Patents

Literature

80results about How to "Unique quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

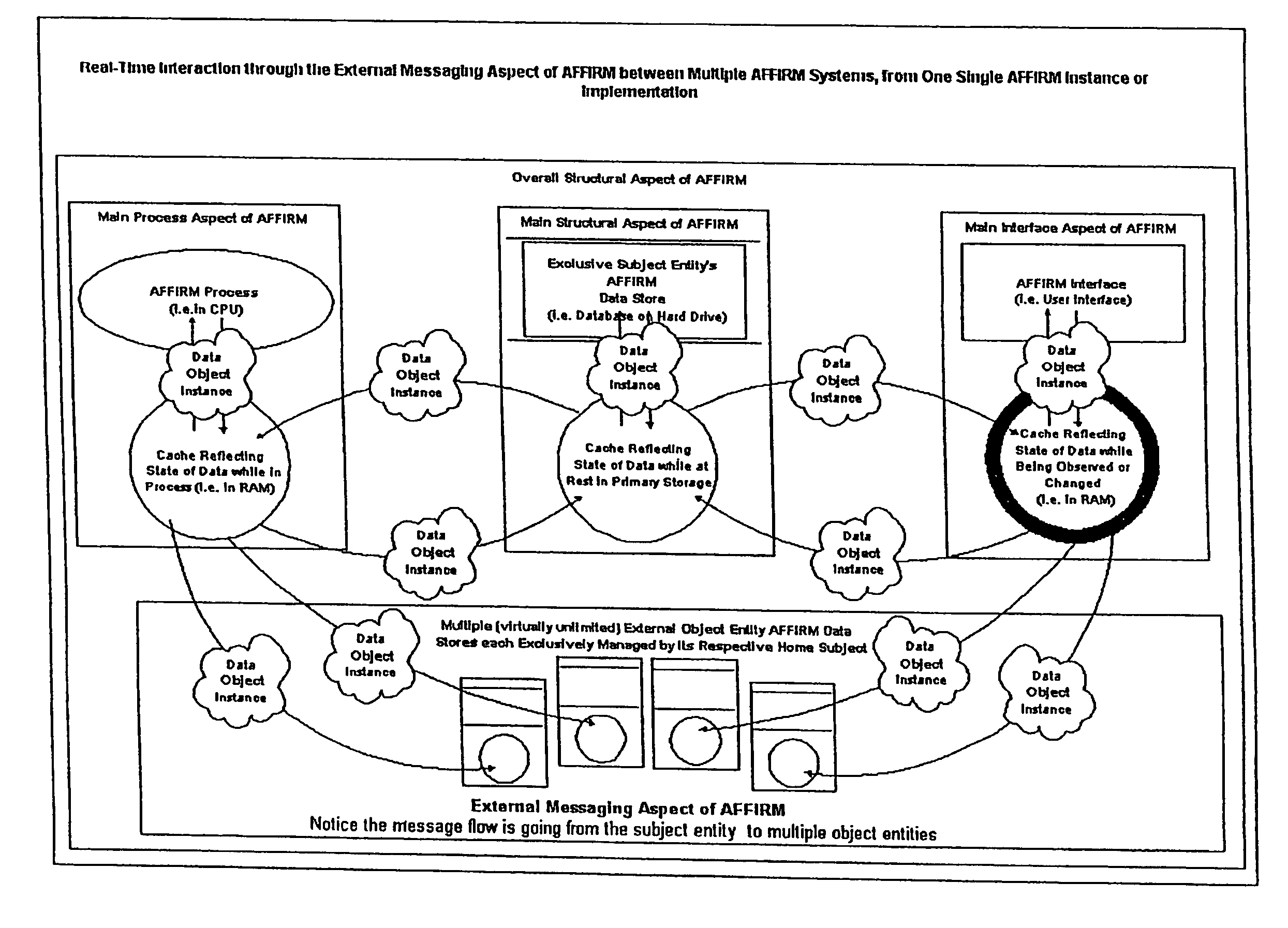

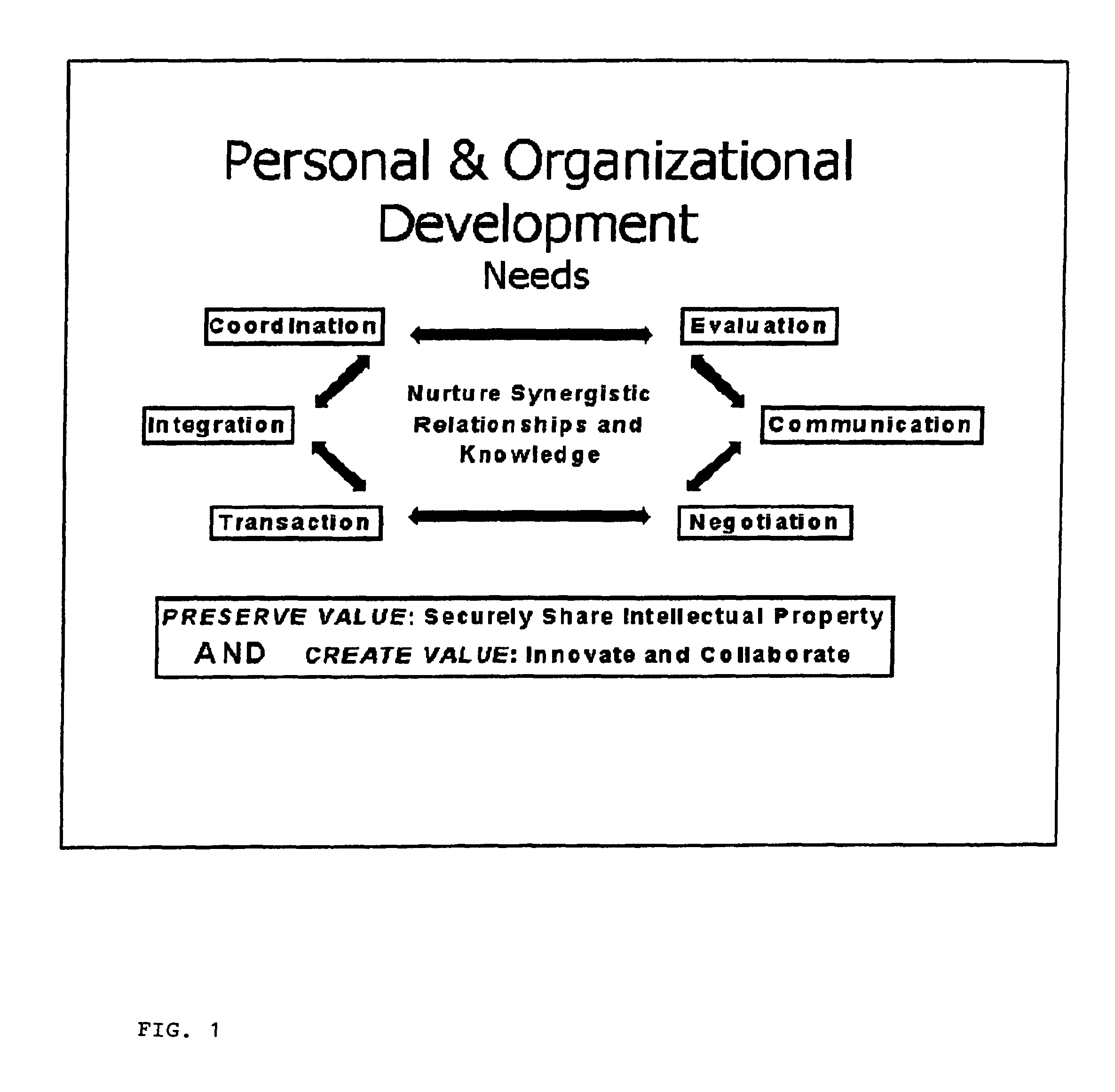

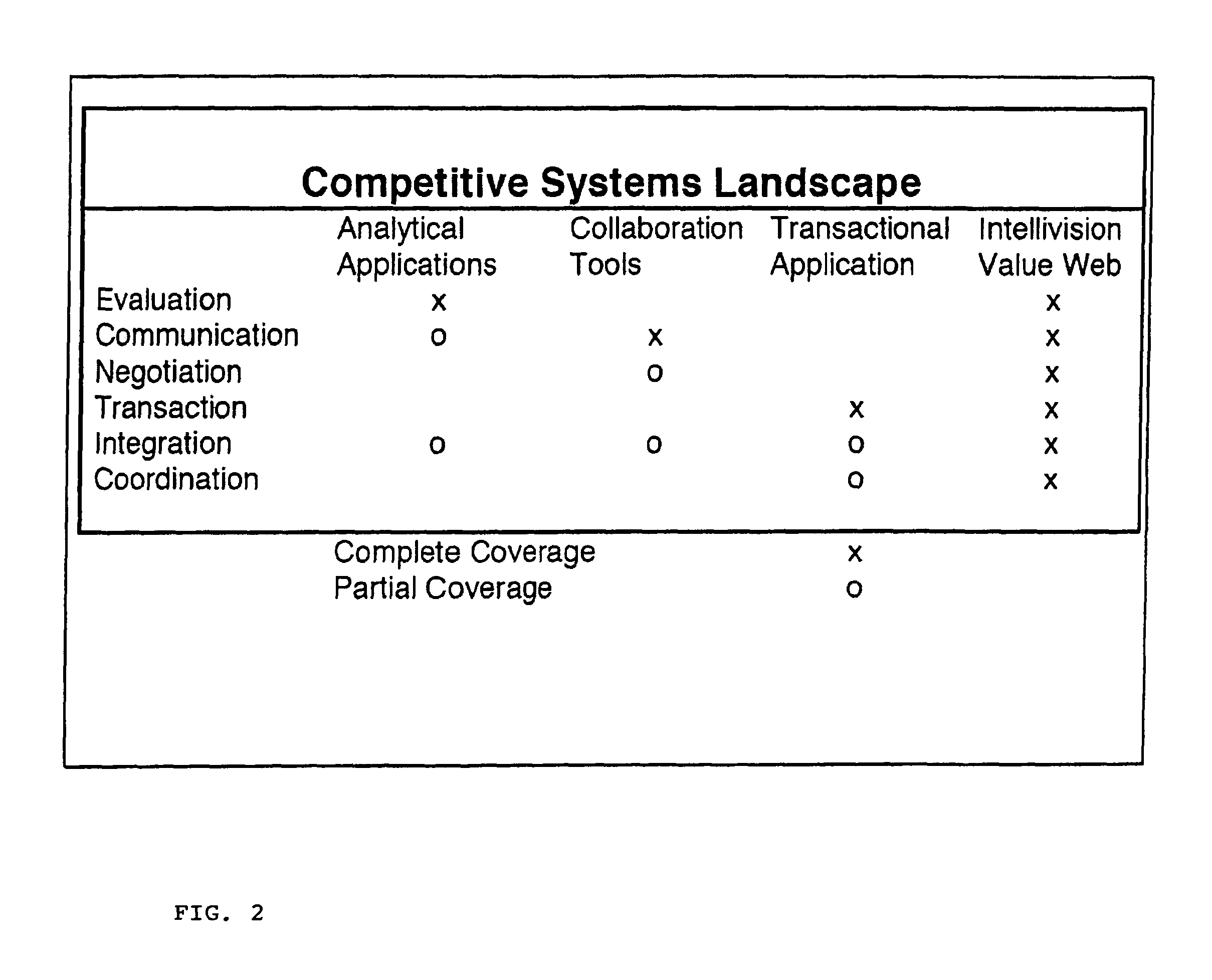

Architectural frameworks, functions and interfaces for relationship management (affirm)

ActiveUS20090006467A1Unique qualityGood tracked and monitoredObject oriented databasesResourcesCustomer relationship managementComputer science

Uniform subject and object oriented data structure adopted in computing device to efficiently store, distribute and process data in a variety of applications. Said data structure comprised of multiple complementary subparts that together and independently facilitate communication (of inputs and outputs) through one or more defined interfaces to facilitate secure access and coordination between given individual subject(s) and other real (physical or metaphysical) entities. Methods are also disclosed that work in tandem with the data structure and interface components to enable and require a single or given human user or other individual personal subject (belonging to a secure AFFIRM network) to maintain exclusive (private) self-control over at least one virtual domain that represents themselves (their actions and their relationships).

Owner:RSVPRO

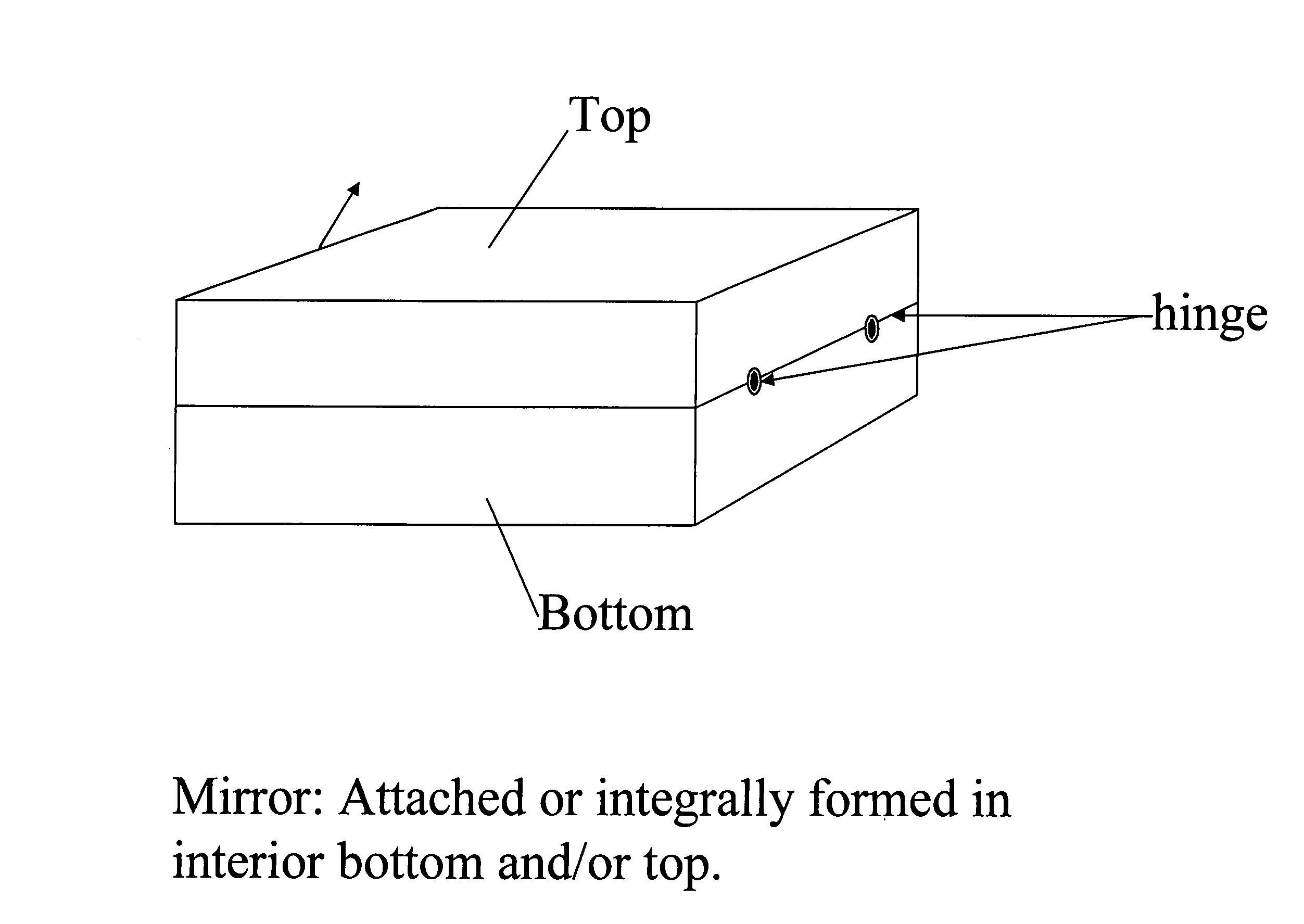

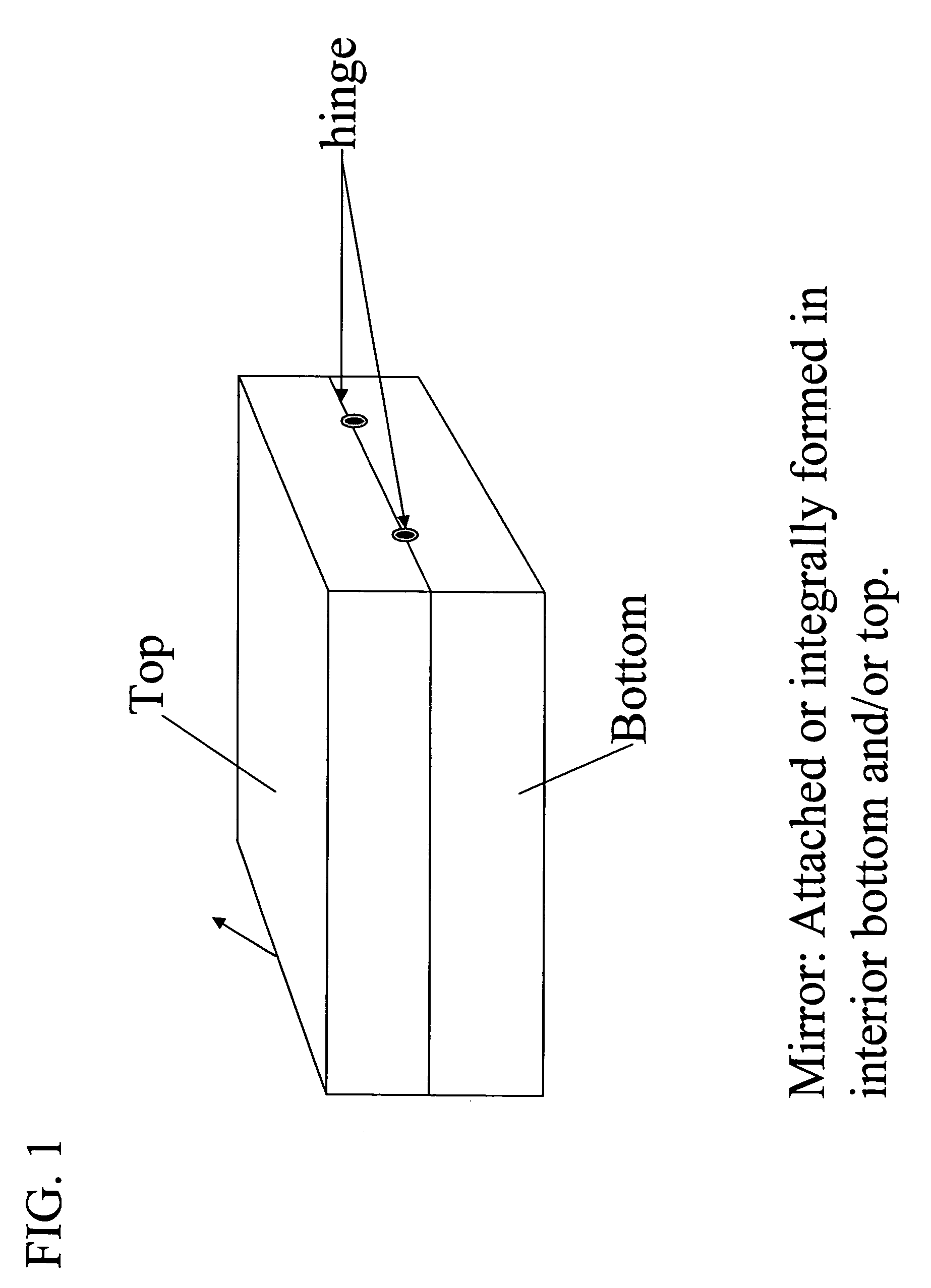

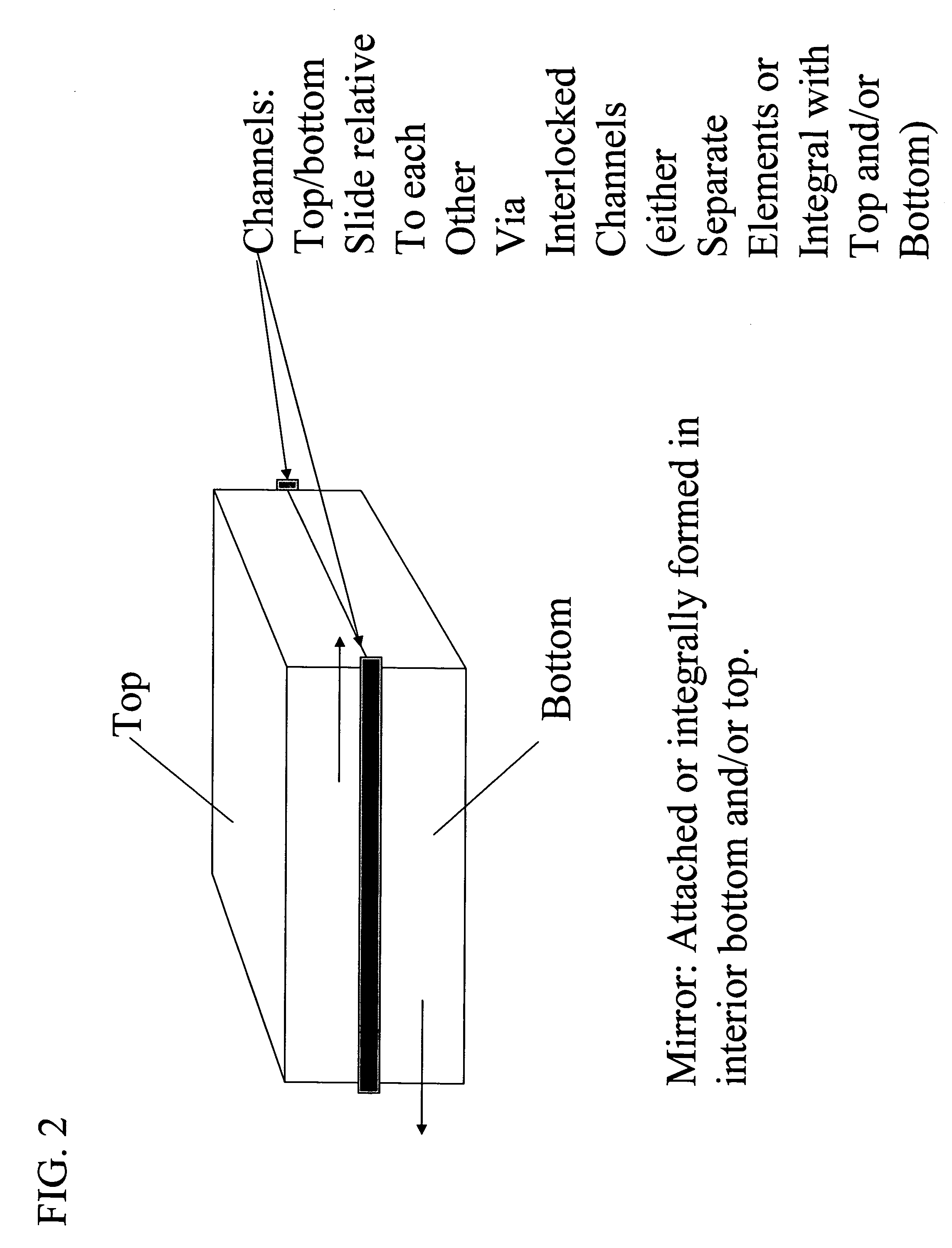

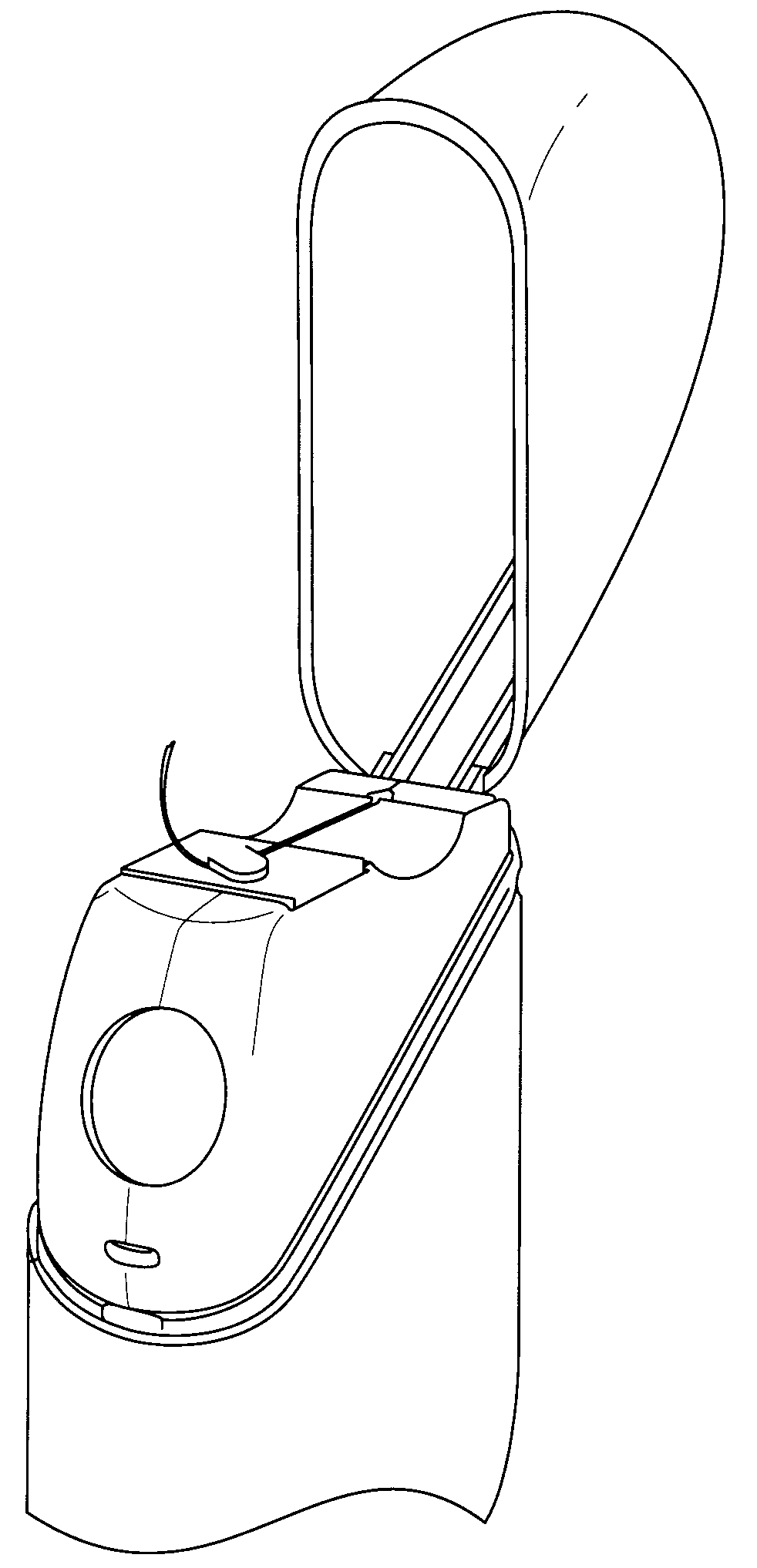

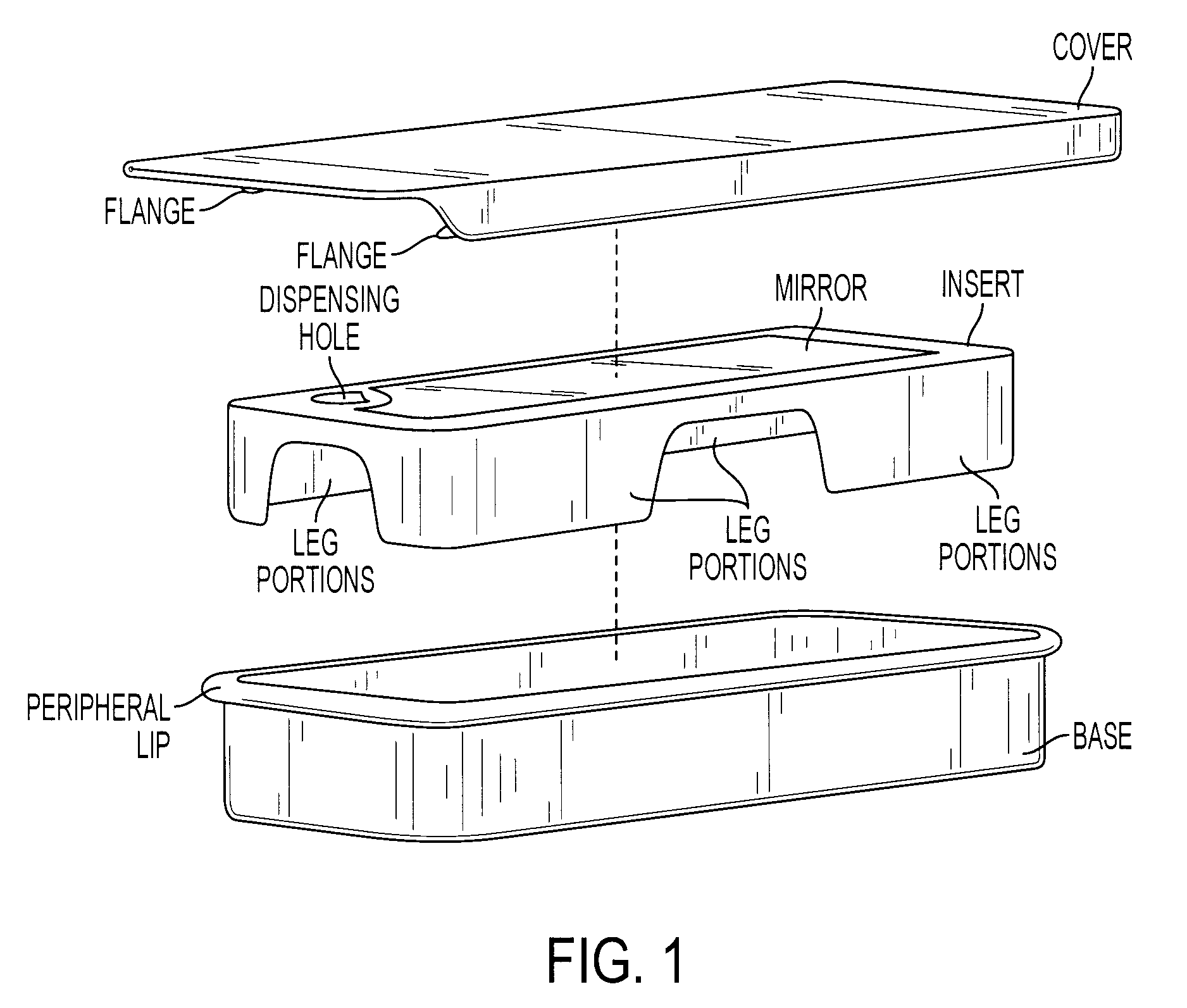

Mirrored oral-product container

InactiveUS7237677B2Unique qualityNervous disorderClosure with auxillary devicesEngineeringOral Product

Owner:BERG ROBERT I

Henna and vegetable dye based compositions for coloring of human hair

ActiveUS20100313362A1Increased free volumeUnique qualityCosmetic preparationsHair removalHair dyesHair Colors

New, effective and non-toxic compounded henna based hair dyes that are non-toxic, natural and hypoallergenic that provide an alternative to conventional hair color. The products are made using 100% Green Chemistry and do not utilize encapsulation.

Owner:VAINSHELBOIM ALEX +1

Architectural frameworks, functions and interfaces for relationship management (AFFIRM)

ActiveUS8849862B2Good tracked and monitoredAvoid insecurityDigital data processing detailsObject oriented databasesCustomer relationship managementComputer science

Uniform subject and object oriented data structure adopted in computing device to efficiently store, distribute and process data in a variety of applications. Said data structure comprised of multiple complementary subparts that together and independently facilitate communication (of inputs and outputs) through one or more defined interfaces to facilitate secure access and coordination between given individual subject(s) and other real (physical or metaphysical) entities. Methods are also disclosed that work in tandem with the data structure and interface components to enable and require a single or given human user or other individual personal subject (belonging to a secure AFFIRM network) to maintain exclusive (private) self-control over at least one virtual domain that represents themselves (their actions and their relationships).

Owner:RSVPRO

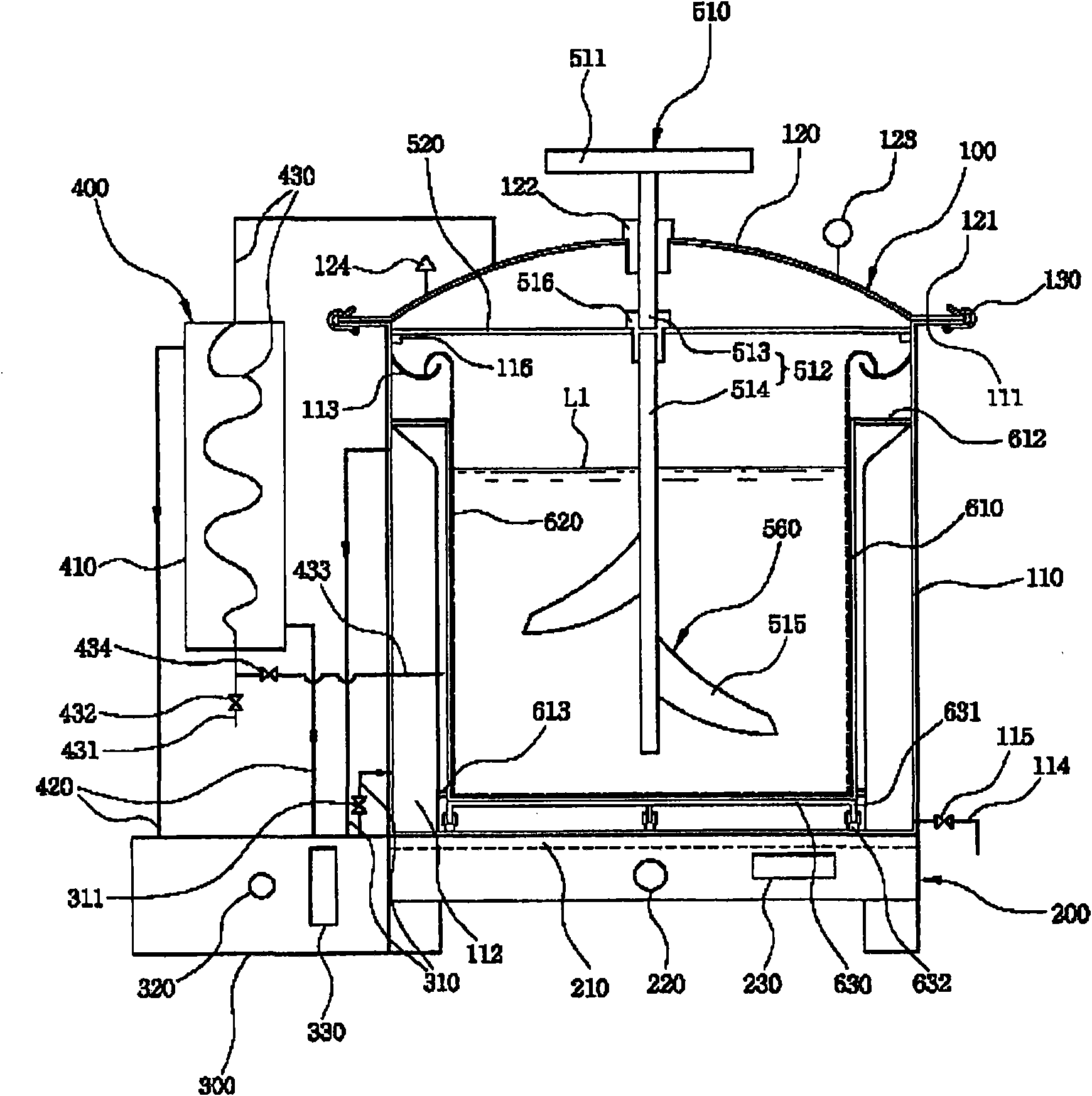

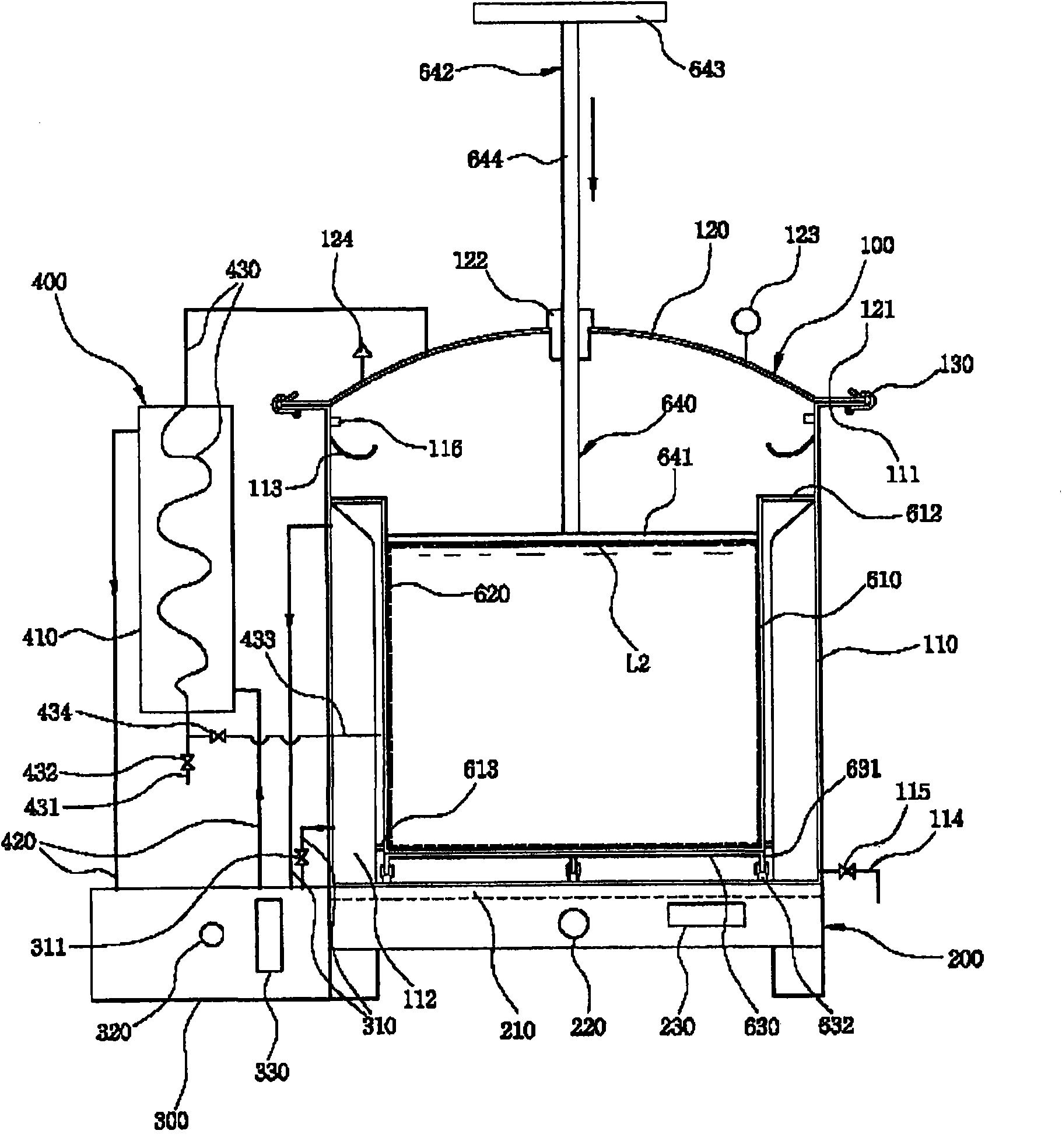

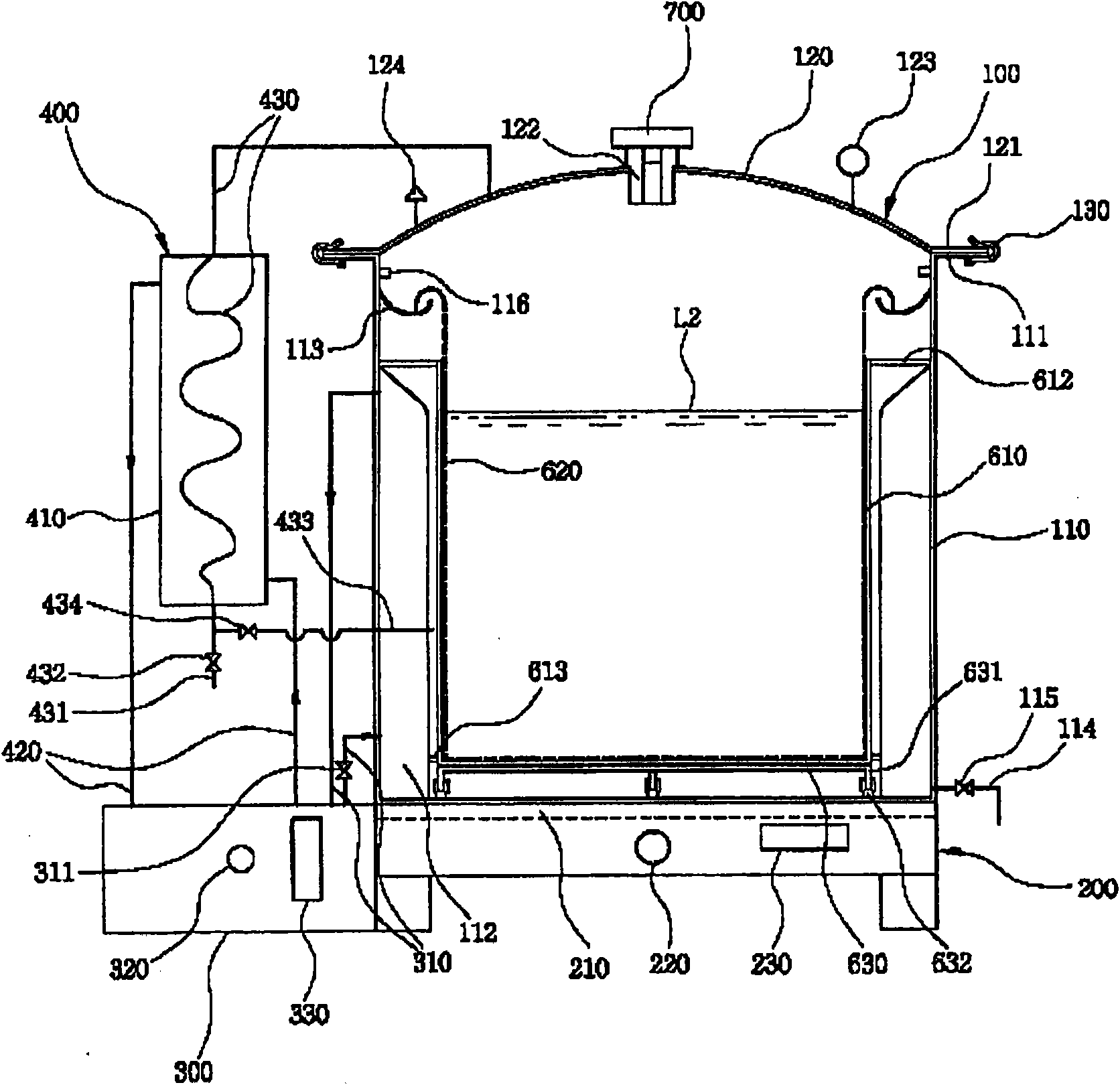

Home-brewed liquor manufacturing apparatus

ActiveCN101679928AEasy to manufactureEasy to operateFermented solutions distillation/rectificationTemperature control using plurality of sensorsComing outDistillation

The present invention relates to a liquor manufacturing apparatus for home use. Particularly, the present invention relates to a liquor manufacturing apparatus for home use, which includes a single device consisting of a heater, the cooler, the condenser, the stirrer and the filter to enable to perform all processes required for liquor preparation and which enables anyone to easily make desired liquor even in general homes using grains, fruits or other plant materials. The liquor manufacturing apparatus for home use comprises: a combined fermentation and distillation tank including a tank body having a cooling jacket mounted at the inside wall surface thereof so as to allow cooling water to be filled therein and to pass therethrough and a lid being adapted to hermetically seal the top portion of the tank body; an electric heater adapted to heat the tank body; a cooler adapted to supply the cooling water to the cooling jacket so as to cool the tank body; a condenser adapted to cool steam and volatile substance coming out of the combined fermentation and distillation tank; a combined steaming and filtering container disposed inside the tank body; a fabric filter disposed inside the combined steaming and filtering container and adapted to contain contents produced in the liquor preparing process; and a stirrer adapted to stir the contents inside the fabric filter during fermentation.

Owner:DAEBONG LS CO LTD

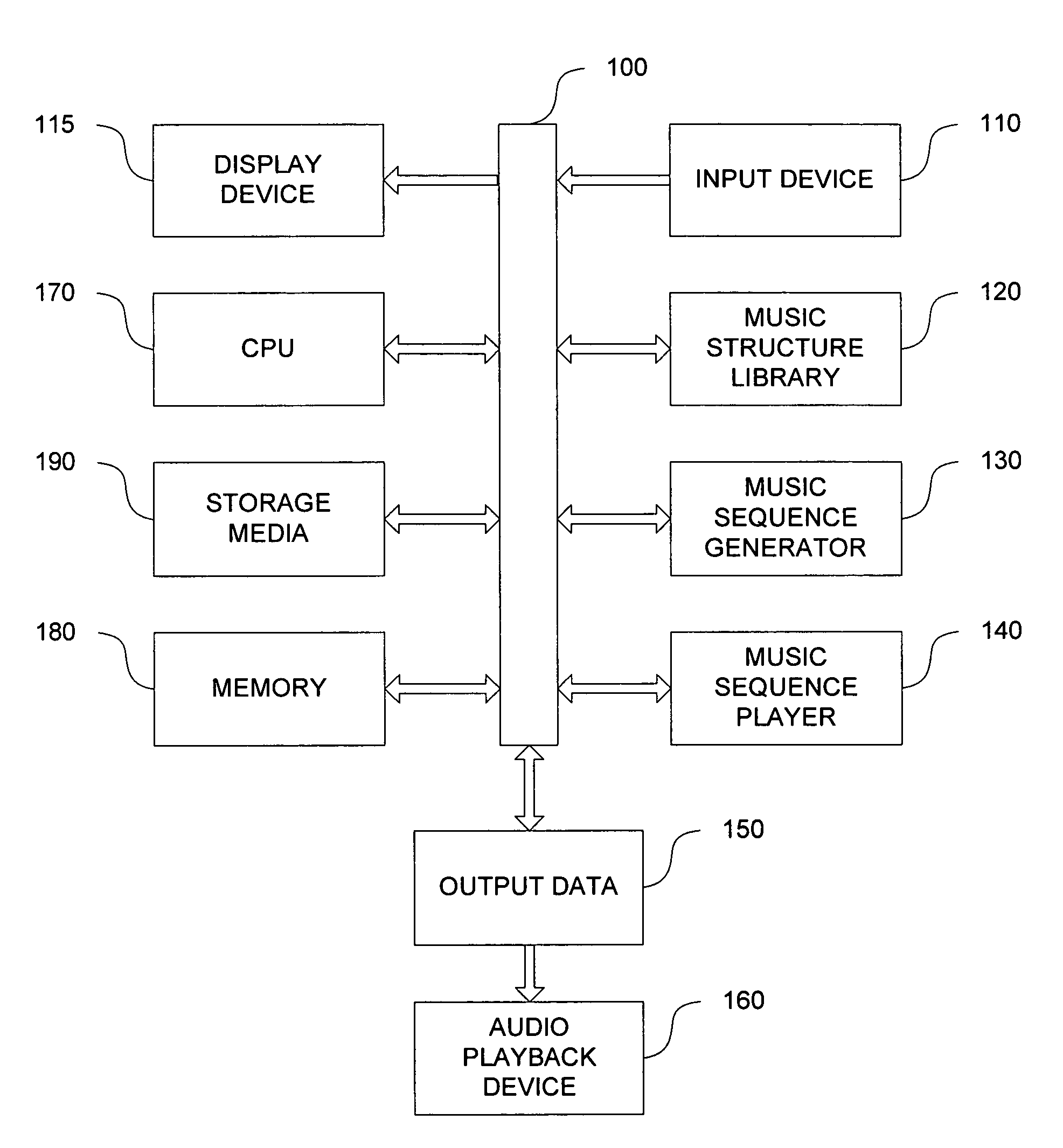

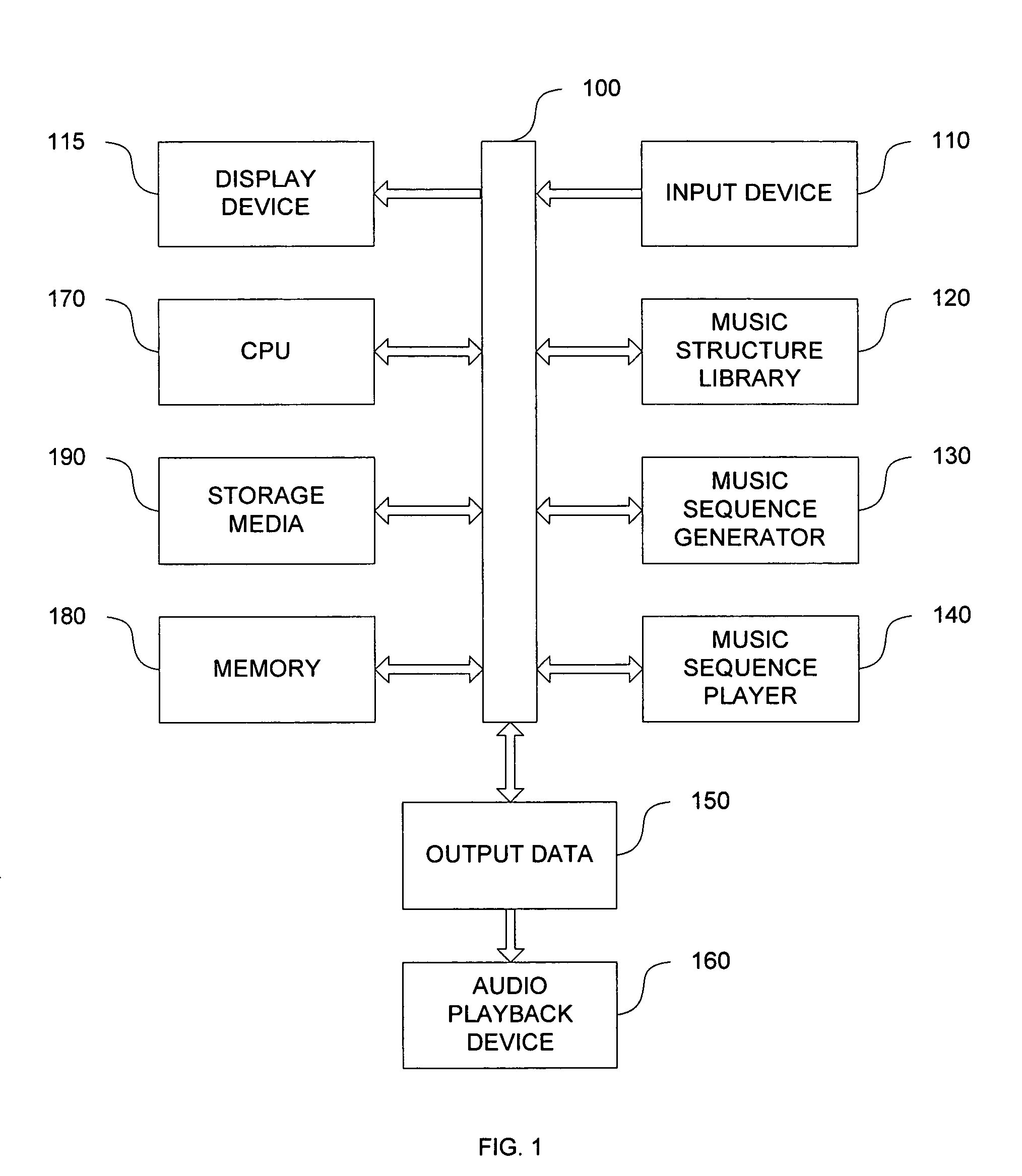

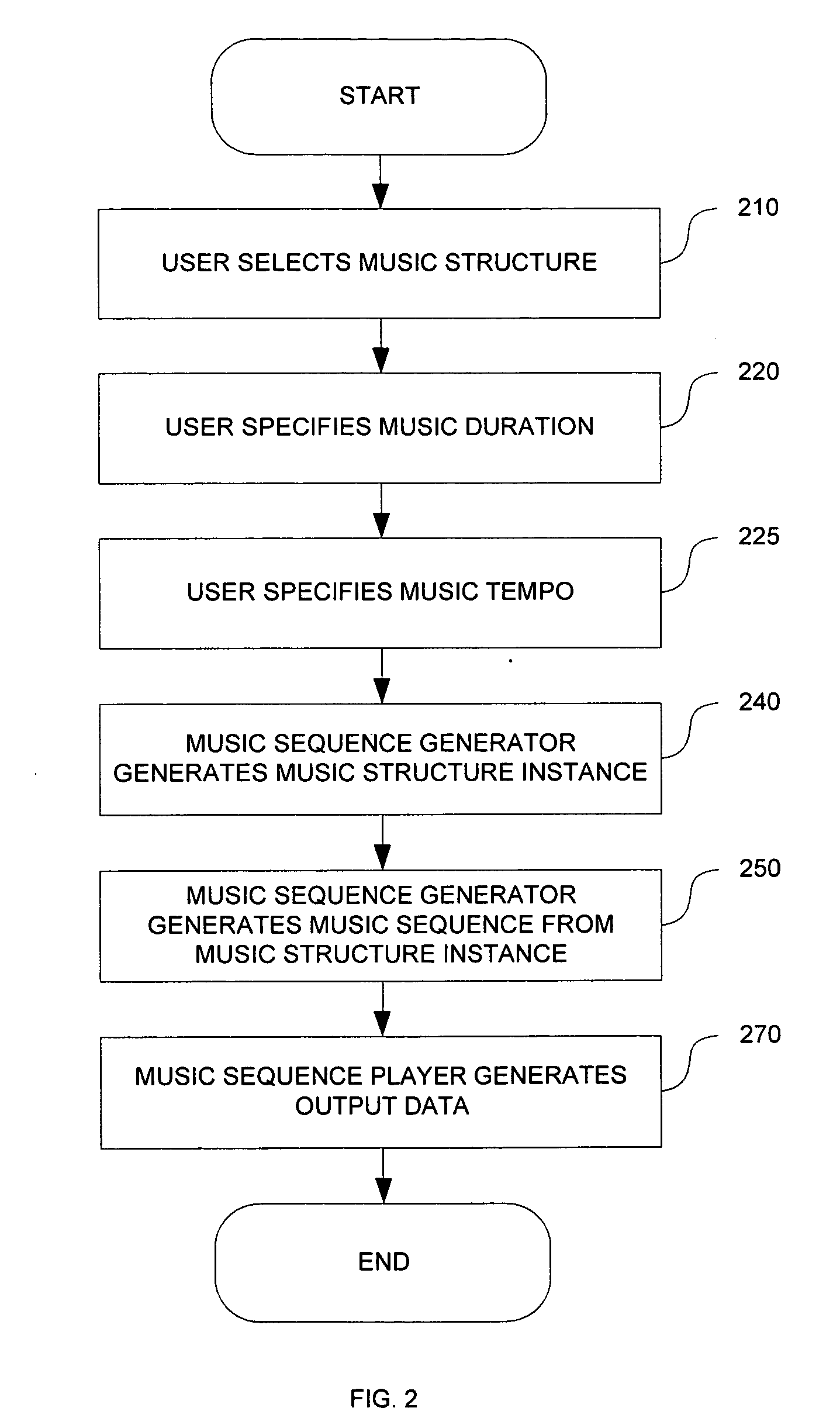

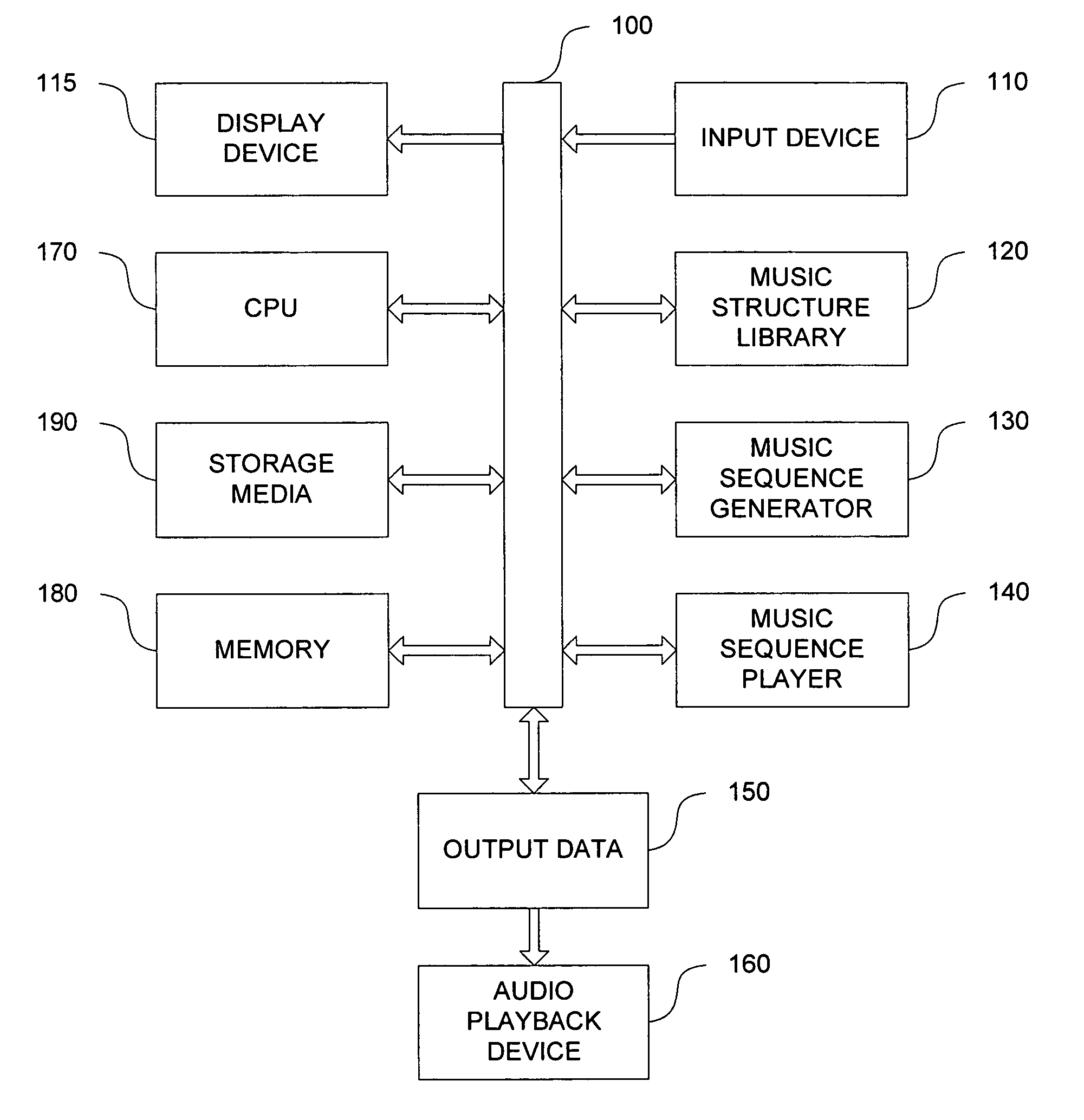

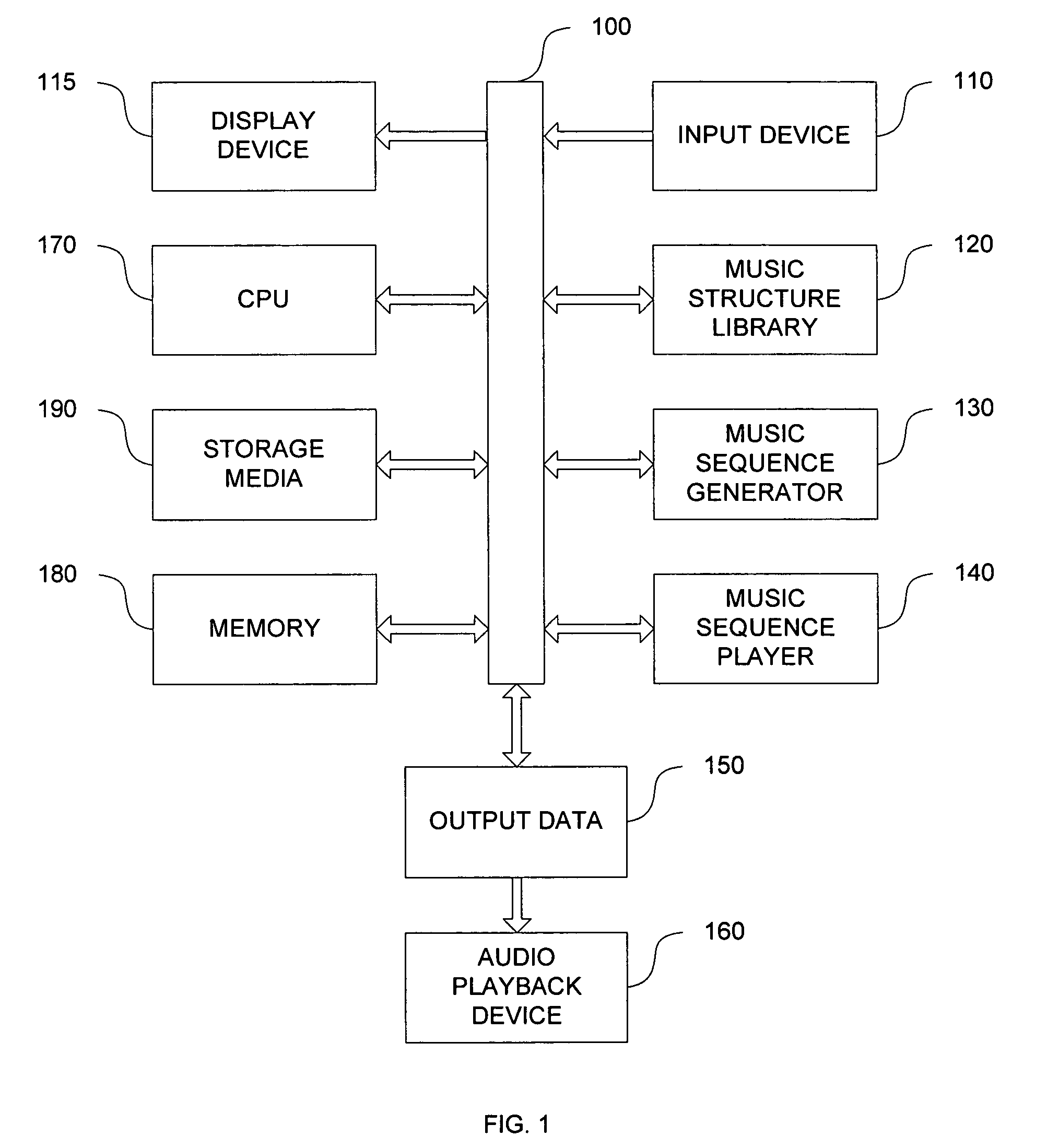

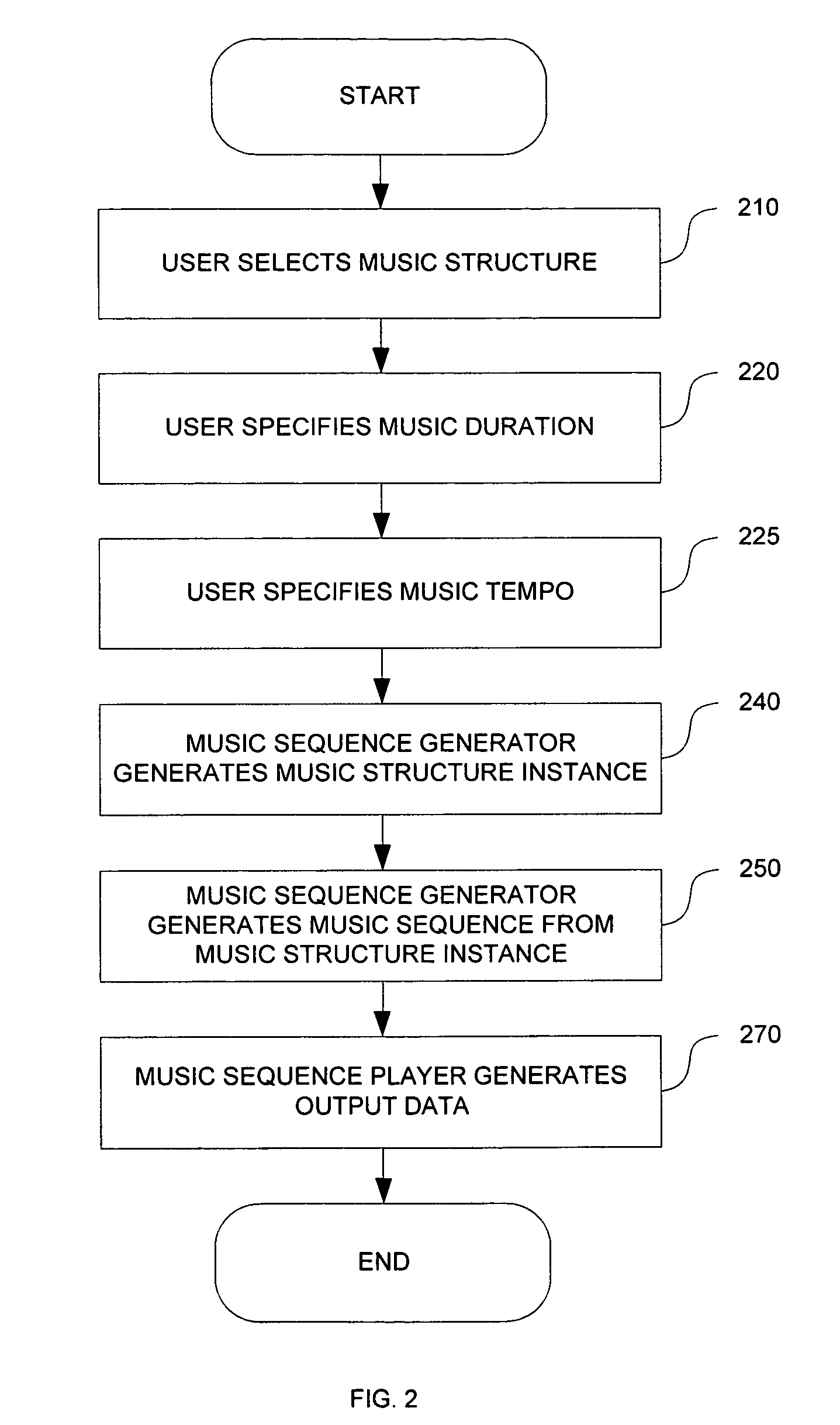

Machine and process for generating music from user-specified criteria

The present invention teaches a machine and process that generates music given a set of simple user-specified criteria. The present invention enables music generation wherein a user may specify the duration and tempo of the music to be generated that may then be played or stored for retrieval and use at a later time and does not require the user to be a skilled composer of music. The present invention allows the user to generate music in a very short period of time wherein the music generated by also has beginnings and endings that occur in a manner that is esthetically appropriate. In addition, transitions within the generated music occur in a manner that is esthetically appropriate. Music generated by the present invention also has unique qualities that are desirable to users that use music in their own products or works.

Owner:HUFFMAN ERIC CHRISTOPHER

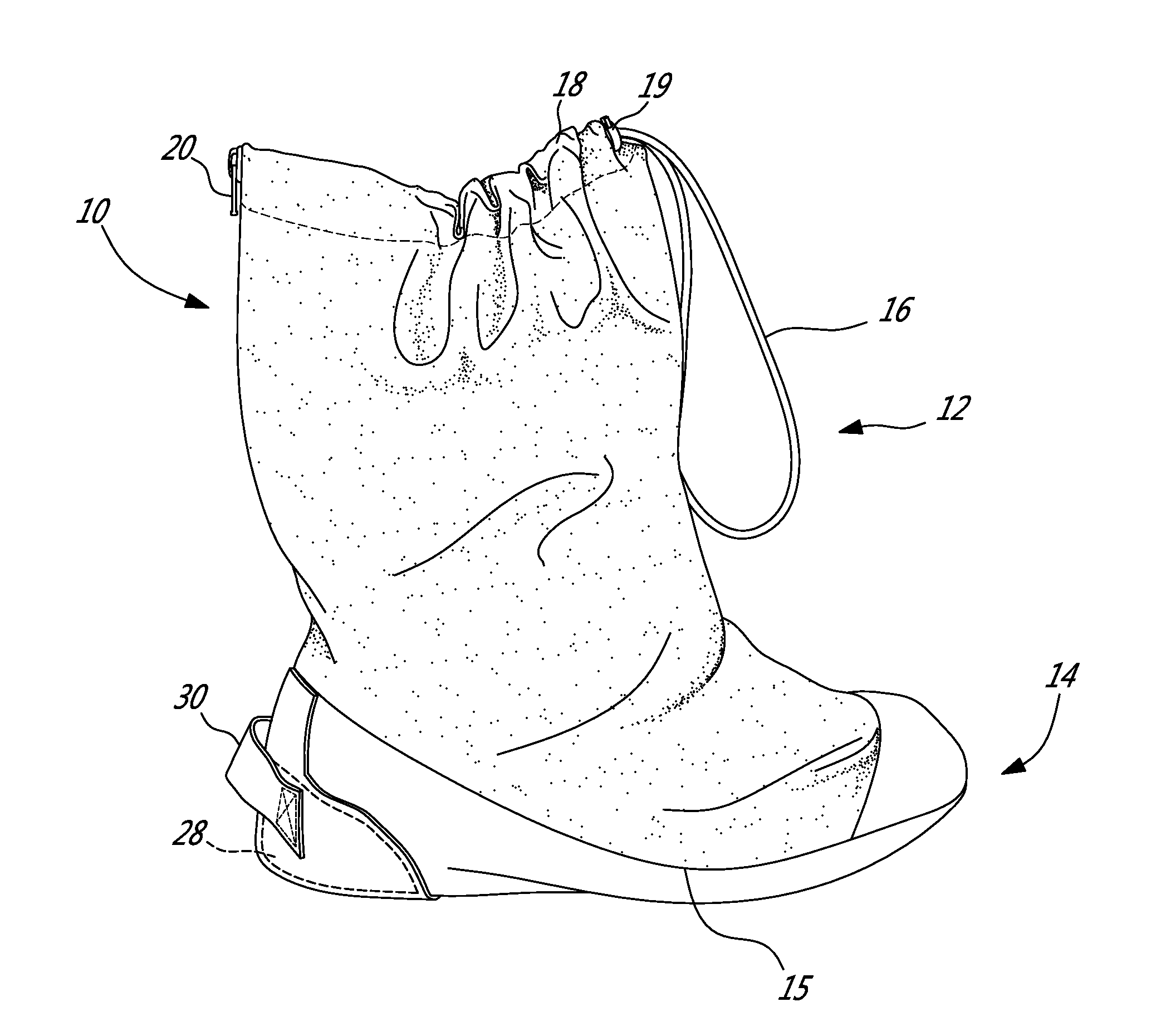

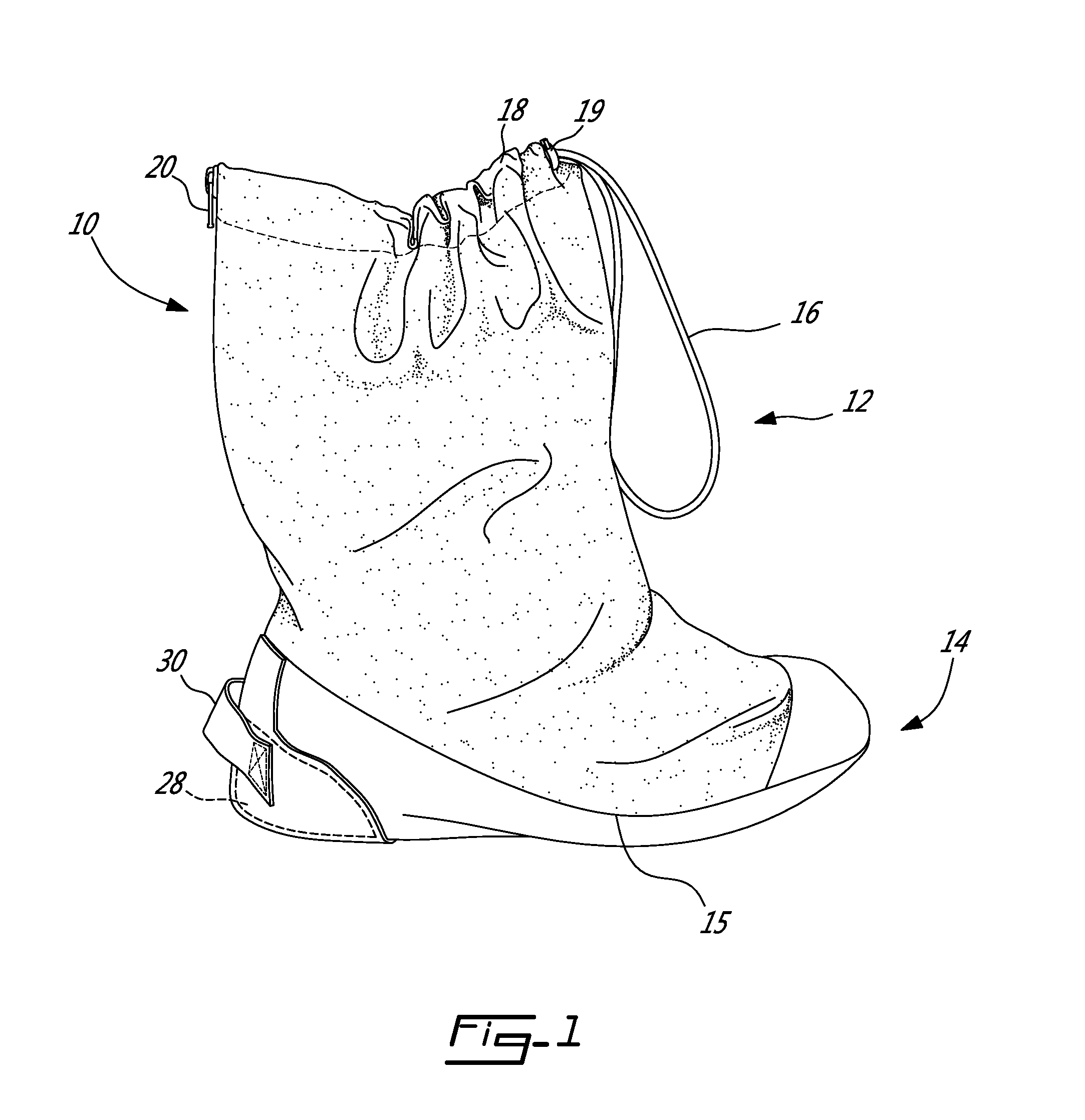

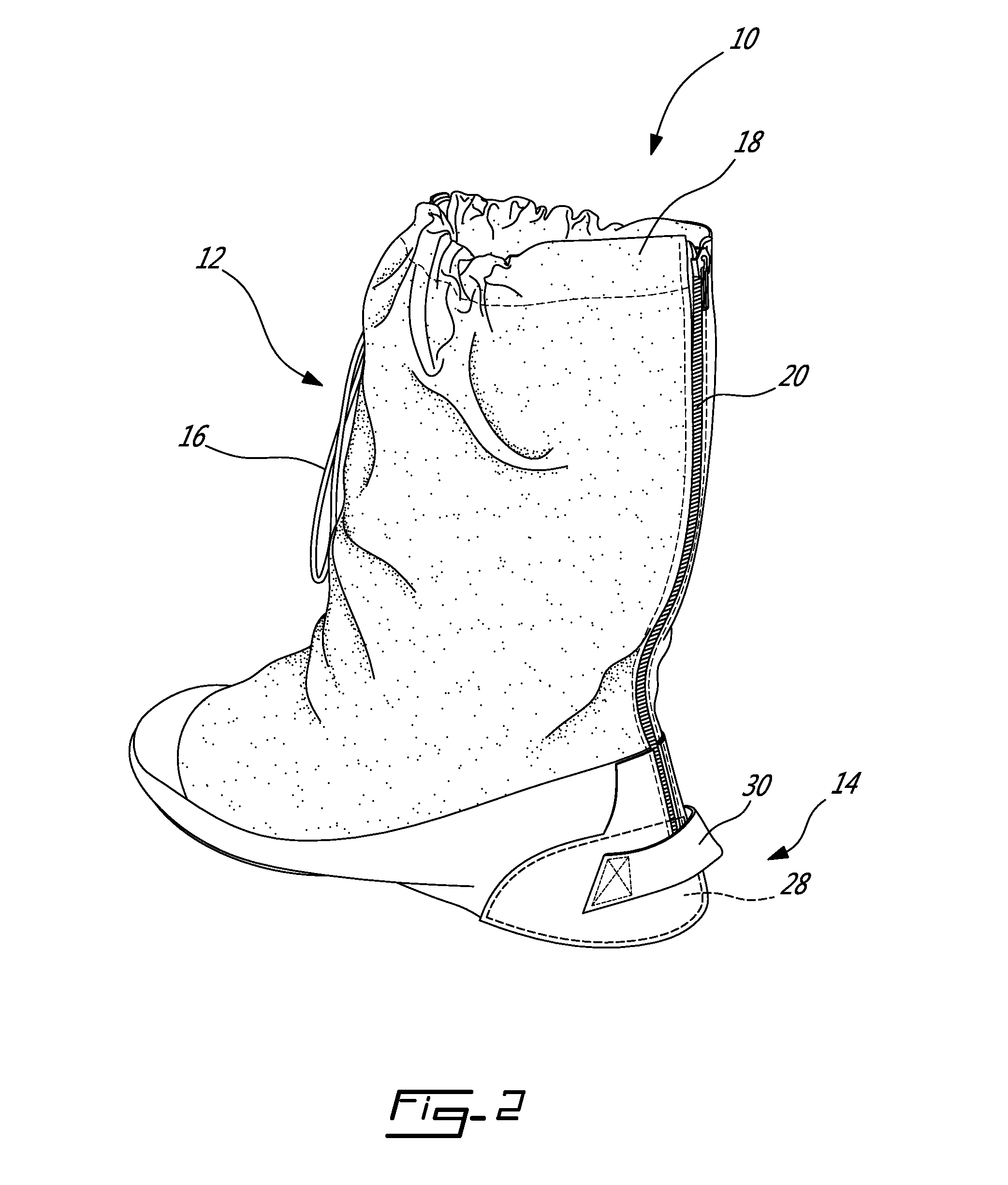

Foldable protective overshoe and method of manufacturing

A protective overshoe has a collapsible upper portion attached to a stretchable lower portion with a collapsible sole. The collapsible sole may be coated directly on the lower portion of a fabric overshoe body. The coating may be applied by dipping the lower portion of the fabric overshoe body into a bath of liquid rubber. Separate toe and heel outsole portions may be provided on the rubber coated lower portion of the fabric overshoe body. The lower portion may further comprise a reinforcing heel insert which is adapted to clip on the heel of the wearer's shoe while providing the required form holding properties to maintain an unobstructed heel opening when the lower portion of the overshoe is longitudinally stretched.

Owner:9225 6619 QUEBEC

Machine and process for generating music from user-specified criteria

The present invention teaches a machine and process that generates music given a set of simple user-specified criteria. The present invention enables music generation wherein a user may specify the duration and tempo of the music to be generated that may then be played or stored for retrieval and use at a later time and does not require the user to be a skilled composer of music. The present invention allows the user to generate music in a very short period of time wherein the music generated by also has beginnings and endings that occur in a manner that is esthetically appropriate. In addition, transitions within the generated music occur in a manner that is esthetically appropriate. Music generated by the present invention also has unique qualities that are desirable to users that use music in their own products or works.

Owner:HUFFMAN ERIC CHRISTOPHER

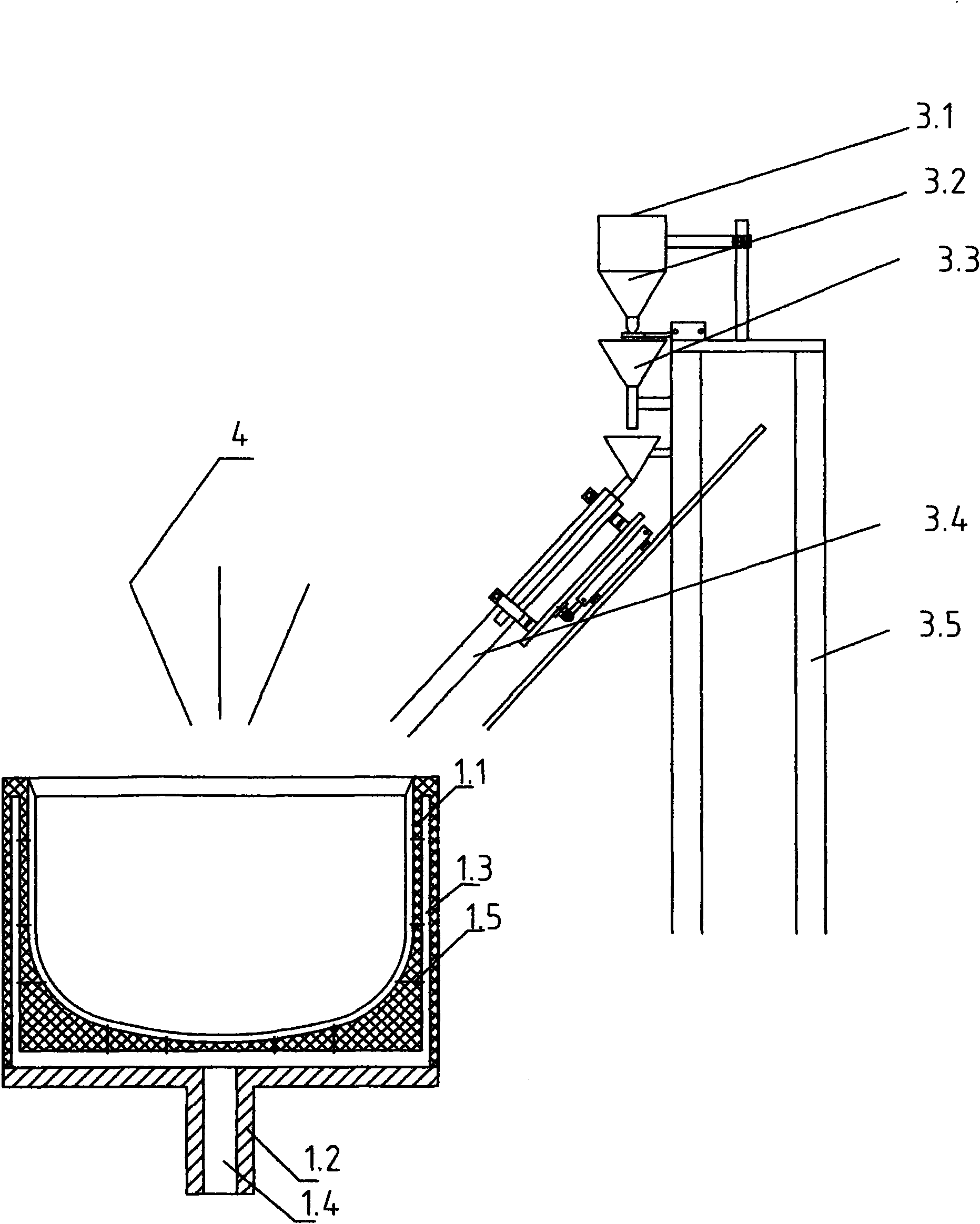

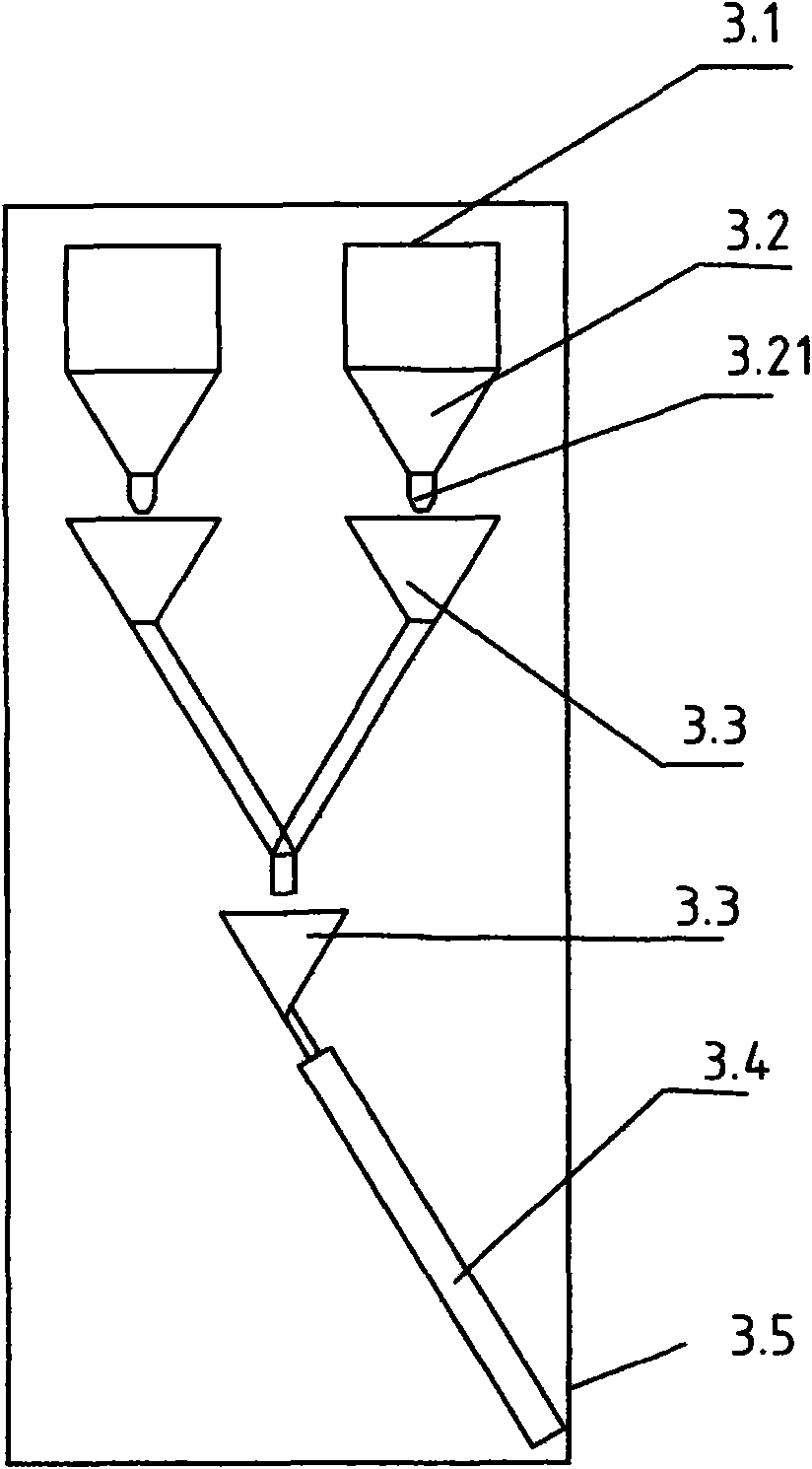

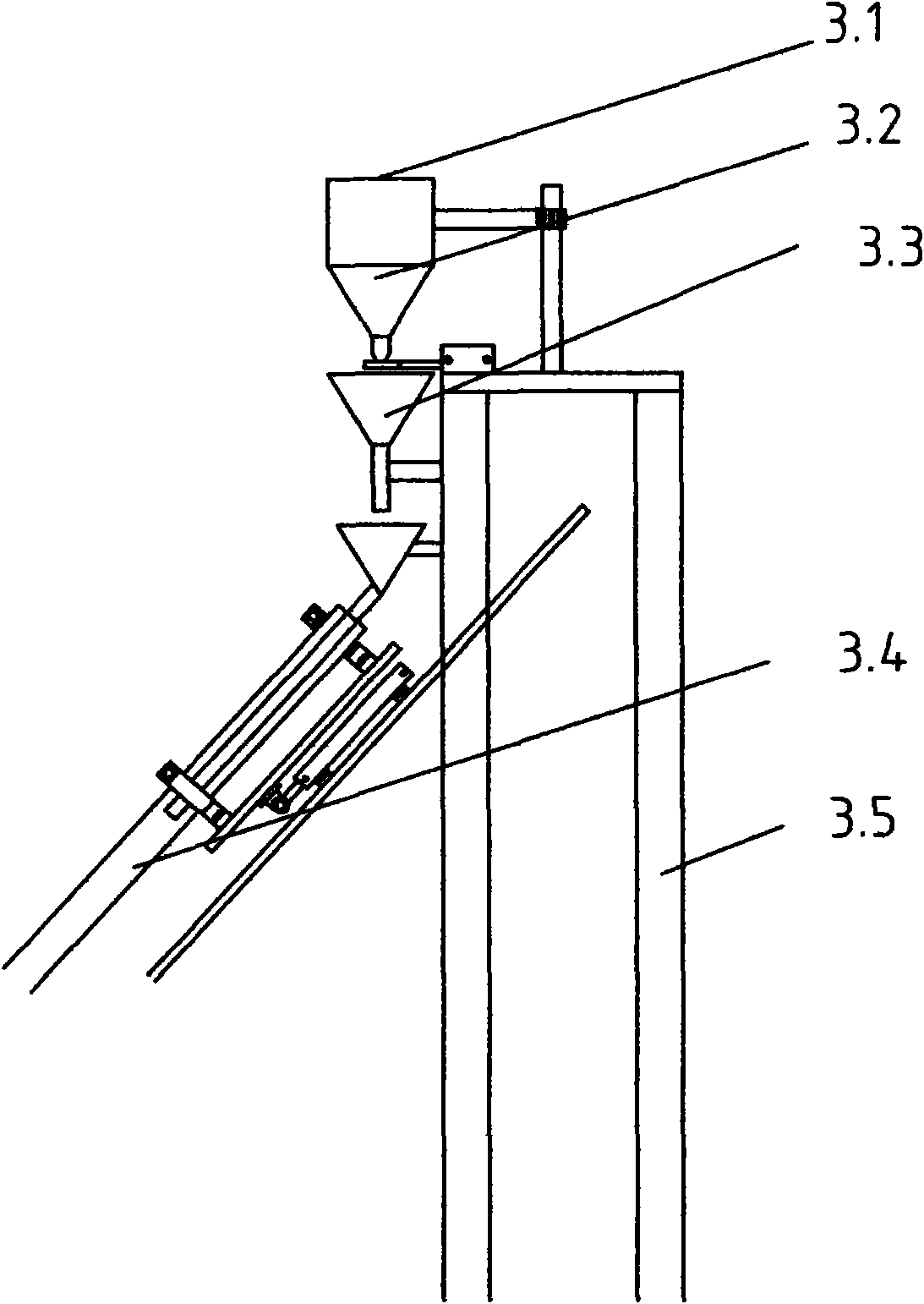

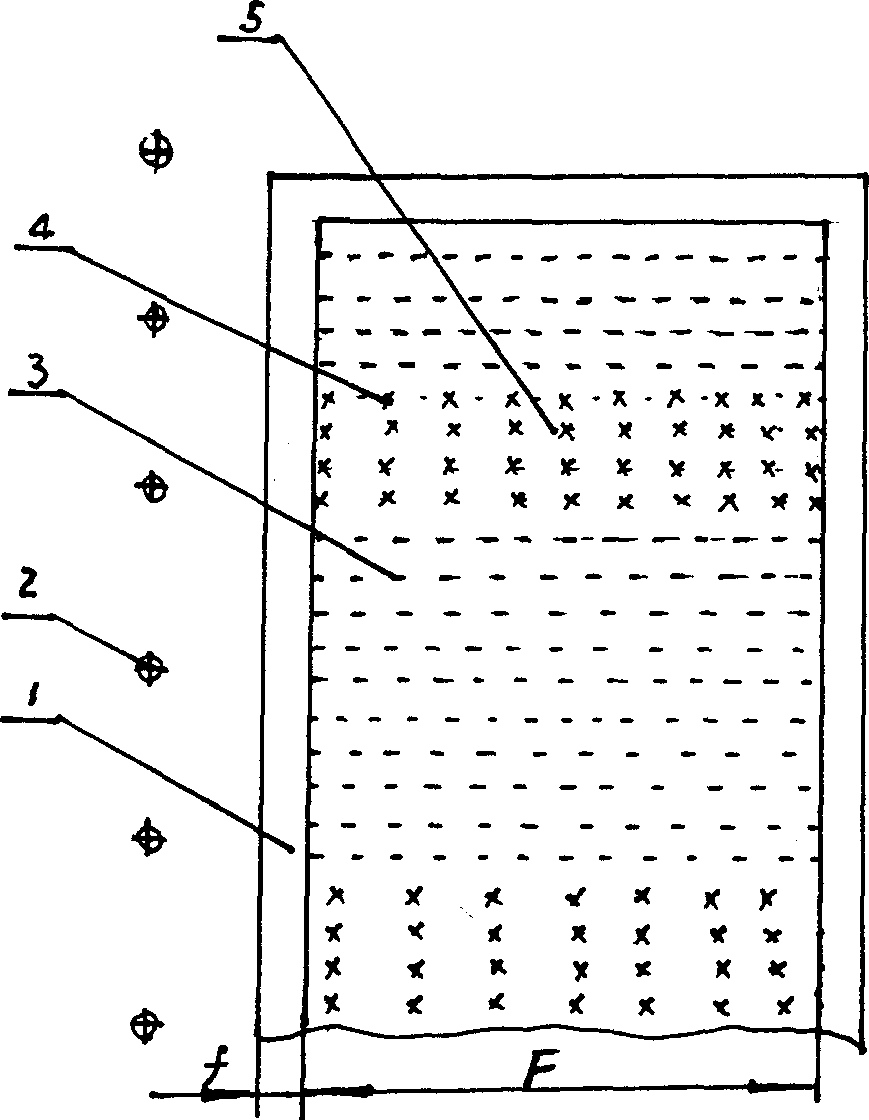

Process for producing arc quartz crucible by vacuum plus coating, equipment, product thereof

InactiveCN101570391AEasy to controlHigh strengthBy pulling from meltGlass shaping apparatusState of artSpray coating

The invention relates to the crucible manufacturing field and is a process for producing an arc quartz crucible by vacuum plus coating, equipment, products thereof. The invention solves the problems that the crucible manufacturing process in the prior art can not solve the operating requirements of long time, high temperature, and high purity of the quartz crucible, a uniform high purity quartz layer can not be formed in the vacuum state by uniform spraying, the layered spraying can not be accurately and timely carried out, and the like; therefore the process and the equipment for producing the arc quartz crucible by vacuum plus coating are provided; the quartz sand is poured into a vacuum mould to shape a prebuilt shape which is put into a founded chamber; a vacuum pump is started and the temperature is controlled, and then the melting and preheating begin; by controlling two hoppers of a double-hopper charging machine, the high-purity quartz sand is sprayed into the quartz crucible in the process of melting, and then mixing spraying coating is sprayed; the vacuum pump is closed during keeping the temperature. The quartz crucible produced by the process and the equipment of the invention has strong non-deformability of long time and exhaustion resistance in high temperature and can be used for long time.

Owner:余姚市启明石英有限公司

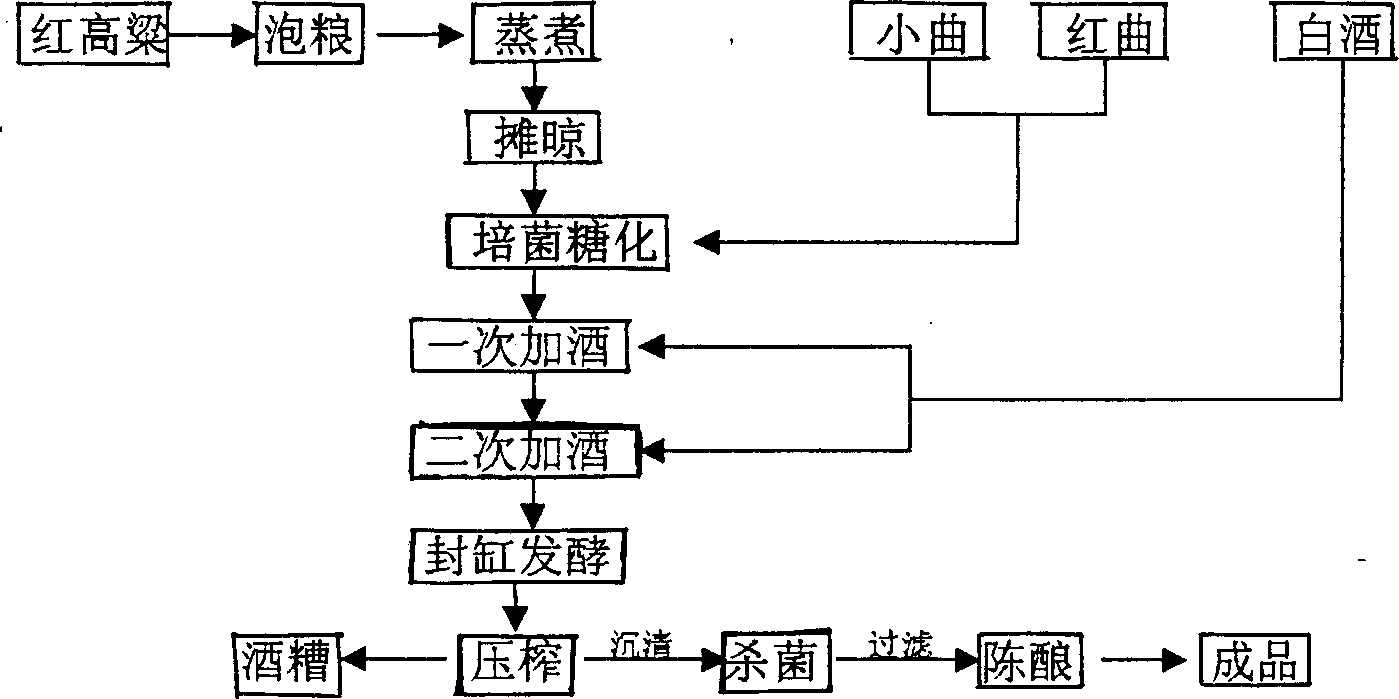

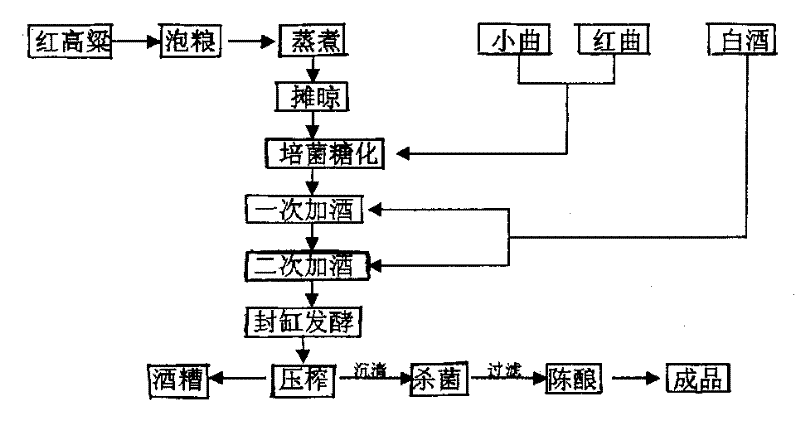

Kaoliang red wine and its production process

The present invention relates to a sweet red liquor and its production method. It is made by using red sorghum, xiaoqu, anka and white liquor according to the mixing ratio of 47-53:01-025:1.5-3:50-150 or using red sorghum, xiaqu and white liquor according to the mixing ratio of 47-53:0.1-0.25;50-150 through the processes of soaking, cooking, tedding, culturing yeast, saccharifying, closed fermentation, pressing, sterilizing, ageing and inspection. It is a low alcohol liquor with high nutritive value.

Owner:左长春

Technology for planting yunnan Dizhu pinellia tube GAP

The technology for planting Yannan Dizhu pinellia tube GAP includes selecting land, selecting seed, preparing land, seedling, preventing diseases and pests, weeding, applying fertilizer, collecting and processing. The artificially planted planting Yannan Dizhu pinellia tube has the medicinal effect and quality of wild Yannan Dizhu pinellia tube maintained, and has high effective component content, stable effective component content and no pollution. Therefore, the technology of present invention can protect and develop the said medicine resource.

Owner:吴桂权

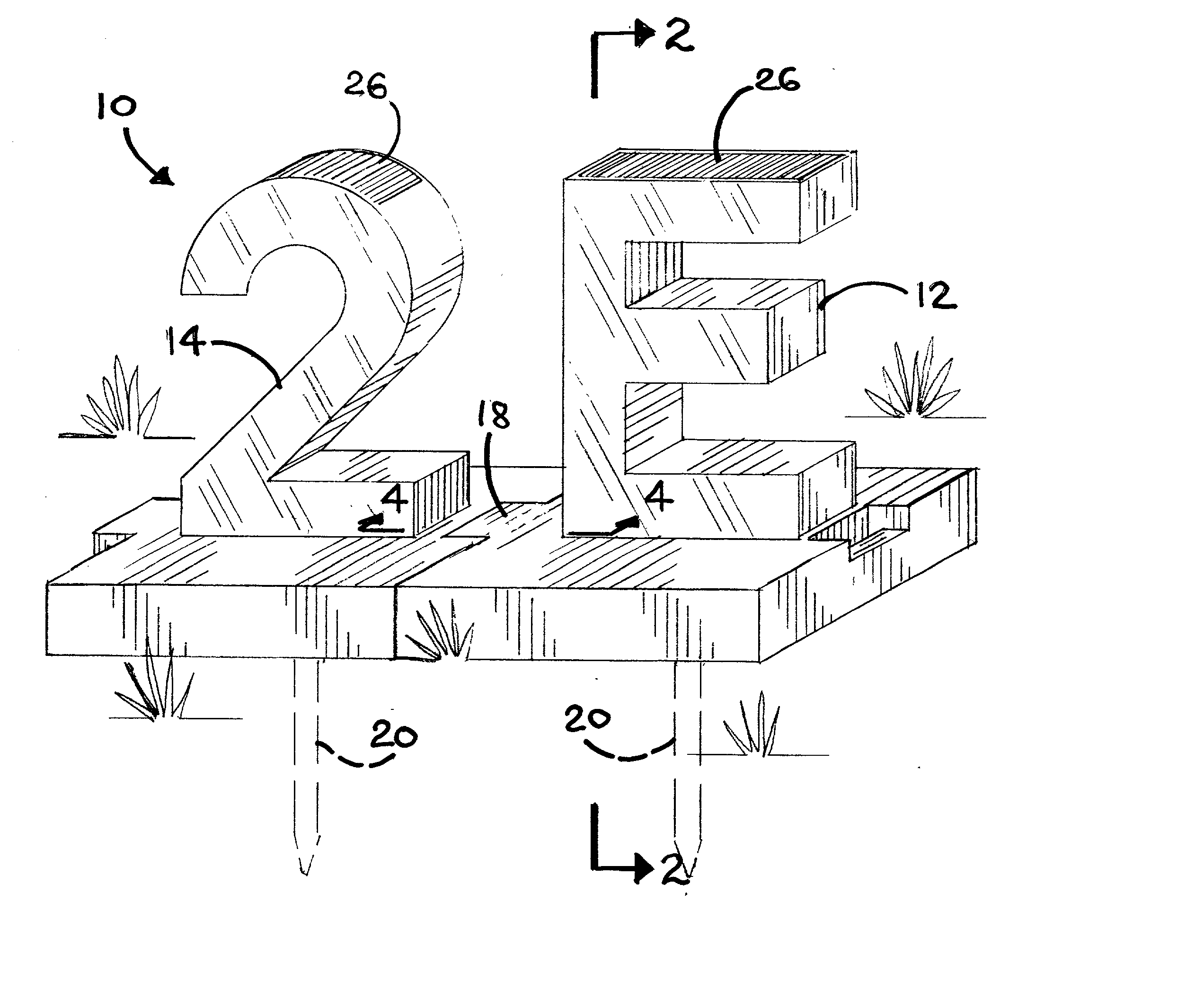

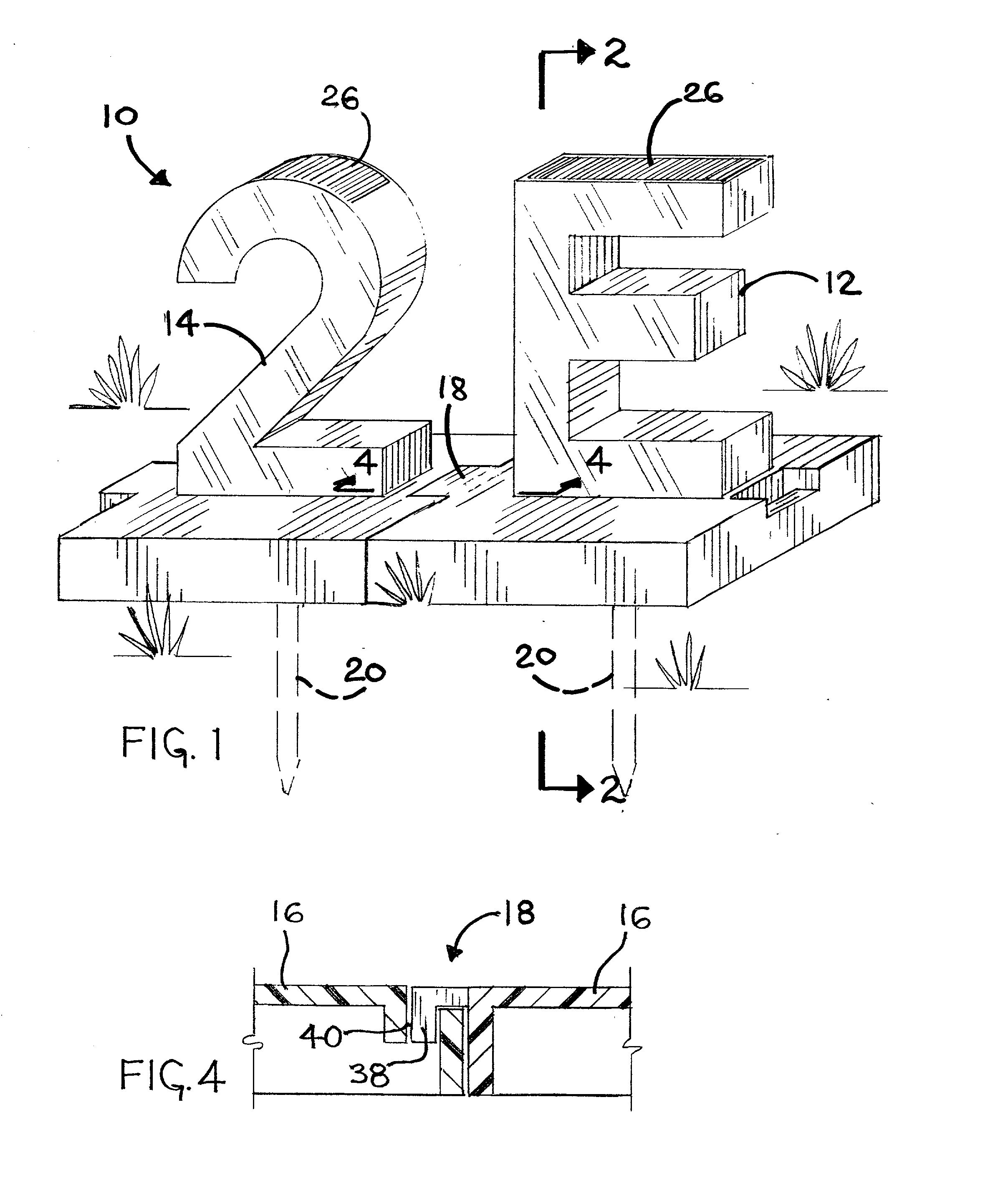

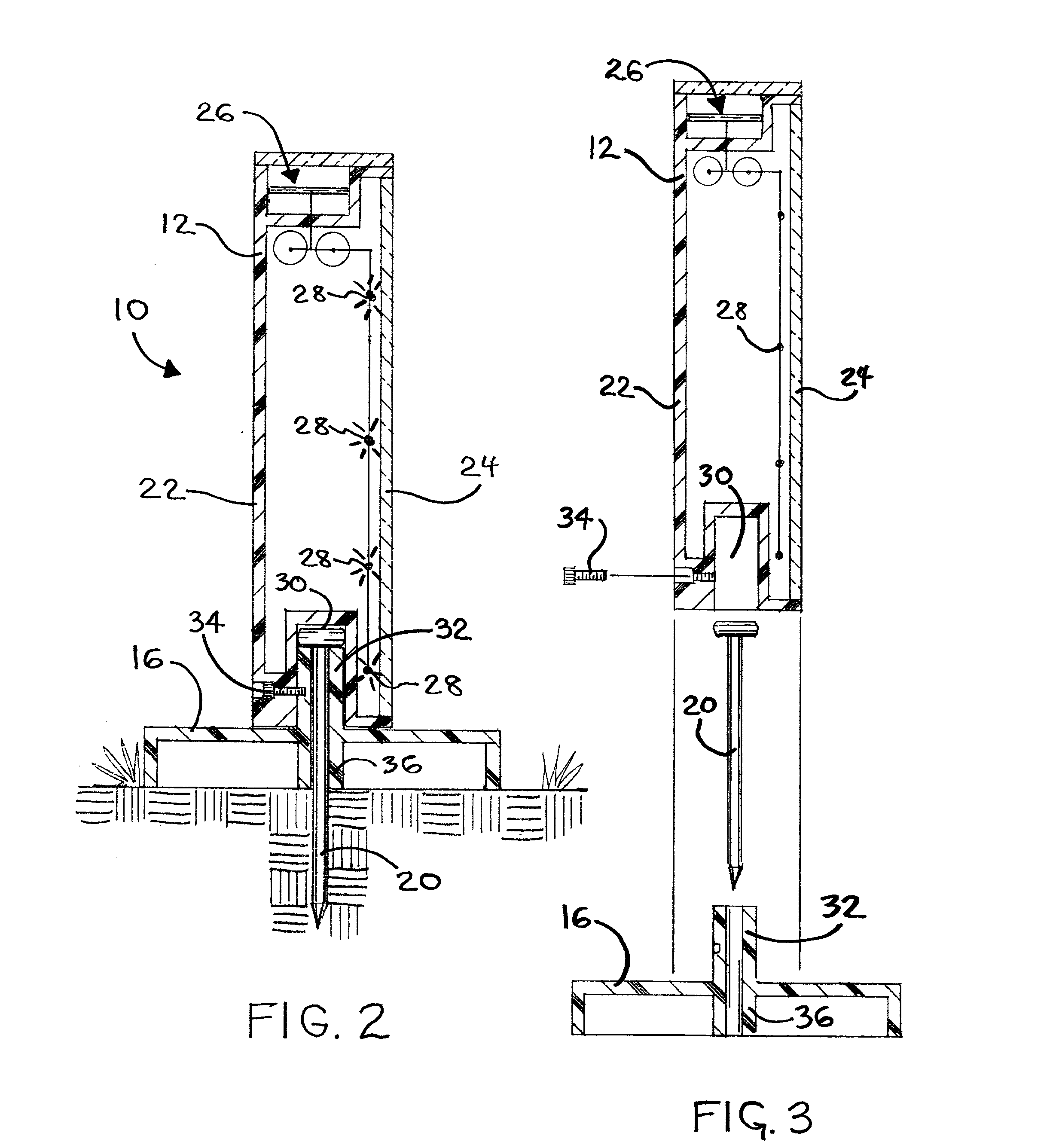

Outdoor numeric/allphabetic lighting

InactiveUS20030009924A1Easy to findUnique qualityVehicle interior lightingProtective devices for lightingEffect lightEngineering

Owner:SAJADIAN ZAHRA NASSRIN

Purple-mouth tea-dust glaze and method for preparing purple-mouth tea-dust glaze product

InactiveCN103360114AUnique qualityThe firing process is easy to controlTemperature controlVomit black

The invention discloses a purple-mouth tea-dust glaze and a method for preparing a purple-mouth tea-dust glaze product. The purple-mouth tea-dust glaze comprises the following components in percentage by weight: 22-35 percent of albite, 10-15 percent of calcium carbonate, 5-8 percent of talc, 2-3 percent of kaoline, 7-8 percent of ferric oxide, 1-2 percent of nickel dioxide, 3-5 percent of magnesium carbonate and the balance of quartz. The method comprises glaze preparation and product preparation, wherein in the product preparation, the steps of blank preparation, feeding and burning, cooling and the like adopt strict temperature control conditions and a uniform glazing method. A ceramic product which is prepared by adopting the prescription and burning process of the purple-mouth tea-dust glaze has unique properties and characteristics, and is yellow and smooth in appearance glaze, has block or black-brown spots; the glaze is doped by yellow and green colors, and looks like tea dusts, and the mouth is provided with a 'purple-mouth edge'; the burning process is convenient to control and is energy-saving, reliability can be realized by virtue of burning temperature control, and the yield of burnt products is high.

Owner:郑国明

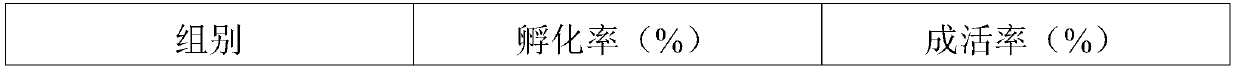

Artificial breeding method of diodon hystrix

InactiveCN109819913AStable sourcePromote peristalsisClimate change adaptationAnimal feeding stuffFlavorDiodon

The invention provides an artificial breeding method of diodon hystrix. The artificial breeding method comprises the following steps of: parent fish sourcing and screening, intensive parent fish breeding, parent fish spawning induction and artificial breeding. According to the artificial breeding method, diodon hystrix parents are enriched in bait nutrition, and the parents can be matured in gonaddevelopment under the artificial breeding condition through coordination of technological conditions of temperature, salinity, dissolved oxygen, pH value, oxygenation power, ammonia nitrogen and nitroso nitrogen, so that the hatchability of the parents is high through artificial spawning induction and hatching. The fry hatched by adopting the method grows fast, balanced in nutrition, strong in immunity, high in meat content and high in survival rate, and the method can be used for large-scale breeding of diodon hystrix fry and meets the requirement of large-scale breeding. Moreover, through three-stage artificial fry breeding, the delicious taste of wild diodon hystrix is kept, the bred diodon hystrix has special quality, flavor and rich nutrition, and the economic benefit and the ecological benefit are remarkably improved.

Owner:HAINAN CHENHAI AQUATIC CO LTD

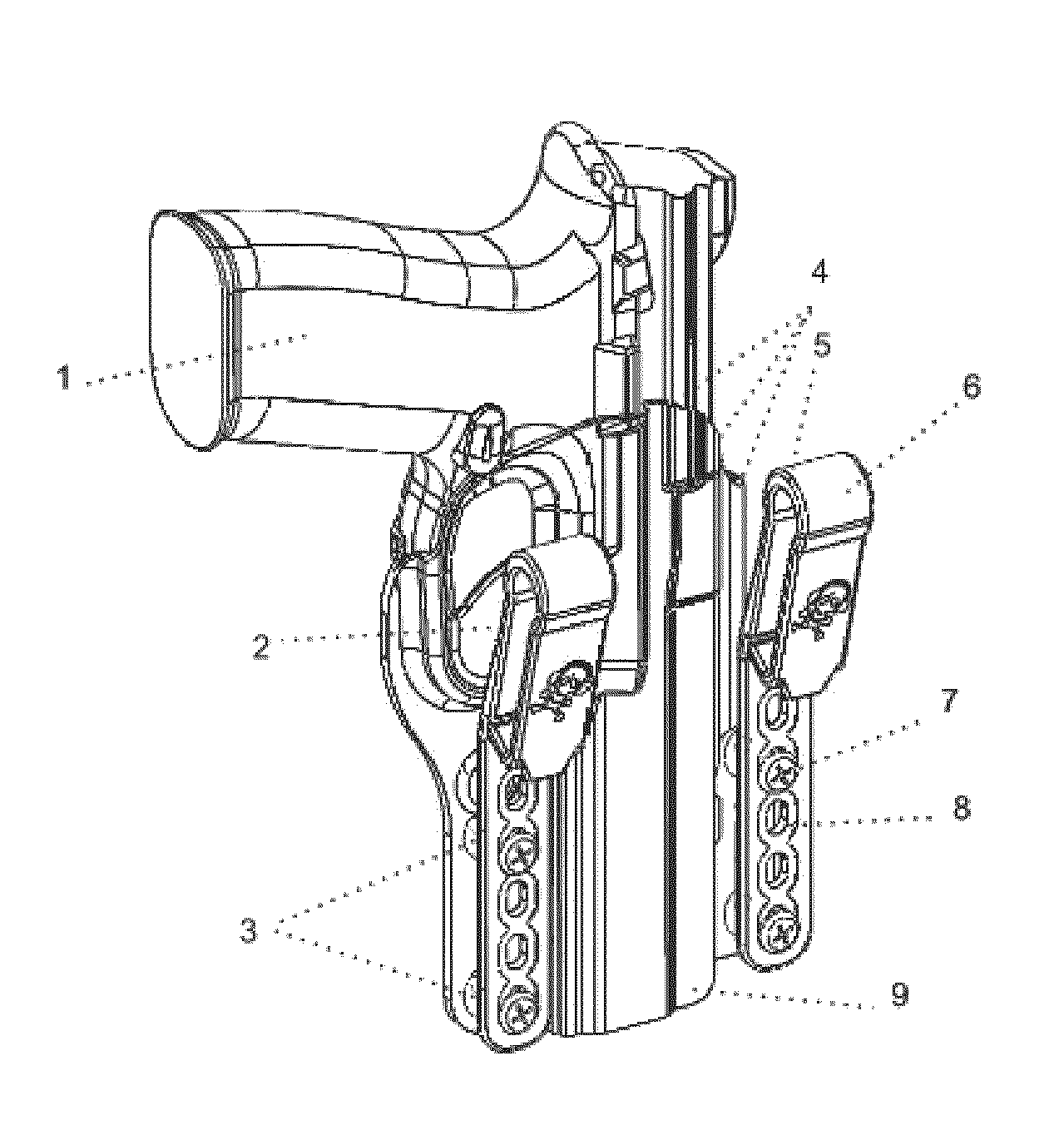

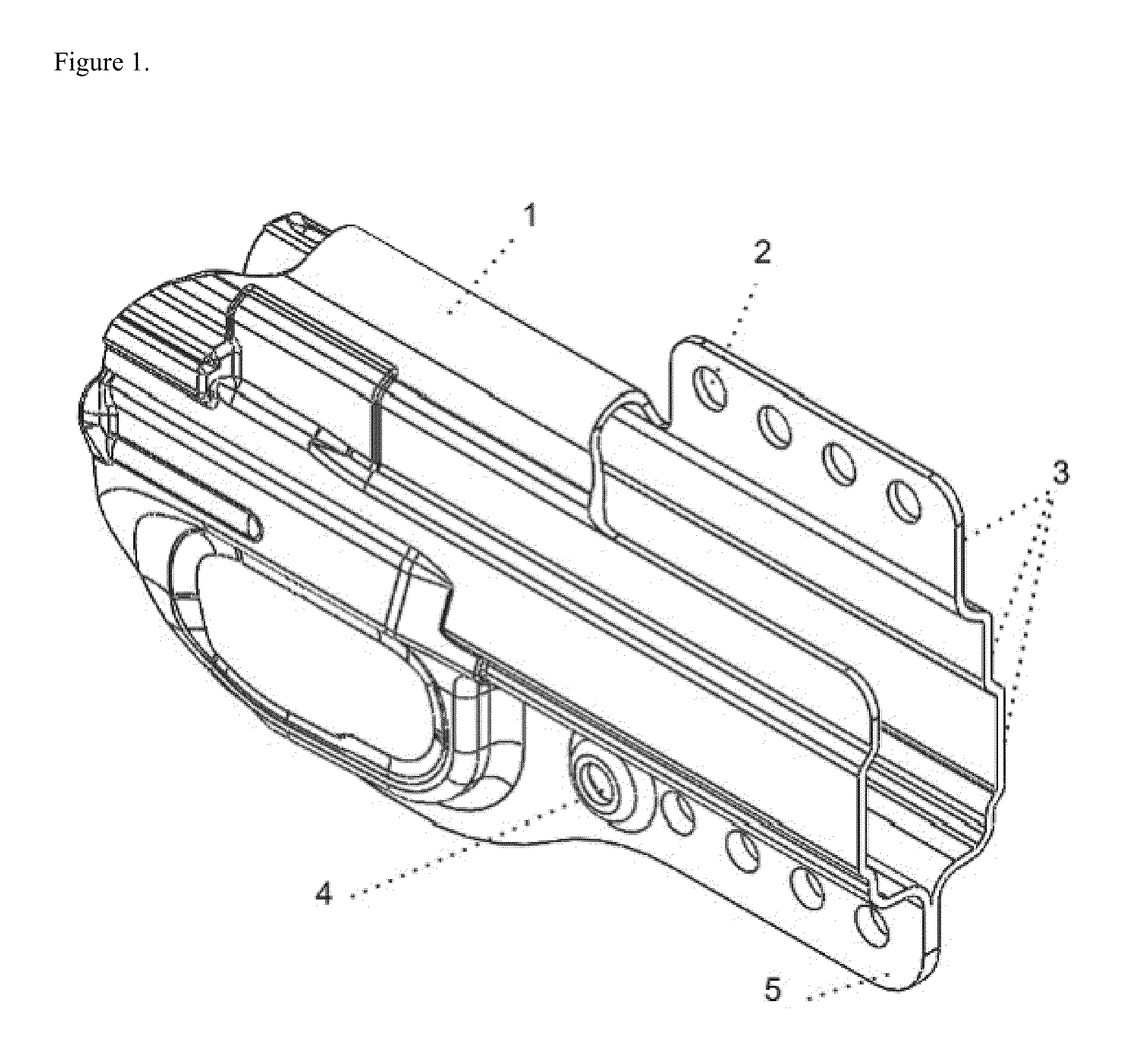

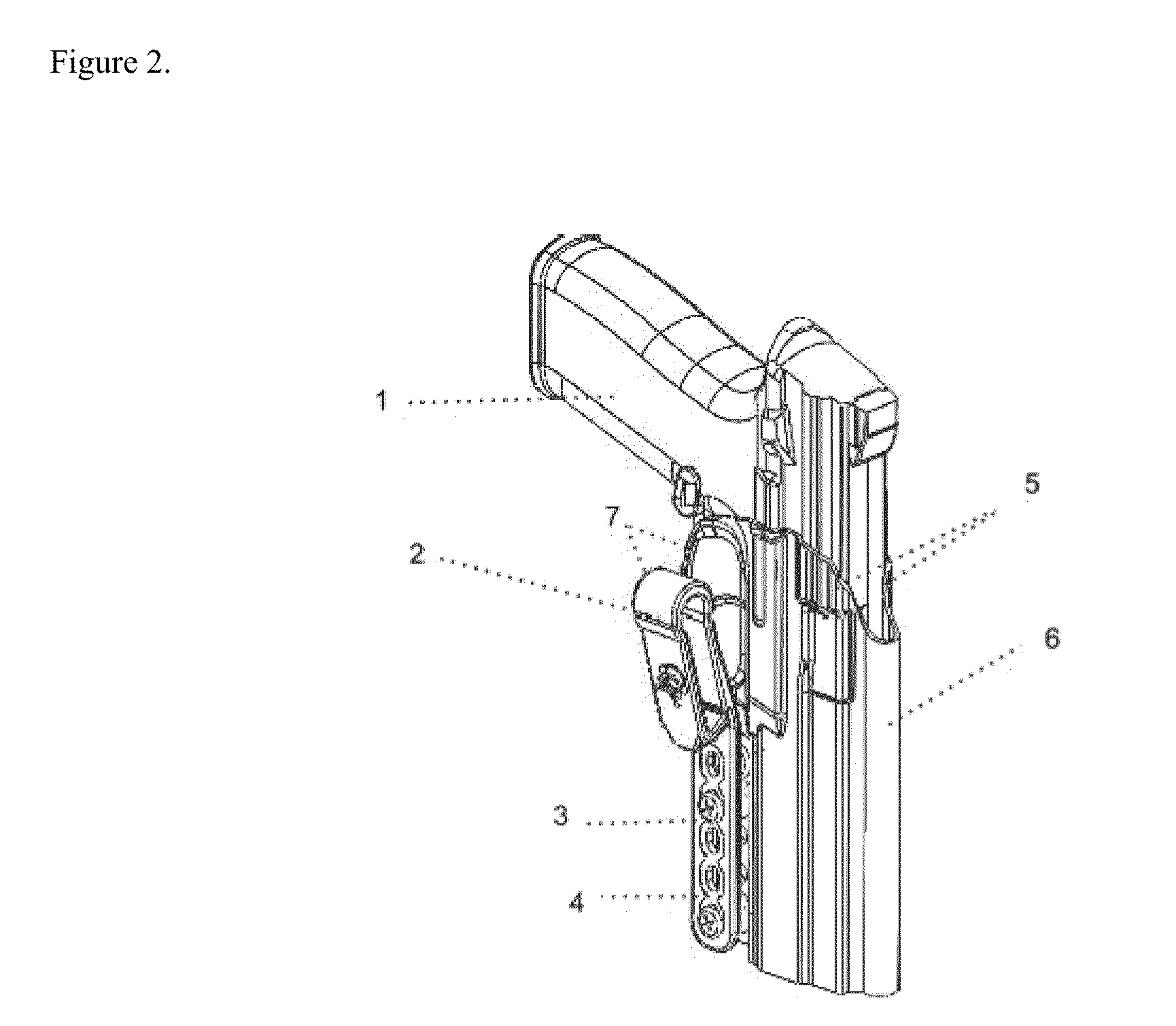

Concealment Holster for a Weapon

InactiveUS20140117064A1Improve comfortReduces carry position movementPursesMoney bagsEngineeringCoating

Disclosed is a specialized holster design and system. The holster disclosed herein is intended to be used by an individual to carry a handgun on his or her person in such a way that the weapon may be partially or completely out of view, securely in place yet immediately available to be drawn from the holster when needed. The holster is variable in ways that also allow the user to make adjustments for comfort and tactical preferences. Once the weapon is drawn the holster remains open allowing one handed re-holstering. Among other attributes, four key features enable in part its broad ranges of functions. These four are the unique outer coating, the retention qualities, fold out attachment tab, and the particularly angled clip. The design enables a novel lightweight holster form fitted to the weapon and maintained securely in place firmly against the user's body in a concealed manner.

Owner:EVANS SCOTT

Formula of local chicken feed containing Chinese herbal medicine additive

InactiveCN104585545AReduce the cost of farmingImprove antibacterial propertiesAnimal feeding stuffDiseaseAnimal science

The invention discloses a formula of a local chicken feed containing a Chinese herbal medicine additive. The local chicken feed comprises the following components in parts by weight: 150-190 parts of bean meal, 500-600 parts of bean, 55-70 parts of cake-shaped rape seed dregs, 2-2.5 parts of soybean oil, 1-2 parts of garlic powder, 2-3 parts of a premix, 1-2 parts of sweet potatoes, 2-3 parts of fish meal, 2-3 parts of Chinese mugwort and 0.26-0.4 part of a Chinese herbal medicine additive. By virtue of the formula, the effects of low cost, high disease resistance and good chicken quality are achieved.

Owner:SHANDONG HONGXIANG POULTRY IND

Production technique of specialty tea

InactiveCN102813015AImprove resource utilizationImprove product added valuePre-extraction tea treatmentTea leafAgroforestry

The invention relates to a production technique of specialty tea. The production technique of the specialty tea includes: subjecting fresh tea leaf to withering, rolling, fermenting and initial drying; performing stuffy piling, namely directly stacking cloth bags containing the tea leaf when the tea leaf is initially dried and spread to cool to about 50 DEG C, slightly compacting for 2-3 hours, timely re-drying sufficiently to improve aroma so as to obtain the novel unique tea. The specialty tea is elongated and tight, is fully dark with golden yellow tip, has elegant and lasting internal aroma, has flower aroma, has mellow taste and is sweet after taste. Soup of the specialty tea is orange and clear with evident clear rim. Infused leaves are red and yellow and are as tender and even as flowers.

Owner:SHAANXI PENGXIANG TEA IND CO LTD

Production method for gold brown glaze and products thereof

The invention discloses a production method for a gold brown glaze and the products of the gold brown glaze. The gold brown glaze is composed of the following constituents in percentage by weight: 12-25% of albite, 15-25% of calcium carbonate, 5-7% of barium carbonate, 10-12% of talcum, 2-8% of kaolin, 7-8% of ferric oxide, and the balance of quartz. The production method comprises the steps of glaze preparation and product preparation, wherein blank preparation, charging and sintering, cooling and the like in the product preparation adopt strict temperature control conditions and a uniform glazing method. Ceramic products prepared by a composition formula and a sintering process for the gold brown glaze disclosed by the invention have unique quality and characteristics, the gold brown glaze is brown in appearance glaze colour, exactly like a shape of sesame gold spots, thick in glaze surface and semitransparent, bulged or recessed points, lines and surfaces present white in the glaze, and generate colours with different depths and are capable of embodying shapes and lines better, and the content is more abundant, harmonious and varied; and the sintering process is convenient to control, sintering temperature control realizes energy conservation and reliability, and sintered products are high in qualified rate.

Owner:郑国明

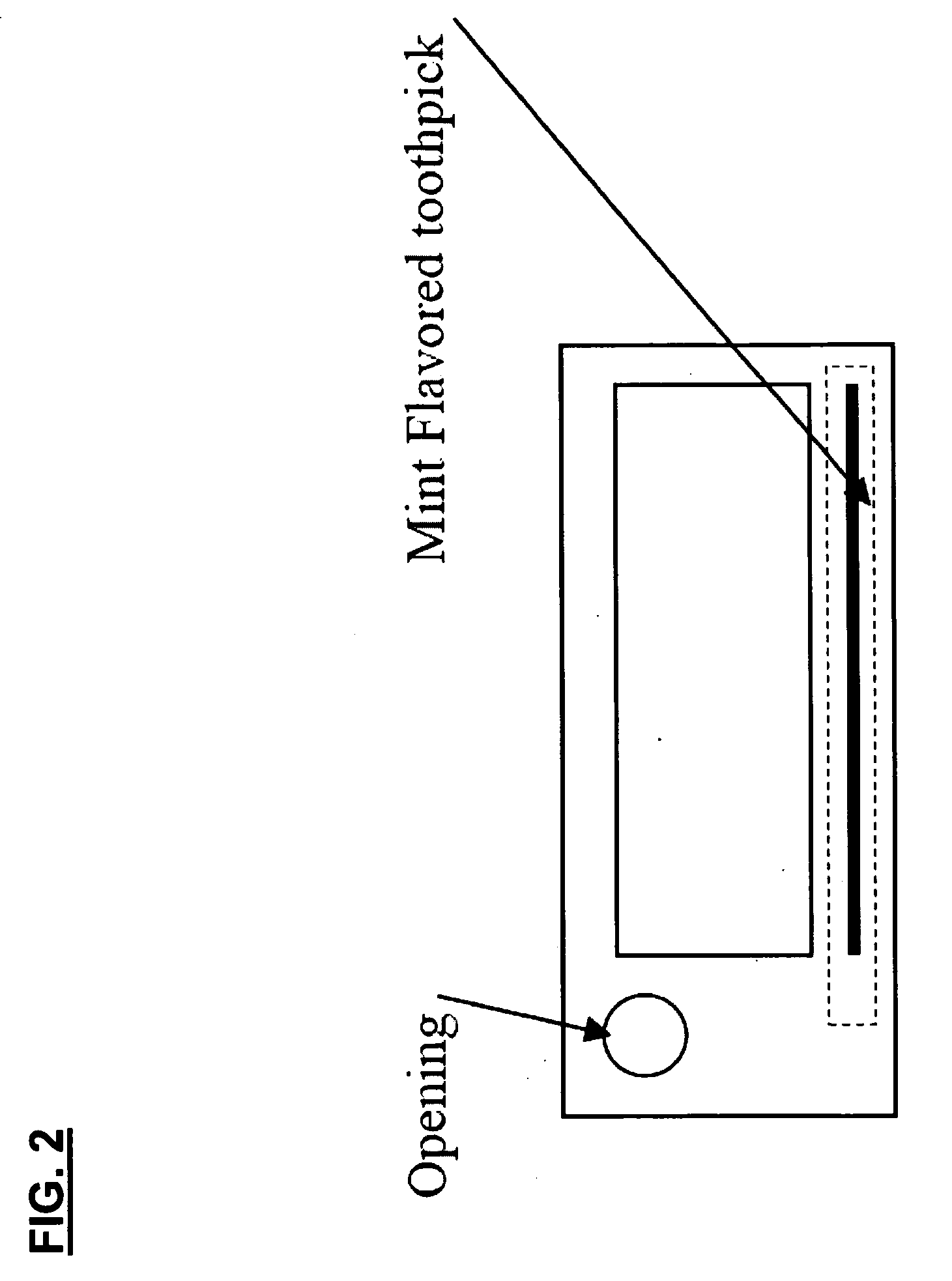

Mint and floss oral-product container

InactiveUS20090101164A1Unique functional qualityOvercome problemsGum massageDental flossDental instrumentsEngineering

An oral-product container is disclosed that includes a plurality of breath fresheners contained therein for breath freshening purposes. The container includes an elongated dental instrument (e.g., a toothpick or dental floss) for hygiene improving purposes contained within the container. In the preferred embodiments, the container has a dispensing opening for dispensing breath fresheners. The container preferably has a laterally movable cover mounted to move between a closed state in which the cover covers both the dispensing opening and the elongated dental instrument and an open state in which the cover exposes both the dispensing opening and the elongated dental instrument.

Owner:BERG ROBERT ISAAC +1

Mosquito-killing and sterilizing air freshener containing Chinese mugwort Chinese herbal medicine and preparation method thereof

The invention relates to a mosquito-killing and sterilizing air freshener containing a Chinese mugwort Chinese herbal medicine and a preparation method thereof. The mosquito-killing and sterilizing air freshener containing the Chinese mugwort Chinese herbal medicine disclosed by the invention comprises the following components in parts by weight: 20 parts of Chinese mugwort, 10-20 parts of sweet wormwood, 10-20 parts of rhizoma atractylodis, 10-20 parts of honeysuckle, and 20-40 parts of absolute ethyl alcohol. The mosquito-killing and sterilizing air freshener containing the Chinese mugwort Chinese herbal medicine disclosed by the invention is compatibility of four pure natural Chinese herbal medicines and is free from any chemical additives; the mosquito-killing and sterilizing air freshener is steady in performance; by being directly sprayed in air, the mosquito-killing and sterilizing air freshener not only has the effects of expelling and killing mosquitoes but also has the effect of sterilizing; in addition, the mosquito-killing and sterilizing air freshener has nice sweet flavour and is a green mosquito-killing and sterilizing air freshener product free from pollution and stimulation.

Owner:HUANGGANG NORMAL UNIV

Processing method of low-sugar preserved spring phyllostachys heterocycla shoots

The present invention belongs to a manufacture method of snack foods and particularly relates to a processing method of low-sugar preserved spring phyllostachys heterocycla shoots. Technical key points are as follows: edible parts of the spring phyllostachys heterocycla shoots are taken as raw materials. The low-sugar preserved spring phyllostachys heterocycla shoots are mainly prepared by the processes of raw material taking, pretreating, color-protecting, rinsing, enzyme deactivating, cooling, seasoning, sugar soaking, drying, packaging, sterilizing, finished product obtaining, etc. The processing technology is used to produce the low-sugar preserved spring phyllostachys heterocycla shoots. The produced preserved phyllostachys heterocycla shoots are golden in color and luster and delicate in mouthfeel, have certain toughness, and are not sticky to hands. The processing technology retains the special flavor of the bamboo shoots, and the product has a sugar content of 20%-30% and is low in sugar contents, and convenient for storage. The processing method can fully utilize the left bamboo shoots after processing, improves the utilization rate of the bamboo shoots, reduces the production costs, improves the production high-tech contents and added values of the products, and opens up a new way for the processing and utilization of the bamboo shoots.

Owner:ZHENGAN COUNTY DINGQING SQUARE BAMBOO SHOOT

Method for producing and processing aged Tie Guanyin tea

InactiveCN105851277AUnique qualityEasy to storePre-extraction tea treatmentClimate change adaptationSunstrokesNatural state

The invention discloses a method for producing and processing aged Tie Guanyin tea. The method includes the steps of selecting raw materials, conducting the primary processing process, achieving balance of moisture of raw tea through re-firing, keeping activity of tea leaves and storing the tea leaves by entering a cellar. The tea can be kept for 10 years or above in the natural state, the tea leaves are naturally oxidized during storage, and the formed aged tea has good quality and special health-care effects. According to tea production and processing, strict requirements need to be met from the raw materials in the method, and the whole process is the optimal production and processing process through proof of long-term practices. The produced aged Tie Guanyin tea is unique in quality, smooth, mellow and sweet in taste, light in color, yellow-red in color, lasting in aroma and obvious in stale flavor, and has the effects of preventing sunstrokes, decreasing internal heat and the like.

Owner:连建设

Chewing gums containing allulose

Chewing gums containing allulose and methods of making such gums are disclosed. In one embodiment, the gum comprises about 5% to about 95% gum base, about 0.1% to about 10% flavoring agent and allulose, the allulose being part or all of the bulk sweetener in the gum. The allulose provides the gum with unique properties; the gum is low in calories and may be non-cariogenic. In other embodiments, the allulose is co-dried with other sweeteners or co-evaporated with other sweeteners or with a plasticizing syrup to produce unique sweetening ingredients and syrups for gum.

Owner:WM WRIGLEY JR CO

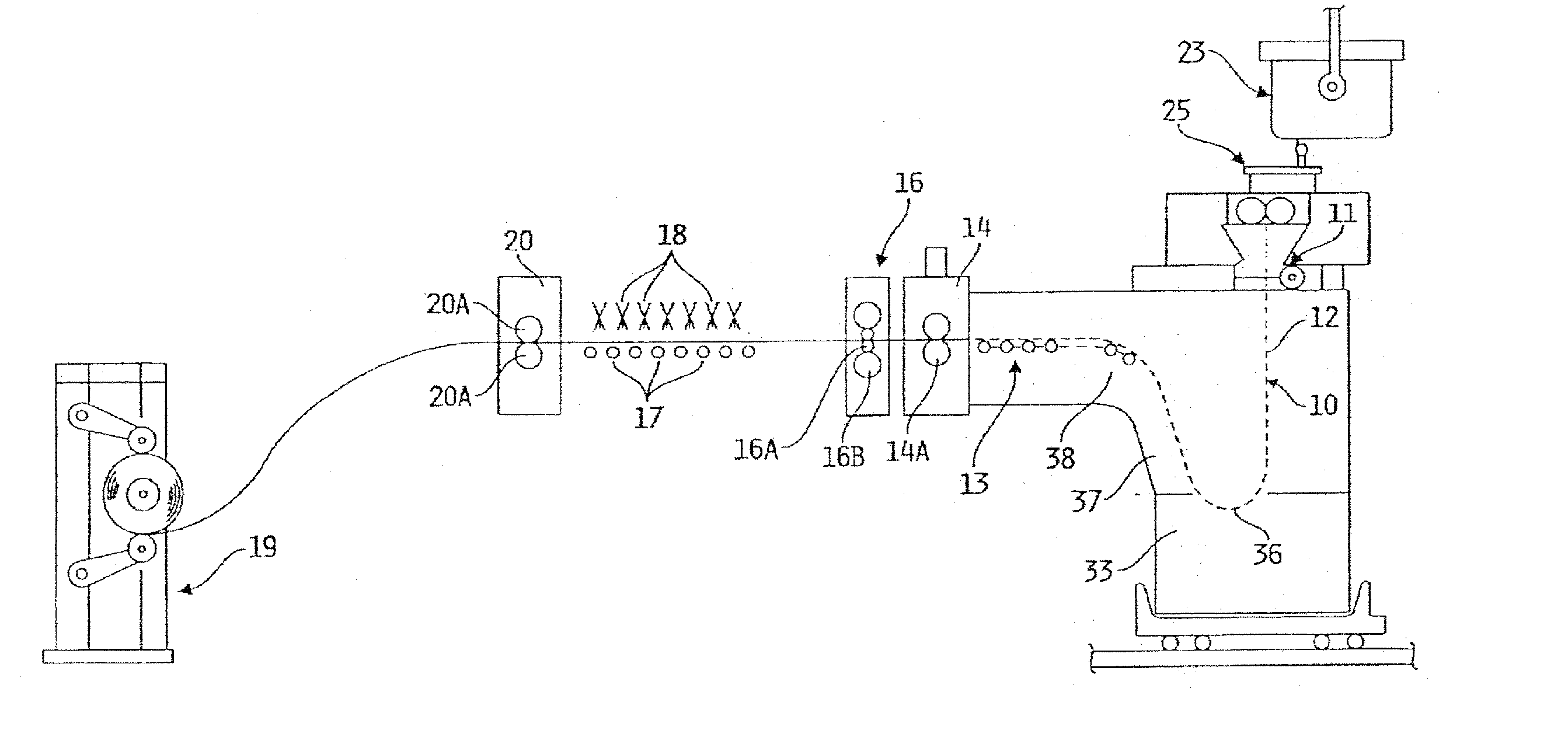

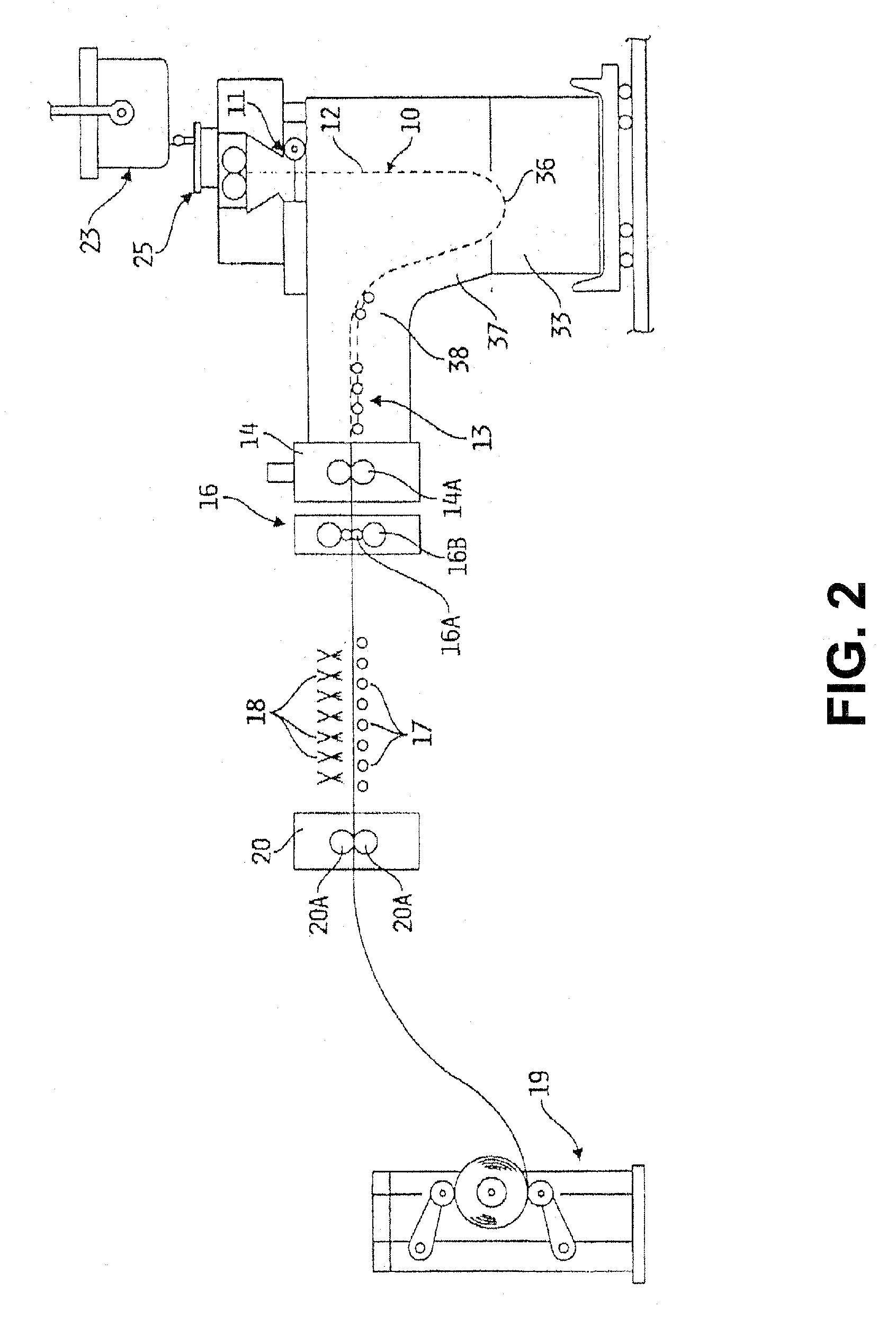

Thin cast strip with controlled manganese and low oxygen levels and method for making same

A method for making a thin cast strip with reduced meniscus marks includes assembling a pair of casting rolls laterally positioned to form a nip therebetween, preparing molten steel having a carbon content in the range of 0.01 to 0.3% by weight, a manganese content between 0.1 and 0.8% by weight, a silicon content between 0.05 and 0.5% by weight, a calcium content between 0.0008 and 0.004% by weight, an aluminum content between 2 and 500 ppm by weight, having a free oxygen content below about 50 ppm at 1600 ° C., forming a casting pool of the molten steel supported on casting surfaces of the casting rolls above the nip, and counter-rotating the casting rolls cause thin strip to be casted downwardly from the nip.

Owner:NUCOR CORP

Rinsed black tea processing method

InactiveCN103976048AUnique qualityBright red soupPre-extraction tea treatmentCooking & bakingBlack tea

The invention relates to a rinsed black tea processing method. The rinsed black tea processing method is characterized by comprising the following steps: a. spreading fresh leaves; b. rinsing green leaves; c. rolling; d. fermenting; e. drying; f. picking out stalks; and g. baking. Rinsed black tea obtained by using a conventional rinsed black tea processing method has dull aroma. The rinsed black tea obtained by adopting unique processes of rinsing, fermentation and baking is red and bright in tea color and has unique aroma; after drinking the rinsed black tea, people are like in natural as if the mind and body are sublimed and purified.

Owner:ENSHI PREFECTURE DIYIJIA INTPROP SERVICES CO LTD

Method for producing eight-treasure sauce

The invention discloses a method for producing eight-treasure sauce, comprising the following steps: various raw materials are prepared and the ratio of flour, soy beans, horsebeans, rice, millet, peanut, wheat germ and medlar is 7:1:0.5:0.3:0.3:0.3:0.5:0.1 by weight proportion; flour is added with water and stirred evenly and brewing material is produced by cooling after cooking; the soy beans, the peeled horsebeans, the rice, the millet, the peanut and the wheat germ are soaked respectively, ground into juice and cooked; the medlar is added with water for soaking, squeezed into juice and cooked; various juices are mixed, salt is added and the mixture is evenly mixed with the brewing material; and a finished product is obtained by fermentation, homogenization and sterilization. The eight-treasure sauce produced by the method has richer and more unique flavour, nutrition and quality, the content of the amino acid is increased by times, and the sauce is more refined and moderately salty and sweet with excellent delicate flavour.

Owner:吴德辉

Method for making floral white tea

The invention discloses a method for making floral white tea, and belongs to the technical field of tea processing. The method comprises the steps of fresh leaves ->sunning the fresh leaves ->shakingthe fresh leaves ->withering adjustment (temperature control, temperature control + natural withering adjustment) ->drying ->finished products. Meanwhile, through continuous test comparison and identification of relevant factors such as time, temperature and humidity and the like involved in the processes of sunning, shaking, withering and the like, reasonable processing technological indexes arescreened out, and the developed white tea (new tea in the year) has no green grass flavor, has flower and fruit flavor, sweet and mellow taste, smoothness and unique quality. The environment of the sunning is accurately controlled, rapid loss of water, which is not conducive to the conversion of contents, is avoided, the internal water loss of the tea leaves is buffered through time and standing in the middle chamber, and transformation of internal substances is promoted.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Dark tea composition capable of preventing and relieving diseases caused by haze pollution and preparation method thereof

The invention discloses a dark tea composition capable of preventing and relieving diseases caused by haze pollution and a preparation method thereof. The composition is composed of dark tea, radix astragali, saposhnicovia divaricata, coix seed, cluster cardamom, notopterygium root, balloonflower root, dried tangerine peel, wild chrysanthemum, lotus leaf, and licorice. The composition can improve and balance the human immunity, especially the lung immunity, and is capable of preventing and relieving the diseases and sub-healthy state caused by haze pollution.

Owner:HUNAN TIANXIA WULING AGRI DEV

Henna and vegetable dye based compositions for coloring of human hair

ActiveUS8034126B2Increased free volumeUnique qualityCosmetic preparationsHair removalBiotechnologyHair dyes

New, effective and non-toxic compounded henna based hair dyes that are non-toxic, natural and hypoallergenic that provide an alternative to conventional hair color. The products are made using 100% Green Chemistry and do not utilize encapsulation.

Owner:VAINSHELBOIM ALEX +1

Crisp kelp biscuits having functional characteristics of slowly digestible starch and making method thereof

InactiveCN105685173ASimple processing technologyLower glycemic indexDough treatmentBakery productsLow glycemic indexSuperfine grinding

The invention belongs to the technical field of food processing and particularly relates to crisp kelp biscuits having functional characteristics of slowly digestible starch and a making method thereof. The crisp kelp biscuits are made from 12.5-15 parts of kelp powder, 100 parts of low-gluten flour, 67.5-70 parts of butter, 20 parts of white sugar, 30 parts of egg liquid, 7.5 parts of milk powder and 12.5 parts of water. The making method comprises the steps that instant dried kelps are grinded by adopting a superfine grinding technology and are screened to make kelp powder (the grinding degree of the kelp powder is 20-40 mesh), and the substitutive low-gluten flour is added to traditional crisp biscuits. The crisp kelp biscuits made by adopting the making method have the functional characteristics of the slowly digestible starch, low glycemic index and a unique flavor.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com