Ceramic core for silica sol precision casting and manufacturing process thereof

A ceramic core and precision casting technology, which is applied in the manufacture of tools, casting molding equipment, casting molds, etc., can solve problems such as complex stainless steel parts in the inner cavity, achieve consistent smoothness, save energy, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

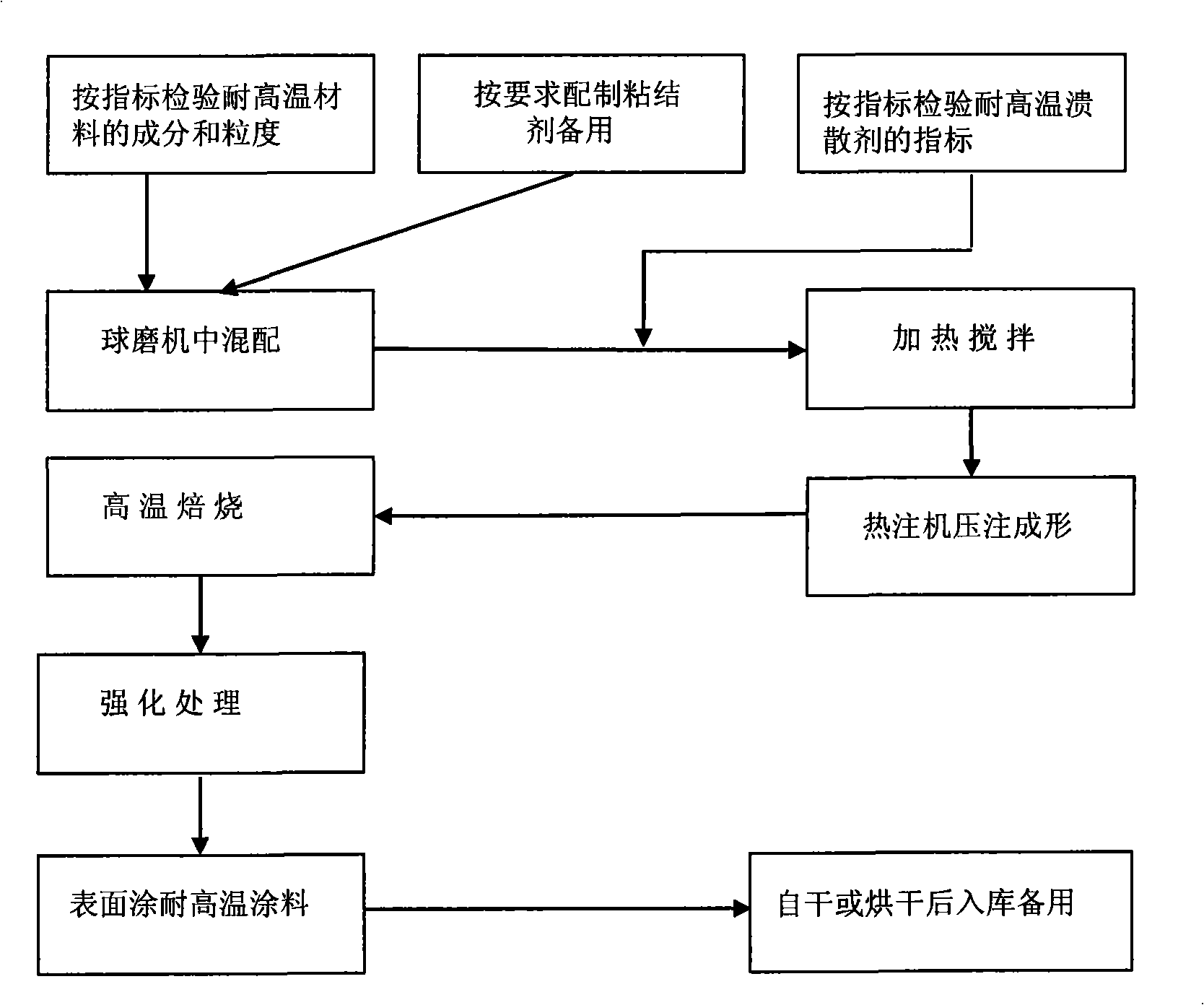

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples.

[0029] a. Inspect the composition and particle size of refined quartz powder and disintegrating agent according to the following indicators:

[0030] SiO of refined quartz powder 2 The content is greater than 96%, and its particle size is 270-325 mesh; the particle size of the disintegrating agent is 270-325 mesh;

[0031] b. According to the following requirements, configure the binder for standby use (the following table is the weight percentage of the components of the binder):

[0032] Example 1

Example 2

Example 3

58# paraffin

60

70

90

Primary Stearic Acid

40

30

10

[0033] c. Add 2-4 parts by weight of disintegrating agent to 100 parts by weight of refined quartz powder, and fully mix in a ball mill for 2 hours (the following table shows the amount of disintegrating agent by weight);

[0034] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com