Patents

Literature

106 results about "Nickel deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

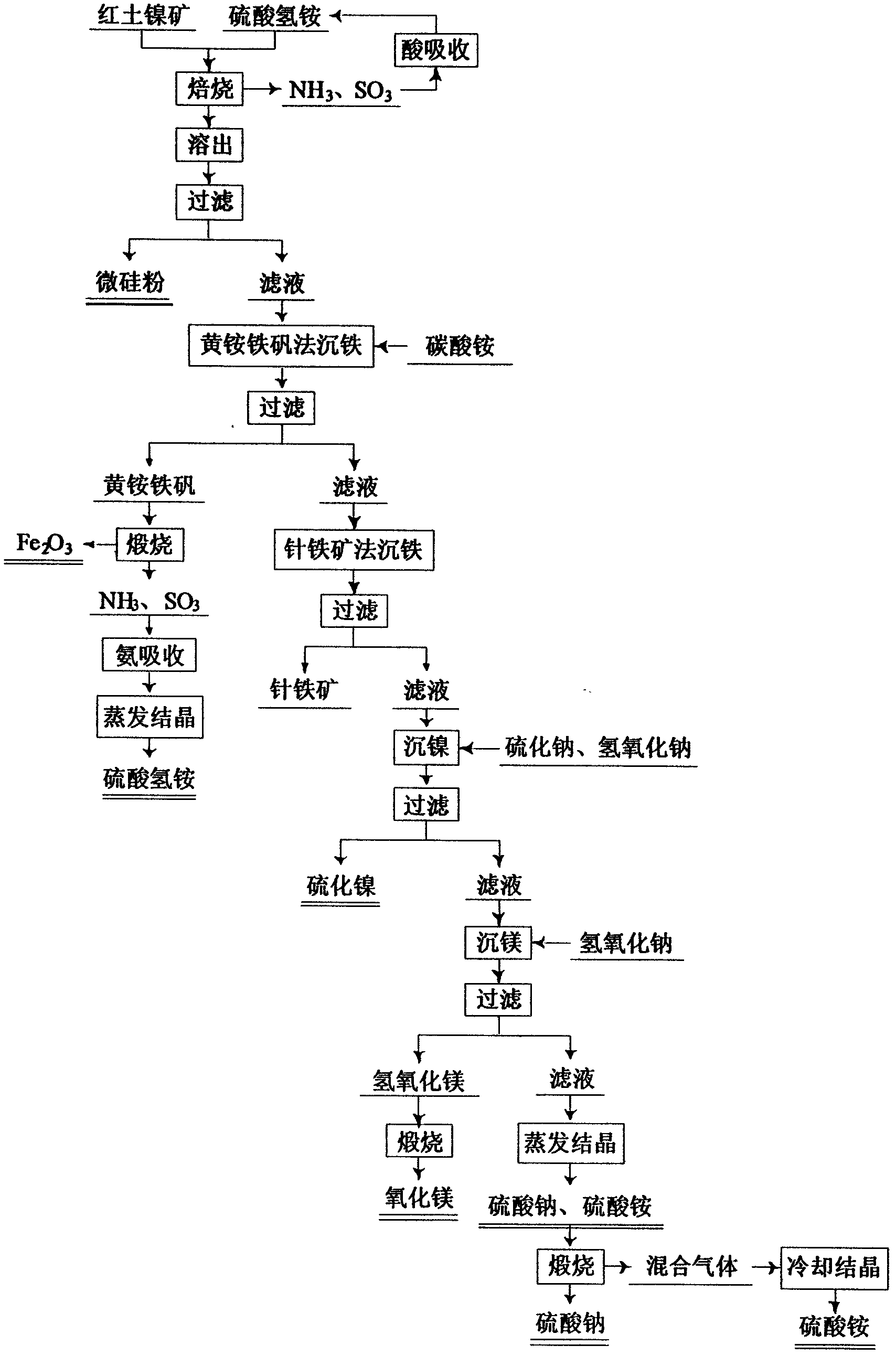

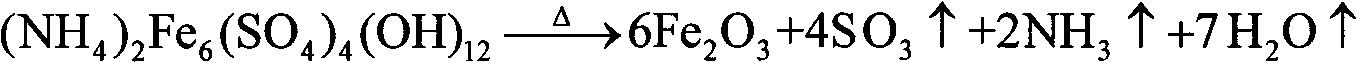

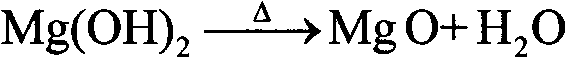

Method for comprehensive utilization of laterite nickel ore

A method for comprehensive utilization of laterite nickel ore comprises the following steps: (1) pulverizing laterite nickel ore, grinding, mixing with ammonium bisulfate, and roasting; (2) dissolving and filtering the roasted clinker to obtain a filtrate, depositing iron by an ihleite method, and depositing iron by a goethite method; (3) performing nickel deposition of the filtrate obtained after iron deposition by sodium sulfide, preparing a nickel sulfide product; (4) performing magnesium deposition of the filtrate obtained after nickel deposition by sodium hydroxide to obtain magnesium hydroxide; (5) washing, drying and calcining magnesium hydroxide to prepare a magnesium oxide product; (6) using the roasted clinker dissolved slag as a microsilica fume product directly, wherein the main component of the slag is silica; (7) calcining ammonium jarosite to obtain an iron oxide product.

Owner:NORTHEASTERN UNIV

Activated solution of magnesium alloy surface micro-arc oxidation ceramic coating surface and activation method

The invention relates to activated solution of a magnesium alloy surface micro-arc oxidation ceramic coating surface and an activation method, which belong to the technical field of magnesium alloy surface processing. The activated solution comprises components by weight percentage: fluoride salts: 5-10%, inorganic acid: 3-10%, organic matter: 1-5%, and water: 80-85%. The activation method includes immersing magnesium alloy samples for preparing micro-arc oxidation ceramic coatings into the prepared magnesium alloy surface micro-arc oxidation ceramic coating activated solution for 10-60 seconds, and immediately immersing the magnesium alloy samples into electroless plating copper solution or electroless plating nickel solution after being taken out and washed by water. The invention increases efficiency, and formed ceramic coating activated surfaces can enable copper and nickel deposition to be uniform and fine in adhesion force.

Owner:HOHAI UNIV CHANGZHOU

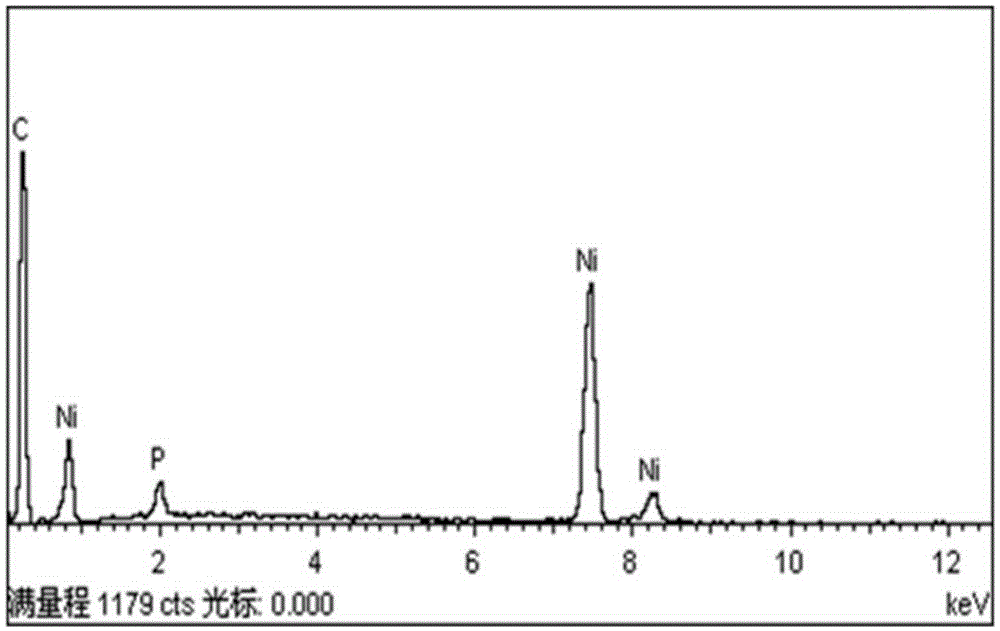

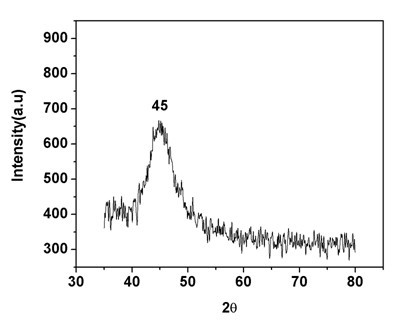

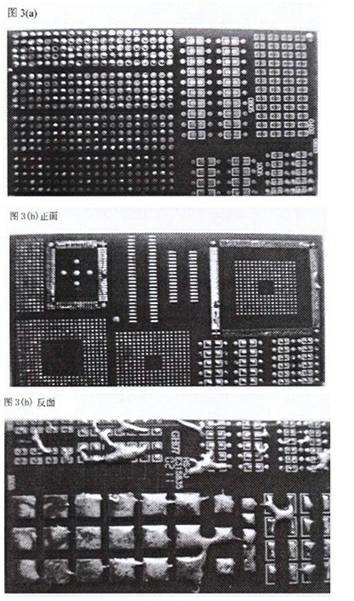

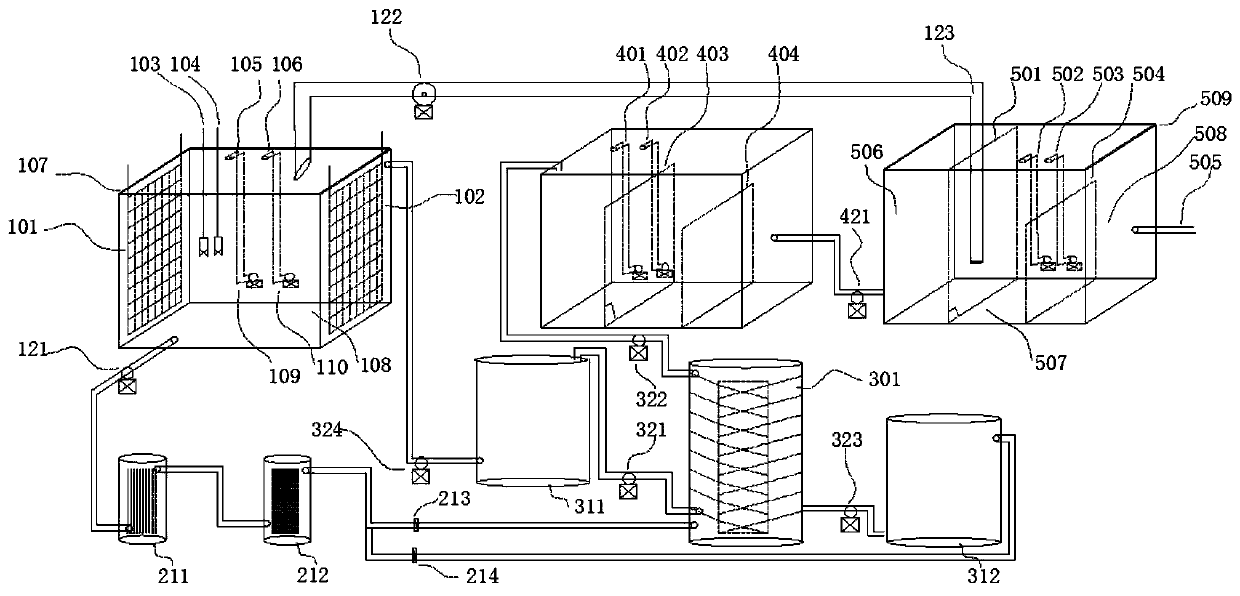

Novel chemical nickel gold production process and chemical nickel plating liquid

InactiveCN109628913AFast deposition rateSolve the difficulty of levelingLiquid/solution decomposition chemical coatingEtchingNickel deposition

The invention discloses a PCB or package substrate chemical nickel gold production new process. The new process comprises the steps of chemical gold pretreatment, deoiling, micro-etching, activation,alkaline chemical nickel, nickel activation, acid chemical nickel, chemical gold, gold surface hole sealing and chemical gold aftertreatment. The invention further provides novel chemical nickel plating liquid. The process is low in nickel cylinder temperature and high in chemical nickel deposition speed; nickel simple substances are difficultly separated out from the wall of a chemical nickel plating liquid stabilizing tank; the horizontal production of chemical nickel gold can be realized; a production line is shortened; the emission of waste water is reduced; and the comprehensive production cost of the production line is reduced. In the novel chemical nickel plating liquid, through adjustment of types of complexing agents and stabilizing agents in the chemical nickel plating liquid, even if under the conditions of higher PH and higher deposition speed, higher P content is achieved to meet various performance requirements of existing chemical nickel gold for the surface treatment ofPCBs and package substrates.

Owner:湖南互连微电子材料有限公司

Polytetrafluoroethylene dispersion for electroless nickel plating applications

InactiveUS6837923B2Increased dispersion contentGood dispersionFibre treatmentInksElectroless nickelViscosity

A low viscosity silicone glycol surfactant together with glycerin is added to a polytetrafluoroethylene dispersion for use with an electroless nickel plating bath. The improved plating bath produces a stable PTFE dispersion that continues to work as the plating bath ages and that produces an electroless nickel deposit with greater than 20 percent by volume of PTFE in the deposit.

Owner:MACDERMID ACUMEN INC

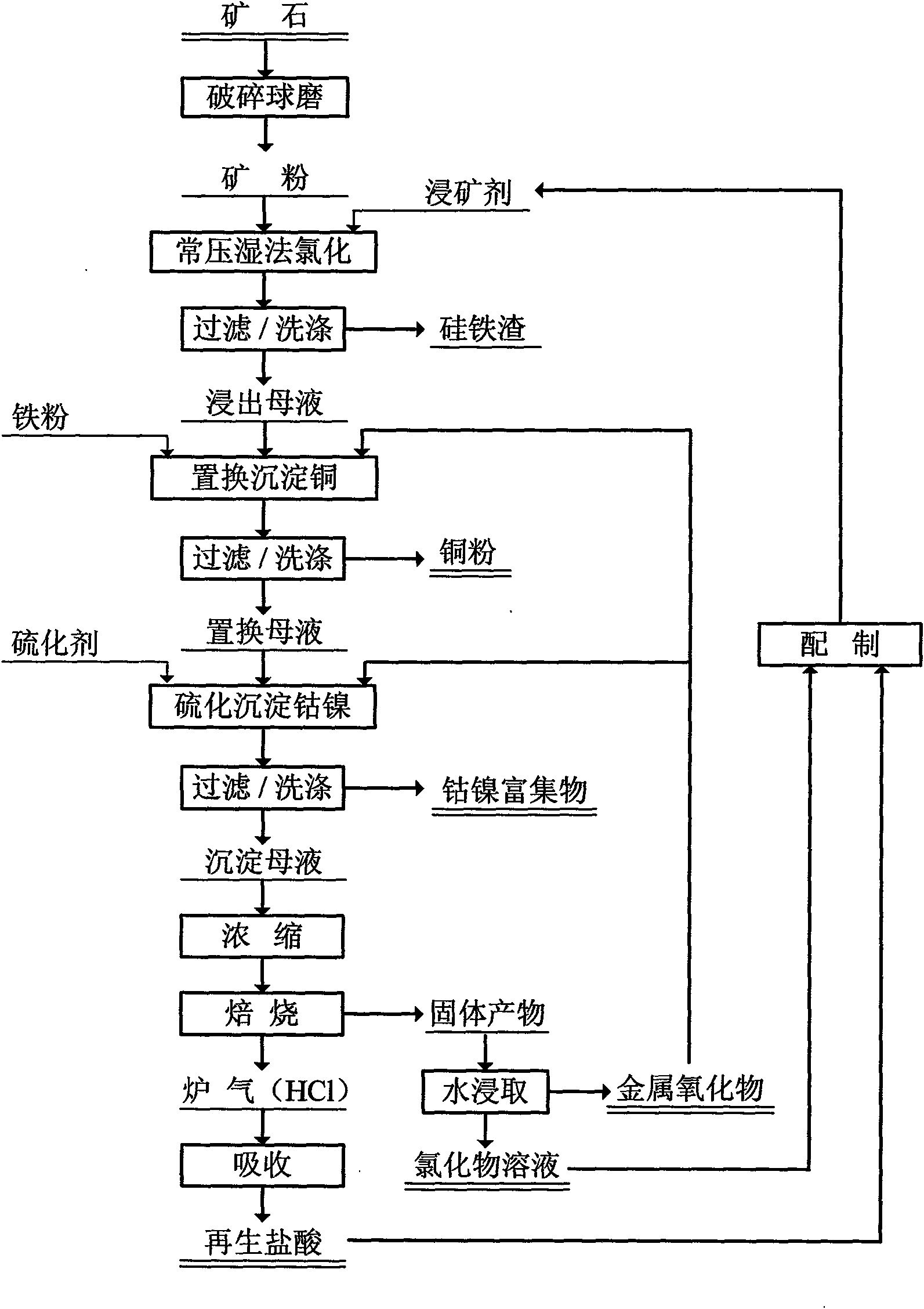

Method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore

ActiveCN101575673AImprove leaching ratePromote circulationProcess efficiency improvementSlurrySulfide

The invention provides a method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore, which uses low-grade complex mixed copper-cobalt ore (sulfide and oxide) as a raw material to extract an intermediate product of the copper and cobalt-nickel by adopting process flows of crushing and grinding ore into slurry, leaching the slurry with acidic villaumite by a wet method, extracting copper powder by reduction and replacement, vulcanizing and depositing nickel (cobalt), concentrating, drying, baking and hydrolyzing deposited mother solution at low temperature and the like. The method comprises main technical points that metallic elements in the mixed copper-cobalt ore are dissolved and leached by the acidic villaumite under normal pressure; copper in leaching liquor is reduced and deposited by a reducing agent; the cobalt and nickel are deposited by a vulcanizing agent to obtain the intermediate product; the mother solution is concentrated, dried, baked and hydrolyzed at low temperature after cobalt-nickel deposition to obtain metal oxide, metal oxychloride and hydrogen chloride containing iron, magnesium and the like; hydrogen chloride is reclaimed to obtain hydrochloric acid, and baked solid is leached into water to obtain chloride solution; and the hydrochloric acid and the chloride solution are used for leaching of ore slurry. The method comprehensively reclaims the copper, the cobalt-nickel and the like, and has the characteristics of high leaching rate of the copper and the cobalt-nickel, less energy consumption, low cost, closed circulation of chlorine (hydrochloric acid), less investment of project engineering and the like. The whole process is concise, clean and environment-friendly. The method is particularly applicable to large-scale industrial production.

Owner:福建常青新能源科技有限公司

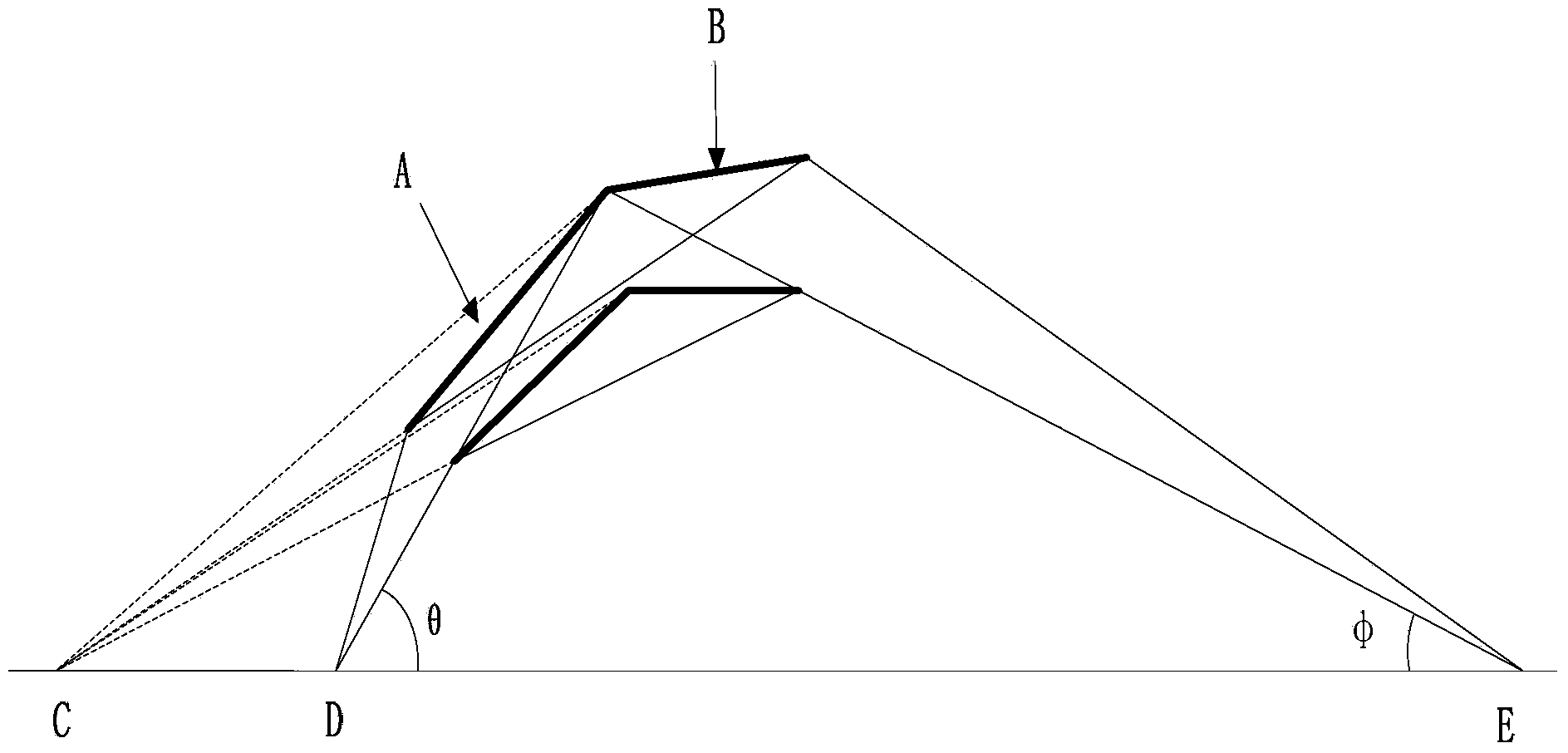

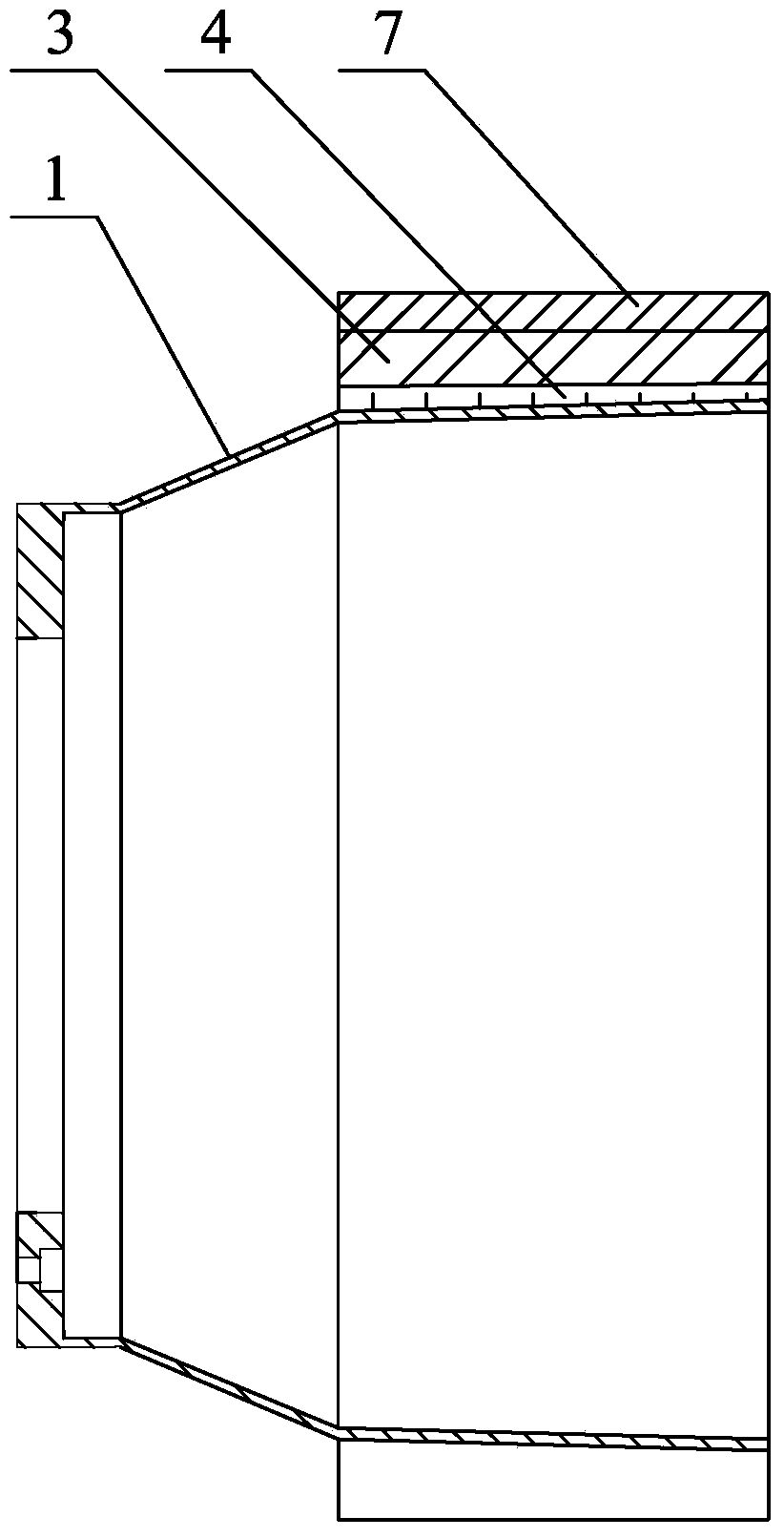

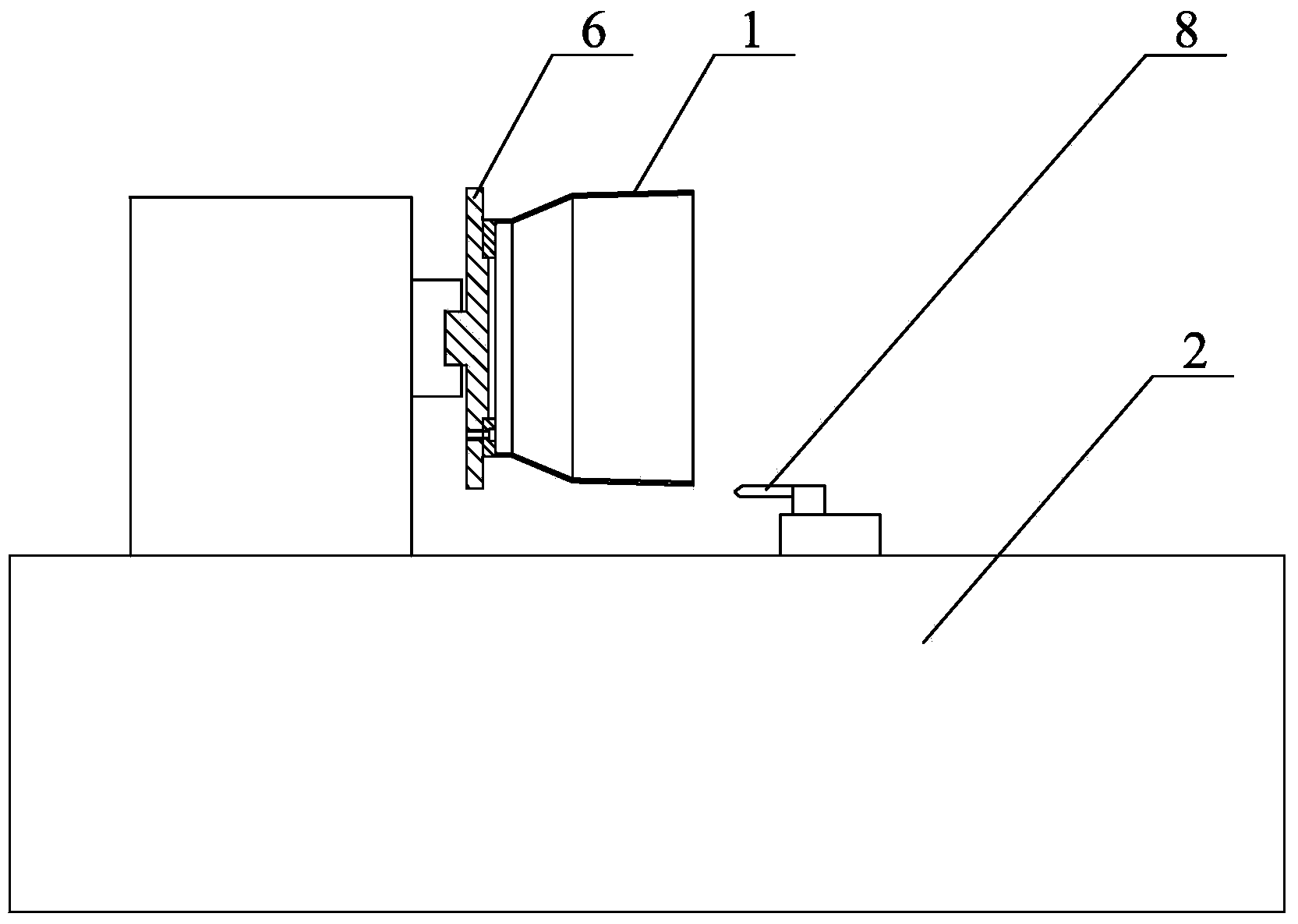

Finish machining method of direct lathe machining of optical collecting mirror in EUV (extreme ultra-violet) lithography light sources

ActiveCN103433507AReduce processing costsGuaranteed face shapeTurning machinesLithographic artistUltraviolet

The invention discloses a finish machining method of direct lathe machining of an optical collecting mirror in EUV (extreme ultra-violet) lithography light sources, belongs to the field of optics and finish machining, and aims at solving the problems that the optical collecting mirror in EUV light sources is machined by adopting a reproducible method, firstly a solid shaft which is matched with the surface type of the required collecting mirror is required to be machined, then the surface of the solid shaft is subjected to nickel deposition treatment, and then the nickel shell is peeled to form a substrate of the collecting mirror. According to the technique of the scheme, the accuracy control required during the machining process is very strict, and the machining cost is increased. The method comprises the following steps: installing and clamping a cylinder blank 1 of the collecting mirror; carrying out rough lathe machining in finish lathe machining; carrying out half-finish lathe machining; carrying out the finish lathe machining; carrying out membrane coating treatment; carrying out manual polishing treatment; carrying out the manual polishing treatment on the surface type of the cylinder blank of the collecting mirror after the membrane coating treatment, so that the surface type of the cylinder blank of the collecting mirror meets the surface type of the collecting mirror, thereby completing the manufacture of the collecting mirror. The finish machining method provided by the invention is used for machining and manufacturing the optical collecting mirror in the EUV lithography light sources.

Owner:HARBIN INST OF TECH

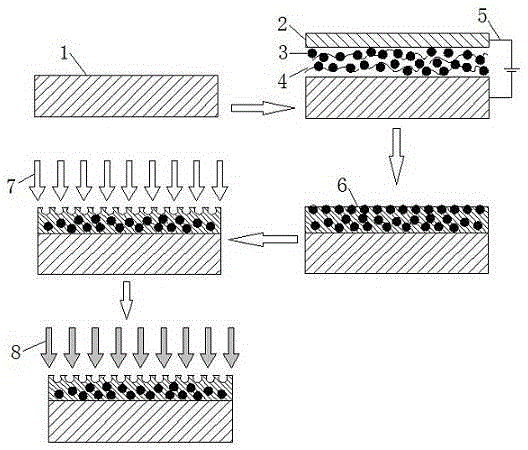

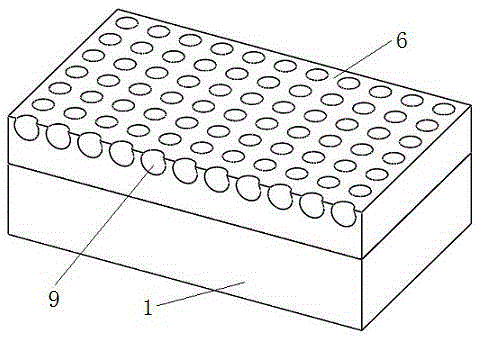

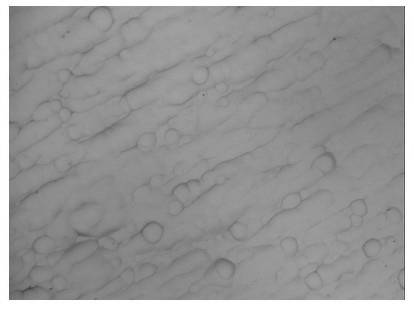

Method for manufacturing ultra-oleophobic metal surface with recessed micropores

The invention discloses a method for manufacturing an ultra-oleophobic metal surface with recessed micropores. The method includes the following steps that a metal substrate is cleaned and dried; a nickel block serving as a positive pole and the metal substrate serving as a negative pole are connected to the positive pole and the negative pole of a power source respectively, and a nickel deposition solution evenly mixed with soluble spherical micronano-particles passes the portion between the positive pole and the negative pole to be powered on to form an electric settled layer, so that the soluble spherical micronano-particles are embedded in a metallic nickel layer and in the surface of the metallic nickel layer; cleaning and drying are conducted; the workpiece is put into a dissolution solution so that the soluble spherical micronano-particles can be dissolved, and the ultra-oleophobic surface of the recessed structure is formed on the surface of the nickel layer; and lower-surface-energy modification is conducted. According to the method, the soluble spherical micronano-particles pass the portion between the negative pole and the positive pole to be embedded in the surface of the deposition layer and in the deposition layer, then the soluble spherical micronano-particles are dissolved, and the oleophobic surface of the recessed structure is formed; and the specification and morphology of the recessed pores can be controlled through the size of the spherical particles so that the pores can be evenly and regularly arranged, batch production is achieved, and good wear resistance and ultra-oleophobic performance are achieved.

Owner:GUANGDONG UNIV OF TECH

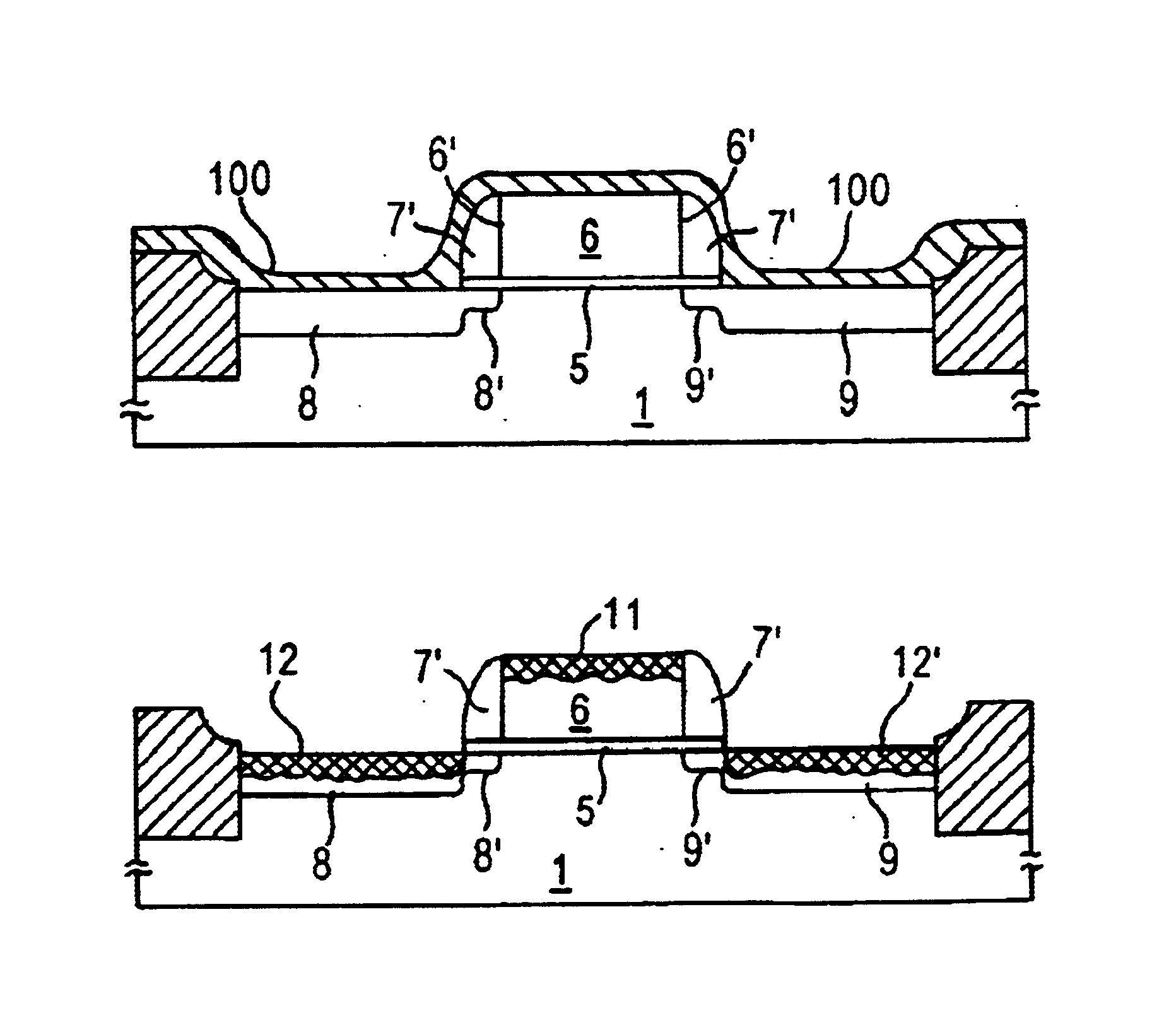

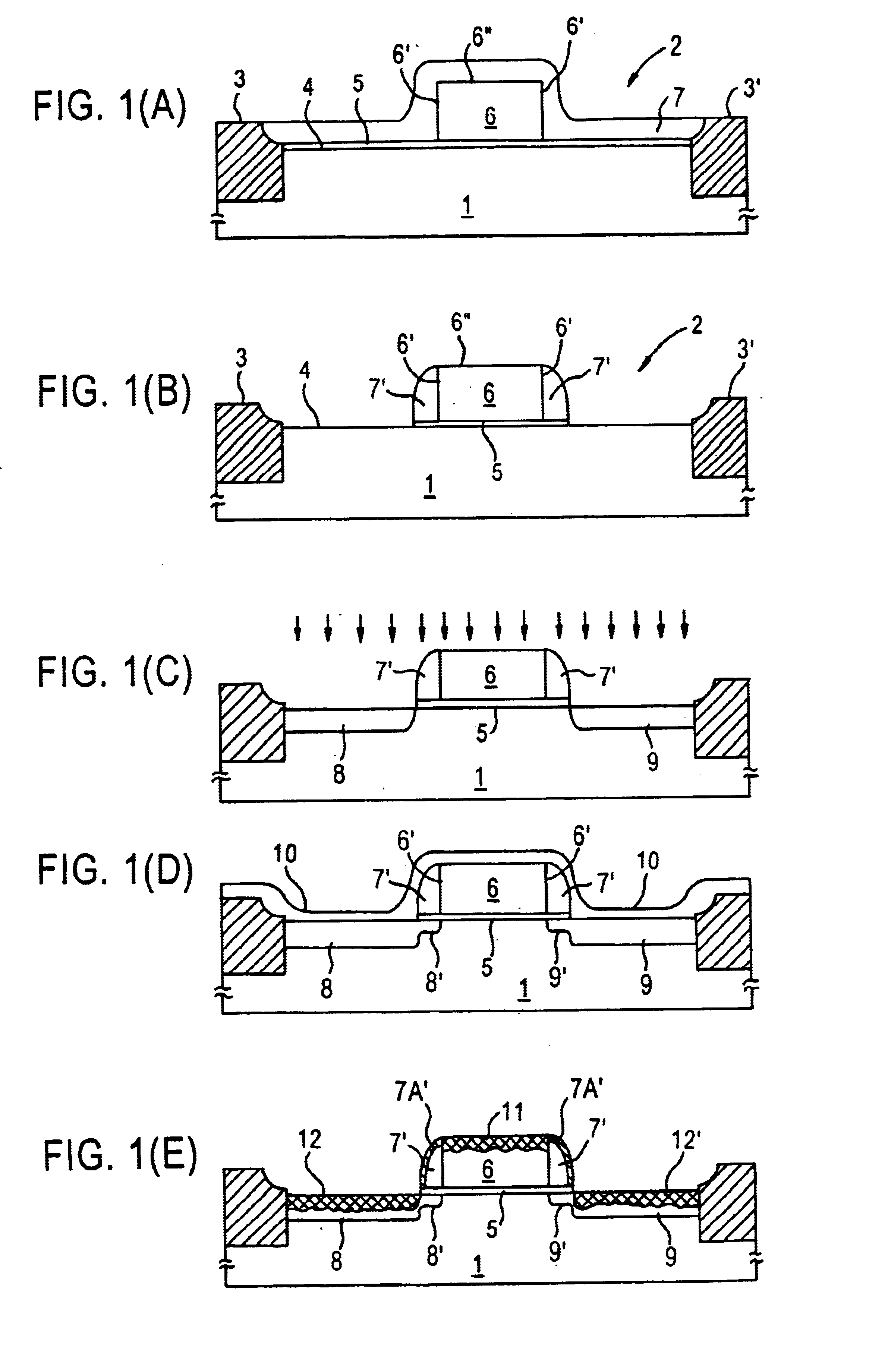

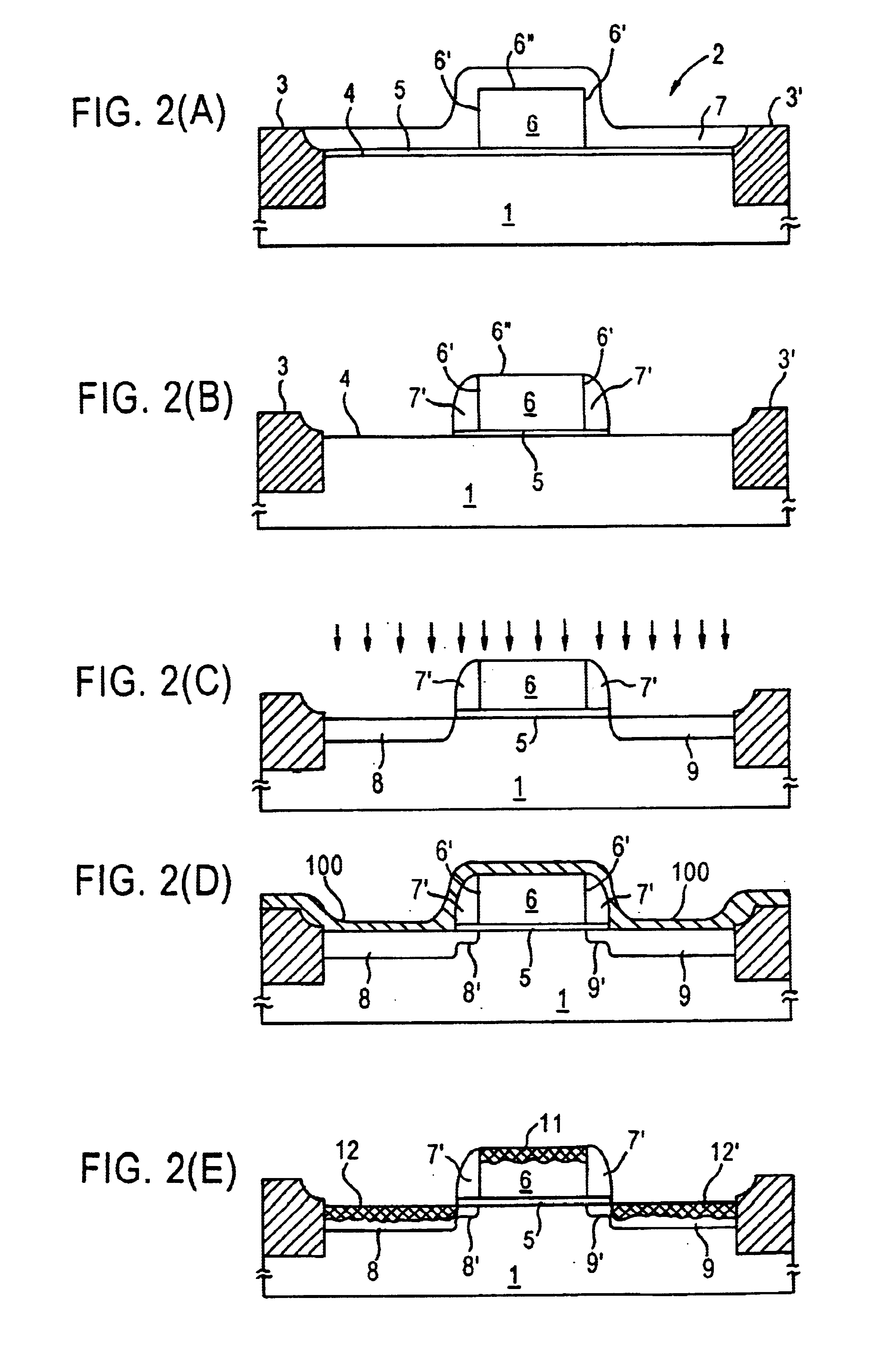

Two-step process for nickel deposition

InactiveUS6841449B1Reduce transistor shortingSemiconductor/solid-state device manufacturingSemiconductor devicesSalicideSputtering

Sub-micron dimensioned, ultra-shallow junction MOS and / or CMOS transistor devices are formed by a salicide process wherein a blanket nickel layer is formed in contact with the exposed portions of the substrate surface adjacent the sidewall spacers, the top surface of the gate electrode, and the sidewall spacers. Embodiments include forming the blanket layer of nickel is formed by the sequential steps of: (i) forming a layer of nickel by sputtering with oxygen gas; and, (ii) forming a layer of nickel by sputtering with argon gas. The two step process for forming the blanket layer of nickel advantageously prevents the formation of nickel silicide on the outer surfaces of the insulative sidewall spacers.

Owner:ADVANCED MICRO DEVICES INC

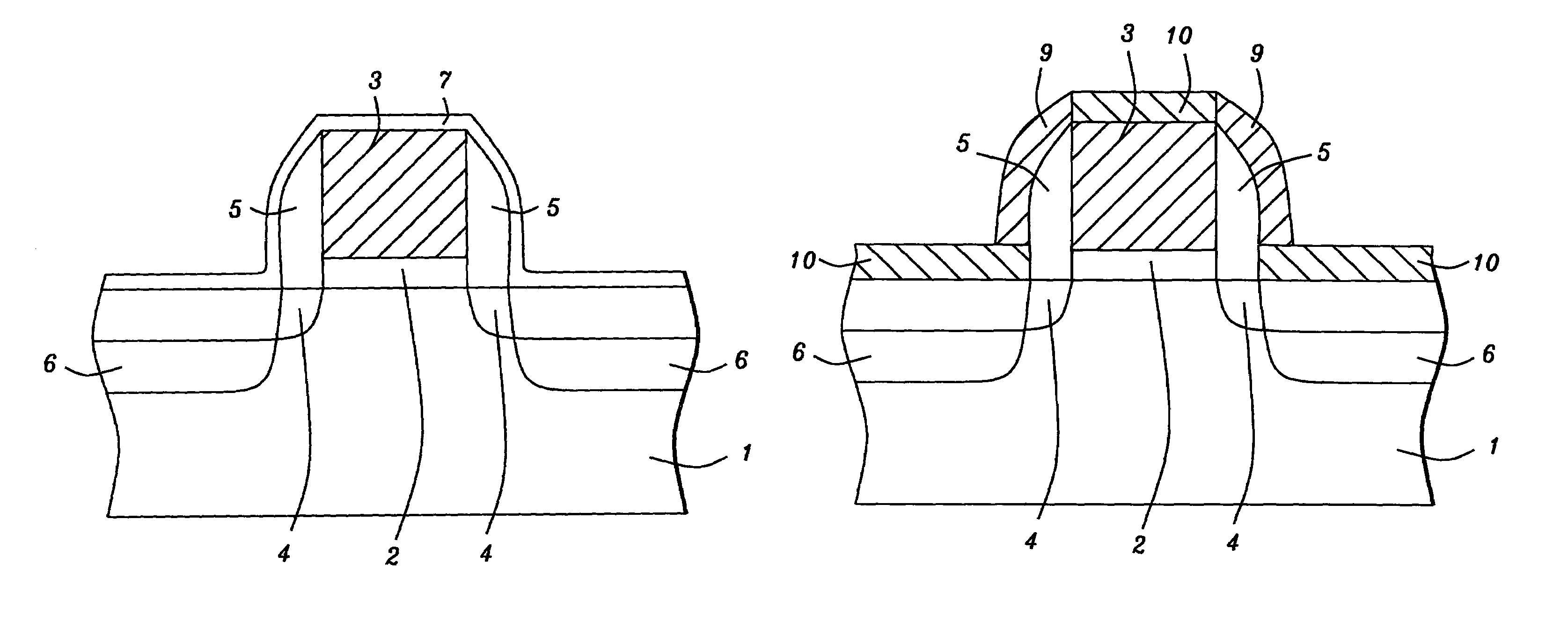

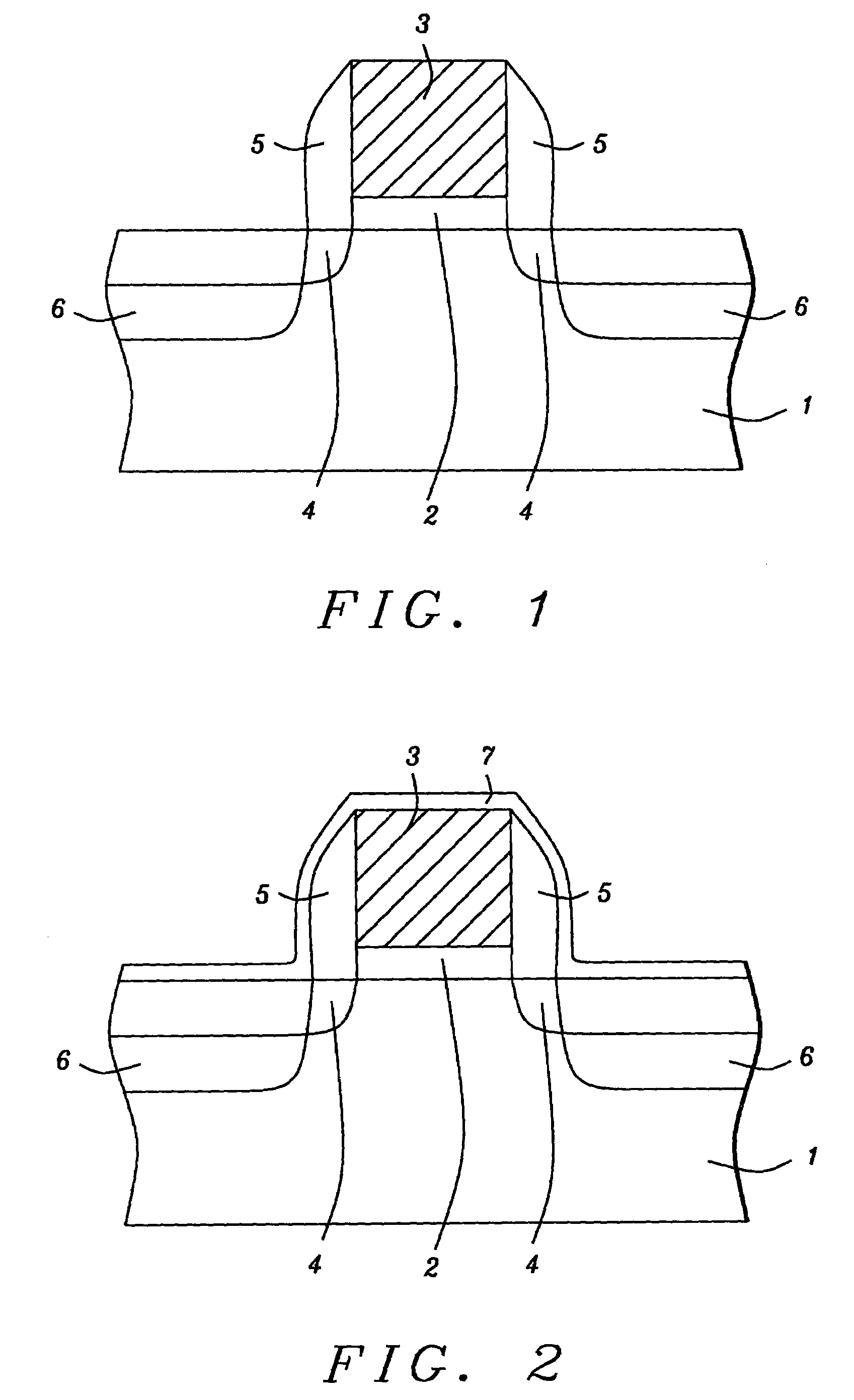

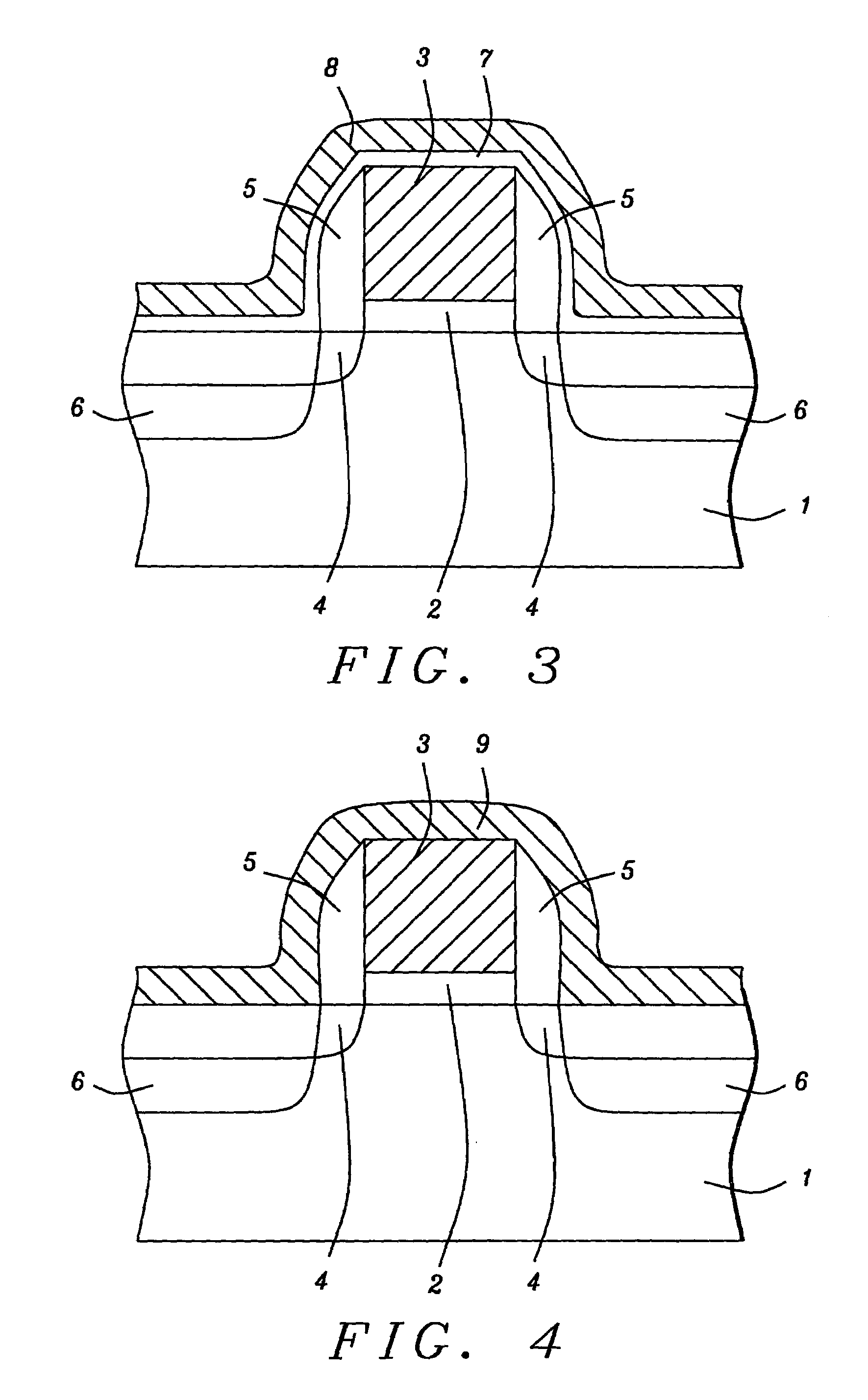

Method of forming metal silicide

ActiveUS7205234B2Reduce instabilityRapid thermal anneal (RTA)Semiconductor/solid-state device manufacturingSemiconductor devicesMOSFETSalicide

A method of optimizing the formation of nickel silicide on regions of a MOSFET structure, has been developed. The method features formation of nickel silicide using an anneal procedure performed at a temperature below which nickel silicide instability and agglomeration occurs. A thin titanium interlayer is first formed on the MOSFET structure prior to nickel deposition, allowing an anneal procedure, performed after nickel deposition, to successfully form nickel silicide at a temperature of about 400° C. To obtain the desired conformality and thickness uniformity the thin titanium interlayer is formed via an atomic layer deposition procedure.

Owner:TAIWAN SEMICON MFG CO LTD

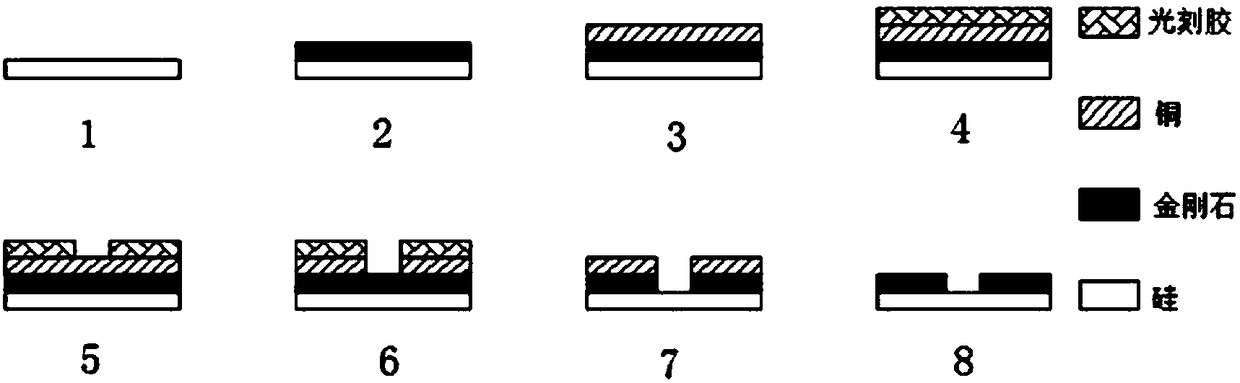

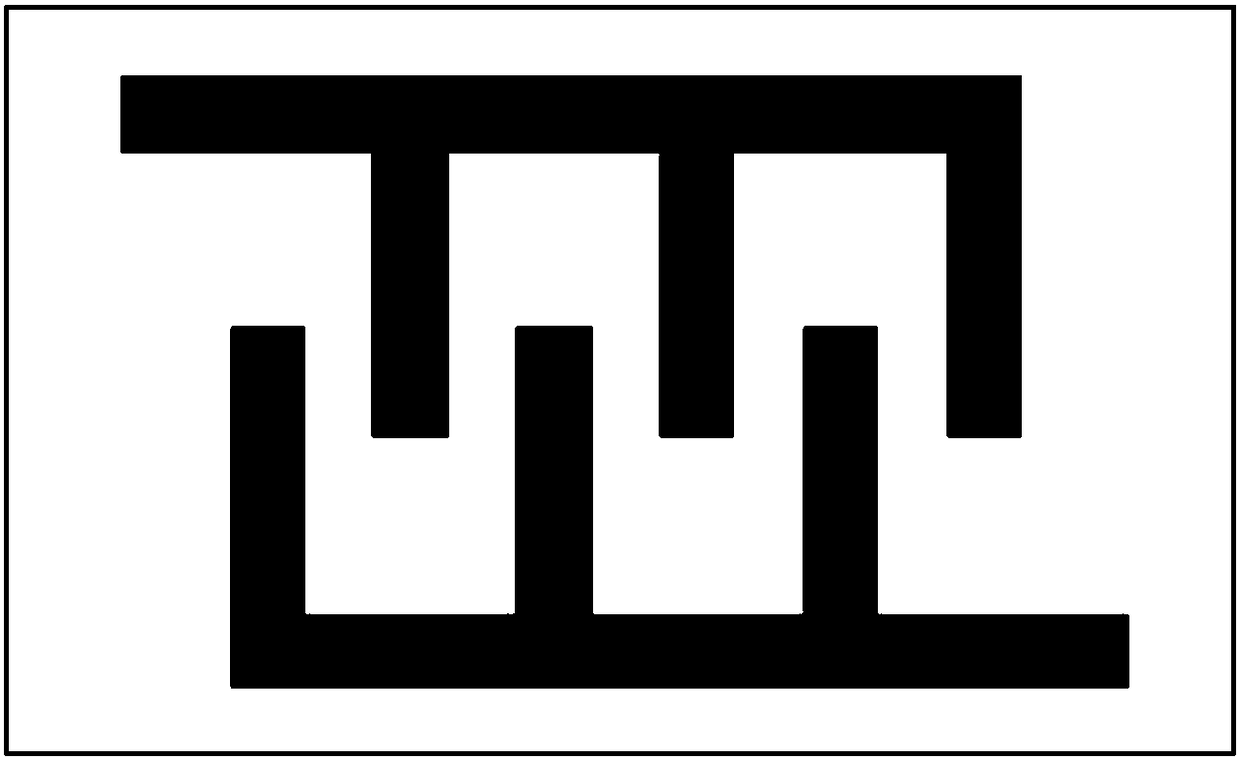

Preparation method of electrochemical alanine biosensor based on boron-doped diamond microelectrode and application thereof

ActiveCN108362751ARealize micro-nano processingOvercome precisionMaterial analysis by electric/magnetic meansElectrochemical biosensorNickel deposition

The invention relates to a preparation method of an electrochemical alanine biosensor based on a boron-doped diamond microelectrode and an application of the preparation method of the biosensor in alanine detection. The method comprises the following steps: employing a vapour deposition method to prepare a boron-doped diamond film at a substrate; employing a physical vapour deposition method for depositing a layer of film coating of metal and / or metal oxide on the surface of the boron-doped diamond film; employing a lithography technology to prepare an electrode pattern on the film coating, and after pickling, completing the preparation of a mask film; employing an etching technology for etching the surface of the boron-doped diamond to prepare a boron-doped diamond microelectrode; and performing nickel deposition modification at the boron-doped diamond microelectrode. The electrochemical alanine biosensor can greatly improve the electrode performance, increases the electrode sensitivity, and has considerable application prospect while being used for detecting the alanine concentration.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparing technology of circuit board nickel and gold deposition

InactiveCN105025662AReduce corrosionReduce generationConductive pattern reinforcementProduction lineBiological activation

The invention belongs to the field of circuit board processing, and specifically relates to a preparing technology of circuit board nickel and gold deposition. The nickel and gold deposition technology comprises the steps of circuit board loading and oil removing; a first time of water cleaning; acid cleaning; a second time of water cleaning; pre-dipping and activation; a third time of water cleaning; nickel deposition; a fourth time of water cleaning; gold deposition; a fifth time of water cleaning; and circuit board unloading. Based on existing equipment, preprocessing, micro-corrosion amount and nickel cylinder control are realized in production line processes, a good technical effect is obtained, and the cost is saved; existing processes are optimized, the corrosion of nickel in the nickel and gold deposition process is reduced, black PADs are reduced, and the weldability of the product is improved; in addition, the preparing technology of circuit board nickel and gold deposition is good in market prospect and economic value.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Nickel-containing wastewater treatment technology

InactiveCN101580317AReduce processing costsMultistage water/sewage treatmentNickel saltNickel deposition

The invention discloses nickel-containing wastewater treatment technology, which comprises the following steps: using sodium hydroxide or ammonia water to adjust the pH value of nickel-containing wastewater to between 5.5 and 9.5; adding dimethylglyoxime into the nickel-containing wastewater under the stirring at normal temperature for a nickel deposition reaction, wherein the molar ratio of the dimethylglyoxime to Ni in a filtrate is 2.2:1-2.4: 1; filtering after the reaction is performed for 20 to 60 minutes; washing a filter cake by hot water with a temperature between 40 and 90 DEG C, and then obtaining a pure nickel chelate through the filtration; using hydrochloric acid, sulfuric acid or nitric acid to dissolve the nickel chelate according to product requirements; and obtaining corresponding nickel salt solution and the dimethylglyoxime after the filtration; recovering the dimethylglyoxime from an acid-dissolved filtrate; removing residual Fe through neutralization; heating hydrolysis and filtration, and then evaporating, washing, crystallizing the filtrate and drying the crystal to obtain a product; merging the filtrates in step two and recovering the dimethylglyoxime; and using the recovered dimethylglyoxime for the nickel deposition reaction. The nickel-containing wastewater treatment technology can ensure that the nickel-containing wastewater reaches the standard after the treatment and the content of the residual Ni is less than 1mg / L, can also completely recover nickel, and has low treatment cost and less equipment investment.

Owner:邱致忠

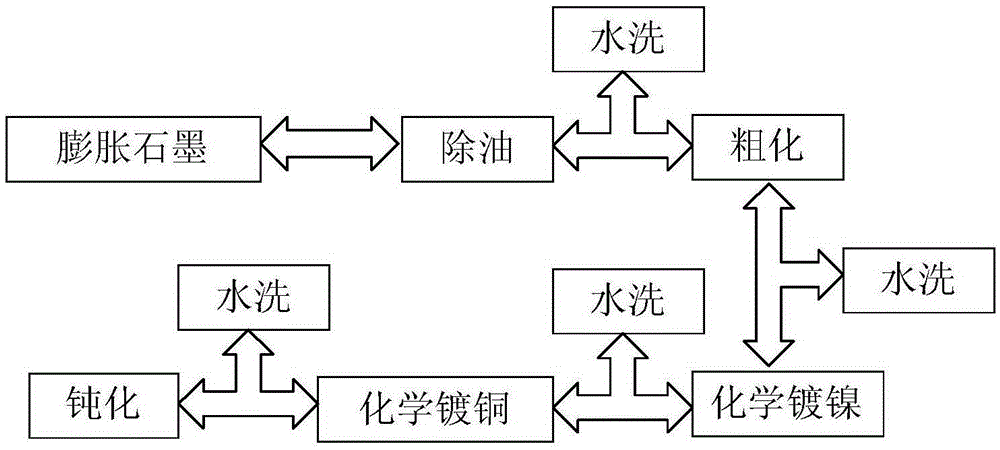

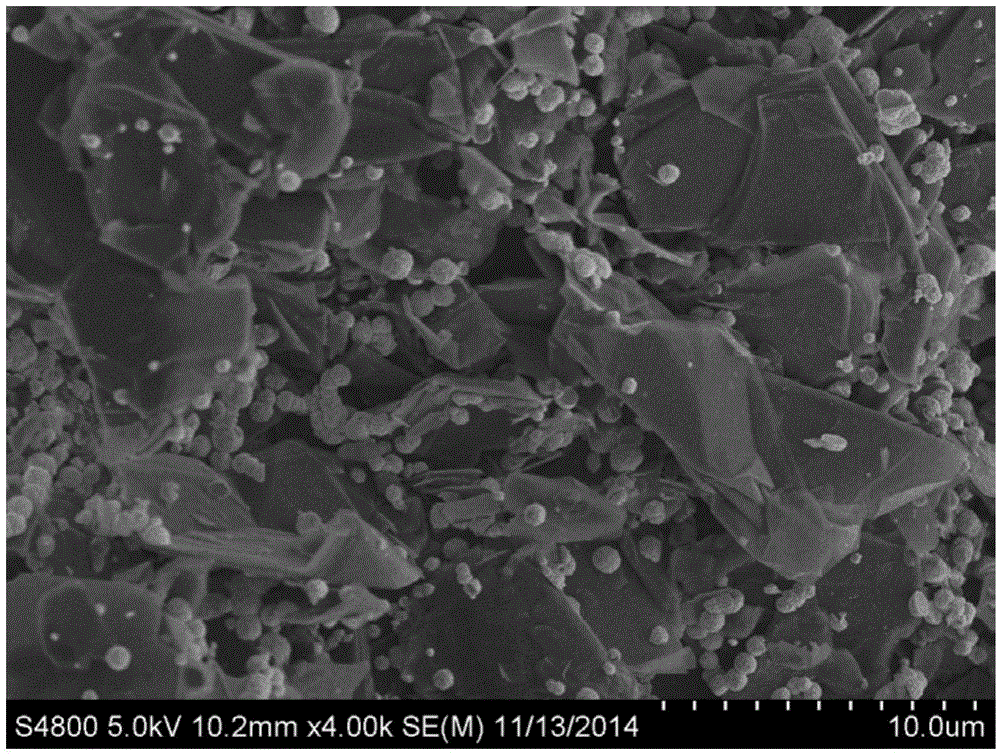

Method for chemically plating copper on surface of expanded graphite

ActiveCN105274504AReduce usageReduce manufacturing costLiquid/solution decomposition chemical coatingCopper platingGraphite

The invention provides a method for chemically plating copper on the surface of expanded graphite. Firstly, the surface of the expanded graphite is chemically plated with nickel to form nickel activated points which are evenly scattered; in chemical nickel plating, an iron stirrer or a nickel stirrer is utilized for carry outing plating with the expanded graphite at the same time and stir mechanically; electrons can be released through oxidization corrosion of metallic iron or nickel in plating liquid; the electrons make contact with the expanded graphite to be conducted to the surface of the expanded graphite, the nickel deposition reaction can be generated on the surface of the expanded graphite, and the nickel activate points which are evenly scattered are formed on the surface of the expanded graphite. Then, the expanded graphite with the evenly-scattered nickel activated points on the surface is put into plating liquid of chemical copper plating to carry out the second step of chemical copper plating. The nickel activated points formed on the surface of the expanded graphite in the first step serve as the catalytic activity center of the chemical copper plating in the second step to catalyze the chemical copper plating reaction, and copper ions can deposit and form a copper plated layer on the surface of the expanded graphite with the nickel activate points as the center.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Chemical nickel deposition solution

InactiveCN102400120ASimple compositionGood attackLiquid/solution decomposition chemical coatingSodium phosphatesPhysical chemistry

The invention relates to a chemical nickel deposition solution applied in the manufacturing industry of printed circuit boards. The chemical nickel deposition solution comprises the following components: (1) 30 to 45 g / L of nickel aminosulfonate, (2) 64 to 75 g / L of composite complexing agent, (3) 18 to 25 g / L of sodium hypophosphite, (4) 0.01 to 0.03 g / L of wetting agent, and (5) the balance of deionized water. Nickel ions are provided by the nickel aminosulfonate and used together with the composite complexing agent, and chemical nickel deposition can be performed at the temperature between 55 and 75 DEG C under the pH value between 5.5 and 6.0. The chemical nickel deposition solution can be implemented at a low temperature; the nickel deposition solution is weakly acidic, energy-saving and environment-friendly; the nickel layer is bright and clean; and the nickel deposition solution is strong in corrosion resistance, good in weldability and stable.

Owner:GUANGDONG TONESET SCI & TECH

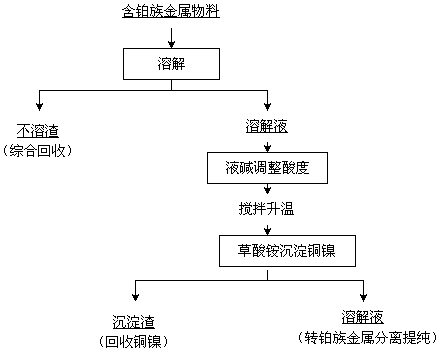

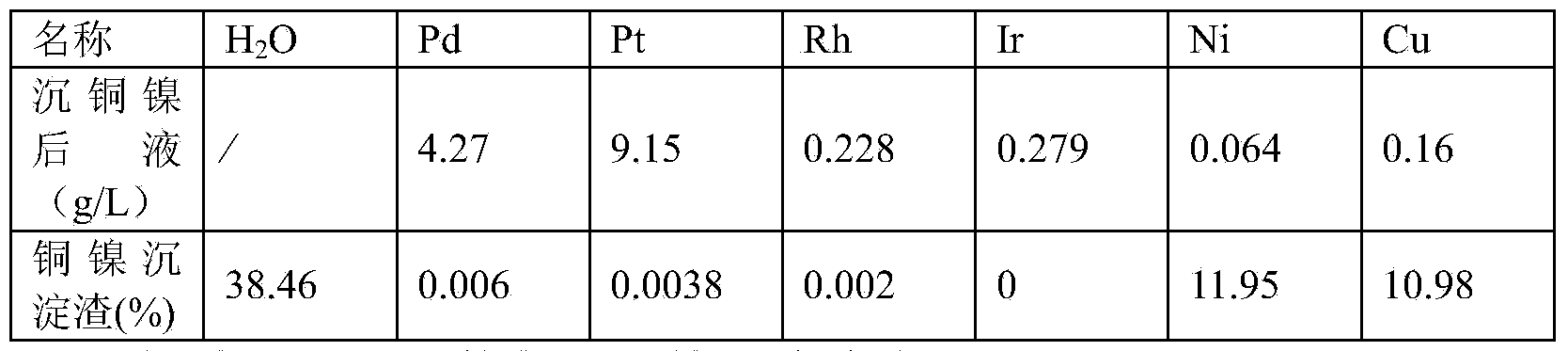

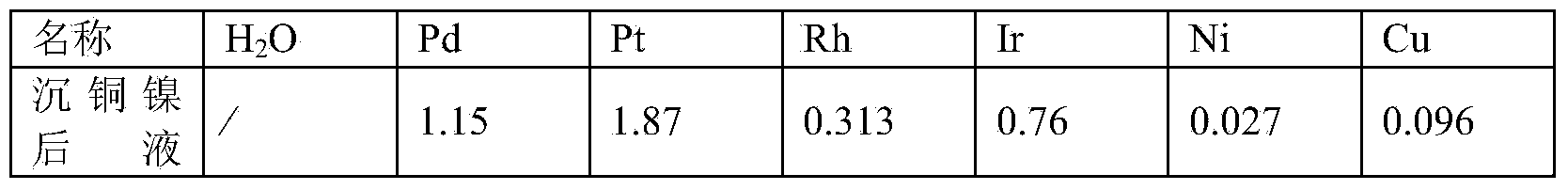

Process for removing base metals in platinum group metal containing material

ActiveCN103526040AWide adaptabilityShort coprecipitation rateProcess efficiency improvementSlagDissolution

A process for removing base metals in a platinum group metal containing material comprises the following steps: taking of the platinum group metal containing material (slag, secondary resources, and the like)-chlorination dissolution-acid adjusting of a dissolution solution-precipitation by use of organic reducing reagent ammonium oxalate-filtering separation of the base metals. The process of the invention is wide in adaptability to materials, simple in operation, reasonable in process connection, short in cycle, low in cost and stable in product quality. Separation of the base metals and noble metals can be performed by directly using raw mineral materials, and according to the condition of the materials, part of technological processes can be connected to reduce the processes and farthest improve the efficiency of separation of the base metals. According to the process of the invention, the copper and nickel removal rate of the platinum group metal containing material is greater than 95%, the content of platinum group metals in copper nickel deposition slag is less than 300g / t, copper, nickel and the like in the slag can be comprehensively recovered, the process structure is brief, the precipitating agent ammonium oxalate is an organic reagent, may not change the solution system, and may not impact noble metal separation purification and copper nickel recovery systems, and the product yield and quality of the platinum group metals can be greatly improved.

Owner:JINCHUAN GROUP LIMITED

Preparation method for modified graphene microchip wave-absorbing composite powder through nickel-cobalt particles

ActiveCN111069591AFacilitate depositionHigher nickel than cobalt contentTransportation and packagingMetal-working apparatusSlurryNickel deposition

The invention relates to a preparation method for modified nickel-cobalt composite powder on the surfaces of graphene microchips. The method is characterized by comprising the steps that a certain quantity of graphene microchips are soaked in oxidizing acid (for example, a 1:1 nitric acid solution) for corrosion activation, and mechanical stirring is performed for 12 hours or longer; then, the graphene microchips are washed and taken out and mixed with a nickel-cobalt salt solution containing a complexing agent and a reducing agent; under the combined action of ultrasonic concussion and mechanical stirring, the graphene microchips are evenly dispersed into the nickel-cobalt salt solution to form slurry, the obtained slurry is poured into a reaction kettle, a reaction is performed for 2-12hours at 120-200 DEG C, and the reduced nickel-cobalt particles can be attached to the surfaces of the graphene microchips in the process; and after the reaction is ended, the reaction kettle is takenout, after being naturally cooled to the room temperature, the reaction kettle is opened to take out the graphene composite powder after being subjected to the reaction, and the powder is dried in avacuum drying box at 50 DEG C. The nickel content of the prepared nickel-cobalt component is higher than its cobalt content in the initial stage of deposition of the alloy particles, the point particle of nickel deposition is adopted for chemocatalysis, cobalt deposition is promoted, and after a certain period, the content ratio of nickel to cobalt after being deposited is close to 1:1. The obtained nickel-cobalt modified graphene powder has the composite wave absorption effects such as electricity loss and magnetism loss.

Owner:HARBIN INST OF TECH AT WEIHAI

Preparation method for electro-deposited nickel and cobalt

InactiveCN105803483AAddress volume expansionImprove protectionPhotography auxillary processesResource utilizationEvaporation

The invention provides a preparation method for electro-deposited nickel and cobalt. According to the preparation method, ferrous sulfate or iron pyrite or zinc sulfide or nickel-cobalt sulfide serves as a reducing agent, and nickel-cobalt hydroxide is soaked completely through one step; then neutralizing and deironing are conducted through the nickel-cobalt hydroxide, silicon and aluminum are removed through neutralization by means of magnesium oxide, leaching residues are washed for recycling nickel and cobalt, P2O4 / 5O7 is removed out of a filtered solution, and saponification, extraction and impurity removal are conducted; and nickel is deposited by means of the P2O4 / 507 through electro-deposited nickel anolyte and industrial grade light-roasted powder or magnesium oxide, nickel hydroxide directly reacts with P2O4 or P5O7 for producing nickel soaps, and a P5O7 / 2O4 extraction solution is used for conducting electrodeposition on nickel or cobalt or conducting evaporative crystallization for producing the electro-deposited nickel or electro-deposited cobalt. A back extraction solution is used for producing manganese sulfate monohydrate and electro-deposited zinc. An anolyte nickel deposition post-solution is used for producing magnesium sulfate heptahydrate through evaporation. By the adoption of the preparation method, the P2O4 nickel soaps and the P5O7 soaps which meet scale production can be obtained, the production cost of the electro-deposited nickel and cobalt is substantially reduced, the problem that anolyte volume expansion is solved, and corrosion of anolyte evaporation to equipment is eradicated; and zero emission of production waste water of the electro-deposited nickel and cobalt is achieved, and environment protection and comprehensive resource utilization are facilitated.

Owner:王贺

Method for producing ammonium metavanadate by using waste catalytic cracking catalyst in oil refinery

InactiveCN104495924AImprove recycling efficiencyVanadium compoundsAmmonium sulfideAluminum ammonium sulfate

The invention relates to a method for producing ammonium metavanadate by using a waste catalytic cracking catalyst in an oil refinery. The method comprises the following steps: mixing the waste catalyst with sulfuric acid, calcium fluoride and water in a mixer, feeding into a curing cabin, and curing in the curing cabin; pulpifying the mixed materials with water; pumping the pulpified liquid into a leaching tank, and heating and stirring for leaching; pumping into a plate filter press for liquid-solid separation, feeding the leachate into a crystallization tank, and adding ammonium sulfate to crystallize; and performing liquid-solid separation, thereby obtaining an aluminum ammonium sulfate product and crystallization master batch; and adding ammonium carbonate into the crystallization master batch to adjust the pH value, adding ammonium persulfate, adding ammonium carbonate to adjust the pH value, heating to react, pumping into the filter press, and performing liquid-solid separation, thereby obtaining ammonium metavanadate. The separated liquid can be also fed into a lanthanum-cerium deposition tank, and ammonium oxalate is added to react to obtain lanthanum oxalate and cerous oxalate, or the separated liquid is fed into a nickel deposition tank, and ammonium sulfide is added to react to obtain nickel sulfide. By adopting the method, the waste catalytic cracking catalyst in the oil refinery can be reused for producing ammonium metavanadate, the problems that the environment can be polluted by the waste catalyst and the land can be occupied are effectively solved, the purity of the produced ammonium metavanadate is even greater than 99%, and the recycling efficiency is high.

Owner:武汉源宸再生资源科技有限公司

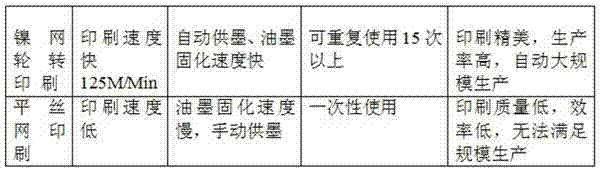

Production process of nickel net for high-precision printing

InactiveCN102330121AFast depositionImprove stabilityScreen printersElectroforming processesWorking temperaturePrinting ink

The invention provides a production process of a nickel net for high-precision printing. The process comprises the steps of: 1, manufacture of a mould, 2, manufacture of a underlying net, and 3, manufacture of the nickel net. The production process is characterized in that: laser puncture adopted in mould manufacture is non-contact processing, cannot cause mechanical extrusion to a material, and protects the material from deformation; the processing precision can be 15mu m, the number of meshes can be 305, and the aperture ratio of a 305-mesh nickel net can be 14 percent; the work temperature of bath solution in manufacture of the underlying net is 45+ / -1 DEG C, the coating has good quality, and the treatment cost is low; application of additive No.1 and additive No.2 can improve the nickel deposition speed, so that nickel can be distributed on the anodic surface more uniformly, and the stability of the bath solution can be improved; when the nickel net is manufactured, tip casting off of the net in a process of producing the nickel net to the underlying net can be realized by a double-pulse power supply, occurrence of single horn shape in the prior art is changed, pore ends of the nickel net are manufactured into a shape of two approximately symmetric horns, and the aperture ratio of the nickel net and printing ink smoothness are improved.

Owner:金昌宇恒镍网股份有限公司

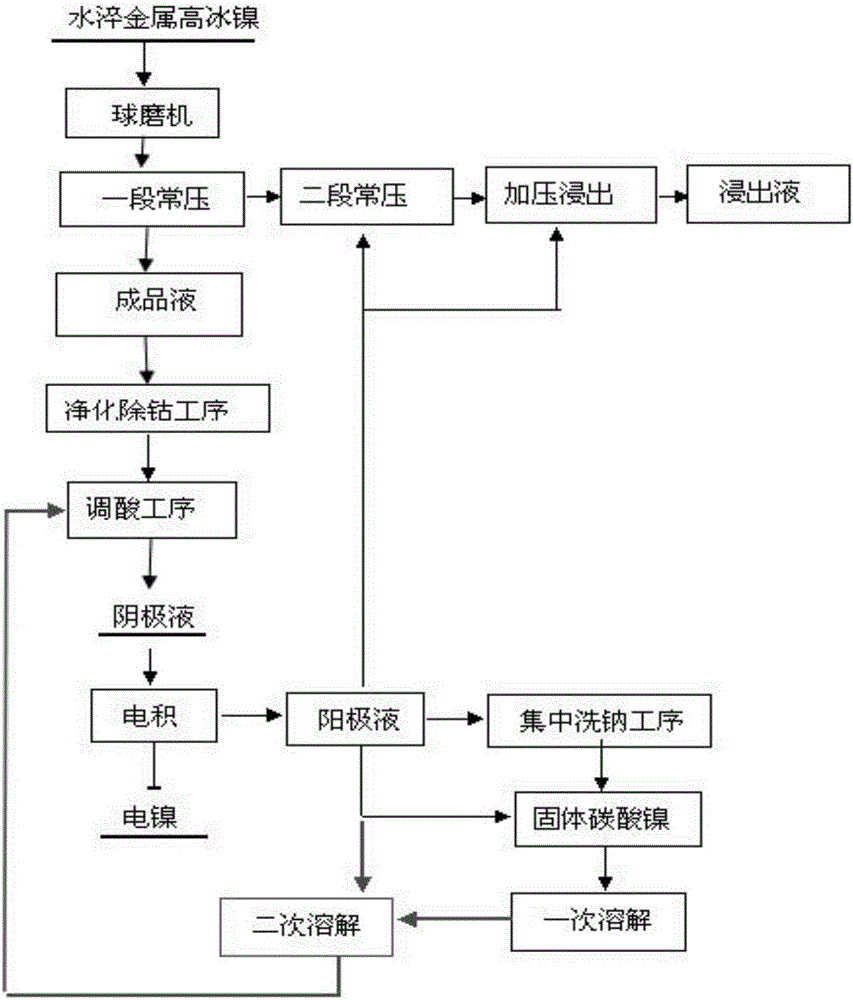

Wet process preparation technique of nickel

ActiveCN106756101AIncrease productionLow cycle costPhotography auxillary processesProcess efficiency improvementPregnant leach solutionNickel deposition

The invention discloses a wet process preparation technique of nickel. The technique comprises the steps that water quenching is conducted on metallized high-nickel matte; ball milling is conducted, deposition is conducted through a thickener, first-section normal pressure is applied, first-section leaching liquid, namely the finished liquid, is subjected to cobalt removal through NIOOH prepared through electrooxidation, purified cobalt-removed post-liquid is obtained through liquid-solid separation, acid adjustment is conducted for electrodeposition, and electro nickel is obtained; and electrodeposition post-liquid is subjected to sodium washing and nickel deposition so that Na+ in a solution can be removed, then anode liquid is mixed with NiCO3 to prepare cathode liquid, then the cathode liquid and the cobalt-removed post-liquid are mixed, subjected to acid adjustment and directly subjected to electrodeposition, and the electro nickel is obtained. The anode liquid and nickel return liquid are converted into the cathode liquid, so that the step that the anode liquid returns to a leaching system is omitted, an original complex and lengthy circulation path is replaced by internal short-path circulation, the circulation cost of the solution is greatly reduced, the yield of the cathode liquid is increased, production loads of a grinding and leaching plant are relieved, and meanwhile, the acid amount of the system can be balanced.

Owner:新疆新鑫矿业股份有限公司

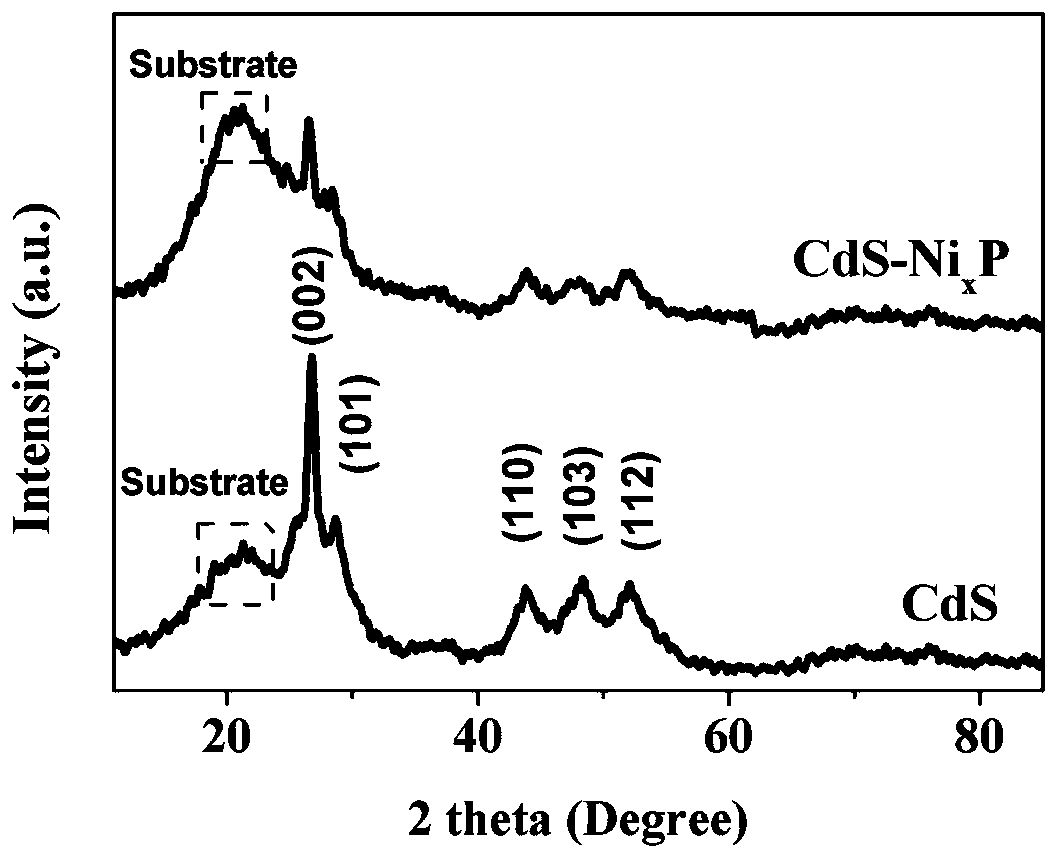

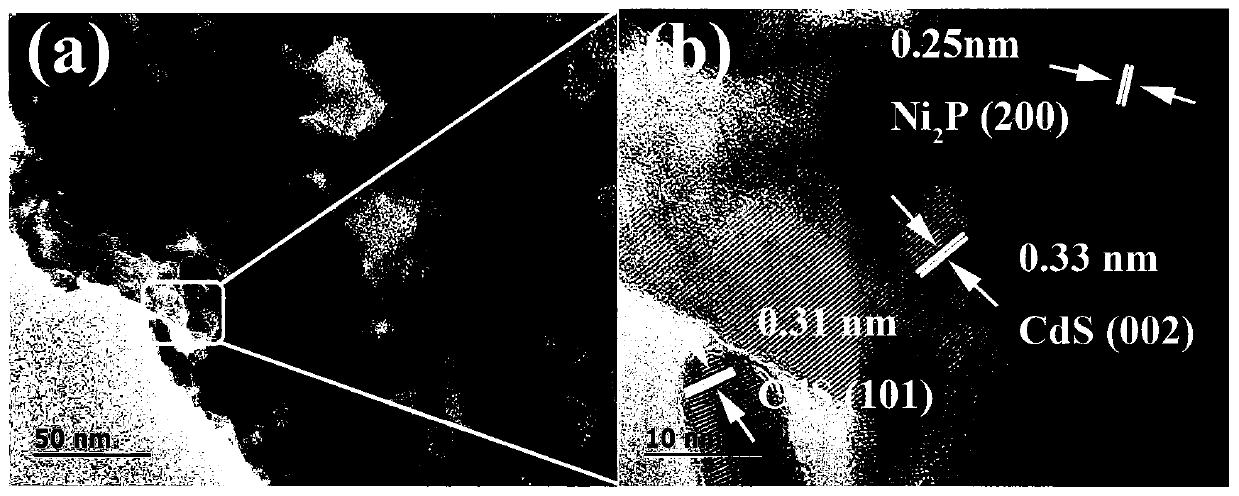

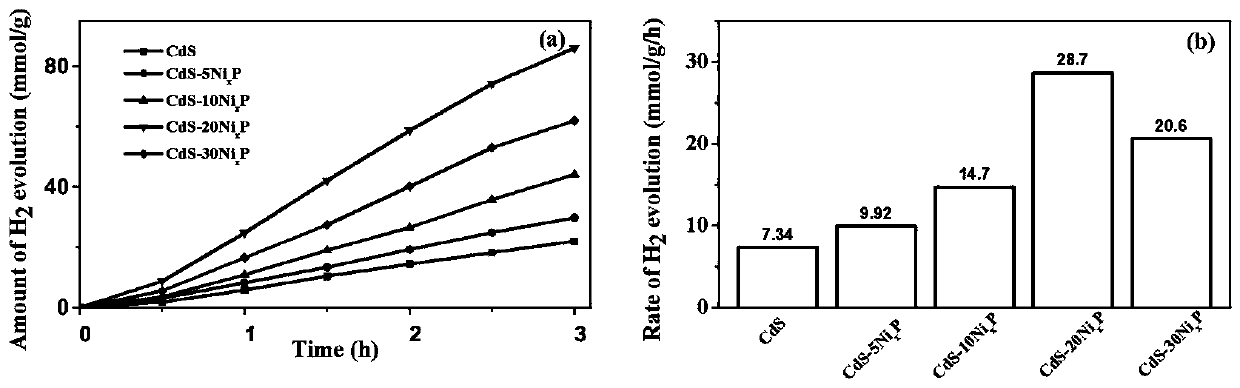

Preparation method of nickel phosphide cocatalyst by photodeposition on cadmium sulfide

InactiveCN110813335AEfficient transferEasy to prepareCatalyst activation/preparationHydrogen productionSodium phosphatesDiethylenetriamine

The invention discloses a preparation method of a nickel phosphide cocatalyst by photodeposition on cadmium sulfide, and the method comprises the following steps: fully dissolving cadmium chloride andsulfur powder in diethylenetriamine, heating in a high-pressure reaction kettle at 80 DEG C for 48 hours, naturally cooling, and cleaning to obtain a cadmium sulfide nanosheet; preparing the cadmiumsulfide nanosheet into a cadmium sulfide solution, adding the cadmium sulfide solution into an aqueous solution containing nickel chloride and sodium hypophosphite, extracting oxygen in the solution,and irradiating by using a simulated sunlight source to obtain the cadmium sulfide / nickel phosphide visible-light-driven photocatalyst. According to the invention, the nickel phosphide cocatalyst is loaded on the surface of the cadmium sulfide nanosheet by adopting a photochemical reduction method, and the deposition amount of nickel phosphide is adjusted by utilizing illumination time, so that the preparation method has the advantages of simplicity, rapidness, high efficiency, low cost and the like. The hydrogen production efficiency of the cadmium sulfide / nickel phosphide photocatalyst undervisible light excitation reaches 28.7 mmol g <-1 > h <-1 >, and the activity of the cadmium sulfide / nickel phosphide photocatalyst is 3.9 times of the activity of cadmium sulfide.

Owner:HARBIN INST OF TECH AT WEIHAI

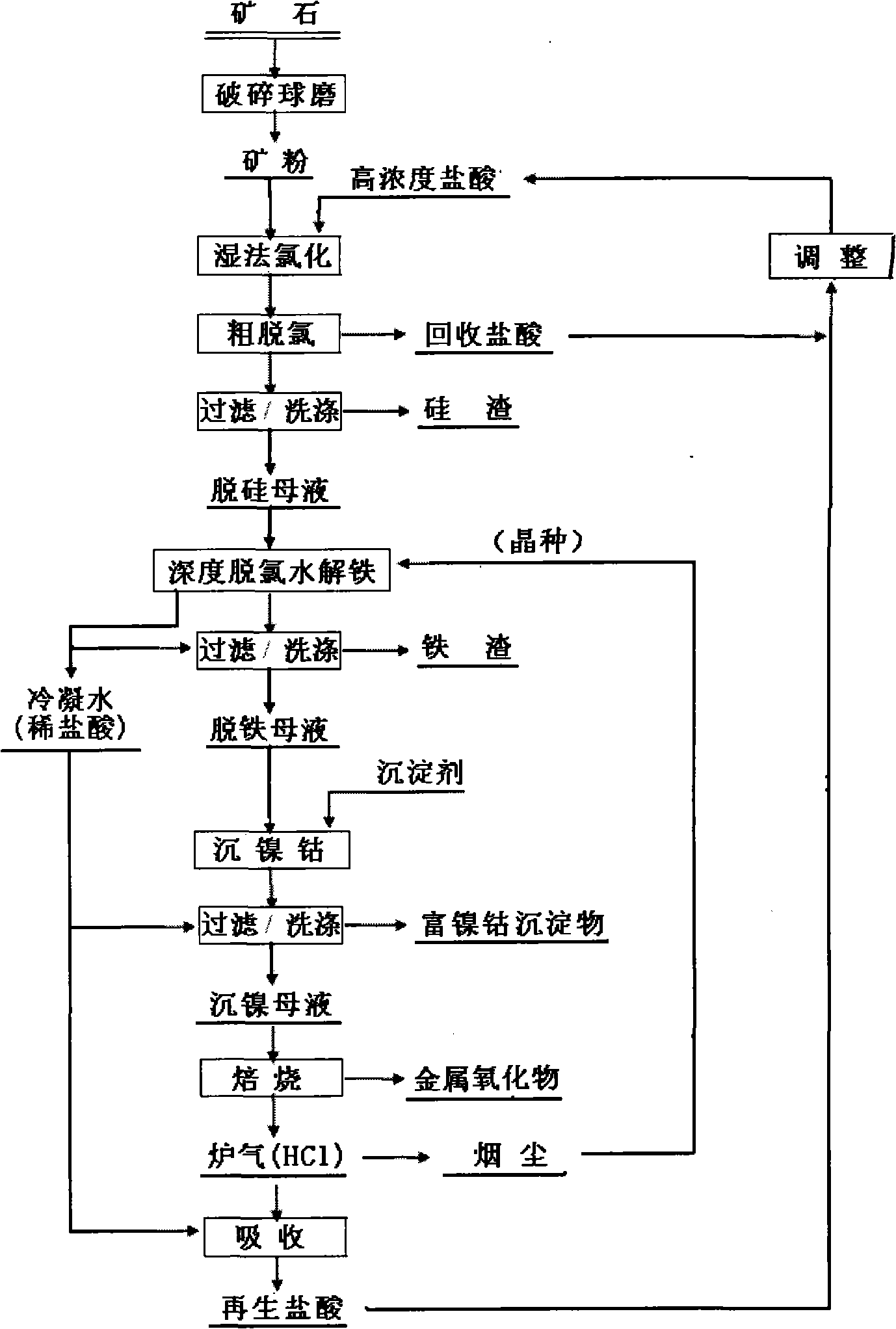

Method for processing nickel cobalt extracted from laterite-nickel ore by chloride cycle desiliconisation ferrous process

InactiveCN101328548AFast dissolutionHigh extraction rateProcess efficiency improvementHigh concentrationSlag

The invention provides a method for treating laterite-nickel ores to extract nickel and cobalt by the chloride cycle silicon iron removal method. Ores are crushed and ball-milled to obtain ore powder, the ore powder is added with hydrochloric acid with high concentration used as a chlorinating agent and heated and stirred in the normal pressure for chlorination to obtain a leaching liquid and silicon slag; the leaching liquid and the silicon slag are separated; the leaching liquid is subjected to heating concentration for dechlorination; hydrochloric acid is reclaimed by the simultaneous condensation of HCl and vapor; a silicon removal mother liquid is obtained through filtration washing; the silicon removal mother liquid is subjected to heating evaporation for obtaining vapor; the obtained vapor is condensed into hydrochloric acid by heat reclaiming; simultaneously because of the hydrolytic precipitation of iron caused by deacidification and the condensation of the liquid, the iron slag and the iron removal mother liquid obtained after the filtration washing are separated; the iron removal mother liquid is added with precipitators, and nickel and cobalt collection and nickel deposition mother liquid obtained by deposition are separated; and the nickel deposition mother liquid is subjected to roasting, which makes metal chloride in the mother liquids hydrolyzed into chlorine hydride and metallic oxide, and generate torch firing soot, and the chlorine hydride is subjected to water absorption to regenerate hydrochloric acid for cyclic utilization.

Owner:CENT SOUTH UNIV

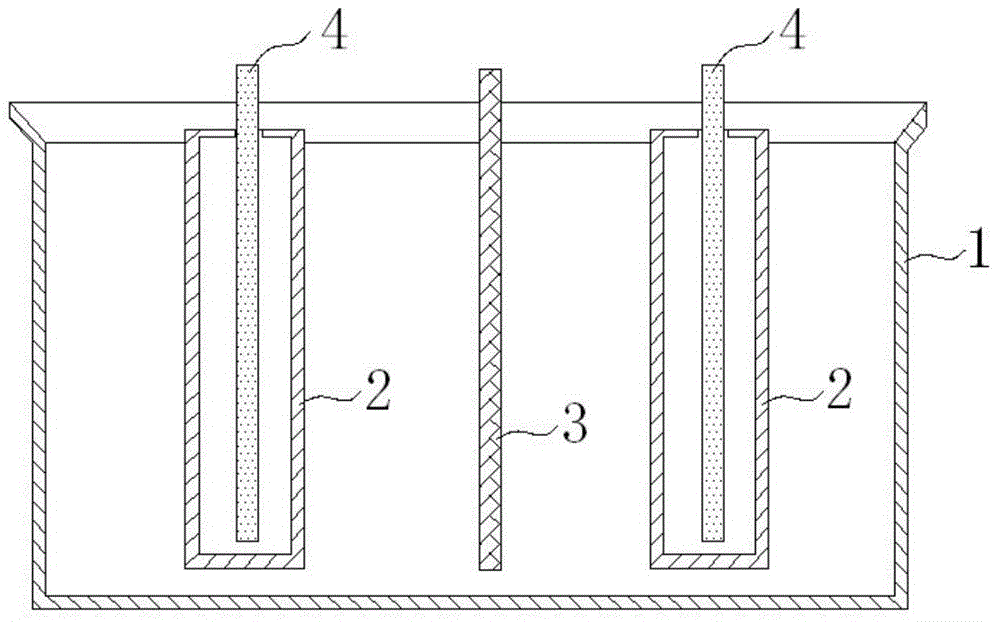

Method of purifying nickel from chemical nickel-plating waste liquid and nickel purification device

InactiveCN104532293AHigh glossReduce consumptionPhotography auxillary processesLiquid wastePurification methods

The invention discloses a method of purifying nickel from chemical nickel-plating waste liquid. The method comprises the following steps: filtering the chemical nickel-plating waste liquid and adjusting the pH value to 8-9; electrolyzing the chemical nickel-plating waste liquid after the pH adjustment, and separating out nickel on a cathode, wherein an anode is located in an anode box, the cathode is located in a cathode chamber, and the anode box is prepared from a ceramic membrane. The anode box prepared from the ceramic membrane is capable of preventing the acid generated by the anode from entering the cathode chamber, thus the adjusted pH environment in the cathode chamber is kept so that the normal separation of nickel on the cathode can be ensured, the high current efficiency of the electrolyzing process can be effectively kept, and the electric energy consumption can be reduced. With the adoption of the nickel purification method, the product nickel deposition surface is flat and smooth, compact in structure and good in metallic lustre, and the quality reaches standard cathode nickel. Correspondingly, the invention further provides a nickel purification device used for realizing the method of purifying nickel from chemical nickel-plating waste liquid.

Owner:WUXI RUISIKE ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

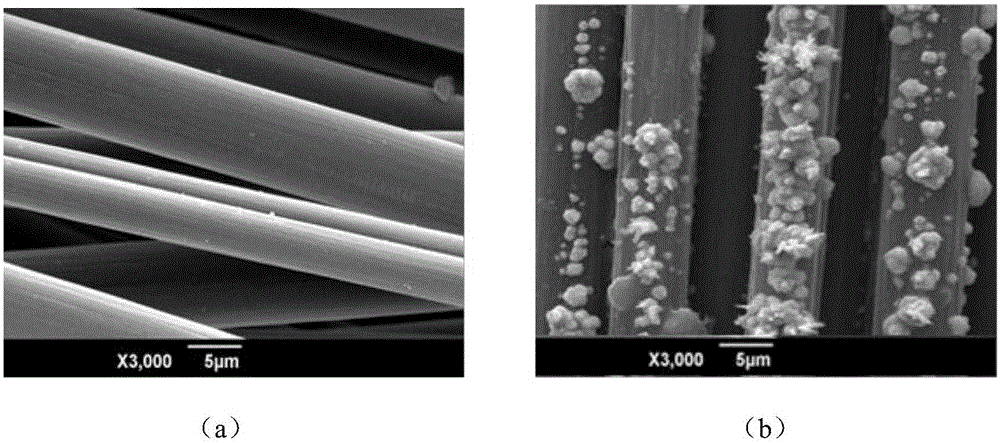

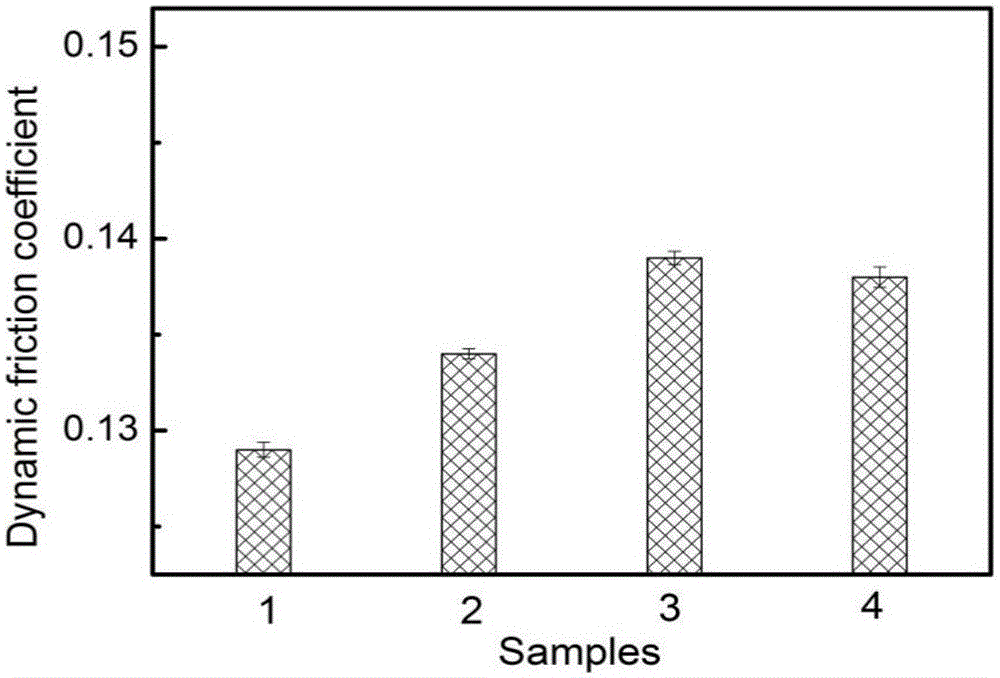

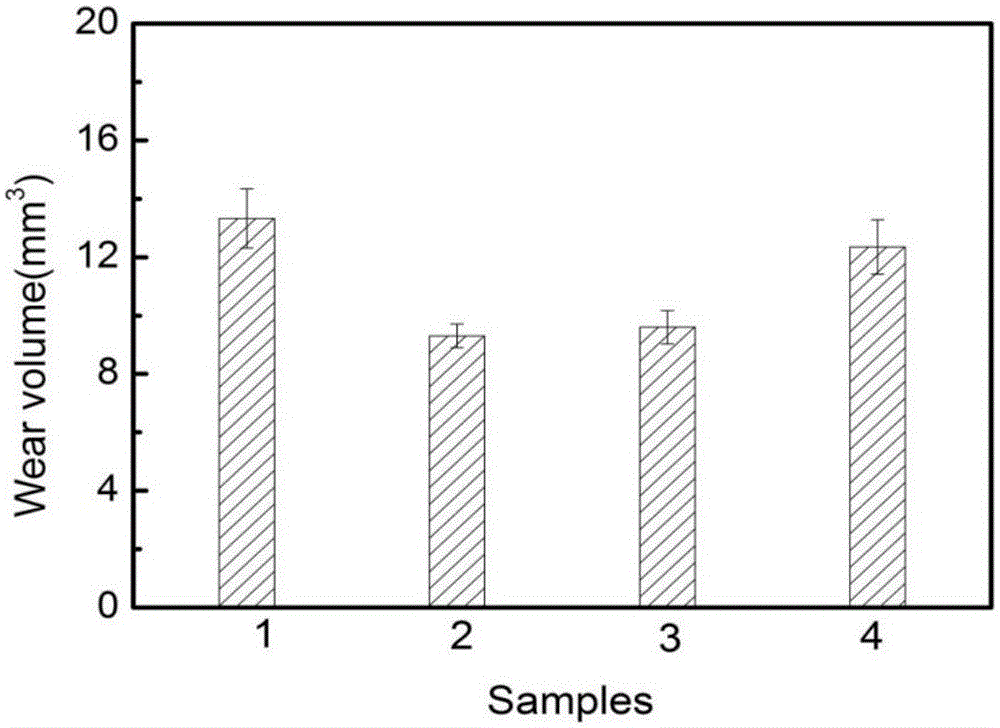

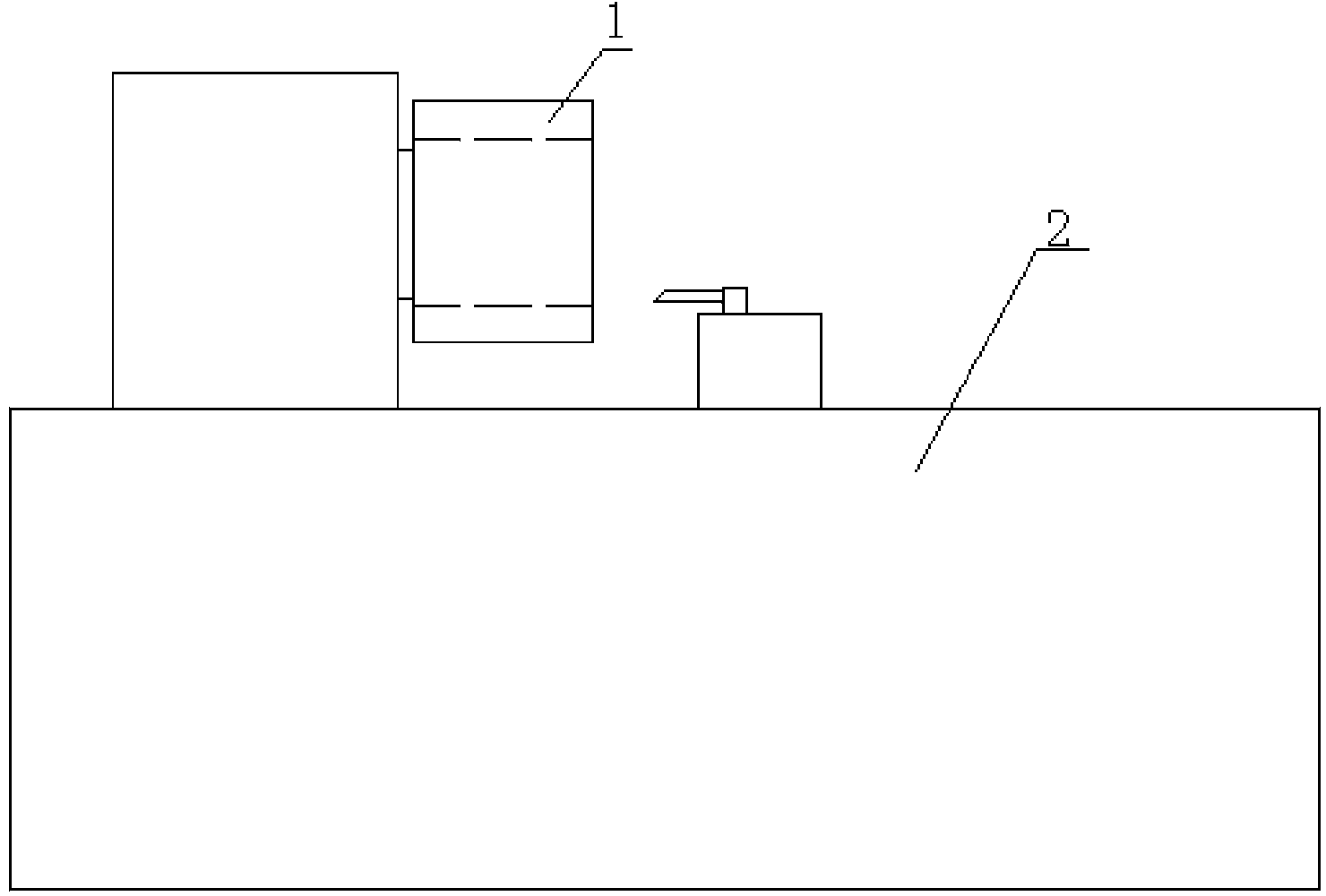

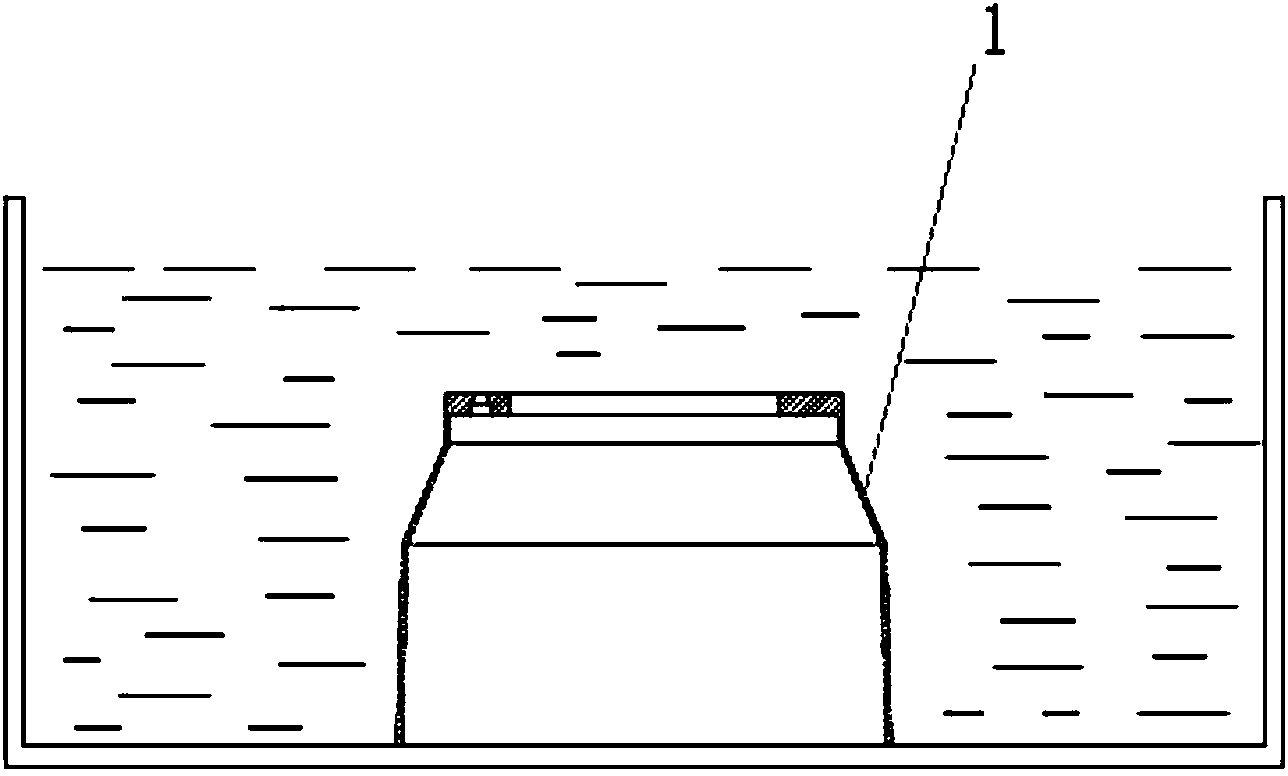

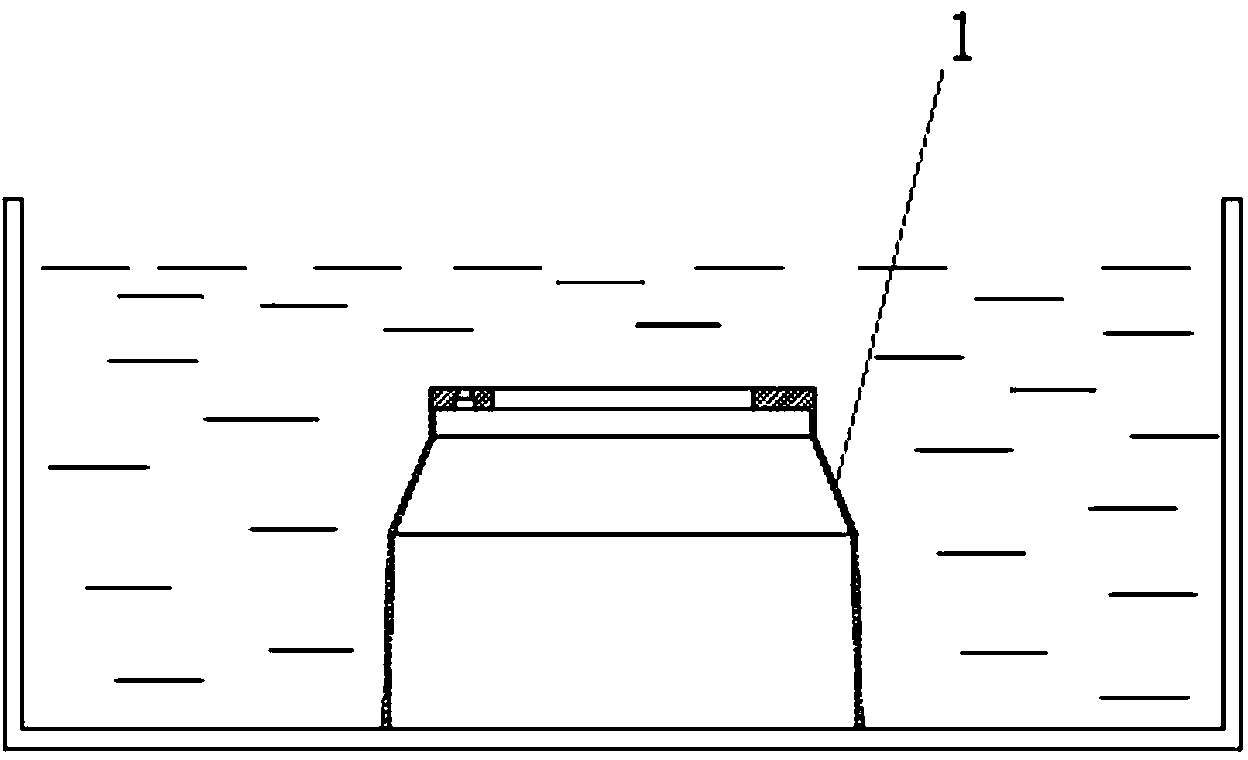

Electrochemically modified carbon cloth reinforced friction material and preparation method thereof

The invention provides an electrochemically modified carbon cloth reinforced friction material and a preparation method thereof. The method adopts a carbon fiber cloth and modified phenolic resin as raw materials, and comprises the following steps: processing the carbon cloth under electrochemical conditions, selecting a composite nickel source as an electrolyte, and processing carbon fibers by adopting an anode oxidation and cathode metal nickel deposition technologies; and spraying the processed carbon cloth with a modified phenolic resin solution, taking out the sprayed carbon cloth, naturally airing, and carrying out hot pressing molding by using a vulcanizing machine. The carbon cloth undergoes anode oxidation and cathode deposition treatment under electrochemical conditions with the composite nickel source as an electrolyte to increase the oxygen-containing function groups on the surface of the carbon cloth and uniformly deposit metallic nickel. The method has the advantages of simple device and high efficiency, and the metallic nickel has large hardness, wear resistance and catalysis activity and greatly improves the bonding strength between the carbon cloth and the resin, so the uniformity of netted polymers formed through cross-linking linear polymers in the vulcanizing process is improved, thereby the friction material has a good tribology performance.

Owner:SHAANXI UNIV OF SCI & TECH

Direct turning and roughing method for optical collecting lens of extreme ultra-violet lithography light source

ActiveCN103447552AShort processing cycleSave time and costTurning machinesNumerical controlUltraviolet

The invention relates to a direct turning and roughing method for an optical collecting lens of an extreme ultra-violet lithography light source, relates to a roughing method for an optical collecting lens, and aims to solve the problem that when an optical collecting lens of an extreme ultra-violet light source if processed by the copying method, a solid shaft fitting the face of the required collecting lens is required to be processed first, then nickel deposition is performed on the surface of the solid shaft, the nickel shell is stripped out to form a base of the collecting lens, according to the technical scheme, the requirements on accuracy control during processing are very stringent, and processing cost is increased. The direct turning and roughing method for the optical collecting lens of the extreme ultra-violet lithography light source includes firstly, rough turning blank, namely rough turning aluminum alloy into a cylindrical workpiece by the aid of an ordinary lathe; and secondly, numerical-control turning, namely turning the cylindrical workpiece by the aid of a numerical-control lathe according to the face of the collecting lens. The method is applied to direct turning and roughing of the optical collecting lens of the extreme ultra-violet light source.

Owner:HARBIN INST OF TECH

Treatment device and method for chemical nickel plating waste liquid

ActiveCN109928553AReduce adsorption pressureReduce consumptionWater contaminantsWaste water treatment from metallurgical processLiquid wasteElectrolysis

Belonging to the technical field of chemical nickel plating wastewater treatment, the invention discloses a treatment device and method for chemical nickel plating waste liquid. Specifically, a pH automatic controller and an ORP automatic controller are utilized for automatic adding of alkali and sodium chloride, electrocatalytic oxidation is employed to break complexing so as to dissociate and precipitate nickel ions at an negative electrode; then resin adsorption is utilized for deep nickel removal to as to make the nickel ion below the emission standard; adding a Fenton reagent into the nickel removed solution for further oxidization of phosphate radical into phosphate radicals easy to precipitate, and under the action of a calcium salt and a flocculant, the product is converted into calcium phosphate precipitate so as to realize up-to-standard emission of nickel and phosphorus. According to the invention, the catalyst is added in electrolysis to produce electrocatalytic oxidation so as to realize the dual effects of oxidation degradation and nickel deposition, thereby not only reducing the terminal oxidant consumption, but also realizing the effect of complexation breaking on anickel-containing complex and increasing the nickel removal effect; a backwashing regeneration auxiliary apparatus is set for resin adsorption; and low recovery of nickel metal and phosphorus-containing fertilizer is carried out respectively at the negative electrode and precipitation tank so as to realize green treatment. Therefore, the device and method have very high economic and environmentalprotection value.

Owner:GUANGDONG UNIV OF TECH

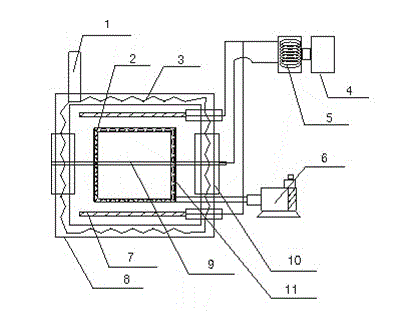

Nickel impact apparatus for nickel electroplating assembly line

The invention discloses a nickel impact apparatus for a nickel electroplating assembly line, and relates to the field of electroplating, wherein the apparatus is applied for the nickel impact process of a work-piece. The nickel impact apparatus comprises an electroplating tank body, an anode and a cathode, wherein the anode and the cathode are arranged in the electroplating tank body, the electroplating tank body is the hollow interlayer, a steam pipe is arranged inside the interlayer, the nickel impact apparatus further comprises an air stirring pipe arranged inside the electroplating tank body, the air stirring pipe is connected with an air blower, the anode and the cathode are connected with a power supply through rectifiers, the electroplating tank body is further provided with a V-shaped groove for fixing the cathode, the air stirring pipe is provided with a plurality of holes, and the steam pipe is provided with a stream pipe inlet. The nickel impact apparatus has the following effects that: the interlayer steam heating is adopted, such that the four side surfaces of the electroplating tank can be concurrently heated so as not to cause the local overheating and the nickel deposition, and form the nickel slag, and so as to avoid the phenomenon of the tank plating.

Owner:TIANJIN DAGANG GALVANIZED FACTORY

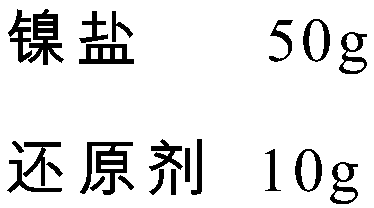

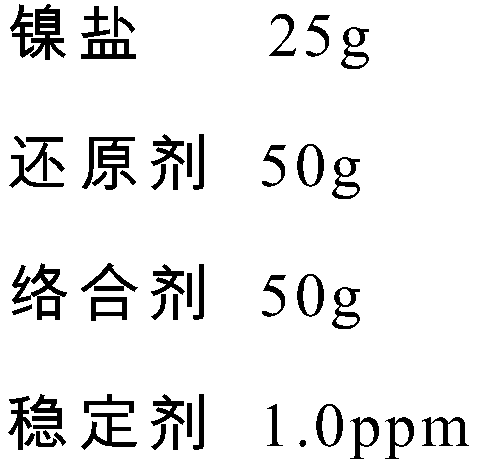

Environment-friendly chemical nickel deposition solution

InactiveCN108251824AReduce concentrationPromote complexationLiquid/solution decomposition chemical coatingNickel saltNitrogen

The invention provides an environment-friendly chemical nickel deposition solution. The environment-friendly chemical nickel deposition solution is prepared from nickel salt, a reducing agent, a complexing agent, a buffering agent, a stabilizing agent and water, wherein the concentration of the nickel salt is 5-50 g / L, the concentration of the reducing agent is 5-50 g / L, the concentration of the complexing agent is 5-50 g / L, the concentration of the stabilizing agent is 0.5-2.0 ppm, and the system pH value is regulated to 4.2-5.5 through the buffering agent. The environment-friendly chemical nickel deposition solution does not contain ammonia or nitrogen, and the content of lead ions is lower than 300 ppm, so that the burden and influence on the environment are greatly reduced; and meanwhile, a nickel-plated layer is stable and good in brightness, and the environment-friendly chemical nickel deposition solution is excellent in electric conductivity and suitable for chemical nickel plating of PCBs, FPCs, semiconductor wafers and the like.

Owner:成功环保科技(南通)有限公司

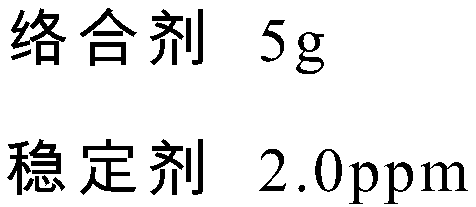

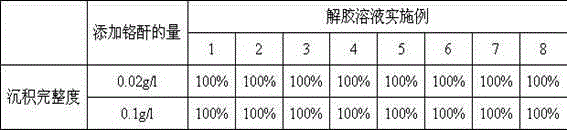

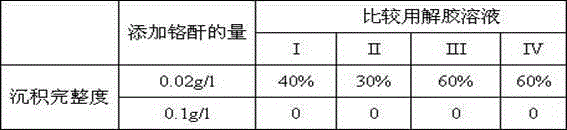

Peptization solution for metalizing modification of plastic surface

ActiveCN103556135AStrong service lifeExtended service lifeLiquid/solution decomposition chemical coatingPeptizationNickel deposition

The invention relates to peptization solution for the metalizing modification of a plastic surface. The peptization solution comprises a certain amount of acid or alkali and a certain amount of reducing agent; the usage amount of the acid or alkli in the chemical nickel deposition solution is 5-200g / l, and the usage amount of the reducing agent in the chemical nickel deposition solution is 1-100g / l. Through the strong reducing agent in the peptization solution, chromic acid carrying in the peptization solution can be reduced in time, thus the influence of chromic acid on palladium is avoided, the plastic metalizing production technology is more stable, and the service life of the peptization solution to be longer; the peptization solution has the characteristics of good stability, strong chromic acid resistance capability, long service life and the like.

Owner:杭州东方表面技术有限公司

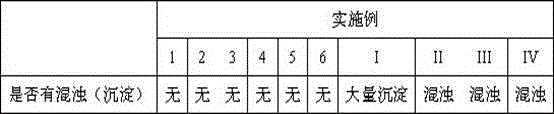

An Environmentally Friendly Electroless Nickel Precipitation Solution for Metallization and Modification of Plastic Surfaces

ActiveCN103556137BAntibacterial agent hasEnvironmentally friendlyLiquid/solution decomposition chemical coatingChemical solutionNickel salt

The invention relates to environment-friendly chemical nickel deposition solution for metalizing modification of a plastic surface. The chemical nickel deposition solution comprises nickel salt, sodium hypophosphite, complexing agent, pH conditioning agent, isothiazolone or isothiazolone derivatives; the usage amount of the nickel salt in the chemical nickel deposition solution is 1-50g / l, the usage amount of the sodium hypophosphite in the chemical nickel deposition solution is 0.5-50g / l, the usage amount of the complexing agent in the chemical nickel deposition solution is 3-100g / l, the usage amount of the isothiazolone or isothiazolone derivatives in the chemical nickel deposition solution is 0.5-300ppm. The isothiazolone or isothiazolone derivatives added in the chemical nickel deposition solution not only can be used as antimicrobial agent in the chemical nickel deposition solution, but also can be used as an environment-friendly stabilizer instead of heavy metal ions, so that the chemical nickel deposition solution has the characteristics of antimicrobial property, environment friendliness, high stability and the like.

Owner:杭州东方表面技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com