Preparation method of conductive wood aerogel

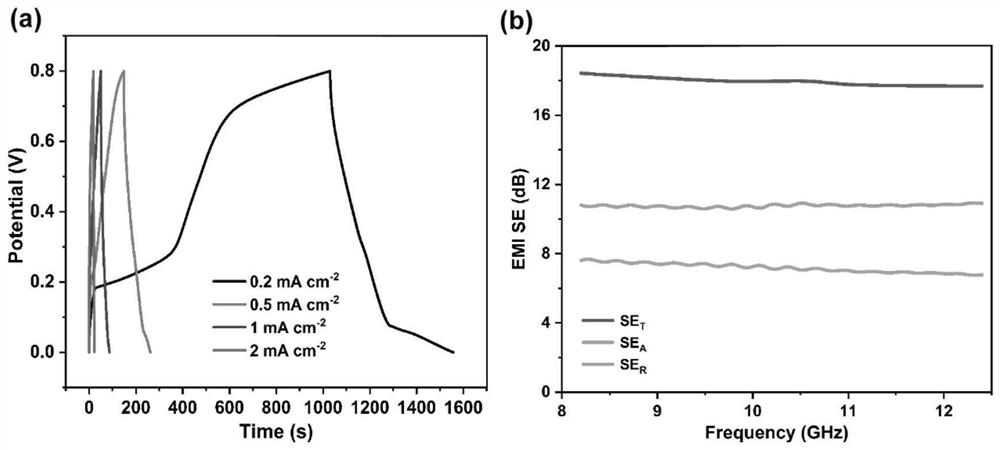

An airgel and wood technology, applied in wood treatment, wood heating, impregnating wood, etc., can solve the problems of complex preparation process and no consideration of multi-functional application of materials, etc., to achieve extensive sources, excellent electromagnetic shielding performance, and enhanced electrical conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) The balsa wood is sliced along the growth direction to obtain a wood substrate with a thickness of 1.5 mm and a length and width of 22.9×10.2 mm.

[0044](2) The wood substrate obtained in step (1) was rinsed repeatedly with deionized water, and then placed in a vacuum drying oven at 60° C. for 12 hours for later use.

[0045] (3) Put the sample in step (2) into an aqueous solution of 2.5 mol / L NaClO, and soak at room temperature for 12 hours.

[0046] (4) Wash the delignified wood substrate in step (3) successively with ethanol and deionized water, and put the sample into a container filled with FeCl 3 solution in a beaker, and then transferred to a vacuum oven for vacuum impregnation for 2h.

[0047] (5) The sample obtained in step (4) was washed with deionized water to remove excess solution, and freeze-dried at -45° C. for 36 hours.

[0048] (6) The sample obtained in step (5) and a vial of pyrrole (1 mL) were sealed in a beaker, and placed in a refrigerator...

Embodiment 2

[0054] (1) Slice the balsa wood along the growth direction to obtain a wood substrate with a thickness of 1.5 mm and a length and width of 22.9×10.2 mm.

[0055] (2) The wood substrate obtained in step (1) was rinsed repeatedly with deionized water, and then placed in a vacuum drying oven at 60° C. for 12 hours for later use.

[0056] (3) Immerse the wood substrate in step (2) in 3 mol / L ammonia solution for 24 hours.

[0057] (4) Wash the delignified wood substrate in step (3) successively with ethanol and deionized water, and put the sample into a container filled with FeCl 3 solution in a beaker, and then transferred to a vacuum oven for vacuum impregnation for 2h.

[0058] (5) The sample obtained in step (4) was washed with deionized water to remove excess solution, and freeze-dried at -45° C. for 36 hours.

[0059] (6) The sample obtained in step (5) and a vial of pyrrole (1 mL) were sealed in a beaker, and placed in a refrigerator at 0° C. for 7 days.

[0060] (7) Pla...

Embodiment 3

[0065] (1) Slice poplar wood along the growth direction to obtain a wood substrate with a thickness of 1.5 mm and a length and width of 22.9×10.2 mm.

[0066] (2) The wood substrate obtained in step (1) was rinsed repeatedly with deionized water, and then placed in a vacuum drying oven at 60° C. for 12 hours for later use.

[0067] (3) Put the sample in step (2) into an aqueous solution of 2.5 mol / L NaClO, and soak at room temperature for 12 hours.

[0068] (4) Wash the delignified wood substrate in step (3) successively with ethanol and deionized water, and put the sample into a container filled with FeCl 3 solution in a beaker, and then transferred to a vacuum oven for vacuum impregnation for 2h.

[0069] (5) The sample obtained in step (4) was washed with deionized water to remove excess solution, and freeze-dried at -45° C. for 36 hours.

[0070] (6) The sample obtained in step (5) and a vial of pyrrole (1 mL) were sealed in a beaker, and placed in a refrigerator at 0° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com