Patents

Literature

203 results about "Aminosulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aminosulfonate modulated pH-induced conformational changes in connexin26 hemichannels Article (PDF Available) in Journal of Biological Chemistry 282(12):8895-904 · April 2007 with 35 Reads

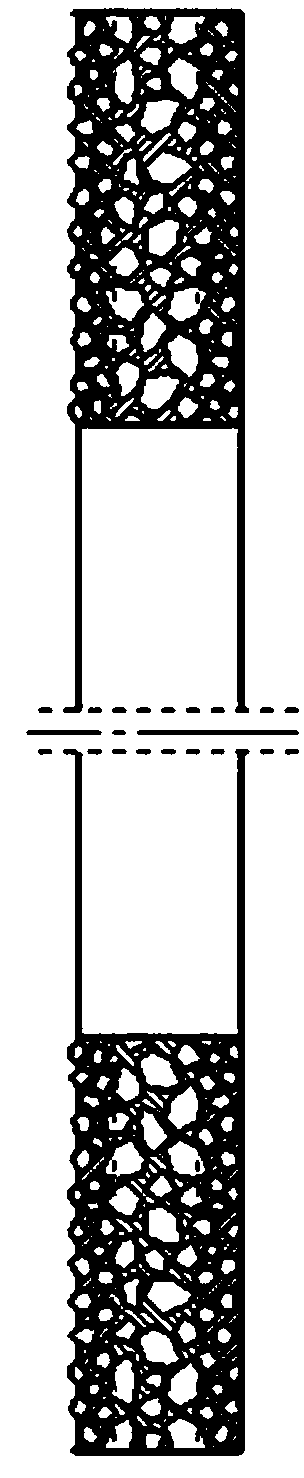

Preparation method of electroplating diamond fret saw

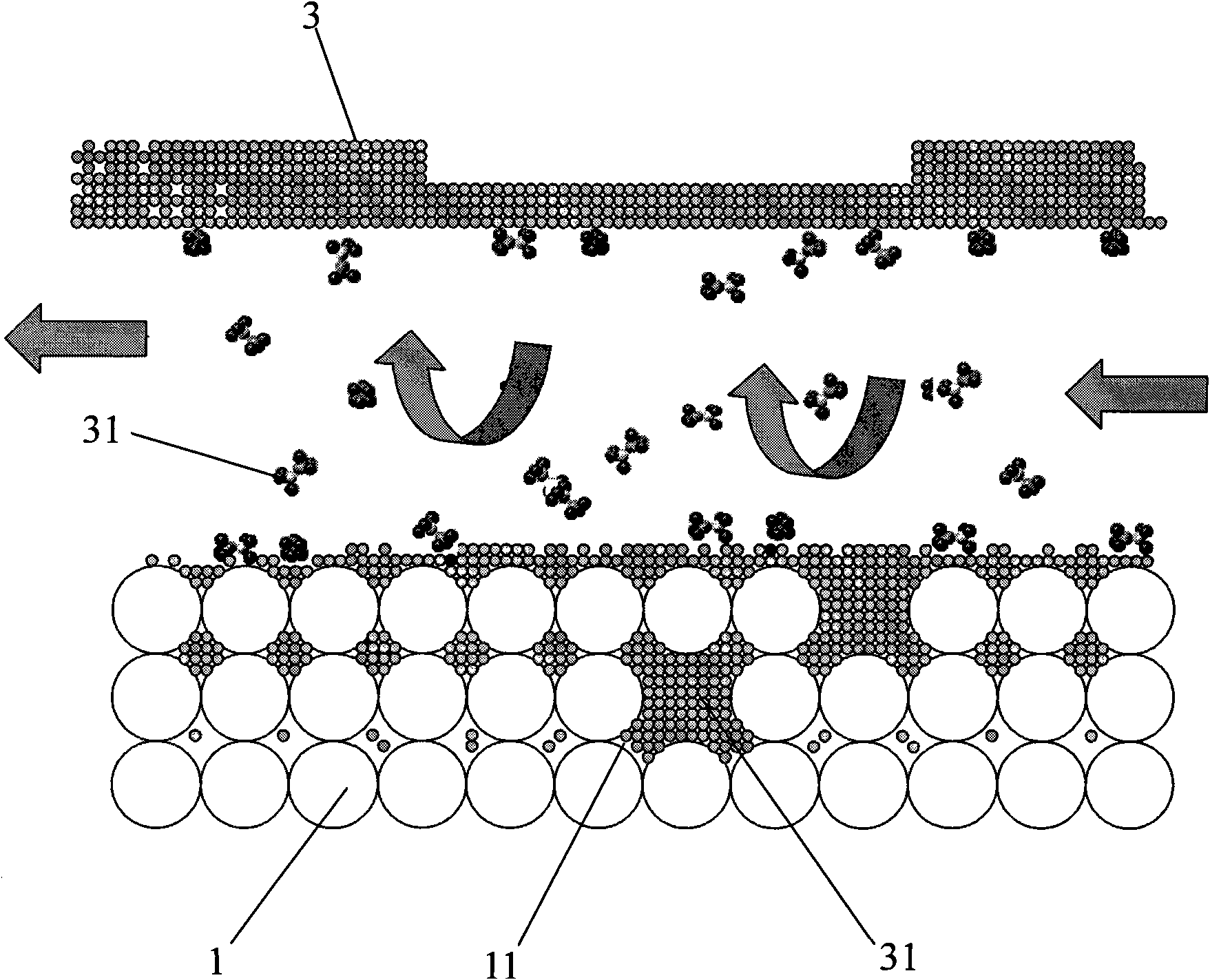

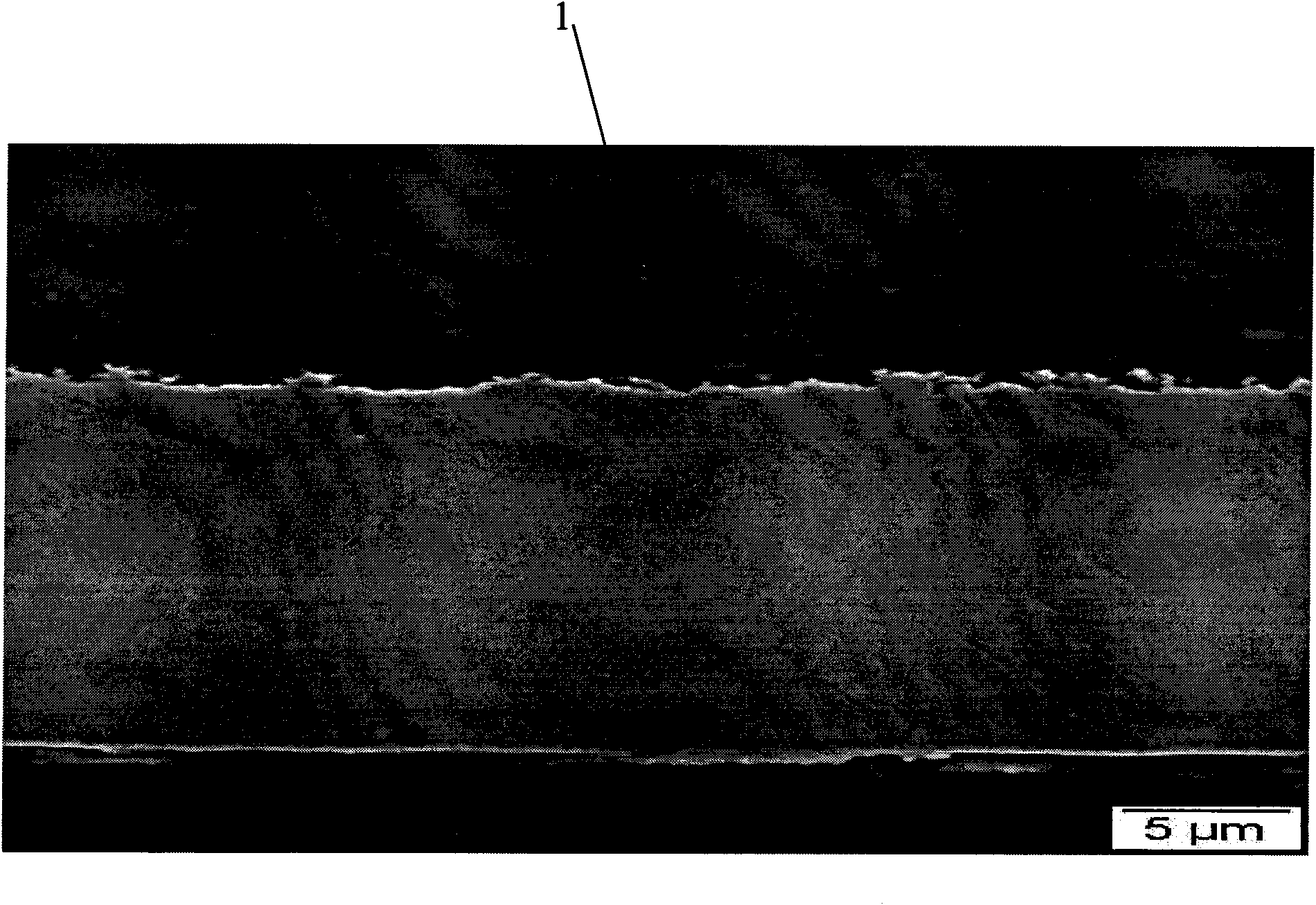

The invention relates to a preparation method of an electroplating diamond fret saw, comprising the following technological processes: 1. roughening processing is carried out to micrometer diamond particles in advance, nanometer diamond powder is added in cationic surface active agents according to the proportion of 1 : 3 by mass ratio, so as to prepare uniform and stable nanometer diamond powder suspending liquid, plating solution is arranged in an electroplating tank, after the weighted nanometer diamond powder suspending liquid is mixed with the micrometer diamond particles according to the proportion of 1 : 3 by mass ratio, and then the mixture is added in the plating solution, the plating solution is circulated continuously, and nickel aminosulfonate is main material in the plating liquid, and boracic acid and nickel chloride are additionally added, and a magnetic stirring device is arranged in the electroplating tank; 2. a steel wire continuously and uniformly passes through the electroplating tank, under the action of electrical current, nickel ions move to cathode from anode, so as to drive the nanometer diamond powder and the micrometer diamond particles to move to the steel wire, so as to lead the steel wire to be plated with the nanometer diamond powder and the micrometer diamond particles, meanwhile, chemical nickel-plating is carried out to the steel wire; 3. after the steel wire is separated from the electroplating tank, wires are wound up after being cleaned and dried. The method can continuously and quickly produce electroplating diamond fret saw, and the production efficiency is high.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

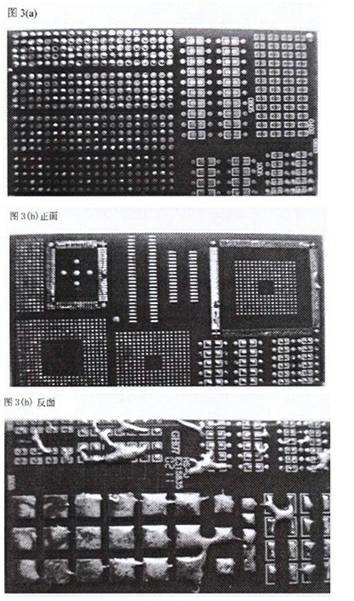

Preparation method for printed circuit board

The invention discloses a preparation method for a printed circuit board. The method comprises the steps of: plating a matte copper or bright copper layer on the copper layer of a graphic line; and plating a nickel sulfate layer or nickel aminosulfonate layer on the matter or bright copper layer of the graphic line. The plating of the matte copper or bright copper layer on the copper layer of the graphic line includes: a. conducting treatment by a 8-10% acidic degreasing agent at room temperature for 5-7min, and carrying out two-stage overflow washing; b. performing micro-etching treatment by 80-100g / L ammonium persulfate or sodium persulfate and 3-5%sulfuric acid at room temperature for 40s, and carrying out two-stage overflow washing. Compared with other making processes, the preparation method for the printed circuit board provided by the invention has a shortest technological process and a minimum wastewater discharge amount. In short, no matter from the aspect of making cost or the aspect of quality, the method provided by the invention is a good choice and has sound advantages.

Owner:深圳市九和咏精密电路有限公司

Manufacturing method of hub type electroplated ultrathin diamond abrasive cutting wheel

ActiveCN106637359AReduce stressStress reliever for low micro stressElectrolytic coatingsChemical platingGrinding wheel

The invention discloses a manufacturing method of a hub type electroplated ultrathin diamond abrasive cutting wheel. The method comprises the steps that a high-precision aluminum alloy matrix is subjected to chemical plating treatment and placed into an electroplating solution containing diamond abrasive materials, the evenly-suspended diamond abrasive materials are wrapped by a plating layer during reduction of a cathode of anode nickel ions under the effect of a direct current electric field, and a composite plating layer with the needed thickness is formed after uniform codeposition is kept for a certain period of time; and the hub type electroplated ultrathin diamond abrasive cutting wheel with the blade thickness of 0.010-0.150 mm is manufactured through the plating layer surface precise grinding, external circle grinding and blade reverse face microcorrosion treating processes. By the adoption of the phosphorous nickel aminosulfonate electroplating solution, by means of the hardness increasing effect of a hardening agent and the microstress effect of a stress removing agent, a low-stress high-hardness novel nickel-based binding agent is obtained, a blade of a cuter of the hub type electroplated ultrathin diamond abrasive cutting wheel has extremely low stress and high strength, and the problem that the cutter of the abrasive wheel is broken due to stress deformation or too low strength in practical application is avoided.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Chemical nickel plating liquid and preparation method

The invention provides chemical nickel plating liquid. The chemical nickel plating liquid is prepared from the following components: nickle salt, a reducing agent, a complexing agent, a buffering agent, a stabilizing agent, a surfactant and deionized water, wherein, the chemical nickel plating liquid is specially prepared from the components in parts by weight: 1000 parts of deionized water, 20 to35 parts of nickel salt, 15 to 32 parts of a reducing agent, 10 to 30 parts of a complexing agent, 2 to 12 parts of a buffering agent, 1 to 15 parts of a stabilizing agent, and 0.01 to 0.2 part of asurfactant. The nickel salt is one or more of nickel sulfate, nickel chloride, nickel acetate, nickel carbonate and nickel aminosulfonate.

Owner:WINSTAR CHEM SHANGHAI

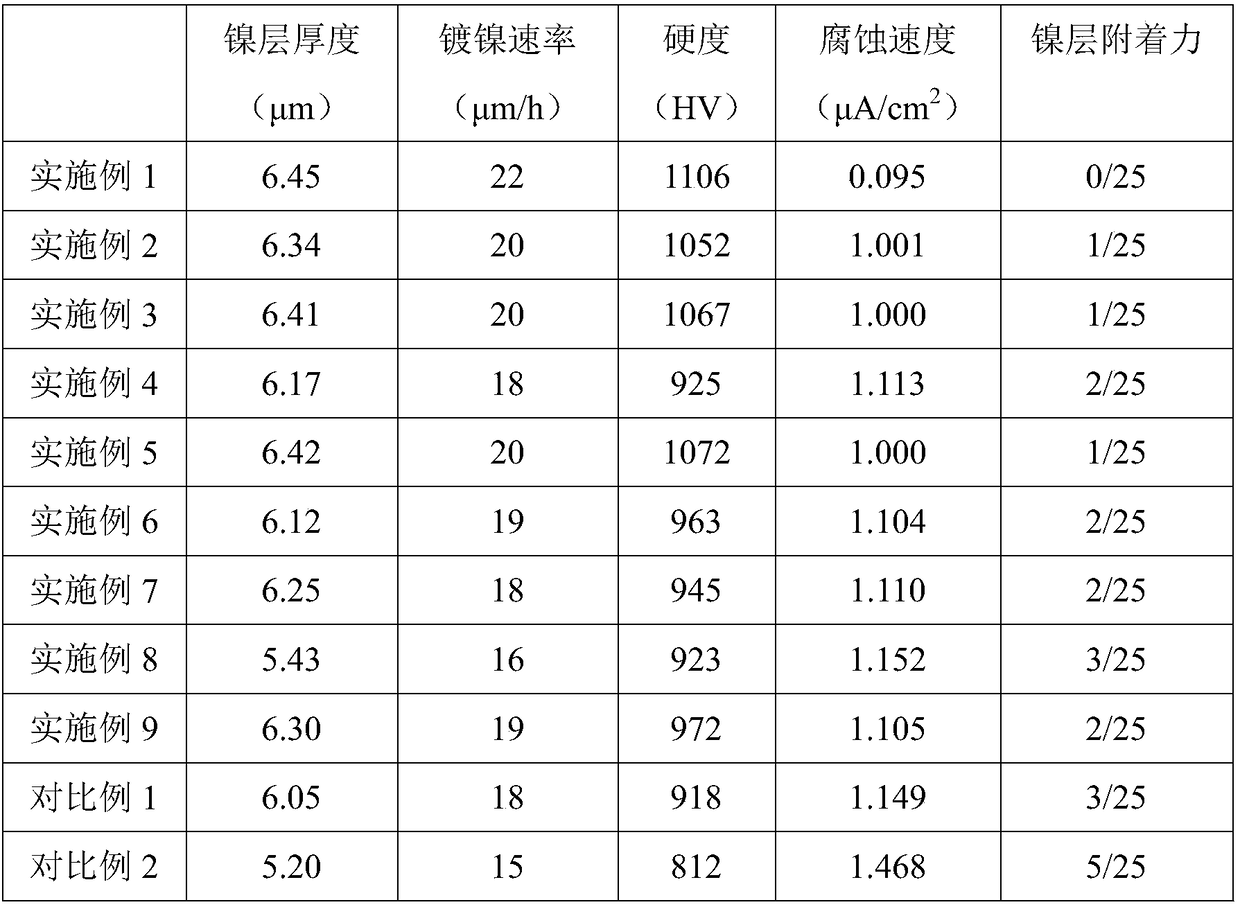

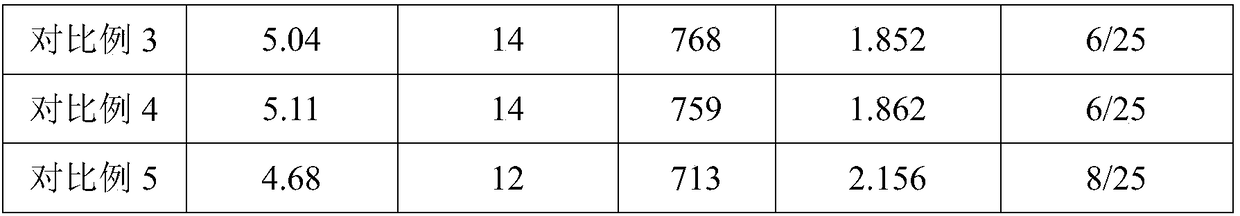

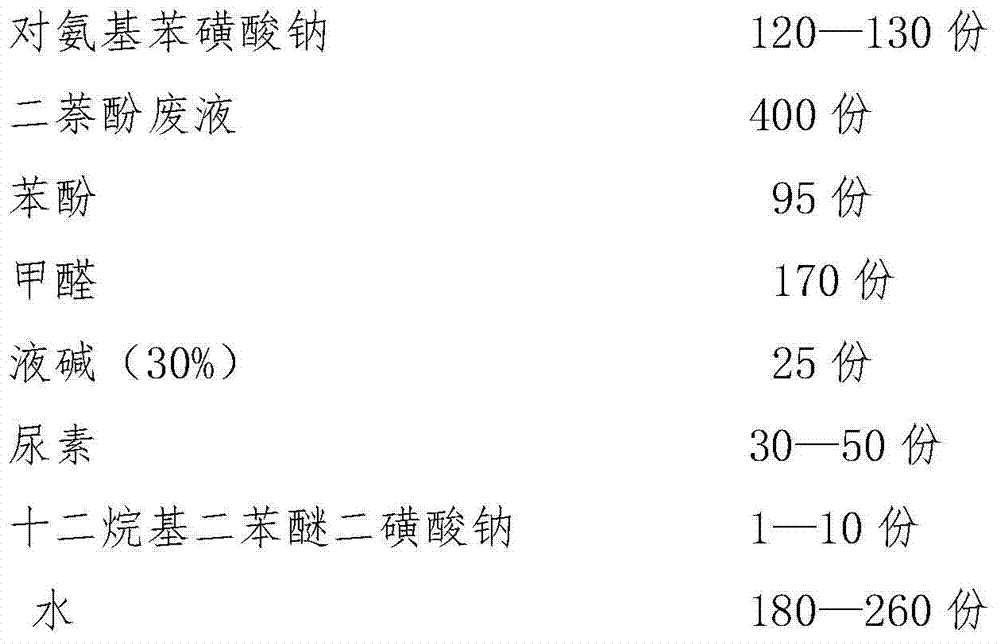

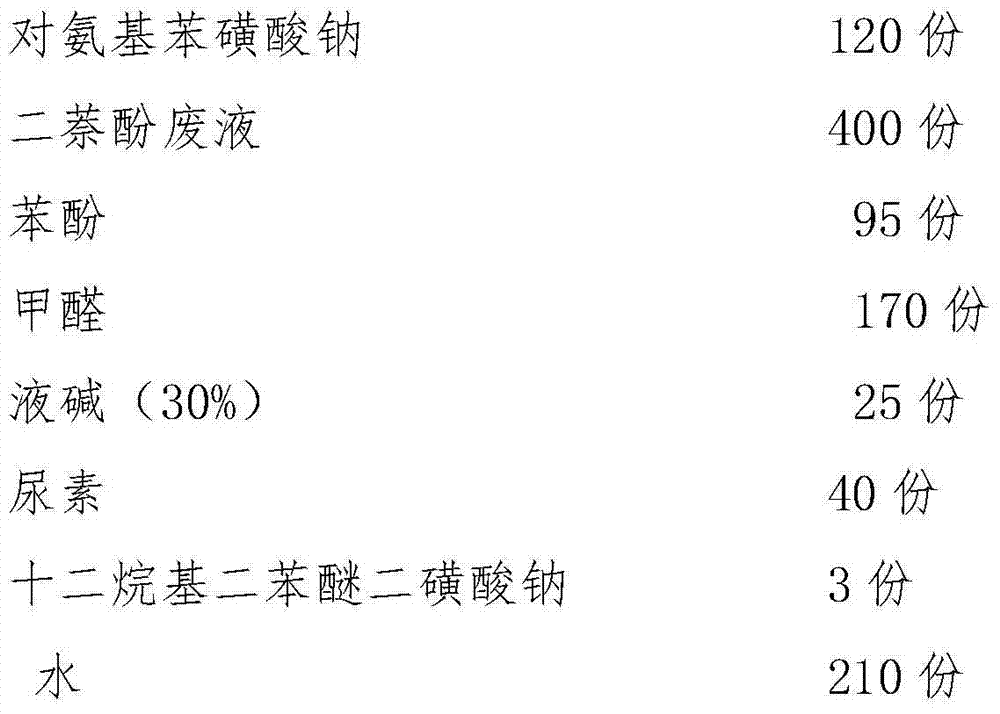

Modified sulfamate efficient water reducer and preparation method thereof

The invention provides a modified sulfamate efficient water reducer and a preparation method thereof, particularly relates to a dinaphthol waste modified sulfamate efficient water reducer and relates to the technical field of waste treatment. The reducer comprises raw materials of, by weight, 120 parts to 130 parts of sodium sulfanilate, 400 parts of dinaphthol waste, 95 parts of phenol, 170 parts of formaldehyde, 25 parts of liquid caustic soda (30%), 30 parts to 50 parts of urea, 1 part to 10 parts of dodecyl diphenyl ether sodium disulfonate and 180 parts to 260 parts of water. By means of the water reducer and the preparation method thereof, dinaphthol waste recycling is achieved, waste water are not needed to be subjected to concentration or any other treatment of physical chemical treatment and the like, energy consumption is saved, and pollution and damage of the waste to the environment and humans are prevented.

Owner:萧县沃德化工科技有限公司

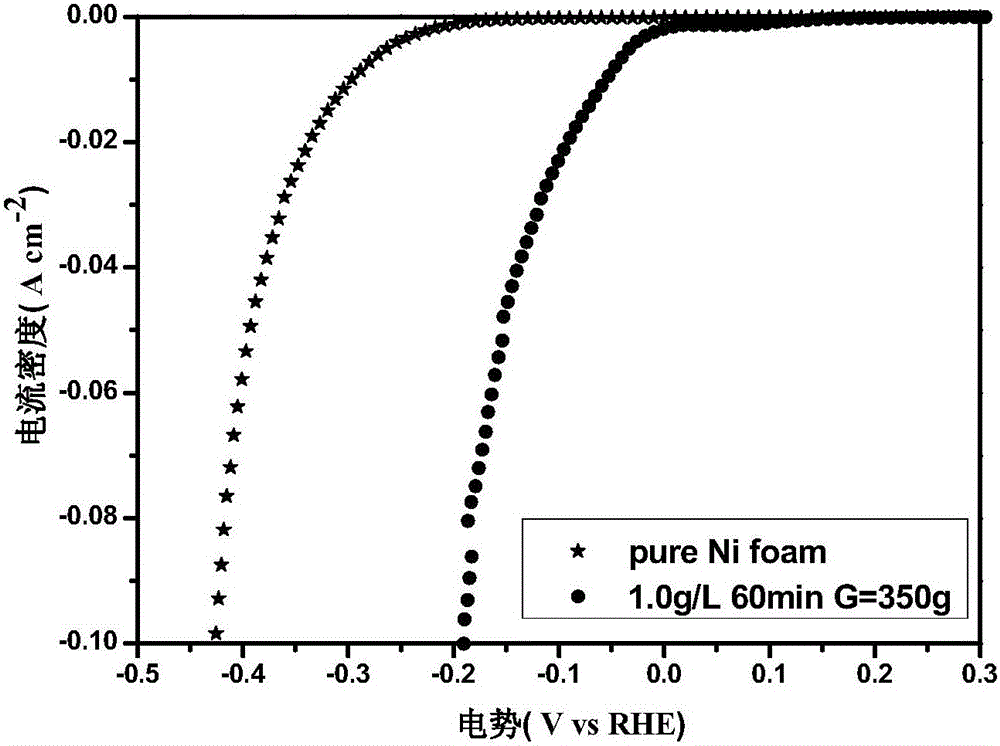

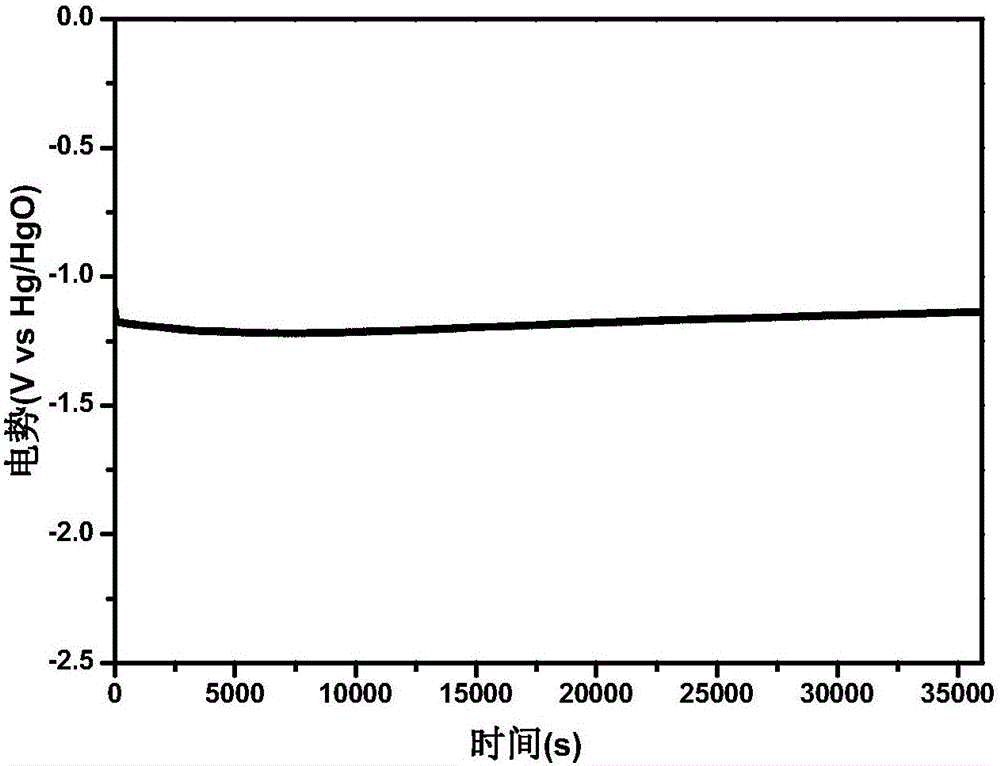

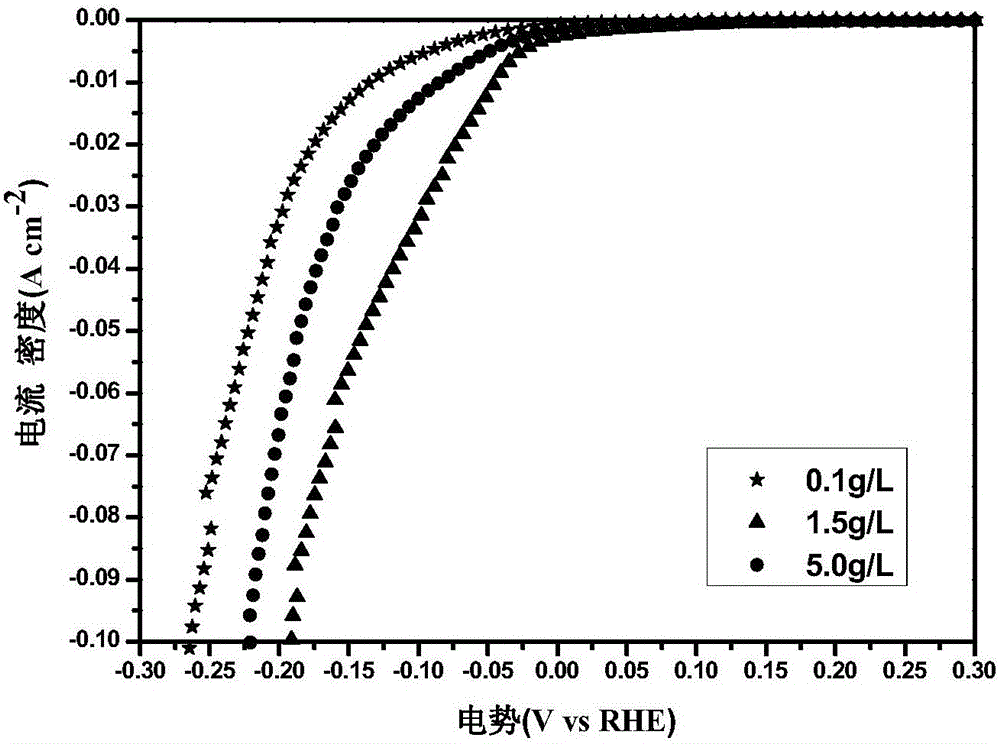

Preparing method of 3D-structuer Ni/rGO composite hydrogen evolution electrode

ActiveCN106087002ALarge specific surface areaPass throughElectrolytic coatingsElectrode shape/formsOverpotentialGraphite oxide

The invention discloses a preparing method of a 3D-structuer Ni / rGO composite hydrogen evolution electrode. The preparing method mainly comprises the steps that graphite oxide is added into deionized water, and ultrasonic treatment is carried out to obtain graphene oxide dispersion liquid; nickel aminosulfonate, nickel chloride and ammonium chloride are added into the graphene oxide dispersion liquid, ultrasonic treatment is carried out to obtain a composite plating solution, a foam nickel substrate subject to ultrasonic and acidification treatment serves as an electro-deposition cathode, a pure nickel pipe serves as an electro-deposition anode, the strength G of a high gravity field is 350 g, the electro-deposition time ranges from 10 min to 100 min, the electro-deposition temperature is 45 DEG C, the electro-deposition current density is 3 A / dm<2>, and a composite coating obtained through preparing is washed with deionized water to be neutral and is dried; and the prepared Ni / rGO composite electrode has the considerable specific surface area, a uniform and stable coating structure and the excellent hydrogen evolution performance. When the current density is 100.0 mA / cm<2>, the hydrogen evolution reaction overpotential is reduced to 190 mV from 240 mV obtained through conventional electro-deposition preparing.

Owner:BEIJING CEI TECH

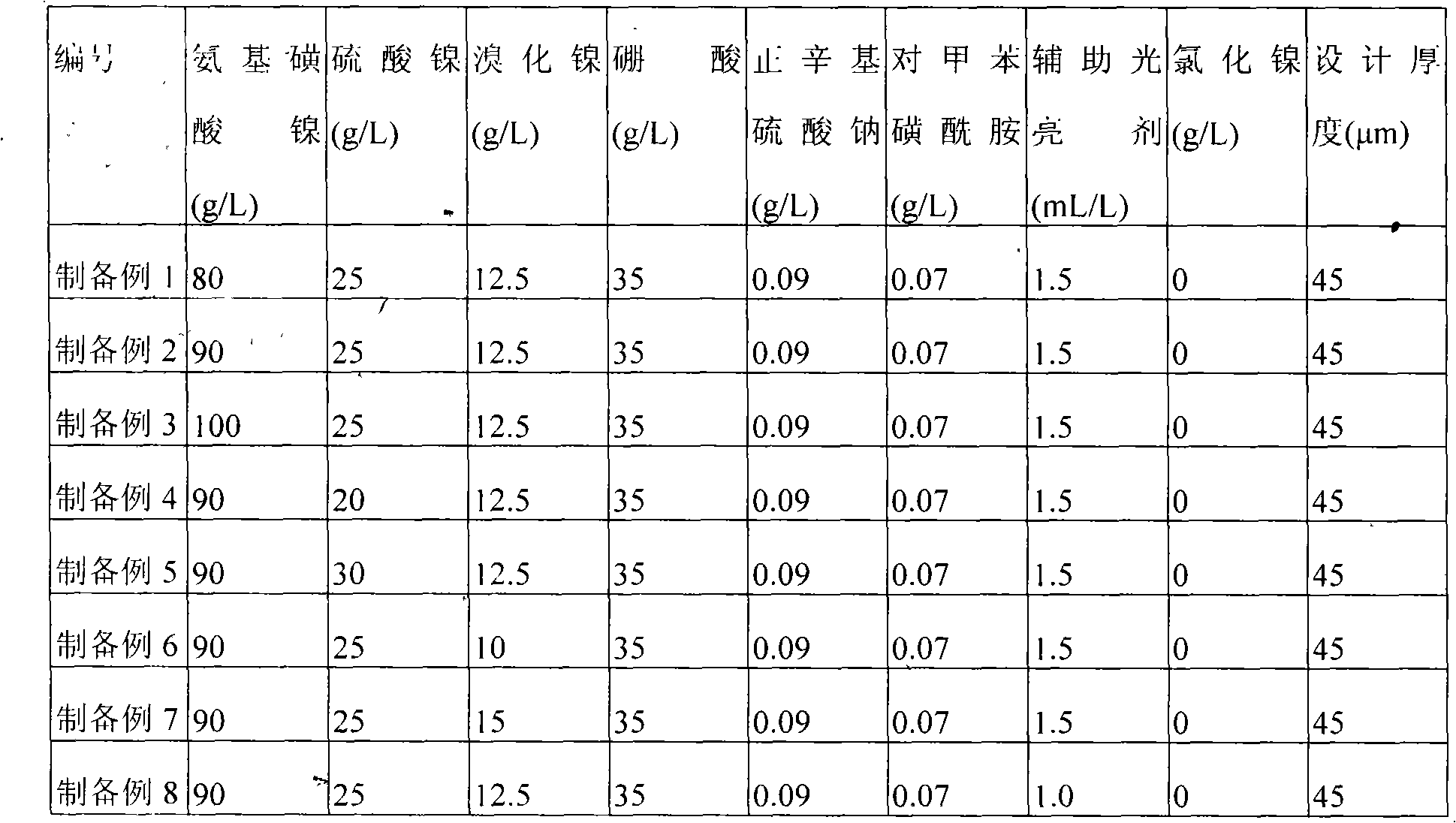

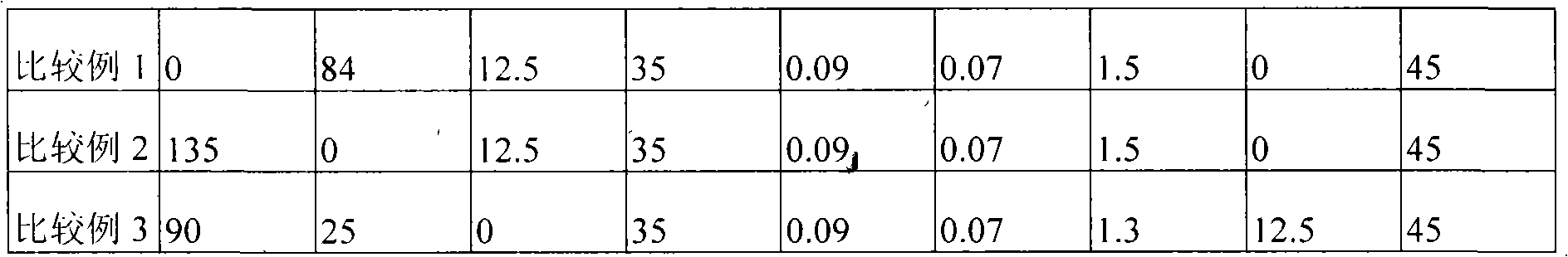

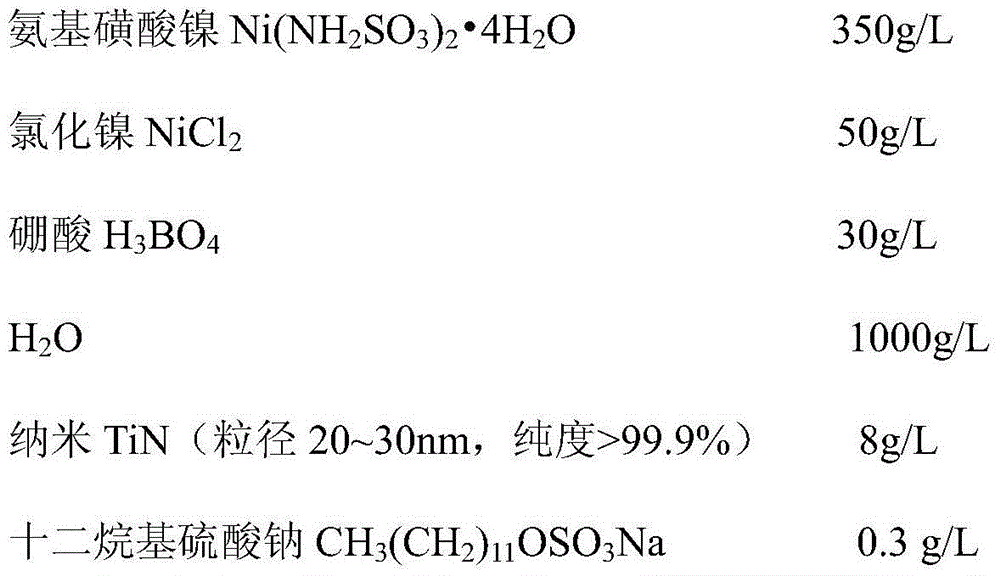

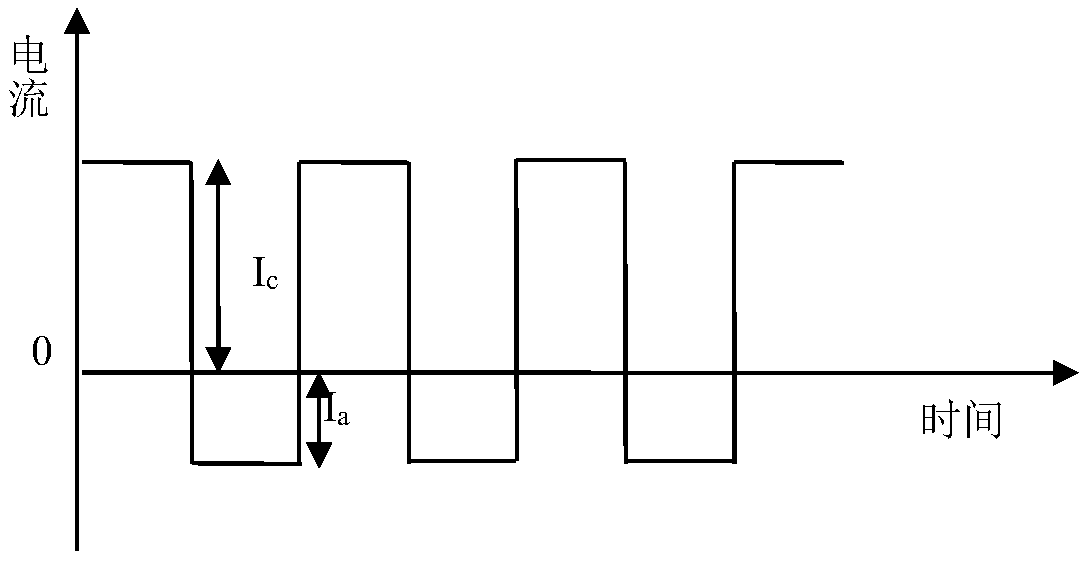

Solution for nickel electroforming, electroforming method using solution and thin nickel plate manufactured by using method

InactiveCN102080237AHigh positioning accuracyTo achieve a bright effectElectroforming processesSulfatePulse power supply

The invention provides a solution for nickel electroforming, an electroforming method using the solution and a thin nickel plate manufactured by using the method. The solution for nickel electroforming contains nickel aminosulfonate and nickel sulfate, and preferably also contains nickel bromide. The solution for nickel electroforming is adopted for electroforming in the method, and preferably a bidirectional pulse power supply is adopted as an electroforming power supply. The thin nickel plate has good thickness uniformity, low stress (pressure stress or tensile stress), smooth inner walls of micropores and no micro burrs or pin holes, and can be used for manufacturing an encapsulation template for transferring soldering paste during flip chip encapsulation.

Owner:KUN SHAN POWER STENCIL

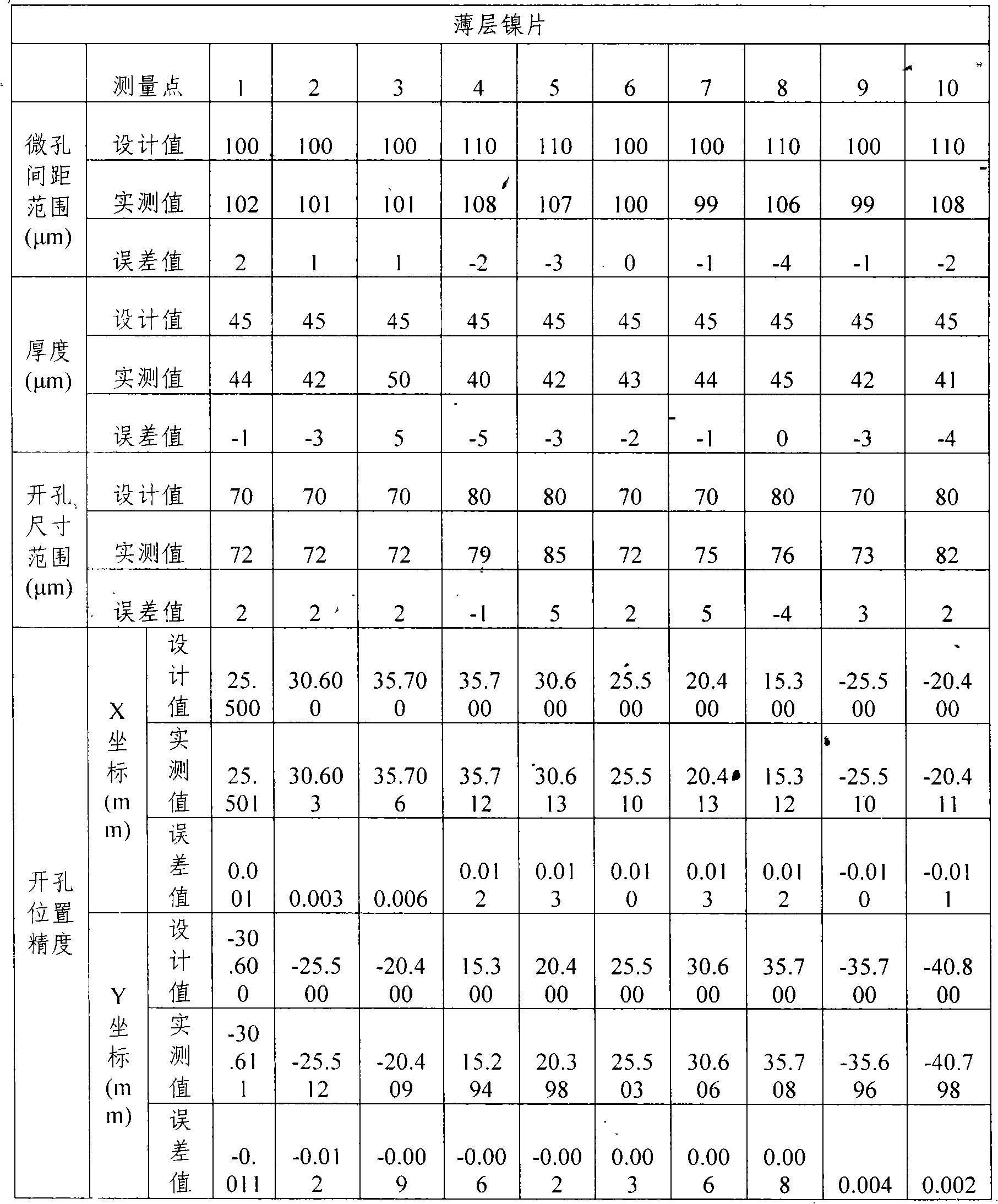

Electrodeposition-laser remelting strengthening process of Ni-nanometer TiN composite layer on surface of nickel base superalloy

InactiveCN104928729ASolve complex processImprove friction resistanceElectrolytic coatingsElectrochemistryPulse power supply

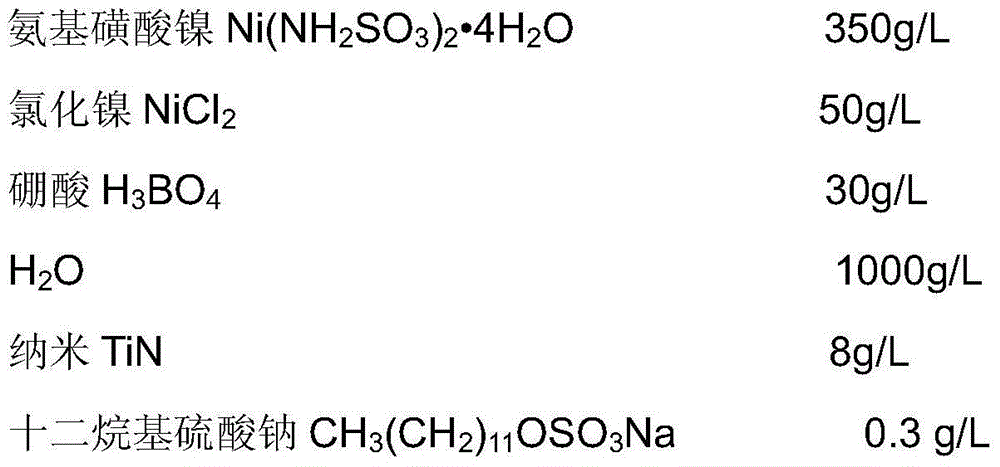

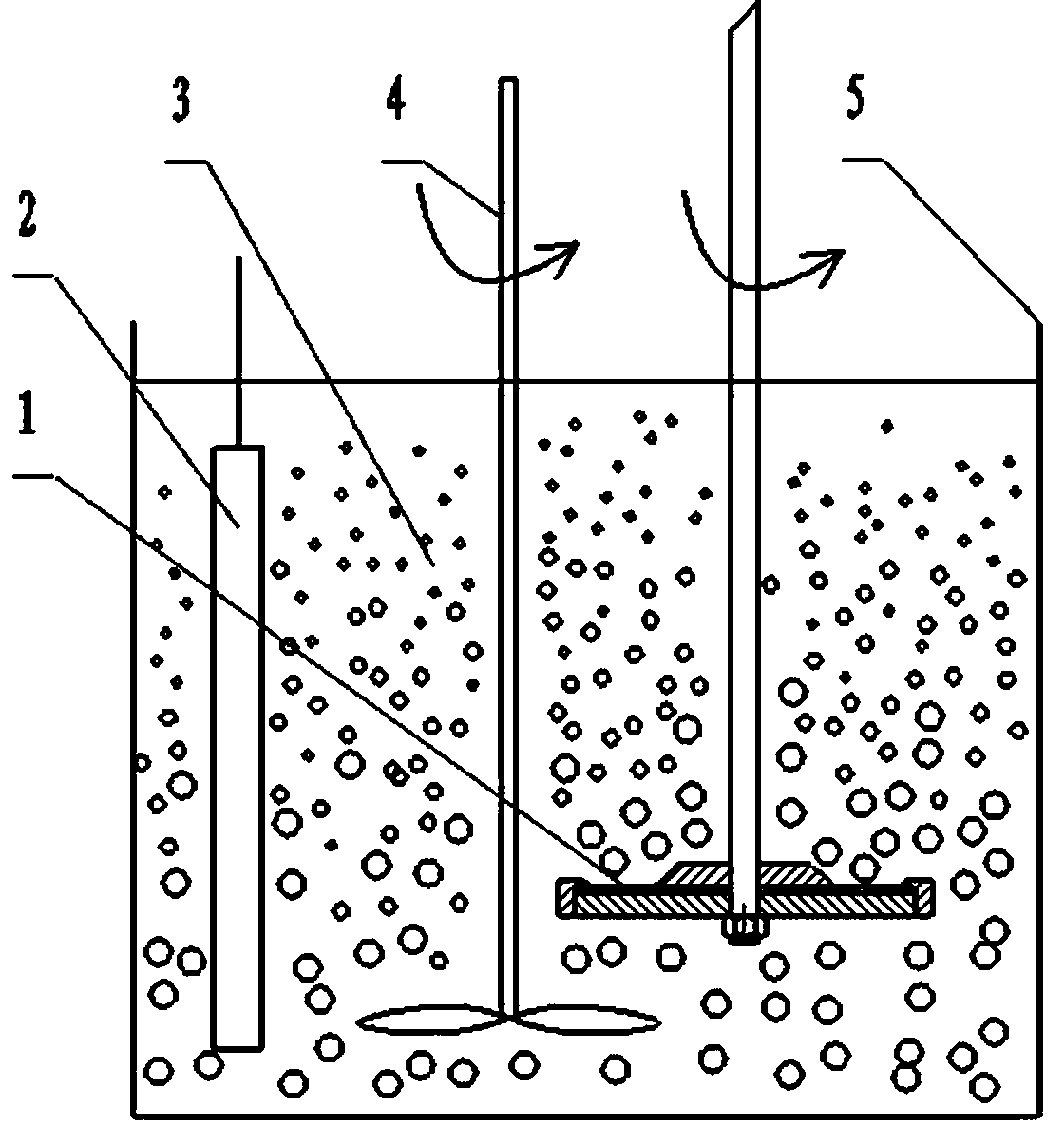

The invention relates to an electrodeposition-laser remelting strengthening process of a Ni-nanometer TiN composite layer on a surface of a nickel base superalloy. The process comprises the following steps: (1) preparation of plating solution: the plating solution comprises such components as nickel aminosulfonate, nickel chloride and water solution of boric acid; (2) preparation of electrodes: the area ratio of an anode to a cathode is 1.5: 1; and the anode and the cathode are arranged in parallel by a distance of 30 mm; (3) composite electrodeposition: a power supply adopts a two-way high-frequency pulse power supply; and (4) laser remelting: a solid pulse laser processor is adopted to perform the one-way laser remelting; and applied power ultrasonic waves, high-intensity magnetic fields and high-frequency pulse current parameters assist the electrodeposition process. The process organically combines the electrodeposition Ni-nanometer TiN composite layer technology with the laser cladding technology, is a new composite processing technology of physics and electrochemistry, and has the advantages of high processing efficiency and quality and wider application range. The process can satisfy the use requirements of nickel base alloy parts under the working conditions of high speed, high temperature, high impact load and corrosion.

Owner:DALIAN UNIV

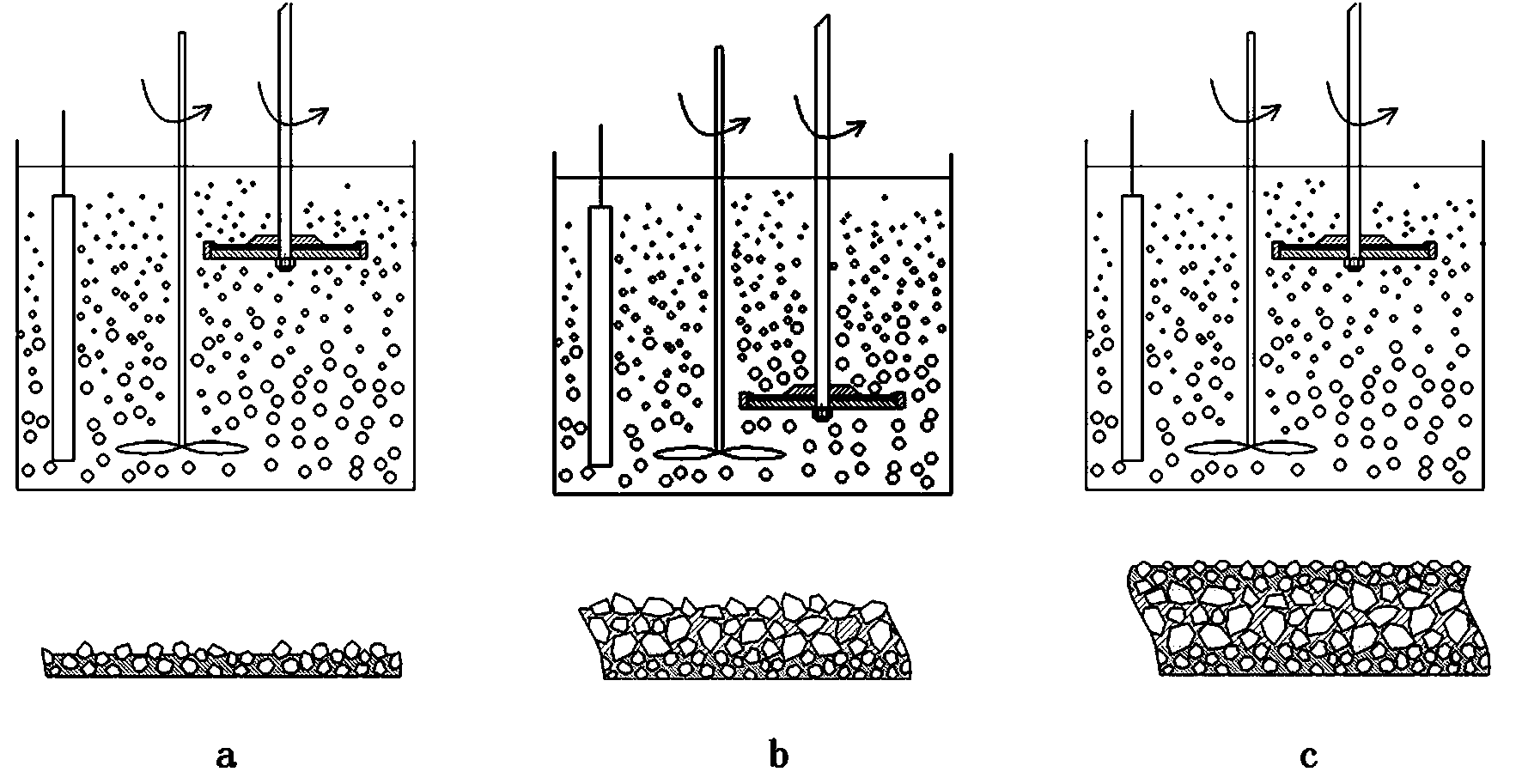

Machining method of multilayer ultrathin diamond blade

ActiveCN103590091ALow input costAchieve layered electrodepositionCellsElectrolytic coatingsElectrolytic agentMaterials science

A machining method of a multilayer ultrathin diamond blade comprises the steps of employing an electro-deposition forming method, taking a surface ground austenitic stainless steel plate as a cathode substrate and sheet nickel as an anode substrate, adopting sulfamate electrolyte with lower internal stress, employing a rotating speed adjustable stirrer, putting the two substrates in the electrolyte, connecting the cathode substrate to a power supply cathode, connecting the anode substrate to a power supply anode, allowing the stirrer to rotate at certain speed, allowing nickel ions and diamond sand to be co-precipitated on the cathode substrate, obtaining multilayer composite sedimentary layers in different powder particles and concentration ratios by adjusting current values and the position of the cathode substrate in an electrolyzer at different time periods in the same electrolyte, demolding, machining to the specified size to form the required ultrathin diamond blade in a multilayer structure, wherein the electrolyte comprises nickel aminosulfonate, nickel chloride, cobalt sulfamate, boric acid, and the diamond sand with the particle size of 2-30 micrometers. The method is simple in technology, good in operability and low in cost, and has the advantages of good machining quality and binding force, long service life and the like.

Owner:SHENYANG ACAD OF INSTR SCI

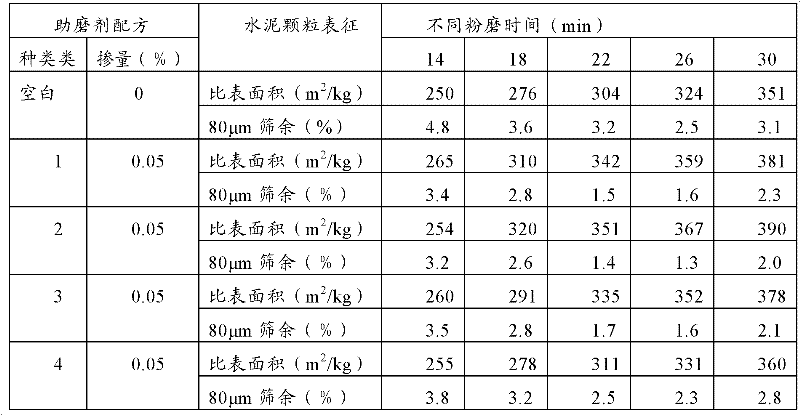

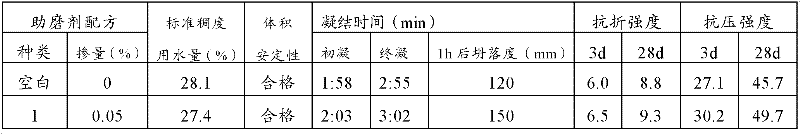

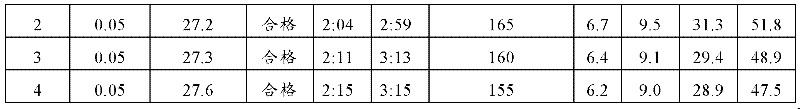

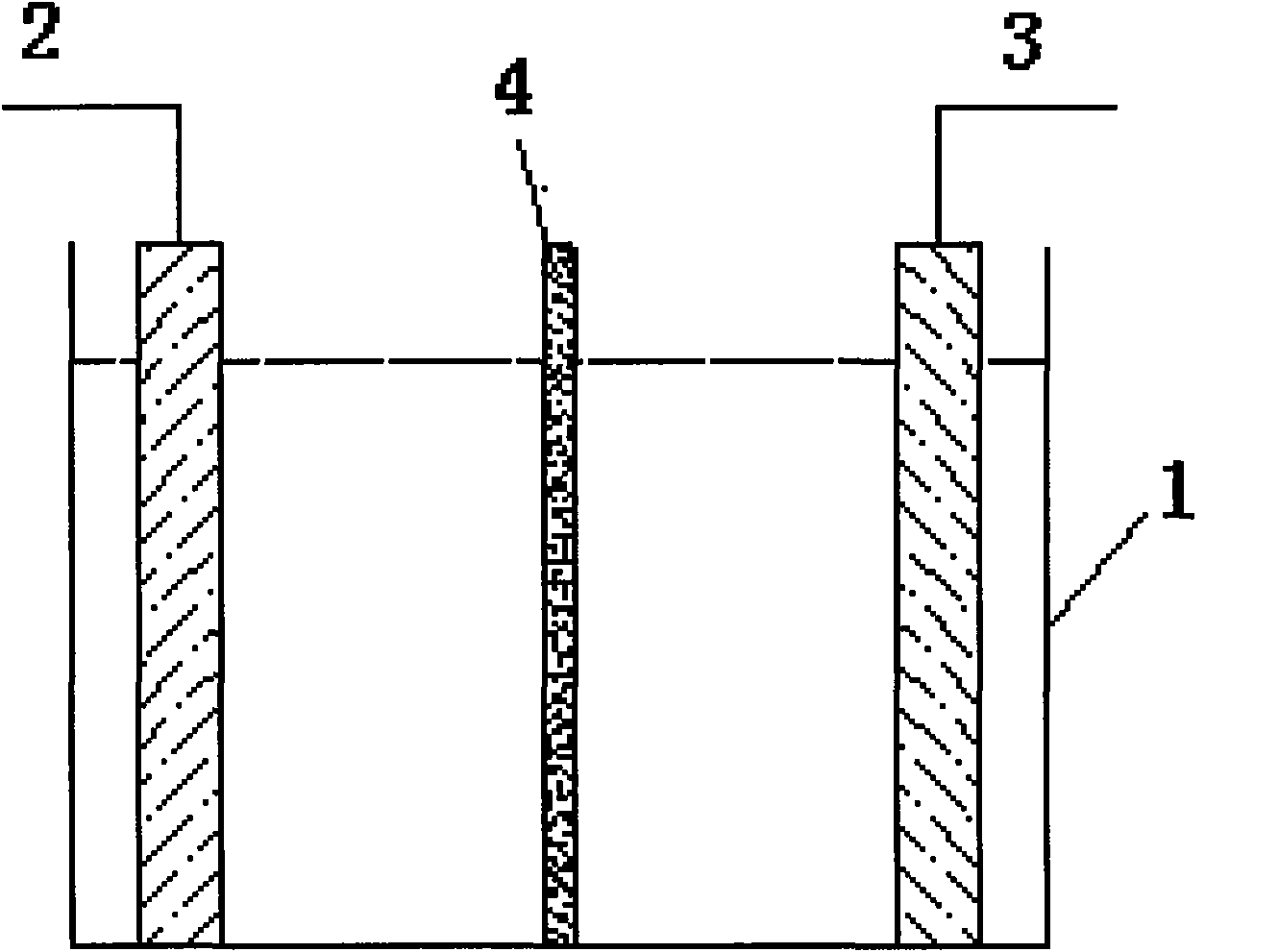

Cement slump-retaining grinding aid as well as preparation method and application thereof

The invention relates to a cement slump-retaining grinding aid as well as a preparation method and an application thereof. The cement slump-retaining grinding aid is composed of the following components in percentage by weight: 4.0-7.0% of sodium tripolyphosphate, 10.0-21.0% of sodium hexametaphosphate, 4.0-10% of ethylene glycol, 0.5-2.0% of carboxylic-group-containing amino sulfonate water reducing agent and 60.0-81.5% of water, wherein the carboxylic-group-containing amino sulfonate water reducing agent is formed by condensation of phenol, sodium p-amino benzene sulfonate and formaldehyde in a molar ratio of (1.1-1.5): (0.9-1.2): (3.5-3.7) with a benzoic acid sulfonation monomer. The addition amount of the cement slump-retaining grinding aid provided by the invention is 0.03-0.1% of the total weight of cement; and the cement slump-retaining grinding aid has the characteristics of simple preparation process and low cost, and can effectively improve the adaptability of cement and additives.

Owner:SHANXI KAIZHOU TECH

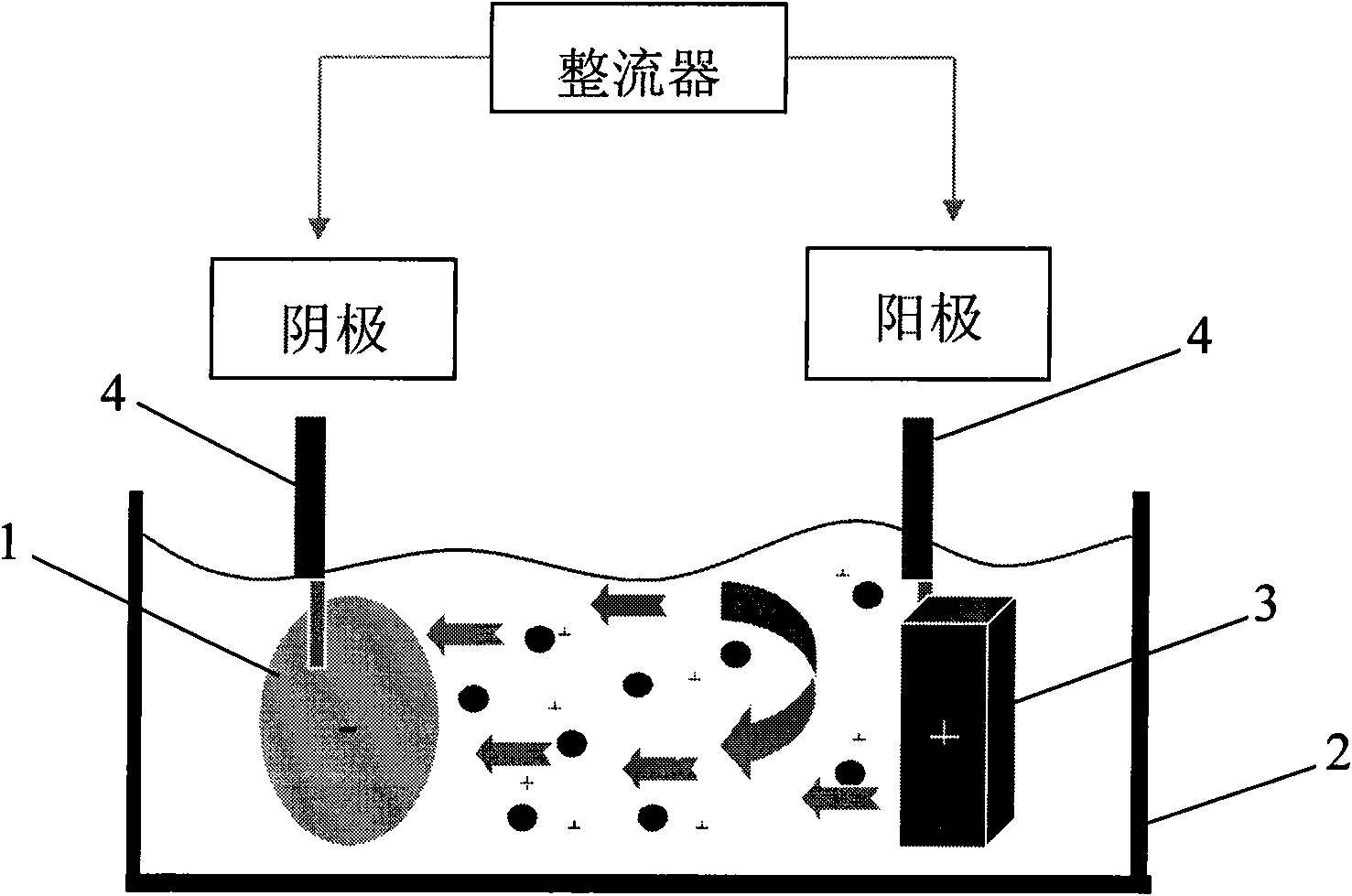

Preparation method of nickel aminosulfonate

InactiveCN101880888ASimple processQuick responseElectrolysis componentsChemical synthesisElectrolysis

The invention relates to a method for directly preparing nickel aminosulfonate with an electrolysis method, which is characterized in that a nickel aminosulfonate solution is directly obtained by placing nickel in a sulfamic acid solution through electrolysis, wherein at least the anodes of an electrolysis cathode and an anode is nickel, the cathode and the anode are separated by an ion exchange membrane, and the electrolyte is a sulfamic acid water solution. Compared with a chemical synthesis method, the invention has the advantages of simple process, fast reaction, short production period, high purity of obtained products, less impurities, no need of additional separation and purification, simple post-treatment and low preparation cost, can directly obtain the nickel aminosulfonate water solution with required purity and concentration in one step by controlling the concentration of the electrolyte and the purity of the nickel, and is particularly suitable for preparing the nickel aminosulfonate water solution for accurate plating.

Owner:宜兴方晶科技有限公司 +1

Chemical nickel deposition solution

InactiveCN102400120ASimple compositionGood attackLiquid/solution decomposition chemical coatingSodium phosphatesPhysical chemistry

The invention relates to a chemical nickel deposition solution applied in the manufacturing industry of printed circuit boards. The chemical nickel deposition solution comprises the following components: (1) 30 to 45 g / L of nickel aminosulfonate, (2) 64 to 75 g / L of composite complexing agent, (3) 18 to 25 g / L of sodium hypophosphite, (4) 0.01 to 0.03 g / L of wetting agent, and (5) the balance of deionized water. Nickel ions are provided by the nickel aminosulfonate and used together with the composite complexing agent, and chemical nickel deposition can be performed at the temperature between 55 and 75 DEG C under the pH value between 5.5 and 6.0. The chemical nickel deposition solution can be implemented at a low temperature; the nickel deposition solution is weakly acidic, energy-saving and environment-friendly; the nickel layer is bright and clean; and the nickel deposition solution is strong in corrosion resistance, good in weldability and stable.

Owner:GUANGDONG TONESET SCI & TECH

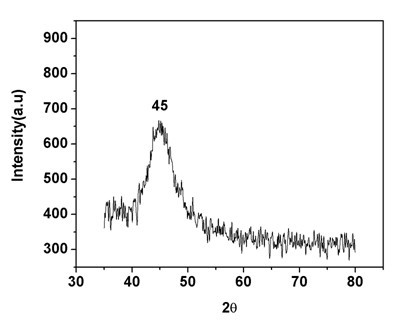

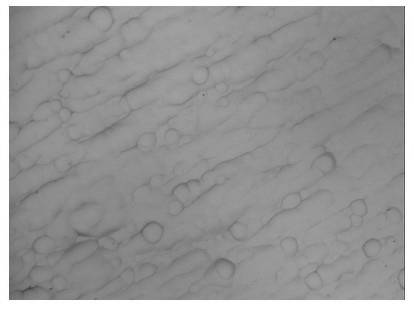

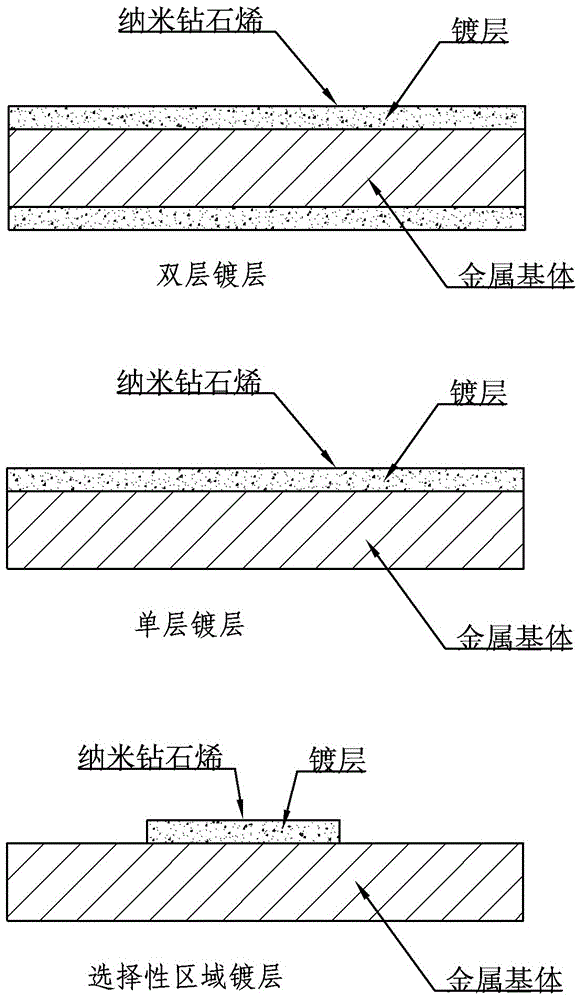

Composite electroplating technology of high-wear-resisting nano diamond alkene

The invention discloses a composite electroplating technology of high-wear-resisting nano diamond alkene, and belongs to the field of electroplating technologies. The method comprises following steps: firstly, electroplating liquid is prepared, a nickel aminosulfonate stock solution, a boric acid aqueous solution and a nickel chloride aqueous solution are mixed and stirred, and heated to 55 DEG C to 60 DEG C, then, lauryl sodium sulfate, saccharin and 1,4-butynediol are added, and electroplating liquid is prepared; nano diamond alkene is added; the nano diamond alkene is ultrasonically dispersed for 2 h in the electroplating liquid, then, composite electroplating liquid is obtained, and the composite electroplating liquid is slowly added into an electroplating bath in batches; thirdly, electroplating is carried out, a cleaned-up to-be-electroplated workpiece is placed in the composite electroplating liquid at the temperature of 55 DEG C to 60 DEG C, the to-be-electroplated workpiece serves as a negative electrode, a pure nickel plate serves as a positive electrode, the electroplating liquid is stirred, and electroplating current of 1-3A / dm<2> is applied; and after electroplating is finished, and an electroplating part is obtained. The thickness of an electroplating layer is reduced, the requirement for heavy metal is reduced, the pollution to the environment is reduced, and hardness, wear resistance and corrosion resistance of the electroplating layer can be obviously improved.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Method for plating nickel on aluminum and aluminum alloy coiled material

The invention discloses a method for plating nickel on aluminum and aluminum alloy coils. After the coils are unrolled, the following steps are successively carried out successively: step 1, degreasing and degreasing the surface of the coils; step 2, pickling the surface of the coils; Step 3, zinc immersion on the surface of the coil for the first time; step 4, zinc stripping; step 5, zinc immersion on the surface of the coil for the second time; The anode is immersed in a mixed solution containing nickel sulfamate, nickel chloride, boric acid, nickel softener, and nickel brightener, and then washed with pure water for more than one time. The invention realizes the continuous electroplating process of the aluminum alloy coil, that is, the nickel electroplating process of the aluminum alloy coil, and forms a firmly bonded, sub-bright, dense, uniform and continuous coating on the surface of the aluminum alloy. The surface of the electroplated aluminum material has the characteristics of nickel and the advantages of aluminum material at the same time.

Owner:尼尔金属(苏州)有限公司

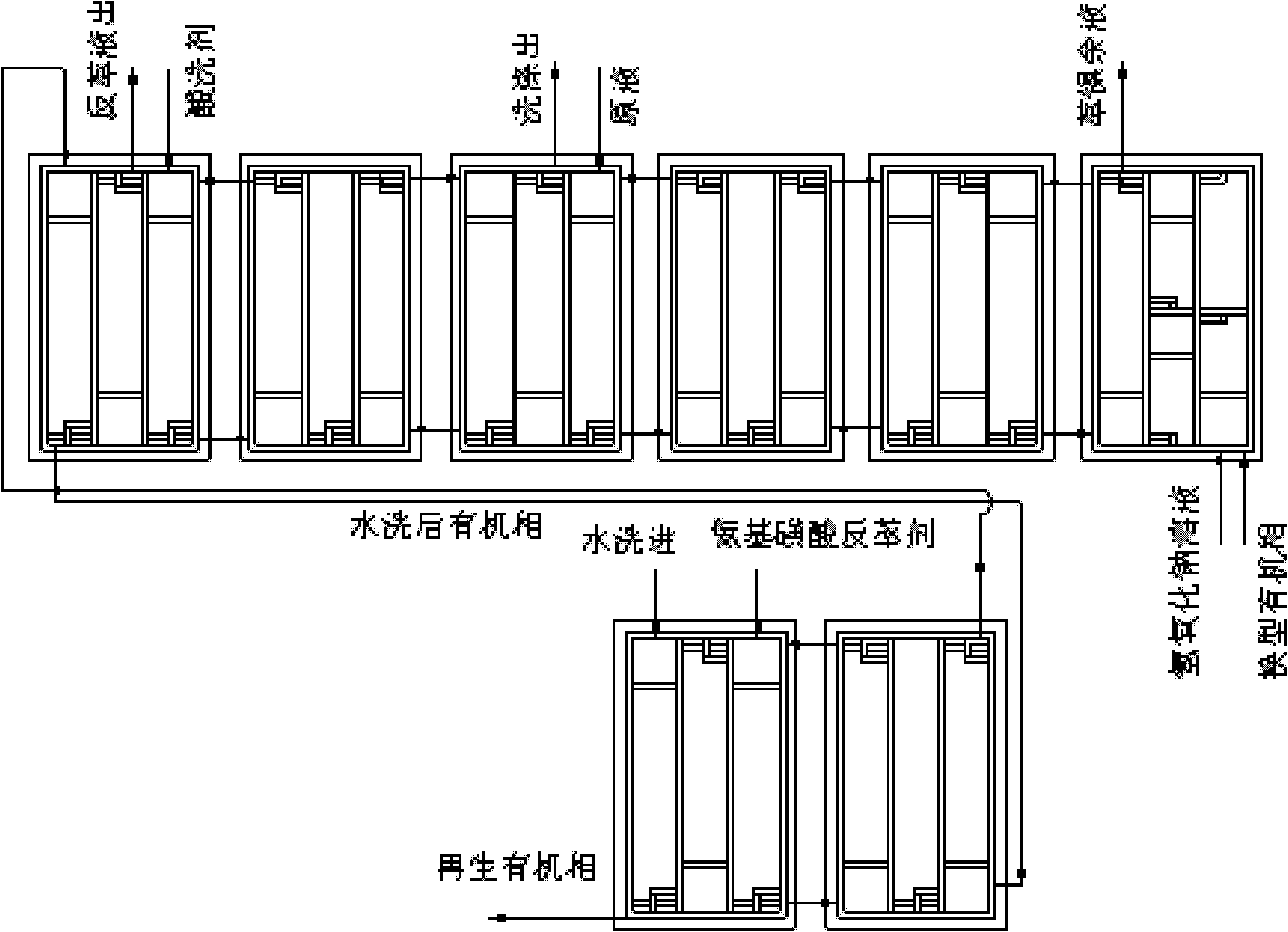

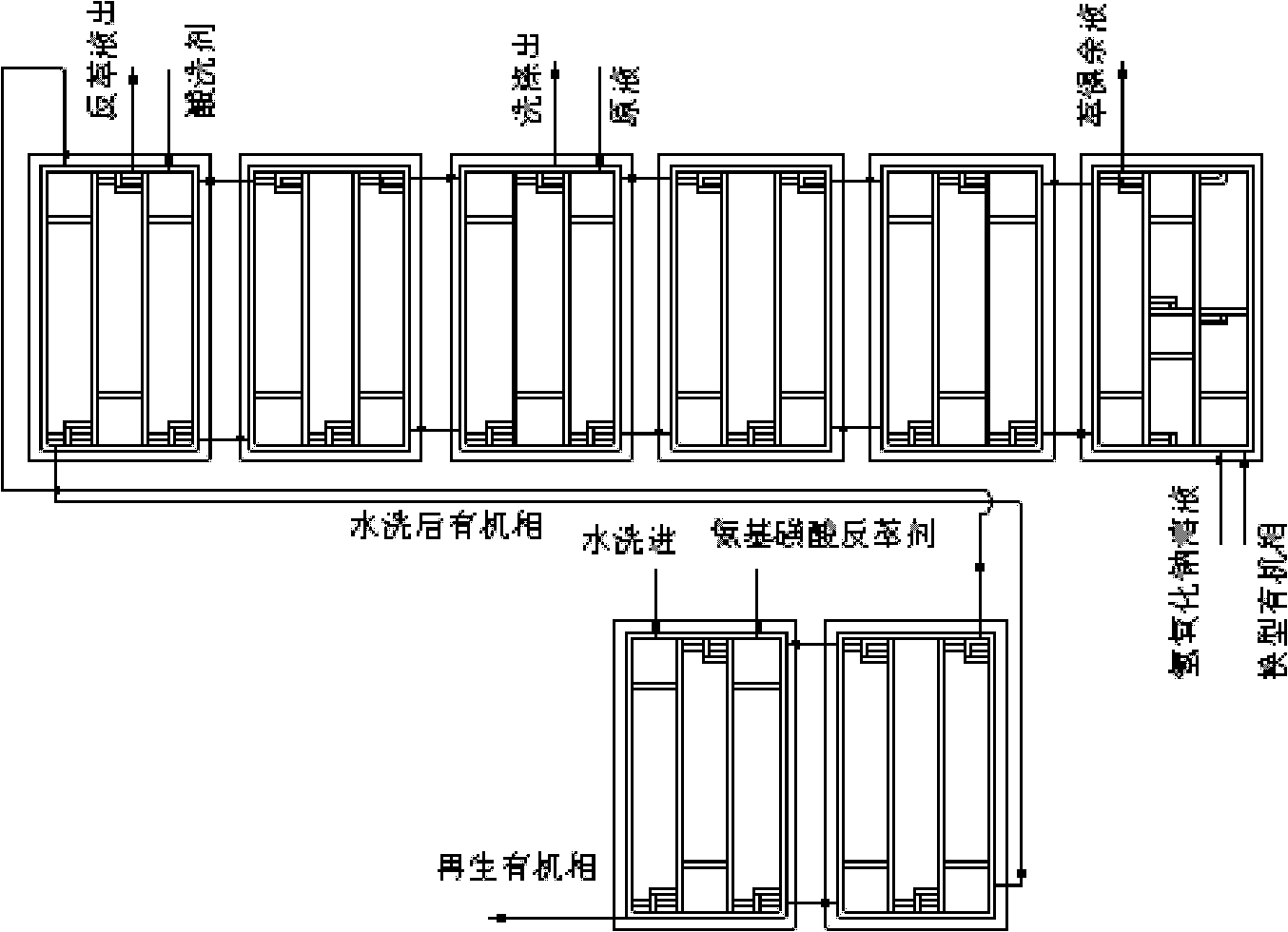

Technology for preparing nickel sulfamate through extraction method

The invention relates to a technology for preparing nickel sulfamate through the extraction method, belonging to the technical field of fine chemicals. The technology is characterized by comprising the following steps: using the raffinate obtained by extracting the two-stage countercurrent leaching liquor of high grade matte nickel and removing impurities as a stock solution to perform an extraction reaction with hard soap which is prepared from an organic phase and a sodium hydroxide solution according to a specific ratio; and washing a loaded organic phase with acid, and using aminosulfonicacid as a stripping agent to prepare a nickel aminosulfonate solution; and performing evaporation concentration, centrifugation and other working procedures to prepare the finished nickel aminosulfonate product. The invention has a simple technology and less loss of nickel. The massive consumption of resources such as water, electricity and the like can be avoided and the invention is a low-carbon production method suitable for future development.

Owner:JILIN JIEN NICKEL IND

Method for plating nano nickel layer on metal workpiece

The invention relates to a method for plating a nano nickel layer on a metal workpiece. The method comprises the following steps of: baking, carbonizing and cleaning the metal workpiece, thoroughly burning off capillary impurities on the surface of the metal workpiece, carbonizing and cleaning the obtained metal workpiece; then putting the metal workpiece into an electroplating bath with bath solution for electroplating; wherein the metal workpiece is used as the cathode of the electroplating bath, the pure nickel target is used as the anode of the electroplating bath, and the bath solution in the electroplating bath is nickel aminosulfonate solution and flows in the electroplating bath; in the electroplating process, the pure nickel target of the anode is electrolyzed into nanometer nickel ions which are deposited in the capillary of the surface of the metal workpiece of the cathode and are regularly arranged into layered nano nickel film in sequence; and finally the metal workpiece is taken out from the electroplating bath and cleaned; wherein the electroplating technique is adopted to fill the nanometer nickel ions in the capillaries of the surface of the metal workpiece in a drilling manner; then the nanometer nickel ions can also be arranged and laminated on the surface of the metal workpiece in sequence, thus being capable of greatly increasing the surface toughness of the metal workpiece so as to strengthening the fragility of the metal workpiece.

Owner:陈仲禾

Antimicrobial pbt material and preparation method thereof

InactiveCN105860452ALarge specific surface areaMultiple potential active sitesSodium diacetatePolyethylene terephtalate

The invention discloses an antimicrobial pbt material. The antimicrobial pbt material is prepared from, by weight, 3-5 parts of polyvinylpyrrolidone, 70-80 parts of caprolactam, 10-13 parts of attapulgite, 1-1.4 parts of zinc acetate, 2-3 parts of gamma-aminopropyltriethoxysilane, 18-20 parts of oxalic acid, 300-370 parts of polybutylene terephthalate, 6-8 parts of octyl isothiazolinone, 1-2 parts of zinc sulfate, 1.7-2 parts of n-salicylanilide, 10-14 parts of butyl acrylate resin, 1-2 parts of bi-decyl dimethyl ammonium bromide, 0.7-1 part of nickel aminosulfonate and 2-3 parts of sodium diacetate. Polyvinylpyrrolidone, sodium diacetate and the like are further added to the material, and therefore the antimicrobial performance of the finished product is further improved.

Owner:CHUZHOU YOUSHENG HIGH POLYMER MATERIAL

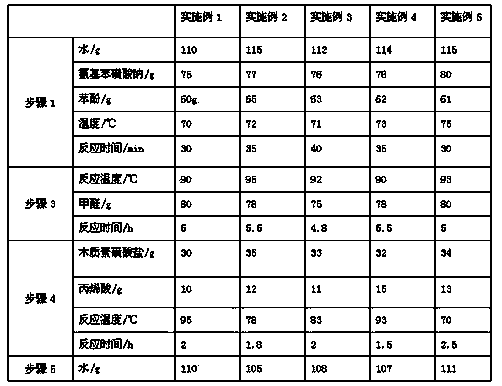

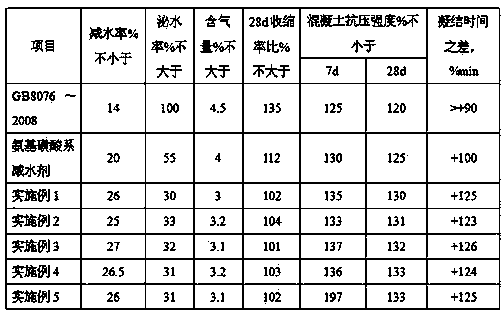

Lignin sulfonate modified aminosulfonic acid series efficient water reducer and preparation method thereof

InactiveCN103965417AReduce manufacturing costSolve the phenomenon of segregation and bleedingPhenolSodium hydroxide

The invention discloses a lignin sulfonate modified aminosulfonic acid series efficient water reducer and a preparation method thereof. The water reducer adopts sodium sulfanilate, phenol and formaldehyde as reactants, sodium hydroxide as an additive product, formaldehyde as a condensation polymer, and lignin sulfonate and acrylic acid as multipolymers; the lignin sulfonate modified aminosulfonic acid series efficient water reducer is prepared via a dissolution stage, an addition stage, a condensation polymerization stage, a copolymerization stage and the like. The lignin sulfonate modified aminosulfonic acid series efficient water reducer overcomes the defect that the aminosulfonic acid series efficient water reducer is overly sensitive to mixing amount, improves water retention property and adaptability, lowers the preparation cost of the aminosulfonic acid series efficient water reducer, and widens the application range of the lignin sulfosalt.

Owner:FUQING YONGCHUN CONCRETE ADMIXTURE

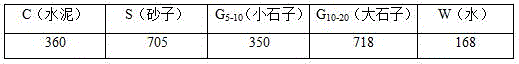

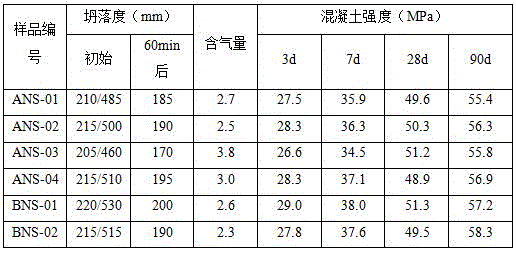

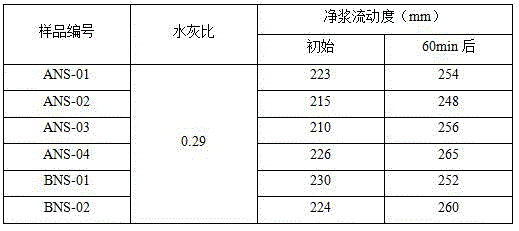

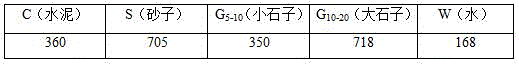

Preparation method of high-strength concrete

InactiveCN105347751AImprove bearing capacityEasy to prepareSolid waste managementHigh strength concreteSuperplasticizer

The invention discloses a preparation method of high-strength concrete comprising the following raw materials in parts by weight: 3 parts of basalt fibers, 2 parts of steel fibers, 4 parts of glass fibers, 100 parts of cement, 90 parts of fly ash, 600 parts of gravels with the particle size of 10-15 mm, 150 parts of gravels with the particle size of 15-20 mm, 800 parts of sand, 130 parts of water, 1.5 parts of an amino-sulfonate high-efficiency water-reducing agent, 10 parts of bentonite, 0.5 part of a super plasticizer, 1 part of an air entraining agent, 0.1 part of a defoaming agent, 0.2 part of a rosin soap, 0.05 part of a tackifier, and 0.3 part of calcium stearate. The preparation method of the high-strength concrete is simple and convenient and can make full use of characteristics of all the raw materials, so that the prepared concrete has the strength significantly improved and improved by 50% or more compared with concrete of the prior art; and square piles prepared by the high-strength concrete have higher single-pile bearing capacity.

Owner:JIANGSU XINGSHA CONSTR ENG GRP

Preparation method of nickel-cubic boron nitride film

The invention relates to a preparation method of a nickel-cubic boron nitride film. The method comprises the following steps of: firstly cleaning anode / cathode base materials and cubic boron nitride powder; putting the treated anode / cathode base materials and cubic boron nitride powder into a plating solution and electroplating, wherein the plating solution is formed by dissolving boric acid, ammonium chloride, nickel aminosulfonate and a lauryl sodium sulfate solution in deionized water; and applying an ultrasonic wave with the power of 250 to 260W and the frequency of 20 to 40KHz to the plating solution during the electroplating process. By leading the ultrasonic wave into the electroplating process and optimizing the formula and the process parameters of the plating solution, the cubic boron nitride powder in the plating layer of the nickel-cubic boron nitride film generated in the electroplating manner is distributed uniformly and is not agglomerated. In addition, the nickel layer in the film is flat relatively; and the cubic boron nitride powder is not agglomerated in the film and is firmly embedded.

Owner:HENAN UNIV OF SCI & TECH

Metal/sulfur-containing nickel composite material as well as preparation method and application thereof

The invention discloses a metal / sulfur-containing nickel composite material as well as a preparation method and application thereof. The preparation method comprises the steps that at least an anode,a cathode and an electroplating solution jointly construct an electrochemical reaction system, the cathode adopts a metal wire and / or a metal sheet, and the electroplating solution is a mixed solutionat least containing nickel salt, a sulfur-carrying agent, a buffering agent and water; and the electrochemical reaction system is electrified for electroplating to obtain the metal / sulfur-containingnickel composite material of which the inner layer is metal and the outer layer is a sulfur-containing nickel material. The metal wire or the metal sheet is adopted as the cathode, the labor cost is reduced, meanwhile, the product is a sulfur-containing nickel short rod or block product, and due to the potential difference between the metal wire or the metal sheet and the sulfur-containing nickelouter layer, the metal wire or the metal sheet has better solubility and can serve as a high-solubility nickel anode; and the method is used in the fields of diamond wire electroplating, nickel aminosulfonate electroplating, electronic product electroplating and the like, and improves the limited current density and the production efficiency.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Electrolyte additive used for electroforming high hardness and low stress nickel workpiece

The invention discloses an electrolyte additive used for electroforming a high hardness and low stress nickel workpiece. The additive comprises an organic additive and a rare earth additive and is characterized in that the organic additive comprises 150-200 g / L of sodium saccharin, 30-50 g / L of ethoxylation butynediol, 10-20 g / L of N,N-diethyl-2-propyneammonium sulfate, 80-120 g / L of PPSOH, 1-2 g / L of S-carboxyethylisothiuronium chloride and 8-10 g / L of sodium vinylsulfonate; and the rare earth additive comprises 0.4-0.8 g / L of lanthanum chloride (LaCl3.7H2O) and 0.2-0.4 g / L of cerium chloride (CeCl3.7H2O). By means of the electrolyte additive, the process effects of a bright and smooth surface, high hardness, low inner stress and the like can be achieved, an electrolyte is easy to maintain, the adding amount and the consumption amount are small, and the electrolyte additive can be used for a nickel aminosulfonate electrolyte system and a nickel sulfate electrolyte system.

Owner:HENAN POLYTECHNIC UNIV

Method for synthesizing modified aminosulfonate superplasticizer from wastewater produced in K acid production process

InactiveCN105645819ALow raw material costReduce dosageWater contaminantsMultistage water/sewage treatmentSuperplasticizerWastewater

The invention relates to a method for synthesizing a modified aminosulfonate superplasticizer from wastewater produced in the K acid production process. According to the method, the modified aminosulfonate superplasticizer is prepared from wastewater produced in the K acid production process, sodium sulfanilate and a compound of phenolic hydroxyl. The synthesized modified sulfamic acid has higher concrete water-reducing rate and excellent slump maintaining performance, and more importantly, a new way for comprehensive utilization of wastewater of a dye intermediate is developed. The cost of raw materials of the superplasticizer is reduced, the environment pressure in the production process of the dye intermediate is also reduced, and the method has good economic and environmental benefits.

Owner:浙江五龙新材股份有限公司

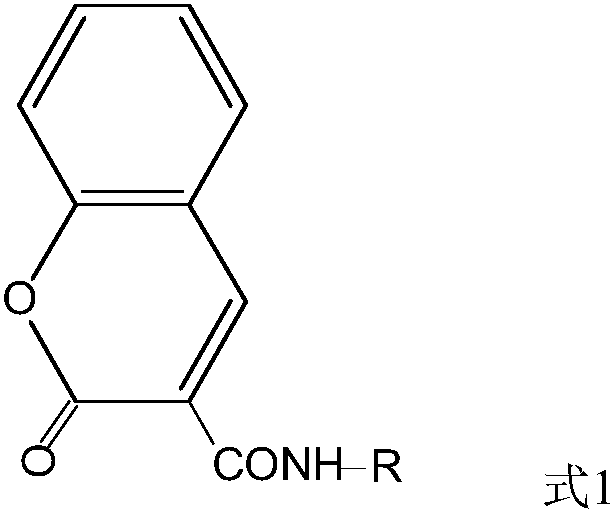

Aqueous fluorescent tracer and preparation method thereof

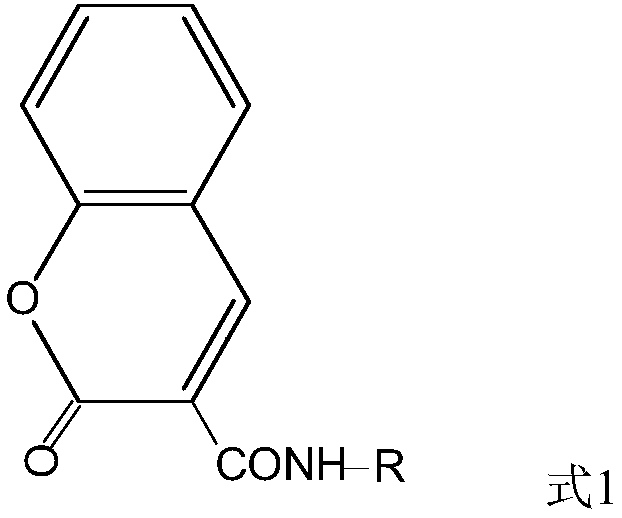

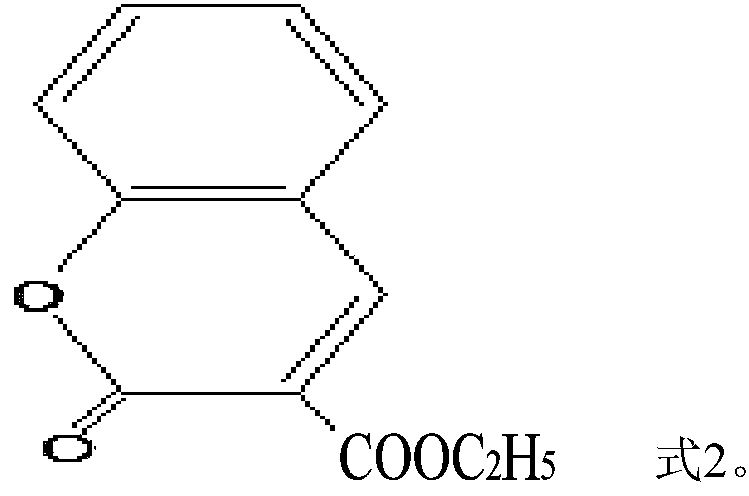

ActiveCN107652256AGood water solubilityLow costOrganic chemistryFluorescence/phosphorescenceChemical structureSolubility

The invention provides an aqueous fluorescent tracer and a preparation method thereof. The aqueous fluorescent tracer has a chemical structure shown in the description; and R in the chemical structureis -SO3Na, -(CH2)2NH(CH2)2SO3Na, -Ph-SO3Na, -Ph-COOC2H2SO3H or a group with the formula being shown in the description. The preparation method of the aqueous tracer comprises the following steps: carrying out a condensation reaction on salicylaldehyde and diethyl malonate with piperidine as a catalyst to obtain a first product; carrying out a hydrolysis reaction on the first product under an alkaline condition to obtain a second product; and reacting the second product with aminosulfonate to prepare the aqueous fluorescent tracer. The aqueous fluorescent tracer has the advantages of good water solubility, low cost, non-toxicity, good chemical and biological stability, good thermal stability, simplicity in analysis operation, small dosage, high sensitivity, and convenience in monitoring.

Owner:PETROCHINA CO LTD

Method for plating copper and copper alloy coiled material with nickel

The invention discloses a method for plating a copper and copper alloy coiled material with nickel. After the coiled material is unfolded, the method sequentially comprises the following continuous steps that 1, the surface of the coiled material is subjected to degreasing and oil removing; 2, the surface of the coiled material is subjected to acid pickling; 3, the surface of the coiled material subjected to acid pickling is electroplated with a nickel layer, wherein the coiled material is adopted as a cathode, a nickel ball is adopted as an anode, the coiled material is soaked in a mixed solution including nickel aminosulfonate, nickel chloride, boric acid, a nickel softening agent, a nickel brightener and a phosphorus containing additive, and cleaning is carried out with purified water one or more times; 4, a purifying process is carried out, wherein the nickel layer is protected; 5, coating treatment is carried out, wherein micropores in the surface of the nickel layer are blocked off through organic matter; and 6, the coiled material is blown and dried. According to the method, a continuous electroplating process,of the copper and copper alloy coiled material, namely, a processof electroplating the copper coiled material with nickel is achieved, and the matte or bright, dense, uniform and continuous clad layer firm in combination is formed on the surface of the copper material. The electroplated surface of the copper material has the characteristic of nickel, and meanwhile the beneficial effects of the copper materials are achieved.

Owner:尼尔金属(苏州)有限公司

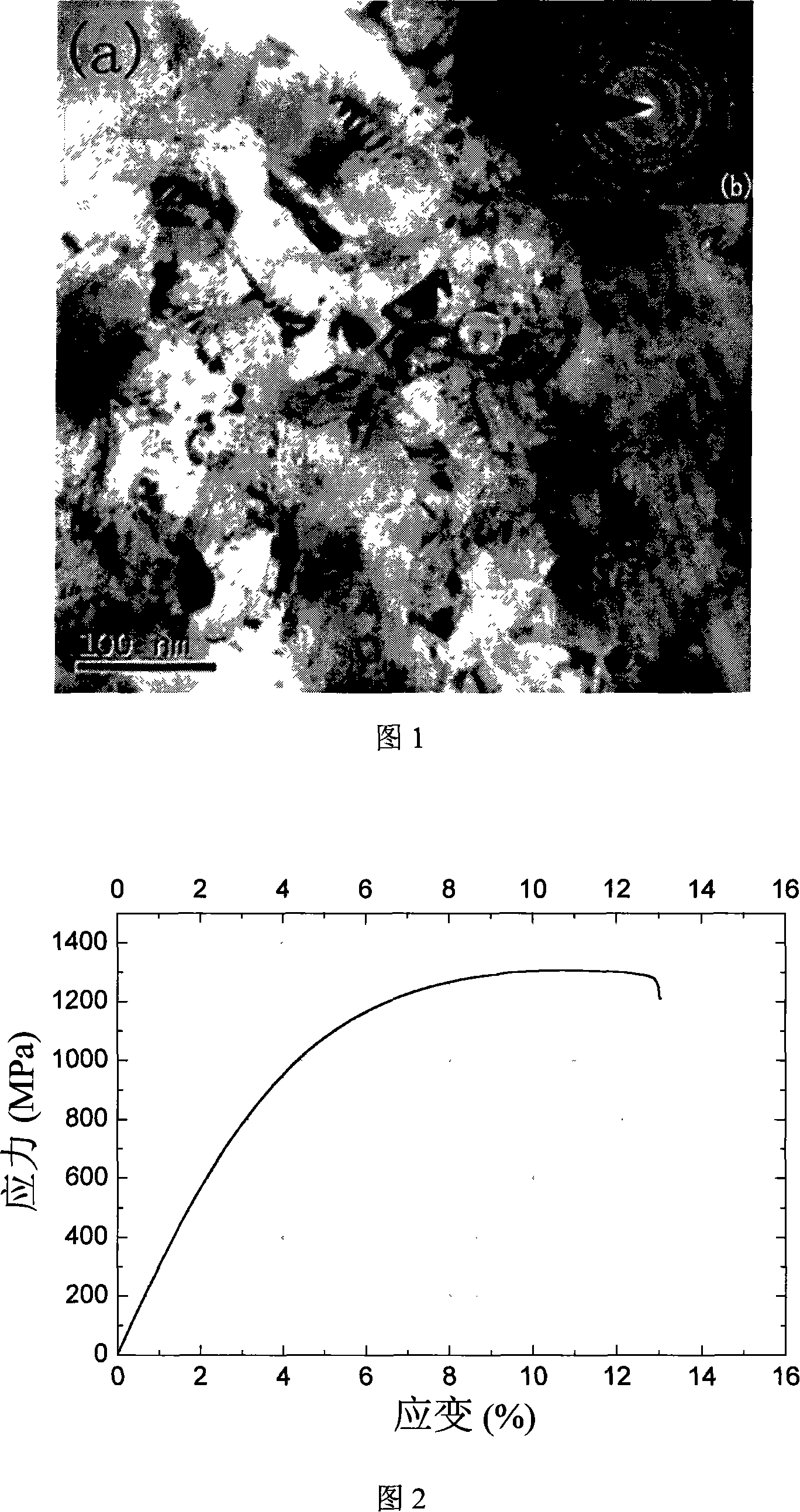

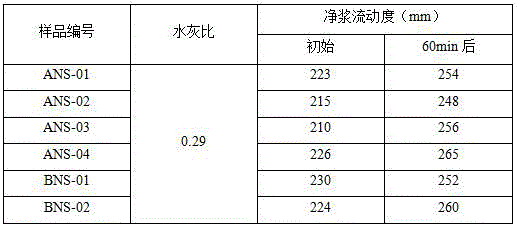

High-strength high-plasticity nano nickel and its plating solvent and preparation method

The invention provides a high strength and high plasticity nano nickel, and a bath solution and a preparation method of the nano nickel. The bath solution consists of nickel sulfamic acid, manganese chloride, nickel chlorite, boric acid, sodium dodecyl sulfate and saccharin; the preparation method is to adopt a DC current deposition method to conduct electric deposition in a nickel aminosulfonate alloy to prepare the nano nickel. The tensile strength of the nano nickel prepared by the invention is 1200 to 1300MPa, the total elongation at break is 12 to 13percent, and the grain size range of the nano nickel is between 10 and 100mm. Compared with the nano nickel prepared by traditional melting methods, the nano nickel prepared by the invention has obviously higher strength, and obviously improved plasticity compared with the general nano nickel prepared by the currently reported electric deposition methods. The invention has advantages of adoption of nickel sulfamic acid as the main salt, has low stress, quite large current capable of being added in plating, easiness in obtaining good plating layer surface quality, etc. The invention is applicable in preparing high strength and high plasticity nano nickel with high efficiency.

Owner:FUZHOU UNIV

Method for synthesizing modified aminosulfonate superplasticizer from wastewater produced in gamma acid production process

InactiveCN105645818ALow raw material costReduce dosageWater contaminantsMultistage water/sewage treatmentSuperplasticizerWastewater

The invention relates to a method for synthesizing a modified aminosulfonate superplasticizer from wastewater produced in the gamma acid production process. According to the method, the modified aminosulfonate superplasticizer is prepared from wastewater produced in the gamma acid production process, sodium sulfanilate and a compound of phenolic hydroxyl. The synthesized modified sulfamic acid has higher concrete water-reducing rate and excellent slump maintaining performance, and more importantly, a new way for comprehensive utilization of wastewater of a dye intermediate is developed. The cost of raw materials of the superplasticizer is reduced, the environment pressure in the production process of the dye intermediate is also reduced, and the method has good economic and environmental benefits.

Owner:浙江五龙新材股份有限公司

Method for synthesizing a modified amino sulfonate water-reducing agent by utilizing wastewater generated in dye intermediate production process

InactiveCN105731858ALow raw material costReduce dosageWater contaminantsMultistage water/sewage treatmentSulfonateSulfamic acid

The invention relates to a method for synthesizing a modified amino sulfonate water-reducing agent by utilizing wastewater generated in the dye intermediate production process. The method comprises the step of preparing the modified amino sulfonate water-reducing agent by adopting the wastewater generated in the naphthalens series dye intermediate production process, sodium amino benzene sulfonate and a chemical compound containing a phenolic hydroxyl. Modified amino sulfonate synthesized by the method has higher concrete water-reducing rate and excellent slump retaining ability, and more importantly, a novel way for the comprehensive utilization of the dye intermediate wastewater is provided. While the raw material cost of the water-reducing agent is reduced, and the environmental pressure in the dye intermediate production process is reduced, therefore, the economic and environment-friendly benefits are good.

Owner:浙江五龙新材股份有限公司

Surface nickel coating grain size regulating method capable of improving corrosion resistance

InactiveCN105506693ANo vulcanization embrittlementQuality improvementCellsSurface engineeringElectricity

The invention provides a surface nickel coating grain size regulating method capable of improving corrosion resistance, and belongs to the field of metal surface engineering, and the surface nickel coating grain size regulating method is used for improving corrosion resistance by adopting a method of electro-depositing Ni coatings with different grain sizes. By adopting a nickel aminosulfonate plating solution system, the grain sizes of the Ni coatings are regulated by controlling electro-deposition parameters in case of not adding any grain refiner. According to the invention, the Ni coatings with different grain sizes ranging from nano scale to micro scale are obtained by adopting a direct-current electro-deposition mode and a pulse electro-deposition mode. On the premise of not adding the grain refiner, the nickel coating grain refinement is realized by regulating the electro-deposition parameters, so that the corrosion resistance of the Ni coatings can be effectively improved while an impurity element segregation problem caused by the additive is avoided. The surface nickel coating grain size regulating method has the advantages such as a simple operation process, low cost, high efficiency and the like.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com