Patents

Literature

119results about How to "Low-carbon and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

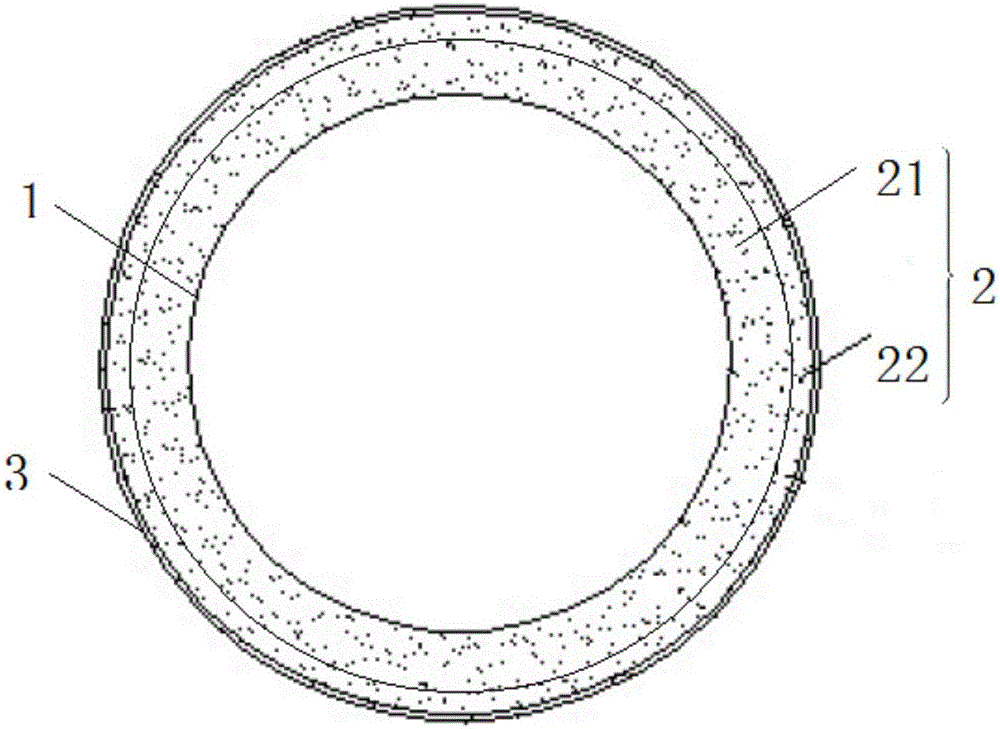

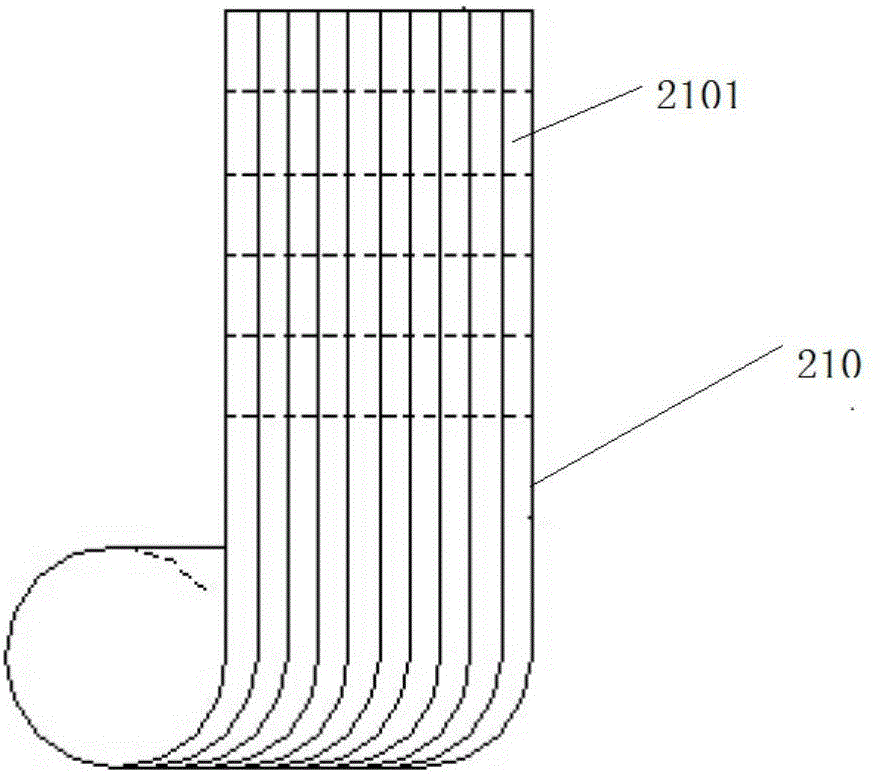

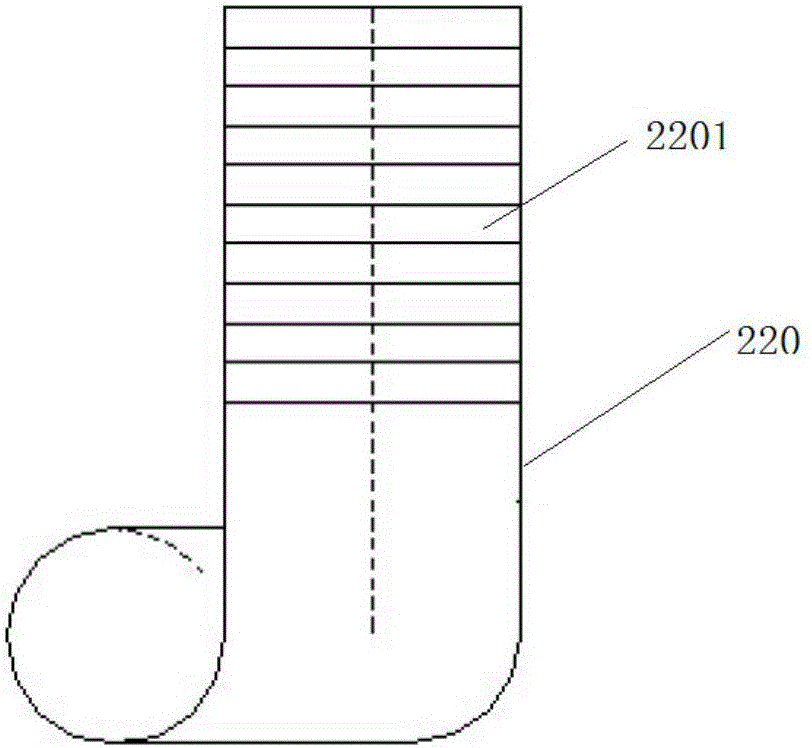

Ultra-large-diameter bamboo winding composite tube and manufacturing method thereof

ActiveCN105715881AImprove axial strengthEnhanced bending and impact resistanceRigid pipesTubular articlesStress distributionFiber

The invention belongs to the related field of composite tubes, and discloses an ultra-large-diameter bamboo winding composite tube. The bamboo winding composite tube comprises a lining layer, a composite strengthening layer and an outer protection layer from inside to outside, and the lining layer is made of fiber blankets or non-woven fabrics with anticorrosive resin in an adhesion manner; the composite strengthening layer is formed in a manner that two different types of bamboo skin curtains are wound outside the lining layer in a layer-by-layer manner according to the proper layer number and the thickness proportion wholly in the ring direction, the bamboo skin curtains are sprayed with the resin in a liquid-leaching manner while winding is carried out, and then bonding curing is carried out; and the outer protection layer is cured on the outer surface of the strengthening layer in a coating manner, and the effects of water prevention, corrosion prevention, radiation prevention and the like are achieved. The invention further discloses a corresponding manufacturing method. Through the ultra-large-diameter bamboo winding composite tube and the manufacturing method, even under the tube diameter obvious expanding condition, the characteristic that the whole structure of the bamboo winding composite tube is free of stress distribution defect can be well kept, and meanwhile comprehensive properties of pressure resistance, ring stiffness, long-term use quality stability and the like can be obviously improved.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

Stone-plastic composite powder for laser sintering 3D manufacturing technology and preparation method of stone-plastic composite powder

ActiveCN103881371ALow costReduce consumptionAdditive manufacturing apparatus3D object support structuresManufacturing technologyNylon 12

The invention provides stone-plastic composite powder for laser sintering 3D manufacturing technology and a preparation method of the stone-plastic composite powder, and relates to composite powder for laser sintering 3D manufacturing technology as well as a preparation method and a use method of the composite powder. The stone-plastic composite powder provided by the invention is used for solving the technical problems of low strength of a sintered workpiece prepared from a wood-plastic composite material and a rice husk powder-hot melt adhesive composite material for the existing laser sintering, and high cost of a sintered workpiece prepared from metal powder or ceramic powder. The stone-plastic composite powder for laser sintering 3D manufacturing technology provided by the invention is composed of nylon 12 powder and limestone powder. The preparation method comprises the steps of adding the nylon 12 powder and the limestone powder into a ceramic grinding tank for grinding and mixing to obtain the stone-plastic composite powder. During laser sintering, a laser beam scans a sub-region in a manner of scanning on a horizontal plane, and the laser power is 15-20 W, so that the laser power is low. The stone-plastic composite powder provided by the invention is applied to the laser sintering 3D manufacturing field.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

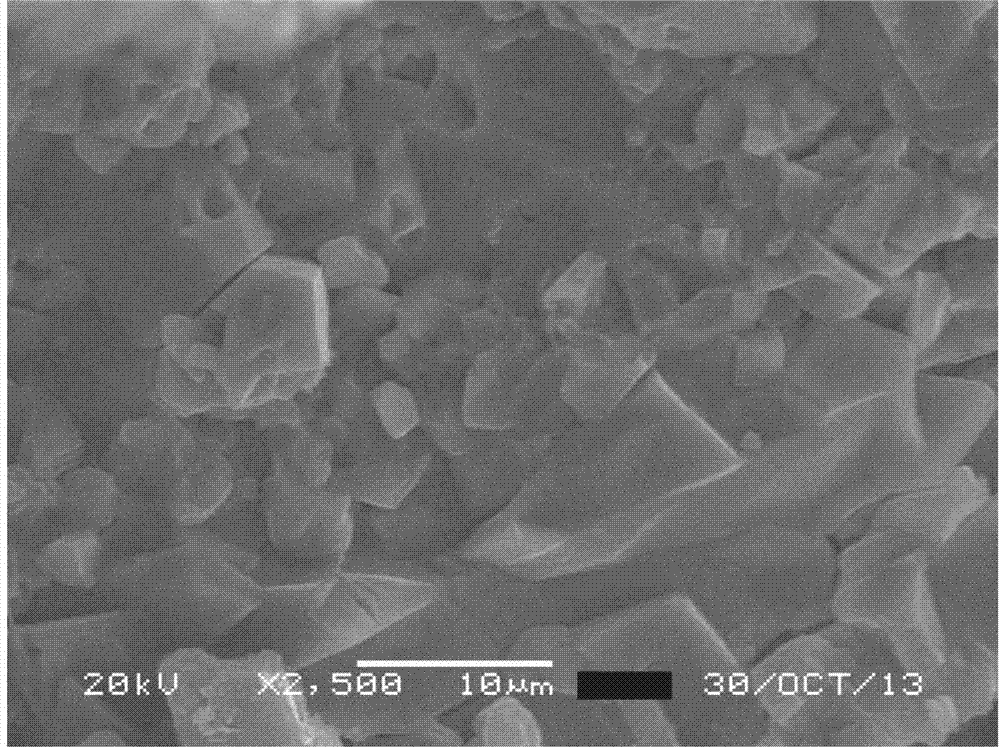

Ceramic binding agent for ceramic grinding block and preparation method thereof

ActiveCN103551971AGood gripLower sintering temperatureAbrasion apparatusGrinding devicesPowder metallurgyOxide

The invention discloses a ceramic binding agent for a ceramic grinding block and a preparation method thereof and belongs to the technical field of powder metallurgy materials. The ceramic binding agent aims at achieving the effects that the retention to diamond is good, the expansion coefficient is matched with expansion coefficients of silicon carbide, brown aluminum oxide and the diamond, and the sintering temperature of a finished product is low. The ceramic binding agent is formed by the following powder materials of, by weight, 20 to 55 kilograms of silicon dioxide, 5 to 25 kilograms of aluminum oxide, 0 to 5 kilograms of zinc oxide, 0 to 5 kilograms of titanium dioxide, 0 to 7 kilograms of zirconium oxide, 10 to 20 kilograms of sodium carbonate, 5 to 15 kilograms of lithium carbonate and 8 to 30 kilograms of boric acid. According to the ceramic binding agent for the ceramic grinding block, the ceramic grinding block has the advantages of being low in sintering temperature, good in self-sharpening, good in sharpness, long in service life, low in carbon and environmentally friendly.

Owner:BOSUN TOOLS CO LTD

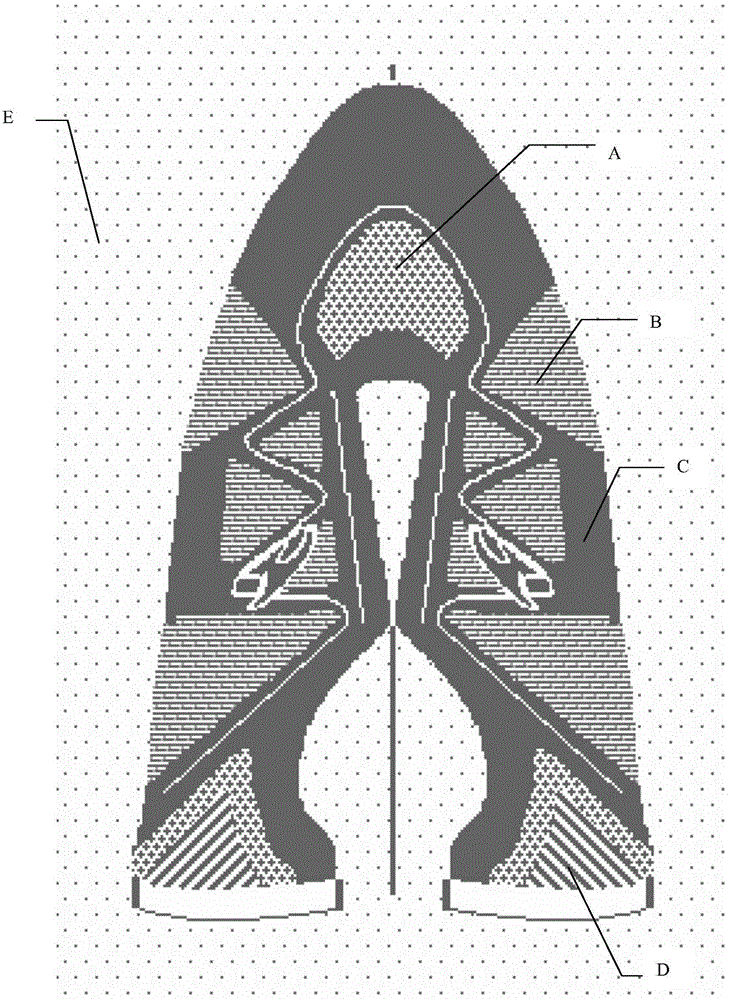

Structure and production method of weft-knitted jacquard shoe upper material

ActiveCN104562401AImprove breathabilityComfortable to wearWeft knittingHeating/cooling textile fabricsEngineeringAir layer

The invention belongs to the field of textiles and provides a structure and a production method of a weft-knitted jacquard shoe upper material. According to the weft-knitted jacquard shoe upper material, terylen low-melting-point color filaments with skin-core structures are adopted, the meshes, esthetic appearance and air permeability of the shoe upper material are realized by utilizing air-layer jacquard tissues as fundamental tissues, loop accumulation tissues or loop transfer tissues on a dual-way jacquard dual-side loop transfer round weft machine; by virtue of cooperation between colors and structural jacquards, functional sections of the shoe upper material are realized; during aftertreatment, a skin layer is fused at a certain temperature under a certain pressure, so that dual-side weft-knitted jacquard shoe upper fabric loops are mutually glued, then cooled and solidified, so that the shoe upper material with appropriate rigidity and hand feeling is obtained; spandex can also be added, so that the elasticity and the density of the fabric are enhanced. The weft-knitted jacquard shoe upper material is variable in pattern, color and style, beautiful in appearance, portable and flexible, favorable in air permeability and comfort in wear; traditional working procedures of cutting, sewing, bonding and the like for shoe materials are not needed, so that the equipment investment and the labor cost are lowered.

Owner:JIANGNAN UNIV

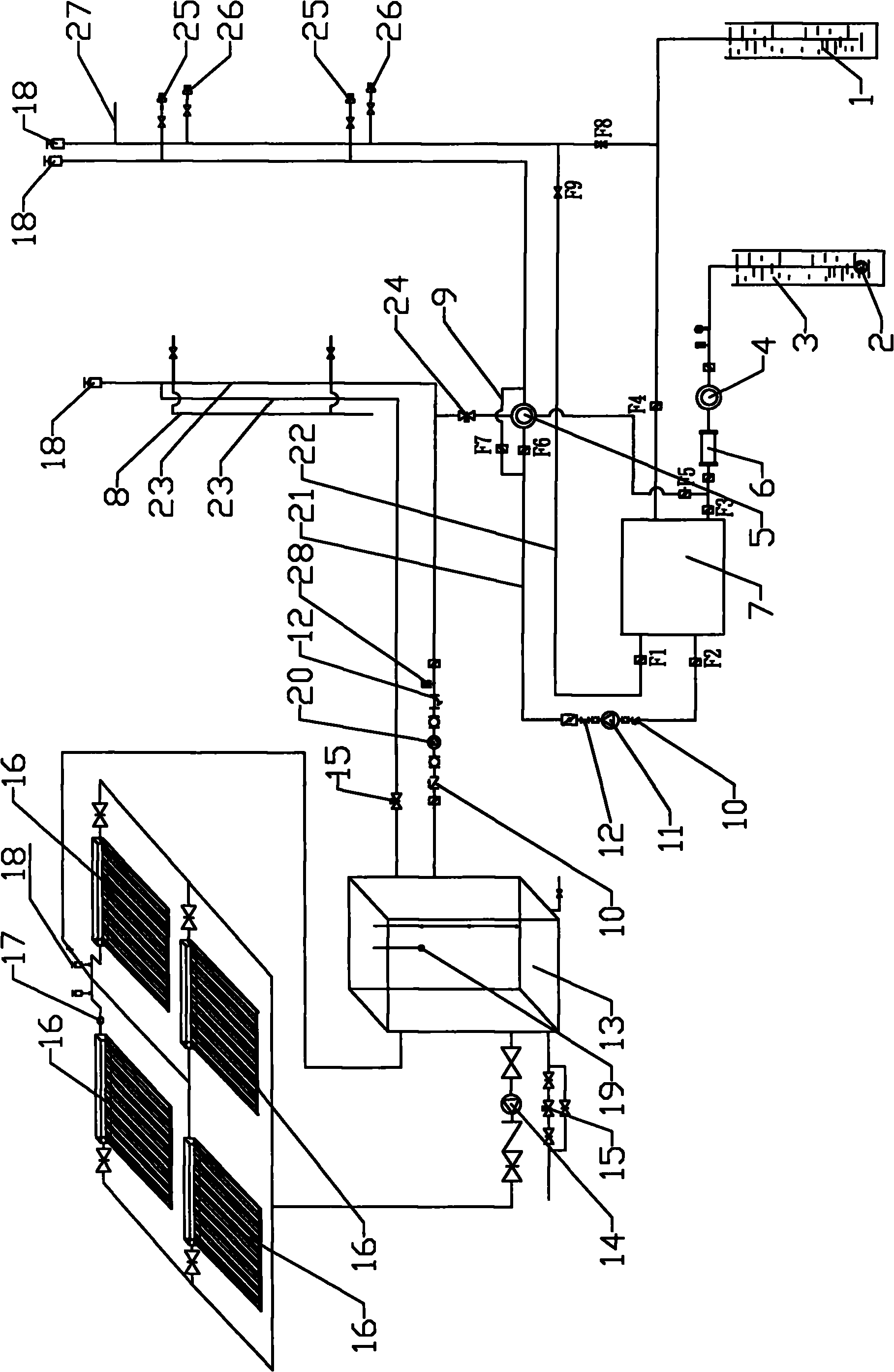

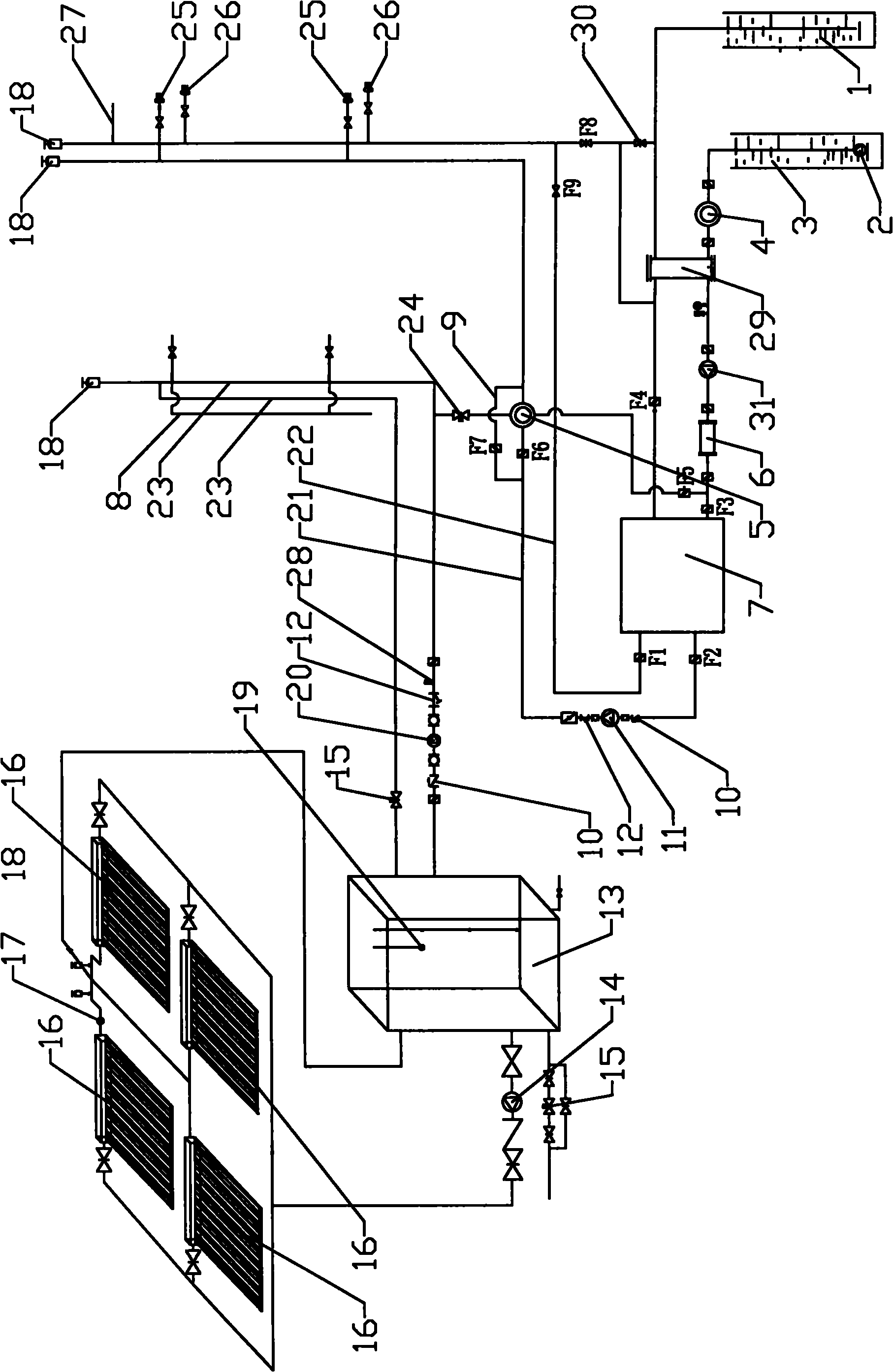

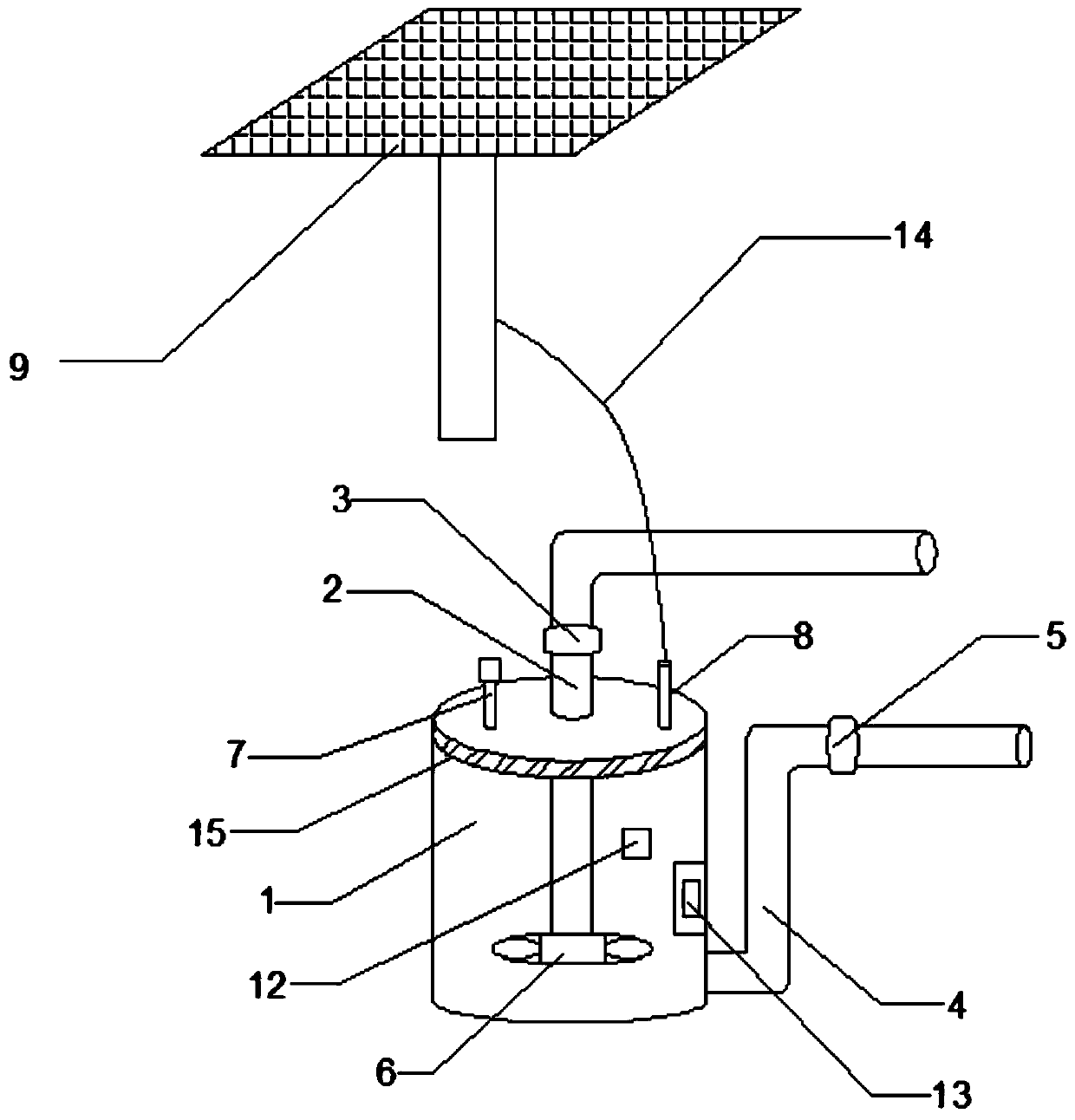

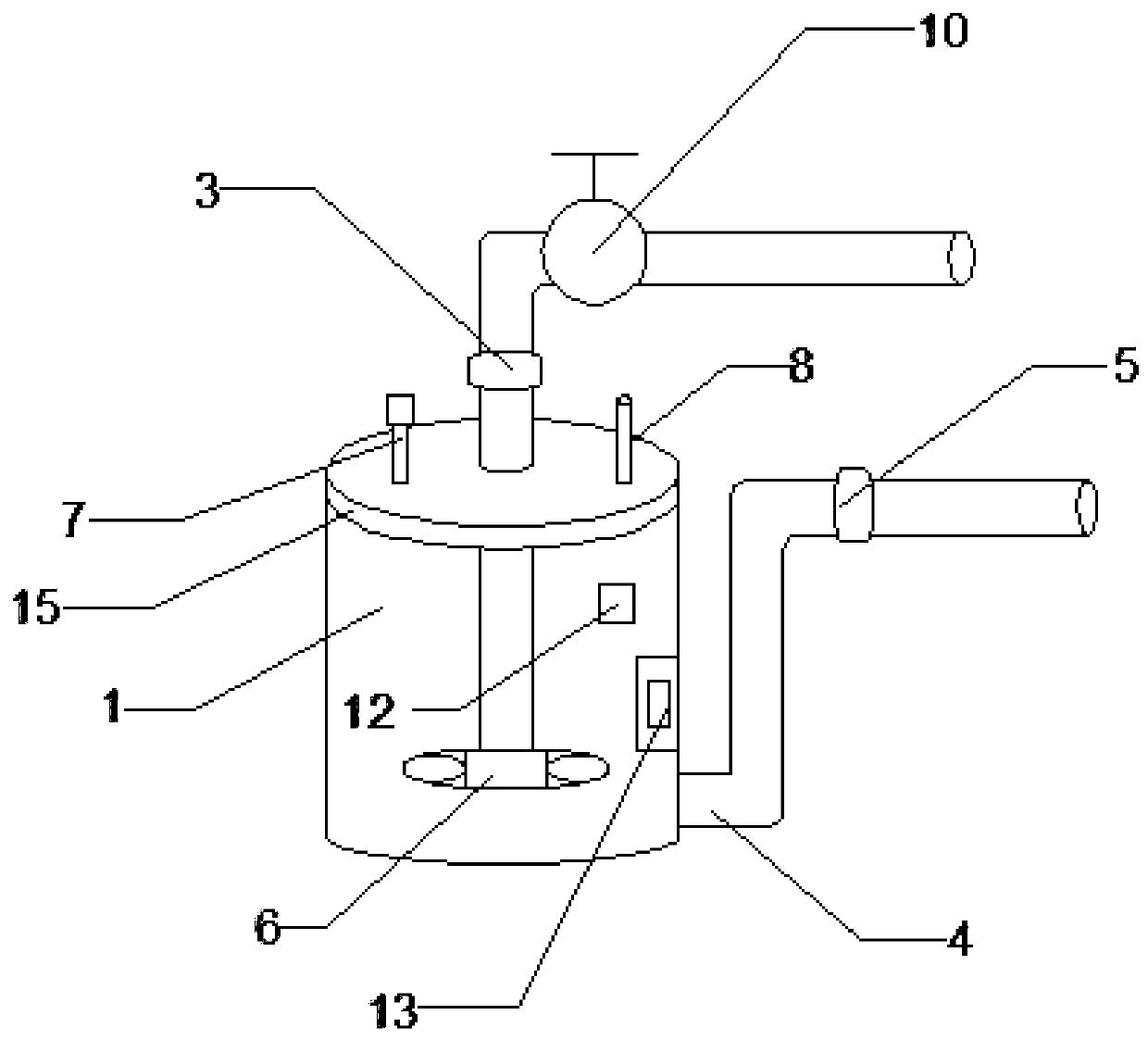

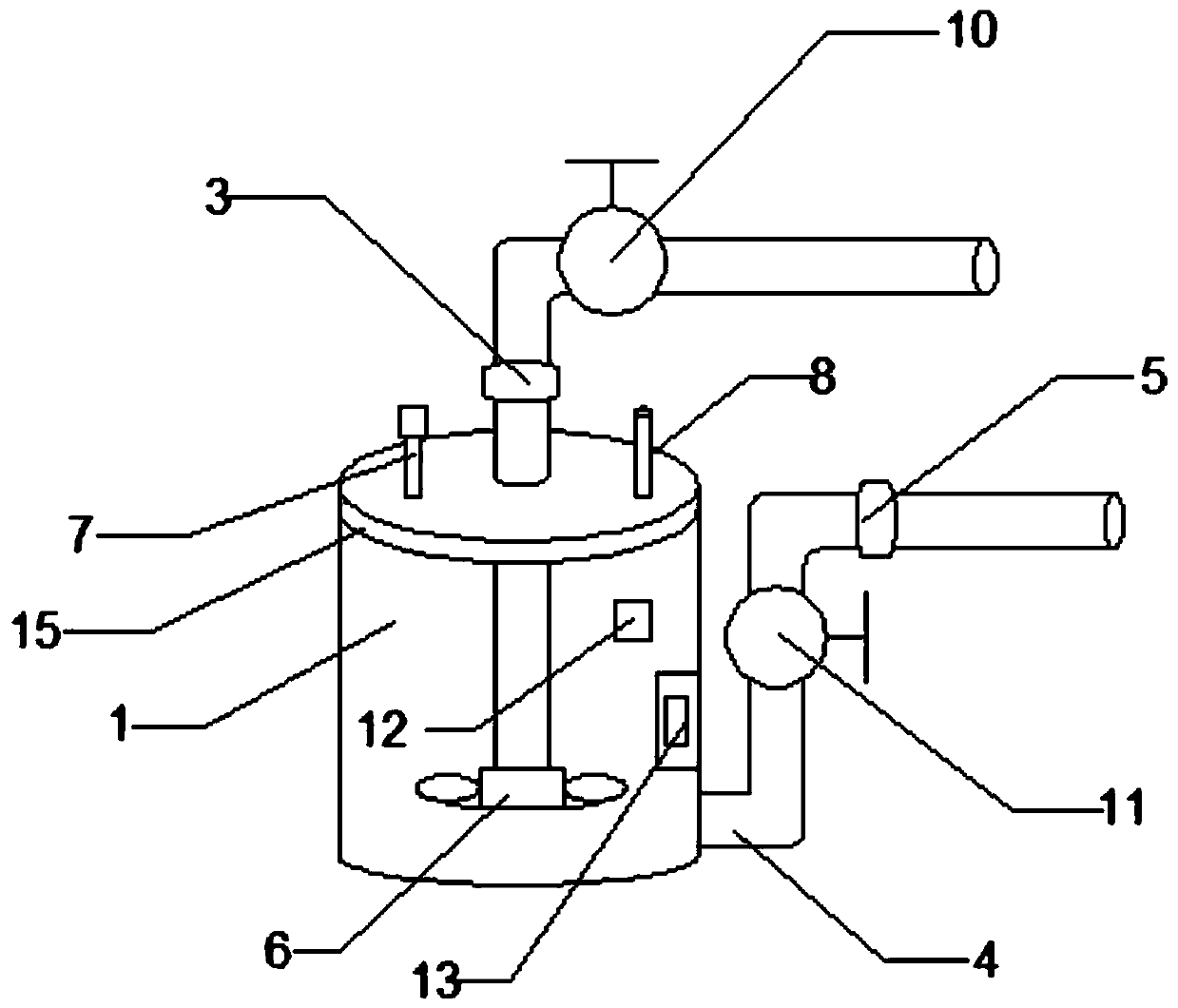

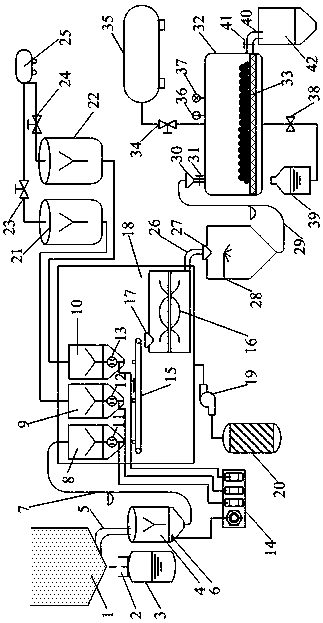

Low-temperature floor radiation heating and refrigerating system device

InactiveCN102155818ARealize heatingReach the temperature difference requirement to control the dew pointCondensate preventionHeating and refrigeration combinationsWater cyclingEngineering

The invention relates to a low-temperature floor radiation hearing and refrigerating system device, comprising a solar hot water circulating system and a heat pump circulating system, wherein the heat pump circulating system comprises a heat pump unit, an underground water circulating system, a main water supply pipe and a main water return pipe, a water inlet end of the heat pump unit is connected with the underground water circulating system and a water outlet end of the heat pump unit is connected with the main water supply pipe and the main water return pipe, the main water supply pipe isprovided with a temperature adjusting device which is connected with the solar hot water circulating system and the underground water circulating system via pipelines respectively, and the main waterreturn pipe is connected with the underground water circulating system via the pipeline; during refrigeration, hot water is fed to the main water supply pipe via the solar hot water circulating system, the temperature of the circulating water in the main water supply pipe is adjusted by the temperature adjusting device, the circulating water is adjusted to the temperature required by no condensation, the circulating water inside an indoor coil pipe is circulated on condition that the temperature of the circulating water is constantly controlled within the scope of dew point, thus the problem that condensed water can be generated by refrigeration in summer easily can be solved.

Owner:刘季林

Preparation method of laser sintering 3D printing rapid prototyping silicon nitride powder material

InactiveCN104744049ASmall median diameterNarrow particle size distributionAdditive manufacturing apparatusMetallurgyStearic acid

The invention discloses a preparation method of a laser sintering 3D printing rapid prototyping silicon nitride powder material. The preparation method is characterized by comprising the following steps: firstly, pretreating silicon nitride ceramic powder with gamma-methacryloxypropyltrimethoxysilane in an ethyl alcohol solvent to obtain pretreated silicon nitride ceramic powder; then, in percentage by mass, adding 75-88% of the pretreated silicon nitride ceramic powder, 5-15% of phenolic resin, 0.5-1.5% of melamine and 0.2-1.5% of glyceryl tristearate into a grinding miller, starting the grinding miller, grinding for 10min at 200r / min, and adding acetone, wherein the sum of all the components is 100%; starting the grinding miller, grinding for 30min at 200r / min, and drying, thus obtaining the laser sintering 3D printing rapid prototyping silicon nitride powder material. The material can be directly prototyped under the condition of laser sintering; the preparation process is simple, the preparation conditions are easy to control, and the production cost is low; therefore the preparation method of the laser sintering 3D printing rapid prototyping silicon nitride powder material can be easily put into industrial production.

Owner:UNIV OF JINAN

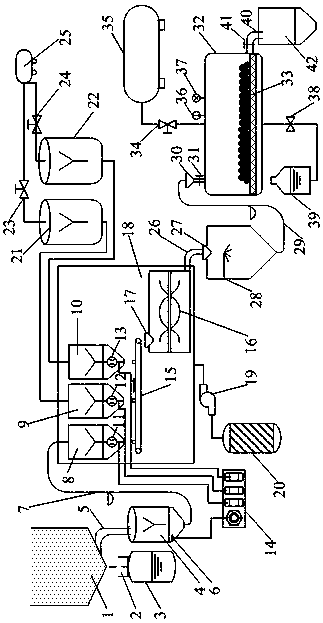

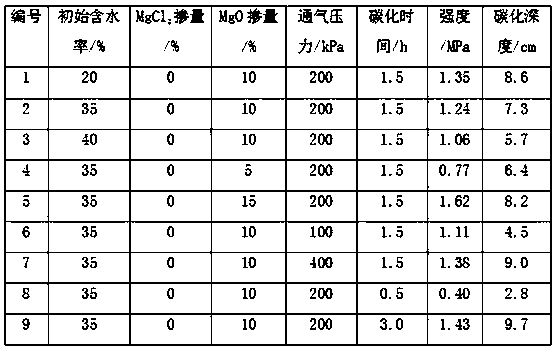

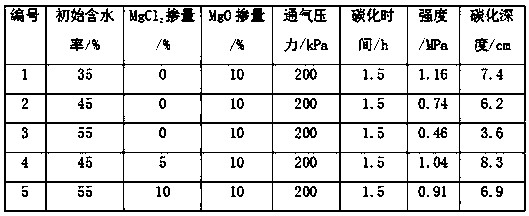

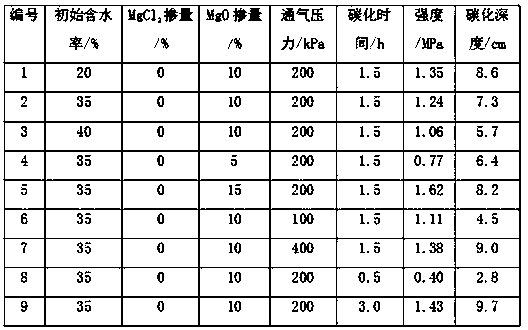

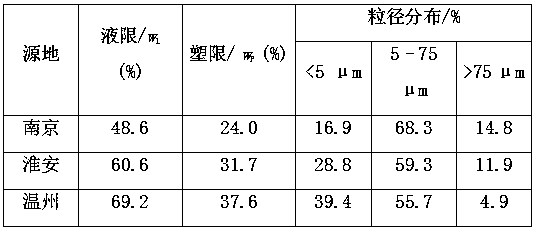

Method for silt soil with ectopic activated magnesium oxide carbonization and solidification

ActiveCN108086297AAdjust dosage in real timeFlexible ratioSludge treatment by de-watering/drying/thickeningSoil preservationSoil propertiesPrill

The invention discloses a method for silt soil with ectopic activated magnesium oxide carbonization and solidification, and belongs to the field of hydraulic and civil engineering. The method includesthe steps of a sludge pretreatment, a uniform mixing of a curing agent, a silt granulation, a carbon dioxide carbonization, a waste gas / waste liquid collection, and a resource utilization. The supplyof the curing agent is regulated by actual measure a water content rate, and a diameter of a grain and a carbon dioxide pressure are regulated according to a soil property, so that a full mixing of the silt and the curing agent and the rapid carbonization of magnesium oxide solidified the sludge grains are realized. Dust and carbon dioxide are absorbed during the operation process to avoid secondary pollution. The method is safe, simple, low in carbon, environmental, and high in continuous operation rate, and the problem of sludge treatment and engineering application is solved. The silt carbonized grains have the advantages of low moisture content, high hardness, high shear strength, large friction coefficient and the like. The silt carbonized grains can be used as a filler such as a roadbed, an airport runway and an engineering backfill, and the reclamation of the slit / sludge and the carbon dioxide is realized. The method for the silt soil with the ectopic activated magnesium oxidecarbonization and solidification has great significance of the engineering construction.

Owner:SOUTHEAST UNIV

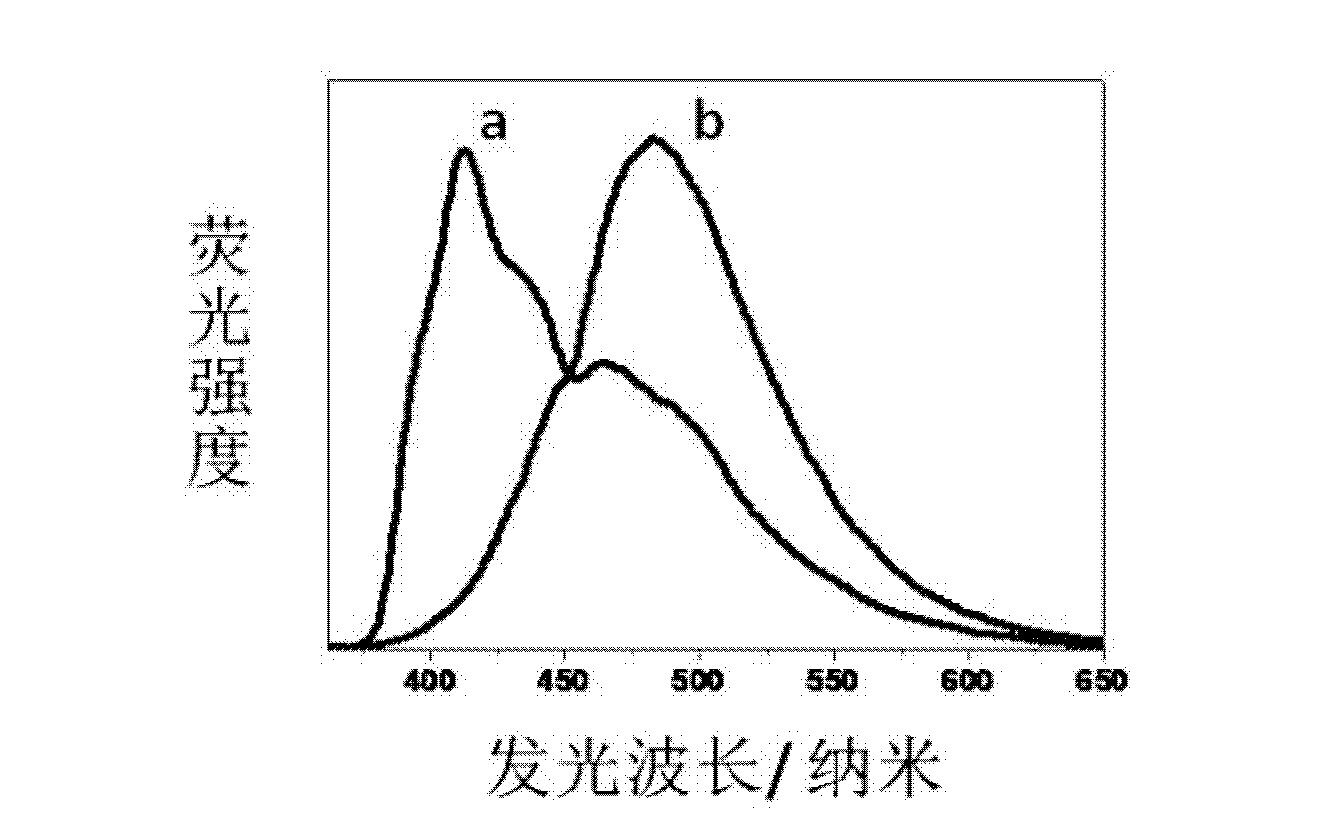

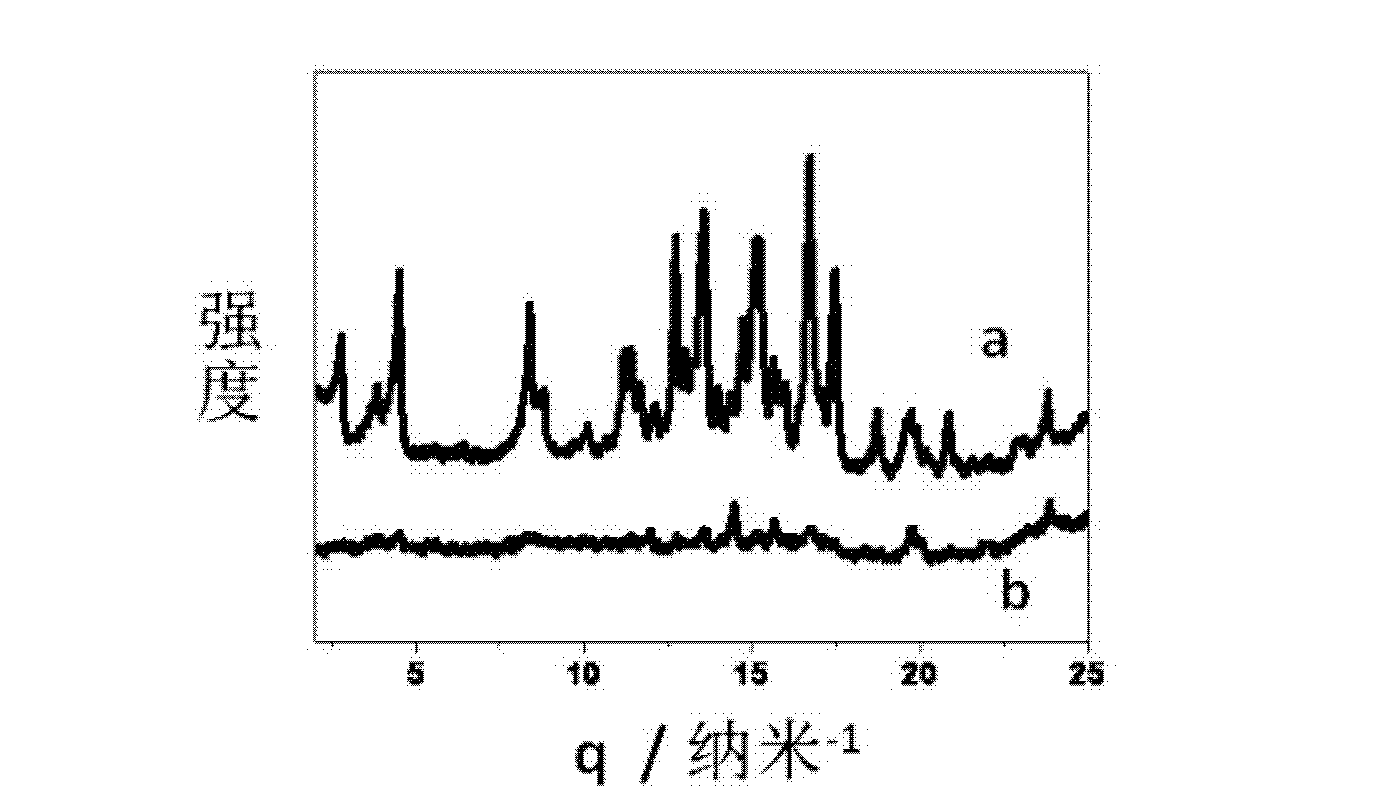

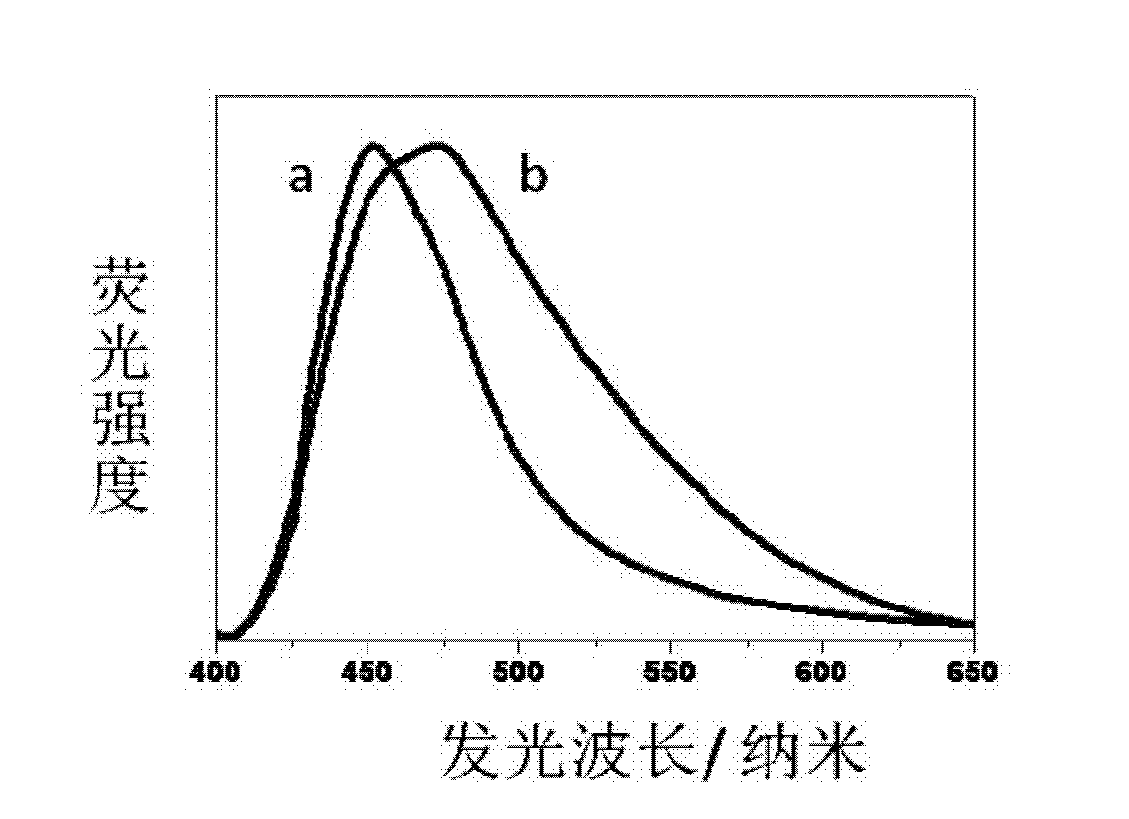

Forced-induced fluorescence color-changing compound and preparation method and application thereof

ActiveCN103030681ASimple processLow-carbon and environmentally friendlyLuminescent/fluorescent substance additionPeptide preparation methodsChemical compoundFluorescence

The invention provides forced-induced fluorescence color-changing compounds and a preparation method and application thereof. The structural formulas of the compounds are shown by a formula (I) and a formula (II). Under the effect of external force, the fluorescence color can be changed. After the compounds are simply treated by using solvent and the like, the original fluorescence color can be restored. On the basis of the compounds, rewritable fluorescence color-changing paper can be prepared by using a simple technology.

Owner:PEKING UNIV

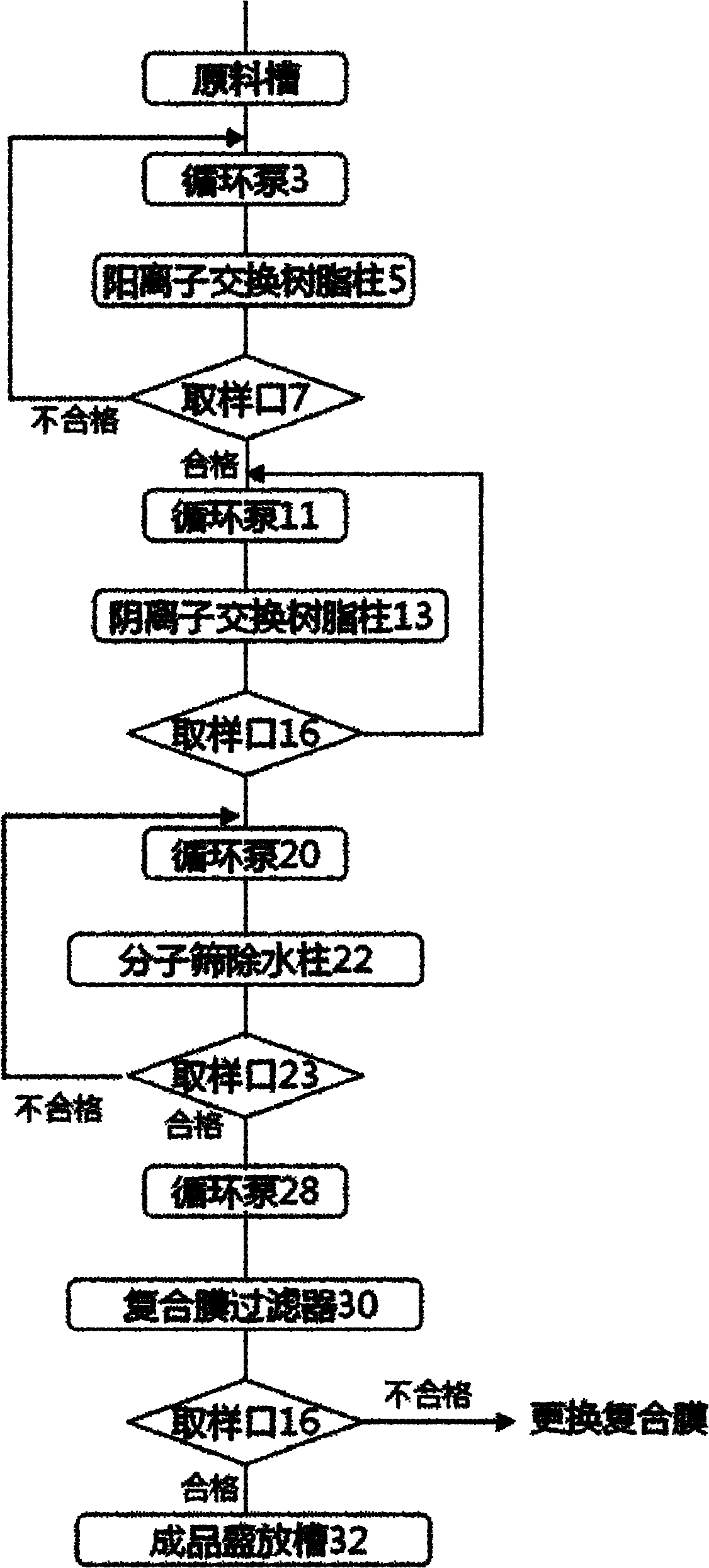

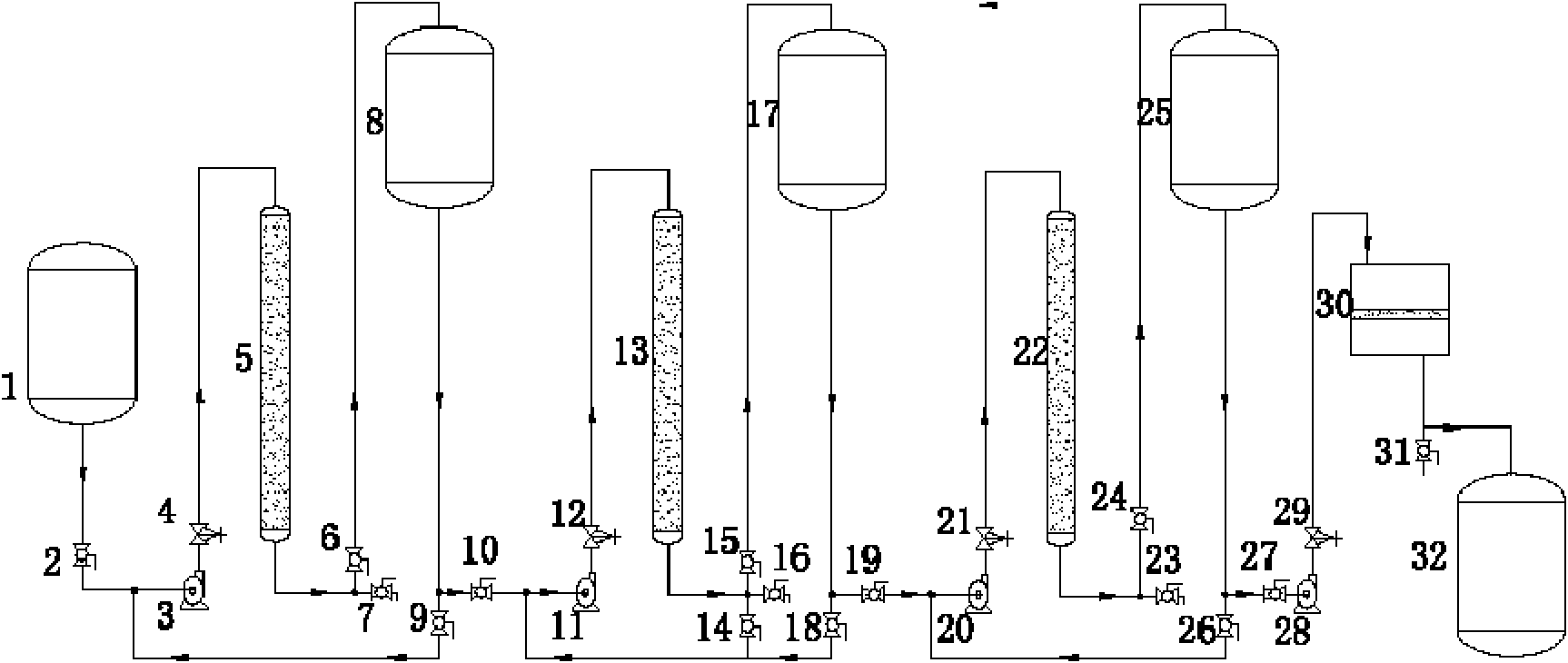

Method and device for preparing ultrapure acetone

ActiveCN101973859AReduce adverse effectsLow-carbon and environmentally friendlyIon-exchange column/bed processesCarbonyl compound separation/purificationWater contentIon exchange

The invention discloses a method and a device for preparing ultrapure acetone. A target product, namely, the ultrapure acetone is obtained by treating industrial acetone with ion exchange resin, removing impurity ions, dehydrating and performing membrane filtration. The purity of the ultrapure acetone is 99.8 percent or higher, the water content is less than 0.1 percent, the impurity ion content of the target product is lower than an index value by detection, the number of particle impurities which are larger than 1.0 mu m is less than 10 / ml and each index value is accordant with SEMI C1.2-96 standard. Compared with the prior art, the method of the invention has the advantages of low carbon, environmental protection and low cost; feed liquor is treated circularly, so that negative influence on the environment can be reduced; the used ion exchange resin and a molecular sieve can be recycled; and a cation exchange unit, an anion exchange unit, and a water content unit and a particle impurity unit, which are independent of and related to one another, are combined into an integrated device, so that the operation process is convenient, the product quality is stable and the device has industrialized production prospect.

Owner:SHANGHAI CHEM REAGENT RES INST

Production process of fiber velvet Raschel blanket

ActiveCN105310378AFeel smoothGood moisture absorption and air permeabilityBlanketFibre typesFiberYarn

The invention relates to a production process of a fiber velvet Raschel blanket. The production process comprises the following steps: 1) selecting yarns; 2) weaving; 3) pre-finishing; 4) dyeing; and 5) post-finishing. The entire production process of the invention is optimized and improved, and the fluffiness of the blanket is improved by improving luster finishing temperature on a front surface; the production process, which makes use of environmental-friendly dyeing auxiliaries during dyeing, is absolutely green and environmental-friendly; a finished product complies with the green, environmental-friendly and ecological development trend of international textile industry and is capable of achieving effects of being natural, environmental-friendly and comfortable; and the project, with implementation, is good in economic and social benefits.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Special material for manufacturing biodegradable antibacterial breathable membrane and preparation method thereof

The invention discloses a special material for manufacturing a biodegradable antibacterial breathable membrane and a preparation method thereof. The preparation method comprises the following steps of: adopting a jet mill to crush and grade 35-50 parts of heavy calcium carbonate, drying till the water content is less than or equal to 0.3%, adding 0.5-3 parts of surface active agent and 0.5-2 partsof activating agent, and fully reacting at a temperature of 110-130 DEG C; then adding 0.5 part of rare-earth antibacterial agent, 0-0.5 part of antioxidant and 0.5-3 parts of processing additive, mixing uniformly, then discharging, using the jet mill for milling and grading, finally adding 45-60 parts of biodegradable material and using a dual-screw extruder to extrude and granulate. The specialmaterial and the preparation method disclosed by the invention have the beneficial effects that the special material for the antibacterial breathable membrane is prepared by adopting methods of two-time surface modification and two-time jet milling and grading and utilizing the biodegradable material, the prepared breathable membrane product has the characteristics of good dispersity and uniformpore-diameter distribution and the like, can be completely biodegraded after being discarded, and has the advantages that the petroleum resources can be saved and the environmental pollution can be reduced and the like.

Owner:池州市锐强新材料有限公司 +1

Preparation method for nano-silicon nitride powder for laser sintering 3D printing technology

InactiveCN104788102ASmall median diameterNarrow particle size distributionAdditive manufacturing apparatusSolventSilicon nitride

The invention discloses a preparation method for a nano-silicon nitride powder for the laser sintering 3D printing technology. The preparation method is characterized by comprising the following steps: firstly, using gamma-glycidoxypropyl trimethoxysilane for the pretreatment of nano-silicon nitride powder in an ethanol solvent to obtain pretreated nano-silicon nitride powder; then, adding the following components by mass percentage into a grinding machine to obtain a mixture I: 84%-90% of pretreated nano-silicon nitride powder, 3%-8% of epoxy resin and 0.4%-1.0% of pyromellitic dianhydride, starting the grinding machine, grinding the mixture I at a revolution speed of 300 rpm for 5 min, and then adding 5%-10% of acetone to obtain a mixture II, turning on the grinding machine, grinding the mixture II at a revolution speed of 300 rpm for 30-40 min, and drying the grinded mixture II to obtain the nano-silicon nitride powder for laser sintering 3D printing technology. The nano-silicon nitride powder for the laser sintering 3D printing technology can be molded directly under laser sintering, is simple in preparation process, low in production cost, and easy to realize industrial production, and the condition is easy to control.

Owner:UNIV OF JINAN

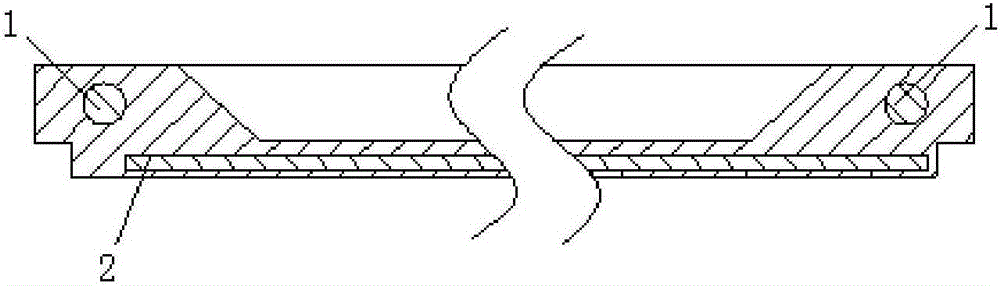

Pure log spliced board and aluminum-wood composited spliced board device using same

InactiveCN105113702AWon't swellWon't archConstruction materialCovering/liningsAdhesiveMechanical engineering

The invention relates to a pure log spliced board and an aluminum-wood composited spliced board device using the same. The pure log spliced board comprises a plurality of pure log boards, a first pure log side board, a second pure log side board, a plurality of screws and a plurality of nuts, each pure log board is made to have a splicing lateral side, an extensible groove slit and multiple screw holes are formed in each splicing lateral side, an adhesive is coated on each splicing lateral side, the pure log boards are arranged, spliced and pressed to form an integrated pure log spliced board body, each screw is penetratingly nested in the corresponding screw hole of the corresponding pure log board, two ends of each screw are tightened and locked by using the nuts, and the pure log side boards are arranged on the splicing lateral sides on two sides of the pure log spliced board body respectively to hide the ends of the screws and the nuts in the spliced board. The pure log spliced board is simple in structure, convenient to assemble and easy to realize, unfavorable factors like material cracking and deforming caused by thermal expansion and cold contraction of pure log are prevented effectively, and a log product is more attractive, more environment friendly and longer in service life.

Owner:彭志军

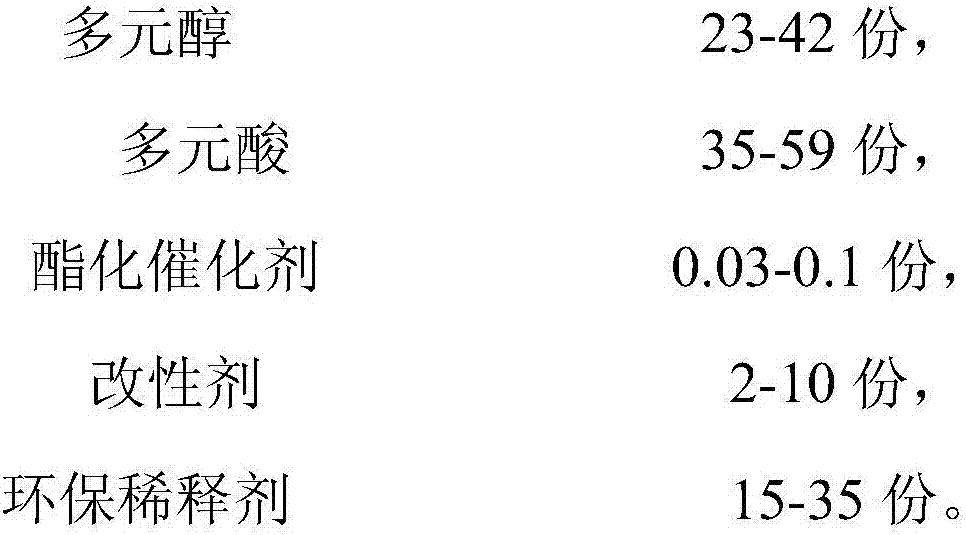

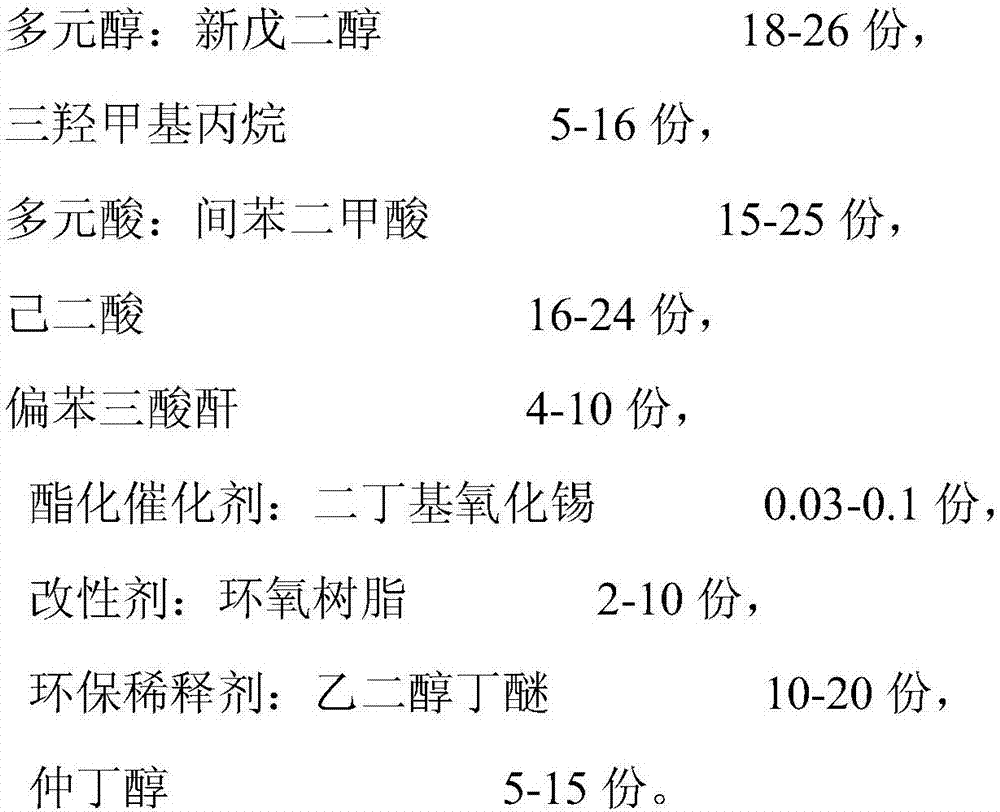

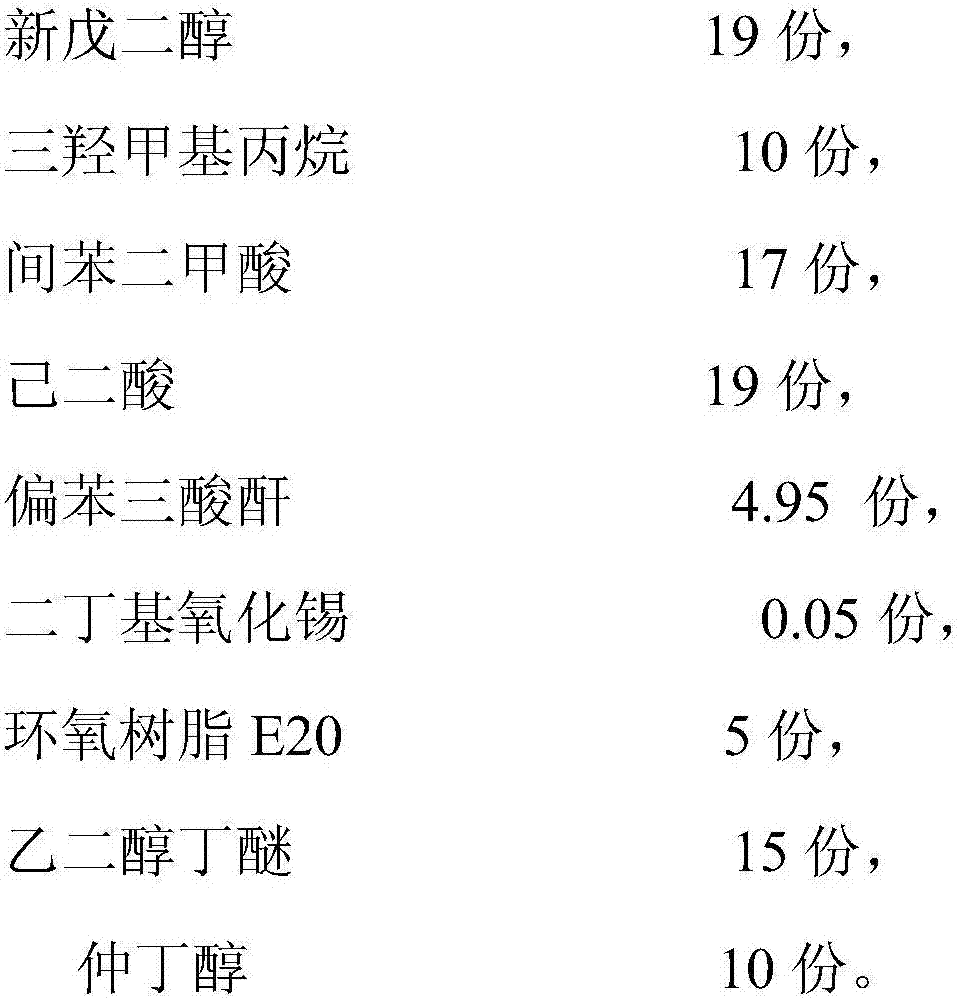

Waterborne epoxy modified polyester resin and preparation method thereof

The invention discloses waterborne epoxy modified polyester resin and a preparation method thereof. The waterborne epoxy modified polyester resin is prepared from the following components in parts by weight: 23-42 parts of polyol, 35-59 parts of polyacid, 0.03-0.1 part of esterification catalyst, 2-10 parts of modifying agent and 15-35 parts of environment-friendly diluent. Waterborne amino baking paint prepared from the waterborne epoxy modified polyester resin has the characteristics of being good in adhesion force, high in fullness and hardness, good in water resistance, and the like.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

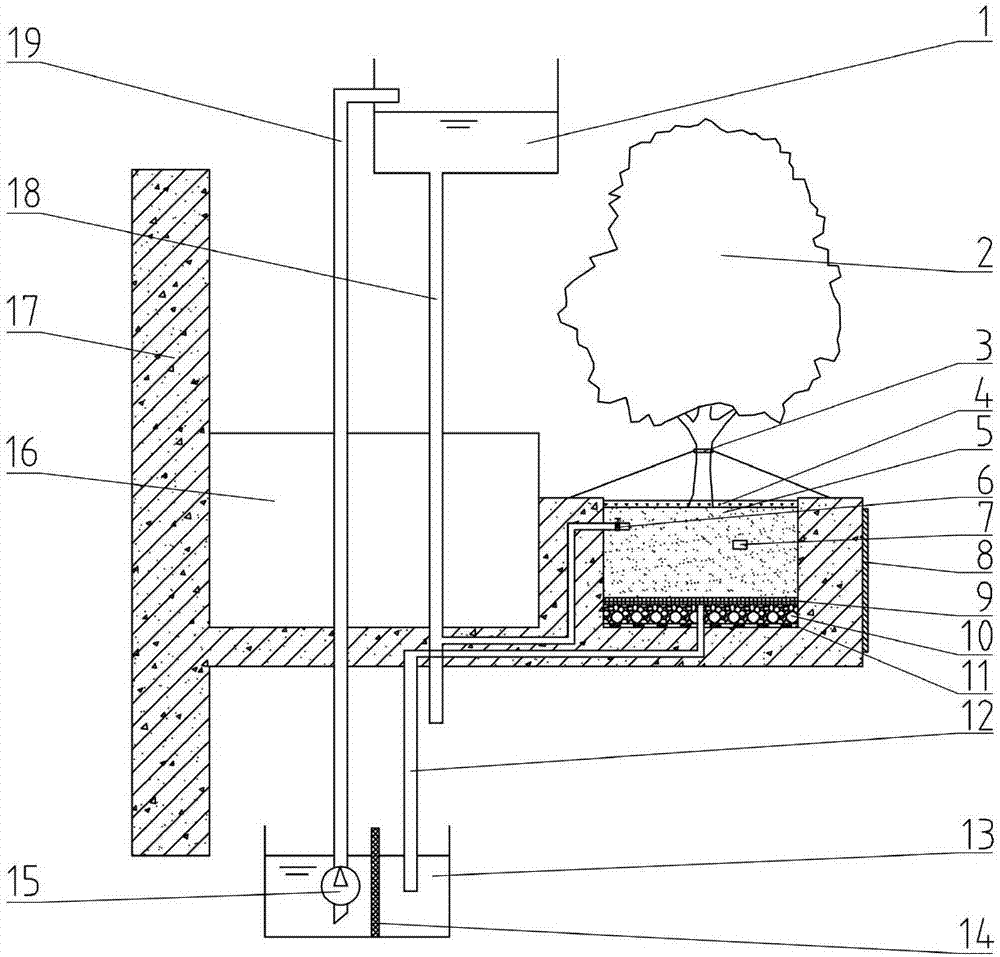

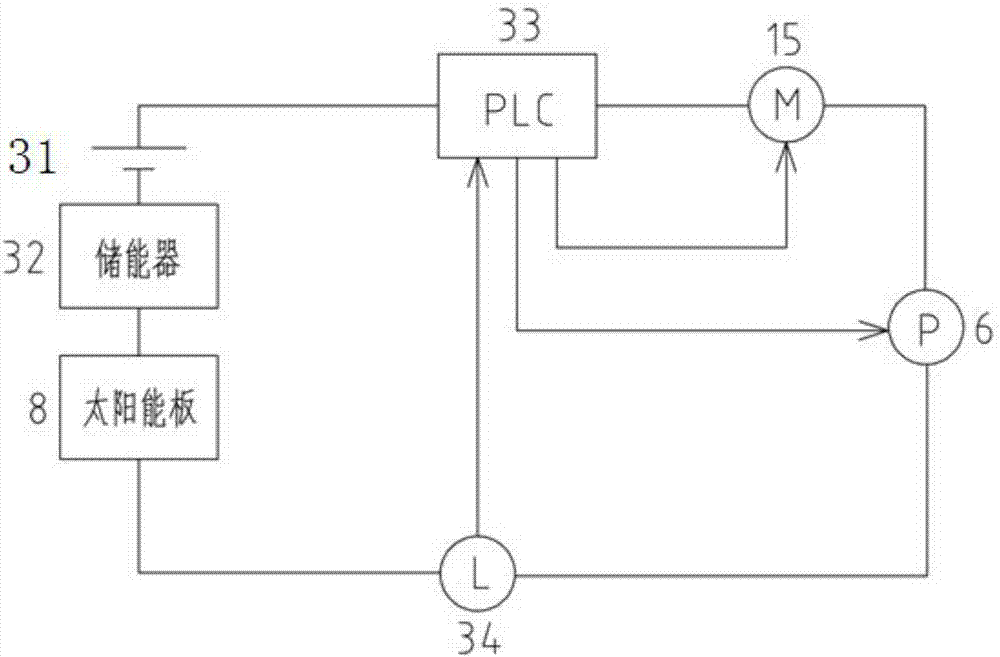

System for intelligently and vertically greening external wall of building and operating method thereof

InactiveCN107278679ALow-carbon and environmentally friendlySelf-acting watering devicesRenewable energy machinesEngineeringSolar power

The invention discloses a system for intelligently and vertically greening an external wall of a building and an operating method thereof. The system comprises greening tanks, wherein an outer side of a balcony at each floor of the high-rise building is provided with one greening tank; a water recycling tank in which a DC water pump is disposed; an irrigating water tank, wherein an upper tank wall of the irrigating water tank is connected with the DC water pump in the water recycling tank via a water supply pipe, and the bottom of the irrigating water tank is connected with a vertically arranged irrigating main pipe; irrigating branch pipes, wherein a soil layer of each greening tank at each floor is connected with the irrigating main pipe vie one irrigating branch pipe; soil humidity sensors respectively arranged in the soil layer of each greening tank at each floor; and a controller and a solar power supply device. According to the system and the method, the problems that in the prior art, the greening effect of the external wall of the building is poor, maintenance is difficult, and safety is poor are solved.

Owner:周鹏飞

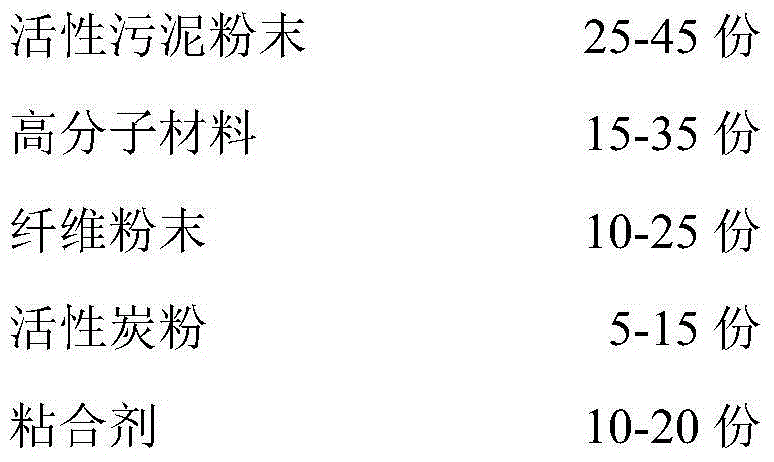

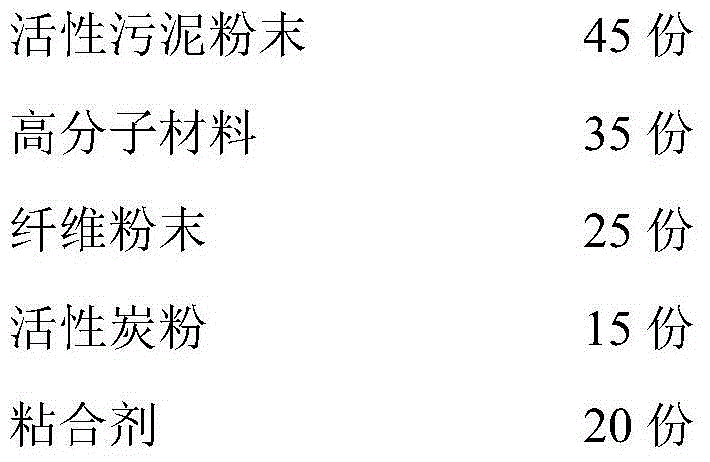

Method for producing degradable plastics by using activated sludge

ActiveCN104530596AAchieve reuseReduce pollutionSludge processingBiological sludge treatmentActivated sludgeActivated carbon

The invention relates to a method for producing degradable plastics by using activated sludge, which comprises the following steps: 1) adding the following substance components in parts by weight into a mixing machine and uniformly mixing: 25-45 parts of activated sludge powder, 15-35 parts of high molecular material, 10-25 parts of fiber powder, 5-15 parts of activated carbon powder, 10-20 parts of adhesive and assistants, wherein the assistants comprise sodium stearate, coupling agent and compatilizer; the mass of the sodium stearate is 2% of that of the activated carbon powder; the mass of the coupling agent is 1% of that of the activated carbon powder; and the mass of the compatilizer is 3-5% of the total mass; and 2) plastifying and extruding the mixture obtained in the step 1) through a single screw extruder, granulating, and performing secondary processing to obtain the biodegradable plastics. The method uses wastes in life, sludge and straws, as the raw materials, realizes reutilization of the wastes, and avoids secondary pollution brought by the existing sludge treatment method; and the obtained plastics can be completely degraded to serve as a fertilizer for improving soil. Thus, the method has the characteristics of low carbon, environment friendliness, simple process, high production efficiency and low cost.

Owner:广东银柏科技有限公司

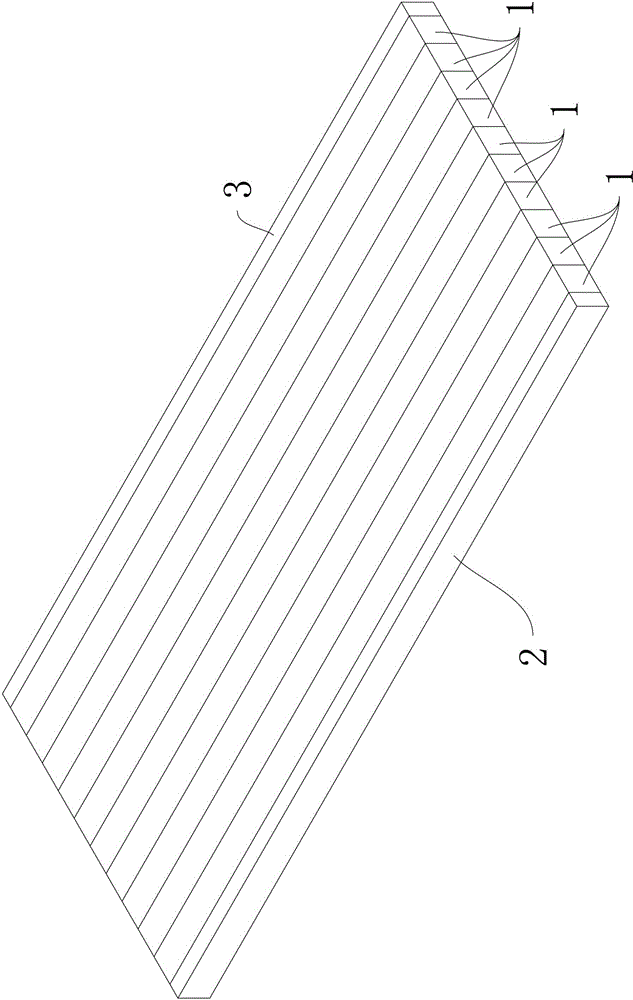

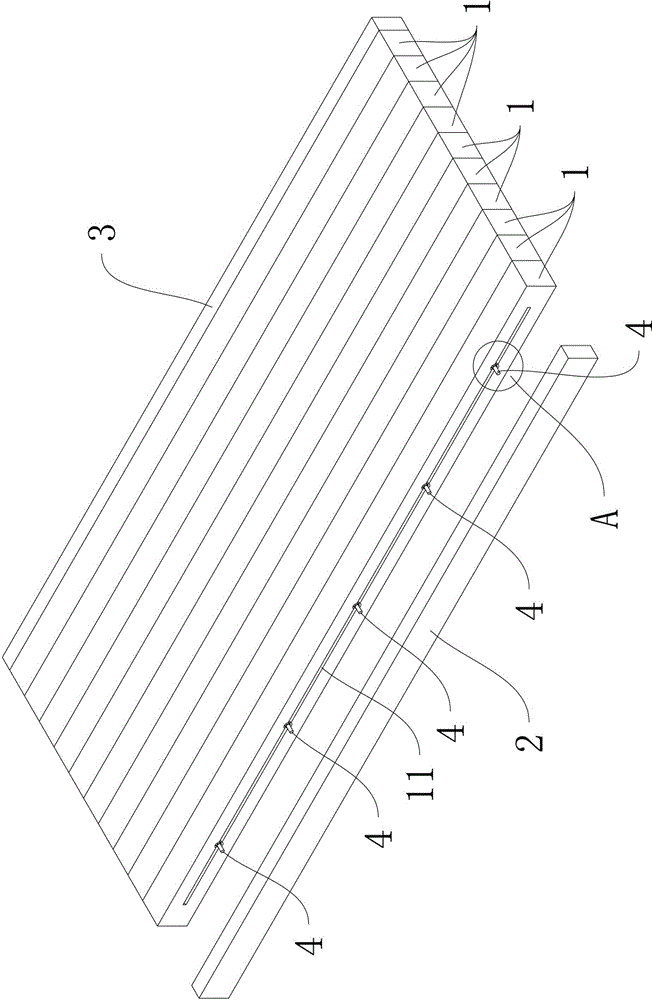

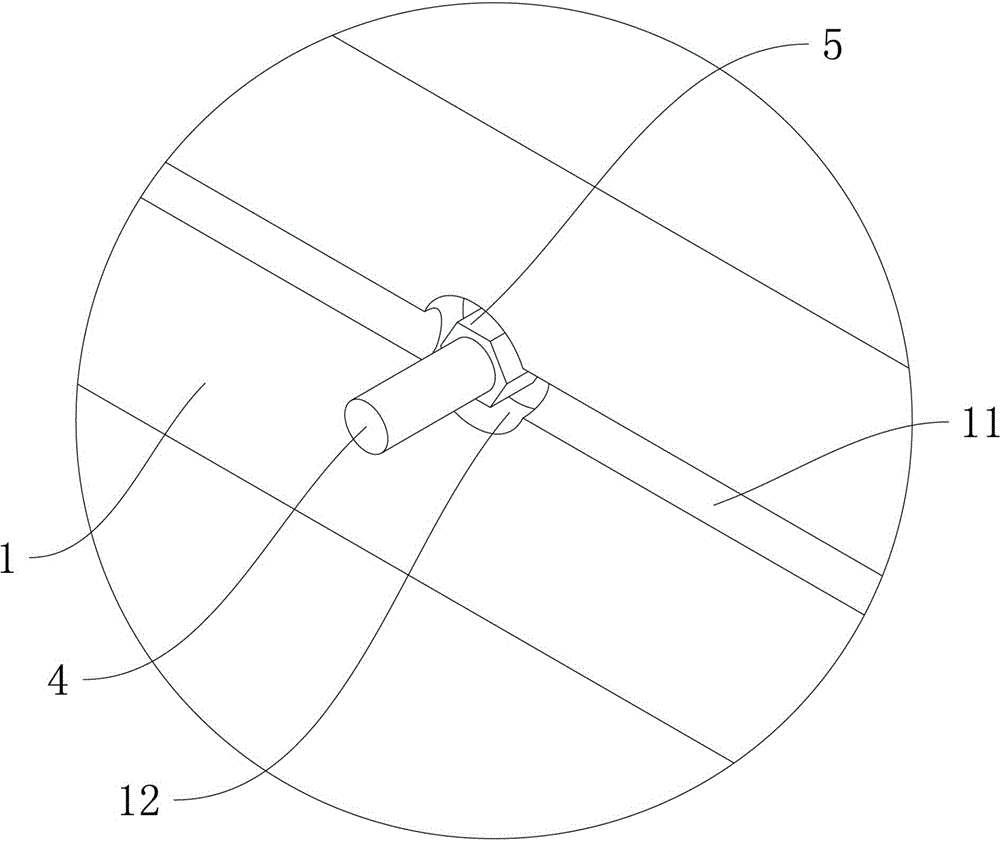

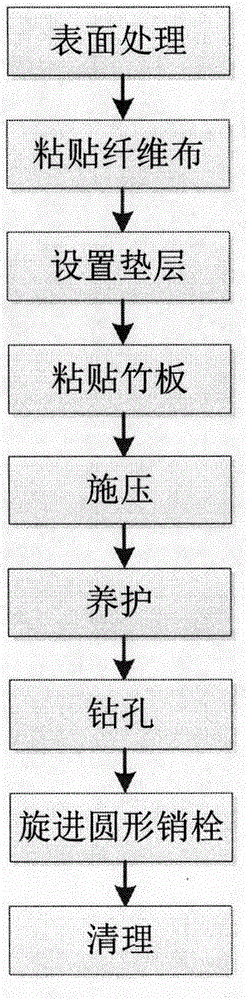

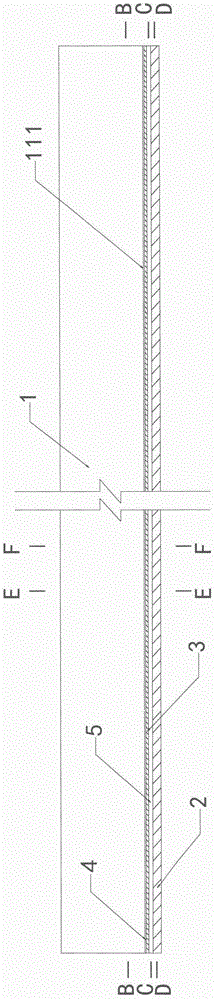

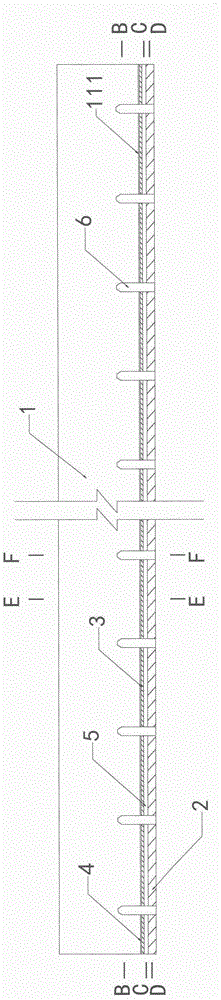

Method for compound reinforcement of wooden beam

The invention belongs to the field of civil engineering and discloses a method for compound reinforcement of a wooden beam. The method is characterized in that at the bottom of the wooden beam (1), fiber cloth (3) is adhered, a base layer (5) is arranged, a bamboo board (2) is adhered and a round bolt (6) is screwed to achieve compound reinforcement of the wooden beam (1). In the method, the bamboo board (2) is used as a reinforcing material, meanwhile the fiber cloth (3) is mechanically anchored, the bonding effect of the bamboo board (2), the fiber cloth (3) and the wooden beam (1) is strengthened through fusion of the round bolt (6) with the bamboo board (2) and the wooden beam (1), and the thickness of epoxy resin glue (4) between the bamboo board (2) and the wooden beam (1) is ensured by arranging the base layer (5) embedded with a solid filling (51). By the adoption of the method, the probability of untimely damage due to bonding layer failure in the wooden beam bending process is reduced, the wooden beam is reinforced by adopting two low-carbon environmentally friendly materials, respective advantages of the two materials are fully played, the bearing capability of the wooden beam is improved, and an original style and features of an old historic building structure restored as the old are achieved.

Owner:NANJING FORESTRY UNIV

Preparing method for fast forming epoxy resin coated sand used for 3D printing

InactiveCN105195679AStable in natureHigh surface glossFoundry mouldsFoundry coresPolymer chemistryFatty acid amide

The invention discloses a preparing method for fast forming epoxy resin coated sand used for 3D printing. The preparing method is characterized in that 3-aminopropyl triethoxy silane is adopted to treat the surface of fused ceramite to obtain pretreated fused ceramite; 77-82% of pretreated fused ceramite, 3-7% of epoxy resin, 0.3-1.0% of melamine and 0.3-1.0% of fatty acid amide are added into a stirrer by mass; the stirrer is started to grind the materials for 10 min at the rotating speed of 200 r / min, then 10-15% of acetone by mass is added, the sum of the mass ratios of all the component is 100%, the stirrer is started at the rotating speed of 200 r / min to perform grinding for 20 min, and the fast forming epoxy resin coated sand used for 3D printing is obtained through drying. The coated sand can be directly formed on the condition of laser sintering and has the advantages that the preparing technology is simple, conditions are easy to control, the production cost is low, and industrial production is easy to realize.

Owner:UNIV OF JINAN

Siphon pump

ActiveCN111255753AEmission reductionReduce construction costsMachines/enginesPump siphonsSiphonExhaust valve

The invention provides a siphon pump which comprises an outer pipe body, a pump core impeller, a water level controller, a water stop valve, a water supplementing valve and a water level sensor, wherein the outer pipe body is of a hollow structure; the top of the outer pipe body is provided with a water guide pipe; the water guide pipe extends to the inside of the outer pipe body; the water stop valve is arranged on the water guide pipe; the pump core impeller is arranged at the tail end of the water guide pipe; a first exhaust valve used for exhausting gas inside the outer pipe body is arranged at the top of the outer pipe body; a water inlet pipe is arranged at the bottom of the outer pipe body; the water inlet pipe extends to a water source; the water supplementing valve is arranged onthe water inlet pipe; both the water level sensor and the water level controller are arranged inside the outer pipe body; and the water level sensor, the water stop valve, the pump core impeller and the water supplementing valve are all connected with the water level controller through signals.

Owner:HAINAN GUANGYUANLONG ENERGY SAVING TECH SERVICE

High-crystal, light and high-strength gauge stuff ceiling

ActiveCN105082353ALight in massLow costCeramic shaping apparatusCement mixing apparatusEmulsionSurface finishing

A high-crystal, light and high-strength gauge stuff ceiling is prepared through the following steps that firstly, a stirring solution is prepared, namely, a polyving akohol solution, the copolymer emulsion of polyvinyl acetate and ethylene, a water reducer, a water-proofing agent, a retarder and a defoaming agent are mixed with water and stirred evenly; secondly, mixed powder is prepared, namely gypsum powder and white cement are evenly mixed; thirdly, gypsum pulp is prepared, namely the mixed powder is poured in a barrel containing the stirring solution, short-cut glass fiber filaments are added during stirring, and even stirring is performed; fourthly, pouring molding is carried out, namely the gypsum pulp is poured in a PVC mold for bottoming, leveling and bottom shielding, and glass fiber gridding cloth and glass fiber bars are placed, wherein the glass fiber bars are placed close to the edge of an inner cavity of the PVC mold, residual pulp is poured in the PVC mold and ironed through a mud plate, a PVC cover plate is placed during knocking, and the periphery is compacted; and after the residual pulp is finally set, the high-crystal, light and high-strength gauge stuff ceiling is obtained through maintaining, drying and surface processing. The high-crystal, light and high-strength gauge stuff ceiling has the beneficial effects of being light in weight, low in transporting and installing cost, high in safety coefficient and the like.

Owner:湖南安雅达建材科技有限公司

Preparation method for rapidly forming YAG transparent ceramic powder material by 3DP (three-dimensional printing) technology

InactiveCN106348745AReduce dosageImprove qualityAdditive manufacturing apparatusMicrometer3D printing

The invention discloses a preparation method for rapidly forming a YAG transparent ceramic powder material by a 3DP (three-dimensional printing) technology. The preparation method includes firstly, granulating YAG transparent ceramic powder to make the same become granulated powder with the grain size 0.1-0.5 micrometer; then, adding, by mass, 85-92% of the granulated YAG transparent ceramic powder, 0.5-1.5% of zinc stearate and 0.2-1.0% of trimellitic anhydride into a stirrer, stirring for 30 minutes at a speed of 300 rpm, heating to reach the temperature of 160-180 DEG C, adding, by mass, 2-8% of ABS resin and 2-8% of thermoplastic phenolic resin with stirring, and continuing stirring at the revolving speed of 350 rpm until the temperature is decreased to the room temperature so as to obtain laser-sintering 3D printing forming type YAG transparent ceramic powder. The laser-sintering 3D printing forming type YAG transparent ceramic powder can be directly formed on a 3D printer and is high in sphericity degree, good in fluidity and high in forming precision. The preparation method has the advantages of simple preparation technologies, easiness in condition control and low production cost, thereby being applied to industrialized production easily.

Owner:UNIV OF JINAN

Carbonization repair method of volatile organic compound-heavy metal compound polluted soil

InactiveCN108672489AHigh evaporative extraction rateImprove extraction efficiencyContaminated soil reclamationResource utilizationCarbonization

The invention discloses a carbonization repair method of volatile organic compound-heavy metal compound polluted soil, and belongs to the field of polluted soil repair. The method comprises the stepsof compound polluted soil pretreatment, organic pollutant separation and extraction, curing agent mixing, granulation of polluted soil uniform mixtures, carbonization of polluted soil uniform mixed granules, storage and maintenance of carbonized polluted soil particles, waste liquid / waste gas collection, waste heat utilization and resource utilization. The heating time, the curing agent mixing quantity and the carbonization time are adjusted by actually measuring the organic matter components and concentrations of the compound polluted soil, heavy metal components and contents, temperature andthe water content, and therefore the optimal work efficiency is achieved. In the working process, volatile organic pollutants are extracted, and dust, waste gas and carbonized heavy metal are absorbed. The method is safe, rapid, low-carbon, environment-friendly and high in continuous working rate, produced carbonized polluted soil particles are high in hardness and strength and low in leaching efficiency and can be used as roadbeds, airfield runways, engineering backfill and the like, and great engineering construction significance is achieved.

Owner:NANJING FORESTRY UNIV

Flower nutrient soil and preparation method thereof

InactiveCN106431575ARich in nutrientsGood water and fat retentionExcrement fertilisersBioloigcal waste fertilisersNutrientFertilizer

The invention discloses a flower nutrient soil and a preparation method thereof. The flower nutrient soil comprises the following components in percentages by weight: 40-50% of bottom mud, 10% of volcanic, 5% of perlite, 15-20% of spent mushroom compost, 15-20% of sawdust and 5-10% of wormcast, and the nutrient soil is prepared from the various components. The flower nutrient soil is abundant in nutrient substances, good in water retention and fertilizer retention properties and good in gas permeability, contains various wastes, and has the advantages of low carbon and environmental protection.

Owner:GUIZHOU UNIV

Preparation for shrimp/crab shell biomass charcoal based supercapacitor electrode material

InactiveCN108002360ALarge specific surface areaHigh specific capacitanceHybrid capacitor electrodesChemical industryCapacitanceCarbonization

The invention relates to a method for preparing a supercapacitor electrode material and in particular to a method for preparing a shrimp / crab shell biomass charcoal based supercapacitor electrode material. The method comprises the following steps: pretreating shrimp / crab shells, and performing primary carbonization, activation and secondary carbonization. By adopting the method, shrimp / crab shellsare adopted as a carbon source of the supercapacitor electrode material, and the supercapacitor electrode material is an activated carbon material prepared from biomass. The supercapacitor electrodematerial prepared by using the method is high in specific surface area and high in specific capacitance, and in addition has the advantages of being good in energy conservation and emission reduction,low in carbon and environmental-friendly, relatively low in equipment requirement, and the like.

Owner:ZHEJIANG OCEAN UNIV

Preparation method of zirconium nitride powder material for 3DP (three-dimensional printing) forming

InactiveCN106380206AReduce dosageReduce pollutionAdditive manufacturing apparatusEpoxyN dimethylformamide

The invention discloses a preparation method of a zirconium nitride powder material for 3DP (three-dimensional printing) forming. The method is characterized by comprising the following steps: adding polyvinyl butyral and sodium hexametaphosphate into zirconium nitride, and carrying out spray drying to obtain granulated zirconium nitride of which the granularity is 30-120 mu m; and adding 86-90 wt% of granulated zirconium nitride, 3-6 wt% of epoxy resin and 0.3-1.5 wt% of dicyandiamide into a grinder, starting the grinder, and grinding at the rotation speed of 200 rpm for 20 minutes, adding 6-10 wt% of N,N-dimethylformamide (totaling 100 wt%), grinding at the rotation speed of 200 rpm for 20-30 minutes, and drying to obtain the zirconium nitride powder material for 3DP forming. The granularity of the obtained zirconium nitride powder material for 3DP forming is 30-150 mu m. The material can be directly formed on a 3D printer, and has high forming precision. The preparation method has the advantages of simple technique, controllable conditions and low production cost, and can easily implement industrial production.

Owner:UNIV OF JINAN

Culture medium for Chinese yams and making method thereof

InactiveCN106831253ARealize resource utilizationAvoid exceeding the standardExcrement fertilisersBioloigcal waste fertilisersBiotechnologyContinuous cropping

The invention discloses a culture medium for Chinese yams and a making method thereof. The culture medium is prepared from, by weight, 10-30% of bottom mud, 25-30% of mushroom residues, 25-30% of corn straw and 20-30% of earthworm cast. The culture medium for the Chinese yams is rich in nutrient substance and good in gas permeability of soil, contains various waste, and being high in recycling and utilizing rate because the waste materials are recycled and lasting in fertilizer efficiency; the yield of the Chinese yams can reach 71% compared with existing yield increase, the yield increase is remarkable, culture cost is low, labor intensity is low, operation is easy, and the continuous cropping obstacles of the Chinese yams can be overcome. The yield of the Chinese yams is high, the Chinese yams are easy to produce on a large scale and popularize, and the culture medium has the advantages of being low in carbon content and environmentally friendly.

Owner:GUIZHOU INST OF SOIL & FERTILIZER +1

Preparation of silicon nitride ceramic powder through laser sintering and rapid moulding

InactiveCN104944962ASmall median diameterNarrow particle size distributionPolyvinyl alcoholTriethylenetetramine

The invention discloses a preparation method of silicon nitride ceramic powder through laser sintering and rapid moulding. The method comprises the following steps: pretreating silicon nitride ceramic powder by using polyvinyl alcohol to obtain the pretreated silicon nitride ceramic powder; then in a grinder, adding the following components by mass percentage: 80-85% of pretreated silicon nitride ceramic powder, 4-8% of phenolic resin, 2-5% of polyvinyl butyral and 0.8-3% of triethylenetetramine, turning on the grinder with rotating speed being 250 rotation / min, grinding for 5 minutes, adding 7-12% of acetone, wherein sum of the components is 100%, and rotating speed of the grinder is 250 rotation / min, grinding for 40-60 minutes, and drying to obtain the silicon nitride ceramic powder. The material can be directly moulded under laser sintering, moulding precision is high, and the method has the advantages of simple preparation technology, easy control of condition, low production cost, and easy industrial production.

Owner:UNIV OF JINAN

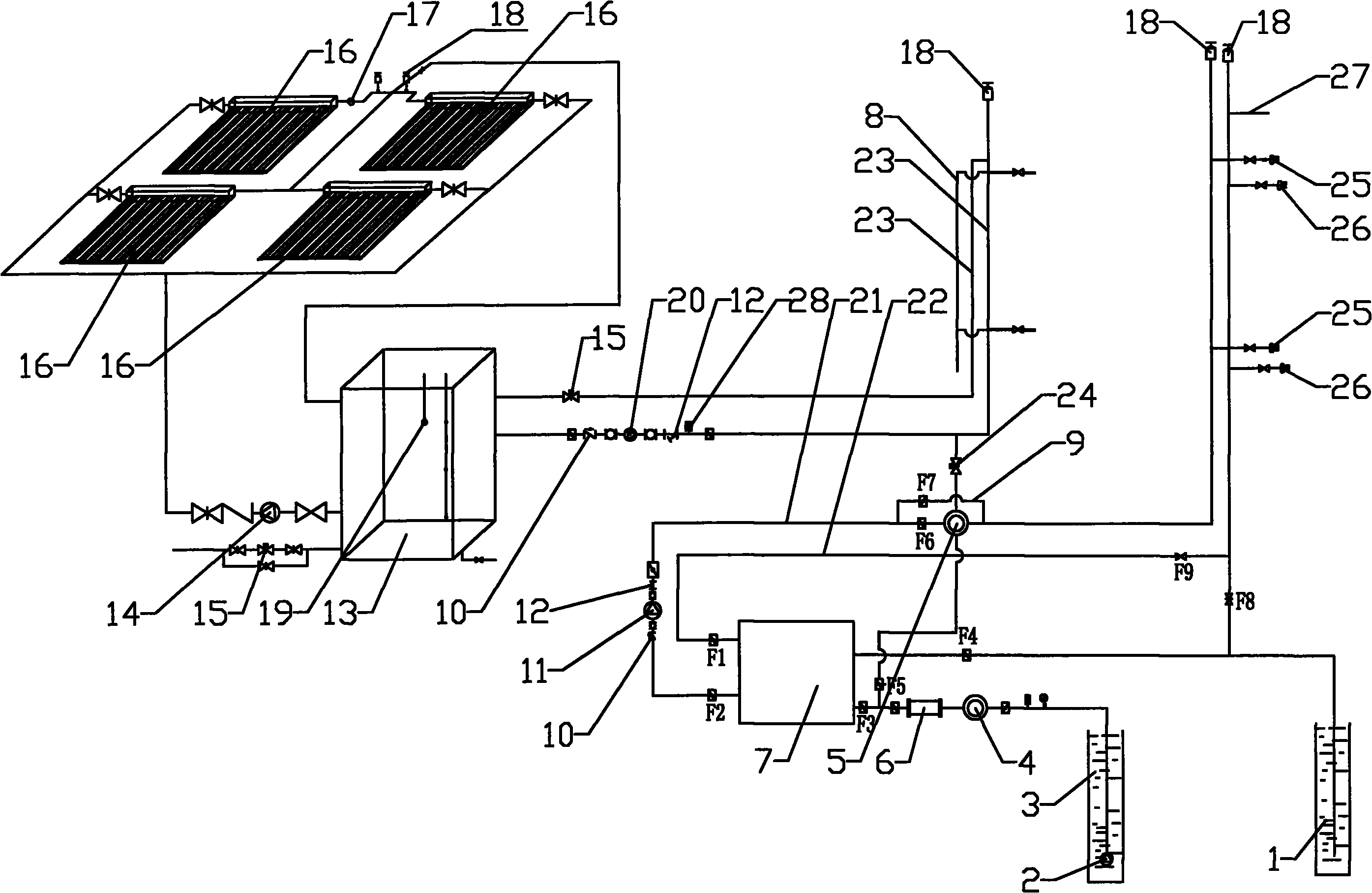

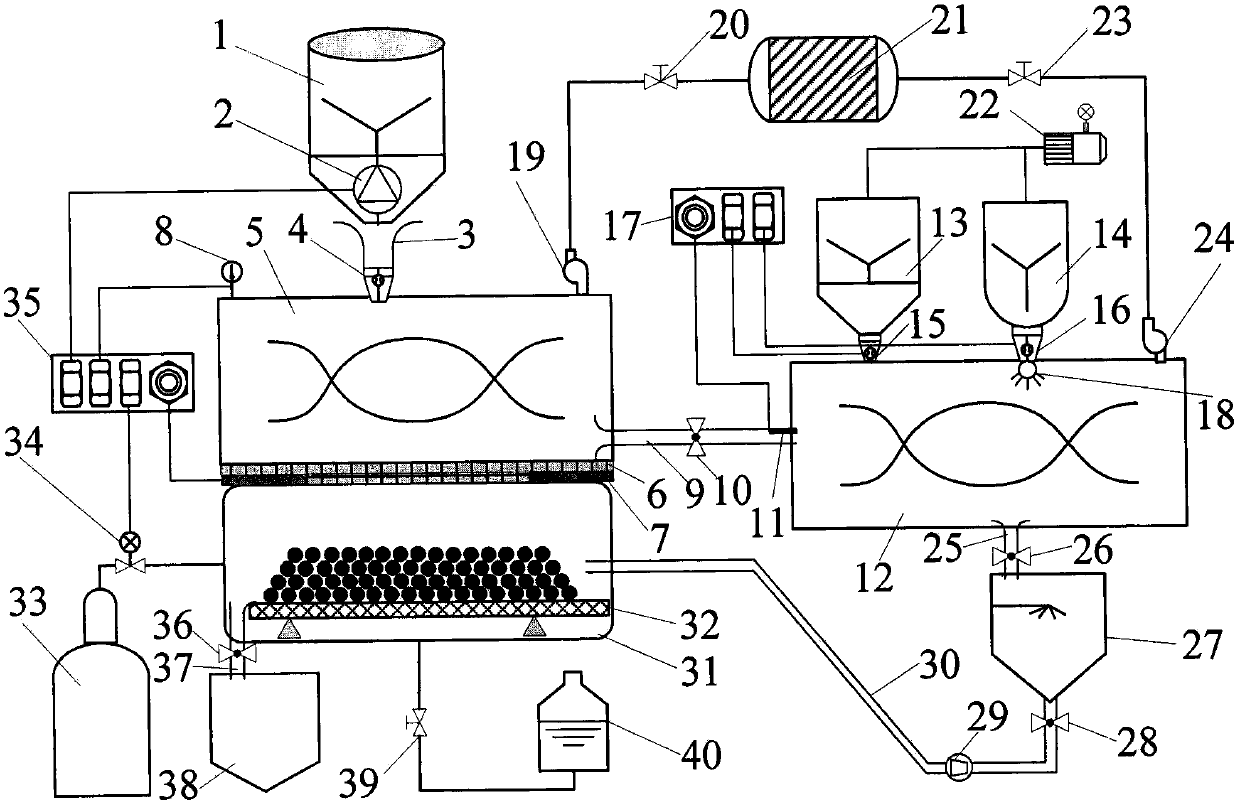

Treatment system for carbonizing and curing silt soil by heterotopic active magnesium oxide

ActiveCN108128991AAdjust dosage in real timeGuaranteed work efficiencyFixation/solidifcation sludge treatmentProcess orientedSludge

The invention discloses a treatment system for carbonizing and curing silt soil by heterotopic active magnesium oxide. The system comprises a pretreatment device, a curing agent supply device, a uniform mixing device, a granulation device, a carbonization device and a collection device. Through the sequential working of the devices, the sufficient blending of silt and a curing and the quick carbonization of a magnesium oxide cured silt granule are completed; thus, the problems of the difficult carbonization and curing of high-water-content and low-permeability silt / sludge soil are solved; multiple sensors particularly arranged in the system are cooperatively used; the supply quantity of the curing agent can be regulated through actually measuring a water content; the particle size of the granule and the pressure of carbon dioxide are regulated according to the property of the soil; the work efficiency is greatly improved; all the devices are more systematized and process-oriented; milldust and the carbon dioxide can be absorbed in the use process of the devices; the secondary pollution is avoided; the carbonized granule of the silt, generated after the devices finish working, is high in hardness and high in shear strength, and can be used as a filling material for a roadbed, an airport runway, engineering backfilling and the like, and the treatment system has great engineeringconstruction significance for the reutilization of silt / sludge in engineering.

Owner:SOUTHEAST UNIV

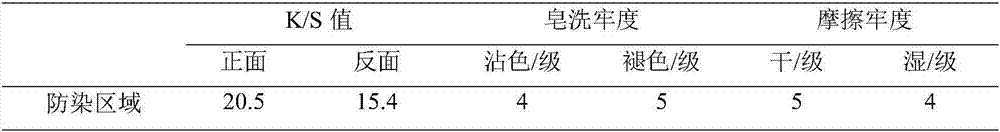

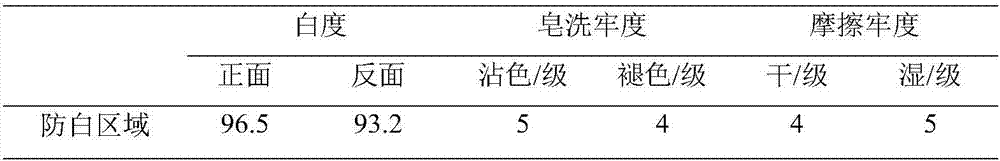

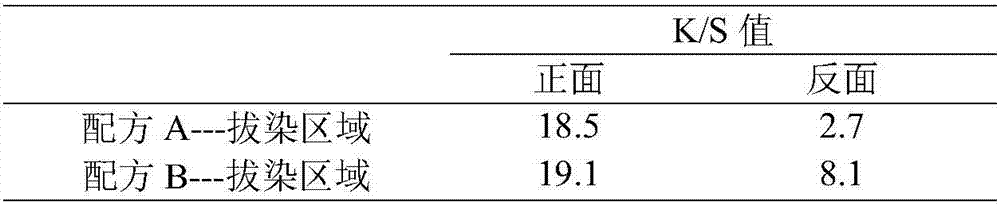

Reactive dye resist printing process based on ink jet printing process

ActiveCN107201682ASimple process operationReduce manufacturing costDyeing processReactive dyePrint-through

The invention discloses a reactive dye resist printing process based on an ink jet printing technology, and belongs to the technical field of ink jet printing. The reactive dye resist printing process comprises the following steps: starching, drying, computer printing color separation and painting (CAD) editing and processing, preparation of dye resistant and white resistant ink, jet printing, ground dyeing, steaming, washing and drying. The reactive dye resist printing process has the advantages that the process is simple to operate, dye resistant designs can adopt the computer printing color separation and painting (CAD) editing and processing, to obtain required patterns, then the patterns can be printed through an ink nozzle controlled through a computer, the printed designs are clear in outlines and vivid and gorgeous in colors, and meanwhile the dosage and cost can be reduced.

Owner:绍兴柯桥越强助剂有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com