Method for online elimination of ammonium bisulfate clogging of air pre-heaters of coal-fired boiler of thermal power plant

An ammonium hydrogen sulfate, coal-fired boiler technology, applied in the combustion method, removal of solid residue, combustion product treatment and other directions, can solve problems such as high cost, reduce economic losses, improve economy and reliability, and reduce resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

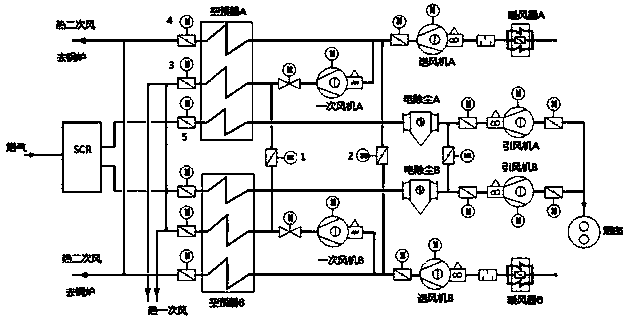

[0032] as attached figure 1 For the typical flue gas system of a coal-fired boiler in a thermal power plant shown, when the unit load is 50% peak load, the operation steps are as follows:

[0033] (1) During normal operation, with figure 1 All dampers are shown in the fully open position.

[0034] (2) When the peak load of the unit reaches 50%, the operation of a single air preheater can meet the requirements. Suppose it is necessary to clear the blockage of ammonium bisulfate in air preheater A and keep air preheater B in normal operation. Firstly, keep the contact baffle plate 1 of the primary air duct at the inlet of the air preheater fully open;

[0035] (3) Keep the connecting baffle plate 2 of the secondary air duct at the inlet of the air preheater fully open;

[0036] (4) Close the baffle plate 3 of the primary air duct at the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com