Patents

Literature

520 results about "Ammonium bisulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium bisulfate, also known as ammonium hydrogen sulfate, is a white, crystalline solid with the formula (NH₄)HSO₄. It is the product of the half-neutralization of sulfuric acid by ammonia.

High-efficiency cleaning mineral separation process of complicated sulfuration mine

The invention discloses an efficient and clean beneficiation method of complex sulfide ore. The method includes the following steps: utilizing an activator selected from one of or some of oxalic acid, ammonium carbonate, ammonium bicarbonate, ammonium sulfate, ammonium bisulfate and ferrous sulfate as a combination; utilizing collectors including xanthate collectors, black collectors, white collectors and thionocarbamate collectors; mixing the activator, the collectors and BC; stirring; and performing flotation separation of the sulfide ore to obtain the sulfur concentrate. The inventive beneficiation method has the advantages of high discrimination property, cleanness and non-toxicity; and is suitable for the flotation separation of the complex sulfide ore, particularly the flotation separation of complex sulfide ore containing pyrrhotites and pyrites with fine dissemination size.

Owner:CENT SOUTH UNIV

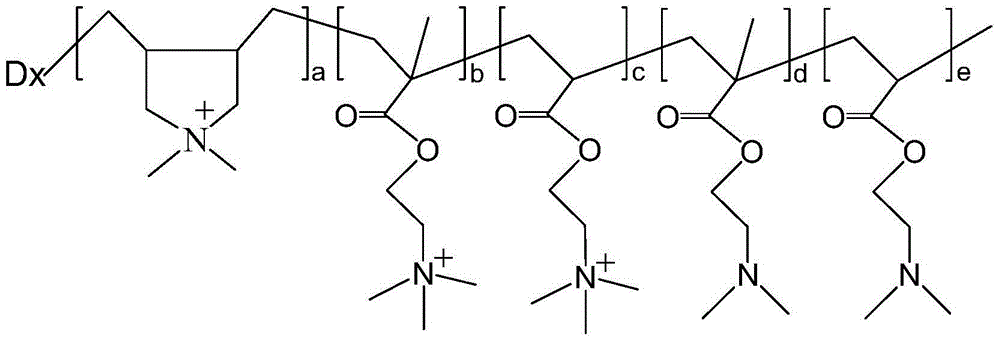

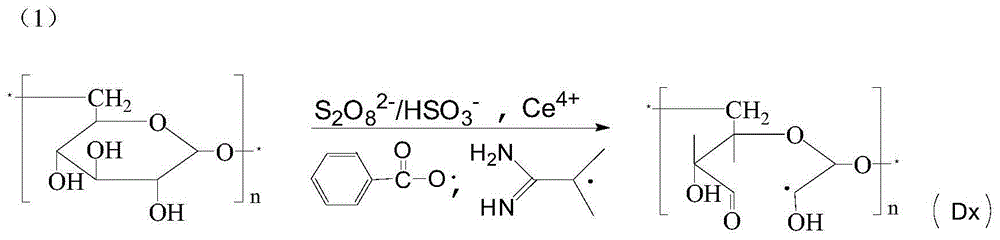

Grafted copolymerized cationic polysaccharide bioflocculant and preparation method thereof

ActiveCN104130351AImprove adsorption capacityHigh positive charge densityWater/sewage treatment by flocculation/precipitationMethacrylateSodium bisulfate

The invention relates to a grafted copolymerized cationic polysaccharide bioflocculant and a preparing method thereof. A product with the cationic degree (DC) of 3-63% is finally prepared through an aqueous solution polymerization technology with a present nonionic polysaccharide bioflocculant (Dx) as a raw material, one or more of dimethyl diallyl ammonium chloride (DMDAAC), methacryloxyethyltrimethyl ammonium chloride (DMC), acryloyloxyethyltrimethyl ammonium chloride (DAC), dimethylaminoethyl methacrylate (DMAEMA), dimethylaminoethyl acrylate (DMAEA) as a monomer, and one or two of ammonium persulfate / sodium bisulfate and dibenzoyl peroxide (BPO) (AIBA) as an initiator. The preparation method is simple, and is easy to control, and the product obtained in the invention has good flocculation effect and high treatment efficiency, and can be widely used in the field of treatment various sewages, the sludge dewatering field and the like.

Owner:威海汉邦生物环保科技股份有限公司

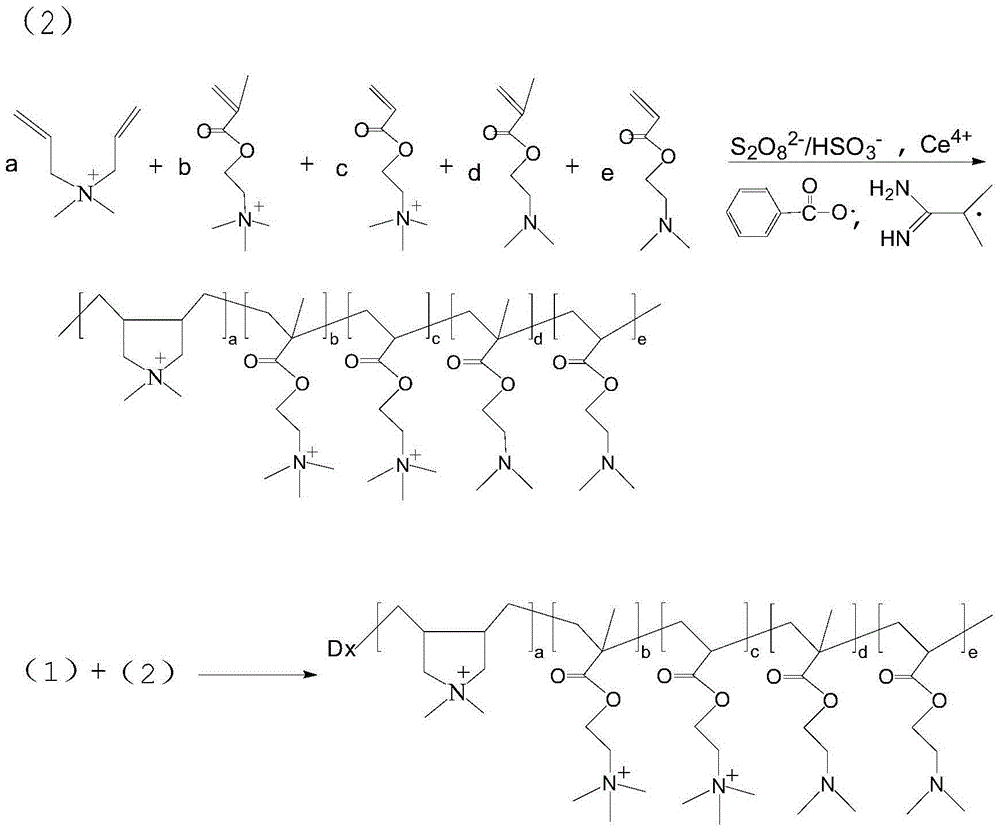

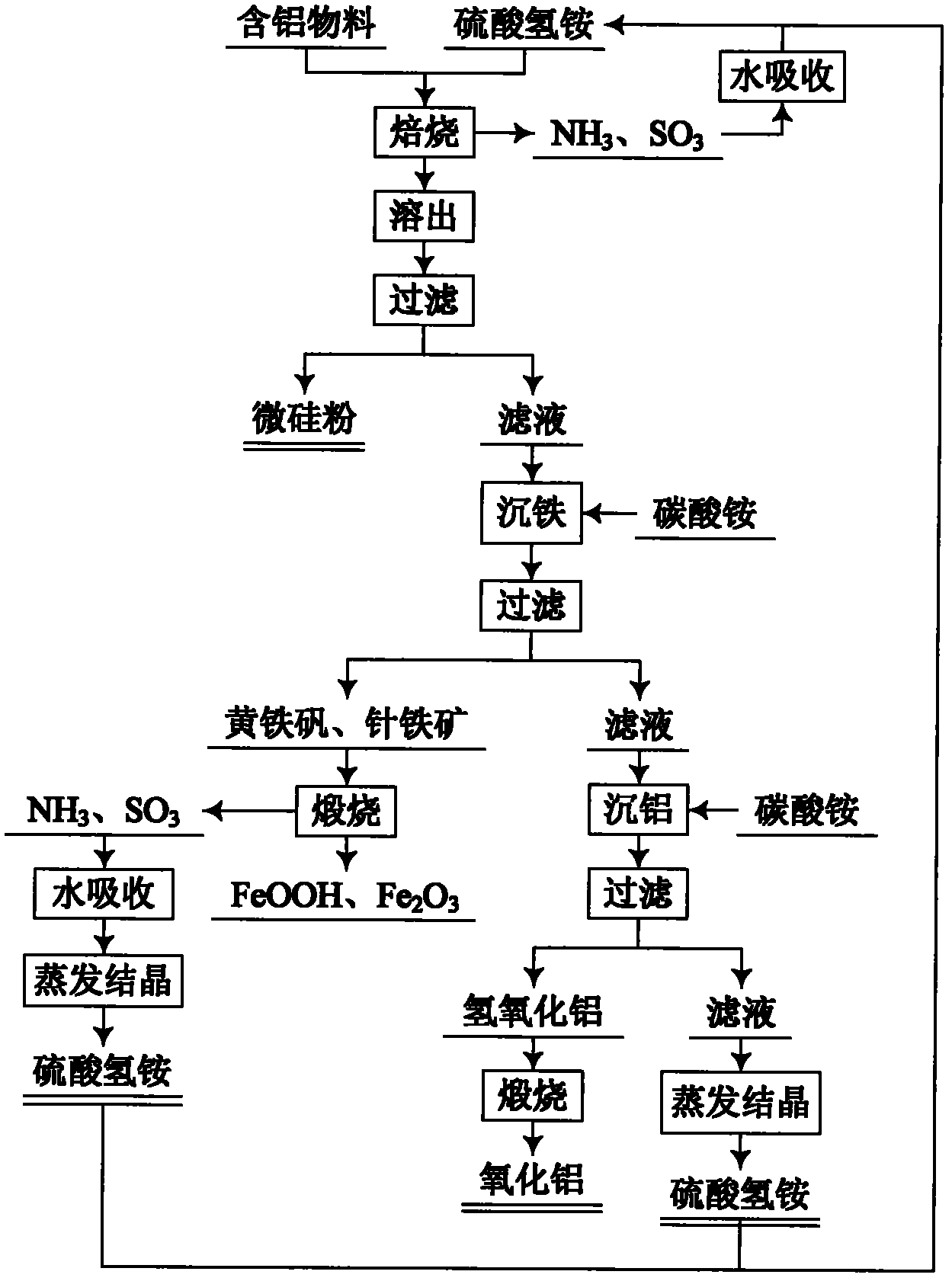

Method for comprehensive utilization of aluminum-containing material

The invention relates to a method for preparing aluminum oxide and other products by aluminum-containing materials of bauxite, alunite, nepheline, fly ash, kaolin, coal gangue and clay. The method comprises the following steps: (1) crushing and grinding an aluminum-containing material, carrying out mixing and baking for the treated aluminum-containing material and ammonium bisulfate; (2) carryingout dissolution and filtering for the baked clinker to obtain a crude ammonium aluminum sulfate solution and aluminum extracting residue; (3) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration more than 1 g / L by adopting a jarosite method, then carrying out an iron precipitating treatment by a goethite method, carrying out an aluminum precipitating treatment for the resulting solution, carrying out calcination for the resulting aluminium hydroxide to prepare aluminum oxide; (4) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration less than 1 g / L by adopting the goethite method, and carrying out an aluminum precipitating treatment to prepare aluminum oxide, or adopting a recrystallization method to carry out purification, adopting a reaction of the ammonium aluminum sulfate crystal and a ammonium carbonate solution to precipitate the aluminum to obtain ammonium aluminumcarbonate, carrying out calcination for the ammonium aluminum carbonate, and adopting a Bayer method to treat the calcined ammonium aluminum carbonate to prepare sandy aluminum oxide; (5) washing anddrying the aluminum extracting residue, wherein the dried aluminum extracting residue is adopted as the silicon dioxide product.

Owner:NORTHEASTERN UNIV

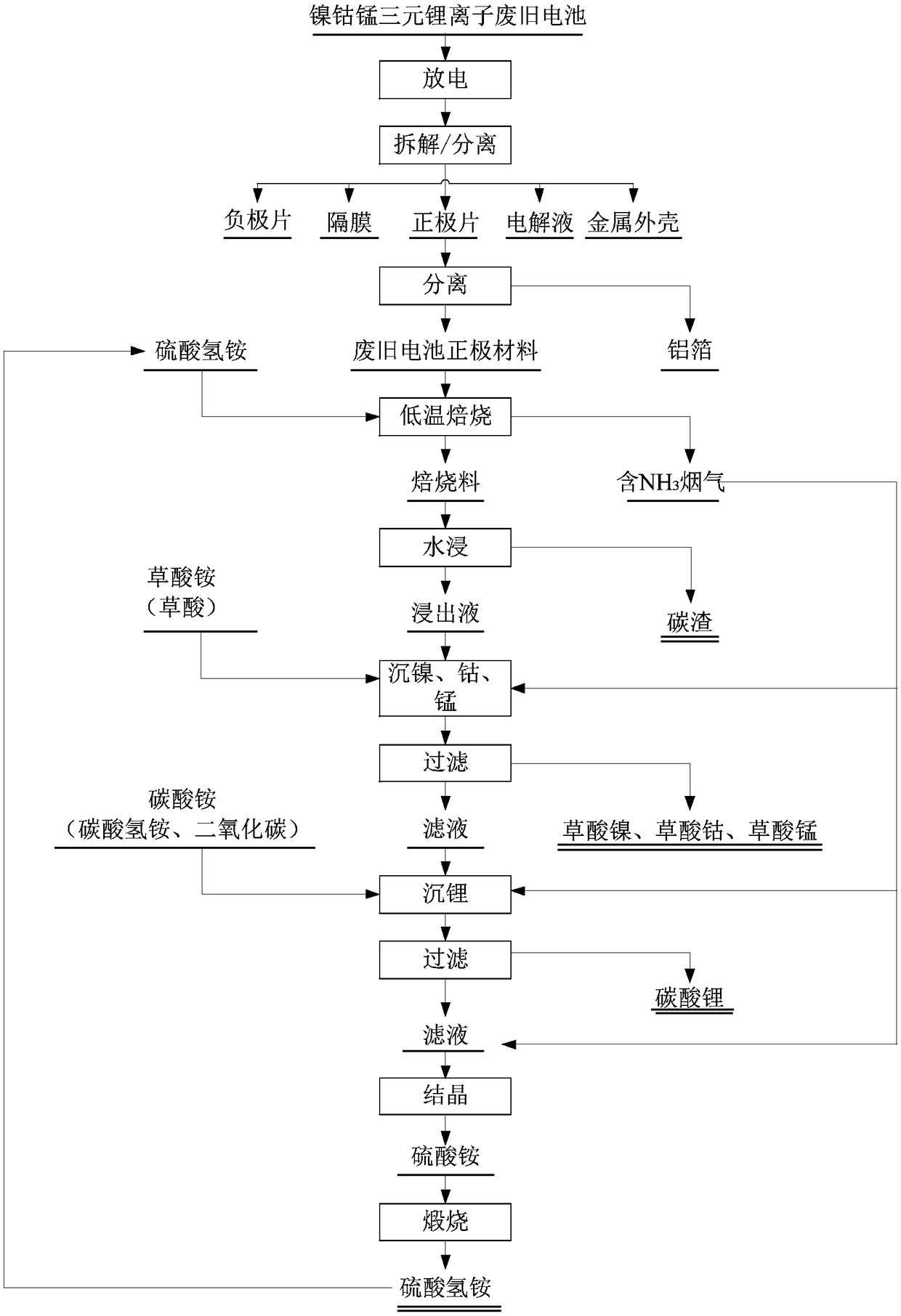

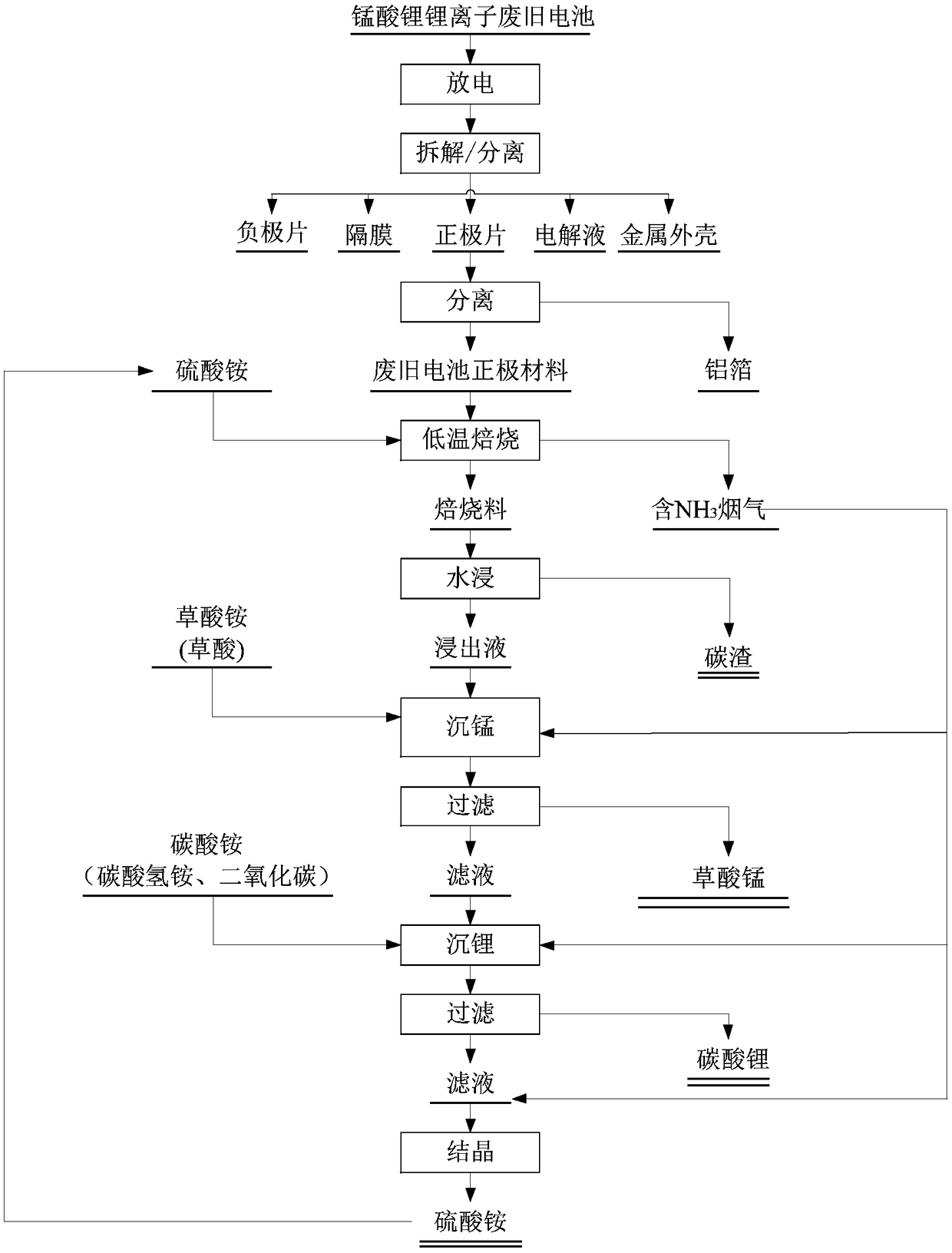

Method for recovering valuable metals from positive electrode material of waste lithium ion battery

ActiveCN108767354AHigh recovery rateAvoid it happening againWaste accumulators reclaimingProcess efficiency improvementLithium-ion batteryMaterials science

The invention provides a simple, efficient and environment-friendly method for recovering valuable metals from a positive electrode material of a waste lithium ion battery; the method comprises the following steps of performing discharging of a salt solution; performing disassembling to separate a positive plate; performing smashing on the positive plate to separate a positive electrode material and an aluminum foil; performing mixed low-temperature roasting on the positive electrode material and a roasting agent ammonium sulfate and / or ammonium bisulfate; performing leaching on the roasted material and separating to obtain carbon and a lixivium; adding a precipitant into the lixivium, and regulating the pH value by using NH<3>-containing flue gas, performing deposition on other metals except Li, and carrying out solid-liquid separation; regulating the pH value of a filtrate by using the NH3-containing flue gas, adding ammonium carbonate or ammonium bicarbonate or pumping CO<2> gas, and carrying out lithium precipitation to obtain a lithium carbonate product. The preparation process is simple, the process conditions are mild, the time required by the process is short, a large amount of acid and alkali do not need to be consumed, and the cost is low; and in addition, recovery of the valuable metals and carbon from the positive electrode material can be effectively realized, themethod is green and environment-friendly, and a large amount of solid waste and wastewater cannot be generated.

Owner:CENT SOUTH UNIV

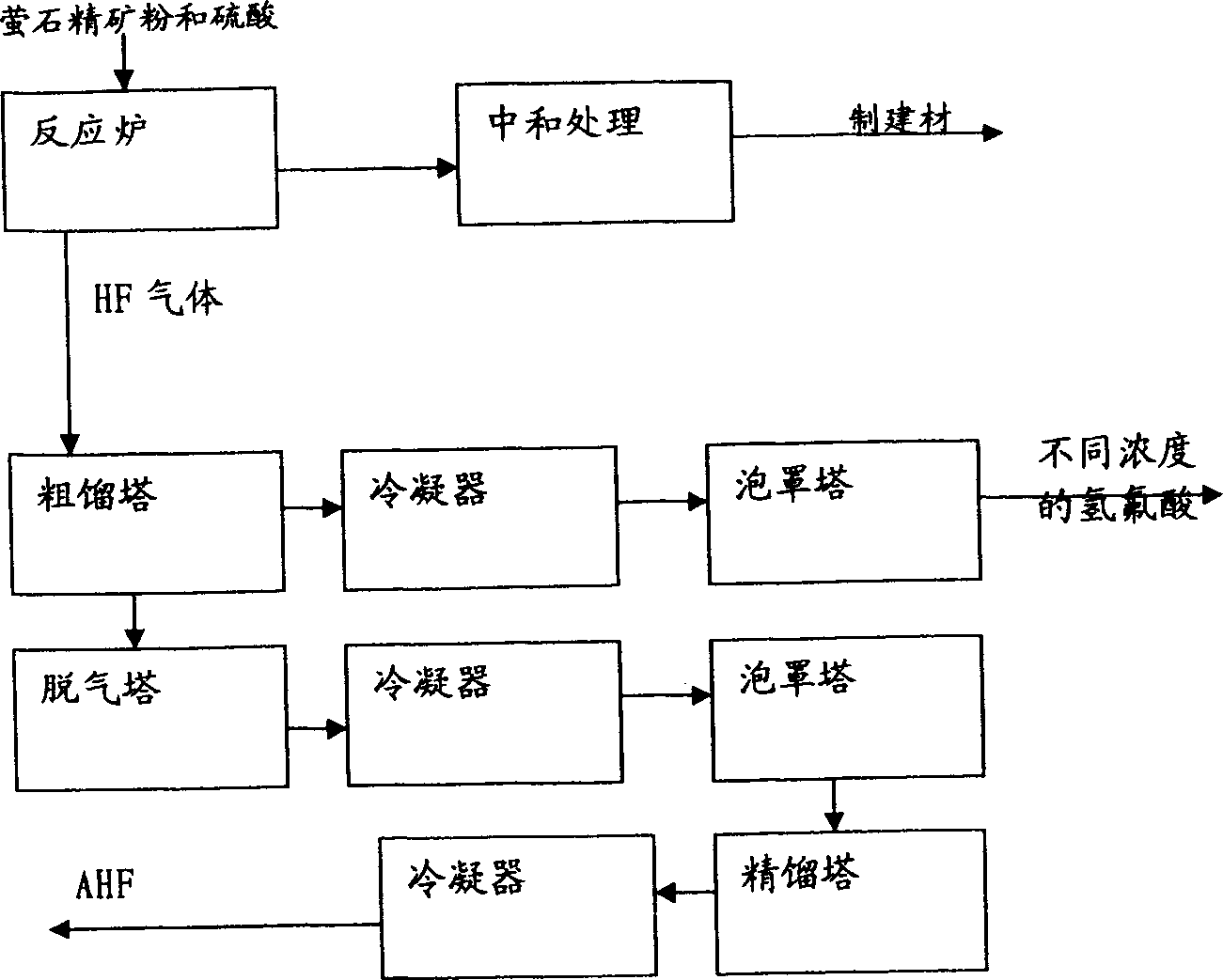

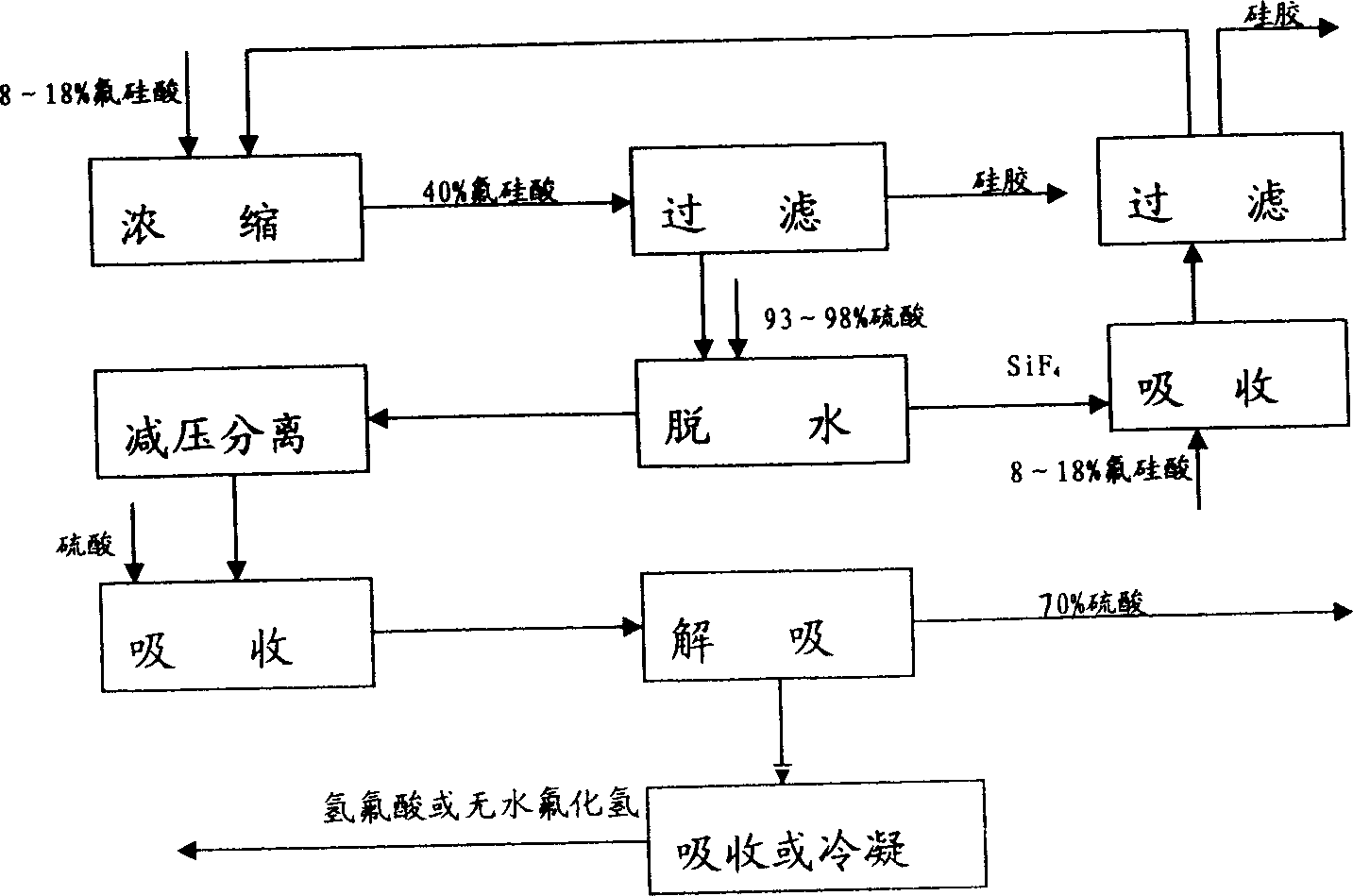

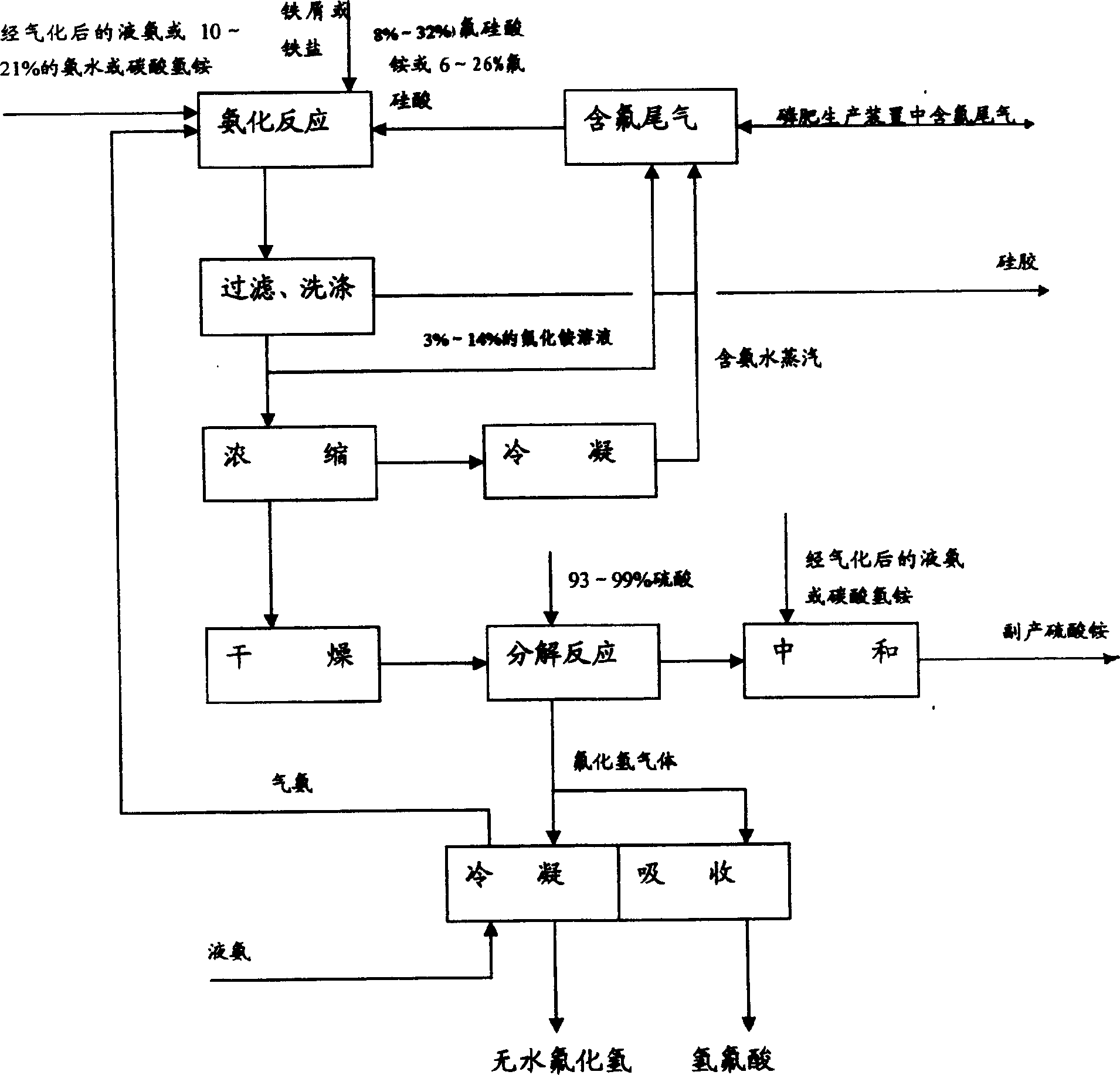

Method for comprehensively utilizing phosphate fertilizer by-product

InactiveCN1554570AReasonable designReduce material requirementsSolid waste disposalFluorine/hydrogen-fluorideIron saltsAmmonium fluorosilicate

The method of comprehensively utilizing phosphate fertilizer by-product includes utilizing ammonium fluoride solution of 3-14% concentration to absorb side product fluorine containing tail gas ammonium fluorosilicate solution; adding iron scrap or iron salt to fluorosilicic acid as one other by-product to eliminate phosphorus; adding liquid ammonia, ammonia water or ammonium bicarbonate; filtering, washing, and eliminating silica precipitate; returning ammonium fluoride solution to phosphate fertilizer absorbing system, concentration and drying to obtain ammonium hydrogen fluoride; reacting solid ammonium hydrogen fluoride and sulfuric acid at high temperature to obtain HF gas, absorbing HF gas to obtain hydrofluoric acid, purification and condensation to obtain anhydrous HF; and mixing the mixture of ammonium sulfate and ammonium bisulfate with ammonium bicarbonate or ammonia in a mixer, curing and crushing to ammonium sulfate fertilizer.

Owner:云南三环化工有限公司 +1

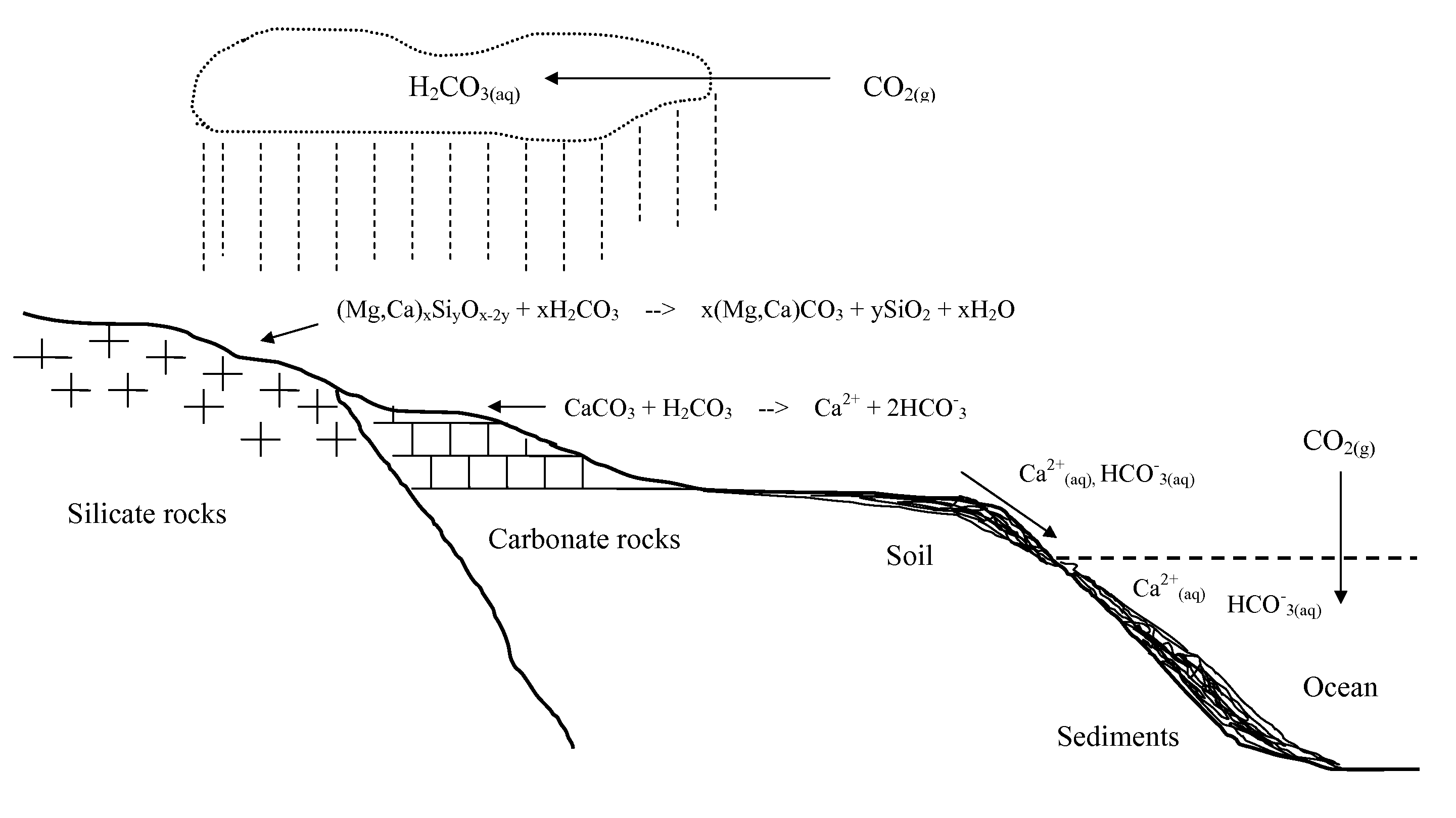

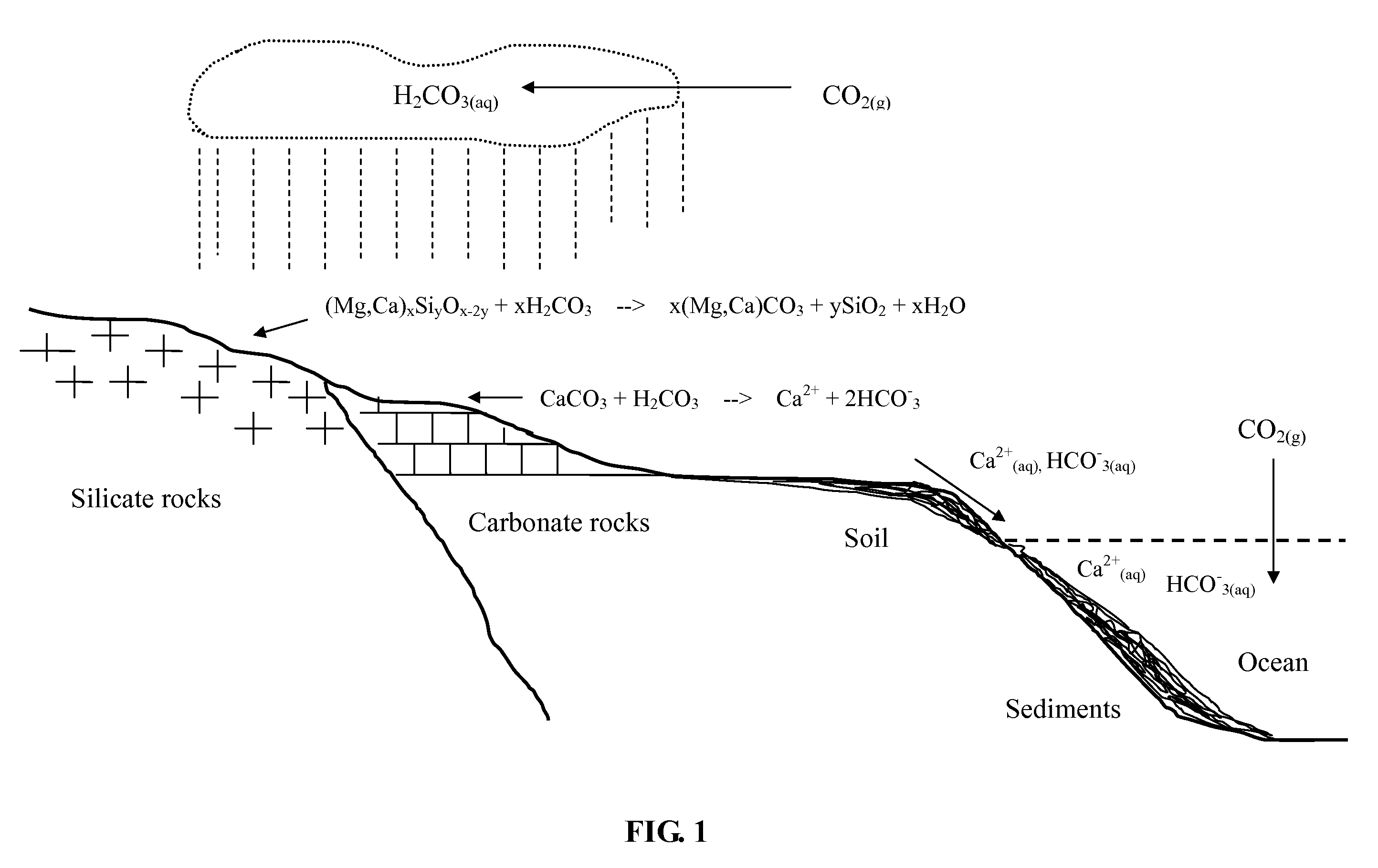

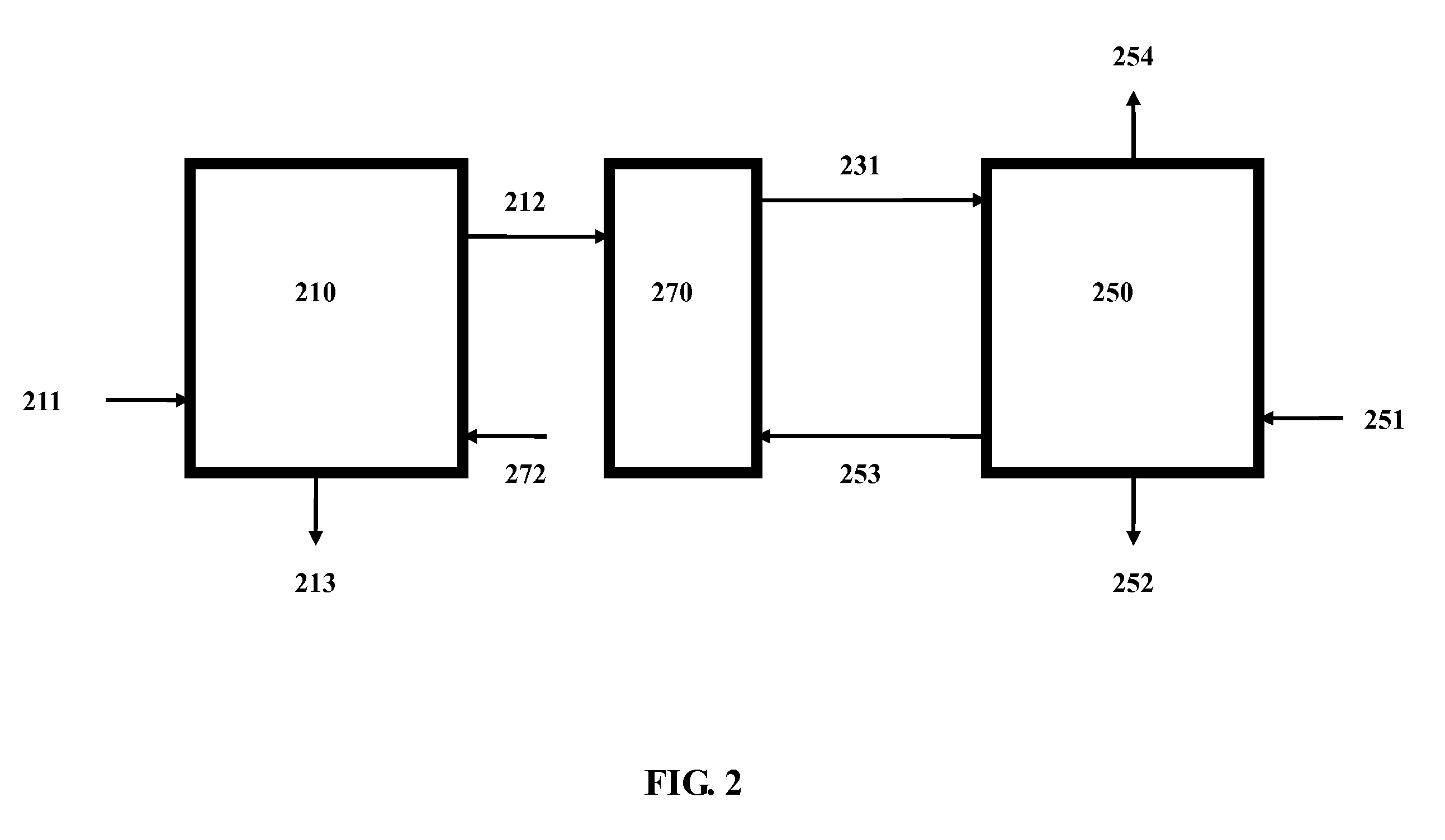

Method for Sequestering Carbon Dioxide

InactiveUS20110038774A1Enhance CO dissolutionMitigate local ocean acidificationCalcium/strontium/barium carbonatesProductsSodium bicarbonateSlag

Owner:ZHONG SHAOJUN

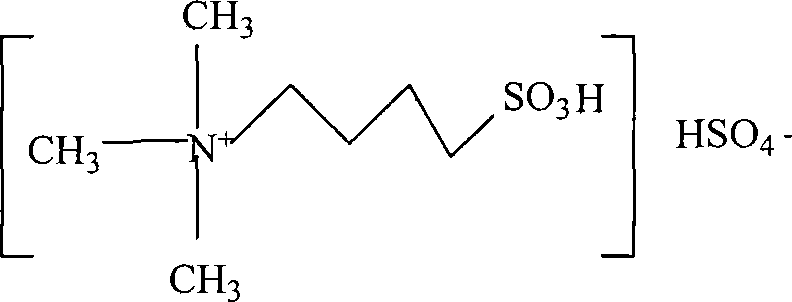

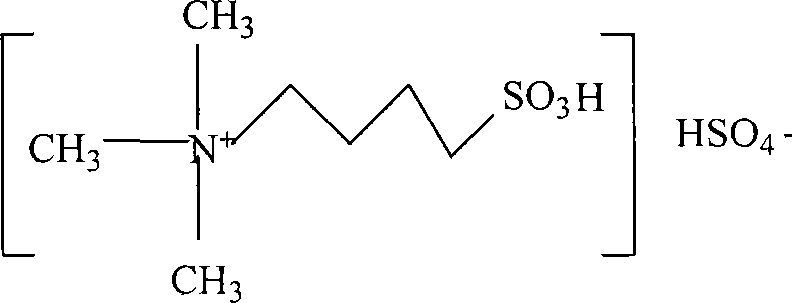

Quaternary ammonium ionic liquid as well as preparation and application method thereof

InactiveCN101182300AUnique physical and chemical propertiesReduce corrosionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMolecular compositionHydrogen Sulfate

A quaternary ammonium salt ionic liquid of the present invention and its preparation and application methods belong to quaternary ammonium compounds, and its molecular composition is N, N, N-trimethyl-N-sulfobutyl-ammonium bisulfate, and its molecular formula is [HSO3-b -N(CH3)3]HSO4, the structural formula is as follows: the quaternary ammonium salt ionic liquid of the present invention is non-corrosive equipment and environment-friendly, and the quaternary ammonium salt ionic liquid catalyst of the present invention is used for nitrobenzene catalytic hydrogenation to synthesize p-amino The phenol reaction is a liquid phase method, the reaction temperature is 60-130° C., and the PAP yield reaches 19.5-88%.

Owner:HEBEI UNIV OF TECH

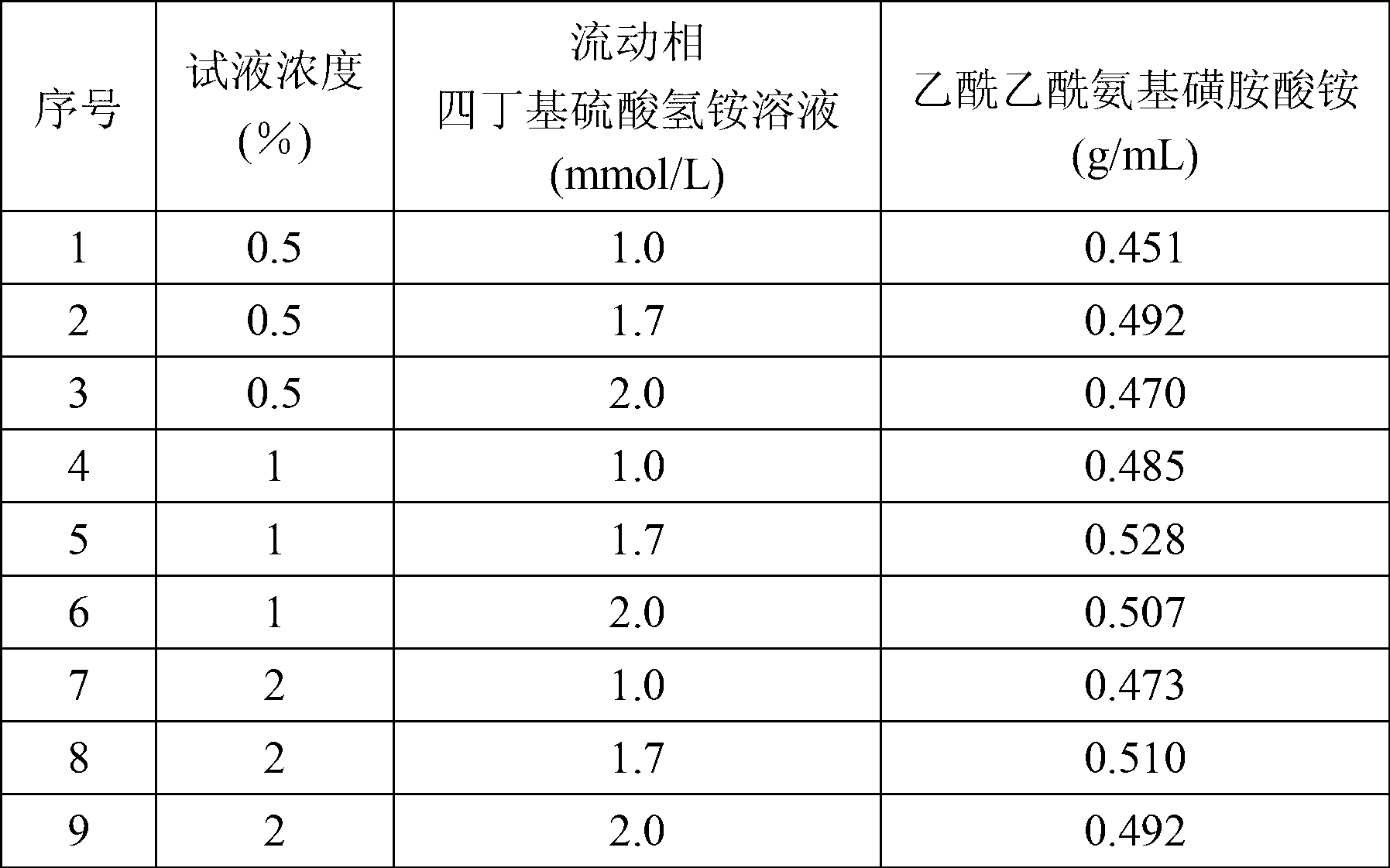

Method for determining N-methylamino ammate in production of acesulfame

ActiveCN103018368AAccurate measurementRapid determinationComponent separationOrganic solventColumn temperature

The invention discloses a method for determining N-methylamino ammate in production of acesulfame. The method mainly comprises the steps of: (1) selecting an analytical chromatographic condition, an ODS column (4.6mm*25cm) or other equivalent chromatographic columns, wherein the wavelength is 250nm, the flow velocity is 1ml / min, the column temperature is 25 DEG C, and the sample amount is 20mu l; (2) preparing tetrabutylammonium hydrogen sulfate solution from deionized water until the molar concentration is 1.0-2.0mmol / L, and preparing a mobile phase from the prepared tetrabutylammonium hydrogen sulfate solution and chromatographic grade methanol according to the volume ratio of 60 to 40; (3) diluting the sample to be tested by an organic solvent according to the volume ratio until the concentration is 0.5-2.0%, so as to prepare a test solution; (4) absorbing the test solution by a microinjector, injecting into an efficient liquid chromatograph, and analyzing by an area external standard method; and (5) recording the content of the N-methylamino ammate in the sample to be tested. By adopting the method disclosed by the invention, the content of the N-methylamino ammate can be accurately and rapidly determined.

Owner:南通宏信化工有限公司

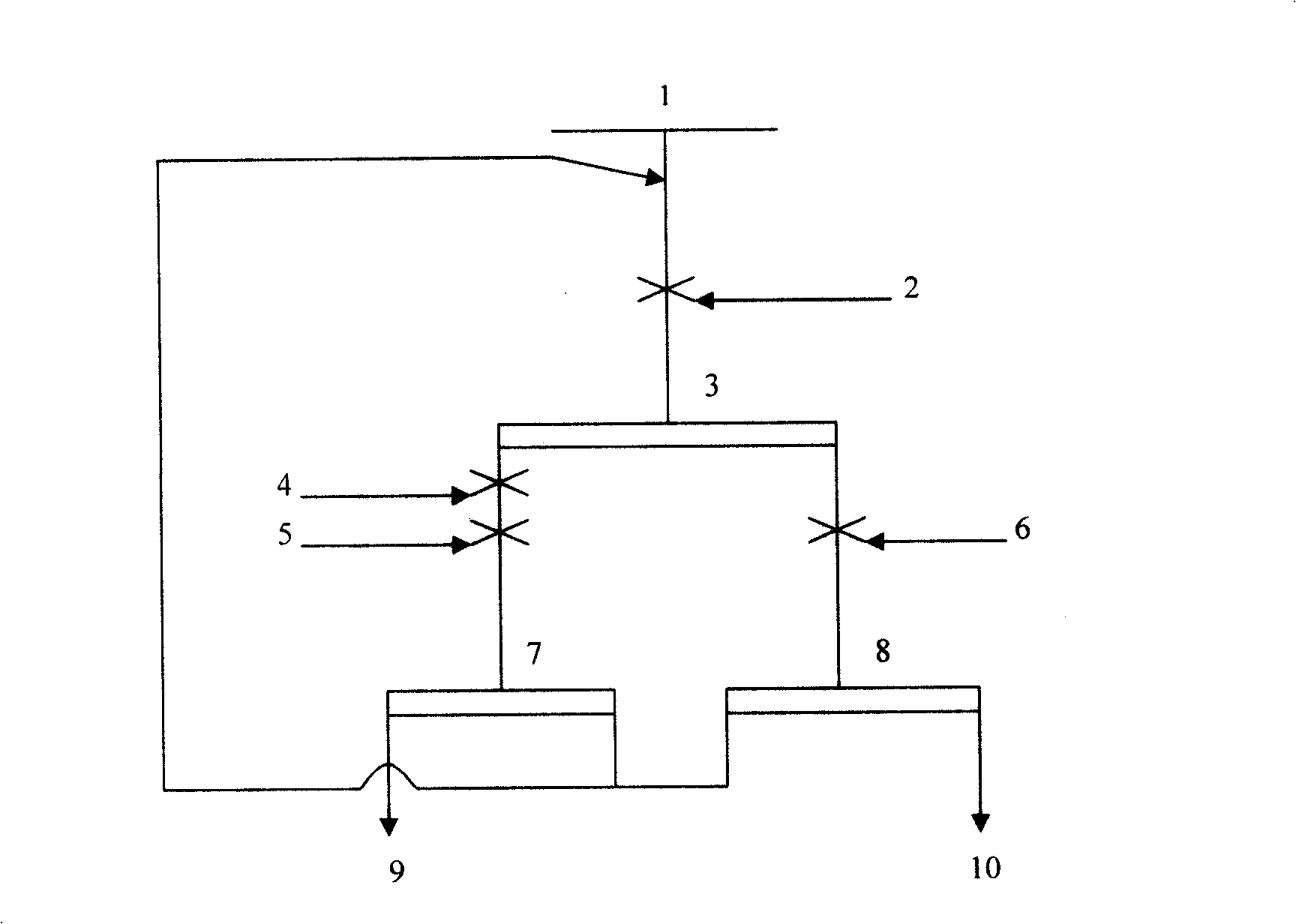

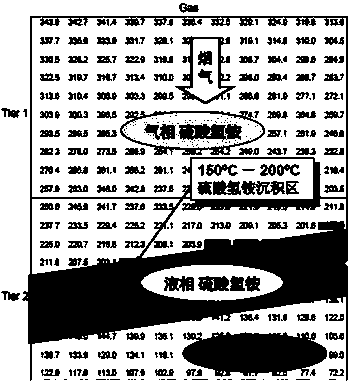

Method for online elimination of ammonium bisulfate clogging of air pre-heaters of coal-fired boiler of thermal power plant

ActiveCN104180378AIncrease temperatureMeet the requirements of normal operation at low loadSolid removalFlue gasEngineering

The invention discloses a method for online elimination of ammonium bisulfate clogging of air pre-heaters of a coal-fired boiler of a thermal power plant. A unit load regulation low-load period is used, according to a reversibility principle of an ammonium bisulfate deposition process, an operation regulation method is put forward, so that one air pre-heater on one single side is isolated from air, a small quantity of high-temperature flue gas is fed, the overall part temperature of each air pre-heater is gradually increased, liquid ammonium bisulfate attached to heat-transfer elements is gasified, and clogging is eliminated. At present, load regulation is frequently performed on coal-fired units in China, and long low-load operation periods exist at night frequently, so that the units can use the load regulation low-load period frequently to perform alternating ammonium bisulfate clogging elimination on air pre-heaters, resistance of the air pre-heaters is reduced, high-pressure water washing after shutdown is avoided, and economic losses are reduced.

Owner:STATE GRID CORP OF CHINA +1

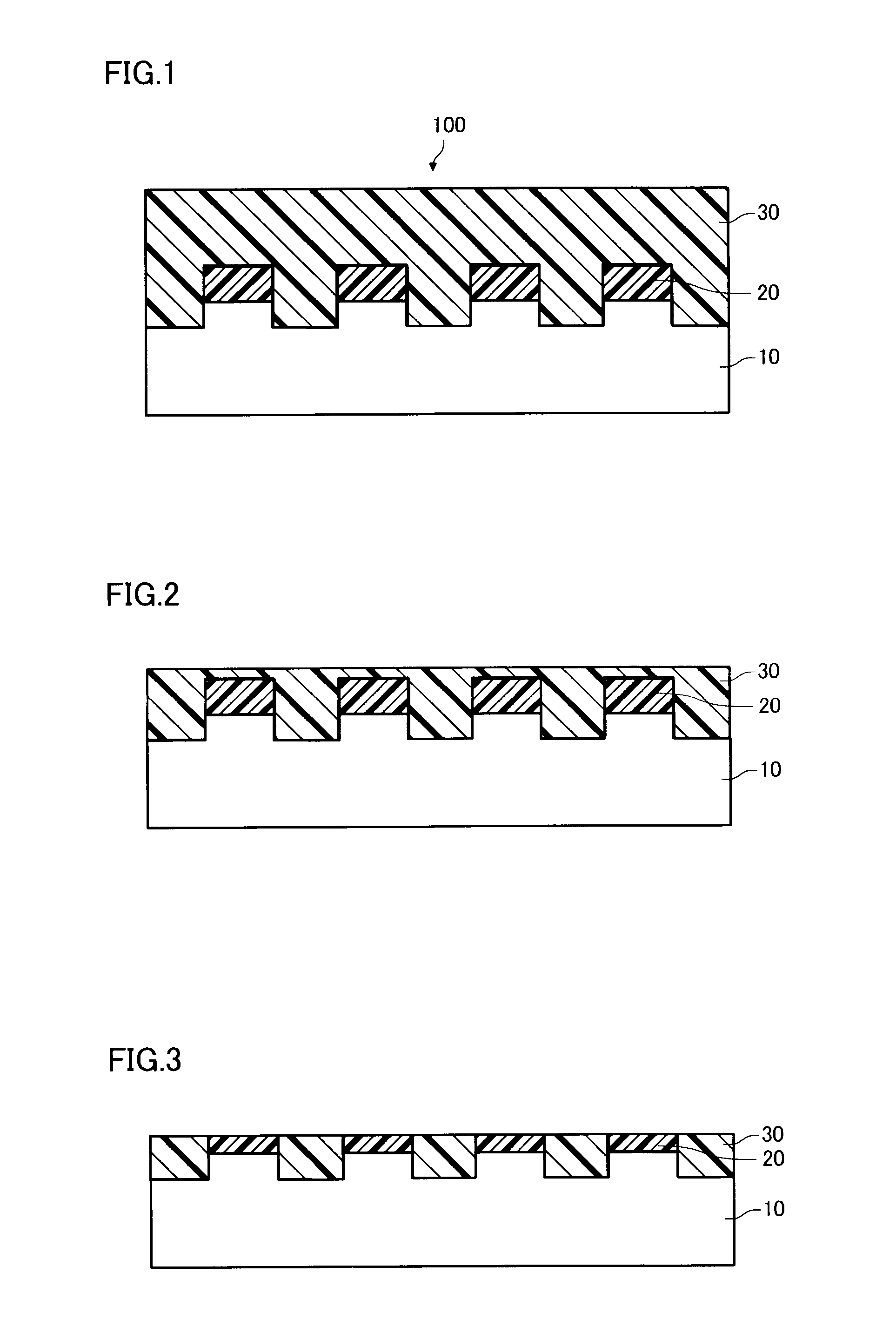

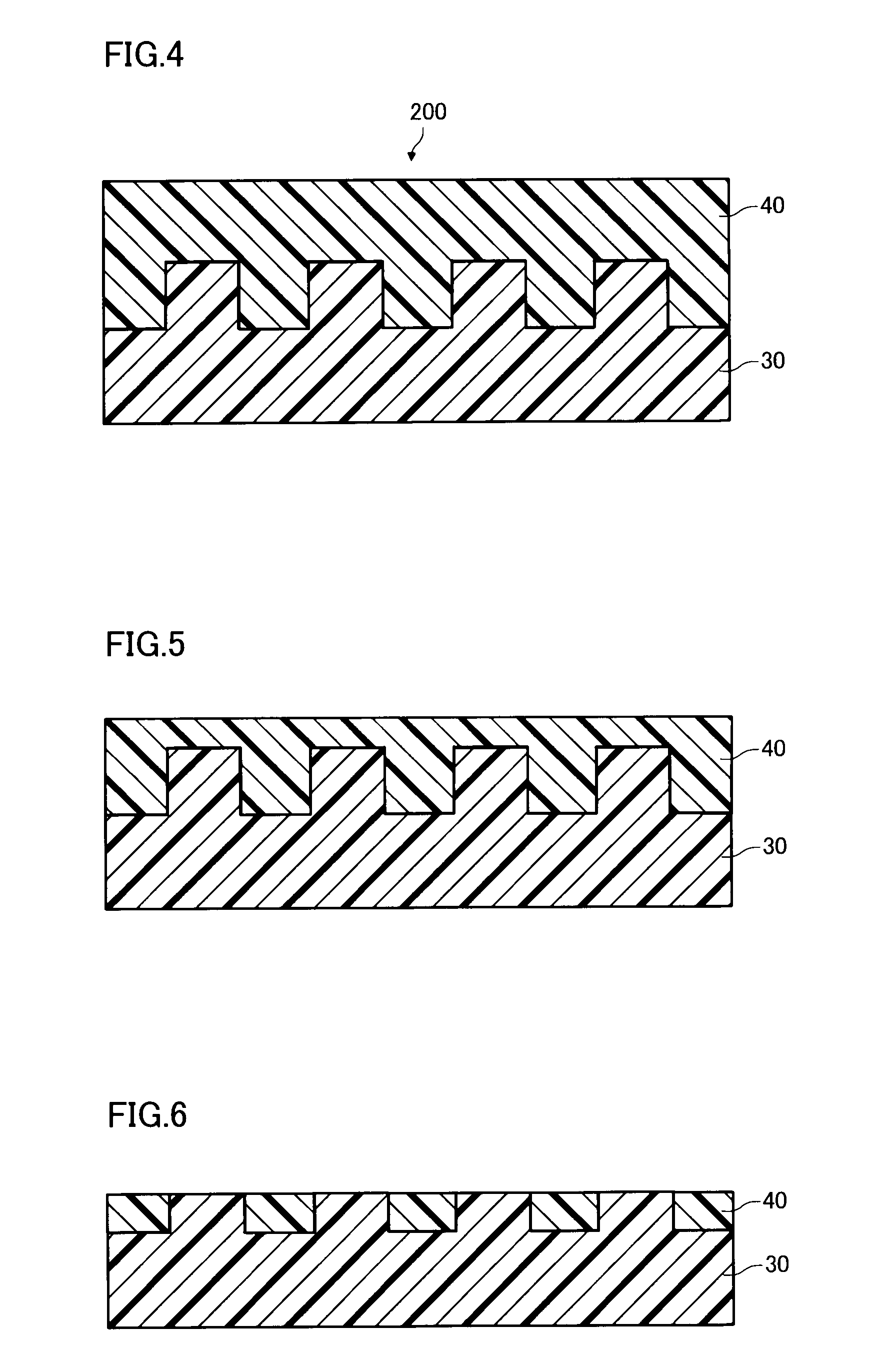

Polishing composition and method for producing a memory hard disk

InactiveUS6280490B1High cutting rateSmall surface roughnessPigmenting treatmentOther chemical processesIron sulfateEthylenediamine

A polishing composition for a memory hard disk, which comprises the following components (a) to (d):(a) from 0.1 to 50 wt %, based on the total amount of the polishing composition, of at least one abrasive selected from the group consisting of silicon dioxide, aluminum oxide, cerium oxide, zirconium oxide, titanium oxide, silicon nitride and manganese dioxide,(b) from 0.001 to 10 wt %, based on the total amount of the polishing composition, of at least one iron salt selected from the group consisting of iron nitrate, iron sulfate, ammonium iron sulfate, iron perchlorate, iron chloride, iron citrate, ammonium iron titrate, iron oxalate, ammonium iron oxalate and an iron chelate complex salt of ethylenediaminetetraacetic acid,(c) from 0.01 to 30 wt %, based on the total amount of the polishing composition, of at least one peroxydisulfate salt selected from the group consisting of ammonium peroxydisulfate, potassium peroxydisulfate and sodium peroxydisulfate, and(d) water.

Owner:FUJIMI INCORPORATED

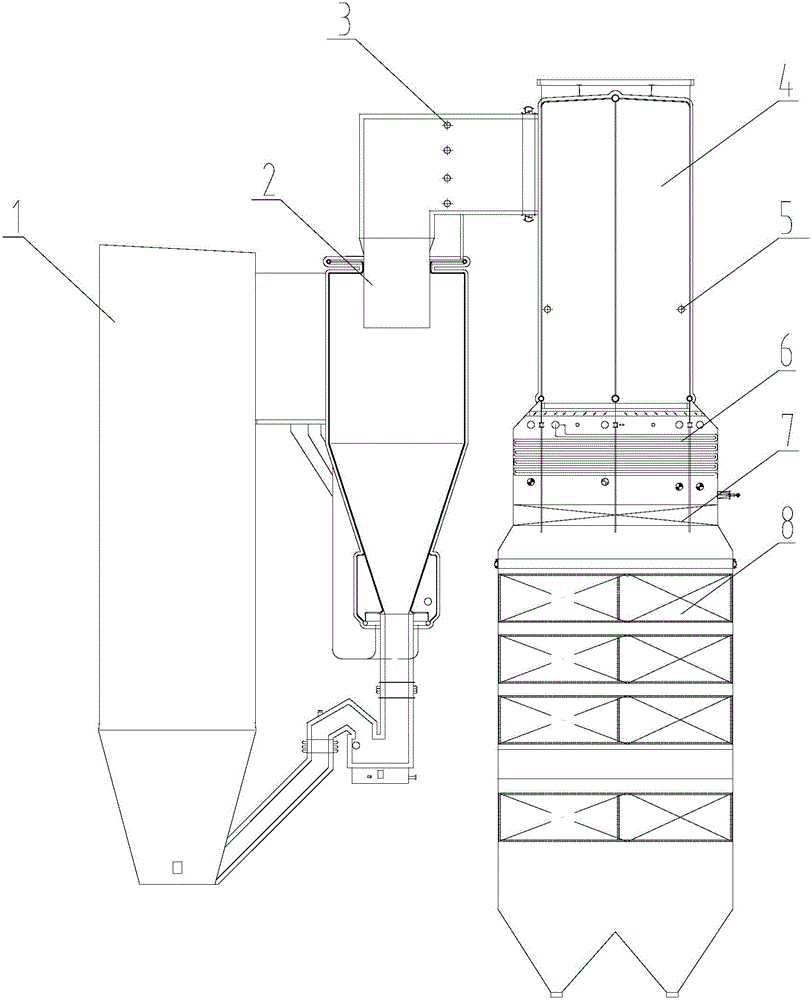

Side-to-side thermal deashing method for rotary air preheater

ActiveCN102042605ALower long-period averageImprove operational efficiencyIndirect carbon-dioxide mitigationSolid removalAir preheaterCold air

The invention relates to a side-to-side thermal deashing method for a rotary air preheater. The method is realized in a way that: loads of a primary air fan, a blowing fan and a draught fan are totally poured to one side by utilizing the low load of a generator set at night; a primary air fan, a blowing fan and a draught fan on the other side are shut down to change the heat transfer situations of the high, medium and low temperature heat transfer elements on the fan shut-down side of the rotary air preheater; a small amount of controlled hot fume at the preheater inlet on the fan shut-down side is utilized to heat the heat transfer elements, and meanwhile, primary cold air and secondary cold air are prohibited to enter the rotary air preheater, so that the heat transfer elements on the fan shut-down side of the rotary air preheater are only heated without releasing heat while rotating; and when the temperature of the heat transfer elements is raised almost to the temperature of the hot air and far higher than the dew point of ammonium bisulfate, ash deposit becomes loosened and the falls off. The invention can be used for periodically and thoroughly removing ash deposit on the heat transfer elements in the medium and high temperature sections, so that the ash deposit can not become severe. The invention can enhance the operating efficiency of the station boiler and lower the station service power consumption rate, and has the advantages of high effectiveness, energy saving, low carbon and emission reduction.

Owner:章礼道

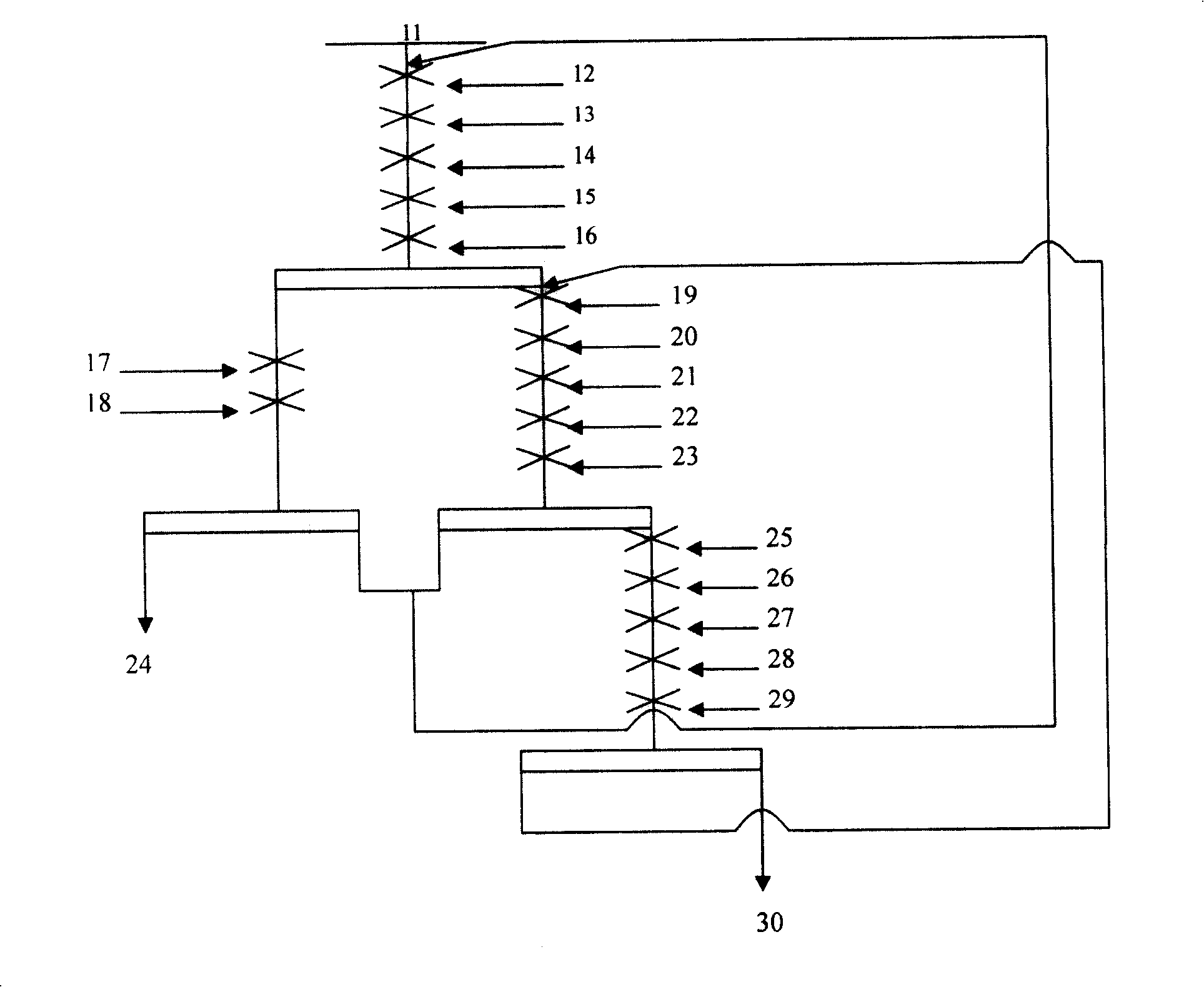

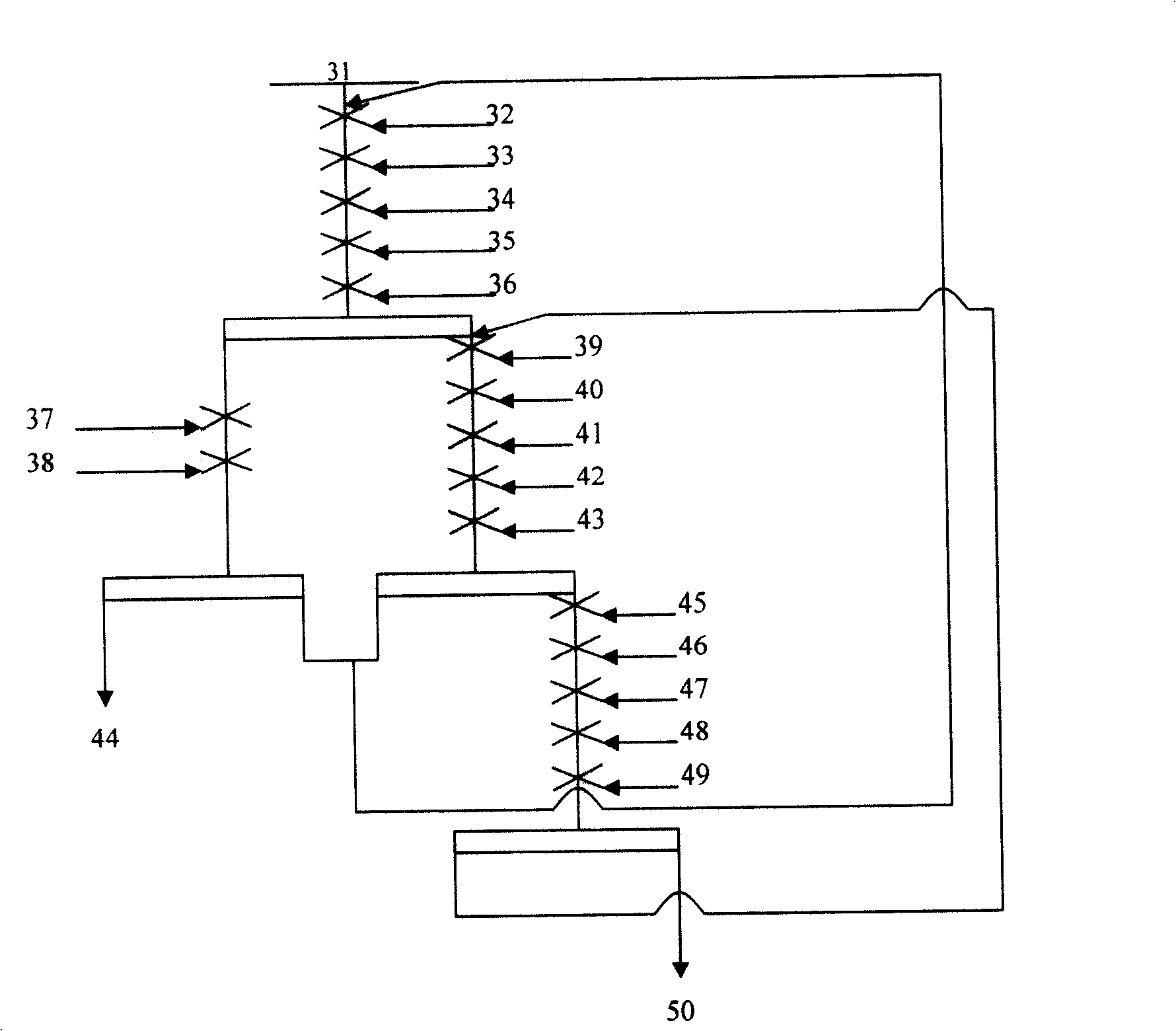

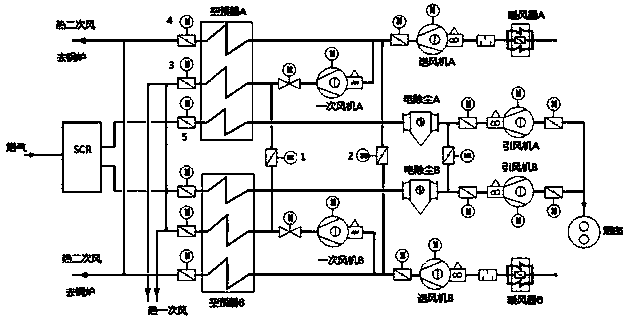

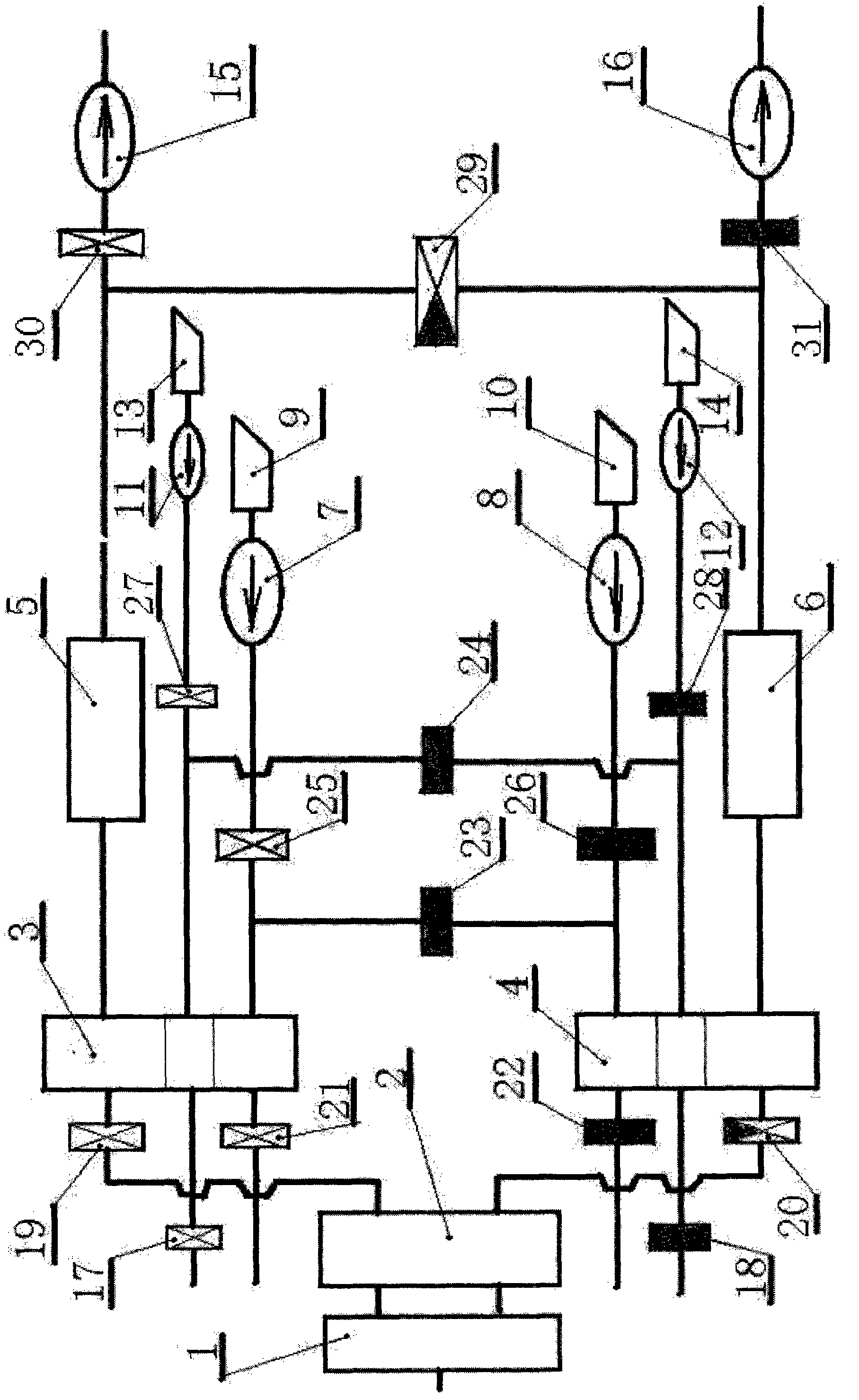

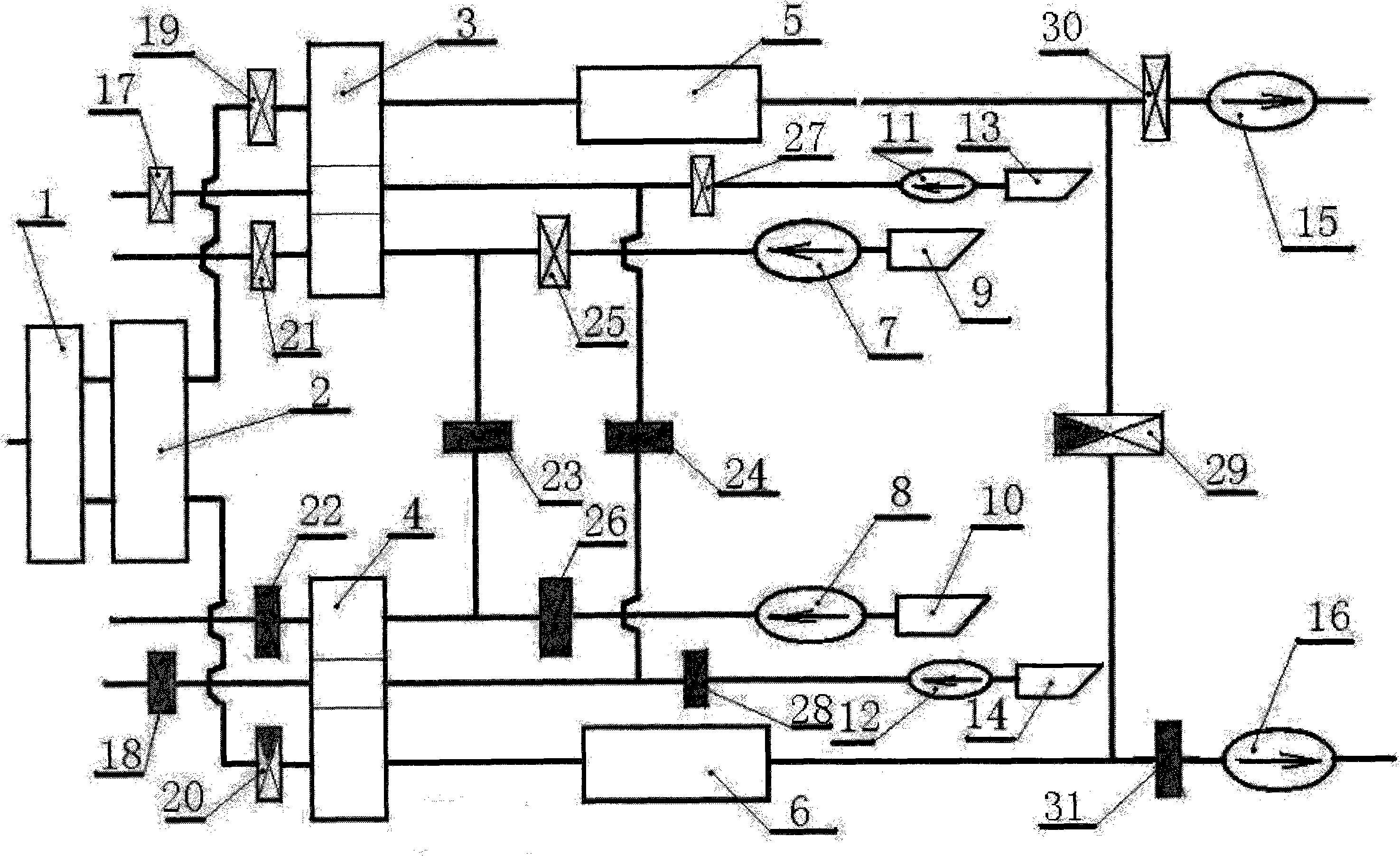

SNCR-SCR combined denitration system and method based on ammonia nitrogen molar ratio detection and regulation

InactiveCN105169917AFlexible operationImprove denitrification efficiencyDispersed particle separationAir preheaterCorrosion

The invention belongs to the technical field of controlling atmospheric pollutants exhausted by coal-fired boilers, and particularly relates to an SNCR-SCR combined denitration system and method based on ammonia nitrogen molar ratio detection and regulation. The system comprises an ammonia-containing storage tank, an air preheater, an SNCR reaction zone, an SCR reaction zone, a first detection system, a second detection system, a third detection system and a control system, wherein the SNCR reaction zone is arranged in a boiler furnace, the SCR reaction zone is arranged in a boiler flue, and the first detection system, the second detection system and the third detection system are connected with the control system. The combined denitration system can achieve full-load denitration operation, is high in denitration efficiency and solves the problem of corrosion and deposition of ammonium bisulfate in follow-up equipment.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

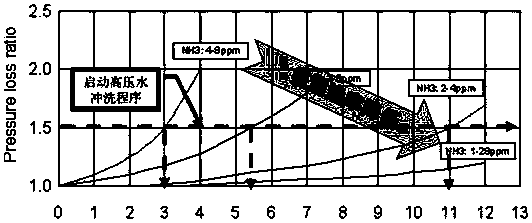

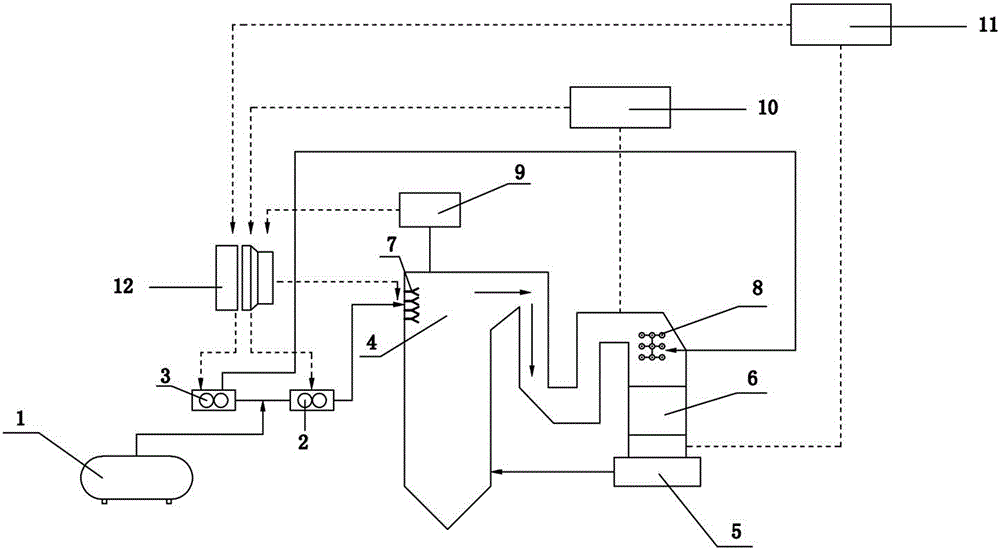

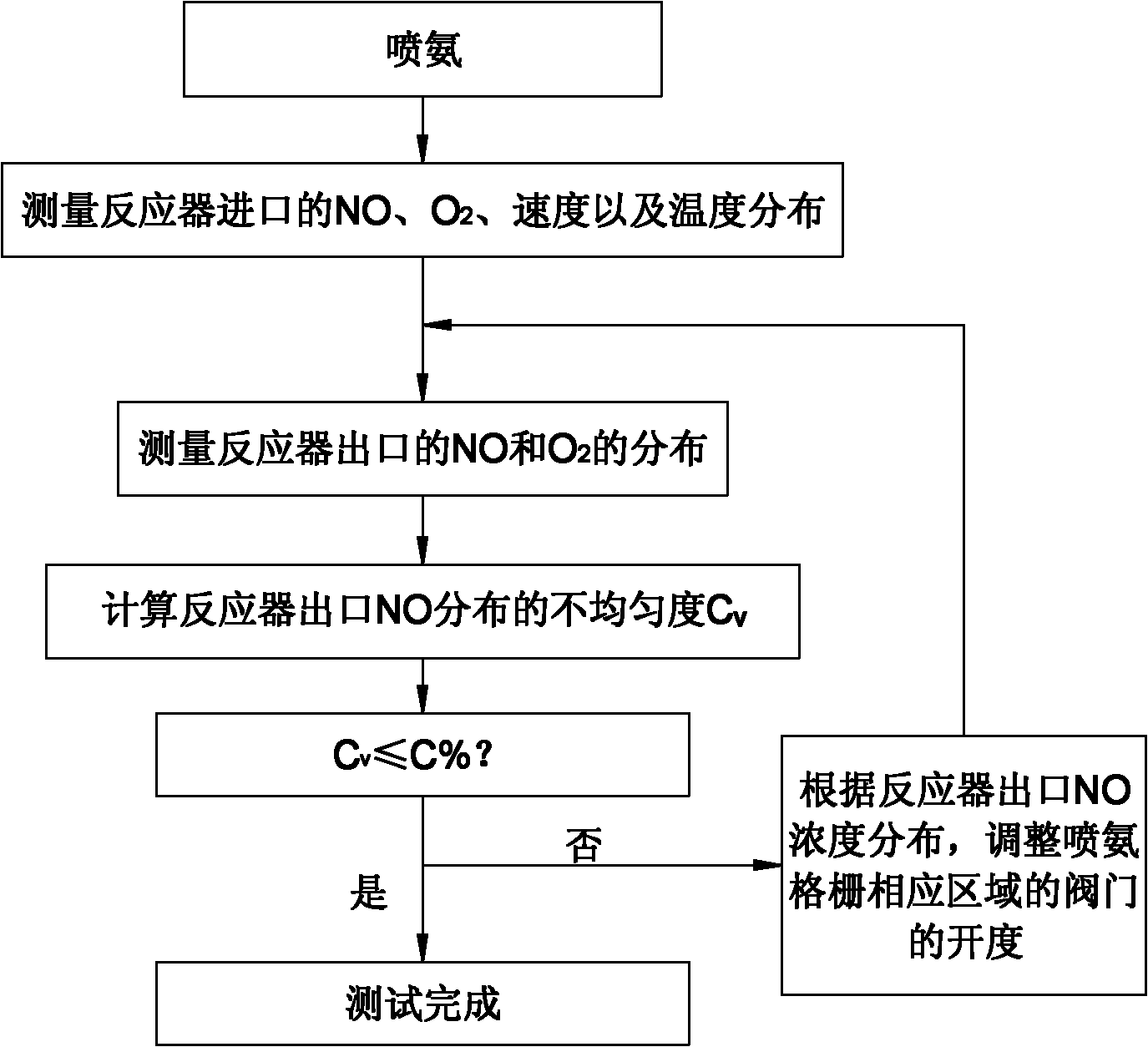

Method for optimized regulation of SCR (Selective Catalyst Reduction) flue gas denitration system in coal-fired power plant

InactiveCN102125800AReduce escapePrevent scalingDispersed particle separationAir preheaterEngineering

At present, a regenerative Junker-type air preheater is used for heating boiler-supplied air in most of large coal-fired power generating sets in China, and ammonium bisulfate results in scaling and corrosion on the surface of heat transfer elements at the medium / low temperature end of the air preheater, thereby threatening the safe and stable operation of the air preheater directly. The invention relates to a method for the optimized regulation of an SCR (Selective Catalyst Reduction) flue gas denitration system in a coal-fired power plant, which comprises the following steps of: (1) jetting ammonia into a denitration reactor; (2) measuring the concentrations, the speeds and the temperature distribution of NO and O2 at an inlet of the denitration reactor; (3) measuring the concentration distribution of NO and O2 at an outlet of the denitration reactor; (4) calculating the unevenness Cv of the concentration distribution of NO at the outlet of the denitration reactor; and (5) comparing the obtained Cv with C%. The method effectively reduces ammonia escape, prevents ammonium bisulfate from scaling and corrosion on the surface of the heat transfer elements of the air preheater, and ensures the safe and stable operation of the air preheater.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY

Method for removing sulfur trioxide from coal-fired flue gas

ActiveCN105477995AFully contactedReduce concentrationDispersed particle separationAir preheaterGas liquid reaction

The invention provides a method for removing sulfur trioxide from coal-fired flue gas. According to the concentration of sulfur trioxide in outlet flue gas of a selective catalytic reduction (SCR) denitration device, a prepared liquid absorbent is sprayed to flue gas in a flue gas passage between the outlet end of the SCR denitration device and an air preheater, and the spraying amount of the liquid absorbent per unit volume of the flue gas is 1-20 times of the mole number of sulfur trioxide required to be removed from the per unit volume of the flue gas. Through the gas-liquid reaction between the liquid absorbent and the sulfur trioxide in the flue gas, sulfur trioxide in the flue gas is removed. The liquid absorbent enters the flue duct in a spraying manner and is atomized into small droplets; the small droplets are evaporated in high-temperature flue gas to form tiny absorbent particles. The particles are large in relatively specific surface area and better in dispersion in the flue gas passage, and can be in contact with sulfur trioxide more fully to enable the reaction to be more fully, so that the concentration of sulfur trioxide in flue gas is greatly reduced, the generation of ammonium bisulfate is reduced, and corrosion and blockage of the air preheater are avoided.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

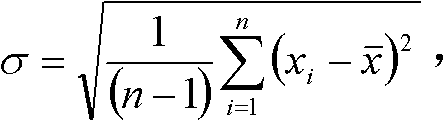

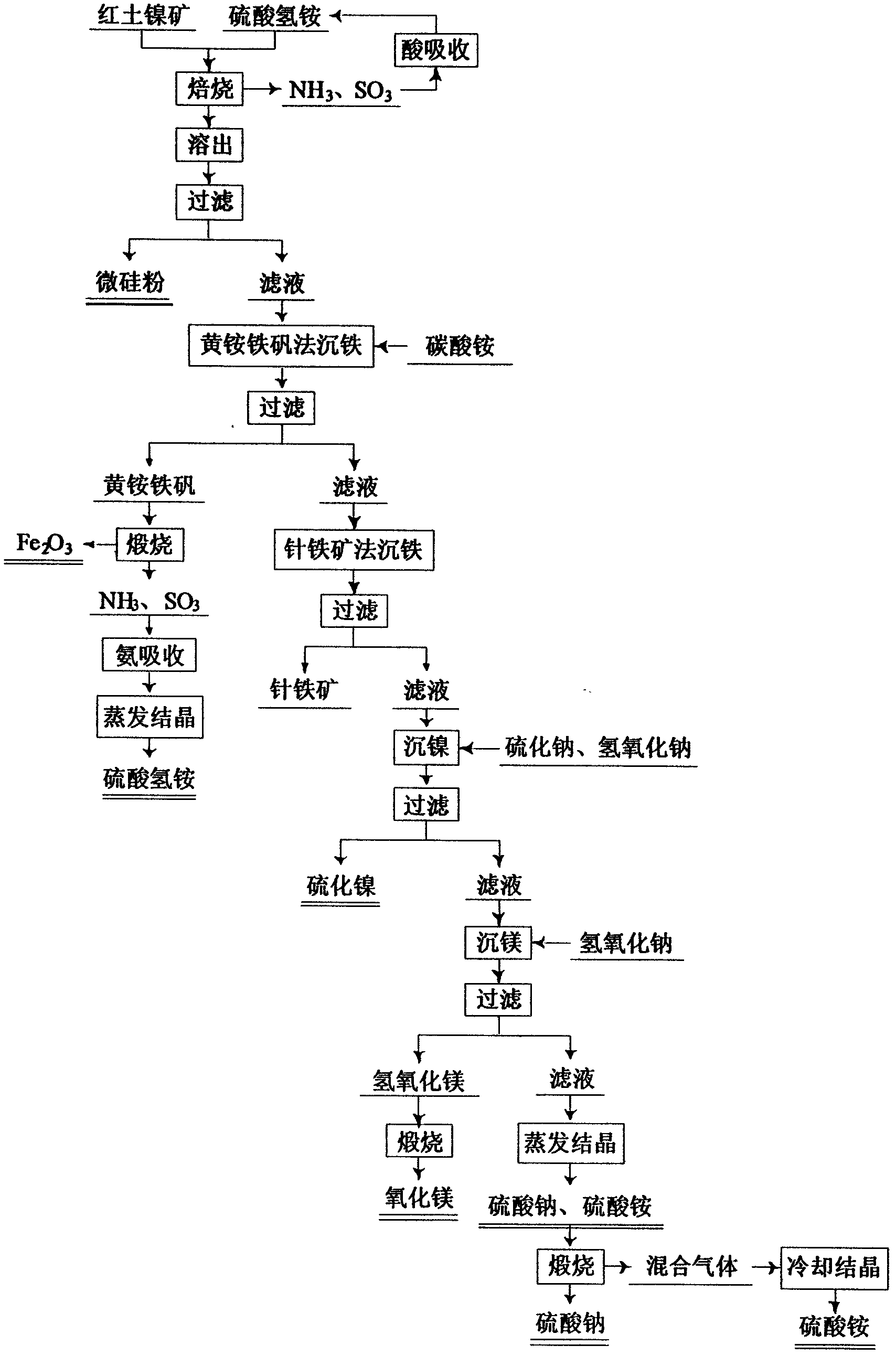

Method for comprehensive utilization of laterite nickel ore

A method for comprehensive utilization of laterite nickel ore comprises the following steps: (1) pulverizing laterite nickel ore, grinding, mixing with ammonium bisulfate, and roasting; (2) dissolving and filtering the roasted clinker to obtain a filtrate, depositing iron by an ihleite method, and depositing iron by a goethite method; (3) performing nickel deposition of the filtrate obtained after iron deposition by sodium sulfide, preparing a nickel sulfide product; (4) performing magnesium deposition of the filtrate obtained after nickel deposition by sodium hydroxide to obtain magnesium hydroxide; (5) washing, drying and calcining magnesium hydroxide to prepare a magnesium oxide product; (6) using the roasted clinker dissolved slag as a microsilica fume product directly, wherein the main component of the slag is silica; (7) calcining ammonium jarosite to obtain an iron oxide product.

Owner:NORTHEASTERN UNIV

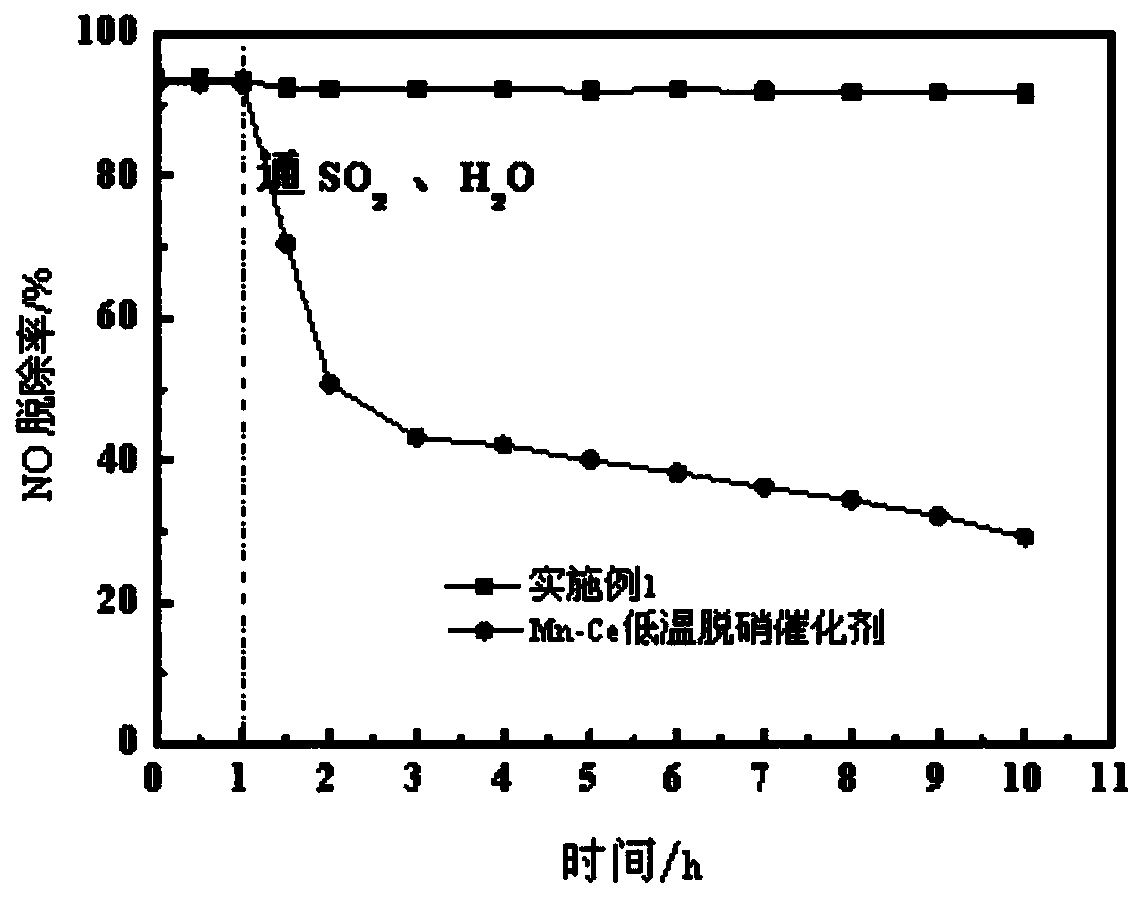

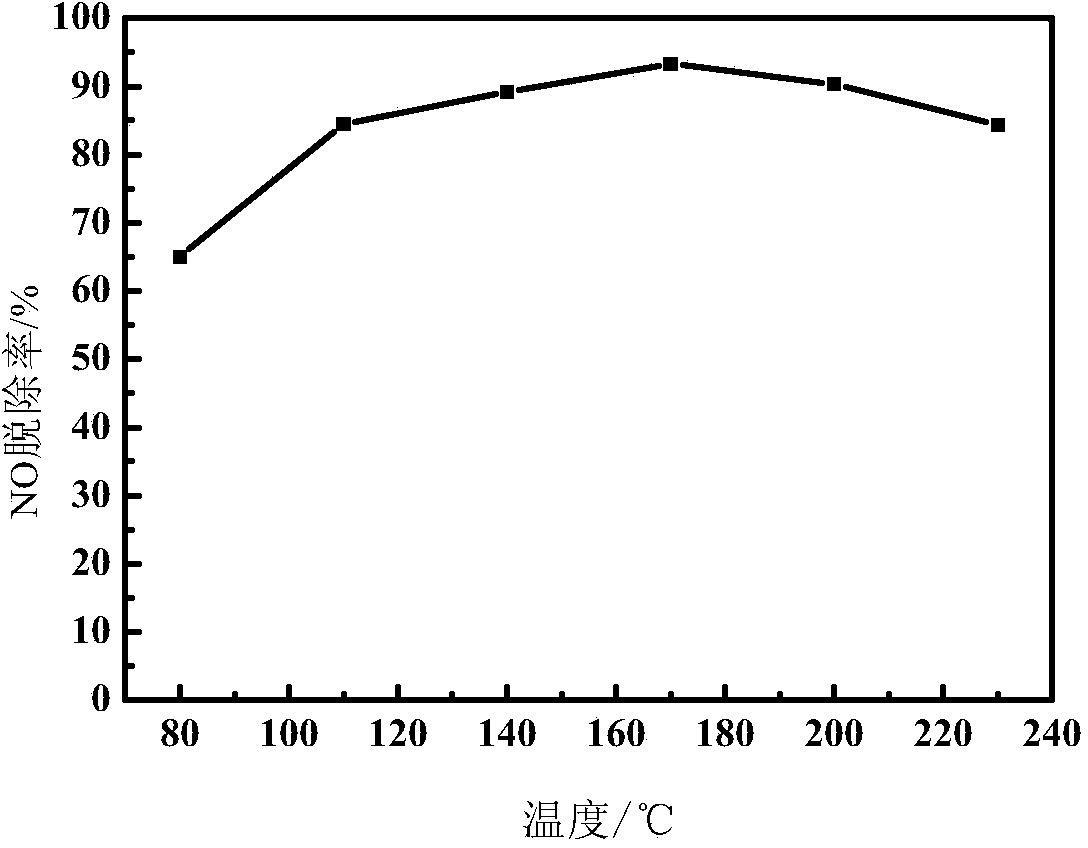

Anti-sulfur film type low-temperature denitration catalyst and preparation method thereof

ActiveCN104138761AAvoid shockEffectively and effectively isolate contactDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSurface layerSulfur

The invention relates to an anti-sulfur film type low-temperature denitration catalyst and a preparation method thereof. The catalyst uses honeycomb ceramic as a carrier, (Mn-Ce-Ox) composite oxides as active ingredients and (Ni-Co-Cu-Sb-Nb-Ox) composite oxides as catalytic assistants, and a surface layer is covered by an anti-corrosion, wearproof, hydrophobic and breathable anti-sulfur functional film. The anti-sulfur functional film can effectively prevent matters such as ammonium bisulfate from contacting the active site of the catalyst, slow down deposition of poisons on the surface of the catalyst, prevent impact of dust in flue gas on the catalyst, effectively solve the problem that the low-temperature SCR catalyst easily causes poisoning, and prolong the service life of the low-temperature catalyst. The denitration rate of the catalyst achieves more than 90 percent at the temperature 140-200 DEG C. The anti-sulfur film type low-temperature denitration catalyst and the preparation method thereof have great significance in industrialized application of the low-temperature SCR denitration catalyst and promotion of an SCR denitration technology in China.

Owner:NANJING UNIV OF TECH

Novel comprehensive utilization technique of industrial waste sulfuric acid

InactiveCN101200439AImprove qualityIncrease profitOrganic chemistryOrganic compound preparationSocial benefitsHydrogen Sulfate

The invention relates to a method for recycling the waste sulfuric acid of the second separation during the production process of the industrial sulfanilamide. The invention method is the novel process of first recycling the organic matter and second treating the waste sulfuric acid, and hydrochloric acid and ammonium hydrogen sulfate or ammonium sulfate with wide application by the treatment of the waste sulfuric acid. The invention not only reduces the environmental pollution and but also decreases the production cost of the industrial sulfanilamide, and has the good environmental protection benefit, the social benefit and the enormous economic benefit.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

Method for preparing solid-state calcium magnesium titanium iron sulfur nitrogen silicon composite fertilizer by using water to quench titanium-containing blast furnace slag

InactiveCN101265136ASolve pollutionMeet needsAmmonium salt fertilisersFertilizer mixturesAir atmosphereHydrogen Sulfate

The invention belongs to a method for producing plant fertilizers, more particularly to a method for producing a solid-state Ca / Mg / Ti / Fe / S / N / Si compound fertilizer from water-quenched blast furnace slag. The invention is characterized in that: the raw materials include titanium oxide-containing water-quenched blast furnace slag, ammonium sulfate, ammonium hydrogen sulfate, ammonium pyrosulfate and ammonium persulfate; the method comprises the following steps: ball-milling Ti-containing water-quenched blast furnace slag to obtain powder of particle size of 60-160 micrometers, mixing the furnace slag powder with 3-20 times of one substance selected from ammonium sulfate, ammonium hydrogen sulfate, ammonium pyrosulfate, ammonium persulfate, or a mixture thereof, heating the resulting mixture up to 200-500 DEG C and maintaining the temperature for 10-65 min, and crushing clinkers to small pieces of 4-12 mm diameter. The invention utilizes Ti-containing water-quenched blast furnace slag and other raw materials to produce plant fertilizers, and thereby realizes environmental protection, Ti resource utilization and nutrient supplementation to plants.

Owner:NORTHEASTERN UNIV

Sulfur-resistant water-resistant, dust removal, denitration and demercuration multifunctional filter material and preparation method thereof

ActiveCN108525514AReduce processing costsImprove stabilityDispersed particle filtrationFiltration separationSulfurComposite function

The invention provides a sulfur-resistant water-resistant, dust removal, denitration and demercuration multifunctional filter material, which is prepared from filter material base cloth, a catalytic filter membrane and a water-resistant and sulfur-resistant composite functional membrane. The effect that dust, NOx and Hg<0> are also removed during the dust removal is achieved; the addition of denitration and demercuration equipment is not needed; the smoke gas treatment cost is greatly reduced; in the temperature region of 140 to 200 DEG C, the dust removal rate is greater than 99 percent; thedemercuration efficiency is greater than 80 percent; the denitration activity is greater than 90 percent. The multifunctional filter material has excellent stability and water-resistant sulfur poisoning-resistant performance; when mixed smoke gas passes through the multifunctional filter materials, dust particles in the smoke gas are firstly filtered away, and are then in contact with catalysts; the poisoning and abrasion effects of the smoke dust on the catalysts are relieved. In addition, through a hydrophobic and antiwear composite functional membrane at the outermost layer of the multifunctional filter material, the deposition and poisoning effects of H2O, SO2 and generated substances such as ammonium bisulfate on the catalysts can be effectively isolated.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

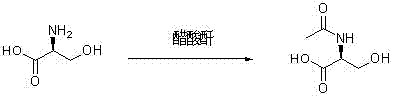

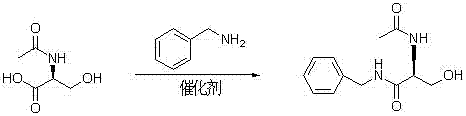

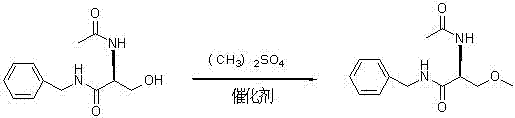

Synthetizing method of lacosamide

InactiveCN103113256AHighlight substantive featuresSignificant progressOrganic compound preparationCarboxylic acid amides preparationPtru catalystAmmonium chloride mixture

The invention provides a synthetizing method of lacosamide. The method comprises the steps of: based on D-serine as a raw material, performing an acylation reaction with acetic anhydride and then performing a condensation reaction with benzylamine; and finally, performing a methylation reaction with dimethyl sulfate, thereby obtaining lacosamide, wherein N,N' dicyclohexylcarbodiimide (DCC) or N,N' carbonyl diimidazole (CDI) is used as a catalyst in the condensation reaction; and a phase transfer catalyst including triethyl benzyl ammonium chloride (TEBA), tetrabutylammonium chloride (TBAC), tetrabutylammonium bromide (TBAB) or tetrabutylammonium hydrogen sulfate (TBAHS) is adopted in the methylation reaction. The method has the advantages of being simple in synthetizing process, moderate in reaction condition, simple in after-treatment, high in yield and high in product purity.

Owner:SUZHOU HONGRUI MEDICAL TECH

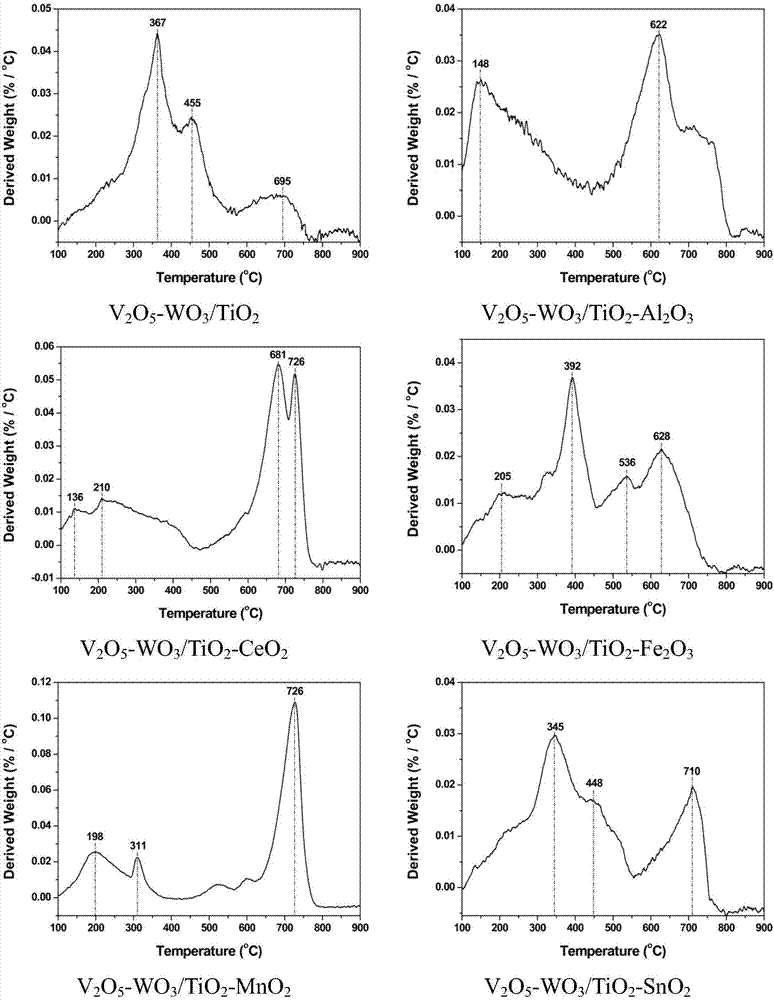

SCR (selective catalytic reduction) denitration catalyst for accelerating ammonium hydrogen sulfate decomposition by low-temperature flue gas, preparation method and application

ActiveCN107262086APromote low temperature decompositionFacilitate decomposition behaviorDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHydrogen SulfateDecomposition

The invention relates to an SCR (selective catalytic reduction) denitration catalyst, in particular to an SCR (selective catalytic reduction) denitration catalyst for accelerating ammonium hydrogen sulfate decomposition by low-temperature flue gas, a preparation method and an application. The SCR denitration catalyst takes composite oxides formed by titanic oxides and transition metal oxides as carriers, vanadium oxides as active components and tungsten oxides as co-catalysts, the molar ratio of transition metal elements to titanium elements in the catalyst is (0.1-0.5):1, and the transition metal oxides include one or more of MnO2, Fe2O3, CeO2, ZrO2, Al2O3, SnO2, Nb2O5 and Sb2O5. An appropriate quantity of transition metal oxides are added into the catalyst, the SCR denitration catalyst for accelerating low-temperature decomposition of ammonium hydrogen sulfate is prepared, and the catalyst accelerates the ammonium hydrogen sulfate to decompose at the temperature lower than 350 DEG C.

Owner:ZHEJIANG UNIV

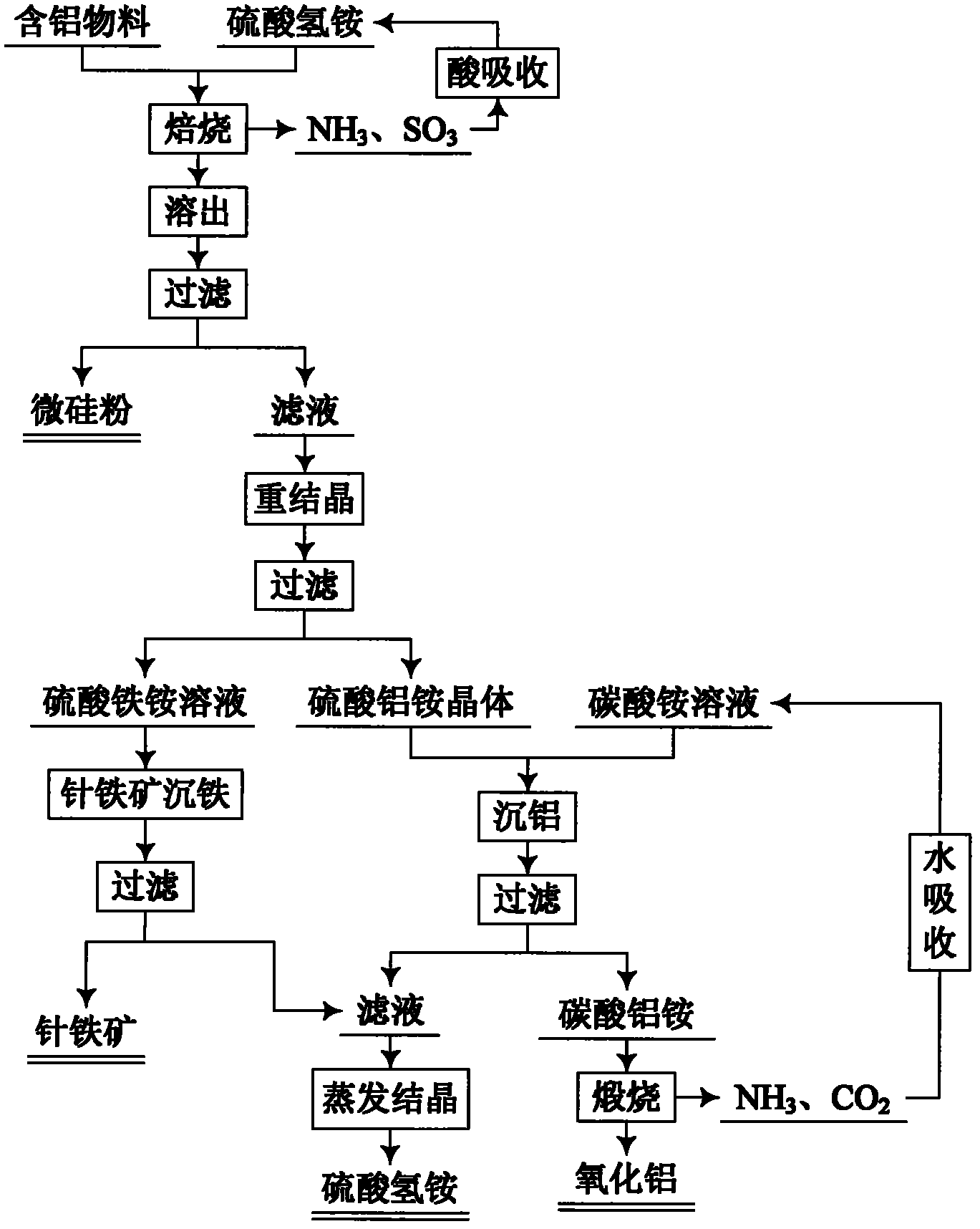

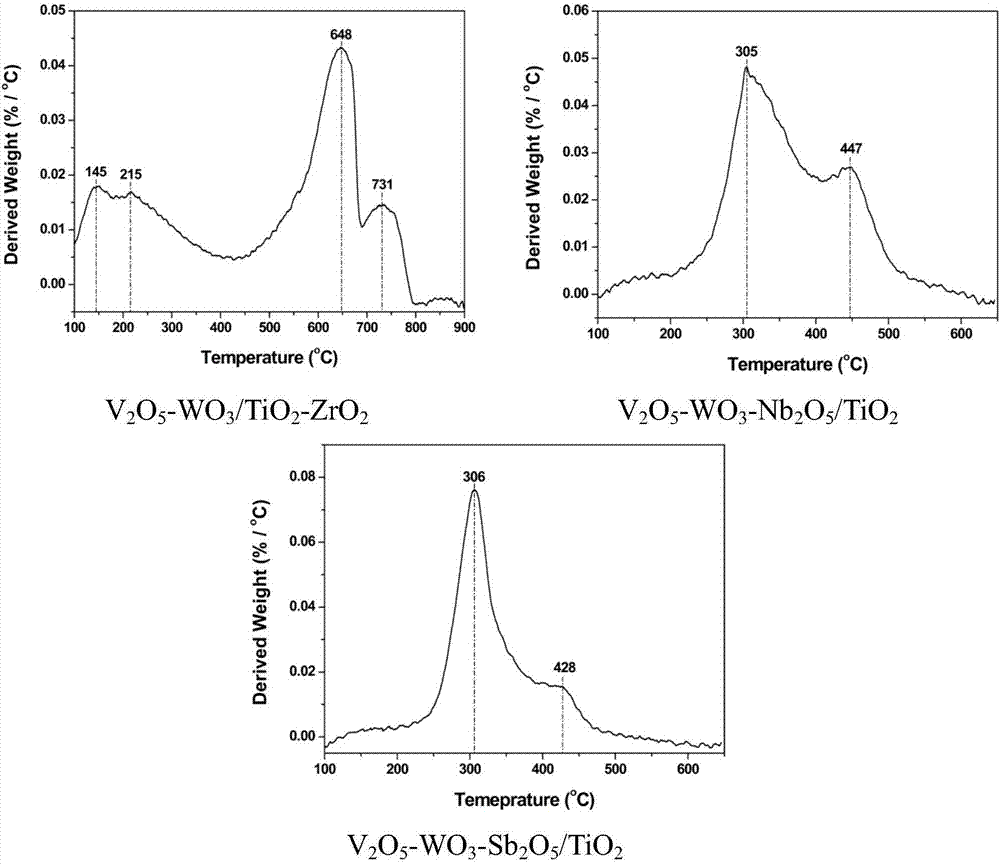

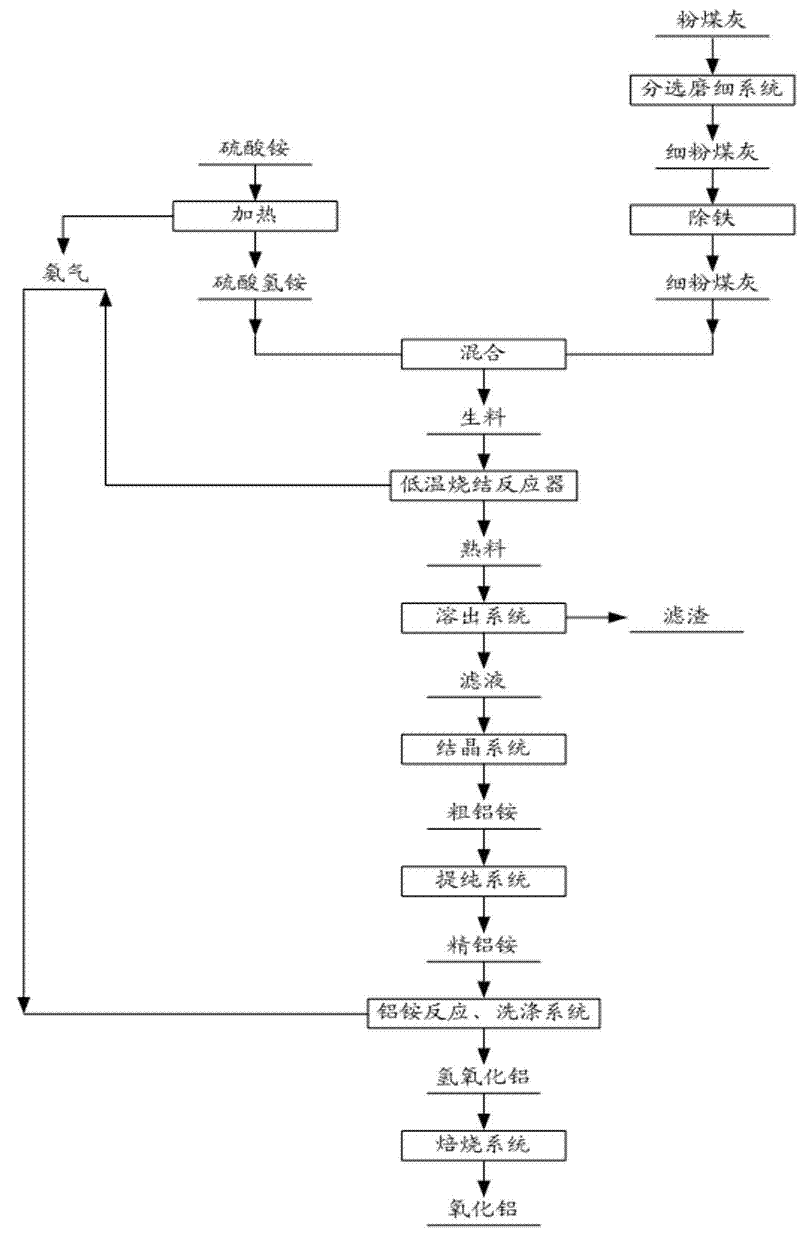

Method for extracting aluminium oxide from pulverized fuel ash

ActiveCN102381723AParticle size range controllableHigh purityAluminium oxide/hydroxide preparationAluminium hydroxidePulverized fuel ash

The invention relates to a method for extracting aluminium oxide from pulverized fuel ash. The method comprises the following steps of: finely grinding the pulverized fuel ash, and then carrying out deferrization treatment; carrying out pyrolysis on ammonium sulphate to prepare ammonium bisulfate and ammonia gas; dissolving out a solid generated after sintering, and then obtaining a solution containing ammonium aluminum sulfate; crystallizing the solution containing the ammonium aluminum sulfate to obtain solid ammonium aluminum sulfate; dissolving the solid ammonium aluminum sulfate and thenpreparing the dissolved solid ammonium aluminum sulfate into a solution reacting with the ammonia gas or ammonia water to generate trihydrate alumina or ammonium sulfate; and roasting the trihydrate alumina to obtain the aluminium oxide. By using the method for extracting aluminium oxide from pulverized fuel ash in the invention, ammonium bisulfate is prepared and the ammonia gas is coproduced, thus, the reaction between the ammonium sulfate and the pulverized fuel ash is convenient to control; and the method is simple, few in side products and easy to realize industrial application.

Owner:北京世纪地和控股有限公司

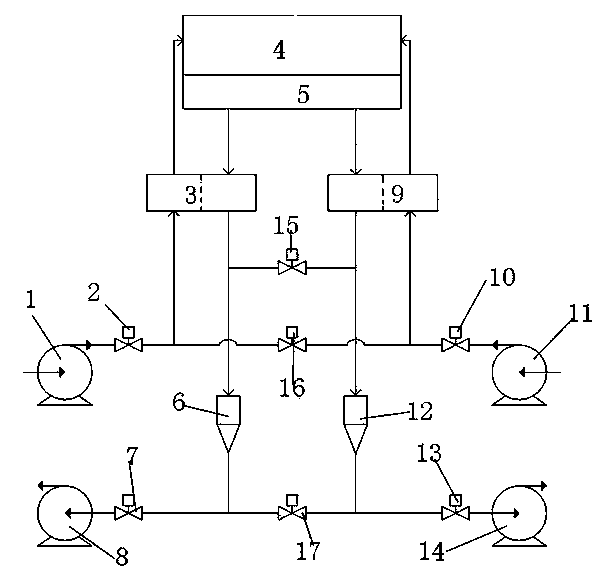

Device and method for preventing ammonium bisulfate from blocking air preheaters of coal-fired boiler

ActiveCN104033921AMeet the output demandGuaranteed uptimeIndirect carbon-dioxide mitigationSolid removalAir preheaterBaghouse

The invention discloses a device and a method for ammonium bisulfate from blocking air preheaters of a coal-fired boiler. The method includes controlling a mass flow ratio of inlet flue gas on flue gas sides of the air preheaters to inlet air on air sides of the air preheaters according to sulfur contents S<ad> of inlet coal of the coal-fired boiler and outlet ammonia slip concentration C<slip NH3> of denitration equipment until the mass flow ratio reaches beta; enabling outlet temperatures of the flue gas sides of the air preheaters to rise and range from 210 DEG C to 320 DEG C and keeping the outlet temperatures of the flue gas sides of the air preheaters unchanged for longer than h hours; opening flue gas communicating doors on pipelines among the air preheaters and dust collectors; enabling inlet temperatures of the dust collectors to be lower than or equal to 160 DEG C. The device and the method have the advantages that the problem that existing air preheaters of a coal-fired boiler are blocked by ammonium bisulfate due to flue gas denitration can be effectively solved; influence of flue gas temperature rise on the dust collectors, particularly bag type dust collectors, can be prevented by means of arranging and adjusting the flue gas communicating doors, and accordingly the device and the method are favorable for normal running of the coal-fired boiler.

Owner:STATE GRID CORP OF CHINA +2

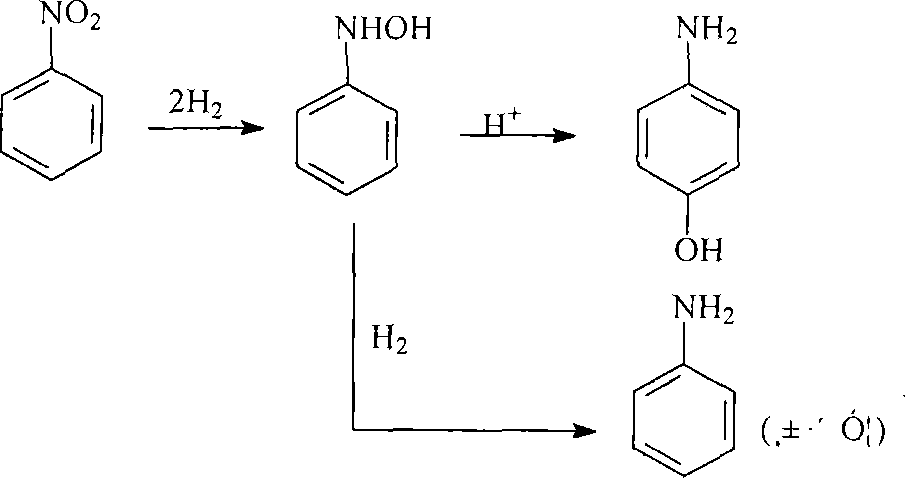

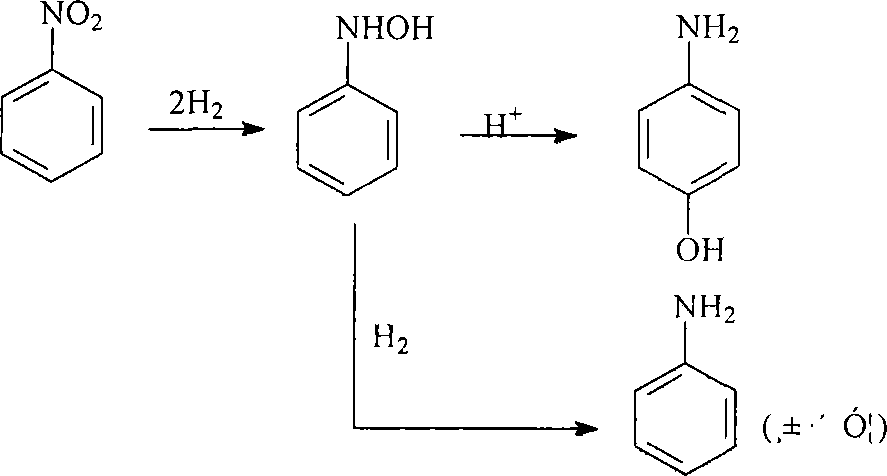

Catalyzer for synthesizing p-aminophenol by nitrobenzene catalytic hydrogenation as well as method for preparing and applying the same

InactiveCN101176852AHigh catalytic activityEasy to prepareOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNitrobenzeneP-Aminophenol

The invention relates to a catalyst used for synthesis of p-aminophenol by catalytic hydrogenation of nitrobenzene, a preparation method and an application method, belonging to catalyst containing both platinum and organic compound field. The catalyst is a supported and bi-functional catalyst, and comprises room temperature ionic liquid of N, N, N-trimethyl-N-sulfobutyl-ammonium bisulfate which is one component of the active components, active metal Pt which is the other component of the active components, and silica gel carrier; wherein, the loading of the room temperature ionic liquid of N, N, N-trimethyl-N-sulfobutyl-ammonium bisulfate is 5 to 50%, while the loading of the active metal Pt is 0.01 to 1.5%. The invention has the advantages that: as a highly active heterogeneous catalyst, the catalyst overcomes the shortcomings that the homogeneous catalyst in prior art can not be used repeatedly, the reaction conditions of the heterogeneous catalyst in prior art are severe and the activity is low, and the problems that the equipment is liable to corrosion and the discharge of wastewater pollutes environment are solved.

Owner:HEBEI UNIV OF TECH

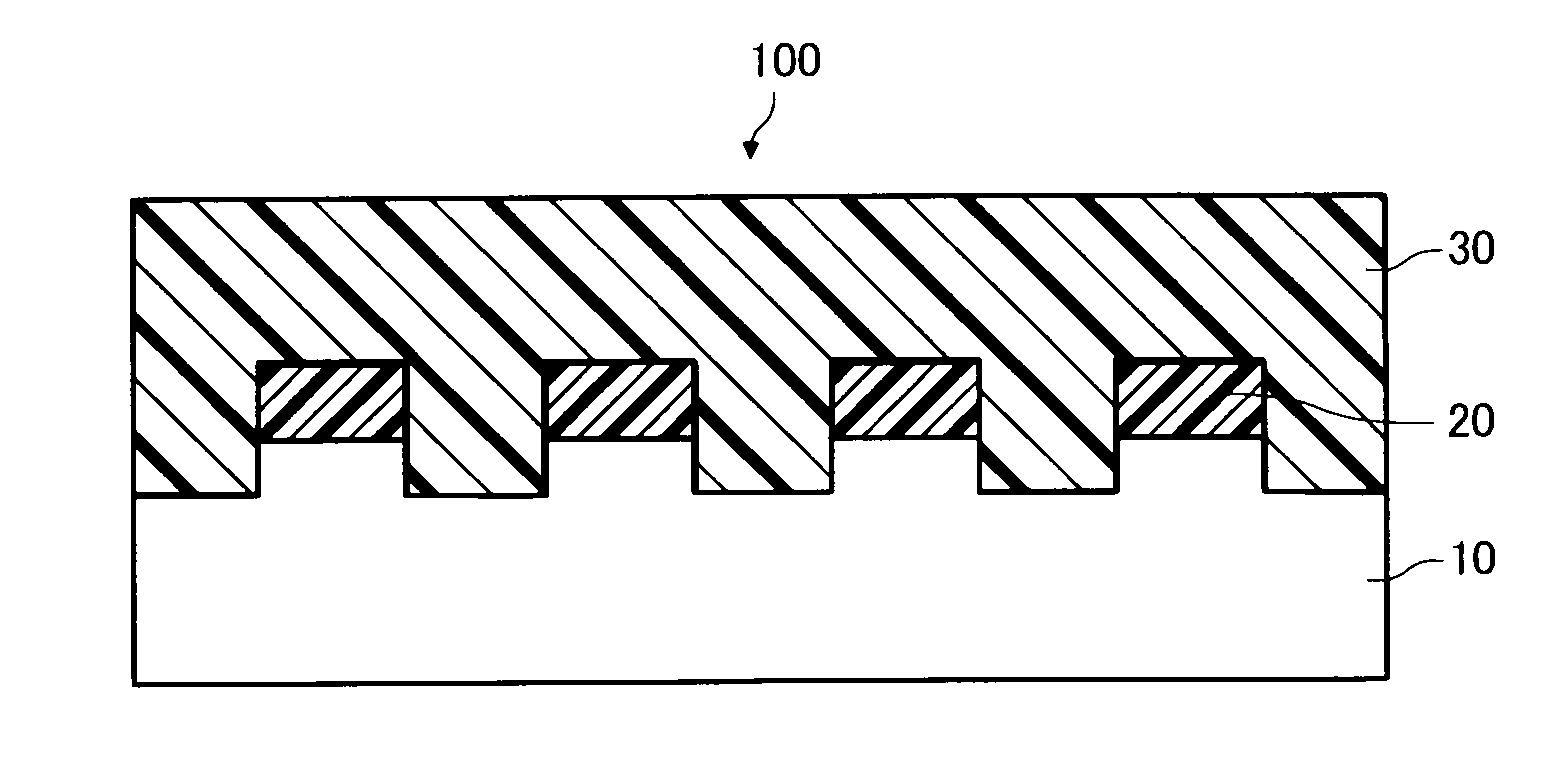

Chemical mechanical polishing aqueous dispersion and chemical mechanical polishing method for semiconductor device

InactiveUS20090325383A1Sufficient and almost equal polishing rateDesired thicknessNanoinformaticsSemiconductor/solid-state device manufacturingColloidal silicaHydrogen Sulfate

A chemical mechanical polishing aqueous dispersion according to the invention includes (A) 0.1 to 4 mass % of colloidal silica having an average particle diameter of 10 to 100 nm, and (B) 0.1 to 3 mass % of at least one ammonium salt selected from ammonium phosphate, diammonium phosphate, and ammonium hydrogen sulfate, the chemical mechanical polishing aqueous dispersion having a mass ratio (A) / (B) of the component (A) to the component (B) of 1 to 3 and a pH of 4 to 5 and being able to simultaneously polish at least two films that form a polishing target surface and are selected from a polysilicon film, a silicon nitride film, and a silicon oxide film.

Owner:JSR CORPORATIOON

Formaldehyde scavenging agent

InactiveCN105727494AClean up thoroughlyProtect healthChemical protectionHuman healthCyanamide compound

The invention discloses a formaldehyde scavenging agent. The formaldehyde scavenging agent is prepared from, by weight percent, 5%-15% of a high-molecular polymer, 1%-5% of silicon dioxide, 1%-10% of ammonium chloride, 4%-12% of ammonium bisulfate, 1%-7% of urea, 3%-8% of a cyanamide compound, 1%-5% of 1-hydroxyethylidene-1,1-diphosphonic acid, 3%-6% of plant extract and the balance water. The formaldehyde scavenging agent can scavenge formaldehyde thoroughly and protect human health and is low in cost.

Owner:SHANGHAI MEISHI ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing Nano powder of alumina from industrial waste

A process for preparing the aluminium oxide nanoparticles from the industrial waste (used Al catalyst or rejected A-alloy) includes grinding, reacting on fused ammonium hydrogen sulfate or its solution, filtering, thermal concentrating, recrystallzing to obtain ammonium aluminium sulfate crystals, preparing its solution, dripping it in the solution of ammonium dicarbonate containing polyethanediol to generate alkaline ammonium aluminium carbonate, drying, and burning.

Owner:SHANGHAI UNIV

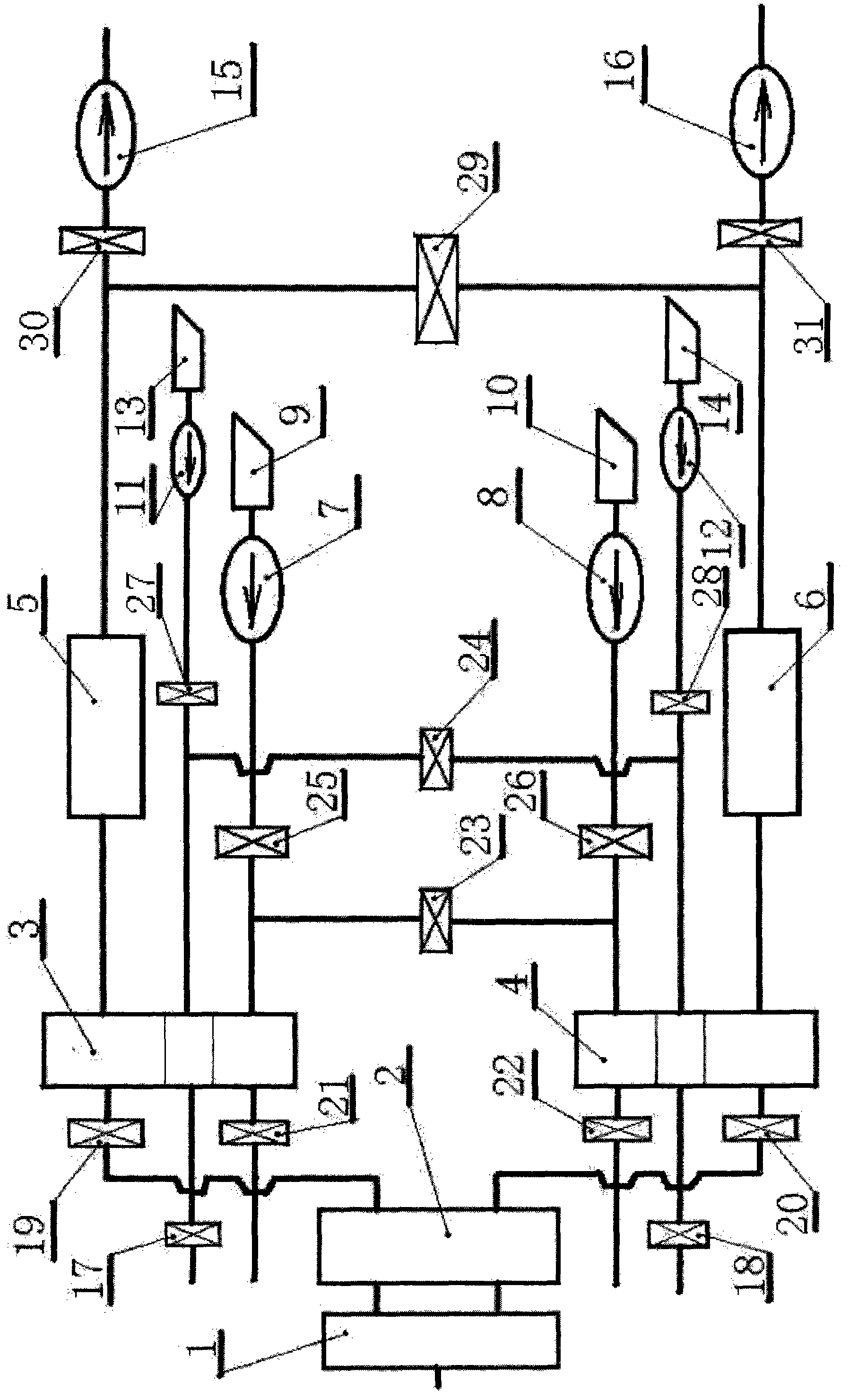

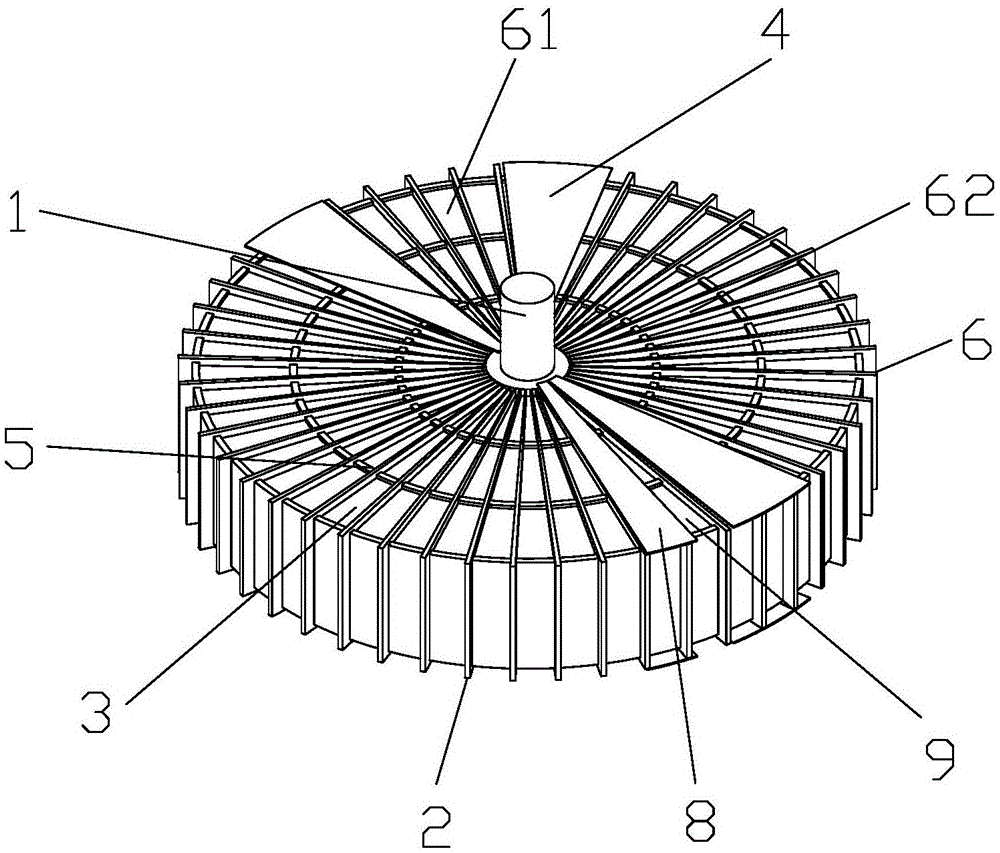

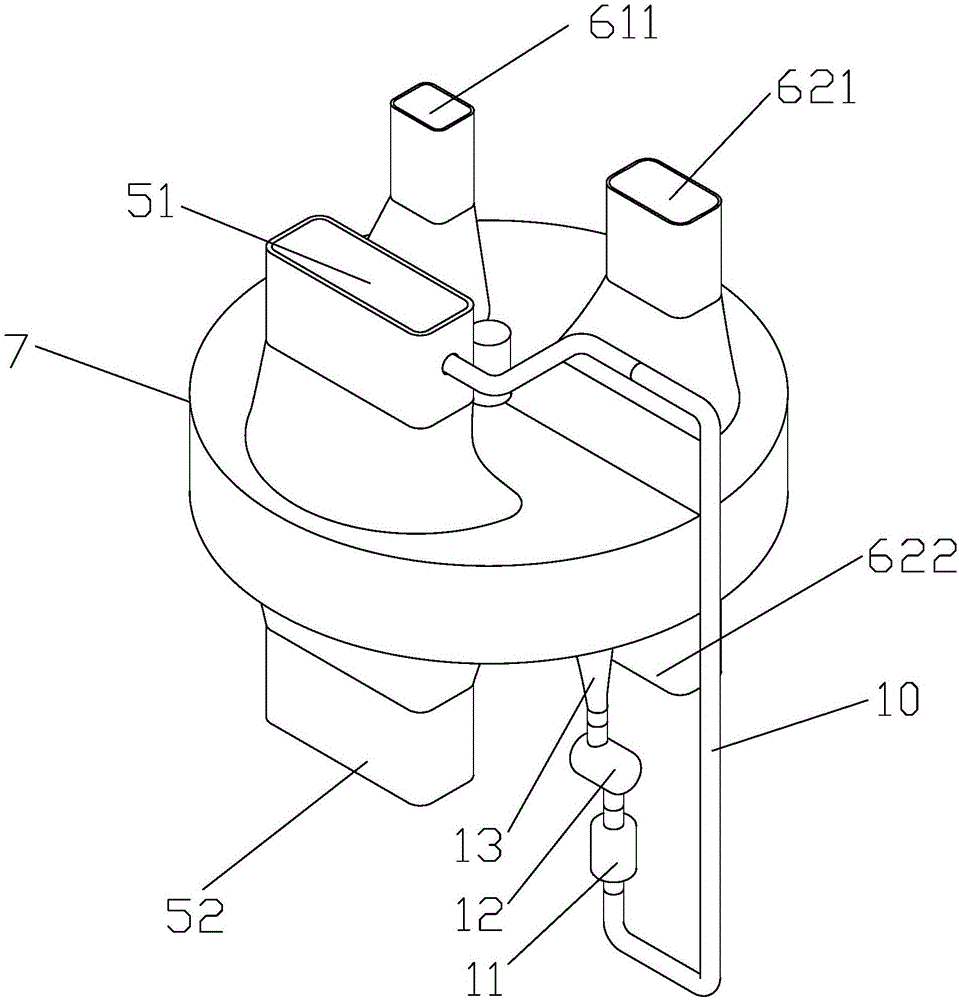

Air pre-heater

ActiveCN105042623AAvoid enteringPlay a sealing roleCombustion processIndirect carbon-dioxide mitigationAir preheaterPositive pressure

The invention provides an air pre-heater. A temperature increase sector plate is arranged at the position, close to a secondary air side, on a smoke side. The included angle alpha between the temperature increase sector plate and a sector plate closest to the temperature increase sector plate ranges from 7 degrees to 8 degrees. The center angle beta of each separation bin is equal to the included angle alpha. The center angle gamma of the temperature increase sector plate ranges from 9 degrees to 10 degrees. The separation bin between the temperature increase sector plate and the sector plate closest to the temperature increase sector plate is a circulation smoke separation bin. One side of a smoke inlet above the smoke side is communicated with a bypass flue. The bypass flue is sequentially connected with a dust remover, a temperature increase smoke induced draft fan and a temperature increase smoke inlet again, and the temperature increase smoke inlet is communicated with the circulation smoke separation bin. Compared with the prior art, high-temperature smoke is guided to the cold end of the air pre-heater, and when the temperature of the cold end is above 147 DEG C, ammonium bisulfate is scaled and gasified again, and the clogging prevention effect is achieved. Through the action of the temperature increase smoke induced draft fan, positive-pressure smoke flow is formed between the smoke side and an air side, pressure of the positive-pressure smoke flow and pressure of positive-pressure air flow of secondary air restrain mutually, and the air leakage problem is effectively solved.

Owner:山东泓江智能设备有限公司

Preparation method of 4-chlorophenylhydrazine hydrochloride

The invention provides a preparation method of 4-chlorophenylhydrazine hydrochloride. The preparation method of the 4-chlorophenylhydrazine hydrochloride includes a diazotization reaction, a reduction reaction and an acidizing reaction. The diazotization reaction includes throwing 4-chlorophenylhydrazine to water; dropping hydrochloric acid to enable the 4-chlorophenylhydrazine hydrochloride to dissolve completely; and dropwise adding a sodium nitrite aqueous solution to obtain a chlorination diazonium parachloroaniline aqueous solution. The reduction reaction includes dropwise adding the chlorination diazonium parachloroaniline aqueous solution to an ammonium sulfite aqueous solution and obtaining diazonium parachloroaniline disulfonate. The acidizing reaction includes dropping the hydrochloric acid to the diazonium parachloroaniline disulfonate; filtering; washing; discharging; stoving; and obtaining a 4-chlorophenylhydrazine hydrochloride end product. The preparation method of the 4-chlorophenylhydrazine hydrochloride is easy to operate by using the sodium nitrite aqueous solution as a reducing agent; and the product seeds out late and side reactions are reduced due to the fact that ammonium chloride and ammonium bisulfate generated in the acidizing reaction have high solubility in the water; and furthermore product quality and product yields are improved effectively due to the fact that the product is incompact in crystallization, good in flow-ability and easy to discharge and wash.

Owner:天津市天川化工有限公司

SNCR and SCR combined denitration device and process

InactiveCN104785080AReduce wasteAvoid defectsLighting and heating apparatusDispersed particle separationAir preheaterPtru catalyst

The invention discloses an SNCR and SCR combined denitration device for CFB boilers. The device consists of a cyclone separator, a tail part flue, a coal economizer and an air preheater, which are connected in sequence, wherein a first layer of spray gun is arranged in a pipeline which is used for connecting the cyclone separator and the tail part flue; a second layer of spray gun is arranged in the tail part flue; a catalyst device is arranged in a pipeline between the coal economizer and the air preheater. The process comprises the following steps: the NOx-containing smoke comes out from a boiler furnace, passes through the cyclone separator and is sprayed into a urea solution or ammonium hydroxide through the first layer of spray gun to carry out SNCR denitration reaction; the smoke generated after the reaction is sprayed into a urea solution or ammonium hydroxide at the second layer of spray gun to become ammonia gas; the ammonia gas enters into the coal economizer and passes through the catalyst device which carries out SCR; the smoke after the reaction treatment enters the air preheater. The SNCR and SCR combined denitrification device for CFB boilers has the advantages that the denitration efficiency is up to 70-90%, the NOx is discharged up to the standard, the final ammonia escape is less than 3 ppm, the generation of ammonium bisulfate is less than SCR, the blocking or corrosion probability is lower than SCR, and the generated pressure loss and catalyst change cost are relatively low.

Owner:浙江菲达脱硫工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com