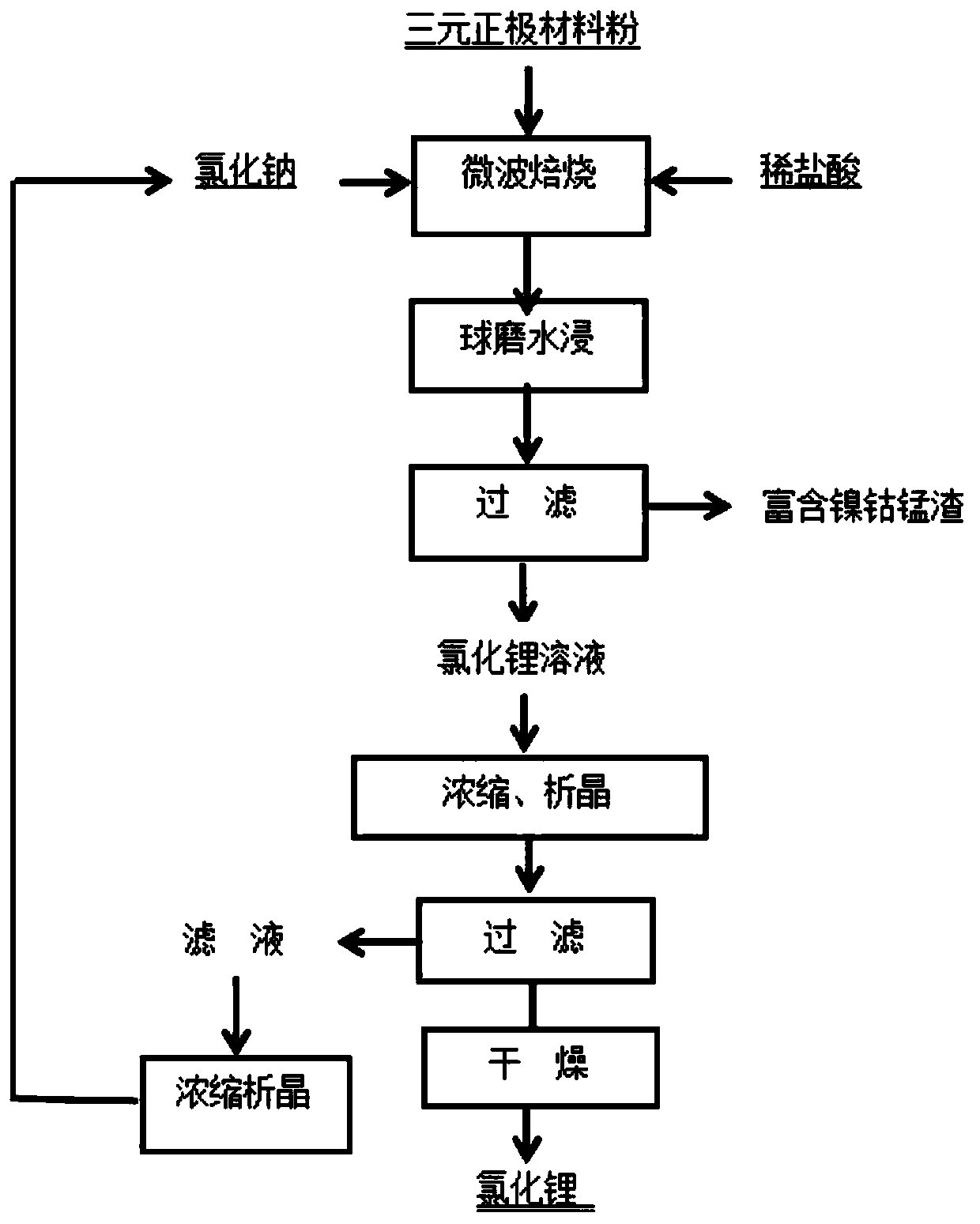

Method for recovering lithium in ternary positive electrode material by microwave roasting

A positive electrode material and microwave roasting technology, which is applied in the field of lithium battery material recycling, can solve the problems of high cost and inconvenient operation, and achieve the effects of increasing the leaching rate, speeding up the water immersion process, and shortening the roasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] After mixing the waste and old ternary positive electrode material with dilute hydrochloric acid, then uniformly mix it with sodium chloride to obtain a mixture; wherein the mass concentration of dilute hydrochloric acid is 18%, and the consumption is 30% of the quality of the waste and old ternary positive electrode material, and the consumption of sodium chloride is 10% of the mass of waste ternary cathode materials;

[0036] Put the mixture into a microwave sintering furnace for roasting to obtain a roasted product; the microwave power is 2.0kW, the roasting temperature is 400°C, and the roasting time is 40 minutes;

[0037]Carry out ball mill water immersion to the roasted product, the solid-liquid ratio of ball mill water immersion is 1:2, the ball mill speed is 200 rpm, the ball mill time is 60min, the lithium in the mixture enters the water to obtain lithium chloride solution, obtains lithium chloride solution through filtration The recovery rate of lithium in th...

Embodiment 2

[0040] After mixing the waste and old ternary positive electrode material with dilute hydrochloric acid, mix it evenly with sodium chloride to obtain a mixture; wherein the mass concentration of dilute hydrochloric acid is 18%, and the consumption is 30% of the quality of the waste and old ternary positive electrode material, and the consumption of sodium chloride is 10% of the mass of waste ternary cathode materials;

[0041] Put the mixture into a microwave sintering furnace for roasting to obtain a roasted product; the microwave power is 2.5kW, the roasting temperature is 500°C, and the roasting time is 30 minutes;

[0042] Carry out ball mill water immersion to the roasted product, the solid-liquid ratio of ball mill water immersion is 1:3, the ball mill speed is 400 rpm, the ball mill time is 30min, the lithium in the mixture enters the water to obtain lithium chloride solution, obtains aluminum chloride solution through filtration . The recovery rate of lithium in the w...

Embodiment 3

[0045] After mixing the waste and old ternary positive electrode material with dilute hydrochloric acid, mix it evenly with sodium chloride to obtain a mixture; wherein the mass concentration of dilute hydrochloric acid is 18%, and the consumption is 30% of the quality of the waste and old ternary positive electrode material, and the consumption of sodium chloride is 10% of the mass of waste ternary cathode materials;

[0046] Put the mixture into a microwave sintering furnace for roasting to obtain a roasted product; the microwave power is 2.8kW, the roasting temperature is 600°C, and the roasting time is 30 minutes;

[0047] Carry out ball mill water immersion to the roasted product, the solid-liquid ratio of ball mill water immersion is 1:5, the ball mill speed is 600 rpm, the ball mill time is 40min, the lithium in the mixture enters the water to obtain lithium chloride solution, obtains lithium chloride solution through filtration . The recovery rate of lithium in the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com