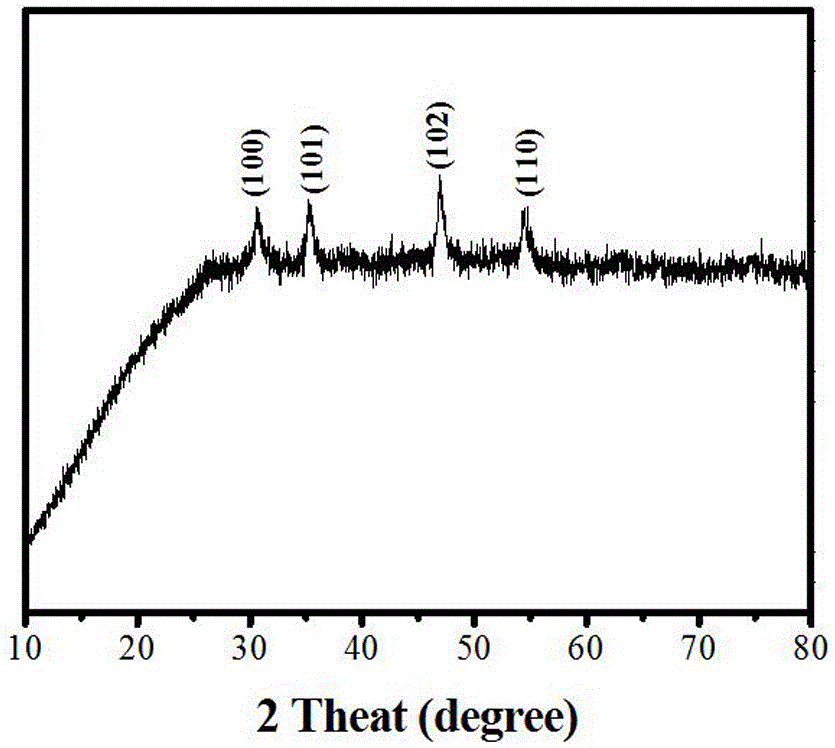

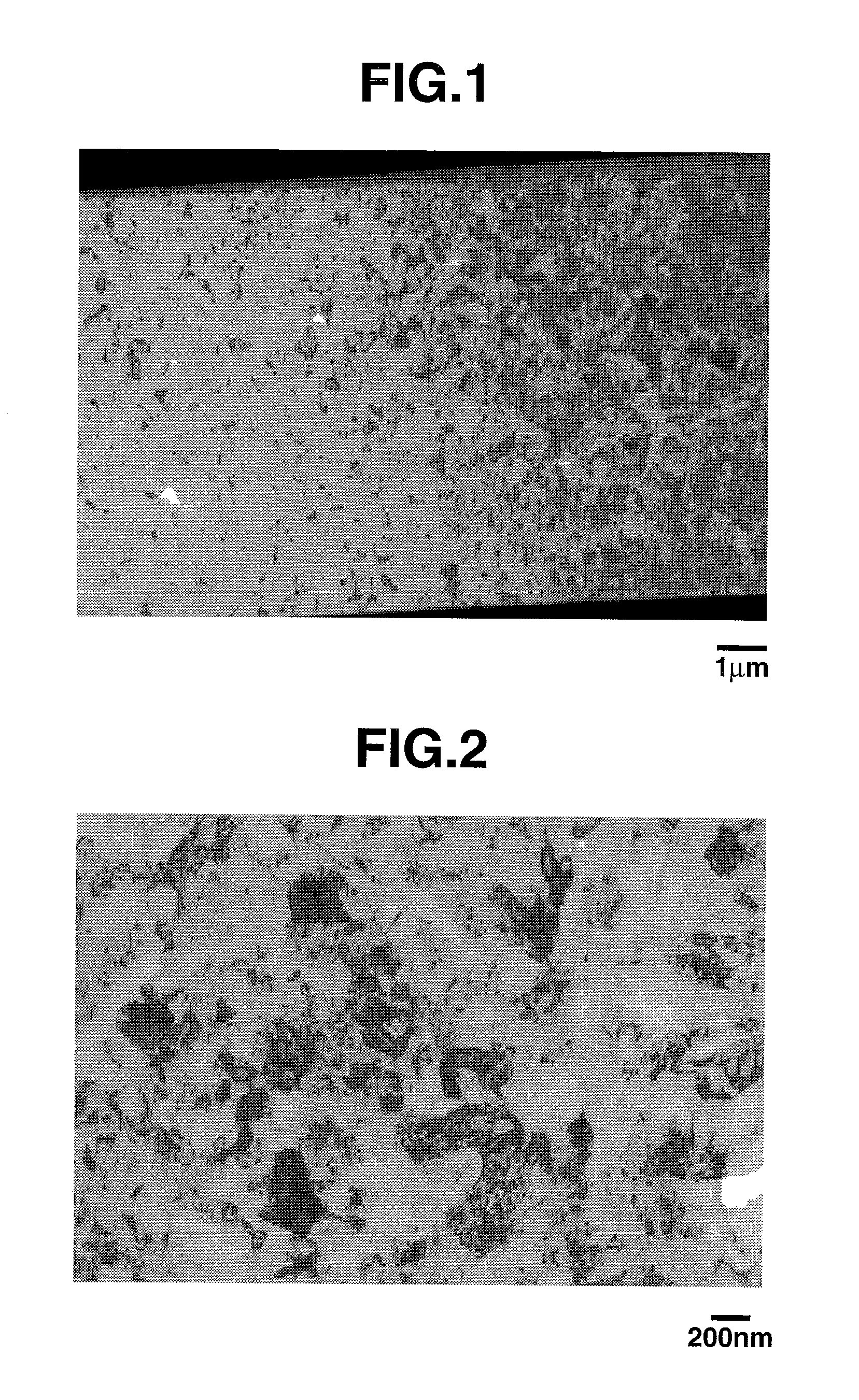

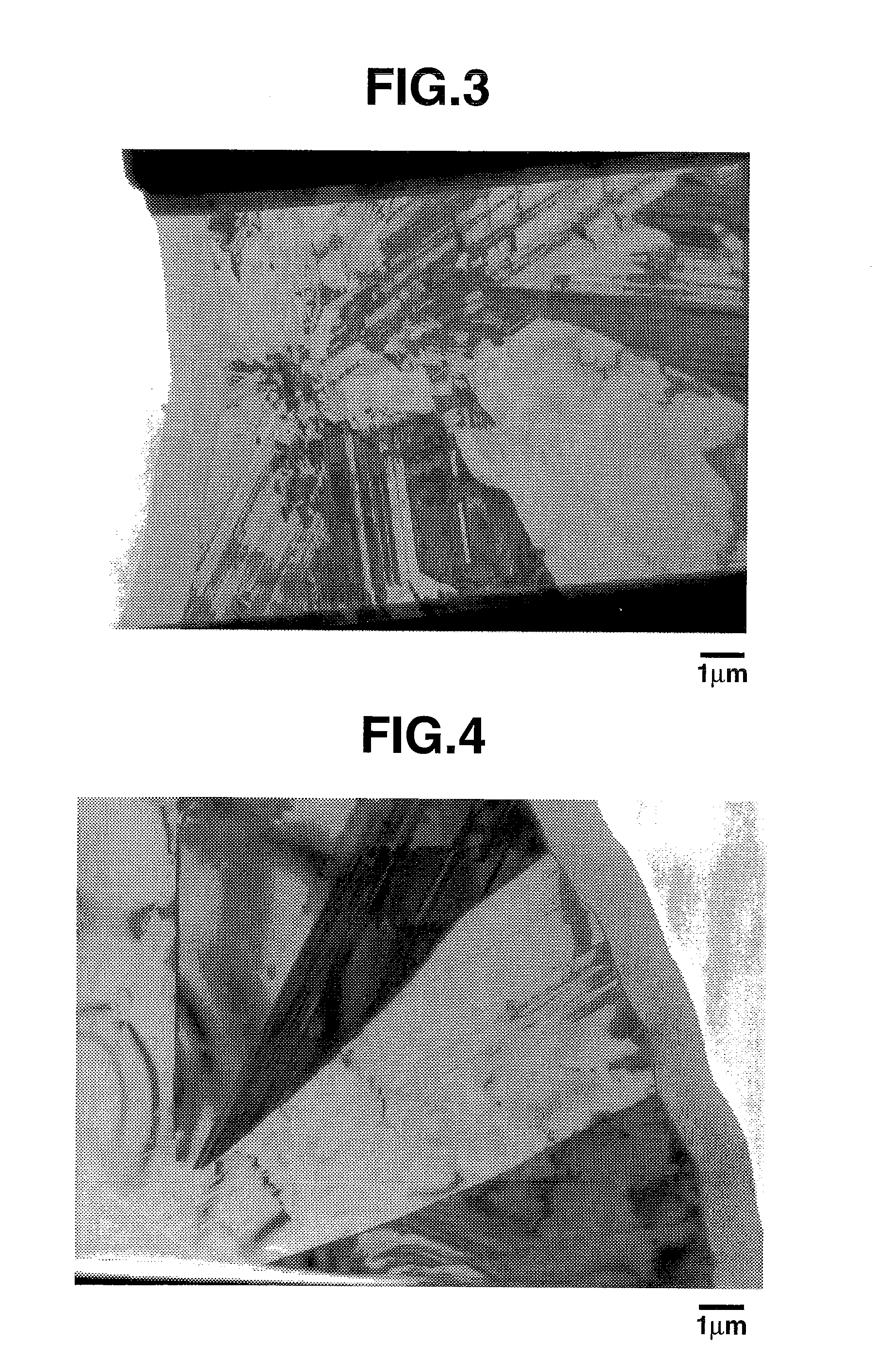

ActiveUS20100266902A1Increase capacityImprove efficiencyMaterial nanotechnologySiliconX-rayFull width at half maximum

This invention provides a negative electrode material for a rechargeable battery with a nonaqueous electrolyte, characterized in that the negative electrode material contains polycrystalline silicon particles as an active material, the particle diameter of crystallites of the polycrystalline silicon is not less than 20 nm and not more than 100 nm in terms of a crystallite size determined by the Scherrer method from the full width at half maximum of a diffraction line attributable to Si (111) around 2θ=28.4° in an x-ray diffraction pattern analysis, and the true specific gravity of the silicon particles is 2.300 to 2.320.

Owner:PANASONIC ENERGY CO LTD +1

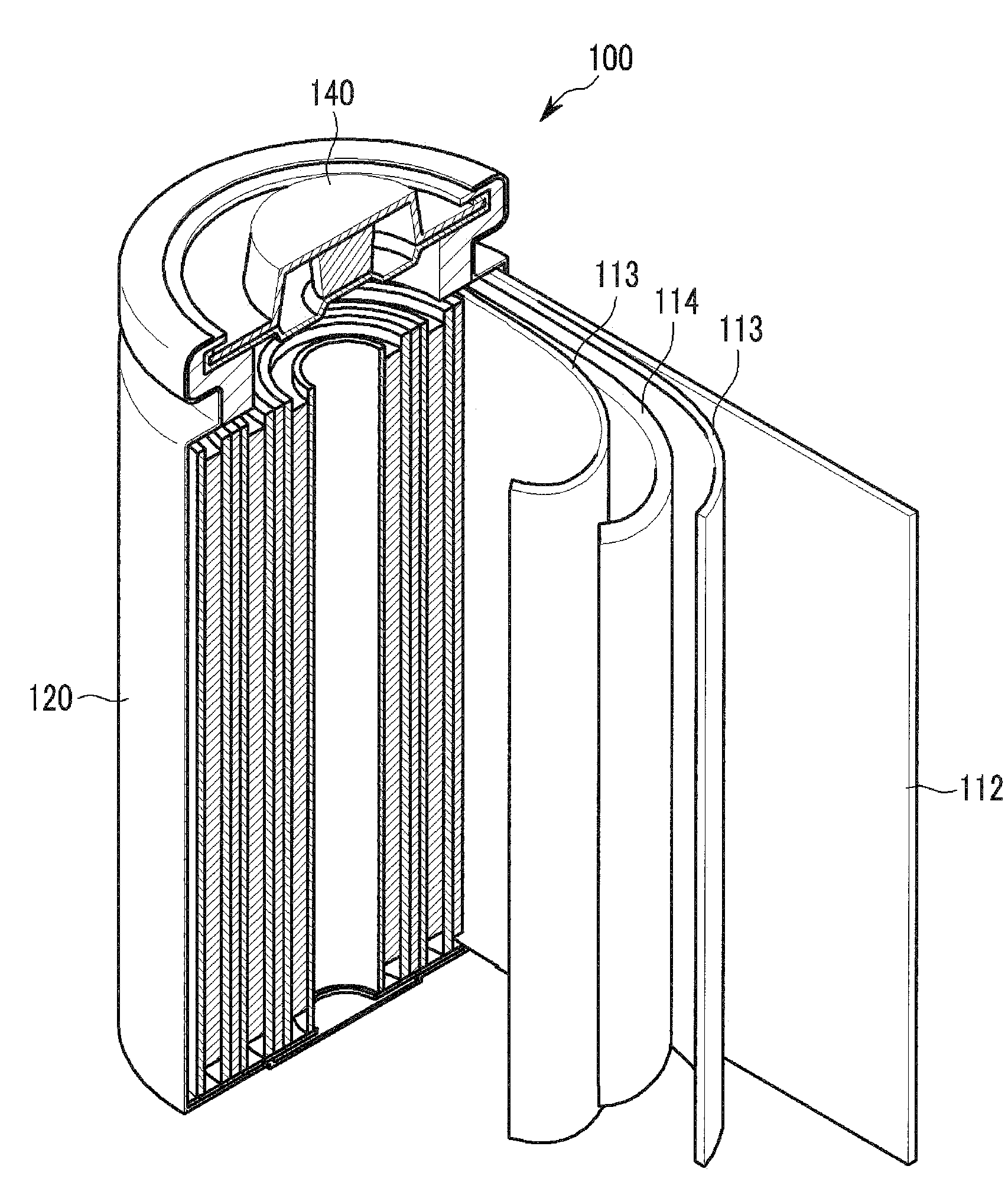

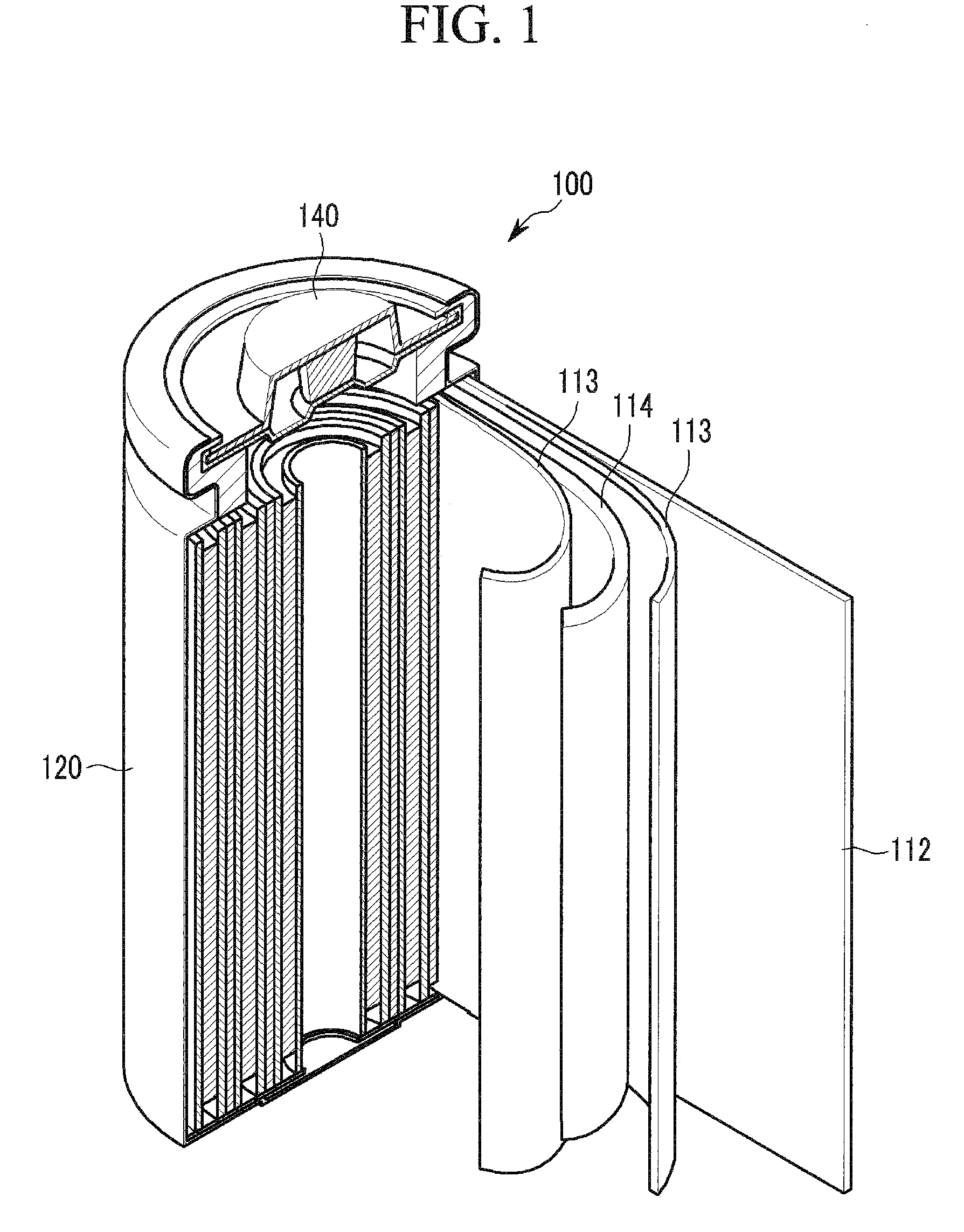

Negative electrode for rechargeable lithium battery, and rechargeable lithium battery including the same

ActiveUS20090136845A1Improved initial formation efficiency and cycle-life characteristicImproved cycle life characteristicsNon-fibrous pulp additionElectrode thermal treatmentCross-linkEngineering

A negative electrode for a rechargeable lithium battery and a rechargeable lithium battery including the same are provided. The negative electrode for a rechargeable lithium battery includes a current collector, and a negative active material layer on the current collector. The negative active material layer includes an interpenetrating network network, and a negative active material in the interpenetrating network network. The interpenetrating network is formed by cross-linking a first polymer having a hydroxyl or amine group and a second polymer having a carboxylic acid group. The negative electrode for a rechargeable lithium battery minimizes volume expansion and imparts good cycle-life characteristics and initial formation efficiency.

Owner:SAMSUNG SDI CO LTD

Tin carbon nanometer compound material for lithium ion battery and method for making same

InactiveCN101202340APromote circulationAlleviate volume changesElectrode manufacturing processesChemical/physical/physico-chemical processesMass ratioSodium-ion battery

The invention discloses a tin-carbon nano-composite and a preparation method which are used for a cathode of a li-ion battery. The steps of the preparation method are as follows: 1) dissoluble stannate or dissoluble tin salt is mixed uniformly with starch in order to obtain admixture; the mass ratio of starch and tin in the dissoluble stannate or tin in the dissoluble tin salt is 1:0.01 to 0.5; 2) the obtained admixture is arranged in inertia gas environment, heated to the temperature of 300 DEG C to 400 DEG C which is kept for 0-10 hours, and then heated to the temperature of 500 DEG C to 1000 DEG C which is kept for 0-10 hours and then cooled to obtain the tin-carbon nano-composite used for the cathode of the li-ion battery. The preparation method of the invention has simple process, low cost, high specific capacity and excellent circulation performance of obtained tin-carbon nano-composite.

Owner:GUANGXI NORMAL UNIV

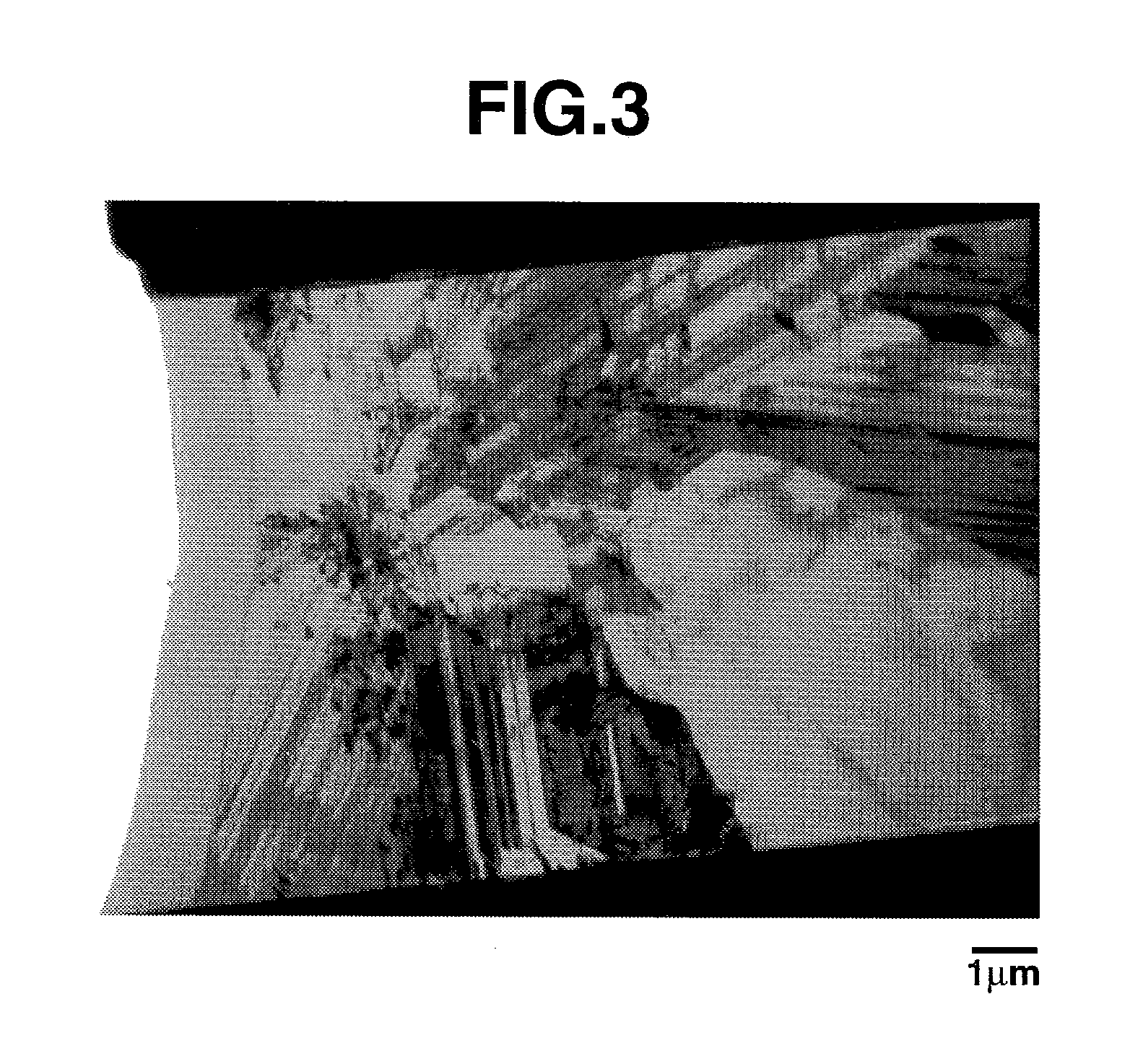

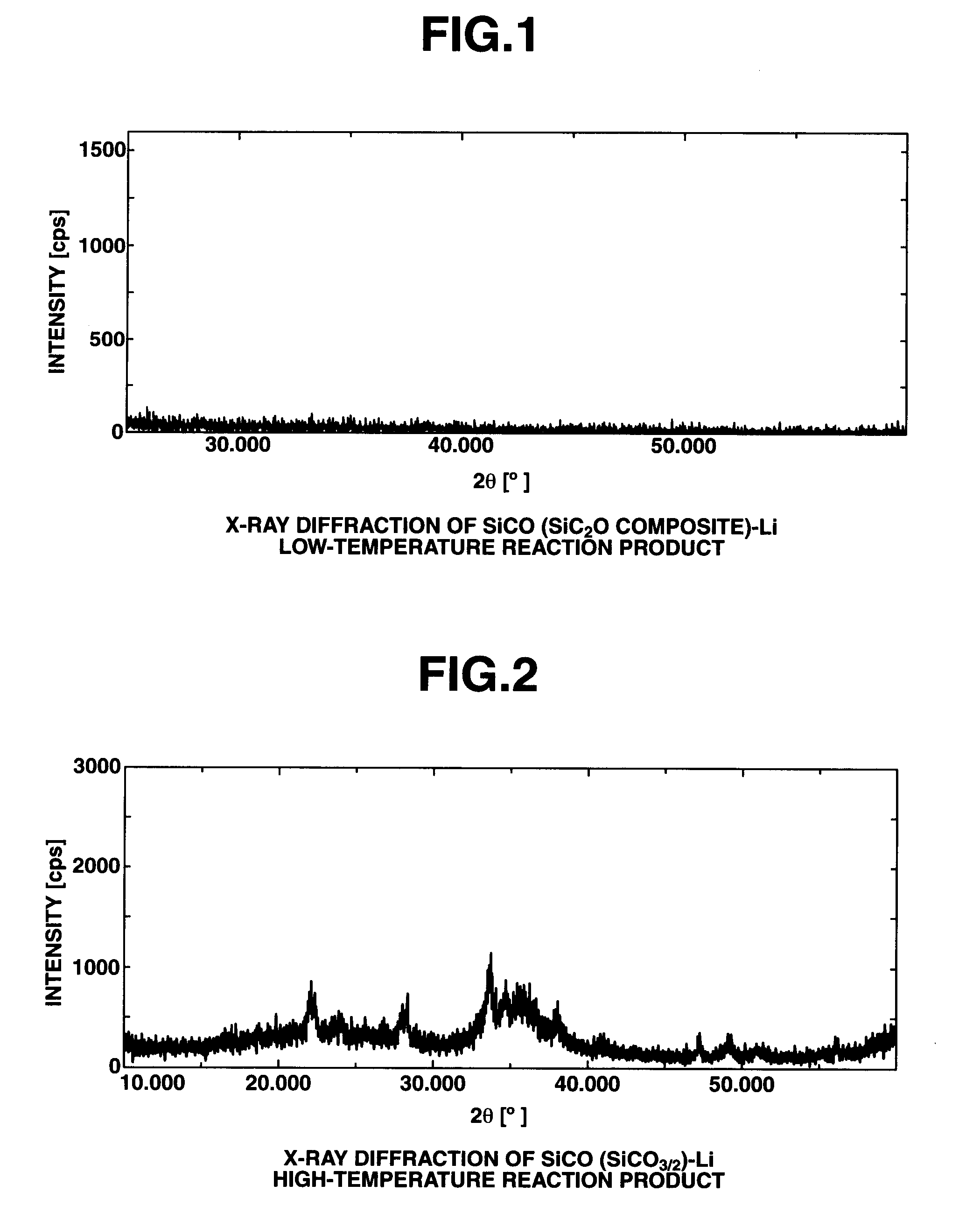

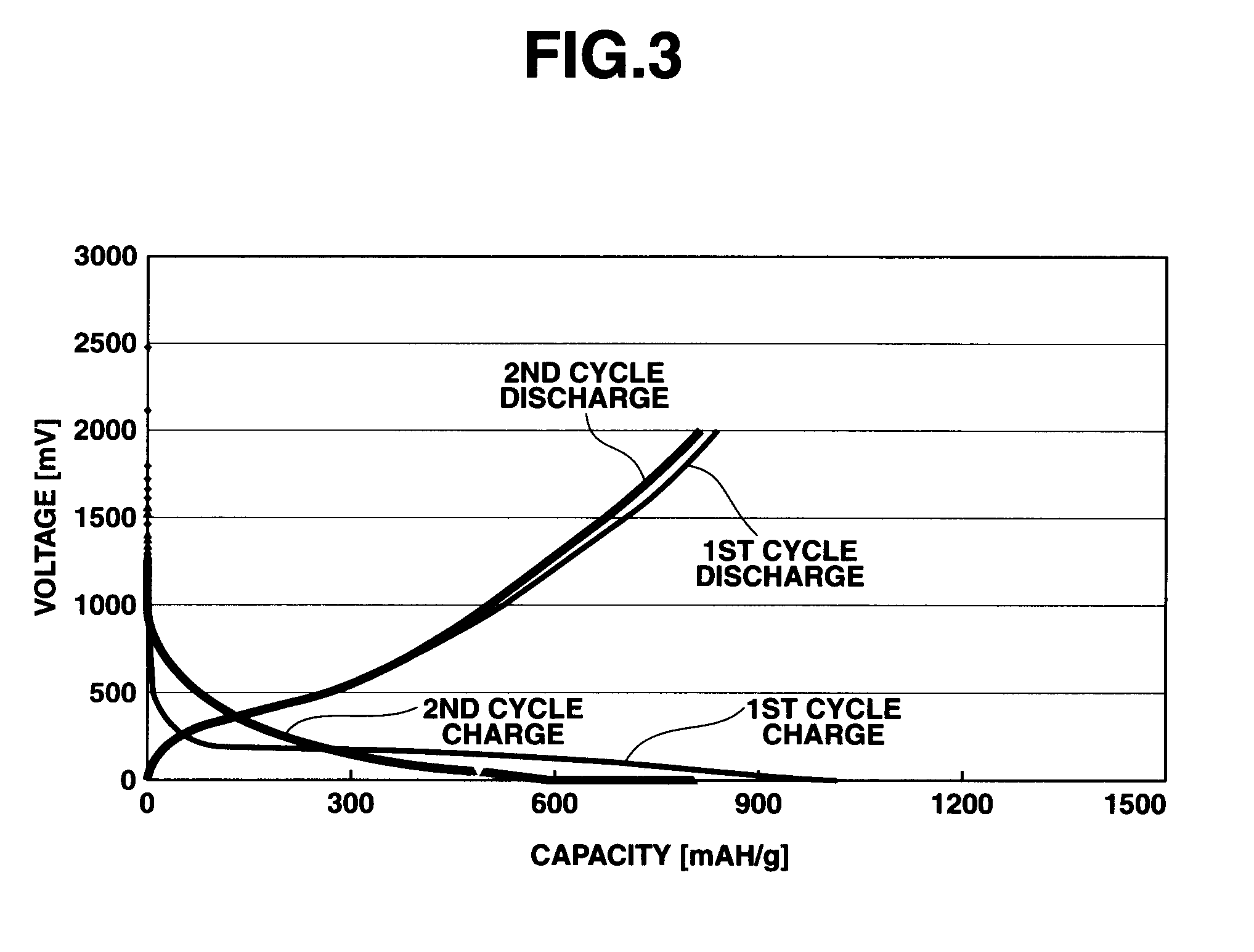

SiCO-Li COMPOSITE, MAKING METHOD, AND NON-AQUEOUS ELECTROLYTE SECONDARY CELL NEGATIVE ELECTRODE MATERIAL

InactiveUS20070224509A1Satisfactory initial efficiencySatisfactory cycle performanceElectrode thermal treatmentCarbon compoundsSiloxaneNon aqueous electrolytes

A SiCO—Li composite is prepared by causing a reactive silane and / or siloxane having crosslinkable groups to crosslink, sintering the crosslinked product into an inorganic Si—C—O composite, and doping the Si—C—O composite with lithium. When the SiCO—Li composite is used as a negative electrode, a lithium ion secondary cell exhibits good cycle performance, unique discharge characteristics and improved initial efficiency.

Owner:SHIN ETSU CHEM IND CO LTD

Non-aqueous electrolyte secondary battery, negative electrode material, and making method

ActiveCN101567438ASmall volume expansionImprove initial efficiencyElectrode manufacturing processesSiliconSilicon oxideSilicon particle

A negative electrode material comprising an active material and 1-20 wt% of a polyimide resin binder is suitable for use in non-aqueous electrolyte secondary batteries. The active material comprises silicon oxide particles and 1-50 wt% of silicon particles. The negative electrode exhibits improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide. The non-aqueous electrolyte secondary battery has a high initial efficiency and maintains improved performance and efficiency over repeated charge / discharge cycles by virtue of mitigated volumetric changes during charge / discharge cycles.

Owner:SHIN ETSU CHEM IND CO LTD

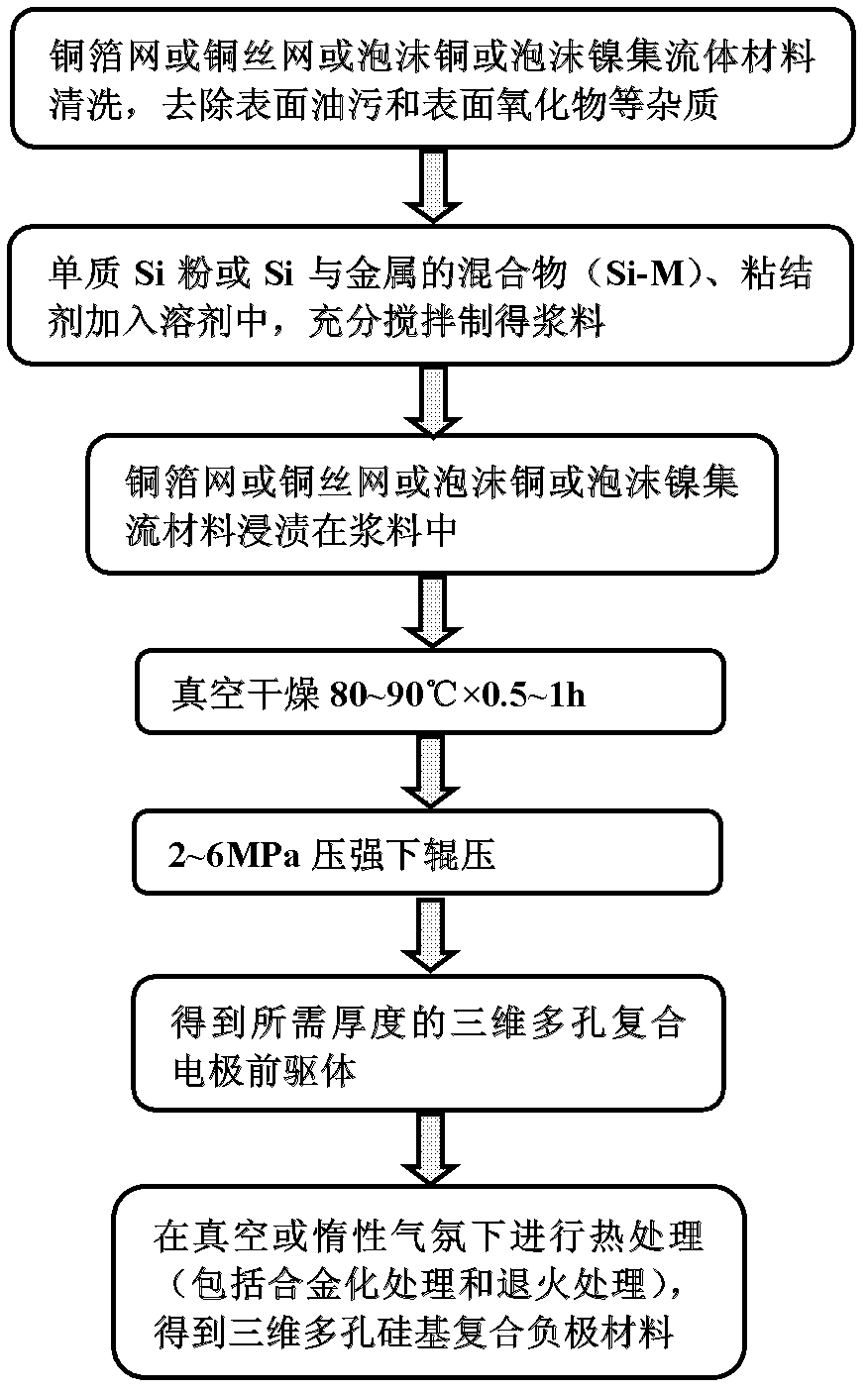

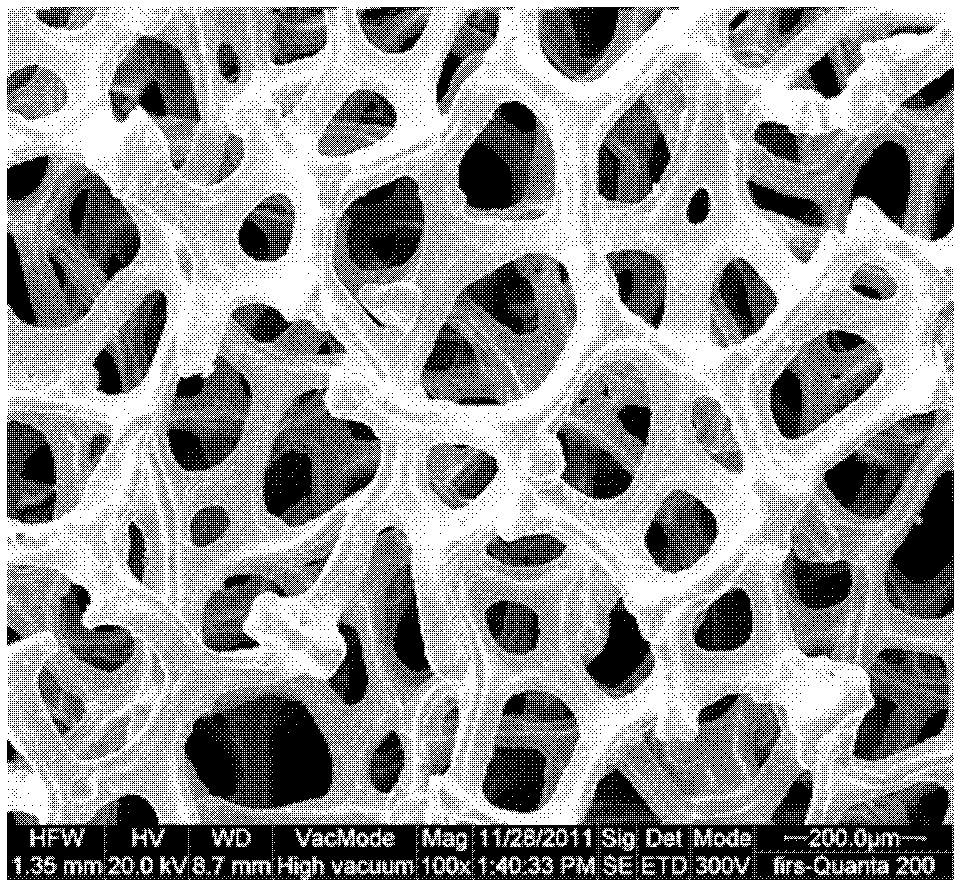

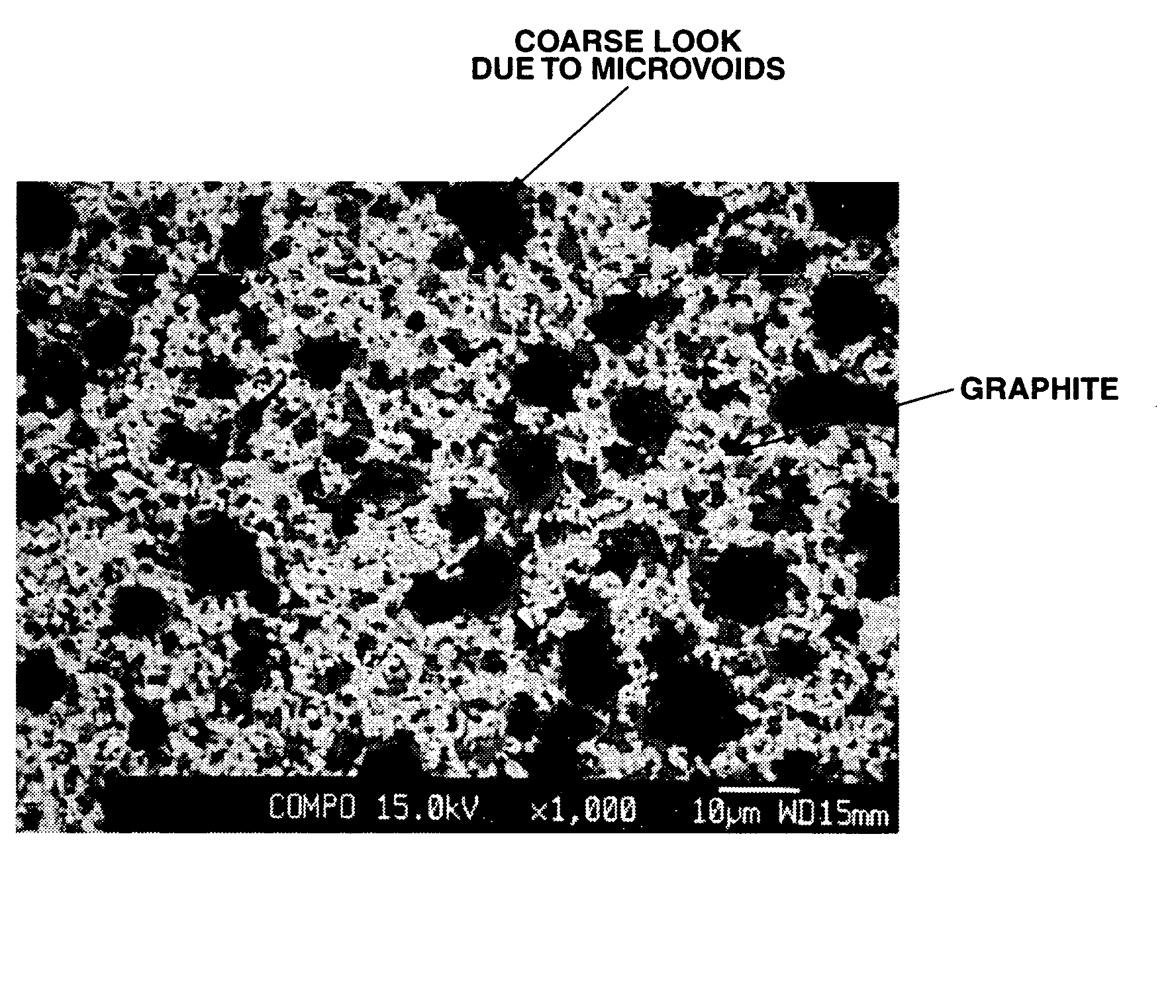

Three-dimensional porous silicon-based composite negative electrode material of lithium ion cell and preparation method thereof

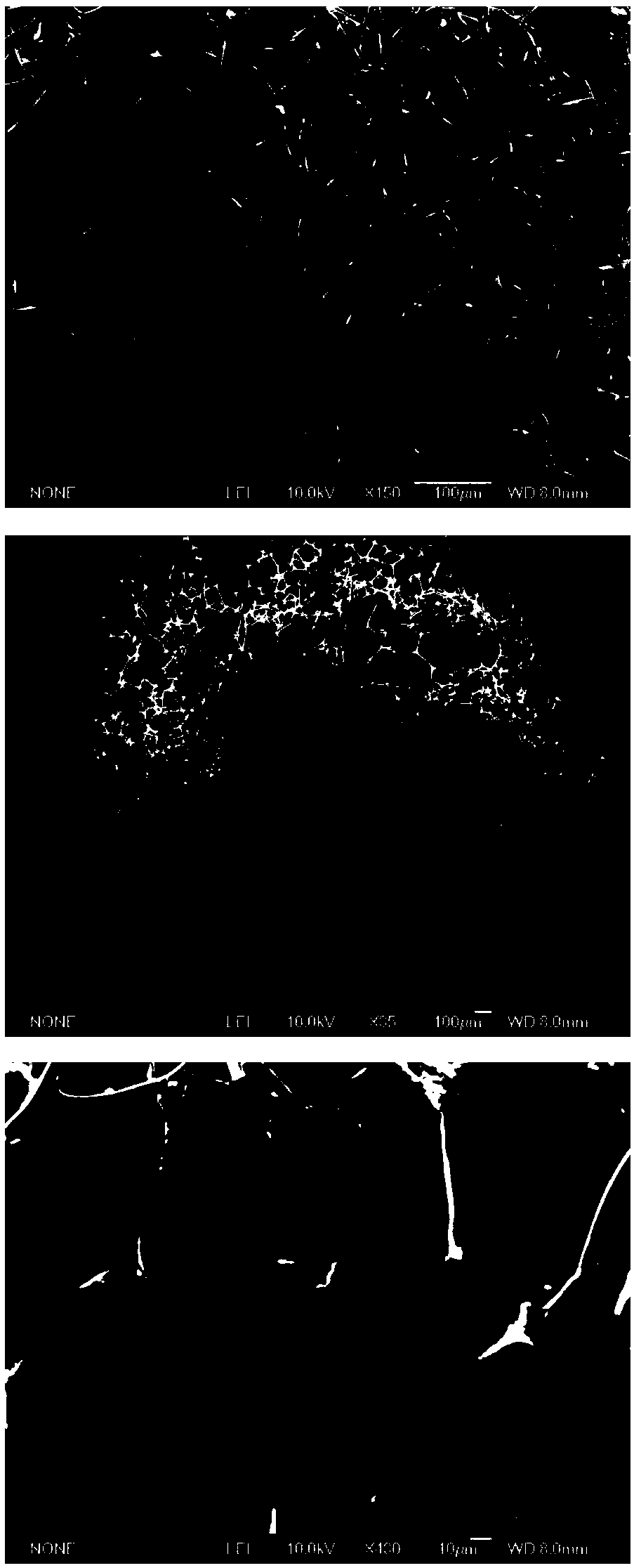

ActiveCN102683655AEasy to operateReduce processing costsElectrode carriers/collectorsSecondary cellsCopper wireCopper foil

The invention discloses a three-dimensional porous silicon-based composite negative electrode material of a lithium ion cell and a preparation method thereof. A collection body material, such as a copper foil net or a copper wire net or foam copper or foam nickel, which has a three-dimensional net structure, enables electrode active substances to be uniformly dispersed in the material and the surface of the material, and has high temperature resistant characteristic and excellent conductivity, is adopted; and a sizing material containing simple substance silicon or a mixture of simple substance silicon and metal M is combined with the copper foil net or copper wire net or foam copper or foam nickel by a dipping method, and then the three-dimensional porous silicon-based composite negative electrode material is formed by a heat treatment (alloying and annealing treatment) manner. According to the invention, based on the three-dimensional porous structure, the forming of silicon metal alloy as well as excellent binding force between the negative electrode material and the three-dimensional porous collection body material, the cell prepared from the porous silicon-based composite negative electrode material has higher discharge specific capacity and first charge-discharge efficiency and excellent cycle performance.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Method for manufacturing negative electrode active material for non-aqueous electrolyte secondary battery, negative electrode active material for non-aqueous electrolyte secondary battery, negative electrode material for non-aqueous electrolyte secondary battery, negative electrode for non-aqueous electrolyte secondary battery, and non-aqueous electrolyte secondary battery

ActiveUS20110287317A1Reduce capacitySmall overall deformationSiliconElectrode thermal treatmentGas phaseElectrical battery

The present invention is a method for manufacturing a negative electrode active material for a non-aqueous electrolyte secondary battery comprising at least depositing silicon on a substrate by vapor deposition by using a metallic silicon as a raw material, the substrate having a temperature controlled to 300° C. to 800° C. under reduced pressure, and pulverizing and classifying the deposited silicon. As a result, there is provided a method for manufacturing a negative electrode active material composed of silicon particles that is an active material useful as a negative electrode of a non-aqueous electrolyte secondary battery in which high initial efficiency and high battery capacity of silicon are kept, cycle performance is superior, and an amount of a change in volume decreases at the time of charge and discharge.

Owner:SHIN ETSU CHEM IND CO LTD

Three-dimensional current collector for metal secondary battery anode and preparation and application thereof

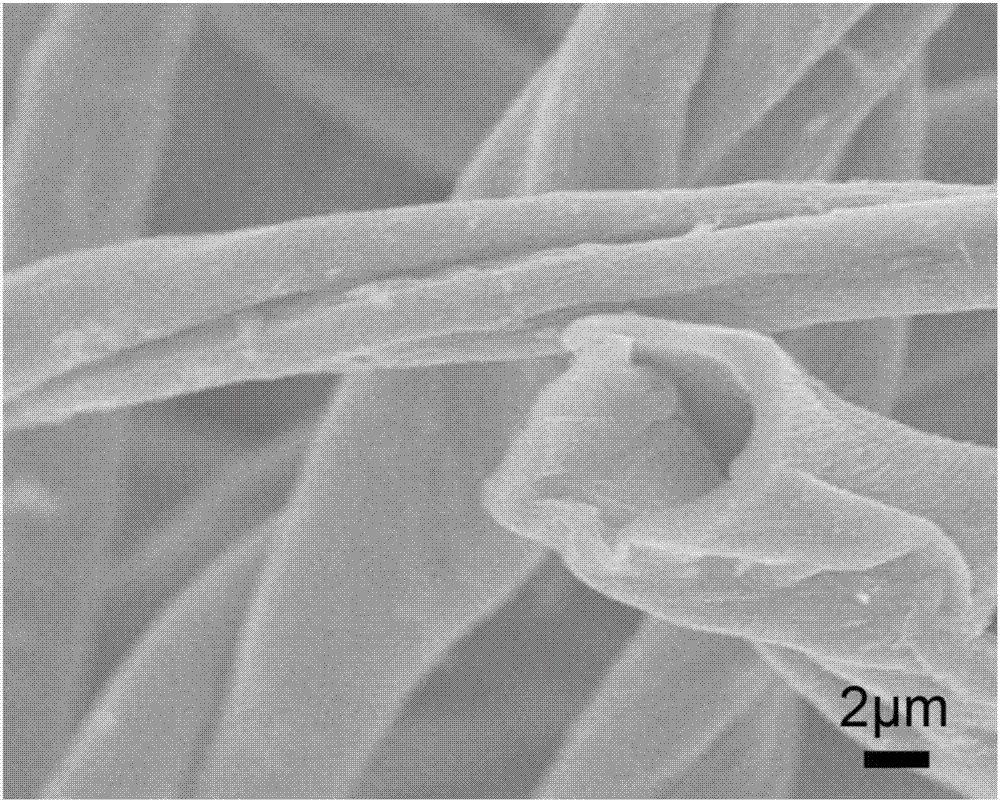

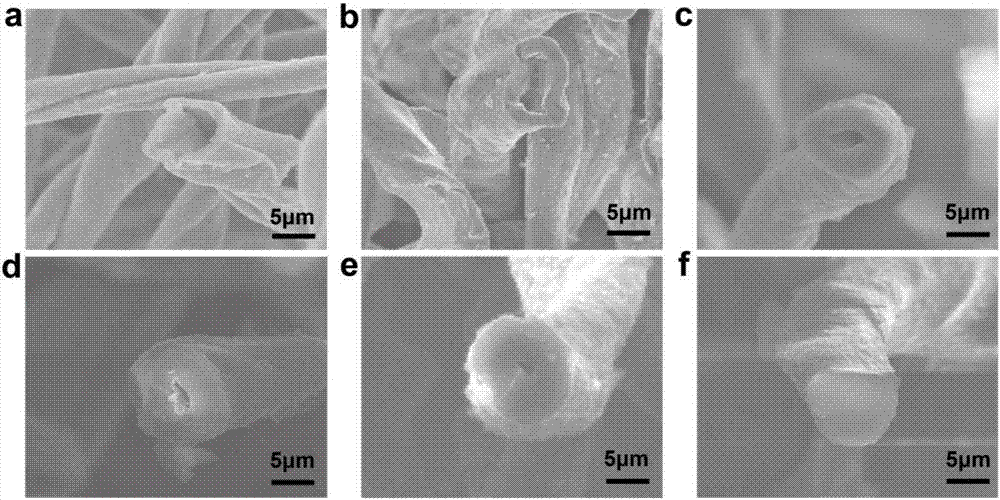

ActiveCN106898778ALarge electroactive surface areaReduce current densityElectrochemical processing of electrodesElectrode carriers/collectorsFiberHollow fibre

The invention provides a three-dimensional porous current collector serving as a metal secondary battery anode current collector; the current collector is a three-dimensional porous hollow carbon fiber current collector having both hollow fiber tubular structure and porous structure. Compared with the traditional flat current collectors, the three-dimensional porous hollow carbon fiber current collector is capable of inhibiting dendritic crystal that occurs during metal deposition / separation, the safety of a metal anode is improved greatly, improved coulombic efficiency and longer cycle life can be achieved, and voltage polarization can be decreased. A method to prepare the three-dimensional porous hollow carbon fiber bobbin current collector is simple and easy, the raw materials are low in price and easy to obtain, and the collector is suitable for large-scale production and has high practical value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

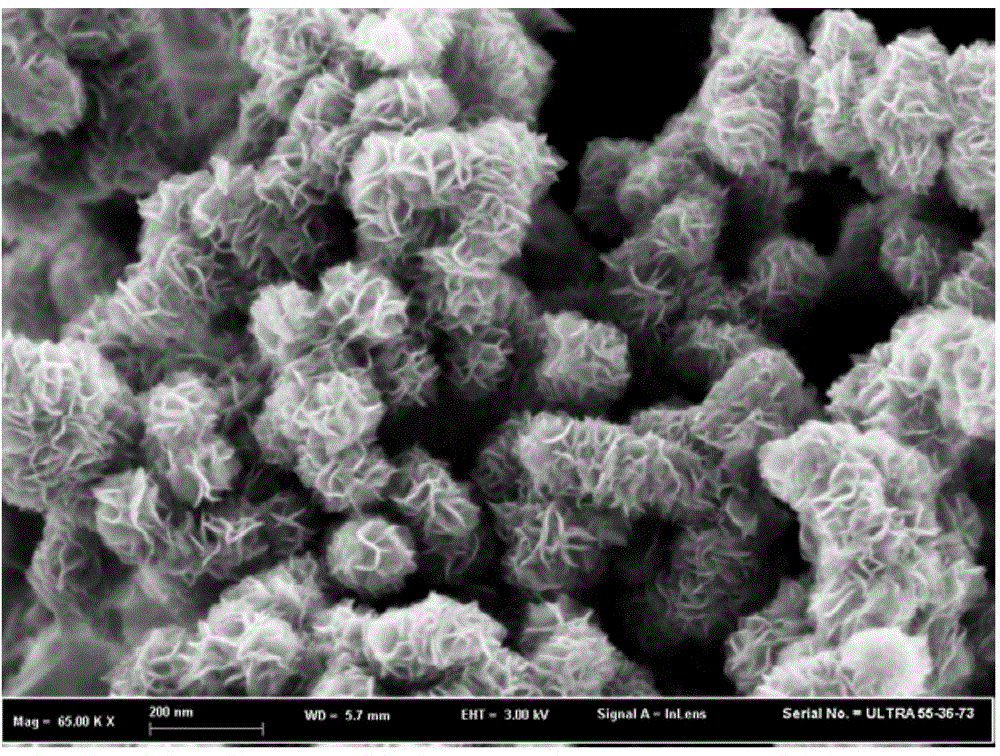

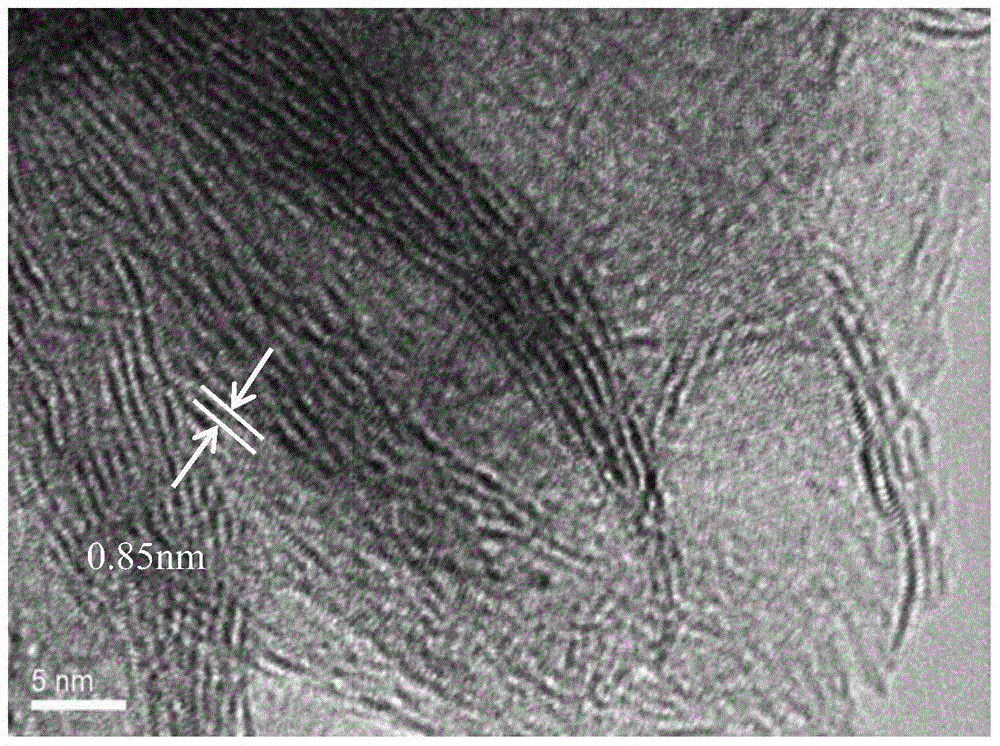

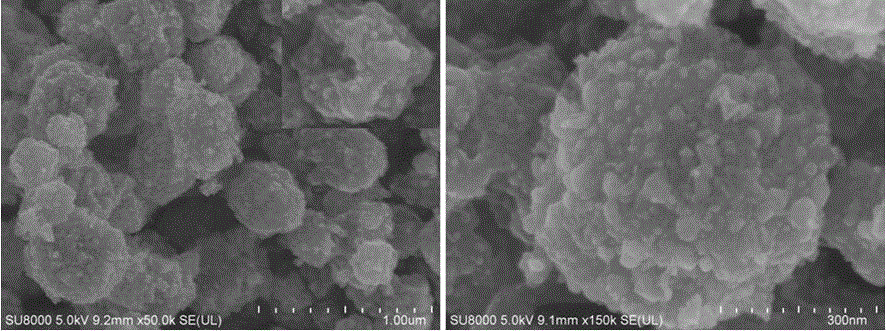

Three-dimensional molybdenum disulfide nanoflower-graphene composite material and application thereof

ActiveCN104857976AFacilitates electron conductionImprove transportation effectMaterial nanotechnologyPhysical/chemical process catalystsUltrasonic dispersionCvd graphene

The invention discloses a preparation method for a three-dimensional molybdenum disulfide nanoflower-graphene composite material and application of the three-dimensional molybdenum disulfide nanoflower-graphene composite material as an electrochemical hydrogen evolution catalyst. According to the invention, the three-dimensional molybdenum disulfide nanoflower-graphene composite material is prepared through a one-step hydrothermal method; and the obtained composite material is used to modify a glassy carbon electrode after ultrasonic dispersion so as to obtain a three-dimensional molybdenum disulfide nanoflower-graphene composite material modified electrode. The three-dimensional molybdenum disulfide nanoflower-graphene composite material is mainly applied to electrochemical hydrogen evolution; and a linear scanning curve (polarization curve) is used to detect the catalytic activity of the synthesized molybdenum disulfide nanoflower-graphene composite material, and a cyclic voltammetry curve is employed for testing the stability of the molybdenum disulfide nanoflower-graphene composite material. According to the invention, synergism of molybdenum disulfide nanoflower and graphene in the three-dimensional molybdenum disulfide nanoflower-graphene composite material is made full use of to improve the catalytic efficiency of electrochemical hydrogen evolution and to effectively enhance the stability of the catalyst so as to allow the catalyst to be used in an acidic environment for a long time.

Owner:远科秦皇岛节能环保科技开发有限公司

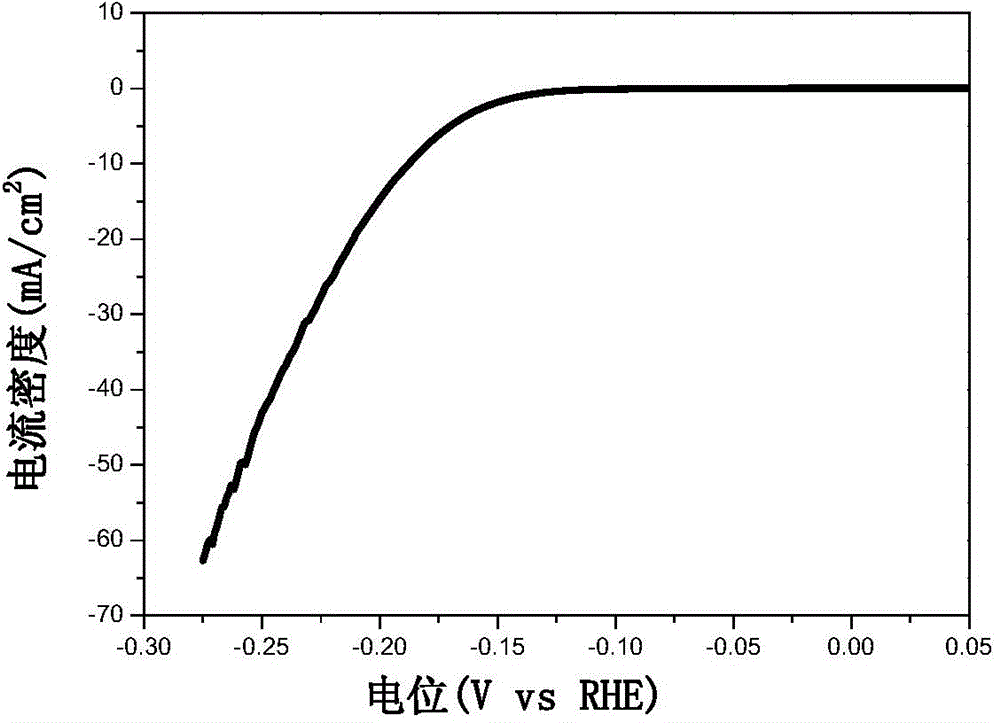

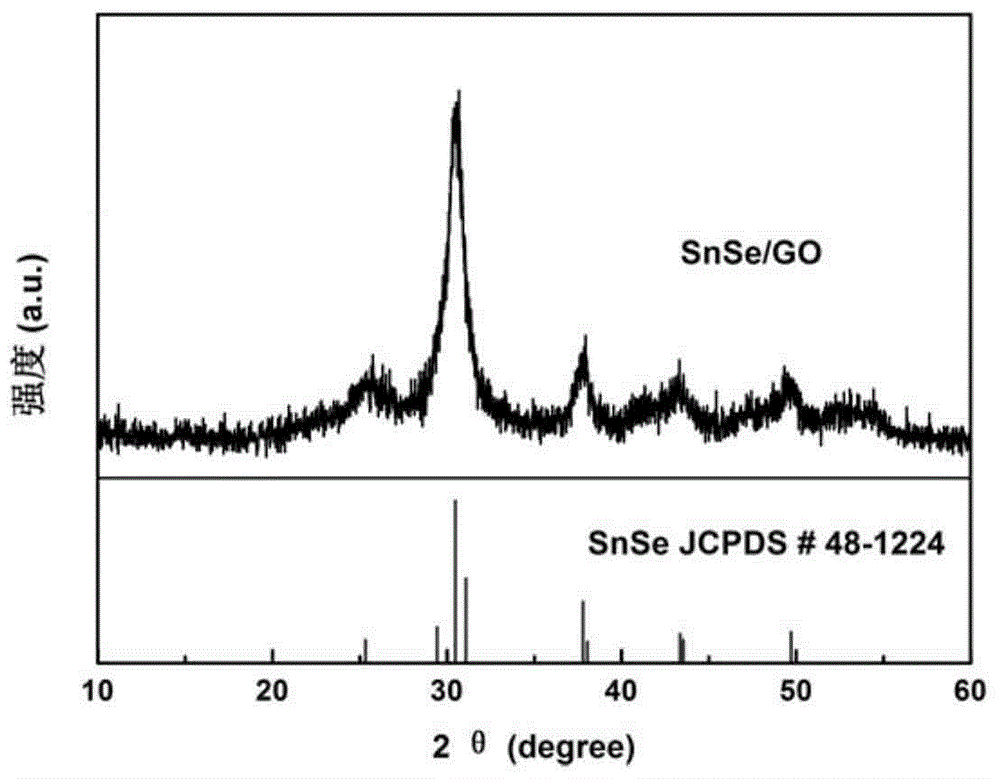

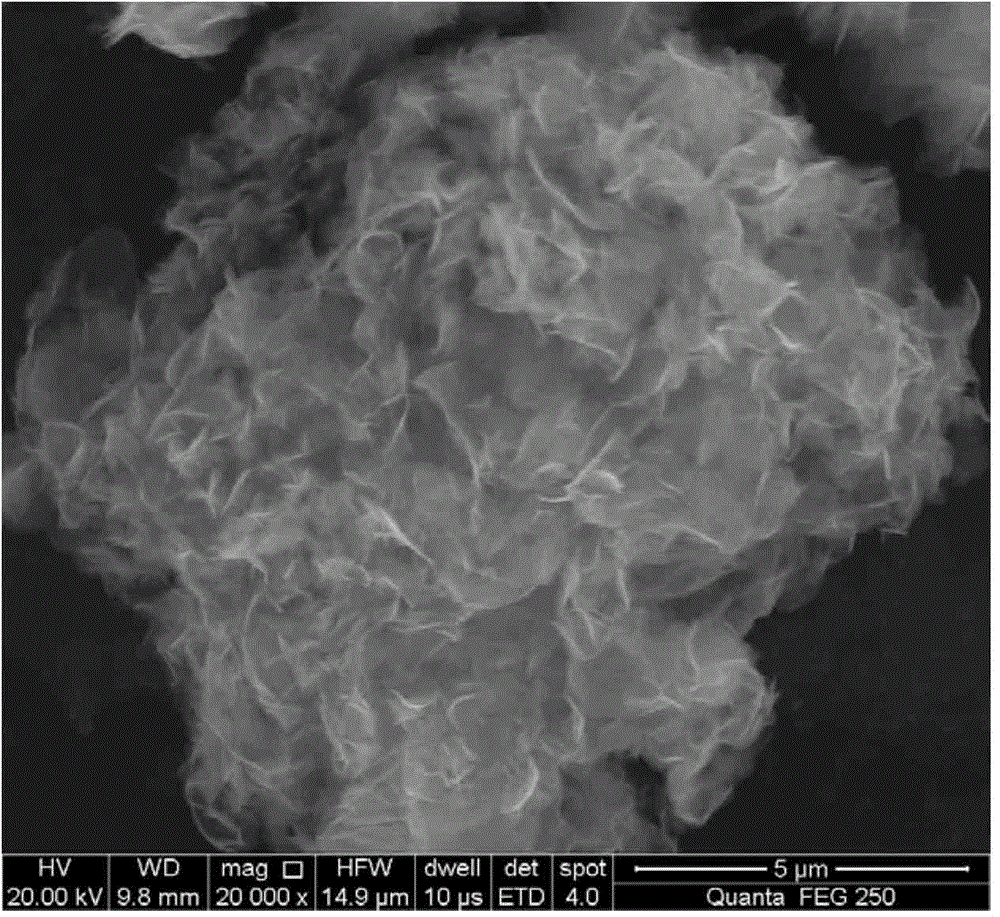

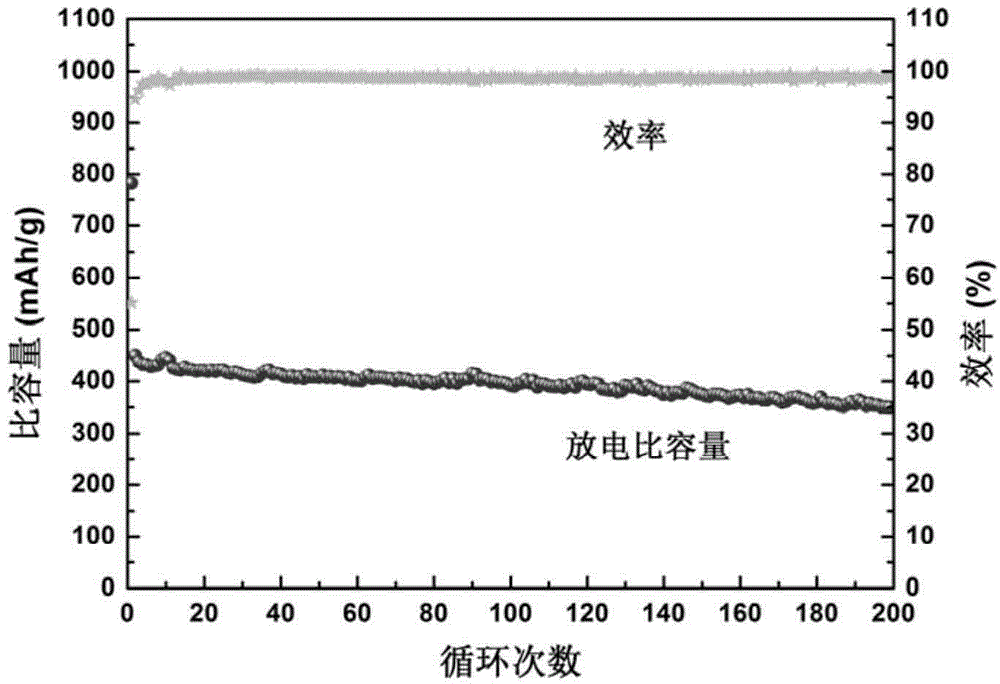

Stannic selenide/graphene oxide negative pole composite material for sodium ion battery and preparation method thereof

ActiveCN104617271AEasy to prepareGood repeatabilityMaterial nanotechnologyElectrode manufacturing processesOperabilitySodium-ion battery

The invention discloses a stannic selenide / graphene oxide negative pole composite material for a sodium ion battery and a preparation method thereof. The negative pole composite material is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The preparation method comprises the following steps of: ultrasonically dispersing graphene oxide powder into a mixed solution of water and ethylene glycol to obtain a dispersion solution; adding tin salt and selenite to the dispersion solution, then carrying out hydrothermal reaction, and placing a hydrothermal reaction product into an inert gas protective tube furnace for heat treatment so as to obtain a negative pole composite material which has nanometer sheet-like morphology and is formed by uniformly growing nanometer stannic selenide on the surface of graphene oxide. The composite material disclosed by the invention can be used for preparing the sodium ion battery which has the characteristics of high discharging specific capacity, excellent magnification property, long cycle life and the like. The preparation method disclosed by the invention has the advantages of simplicity, reliability, good process repeatability, high operability, low cost and suitability for industrialized production.

Owner:CENT SOUTH UNIV

Foam metal matrix oxide electrode used in lithium-ion battery cathode and preparation method thereof

ActiveCN102013470AExtended service lifeIncrease capacityElectrode carriers/collectorsOxide compositeAlloy

The invention relates to a preparation method of a foam metal matrix oxide electrode used in the lithium-ion battery cathode, relating to a metal electrode used in the lithium-ion battery cathode and a preparation method thereof. The invention aims to solve the problems of the existing lithium-ion battery anode material that the specific capacity is low, the cycle performance is poor and the preparation method is complicated. The foam metal matrix oxide electrode uses one or two of foam metals comprising Cu, Ni and Fe as the matrix. The preparation method of the foam metal matrix oxide electrode comprises the following steps: 1) cleaning with acid solution; 2) soaking with alkaline solution; and 3) generating one or two of the corresponding transition metal oxides, namely CuO, Cu2O, NiO, Ni2O, Fe2O3 and Fe3O4 on the foam metal in situ through low-temperature roasting and other steps to obtain the foam metal / transition metal oxide composite electrode. The preparation method is simple, the electrode has high specific capacity, long cycle life and excellent rate performance; and the electrode is suitable for the lithium-ion battery system of an electric vehicle.

Owner:HARBIN INST OF TECH

Lithium metal battery, electrode plate for same and method for preparing electrode plate

ActiveCN108899472ASimple structureAlleviate interface instabilitySecondary cellsNon-aqueous electrolyte accumulator electrodesMetallic lithiumElectrical battery

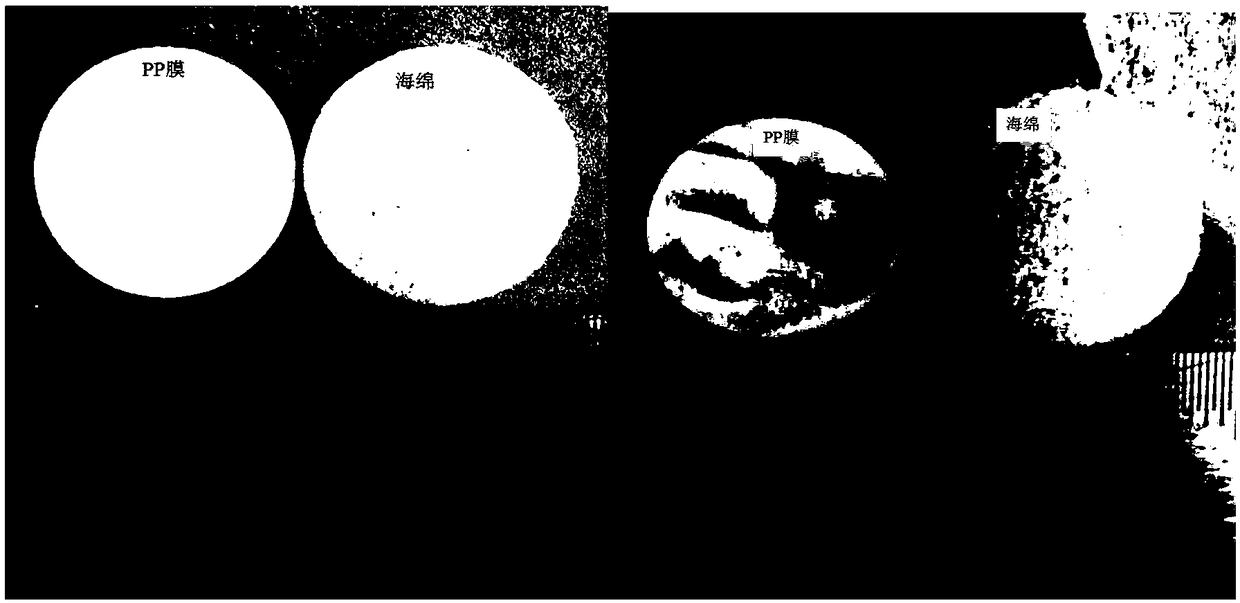

The invention provides a negative electrode plate for a lithium metal battery. Metallic lithium plates and sponges are compressed to obtain the negative electrode plate. The negative electrode plate has the advantages that the traditional lithium metal battery structures can be simplified when the negative electrode plate is applied to the lithium metal battery, electron barrier effects can be realized by sponge elastic interface layers instead of diaphragms, and volume change and the instability of interfaces inside the battery can be relieved by elastic interface materials in battery cycle;sponge medium layers are excellent in electrolyte solution wettability, and are high in thermal deformation resistance as compared with common polypropylene diaphragms; elastic three-dimensional framework structures of the sponges are favorable for inhibiting dendrite growth in lithium metal battery cycle procedures and relieving the volume change of negative electrodes, and accordingly further development of the lithium metal battery can be promoted from another angle by composite metal lithium negative electrodes which are designed by the aid of sponge materials and are free of diaphragm structures.

Owner:UNIV OF SCI & TECH OF CHINA

Cos@carbon nano-cage as well as preparation method and application thereof

InactiveCN106450200ASolve the problem of greatly reduced cycle stabilityImprove cycle performanceCell electrodesSecondary cellsMetallic sulfideLithium-ion battery

The invention provides a Cos@carbon nano-cage as well as a preparation method and application thereof. Cobalt-base metal organic framework materials (ZIF-67) are synthesized as a carbon source and a cobalt source and are taken as a precursor to be directly calcined with powdered sulfur so as to obtain a composite nanomaterial of the Cos@carbon nano-cage. According to the Cos@carbon nano-cage, the problems that the structure is collapsed, the material is powdered, and the cycle performance is greatly decreased when the volume of the metal sulfide is changed too much during the charging and discharging are solved. The carbon nano-cage can supply more lithium storage gaps, so that the integral electrical conductivity of the material is improved, the volume change caused by the disembedding of lithium ions can be effectively relieved, and the agglomeration of CoS particles can be further prevented. Therefore, the composite material has relatively good application prospect in electrode materials of lithium ion batteries.

Owner:FUJIAN NORMAL UNIV

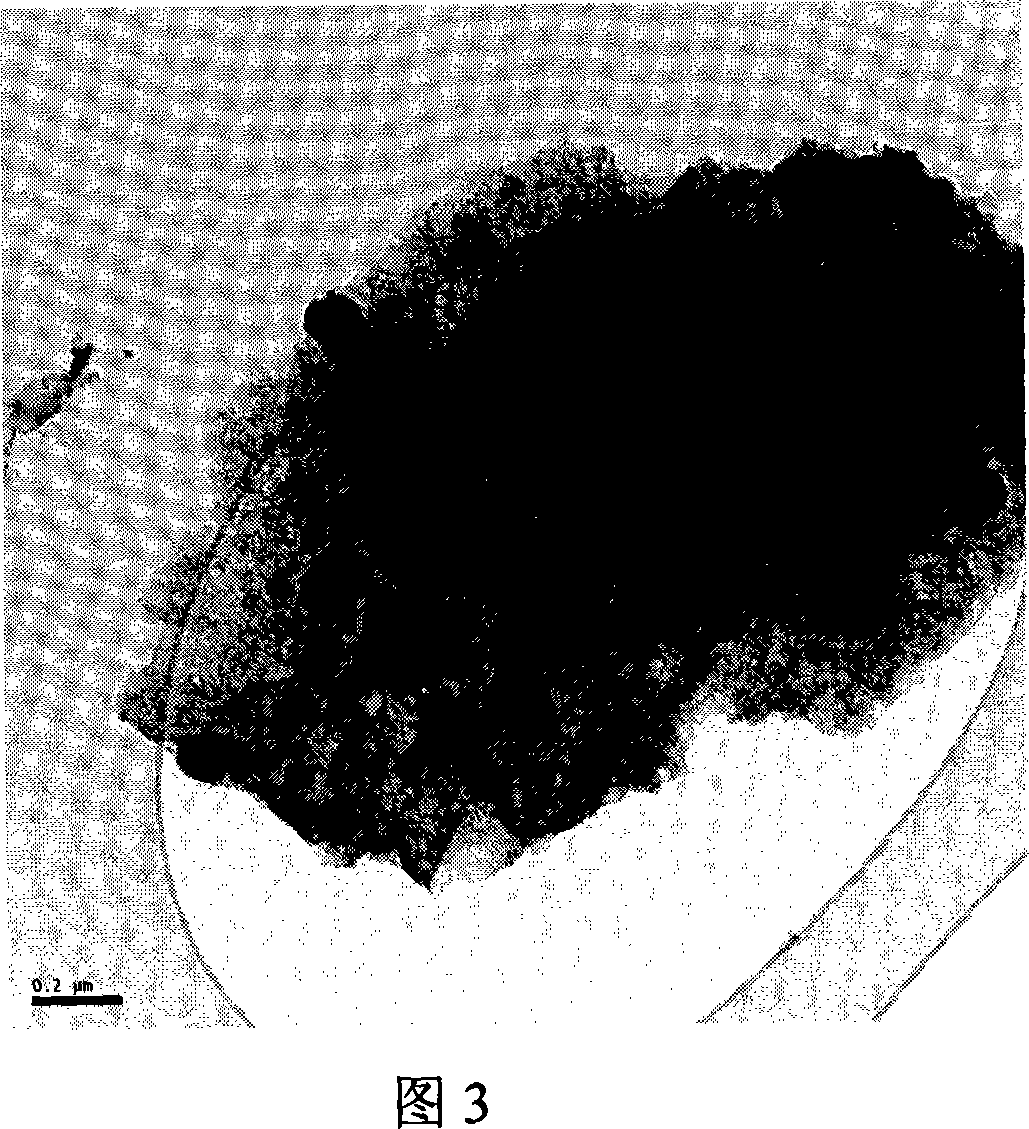

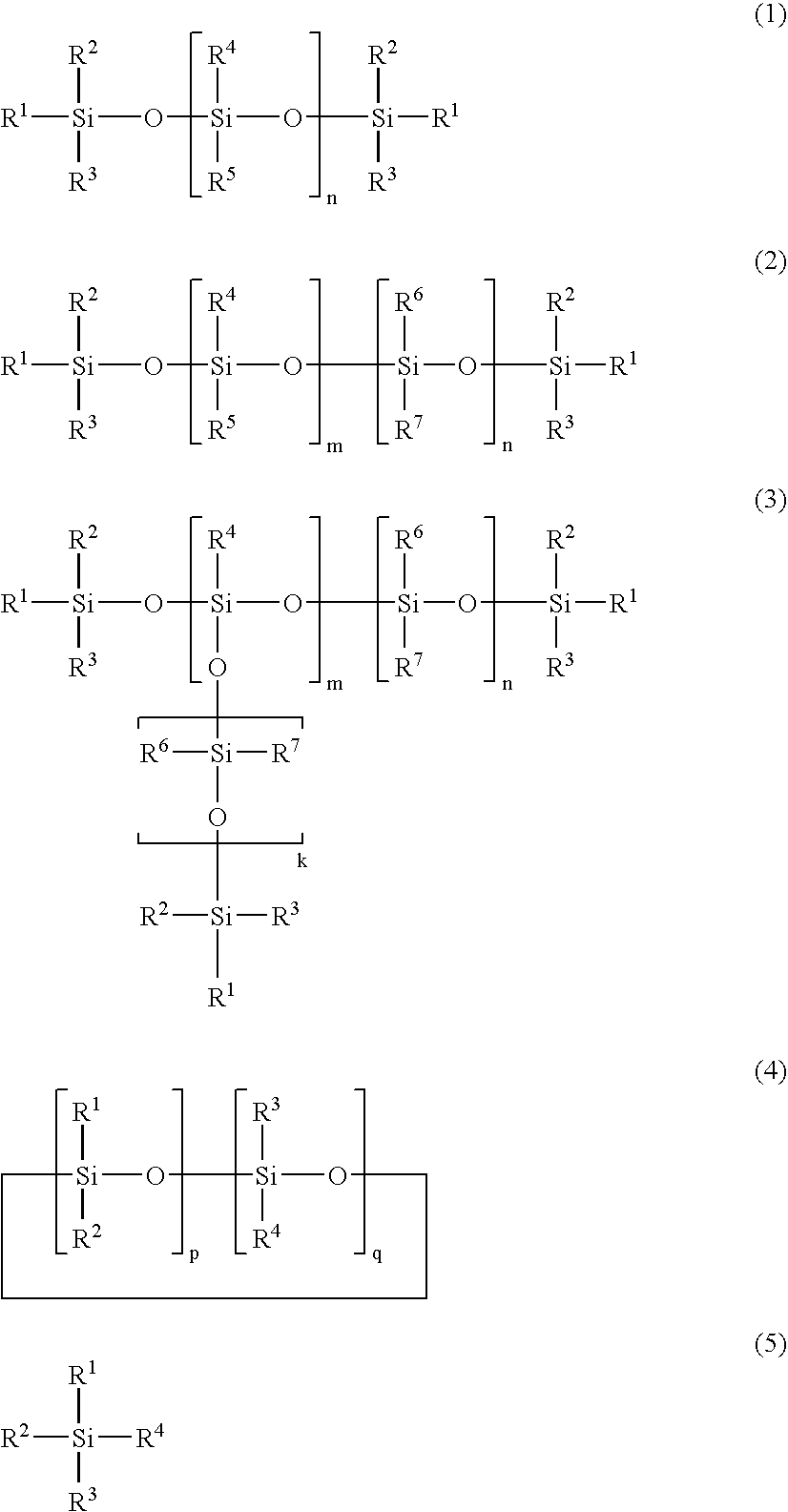

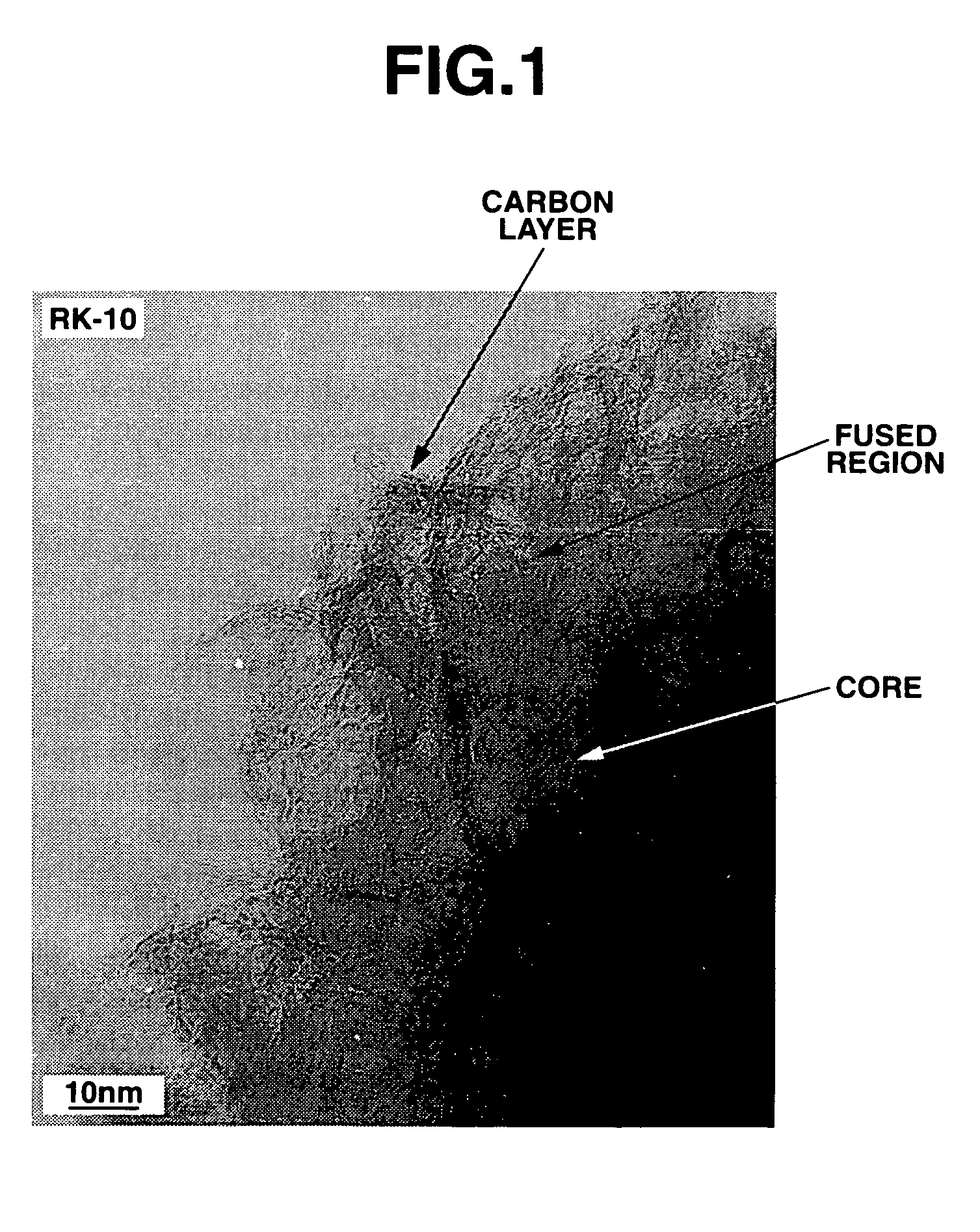

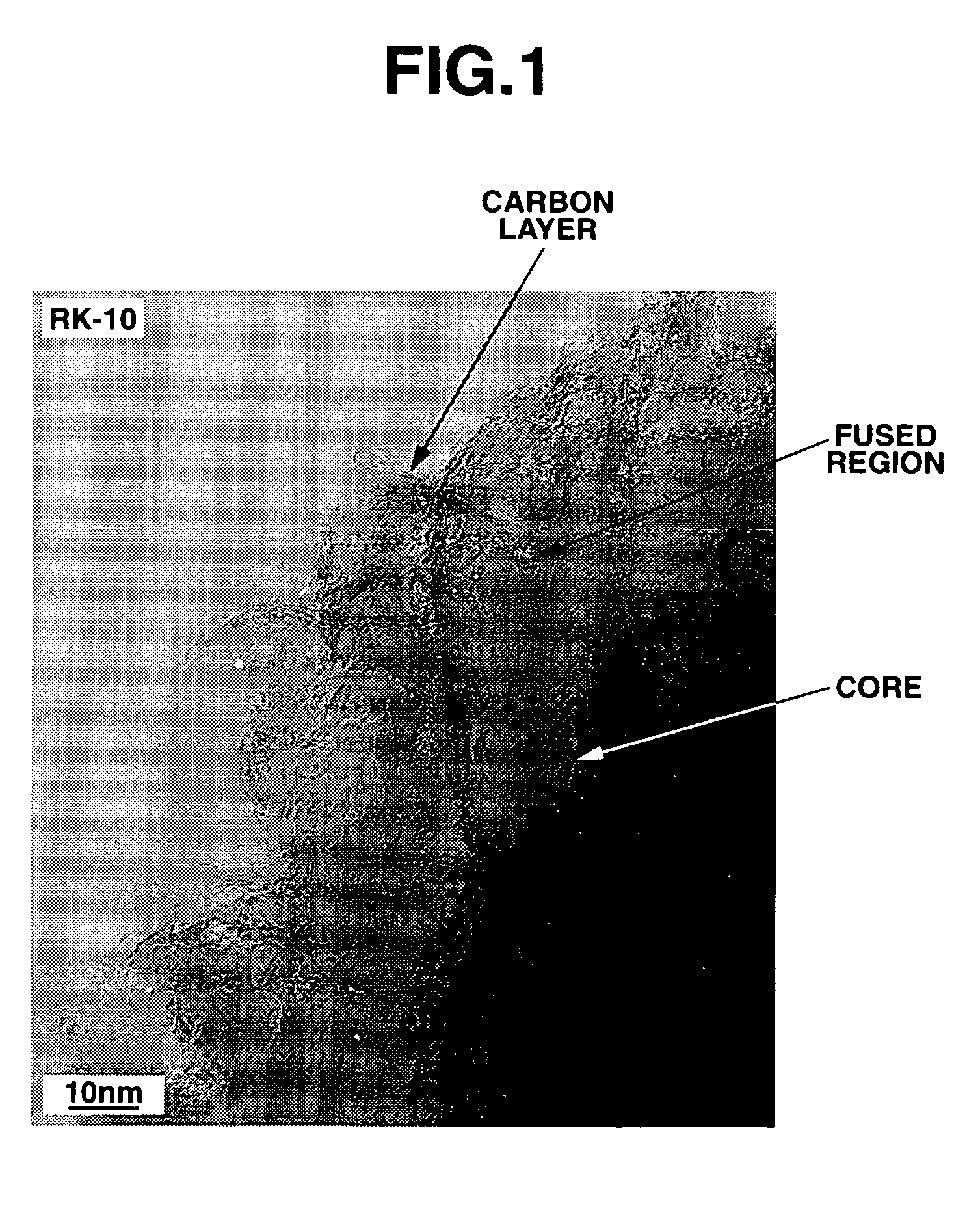

Si-C-O composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

InactiveUS7658863B2Improve cycle performanceInferior capacityCell electrodesPretreated surfacesMetallurgySilanes

A Si—C—O composite powder is obtained by curing a reactive silane or siloxane having crosslinkable groups through heat curing or catalytic reaction into a crosslinked product and sintering the crosslinked product in an inert gas stream at a temperature of 700-1,400° C. into an inorganic state. It exhibits satisfactory cycle performance when used as the negative electrode material for non-aqueous electrolyte secondary cells.

Owner:SHIN ETSU CHEM CO LTD

Tin cobalt alloy/ graphene composite material and preparation method thereof

InactiveCN104064739AInhibition of volume changeAlleviate volume changesCell electrodesSecondary cellsSolventGlycol synthesis

The invention discloses a tin cobalt alloy / graphene composite material and a preparation method of the tin cobalt alloy / graphene composite material. The preparation method of the tin cobalt alloy / graphene composite material includes the following steps that firstly, graphene oxide is dispersed into methyl alcohol or ethylalcohol or ethylene glycol or diethylene glycol, and then suspension liquid is prepared; secondly, cobalt salt and tin slat of which the mass ratio of the sum of mass to the mass of graphene oxide ranges from 60:1 to 30:1 dissolve in the suspension liquid prepared through the first step, wherein the molar ratio of a cobalt element to a tin element ranges from 1: 0.66 to 1:3; thirdly, a sodium borohydride alcoholic solution of which the concentration ranges from 1 mol / L to 2.5 mol / L is prepared, alcohol used in the first step is used in this step, the sodium borohydride alcoholic solution is mixed with the suspension liquid obtained through the second step, nitrogen is injected, and after 10 minutes of bubbling, solvent heat treatment is conducted, wherein solvent heat treatment refers to the process that a mixture reacts for 6 h to 12 h at the temperature of 100 DEG C to 160 DEG C in a closed reaction kettle and then is cooled to the room temperature, and the molar ratio of the cobalt element in sodium borohydride to the cobalt element in the cobalt salt is 6-13 to 1; fourthly, a sample obtained in the third step is repeatedly washed centrifugally in ethyl alcohol and deionized water, and a product is obtained after vacuum drying.

Owner:CHANGSHA GUORONG NEW ENERGY

Method for preparing lithium ion battery cathode material ZnFe2O4/C nano fibers

InactiveCN102154739AControl diameterSolve reunionCell electrodesFilament/thread formingFiberCyclic process

The invention discloses a method for preparing lithium ion battery cathode material ZnFe2O4 / C nano fibers. The method has the advantages that: 1, the preparation process flow is short, the diameter of the nano fibers can be controlled more effectively, nano fiber precursors with regular structure are obtained, and the lithium ion battery cathode material ZnFe2O4 / C nano fibers with uniform structure are prepared by combining different change of two polymers in the calcining process; and 2, the prepared lithium ion battery cathode material ZnFe2O4 / C nano fibers are apparently nano fibers, the diameter of the nano fibers is about 200 to 400 nanometers, ZnFe2O4 nano granules are distributed in the continuous phase of carbon in the internal structure, and meanwhile, because of the carbon, the volume change in the electrode circulating process is greatly relieved, the problem of granule agglomeration in the circulating process is solved and the electrochemical circulating stability is improved.

Owner:XIANGTAN UNIV

Negative electrode material for nonaqueous electrolyte secondary battery

ActiveUS8734991B2Increase capacityImprove efficiencyMaterial nanotechnologySiliconX-rayFull width at half maximum

This invention provides a negative electrode material for a rechargeable battery with a nonaqueous electrolyte, characterized in that the negative electrode material contains polycrystalline silicon particles as an active material, the particle diameter of crystallites of the polycrystalline silicon is not less than 20 nm and not more than 100 nm in terms of a crystallite size determined by the Scherrer method from the full width at half maximum of a diffraction line attributable to Si (111) around 2θ=28.4° in an x-ray diffraction pattern analysis, and the true specific gravity of the silicon particles is 2.300 to 2.320.

Owner:PANASONIC ENERGY CO LTD +1

Si-C-O composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

InactiveUS20060022198A1Improve cycle performanceInferior capacityConductive materialActive material electrodesMetallurgySilanes

A Si—C—O composite powder is obtained by curing a reactive silane or siloxane having crosslinkable groups through heat curing or catalytic reaction into a crosslinked product and sintering the crosslinked product in an inert gas stream at a temperature of 700-1,400° C. into an inorganic state. It exhibits satisfactory cycle performance when used as the negative electrode material for non-aqueous electrolyte secondary cells.

Owner:SHIN ETSU CHEM IND CO LTD

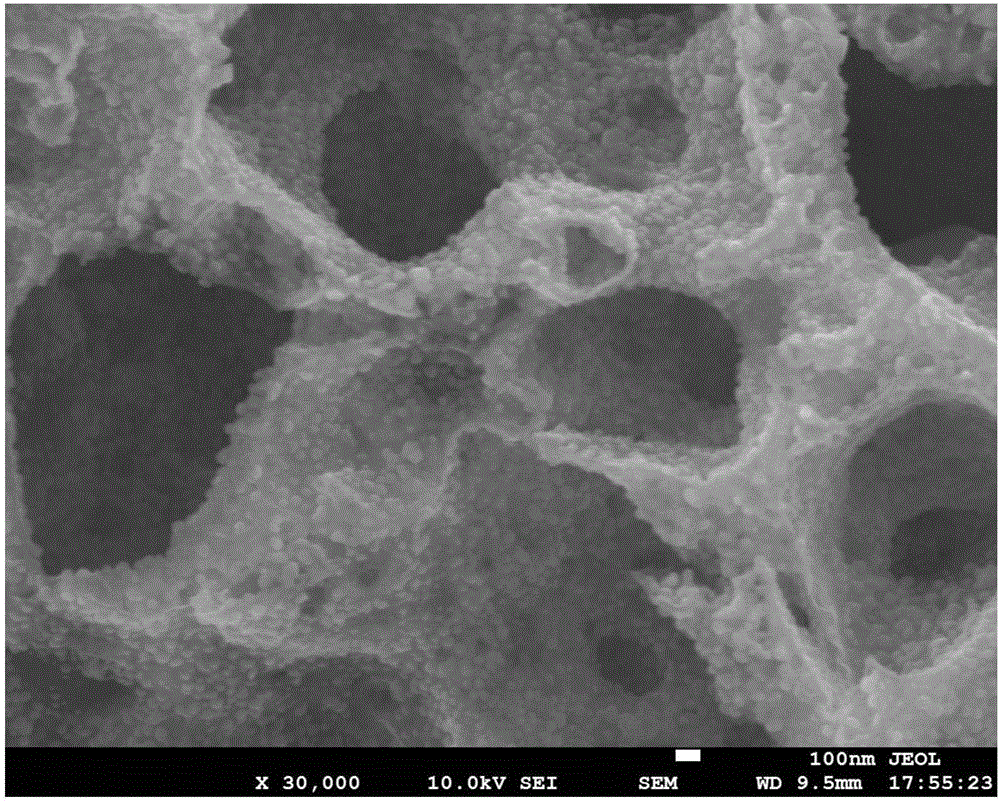

Porous graphene supported carbon coated iron oxide nanoparticle composite material and preparation method thereof

ActiveCN106207121AAlleviate volume changesHigh lithium storage capacityCell electrodesWater bathsPorous graphene

The invention belongs to the technical field of lithium ion battery materials, and specifically relates to a porous graphene supported carbon coated iron oxide nanoparticle composite material and a preparation method thereof. The porous graphene supported carbon coated iron oxide nanoparticle composite material is prepared from the following steps: (1) directly preparing graphene oxide with graphite ore as a raw material by using a closed oxidation method; (2) preparing a ferric salt aqueous solution, wherein the specific steps are as follows: weighing and dissolving cetyl trimethyl ammonium bromide in water to obtain a clear cetyl trimethyl ammonium bromide solution, adding a ferric salt, stirring until the ferric salt is completely dissolved, and adding an ammonia solution to prepare the ferric salt aqueous solution; and (3) stirring and ultrasonic mixing the graphene oxide solution with the ferric salt aqueous solution, placing the mixture in a water bath kettle, reacting at 80-100 DEG C for 0.5-5h, stewing at a room temperature, removing clear liquid, freeze drying a head product, and carrying out heat treatment on the head product in an inert atmosphere to obtain the porous graphene supported carbon coated iron oxide nanoparticle composite material.

Owner:SHANXI UNIV

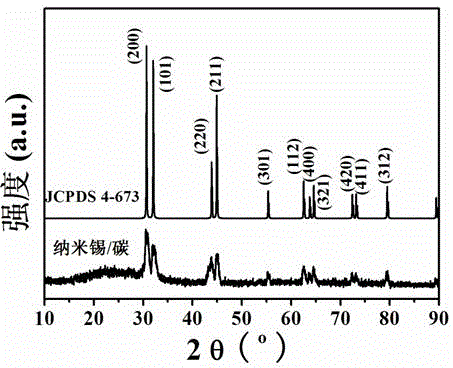

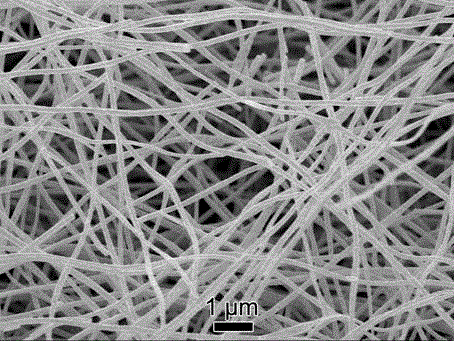

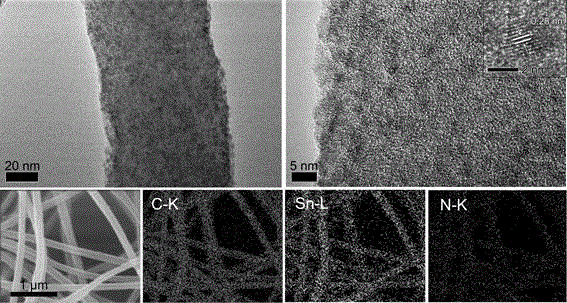

Method for preparing nano tin/carbon composite nanofibers through electrospinning technology

ActiveCN104466140AIncrease contentImprove volume changeCell electrodesCarbon compositesPorous carbon

The invention discloses a method for preparing nano tin / carbon composite nanofibers through the electrospinning technology. The method includes the steps that first, stannous chloride, polymethyl methacrylate and polyacrylonitrile are prepared into composite nanofibers through the electrospinning technology; then calcination is conducted under the nitrogen atmosphere, so that the polyacrylonitrile is carbonized, SnCl2 is decomposed, the polymethyl methacrylate is subjected to pyrolysis, accordingly, a porous structure is formed, and the nano tin / carbon composite nanofibers are obtained. The method has the advantages that the preparation technology is simple, the reaction condition is easy to control, and the repetitive rate is high; obtained Sn particles are only 1-2 nm and are evenly inlaid N-doped porous carbon nanofibers, and the mass percent of the Sn can reach 60-65%. The composite material is of a three-dimensional net structure which is formed by interweaving nanofibers from the microcosmic view, the composite material can be directly used as the negative electrode of a sodium-ion battery without a binding agent, high electrochemistry sodium storage reversible capacity can be achieved, excellent rate capability and cycling stability are achieved, and the application prospect is very bright.

Owner:NANKAI UNIV

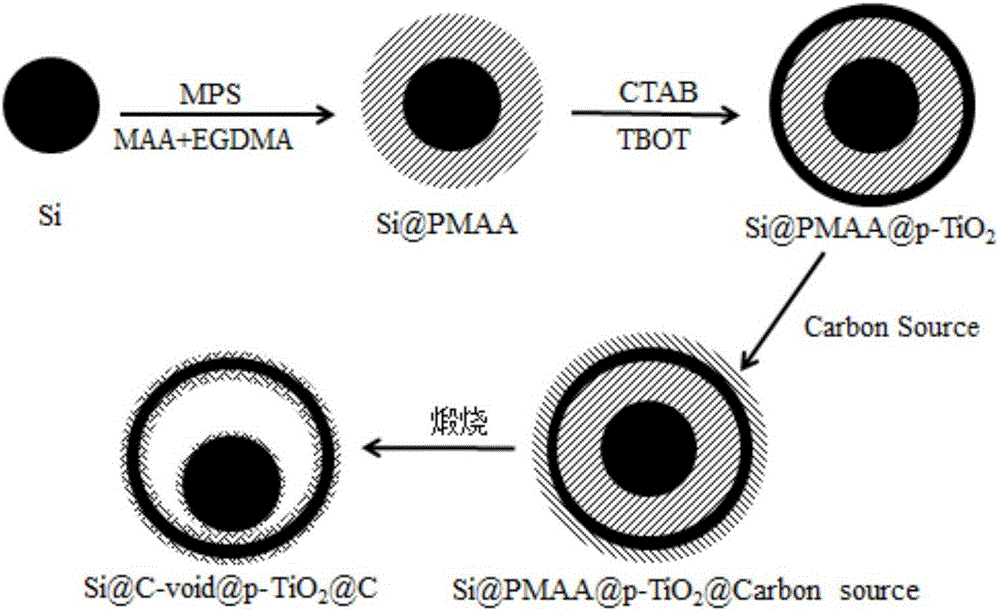

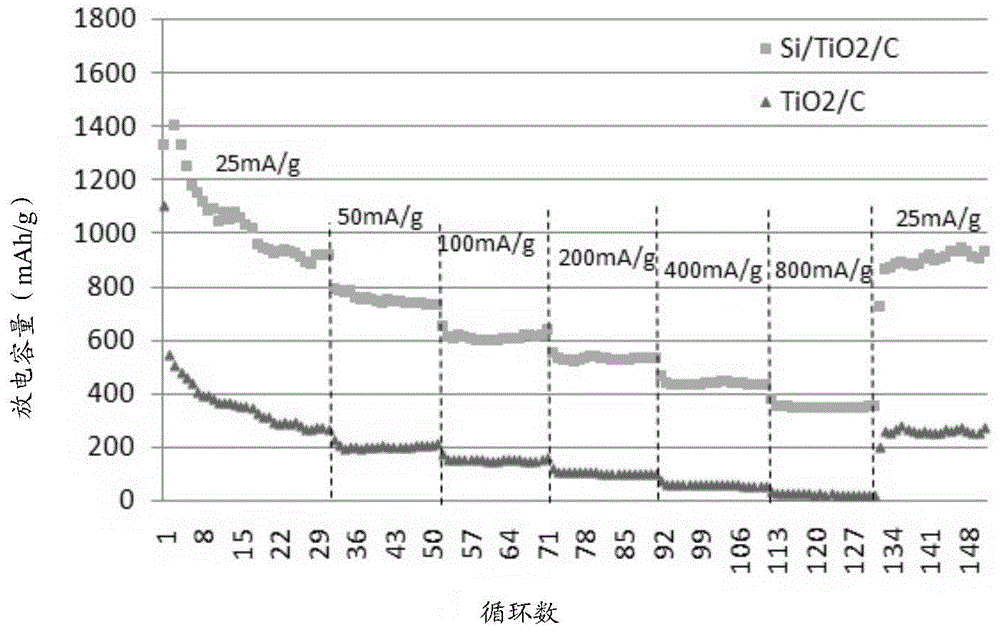

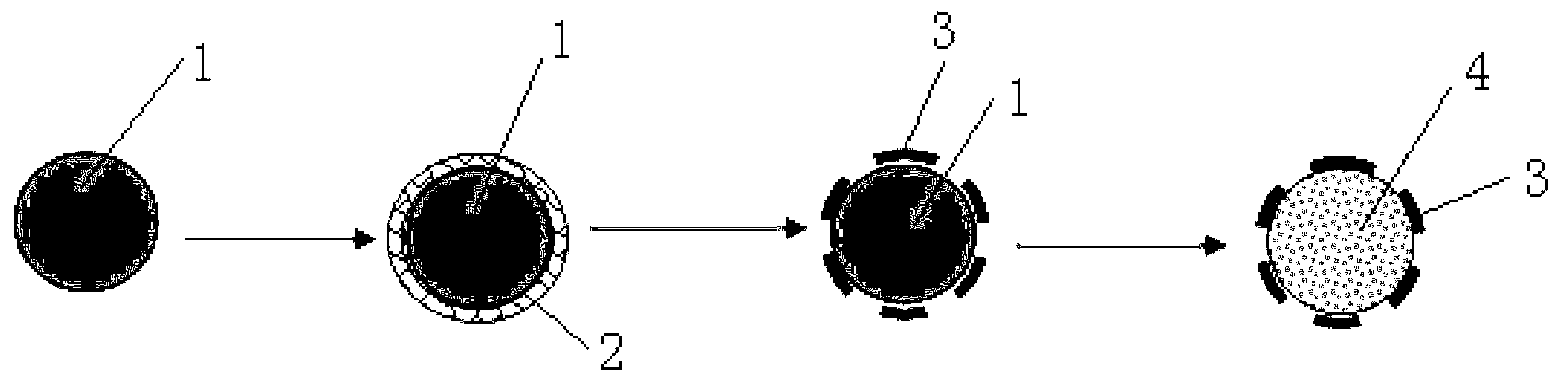

Silicon-based composite cathode material for lithium-ion battery and preparation method thereof

ActiveCN106784714AImprove efficiencyImprove cycle stabilityCell electrodesSecondary cellsCarbonizationLithium electrode

The invention discloses a silicon-based composite cathode material for a lithium-ion battery and a preparation method thereof. The silicon-based composite cathode material for the lithium-ion battery adopts a yolk-shell structure with nanometer silicon as the inner core and with porous titanium dioxide (p-TiO2(at)C), which is coated by pyrolytic carbon inside and outside, as the shell layer. The composite material Si(at)C-void(at)p-TiO2(at)C with the yolk-shell structure is prepared by using a precipitation-codistillation method to coat an organic layer on the surface of the nanometer silicon, using a soft template method to coat a mesoporous TiO2 inorganic layer on the surface of the organic layer in a hydrolyzed manner, coating an organic carbon source on the surface of the mesoporous TiO2 shell layer and carrying out high-temperature carbonization on the organic carbon source under the inert atmosphere. The prepared silicon-based composite cathode material for the lithium-ion battery has the advantages that the high capacity of the silicon material and the high stability of TiO2 are sufficiently utilized, the volume expansion of the nanometer silicon is effectively inhibited through a cavity core-shell structure, a conductive network is constructed within the material by using the pyrolytic carbon, and the first-week coulombic efficiency and cycling stability of the material are enhanced through the synergistic effect of the components; therefore, the silicon-based composite cathode material for the lithium-ion battery is an ideal lithium-ion battery cathode material.

Owner:SHAANXI COAL & CHEM TECH INST

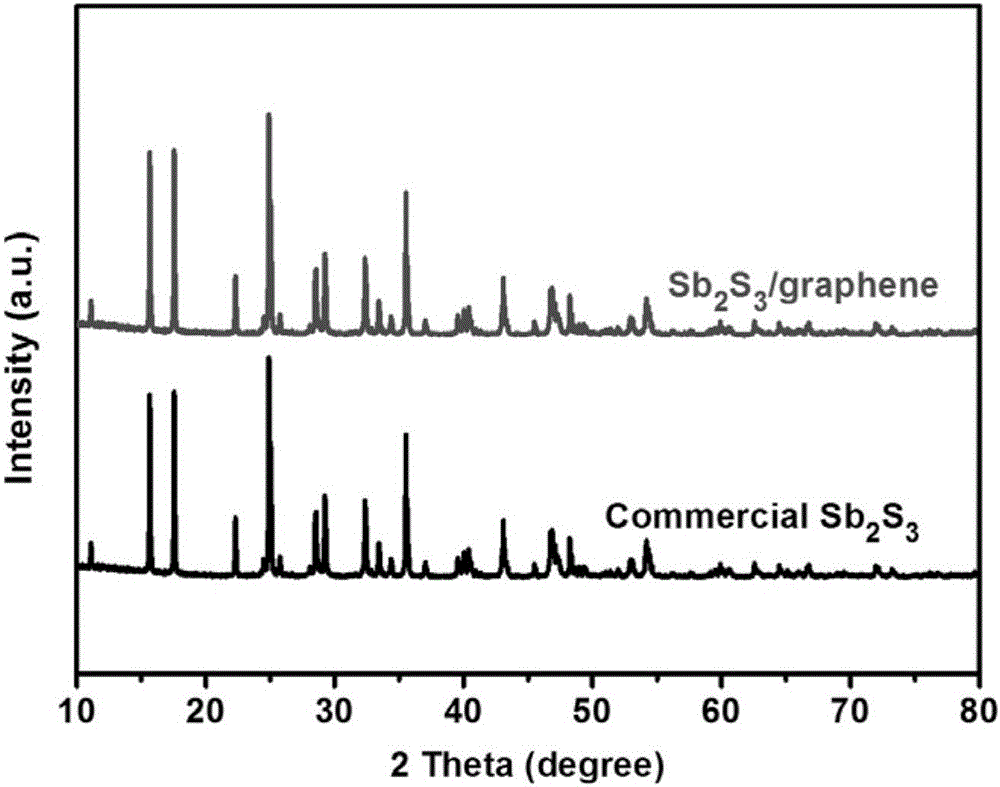

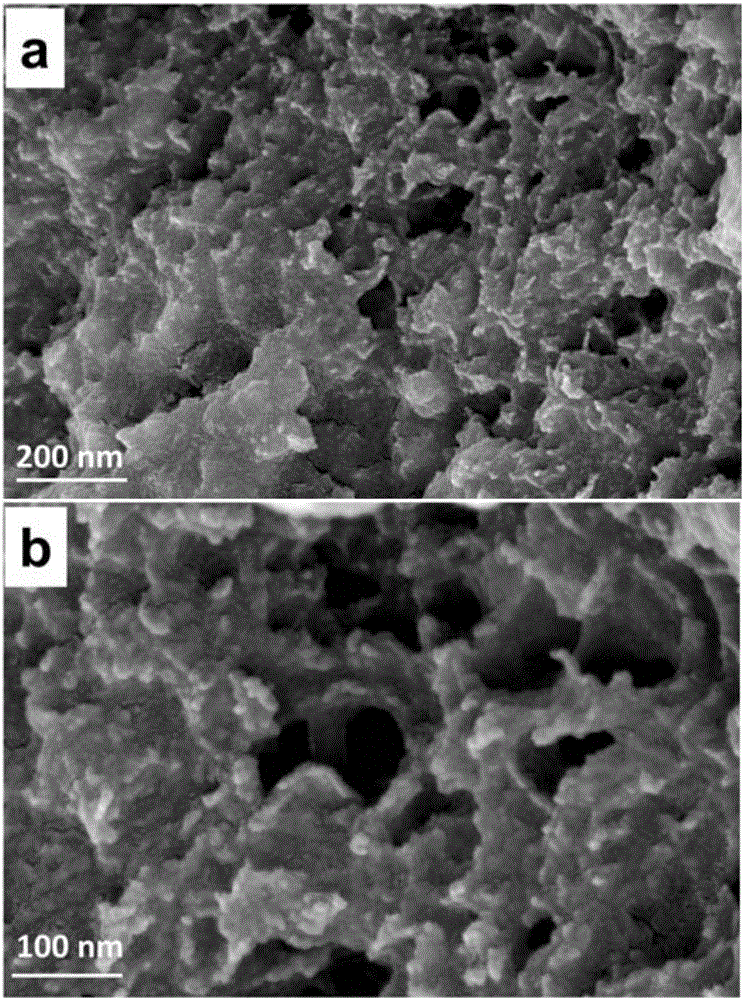

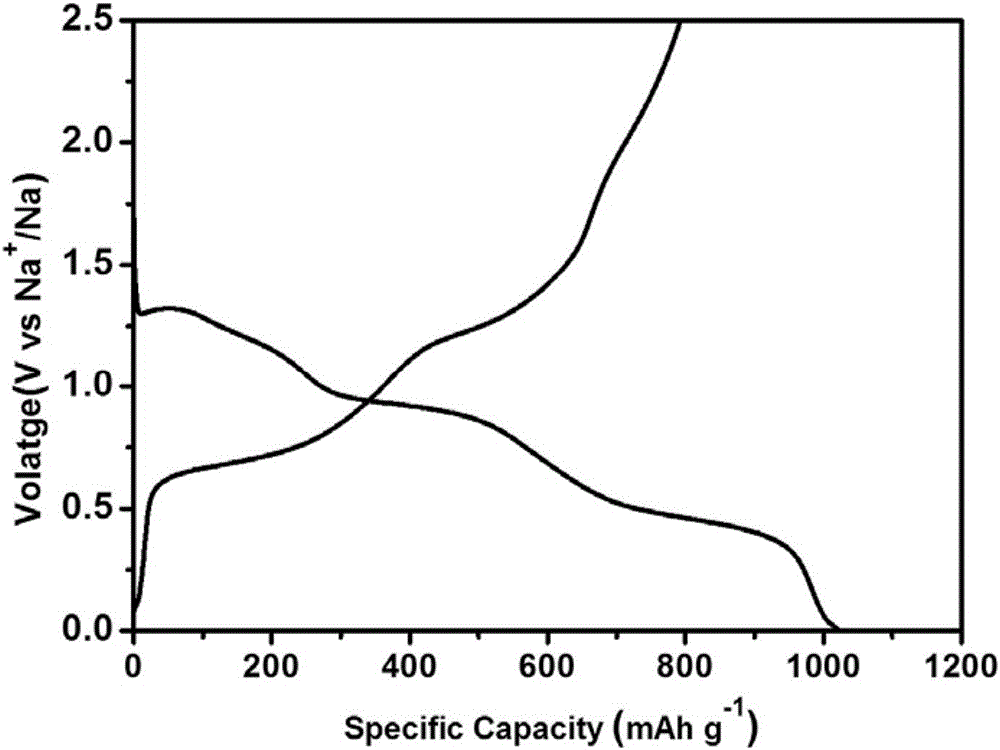

Antimony sulfide based composite material of sodium-ion battery and preparation method of antimony sulfide based composite material

ActiveCN105720251AShape is easy to controlEasy to prepareCell electrodesSecondary cellsElectrical batteryOxide composite

The invention discloses an antimony sulfide based composite material of a sodium-ion battery and a preparation method of the antimony sulfide based composite material. The preparation method comprises the following steps of dissolving antimony sulfide in a medium, adding a graphene oxide solution, enabling the graphene oxide solution to be fully and uniformly dispersed with ultrasound for 1-600 minutes, mixing the graphene oxide solution, sulfite and an acid solution, stirring the mixed solution for 5-600 minutes, carrying out solid-liquid separation and drying to obtain a precursor of an amorphous antimony sulfide and graphene oxide composite material, and roasting the precursor for 1-24 hours at 250-550 DEG C under an inertia or reduction atmosphere to obtain the antimony sulfide based composite material of the sodium-ion battery. The composite material prepared according to the method can be used for a negative electrode material of the sodium ion battery, the specific capacity reaches 680mAh g<-1> when the current density is 2Ag<-1>, and the specific capacity retention rate is over 96% after circulation of 100 times. Compared with a traditional hydrothermal method, the preparation method has the advantages of short flow, simplicity in process, relatively low energy consumption, low production cost and the like, and is easy for mass production.

Owner:SOUTH CHINA UNIV OF TECH

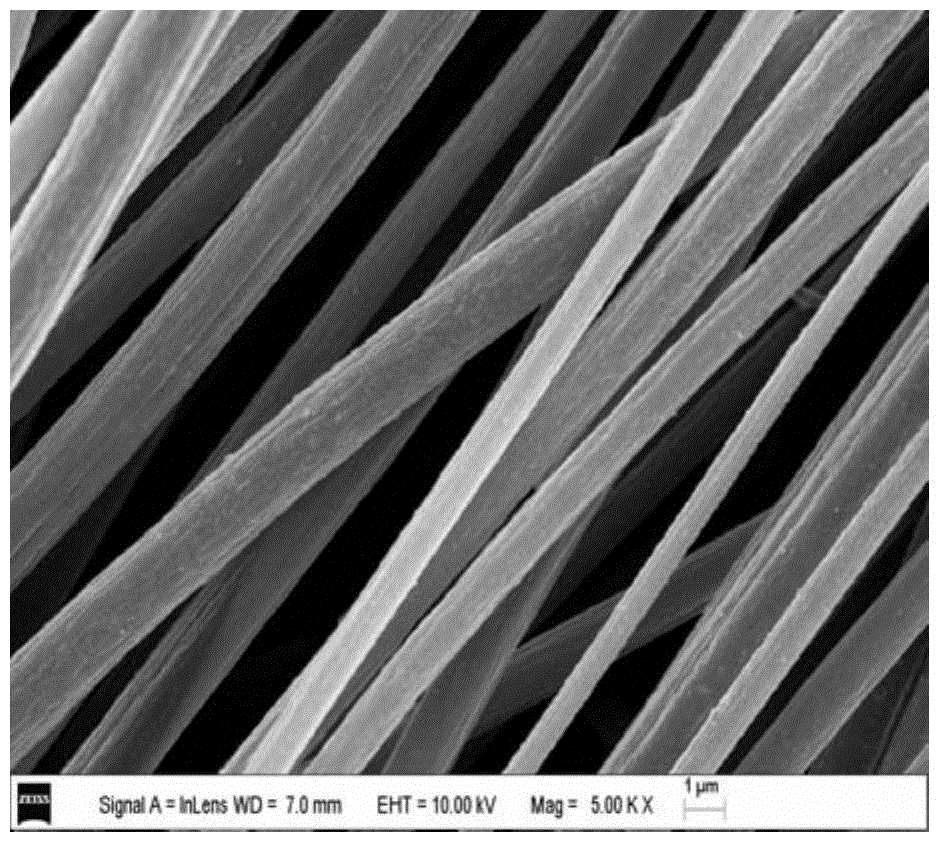

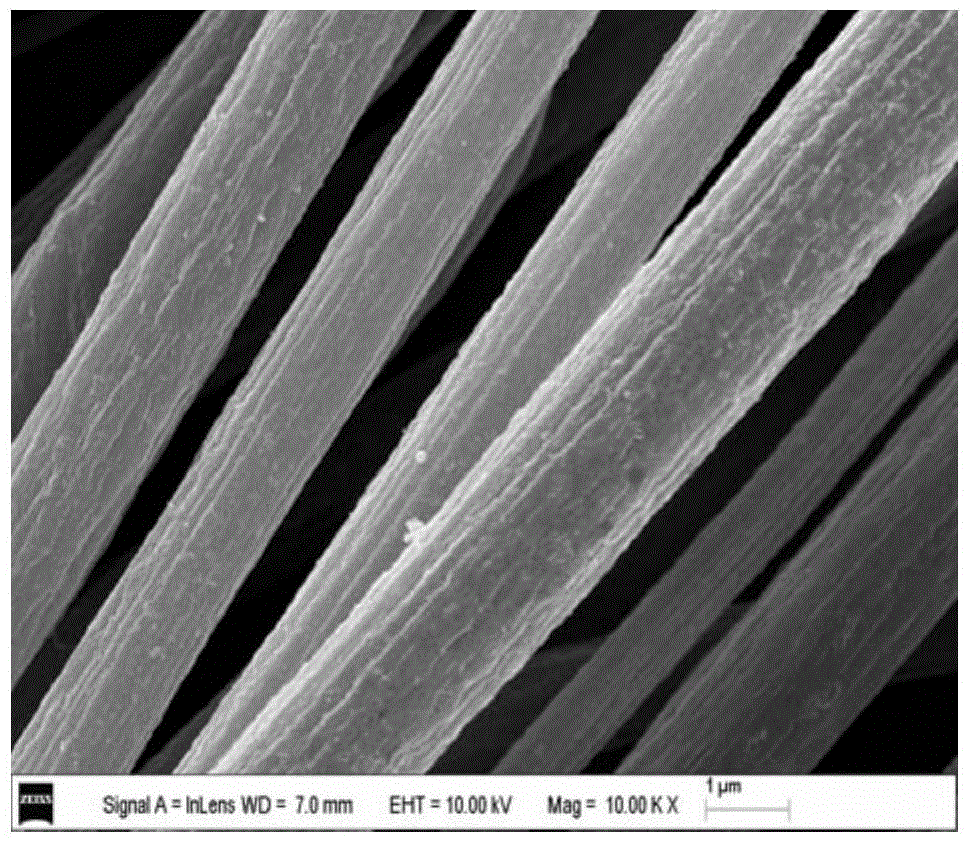

Si-TiO2-C nano fiber composite thin film, preparation method and application thereof

ActiveCN104835949AImprove the preparation of Si-TiO

<sub>2</sub>

Efficiency of -C nanofiber composite filmsImprove efficiencyMaterial nanotechnologyCell electrodesFiberNano silicon

The invention provides a Si-TiO2-C nano fiber composite thin film, a preparation method and an application thereof. The preparation method for preparing the Si-TiO2-C nano fiber composite thin film includes following steps: (1) providing a spinning liquid which contains nano silicon powder, a titanium precursor and a carbon precursor; (2) performing electrostatic spinning to the spinning liquid to prepare a nano fiber film; (3) pre-oxidizing the nano fiber film under an oxygen-containing atmosphere at 100-300 DEG C to obtain a stabilized nano fiber film; and (4) carbonizing the stabilized nano fiber film under an non-oxidizing atmosphere at 500-1000 DEG C to obtain the Si-TiO2-C nano fiber composite thin film. By means of the method, the Si-TiO2-C nano fiber composite thin film can be prepared quickly and effectively. The preparation method is simple in operations, is convenient and quick, and can easily achieve large-scale production.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Silicon carbon composite material, preparation method thereof as well as lithium ion battery

ActiveCN103236525AProlong the cycle life of lithium deintercalationLarge specific surface areaCell electrodesSecondary cellsCarbon compositesPorous carbon

The invention discloses a silicon carbon composite material, a preparation method thereof as well as a lithium ion battery. The silicon carbon composite material is structurally formed by coating a porous carbon layer on amorphous porous silicon; the hole wall of the amorphous porous silicon is in an amorphous state; and the specific surface area of the silicon carbon composite material is 10 to 200m<2> / g. When the silicon carbon composite material is applicable to the lithium ion battery, in a lithium intercalating process, the amorphous porous silicon isotropically expands, and the problems of pulverization and dropping off of amorphous porous silicon particles from an electrode caused by volumetric change can be solved. The hole wall of the amorphous porous silicon is at the amorphous state, so that a porous structure can be prevented from collapsing, the volumetric change in the lithium intercalating process can be reduced, and the lithium de-intercalating cycle life of the amorphous porous silicon is effectively prolonged. The specific surface area of the amorphous porous silicon of the silicon carbon composite material is large, a contact surface between the silicon carbon composite material which serves as the anode material and an electrolyte solution is increased, and lithium ions can be quickly exchanged on the contact surface.

Owner:CHERY AUTOMOBILE CO LTD

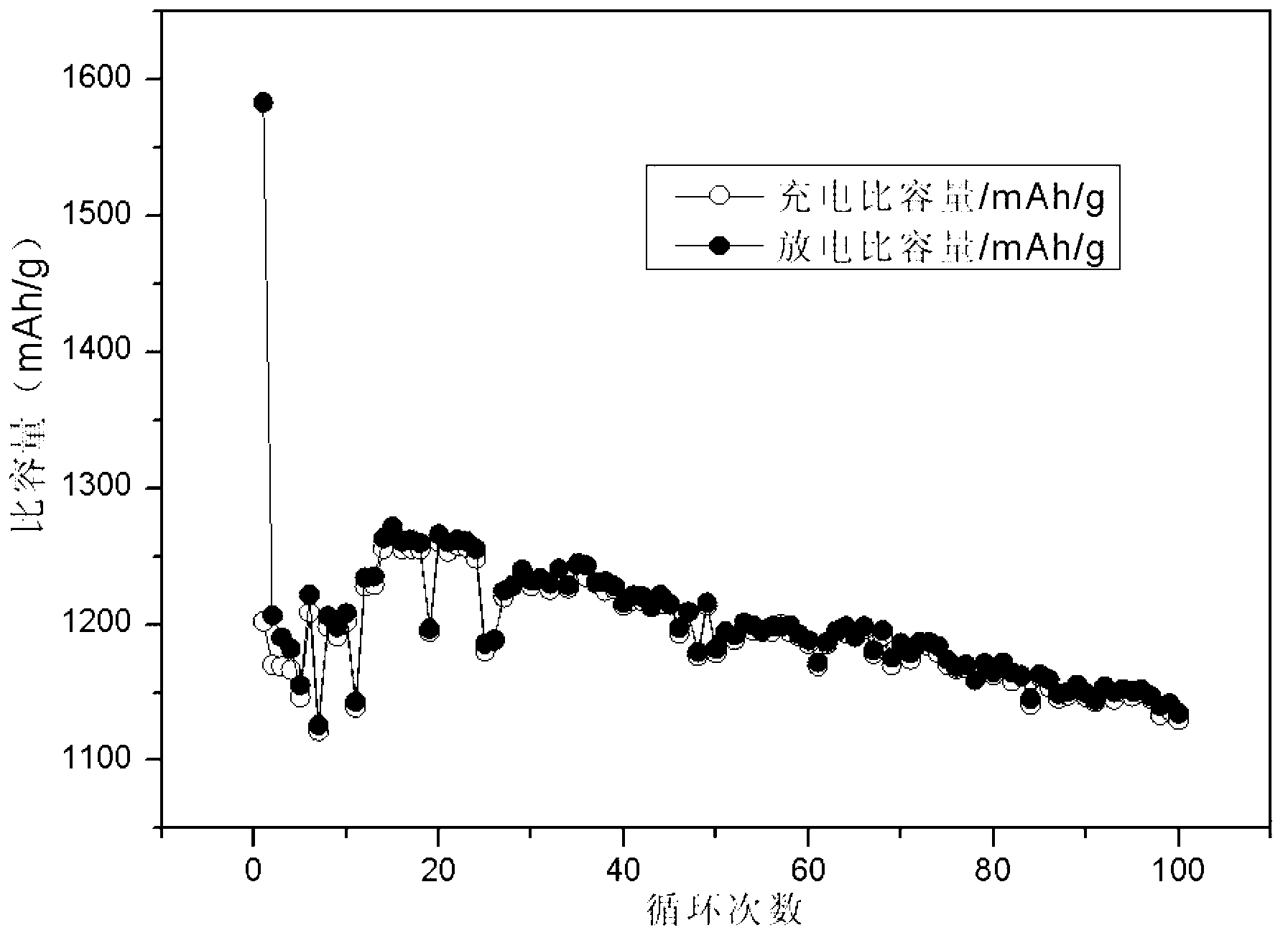

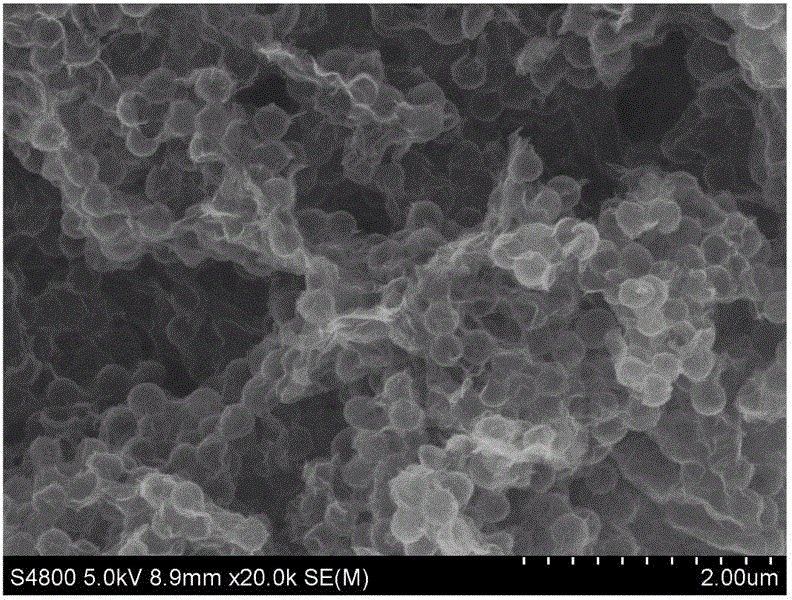

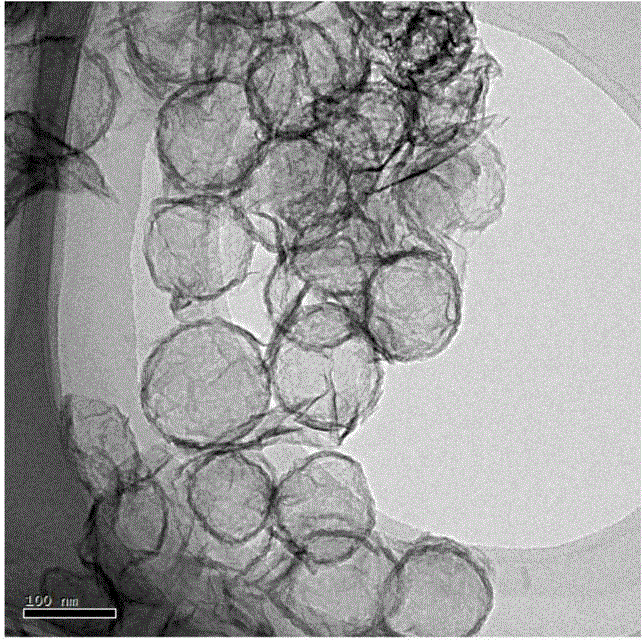

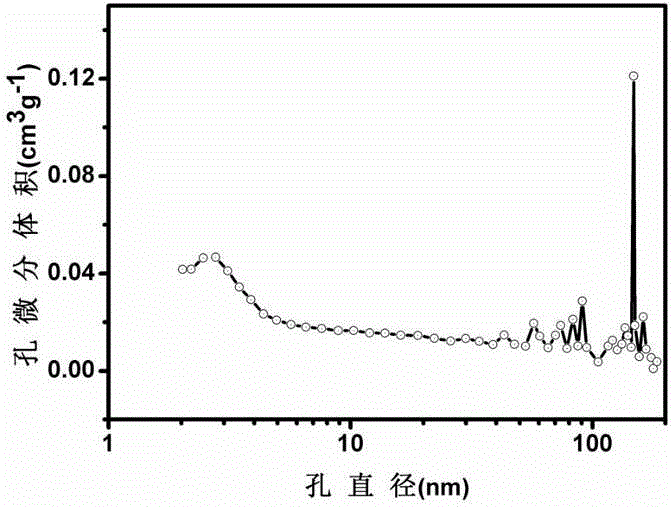

Three dimensional graphene/hollow carbon sphere/sulfur composite material, preparation method thereof, and application in lithium-sulfur batteries

ActiveCN104916828AHigh specific capacityImprove cycle performanceMaterial nanotechnologyCell electrodesLithium–sulfur batteryLithium sulfur

The invention discloses a three dimensional graphene / hollow carbon sphere / sulfur composite material, a preparation method thereof, and an application in lithium-sulfur batteries. The three dimensional graphene / hollow carbon sphere / sulfur composite material comprises nanometer elemental sulfur and a three dimensional graphene-hollow carbon sphere nano-compound, and the nanometer elemental sulfur is distributed in the three dimensional graphene-hollow carbon sphere nano-compound. The preparation method comprises the following steps: dispersing the three dimensional graphene-hollow carbon sphere nano-compound in an alcohol and water mixed solvent to obtain a suspension; and adding an aqueous solution of Na2S.9H2O and Na2SO3 into the suspension, adding an acidic solution, and reacting to obtain the three dimensional graphene / hollow carbon sphere / sulfur composite material. The composite material has the advantages of high specific capacity, stable cycle performances, and excellent rate performance and coulombic efficiency, the preparation method has the advantages of simplicity, convenience and good effect, and the composite material can be applied in the preparation of lithium-sulfur battery positive electrode materials.

Owner:NAT UNIV OF DEFENSE TECH

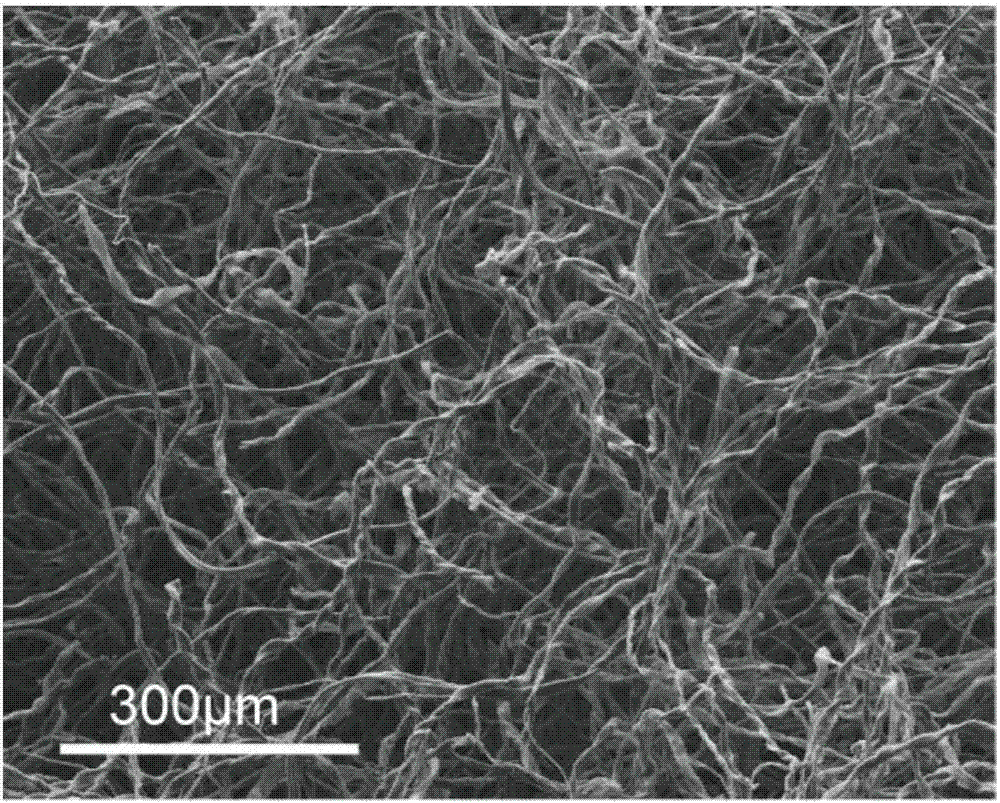

Three-dimensional porous copper/graphene composite current collector for secondary metal lithium battery negative pole

InactiveCN107785586AImprove utilization efficiencyAlleviate volume changesElectrode carriers/collectorsSecondary cellsHydrogenMetal foil

The invention relates to a preparation method of a three-dimensional porous copper / graphene composite current collector for a secondary metal lithium battery negative pole. The preparation method includes: putting a nano porous metal foil into a quartz boat, and calcining for 0.5-5min at temperature of 800-1000 DEG C in an atmosphere of argon and hydrogen; feeding ammonia gas, acetylene, argon andhydrogen, and allowing reaction in the condition for 2-10min to obtain the three-dimensional porous copper / graphene composite current collector. The invention further provides a method of utilizing the current collector to prepare the metal lithium negative pole.

Owner:TIANJIN UNIV

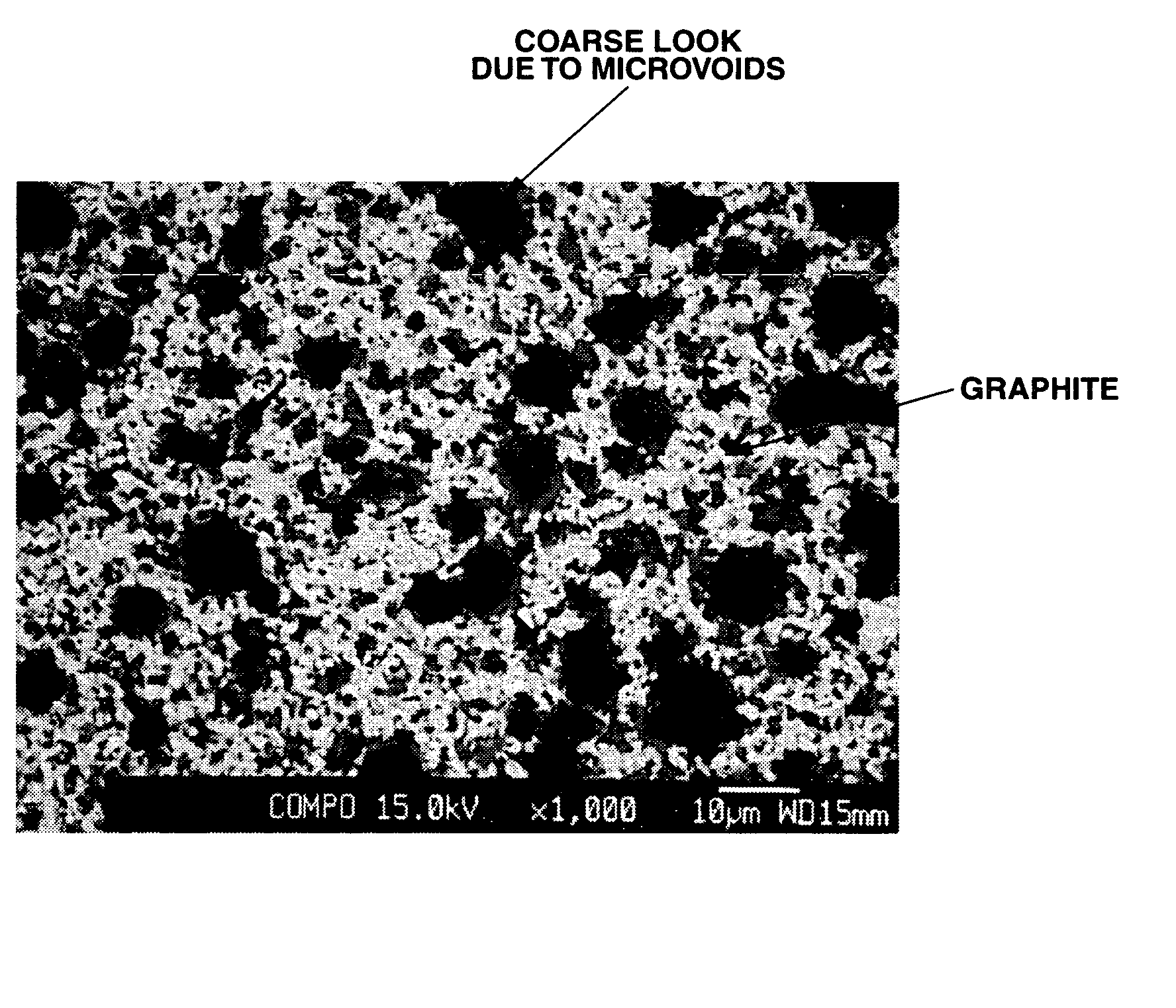

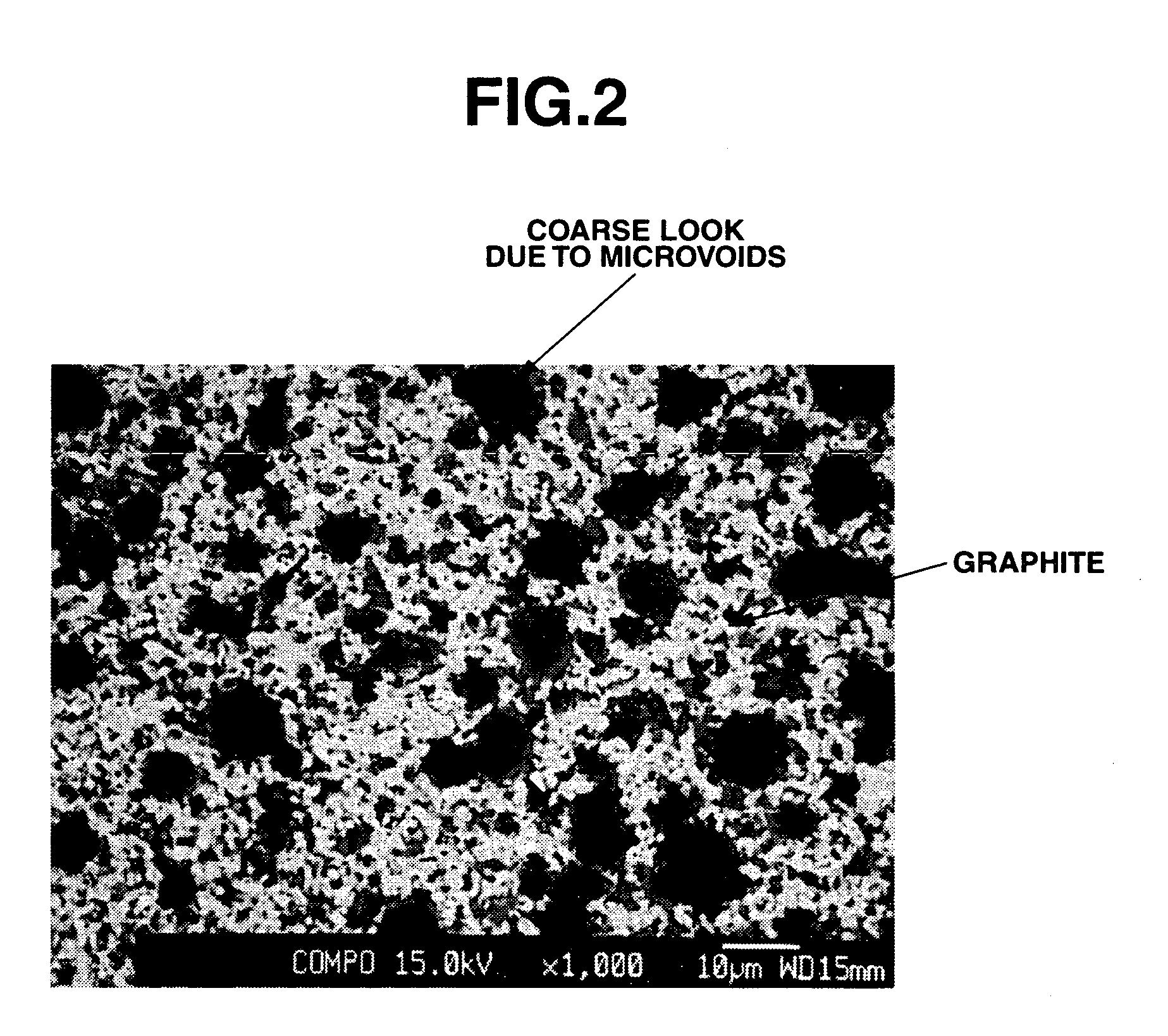

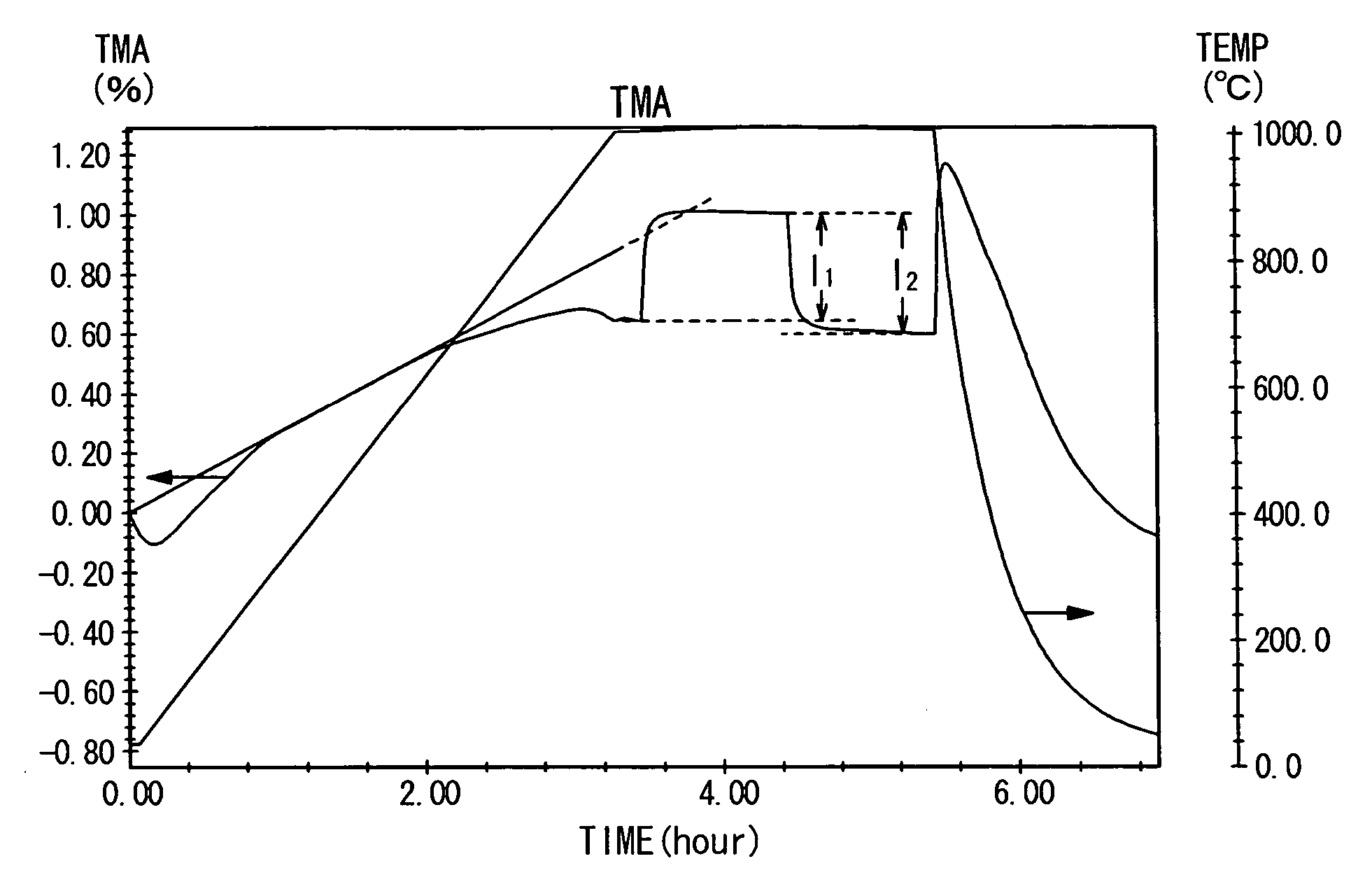

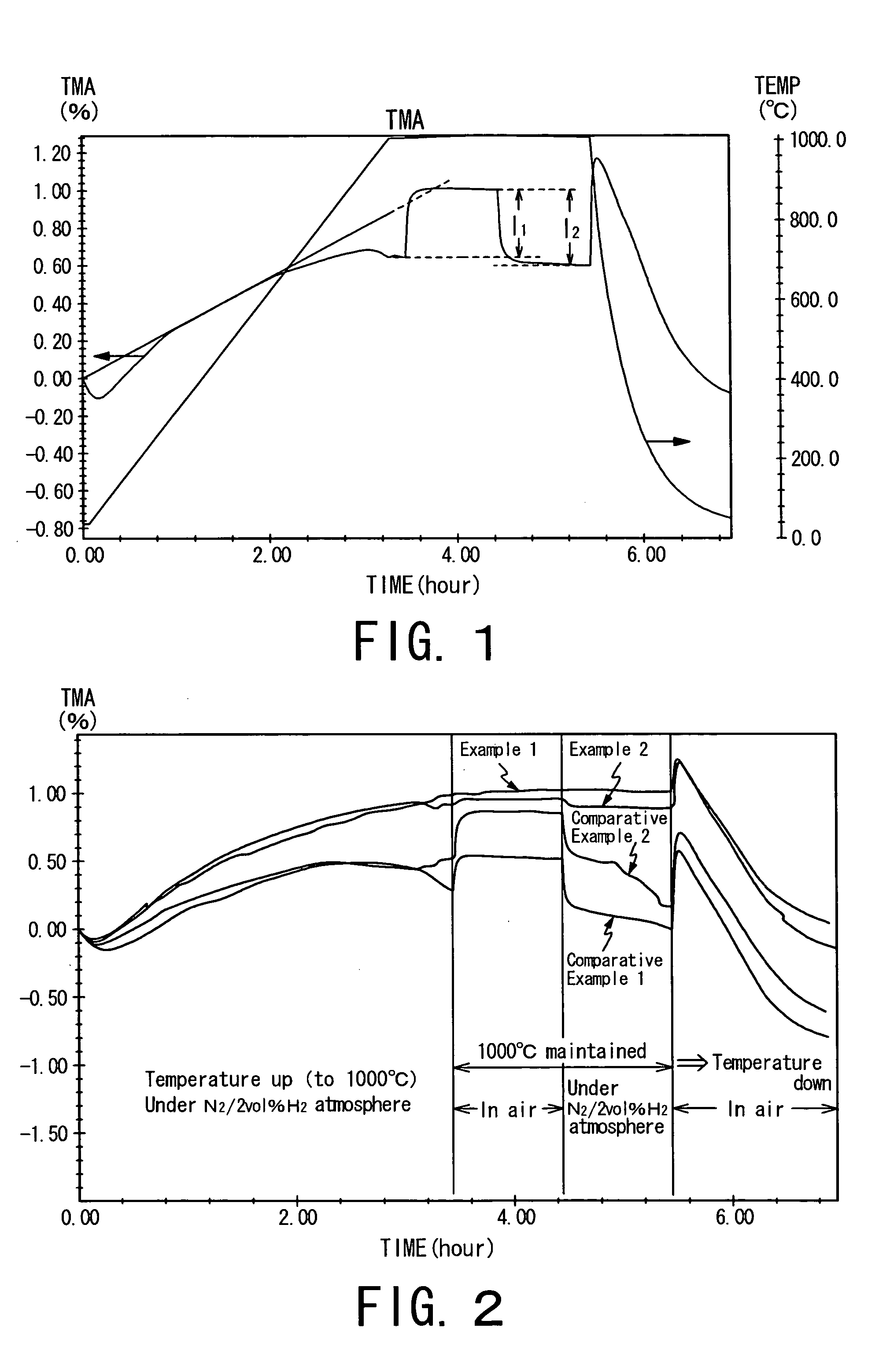

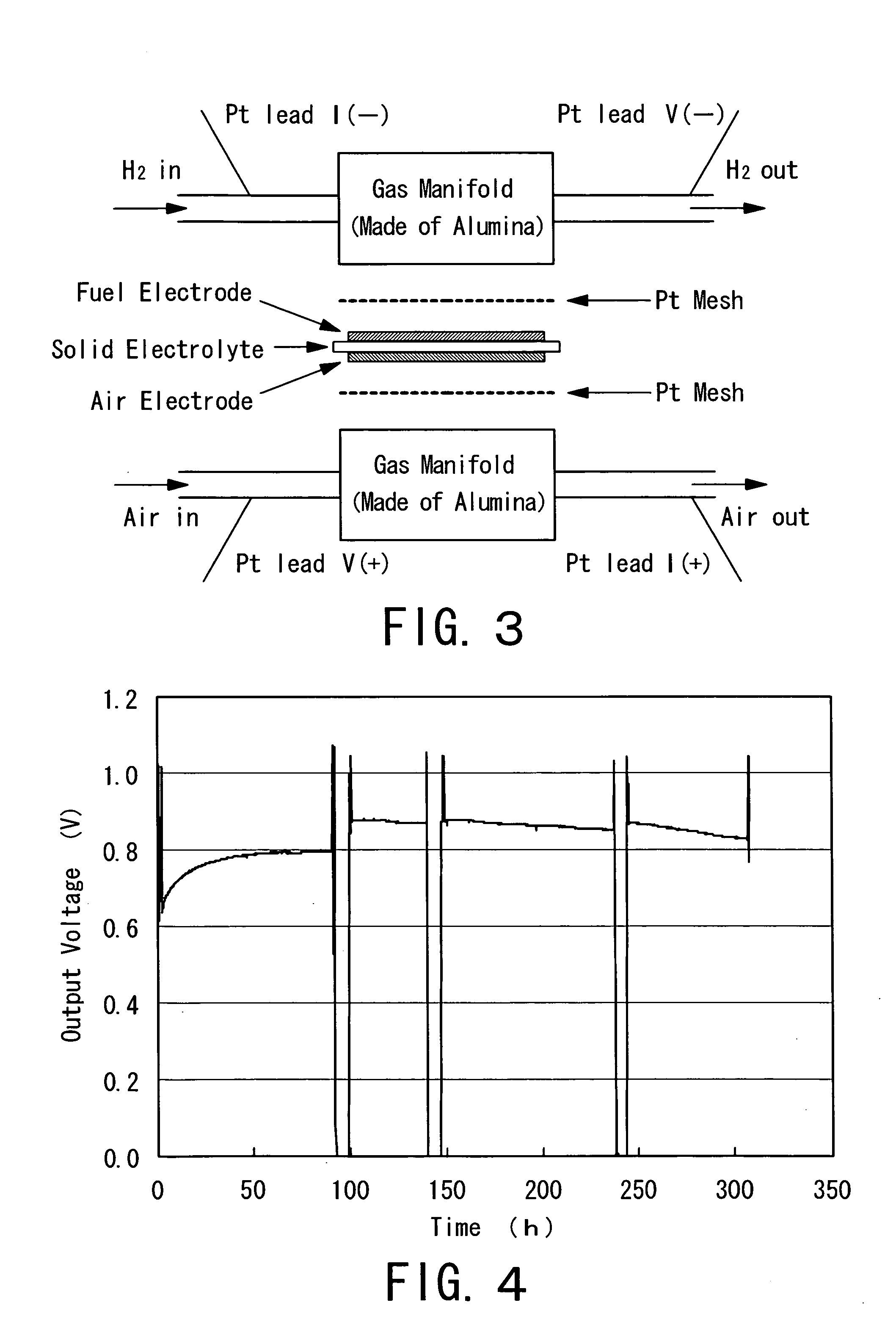

Fuel electrode material, a fuel electrode, and a solid oxide fuel cell

InactiveUS20060110633A1Stably maintaining power generationAlleviate volume changesFinal product manufactureActive material electrodesFuel cellsEngineering

A material for a fuel electrode of a solid oxide fuel cell with which volume change of the fuel electrode can be reduced as compared to the conventional one even if the fuel electrode is exposed to an oxidation-reduction cycle, a fuel electrode for a solid oxide fuel cell prepared by sintering the fuel electrode material, and a solid oxide fuel cell capable of stably maintaining power generation even if a fuel electrode thereof is exposed to an oxidation-reduction cycle. The fuel electrode material includes a material powder containing at least one of nickel and nickel oxide, wherein the material powder further contains at least one of titanium oxide (IV) and a titanium source capable of changing into titanium oxide (IV) by heat treatment in air. The fuel electrode material is sintered to prepare the fuel electrode, which is provided for the solid oxide fuel cell.

Owner:TOHO GAS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com