Chemical nickel deposition solution

A technology for electroless nickel precipitation and nickel sulfamate, which is applied in the field of chemical nickel precipitation solution, can solve the problems of high energy consumption for maintaining the bath temperature, short service life of the solution, high energy consumption for heating and heating, etc. Liquid stability and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

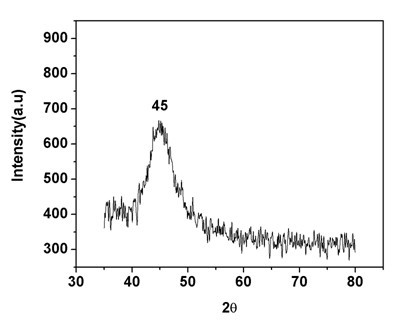

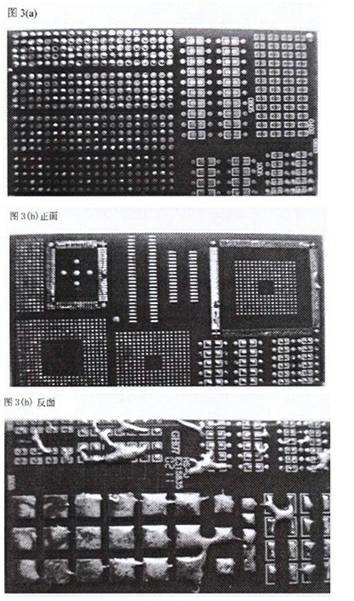

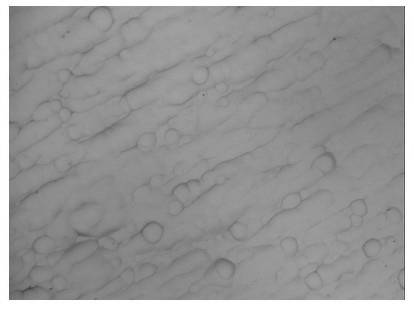

Image

Examples

Embodiment 1

[0054] Chemical nickel deposition solution 1, the components and dosage are:

[0055] Nickel sulfamate 36g / L

[0056] Citric acid 9g / L

[0057] Succinic acid 17g / L

[0058] Sodium hypophosphite 20g / L

[0059] Sodium acetate 20g / L

[0060] Propoxy acid 18g / L

[0061] Sodium Lauryl Sulfate 0.03g / L

[0062] L-Threonine 0.15g / L

[0063] Deionized water balance

[0064] pH=5.7

[0065] Use this nickel deposition solution to deposit on the above object c). The temperature is 55°C. Sink for 20 minutes. The nickel layer is smooth. The thickness is 43 micro inches. The phosphorus content is 7.9%.

Embodiment 2

[0067] Chemical nickel deposition solution 2, the components and dosage are:

[0068] Nickel sulfamate 36g / L

[0069] Citric acid 9g / L

[0070] Succinic acid 17g / L

[0071]Sodium hypophosphite 20g / L

[0072] Sodium acetate 20g / L

[0073] Propoxy acid 18g / L

[0074] Sodium Lauryl Sulfate 0.03g / L

[0075] L-Threonine 0.15g / L

[0076] Deionized water balance

[0077] pH=5.7

[0078] Use this nickel precipitation solution to implement on the above-mentioned object a). The temperature is 55°C. Sink for 20 minutes. The nickel layer is smooth. The thickness is 40 micro inches. The phosphorus content is 8.3%.

Embodiment 3

[0080] Chemical nickel deposition solution 3, the components and dosage are:

[0081] Nickel sulfamate 40g / L

[0082] Citric acid 13g / L

[0083] Succinic acid 18g / L

[0084] Sodium hypophosphite 22g / L

[0085] Sodium acetate 20g / L

[0086] Propionic acid 18gL

[0087] Sodium Lauryl Sulfate 0.03g / L

[0088] L-Threonine 0.20g / L

[0089] Deionized water balance

[0090] pH=5.5

[0091] Use this nickel precipitation solution to implement on the above-mentioned object a). Temperature 60°C. Sink for 20 minutes. The nickel layer is smooth. The thickness is 58 micro inches. The phosphorus content is 8.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com