Patents

Literature

83 results about "Ammonium bisulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium bisulfite is colorless crystals which are soluble in water.It is noncombustible. It is corrosive to aluminum.It is a strong irritant to skin and mucous membranes.

Preparation method of polymer for polyacrylonitrile base carbon fiber precursors

ActiveCN101161694ANarrow molecular weightMolecular orderFibre chemical featuresCarbon fibersPolymer science

A method for preparing polymer for PAN precursor, by copolymerizing the water phase suspend using ammonium persulphate-ammonium sulfite or ammonium bisulfite as a primosome, is disclosed. The polyacrylonitrile powder material is obtained by adding the first monomer acrylonitrile, the second monomer crylic acid, methyl acrylate or acrylamide, and the third itaconic acid, or the first monomer crylic acid, the second monomer methyl acrylate or itaconic acid, and inorganic oxidation-reduction primosome without any metallic ion which comprises ammonium persulphate, ammonium sulfite or ammonium bisulfite and acidified deionized water into the polymerization kettle in defined proportions, controlling the temperature and stirring to react for a time, and discharging by removing the residual monomer, washing and drying. The average molecular weight is from 17.5 myriads to 26.1 myriads, and the distribution index of molecular weight is from 2.70 to 2.91; the intension of polyacrylonitrile precursor tested by spinning sample is from 4.58 to 6.61 CN / dtex; and the carbon fiber strength is 3.61-5.06MPa.

Owner:吉林碳谷碳纤维股份有限公司

Methylsulfonic acid preparing process

InactiveCN1810780ANo pollution in the processRaw materials are easy to getSulfonic acid preparationSulfate radicalsWater insoluble

The environment friendly methyl sulfonic acid preparing process includes the following steps: the reaction of the water solution or solid of ammonium sulfite or mixture of ammonium sulfite and ammonium bisulfite with dimethyl sulfate at high temperature to produce ammonium methyl sulfonate; treating the reacted solution containing ammonium methyl sulfonate and ammonium sulfate with calcium hydroxide or other compound capable of producing precipitate with sulfate radical ion to produce water soluble calcium methyl sulfonate, water insoluble calcium sulfate and ammonium hydroxide; treating obtained calcium methyl sulfonate with strong acid capable of forming precipitate with calcium ion; and final decompression distilling to obtain methyl sulfonic acid. The present invention has facile material, simple technological process, high product quality, low cost and no environmental pollution, and is suitable for industrial production.

Owner:HEBEI YANUO CHEM IND

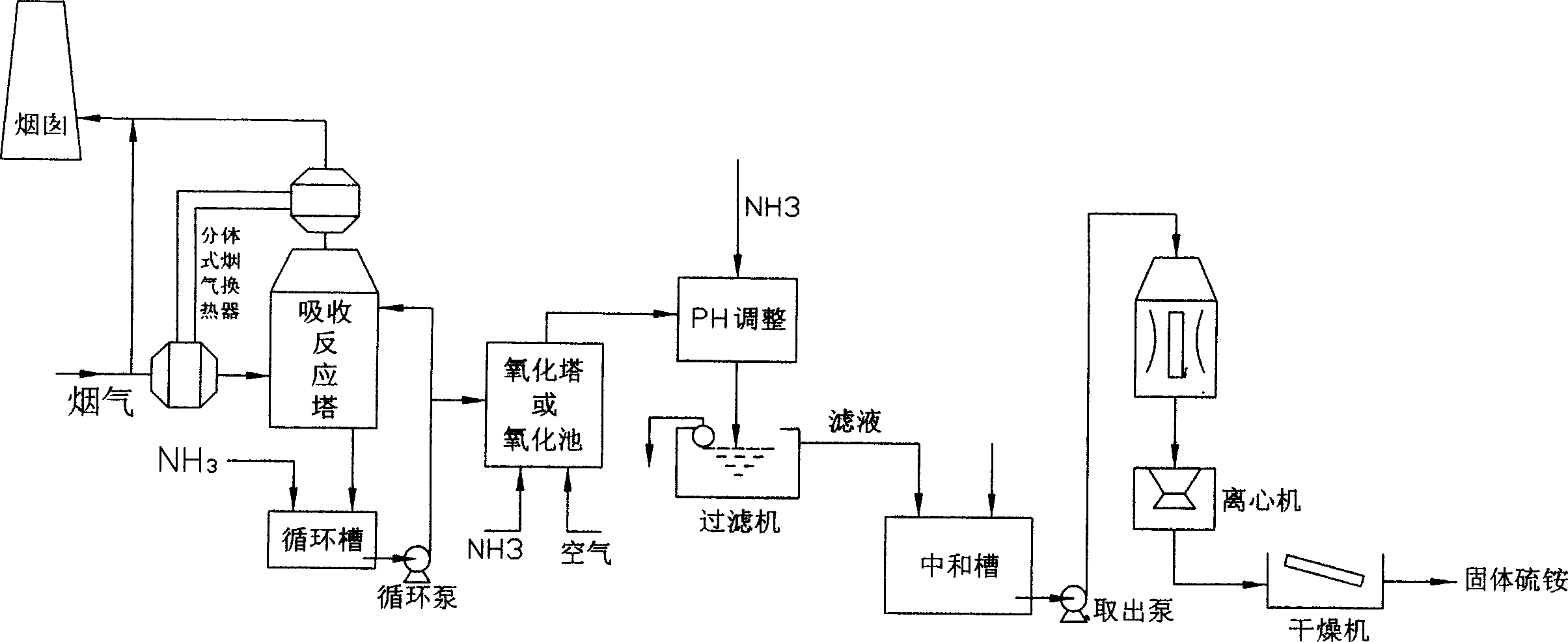

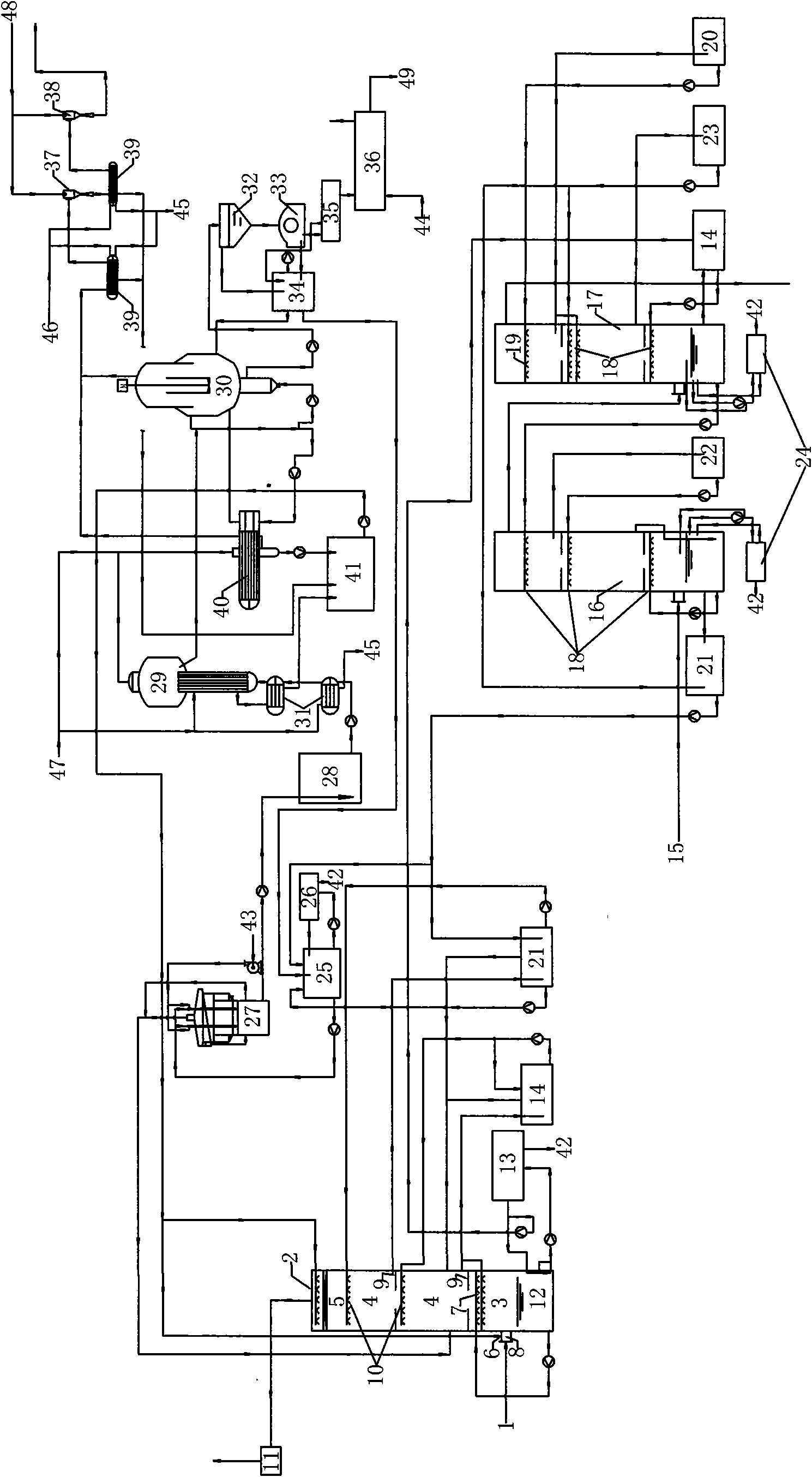

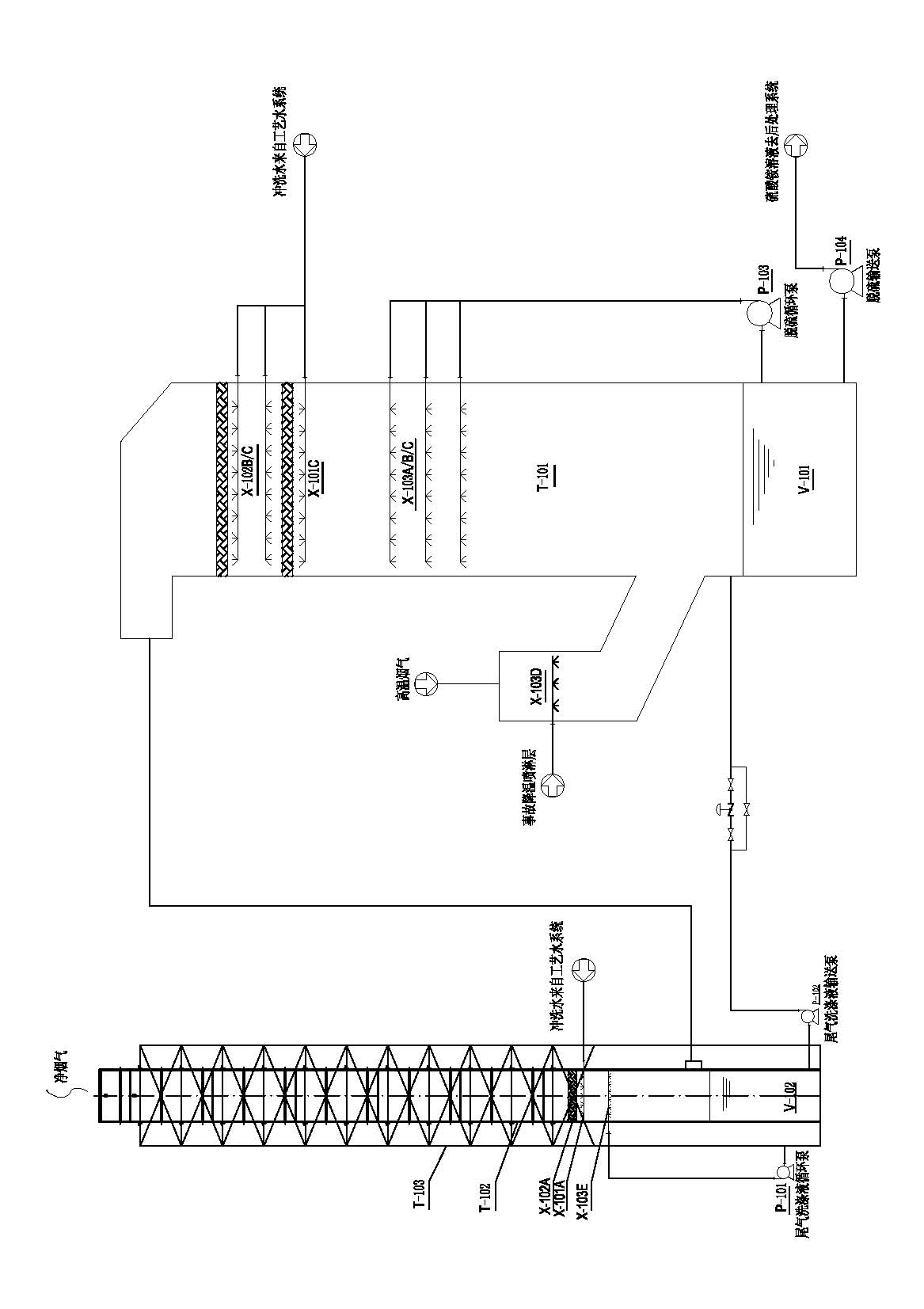

Smoke desulfurization and denitrification integration method and special device thereof

InactiveCN103212281AIncrease the amount of dissolutionIncrease oxidation rateDispersed particle separationAir quality improvementLiquid wasteNitric oxide

The invention discloses a smoke desulfurization and denitrification integration method and a special device thereof. The method is characterized in that a wet-method process is used in one technological system to simultaneously remove sulfur dioxide and nitrogen oxide in the smoke; an ammonium method is used for desulfurization, ammonia water is also used as a desulfurizer of the sulfur dioxide and a neutralizing agent for byproduct nitric acid produced in the denitrification process; an oxidization reduction method is used for the denitrification, a desulfurization byproduct ammonium sulfite or ammonium bisulfite is used as a reducing agent, urea is used as a reducing agent, a quinine-contained hydroxyl compound is used as a catalyst, air is blown into the denitrification circulating liquid so as to provide the dissolving oxygen and the oxidant for the oxidization reaction of the nitrogen oxide; a byproduct ammonium nitrate of the denitrification reaction is placed into the desulfurization liquid so as to recycle the nitrogen ammonium; and ammonia nitrogen chemical fertilizer ammonium sulfate and ammonium nitrate are recycled, and the entire technological flow is free from discharging sulfur-contained or ammonia nitrogen-contained waste liquid out of the system. Due to the adoption of the method, the integration of the desulfurization and the denitrification can be realized, the device is miniaturized, and no waste liquid is discharged in the technological process.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

Method for preparing sulfur and processing tail gas by taking ammonium bisulfite as intermediate

ActiveCN102211762AShort processSave construction investmentDispersed particle separationSulfur preparation/purificationAqueous solutionAmmonia

The invention discloses a method for preparing sulfur and processing tail gas by taking ammonium bisulfite as an intermediate and belongs to the technical field of sulfur recovery. The method is characterized by comprising the following steps: 1) separating NH3 from an acidic water stripping device by adopting the prior art to obtain gas ammonia or aqua ammonia; 2) oxidizing all non SO2 sulfides in the tail gas into SO2 through burning the tail gas in a Claus sulfur recovery device; 3) reacting the tail gas after burning and the NH3 separated from the acidic water stripping device in a liquid phase to produce NH4HSO3 and (NH4)2SO3, and discharging the purified tail gas; and 4) atomizing the NH4HSO3 and (NH4)2SO3 water solution, spraying the water solution into a reacting furnace of the Claus sulfur recovery device, decomposing the NH3 into N2 after thermal decomposition, and enabling SO2 to participate in Claus reaction to obtain an elemental sulfur. Compared with the tedious technical process of the prior art, the method has greatly shortened process, and construction investment, operating cost and energy consumption are reduced by more than 30%.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

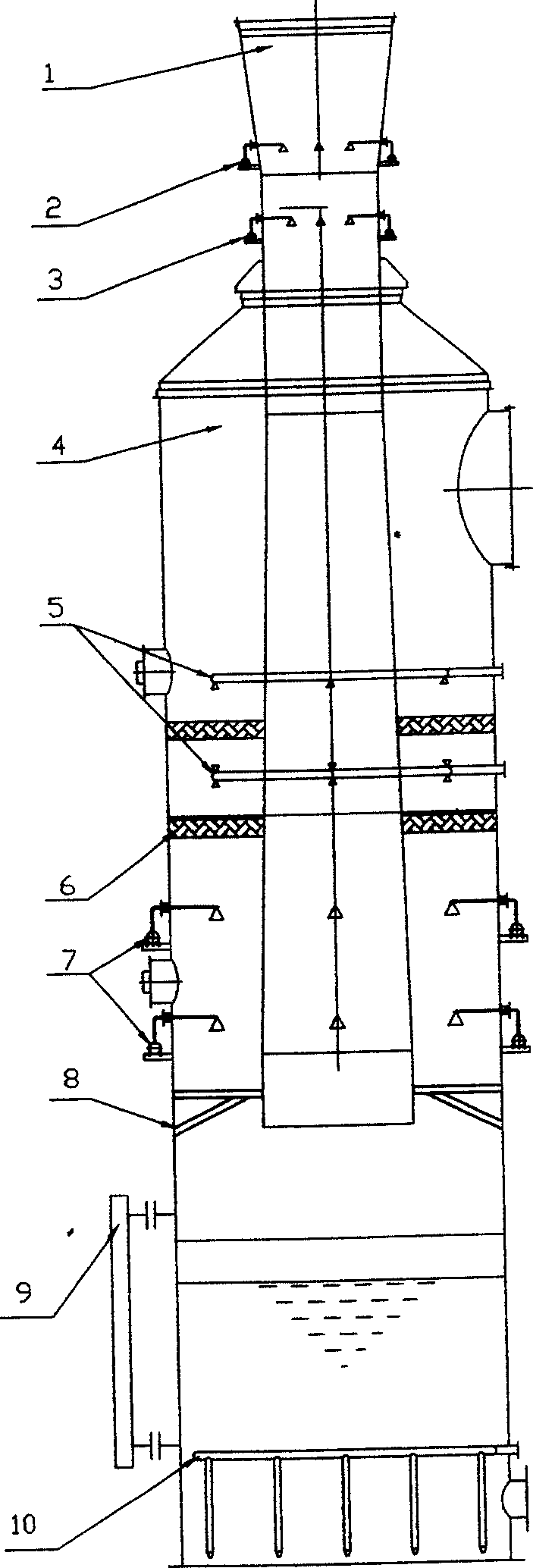

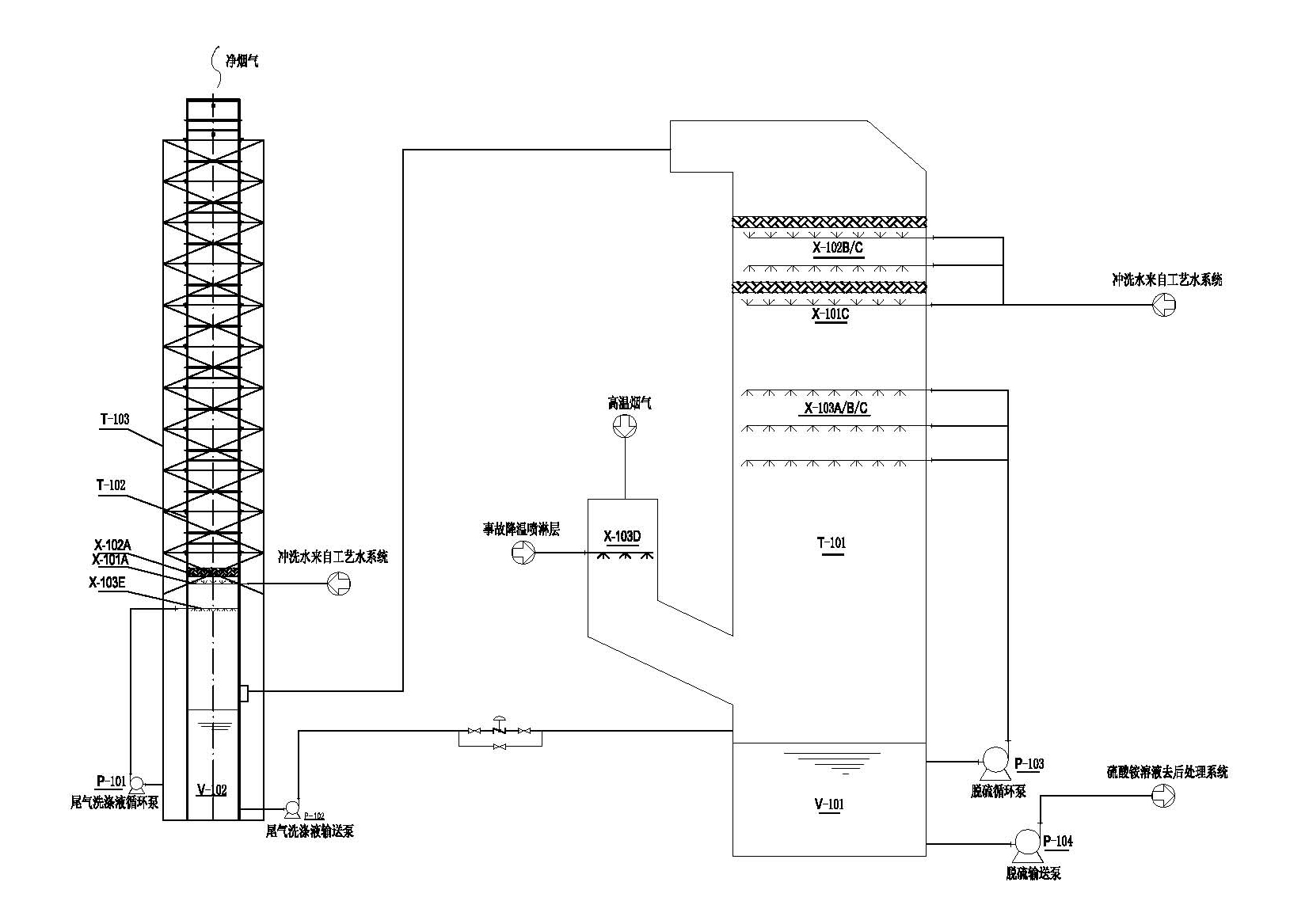

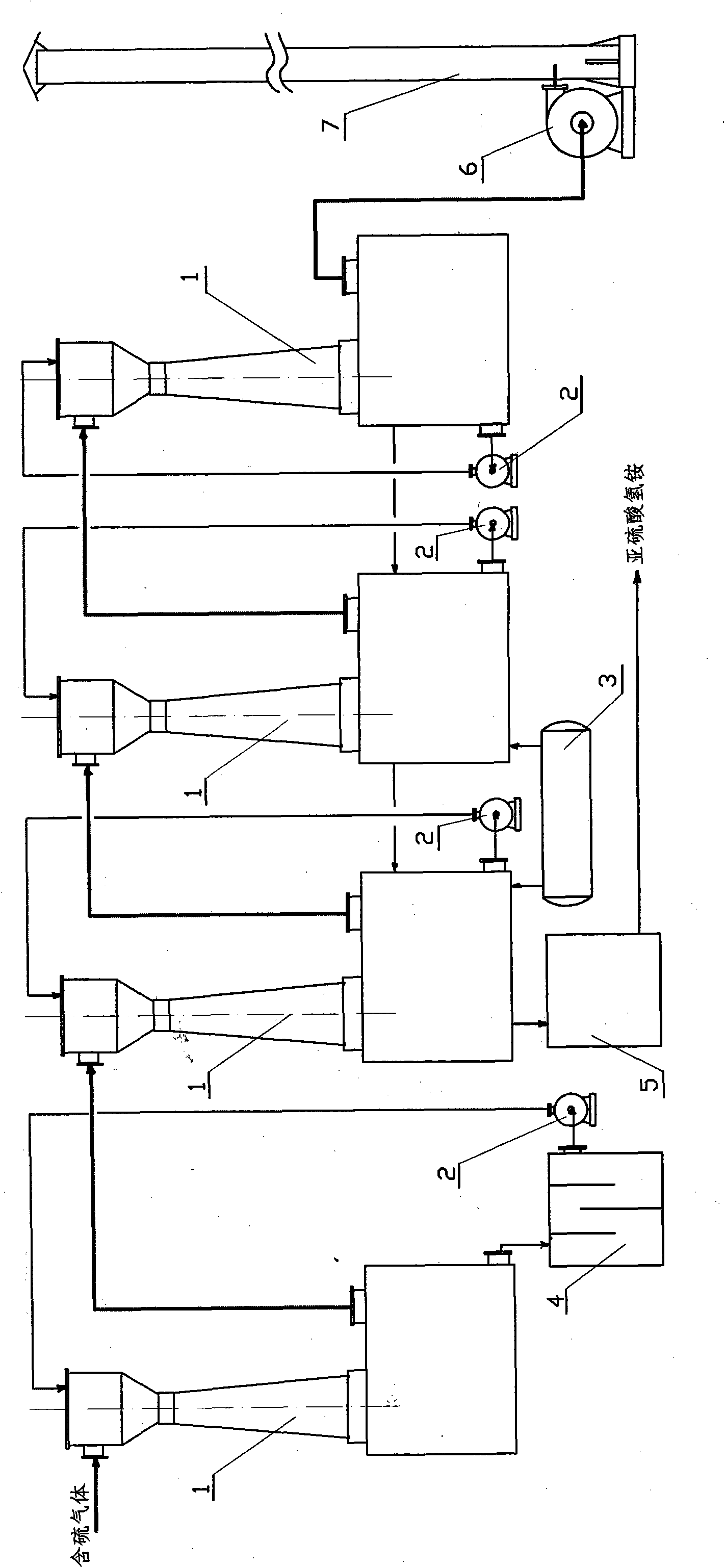

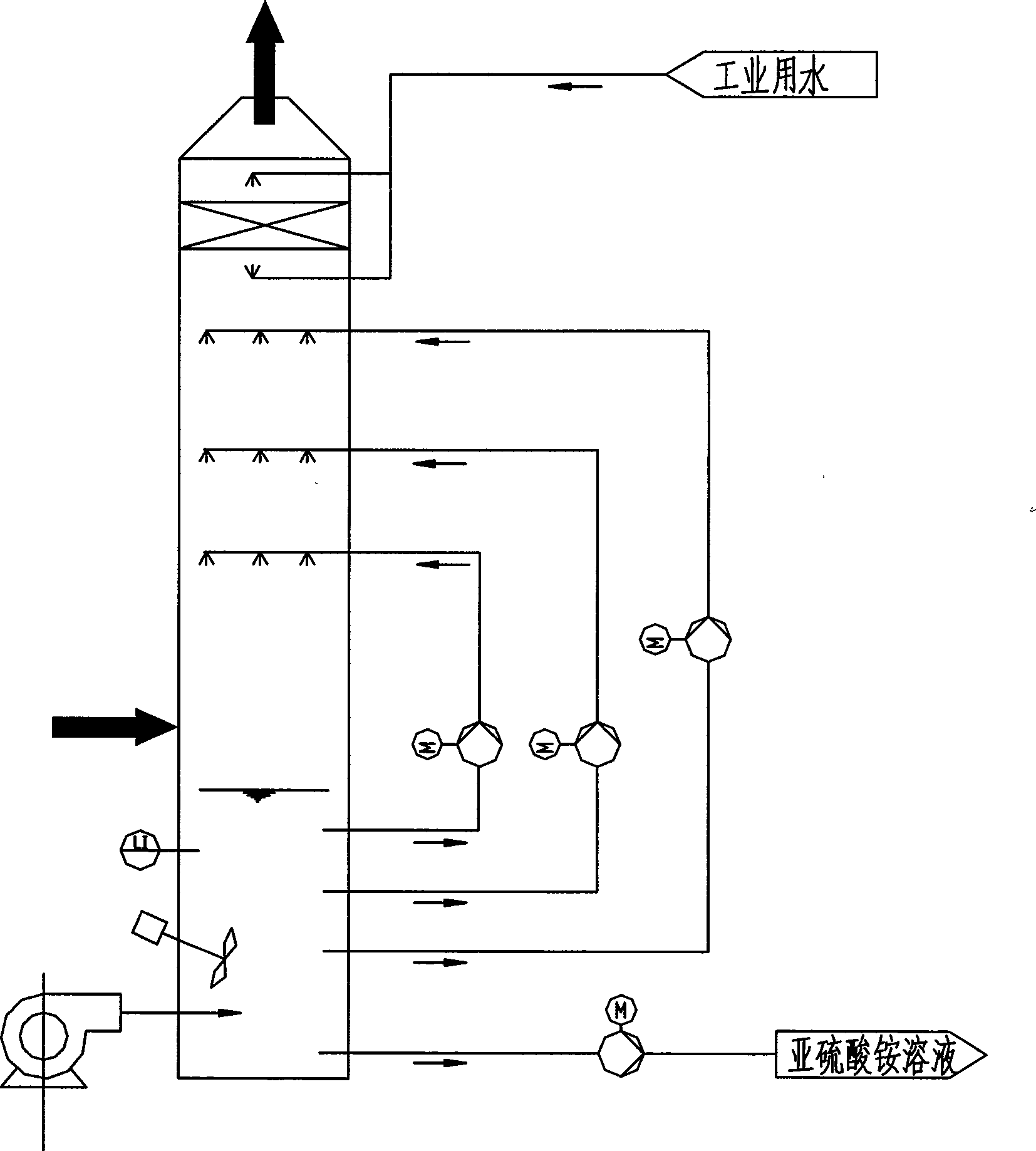

Method for desulfurizing high-sulphur boiler flue gas to prepare high-purity ammonium bisulfite

ActiveCN102755823ASimple processLow investment costCombination devicesAmmonium sulfitesIon exchangeDust control

The invention relates to a method for removing and recycling SO2 in high-sulphur boiler flue gas and discloses a method utilizing ammonia water as material and recycling desulfuration to prepare ammonium bisulfite with high SO2 / NH3 value and high purity. The method comprises the steps of (1) performing dry dedusting on high-sulphur boiler flue gas, and cooling through wet dust collection, (2) utilizing ammonia water as absorbents to absorb SO2 in flue gas in a triple tandem desulfurizing absorption tower, controlling the absorbing temperature through an exterior circulation cooling mode, preparing ammonium bisulfite solution with high SO2 / NH3 value, and discharging with standard level after water scrubbing and demisting, (3) removing high chemical valence insoluble heavy metal ions such as ferric iron through microfiltration, and (4) removing heavy metal ions through chelating ion exchange resins to obtain products. According to the method, the concentration of SO2 in flue gas after desulfurization is low, SO2 in high-sulphur boiler flue gas is effectively recycled, and ammonium bisulfite solution with high SO2 / NH3 value and high purity is prepared.

Owner:JIANGSHAN TAIGE CHEM

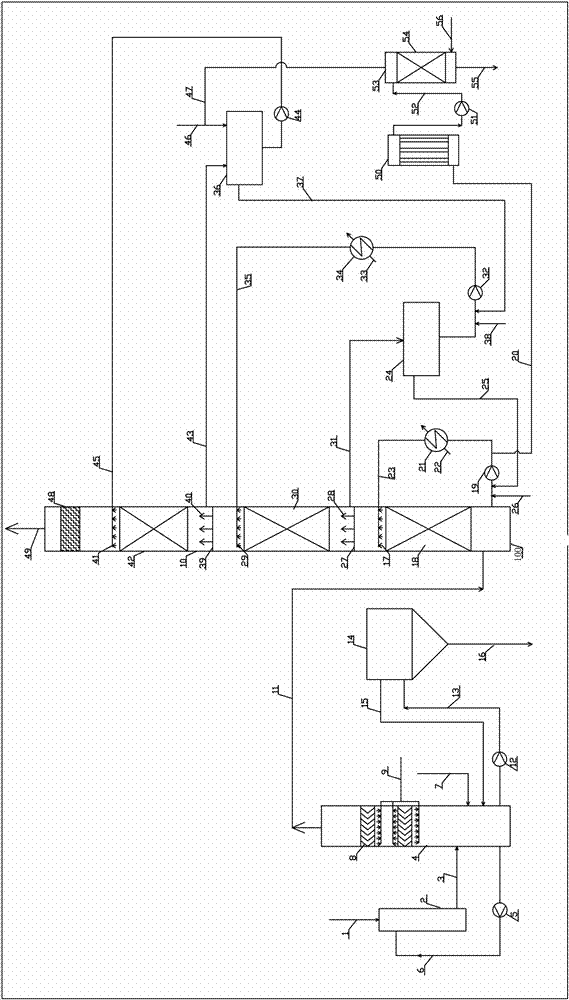

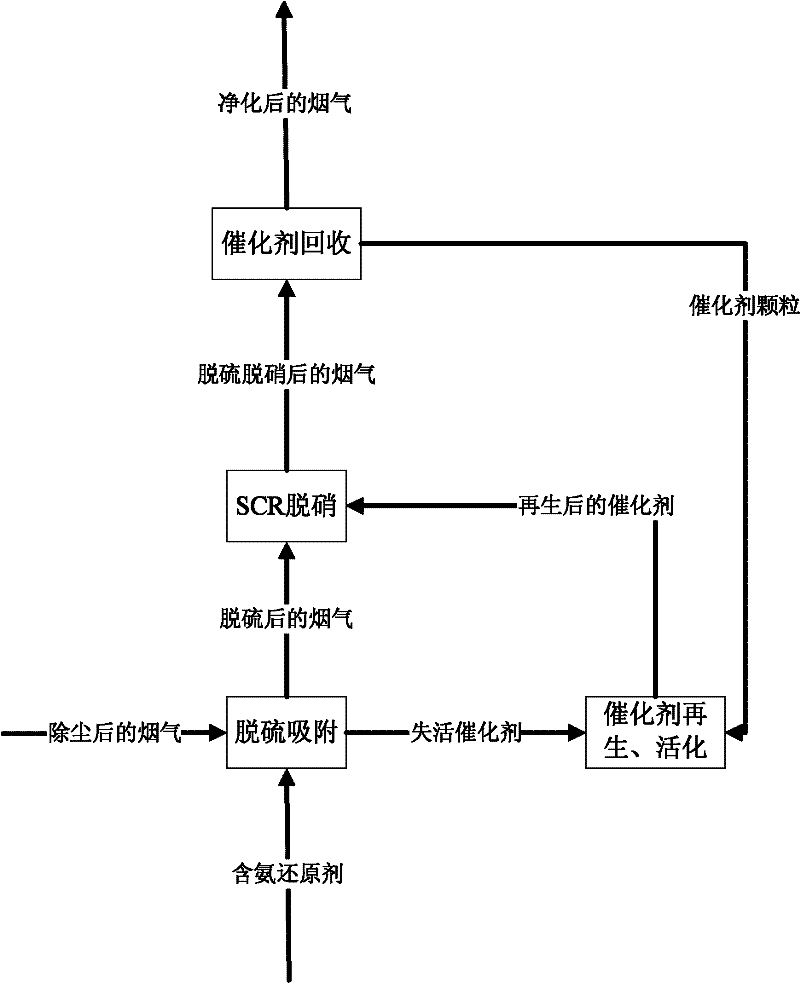

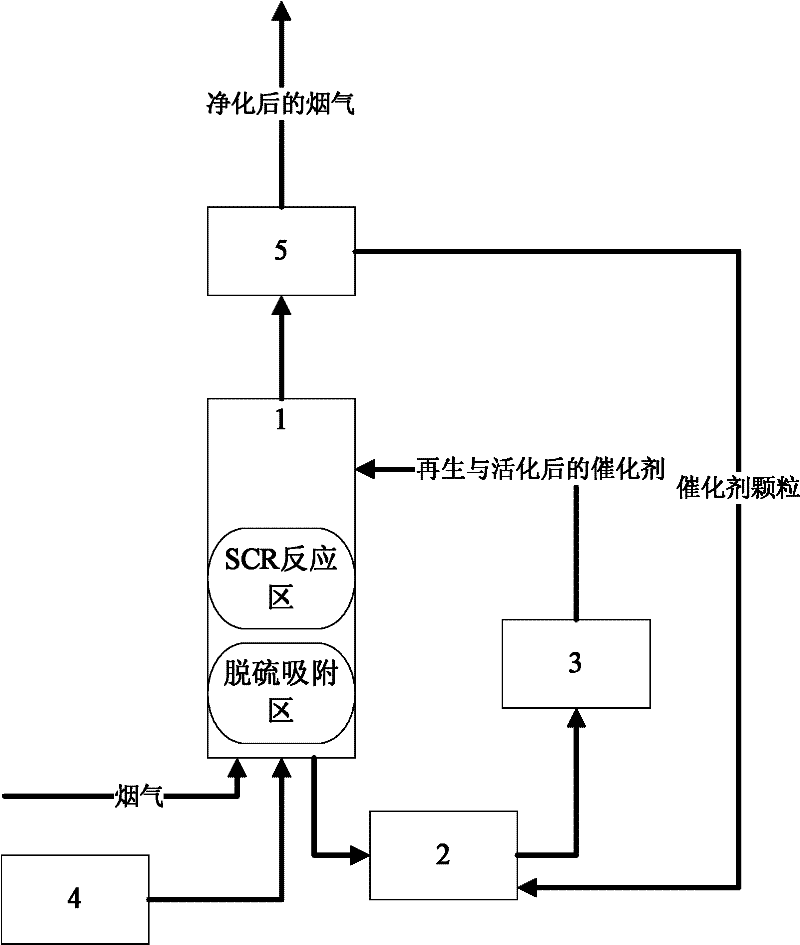

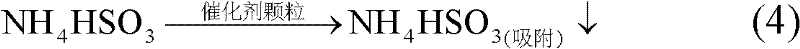

Fluidized bed-based flue gas combined desulfurization and denitration process

ActiveCN102512952AIncrease profitAchieve recyclabilityDispersed particle separationGas phaseReducing agent

The invention discloses a fluidized bed-based flue gas combined desulfurization and denitration process. An ammonia-containing reducing agent and flue gas after dust removal are subjected to gas-phase desulfurization reaction at a desulfurization region; ammonia and sulfur dioxide react under the action of vapor to generate ammonium sulfite and ammonium bisulfite to be adsorbed by an SCR (Selective Catalytic Reduction) denitration catalyst; desulfurized flue gas is subjected to SCR denitration reaction of the ammonia-containing reducing agent and nitrogen oxide at the SCR reaction region; and after being desulfurized, regenerated and activated, catalyst grains are circulated back to the SCR reaction region to be reutilized. The invention discloses a device for implementing the process. Through the process, liquid-state sectional desulfurization and denitration are realized in a fluidized reaction tower, so that adverse effect of the sulfur dioxide in medium and low-temperature flue gas on SCR catalytic desulfurization is overcome; and the process is suitable for desulfurization and denitration of low-temperature and high-sulfur flue gas of industrial boiler kiln and has broad market application prospect.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

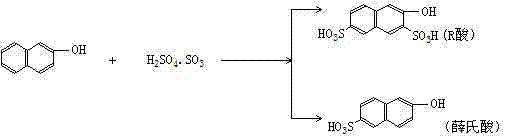

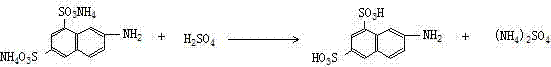

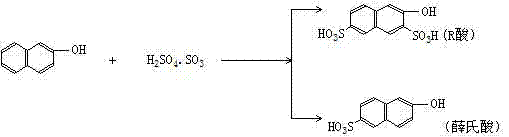

Process for preparing amino G acid

The invention relates to a process for preparing amino G acid, which belongs to the technical field of amino K acid production process. The process comprises the steps of sulfonating, salting out by ammoniacal liquor, treating G salt mother liquor, ammoniating G salt ammonium base sulfite, treating dehydrated liquid and the like, ammonium base sulfite is employed as a catalyst for replacing ammonium bisulfite, so that the pressure generated during ammonification process can be effectively reduced, the reaction time can be shortened, and the product yield and content can be increased. The method is characterized in that two streams of waste water are respectively treated, 2-naphthol is hydrolyzed and recovered by G salt mother liquor, neutralized for reaching the standard, and then exhausted; ammonium sulfate-rich effluent is used for producing fertilizer, and the zero discharge is realized. The unit consumption of the raw material 2-naphthol is decreased from 0.75 ton / ton in a traditional process to less than 0.64 ton / ton when the problem of waste water treatment is solved, so that the production cost is reduced, the production safety coefficient is high and no harmful gas is discharged. The process of the invention solves the problems that two streams of waste water are generated during the present production process, the difficulty of waste water treatment is large, the production cost is high and the large harm on environment is caused.

Owner:湖北鑫慧化工有限公司

Smoke desulfurizing method by amino-thiamine method

InactiveCN1647849AIncrease profitImprove reaction efficiencyDispersed particle separationThiamineAmmonium bisulfite

Owner:JIANGSU HEYICHANG ENVIRONMENTAL PROTECTION ENG & TECH

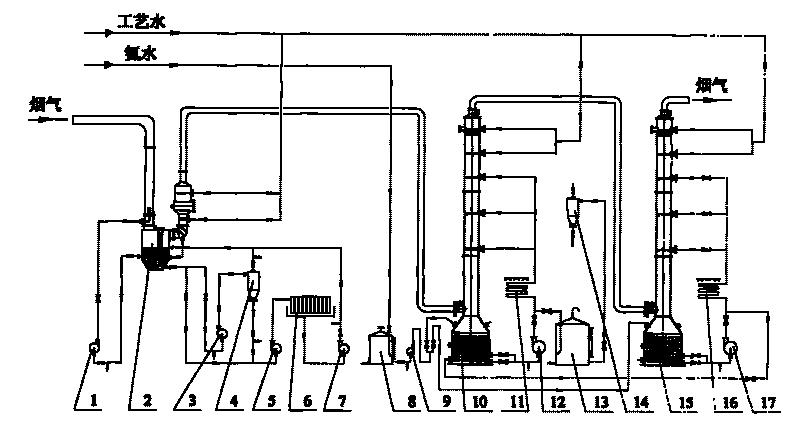

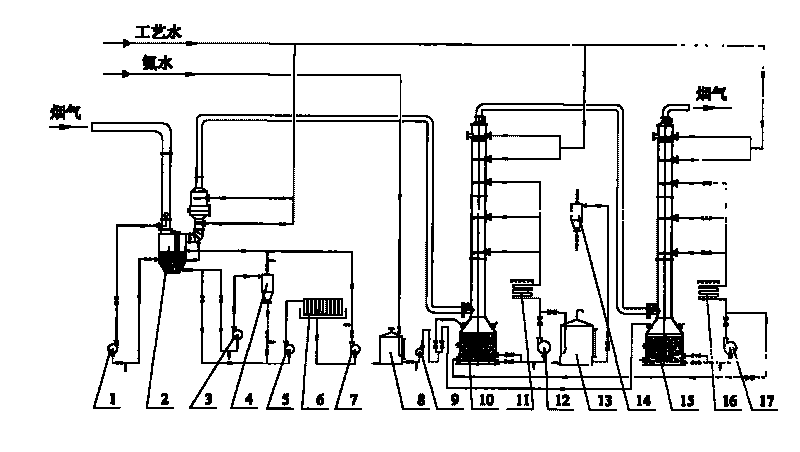

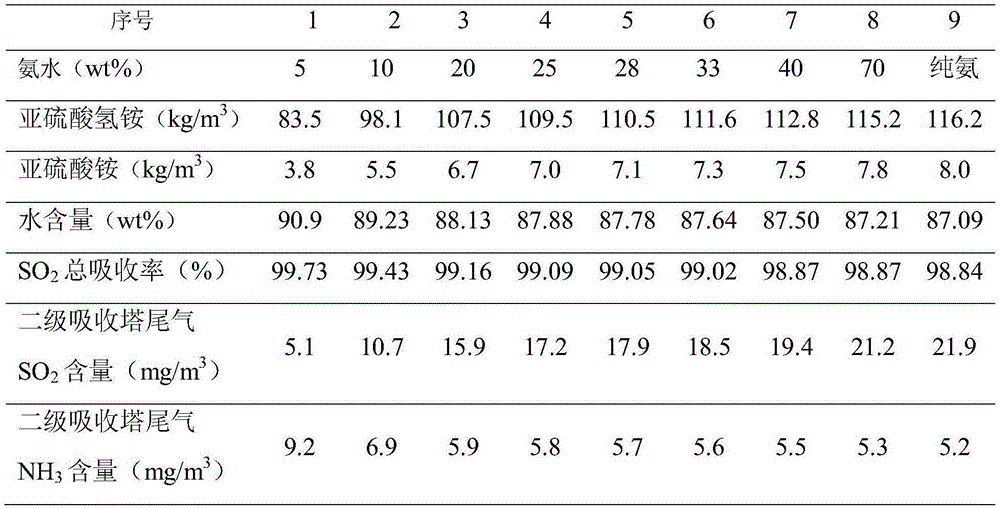

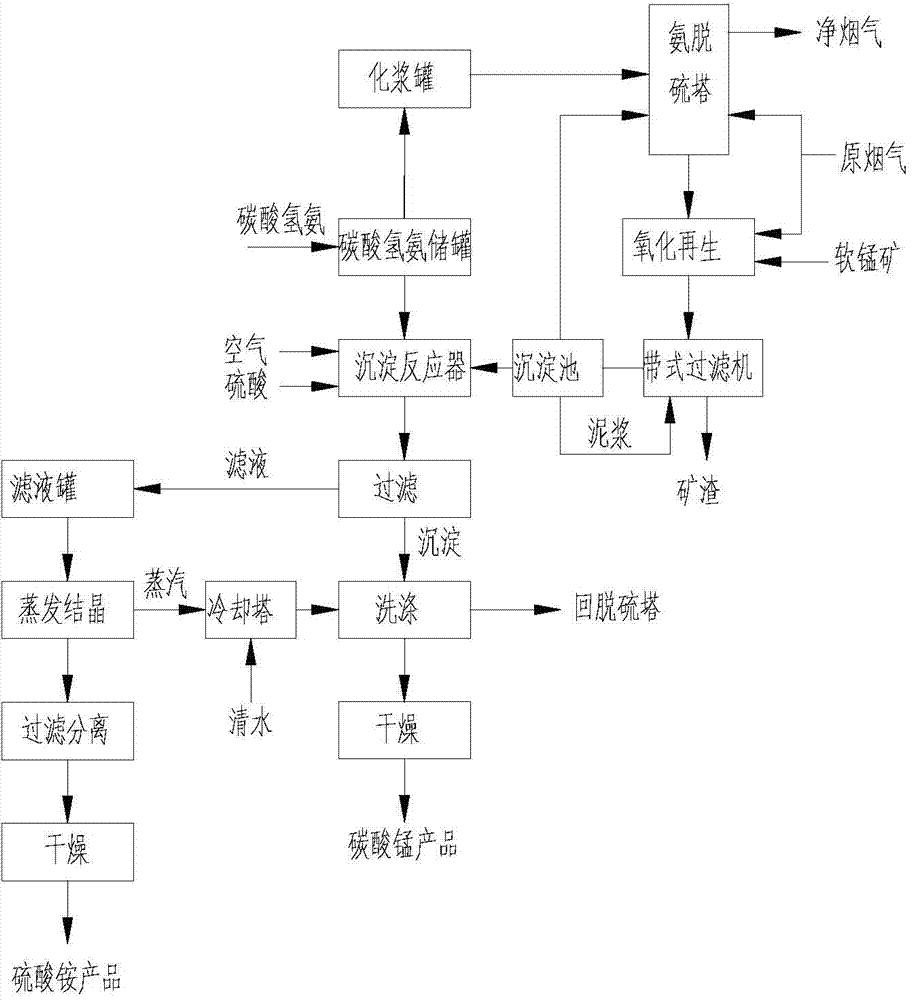

Twin tower type recovering sulfur resource ammonia desulfuration equipment and method

ActiveCN101708412AHigh purityGuaranteed purityUsing liquid separation agentAmmonium sulfitesPollutionBy-product

The invention discloses twin tower type recovering sulfur resource ammonia desulfuration equipment and a method. The equipment comprises a dynamic wave washing tower, a primary absorption tower, a secondary absorption tower and the like; the exhaust gas passes through the dynamic wave washing tower to remove ash and passes through a dynamic wave washer to lower the temperature, and then enters the primary absorption tower and the secondary absorption tower in sequence; the primary absorption tower and the secondary absorption tower are both provided with five spraying layers; the lower three spraying layers spraying and absorbing the exhaust gas; the upper two spraying layers are used for preventing ammonia escape; and the exhaust gas is discharged after being sprayed and absorbed by the primary absorption tower and the second absorption tower. The invention has the following advantages: 1) the purity of the by-product is high; 2) the twin tower design can not only obtain higher desulfurization efficiency, but also produce by-product with high purity; 3) the technology takes ammonium acid sulfite as the ultimate by-product, not only saving the technologies of crystallization and drying in the traditional technology, but also improving the additional value of the by-product; and 4) the technology in the invention can be recycled and has no secondary pollution.

Owner:ZHEJIANG UNIV

Method for preparing sulfur and processing tail gas by taking ammonium bisulfite as intermediate

ActiveCN102211762BShort processSave construction investmentDispersed particle separationSulfur preparation/purificationAqueous solutionAmmonia

The invention discloses a method for preparing sulfur and processing tail gas by taking ammonium bisulfite as an intermediate and belongs to the technical field of sulfur recovery. The method is characterized by comprising the following steps: 1) separating NH3 from an acidic water stripping device by adopting the prior art to obtain gas ammonia or aqua ammonia; 2) oxidizing all non SO2 sulfides in the tail gas into SO2 through burning the tail gas in a Claus sulfur recovery device; 3) reacting the tail gas after burning and the NH3 separated from the acidic water stripping device in a liquidphase to produce NH4HSO3 and (NH4)2SO3, and discharging the purified tail gas; and 4) atomizing the NH4HSO3 and (NH4)2SO3 water solution, spraying the water solution into a reacting furnace of the Claus sulfur recovery device, decomposing the NH3 into N2 after thermal decomposition, and enabling SO2 to participate in Claus reaction to obtain an elemental sulfur. Compared with the tedious technical process of the prior art, the method has greatly shortened process, and construction investment, operating cost and energy consumption are reduced by more than 30%.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

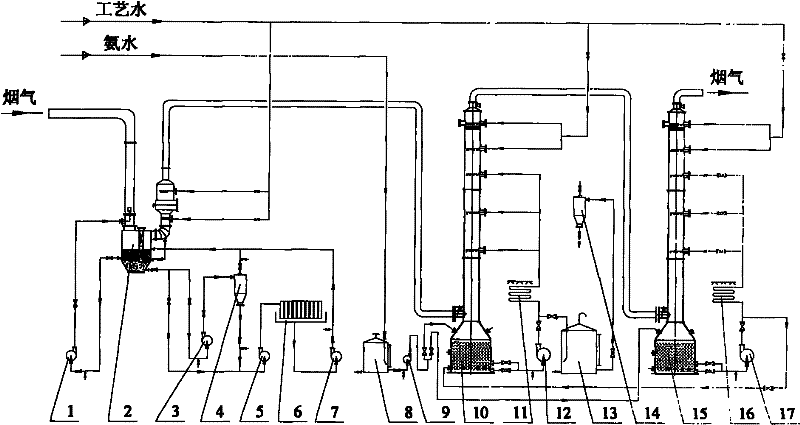

Sintering flue gas desulfurization combined coking coal gas deamination cycling technology and cycling system

InactiveCN101549246AAchieve recyclingThe solution is not easy to obtainDispersed particle separationAmmonium sulfatesCoke ovenAmmonium bisulfite

The invention relates to a sintering flue gas desulfurization combined coking coal gas deamination circulation cycling technology, which comprises the following steps: (1) removing sulfur dioxide in the sintering flue gas using ammonium sulfite solution as desulfurization agent to generate ammonium bisulfite solution; (2) remove ammonia in the coking coal gas using the ammonium bisulfite solution obtained in the step (1) as deamination agent to obtain ammonium sulfite solution, using part of the ammonium sulfite solution as desulfurization agent in step (2), and oxidizing other ammonium sulfite solution into ammonium sulfate solution; (3) evaporating the ammonium sulfate solution, crystallizing, separating and drying to obtain the ammonium sulfate product. A sintering flue gas desulfurization combined coking coal gas deamination cycling system comprise a sintering flue gas desulfurization system, a coking coal gas deamination system and a ammonium sulfate preparation system. The invention removes ammonia in the coking coal gas efficiently while removing SO2 from sintering flue gas, reduces the raw material cost of desulfurization and deamination at the same time.

Owner:杭州三和环保技术工程有限公司 +1

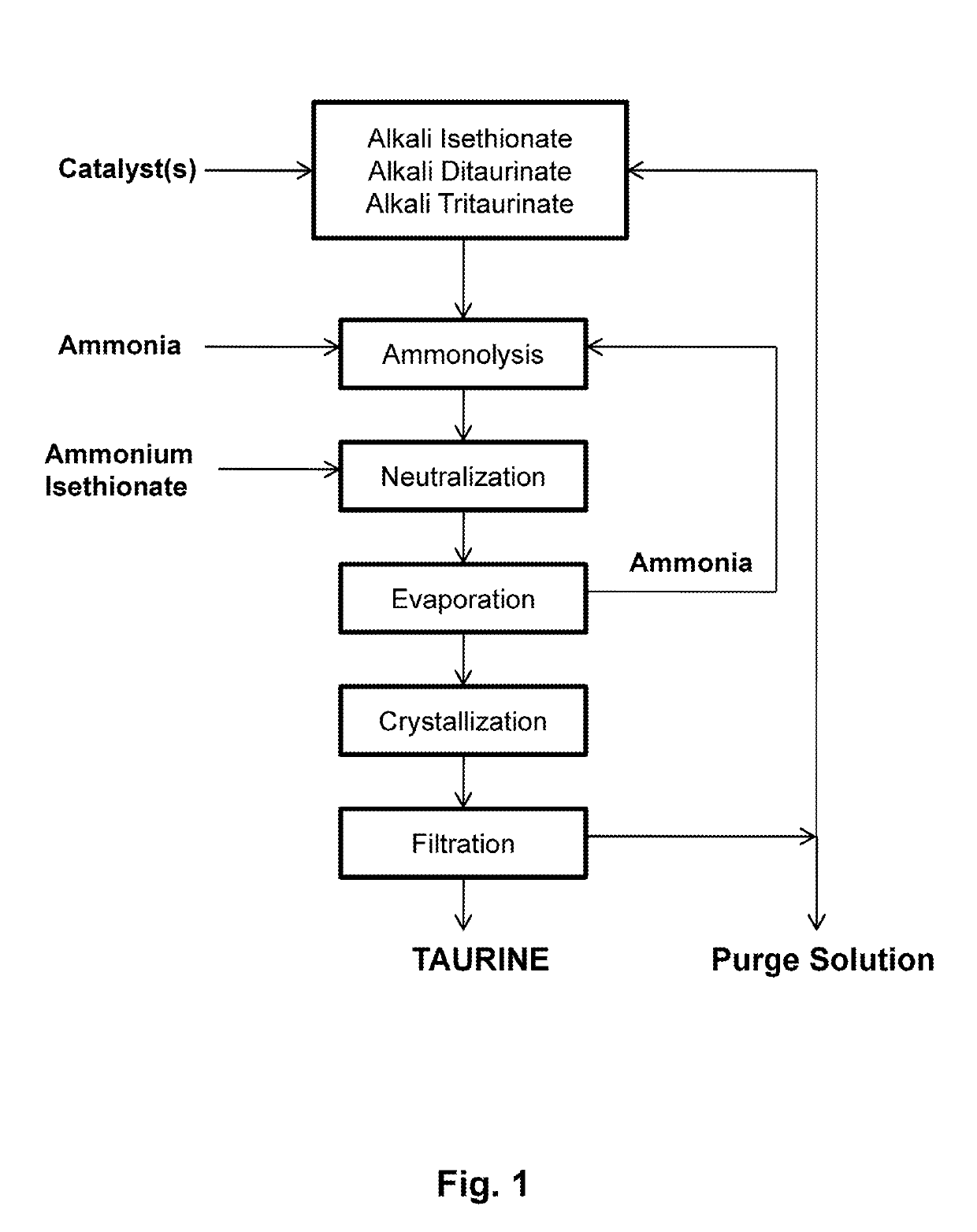

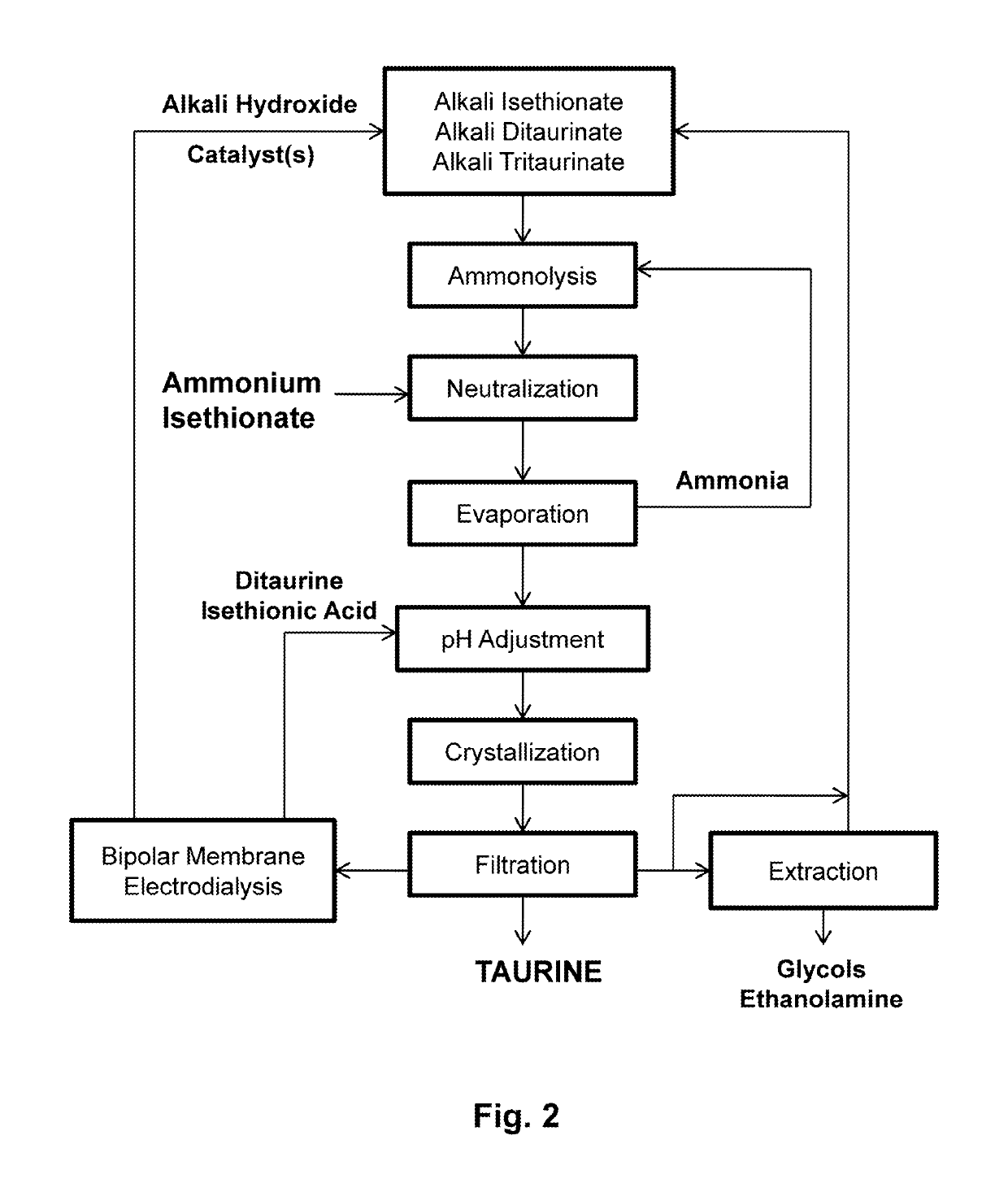

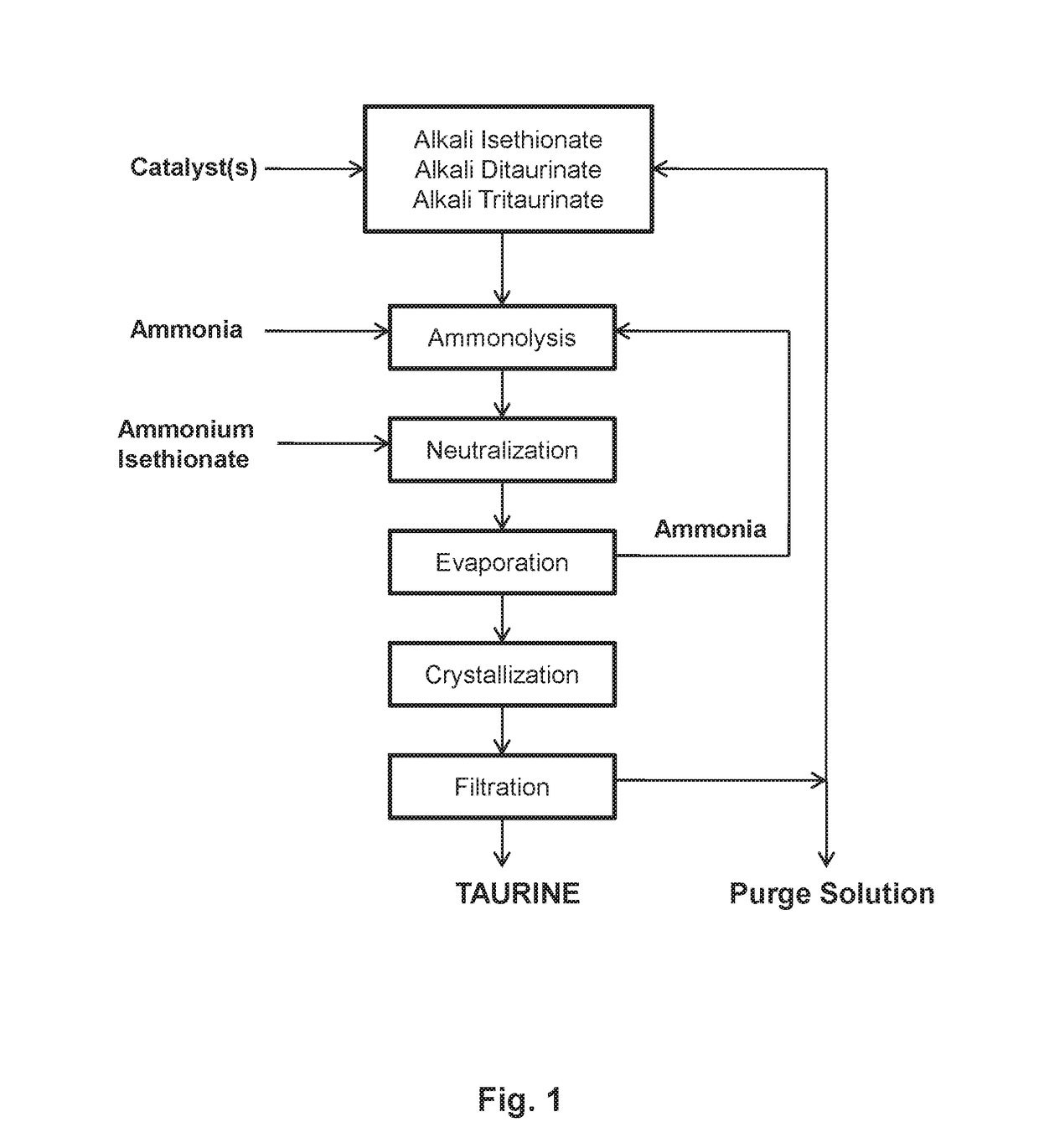

Process for producing taurine

ActiveUS20190135739A1Simple processOrganic compound preparationSulfonic acids salts preparationTaurineAqueous solution

There is disclosed a process for producing taurine by reacting 2-oxazolidinone with ammonium sulfite, or ammonium bisulfite, or a mixture of ammonium sulfite and ammonium bisulfite in an aqueous solution to form ammonium taurinate and ammonium bicarbonate. Taurine is obtained by decomposing ammonium taurinate to taurine and ammonia and recovered by solid-liquid separation.

Owner:VITAWORKS IP LLC

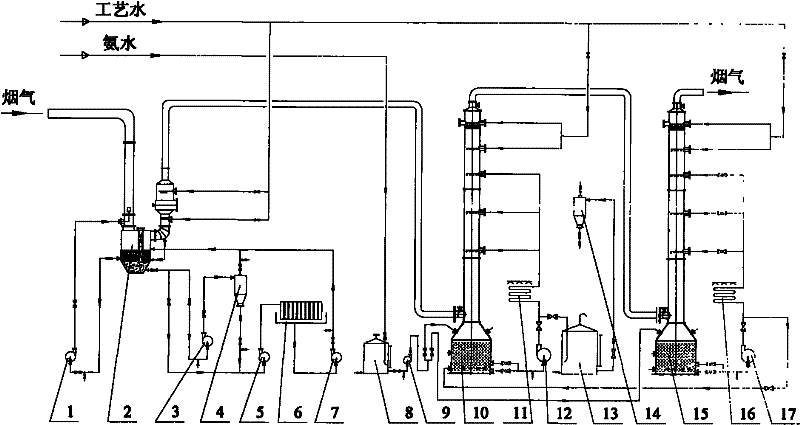

Monotower ammonia desulfuration recovery method for removing aerosols in flue gas

InactiveCN101927129AHigh recovery rateSimple and fast operationDispersed particle separationAmmonium sulfatesRecovery methodFlue gas

The invention relates to a monotower ammonia desulfuration recovery method for removing aerosols in flue gas, which is characterized in that the flue gas desulfuration process is carried out in a combined desulfuration tower with a plurality of functions; the high-temperature flue gas enters from the side surface of the desulfuration tower; the lower part of the desulfuration tower is an oxidation section, the middle part thereof is a main absorbing section and the upper part thereof is a demisting section. In order to remove the SO2 aerosols possibly existing in the desulfuration process and reduce the entrainment of an ammonium sulfate solution in the flue gas (the entrainment of the ammonium sulfate solution refers to the amount of 10-35 percent (m / m) concentration of the ammonium sulfate solution contained in the desulfurated flue gas), a tail gas washing tower is additionally arranged in the rear of the desulfuration tower, and a high-flow nozzle is designed in the tail gas washing tower; and the flue gas departing from the desulfuration tower is washed by utilizing clear water, therefore, the entrainment of the ammonium sulfate solution in the flue gas is reduced, the ammonium bisulfate (ammonium bisulfite) aerosols are absorbed and dissolved, and the recovery rate of ammonium sulfate products is improved.

Owner:JIANGSU HEYICHANG ENVIRONMENTAL PROTECTION ENG & TECH

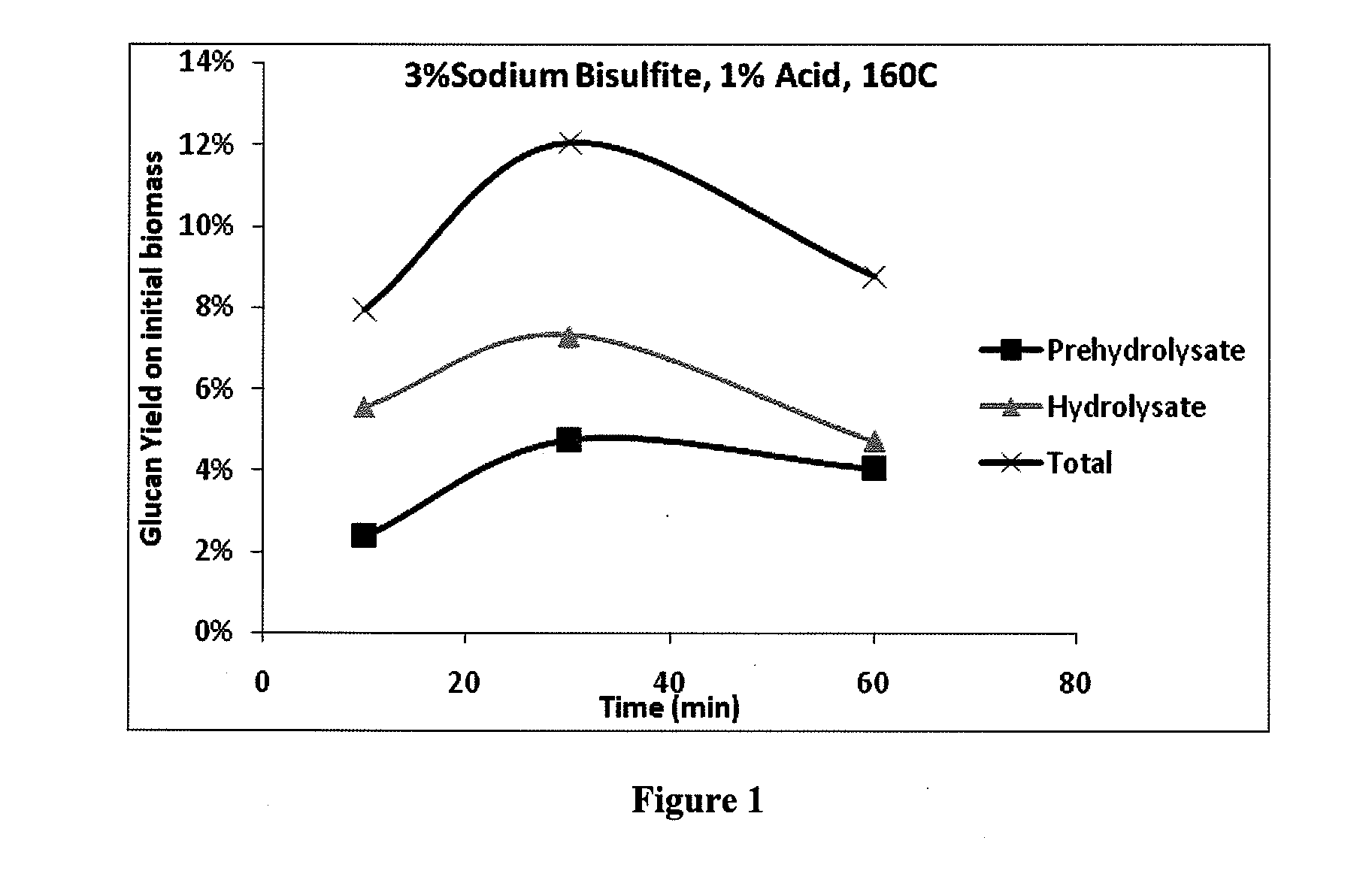

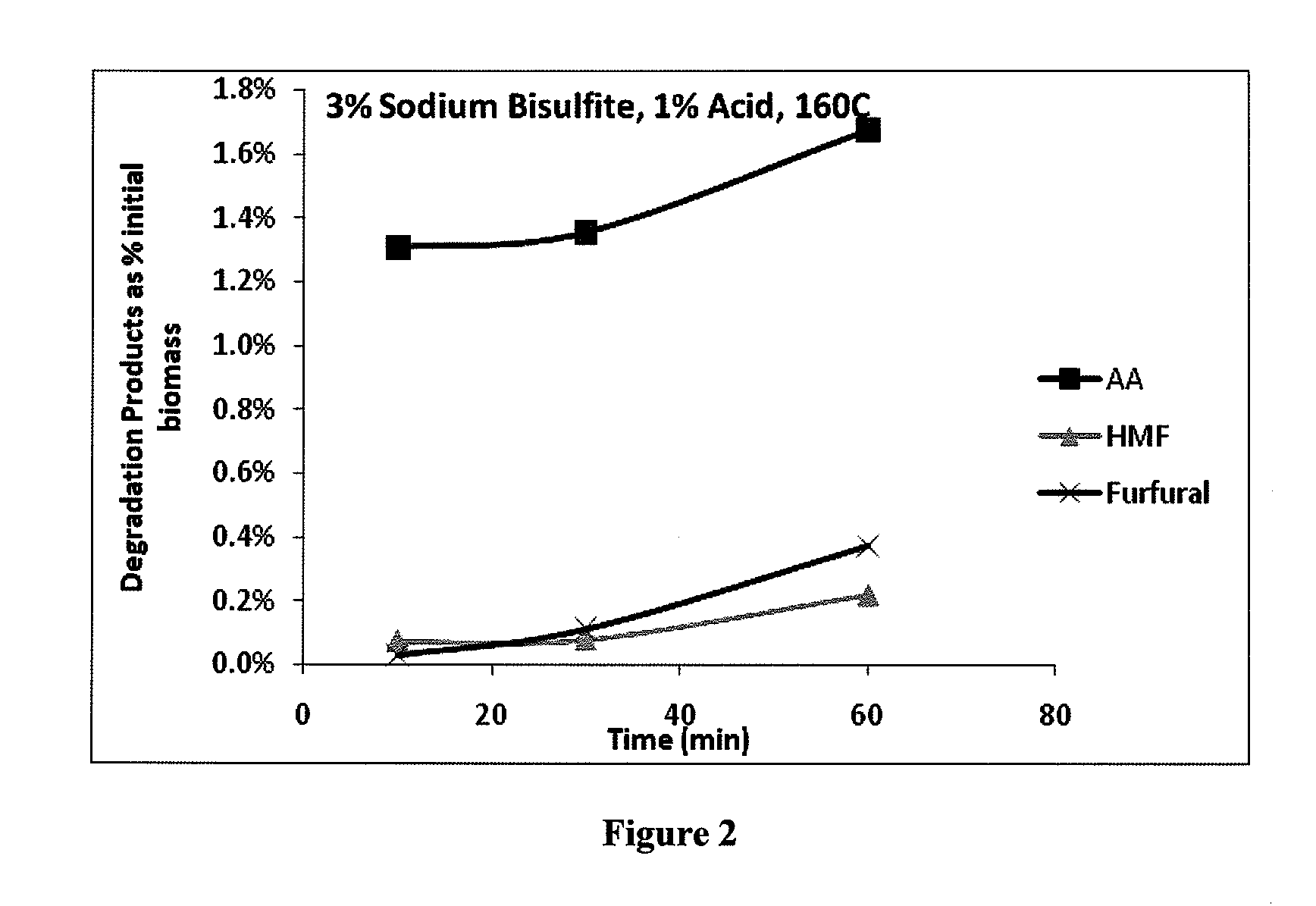

Pretreatment of Ligno-Cellulosic Biomass with Sulfonation

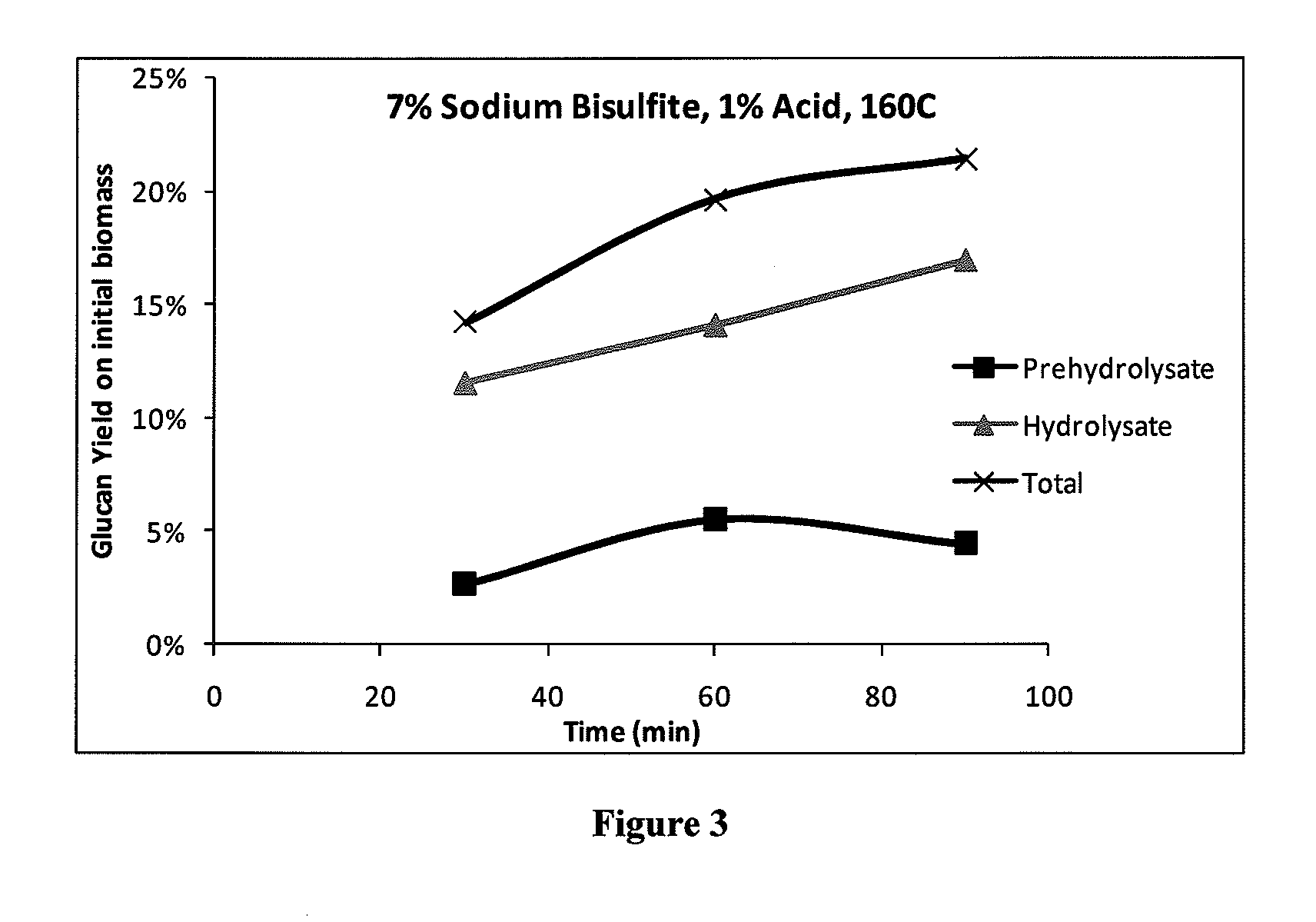

InactiveUS20110124056A1Low costReduce complexityPulping with acid salts/anhydridesPulp by-products recoveryCelluloseDry weight

Provided are methods for the pretreatment of ligno-cellulosic biomass such as softwoods with bisulfite such as ammonium bisulfite without the need for exogenous acid. In one variation, a method of pretreating ligno-cellulosic biomass is provided including the following steps: a) providing ligno-cellulosic biomass; b) contacting the ligno-cellulosic biomass with a solution comprising bisulfite at an amount between 1 and 10% of a dry weight of the ligno-cellulosic biomass to form a slurry; c) heating the slurry to a first temperature of 150-210° C. for a first period of time to form a first mixture; d) cooling the first mixture to a second temperature of 100-200° C. to form a second mixture; and e) maintaining the second mixture at the second temperature for a second period of time to form pretreated ligno-cellulosic biomass; wherein the first temperature is higher than the second temperature.

Owner:CHEVROU USA INC

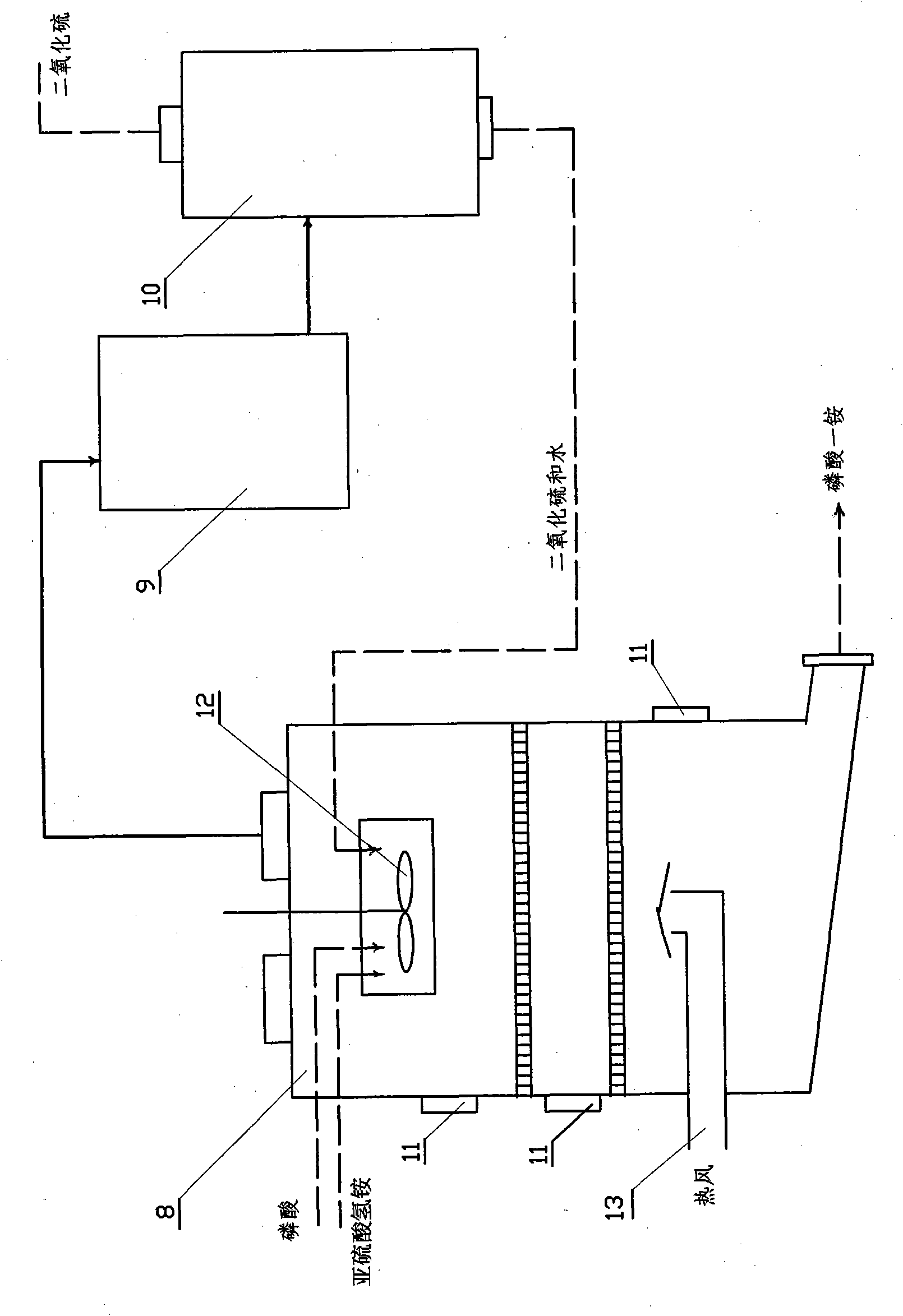

Method for preparing fertilizer grade monoammonium phosphate from sulfurous gases by ammonia-process desulfurization

ActiveCN101987278ALarge market consumptionAlkali orthophosphate fertiliserDispersed particle separationSlagPhosphoric acid

The invention discloses a method for preparing fertilizer grade monoammonium phosphate from sulfurous gases by ammonia-process desulfurization, which comprises the following steps: (1) adopting four stages to absorb SO2 from gases; at the first stage, washing smoke by water, removing dust slag and reducing the temperature of smoke; at the second stage, absorbing SO2 by ammonia or ammonium sulfiterepeatedly to obtain ammonium bisulfite; at the third stage, absorbing SO2 by an absorption liquid with high alkalinity continuously; and at the fourth stage, washing by clean water to recycle residual ammonia and SO2; (2) generating a monoammonium phosphate solution after acidolysis: carrying out acidolysis on the obtained ammonium bisulfite solution in the last step by phosphoric acid in an acidolysis device, producing the monoammonium phosphate solution and giving out gas SO2; (3) producing the product monoammonium phosphate: carrying out conventional dehydration, crystallization and drying processes on the monoammonium phosphate solution to obtain the monoammonium phosphate fertilizer; and (4) producing sulfuric acid with the recycled SO2. By using the method of the invention, SO2 in the sulfurous gases can be fully recycled, and meanwhile, the monoammonium phosphate fertilizer with large consumption in the market is produced. The method is applicable to the thermoelectricity enterprises, the enterprises manufacturing sulphuric acid or the enterprises sintering sulfur-containing raw ores.

Owner:丁正元

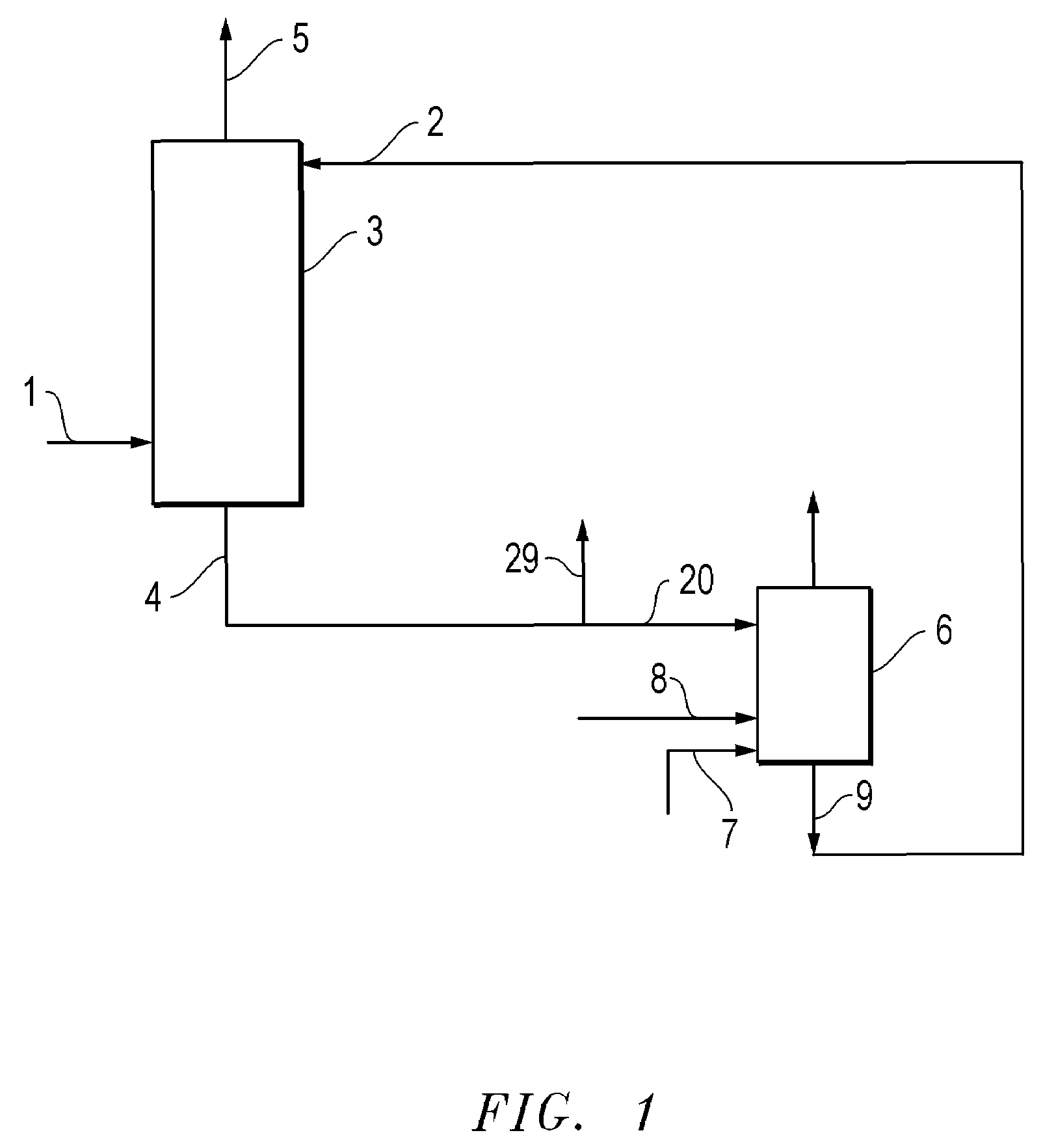

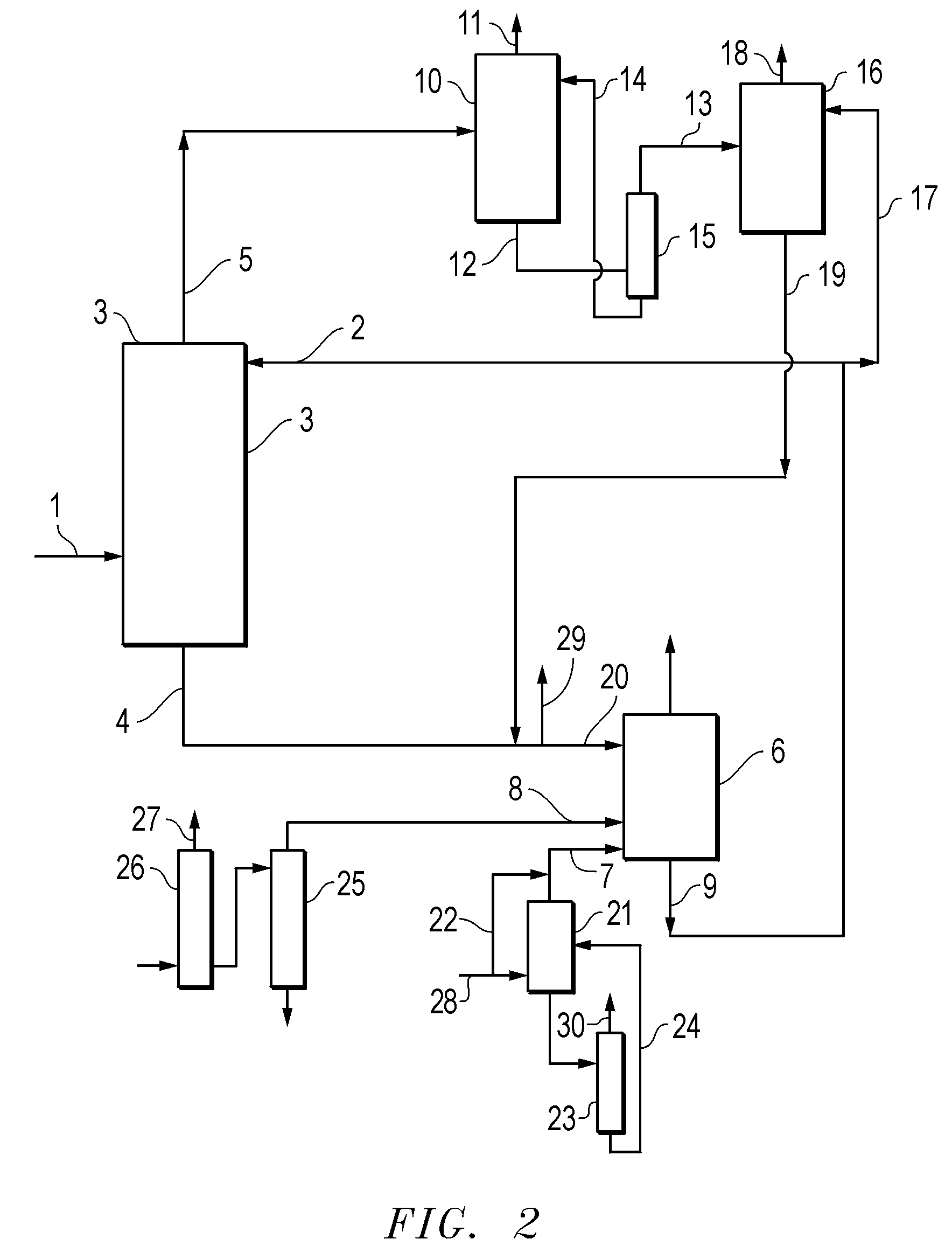

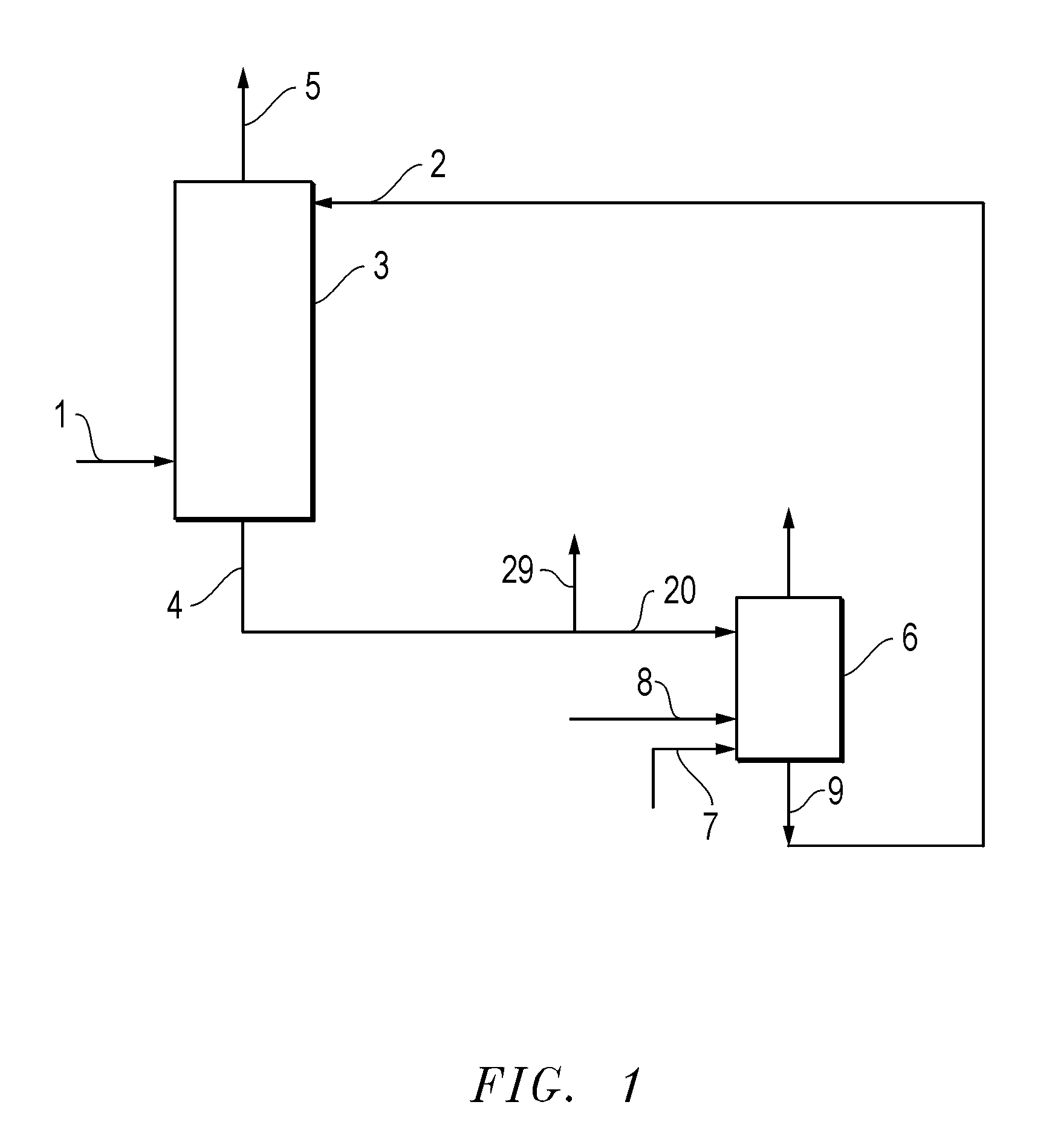

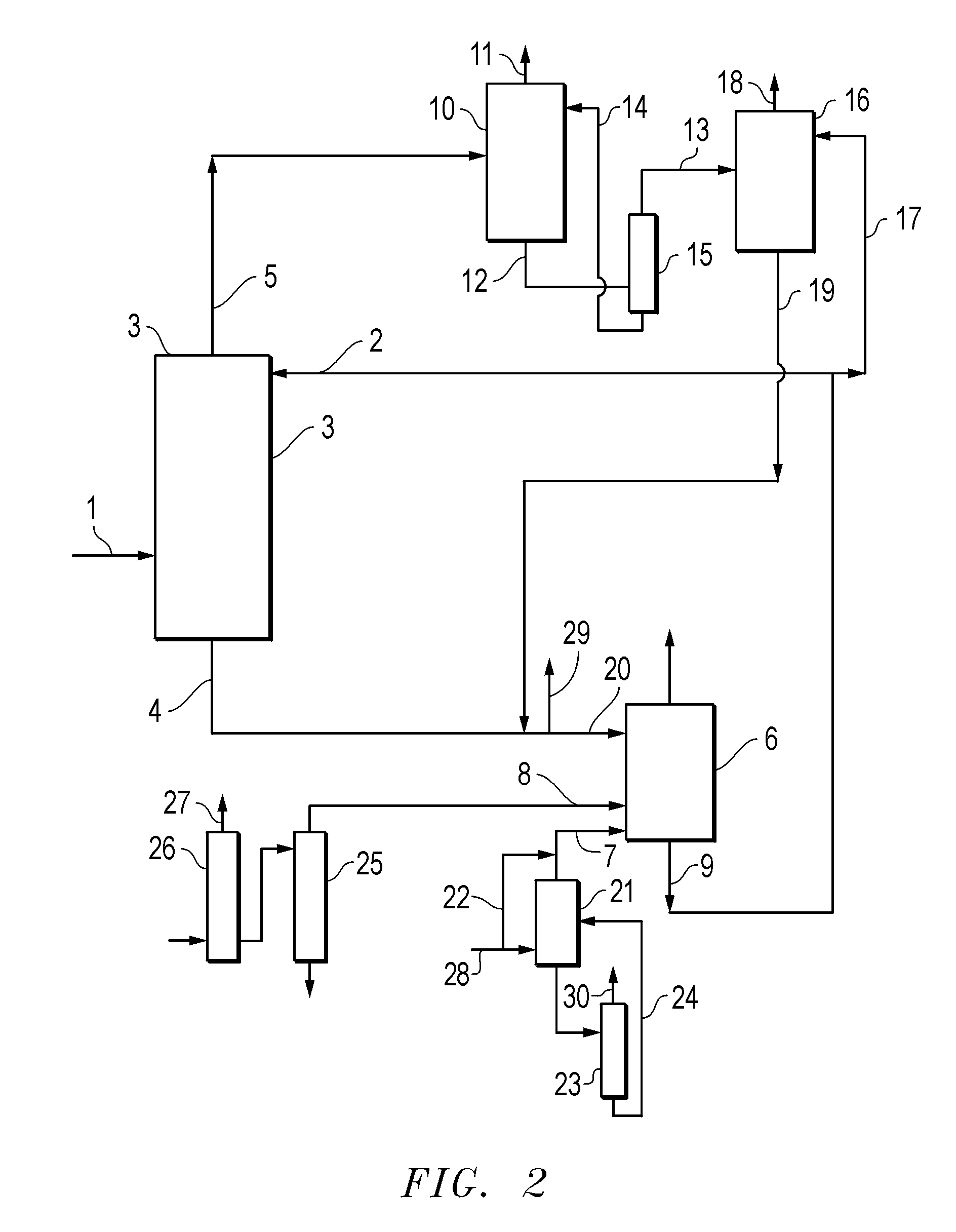

Process for treating a gas stream

ActiveUS7390470B2Efficient removalLow costCyanogen compoundsExhaust apparatusAmmonium bisulfateSulfur containing

Processes for selectively removing sulfur-containing compounds from a gas are described herein. The processes generally include contacting a first gas including carbon dioxide and hydrogen sulfide with a scrub solution including ammonium bisulfite and ammonium sulfite in a first contact zone to produce a first contact zone effluent liquid including ammonium thiosulfate and a first contact zone overhead gas including carbon dioxide.

Owner:THIOSOLV

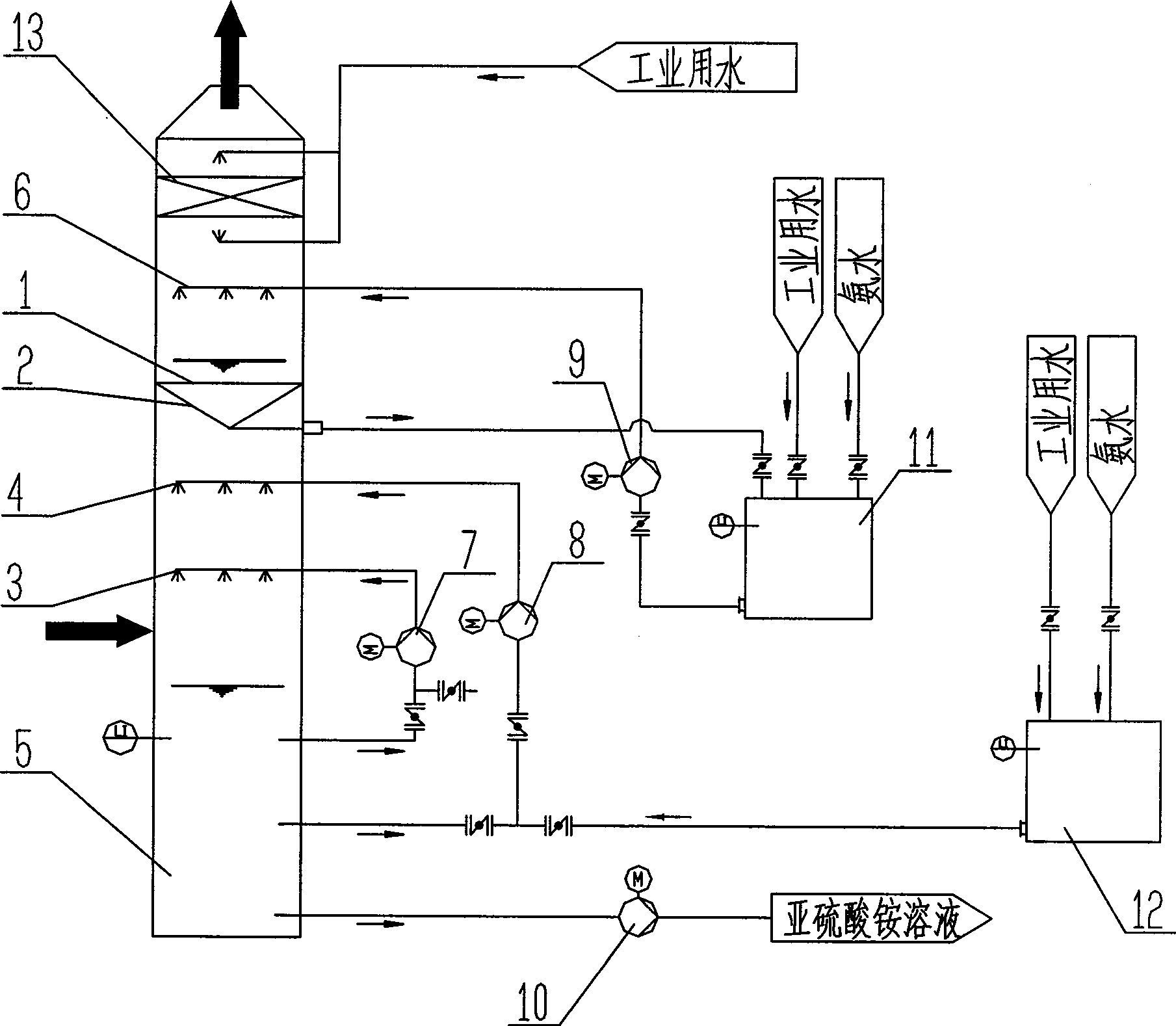

Three-circulation three-segment desulfurizing tower for sintered flue gas

ActiveCN101474529APromote formationImprove absorption rateDispersed particle separationHigh concentrationHydrogen

The invention provides a sintering flue gas ternary cycle three-stage thionizer. The grading absorption is realized by adopting three-stage absorption and strictly controlling the parameters of absorption liquid of each circulation section, thus being capable of guaranteeing that the sintering flue gas has higher SO2 absorptivity, the loss of the ammonia of a system outlet is minimum and ammonium sulfite with higher concentration and hydrogen sulfite ammonium acetate are output, and being beneficial to forming the final product serving as fertilizer to be sold. Finally, the changing waste into valuable of environment treatment is realized by treatment of wastes with processes of wastes against one another, which is line with recycling economy and sustainable development advocated by the nation.

Owner:无锡高达环境科技有限公司 +1

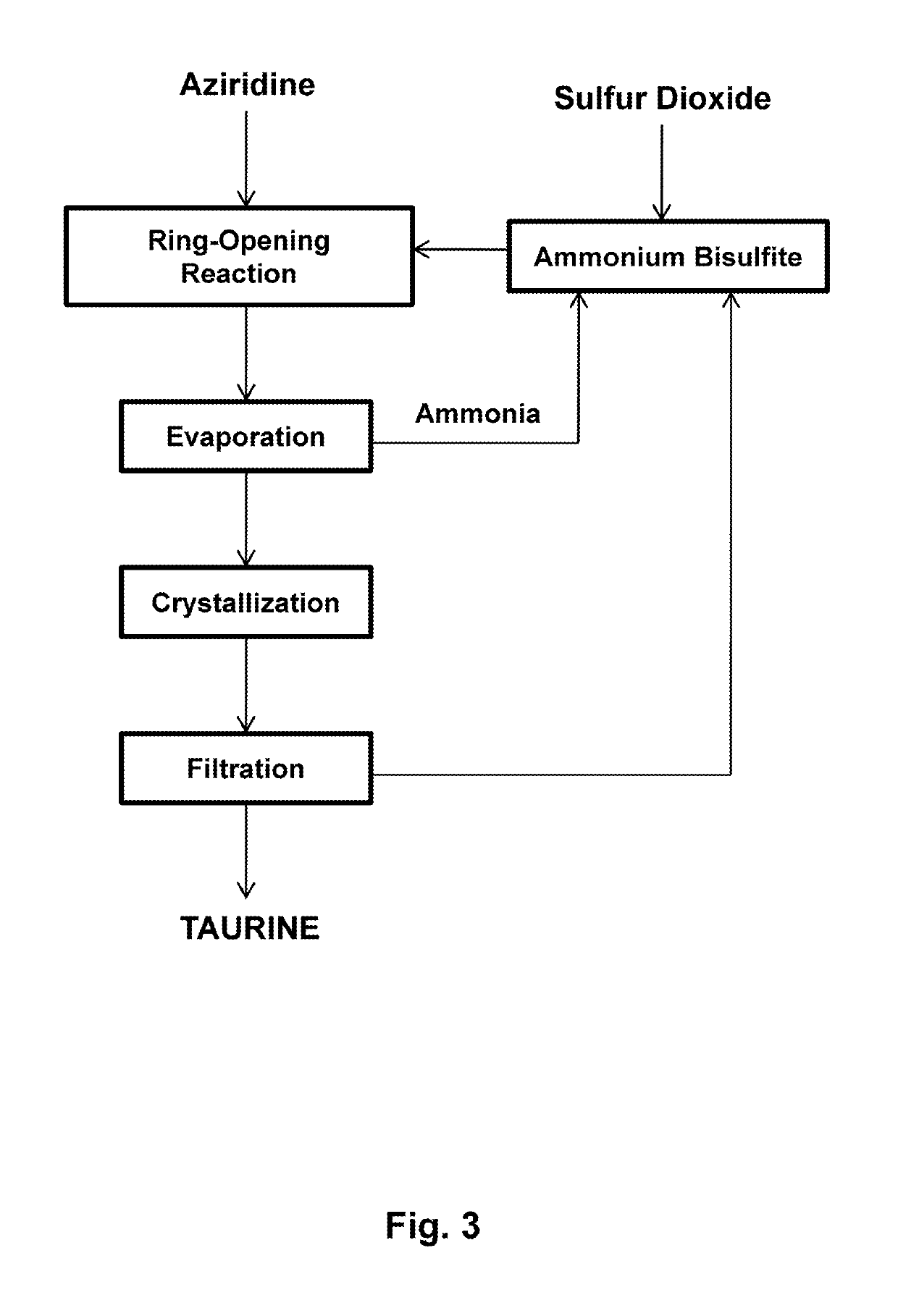

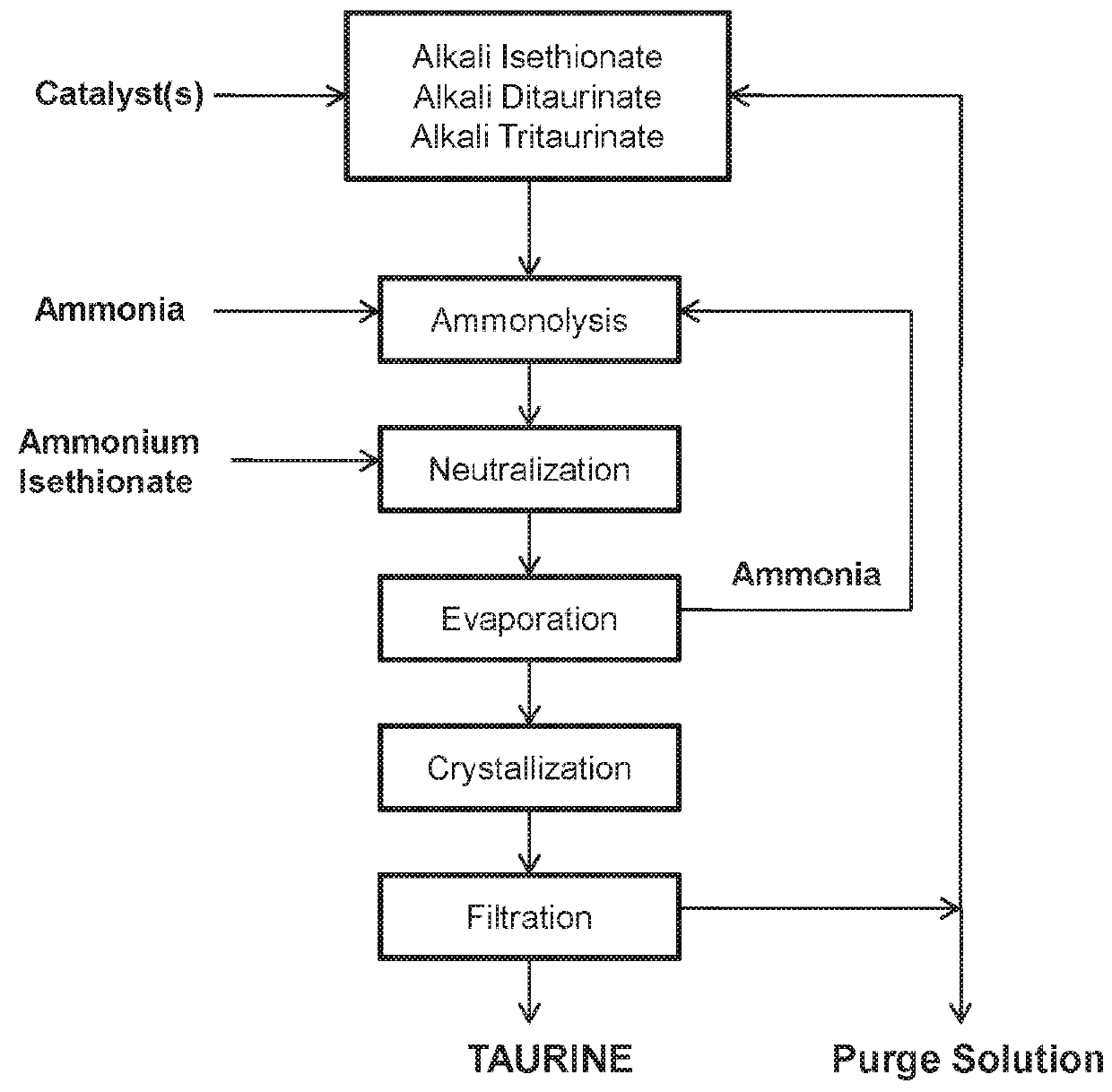

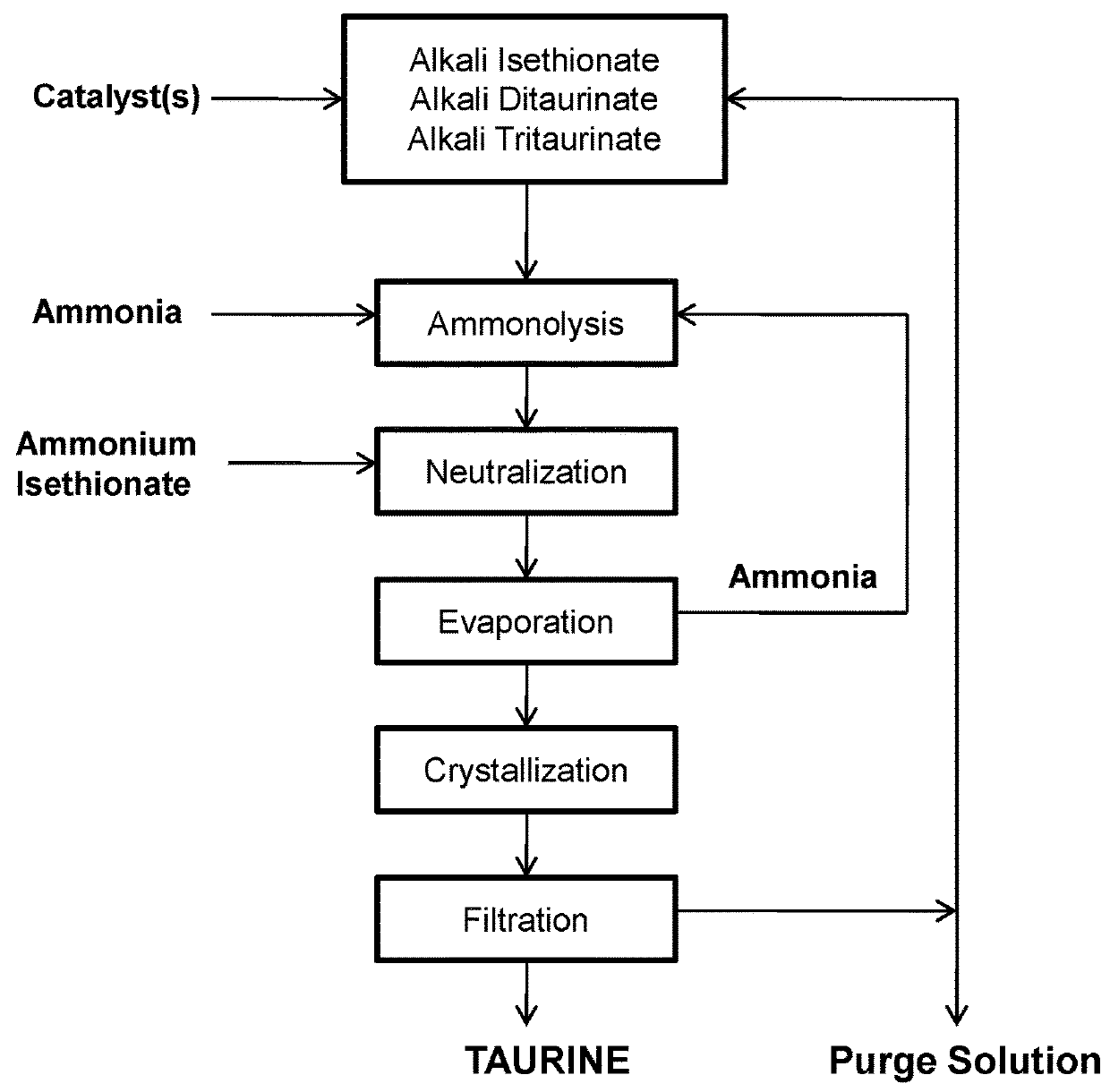

Cyclic process for producing taurine

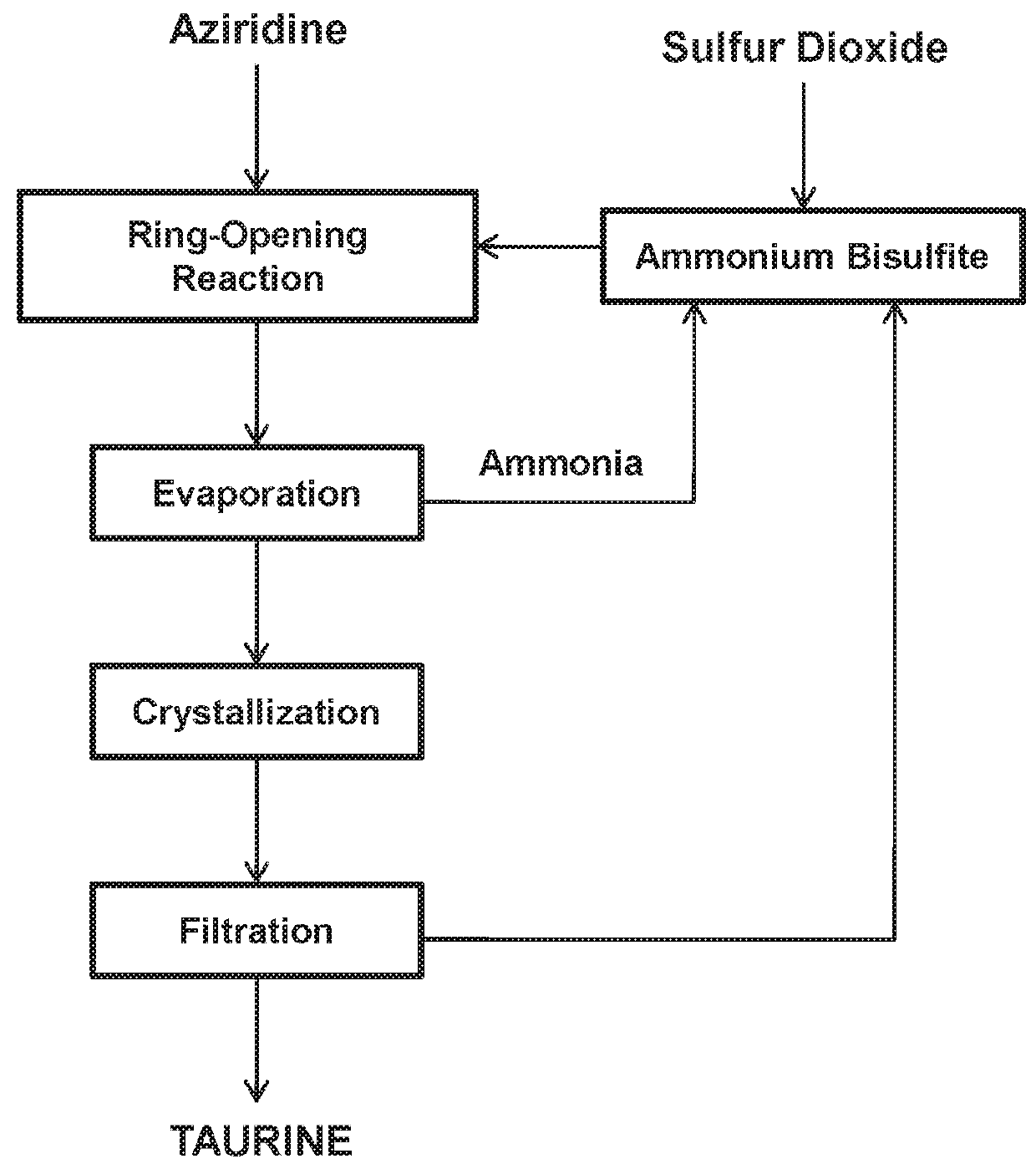

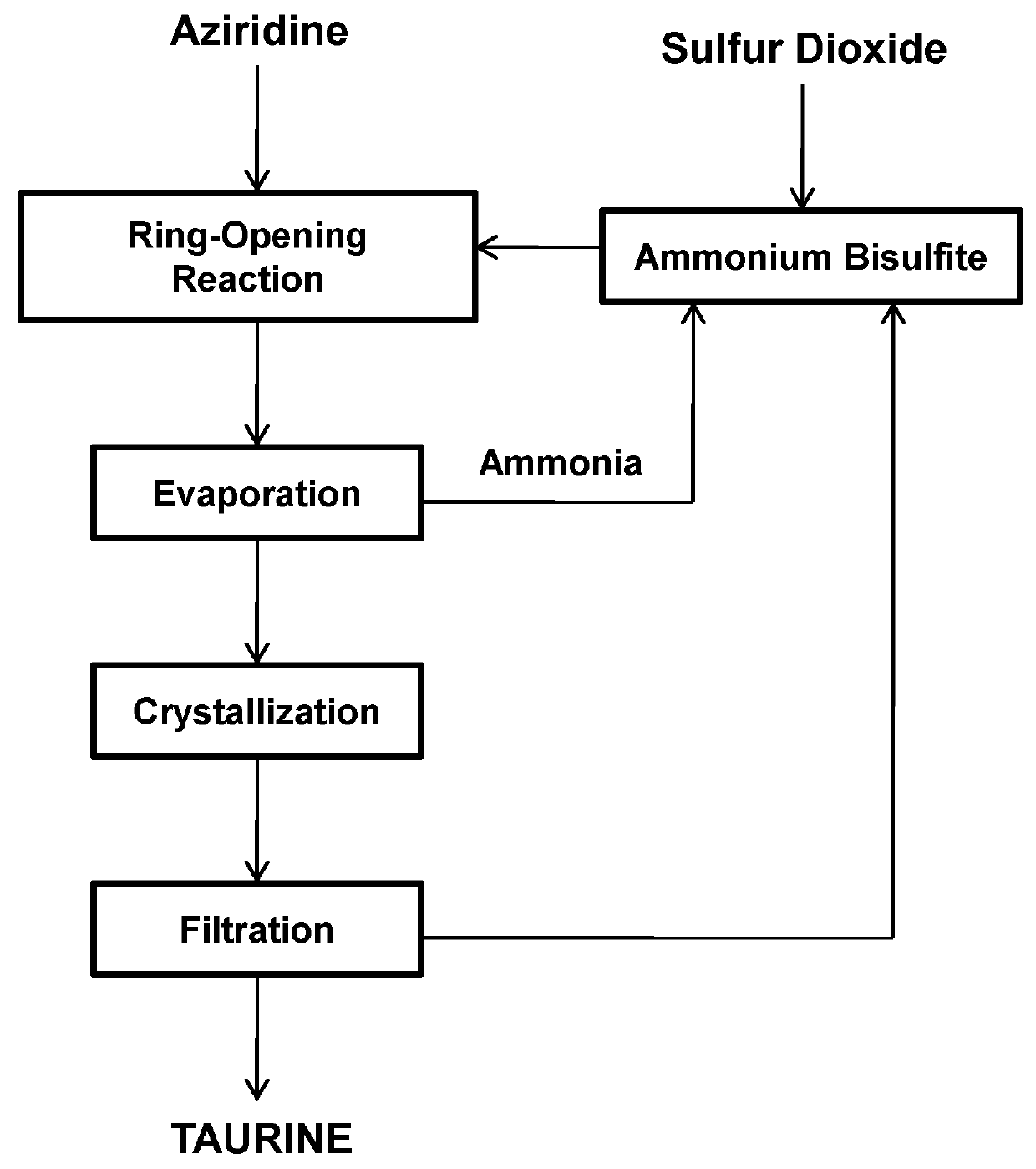

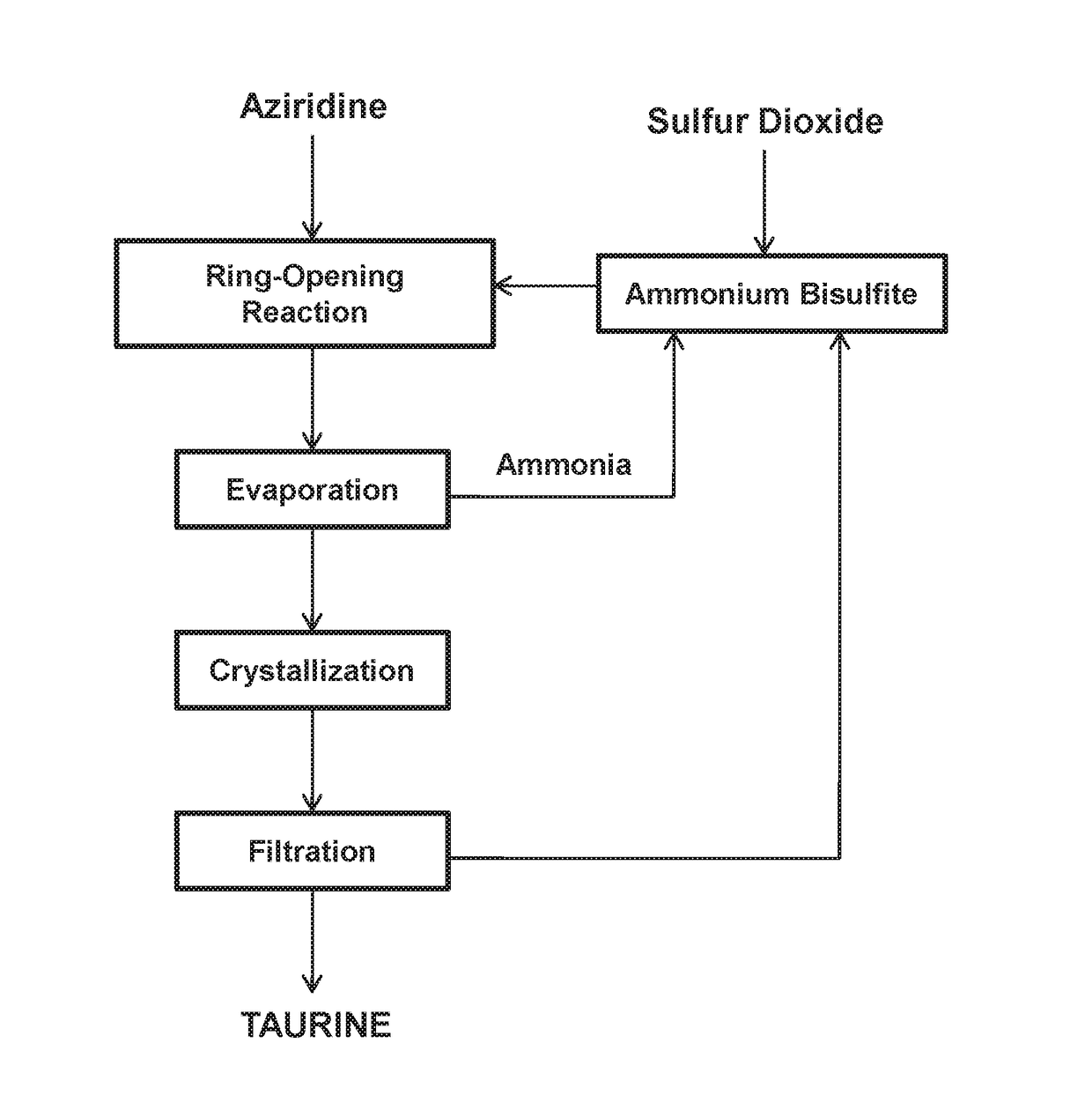

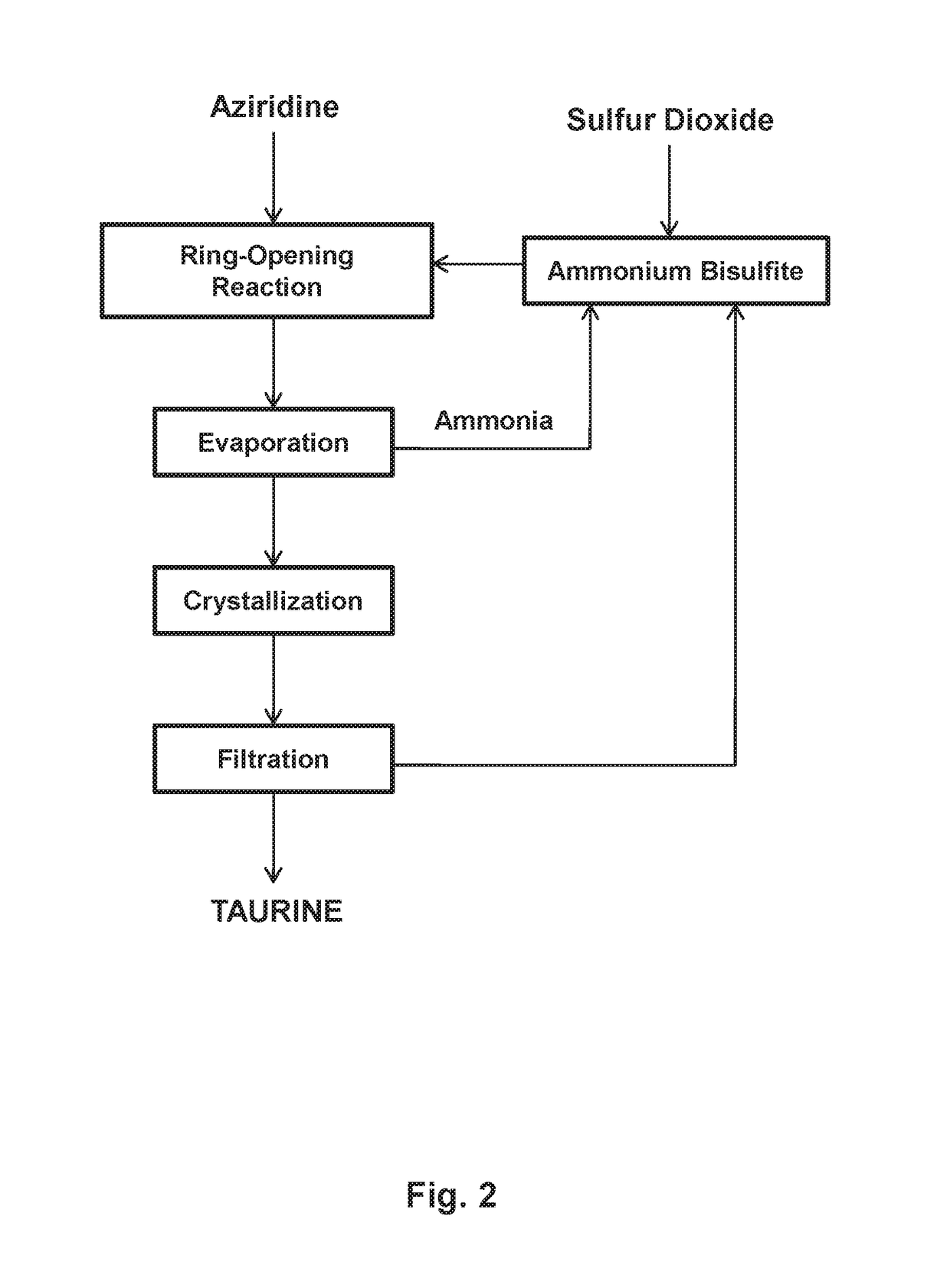

ActiveUS20180093946A1Quality improvementImprove production yieldOrganic compound preparationSulfonic acids salts preparationCyclic processAziridine

There is disclosed a process for producing taurine from aziridine by (a) adding gaseous aziridine or a solution of aziridine to a solution of ammonium bisulfite, or ammonium sulfite, or a mixture of ammonium bisulfite and ammonium sulfite to form ammonium taurinate; (b) decomposing ammonium taurinate by heating and removing ammonia from (a) to obtain a crystalline suspension of taurine; and (c) separating taurine by means of solid-liquid separation.

Owner:VITAWORKS IP LLC

Process for producing taurine

InactiveUS20180162806A1Simple processOrganic reductionOrganic compound preparationCarboxylic saltAziridine

There is disclosed a process for producing taurine by decomposing ammonium taurinate to taurine and ammonia. Ammonium taurinate is prepared by the hydrogenation of ammonium 2-nitroethanesulfonate, by the reaction of aziridine with ammonium bisulfite, or by mixing alkali taurinate with an ammonium salt selected from the group from ammonium isethionate, ammonium bisulfite, ammonium sulfite, ammonium sulfate, ammonium bisulfate, ammonium chloride, ammonium bromide, ammonium nitrate, ammonium phosphate, ammonium hydrogen phosphate, ammonium dihydrogen phosphate, ammonium carbonate, ammonium bicarbonate, ammonium carboxylate, ammonium alkyl sulfonate, ammonium aryl sulfonate, and a mixture of two or more thereof.

Owner:VITAWORKS IP LLC

Cyclic process for producing taurine

ActiveUS10112894B2Quality improvementImprove production yieldOrganic compound preparationSulfonic acids salts preparationCyclic processAziridine

There is disclosed a process for producing taurine from aziridine by (a) adding gaseous aziridine or a solution of aziridine to a solution of ammonium bisulfite, or ammonium sulfite, or a mixture of ammonium bisulfite and ammonium sulfite to form ammonium taurinate; (b) decomposing ammonium taurinate by heating and removing ammonia from (a) to obtain a crystalline suspension of taurine; and (c) separating taurine by means of solid-liquid separation.

Owner:VITAWORKS IP LLC

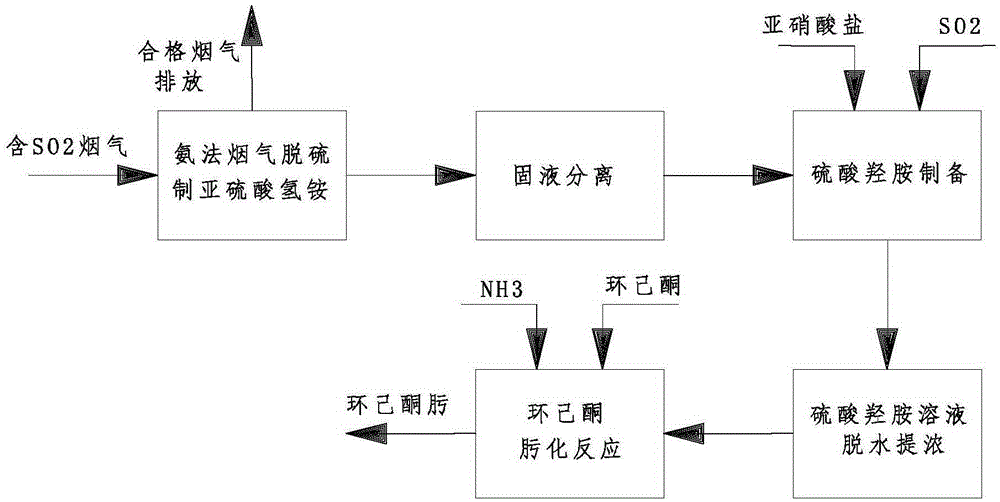

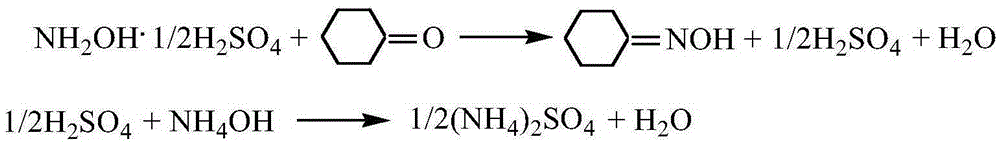

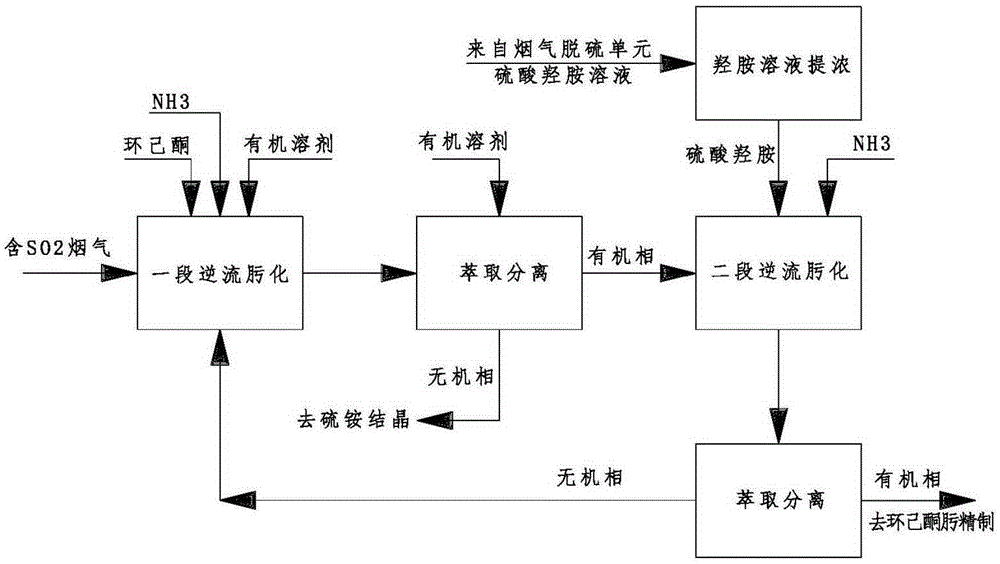

Method for producing by-product cyclohexanone-oxime through flue gas desulphurization by ammonia method

ActiveCN105348145ASolve the problem of desulfurizationIncrease added valueDispersed particle separationOximes preparationResource utilizationHydroxylamine sulphate

The invention discloses a method for producing by-product cyclohexanone-oxime through flue gas desulphurization by an ammonia method. The method comprises the following steps: ammonia or ammoniacal liquor is taken as an absorbent, sulfur dioxide in flue gas is absorbed in a flue gas absorbing tower, then ammonium bisulfite is prepared; the ammonium bisulfite is subjected to a reaction with nitrite and sulfur dioxide to prepare hydroxylamine sulphate; and the hydroxylamine sulphate and cyclohexanone are subjected to a reaction by employing a counter current oximation mode to produce cyclohexanone-oxime. The method has the advantages that SO2-containig flue gas is discharged with a standard, a sulfur resource in the flue gas and an ammonia resource in a desulfurizer can be recovered, a cyclohexanone-oxime product which has the advantages of high additional value and large product market space can be produced, high grade resource utilization of the by-product can be enhanced, waste can be changed into valuables, and economic benefit of flue gas desulphurization by the ammonia method can be increased.

Owner:SINOPEC NANJING ENG & CONSTR +1

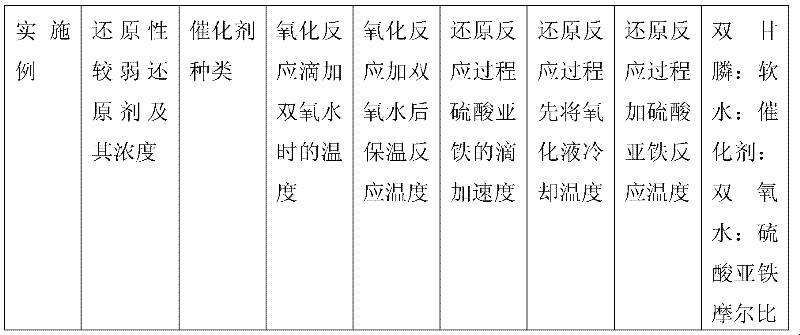

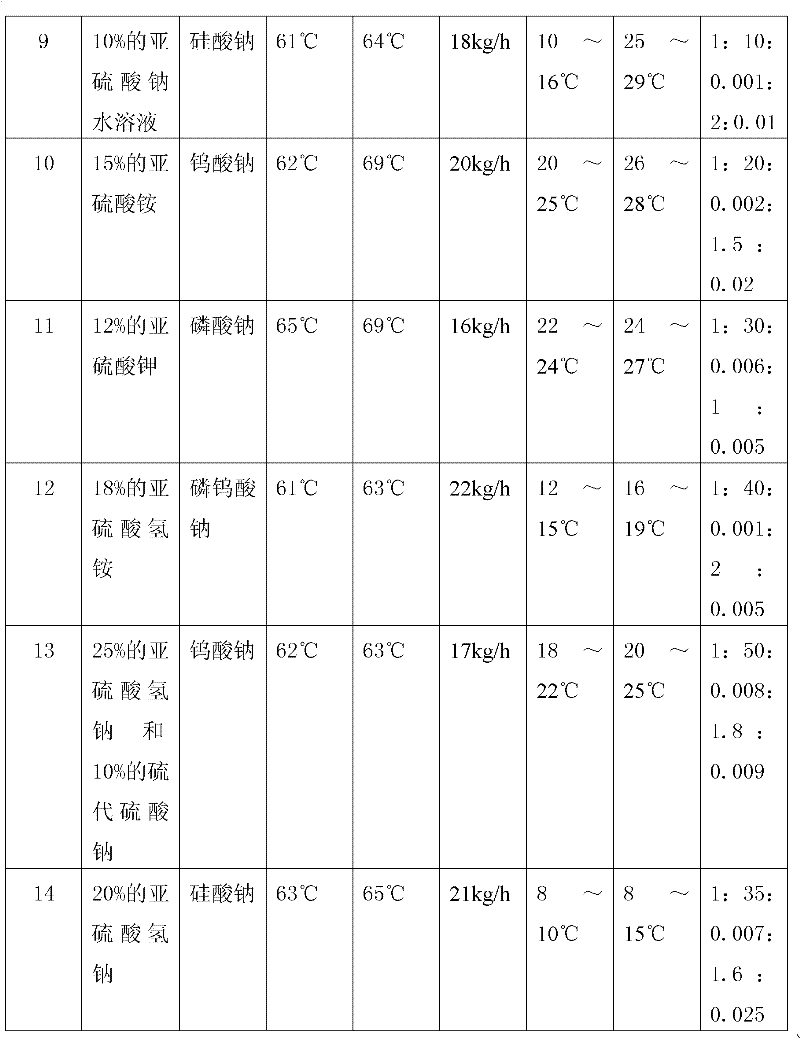

Preparation method for glyphosate

InactiveCN102649799AReduce consumptionLess fixed investmentGroup 5/15 element organic compoundsSulfite saltCatalytic oxidation

A preparation method for glyphosate comprises the steps as follows: oxydol is adopted for catalytic oxidation of a pmida raw material to obtain oxidation liquid, sulfide reductant with weaker reducibility is added into the oxidation liquid to consume excess oxydol in the oxidation reaction, then ferrous sulfate is added for reduction, and finally separation and drying are conducted so as to prepare the glyphosate; and the sulfide reductant with the weaker reducibility is any one or any combination of sodium sulfite, ammonium sulfite, potassium sulfite, ammonium bisulfite, sodium thiosulfate and sodium bisulfite. According to the method provided by the invention, the amount of the ferrous sulfate reductant is low, so as to save the raw material cost; the technical problem that the glyphosate prepared by the process in the prior art is yellowish is solved due to oxidation, reduction and other treatments in the method; meanwhile, the purity of the glyphosate prepared by using the method is high, the content of the glyphosate in solid powder is more than 96 percent, and the yield is more than 82 percent; and through the adoption of the method, the consumption of raw and auxiliary materials is lower, ammonia water, sulfuric acid and other raw materials are not used in the process.

Owner:CHONGQING UNISPLENDOUR CHEM

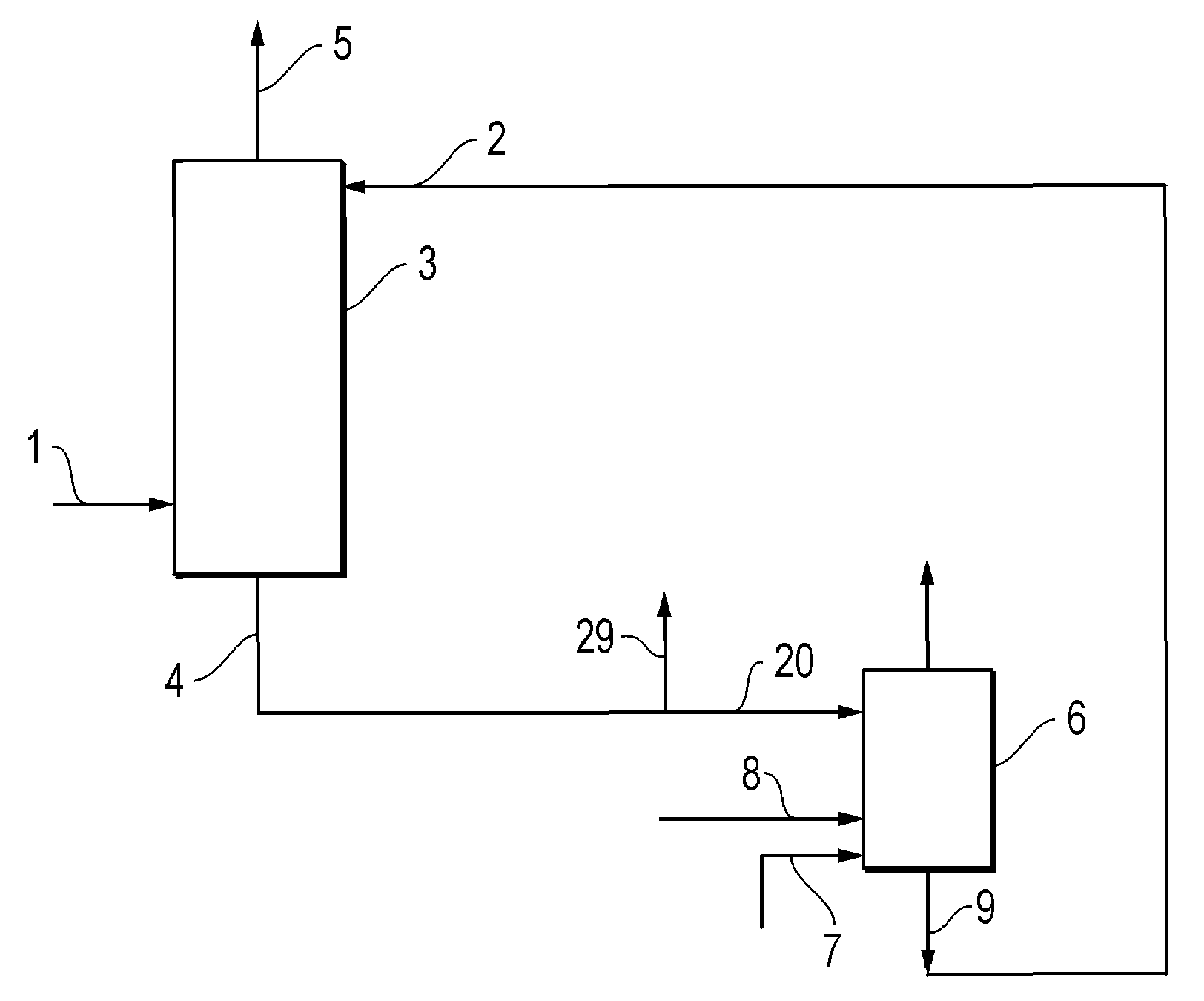

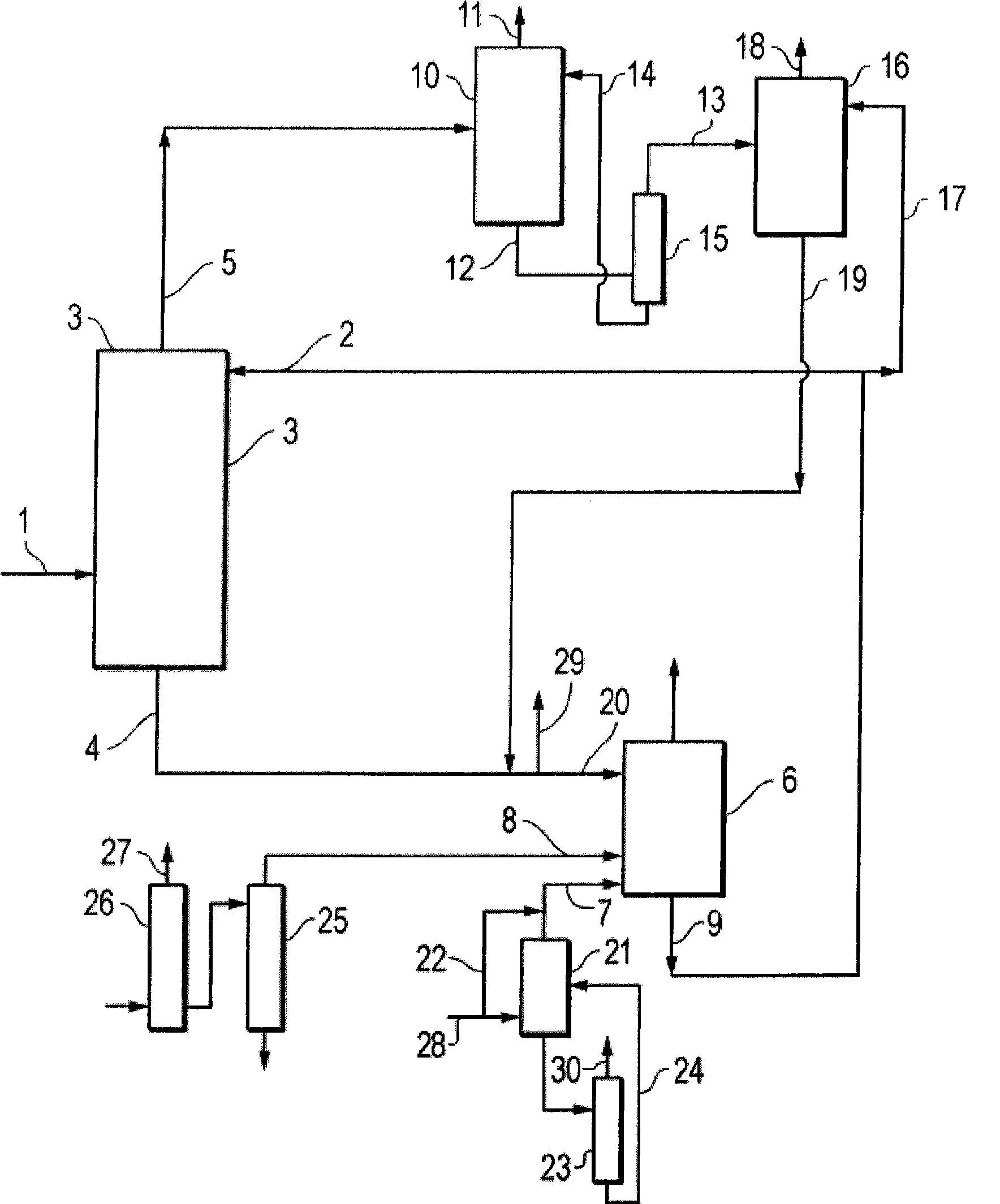

Process for Treating a Gas Stream

ActiveUS20070269357A1Efficient removalLow costCyanogen compoundsExhaust apparatusSolventSulfur dioxide

A process for treating a gas comprising hydrogen suilfide and carbon dioxide by contacting the gas with a scrub solution comprising ammonium sulfite and ammonium bisulfite in a first contact zone to produce ammonium thiosulfate. The scrub solution can be formed in a second contact zone by contacting ammonia and hydrogen sulfide with an aqueous solution. The oxidation potential of the first contact zone effluent liquid can be controlled by modulating the amount of sulfur dioxide supplied to the second contact zone. Alternatively, the sulfite concentration of the first contact zone effluent can be measured with an infrared analyzer and the amount of sulfur dioxide supplied to the second contact zone modulated in response. Additionally, the amount of ammonia supplied to the second contact zone can be modulated in response to the pH in the second contact zone. The process can further comprise a solvent scrubber to remove carbon dioxide from the first contact zone overhead gas. A third contact zone can be included in the process to separate the hydrogen sulfite from the carbon dioxide in the solvent regenerator overhead gas.

Owner:THIOSOLV

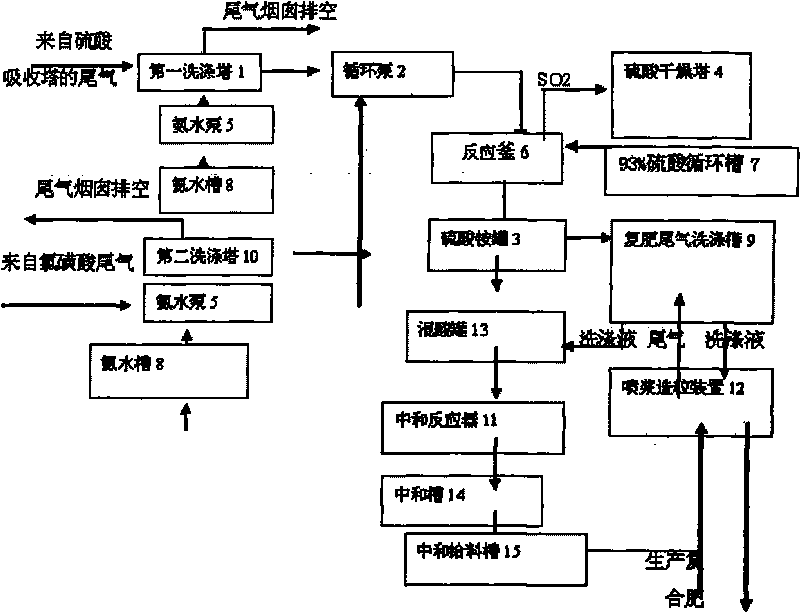

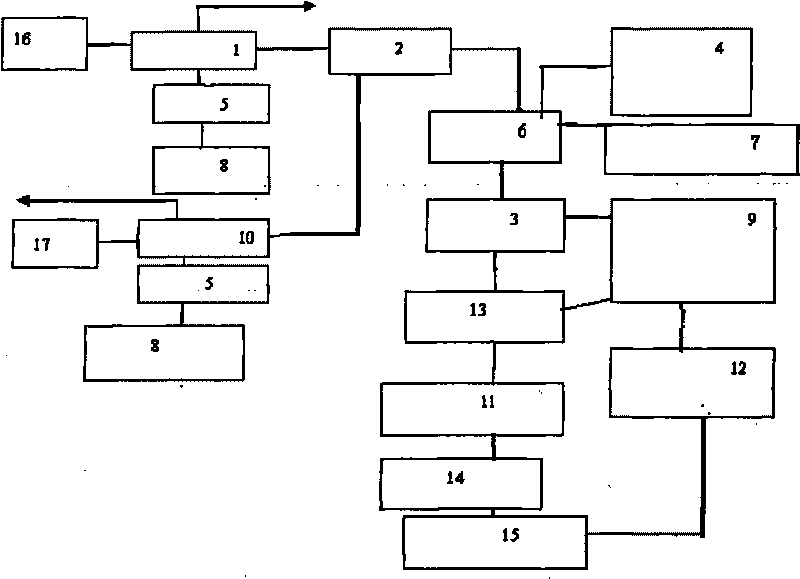

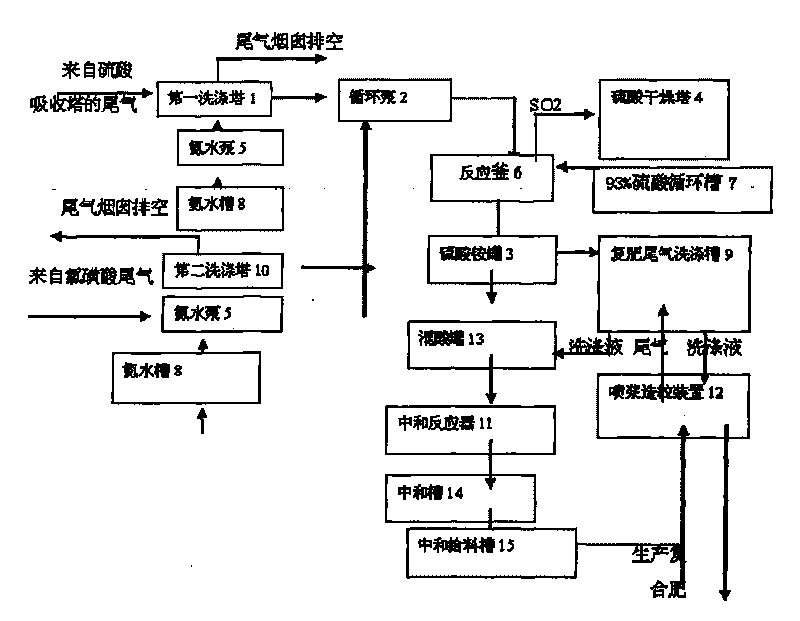

Process and equipment for producing potassium sulfate compound fertilizer by integrally utilizing tail gas generated in sulphuric acid production

ActiveCN101723411AReduce wasteReduce pollutionSulfate/bisulfate preparationFertilizer mixturesChlorosulfuric acidPotassium sulfate

The invention relates to a process and equipment for producing potassium sulfate compound fertilizer by integrally utilizing tail gas generated in sulphuric acid production, belonging to the technical field of fertilizer manufacture. The process comprises the following steps: washing sulphuric acid tail gas and chlorosulfonic acid tail gas with ammonia water; preparing ammonium sulfate by the generated ammonium bisulfite and ammonium sulfite; and producing the potassium sulfate by the prepared ammonium sulfite. The equipment for the process includes a reaction kettle which is communicated with a first washing tower and a second washing tower through a circulating pump and a pipeline, wherein the first washing tower and an ammonia vessel are connected with a sulphric acid tail gas exhaust device; and the second washing tower and the ammonia vessel are connected with a chlorosulfonic acid tail gas exhaust device. The process uses the ammonium bisulfite and the ammonium sulfite generated in the tail gas treatment of sulphuric acid production and chlorosulfonic acid, wherein the sulphric acid is used to decompose the sulfur dioxide generated by the ammonium bisulfite and the ammonium sulfite to reproduce sulphric acid, and the produced ammonium sulfate is applied to the compound fertilizer system for producing the compound fertilizer so as to reduce resource waste and environmental pollution.

Owner:山东聊城鲁西化工第五化肥有限公司

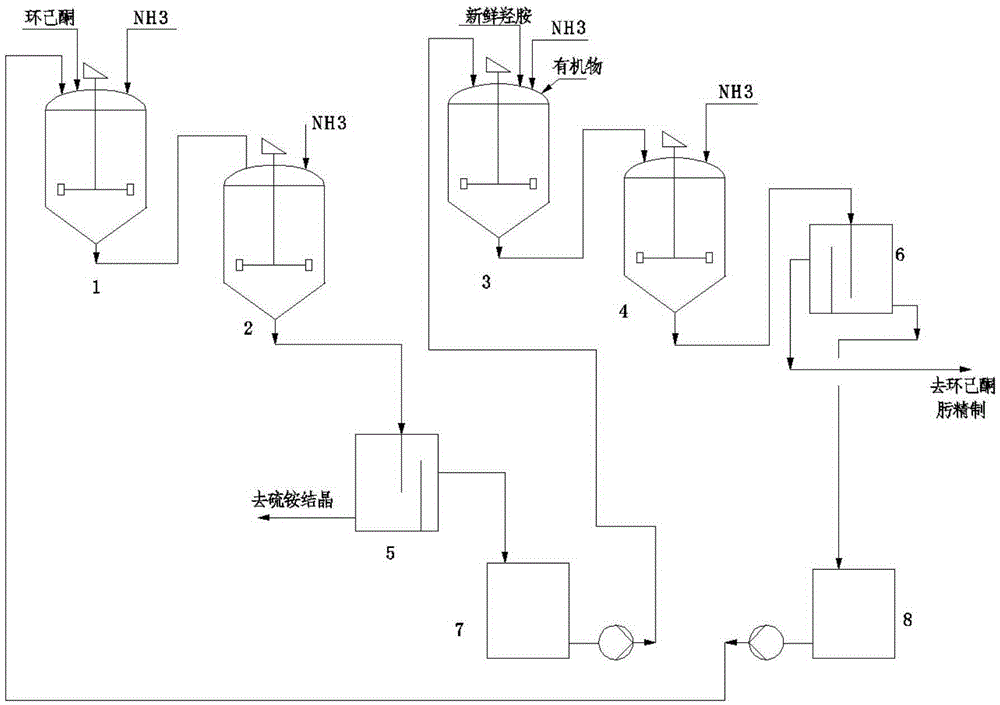

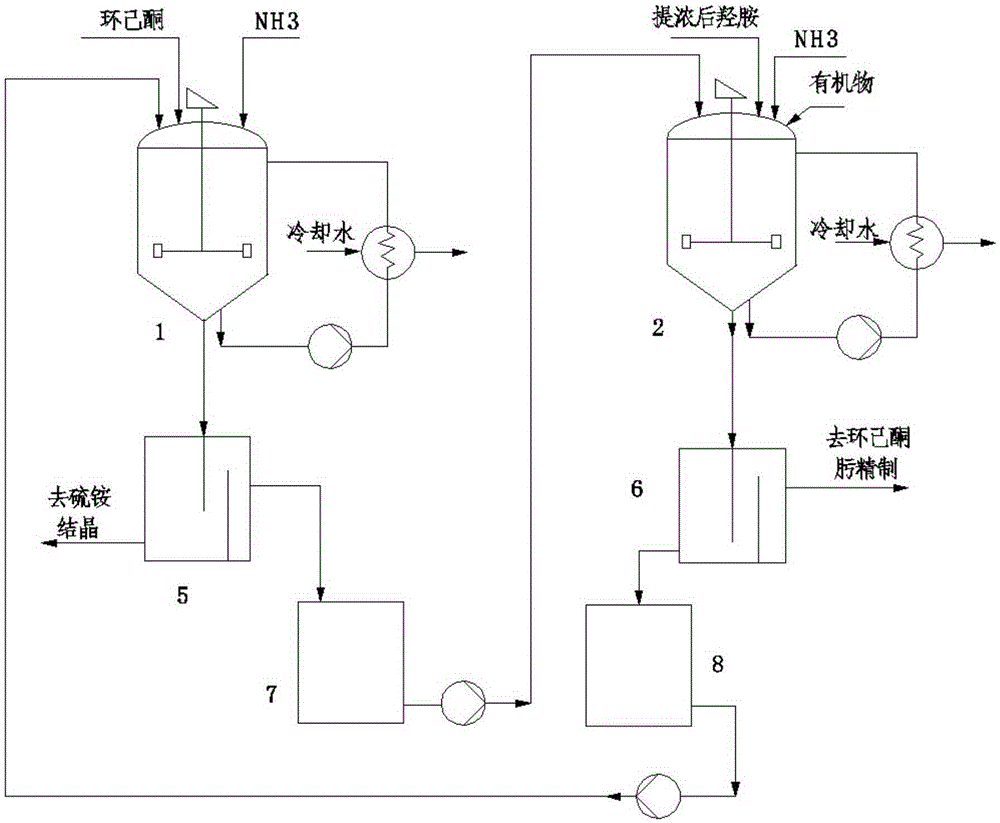

Cyclohexanone oxime synthesis method

ActiveCN105384656ALow Hydroxylamine Sulfate ConcentrationIncrease water contentOximes preparationSynthesis methodsHydroxylamine sulfate

The invention discloses a cyclohexanone oxime synthesis method. In the process of preparing a flue gas desulfurization byproduct cyclohexanone oxime, sulfur dioxide in flue gas is absorbed by utilizing ammonia or ammonia water as an absorbent to prepare ammonium bisulfite, and the ammonium bisulfite serving as a raw material reacts with cyclohexanone by means of counter-current oximation to prepare cyclohexanone oxime. According to the method, by increasing the concentration of hydroxylamine sulfate and adding the organic solvent, the diffusion performance of a reaction system is improved and consumption of cyclohexanone is reduced; furthermore, due to the extraction effect of the organic solvent, the total content of cyclohexanone-oxime and cyclohexanone in the inorganic phase which leaves a cyclohexanone oxime synthesis system can be reduced to lower than 0.30wt%, and the yield of the cyclohexanone oxime synthesis reaction is increased.

Owner:SINOPEC NANJING ENG & CONSTR +1

Double-tower ammonia desulfurization device and method for recovering sulfur resources

ActiveCN101708412BHigh purityGuaranteed purityUsing liquid separation agentAmmonium sulfitesFlue gasSulfur

The invention discloses a double-tower ammonia desulfurization device and method for recovering sulfur resources. The device includes a dynamic wave scrubber, a primary absorption tower, a secondary absorption tower, etc. After the flue gas is removed from the ash by the dynamic wave scrubber, the temperature is lowered by the dynamic wave scrubber, and the flue gas enters the primary absorption tower and the secondary absorption tower in turn. , the first-level absorption tower and the second-level absorption tower are equipped with 5 spray layers, the lower three spray layers spray and absorb the flue gas, and the upper two spray layers prevent ammonia from escaping. The absorption tower and the secondary absorption tower are discharged after spraying and absorbing. The present invention has the following advantages: 1) the purity of by-products is high; 2) the double-tower design can not only obtain higher desulfurization efficiency, but also produce high-purity by-products; 3) this process uses ammonium bisulfite as the final The by-product not only omits the process of crystallization and drying in the previous process, but also improves the added value of the by-product; 4) the process of the present invention is all recycled without secondary pollution.

Owner:ZHEJIANG UNIV

Technology and device for reducing drag of desulfurization tower of flue gas desulfurization system of sintering machine

PendingCN109107304AReduce tower resistanceExtended service lifeUsing liquid separation agentSulfateProcess engineering

The invention discloses a technology and a device for reducing drag of a desulfurization tower of a flue gas desulfurization system of a sintering machine. The method comprises the following steps ofpretreatment, reverse absorption, demisting, solution oxidizing, filtering, and process water treatment. The method has the beneficial effects that the flue gas entering the desulfurization tower is cooled and dedusted by a gas high-efficiency water cooling and dedusting device and a bag type deduster or an electric deduster, and two spraying assemblies are used for spraying and cooling, so that the temperature difference between flue gas and absorbing liquid is reduced, the separating rate of ammonia sulfate is reduced, and the blockage due to crystallizing in the tower is reduced; the absorbing rate of sulfur dioxide is improved, the emission amount of ammonium sulfite and ammonium sulfite aerosol along with flue gas is reduced, the loss of ammonia is reduced, and the concentration of escape ammonia is lower than 10mg / Nm<3>; the aerosol in the flue gas can be quickly and effectively removed, the quality of flue gas entering the desulfurization tower is greatly improved, the drag of the desulfurization tower is reduced, and the service life of the desulfurization tower is prolonged.

Owner:云南天朗环境科技有限公司

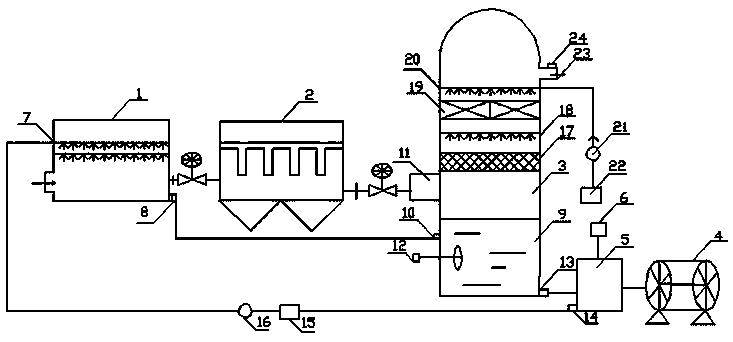

Recycling ammonia desulphurization process

ActiveCN104740987AIncrease added valueSuitable reducibilityDispersed particle separationAmmonium sulfatesSodium bicarbonatePyrolusite

The invention discloses a recycling ammonia desulphurization process. According to the process, ammonium bicarbonate is used as an absorption agent to absorb sulfur dioxide smoke so as to generate an ammonium bisulfate intermediate product, the ammonium bisulfate intermediate product is used for reducing and carbonizing pyrolusite by utilizing the oxidization performance of the pyrolusite, and high-quality manganese carbonate and ammonium sulfide products are obtained; the sulfur dioxide smoke, ammonium bicarbonate and pyrolusite raw materials selected in the process are wide in source and cheap in price, the manganese carbonate and ammonium sulfide products with relatively high additional values are obtained, the economic benefit is remarkable, and the problems of low oxidization efficiency in the process of preparing ammonium sulfide from ammonium bisulfate and high production cost in the manganese carbonate preparation process can be overcome; moreover, the process is simple to operate, the process conditions are moderate, the reaction can be completed under a room temperature condition, the prepared product is high in quality, and the industrialized production requirement can be met.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

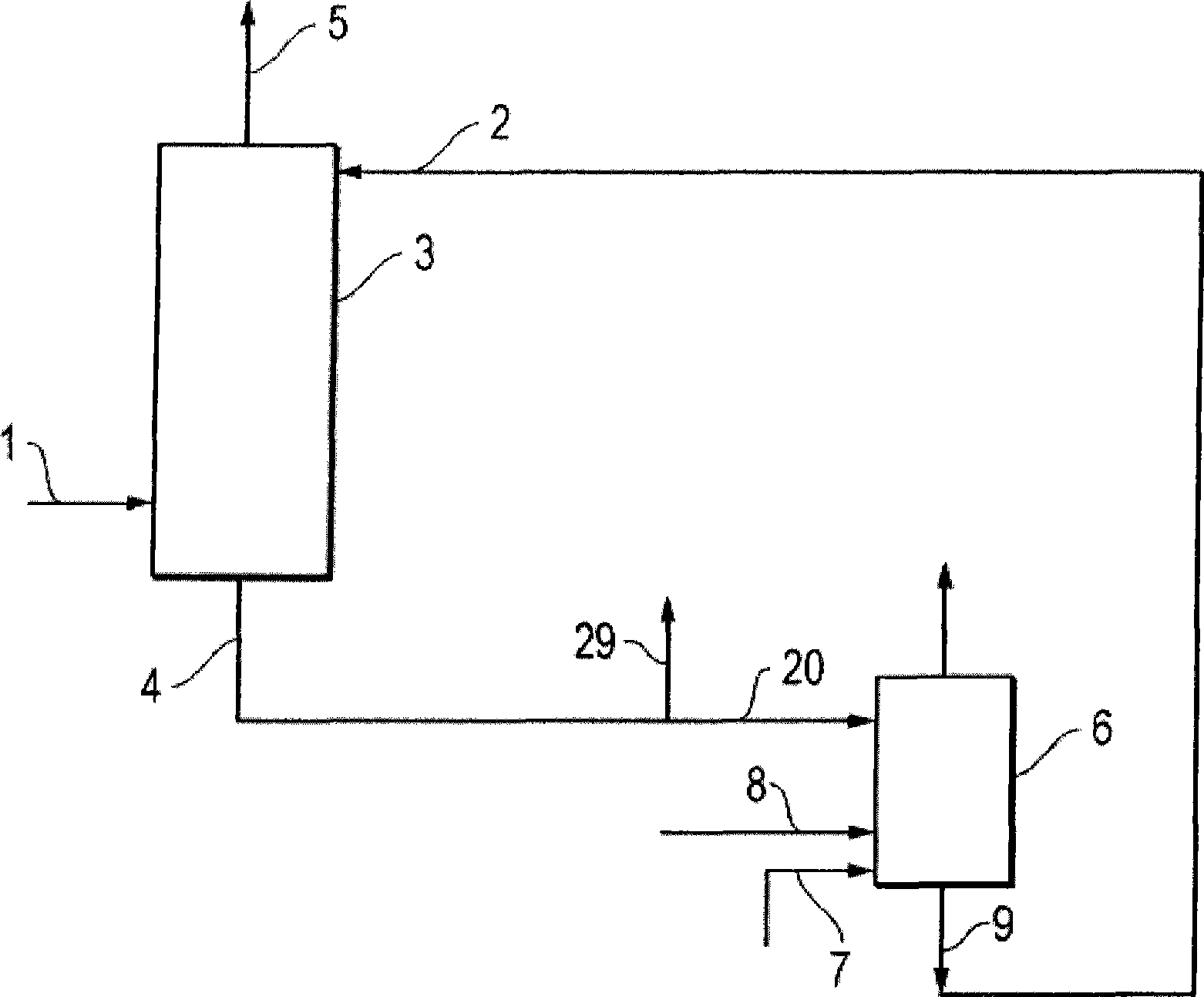

Process for treating a gas stream

InactiveCN101479022AHas economic valueHave market valueControlling ratio of multiple fluid flowsDispersed particle separationHydrogenWastewater

The invention relates to a gas treating process of generating ammonium thiosulfate by contracting a gas (1) comprising hydrogen suilfide and carbon dioxide with a scrub solution (2) comprising ammonium sulfite and ammonium bisulfite in a first contact zone (3). The scrub solution can be formed in a second contact zone (6) by contacting ammonia (8) and hydrogen sulfide (7) with an aqueous solution. The oxidation potential of the first contact zone effluent liquid can be controlled by modulating the amount of sulfur dioxide supplied to the second contact zone. Alternatively, the sulfite concentration of the first contact zone can be measured by an infrared analyzer and can be modulated in response to the amount of sulfur dioxide supplied to the second contact zone. Additionally, the amount of ammonia supplied to the second contact zone can be modulated in response to the pH in the second contact zone.

Owner:THIOSOLV

Anticorrosion aerated brick and making method thereof

The invention discloses an anticorrosion aerated brick, which is characterized by being made of the following raw materials by weight part: 14-16 of quicklime, 24-26 of fluorite slag, 1-2 of hydrogen peroxide, 8-9 of cement, 0.2-0.4 of ammonium bisulfite, 0.4-0.6 of salt cake, 10-12 of urban road waste cement road slag, 2-4 of zirconia, 6-8 of fly ash, 5-8 of acrylic fiber, 1-3 of magnesium aluminometasilicate, 7-9 of dibenzylidene sorbitol, 4-7 of perfluoroalkylethyl acrylate, 0.3-0.7 of N-vinyl pyrrolidone, 6-8 of olive oil, 0.3-0.5 of citronella grass, 0.2-0.6 of folium artemisiae argyi, 3-5 of an additive, and a proper amount of water. The aerated brick made by the invention has good anticorrosion effect and good wear resistance, can effectively prevent external force and internal stress damage and resist acid liquor corrosion or flue gas scouring, can effectively prolonging the service life of the matrix, and reduces energy consumption. Meanwhile, by optimizing the formula materials, cracks on a green body are reduced, the qualified rate and the compressive strength of the finished product are excellent.

Owner:重庆市霖垚诚首环保建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com