Patents

Literature

433results about How to "Good collapsibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali-activated high-performance water reducer and preparation method thereof

ActiveCN103011662AHigh water reduction rateEnhancement effect is goodBlack liquorProcess engineering

The invention discloses an alkali-activated high-performance water reducer and a preparation method thereof. The alkali-activated high-performance water reducer comprises a composite alkali-activator, a composite water reducer, black liquor of a paper mill, a composite retarder, a composite air entraining agent, a composite thickener, a composite regulator and the balance of water. The preparation method for the alkali-activated high-performance water reducer comprises the following steps of: adding the components and water to a reaction kettle in sequence; and mixing and carrying out a reaction on the components and the water under the room-temperature environment to obtain the finished product. The alkali-activated high-performance water reducer disclosed by the invention can activate the cementitious activity of the mixed materials such as slag, coal ash, gangue and the like, has excellent adaptability to different cements and highly doped concrete, and can greatly reduce the adding amount of cement clinker. The alkali-activated high-performance water reducer has the characteristics of a high water-reducing agent, good peaceability, a remarkable reinforcing effect, a good collapse preventing effect, adjustable setting time and the like. Moreover, the external additive has a simple production process, no pollution, low energy consumption and low cost, can solve an environmental pollution problem of the black liquor of the paper mill, and has good practicability.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

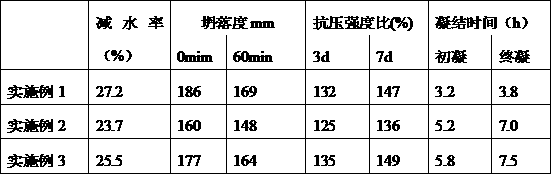

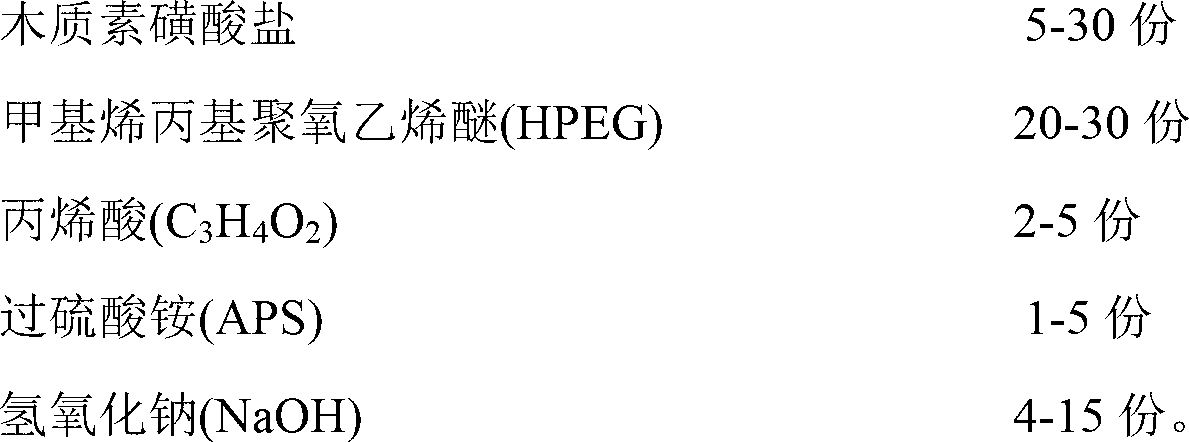

Lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and preparation method thereof

The invention discloses a lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and a preparation method thereof. The high-performance water reducer comprises the components in parts by weight: 5-30 parts of lignosulfonate, 20-30 parts of methyl allyl polyethenoxy ether, 2-5 parts of acrylic acid, 1-5 parts of ammonium persulfate, 4-15 parts of sodium hydroxide and water. The preparation method comprise the steps as follows: lignosulfonate, methyl allyl polyethenoxy ether and acrylic acid are directly synthesized under the action of ammonium persulfate, and the mixture is neutralized by sodium hydroxide to obtain the high-performance water reducer. As the high-performance water reducer is made from natural recycled materials, the high-performance water reducer is low in price, stable in performance, high in water-reducing rate, good in collapse prevention property, remarkable in improved effect, and is unlikely to bleed, separate and deposit after concrete is added, the quality problems of sand leakage, honeycomb-like phenomenon and leakage due to cracking in the middle and low-strength concretes are effectively avoided, and the safety performance is improved.

Owner:MAANSHAN CHINASEA NEW MATERIAL

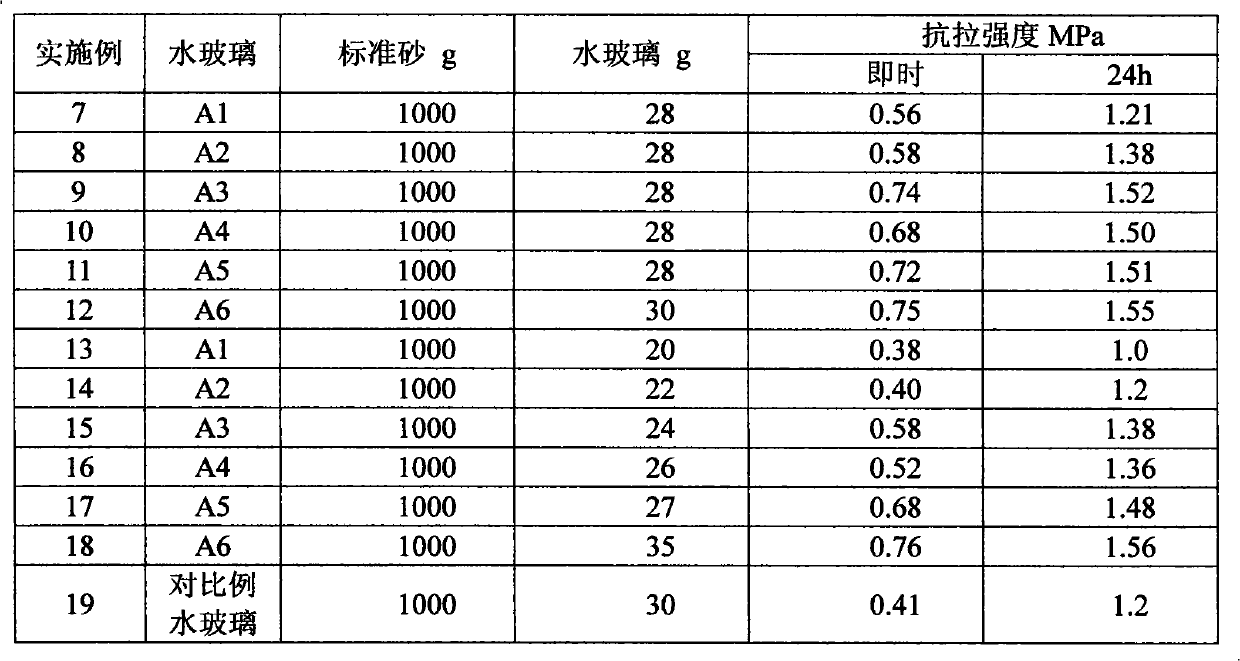

Adhesive for casting mold, manufacturing core and method of manufacturing the same

InactiveCN101108407AReduce the amount addedHigh strengthFoundry mouldsFoundry coresPentaerythritolPolyethylene glycol

A cohesion agent for casting module and making core is provided, which is characterized in that: the mass per centage ration of the main chemical component of the cohesion agent is SiO2, 23 to 31, K2O 0.5 to 28, Na2O 1 to 21, modifying agent 0.5 to 21 and excess water. Wherein, the modifying agent chooses one or two in sorbierite, xylitol, mannite, maltitol, glycol, propanediol, glycerol, pentaerythritol, diglycol, propylene glycol, carbowax, PPG and polyglycerol, the adding volume is 0.5 to 21 per cent. When using the cohesion agent to prepare sand mole core, the dosage is little, the old sand can be recycled and the prepared core has good collapse performance.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Modified sodium silicate binder for cold core box and preparation thereof

ActiveCN101947637AWide variety of sourcesImprove working environmentFoundry mouldsFoundry coresZinc hydroxideAluminium hydroxide

The invention aims to provide a modified sodium silicate binder for a cold core box and a preparation method thereof. The binder has the advantages of wide raw material sources, no toxicity or smell and good mechanical property and is applicable to mechanized core manufacture of the cold core box and manual core manufacture. The modified sodium silicate binder comprises the following chemical compositions in percentage by mass: 20 to 30 percent of SiO, 10 to 20 percent of Na2O, 0.5 to 19 percent of K2O, 1.0 to 20 percent of modifier and the balance of water, wherein the modifier can be aluminium hydroxide and / or zinc hydroxide, or one or more of amylin, sugar, molasses, polyacrylamide, sodium polyacrylate, sodium tripolyphosphate, cellulose, humic acid, sodium humate, sorbierite, xylitol and sodium silicate are added.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Thin-walled circular type investment casting shell and preparation method thereof

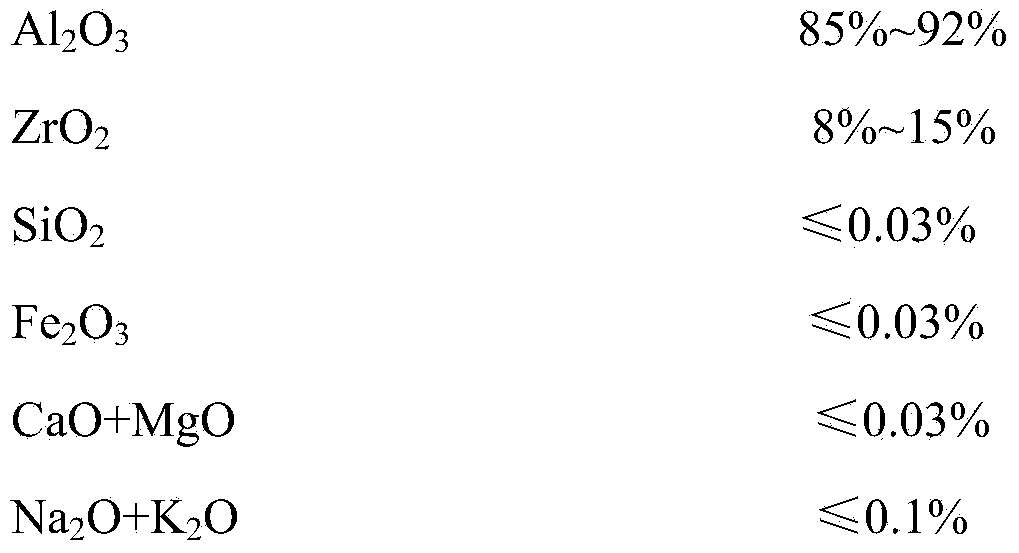

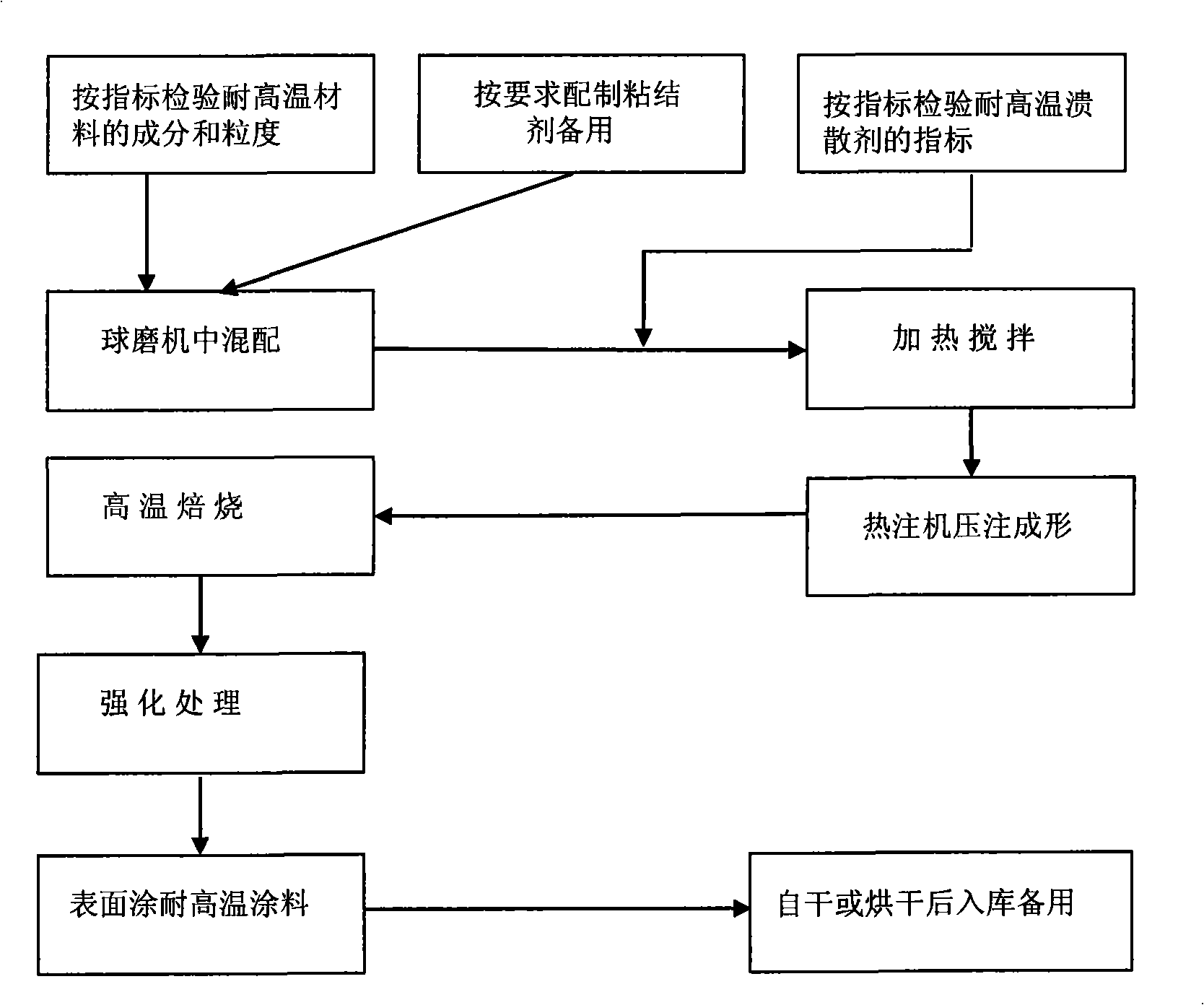

ActiveCN104368757AImprove high temperature performanceGood collapsibilityFoundry mouldsFoundry coresWaxSurface layer

The invention relates to a thin-walled circular type investment casting shell and a preparation method thereof, aiming at solving the defects that for the existing high-temperature alloy large thin-walled complicated circular type casting shell production technology, the casting pouring steel leaks, the surface quality is bad, the casting is difficult to clean, the size precision is low and the like, and belonging to the technical field of an aeroengine. A shell is made of new surface layer refractory powder, a back layer refractory powder and a sand lining material, and the invention provides a formula for all layers of paints of the shell; in addition, the invention further provides a manufacturing method of the thin-walled circular type investment casting shell, and the manufacturing method comprises the following steps: performing oil removal treatment on the surface of a wax mold module, carrying out paint preparation, sand lining and drying, shell dewaxing and shell roasting procedures, and particularly, the reinforcement step is added during the sand lining process, so that the shell has excellent high-temperature performance and good collapse performance at low temperature, and can bear molten metal with the pouring temperature being higher than 1600 DEG C, and can be used for casting high-temperature alloy large thin-walled circular vacuum castings such as K4169, K438, K418 and K4648.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Molding sand and preparation method thereof

InactiveCN103521681AGood collapsibilityImprove adhesionFoundry mouldsFoundry coresSodium metasilicateSodium Bentonite

The invention discloses molding sand. The molding sand is characterized by being prepared from the following materials in parts by weight: 200-240 parts of quartz sand, 30-35 parts of sericite, 60-70 parts of kaolin, 30-40 parts of calcium carbonate, 10-15 parts of coke powder, 10-15 parts of clays, 2-4 parts of titanium dioxide, 4-5 parts of aluminum oxide powder, 20-30 parts of argil, 3-4 parts of asphalt, 10-15 parts of bentonite, 3-4 parts of ammonium dihydrogen phosphate, 4-5 parts of sodium metasilicate, 2-3 parts of sodium dodecyl benzene sulfonate and an appropriate amount of water. According to the invention, the quartz sand, the sericite and the kaolin are used and roasted to achieve abundant pores and good gas permeability, moreover, mobility is good, and grinding of added calcium carbonate, clay, titanium dioxide, asphalt, and the like is combined, so that the molding sand has excellent cohesiveness, plasticity and heat stability, and also has high collapsibility. The molding sand material disclosed by the invention is fine and uniform; a casting piece produced by the molding sand has a smooth surface and a few flaws.

Owner:HEFEI CITY TENVER PRECISION CASTING

Ceramic core for silica sol precision casting and manufacturing process thereof

InactiveCN101537473AShorten roasting timeLow firing temperatureFoundry mouldsMould handling/dressing devicesTemperature resistanceChoice making

The invention discloses a ceramic core for silica sol precision casting and a manufacturing process thereof. Main body components of the ceramic core comprise refined quartz powder and a proper amount of collapsing agent, and the surface of the ceramic core is coated with high-temperature resistant paint with a thickness of 0.1 to 0.2 millimeter; and at the same reasonable manufacturing processes such as mixing, core making and roasting are adopted. In the ceramic core for casting, the unique material mixing and manufacturing processes are adopted, and the reasonable use of the refined quartz powder and the collapsing agent improves the collapsibility of the ceramic core after casting considerably, the high-quality high-temperature resistant material in ingredients enables the core to resist the erosion of high-temperature molten metals, and the high-temperature resistant paint on the surface of the ceramic core not only improves the high temperature resistance during casting, but also increases the cooling speed of the molten metal.

Owner:上海市机械制造工艺研究所有限公司

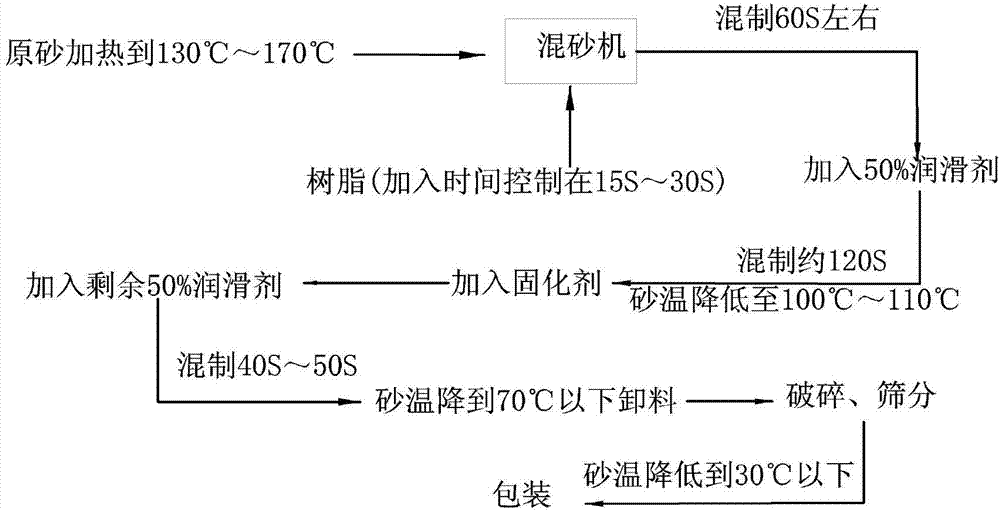

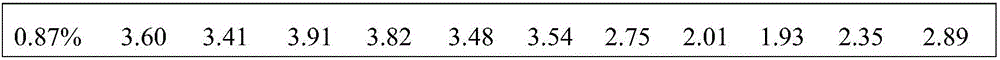

Easy-to-fill precoated sand and preparation process thereof

ActiveCN103658506AHigh molding strengthHigh temperature strengthFoundry mouldsMould handling/dressing devicesUltimate tensile strengthHot Temperature

The invention discloses easy-to-fill precoated sand and a preparation method thereof. Raw materials comprise roughing sand, phenolic resin, curing agents, lubricating agents and additives. The preparation method comprises the following steps that the roughing sand is heated to 130 to 170 DEG C, then, the phenolic rein, a half quantity of the lubricating agents, the curing agents and the rest half quantity of lubricating agents are sequentially added, finally, the discharging is carried out, and then, crushing, sieving and package are carried out. Through the improvement on the raw material ingredients and the preparation process, the forming intensity of the precoated sand is high, the high-temperature intensity is high, the deformation quantity is small, the flowability is good, complicated sand cores can be produced, the surface smoothness of the molding sand is good, the collapsibility performance is excellent, castings can be easily subjected to the vibration sand falling treatment, the precoated sand gas producing quantity is reduced, and the high-temperature performance and other casting performance of the precoated sand are improved.

Owner:ANSHUN UNIV

Caking agent

ActiveCN101444823AHomogeneous miscibilityEasy to useFoundry mouldsFoundry coresSolubilityFoaming agent

The invention relates to a caking agent, which comprises the key components according to the parts by weight: 50-90 parts of water glass, 3-15 parts of water solution of strong hydrophilicity organic polymer materials, 0-5 parts of water-solubility inorganic modifier, and 0.1-5 parts of surface active agent; wherein, the modulus M of the water glass is 1.9-3.5, and the density is 1.1-1.6g / cm<3>; the number average molecular weight of high molecular is 0.5-22 million; the weight percentage composition of high molecular in the water solution is 5-55wt%. Sand mold prepared by using the caking agent is characterized by hot air hardening, wet hygrometric state cleaning, and caking agent reusage, and has the advantages of good collapsibility and can realize complete recovery and reuse of old sand.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Molding sand capable of quick air permeation and heat dissipation and preparation method thereof

InactiveCN103586399AImprove smoothnessImprove adhesionFoundry mouldsFoundry coresPorositySodium Bentonite

The invention relates to a molding sand capable of quick air permeation and heat dissipation, which is prepared from the following raw materials in parts by weight: 100-120 parts of return sand, 140-150 parts of quartz sand, 30-40 parts of dry coal ash, 50-60 parts of vitrified microbead, 14-20 parts of hydroxyl-aluminum pillared bentonite, 1-2 parts of sodium carboxymethyl cellulose, 20-25 parts of starch, 2-3 parts of raw tung oil, 1-2 parts of lime powder, 4-5 parts of calcium fluoride, 4-5 parts of aluminum nitride, 40-45 parts of haydite, 4-5 parts of cement and a right amount of water. The return sand, quartz sand and the like are calcined, pulverized and subjected to high-temperature calcination, and the sodium carboxymethyl cellulose and other assistants are dispersed and ground, so that the molding sand has excellent smoothness, binding property, toughness and plasticity; the vitrified microbeads are utilized to greatly enhance the air permeability and reduce the subsurface porosity; the starch is utilized to enhance the collapsibility; and the aluminum nitride is utilized to increase the heat conductivity and enhance the production efficiency.

Owner:CHANGLI FORGING

Preparation method and usage method for foundry silicate binder

The invention provides a preparation method for a foundry silicate binder. Sodium silicate with modulus of 1.9-3.0 is subjected to spraying and drying to obtain foundry silicate binder. According to the preparation method, the sodium silicate is firstly modified and the modified sodium silicate is subjected to spraying and drying to obtain foundry silicate binder. According to the preparation method, the sodium silicate or the modified sodium silicate is subjected to spraying and drying, moisture in the atomized sodium silicate can be carried away by high-temperature air in the spraying and drying processes, the obtained foundry silicate binder is hollow and fluffy solid powder, and is only needed to be dissolved in water to prepare a solution with needed concentration before use due to good quick dissolution property. With the method, the problem of the existing sodium silicate binder can be well avoided, the sodium silicate can be always in a best usage state, the binding property is good, the addition quantity is less, the collapsibility is good, the foundry silicate binder is beneficial to recovery of used sand, and the pollution to the environment can be reduced.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Method of preparing water-soluble mold core

InactiveCN101229574ANo pollution in the processGood water solubilityFoundry moulding apparatusSolubilityResin matrix

The invention pertains to a casting moulding technical field, which relates to improvement of a technical mold core for casting and molding resin matrix composites. The steps in the invention are the following: preparing aqueous solution of a bonder-adding aggregate-adding plaster powder-defoaming-casting moulding- drying- post-processing. Solidification has advantages of room temperature curing and good temperature endurance, good water solubility at room temperature and no environmental pollution.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Coated sand and preparation method thereof

InactiveCN104325065AEasy to prepareGuaranteed liquidityFoundry mouldsFoundry coresParaffin waxPhosphate

The present invention discloses coated sand and a preparation method thereof. The coated sand is prepared from the following raw materials: raw sand, a binder, a curing agent, an additive and a lubricant, wherein the raw sand is prepared by mixing quartz sand and pearl sand according to a weight ratio of 3:1, the binder is a mixture of a furan resin, isocyanate and paraffin wax, the curing agent is a mixture of fatty amine, acetic acid and sodium silicate, the additive is a mixture of expanded graphite, silicon carbide and sodium methyl silanolate, and the lubricant is a mixture of silicone oil, phosphate ester and calcium stearate. The preparation method comprises: (1) preparing a binder; (2) preparing a curing agent; (3) preparing an additive; and (5) mixing, wherein phosphate ester is added to raw sand, the additive is added, complete mixing is performed, silicone oil is added after mixing, the binder is added to mix, calcium stearate and the curing agent are sequentially added after uniformly mixing, and mixing is performed to obtain the coated sand.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

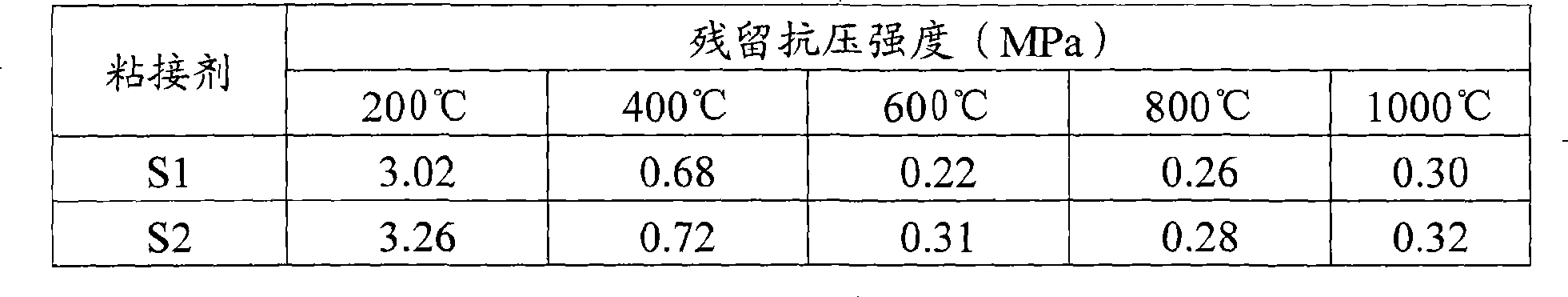

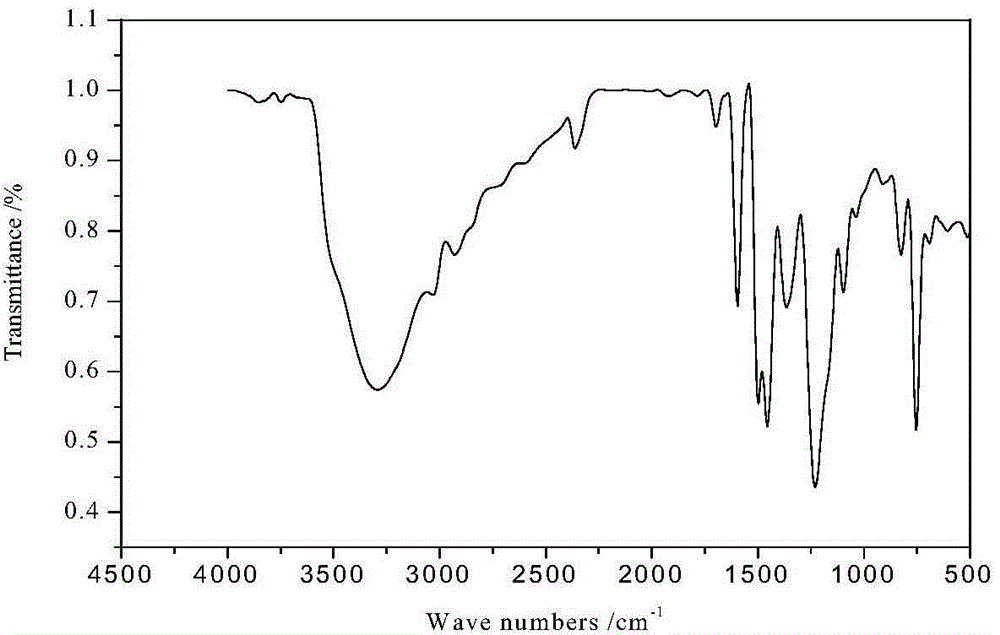

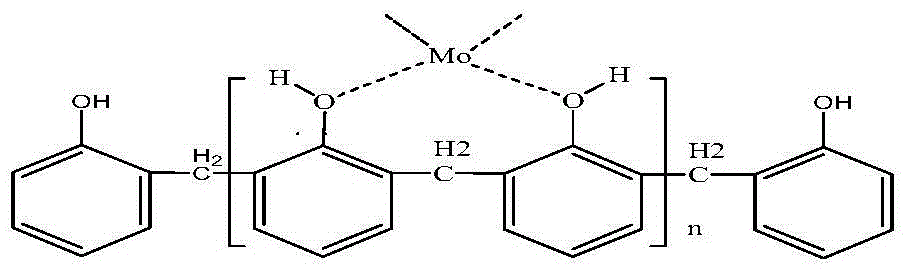

Fast-curing type high-temperature resistant binder and pre-coated sand thereof

ActiveCN104588569AFast aggregationLow in free phenolsFoundry mouldsFoundry coresRoom temperatureHigh intensity

The invention discloses a fast-curing type high-temperature resistant binder. The binder is molybdenum modified high o-phenolic resin, and the binder has a structure shown in the specification). The invention further discloses a pre-coated sand in which the molybdenum modified high o-phenolic resin is used as binder; with specially selected dehydrating agent, curing agent and lubricating agent, with optimized dosage, without adding functional auxiliaries like fire-resistant particles and accelerant, the curing speed of the pre-coated sand can be improved significantly, furthermore, the high-strength high-temperature bending strength of the fast-curing type high-temperature resistant pre-coated sand is equal to or greater than 6.0MPa, the normal-temperature tensile strength is 3.0MPa, the heat bending strength is equal to or greater than 3.0Mpa, the low tolerance is equal to or less than 18mL / g, and the radiating property is improved significantly. When the preparation method disclosed by the invention is utilized, the effect is more significant, i.e., the novel pre-coated sand with completely improved combination property is obtained by the improvement of the pre-coated sand raw materials and the method.

Owner:通辽市仁创铸造材料有限公司

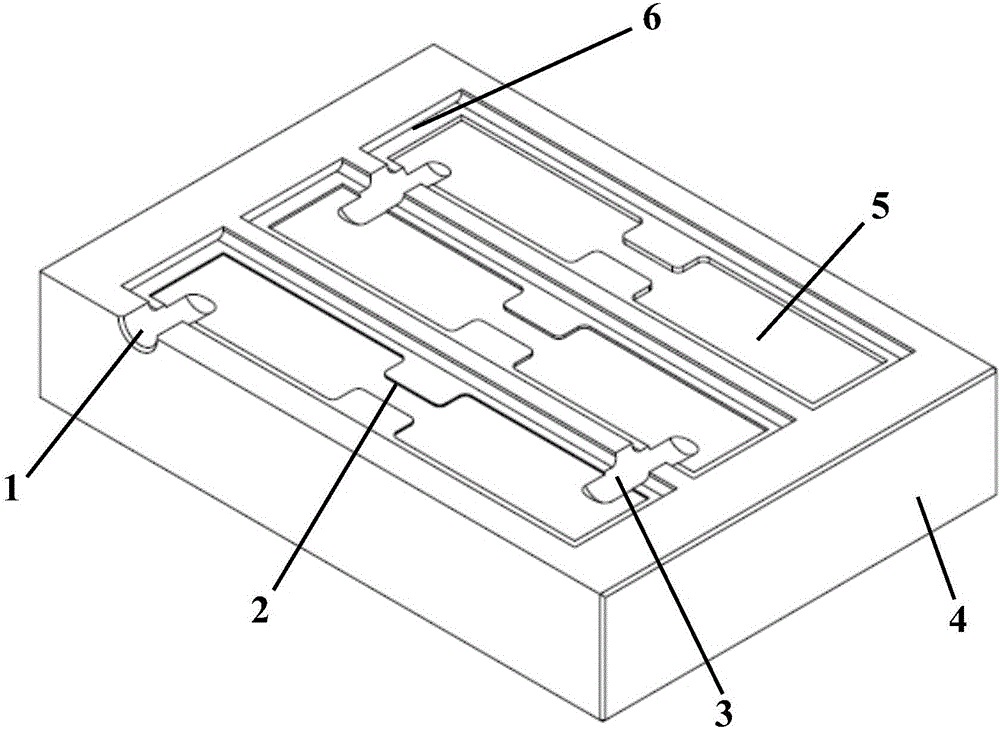

Casting mold and forming method for box body of gearbox

ActiveCN105382206AClear outlineFilled tightlyFoundry mouldsFoundry coresCasting moldMaterials science

The invention provides a casting mold and forming method for a box body of a gearbox and belongs to the technical field of liquid formation of metal. The forming method comprises the following steps that precoated sand is used for core shooting, so that precoated sand blocks are manufactured, then an outer precoated sand mold layer is formed by splicing the precoated sand blocks, and the outer precoated sand mold layer and a sand core are used for forming a casting cavity of the box body of the gearbox; and finally the box body of the gearbox is manufactured through the casting mold in a low-pressure casting way. According to the specific structure of the casting mold, the sand core is located in the center of the casting mold; the casting cavity is formed in the outer layer of the sand core and mainly formed by the sand core and the outer precoated sand mold layer; an outer resin sand mold layer is arranged on the outer layer of the outer precoated sand mold layer, and the outer precoated sand mold layer and a sand box are connected through the outer resin sand mold layer, so that the casting mold is formed. According to the casting mold and forming method for the box body of the gearbox, the cavity which is formed by the precoated sand and used for large complicated castings is used for low-pressure casting for the first time, the precoated sand blocks are subjected to core shooting under pressure, high-temperature sintering formation is conducted, filling is compact, and the situations that sand filling is incompact and sand adhesion defects are caused due to human factors during resin sand molding are avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Preparation of coated sand by use of phosphate inorganic binder and molding method thereof

ActiveCN104289661AGood collapsibilityRealize recyclingFoundry mouldsFoundry coresGranularityWater vapor

The invention discloses preparation of coated sand by the use of a phosphate inorganic binder and a molding method thereof. Preparation of the coated sand comprises the following steps: uniformly mixing the phosphate inorganic binder and quartz sand; heating and drying to a semi-dry state; adding calcium stearate with the granularity being 600 meshes and uniformly mixing; and drying and cooling so as to obtain the phosphate inorganic binder coated sand which is in a dry arenaceous state. During molding of the coated sand, the coated sand undergoes hydration only by high temperature steam, the binder is dissolved, sand grains are connected, and finally hot-air is blown for drying and curing molding. The hardening speed is fast. During preparation and curing molding of the coated sand, smell or any harmful gas or substance is not generated. The sand mould has low gas-forming property, is harmless to the health of workers, causes no pollution to the environment and is energy-saving and environmentally friendly. The coated sand provided by the invention has characteristics of high strength, high temperature resistance, low gas evolution, no curing agent required for molding and good storage stability.

Owner:HUBEI UNIV OF TECH +1

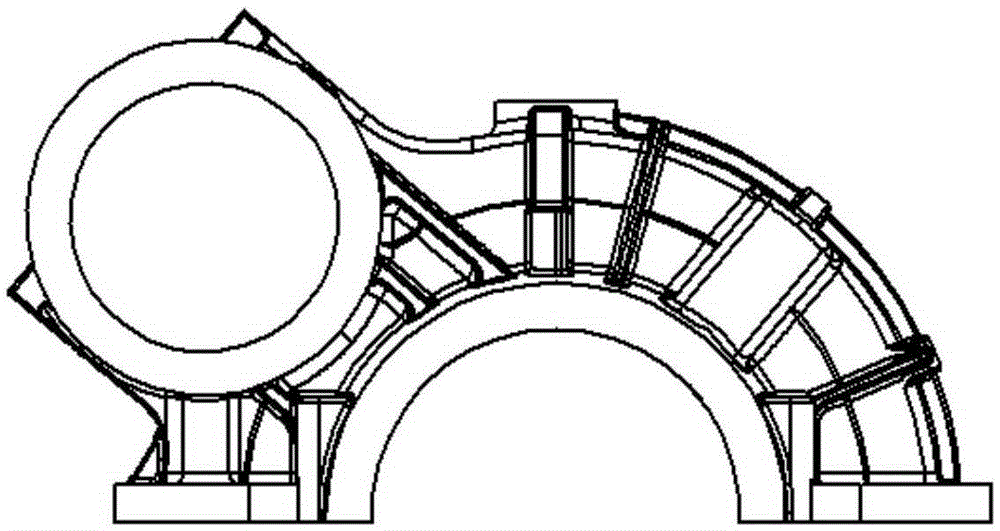

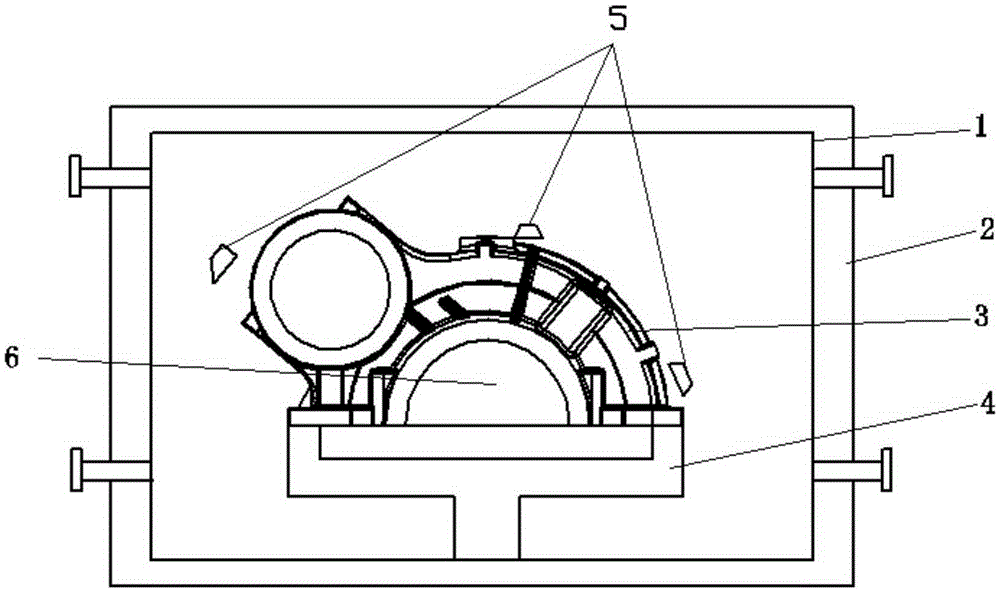

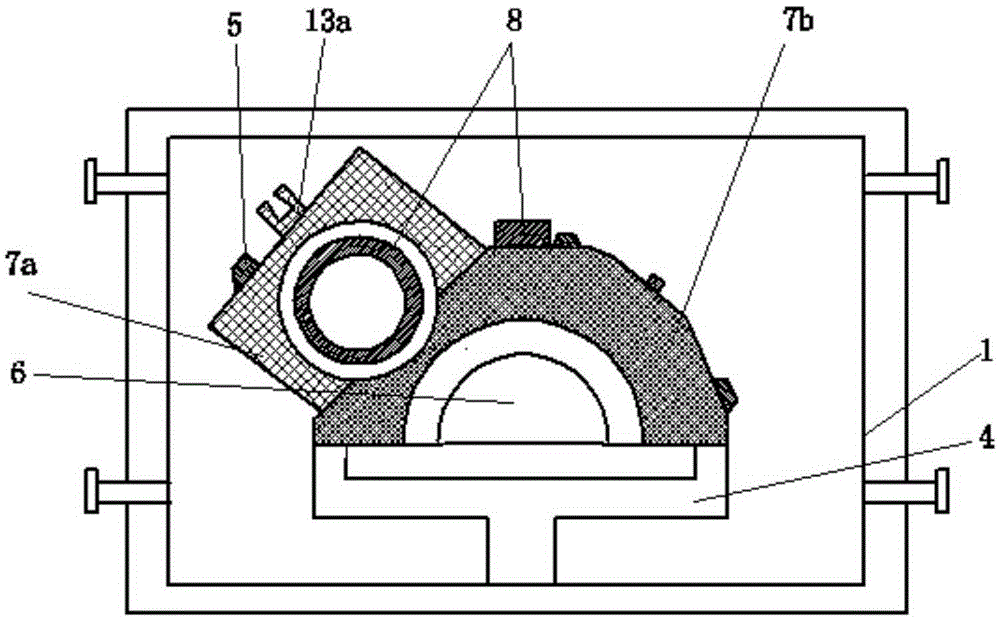

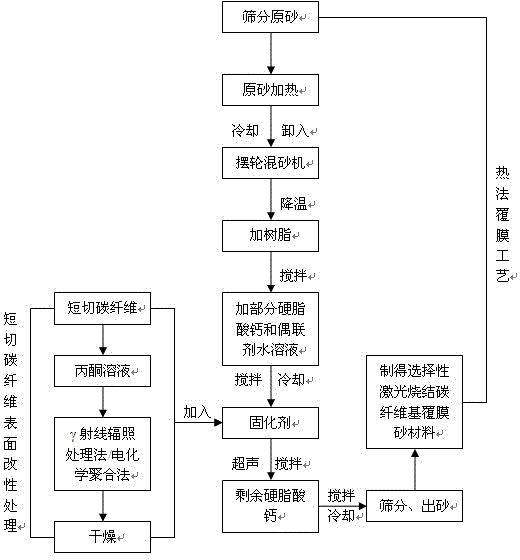

Carbon fiber-based precoated sand material for selective laser sintering and preparation method thereof

InactiveCN104308072AImprove thermal stabilityEnhancement effect is goodFoundry mouldsFoundry coresFiberSelective laser sintering

The invention discloses a carbon fiber-based precoated sand material for selective laser sintering and a preparation method thereof. The carbon fiber-based precoated sand material comprises chopped carbon fibers, crude sand, an organic binder, a curing agent, a lubricant, a coupling agent and a dispersant. The preparation method comprises the following steps of carrying out surface modification treatment on the chopped carbon fibers, heating the crude sand, adding resin, adding a part of calcium stearate and a prepared coupling agent aqueous solution, adding a chopped fiber-containing urotropine curing agent, adding the rest of the calcium stearate, carrying out cooling and carrying out screening and sand discharge to obtain the product. The carbon fiber-based precoated sand material has the advantages that 1, the carbon fibers have thermal conduction effects, limit integral shrinkage of a sintered part to a certain degree and reduce warp phenomenon in molding, and 2, through laser sintering, the precoated sand substantially improves resin precoated sand thermostability, promotes curing reaction of phenolic resin at locals in the sintered layer and between the sintered layers and obviously improves laser sintering forming part blank strength.

Owner:NANCHANG HANGKONG UNIVERSITY

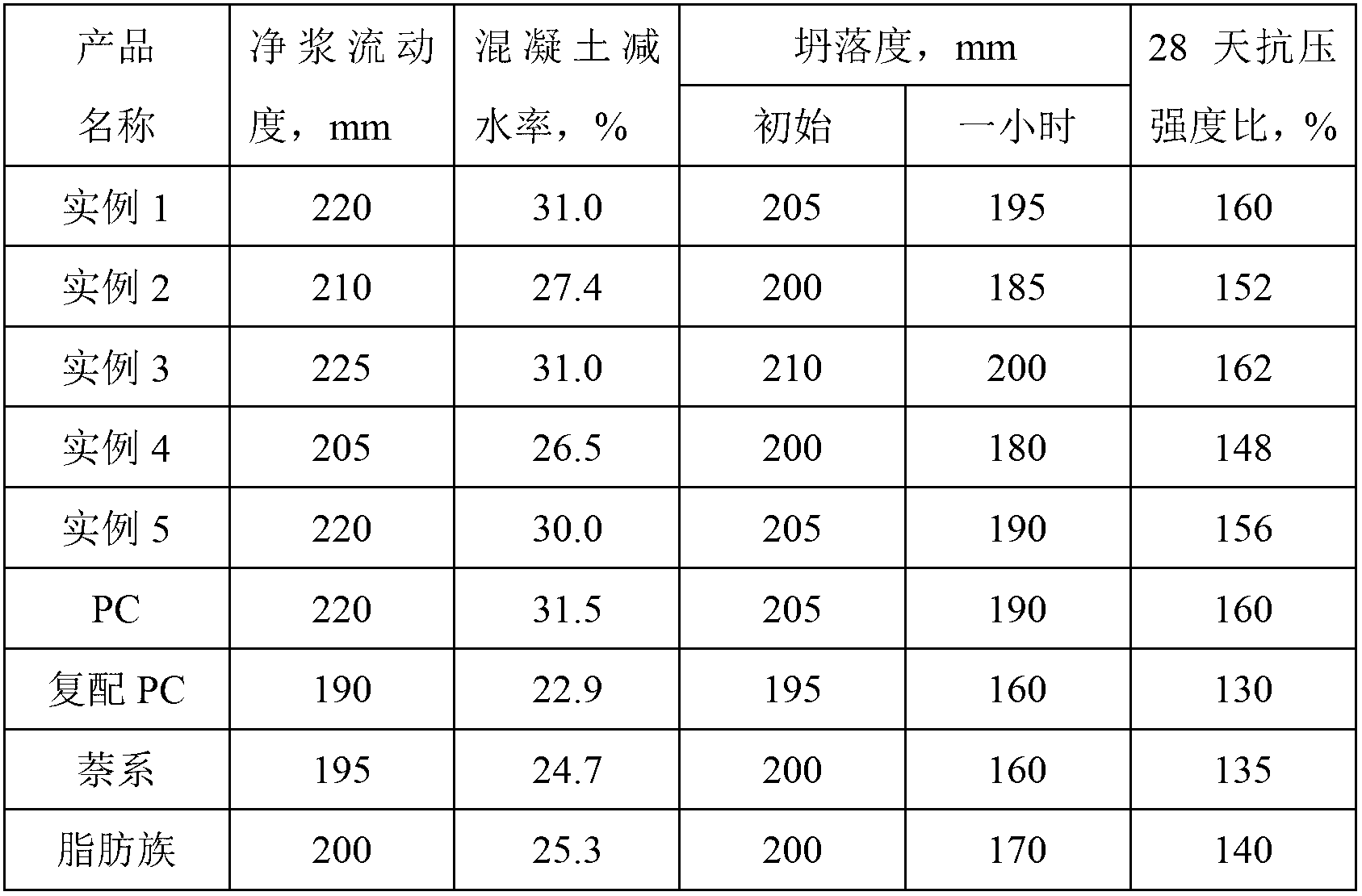

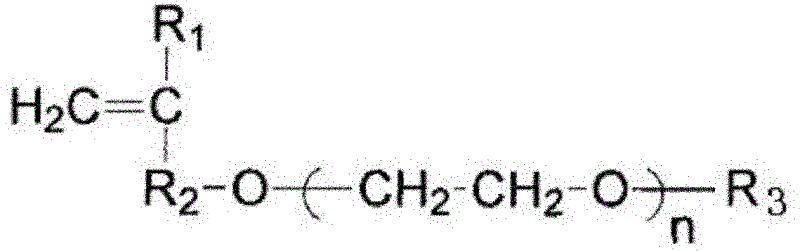

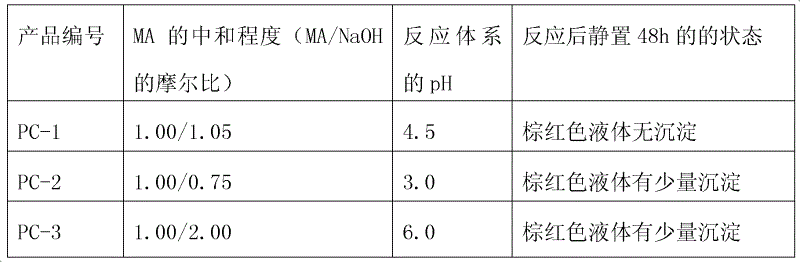

Allyl polyglycol ether polycarboxylic acid water reducer and synthetic method thereof

InactiveCN102617063AHigh polymerization activitySolve the problem of low contentMaleopimaric acidPolymer science

The invention discloses a synthetic method of an allyl polyglycol ether polycarboxylic acid water reducer. According to the method, allyl ether polyethylene glycol macromers, maleic anhydride (MA), acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and the like are used as main raw materials, a water-soluble hydroperoxide is used as an initiator, a transition metal salt is used as a catalyst, and polymerization is initiated in a specific pH range (2.5-6.0). The method makes the content of maleic acid in a polymer be greatly improved, the water reduction effect be good, and the product cost be greatly reduced and the product applicability be extensive especially replacing parts of acrylic acid by maleic acid, so the method is convenient for industrialized production and popularization.

Owner:CHANGZHOU INST OF CHEM

Easily-scattered precoated sand and preparation method thereof

ActiveCN104226888AEasy to prepareReasonable formulaFoundry mouldsFoundry coresFatty amineRoom temperature

The invention discloses easily-scattered precoated sand and a preparation method thereof. The easily-scattered precoated sand is prepared from the following raw materials in parts by weight: crude sand, a silane coupling agent, a bonding agent, a curing agent, an additive and a lubricating agent, wherein the crude sand is screened by a 300-mesh sieve, and consists of 80% of fresh sand and 20% of used sand. The preparation method comprises the following steps: (1) preparing the bonding agent, namely, putting epoxy resin and modified starch into a stirrer, stirring, sequentially feeding clay and silicone oil, and stirring for 20-40 minutes to obtain the bonding agent; (2) preparing the curing agent, namely, feeding polyethylene polyamine, polyurethane and fatty amine into a ball mill in parts by weight, and carrying out dry ball-milling for 60-80 minutes to obtain the curing agent; (3) mixing, namely, heating the crude sand up to 35-40 DEG C, then putting the heated crude sand into a sand mixer, feeding the bonding agent, the silane coupling agent and the lubricating agent, and fully mixing; then, feeding the additive under at room temperature; and finally, feeding the curing agent and fully mixing to obtain the precoated sand.

Owner:广东越翼包装材料科技有限公司

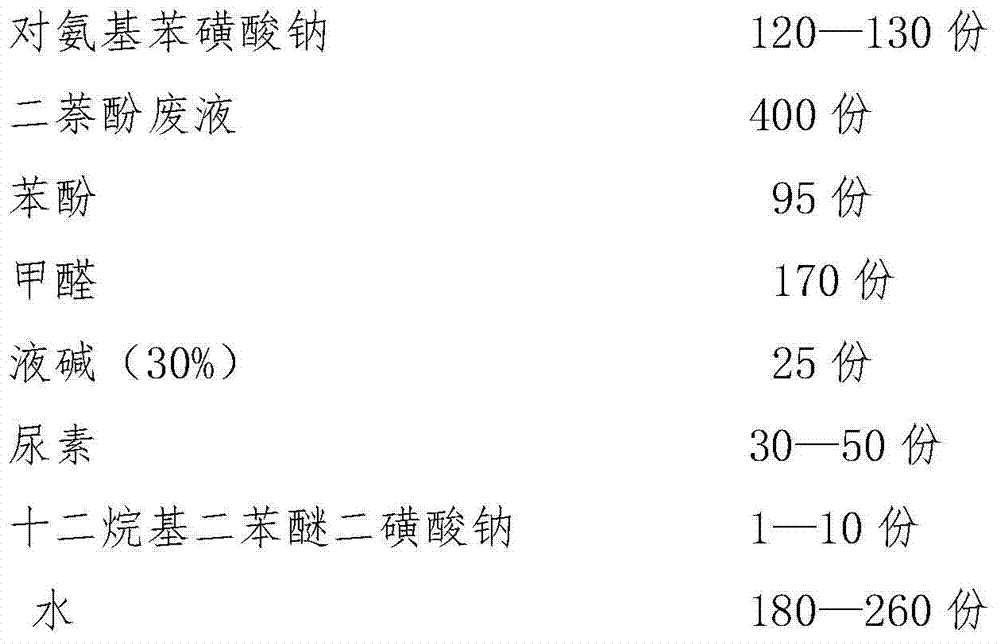

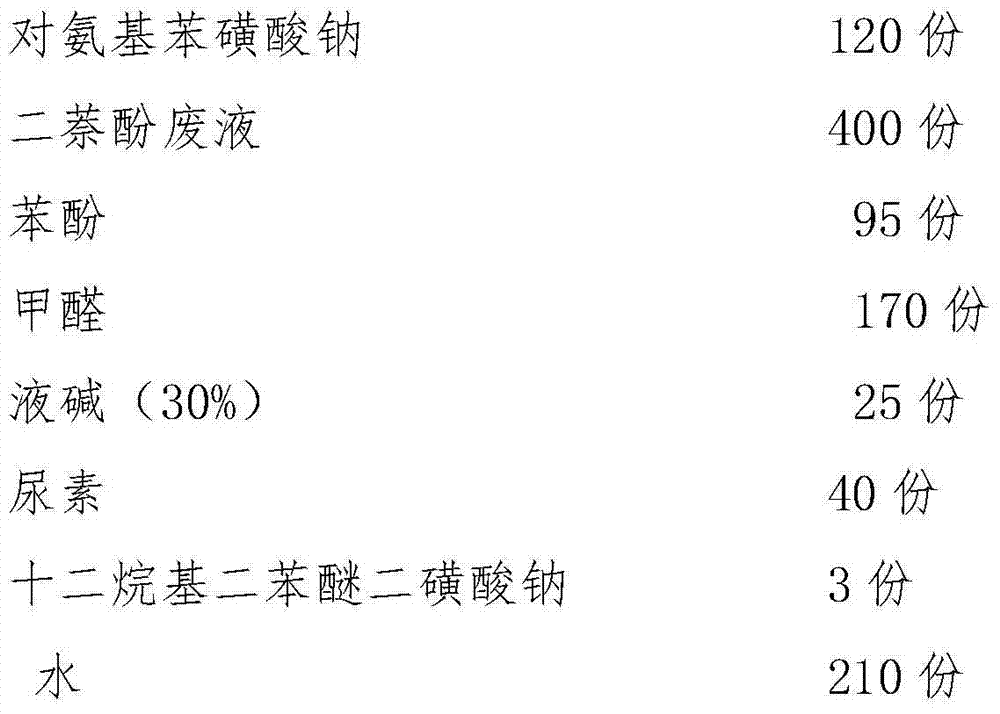

Modified sulfamate efficient water reducer and preparation method thereof

The invention provides a modified sulfamate efficient water reducer and a preparation method thereof, particularly relates to a dinaphthol waste modified sulfamate efficient water reducer and relates to the technical field of waste treatment. The reducer comprises raw materials of, by weight, 120 parts to 130 parts of sodium sulfanilate, 400 parts of dinaphthol waste, 95 parts of phenol, 170 parts of formaldehyde, 25 parts of liquid caustic soda (30%), 30 parts to 50 parts of urea, 1 part to 10 parts of dodecyl diphenyl ether sodium disulfonate and 180 parts to 260 parts of water. By means of the water reducer and the preparation method thereof, dinaphthol waste recycling is achieved, waste water are not needed to be subjected to concentration or any other treatment of physical chemical treatment and the like, energy consumption is saved, and pollution and damage of the waste to the environment and humans are prevented.

Owner:萧县沃德化工科技有限公司

Manufacturing method of composite shell of large diffuser precision casting

ActiveCN104923729AImprove pass rateGood collapsibilityFoundry mouldsFoundry coresInsulation layerTransition layer

The invention belongs to a precision casting technology, and relates to a manufacturing method of a composite shell of a large diffuser precision casting. The manufacturing method of the composite shell of the large diffuser precision casting is characterized by comprising the following steps of smearing investment precoat; smearing a transition layer coating; smearing a heat-insulation layer coating; smearing a reinforcement layer coating; and smearing a seal layer coating. By the manufacturing method of the composite shell of the large diffuser precision casting, collapsibility of the shell is improved, and the difficulty of unshelling is reduced; and the heat-insulation performance of the shell is improved, shortcomings of undercasting and loosening of the casting are avoided, and the yield of the casting is improved.

Owner:AECC AVIATION POWER CO LTD

Preparation method of precision-investment casting single-crystal high-temperature alloy thin-wall sample

ActiveCN106001513AReduce the incidence of recrystallizationAvoid deformationPolycrystalline material growthFoundry mouldsInjection pressureTime range

The invention relates to a preparation method of a precision-investment casting single-crystal high-temperature alloy thin-wall sample. In the wax mould preparation process, a plate-shaped ceramic core is put into a mould, and the ceramic core is used as a support of wax; the mould is closed, the wax is injected into the mould, the injection pressure of the wax ranges from 5 bar to 8 bar, the temperature of the wax ranges from 60 DEG C to 80 DEG C, and the pressure maintaining time ranges from 60 s to 120 s; and wax moulds of a certain thickness are formed on the two sides of the plate-shaped ceramic core, and the wax moulds are closely attached to the surface of the ceramic core. According to the thickness of the designed thin-wall sample, the wax moulds on the two sides of the ceramic core are thinned, the rotating speed of a spindle is controlled to range from 500 r / min to 6,000 r / min, the feed speed is controlled to range from 30 mm / min to 450 mm / min, and the axial cutting depth is controlled to range from 0.03 mm to 0.5 mm. The wax moulds of the thin-wall sample are prepared, after a mould set is formed by the wax moulds of the thin-wall sample, a shell is prepared through shell coating, directional solidification pouring is completed in a vacuum induction single crystal furnace, and therefore the single-crystal high-temperature alloy precision casting thin-wall sample is prepared. According to the preparation method, the problems of short run and undercasting of the wax moulds in the deformation and directional solidification process in the mould pick-up and finishing process can be completely avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Soluble salt core for extrusion casting and its making process

InactiveCN1739883AGood collapsibilityHigh dimensional accuracyFoundry mouldsFoundry coresHigh surfaceHigh pressure

The making process of soluble salt core for extrusion casting includes the following steps: mixing roasted marketable table salt in 70-85 wt%, high aluminum bauxite in 7-16 wt%, water glass in 6-10 wt% and water in 2-5 wt% successively and fully and letting stand for over 5 min; applying the mixture into metal mold with required complicated inner cavity shape and pressing in press for densifying, blowing CO2 gas and demolding; and stoving the soluble salt core at 150 deg.c or over for over 2 hr. The soluble salt core can bear the high pressure and high temperature of extrusion casting and can obtain casting with high size precision and high surface smoothness. After the casting is set in water, the soluble salt core will dissolve and disintegrate well. The soluble salt core has less making steps, low production cost, and less corrosion to equipment.

Owner:SOUTH CHINA UNIV OF TECH

Easily scattered precoated sand and preparation method thereof

InactiveCN103567360AGood collapsibilitySand cleaning is easyFoundry mouldsFoundry coresRiver sandUrea

The invention discloses easily scattered precoated sand and a preparation method thereof. The easily scattered precoated sand is prepared from the following raw materials in parts by weight: 60-80 parts of zircon sand, 15-20 parts of river sand, 10-15 parts of montmorillonoid, 2-4 parts of thermoplastic phenolic resin, 0.5-1 part of anilino-methyl-triethoxysilane, 4-6 parts of triethyl citrate, 2-3 parts of polyvinyl formal, 10-15 parts of urotropine, 3-4 parts of urea, 1.5-2.5 parts of potassium dichromate, 4-6 parts of manganese ore slag, 2-3 parts of salicylic acid, 3-5 parts of butadiene-acrylonitrile rubber powder, 4-8 parts of ethylene bis-stearamide and 3-6 parts of composite powder. The precoated sand has excellent scattering property, the sand is easily cleaned after a casting is cooled and is subjected to sand shakeout, an inner cavity is smooth, the labor intensity of cleaning is obviously reduced, and the precoated sand has the characteristics of high strength, high liquidity, high air release amount, high heat resistance, high air permeability and the like. Moreover, the defects of sand adhesion, air holes, cracks and the like in the casting can be overcome, the surface quality of the casting is improved, and the precoated sand is suitable for production of nonferrous metal castings such as aluminum alloys and copper alloys.

Owner:TONGLING JINGWEI FLUID SCI & TECH

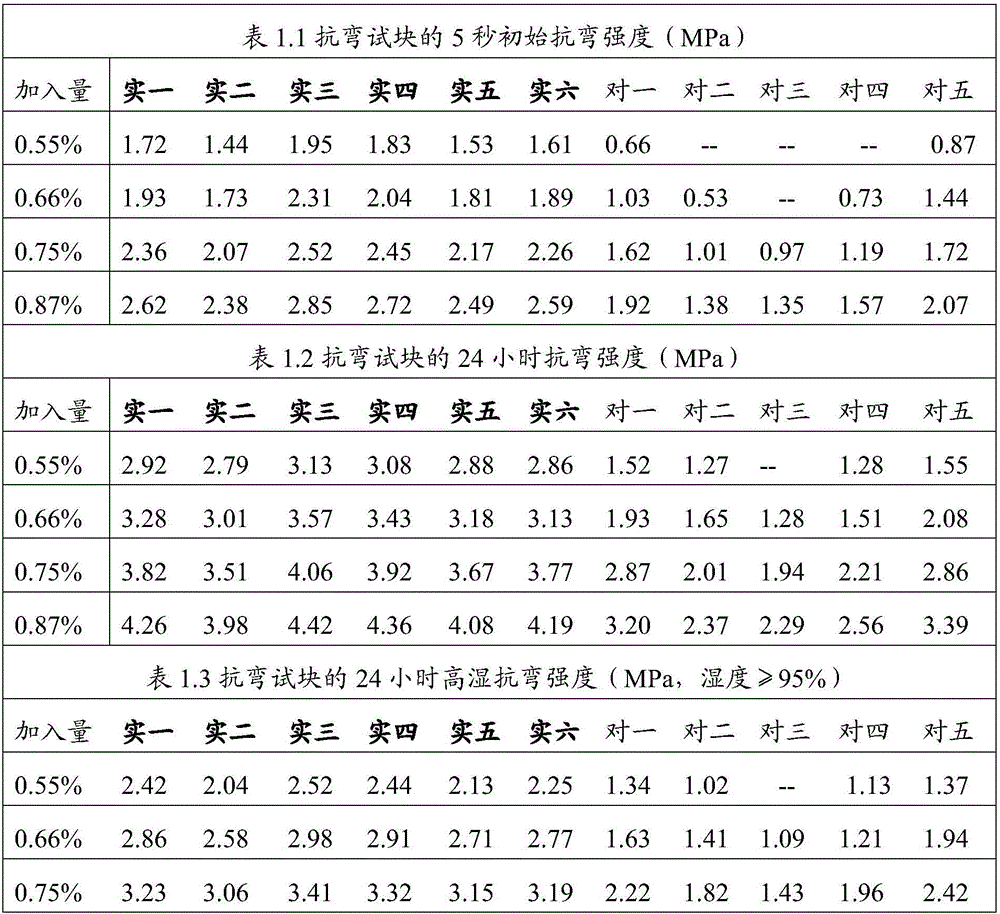

Cold core box binder and casting molding body

ActiveCN106040966AImprove room temperature performanceImprove room temperature strengthFoundry mouldsFoundry coresTarHydrocarbon solvents

The invention discloses a cold core box binder and a casting molding body and belongs to the technical field of binders. The cold core box binder comprises a first component. The first component is composed of, by weight, 40-80 parts of benzyl ether phenolic resin, 1-50 parts of high-boiling-point ester and / or hydrocarbon solvents and 0.1-10 parts of tackifying auxiliaries, wherein the content of hydroxymethyl of the benzyl ether phenolic resin is 32%-50%. According to the cold core box binder, the resin using amount is decreased to 0.55%-0.75% under the condition that the strength of a resin sand mold core is ensured; compared with the prior art, the resin using amount is greatly decreased, and the collapsibility of the resin sand mold core is greatly improved; and meanwhile, the residual quantity of tar on a metal mold is decreased, and the production efficiency is improved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Inorganic binder, preparation method and application thereof

InactiveCN103111581AExtend the usable timeExtended use timeFoundry mouldsFoundry coresO-Phosphoric AcidAluminium hydroxide

The invention discloses a casting inorganic binder suitable for curing by hot air, a preparation method and application thereof, wherein the binder contains 30-40 parts of 200-400-mesh aluminium hydroxide, 140-180 parts of 80-90% phosphoric acid, 6-12 parts of 200-400-mesh boric acid, 10-20 parts of 200-400-mesh magnesium carbonate, 5-10 parts of 200-400-mesh zinc oxide, and 150-280 parts of water. The binder disclosed by the invention is cured by hot air; dust pollution of adding a powder curing agent when the sand is mixed is avoided; core sand can be used for a long period of time; no substance with poison or pungent odor is discharged in the whole process; the poured cast oil sand is easily cleaned; and the workload of a worker is reduced.

Owner:HUBEI UNIV OF TECH

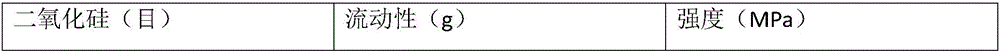

High-fluidity phosphate inorganic binder sand and preparation method thereof

The invention belongs to the field of casting and particularly relates to high-fluidity phosphate inorganic binder sand and a preparation method thereof. The high-fluidity phosphate inorganic binder sand comprises, by mass, 2500 parts of burnt sand, 100 parts of a phosphate inorganic binder, 8 parts of a metallic oxide curing agent and 5 parts of an addition agent. The addition agent comprises a solution prepared by one or more nonionic surface active agents such as alkyl glycoside, 1-61, 1-62, S-80 and MOA-9P, and silicon dioxide with the granularity at 400-1200 meshes and mixed with the solution; and the weight ratio of the nonionic surface active agents to the silicon dioxide is 1:5-1:3. According to the high-fluidity phosphate inorganic binder sand and the preparation method thereof, while the inherent advantages of cleanliness and environment protection, good collapsibility, high strength and the like of the phosphate binder sand are maintained, the fluidity of the phosphate binder sand is greatly improved, and requirements for novel green casting materials and a casting method in modern casting production are met.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Metal component casting process

ActiveCN102806310AExcellent recycling rateGood collapsibilityFoundry mouldsFoundry coresWaxPlaster mold casting

The invention discloses a metal component casting process, which comprises the following steps: (1) manufacturing a mold sample, (2) manufacturing a silica gel outer mold, (3) manufacturing a wax mold, (4) molding, and (5) carrying out casting, shaking-out and finishing, wherein the molding process adopts combination of a lost-wax precision casting process, a plaster mold casting process and a self-hardening resin sand mold casting process to carry out modification grafting on a casting mold system so as to successfully develop a metal component casting process. Results of process performance tests, technical analysis and production applications of the new process show that the new casting method has the following characteristics that a casting surface is fine, casting quality is good, a specification size is large, flatness is good, cost is low, a production cycle is short, molding is rapid, collapsibility is good, the material can be subjected to dry regeneration and recovery utilization, pollution is less, energy sources are saved, and the bottleneck of metal component casting is solved. In addition, the process of the present invention is applicable for molding of various alloy castings.

Owner:上海浦宇铜艺装饰工程股份有限公司

Environment-friendly casting molding sand and preparation method thereof

ActiveCN104057013APrevent shrinkageImprove yieldFoundry mouldsFoundry coresDispersityEnvironmental resistance

The invention discloses environment-friendly casting molding sand which is made of the following raw materials in parts by weight: 200-230 parts of quartz sand, 50-60 parts of sodium bentonite, 20-30 parts of red soil, 30-40 parts of talcum powder, 20-30 parts of zinc oxide, 20-24 parts of Chinese medicine residue, 40-45 parts of straw powder, 2-3 parts of carboxymethyl cellulose, 5-8 parts of brown sugar, 1-2 parts of fatty alcohol polyoxyethylene ether, 40-50 parts of brick trash powder, 2-3 parts of boric acid, 40-45 parts of perlite, 2-3 parts of polyving alcohol, 1-2 parts of tung oil, 30-35 parts of bamboo charcoal and a proper amount of water. According to the invention, the brick trash powder is adopted, the Chinese medicine residue, the straw powder and the like are sintered at high temperate, the sand is loosened, breathable and good in collapsibility and is environmental-friendly and energy-saving, and with the combination of talcum powder, the dispersity and the plasticity are improved; due to adoption of brown sugar, tung oil and carboxymethyl cellulose as binding agents, the sand is not only good in binding effect, but also not affected in collapsibility at high temperature; the pass percent of cast pieces is improved, and the casting cost is lowered.

Owner:中合基铭实业江苏有限公司

Method for improving deformability of oxide ceramic shells precisely cast by titanium-aluminum alloy

ActiveCN105290313AGood collapsibilityReduce intensityFoundry mouldsFoundry coresOxide ceramicCombustion

The invention discloses a method for improving the deformability of oxide ceramic shells precisely cast by titanium-aluminum alloy. The method comprises the steps that polypropylene fiber and graphite powder are added in the preparing process of precisely casting the shells, and combustion is achieved through high-temperature roasting of the polypropylene fiber and the graphite powder so as to form pores in the shells and improve the deformability. Particularly, in the steps of slurry preparation and slurry coating on the shells in the preparation process of precisely casting the shells, the polypropylene fiber is wound on the surfaces of the oxide shells, and back-layer slurry containing graphite powder is adopted for coating. By the adoption of polypropylene fiber winding during shell preparation and preparation of the back-layer slurry containing the graphite powder in the method, the deformability of the shells is effectively improved, accordingly the cold and hot cracking tendency occurred in the solidification process of castings is effectively reduced, and the qualified rate of the castings is improved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com