Patents

Literature

192results about How to "Avoid exceeding the standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

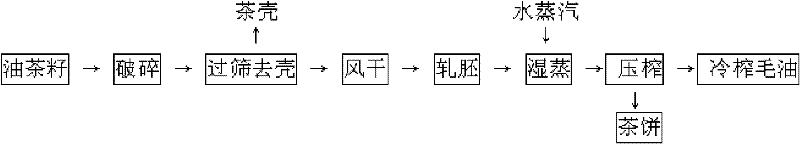

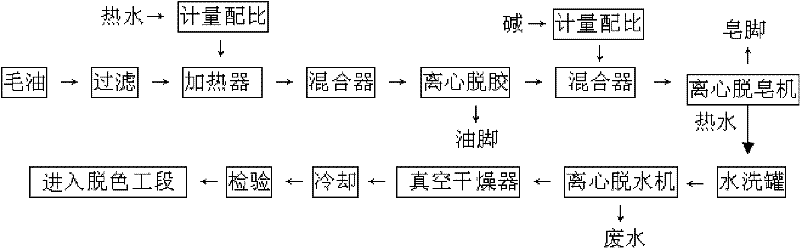

Low-temperature cold-pressing and bivariate continuous refining and processing method for oiltea camellia seed oil

InactiveCN102329690AAvoid it happening againEasy to dryFatty-oils/fats refiningFatty-oils/fats productionSocial benefitsActivated carbon

The invention discloses a low-temperature cold-pressing and bivariate continuous refining and processing method for oiltea camellia seed oil, which mainly comprises the following technical steps of squeezing, leaching, degumming, deacidifying, decoloring, deodorizing, winterizing, dewaxing and the like. In the method, the technology of low-temperature drying and low-temperature squeezing and the bivariate mixed decoloring technology of activated carbon and activated clay are adopted to adsorb and decolor oil, thereby preventing from generating harmful substances, such as benzopyrene, coking objects, carbide and the like, and improving the quality and the grade of the product. The method has good economic benefit and social benefit.

Owner:贵州大龙健康油脂有限公司

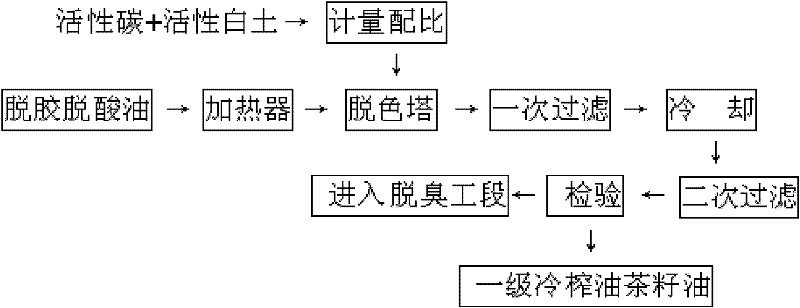

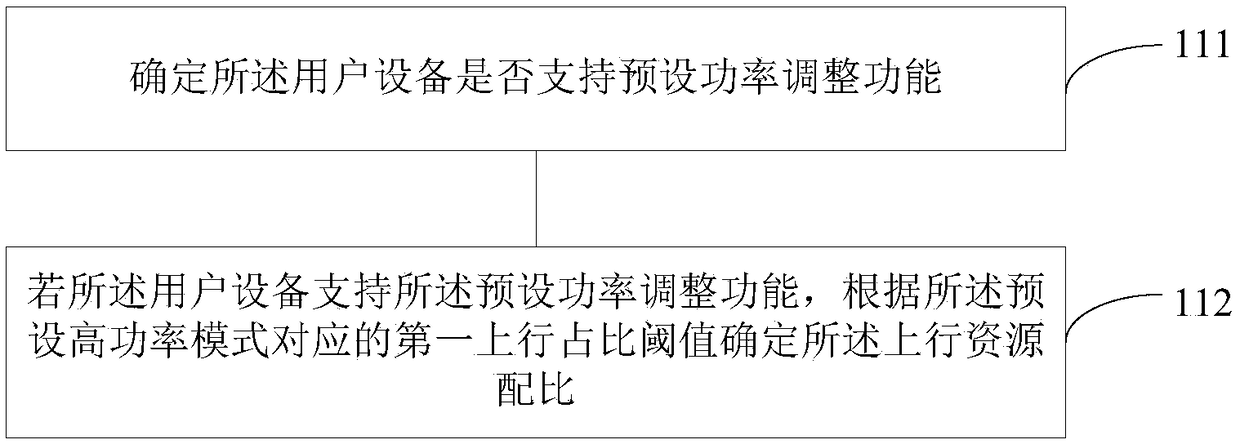

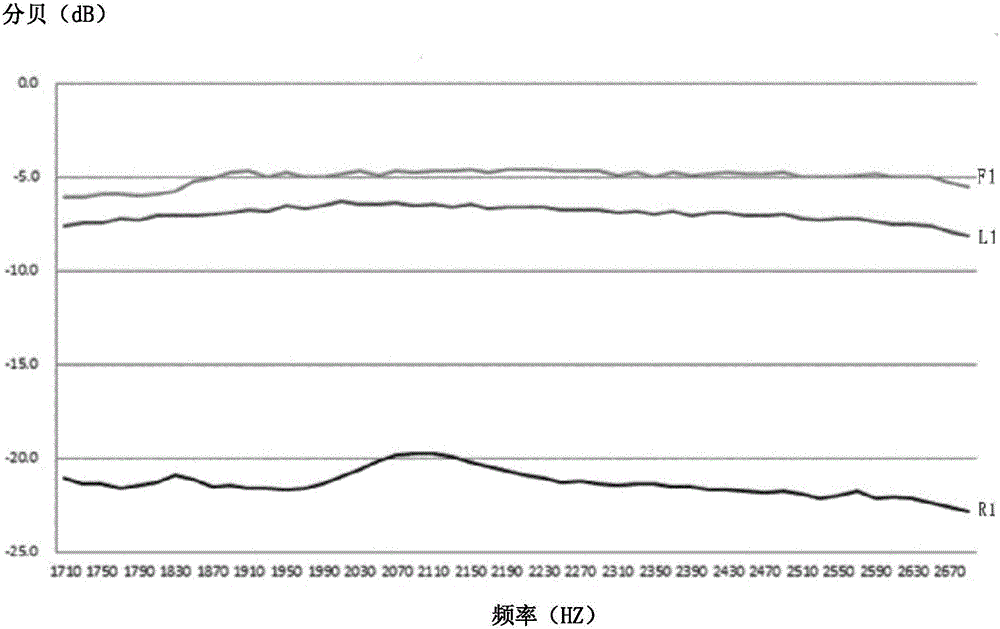

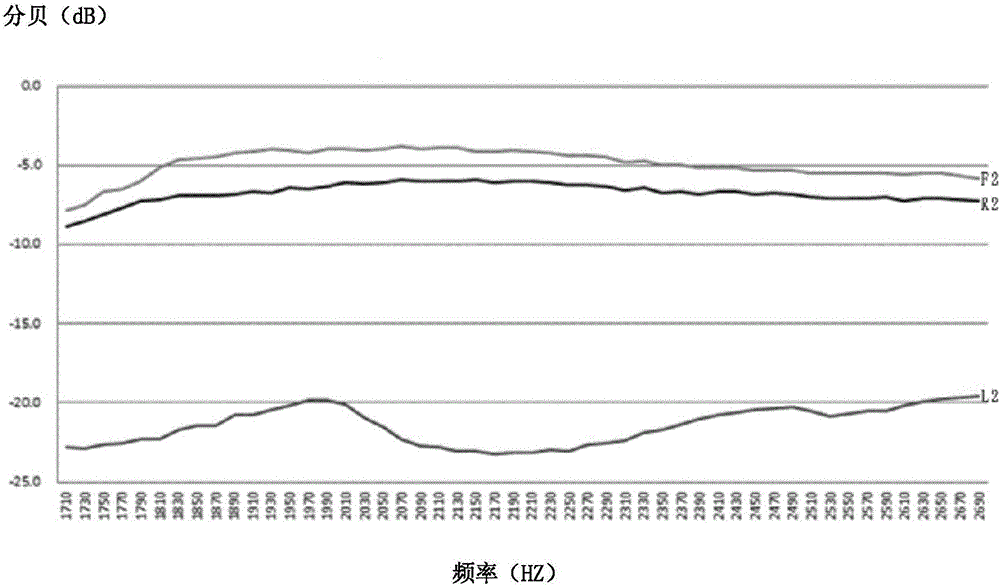

Method and device for controlling uplink transmission power, base station and user equipment

ActiveCN108702709AImprove the ability of uplink information transmissionWill not affect healthPower managementNetwork data managementInformation transmissionUplink transmission

The invention provides a method and device for controlling uplink transmission power, a base station and user equipment, wherein the method comprises the steps of determining the uplink resource ratioof the user equipment in a preset high-power mode; if the uplink resource allocation ratio is larger than or equal to a preset uplink duty ratio threshold value corresponding to the preset high-powermode, determining power adjustment information; sending the uplink resource allocation and the power adjustment information to the user equipment, so that the user equipment performs uplink information transmission according to the uplink resource proportion in the preset high-power mode; controlling the uplink transmission power according to the power adjustment information. The method for controlling uplink transmission power provided by the invention is adopted, when the UE is configured to perform uplink information transmission according to a higher uplink resource allocation ratio, theUE can be configured to adjust the uplink transmission power according to the power adjustment information, so that the exceeding of the SAR is effectively avoided., meanwhile, the uplink informationtransmission capability of the UE in a preset high-power transmission mode is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

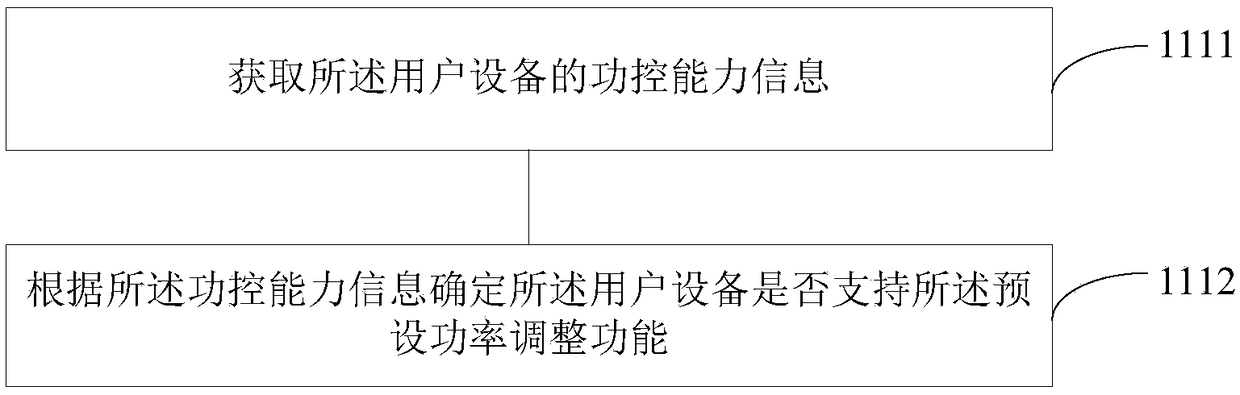

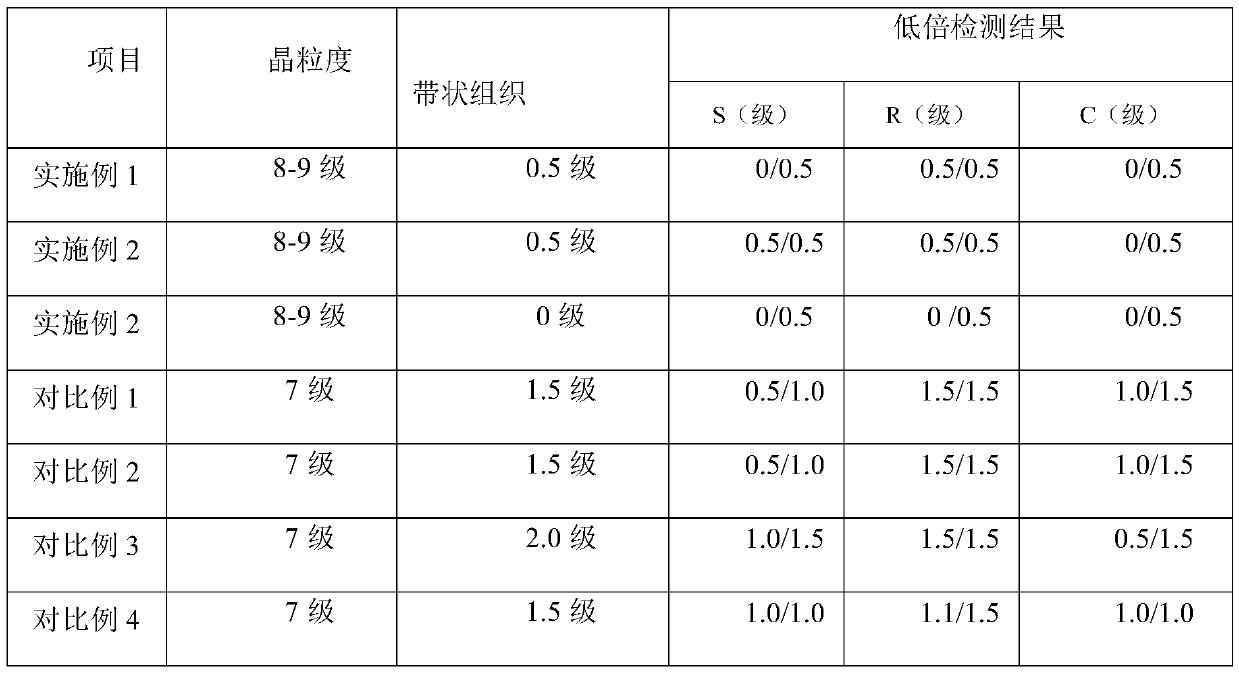

Non-quenched and tempered steel for automobile parts and production process thereof

ActiveCN110791708APromote precipitationPlay a role in precipitation strengtheningUltimate tensile strengthToughness

The invention discloses non-quenched and tempered steel for automobile parts and a production process thereof. The non-quenched and tempered steel comprises less than or equal to 0.20% of Ni, 0.010-0.025% of Ti, 0.012-0.025% of Nb and 0.013-0.019% of N. The process comprises converter smelting, LF refining, RH vacuum treatment, continuous casting and rolling. According to the non-quenched and tempered steel, through reasonable design of components, trace elements such as Ni, Nb, Ti and N are added to refine grains and improve the strength and toughness of the material; refining is carried outthrough a narrow component control technology, soft reduction is used in the continuous casting process, reasonable parameters are adopted to reduce the low-power defects of a casting blank, and the density of the material can be improved; and the structure is uniform through a high-temperature diffusion process in the rolling process, the grains are refined through a controlled cooling and controlled rolling technology, the strength is improved, and finally the comprehensive performance of the material is greatly improved.

Owner:ZENITH STEEL GROUP CORP

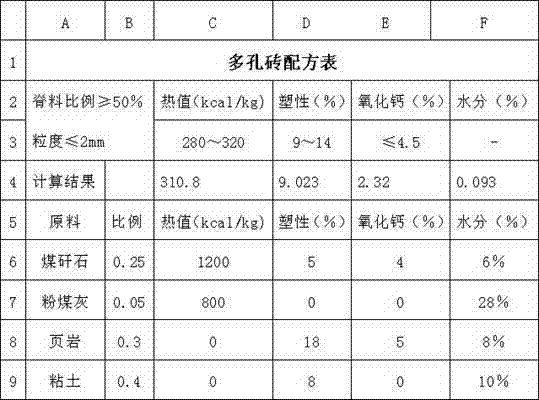

Brick making method

ActiveCN102503371ATo achieve the effect of saving electricityAvoid exceeding the standardCeramic materials productionClaywaresBrickCombustion

The invention relates to a brick making method, which uses raw materials of coal gangue, furnace clinker, shale, coal ash and clay and prepared according to the steps of (1) smashing and grinding the raw materials to be particles with the particle size below 2mm; (2) evenly mixing the particles of the raw materials, adding warm water to mix and make mud materials, and then conducting ageing treatment for more than 24 hours; (3) adopting a vacuum brick squeezing machine with the vacuum degree of -0.07MPa to -0.08MPa and molding moisture of 13.5%-14.5% to make the mud materials into green bricks, and adding a transducer on a main motor of the vacuum brick squeezing machine; (4) placing the green bricks into a drying hole to remove moisture and dry in a concentration mode; (5) adopting residual carbon of raw material gangue, furnace clinker and coal ash, and roasting by adopting a method of taking internal combustion as the principal thing and external combustion as the minor thing; and (6) cooling to obtain end products and detecting the content of calcium oxide. The brick making method is low in coal consumption and power consumption and stable in quality of made bricks.

Owner:河南华新奥建材股份有限公司

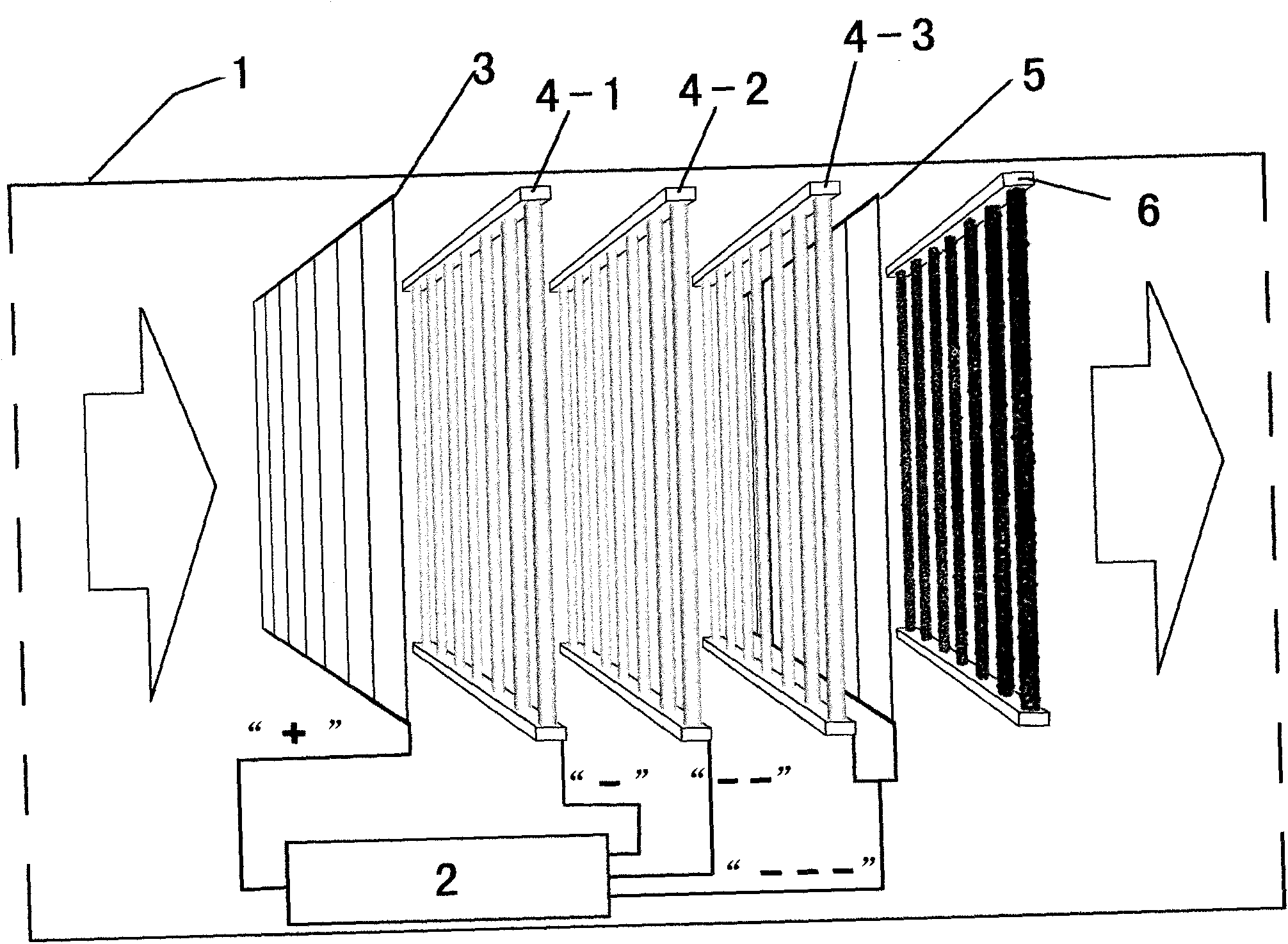

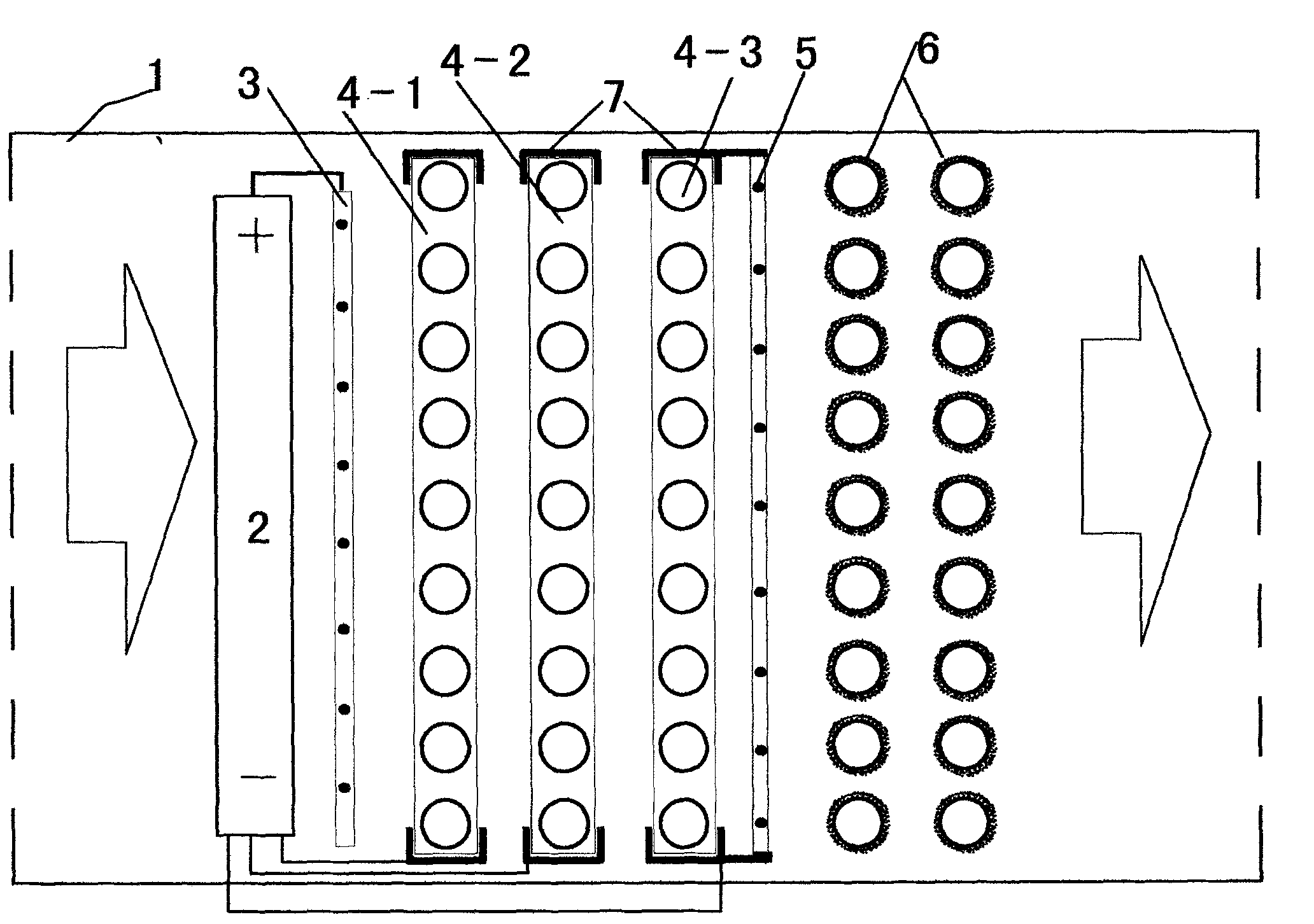

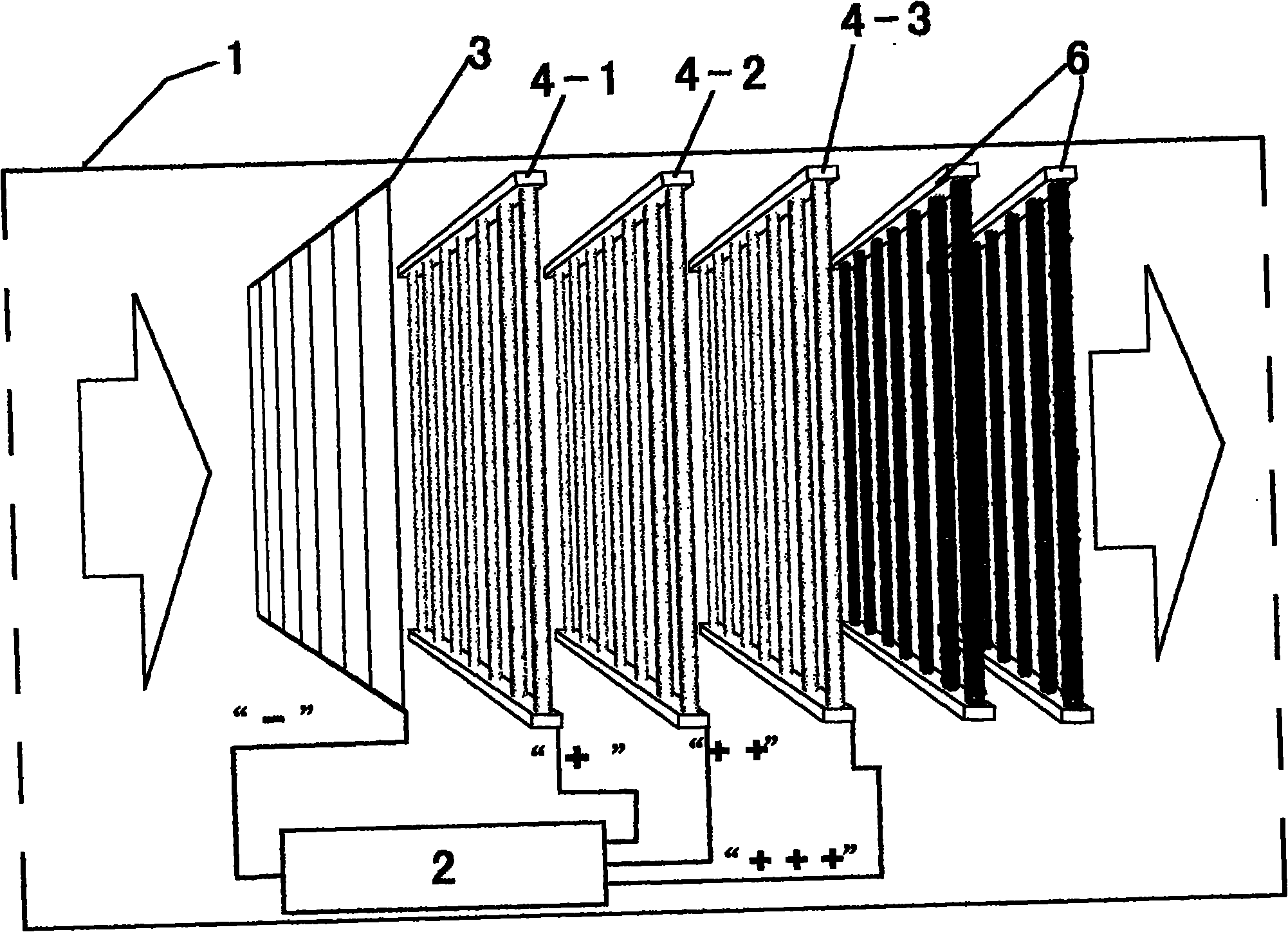

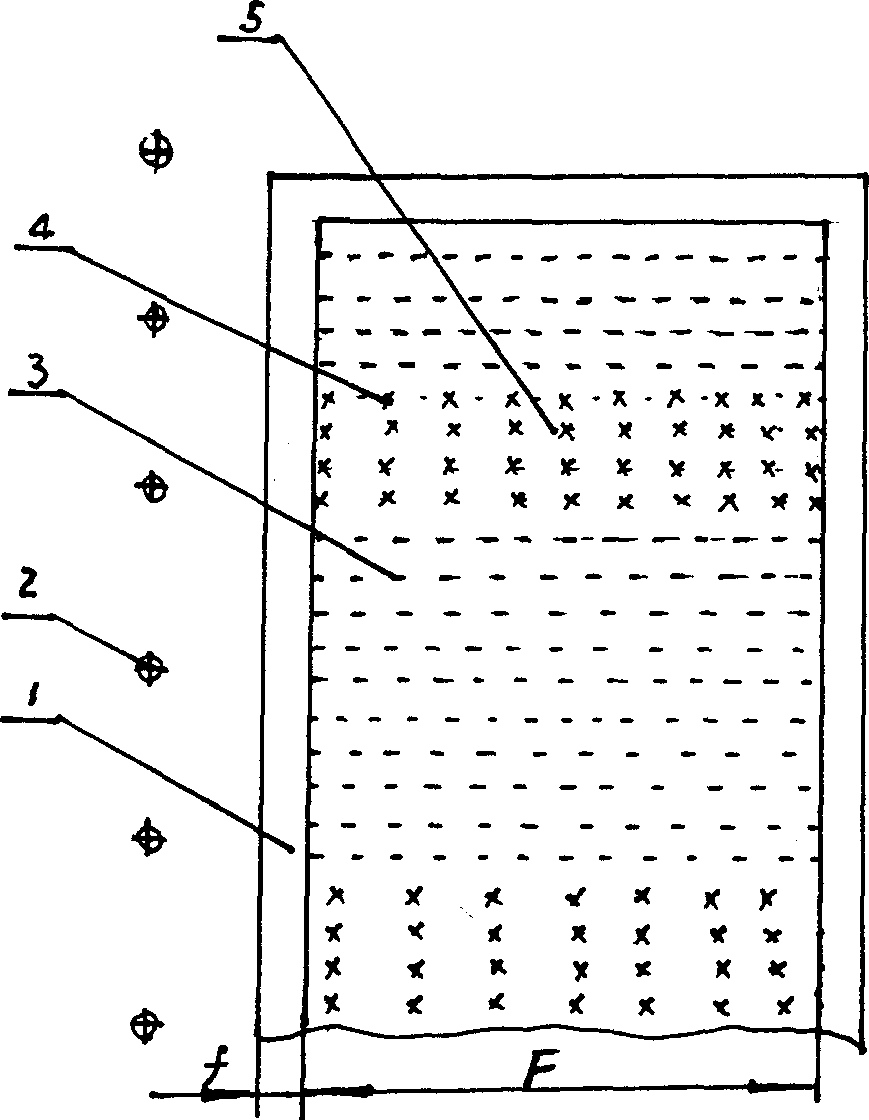

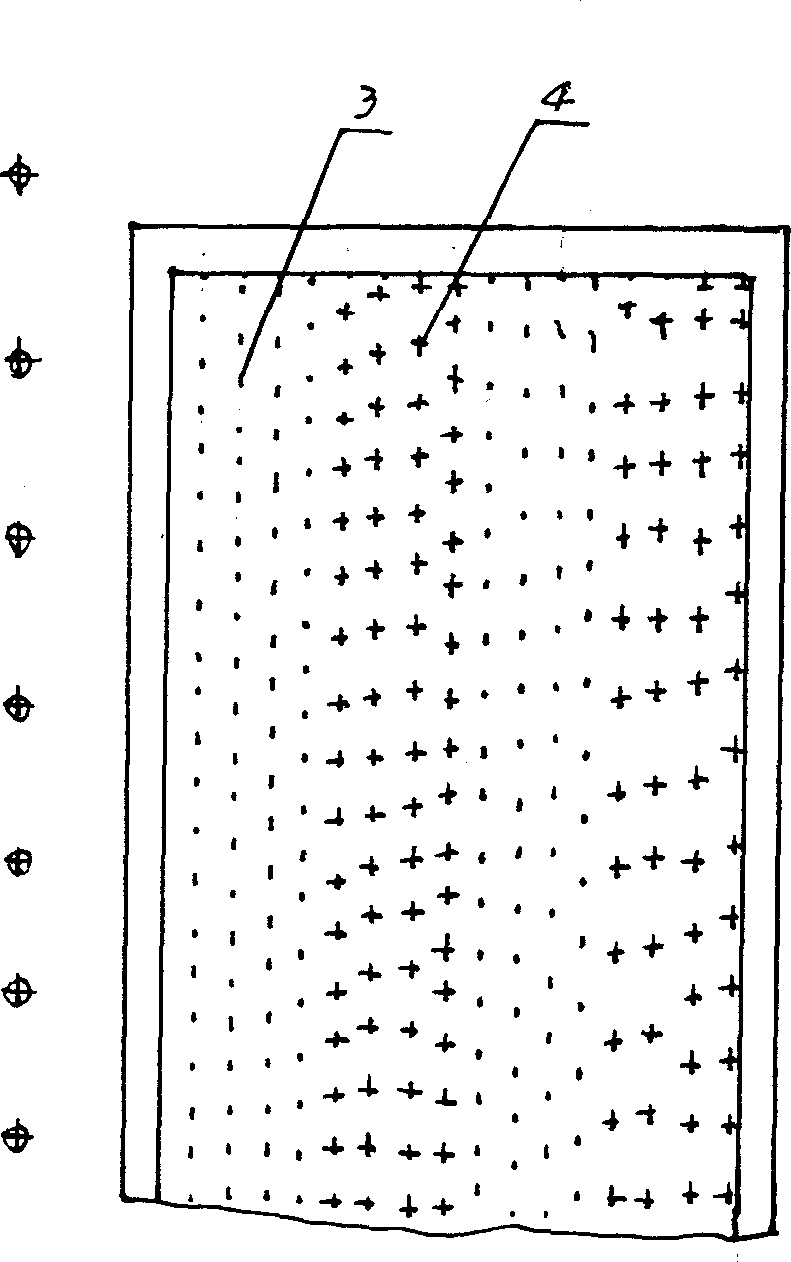

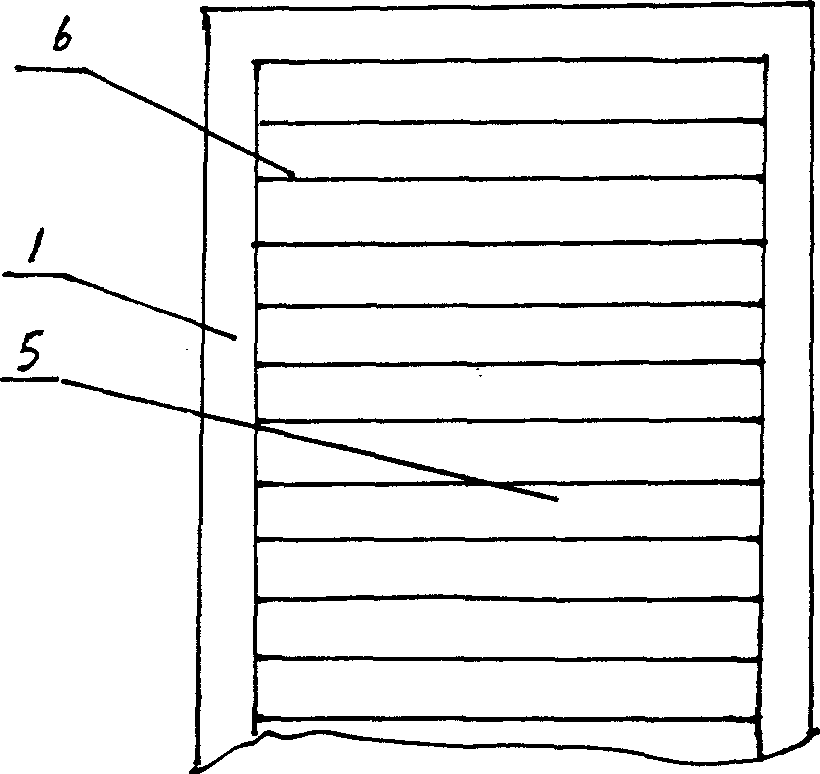

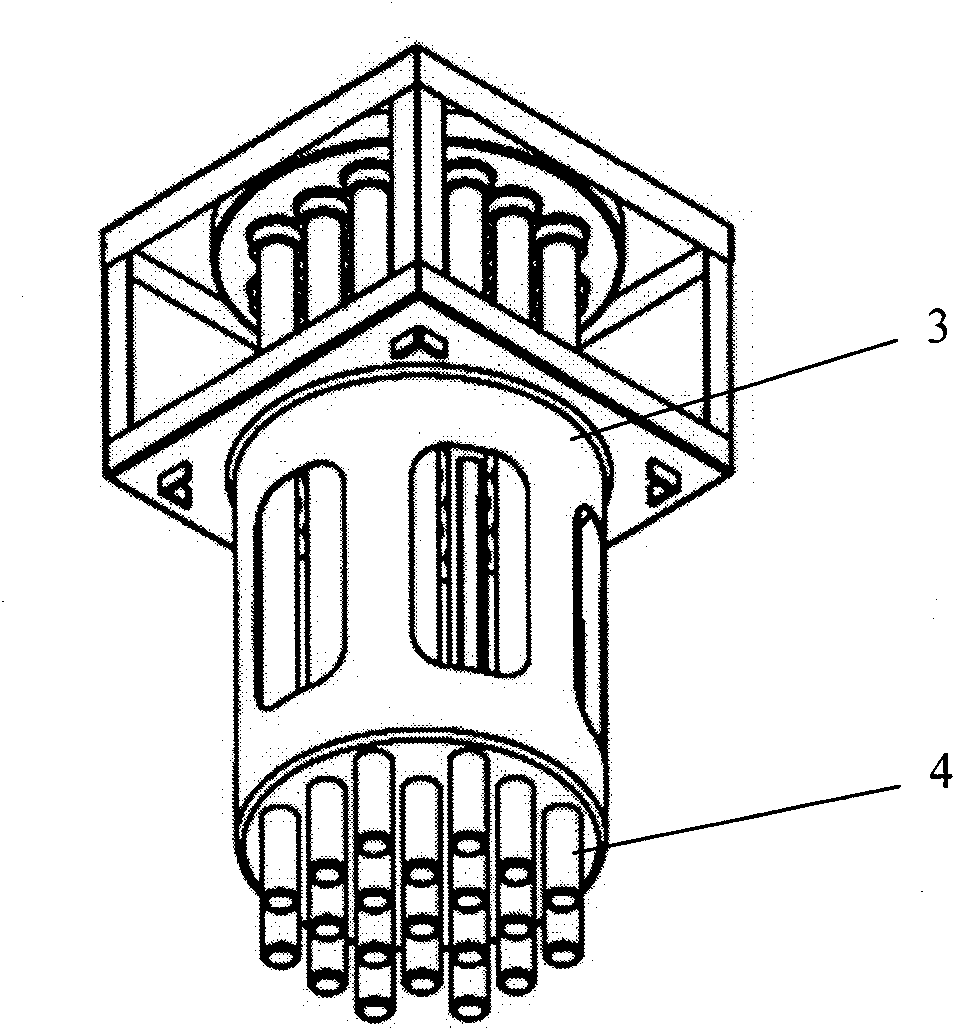

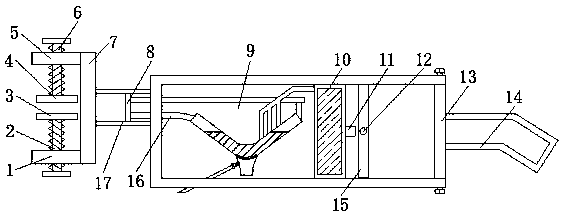

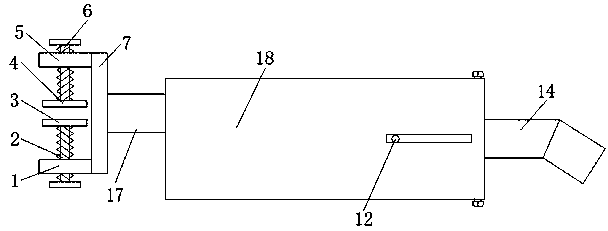

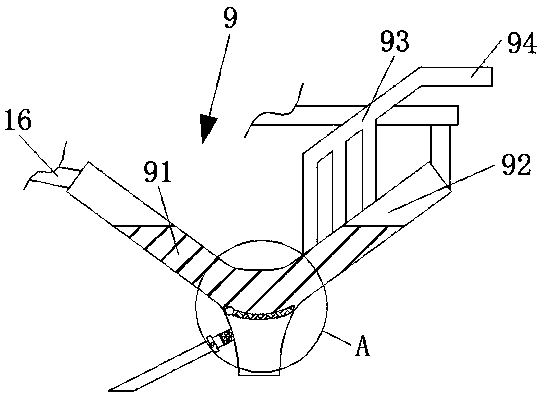

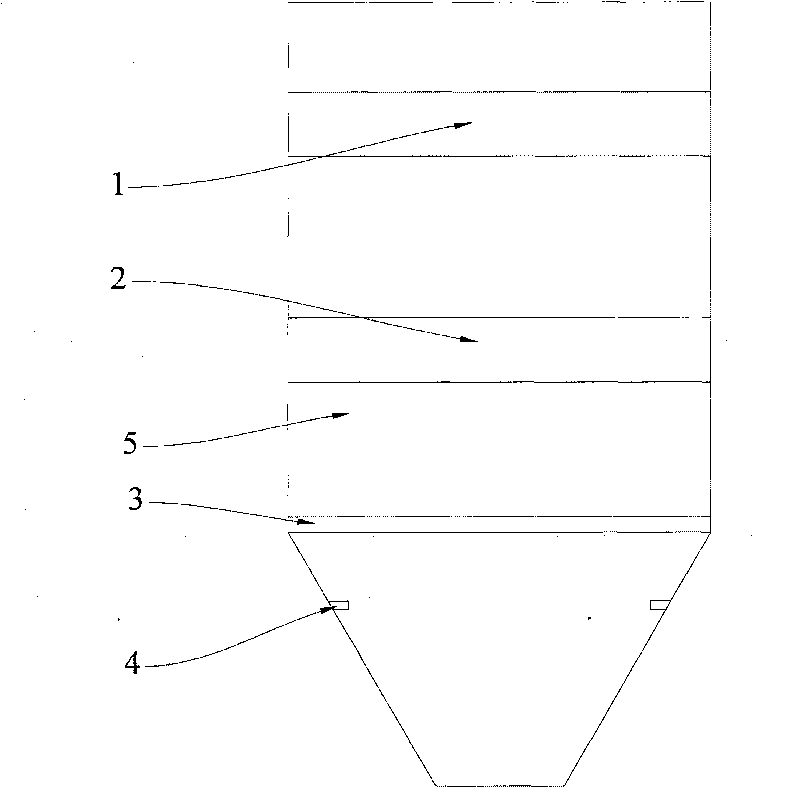

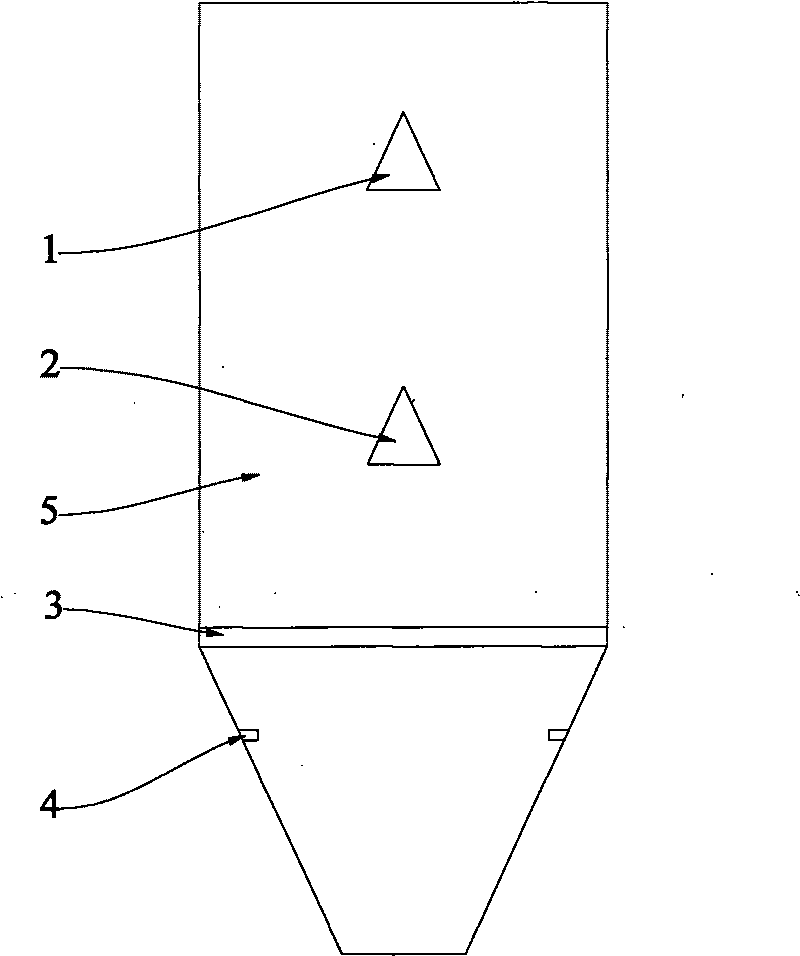

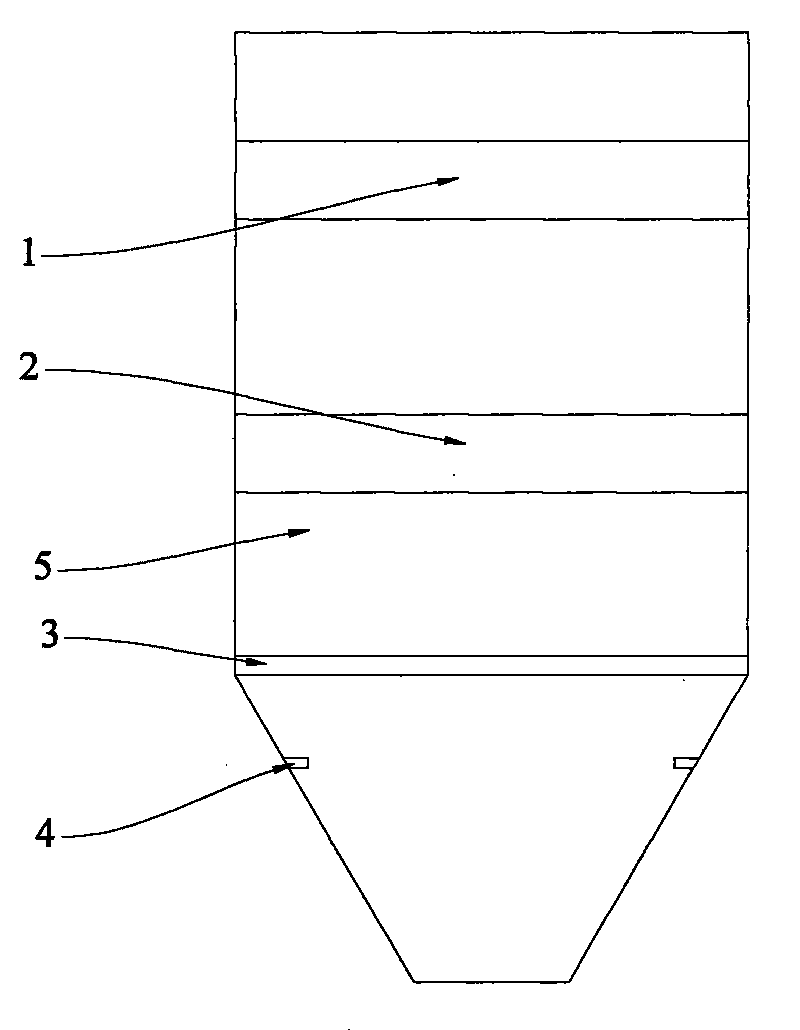

New method and device for air purification

InactiveCN102038973AHigh voltageIncrease wind speedDeodrantsExternal electric electrostatic seperatorAir volumeDecomposition

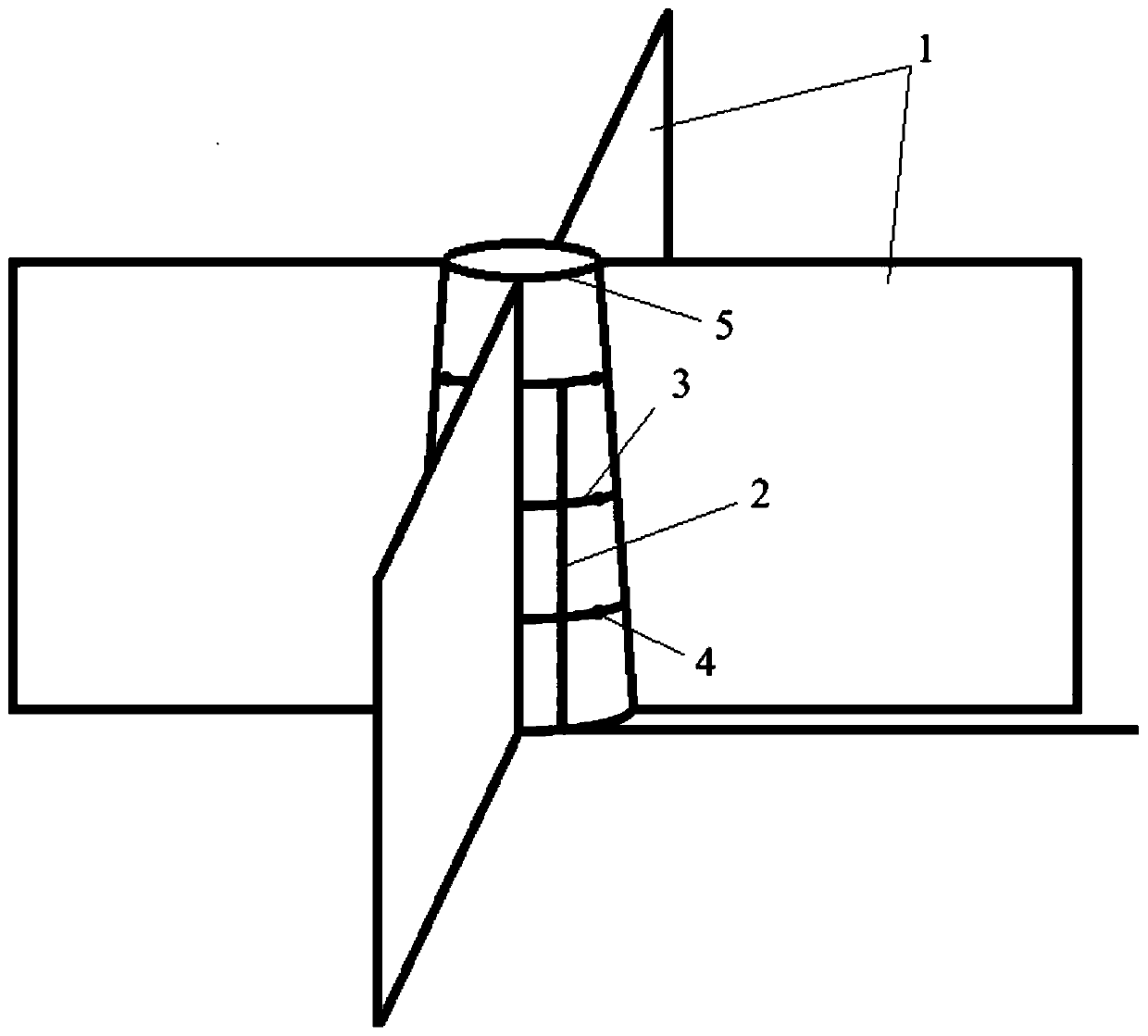

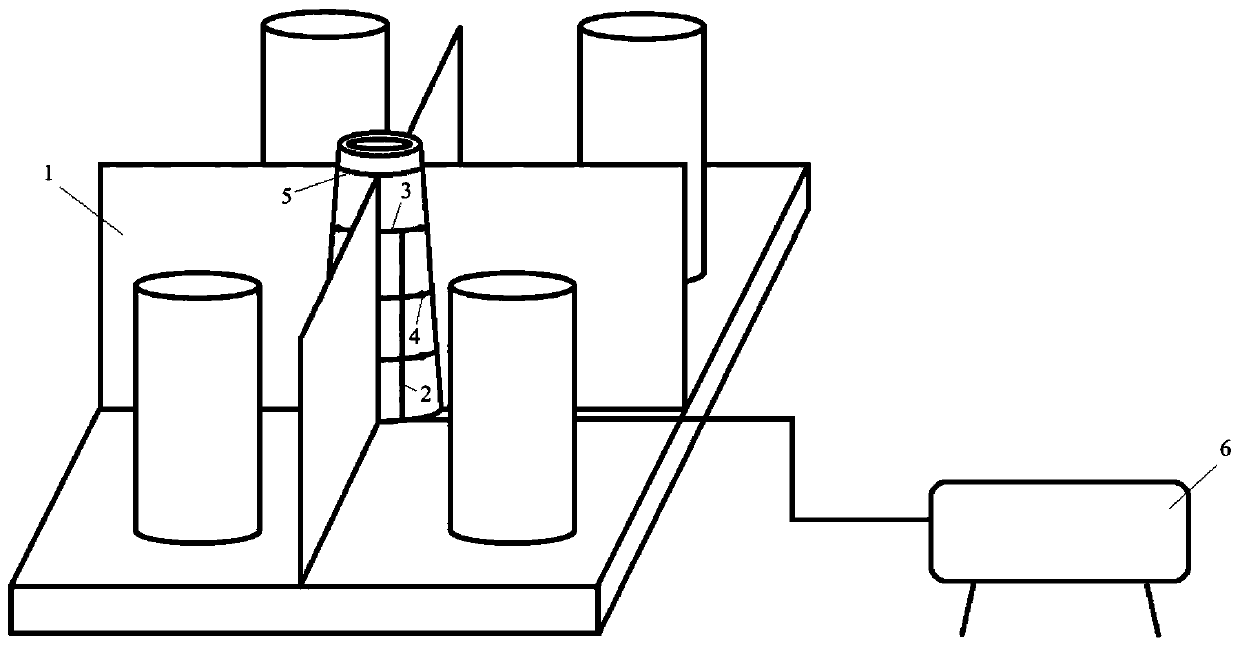

The invention discloses a new method and a device for air purification. The device comprises an enclosure (1), a charge electrode grid (3), multi-stage adsorption accelerating grids (4-1, 4-2, 4-3 and the like), a negative ion emitter (5), an ozone decomposition unit (6), a high-frequency high-voltage power supply (2) and the like, wherein the charge electrode grid (3), the multi-stage adsorption accelerating grids (4-1, 4-2, 4-3 and the like), the negative ion emitter (5) and the ozone decomposition unit (6) are arranged in the enclosure (1). When high air quantity is needed, a fan can be arranged in front of the charge electrode grid (3) or in front of an air outlet. The device is characterized in that: in the enclosure, the (3), the (4-1, 4-2, 4-3 and the like), the (5) and the (6) are sequentially arranged in the direction from an air inlet to the air outlet. The (2) is arranged in a closed space. An electric field is arranged downwind or upwind in the direction from the charge electrode grid (3) to the negative ion emitter (5). The field intensity is of gradient. The high-frequency high-voltage power supply (2) has multi-stage voltage output. When the electric field is arranged downwind, the high-voltage '+' pole is connected with the (3), and the high-voltage '-' pole is connected with the first, second and third adsorption accelerating poles (4-1), (4-2) and (4-3) and the negative ion emitter (5) respectively. When the electric field is arranged upwind, the poles of the (2) are connected reversely, and the (5) is removed at the same time. The device has simple and reasonable integral structure, is sufficient to decompose and adsorb pollutants, generates more negative oxygen ions, and is convenient to clean.

Owner:孙家齐 +2

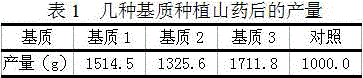

Technology for planting yunnan Dizhu pinellia tube GAP

The technology for planting Yannan Dizhu pinellia tube GAP includes selecting land, selecting seed, preparing land, seedling, preventing diseases and pests, weeding, applying fertilizer, collecting and processing. The artificially planted planting Yannan Dizhu pinellia tube has the medicinal effect and quality of wild Yannan Dizhu pinellia tube maintained, and has high effective component content, stable effective component content and no pollution. Therefore, the technology of present invention can protect and develop the said medicine resource.

Owner:吴桂权

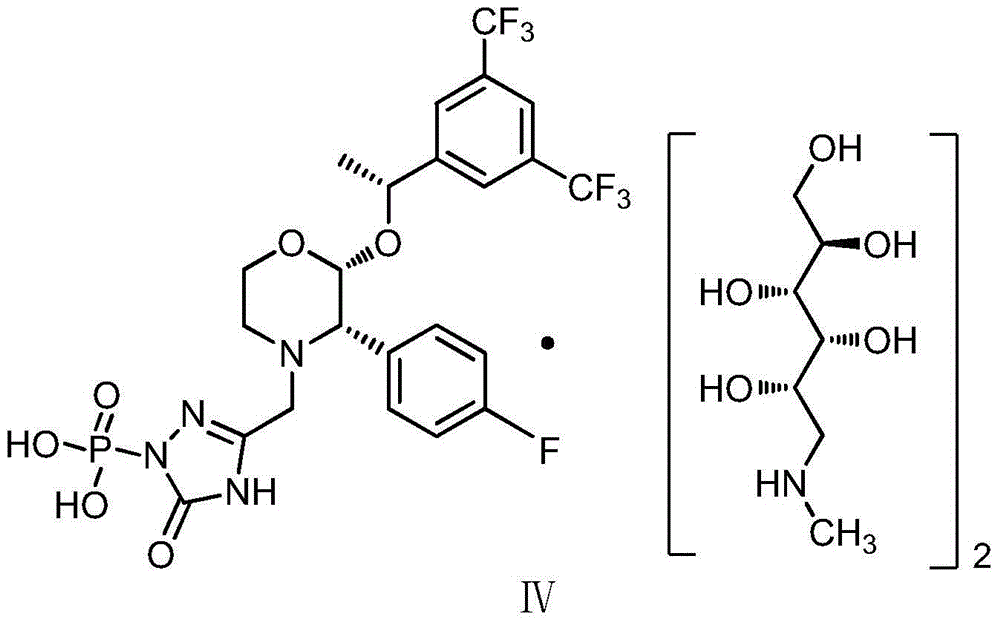

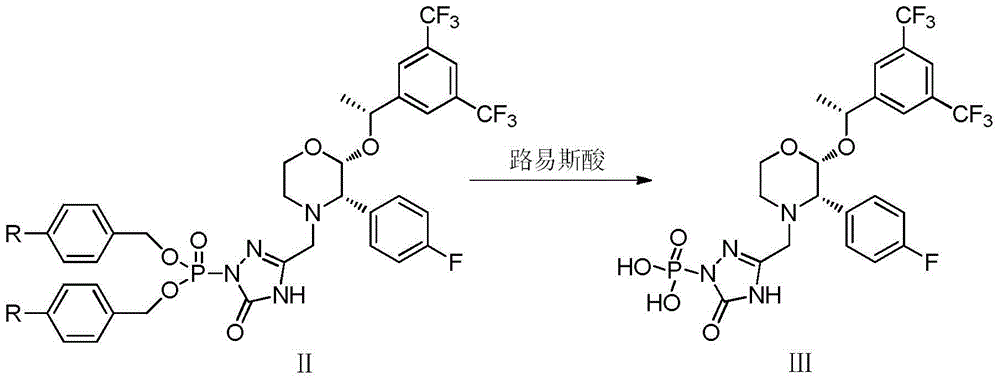

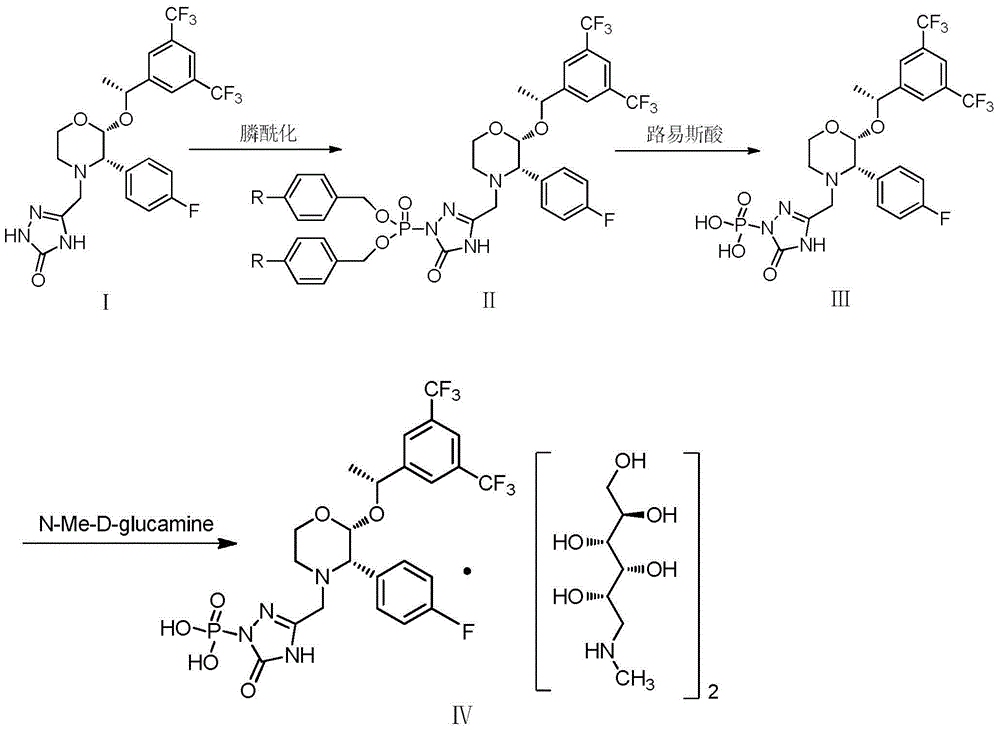

Preparation method of fosaprepitant dimeglumine

ActiveCN104650142AReduce usageAddressing Safety Concerns in Hydrogenation ReactionsOrganic compound preparationGroup 5/15 element organic compoundsFosaprepitant dimeglumineMethyl group

The invention provides a preparation method of fosaprepitant dimeglumine. The preparation method comprises the following steps: by taking aprepitant as a raw material, carrying out phosphorylation on the raw material under an alkaline condition to obtain a dibenzyl ester intermediate; further hydrolyzing the intermediate to obtain fosaprepitant; and further reacting with N-methyl-D-glucosamine to obtain the fosaprepitant dimeglumine. The method provided by the invention is simple to operate and mild in reaction condition, and avoids pressurization and v, so that the method is safe and effective and suitable for industrial production on a large scale.

Owner:LUNAN BETTER PHARMA

Antenna system and electronic equipment employing same

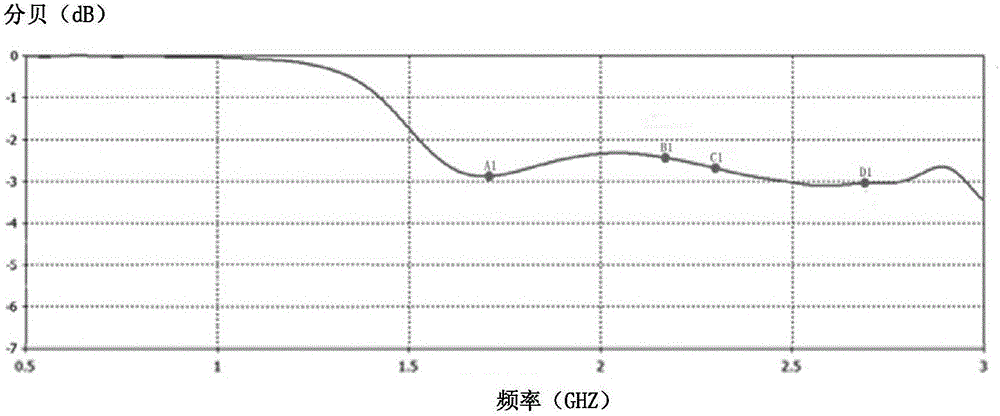

InactiveCN106129616AExpand coverageAvoid exceeding the standardRadiating element housingsAntennas earthing switches associationElectronFeed point

The invention provides an antenna system, which comprises a metal back shell, a system ground unit, an upper antenna module and a lower antenna module, wherein the upper antenna module comprises a main low-frequency antenna, a three-in-one small antenna, a dynamic adjustable switch and a first ground point; each of the main low-frequency antenna and the three-in-one small antenna comprises a low-frequency feed point and a three-in-one small antenna feed point; the lower antenna module comprises a first medium-high frequency antenna, a second medium-high frequency antenna and a second ground point; and each of the first medium-high frequency antenna and the second medium-high frequency antenna comprises a first medium-high frequency feed point and a second medium-high frequency feed point. The invention further provides electronic equipment. The electronic equipment comprises the antenna system. Compared with a related technology, the antenna system provided by the invention has the advantage that the technical problem that the antenna performance is affected by holding in a hand is solved.

Owner:AAC PRECISE MFG TECH CHANGZHOU

Nuclear reactor spent fuel dry type storage house

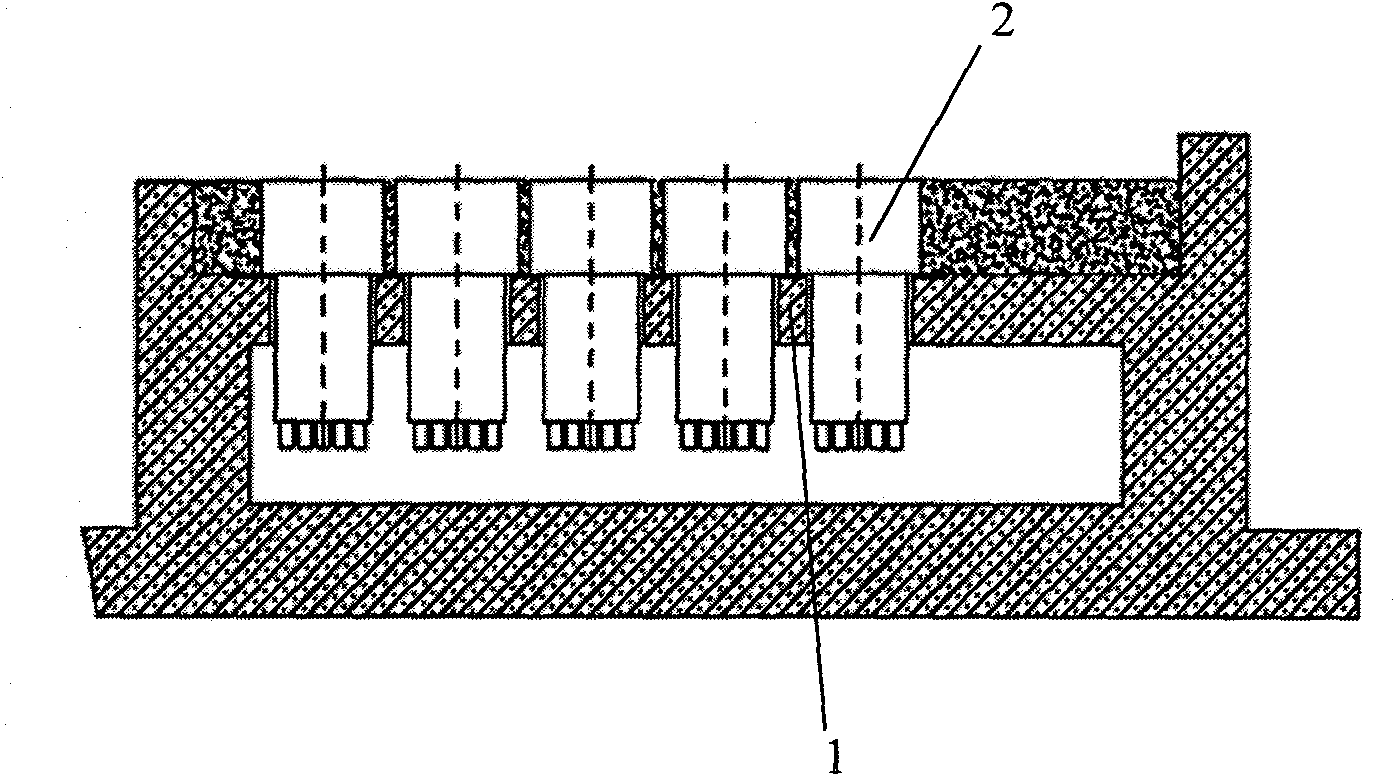

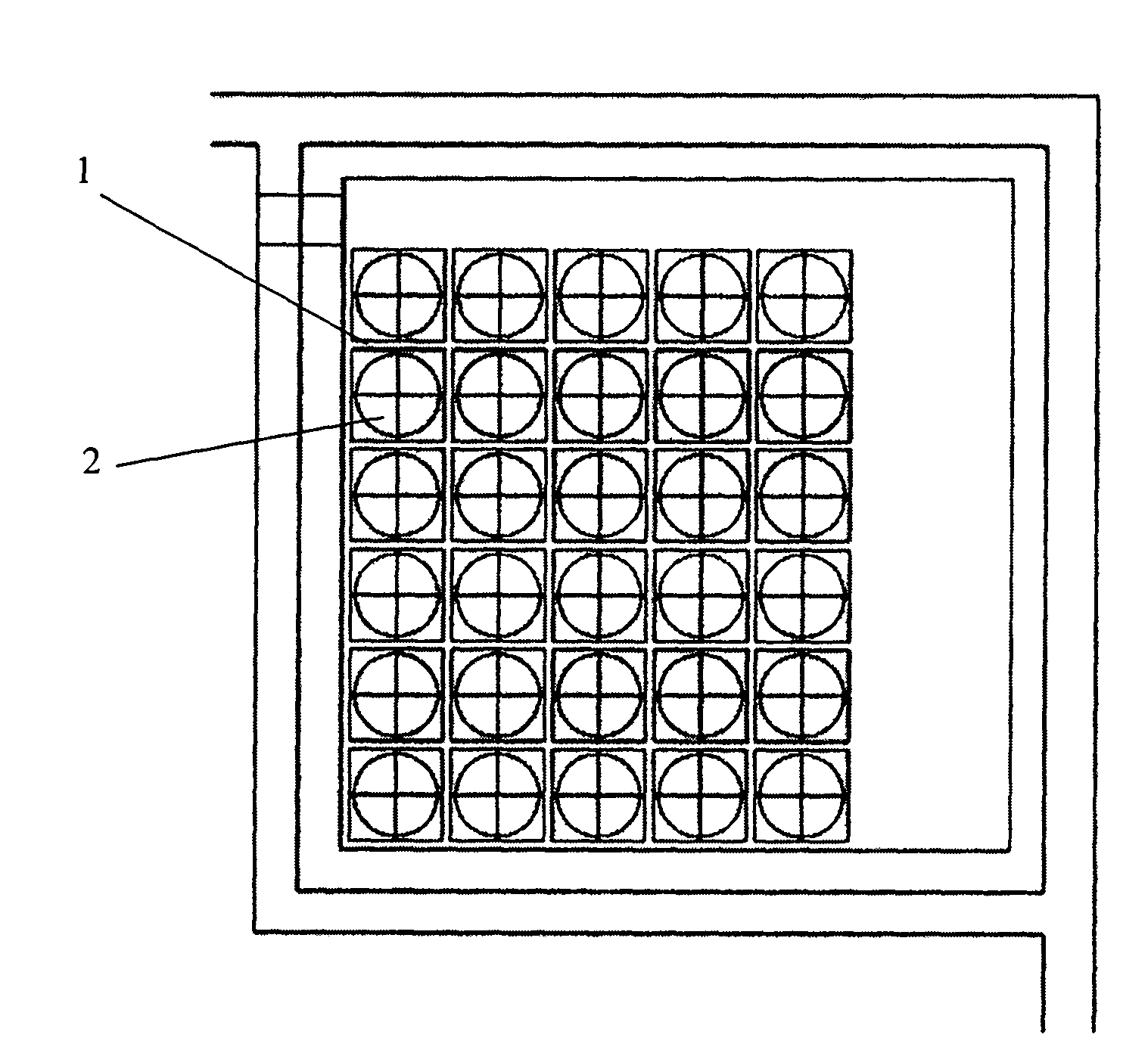

InactiveCN102097142ASimple operation and maintenanceSmall amount of operation and maintenanceNuclear energy generationReactor fuel elementsNuclear reactor coreNuclear reactor

The invention relates to a nuclear reactor spent fuel storage technology, in particular to a nuclear reactor spent fuel dry type storage house. A house body of the storage house is arranged in a factory; the top of the house body has a pound-shaped girder framework structure; a storage barrel is arranged in each vertical hole of a pound-shaped girder; a plurality of storage pipes are arranged in the storage barrel; each storage pipe is used for storing spent fuels; the storage barrels are poured with heavy concrete after being positioned, so the upper part of the storage house has an integrated structure and radioactive shielding function; the storage house is provided with an air exhaust cooling facility so as to keep refreshing the air in the house and keep a certain negative pressure and a proper temperature; and a heavy concrete shielding layer is arranged at the periphery of the whole storage house. The storage house is good in shock resistance, compact in structure, easy in operation, and low in running maintenance cost and whole production cost.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Automobile waste gas treatment device

InactiveCN109026319AWill not accumulateImprove cleaning efficiencyGas treatmentDispersed particle filtrationUser needsDischarge efficiency

The invention discloses an automobile waste gas treatment device. The device comprises a shell, a connecting tube is arranged at one end of the shell, the other end of the shell is fixedly connected with a baffle through a bolt, and an exhaust pipe is arranged on the side, opposite to the shell, of the baffle. A connecting flange is arranged at the end, opposite to the shell, of the connecting pipe. An air inlet partition plate is arranged in the connecting pipe, and a first limiting plate and a second limiting plate are arranged on the side, opposite to the connecting pipe, of the connectingflange. The second limiting plate is located above the first limiting plate, a second screw rod penetrates through the second limiting plate, and a second clamping plate is arranged at the bottom endof the second screw rod. The baffle, a pull rod and a cleaning ring are arranged, so that after the device is used for a period of time and when a user needs to clean carbon deposit on the inner wallof the shell, a large amount of carbon deposit cannot be accumulated in the shell, the carbon deposit removing efficiency is improved, the waste discharge efficiency is improved, and the phenomenon that automobile tail gas exceeds a standard is avoided.

Owner:陈益香

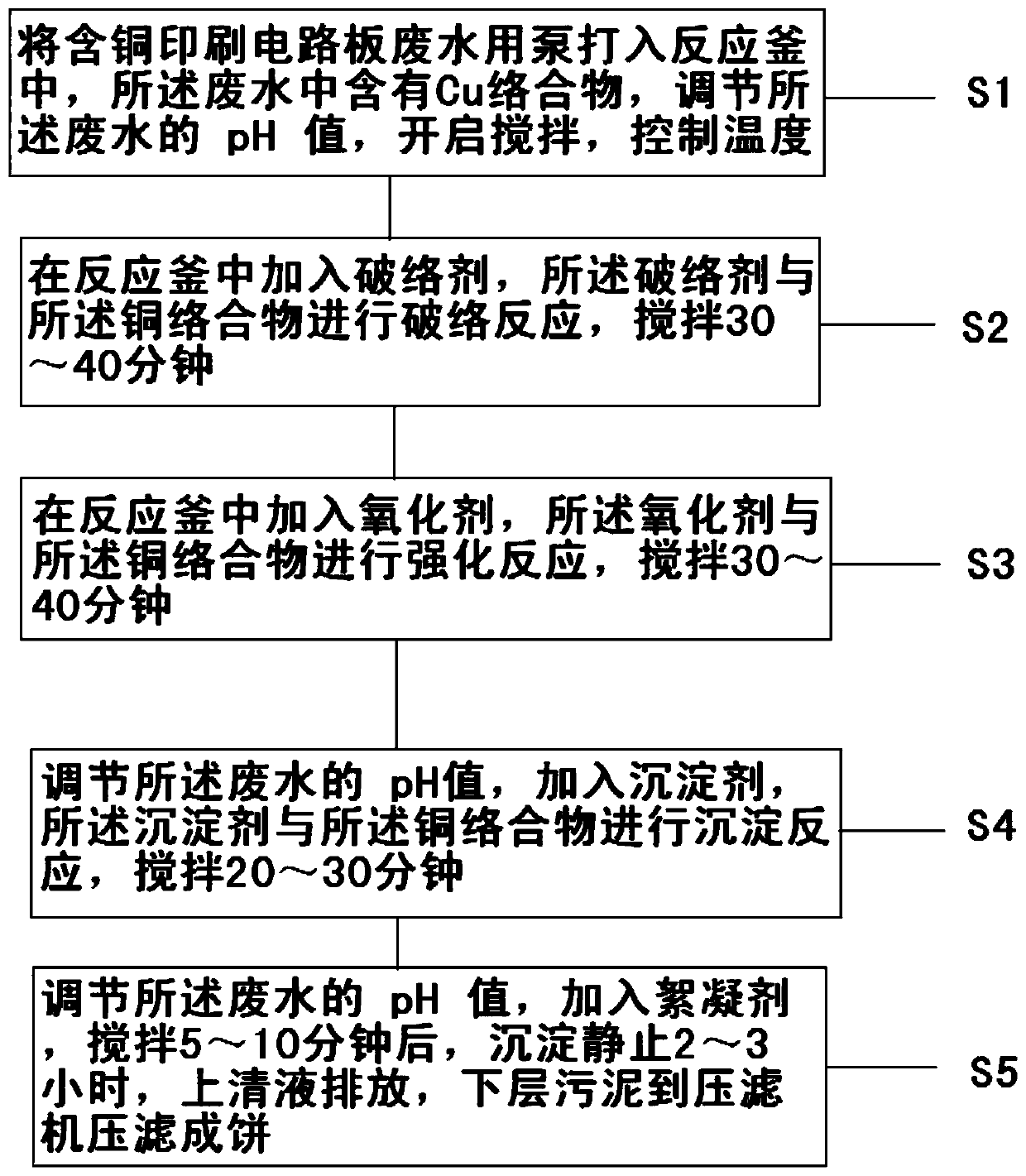

Copper-containing printed circuit board wastewater treatment method

InactiveCN110683676AOvercome yellowing of water qualityOvercome the shortcomings of poor precipitation effectSludge treatmentWater contaminantsPulp and paper industryPrinted circuit board

The invention discloses a copper-containing printed circuit board wastewater treatment method which specifically comprises the following steps: step 1, pumping copper-containing printed circuit boardwastewater, which contains copper complex, into a reaction kettle by using a pump, and adjusting the pH value of the wastewater, step 2, adding a complex breaking agent into the reaction kettle, carrying out complex breaking reaction on the complex breaking agent and the wastewater copper complex, and stirring for 30-40 minutes; step 3, adding an oxidizing agent into the reaction kettle, carryingout enhanced reaction on the oxidizing agent and the wastewater copper complex, and stirring for 30-40 minutes; 4, adjusting the pH value of the wastewater, adding a precipitant, carrying out precipitation reaction on the precipitant and the wastewater copper complex, and stirring for 20-30 minutes; and step 5, regulating the pH value of the wastewater, adding a flocculating agent, stirring for 5-10 minutes, precipitating and standing for 2-3 hours. The invention solves the problems of high cost and poor precipitation effect in the existing wastewater treatment method.

Owner:JINDUICHENG MOLYBDENUM CO LTD

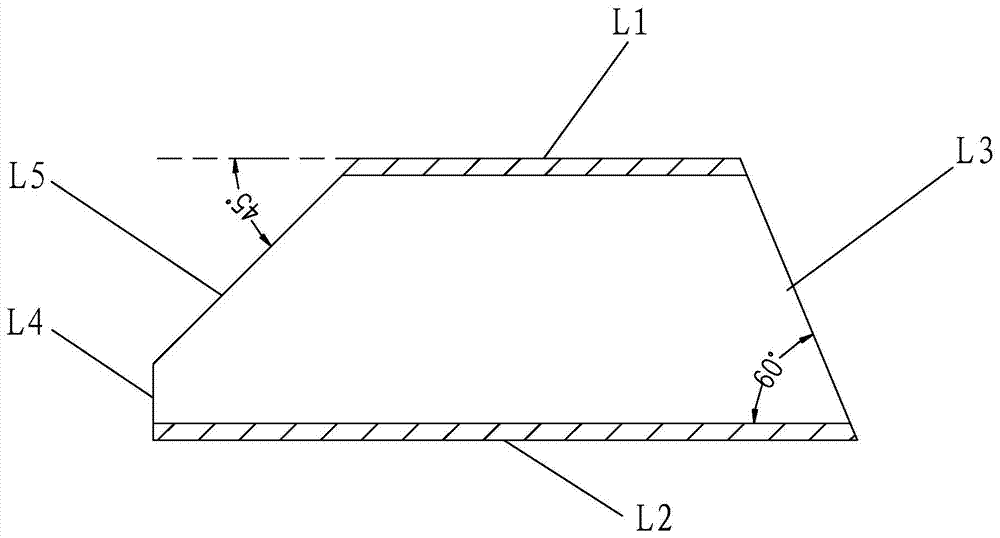

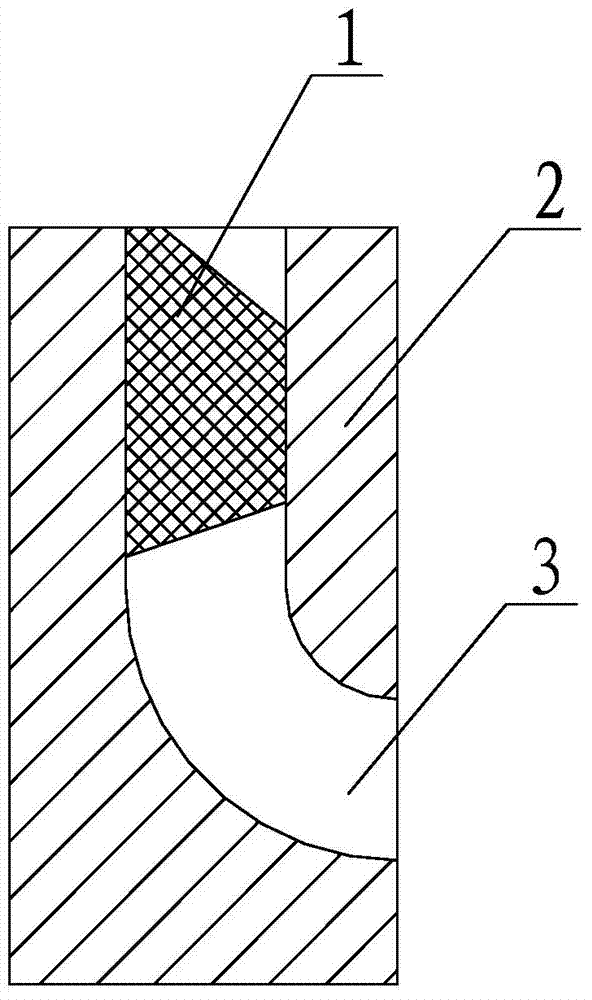

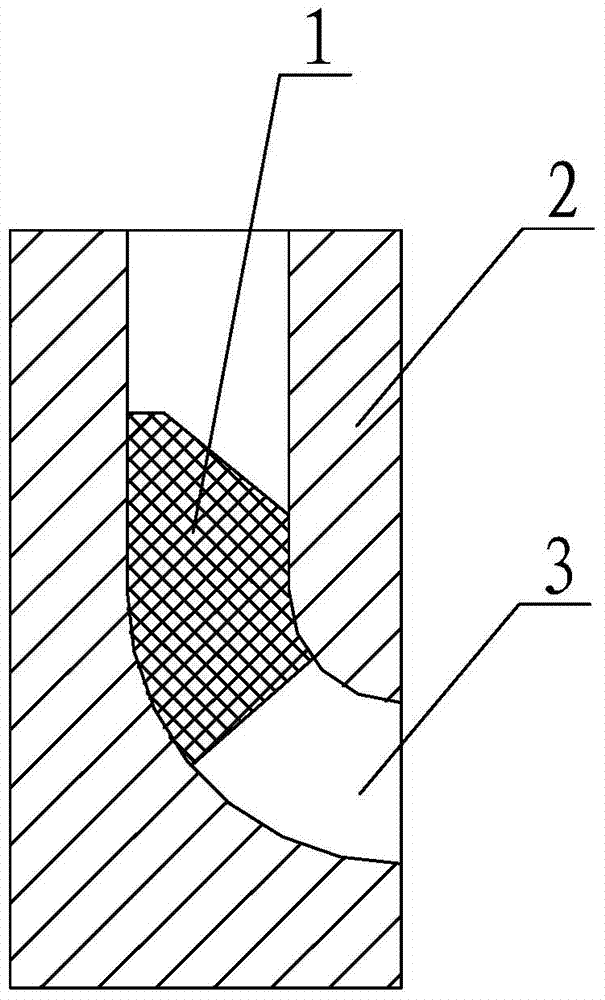

Cold forming process for non-ferrous metal seam elbow

The invention discloses a cold forming process for a non-ferrous metal seam elbow. The process comprises the following steps of: firstly, cutting into a processing pipe fitting; secondly, applying a lubricant on the processing pipe fitting and then placing the processing pipe fitting in a mold cavity of an elbow cold forming machine; thirdly, conducting non-ball stamping by using a non-ball stamping manner; fourthly, conducting ball passage stamping by a steel ball passage pushing manner for more than two times to obtain a formed elbow; fifthly, surface-treating the formed elbow, and then heat-treating; and sixthly, conventionally chamfering the port of the heat-treated elbow to obtain a finished elbow product. A seam pipe blank is used as a raw material, so that the cost can be obviously reduced, meanwhile, a welding seam is arranged at one side of an outer bending part of the mold cavity, and the stamping is conducted by the steel ball passage pushing manner, so that the central part of the elbow is prevented from being thinned too much to exceed standard; by gradually adjusting the size of the diameter of a steel ball, the maximum thinned position of the processing pipe fitting when being subjected to ball passage stamping is slowly moved, so that the outer arc central position of the elbow is prevented from being thinned too much to exceed standard.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

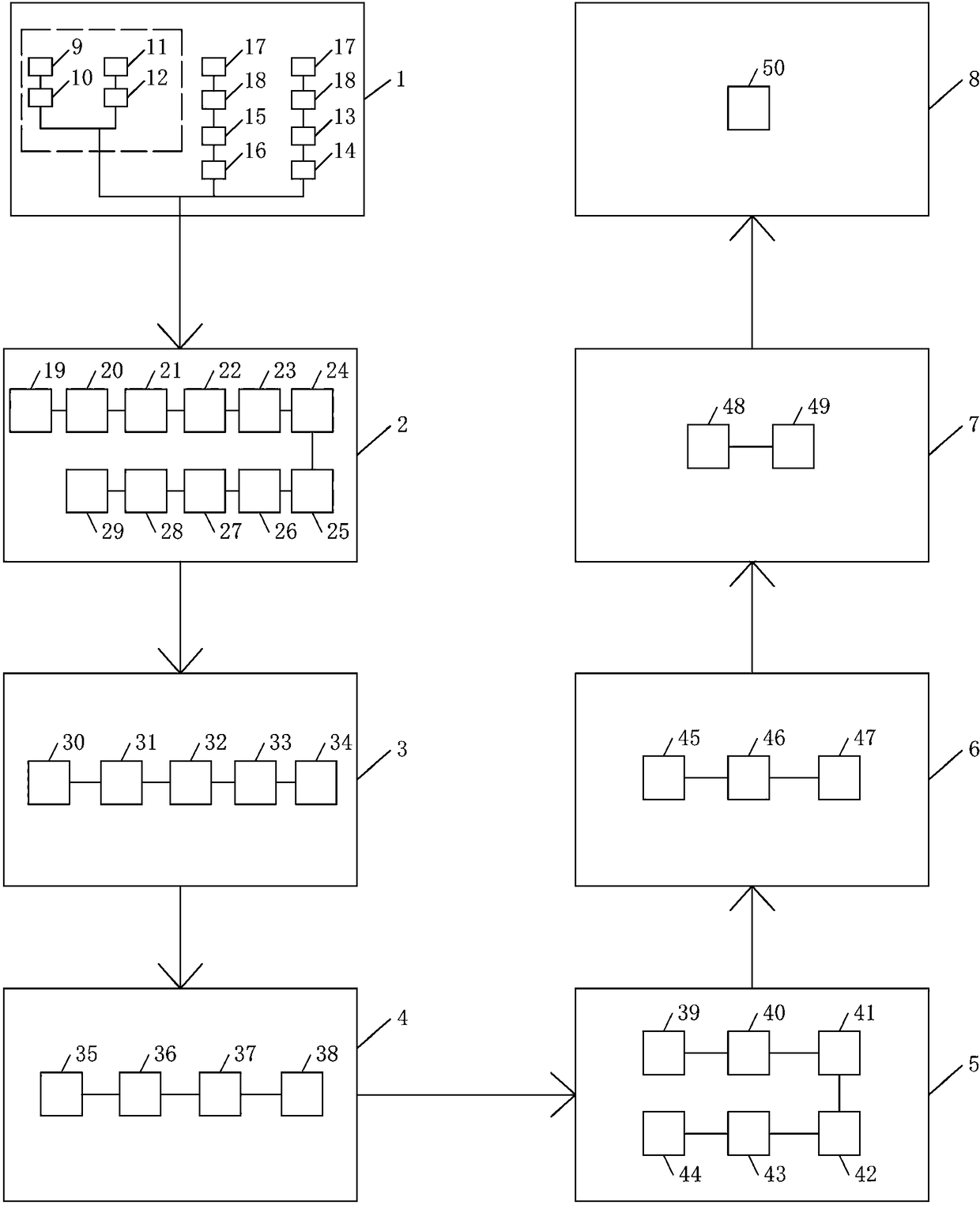

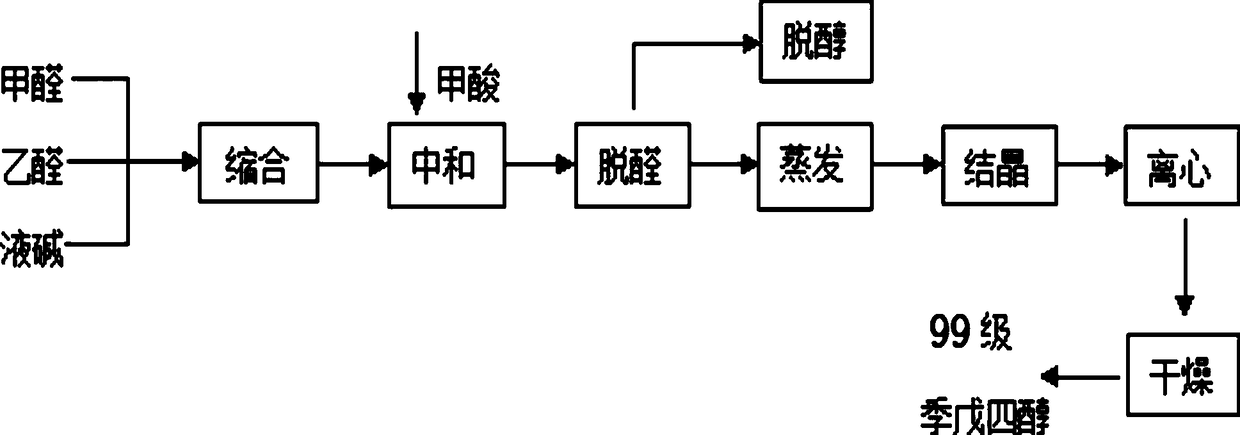

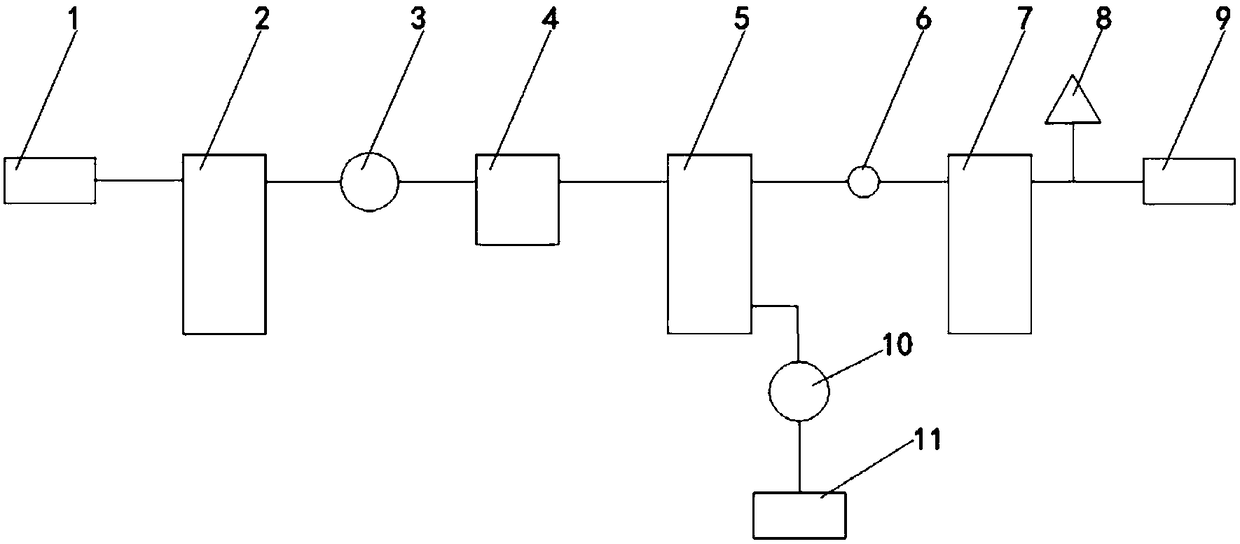

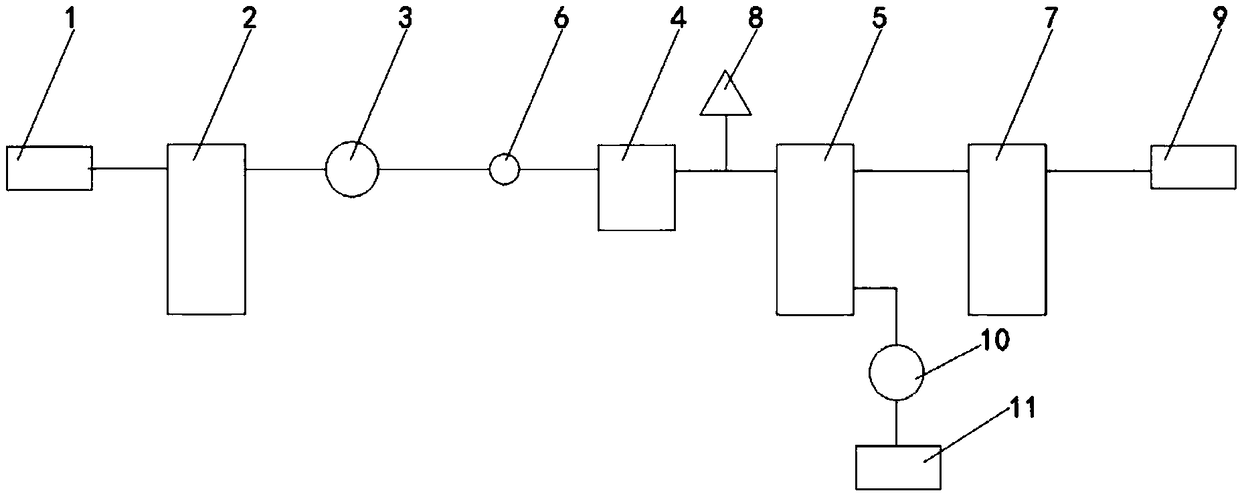

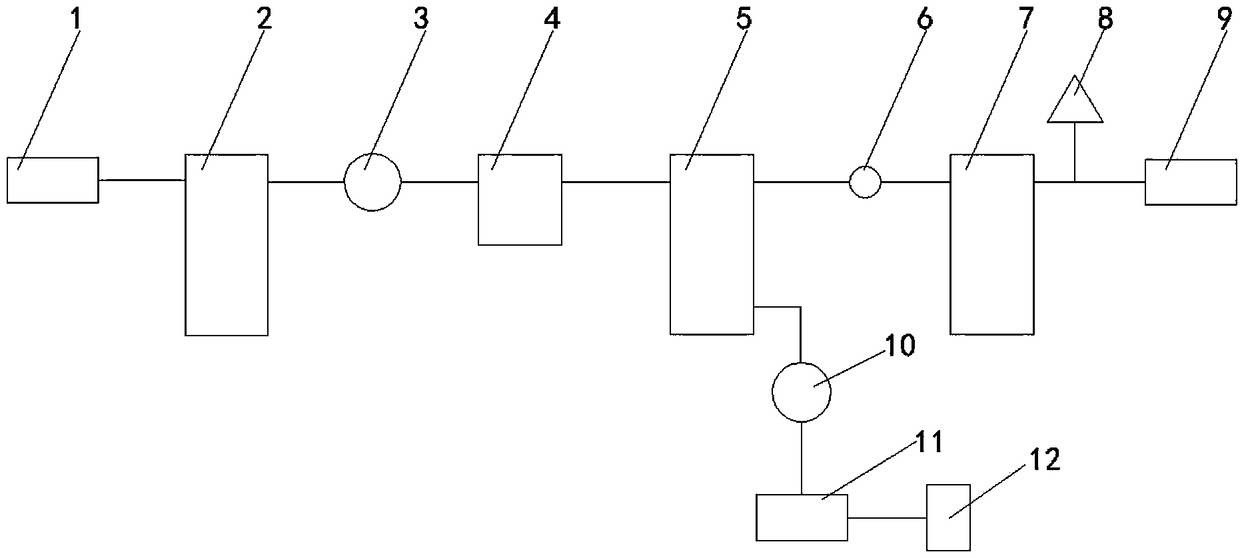

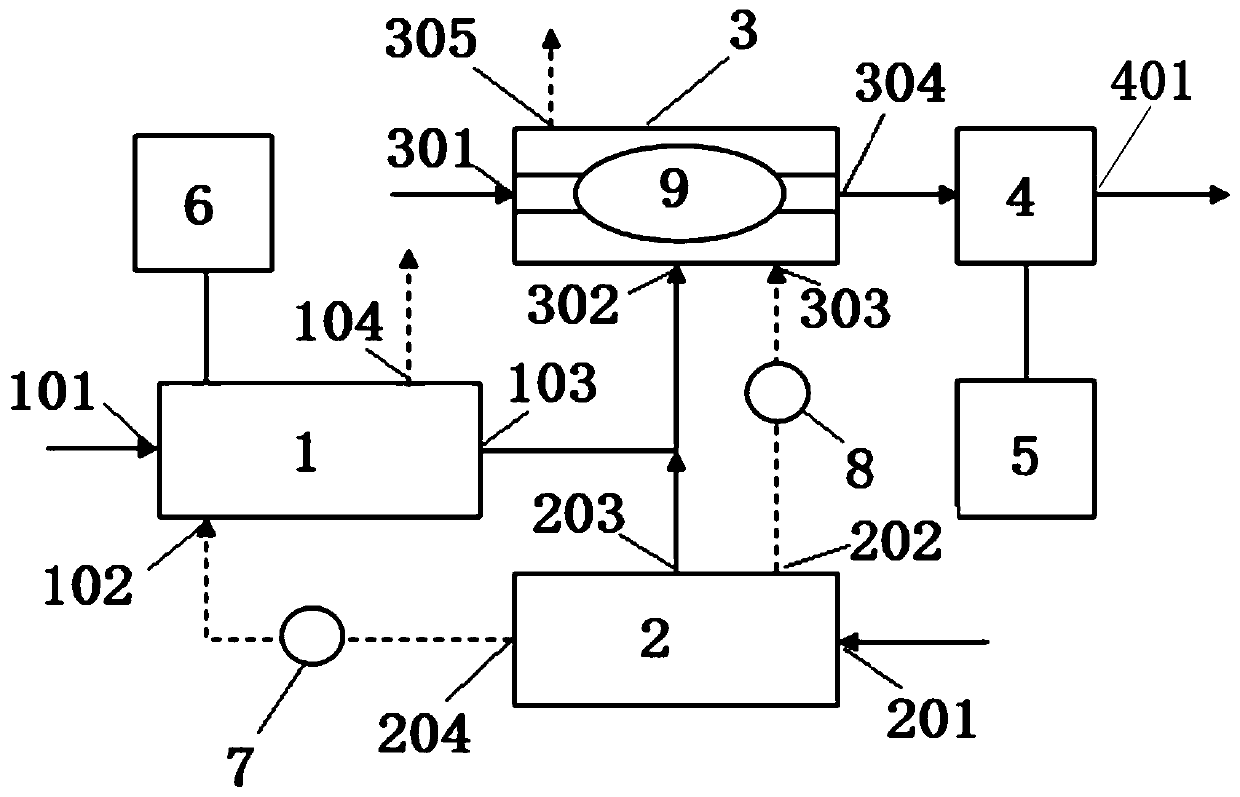

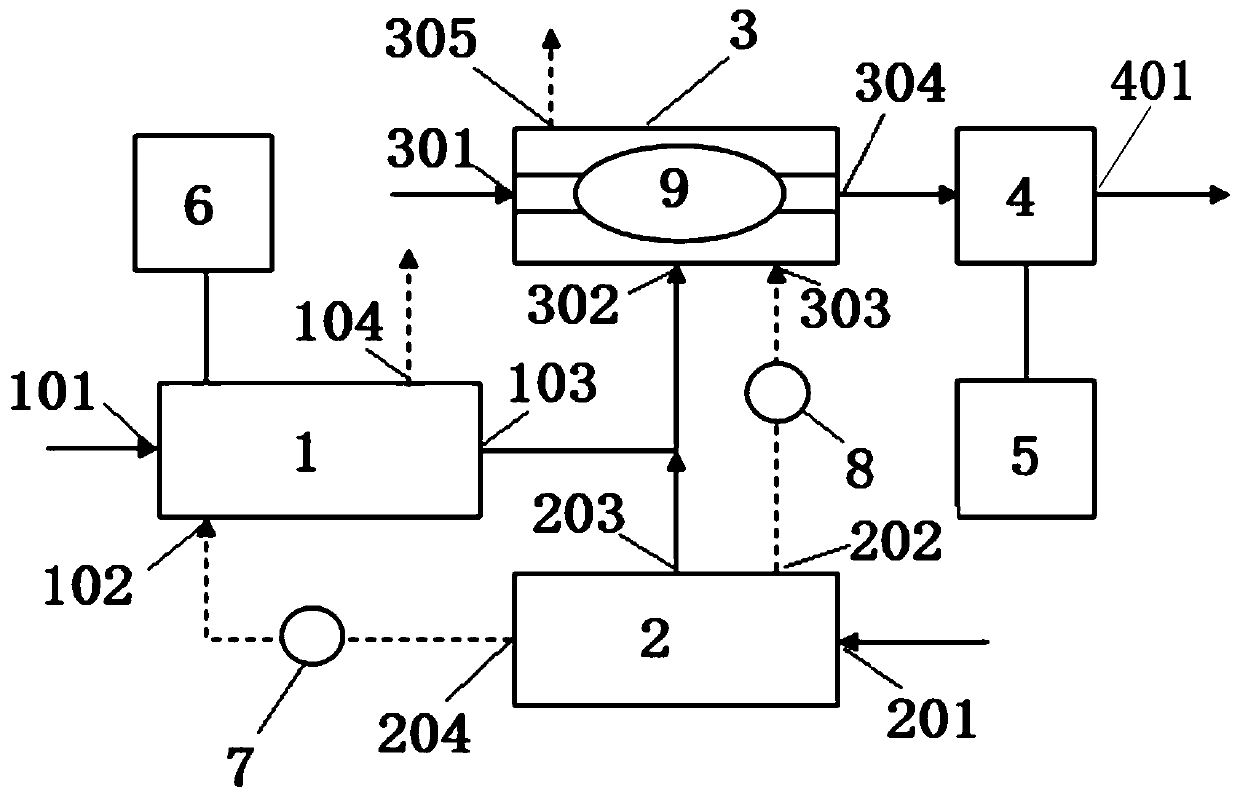

Production system and production technology for 99-grade pentaerythritol

ActiveCN109438182AAvoid exceeding the standardAvoid condensationOrganic compound preparationHydroxy compound separation/purificationMethyl aldehydeEvaporation

The invention discloses a production system and a production technology for 99-grade pentaerythritol. The production system comprises a feeding unit, a reaction unit, an aldehyde removal unit, an alcohol removal unit, an evaporation unit, a crystallization unit, a centrifugal unit and a drying unit. A sodium method is adopted to continuously produce the pentaerythritol, formaldehyde and acetaldehyde are taken as raw materials to carry out condensation reaction under caustic soda liquid catalysis, formic acid is used for neutralization after reaction ends, and therefore, pentaerythritol and a byproduct, i.e., sodium formate are generated; then, through working procedures, including aldehyde removal, alcohol removal, evaporation, crystallization, separation, drying and the like, the 99-gradepentaerythritol finished product is obtained. According to the production system and the production technology, a pentaerythritol, dipentaerythritol and tripentaerythritol co-production technology can be realized, the generation of byproducts can be reduced so as to improve purity and yield, the removal rate of methyl aldehyde can be 99.9% by aldehyde removal, and the quantity of residual methylaldehyde in the product is reduced. The production system has the advantages of high automation degree and small labor intensity and personnel intensity, meanwhile, the production efficiency of the pentaerythritol is improved, and the production cost is reduced.

Owner:CHIFENG RUIYANG CHEM

Nano zinc oxide enteric-coated pellet and preparation method thereof

InactiveCN109276561AAchieve antidiarrheal effectRealize that most of zinc oxide exerts anti-diarrheal effect in molecular form in the small intestineInorganic active ingredientsDigestive systemIsolation layerTalc / Zinc Oxide

The invention relates to a nano zinc oxide enteric-coated pellet and a preparation method thereof. Existing zinc oxide products for preventing and controlling piglet diarrhea are no longer able to meet market demands. The nano zinc oxide enteric-coated pellet sequentially comprises a zinc oxide pellet core, an isolation layer, an enteric layer and a protective layer from inside to outside. The selected zinc oxide raw material is pharmaceutical grade 99% zinc oxide which is subjected to nano treatment or ordinary feed grade zinc oxide with a purity of more than 95%, the zinc oxide particle sizeis below 3,000 mesh, and the nano zinc oxide enteric-coated pellet is prepared from the raw materials in parts by mass: 30-90 parts of the nano zinc oxide pellet core, 0-40 parts of the sum of the isolation layer and the protective layer and 10-30 parts of the enteric layer. According to the nano zinc oxide enteric-coated pellet and the preparation method thereof, excessive zinc is avoided, zincpollution is reduced, the dosage is small, zinc emissions in animal faeces are greatly reduced, soil pollution is prevented, and environmental protection is achieved.

Owner:浙江诚缘生物科技有限公司

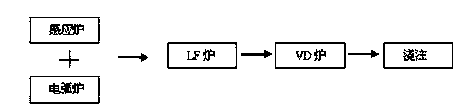

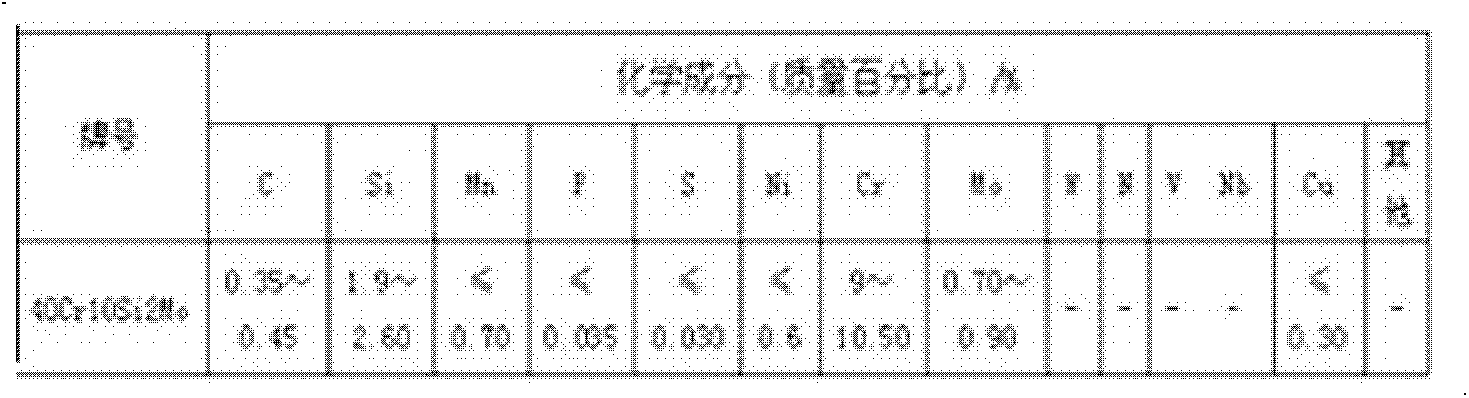

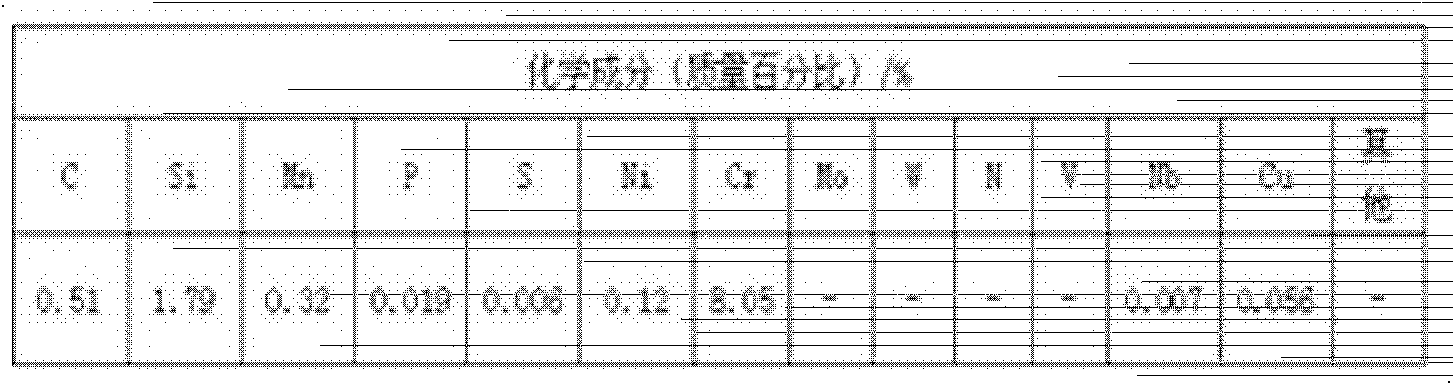

Smelting method of martensite steel for air valve of internal combustion engine

InactiveCN103667600AHigh recovery rateSolve the problem of high burning lossElectric furnaceElectric arc furnaceExternal combustion engine

The invention discloses a smelting method of martensite steel for an air valve of an internal combustion engine. The smelting method comprises the following steps: (1), smelting a chromium-containing alloy material in an induction furnace to obtain alloy mother liquor, and smelting waste steel in an electric-arc furnace to obtain molten steel; (2), mixing the alloy mother liquor obtained in the step (1) into a tapping ladle of the electric-arc furnace; (3), enabling the molten steel mixed with steel to enter an LF (ladle furnace) station for refining, carrying out deoxidation, desulfurization, and component fine adjustment operation, and tapping after the components are qualified; (4), enabling LF refined steel to enter a VD (Vacuum Degassing) station to carry out vacuum degassing operation, casting the discharged steel, and cooling and de-molding to obtain a steel ingot. The method is adopted to produce an alloy element, so that a burnout rate is lowered, an alloy recovery rate is high and a material selection range is large.

Owner:JIANGSU XINYUE AUTOMOTIVE COMPONENTS +1

Vanadium-removing and aluminum-removing reagent used of titanium tetrachloride, preparation method and use method thereof

ActiveCN104150530AIncrease productivityAvoid exceeding the standardTitanium halidesAluminium chlorideTitanium tetrachloride

The invention belongs to the field of production of titanium tetrachloride and particularly relates to a vanadium-removing and aluminum-removing reagent used of the titanium tetrachloride, a preparation method and a use method thereof. The invention aims to solve a technical problem of providing the reagent which can be used for removing vanadium and aluminum from the titanium tetrachloride. To solve the technical problem, the reagent is composed of following substances, by mass, 6%-10.0% of titanium trichloride, 1%-2% of titanium dichloride oxide, 3.5%-5.0% of aluminium chloride and the balance titanium tetrachloride. In the reagent, the added titanium dichloride oxide can react with aluminium chloride in crude titanium tetrachloride to generate a complex precipitate so that an object of removing vanadium while aluminum is removed at the same time is achieved. Without an aluminum removing process not being introduced, aluminum in the titanium tetrachloride is free from exceeding a standard. A yield rate of a refining process of the titanium tetrachloride is increased.

Owner:PANGANG GROUP TITANIUM INDAL

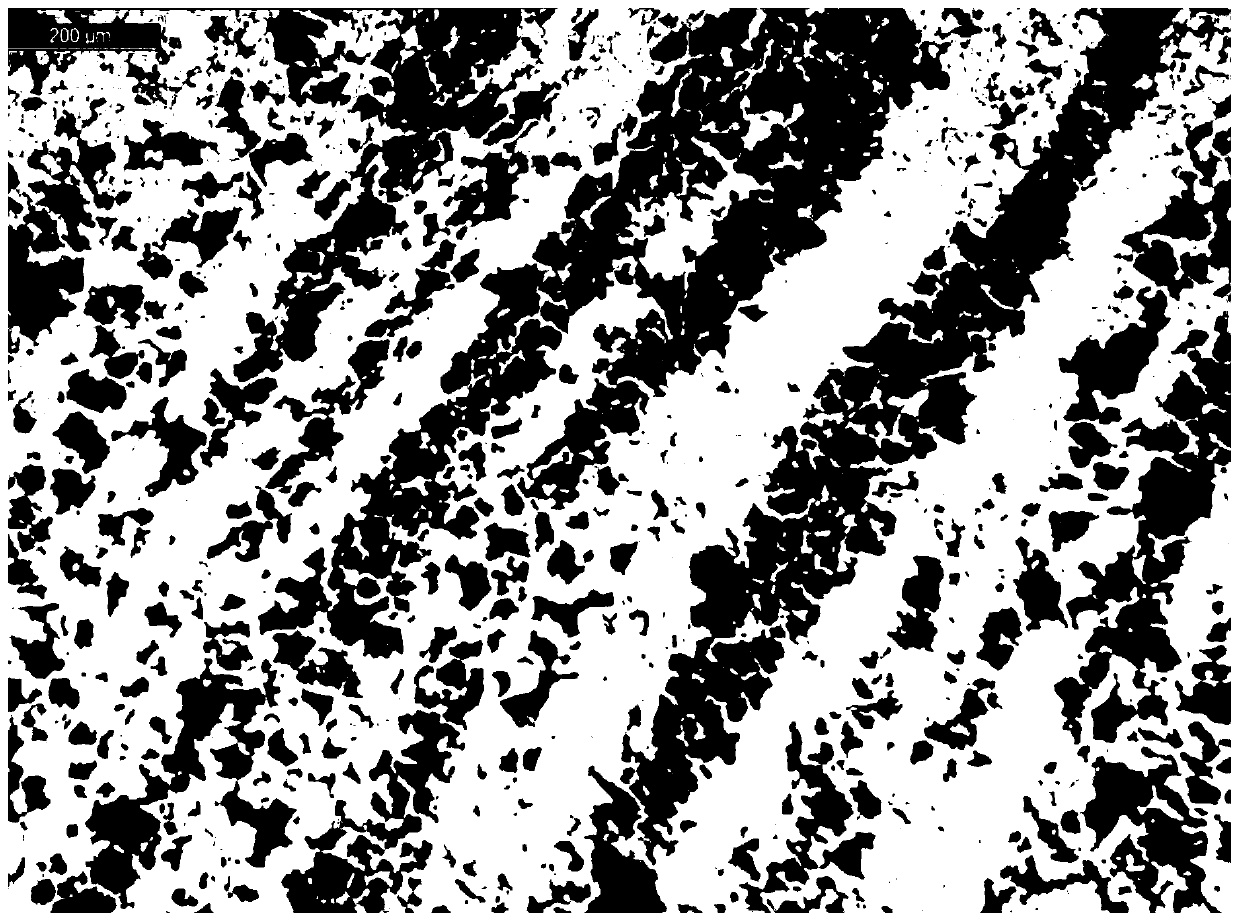

Cooling process for eliminating banded structure of steel ingot

The invention relates to a cooling process for eliminating a banded structure of a steel ingot, and belongs to the technical field of steel ingot cooling. The cooling process comprises the following specific steps that (1) before pouring is carried out, a central pouring pipe and steel ingot molds are mounted on a pouring bottom plate; (2) pouring is started after mounting is finished; (3) a ventilation cooling device is prepared in advance, and a steel ingot air cooling device is hoisted to the position between the central pouring pipe and the steel ingot molds within 5 minutes after pouringis finished; (4) an air compressor is started, cold air is blown out from an air outlet hole of an air outlet pipe, and the steel ingot is cooled; and (5) after the steel ingot is cooled, the steel ingot molds are disassembled, the steel ingot is taken out, sampling detection is carried out, and the steel ingot is put in storage after being detected to be qualified. According to the cooling process, a heat insulation baffle is arranged between the steel ingot molds, and the size of the cold air flow is controlled in the cooling process, so that the situation that the banded structure exceeds the standard due to the fact that the cooling speed of the inner side and the outer side of the steel ingot is inconsistent can be effectively avoided.

Owner:SHANDONG BAODING HEAVY IND

Preparation method for quick-frozen okra

InactiveCN105192052AConsistent colorUniform sizeFruits/vegetable preservation by freezing/coolingQuick FreezeFluidized bed

The invention discloses a preparation method for quick-frozen okra. The preparation method is characterized by comprising the following steps: blanching: blanching cleaned okra for deactivation; cooling; quickly spraying water on the blanched okra for cooling; draining: draining the cooled okra by mechanical vibration and blowing; quick freezing: flatly spreading the drained okra in a fluidized bed individual quick-freezing machine for individual quick freezing. The okra prepared by adopting the preparation method for the quick-frozen okra is dark green, consistent in colour and lustre, free of individual adhesion and uniform in size, and has a bacterial clump amount (per gram) being not more than 10000, and an excrement colon bacillus amount (per 100gram) being less than 3. According to the preparation method for the quick-frozen okra, the colour and lustre as well as mouthfeel of the okra are better kept in the preparation process of the quick-frozen okra, the loss of beneficial components is reduced to minimum, and hygienic indexes reach national standards.

Owner:宁夏天瑞产业集团现代农业有限公司

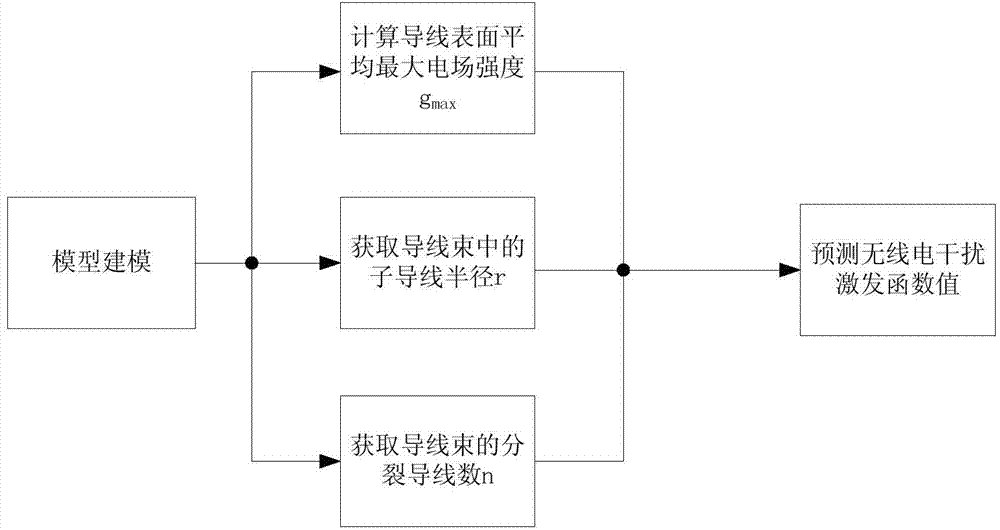

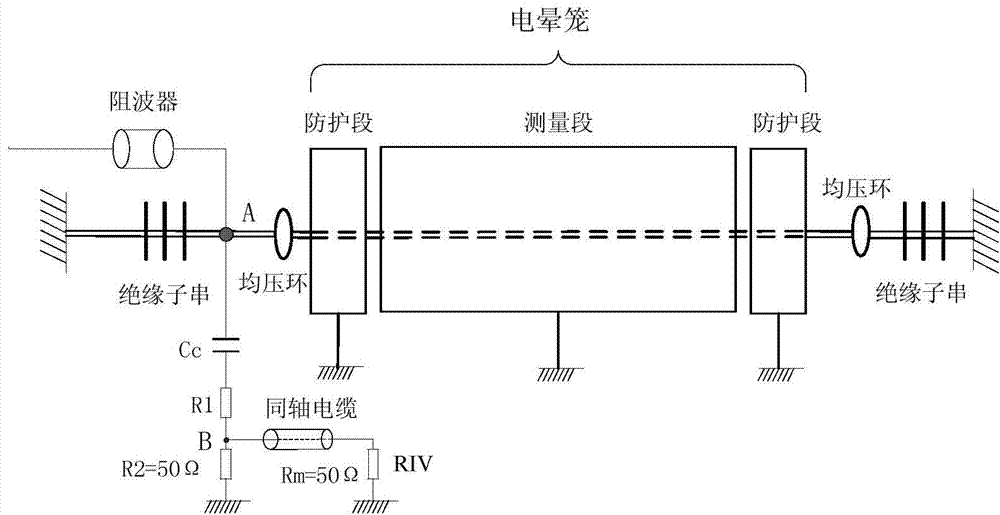

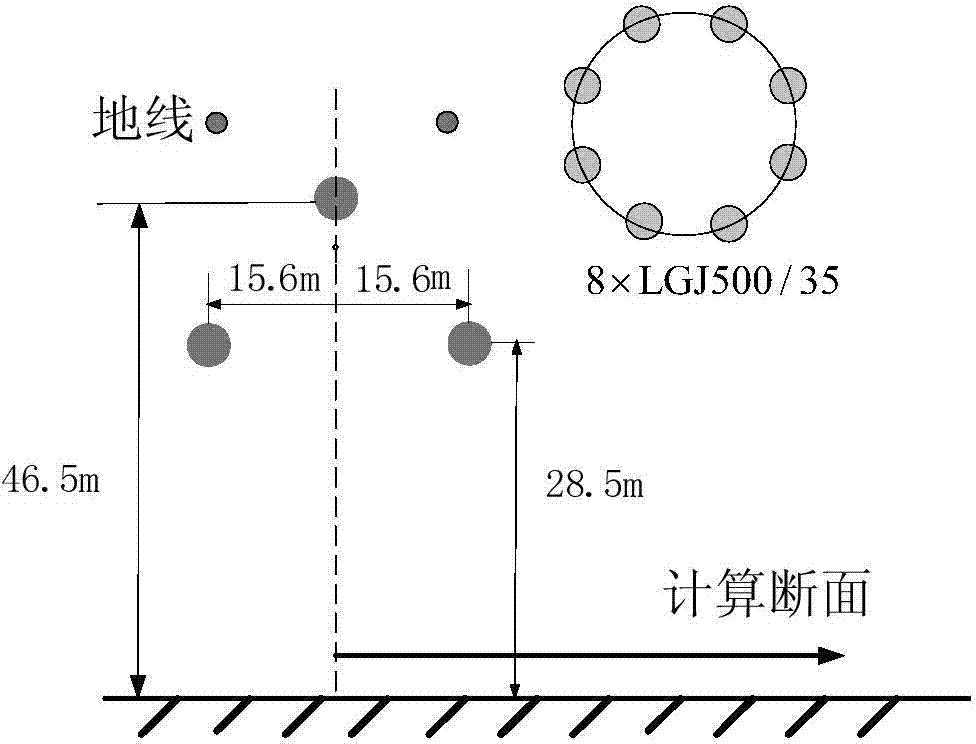

High-voltage transmission line radio interference excitation function determination method

ActiveCN104715151AGood effectAvoid exceeding the standardSpecial data processing applicationsElectrical field strengthHigh pressure

The invention relates to a high-voltage transmission line radio interference excitation function determination method which comprises the first step of acquiring a wire split number and radius of branch wires, the second step of establishing a transmission line simulation model, the third step of acquiring average maximum electric field intensity of the wire surface through the transmission line simulation model, and the fourth step of determining a radio interference excitation function value of the transmission line simulation model. According to the technical scheme, the high-voltage transmission line radio interference excitation function determination method is more accurate and reliable on the aspect of predicting a high-voltage transmission line radio interference level.

Owner:STATE GRID CORP OF CHINA +1

Cooling structure for dry method coke quenching

The invention relates to a cooling structure for dry method coke quenching, which comprises a body, a gas distribution pipe, a gas collection umbrella and a baiting device, wherein the gas distribution pipe can guide cold smoke gas generated by drying treatment on coal briquettes into the body, and is arranged in the body, the gas collection umbrella can discharge the smoke gas through the heat exchange out of the body, and is arranged under the gas distribution pipe, and the baiting device can be used for carrying pyrolysate products in the body so that the pyrolysate products can be discharged from the cooling structure at the preset speed. The cooling structure for dry method coke quenching of the invention belongs to a semi-coking cooling structure using gas as a carrier, which can realize the dry method coke quenching. The structure realizes the dry method coke quenching by a specific structural method, saves the water sources, and simultaneously reduces the environment pollution.

Owner:北京嘉德信达投资有限公司 +1

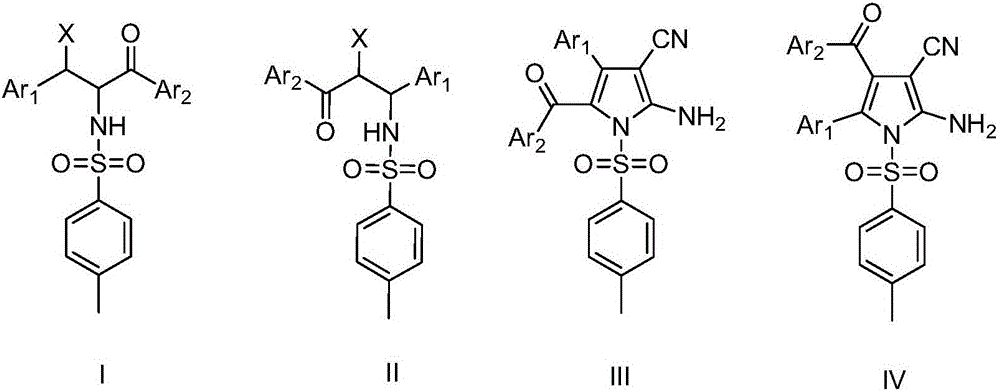

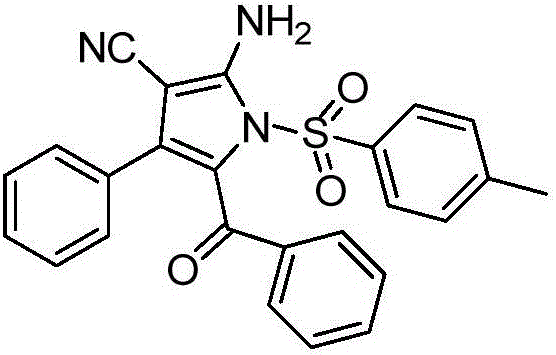

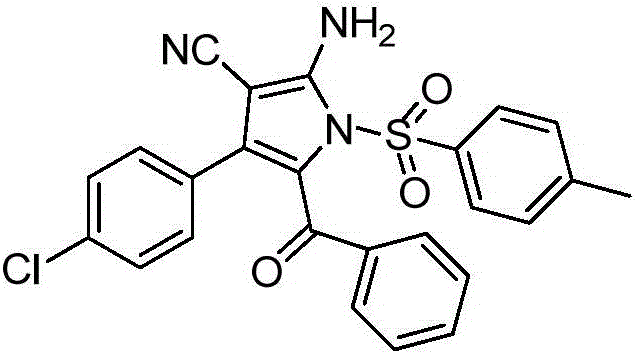

Synthetic method of penta-substituted 2-amino pyrrole derivatives

The invention discloses a synthetic method of penta-substituted 2-amino pyrrole derivatives, wherein the method comprises that in an organic medium with relatively large polarity, arone of o-amino halogen and malononitrile are subjected to a reaction in one step under the action of an alkali, and the penta-substituted 2-amino pyrrole derivatives can be obtained. Compared with a traditional method, the method adopts the low-price ordinary alkali as an accelerant, effectively reduces the cost, and has the advantages of simple synthetic steps and high reaction yield; especially in construction of a drug with a pyrrole ring, with use of the method, the problem that the residual amount of heavy metals in the drug exceeds standards due to use of the heavy metals for catalysis can be avoided. In addition, no matter arone of o-amino halogen is alpha-amino-beta-halogen arone or alpha-halogen-beta-amino arone, amino in the synthetic products is located at 2-site of the pyrrole ring and has high region selectivity. The synthetic penta-substituted 2-amino pyrrole derivatives can be used in the fields of synthesis of fused heterocyclic compounds, natural antibiotics and anticancer drugs and modification research of natural product structures.

Owner:SHAANXI NORMAL UNIV

Novel wastewater fluorine-removing technology

InactiveCN105036406AAvoid excessive heavy metalsSimple processWaste water treatment from metallurgical processMultistage water/sewage treatmentAluminium saltsPollutant

The invention relates to a novel wastewater fluorine-removing technology. The original technology and equipment can be maximally utilized, waste acid is subjected to a vulcanization treatment so as to remove most heavy metal pollutants, then the waste acid is pre-neutralized in the gypsum step, and the fluorine content of gypsum filtrate in the outlet can be controlled under 60-100 mg / L. Then calcium carbide slag is used to neutralize gypsum filtrate, a flocculating agent is added to carry out flocculation, finally the filtrate is filtered to remove the heavy metal pollutants in wastewater, and the fluorine concentration of the flocculation filtrate can be controlled under 20 to 40 mg / L. Then an aluminum sulfate solution is added to absorb and complex the fluorine ions, the fluorine concentration of wastewater can be reduced to 5 mg / L or less, and other element concentrations are qualified.

Owner:JIANGXI COPPER

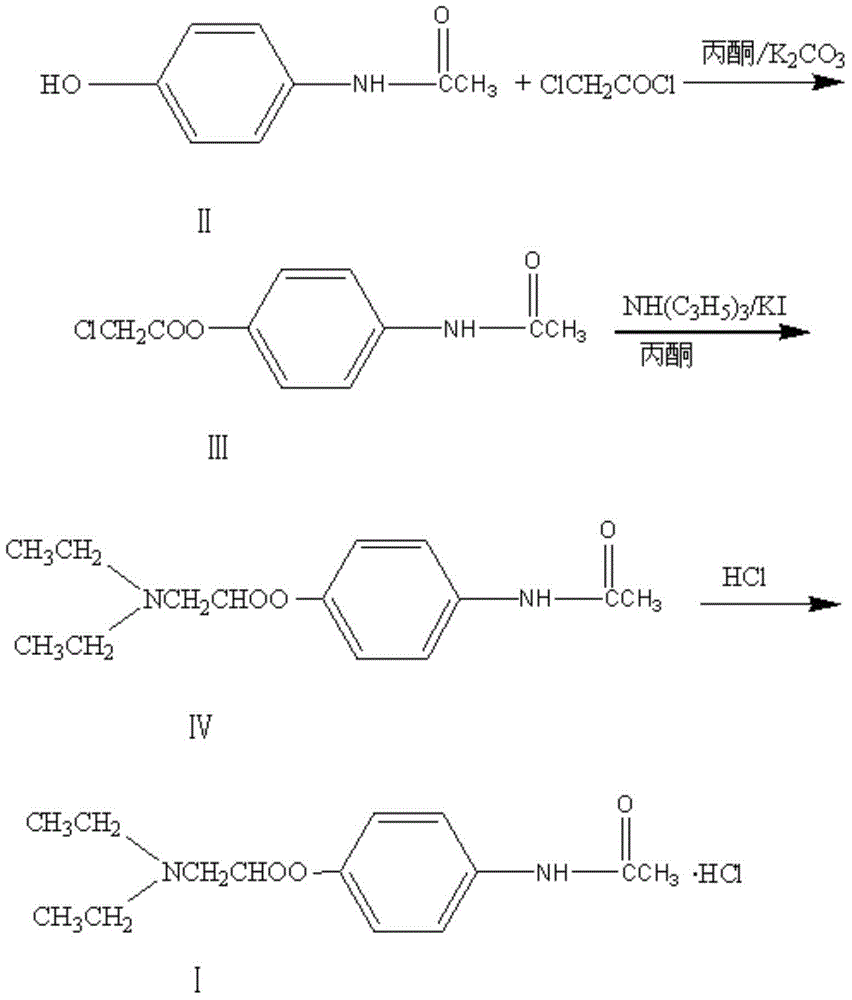

Improved propacetamol hydrochloride preparation process

InactiveCN105218390AReduce the hassle of handlingReduce churnOrganic compound preparationCarboxylic acid amide separation/purificationPropacetamolOrganic matter

The invention belongs to the field of synthesis of organic matters with carbon rings and provides an improved propacetamol hydrochloride preparation process. The process comprises: 1) carrying out acylation reaction to synthesize 4-acetamido phenol chloracetate; 2) carrying out ammonolysis reaction on the 4-acetamido phenol chloracetate to synthesize propacetamol; 3) purifying a propacetamol coarse product; 4) synthesizing propacetamol hydrochloride; and 5) carrying out purification on the propacetamol hydrochloride. By virtue of purification treatment on the propacetamol coarse product, the standard-exceeding problem of the propacetamol coarse product in projects such as residues on ignition caused by quality problem of initial and auxiliary materials is solved, and meanwhile, the refining efficiency is improved. The yield of the product improved through the process is remarkably improved: the yield of the product before improvement is about 50-60% and the yield of the product after improvement is about 60-70%.

Owner:蚌埠丰原涂山制药有限公司

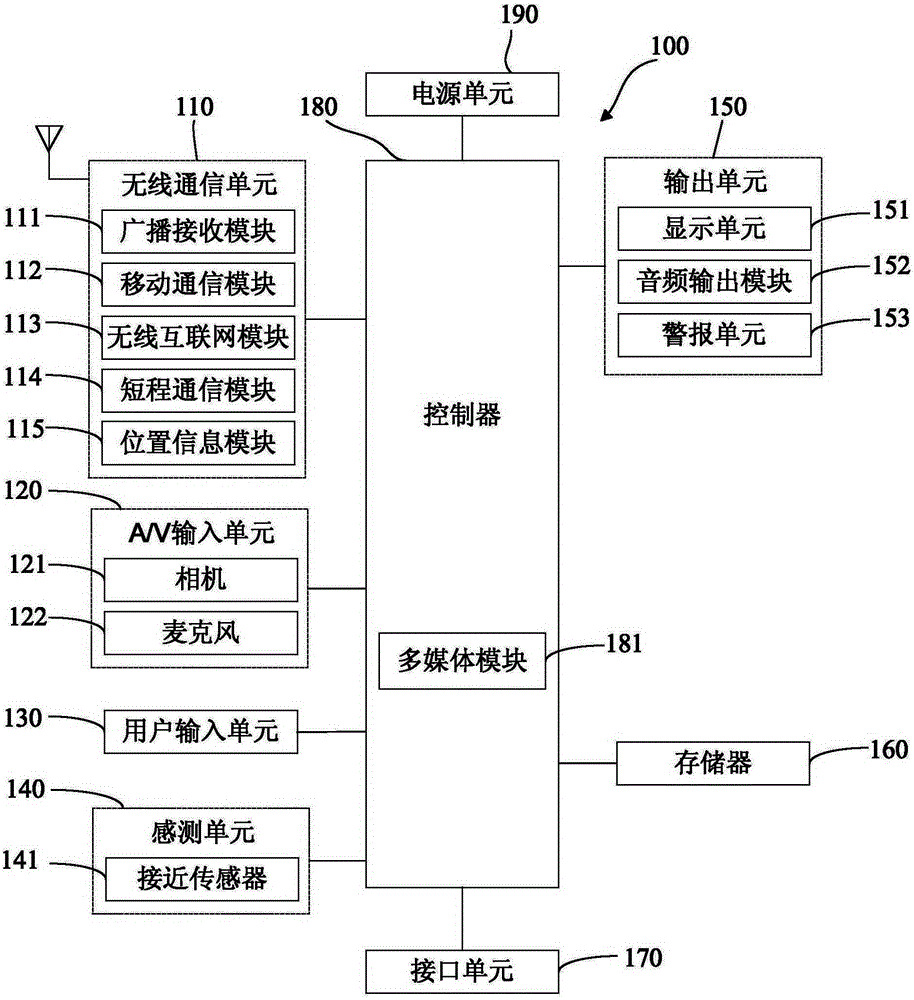

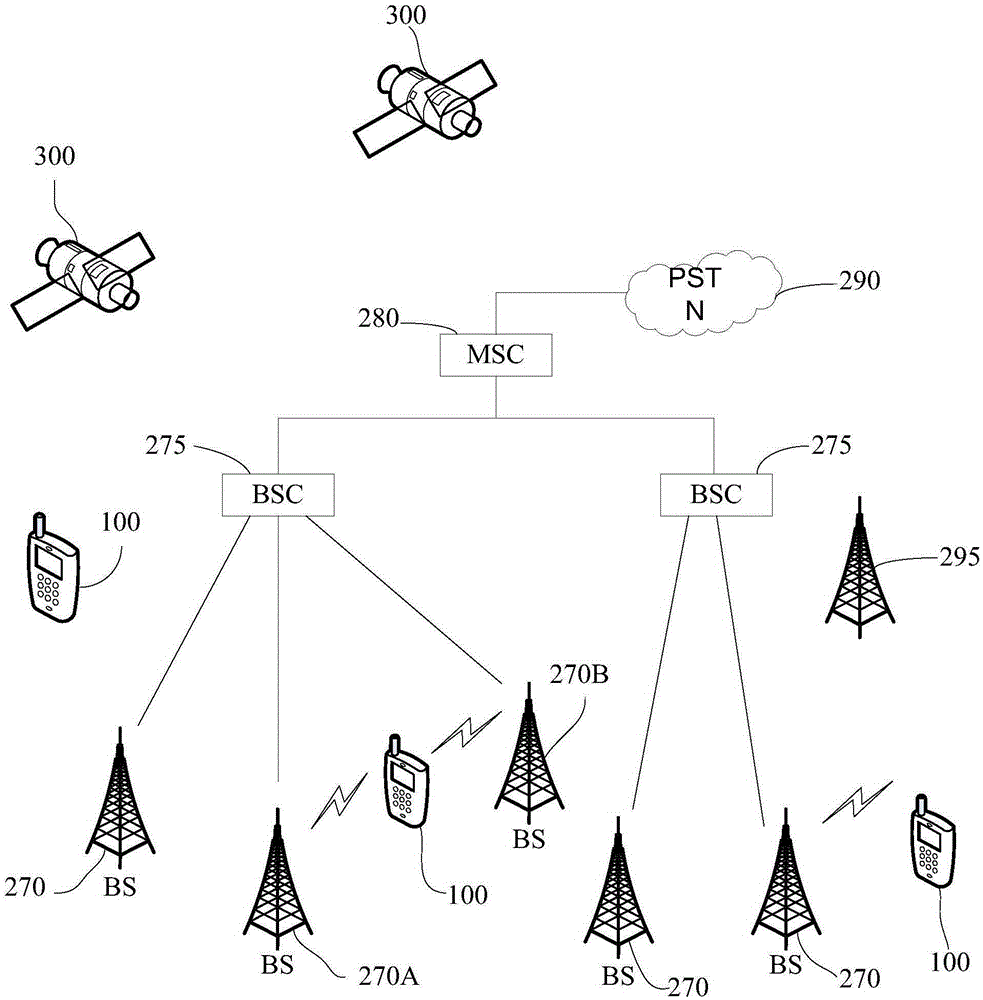

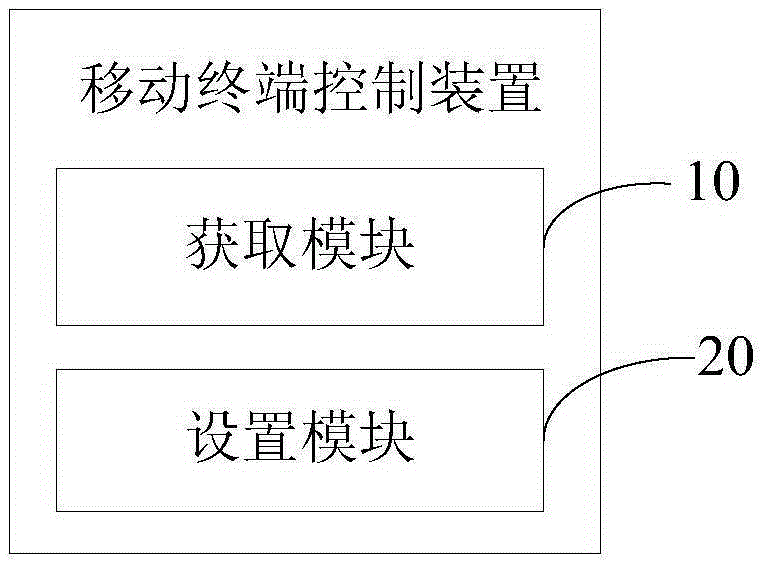

Mobile terminal control method and device

InactiveCN105357362AFlexible communicationAvoid exceeding the standardSubstation equipmentTraffic capacityComputer module

The invention discloses a mobile terminal control device. The mobile terminal control device comprises an obtaining module and a setting module, wherein the obtaining module is used for obtaining a first surplus flow value in a preset time interval of a first subscriber identity module card for performing network communication currently, and obtaining a second subscriber identity module card installed on a mobile terminal with the first subscriber identity module card and having a surplus flow threshold value more than a second preset threshold value when the first surplus flow value is less than or equal to a first preset threshold value; and the setting module is used for setting the second subscriber identity module card as the subscriber identity module card for performing network communication currently. The invention further provides a mobile terminal control method. According to the invention, flow waste of other subscriber identity module cards, besides default subscriber identity module cards, can be avoided; simultaneously, flow exceeding of the default subscriber identity module cards can be avoided; and thus, the mobile terminal is more flexible to communicate.

Owner:NUBIA TECHNOLOGY CO LTD

RO water treating system and control method thereof

PendingCN108341463APracticalIncrease flexibilityWater treatment parameter controlTreatment involving filtrationHigh pressureWater pipe

The invention provides a RO water treating system and a control method thereof. The system comprises a water treating module, a control module and a booster pump, which are arranged between a raw water inlet pipe and a water purifying faucet, and the system further comprises a pressure sensor and a one-way valve; the water treating module comprises a RO filter element, the booster bump is connected with a water inlet end of the RO filter element, the pressure sensor is arranged between the booster bump and the water purifying faucet, the one-way valve is arranged between the raw water inlet pipe and the pressure sensor, and the pressure sensor is used for detecting pressure between the one-way valve and the water purifying faucet; a control module receives a signal of the pressure sensor and controls on-off of the RO water treating system. According to the system, an original high-tension switch and a low-tension switch are canceled, one pressure sensor completes the control on the whole RO water treating system, the inner space of a RO machine is saved, the production cost of the RO machine is reduced, the structure is simple, the assembly is convenient and quick, and the production efficiency is improved.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

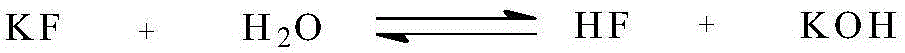

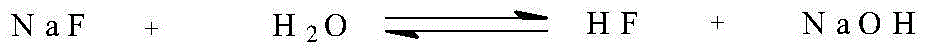

Method for treating fluosilicate waste residues

ActiveCN104591223AEfficient separationLess mass percentage contentAlkali metal fluoridesPotassium fluorideFiltration

The invention discloses a method for treating fluosilicate waste residues. The method comprises the following steps: determining the total content of fluosilicate in the waste residues, so as to determine the usage amount of sodium hydroxide required to react with fluosilicate; mixing the waste residues and water according to the mass ratio of (1:30) to (1:40), heating up, then, adding a sodium hydroxide solution, stirring and reacting; removing manganese ions and permanganate ions from the solution obtained through reaction in the step (2); carrying out first-time filtration on the solution obtained in the step (3) so as to obtain a first filtrate and filtrated residue; concentrating and crystallizing the first filtrate, and then, carrying out second-time filtration so as to obtain sodium fluoride solid and a second filtrate; concentrating and crystallizing the second filtrate, then, carrying out third-time filtration so as to obtain a crude product potassium fluoride solid and a third filtrate, and recrystallizing the crude product potassium fluoride solid, so as to obtain a product potassium fluoride and a fourth filtrate. The method disclosed by the invention is aimed at treating and utilizing the fluosilicate waste residues generated from potassium permanganate and sodium fluosilicate which serve as raw materials.

Owner:广东航鑫科技股份公司

Harmless treatment method of cyanide-containing tailings

InactiveCN109332354AHarm reductionNo pollutionSolid waste disposalTransportation and packagingFreezing thawingDigestion

The invention provides a harmless treatment method of cyanide-containing tailings, and belongs to the field of mine waste residue treatment. The harmless treatment method of the cyanide-containing tailings comprises the following steps that immobilization treatment is carried out on the cyanide-containing tailings through pretreatment, wheel grinding mixing and digestion steps; a consolidating agent and a cementing material are added into the cyanide-containing tailings after immobilization treatment to consolidate and prepare harmless filling materials; the harmless filling materials are cured, and the materials are piled into a tailing pond; and according to the pretreatment, multifunctional water-soluble polymer is added to the cyanide-containing tailings, and the mixture is sent into aconcentration tank, stir and filter pressing are carried out to obtain concentrated ore pulp. According to the harmless treatment method of the cyanide-containing tailings, the cyanide-containing tailings are used for preparing the filling materials which are not compatibilized, do not greatly shrink, have excellent compressive strength, do not have cyanide toxicity, and have good freezing-thawing resistance and heat resistance. The treatment method has mature process, high settling rate, large cyanide capture amount, cost saving, construction in all seasons, less reagent consumption, large treatment amount, continuous treatment, low energy consumption, and can realize sustainable development of economy, society and environment.

Owner:宁波纯力固废科技有限责任公司

Organic solid fuel pyrolysis, gasification and incineration integrated device and treatment method

InactiveCN110030558AEfficient use ofImprove processing efficiencyIncinerator apparatusCatalytic reformingFlue gas

The invention discloses an organic solid fuel pyrolysis, gasification and incineration integrated device and a treatment method. The organic solid fuel pyrolysis, gasification and incineration integrated device comprises a pyrolysis gasification device, an incineration device, a catalytic reforming device, a condensation device and a collecting device, wherein the pyrolysis gasification device isused for carrying out pyrolysis gasification treatment on the input organic solid fuel and outputting pyrolysis gas and coke, the pyrolysis gas is introduced into the catalytic reforming device, and the coke is fed into the incineration device; the incineration device is used for incinerating the coke and generating high-temperature flue gas, the high-temperature flue gas is respectively introduced into the pyrolysis gasification device and the catalytic reforming device, and is used for providing heat for the pyrolysis gasification device and the catalytic reforming device; a catalyst is arranged in the catalytic reforming device for carrying out catalytic reforming on the gas generated by the pyrolysis gasification device and the incineration device; the condensation device is used for carrying out condensation treatment on the gas output by the catalytic reforming device, and outputting combustible gas and condensed liquid; the collecting device is used for collecting the condensedliquid output by the condensation device. According to the organic solid fuel pyrolysis, gasification and incineration integrated device and the treatment method, the pyrolysis, gasification and continuous heating conversion of the organic solid fuel can be realized.

Owner:XI AN JIAOTONG UNIV

Culture medium for Chinese yams and making method thereof

InactiveCN106831253ARealize resource utilizationAvoid exceeding the standardExcrement fertilisersBioloigcal waste fertilisersBiotechnologyContinuous cropping

The invention discloses a culture medium for Chinese yams and a making method thereof. The culture medium is prepared from, by weight, 10-30% of bottom mud, 25-30% of mushroom residues, 25-30% of corn straw and 20-30% of earthworm cast. The culture medium for the Chinese yams is rich in nutrient substance and good in gas permeability of soil, contains various waste, and being high in recycling and utilizing rate because the waste materials are recycled and lasting in fertilizer efficiency; the yield of the Chinese yams can reach 71% compared with existing yield increase, the yield increase is remarkable, culture cost is low, labor intensity is low, operation is easy, and the continuous cropping obstacles of the Chinese yams can be overcome. The yield of the Chinese yams is high, the Chinese yams are easy to produce on a large scale and popularize, and the culture medium has the advantages of being low in carbon content and environmentally friendly.

Owner:GUIZHOU INST OF SOIL & FERTILIZER +1

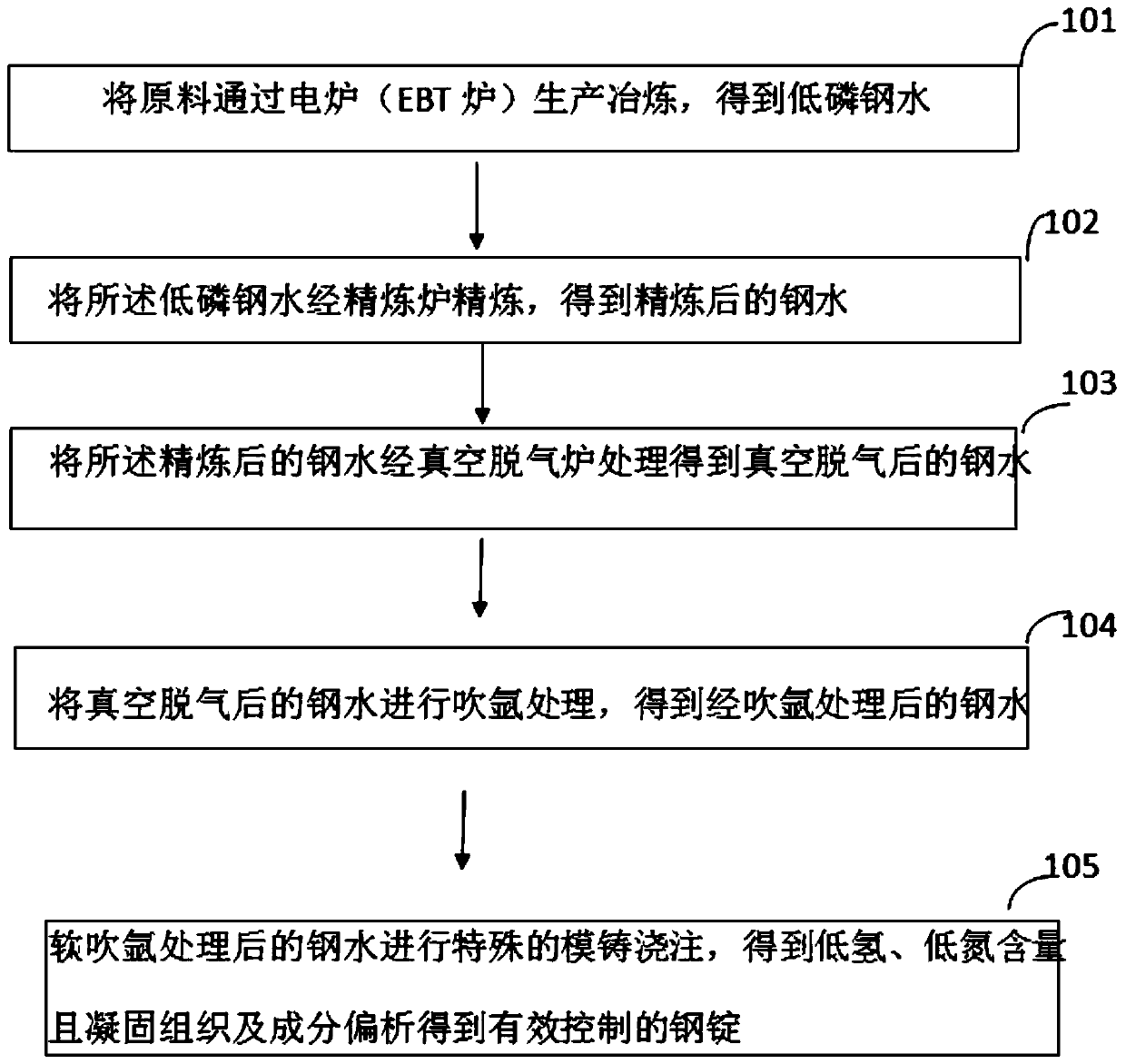

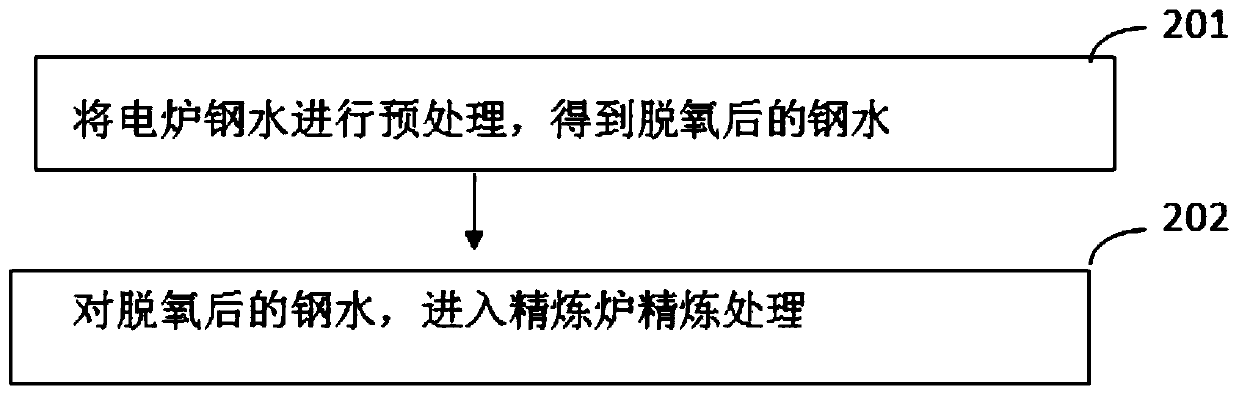

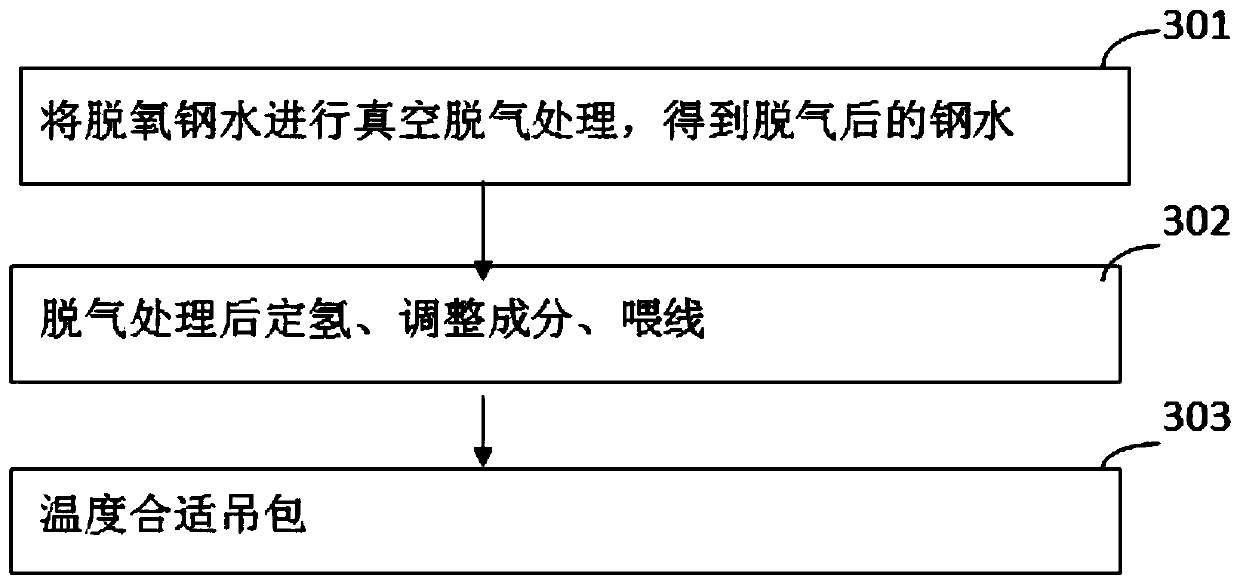

Production method for plastic mold steel refined cast ingot low in sulfur, phosphorus and inclusion content

The invention relates to a production method for a plastic mold steel refined cast ingot low in sulfur, phosphorus and inclusion content. The production method comprises the following steps that a rawmaterial is subjected to production smelting through an electric furnace (EBT furnace), molten steel is obtained; the molten steel is refined through a refining furnace, and refined molten steel is obtained; the refined molten steel is processed through a vacuum degassing furnace, and molten steel subjected to vacuum degassing is obtained; argon blowing treatment is conducted on the molten steelsubjected to vacuum degassing, and molten steel subjected to argon blowing is obtained; and special mold casting is conducted on the molten steel subjected to argon blowing, and the steel ingot whichis low in hydrogen and nitrogen content and of which the solidification structure and component segregation are effectively controlled. According to the production method for the plastic mold steel, the large-size plastic mold steel which is high in purity and low in sulfur and phosphorus content can be produced, and the inclusion content and the contents of impurity elements including sulfur andphosphorus are effectively controlled.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com