Patents

Literature

47results about How to "Natural antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hemp knitting face fabric

The invention provides a china-hemp knitting fabric. The fabric comprises a china-hemp mixed yarn with count of 60-21, wherein blending percentage of the china-hemp mixed yarn by weight is that: 50 to 60 percent of china-hemp, and 40 to 50 percent of cotton. The fabric has the advantages that: 1) the china-hemp fiber is an environment-friendly fiber, has the characteristics of natural sterilization, ultraviolet resistance, moisture absorption and perspiration elimination, and can be applied to development of knitting products to lead the fiber to be industrialized, and has wide prospect; 2) cotton, Modal, viscose and other fiber compositions with excellent toughness are selected, and can be assorted into various combinations with the china-hemp fiber for blended spinning so as to weaken rigidity of blended yarns and improve the feasibility of china-hemp yarn for knitting fabric; and 3) the china-hemp knitting fabric overcomes the problem of urticant feeling.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

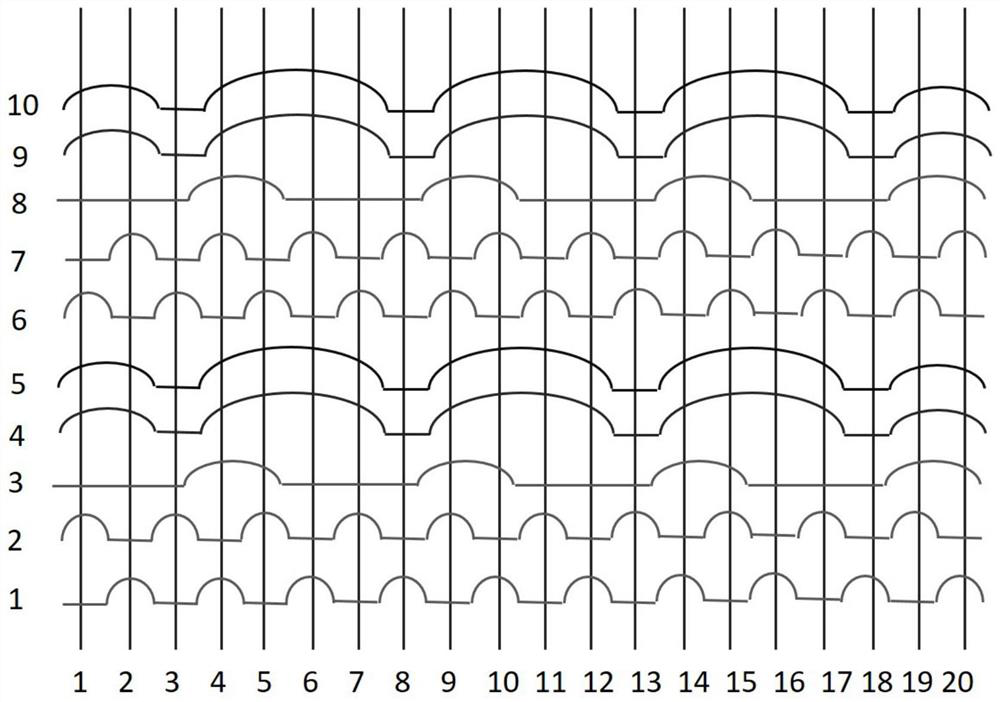

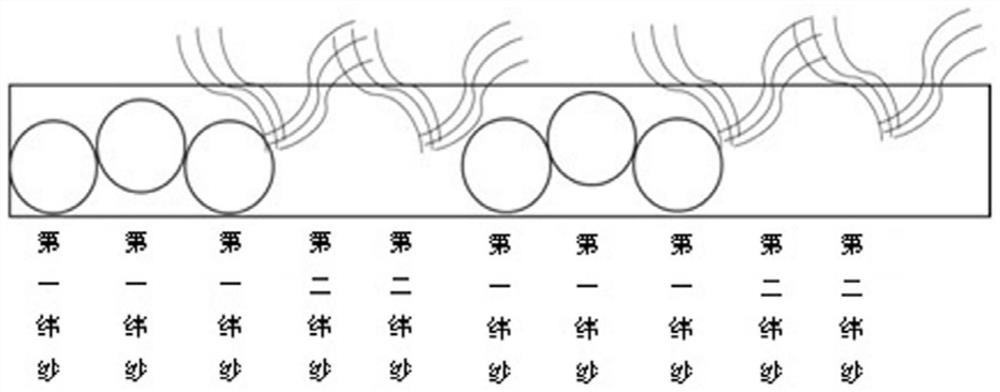

Method for manufacturing Chinese hemp multi-component covering type two-sided knit fabric

ActiveCN101498074ANatural antibacterialNatural UV resistanceWeft knittingWarp knittingYarnUltraviolet

The invention relates to a manufacture method of a hemp, polycomponent, covering and double-knitted fabric, which comprises the following steps: (1), weaving 30 percent of hemp, 35 percent of terylene and 35 percent of cotton by weight percentages into hemp blended yarn with a yarn number of 40 and then weaving the hemp blended yarn with moisture-bsorbing and rapidly-drying terylene yarn into a fabric under the condition that the weight ratio of the hemp blended yarn to the moisture-bsorbing and rapidly-drying terylene yarn is 55-65 to 35-45; (2) bleaching and heating a solution at a speed of 2 DEG C / min to a temperature of 98 DEG C under the condition that a bath ratio is 1 to 12, bleaching the solution at the temperature for 30 minutes, cooling the solution at a speed of 2 DEG C / min to 25 DEG C and washing the solution for 20 minutes; (3) dyeing; and (4) post-treatment technology. The invention has the advantages that hemp fibers have wide prospects after being applied to fabrics because the hemp has natural superior characteristics of antibacterium, ultraviolet ray resistance, moisture absorbable and breathable properties, and the like, the fabric adopts the blended yarn of the hemp, the cotton and the terylene to weaken the rigidity of the blended yarn, and the hemp fabric solves the problem of scratchiness and has bright colors and high color fastness.

Owner:北京铜牛集团有限公司

Antibacterial packaging paper

The invention discloses antibacterial packaging paper. A preparation process comprises: preparation of packaging paper, preparation of a waterproof agent coating, and preparation of an antibacterial agent coating. According to the antibacterial packaging paper disclosed by the invention, the processing raw materials are bamboos and waste timbers. As bamboo fiber is naturally antibacterial, timbers are replaced by bamboos, so that cutting of trees is avoided, the environment is protected, the ecological balance is maintained, waste is turned into wealth as waste timbers are used, and the cost is saved; the bamboo fiber and wood fiber are matched in use, so that the strength and flexibility of paper are remarkably improved and the packaging paper is wide in using range; the waterproof layer and the antibacterial layer are natural materials which do not harm human body and environment and play natural roles of preventing water and resisting bacteria; in a delignification process, the raw materials are pre-treated by using white rot fungi first, so that the time and dosage for delignification by hydrogen peroxide are reduced; hydrogen peroxide further can disinfect and bleach the packaging paper, is safe and non-toxic, and does not cause the environmental pollution, thereby killing two birds with one stone and saving the cost.

Owner:HEFEI LONGFA PACKING CO LTD

Method for making multifunctional different-functional China-hemp elastic knitted fabric

ActiveCN104278422AFacilitated DiffusionAchieve quick drying effectSucessive textile treatmentsWeft knittingPolyesterYarn

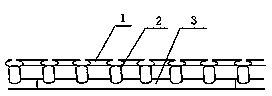

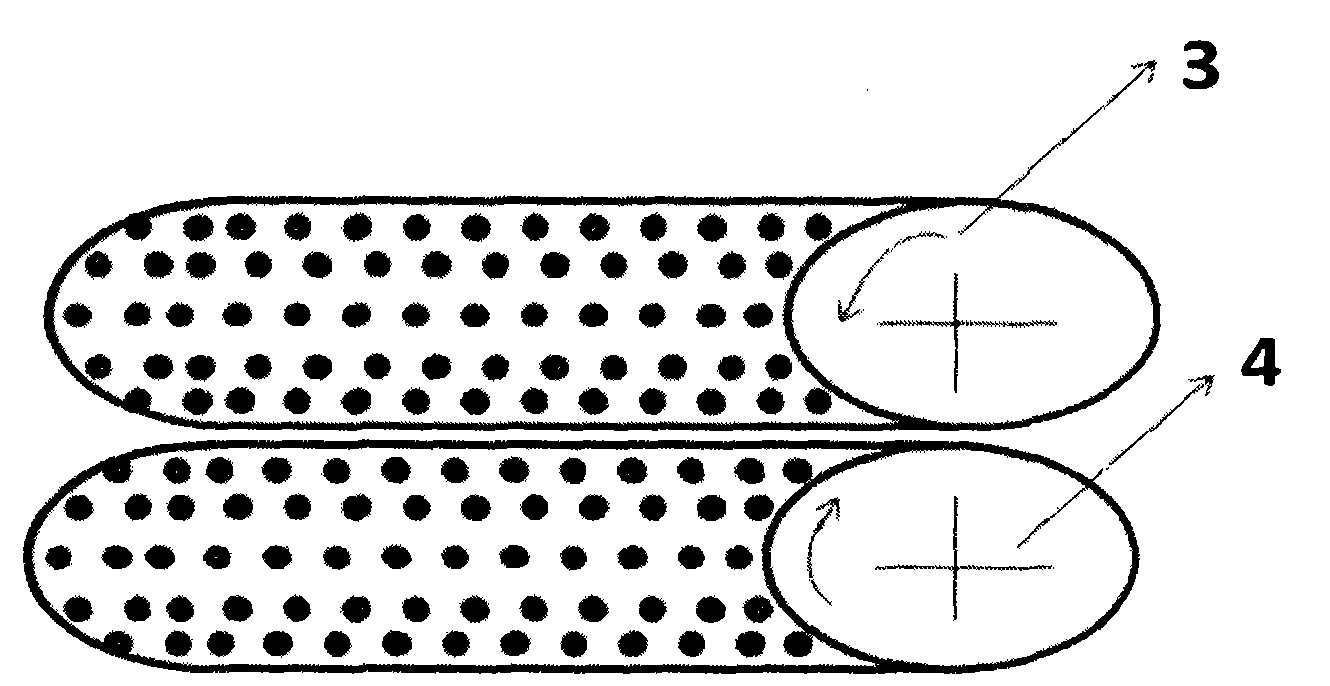

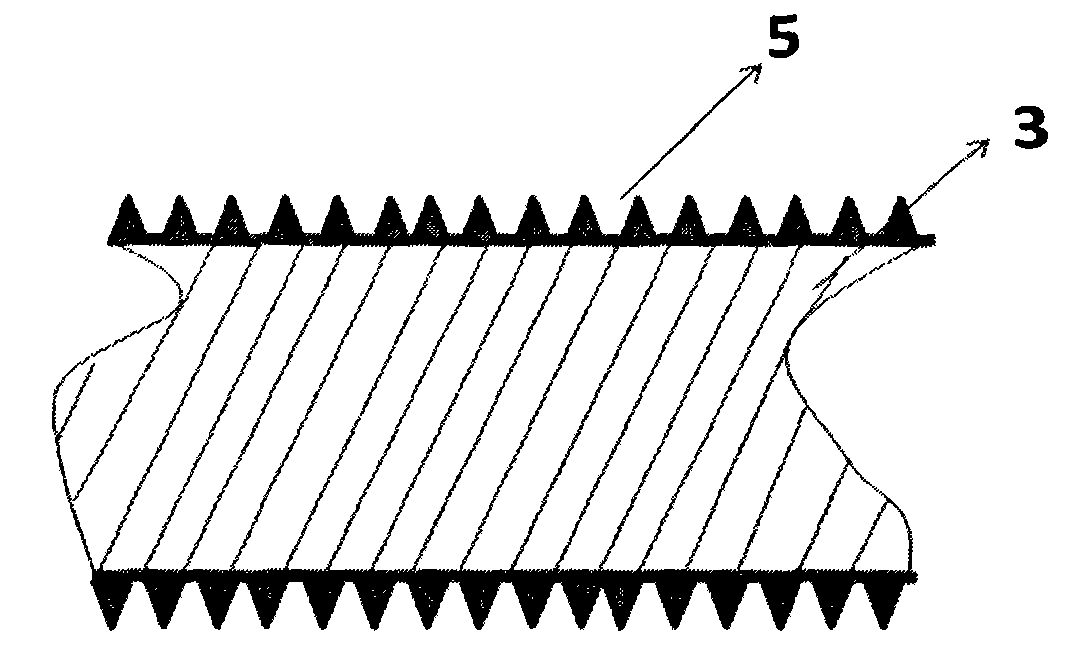

The invention discloses a method for making a multifunctional different-functional China-hemp elastic knitted fabric. The process flow of the method comprises the steps of spinning, winding, knitting, printing and dyeing, after finishing and inspection. The fabric consists of a surface layer and an inner layer, wherein the outer surface of the inner layer is covered with the surface layer; the inner layer is a China-hemp fiber layer; the surface layer is a moisture absorbing and quick drying polyester fiber layer; the China-hemp fiber layer is connected with the polyester fiber layer in a weaving manner through a middle connecting layer; the polyester fiber layer is woven into an air-permeable mesh structure with grooves; the China-hemp fiber layer is woven into a planar structure; fibers are special-shaped fibers, have large surface areas, and are provided with the grooves. The surface fiber layer is woven into the air-permeable mesh structure; the grooves are 0.5*3 millimeters, and are distributed uniformly, so that outward dispersion of water is facilitated; meanwhile, liquid-state water in the China-hemp fiber layer is transmitted or dispersed effectively by using the capillary action of the fiber groove structure, and is conveyed onto the outer surface of the fabric by means of gaps between fibers and China-hemp yarns or gaps among fibers.

Owner:JIHUA 3542 TEXTILE CO LTD

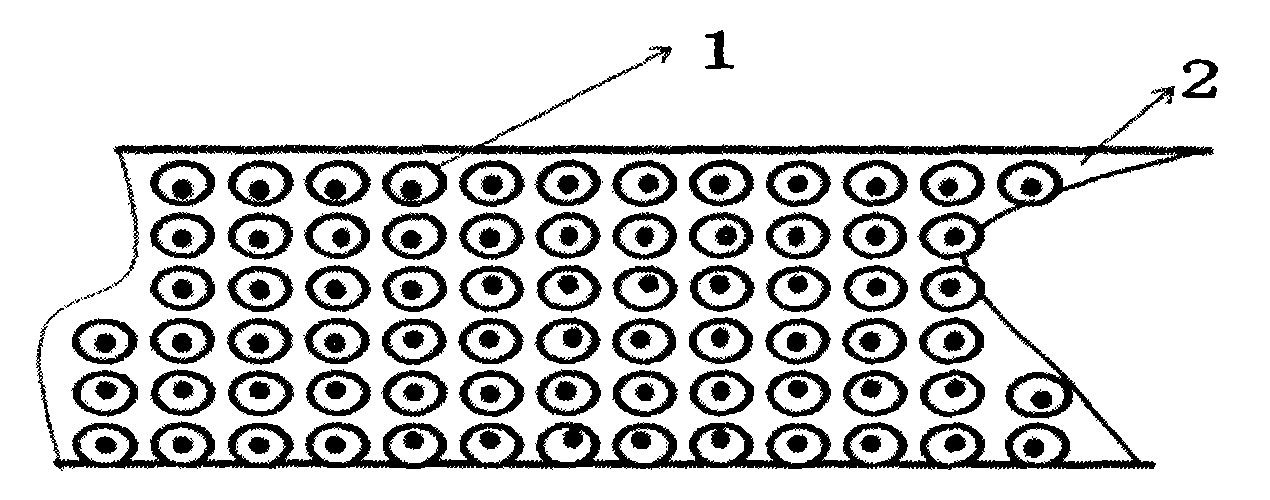

Bubble type flexible non-woven cloth and manufacturing method thereof

The invention discloses a piece of bubble type flexible non-woven cloth and a manufacturing method of the bubble type flexible non-woven cloth. Raw materials, namely, polylactic acid high polymers, are solidified into the cloth through melt spinning net laying and twice hot rolling. Annular nips are formed through the first time of hot rolling, point nips are formed through the second time of hot rolling, and finally the bubble type non-woven cloth is formed. Due to the fact that the nip area is small and the three-dimensional structure is obvious, the non-woven cloth is excellent in flexibility, small in contact area when making contact with the skin, fresh and cool, can not be attached to the human body, enables a user to feel nice and cool, and can be widely applied to disposal medical treatment and public health products such as sanitary towels, paper diapers, adult incontinence trousers, surgical gowns and operation cushions through combination with the advantages of polylactic acid fibers. Meanwhile, the polylactic acid raw materials have the advantages that the polylactic acid raw materials can be completely and naturally circulated and can be decomposed in a biological mode, energy consumption is lowered, and the environment protection role is played.

Owner:HAINING WEITAI BIOTECH CO LTD

High-performance wood-plastic composite material and preparation method thereof

The invention discloses a high-performance wood-plastic composite material and a preparation method thereof. The material is prepared from the following components in parts by weight: 60 to 80 parts of peanut hull powder, 30 to 50 parts of bamboo powder, 60 to 90 parts of abandoned plastics, 15 to 25 parts of epoxy resin, 4 to 6 parts of mineral fibers, 5 to 7 parts of magnesium carbonate whiskers, 4 to 6 parts of nano calcium carbonate, 6 to 9 parts of maleic anhydride, 3 to 5 parts of an organosilicone water-proofing agent, 2 to 4 parts of an 168 antioxidant, 3 to 5 parts of a red phosphorus fire-retardant and 3 to 5 parts of a 788 light stabilizer. The preparation method comprises the processing steps of modified pre-treatment, mixing at high speed, hot press molding, cooling setting and the like. The wood-plastic composite material obtained through the method has the advantages of high compressive strength, high abrasive resistance, low cost, high distortion temperature and the like, and the material and the method, provided by the invention, also have the advantages of simple processing technique, short processing time, low cost and the like, and are suitable for industrial production.

Owner:许超群

Bactericidal and antiallergic non-woven fabric

InactiveCN102704188AImprove breathabilityGood instant water absorptionNon-woven fabricsPolymer scienceNonwoven fabric

The invention relates to a non-woven textile made from fibers, and especially to a non-woven fabric for sanitary towel fabrics, protection pad fabrics or paper diapers, in particular to a bactericidal and antiallergic non-woven fabric. The non-woven fabric is prepared by bamboo fibers, base fibers and silk cotton according to the following parts by weight and steps: (1) proportions: 15-30 parts of bamboo fibers, 40-60 parts of base fibers and 10-20 parts of silk cotton; (2) steps: step 1. performing at least two-time cotton blending and at least two-time loosening operations on the bamboo fibers, base fibers and silk cotton; step 2. paving the bamboo fibers, base fibers and silk cotton treated by the cotton blending and loosening operations in step 1 to a net through a lapping machine and combing the bamboo fibers, base fibers and silk cotton through a combing machine; and step 3. carrying out hot rolling on the bamboo fibers, base fibers and silk cotton through a hot rolling mill. The bamboo fibers and the silk cotton are added in the non-woven fabric, so that the non-woven fabric is smoother, bactericidal and bacteriostatic and has the faint scent of bamboo.

Owner:重庆百亚卫生用品股份有限公司

Environment-friendly latex paint for wall bodies and preparation method thereof

InactiveCN108314944ALow costNo health hazardAntifouling/underwater paintsPaints with biocidesFiberAntiseptic Agent

The invention discloses environment-friendly latex paint for wall bodies and a preparation method thereof and relates to the technical field of wall body paint. The environment-friendly latex paint isprepared from the following raw materials in parts by weight: 35 to 42 parts of main material, 3 to 10 parts of thalatherm, 6 to 15 parts of wollastonite powder, 8 to 16 parts of calcium carbonate, 5to 10 parts of mica, 3 to 8 parts of attapulgite, 4 to 6 parts of titanium dioxide, 4 to 8 parts of bamboo fiber, 3 to 8 parts of ceramic fiber, 1 to 3 parts of nano silicon dioxide, 1 to 3 parts ofnano titanium dioxide, 1 to 3 parts of nano zinc oxide, 4 to 7 parts of silane coupling agent, 5 to 8 parts of dispersal latex powder, 1 to 2 parts of dispersant, 2 to 4 parts of anti-bacterial and antiseptic agent and 2 to 4 parts of film form aid. The raw materials of the environment-friendly latex paint for the wall bodies disclosed by the invention are chemical substances which have no toxin and are not prone to volatilizing, and the latex paint has the advantages of no formaldehyde matter, stable chemical property, no harm to human body health, good adhesion, easiness in being painted evenly, simple and easy preparation technology, low raw material cost and suitability for large-scale popularization and production.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Method for producing antibacterial towels

InactiveCN105887484AGood antibacterial propertiesMaintain antimicrobial propertiesBiochemical fibre treatmentGrip property fibresLong actingEnvironmentally friendly

The invention discloses a method for producing antibacterial towels, and relates to the technical field of towel articles. The method includes steps of A, preparing raw materials including pure cotton yarns and bamboo fibers with a proportion of 3:2; B, carrying out antibacterial treatment on the raw materials, to be more specific, 1) washing and decontaminating the bamboo fibers by the aid of distilled water and drying the bamboo fibers by the aid of a loose dryer at a low baking temperature of 45-55 DEG C, 2) picking and decontaminating the pure cotton yarns, immersing the pure cotton yarns in antibacterial solution for 60-120 minutes and then drying the pure cotton yarns; C, weaving each group of warp yarns and each group of weft yarns in a staggered manner to obtain towels in required styles; D, carrying out finishing on the towels, to be more specific, cutting and trimming the towels woven at the step C and sewing the edges of the towels to completely produce the antibacterial towels. Each group of warp yarns comprises two corresponding pure cotton yarns and the single corresponding bamboo fiber, and each group of weft yarns comprises the single corresponding pure cotton yarn and the single corresponding bamboo fiber. Compared with the prior art, the method has the advantages that the antibacterial towels produced by the aid of the method are safe and are environmentally friendly, and long-acting antibacterial effects can be realized by the antibacterial towels.

Owner:SOUTHERN CHINA REGENERATED COTTON YARN WUZHOU CO LTD

Nonwoven fabric anti-tear and antibacterial capacitor composite separator material

InactiveCN105990034AHigh tensile strengthGood chemical stabilityHybrid capacitor separatorsHybrid/EDL manufactureMicrocrystalline waxPolyvinyl alcohol

The invention discloses nonwoven fabric anti-tear and antibacterial capacitor composite separator material which is prepared by the raw material of the following parts by weight: 35-40 parts of polyvinyl alcohol fiber, 33-35 parts of mekralon, 10-13 parts of polyacrylonitrile powder, 30-32 parts of acetone, 72-75 parts of N,N-dimethyl formamide, 8-10 parts of water soluble PVA fiber of 70 DEG C, 5-6 parts of ptfe emulsion, 4-5 parts of bamboo charcoal fiber, 1-1.3 parts of chitosan, 8-9 parts of clay, a moderate amount of hydrochloric acid solution of which the concentration is 5wt%, 2-3 parts of ammonium dihydrogen phosphate, 5-6 parts of nanometer zinc oxide, 2-2.5 parts of microcrystalline wax and 2-3 parts of shell-lac. The bamboo charcoal fiber, the nanometer zinc oxide and the chitosan are added in preparation of the product through a series of technique means so that toughness and strength of the product can be enhanced, the product also has natural antibacterial property and prevents deterioration and corruption of the separator material and thus the service life can be prolonged.

Owner:ANHUI SUREPHON CAPACITOR CO LTD

Preparation method of composite palm fiber mat

InactiveCN107048854AModerate hardnessNatural antibacterialStuffed mattressesSpring mattressesPalm fiberMaterials science

The invention discloses a preparation method of a composite palm fiber mat. According to the method, by weight, 10-20 parts of low-melting-point fibers, 20-40 parts of mountain palm fibers, 20-40 parts of coconut fibers and 10-20 parts of bamboo fibers are weighed and mixed, net laying and carding are conducted, a net is formed by means of air flow, the net enters an oven to be roasted, pressed and cooled, and the prepared palm mat has the advantages of being free of formaldehyde, moderate in hardness, not likely to mildew or generate insects and the like.

Owner:思南县唯一山棕制品厂

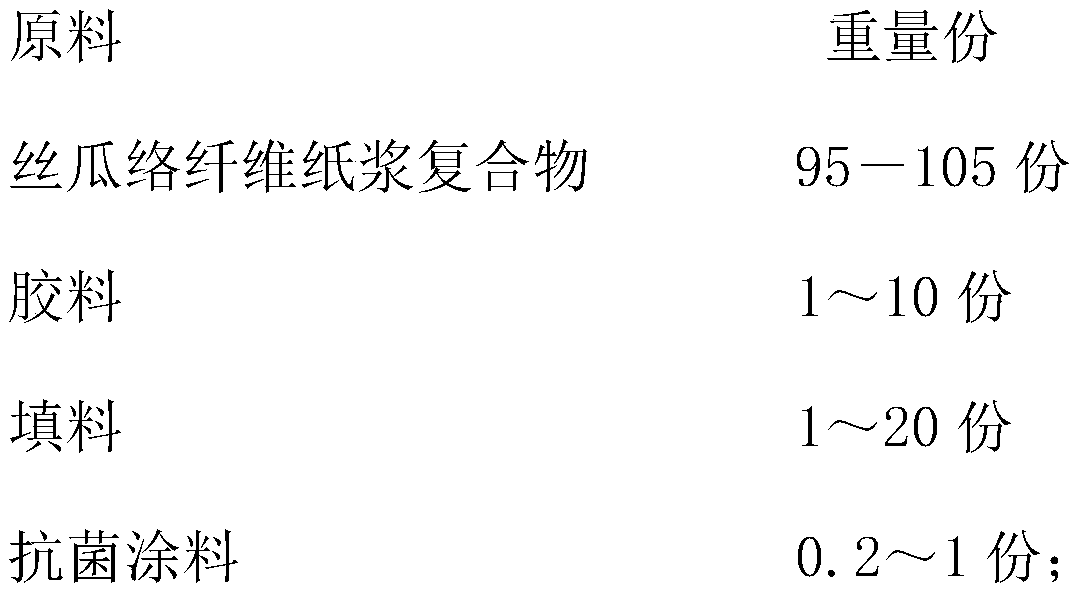

Loofah sponge fiber antibacterial packaging paper and preparation method

ActiveCN109868687AHigh strengthGood moisture absorption and air permeabilityFlexible coversWrappersFiberMaterials preparation

The invention discloses a loofah sponge fiber antibacterial packaging paper and a preparation method. The packaging paper consists of a loofah sponge fiber pulp compound, a filler, a glue material andan antibacterial coating according to a certain proportion. The steps are as follows: (1) raw material preparation: weighing raw materials according to the proportion for standby application; (2) loofah sponge fiber pulp compound pretreatment: placing loofah sponge in an oven and performing drying, soaking the dried loofah sponge in a sodium hydroxide solution, and washing the loofah sponge fiberwith clear water until neutrality and then performing drying; (3) glue material preparation: weighing chitosan according to a weight ratio, adding water, performing gelatinization after boiling, andperforming cooling to room temperature; (4) papermaking: adding the loofah sponge fiber pulp compound, the glue material and the filler to water according to a certain proportion, performing stirring,and then pouring the mixture into a sheet-making machine to carry out papermaking; and (5) surface coating: putting coated papers in a shady and cool place to perform drying in the air to obtain theloofah sponge fiber antibacterial packaging paper. The packaging paper is non-toxic and harmless, can be naturally degraded, and has obvious antibacterial effects. The method is simple, and no additional process steps, equipment and resource consumption are needed.

Owner:JINGCHU UNIV OF TECH

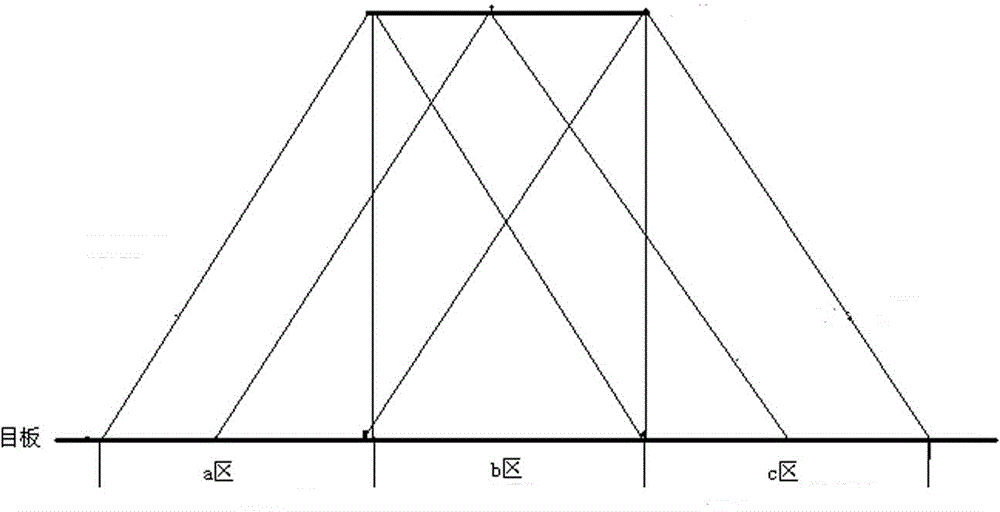

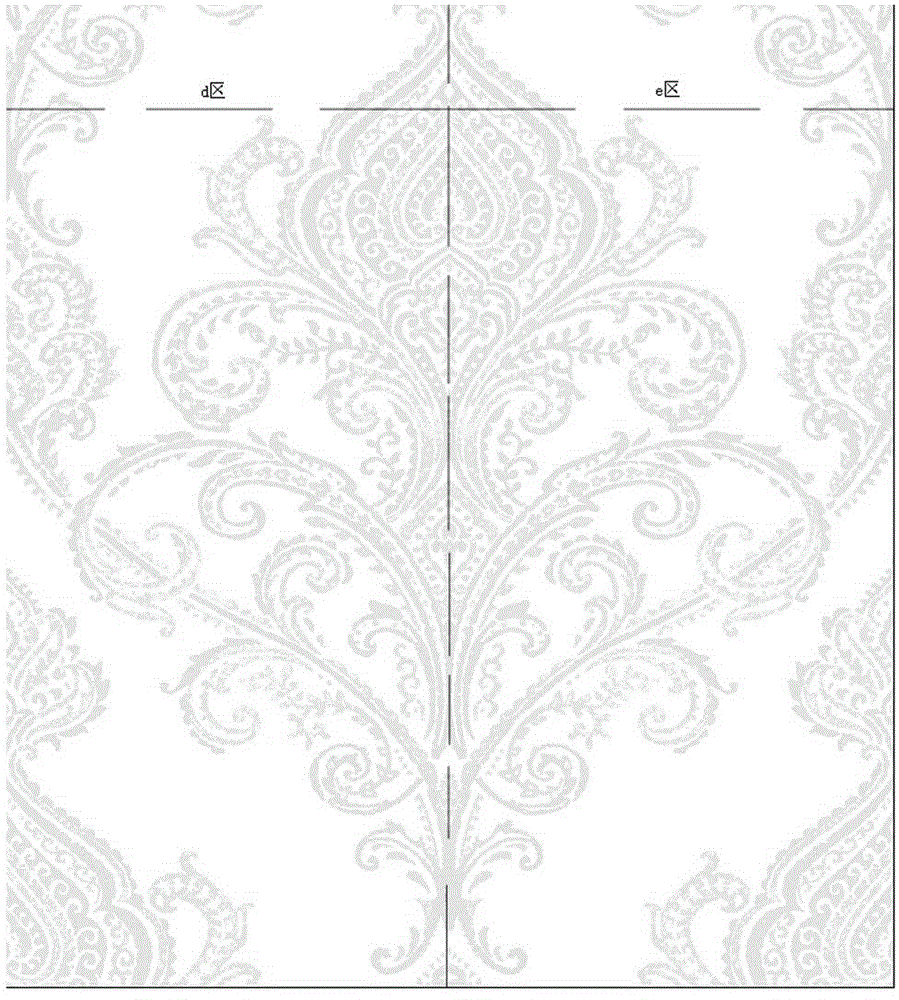

Hemp yarn dyed single-pattern jacquard thread blanket and production process thereof

Disclosed are a hemp yarn dyed single-pattern jacquard thread blanket and a production process thereof. The hemp yarn dyed single-pattern jacquard thread blanket is woven from 100% dyed hemp fiber and has an overall single pattern in a size of 176*220 cm, the sizing material of the hemp fiber is phosphate sizing, so that the problems of yarn stopping or uneven fabric surface tension due to hairiness tangling of coarse yarn, and the defects of the thread blanket can be reduced. The hemp yarn dyed single-pattern jacquard thread blanket has natural antibacterial property, uvioresistance, skin absorbency and high comfort level; the overall single pattern is more applicable to the style of hemp materials; under the premise of not changing the loom setting of existing weaving machines, the hemp yarn thread blanket with the special ultra-wide single pattern can be obtained through special needle dropping drawing-in and tying-in operations and a card manufacturing process, the pattern size of the production process is twice as large as that existing weaving machines can weave out, so that the production process of the hemp yarn dyed single-pattern jacquard thread blanket is a breakthrough of existing weaving techniques.

Owner:JIANGSU YUEDA HOME TEXTILE

Preparation method of enteromorpha regenerated cellulose fibers

InactiveCN106757454AImprove wet strengthStrong water absorptionArtificial filament washing/dryingMonocomponent cellulose artificial filamentPolyesterN dimethylformamide

The invention discloses a preparation method of enteromorpha regenerated cellulose fibers. The preparation method comprises the following steps: crushing enteromorpha and putting the crushed enteromorpha in a hydrolytic solution; adding sodium hydroxide into the hydrolytic solution and then cooking the solution to obtain a mixed liquid A; adding ethanol into the mixed solution A, and then removing water to obtain enteromorpha pulp; adding sodium hypochlorite into the enteromorpha pulp to be bleached to obtain an enteromorpha regenerated cellulose fiber stock solution; adding dimethyl sulfoxide and N,N-dimethylformamide into the enteromorpha regenerated cellulose fiber stock solution to obtain an enteromorpha regenerated cellulose fiber spinning stock solution; and feeding the enteromorpha regenerated cellulose fiber spinning stock solution into a spinning device to extrude a spinning solution thick flow, then performing concentration and curing, and stretching and lengthening the thick flow under the action of a winding force to obtain the enteromorpha regenerated cellulose fibers. The preparation method disclosed by the invention is simple in process. The fineness of the nteromorpha regenerated cellulose fibers is less than or equal to 1dex, the dry strength is 37.5 cn, the wet strength is 26.8 cn, and the spinning condition is superior to that of cotton, polyesters, artificial cotton and the like.

Owner:威海红印食品有限公司

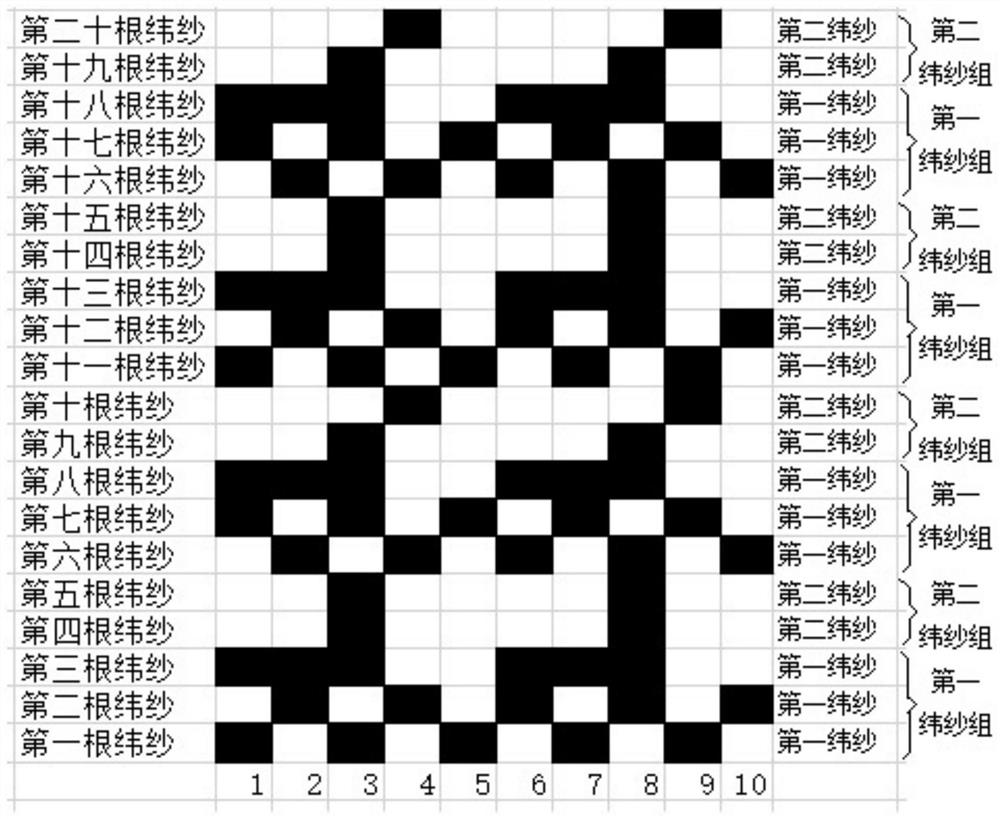

Antibacterial warm-keeping fabric, weaving method, preparation process and textile product

PendingCN112575429AHas a natural antibacterialGood flexibilityOrnamental textile articlesWoven fabricsCotton fibreProcess engineering

The invention discloses an antibacterial warm-keeping fabric, a weaving method, a preparation process and a textile product. The antibacterial warm-keeping fabric comprises warp yarns and weft yarns;the antibacterial warm-keeping fabric is formed by weaving the warp yarns and the weft yarns, and the warp yarns are blended yarns formed by blending cotton fibers and warm ginger fibers; the weavingmethod is mainly characterized in that yarns containing warm ginger fibers are adopted to weave the antibacterial warm-keeping fabric; the preparation process comprises the steps of spinning, weaving,gray fabric high-temperature steaming, velvet cutting, velvet brushing, singeing, blank inspecting, desizing, scouring and bleaching, reverse side light sanding, dyeing, shaping and finished productobtaining, wherein in the weaving process, yarn containing the warm ginger fibers needs to be woven into the antibacterial warm-keeping fabric. The fabric adopted by the textile product is the antibacterial warm-keeping fabric, or the adopted fabric applies the weaving method, or the adopted fabric applies the preparation process. The antibacterial warm-keeping fabric, the weaving method, the preparation process and the textile product have the advantages of being good in warm-keeping effect, good in antibacterial performance, high in safety, high in comfort and the like.

Owner:SHENZHEN PURCOTTON TECH

Emergency rescue garment inner layer material and preparation method thereof

InactiveCN108128006AEnhance capillary wicking effectImprove breathabilityLamination ancillary operationsSynthetic resin layered productsEnvironmental resistancePolyester

The invention relates to an emergency rescue garment inner layer material and a preparation method thereof, and belongs to the technical field of garment textile. Fine denier polyester filaments whichhave the advantages that capillary tubes are fine and many, and the capillary core suction effect of the textile can be obviously enhanced for further improving the textile ventilation performance and moisture guide performance are compounded with polyester staples; carding and net laying are performed to form a fine denier polyester fiber net; then, carding and net laying are performed with bamboo fiber which has good wear-resistant performance, drapability, good moisture absorption performance, good moisture permeability, ventilation performance, natural antibacterial and deodorization functions and excellent dyeing performance and is also called as breathing environment-friendly fiber to form a composite bamboo fiber net; unidirectional moisture guide fiber spunlaced cloth with good moisture gradient continuity and obvious differential capillary effects is formed, so that sweat is adsorbed to the outer surface layer of the fabric and is fast volatilized under the effect of the differential capillary effects; the ventilation and moisture permeability are improved; the comfort degree is improved.

Owner:俞小峰

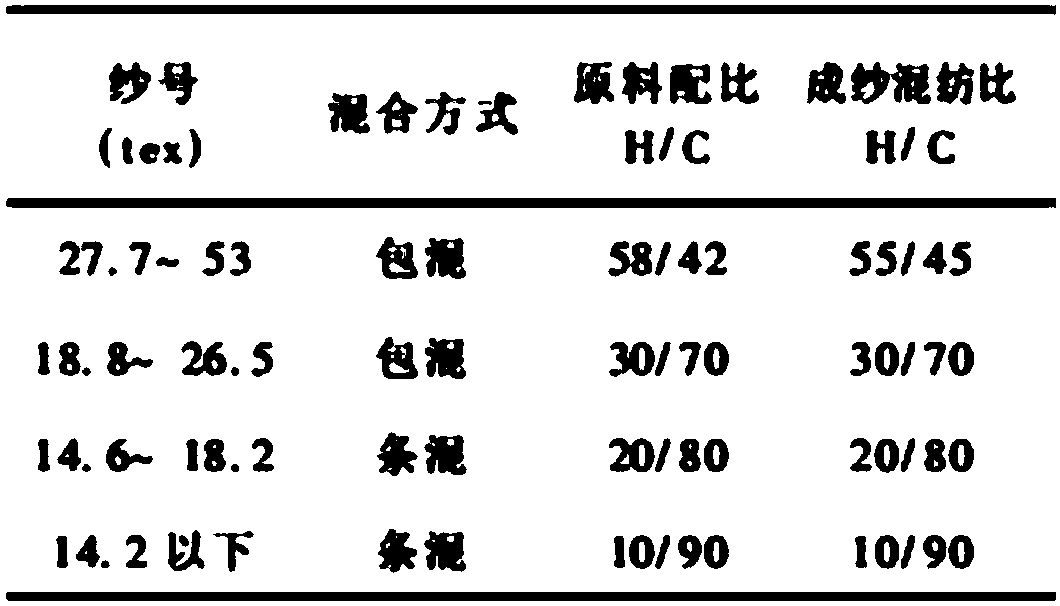

Jute fiber and synthetic fiber blended yarn and method for preparing same

InactiveCN108085814ANatural antibacterialNatural skin care and cleaningTextile treatment by spraying/projectingYarnYarnPolymer science

The invention discloses a jute fiber and synthetic fiber blended yarn and a method for preparing the same. The method includes steps of (1), carrying out surface modification on jute fibers by the aidof surfactants I to obtain modified jute fibers; (2), carrying out surface modification on synthetic fibers by the aid of surfactants II to obtain modified synthetic fibers; (3), blending the modified jute fibers and the modified synthetic fibers to obtain the jute fiber and synthetic fiber blended yarn. The jute fiber and synthetic fiber blended yarn and the method have the advantages that the method is the optimal method for blending the jute fibers and the synthetic fibers to obtain the jute fiber and synthetic fiber blended yarn, so that the shortcomings of the jute fibers can be overcome; the synthetic fibers are soft and are good in length uniformity and free of staple fibers or short velvet; merits of the jute fibers are gathered on the jute fiber and synthetic fiber blended yarn prepared by the aid of the method, the shortcomings of the synthetic fibers can be overcome, and accordingly the jute fiber and synthetic fiber blended yarn can become the first choice of high-end clothes, bedding towels and quilts and ornaments day by day.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

Soft radiation-proof fabric and processing technology thereof

The invention discloses a soft radiation-proof fabric and a processing technology thereof, wherein the soft radiation-proof fabric is woven by silk fiber, ultra-low carbon stainless steel short fiber, polylactic acid fiber and polyester fiber in a mixing manner, wherein the silk fiber, the ultra-low carbon stainless steel short fiber, the polylactic acid fiber and the polyester fiber are mixed according to the mass ratio of (10-20) to (10-20) to (20-35) to (20-30). According to the soft radiation-proof fabric disclosed by the invention, various components are reasonable in proportion; the textile is high in compliance, high in ultraviolet resistance, wearable and free of fading.

Owner:关捷

Manufacturing method of natural bamboo-fiber hemostatic gauze

InactiveCN107281534ASmooth and clean surfaceWell-proportionedSurgical adhesivesPharmaceutical delivery mechanismFiberMedicine

The invention relates to the field of medical supplies, and particularly relates to a manufacturing method of water-soluble bamboo-fiber hemostatic gauze. The method comprises five procedures of pretreatment, an alkali reaction, an ether reaction, washing treatment and post treatment. The manufacturing method is a method for producing hemostatic gauze, which is simple in production process, relatively few in the kinds of used raw materials and reagents, and further better in effects, particularly in degradation effects.

Owner:宣晓星

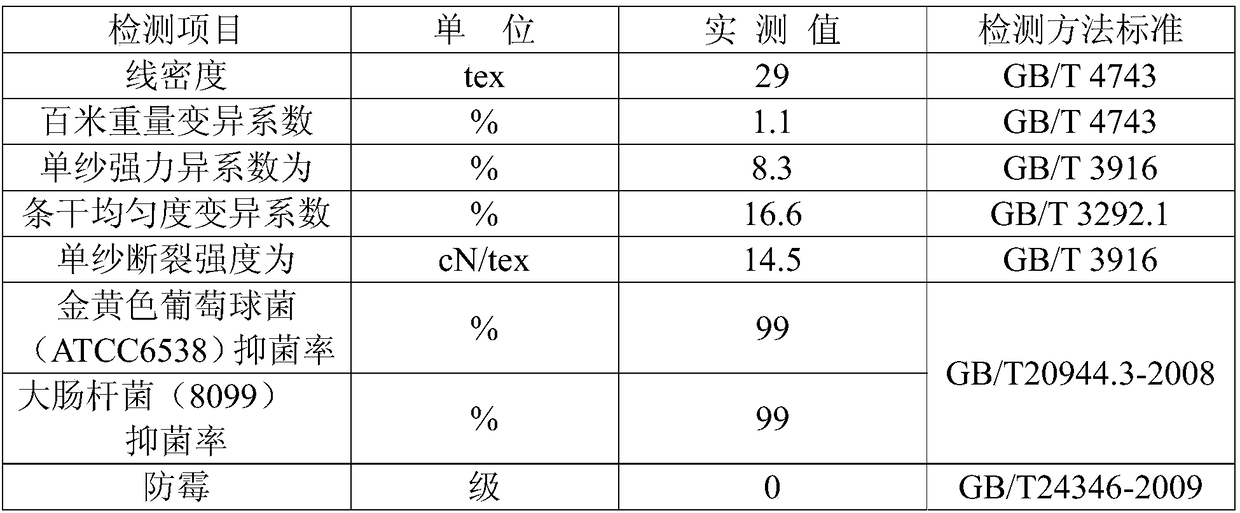

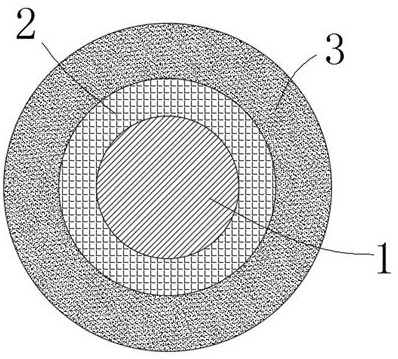

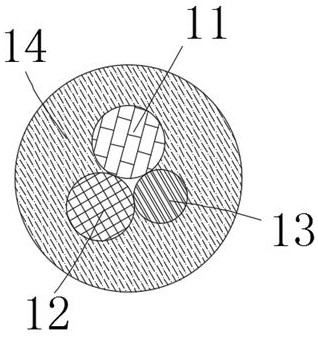

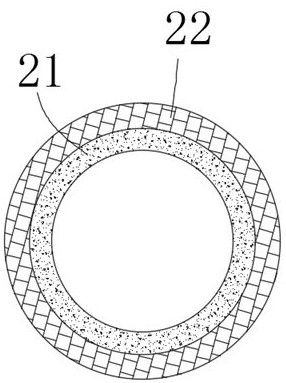

High-strength vortex spinning yarn and production method thereof

PendingCN111663218AGood moisture absorption and air permeabilityStretch, crisp and fluffy warmthContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention discloses a high-strength vortex spinning yarn. The high-strength vortex spinning yarn comprises a core yarn layer, a wrapping layer and a covering yarn layer. The wrapping layer is arranged on the outer surface of the core yarn layer, the covering yarn layer is arranged on the outer surface of the wrapping layer, and the core yarn layer comprises a first strand, a second strand, a third strand and a core fiber layer. The first strand, the second strand and the third strand are mutually wound, the core fiber layer is arranged on the outer side of the first strand, the outer sideof the second strand and the outer side of the third strand, and the wrapping layer comprises a first wrapping fiber layer and a second wrapping fiber layer. The second wrapping fiber layer is arranged on the outer surface of the first wrapping fiber layer, and the yarn wrapping layer comprises an acrylic fiber wrapping layer and a tencel fiber wrapping layer. The invention further provides a production method for the high-strength vortex spinning yarn. The yarn has less hairiness and is free of pilling, uniform in core yarn stress, good in structural strength, not prone to breakage and capable of being used as high-strength yarn.

Owner:江苏京正特种纤维有限公司

A medicate pet cushion and its preparation method

InactiveCN108887183AAvoid environmental problemsSolve the big problem of handling non-conforming productsAnimal housingBird housingsFiberCellulose

A sanitary material pet cushion and a preparation method thereof relate to that technical field of pet appliances. A hygienic material core is use as a carrier, and that hygienic material core comprise a high water-absorbing raw wood pulp fiber and a high-molecular water-absorbing resin, and colloidal adhesive, food-grade cellulose and lignocellulose are added into the hygienic material core, andthe colloidal adhesive and the food-grade cellulose account for 1.5 percent of the total weight of raw materials. 4% of the total weight of lignocellulosic materials. 6%, wherein the weight ratio of colloidal binder to food grade cellulose is 1: 2 5. A manufacture method comprises pulverize, mixing and granulation, spraying and drying process, the nonconforming products of the sanitary material factory are crushed, A superabsorbent primary wood pulp fib and a macromolecule water-absorbent resin are left as a core of a sanitary material and a colloidal adhesive is mix, Chromogenic agent, antibacterial deodorant, after granulation spraying food-grade cellulose aqueous solution and sticking to lignocellulose after drying, can quickly absorb liquid, lock off odor odor, make pet feet feel soft, with light weight, fast water absorption characteristics.

Owner:孟健

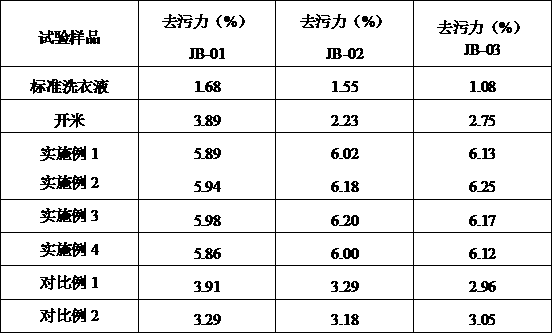

Laundry detergent for removing yellow spots and pigments and preparation method thereof

InactiveCN109609302AHigh transparencyReduce viscosityNon-ionic surface-active compoundsPolymeric surface-active compoundsActive agentLimonene

The invention discloses a laundry detergent for removing yellow spots and pigments and a preparation method thereof. The laundry detergent is prepared from, by mass, 5-10% of alkyl glycoside, 10-15% of aliphatic alcohol polyoxyethylene ether sodium sulfate of the type 70, 5-10% of potassium coconut oleate soap, 10-15% of isotriol polyoxyethylene ether, 5-10% of dodecyl sucrose ester, 1-5% of coconut oil diethanolamide, 1-5% of sodium citrate, 5-10% of D-limonene, 1-5% of ethylene glycol and deionized water as the balance. According to the laundry detergent, the surfactant alkyl glycoside, thealiphatic alcohol polyoxyethylene ether sodium sulfate of the type 70 and the isotriol polyoxyethylene ether are compounded through sodium citrate, a compound mixed surfactant is thus obtained, and solubility can be increased well by adding coconut oil diethanolamide and ethylene glycol, and the transparency of the compound surfactant is improved and the viscosity is reduced, meanwhile the D-limonene high in decontamination ability is added, and the prepared laundry detergent can effectively remove or clear away the yellow spots and pigments existing on clothes.

Owner:郑州君萍化工科技有限公司

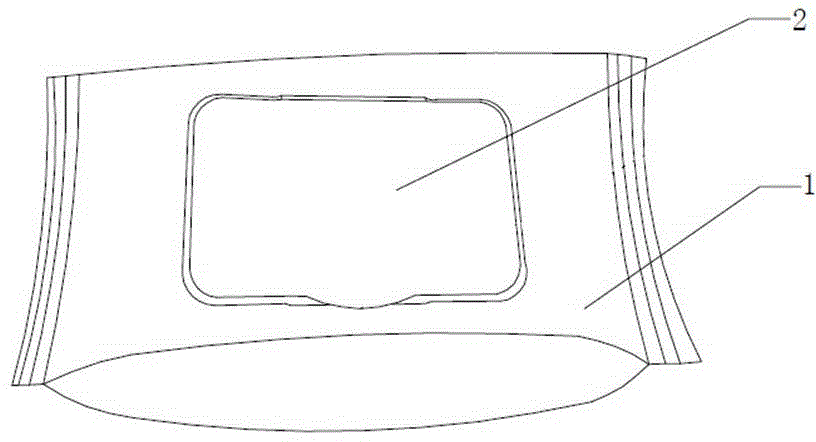

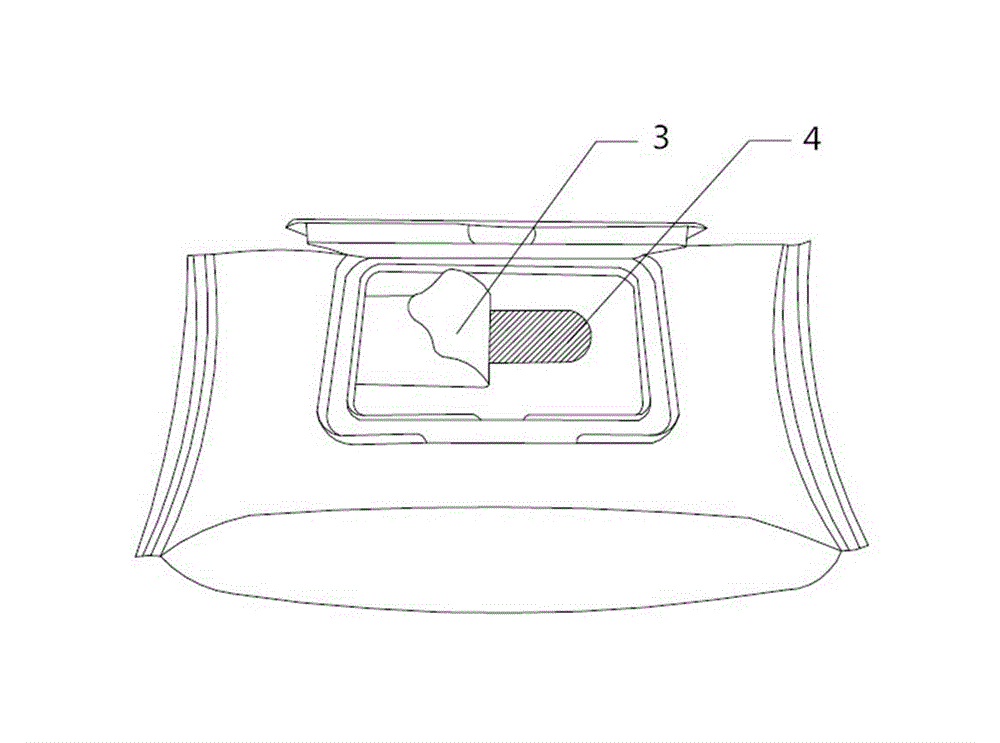

Wet tissue substitute convenient for baby to use

InactiveCN104434546AReduce shipping costsGood air permeabilityCosmetic preparationsToilet preparationsWoven fabricBiomedical engineering

The invention discloses a wet tissue substitute convenient for a baby to use. The wet tissue substitute comprises a packaging bag and a dry wet tissue contained in the packaging bag. The dry wet tissue is formed by a non-woven fabric layer and auxiliaries added on the non-woven fabric layer, and the auxiliaries can be arranged on the non-woven fabric layer and can also be arranged inside the non-woven fabric cloth. Non-woven fabric is formed by processing bamboo fibers, and the residual space, except the dry wet tissue, in the packaging bag contains plain boiled water, wherein the weight of the plain boiled water is 3.5 times that of the non-woven fabric layer. Compared with the prior art, due to the fact that a preservative does not need to be added for mold prevention, use is more healthy and safer, and the wet tissue substitute is especially suitable for the baby. Furthermore, due to the fact that the whole wet tissue substitute is dry, the weight of the wet tissue substitute can be lowered to one fifth of the original weight under the same sheet number and the same size, the transportation cost is greatly lowered, and better energy conservation and better environmental friendliness are achieved.

Owner:付强

Blended yarn of fine denier nylon yarns, bamboo fibers and viscose fibers

The invention provides a blended yarn of fine denier nylon yarns, bamboo fibers and viscose fibers. The blended yarn comprises following components in parts by weight: 45-55 parts of the fine denier nylon yarns, 30-40 parts of the bamboo fibers and 20-30 parts of viscose fiber. The blended yarn can complement the characteristics of the fine denier nylon yarns, the bamboo fibers and the viscose fibers and can express the advantages of the three types of fibers.

Owner:HAIAN ZHONGSHAN SYNTHETIC FIBER

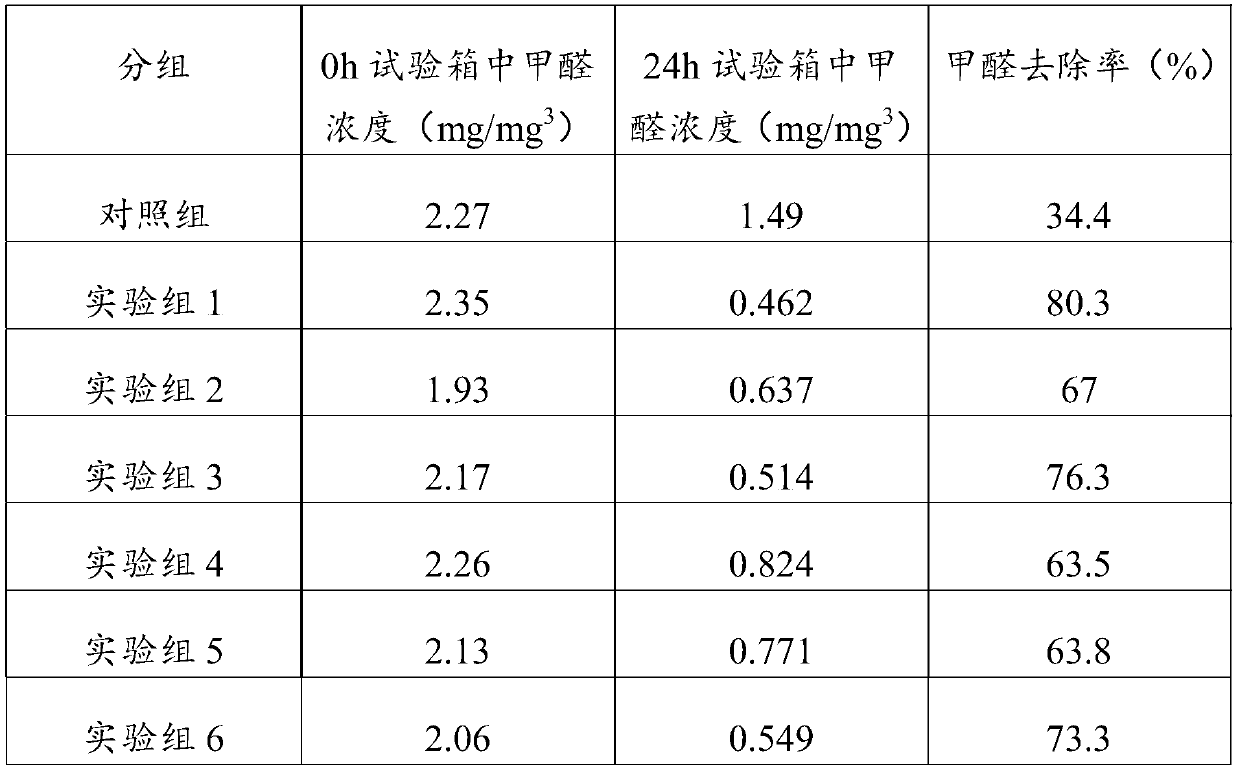

Formaldehyde removal material and preparation method and application thereof

InactiveCN109893991ASolve moldySolve the technical problem of sourDispersed particle separationAir filterTime of use

The application discloses a formaldehyde removal material and a preparation method and application thereof. The formaldehyde removal material is made from, by weight, 10-60 parts of plant polyphenols,10-60 parts of alumina and 10-80 parts of a silicate mineral. The application also discloses the preparation method of the formaldehyde removal material, and application of the formaldehyde removal material as a filter element material for air filters or in purifying air in furniture. The application is mainly intended to provide the plant polyphenol material for formaldehyde removal to solve thetechnical problem that existing activated carbon products for formaldehyde removal experience mildew and sourness after a period of time of use, and also solve the problem that the prior chemical preparations for formaldehyde removal are corrosive, have irritating odor, have unstable physical and chemical indexes at normal temperature and cause harm to human bodies during production.

Owner:王盛桂

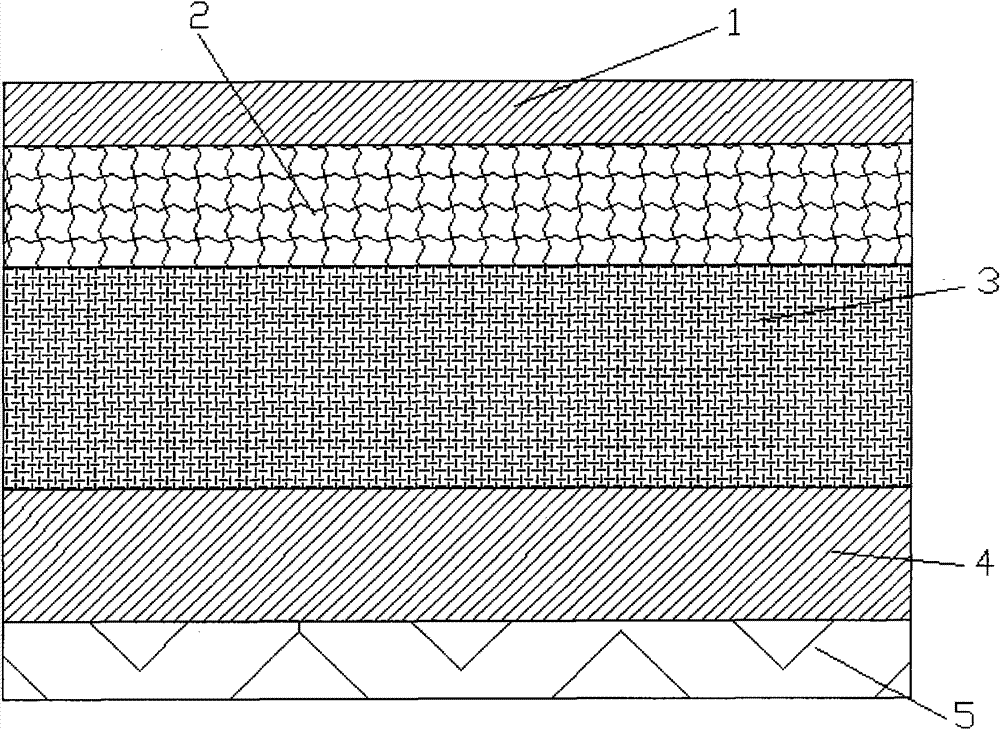

Antibacterial raw bamboo fiber sanitary napkin

InactiveCN104510576AImprove breathabilityInstant water absorptionAbsorbent padsSurface layerAbsorption layer

The invention provides an antibacterial raw bamboo fiber sanitary napkin which comprises a surface layer, an antibacterial layer, a water absorption layer, a waterproof layer and a bottom layer. The antibacterial raw bamboo fiber sanitary napkin is characterized in that the surface layer is adhered with the bottom layer, the antibacterial layer is arranged between the surface layer and the water absorption layer, the waterproof layer is arranged between the water absorption layer and the bottom layer, and the antibacterial layer is a raw bamboo fiber layer. The raw bamboo fiber layer is arranged between the surface layer and the water absorption layer, menstrual blood is deodorized and sterilized by the antibacterial layer after the sanitary napkin absorbs the menstrual blood, effects are remarkable, action duration is long, undesirable odor of women in a menstrual period is effectively decreased, and bacterial infection is avoided.

Owner:王志全

Carpet detergent with antibacterial action

InactiveCN104450235AImprove decontamination abilityImprove wetting abilityOrganic detergent compounding agentsNon-ionic surface-active compoundsWhitening AgentsOleic Acid Triglyceride

The invention discloses a carpet detergent with antibacterial action, which is prepared from the following components in percentage by weight: 10-15% of triethanolamine, 5-10% of coconut acyl diethanolamine, 1.5-2.5% of non-ionic wetting agent, 0.5-1.5% of aromatic, 0.05-0.15% of antimicrobial agent, 5-8% of isopropanol, 2.5-4.5% of sulfurized oleic acid disodium salt, 0.5-1.5% of fluorescent whitening agent and 65-85% of water. The carpet detergent with antibacterial action has the advantages of high dirt-removing power, no toxicity, high safety, high wetting ability and high permeability, has natural antimicrobial ability and aroma, does not damage the carpet surface, and is suitable for cleaning carpets in hotels and household.

Owner:SUZHOU LOTTE CHEM TECH

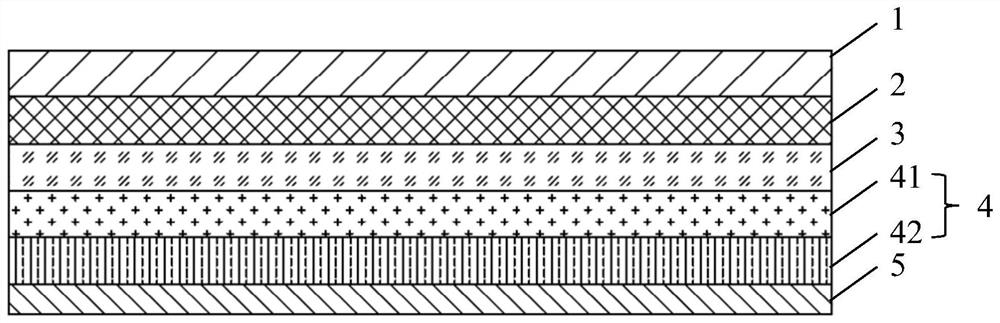

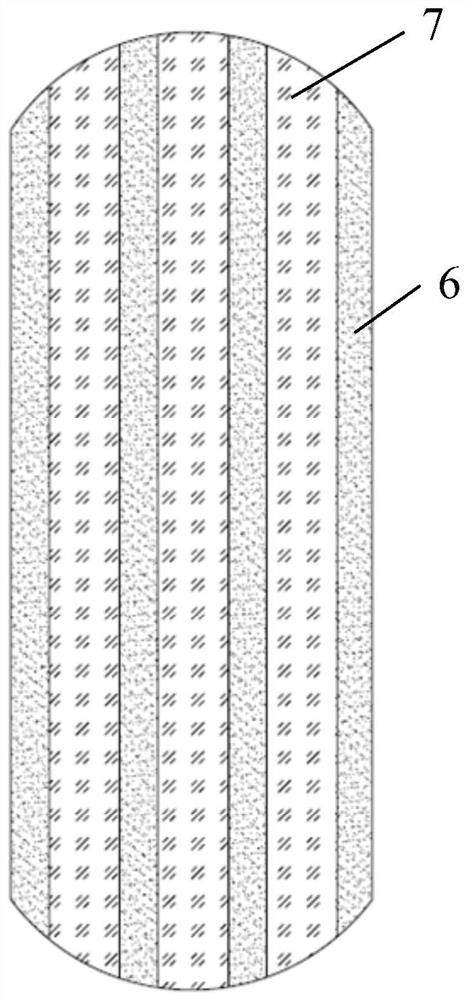

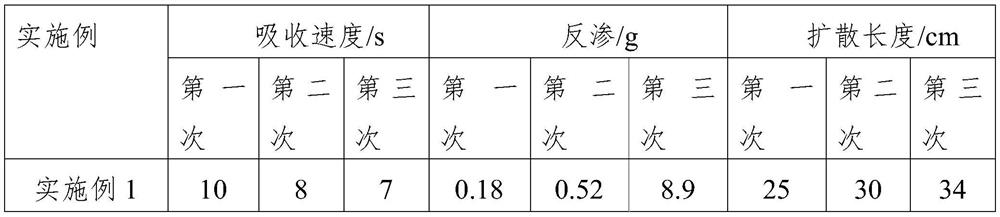

Antibacterial absorptive article and preparation method thereof

ActiveCN114366448AGood antimicrobial activityNatural AntibacterialAbsorbent padsBaby linensPolymer scienceFluff pulp

The invention relates to an antibacterial absorptive article and a preparation method thereof. The antibacterial absorptive article sequentially comprises a surface layer, an absorption core body and a bottom film layer from top to bottom, coconut oil is added into the surface layer; the absorption core body comprises an upper-layer absorption body and a lower-layer absorption body; the upper-layer absorber is made of a latex material; the lower-layer absorber is composed of a liquid absorbing material layer and a non-woven fabric layer wrapping the liquid absorbing material layer; the liquid absorption material layer is formed by alternately arranging a plurality of fluff pulp strip-shaped structures and a plurality of super absorbent resin strip-shaped structures at intervals. The antibacterial absorptive article has the advantages that the antibacterial absorptive article is excellent in antibacterial performance, can moisten skin, improve dry skin and prevent allergy of a user in the using process, and is high in absorption speed, low in reverse osmosis, good in dryness and smoothness, free of breakage and lump after being absorbed and the like.

Owner:诺宸股份有限公司

Silk fabric detergent and preparation method thereof

InactiveCN109576078AHigh transparencyReduce viscositySoap detergents with organic compounding agentsOrganic detergent compounding agentsSolubilityEcological safety

The invention discloses a silk fabric detergent which comprises, by mass, 8-13% of alkyl glycoside, 10-15% of alkylphenol polyoxyethylene ether, 10-15% of alpha-alkenyl sulfonate, 5-10% of coconut oleate potassium soap, 8-13% of iso-tridecanol polyoxyethylene ether, 3-8% of lauryl sucrose ester, 1-5% of coconut oil diethanolamide, 1-5% of chitosan, 0.1-5% of sodium citrate, 1-5% of D-limonene, 1-5% of diethanol and the balance of deionized water. Alkyl glycoside is a novel nonionic surfactant comprehensive in performance, has high surface activity, high ecological safety and solubility, is aninternationally recognized preferred green functional surfactant and is biodegradable and quick and thorough in degradation, so that the problem of secondary contamination caused by the surfactant after decontamination is avoided; alkyl glycoside is environment-friendly, so that the objective of using renewable biomass resources to replace fossil raw materials to prepare environment-friendly surfactants is achieved.

Owner:郑州君萍化工科技有限公司

A kind of method that utilizes garlic skin to make paper pulp

InactiveCN103952941BSolve pollutionReduce consumptionPulping with inorganic basesNon-woody plant/crop pulpAdditional valuesPulp and paper industry

The invention discloses a method for manufacturing pulp by using garlic slices, belonging to the technical domain of regenerating and utilizing of waste resources. The pulp is produced by pretreating, stewing, cleaning and screening the waste garlic slices taken as raw materials. According to the method, the comprehensive utilization of the waste garlic slices is realized, the production process is simple, the practicability is strong, and the additional value of the product is improved. A NaOH solution is taken as a main reagent, so that the pulp is cheap and available, and free of toxicity or harm, the treatment cost can be reduced, good economic and environmental benefits are obtained when resources are saved, and high efficiency, high quality and pollution-free utilization of resources are achieved.

Owner:青岛福创环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com