Patents

Literature

209results about "Wood cryogenic treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing technology for moso bamboo for bamboo-woven basket

InactiveCN105904556AHigh strengthImprove toughnessPressure wood treatmentWood treatment detailsFiberHigh pressure

The invention provides a processing technology for moso bamboo for a bamboo-woven basket. The processing technology comprises the following steps that the moso bamboo freshly cut is placed into a refrigeration house with the temperature ranging from 10 DEG C to 15 DEG C to be frozen; the frozen moso bamboo is taken out and subjected to high-temperature processing for 30-60 min, the processing temperature ranges from 120 DEG C to 150 DEG C, and then the moso bamboo is placed in a closed pressure processing tank to be subjected to high-pressure processing; and the root of the moso bamboo subjected to high-pressure processing is cut away, bamboo breaking is conducted through a bamboo breaking machine, a bamboo skin is formed and tailored according to the specification of a needed bamboo-woven product, then, the tailored bamboo skin is dried, and the water content of the bamboo skin is not larger than 4%. The operation of the processing technology is easy to achieve. The moso bamboo processed through the processing technology is used for weaving the bamboo-woven product, the mould proof, high-temperature resisting and severe cold resisting capability and the anti-yield strength of the bamboo-woven product can be greatly improved, and the connection strength of bamboo fiber is obviously improved.

Owner:FUNAN FANGLIU ARTS & CRAFTS CO LTD

Preparation method of antibacterial mould-proof plywood for decoration

ActiveCN107351197AInhibit residual mold activityGood flexibilityRadiation/waves wood treatmentNon-macromolecular adhesive additivesCelluloseHuman health

The invention mainly relates to the technical field of machining of artificial boards, and discloses a preparation method of antibacterial mould-proof plywood for decoration. The preparation method comprises drying, dipping, freezing, gluing, hot pressing and arrangement; the method is simple, safe and nontoxic; the obtained plywood for decoration reaches the mould inhibition rate of 76.3%, and contains no poisonous chemical reagent; the human health is guaranteed in the preparation and use process of the plywood; a veneer is firstly dried at low temperature, so that the water content is lower than the water content of a conventional veneer, the activity of the mould remained in the veneer is inhibited, the moulding is inhibited, the absorption of treatment solution in later treatment process is promoted, and the production efficiency is improved; and the dried veneer is put in sodium selenite solution for ultrasonic dipping, so that the sodium selenite solution is fully infiltrated in the veneer to inhibit growth of infectious microbes, the binding force of lignin to cellulose is reduced, the softness of the veneer is improved, breakage is prevented, and the machining performance and the use performance of the plywood are improved.

Owner:徐州市嘉翔木业有限公司

Method for improving corrosion resistance of wicker products

ActiveCN106182248AImprove organizational structureImprove insect and mildew resistanceRadiation/waves wood treatmentWood treatment detailsHigh humidityHardness

The invention discloses a method for improving corrosion resistance of wicker products. The method comprises the following steps: (1) skin removal of wickers, (2) softening treatment, (3) wicker weaving, and (4) anti-corrosion treatment. Various steps of the method are matched scientifically and reasonably, and the manufactured wicker products are good in insect prevention, mildew prevention and corrosion resisting effects and are high in surface hardness. Compared with the prior art, the method has the characteristics that the surface hardness of the wicker products can be improved by about 25%, the wicker products are used under the condition of high acid and alkali, the anti-corrosion time of the wicker products can be 4-5 times longer than the original anti-corrosion time, the service life can be prolonged by about 30% under the conventional using conditions, and can be prolonged by 40% or above under the condition of high humidity, use stability is good, anti-deformation ability is high, corrosion resistance is good, and use value is high.

Owner:阜南县猛发工艺品有限公司

Preparing method for bamboo strips used for bamboo craft weaving

ActiveCN106738155AImprove toughnessIncrease elasticityWood treatment detailsReed/straw treatmentChemistry

The invention discloses a preparing method for bamboo strips used for bamboo craft weaving. The preparing method includes the following steps that firstly, a bamboo tube is put into first soaking liquid to be subjected to primary soaking for 1-2 days under the temperature ranging from 50 DEG C to 60 DEG C; secondly, the bamboo tube obtained after primary soaking is subjected to freezing treatment; and thirdly, the frozen bamboo tube is put into a second soaking solution to be subjected to secondary soaking for 1 h to 3 h under the temperature ranging from 50 DEG C to 60 DEG C, and the bamboo strips are obtained. The bamboo strips treated through the preparing method have good flexibility and are very suitable for weaving of various crafts.

Owner:GUANGXI POLYTECHNIC

Molding and color changing preventing treatment method for rubber wood panel

InactiveCN106182275AImprove mildew resistanceEnhanced anti-tarnish propertiesRadiation/waves wood treatmentWood treatment detailsEngineeringColor changes

The invention discloses a molding and color changing preventing treatment method for a rubber wood panel. The method comprises the first step of treating fluid preparing and the second step of molding and color changing preventing treatment. Various steps in the method are matched scientifically and reasonably, the molding and color changing preventing performance of the rubber wood panel is excellent, and under the normal usage condition, the phenomena of molding and color changing of the rubber wood panel cannot happen in ten years. The rubber wood panel has the light traditional Chinese medicine scent, the immunity of the human body can be improved when the rubber wood panel is used in living homes, and the using value is high.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

Bamboo chip softening treatment method

InactiveCN106166778AGood flexibilitySuitable for compilationWood treatment detailsWood cryogenic treatmentSaline waterAlcohol

The invention discloses a bamboo chip softening treatment method, and belongs to the technical field of manufacture of bamboo products. The bamboo chip softening treatment method includes the steps: firstly, placing bamboo chips into a refrigeration house and freezing the bamboo chips for 5-8 hours at the temperature ranging from -5 DEG C to 0 DEG C; secondly, taking out the bamboo chips, placing the cold bamboo chips into soaking fluid at the temperature of 50-60 DEG C, and soaking the bamboo chips for 1-2 hours in a heat retaining manner under the ultrasonic condition of 80W power and 50Khz frequency; thirdly, taking out the bamboo chips and rinsing the bamboo chips with 0.9wt% saline water at the temperature ranging from -5 DEG C to 0 DEG C. The soaking fluid is prepared by mixing 50 parts of absolute ethyl alcohol, 2 parts of cardanol, 1 part of zinc stearate and 100 parts of deionized water with electric conductivity lower than 5muS / cm in parts by weight. The bamboo chips treated by the method have excellent softness and are quite suitable for fabricating various handicrafts.

Owner:三江县善茶轩工艺品有限公司

Method for utilizing dendrocalamus affinis leaves to process zongzi wrapping leaves

ActiveCN106142268ACultivation is simpleHigh economic valueLiquid surface applicatorsWrappersFood safetyCopper

The invention discloses a method for utilizing dendrocalamus affinis leaves to process zongzi wrapping leaves. Dendrocalamus affinis leaves are adopted as a processing material for zongzi wrapping leaves. The method comprises the technological processes of dendrocalamus affinis leaf picking, green color protecting through a green-preserving agent, sorting and stacking, ultralow temperature freezing treatment, drying, and discharging and dampening, wherein the green color protecting technology comprises the steps of placing the leaves in sodium copper chlorophyllin to be soaked for 20 min, and then, placing the soaked leaves into an electrochemical device to be subjected to electrochemical treatment. According to the method, the dendrocalamus affinis leaves can be utilized to supplement the zongzi wrapping leaf resource, and the contradiction between supply and demand is relieved; the green color of the zongzi wrapping leaves is achieved through utilizing the sodium copper chlorophyllin, and the food safety problem is avoided; and the reaction is promoted through adopting an electrochemical manner.

Owner:CHONGQING ACADEMY OF FORESTRY SCI

Methods and devices for evaluating the contents of materials

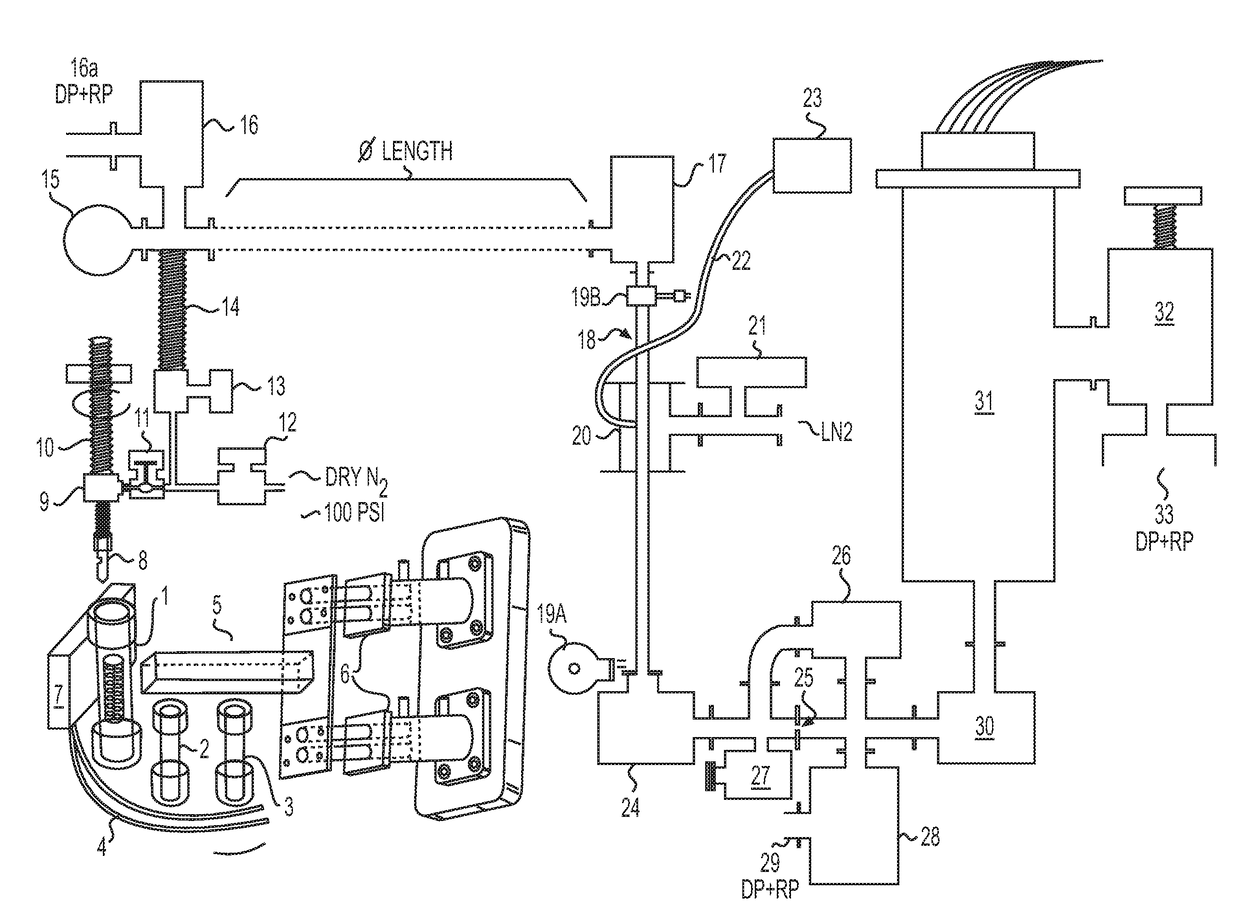

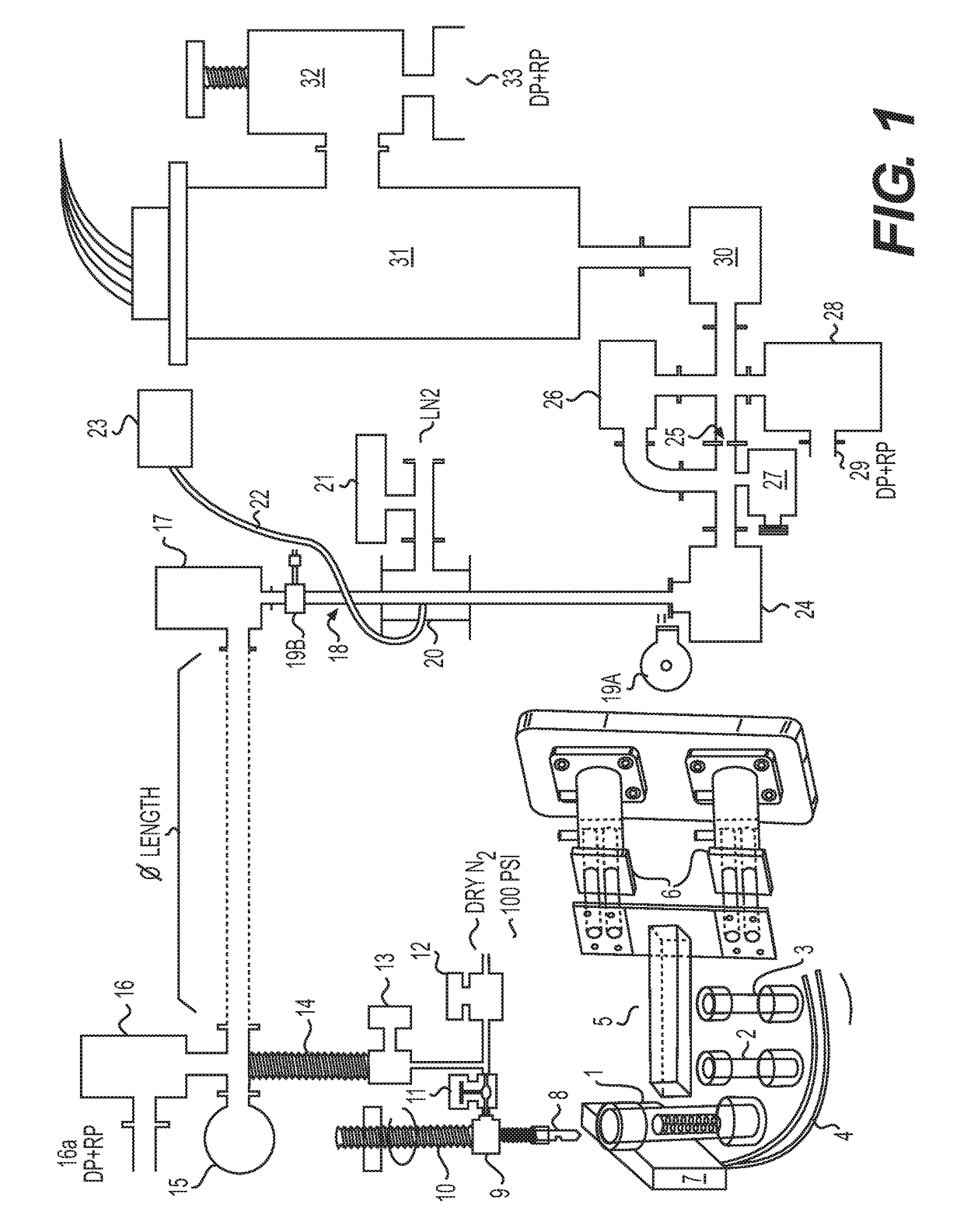

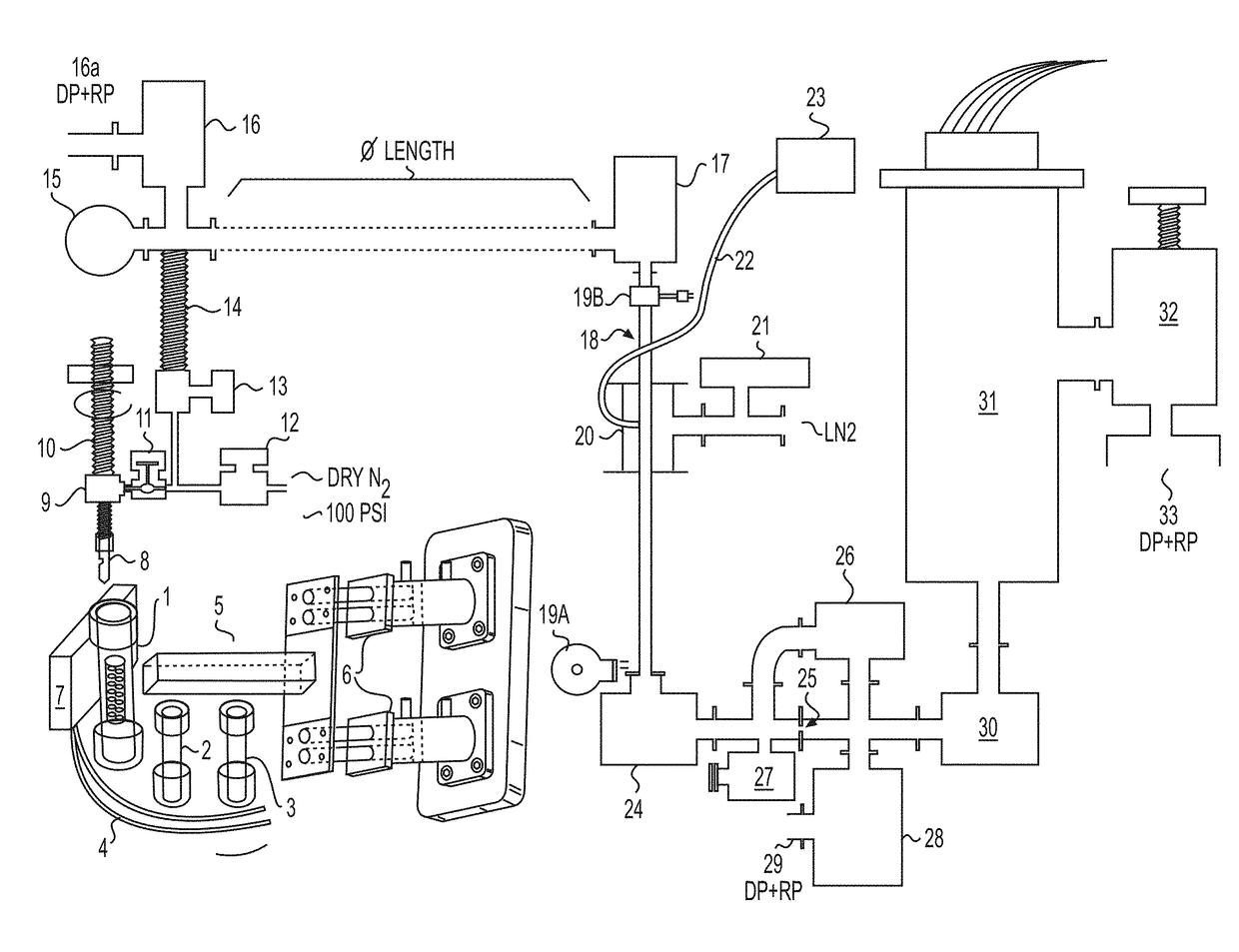

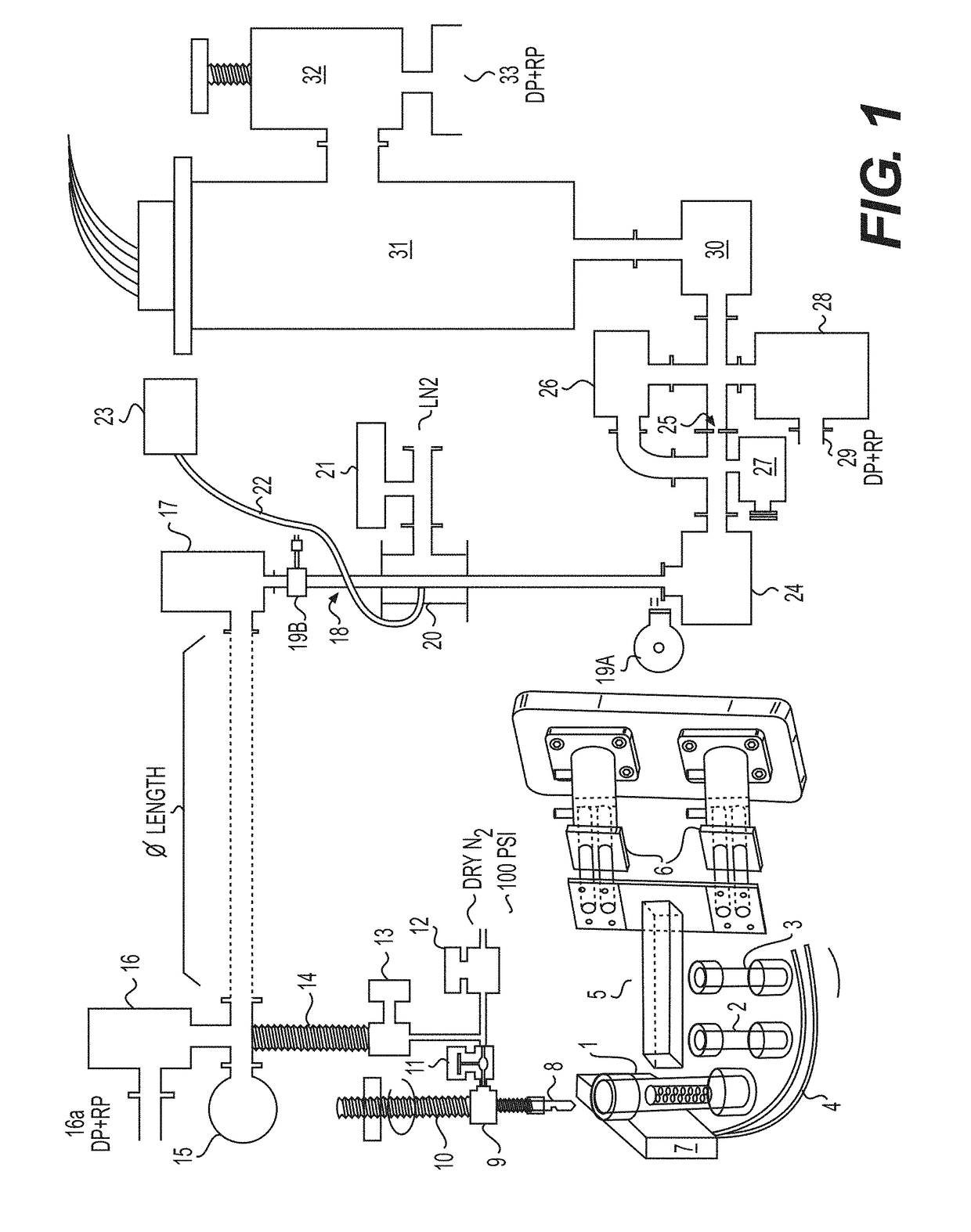

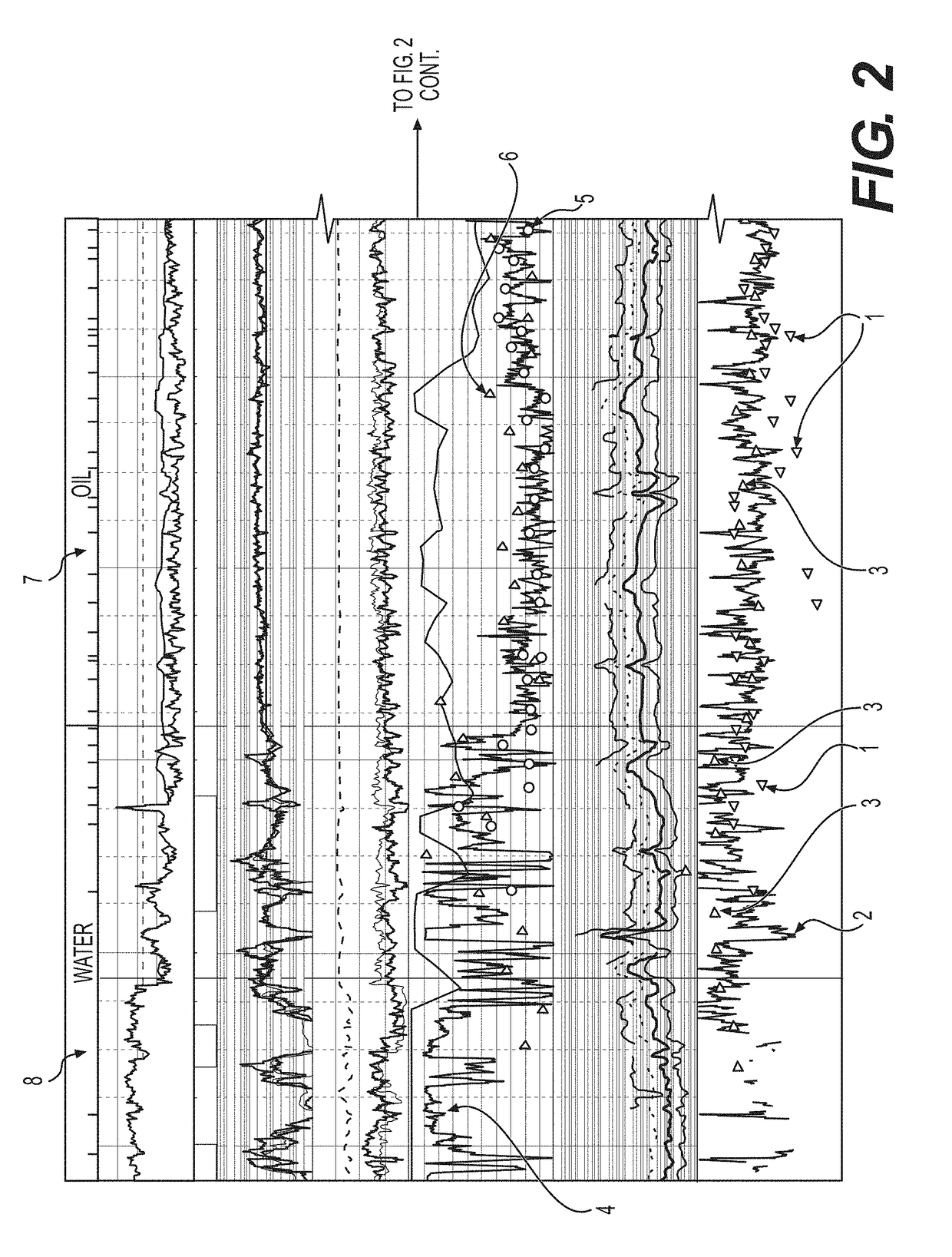

ActiveUS20180195383A1Reduce pressureEliminate gasWithdrawing sample devicesMaterial strength using tensile/compressive forcesHardnessPetroleum

Methods for determining the hardness and / or ductility of a material by compression of the material are provided as a first aspect of the invention. Typically, compression is performed on multiple sides of a geologic material sample in a contemporaneous manner. Devices and systems for performing such methods also are provided. These methods, devices, and systems can be combined with additional methods, devices, and systems of the invention that provide for the analysis of compounds contained in such samples, which can indicate the presence of valuable materials, such as petroleum-associated hydrocarbons. Alternatively, these additional methods, devices, and systems can also stand independently of the methods, devices, and systems for analyzing ductility and / or hardness of materials.

Owner:SMITH MICHAEL P

Softening process method of willow twigs

InactiveCN106217562APenetrate fastImprove anti-corrosion performanceWood treatment detailsReed/straw treatmentTwigWillow

The invention discloses a softening process method of willow twigs. The softening process method of the willow twigs comprises the following steps of (1) pre-processing the willow twigs, (2) pre-drying the willow twigs. (3) preparing a mixed process liquid. (4) primarily soaking and drying, (5) primarily deforming at a low temperature, (6) secondarily soaking and drying, (7) secondarily deforming at a low temperature, and (8) preserving heat and drying. According to the method provided by the invention, the softening process effect is uniform, the phenomena such as breakage and cracking during weaving can be well prevented, the yield of the processed willow twigs is high and can achieve more than 98.2 percent, and the weaving speed can be improved by 10 to 15 percent, so that the softening process method of the willow twigs has a better use value.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

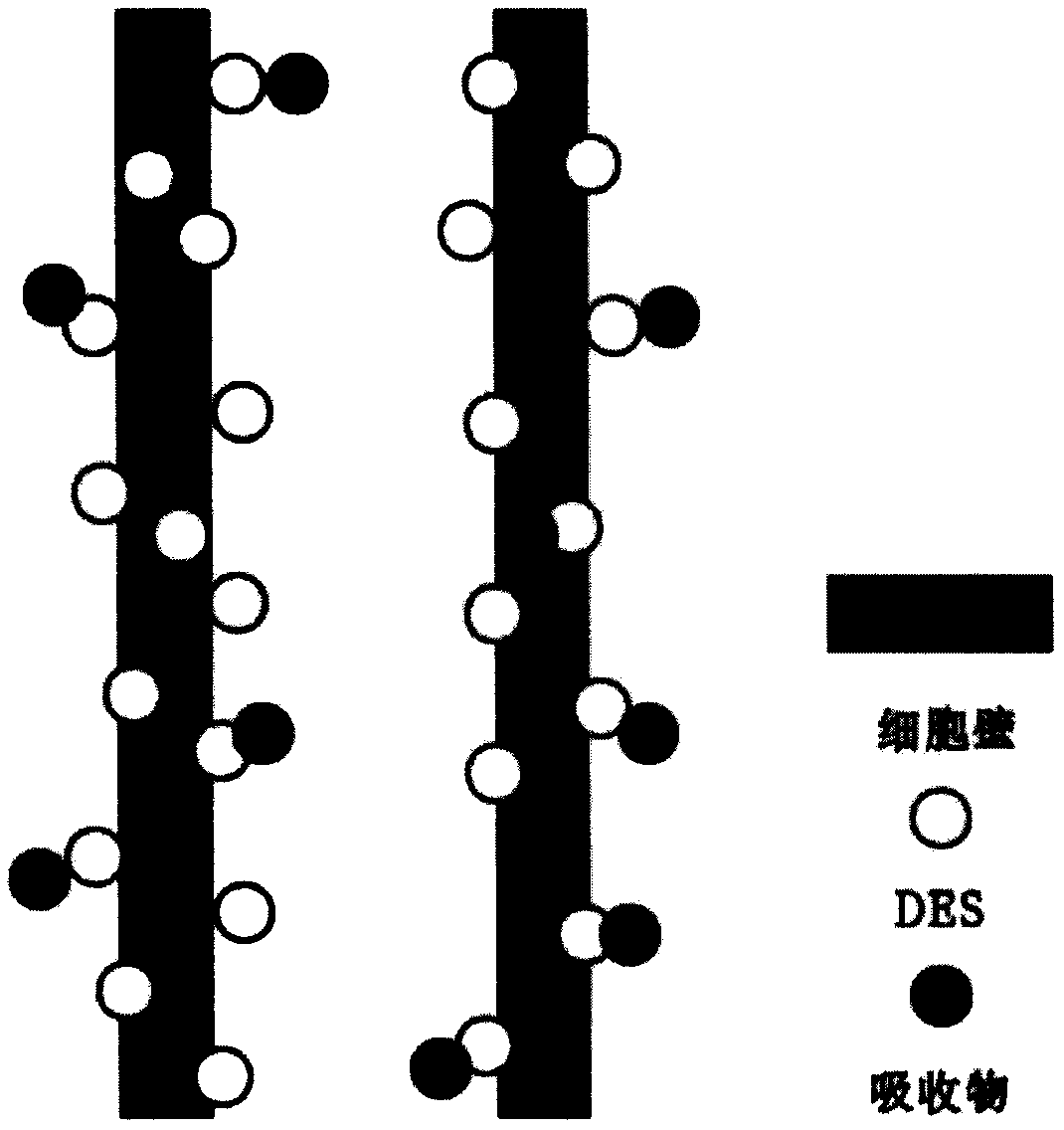

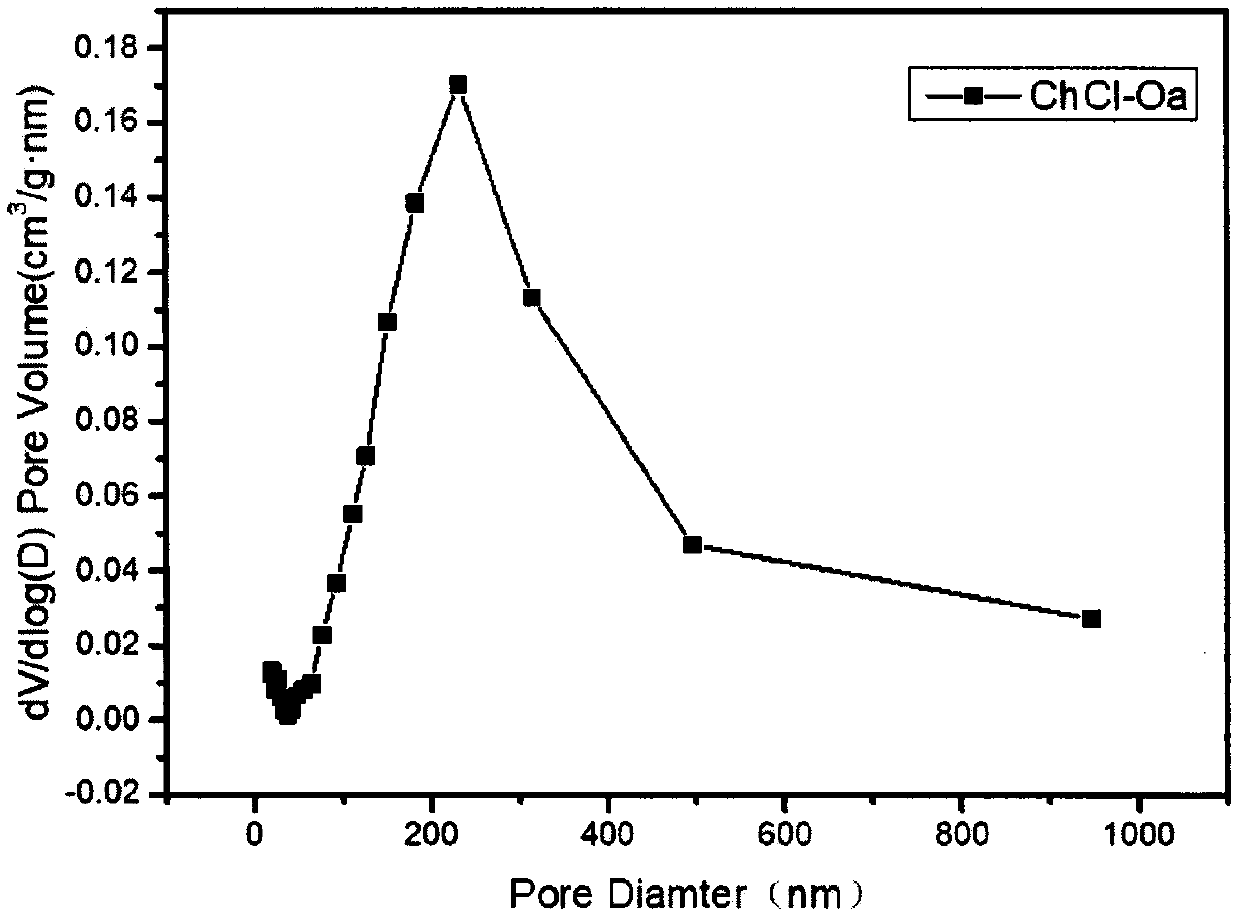

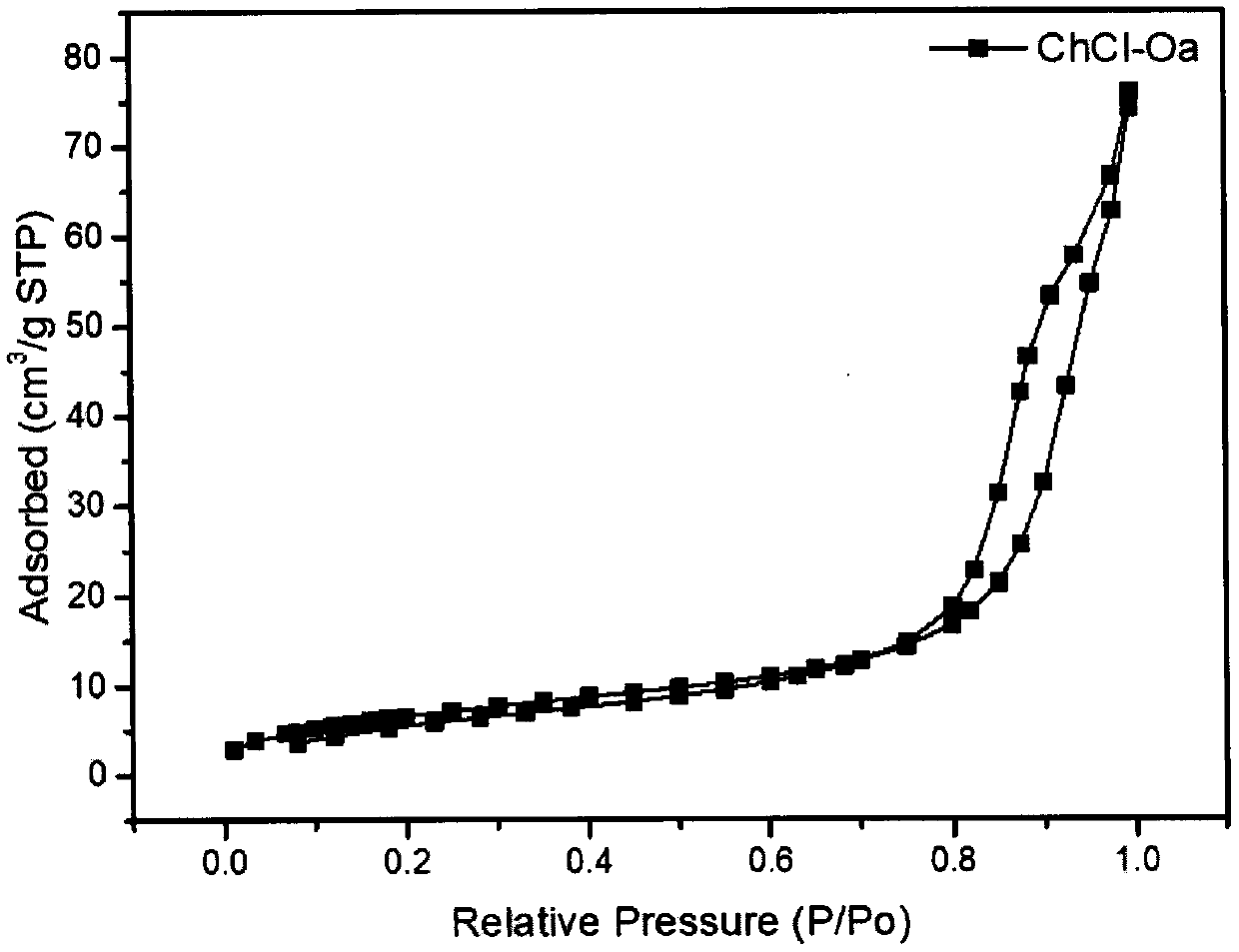

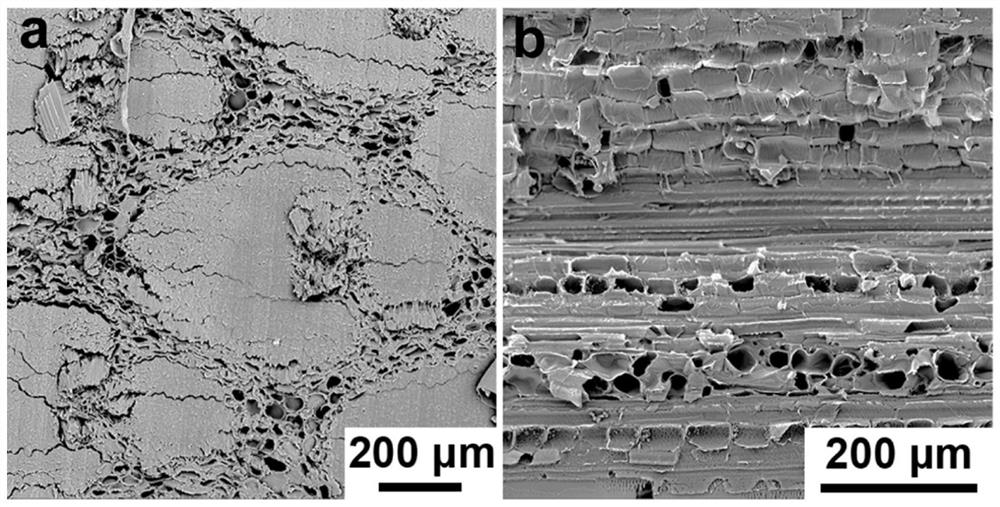

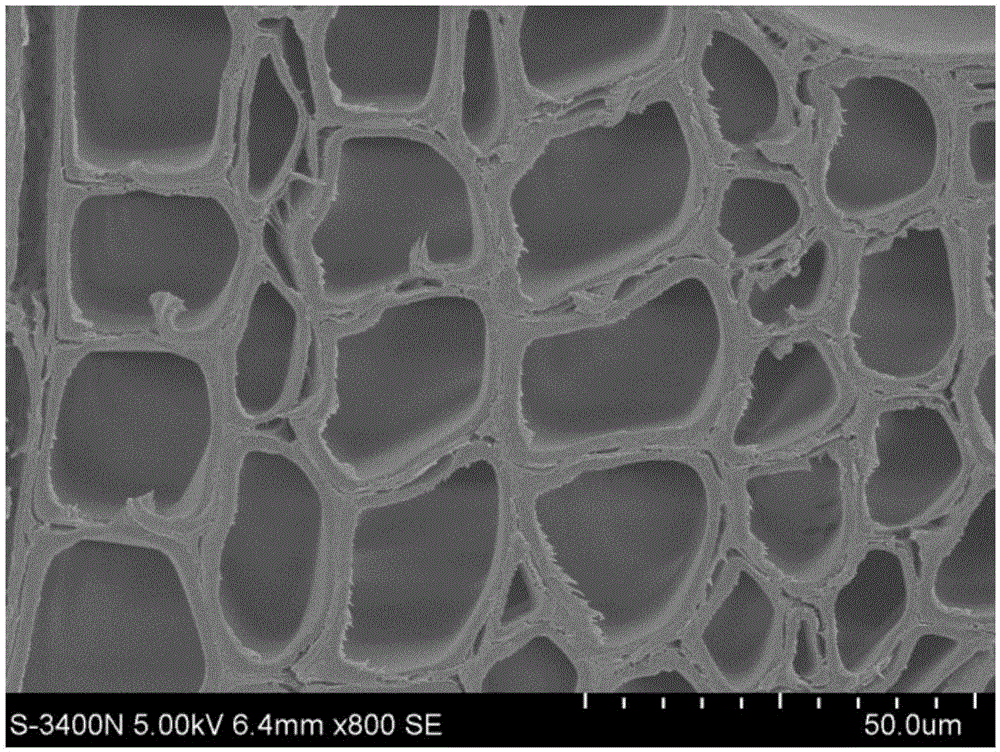

Preparation method of porous structure functional wood base material

ActiveCN110171044ADissolved and separated wellStrong hydrogen bondWood treatment detailsWood cryogenic treatmentPorosityResource utilization

The invention discloses a preparation method of a porous structure functional wood base material. The preparation method comprises the following steps: heating choline chloride and binary acid at thetemperature of 60 to 90 DEG C for 0.5 to 2 h to synthesize an eutecticevaporate solvent (DES), then carrying out immersion treatment on wood at the temperature of 60 to 120 DEG C for 4 to 10 h so as to remove lignin and hemicellulose, then adding H2O2 and adjusting pH value to be 9 to 11with a NaOH solution, and finally carrying out freeze drying to obtain the porous structure wood base material.The preparation method is characterized in that the preparation technology is simple, environmentally-friendly, low in cost and free of subsequent treatment problem; the obtained wood base material ishigh in porosity, reasonable in hole structure distribution, moderate in hole diameter, low in density and excellent in adsorption performance; and the used DES reaction reagent can be used repeatedly, the removed lignin can be recycled, and the utilization rate of resources is improved. The porous structure functional wood base material can perform corresponding modification treatment accordingto different requirements, and is applied to the fields of buildings, medicine, sewage purification and the like.

Owner:林扬东方(北京)科技有限公司

Wood processing and arranging method

ActiveCN107175738ASo as not to damageControl gas productionWood treatment detailsPretreatment apparatusTime rangeRoom temperature

The invention discloses a wood processing and arranging method. Wood is cut and dried; the wood is soaked in an aqueous solution of a composite loosening agent with the mass concentration being 20% for 10 h to 20 h; the wood is refrigerated for 12 h under the condition of -4 DEG C; the frozen wood is put under the room temperature to be naturally unfrozen; a treatment solution is prepared; the unfrozen wood is put into a closed soaking tank, the soaking tank is full of a treatment solvent, the temperature is increased to range from 60 DEG C to 80 DEG C, and the soaking time ranges from 10 h to 20 h; and the wood is subjected to standing to be cooled to the room temperature, the treatment solvent is discharged out, the treatment solvent on the surface of the wood is cleared away, and the wood is dried. By means of the aqueous solution of the composite loosening agent, the wood is soaked, the composite loosening agent can generate bubbles, and therefore a loosening function can be achieved on the interior of the wood through the bubbles, and permeation of more treatment solution is achieved in the treatment solution permeation process. Then refrigerating is carried out, the density of ice is smaller than that of water, besides clearances between the wood are eliminated, the sizing function can be achieved, and a later treatment agent can enter the wood more smoothly.

Owner:浙江润格木业科技有限公司

Treatment method capable of improving flexibility of osier

InactiveCN107471374AGood flexibilityEnhance aggregation abilityRadiation/waves wood treatmentWood treatment detailsCelluloseMicrowave

The invention belongs to the technical field of willow artwork, and particularly discloses a treatment method capable of improving the flexibility of osier. The treatment method specifically comprises the following steps: (1) ethanol solution soaking, constant-temperature fermentation and variable-temperature freezing treatment; and (2) microwave drying, vacuum soaking and variable-temperature drying treatment. According to the treatment method disclosed by the invention, pretreatment is carried out at first, and ethanol molecules are enabled to permeate into cellulose as protective mediums, so that the aggregation capacity among cellulose molecules is effectively improved, and the strength of the osier is effectively increased; and then the microwave drying and the vacuum soaking for a treatment liquid are carried out, the permeation time of the treatment liquid is effectively shortened, and the permeation efficiency is increased, so that the treatment liquid is capable of permeating into osier bark to soften and enable the bark to be closely bonded with an inner wood layer, bark peeling is avoided, high flexibility is achieved, the occurrence of a cracking phenomenon in a weaving process is effectively prevented, the weaving difficulty of the osier is lowered, the high-temperature-resistant and sun-screening capacity of the osier is improved, and the service life of the osier is effectively prolonged.

Owner:阜南县金威工艺品有限公司

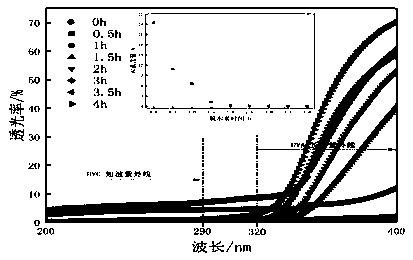

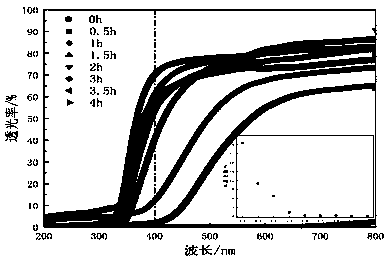

Preparation method of ultraviolet-shielding transparent wood

InactiveCN110154183AHigh optical transmittanceReduce harmWood treatment detailsPretreatment apparatusSupercritical dryingFiber

The invention discloses a preparation method of ultraviolet-shielding transparent wood. The preparation method comprises the following steps: firstly, pretreating wood sample to swell the wood samples, then treating the swelled wood samples by sodium chlorite and glacial acetic, and controlling a delignification process to obtain wood substrates with different lignin content; carrying out dehydration treatment on the sample by adopting an organic solvent gradient method, a freeze drying method or a supercritical drying method to further obtain dehydrated wood substrates with different lignin content; and carrying out dipping by using a pre-polymer which has a refractive index close to the fiber refractive index of a fiber and has high optical transmittance, and then carrying out curing. Through exploration of the ultraviolet shielding property of the transparent wood with different lignin content, the transparent wood with an ultraviolet shielding function is obtained. The obtained ultraviolet-shielding transparent wood has extremely good ultraviolet shielding characteristic and high light transmission, wherein the ultraviolet shielding effect reaches 90%, and light transmittance reaches 73% or above.

Owner:SHAANXI UNIV OF SCI & TECH

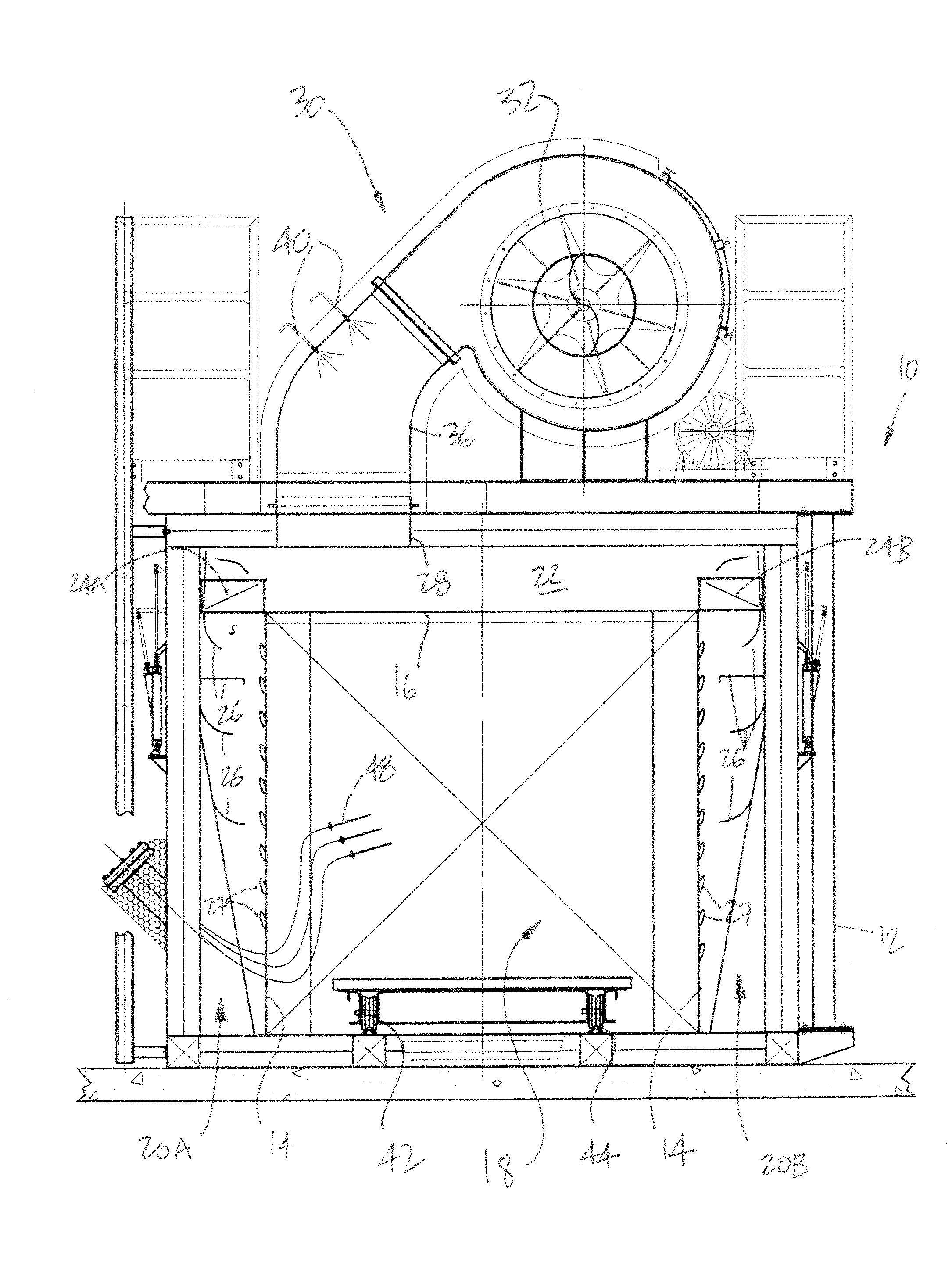

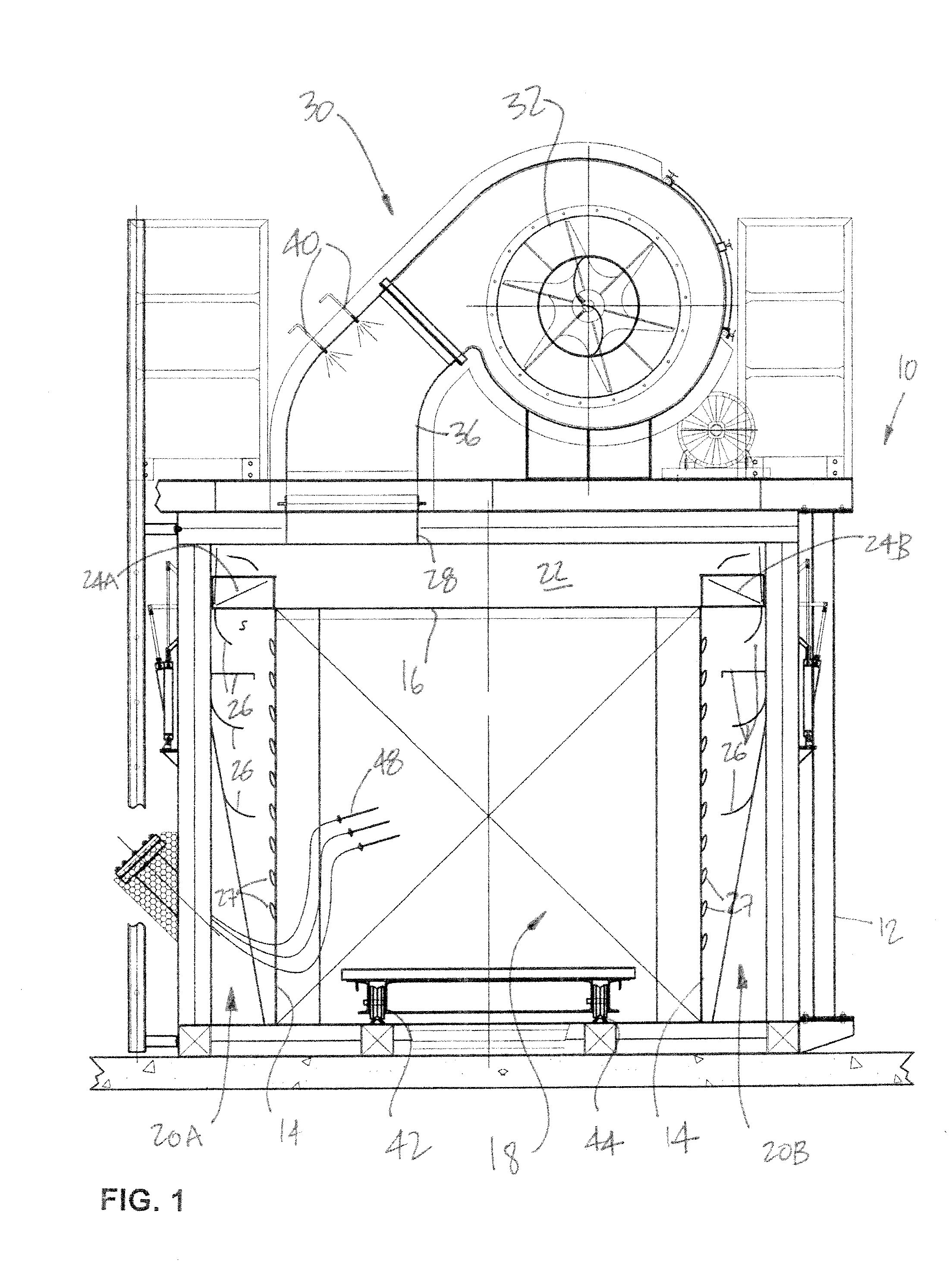

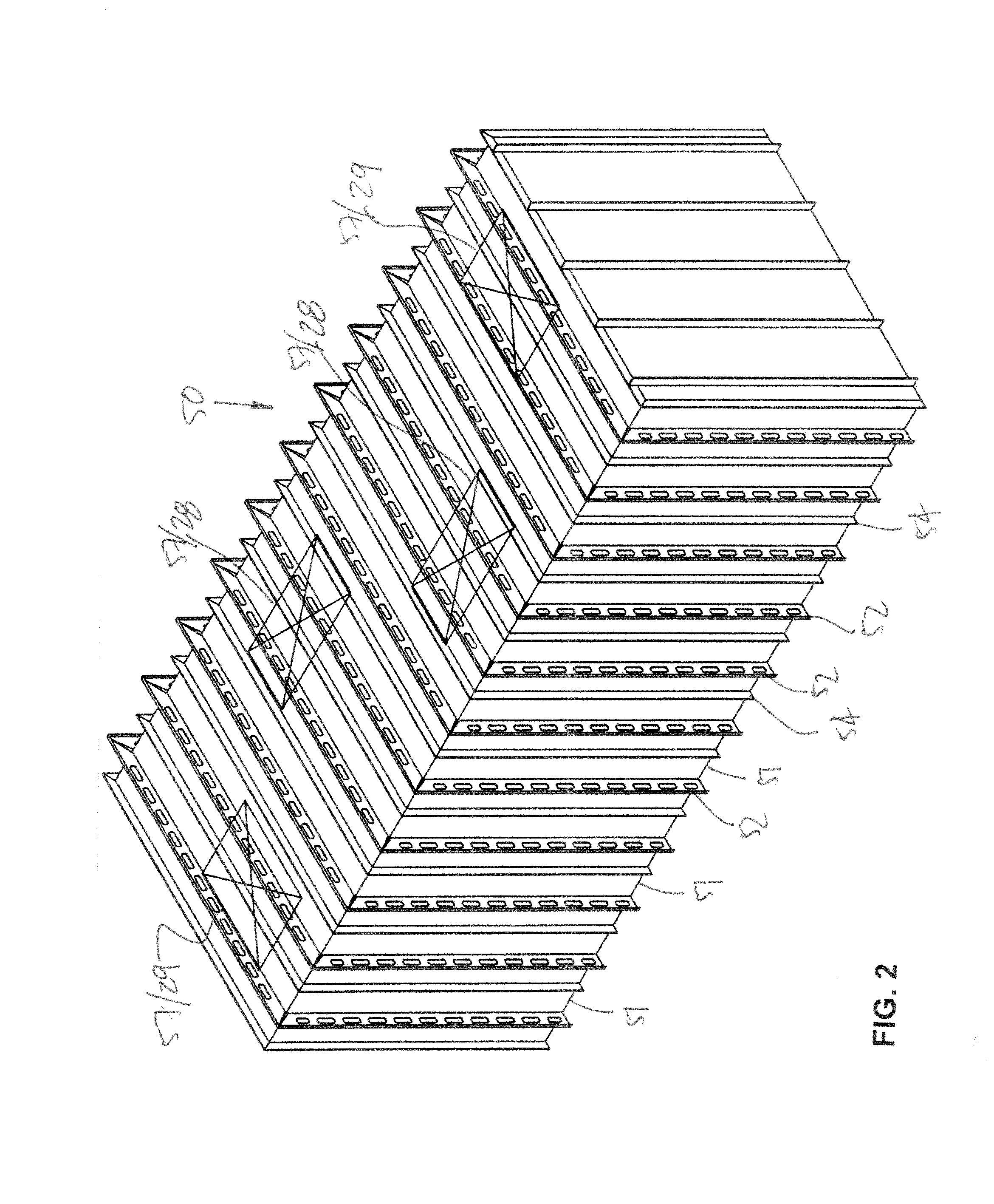

Apparatus and Method for Thermo-Transformation of Wood

An apparatus for thermo-transformation of wood planks comprises a chamber delimited by upright perforated walls, a top wall and end walls and having a closable entry for receiving wood planks into the chamber. A shell surrounds the chamber and is spaced therefrom to define a first vertical plenum with the first perforated wall, a second vertical plenum with the second perforated wall, and a horizontal plenum with the top wall. A ventilation system is in fluid communication with the plenums to produce a flow of heated air in the plenums. Vanes are actuatable to close / open access to the vertical plenums, to allow heated air into at least one of the vertical plenums, through the chamber via the perforated walls, and out from at least the other of the vertical plenums, to return to the ventilation system. A method for the thermo-transformation of wood is also provided.

Owner:AIREX IND

Method for preventing deformation and cracking of pines

InactiveCN107379178APrevent deformation and crackingDeformation and cracking are easyImpregnation spraying apparatusWood treatment detailsFiberBatch processing

The invention mainly relates to the technical field of wood product processing, and discloses a method for preventing deformation and cracking of pines. The method comprises arrangement, refrigeration, fermentation, primary drying, humidification and secondary drying; the method is simple and convenient in batch processing; no poisonous reagent is added in the treatment process to achieve safety and health; the water content of the treated pines is stable, and the water absorbing capacity is reduced, so that deformation and cracking are radically prevented, the service life is prolonged by 14.5%, and the use value of pine products is obviously improved; the cut pines are cut according to needed lengths; pine barks are retained; the protecting effect of the pine barks is improved, so that the color change in the pine treatment process is inhibited, and later unified bleaching treatment is convenient; and pine sections are put in a treatment chamber to gradually cool for refrigeration, so that the water in the pines is reduced under low-temperature environment, gaps among pine fibers are increased, the resistance of the pines to temperature and humidity is improved, the influence of environmental change to the pines is relieved, and deformation and cracking of the pines are prevented.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

High quality staining method for tables and chairs

ActiveCN107457860AImprove the quality of useExtended service lifeRadiation/waves wood treatmentWood treatment detailsStainingIrradiation

The invention discloses a high quality staining method for tables and chairs. The high quality staining method for tables and chairs comprises the following steps of: (1) surface treatment of a wood; (2) irradiation treatment; (3) acetylating treatment; (4) staining treatment; and (5) poikilothermic treatment. The staining method for tables and chairs is specially improved, so that the staining dye-uptake and the staining stability are effectively enhanced, the comprehensive using quality of the tables and chairs is enhanced and the service lives of the tables and chairs are prolonged, so that the high quality staining method for tables and chairs has very good promotional value and economical benefit.

Owner:安徽嘉美工艺品有限公司

Moth-resistant treating method for wicker straw

InactiveCN106272816AIncrease storage capacityHigh bonding strengthRadiation/waves wood treatmentWood treatment detailsMedicinePre treatment

The invention discloses a moth-resistant treating method for wicker straw. The method comprises the following steps: (1) pretreating straw raw materials; (2) preparing a moth-resistant treating solution; (3) modifying; (4) treating at low temperature; (5) repeatedly treating for the second time; (6) weaving at constant temperature. The straw treated according to the method provided by the invention has better moth-resistant and mold-proof characteristics, excellent flexibility, folding resistance, tensile strength and weaving property; the prepared products have the characteristics of environmental protection, safety and no harm to a human body; the service life of the products is 2-3 years longer than that of the products prepared according to the conventional method; the popularization value is higher.

Owner:FUNAN YONGXING ARTS & CRAFTS

Treatment method of wickerwork raw material wickers

ActiveCN107186846AAntioxidantThermally stableWood treatment detailsReed/straw treatmentAlkaline waterFiber

The invention relates to the technical field of wickerwork artware and discloses a treatment method of wickerwork raw material wickers. The method comprises the following steps that (1) newly-cut wickers are dewatered through natural drying, the high temper of the wickers is improved, heating treatment is conducted in alkaline water, thus peeling is facilitated, the glossiness of the wickers can be improved, and cold treatment is conducted after peeling; (2) the wickers subjected to cooling treatment are immediately steeped through a steeping solution A, the steeping solution can be rapidly adsorbed by fibers with negative charges under the effect of positive charges in the aqueous solution, a thin film is formed on the surface of each fiber, binding force among the fibers is reinforced, and shrinkage deformation of the fibers is prevented; and (3) the wickers are heated and baked in a drying oven after being steeped by the steeping solution A and then put into a steeping solution B for steeping, the steeping solution B has oxidation resistance and heat stability, connection points among the fibers are protected, and heating deformation of the fibers is prevented.

Owner:阜南县猛发工艺品有限公司

Preparation method of superhydrophobic wood sponge

InactiveCN110497492AUniform particlesLittle difference in hydrophobicityWood treatment detailsThermal wood treatmentAcetic acidWater baths

A preparation method of superhydrophobic wood sponge comprises the following steps: mixing a NaOH solution having a concentration of 2.3-2.6 mol / L with a Na2SO3 solution having a concentration of 0.3-0.5 mol / L according to a volume ratio of 1:1, immersing dried light wood blocks in the obtained mixed solution, and processing the wood under a boiling condition for 18-26 h; then immersing the wood into a sodium chlorite solution having a concentration of 1-2%, performing heating in a water bath at 80-95 DEG C, rinsing the wood, and freeze-drying the rinsed wood; and immersing the wood in a mixedsolution of ethanol, water, glacial acetic acid and methyltrimethoxysilane, processing the wood at 20-40 DEG C for 3-6 h, taking out the wood, carrying out vacuum drying at 30-70 DEG C for 1-2 h, anddrying the obtained wood at 90-130 DEG C. The superhydrophobic wood sponge prepared by the method has the advantages of high hydrophobicity, high porosity and strong adsorption performance, and can be used as an oil spill adsorption material to adsorb and purify polluted water.

Owner:BEIJING FORESTRY UNIVERSITY

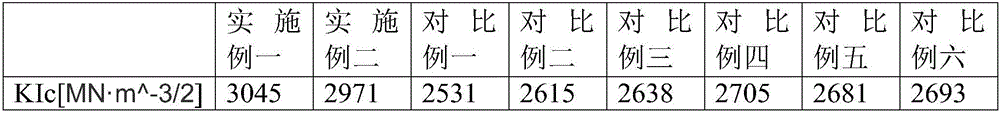

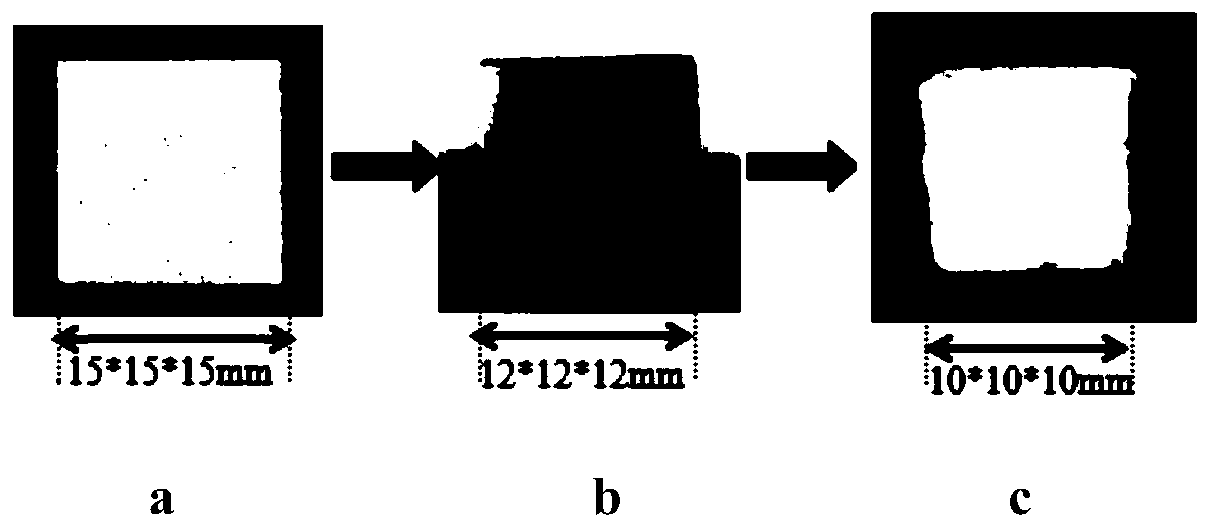

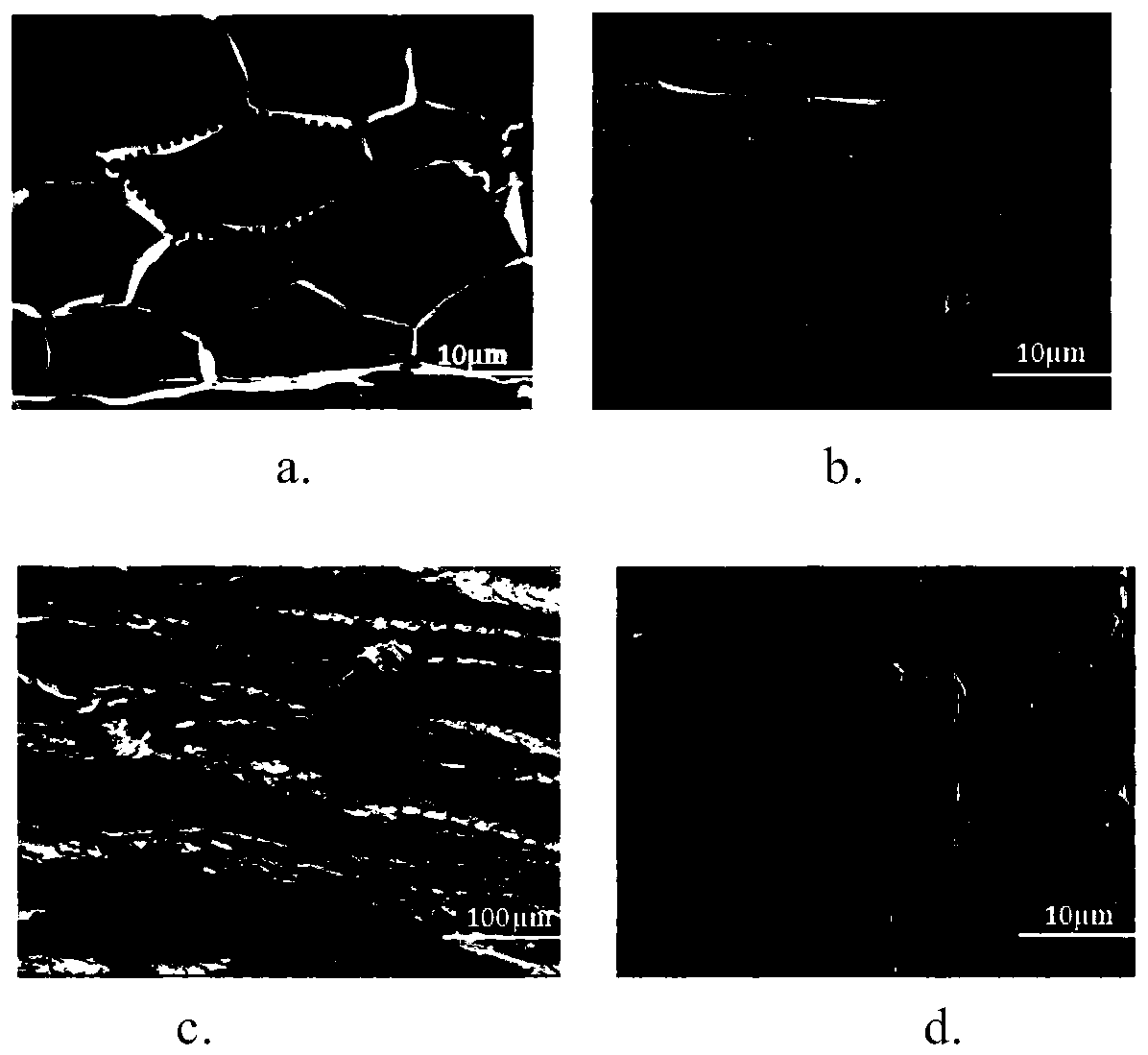

Preparation method of high-performance bamboo steel composite material

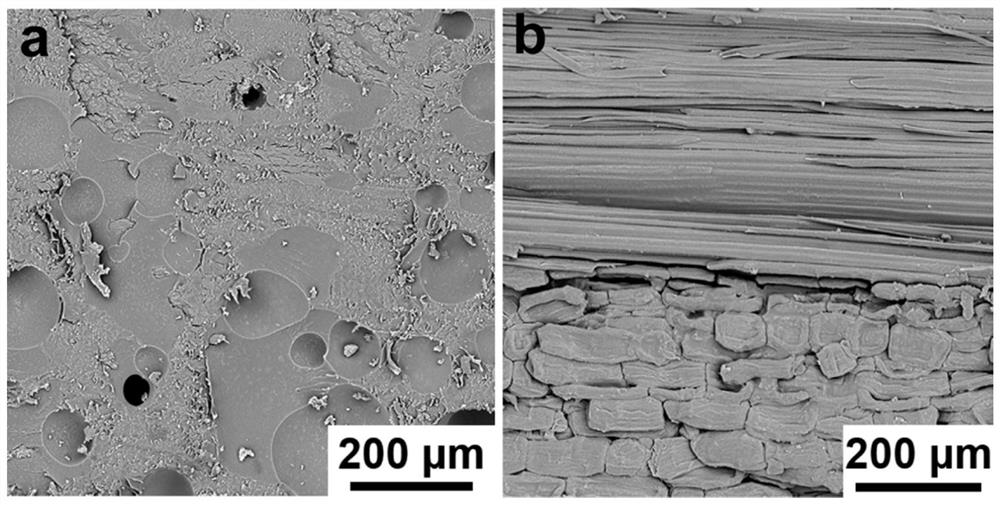

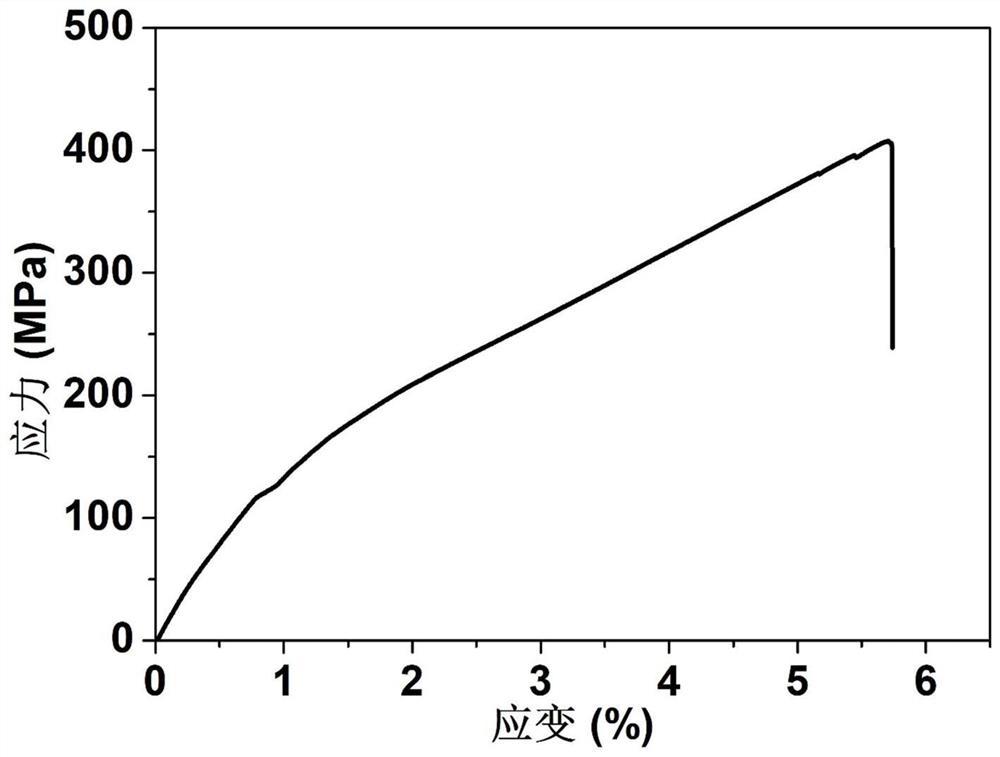

InactiveCN112356196ARemove completelyRetain natural colorWood compressionWood treatment detailsEpoxyFreeze-drying

The invention discloses a preparation method of a novel bamboo steel composite material, and belongs to the technical field of bamboo artificial boards and bamboo engineering materials. The method comprises the following steps: (1) removing lignin and hemicellulose in the bamboo wood by a two-step method, (2) breaking through a pore structure in the bamboo wood by using a freeze-drying process, (3) carrying out vacuum impregnation epoxy resin treatment on an obtained bamboo wood framework, and (4) carrying out hot-pressing curing to realize densification of the bamboo wood, thereby obtaining the bamboo-steel composite material with high fiber content. The bamboo steel material provided by the invention has the advantages of high bamboo utilization rate, excellent mechanical properties, high dimensional stability, low thermal conductivity and the like, and is expected to be applied to the fields of energy-saving buildings, bridges, transportation, aerospace and the like.

Owner:CHONGQING UNIV

Methods and devices for evaluating the contents of materials

ActiveUS20180306031A1Reduce pressureEliminate gasWithdrawing sample devicesMaterial strength using tensile/compressive forcesHardnessPetroleum

Methods for determining the hardness and / or ductility of a material by compression of the material are provided as a first aspect of the invention. Typically, compression is performed on multiple sides of a geologic material sample in a contemporaneous manner. Devices and systems for performing such methods also are provided. These methods, devices, and systems can be combined with additional methods, devices, and systems of the invention that provide for the analysis of compounds contained in such samples, which can indicate the presence of valuable materials, such as petroleum-associated hydrocarbons. Alternatively, these additional methods, devices, and systems can also stand independently of the methods, devices, and systems for analyzing ductility and / or hardness of materials.

Owner:SMITH MICHAEL

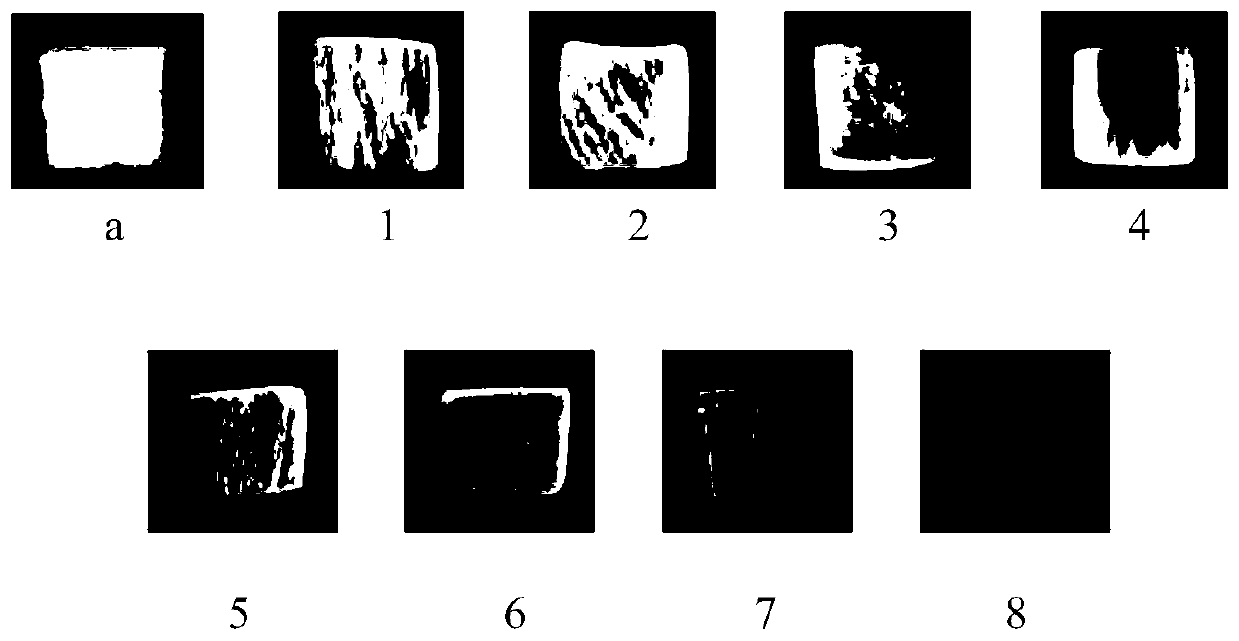

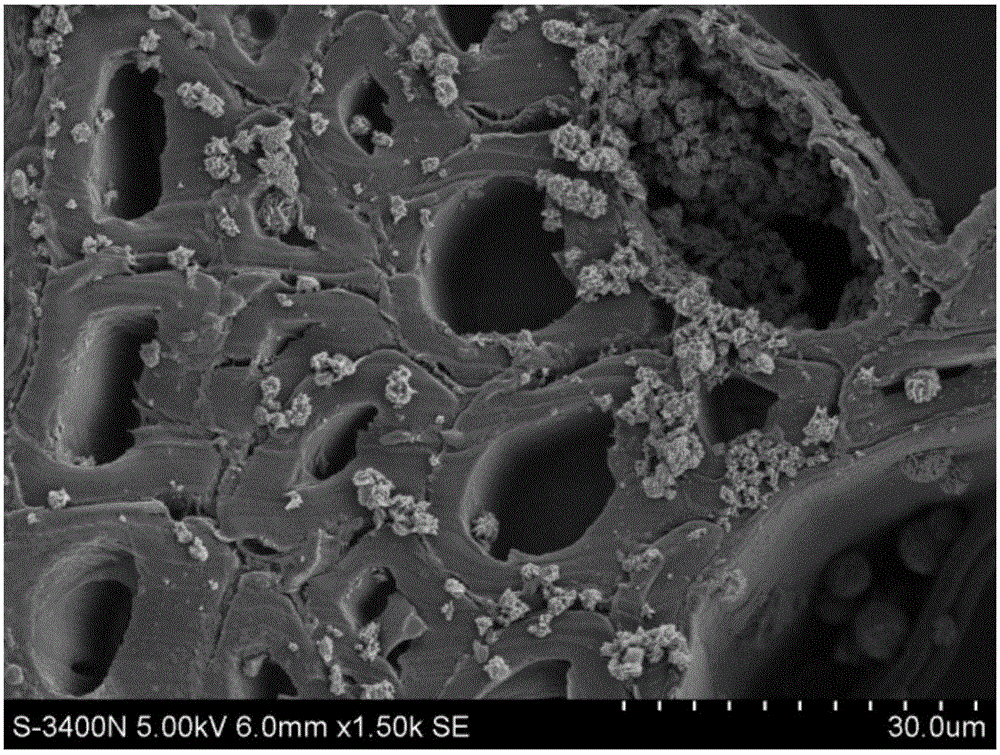

Bamboo multi-micropore treatment method as well as product and application

InactiveCN107175739ADredge the internal structureAchieving a microporous structurePressure wood treatmentWood treatment detailsPorosityFreeze-drying

The invention belongs to the technology of wood science and technology specialty emphasis in the forestry engineering field, and particularly relates to a bamboo multi-micropore treatment method as well as a product and an application. The bamboo multi-micropore treatment method comprises the following steps of: (1) taking materials; (2) performing saturated water treatment: performing saturated water treatment on bamboo; (3) performing pre-freezing treatment: cooling treated bamboo and preserving the heat; (4) performing freezing treatment: freezing bamboo treated in step (3); (5) performing vacuum drying: performing vacuum drying on the bamboo treated in step (4); and (6) storing: performing sealing storage on the bamboo treated in step (5). The bamboo has porosity of 57%-83%, and moisture content of 6%-12%. Subsequent processing for the bamboo comprises the following steps of: bamboo drying, bamboo recombining and bamboo anti-corrosion mildew-proof treatment. The bamboo is treated through special means, and the freeze-dried bamboo is processed subsequently, so that the multi-micropore structure of the bamboo is realized, and permeability of the bamboo is improved.

Owner:国家林业局竹子研究开发中心

Preparing method for antibacterial and ultraviolet-resisting wood and obtained product

InactiveCN106003309AImprove thermal stabilityHas broad-spectrum antibacterial propertiesWood treatment detailsPressure impregnationNanoparticleUltraviolet

The invention provides a method for preparing antibacterial and anti-ultraviolet wood, comprising sequentially using wood impregnating solution A and wood impregnating solution B to impregnate wood, wherein the wood impregnating solution A is an aqueous solution of zinc salt, and the wood impregnating solution B Aqueous solution of alkali. The invention also proposes the material prepared by the preparation method. The wood treatment process proposed by the present invention uses a wet chemical method to generate nano-zinc oxide in situ inside the wood. The binding force between the nano-particles and wood components is strong, it is not easy to be lost, and the modification effect is long-lasting. The wood treatment method can not only endow the wood with excellent antibacterial properties and anti-ultraviolet properties, but also has good thermal stability.

Owner:BEIJING FORESTRY UNIVERSITY

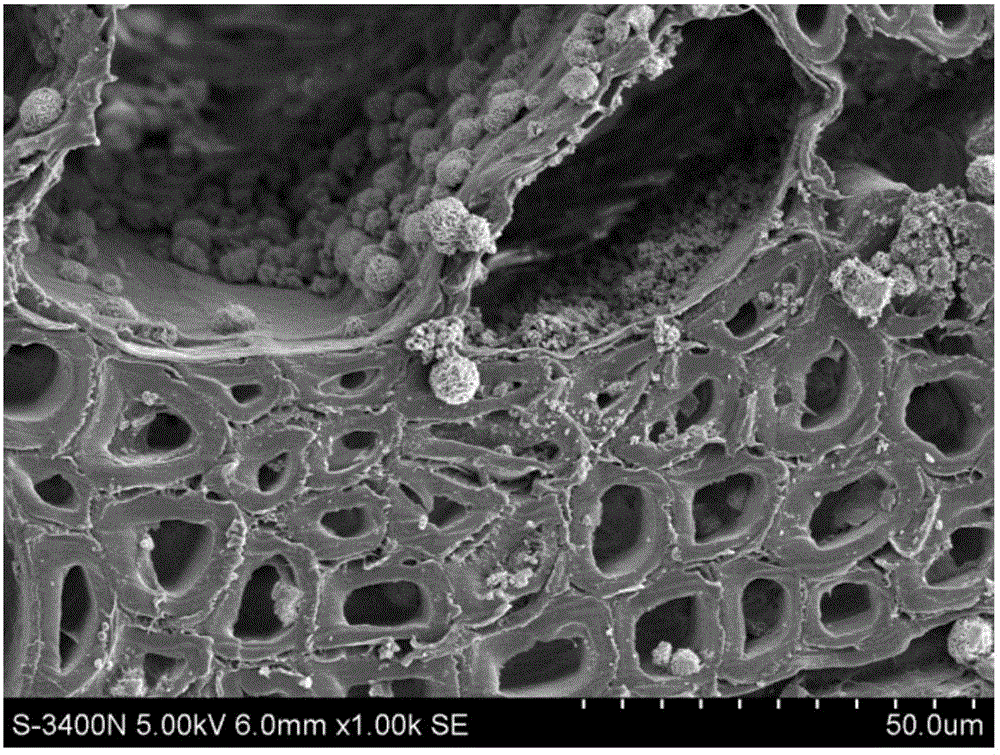

Preparation method of conductive wood aerogel

ActiveCN113119256AAchieving continuous loadHigh purityWood treatment detailsWood cryogenic treatmentAlcoholPolypyrrole

The invention discloses a preparation method of a conductive wood aerogel. The preparation method comprises the following steps: slicing wood in the direction perpendicular to the growth direction, and obtaining a cross section wood base plate; immersing the substrate into a delignification buffer solution, and heating to carry out delignification treatment; soaking the obtained delignification wood base plate in a ferric chloride solution, and then performing freeze drying; sealing the obtained sample and a pyrrole solution together, and performing in-situ synthesis of polypyrrole in wood cell walls by using an in-situ chemical vapor deposition method; then, soaking the sample in a mixed solution of silver nitrate, dimethyl sulfoxide and sodium citrate, wherein dimethyl sulfoxide serves as a reducing agent, sodium citrate serves as a complexing agent, silver nanoparticles are generated on the surface of polypyrrole in situ, the sample is washed in ethyl alcohol, and thus the conductive wood aerogel is obtained. The method is simple in preparation process, mild in reaction condition and beneficial to industrial production, and can be widely applied to the fields of electricity, antibiosis, electromagnetic shielding materials and the like.

Owner:BEIJING FORESTRY UNIVERSITY

Softening method capable of improving weaving performance of rattan

InactiveCN107283575AAvoid harmIncrease profitRadiation/waves wood treatmentWood treatment detailsMicrowaveSpoilage bacteria

The invention belongs to the technical field of rattan processing, in particular to a softening method for improving rattan weaving performance. The specific method is as follows: (1) put the harvested rattan into a freezer for constant temperature freezing, take it out, and treat it with constant temperature steam to obtain One-time treatment of rattan; (2) Immerse the primary treatment of rattan in the softening solution and pass it through ultrasonic waves for ultrasonic treatment, drain the liquid, wrap it with plastic wrap, put it in a refrigerator for constant temperature refrigeration, take it out, and uncover it (3) Microwave-dry the rattan for the second treatment; the rattan treated by the present invention has a bending angle of 80-81 degrees during weaving and use, which effectively reduces the difficulty of weaving, It saves time and labor, improves weaving efficiency, not only does not deform and crack, has strong bearing capacity, good dimensional stability, tensile strength, compression resistance and elastic strength have been greatly improved, but also can improve its antibacterial and anti-sunshine ability, and inhibit spoilage bacteria growth, prolonging its lifespan.

Owner:阜南县宏达工艺品厂

Method for wood color preserving and degreasing

ActiveCN107214800AImprove permeabilityGood degreasing effectPressure wood treatmentWood treatment detailsPre treatmentLiquid nitrogen

The invention relates to a method for wood color preserving and degreasing and belongs to the technical field of wood treatment. According to the method, to-be-degreased wood is soaked with water, sprayed with liquid nitrogen, frozen and dried to obtain dry wood; the dry wood is subjected to micro-blasting to obtain pre-treated wood; tea bran is ground, mixed with water, subjected to heating boiling and centrifugal treatment, and separated to obtain upper layer liquid, the upper layer liquid is concentrated to obtain concentrated liquid, and then the concentrated liquid, a sodium bicarbonate solution, potassium permanganate and the like are evenly stirred to obtain self-prepared degreasing color preserving liquid; and then the self-prepared degreasing color preserving liquid is put into a steam generator, the pre-treated wood is treated through steaming, and wood degreasing can be finished. Wood permeability is effectively improved, the wood degreasing rate is remarkably increased, and meanwhile the good color preserving effect is achieved.

Owner:安徽嘉美工艺品有限公司

Wicker flowerpot manufacturing method

InactiveCN107379163ADamaged will notIncrease moisture contentWood treatment detailsCane mechanical workingSaline waterWarm water

The invention discloses a wicker flowerpot manufacturing method. The wicker flowerpot manufacturing method includes the following steps that (1) wickers which are even in thickness and free of plant diseases and insect pests are harvested, paved and aired until leaves are dried up, and then the dried-up leaves are removed; (2) the wickers obtained after leaf removal are washed with saline water for impurity removal, are placed into warm water at the temperature ranging from 50 DEG C to 60 DEG C to be soaked for 30 minutes, and are taken out after soaking to be subject to wicker skin stripping; (3) the wickers obtained after skin stripping is dried with hot air at the temperature ranging from 30 DEG C to 40 DEG C until the water content of the wickers is lower than 10%; (4) the dried wickers are soaked with a made-to-order soaking solution at 40 DEG C for 4 hours, then wicker surfaces are thoroughly washed with clean water; the wickers treated through the above steps are woven into flowerpots; and (6) the woven flowerpots are placed into a refrigeration house for refrigeration for 5 hours, are taken to be directly placed into a made-to-order soaking solution at 60 DEG C for 2 hours and are taken out after soaking is finished, and the surfaces are thoroughly washed with clean water to obtain finished products.

Owner:ANHUI MEIJING ARTS & CRAFTS CO LTD

Making-old treatment method for wooden product

ActiveCN106182263AGood removal effectEasy to operateElectric wood treatmentWood treatment detailsMedicinePre treatment

The invention discloses a making-old treatment method for a wooden product. The method comprises the first step of wooden product pretreatment, the second step of making-old treatment and the third step of drying quality keeping treatment. The method is overall simple and high in treatment efficiency, and the making-old treatment can be finished in one day. Compared with the traditional treatment manners in which the making-old treatment is finished in at least one week and even in one month, the work efficiency is greatly improved, and the manufacturing cost is reduced. The surface of the wooden product subjected to making-old treatment is smoother and more compact, the humidity resistance is better, and the water absorbing rate is reduced by about 15%. During using, the cracking rate is reduced by about 20%, the durable duration of the wooden product is prolonged by 10% or more, and the using value is high.

Owner:阜南县猛发工艺品有限公司

Method for improving moisture-proof and waterproof performance of palm leaves

InactiveCN108748510AImprove waterproof and moisture-proof performanceImprove weaving utilizationWood treatment detailsOpen tank impregnationPropolisEngineering

The invention belongs to the technical field of weaving, and particularly relates to a method for improving the moisture-proof and waterproof performance of palm leaves. The method comprises the following steps that (1) the harvested palm leaves are immersed in chitosan solution for heat preservation and immersing, the palm leaves are taken out after the solution drains, and the palm leaves are subjected to high-temperature high-pressure steam treatment and then cooling treatment; (2) the palm leaves are placed into an electric field for electric field treatment and are immersed in an impregnating agent for immersing, the palm leaves are taken out after the agent drains, wherein the impregnating agent is prepared from the following raw materials of propolis, alkyl glycoside, sodium alginate, coagulating polysaccharide, kaolin, sodium chloride, borax and water; and (3) the palm leaves is subjected to constant-temperature freezing treatment, and is dried to constant weight. According tothe method, the surfaces of the palm leaves can be effectively isolated from the outside environment, a woven product of the palm leaves is protected from being influenced by an external rainwater moist environment, a high-efficiency moisture-proof and waterproof effect is achieved in daily use, the service life is prolonged, moreover, the phenomena of cracking or breakage in the weaving and usingprocesses are effectively avoided, and the weaving utilization rate of the palm leaves is greatly improved.

Owner:阜南县富昌恒业工艺品有限公司

Preparation method for anti-bending bamboo-wood composite board

ActiveCN107696217AHigh bonding strengthImprove toughnessWood treatment detailsLaminationAdhesiveFreeze and thaw

The invention discloses a preparation method for an anti-bending bamboo-wood composite board and belongs to the technical field of construction boards. According to the preparation method for the anti-bending bamboo-wood composite board, wood-destroying fungi and a culture medium are stirred, mixed, cultivated and activated, and a wood-destroying fungus solution is obtained; bamboo splits are soaked in the wood-destroying fungus solution, a freezing and thawing cycle is conducted, and preprocessed bamboo splits are obtained; the bamboo splits are dried, glued, hot-pressed, cooled and cut, andsurface boards are obtained; selected wood is smashed, so that wood chips are obtained; the wood chips are soaked in the wood-destroying fungus solution, taken out and subjected to the freezing and thawing cycle, and preprocessed wood chips are obtained; the preprocessed wood chips are dried, mixed with glue, hot-pressed, cooled and cut, and a block board is obtained; and one surface board, adhesives, the block board, adhesives and the other surface board are assembled, hot-pressed and cooled, and then the anti-bending bamboo-wood composite board is obtained. The bamboo-wood composite board has the excellent anti-bending performance and bonding strength.

Owner:佛山市南海区狮山冠锋木业制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com