Monotower ammonia desulfuration recovery method for removing aerosols in flue gas

A technology of ammonia desulfurization and recovery method, which is applied in the field of flue gas desulfurization technology, can solve the problems of low recovery rate of ammonium sulfate and the existence of aerosol, etc., and achieve the effect of solving low recovery rate, improving recovery rate and increasing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

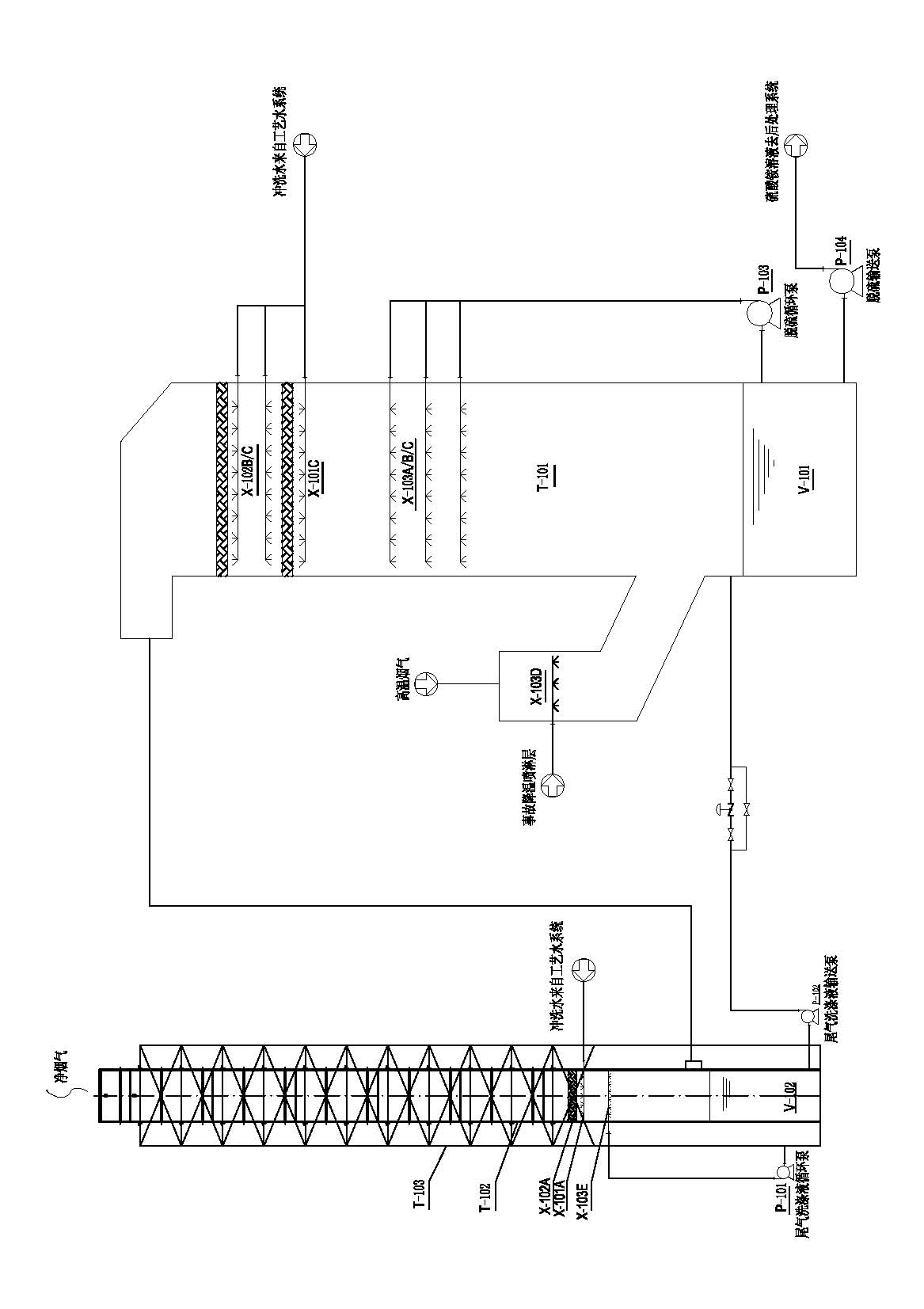

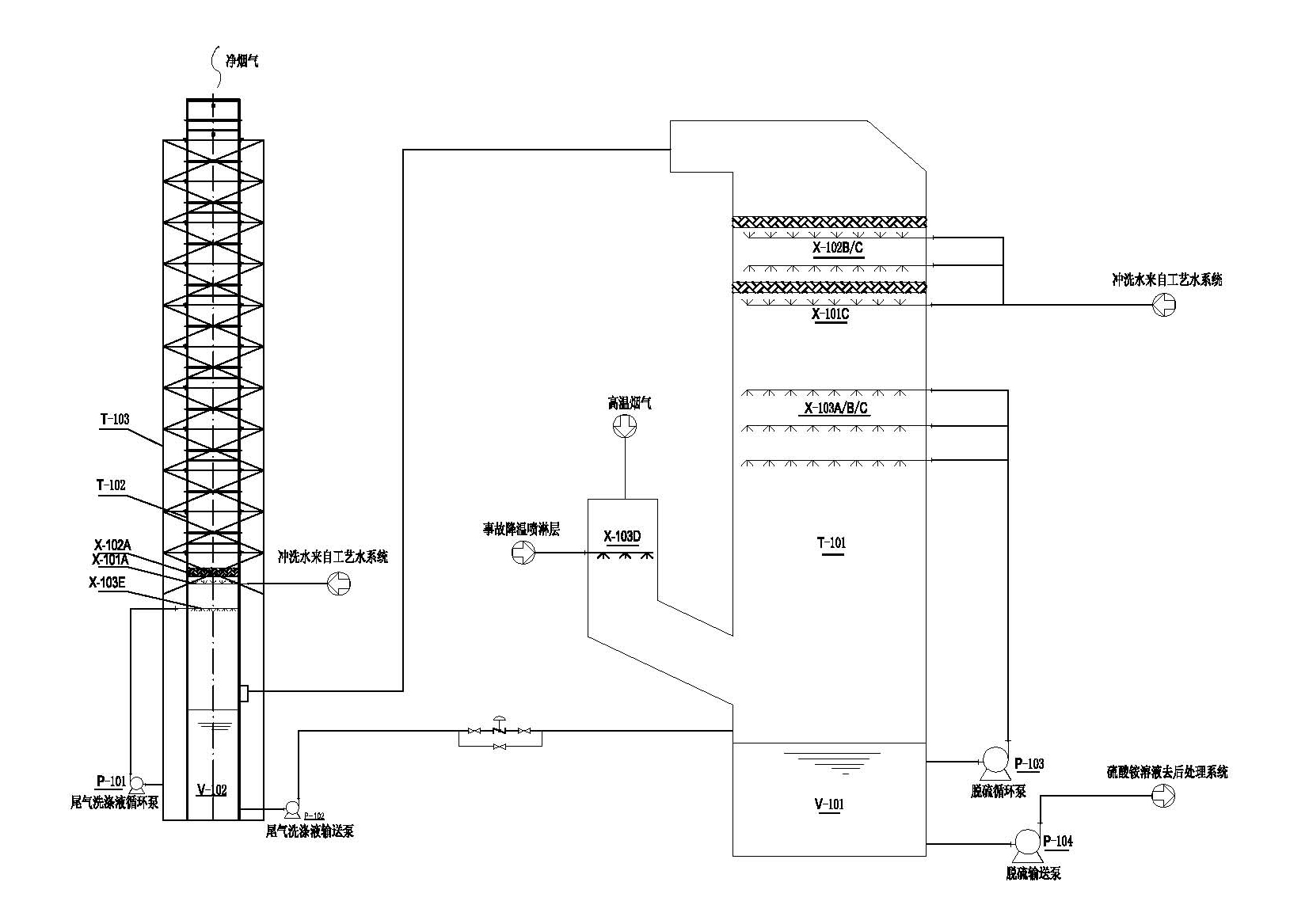

[0022] Such as figure 1 shown.

[0023] A single-tower ammonia desulfurization recovery method for removing aerosol in flue gas is characterized in that it comprises the following steps:

[0024] Firstly, let the high-temperature flue gas enter the desulfurization tower from the smoke inlet on the side of the desulfurization tower T101, and set at least one spray layer in the desulfurization tower and above the smoke inlet (it can be used in specific implementation. figure 1 The three-layer structure shown in, figure 1 The middle three spray layers are X-103A, X-103B, X-103C from the bottom to the last), according to the ratio of spray liquid and flue gas of 1-3:1 to the high-temperature flue gas entering the degassing tower Spraying (spray liquid is measured in flow rate, liters per second, flue gas is measured in volume, cubic meters), and the spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com