High-crystal, light and high-strength gauge stuff ceiling

A ceiling and lightweight technology, applied in cement mixing devices, clay preparation devices, ceramic molding machines, etc., can solve the problems of decorative gypsum ceilings such as heavy weight, low safety factor, high transportation and installation costs, and achieve light weight and low cost , the effect of light unit mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

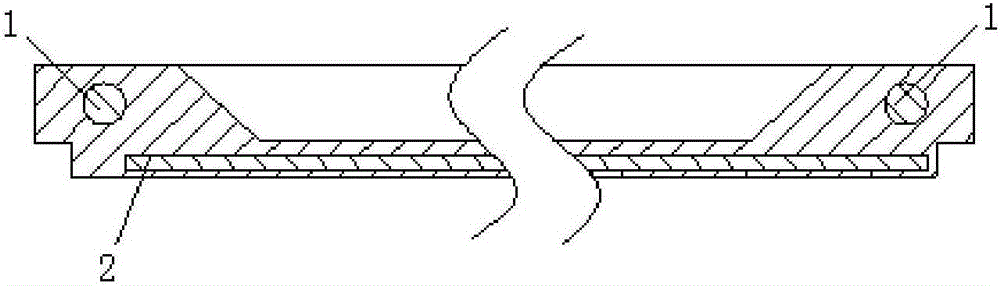

Image

Examples

Embodiment

[0033] This embodiment includes the following steps:

[0034] (1) Prepare stirring solution

[0035] Use a measuring cup to measure 1200g of water, 108g of polyvinyl alcohol solution (solution mass concentration 8%), and 84g of 707 latex (solution mass concentration 40%). After mixing, add 2.4g of water reducing agent, 18g of water repellent, and 0.84g of retarder , defoamer 0.36g, stir well, obtain 1413.6g stirring solution;

[0036] (2) Preparation of mixed powder

[0037] Mix 2300g of gypsum powder and 92g of white cement evenly to obtain a mixed powder;

[0038] (3) Preparation of gypsum slurry

[0039] Pour the mixed powder obtained in step (2) into a bucket filled with the stirred solution obtained in step (1), add 34 g of chopped glass fibers while stirring, and stir for 30 seconds to obtain a gypsum slurry;

[0040] (4) Pouring molding

[0041] Pour 1 / 3 of the gypsum slurry obtained in step (3) into the PVC mold to make a base, touch it flat, cover the bottom, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com