A kind of preparation method of conductive wood aerogel

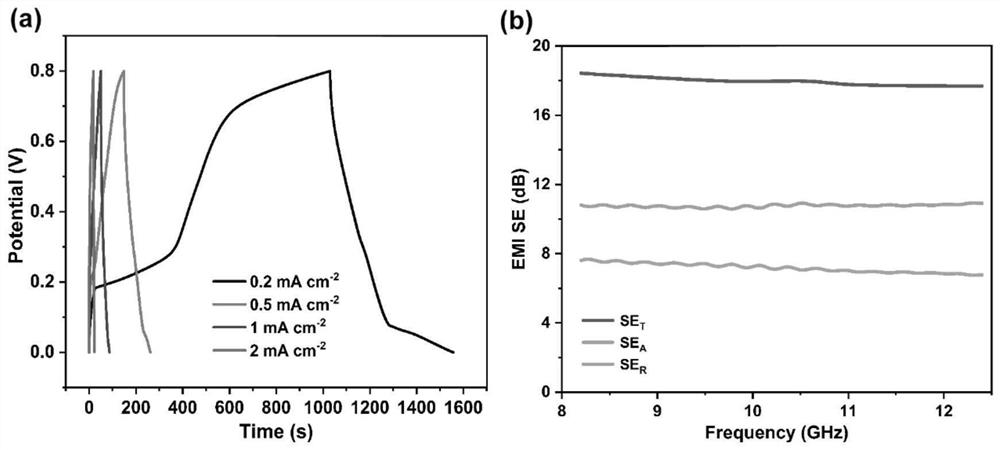

An airgel and wood technology, applied in the field of composite materials, can solve the problems of multi-functional application of materials and complex preparation process, etc., and achieve the effects of excellent electromagnetic shielding performance, wide sources, and high antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) The balsa wood is sliced along the growth direction to obtain a wood substrate with a thickness of 1.5 mm and a length and width of 22.9×10.2 mm.

[0044](2) The wood substrate obtained in step (1) was rinsed repeatedly with deionized water, and then placed in a vacuum drying oven at 60° C. for 12 hours for later use.

[0045] (3) Put the sample in step (2) into an aqueous solution of 2.5 mol / L NaClO, and soak at room temperature for 12 hours.

[0046] (4) Wash the delignified wood substrate in step (3) successively with ethanol and deionized water, and put the sample into a container filled with FeCl 3 solution in a beaker, and then transferred to a vacuum oven for vacuum impregnation for 2h.

[0047] (5) The sample obtained in step (4) was washed with deionized water to remove excess solution, and freeze-dried at -45° C. for 36 hours.

[0048] (6) The sample obtained in step (5) and a vial of pyrrole (1 mL) were sealed in a beaker, and placed in a refrigerator...

Embodiment 2

[0054] (1) Slice the balsa wood along the growth direction to obtain a wood substrate with a thickness of 1.5 mm and a length and width of 22.9×10.2 mm.

[0055] (2) The wood substrate obtained in step (1) was rinsed repeatedly with deionized water, and then placed in a vacuum drying oven at 60° C. for 12 hours for later use.

[0056] (3) Immerse the wood substrate in step (2) in 3 mol / L ammonia solution for 24 hours.

[0057] (4) Wash the delignified wood substrate in step (3) successively with ethanol and deionized water, and put the sample into a container filled with FeCl 3 solution in a beaker, and then transferred to a vacuum oven for vacuum impregnation for 2h.

[0058] (5) The sample obtained in step (4) was washed with deionized water to remove excess solution, and freeze-dried at -45° C. for 36 hours.

[0059] (6) The sample obtained in step (5) and a vial of pyrrole (1 mL) were sealed in a beaker, and placed in a refrigerator at 0° C. for 7 days.

[0060] (7) Pla...

Embodiment 3

[0065] (1) Slice poplar wood along the growth direction to obtain a wood substrate with a thickness of 1.5 mm and a length and width of 22.9×10.2 mm.

[0066] (2) The wood substrate obtained in step (1) was rinsed repeatedly with deionized water, and then placed in a vacuum drying oven at 60° C. for 12 hours for later use.

[0067] (3) Put the sample in step (2) into an aqueous solution of 2.5 mol / L NaClO, and soak at room temperature for 12 hours.

[0068] (4) Wash the delignified wood substrate in step (3) successively with ethanol and deionized water, and put the sample into a container filled with FeCl 3 solution in a beaker, and then transferred to a vacuum oven for vacuum impregnation for 2h.

[0069] (5) The sample obtained in step (4) was washed with deionized water to remove excess solution, and freeze-dried at -45° C. for 36 hours.

[0070] (6) The sample obtained in step (5) and a vial of pyrrole (1 mL) were sealed in a beaker, and placed in a refrigerator at 0° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com