Modified sulfamate efficient water reducer and preparation method thereof

A technology of sulfamate and high-efficiency water reducer, which is applied in the field of waste liquid treatment, can solve the problems of great harm to the human body and the environment, difficult biochemical degradation, strong acid-base buffering ability, etc., to reduce slump loss and pollution , Good collapse-retaining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

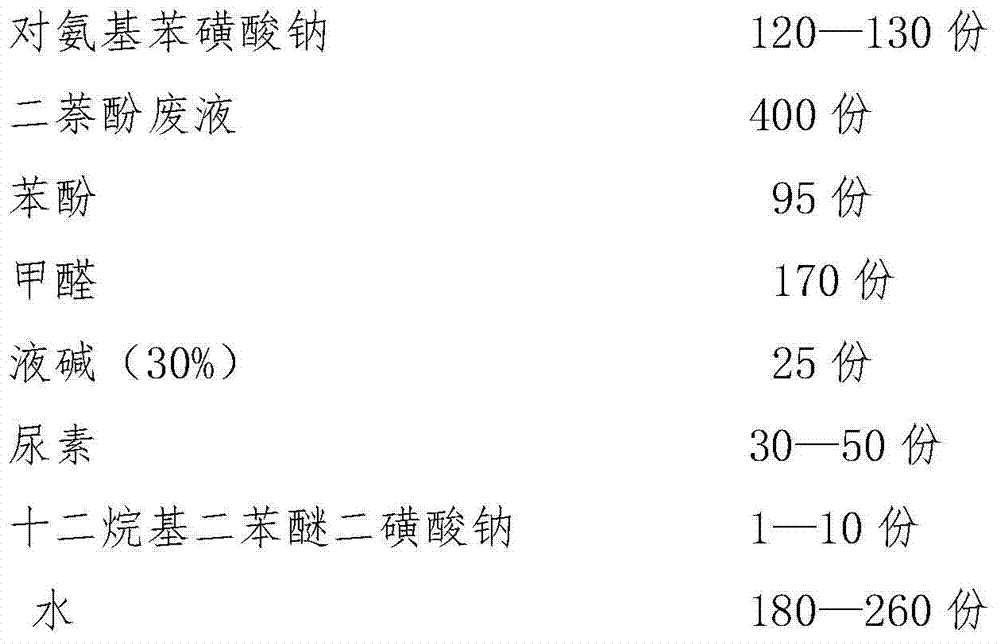

[0022] A modified sulfamate high-efficiency water reducer, the raw materials are calculated in parts by weight, and the proportioning ratio is:

[0023]

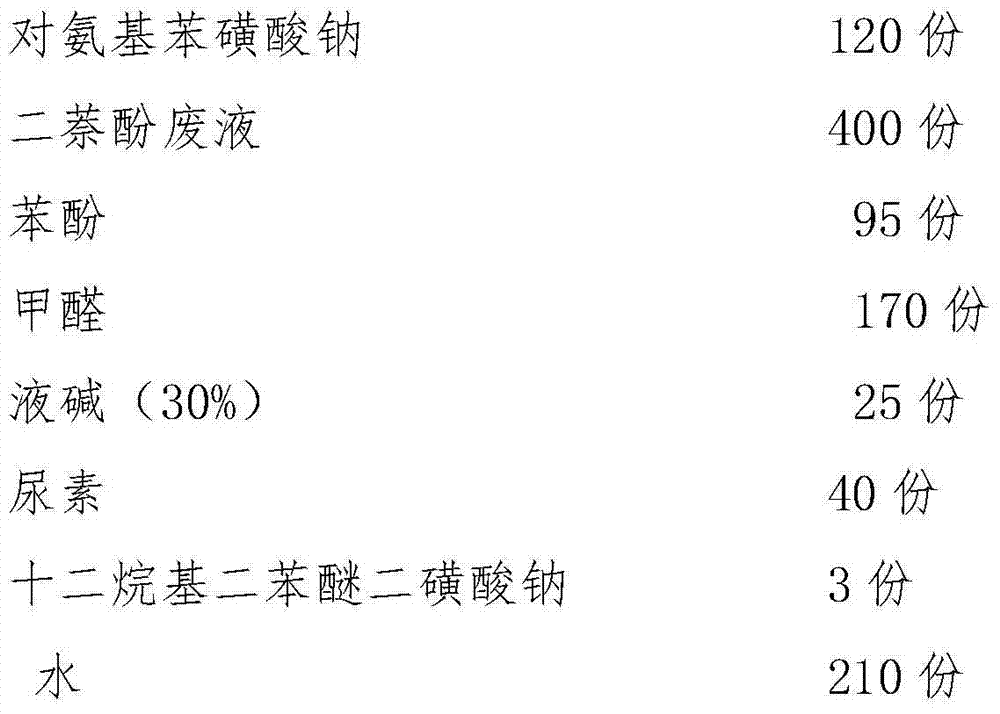

[0024] The synthesis process is as follows: put 400 parts of binaphthol waste liquid and 40 parts of urea into a four-necked flask according to the mass parts in this example, and heat to 40°C while stirring, and start to add 120 parts of sodium p-aminobenzenesulfonate, 95 parts of phenol Continue to stir while heating to 60°C, add 25 parts of liquid caustic soda, adjust the pH value, then add 5 parts of sodium dodecyl diphenyl ether disulfonate and stir evenly, then weigh 170 parts of formaldehyde and put it into the constant pressure funnel , Add formaldehyde dropwise at 60-85°C, and complete the dropwise addition within 2-3 hours. After the dropwise addition, raise the temperature to 95-105°C and keep it warm for 3-6 hours. After the heat preservation, add 210 parts of water and cool down to get the sample.

Embodiment 2

[0026] A modified sulfamate high-efficiency water reducer, the raw materials are calculated in parts by weight, and the proportioning ratio is:

[0027]

[0028]

[0029] According to the mass parts in this example, the synthesis steps are as in Example 1.

Embodiment 3

[0031] A modified sulfamate high-efficiency water reducer, the raw materials are calculated in parts by weight, and the proportioning ratio is:

[0032]

[0033] According to the mass parts in this example, the synthesis steps are as in Example 1.

[0034] The binaphthol waste liquid modified sulfamate high-efficiency water reducer is used in the concrete of construction projects, wherein the binaphthol waste liquid modified sulfamate water reducer is added to the concrete mixture in the form of an aqueous solution. The dosage is 0.5%-1.5% of the cement weight, preferably 0.8-1.2% of the cement weight.

[0035] Comparison table of compressive strength between the product of the present invention and commonly used sulfamate water reducers

[0036]

[0037] Comparison table of the slump between the product of the present invention and the commonly used sulfamate water reducer

[0038]

[0039] Comparison table of the gas content of the product of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com