Formaldehyde removal material and preparation method and application thereof

A formaldehyde and raw material technology, applied in the field of formaldehyde removal materials and its preparation, can solve the problems of corrosion, pungent smell, mold, etc., and achieve the effect of stable physical and chemical indicators, not easy to mold, and many internal pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

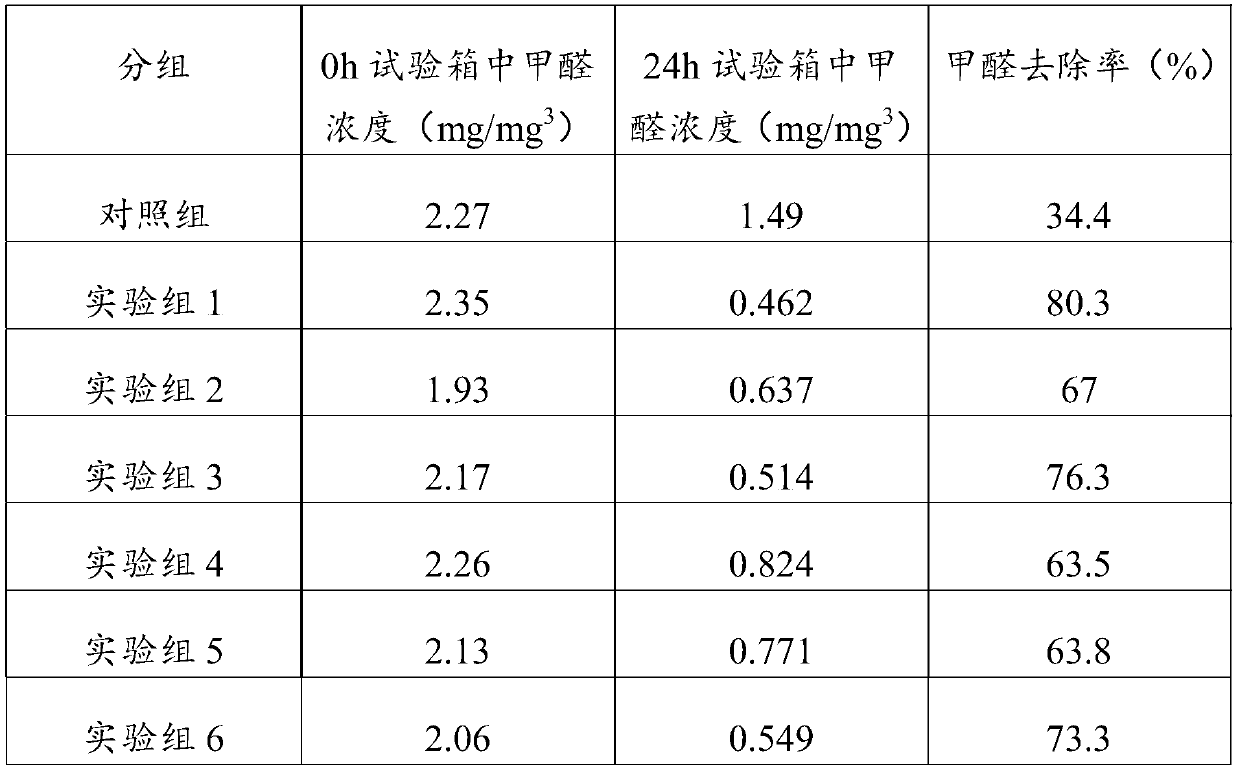

Examples

Embodiment 1

[0028] A formaldehyde-removing material comprises the following raw material components in weight fractions: 30 parts of tea polyphenols, 10 parts of aluminum oxide and 10 parts of kaolin.

[0029] The preparation method of above-mentioned formaldehyde removal material, comprises the following steps:

[0030] Ball milling alumina to an average particle size of 5.0 μm to obtain raw material micropowder 1;

[0031] Ball mill kaolin until the average particle size is 10.0 μm to obtain raw material micropowder 2;

[0032] Mix raw material micropowder 1 and raw material micropowder 2 evenly, then calcinate at 400°C for 6 hours, cool, and pulverize to 200 mesh fine powder to obtain raw material micropowder 3;

[0033] Mix tea polyphenols and raw material micropowder 3 evenly, granulate into balls with a particle diameter of 5mm, and dry at 300°C for 2 hours to obtain a formaldehyde-removing material.

Embodiment 2

[0035] A formaldehyde-removing material comprises the following raw material components in weight fractions: 10 parts of apple polyphenols, 40 parts of aluminum oxide and 40 parts of clay.

[0036] The preparation method of above-mentioned formaldehyde removal material, comprises the following steps:

[0037] Alumina ball milling to an average particle size of 10.0 μm to obtain raw material micropowder 1;

[0038] Ball mill the clay until the average particle size is 5.0 μm to obtain the raw material powder 2;

[0039] Mix raw material micropowder 1 and raw material micropowder 2 evenly, then calcinate at a temperature of 550° C. for 5 hours, cool, and pulverize into 200-mesh fine powder to obtain raw material micropowder 3;

[0040] Mix apple polyphenols with raw material micropowder 3 evenly, granulate into a ball with a particle diameter of 3mm, and dry at 200°C for 3 hours to obtain a formaldehyde-removing material.

Embodiment 3

[0042] A formaldehyde-removing material comprises the following raw material components in weight fractions: 20 parts of tea polyphenols, 10 parts of aluminum oxide and 40 parts of kaolin.

[0043] The preparation method of above-mentioned formaldehyde removal material, comprises the following steps:

[0044] Alumina ball milling to an average particle size of 7.0 μm to obtain raw material micropowder 1;

[0045] Ball mill kaolin until the average particle size is 8.0 μm to obtain raw material powder 2;

[0046] Mix raw material micropowder 1 and raw material micropowder 2 evenly, then calcinate at 300° C. for 7 hours, cool, and pulverize into 300-mesh fine powder to obtain raw material micropowder 3;

[0047] Mix tea polyphenols and raw material micropowder 3 uniformly, granulate into balls with a particle diameter of 4 mm, and dry at 200° C. for 4 hours to obtain a formaldehyde-removing material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com