Production method for gold brown glaze and products thereof

The technology of glaze and golden sauce is applied in the production field of golden sauce glaze and its products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

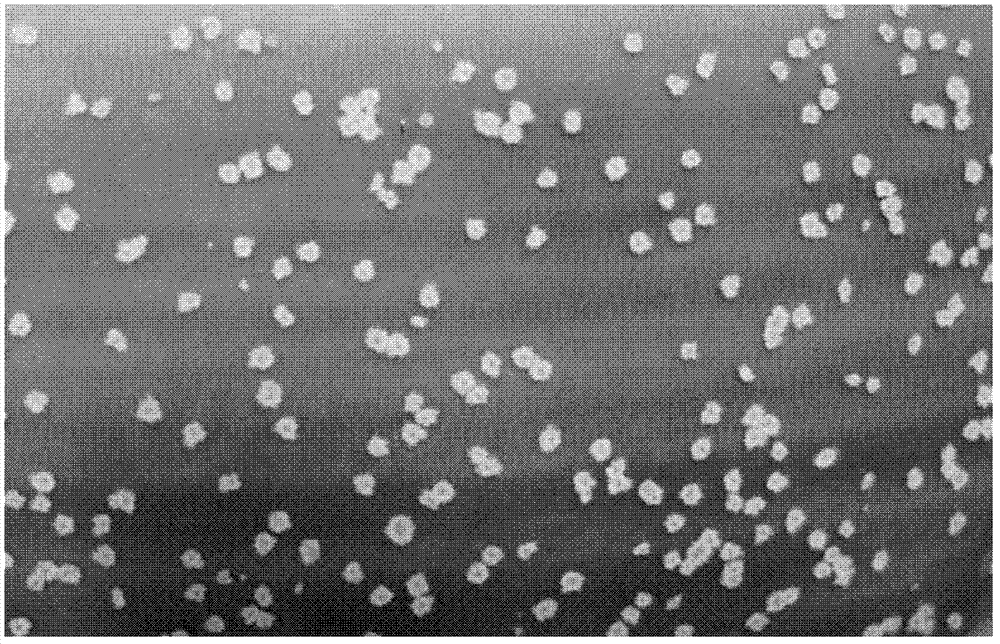

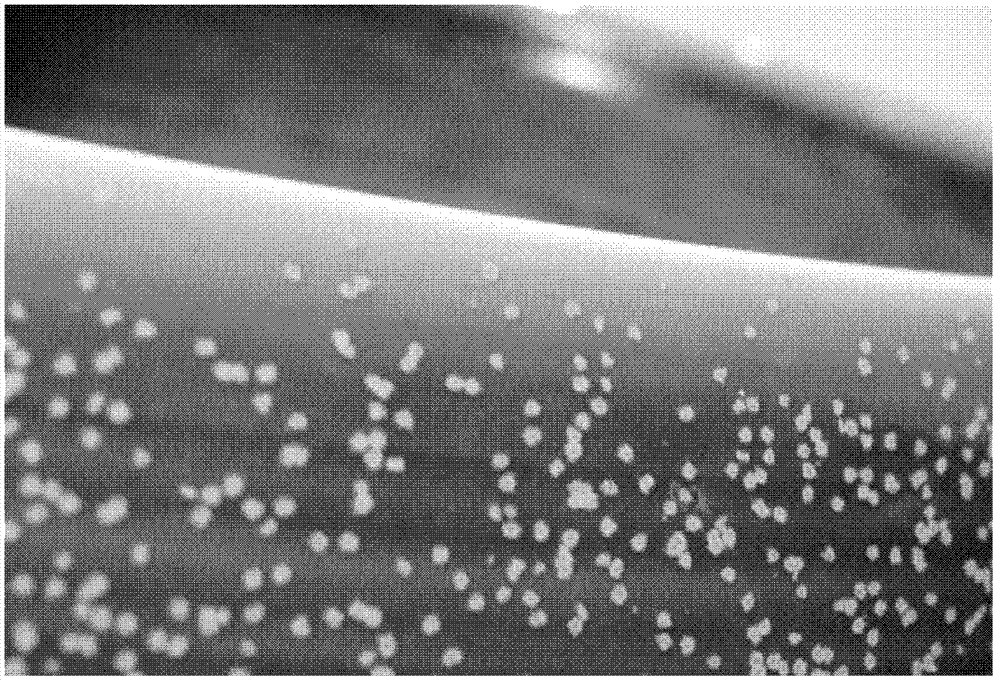

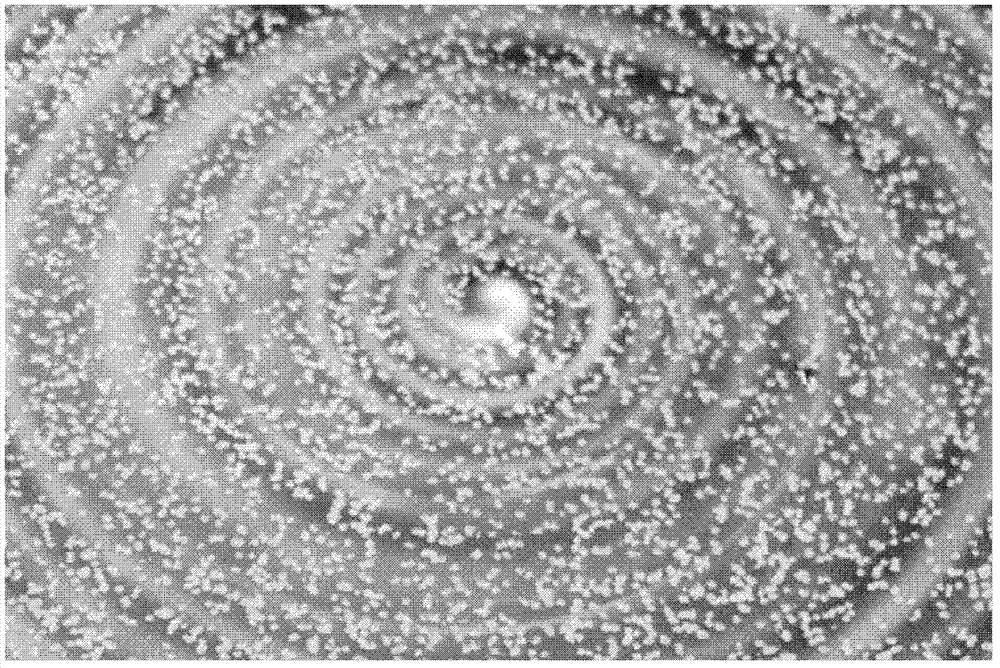

Image

Examples

Embodiment 1

[0031] Preparation of glaze slurry:

[0032] Take 20 parts by weight of albite, 20 parts by weight of calcium carbonate, 5.5 parts by weight of barium carbonate, 12 parts by weight of talc, 6 parts by weight of kaolin, 8 parts by weight of iron oxide and 29.5 parts by weight of quartz; add 110 parts by weight of water, and grind in a ball mill Glaze slurry, the glaze slurry passes through a 250 mesh or finer sieve for use; the steps of grinding into a glaze slurry include weighing the raw materials, putting into the ball milling tank, adding water, sealing the lid, grinding, opening the lid, putting the glaze water, filtering, and adjusting the concentration ;

[0033] Product preparation:

[0034] Follow the steps below;

[0035] To make a blank, the formed porcelain blank is sintered at 800°C for 4 to 5 hours and cooled naturally for later use;

[0036] Apply glaze, sinter the biscuit into a porcelain blank and apply the glaze according to the conventional method, without shrinkage ...

Embodiment 2

[0044] The process is the same as in Example 1, except that the composition of the glaze slurry is different. The composition of the glaze slurry in this example is: take 12 parts by weight of albite, 15 parts by weight of calcium carbonate, 5 parts by weight of barium carbonate, 10 parts by weight of talc, 2 parts by weight of kaolin, 7 parts by weight of iron oxide, 49 parts by weight of quartz; add water 110 Parts by weight, ground into glaze slurry in a ball mill for later use.

Embodiment 3

[0046] The process is the same as in Example 1, except that the composition of the glaze slurry is different. The composition of the glaze slurry in this example is: take 25 parts by weight of albite, 25 parts by weight of calcium carbonate, 7 parts by weight of barium carbonate, 12 parts by weight of talc, 8 parts by weight of kaolin, 8 parts by weight of iron oxide, 15 parts by weight of quartz; add water 110 Parts by weight, ground into glaze slurry in a ball mill for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com