Antimony sulfide based composite material of sodium-ion battery and preparation method of antimony sulfide based composite material

A technology for sodium ion batteries and composite materials, which is applied in the field of antimony sulfide-based composite materials for sodium ion batteries and its preparation. It can solve the complex preparation process, high price of precursor materials, and limitations on the large-scale application of antimony sulfide/graphene composite materials, etc. problems, to achieve the effect of simple preparation method, superior cycle performance and superior rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

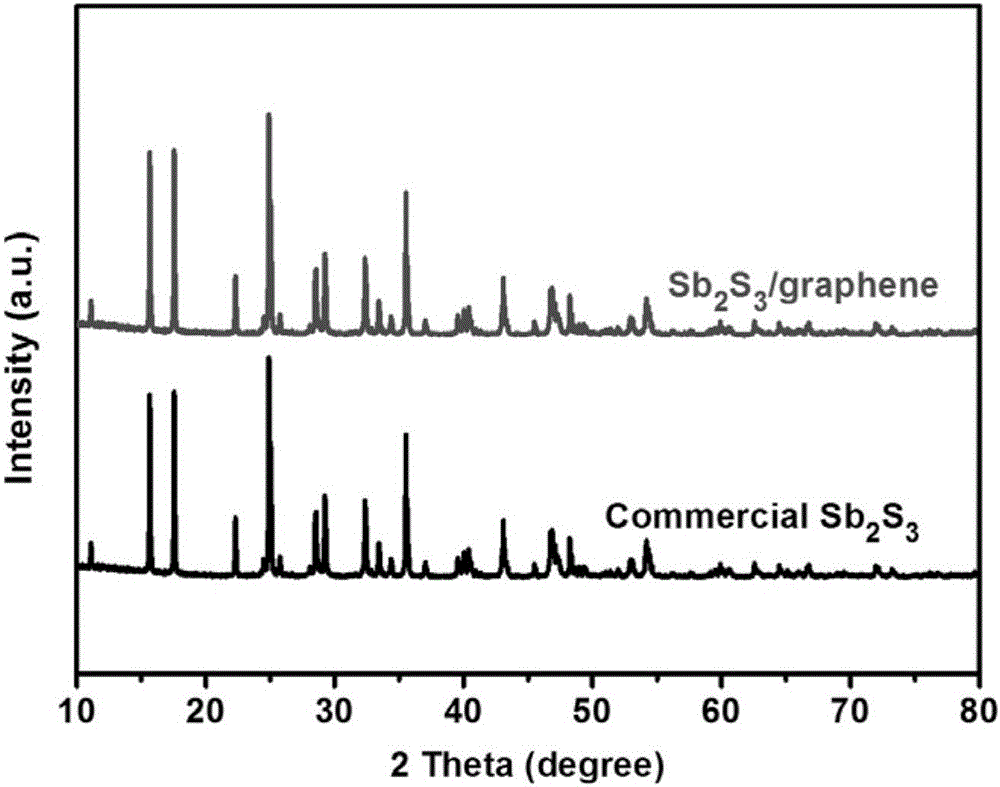

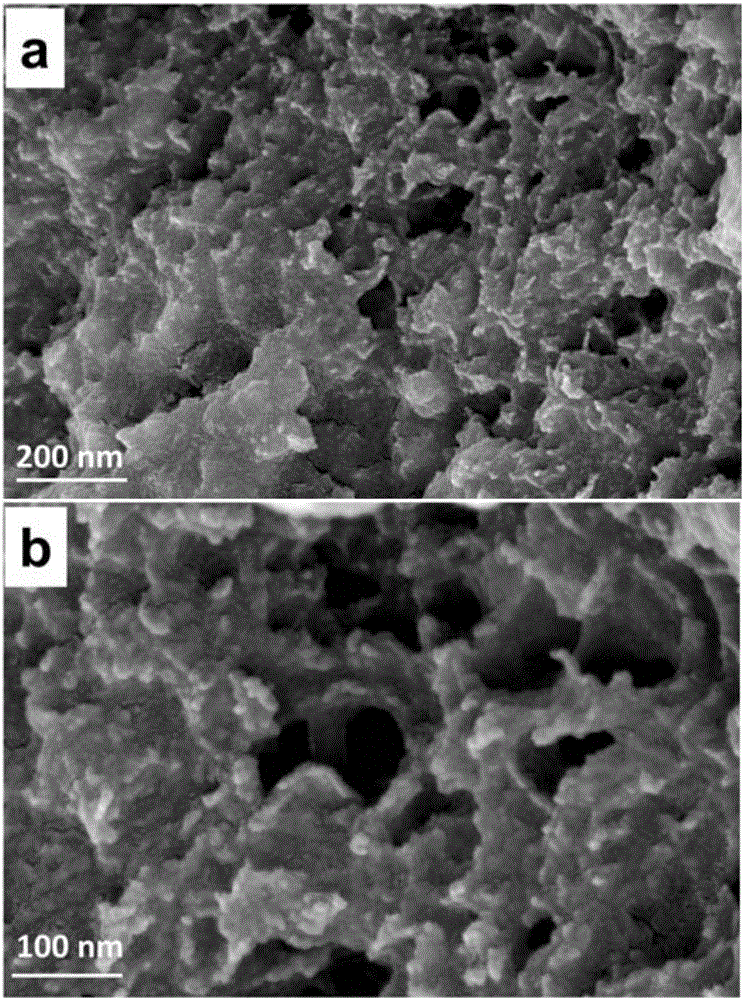

[0037] 0.1 mmol commercial Sb 2 S 3 Stir to dissolve in 1000ml with a concentration of 0.1molL-1 In the sodium sulfide solution (the molar ratio of antimony sulfide to sodium sulfide is 0.001:1), add 0.1mgml to the above solution -1 Graphene oxide solution, the mass ratio of graphene oxide and antimony sulfide in the graphene oxide solution is 0.001:1, and ultrasonic treatment for 1 minute. Add the sonicated solution to 50 mmol of sodium sulfite and a concentration of 5 mol L -1 mixed solution of sulfuric acid (the molar ratio of sodium sulfite to sodium sulfide is 0.5:1, and the molar ratio of sulfuric acid to sodium sulfide is 0.5:1), stirred for 5 minutes, centrifuged, and freeze-dried the precipitate to obtain a precursor. The precursor was placed in a nitrogen atmosphere at 250 o C was sintered for 24 hours to obtain Sb 2 S 3 / graphene material. Sb 2 S 3 For the physical and chemical properties of graphene materials, see figure 1 with figure 2 . XRD shows tha...

Embodiment 2

[0039] 30 mmol of commercialized Sb 2 S 3 Stir to dissolve in 2ml with a concentration of 5molL -1 Potassium sulfide solution (the molar ratio of antimony sulfide to potassium sulfide is 3:1), add 30mgml to the above solution -1 Graphene oxide solution, the mass ratio of graphene oxide and antimony sulfide in the graphene oxide solution is 0.5:1, and ultrasonic treatment for 600 minutes. Add the sonicated solution to 50 mmol of ammonium sulfite and potassium sulfite mixture (the molar ratio of ammonium sulfite to potassium sulfite is 1:1) and 0.01 molL -1 In the mixed solution of nitric acid and acetic acid (the molar ratio of nitric acid and acetic acid is 1:3) (the molar ratio of sulfite to potassium sulfide is 5:1, and the molar ratio of acid to potassium sulfide is 3:1), stirring for 10 hours, Precursor obtained by vacuum filtration and blast drying of filter residue. The precursor was placed in an argon atmosphere at 550 o C was sintered for 1 hour to obtain Sb 2 S ...

Embodiment 3

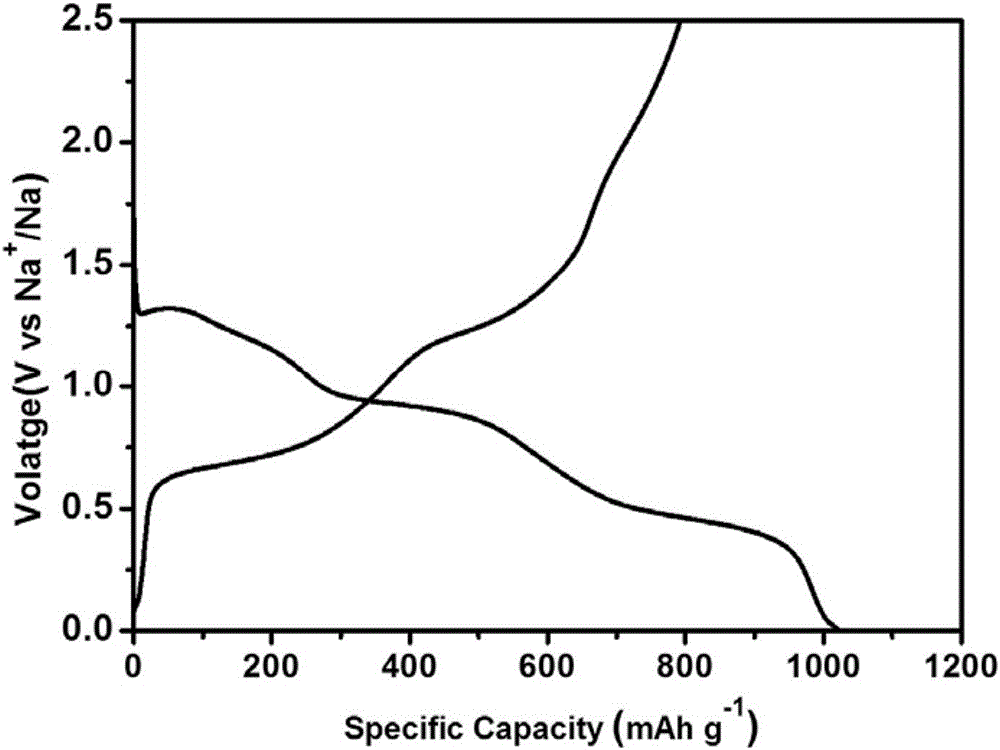

[0041] 30 mmol of commercialized Sb 2 S 3 Stir to dissolve in 8ml with a concentration of 2.5molL -1 In the mixed solution of ammonium sulfide and sodium sulfide (the molar ratio of ammonium sulfide and sodium sulfide is 1:3) (the molar ratio of antimony sulfide and sulfide salt is 1.5:1), add 15mgml to the above solution -1 The graphene oxide solution, the mass ratio of graphene oxide and antimony sulfide in the graphene oxide solution is 0.25:1, and ultrasonic treatment for 300 minutes. Pour the mixture of 55mmol ammonium bisulfite and 35mmol nitric acid (the molar ratio of sulfite to sulfide is 2.75:1, and the molar ratio of acid to sulfide is 1.75:1) into the above solution and stir for 8 hours , centrifuge and vacuum dry the precipitate to obtain the precursor. The precursor at 3%vol.H 2 / N 2 Atmosphere 300 o C was sintered for 5 hours to obtain Sb 2 S 3 / graphene material. The resulting product was assembled into a button battery to measure its charge and discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com