Natural mildew-proof sound-insulation density board

A density board, natural technology, applied in the direction of manufacturing tools, flat products, household components, etc., can solve the problems that affect the appearance and strength of density boards, affect the use effect of density boards, shorten the service life of density boards, etc., to avoid mildew problems, Improve the effect of antibacterial and anti-mildew, and inhibit the effect of water absorption and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

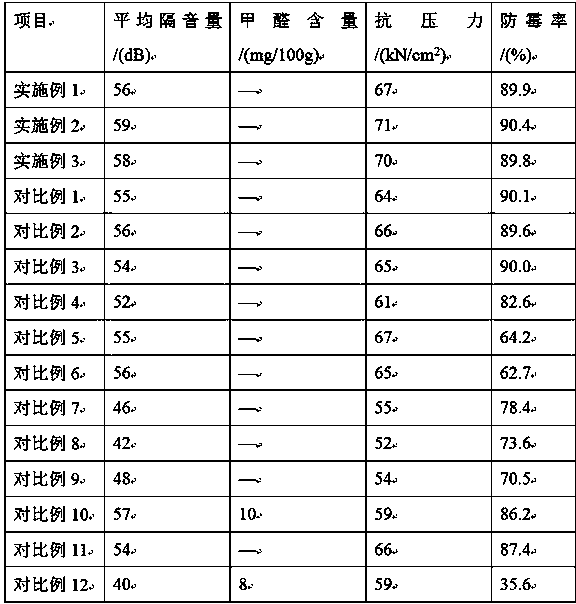

Examples

Embodiment 1

[0018] A kind of preparation method of natural mildew-proof soundproof density board, comprises the following steps:

[0019] (1) Wood crushing: crush the wood into 3~4cm long and 0.6~1.2cm wide wood segments, soak in acetic acid solution at 2~6°C for 10 hours, which can prolong the length of wood fibers and avoid damage caused by shorter fibers. The density board has low strength, and can avoid the problem of uneven density board structure caused by longer fibers, and improve the strength and durability of the density board. Take it out, drain it, and soak the wood section;

[0020] (2) Drying: Put the soaked wood section in a freeze dryer, and freeze-dry it at -46°C until the water content is 21~23%, so as to increase the porosity of the wood section, reduce fiber breakage during longitudinal rolling, and increase the density of the density board. The strength of the wood section is longitudinally rolled, and the wood fiber is separated to obtain the wood fiber;

[0021] (3...

Embodiment 2

[0027] A kind of preparation method of natural mildew-proof soundproof density board, comprises the following steps:

[0028] (1) Wood crushing: Crush the wood into 3~4cm long and 0.6~1.2cm wide wood segments, soak in acetic acid solution at 2~6°C for 11 hours, which can prolong the length of wood fibers and avoid damage caused by shorter fibers. The density board has low strength, and can avoid the problem of uneven density board structure caused by longer fibers, and improve the strength and durability of the density board. Take it out, drain it, and soak the wood section;

[0029] (2) Drying: Put the soaked wood section in a freeze dryer, and freeze-dry it at -45°C until the water content is 21-23%, increasing the porosity of the wood section, reducing fiber breakage during longitudinal rolling, and improving the density of the density board. The strength of the wood section is longitudinally rolled, and the wood fiber is separated to obtain the wood fiber;

[0030] (3) Mi...

Embodiment 3

[0036] A kind of preparation method of natural mildew-proof soundproof density board, comprises the following steps:

[0037] (1) Wood crushing: crush the wood into 3~4cm long and 0.6~1.2cm wide wood segments, soak in acetic acid solution at 2~6°C for 12 hours, which can prolong the length of wood fibers and avoid damage caused by shorter fibers. The density board has low strength, and can avoid the problem of uneven density board structure caused by longer fibers, and improve the strength and durability of the density board. Take it out, drain it, and soak the wood section;

[0038](2) Drying: Put the soaked wood section in a freeze dryer, and freeze-dry it at -44°C until the water content is 21-23%, increasing the porosity of the wood section, reducing fiber breakage during longitudinal rolling, and improving the density of the density board. The strength of the wood section is longitudinally rolled, and the wood fiber is separated to obtain the wood fiber;

[0039] (3) Mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com