Patents

Literature

57 results about "Balsa wood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ochroma is a genus of flowering plants in the mallow family, Malvaceae, containing the sole species Ochroma pyramidale, commonly known as the balsa tree.It is a large, fast-growing tree that can grow up to 30 m tall. Balsa wood is a very lightweight material with many uses. Balsa trees are native to southern Brazil and northern Bolivia, north to southern Mexico

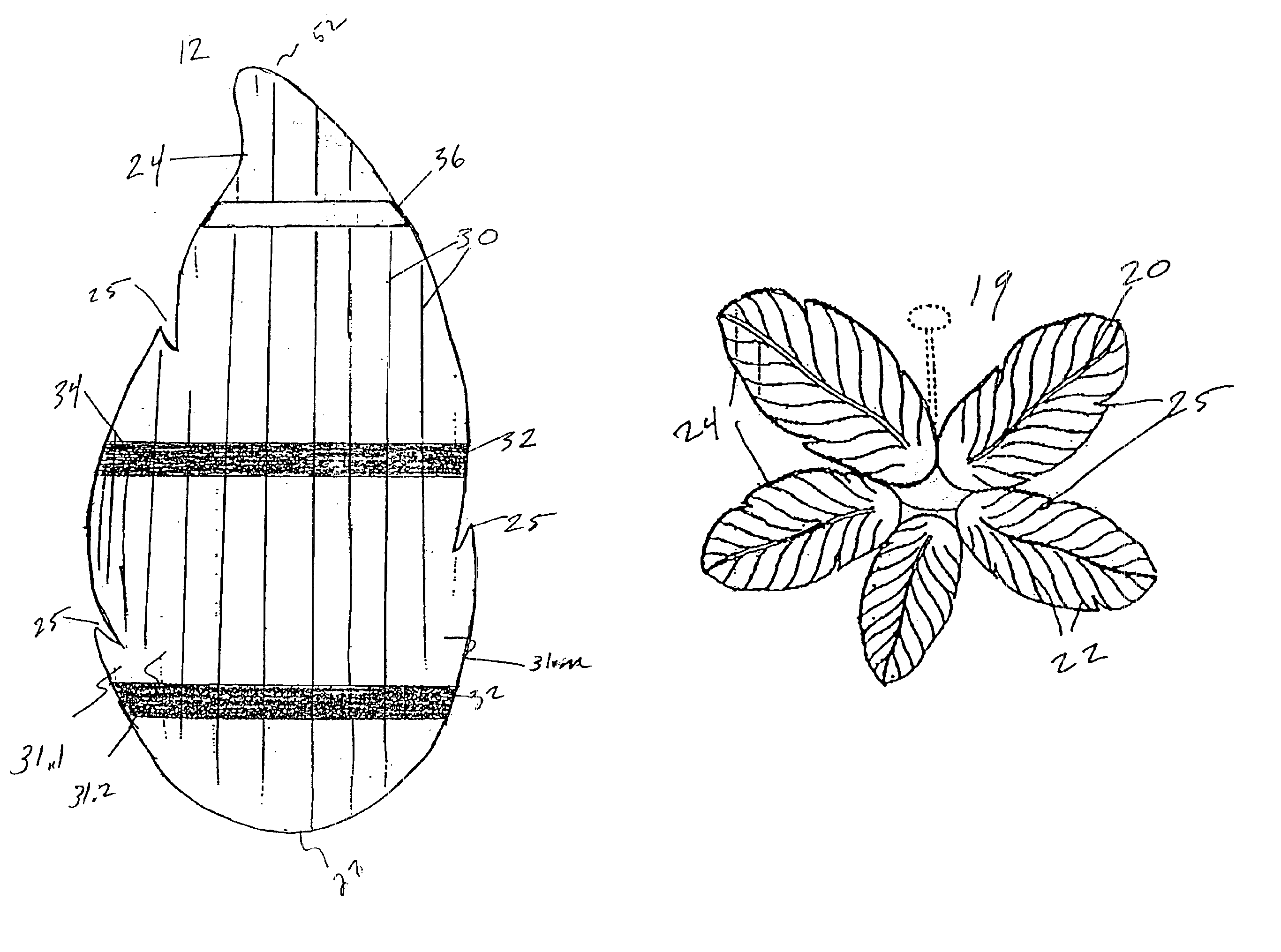

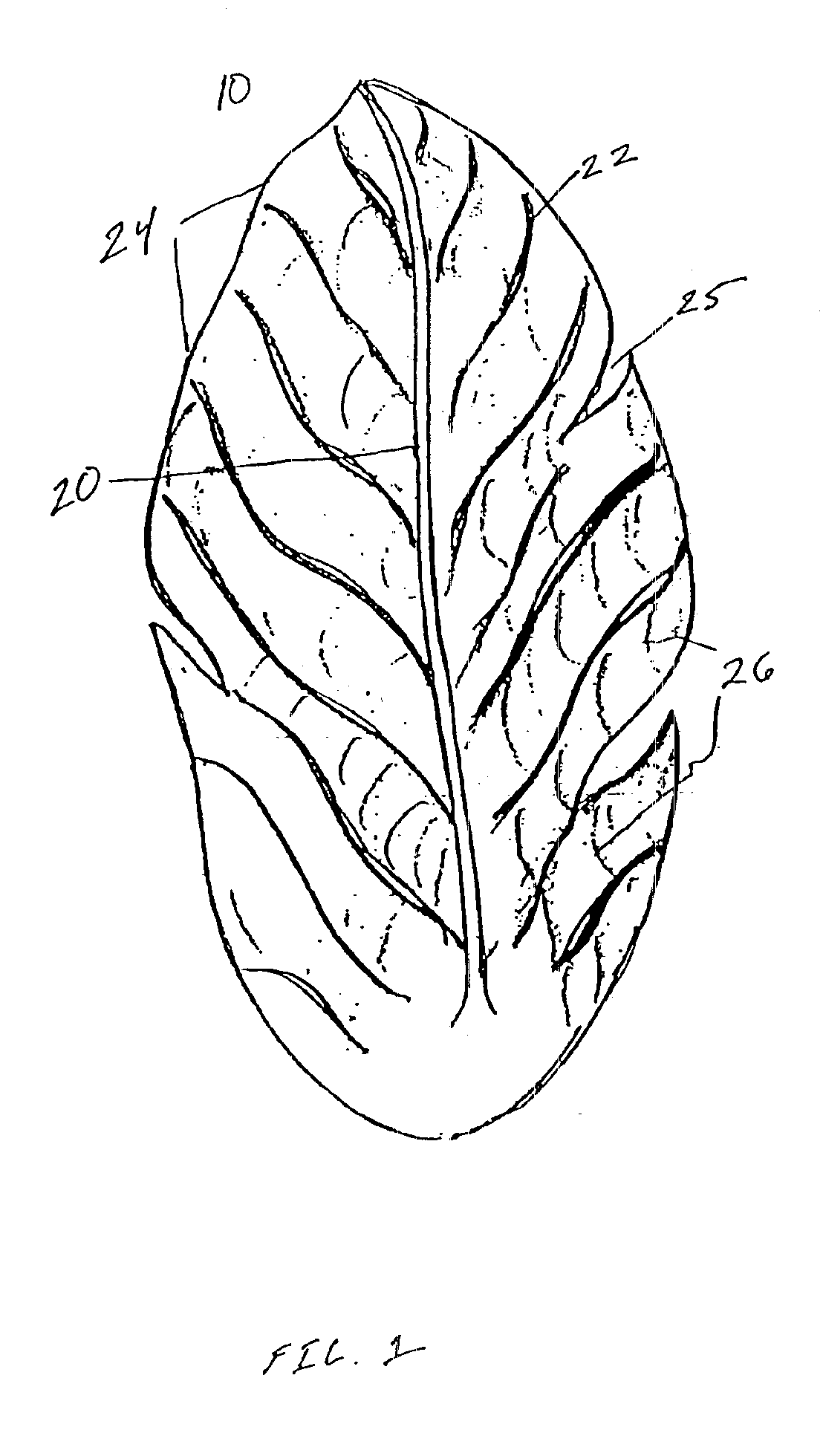

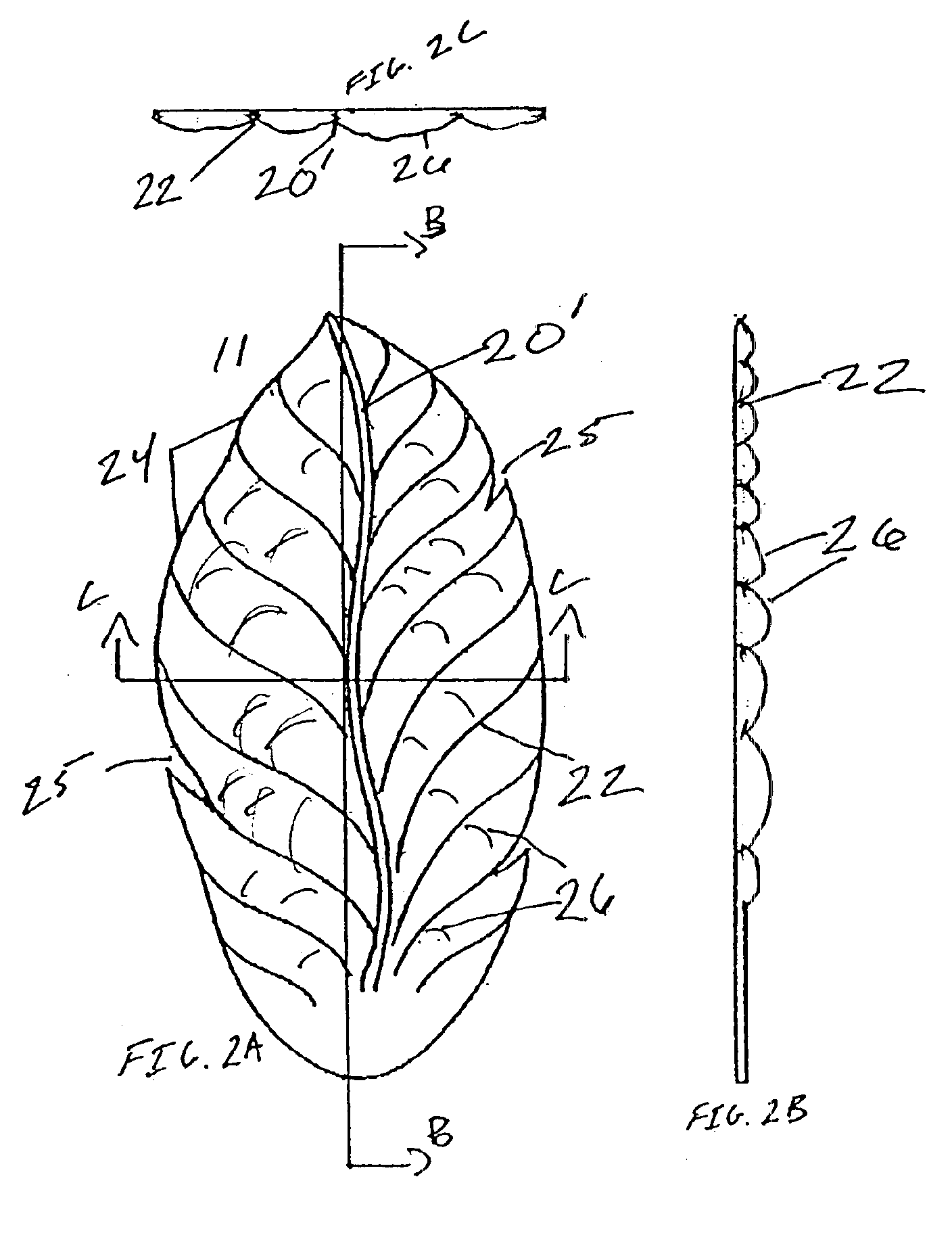

Fan blade

A fan blade has a three dimensional shape that resembles a leaf. The blade is made of balsa or other suitable wood with the grain of the wood running along its length. The obverse surface of the blade is contoured and has a central vein and lateral veins running from the central vein to opposite edges. The reverse side has one or more channels. Braces are set in the channels. The braces are also made of balsa or comparable wood and their grain runs transverse to the direction of the gain of the blade.

Owner:CARTWRIGHT THOMAS

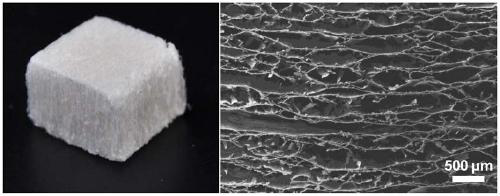

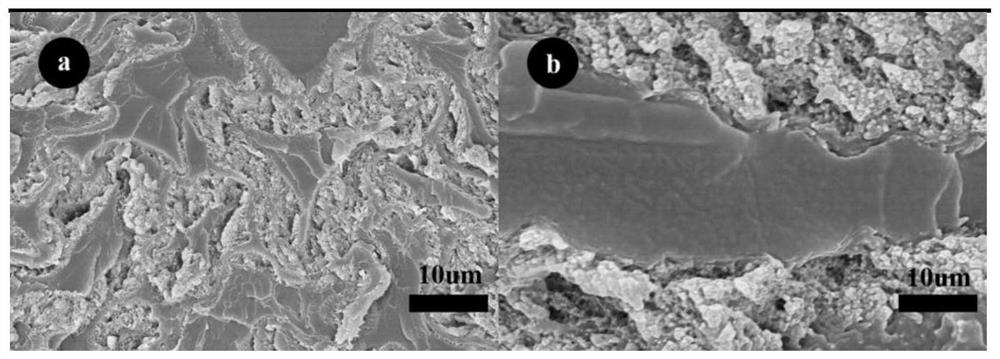

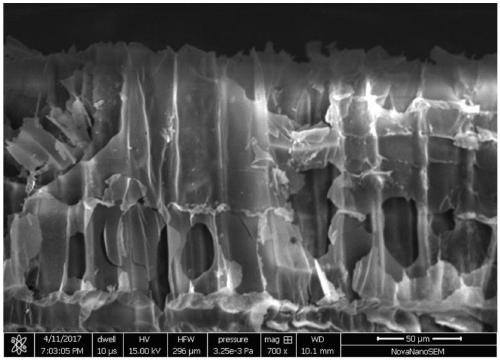

Anisotropic wood-based nanofiber aerogel and preparation method thereof

The invention discloses an anisotropic wood-based nanofiber aerogel. The aerogel is obtained by the following steps: light wood with a density of 80-150 mg / cm<3> is adopted, delignification treatmentis performed, dehemicellulose treatment is performed to prepare a wood-based nanofiber hydrogel, water in the hydrogel is replaced to obtain a nanofiber alcohol sol, freeze drying is performed, and therefore the aerogel is obtained. The invention also discloses the specific preparation method. According to the method provided by the invention, the wood-based nanofiber aerogel prepared by the method has a low density, high porosity, good compression performance and elasticity, is a green environmentally-friendly aerogel material, has low preparation costs, can be produced in a large scale, andhas board application prospects in the fields of thermal insulation, noise insulation, adsorption catalysis, biomedicine, energy storage and the like.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Method for preparing sandwich material PET foam for wind power generation blade

The invention relates to a method for preparing sandwich material PET foam for a wind power generation blade. The preparation method comprises the following steps of: feeding PET sheets into supercritical fluid under a high-pressure preheating environment, keeping the PET sheets for certain time, and then thermally treating the PET sheets by a quick pressure reduction method so as to reduce the solubility of gas in the polymer and initiate bubble nucleation and increment. Compared with the prior art, when the PET foam is prepared by using a supercritical CO2 fluid method, the CO2 has the characteristics of lower critical temperature, realization of supercritical operation nearby room temperature, low critical pressure, no-toxicity, combustion resistance, high-purity industrial product and the like. By using the method, the PET foam is used for replacing PVC foam, and the Balsa wood has low price and good effect.

Owner:SHANGHAI YUEKE COMPOSITE

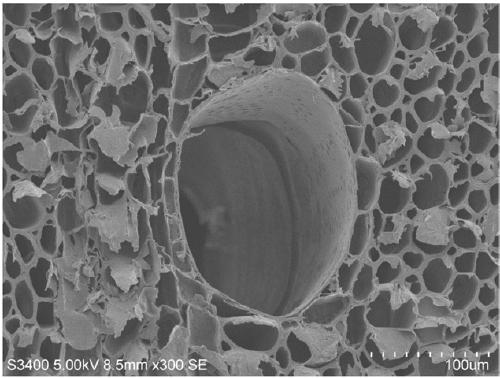

Method for preparing functional photothermal composite phase change heat storage material

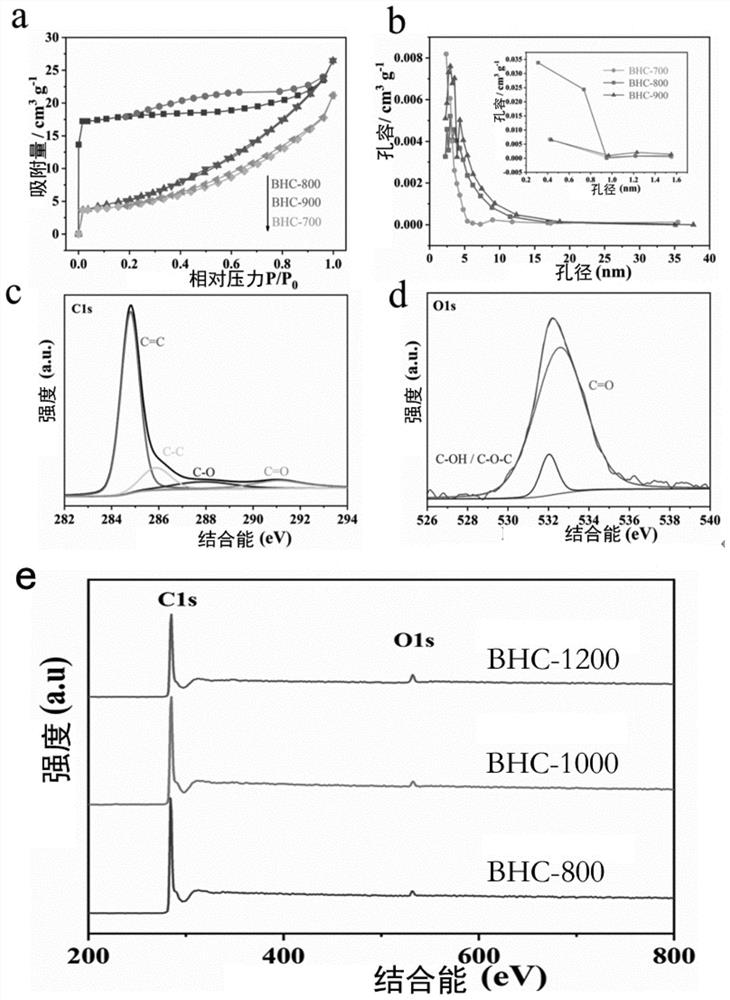

InactiveCN110358505AIncrease specific surface area and porosityImprove adsorption capacityHeat-exchange elementsPorosityCell wall

The invention provides a method for preparing a functional photothermal composite phase change heat storage material. A cellulose-based carbon aerogel is prepared by adopting a vacuum pyrolysis technology with a lignin and hemicellulose partially-removed balsa cellulose aerogel as a matrix, and a phase change material PEG6000 is impregnated in the cellulose-based carbon aerogel by a vacuum impregnation process. The method improves the porosity and the specific surface area of balsa wood by completely breaking a part of the cell wall structure of the wood, opening cell corners and penetrating through a part of a pit film, provides the adsorption capacity and the accommodating capacity of the phase change material by completely retaining the three-dimensional structure of the cellulose aerogel, and provides a novel green packaging material with the advantages of broad sources, low price, simplicity in processing, safeness, environmental friendliness and wide application range for the composite phase change energy storage material, and realizes photothermal conversion by using the photothermal effect of the carbon aerogel, so the functional enhancement of the composite phase change heat storage material is achieved.

Owner:BEIJING FORESTRY UNIVERSITY

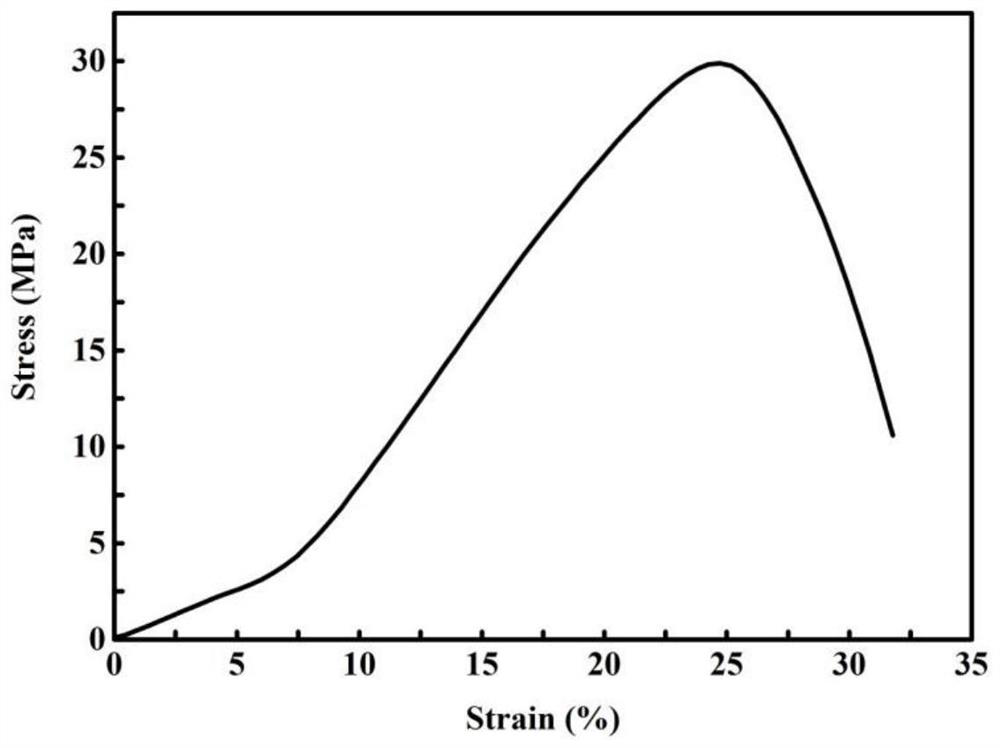

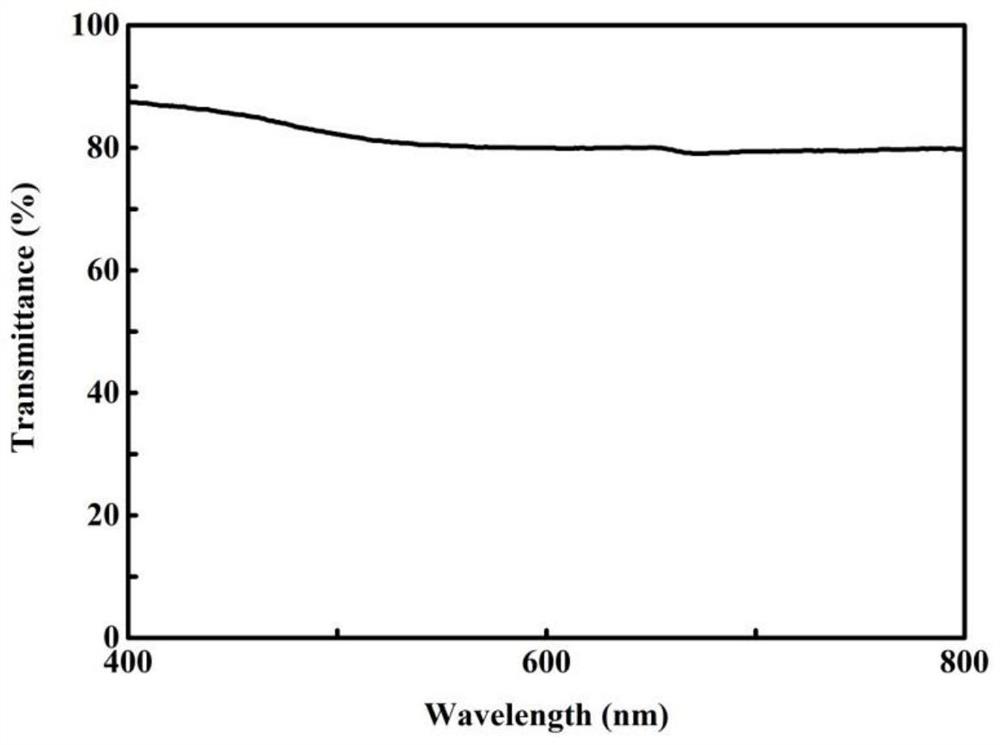

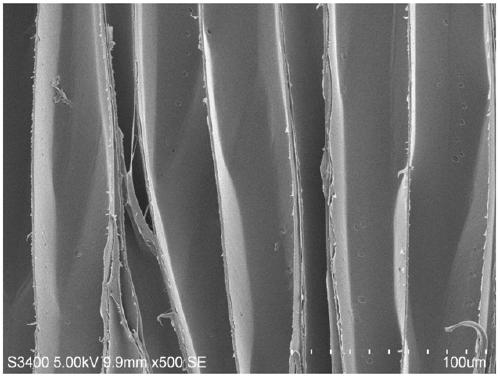

Method for preparing elastic wood based on ultraviolet light initiated graft polymerization

ActiveCN111978490APrevent crushingGuaranteed natural mechanical propertiesOpen tank impregnationFiberPolymer science

The invention discloses a method for preparing elastic wood based on ultraviolet light initiated graft polymerization. The method comprises the following steps: by using balsa wood as a raw material,carrying out mild delignification treatment by using an acidic sodium chlorite solution to obtain a complete wood fiber skeleton; treating the obtained product with a sodium hydroxide alkaline solution; preparing a mixed solution of an acrylamide monomer and a cross-linking agent, and regulating the mixing ratio of the acrylamide monomer and the cross-linking agent; fully mixing the obtained product with an acrylamide monomer through an impregnation method; and putting the obtained product into a mold, and initiating a grafting cross-linking reaction through ultraviolet light with the wavelength of 320-380 nm to obtain polyacrylamide / wood fiber skeleton composite gel, namely the elastic wood. According to the method, the elastic wood can be prepared under the condition that a chemical initiator is not used, and due to the fact that the elastic wood has high biocompatibility, excellent mechanical performance and excellent light transmission performance, the elastic wood has potential application value in the fields of artificial skin, biosensors, soft tissue engineering materials, wearable flexible electronic base materials, stimulus response soft robots and the like.

Owner:NANJING FORESTRY UNIV

Method of contouring fabric using half-hard brass

A device for shaping and contouring a fabric or the like in sewing and handicraft projects. In one configuration, the device includes a strip of solid and ductile metal that is configured to be directly adhered to a fabric surface. At lease one layer of acrylic pressure-sensitive adhesive is formed on a bonding of the metal. The shaping device can be bent into various contours and is strong enough to cause material such as tapestry or balsa wood to assume the contours of the shaping device.

Owner:JO DEES

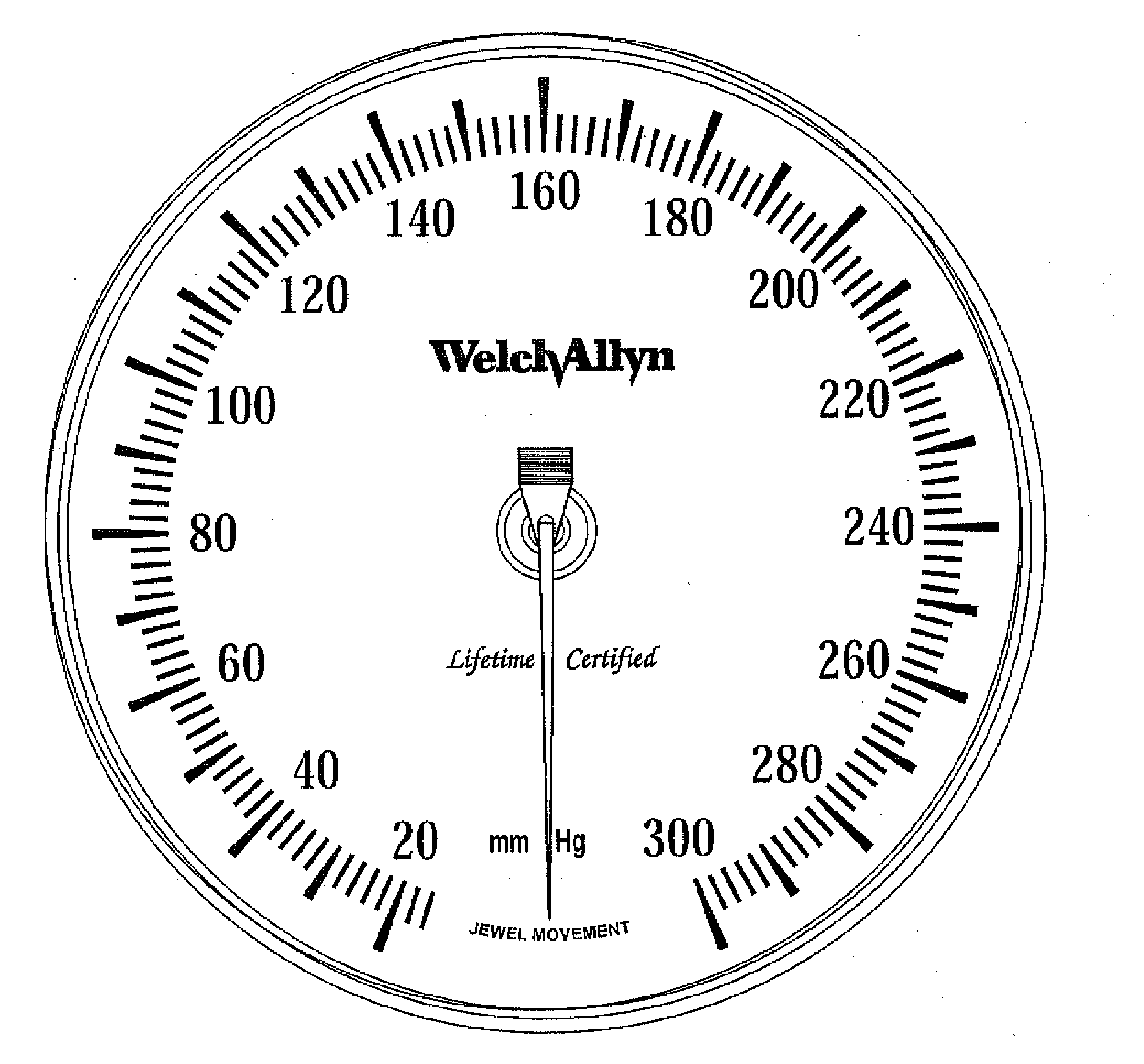

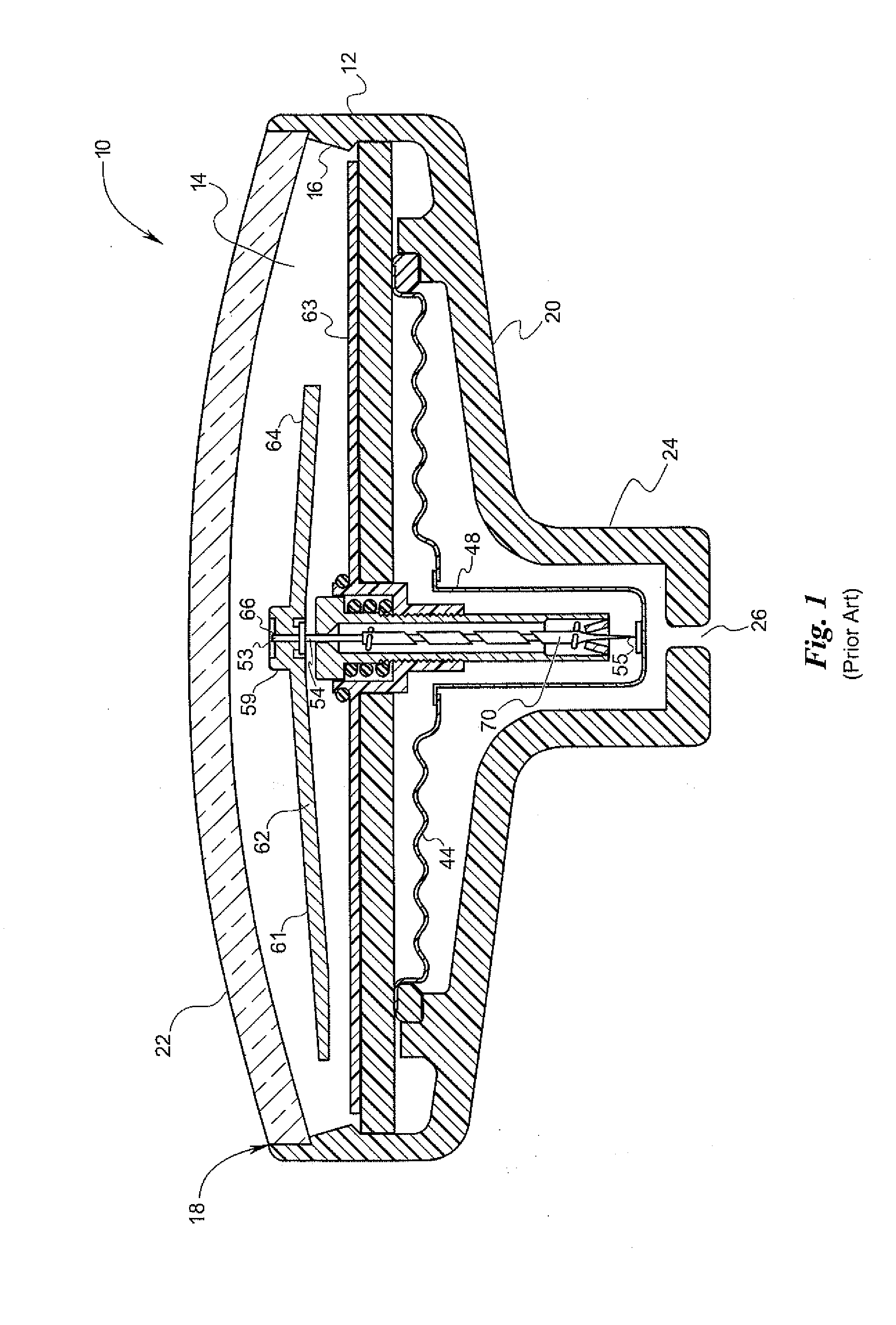

Pointer for use in a gauge, a gauge employing the pointer, and a method of making the pointer

InactiveUS20090205559A1Indication apparatusFluid pressure measurement by mechanical elementsEngineeringBiomedical engineering

A gauge for measuring the magnitude of a measurable quantity, such as fluid pressure. The gauge includes a rotatable axle or shaft intended to rotate in response to different magnitudes of the quantity being measured and includes a dial possessing indicia corresponding to different magnitudes of such quantity. The improvement in the gauge relates to a very light-weight pointer having a needle section and a counterbalance section, in which the needle section is formed of a relatively light mass material, preferably balsa wood. The counterbalance section may be fashioned of a different, denser material. The surface of the counterbalance section may be provided with a series of parallel depressions that aid in cutting or trimming the counterbalance section to achieve a balance of the pointer about the axle or shaft. A method of making such a pointer is also disclosed.

Owner:WELCH ALLYN INC

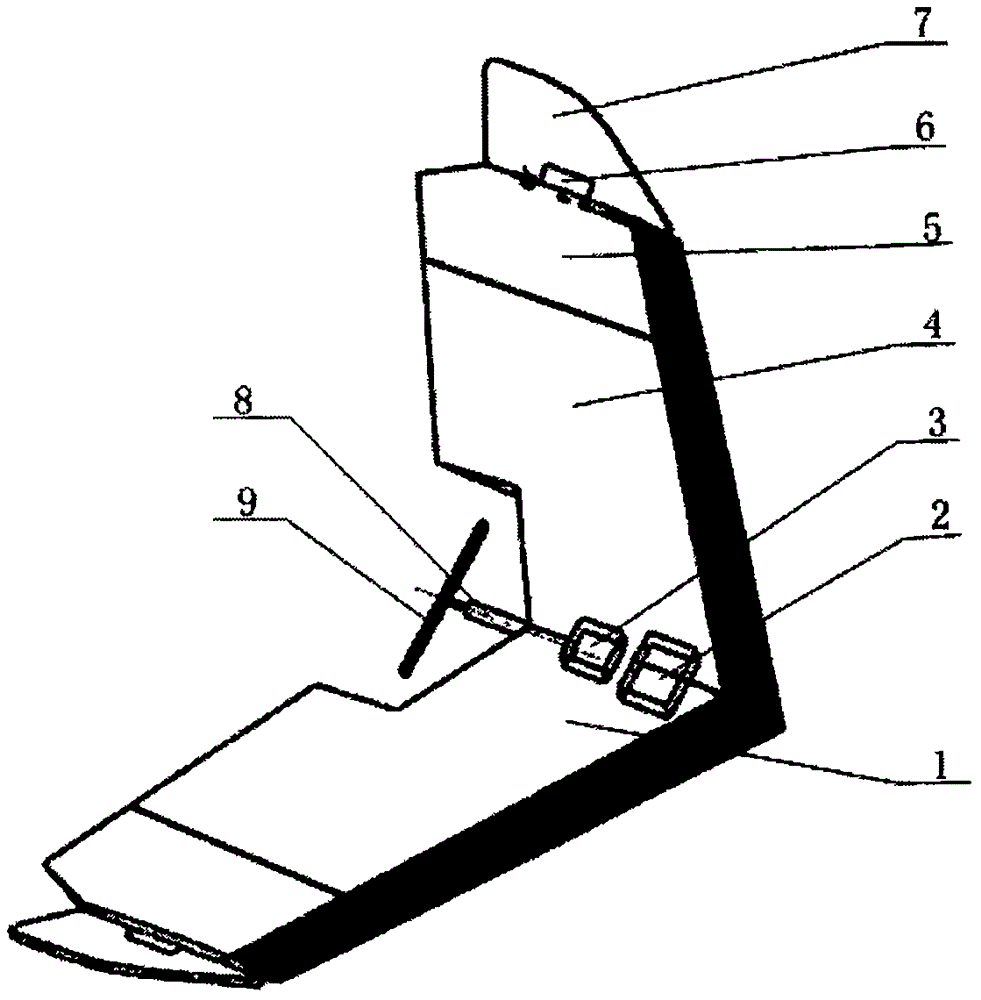

Winglet rotation device of minitype fixed wing unmanned aerial vehicle

InactiveCN106516083AIncrease flight time and rangeAdjust in timeAircraft stabilisationWing adjustmentsVehicle frameOpen source

The invention relates to a winglet rotation device of a minitype fixed wing unmanned aerial vehicle. The winglet rotation device of the minitype fixed wing unmanned aerial vehicle comprises an unmanned aerial vehicle frame, a winglet and a rotation mechanism. The unmanned aerial vehicle frame is composed of an unmanned aerial vehicle body, an open-source flight controller, am electronic governor, a motor and a propeller, wherein an unmanned aerial vehicle main wing segment is made of an EPP foam material, is light in specific gravity and good in elasticity, and is widely applied to remote sensing unmanned aerial vehicles; and an unmanned aerial vehicle wingtip segment is made of a balsa wood material, and the main wing segment and the wingtip segment are fixedly connected together. The rotation mechanism is composed of a biaxial motor and a connecting plate. The electronic governor is controlled by the flight controller, then the biaxial motor is controlled to rotate, and finally the angle of the winglet is adjusted, to automatically adapt to the change of the flight attitude of the unmanned aerial vehicle. The winglet rotation device is diverse in adjustable angles, and the flight attitude of the unmanned aerial vehicle is automatically identified by using the flight controller, so that the angle is adjusted more timely, the aerodynamic performance of the wings is better improved, and the endurance and voyage of the unmanned aerial vehicle in operation are increased.

Owner:NORTHWEST A & F UNIV

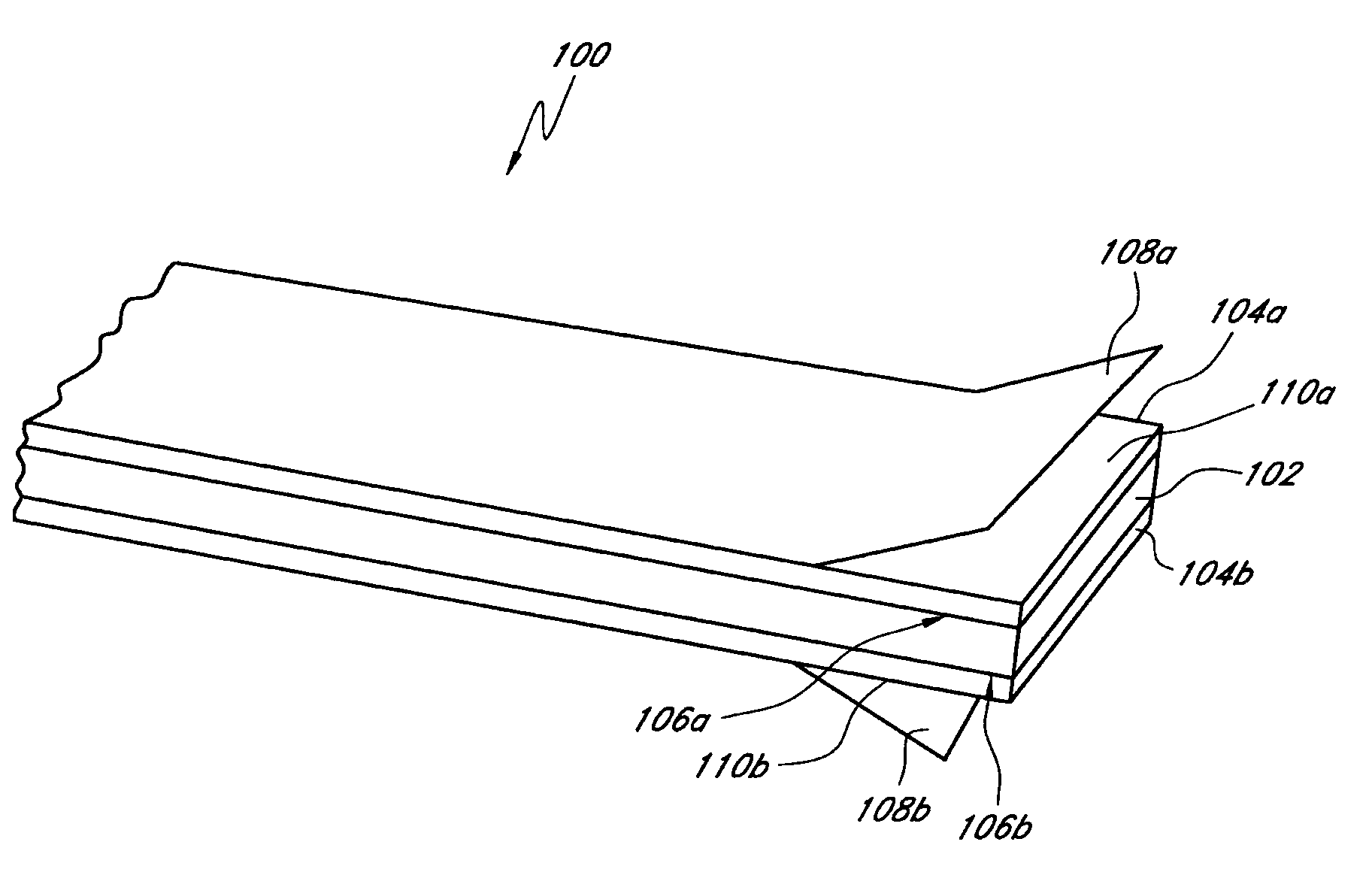

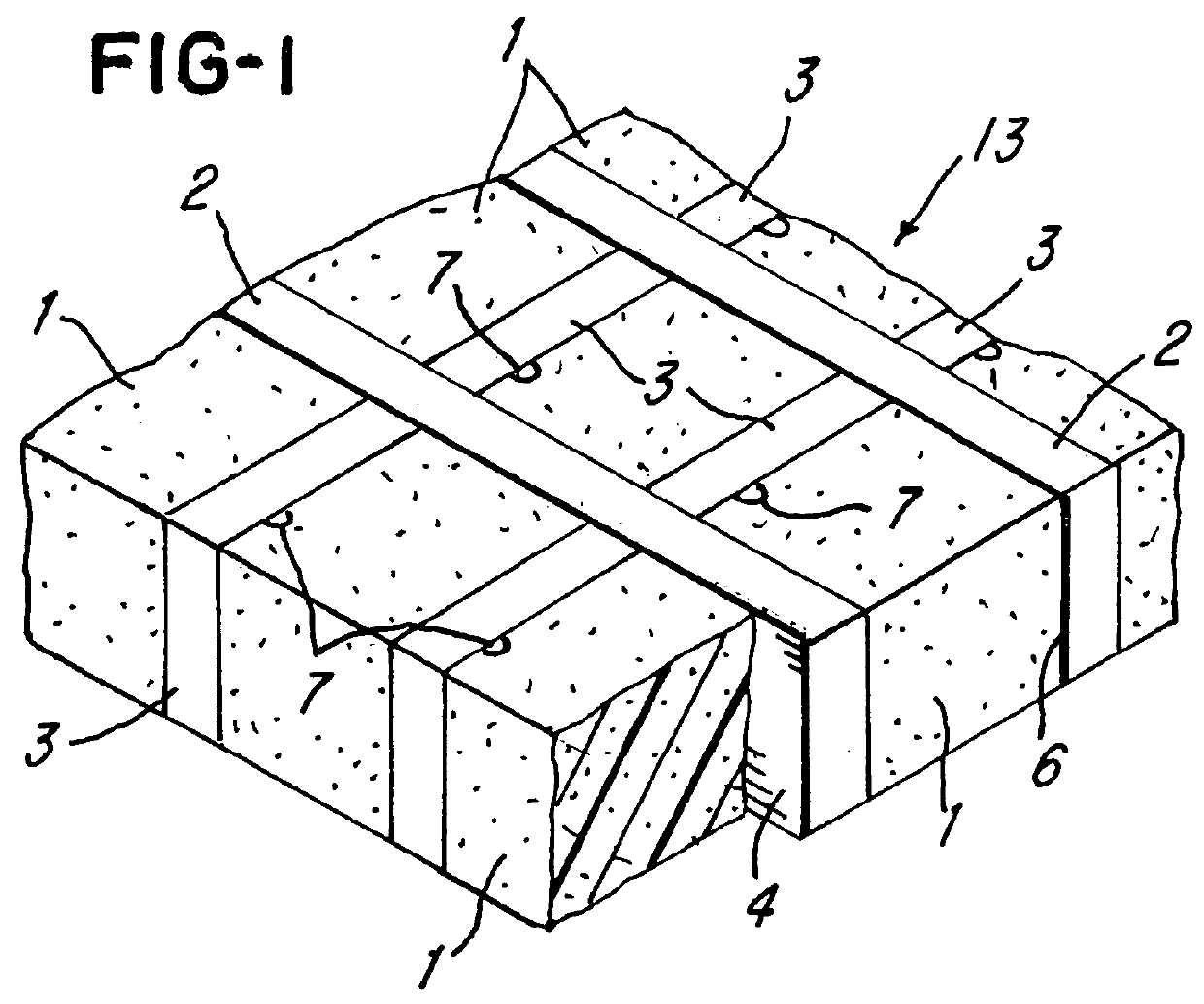

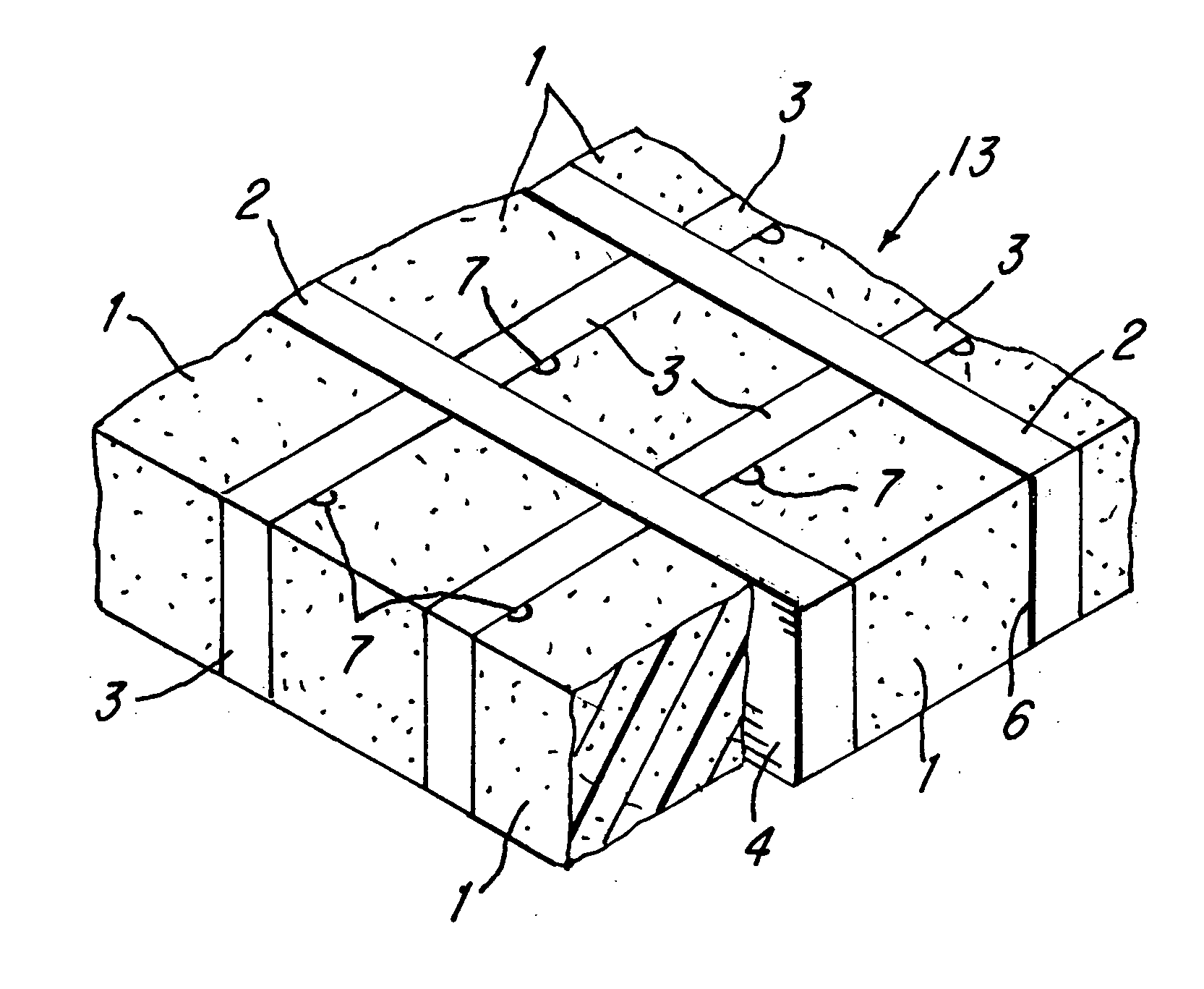

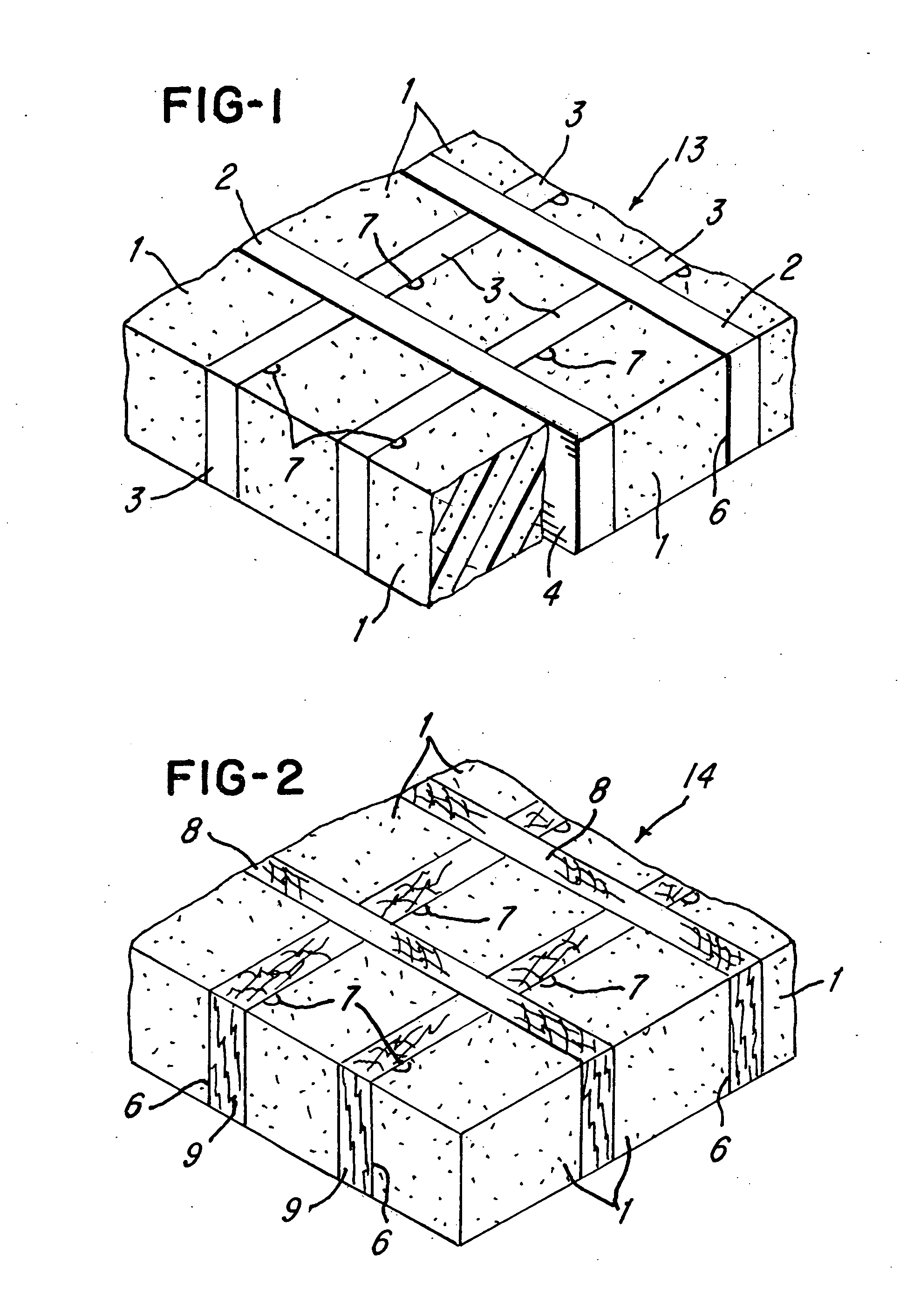

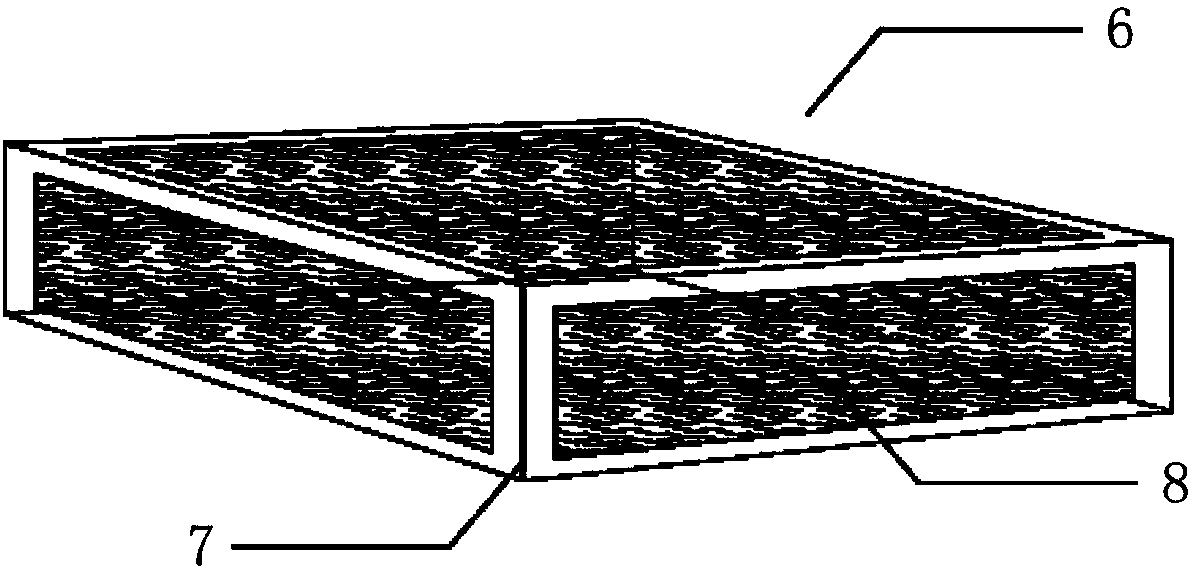

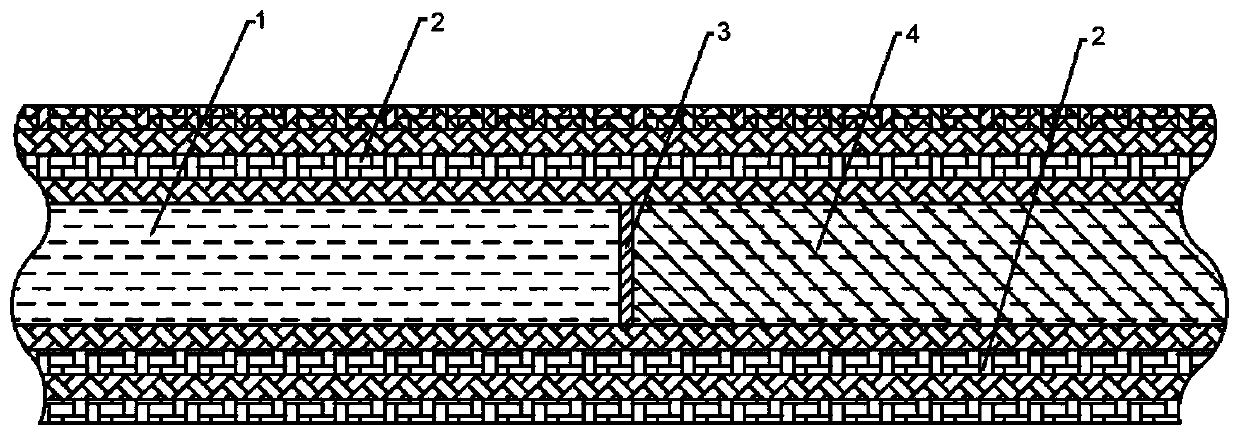

Composite cores and panels

InactiveUS8389104B2Low propertyLow costPropellersMechanical working/deformationEdge surfaceHigh density

A composite core panel has opposite side surfaces for receiving skins to form a composite sandwich panel. The core panel includes a plurality of spaced blocks of low density cellular material such as foam plastics and have opposite side surfaces forming the side surfaces of the core panel and opposite edge surfaces extending between the side surfaces. A plurality of parallel spaced elongated primary strips of structural cellular material such as balsa wood or engineered foam have a higher density and extend between the blocks, and the blocks have side surfaces adhesively attached to edge surfaces of the blocks. A plurality of parallel spaced secondary strips of structural high density cellular material such as balsa wood or engineered foam extend transversely to the primary strips and have end surfaces adhesively attached to the primary strips and side surfaces adhesively attached to the blocks.

Owner:METYX USA INC

A preparation method of a porous wood carbon modified metal lithium anode material

ActiveCN109119602ARelief of severe volume changesAlleviate volume changesNegative electrodesCarbon preparation/purificationMetal nitrateLithium

A preparation method of a porous wood carbon modified metal lithium anode material comprises that following steps: (1) taking wood of transverse cut balsa wood, cutting into wood chips; (2) carbonizing and activating the balsa wood chips at high temperature in a protective atmosphere to obtain activated balsa wood carbon material; (3) preparing a metal nitrate or metal acetate solution, and soaking the balsa wood carbon material in the solution for 1-3h, and then putting the material into a tubular furnace, loading the polytetrafluoroethylene powder into a ceramic boat and placing the polytetrafluoroethylene powder on the front part of the air inlet, and calcining the polytetrafluoroethylene powder at high temperature to obtain a metal fluoride modified balsa wood carbon material; and (4)depositing metal lithium into the pore channel structure of the metal fluoride modified balsa wood carbon material by electrodeposition under the protection of argon gas, thereby obtaining the modified metal lithium anode material. The invention can effectively solve the problems of low coulomb efficiency and short cycle life of the battery caused by the growth of metal lithium dendritic crystal in the charging and discharging process of the battery of the metal lithium negative electrode material.

Owner:ZHEJIANG UNIV OF TECH

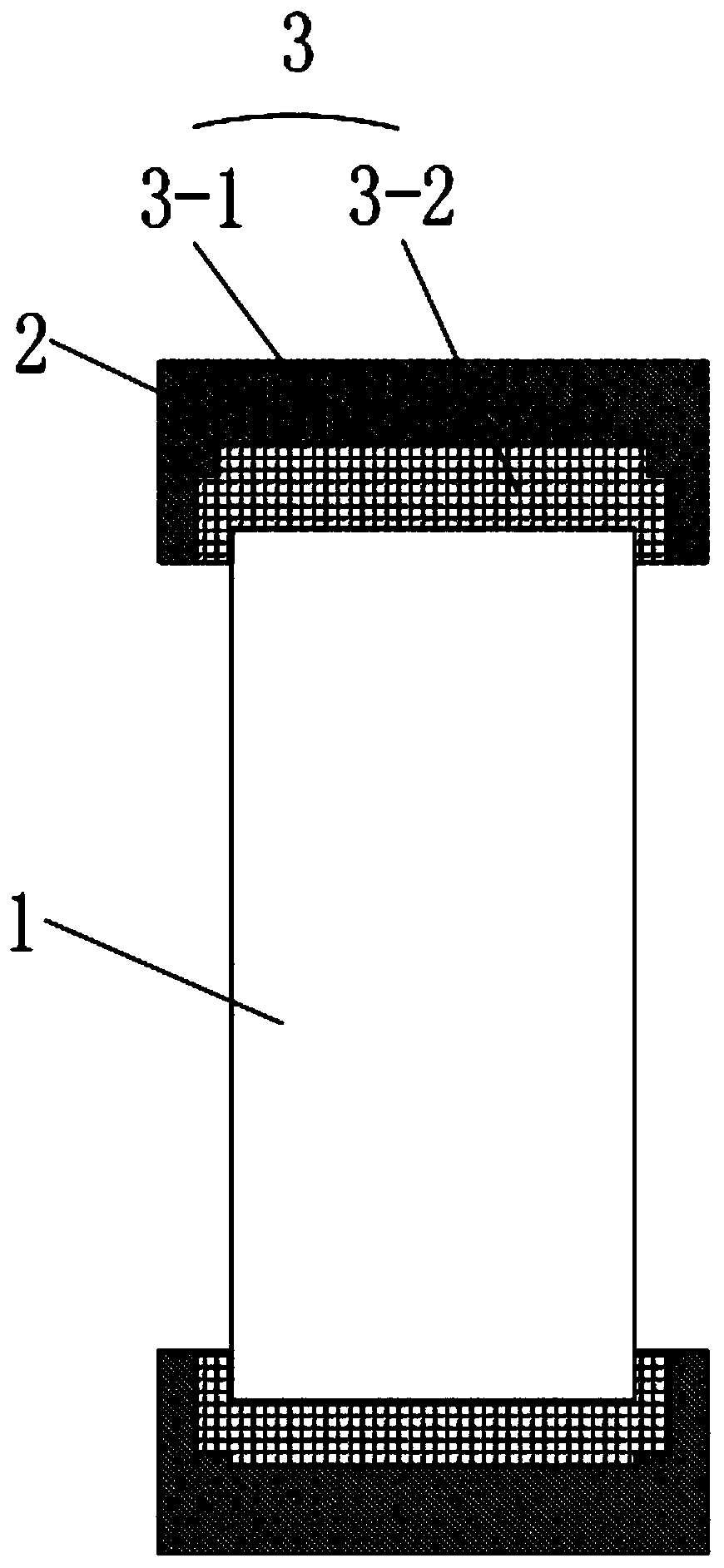

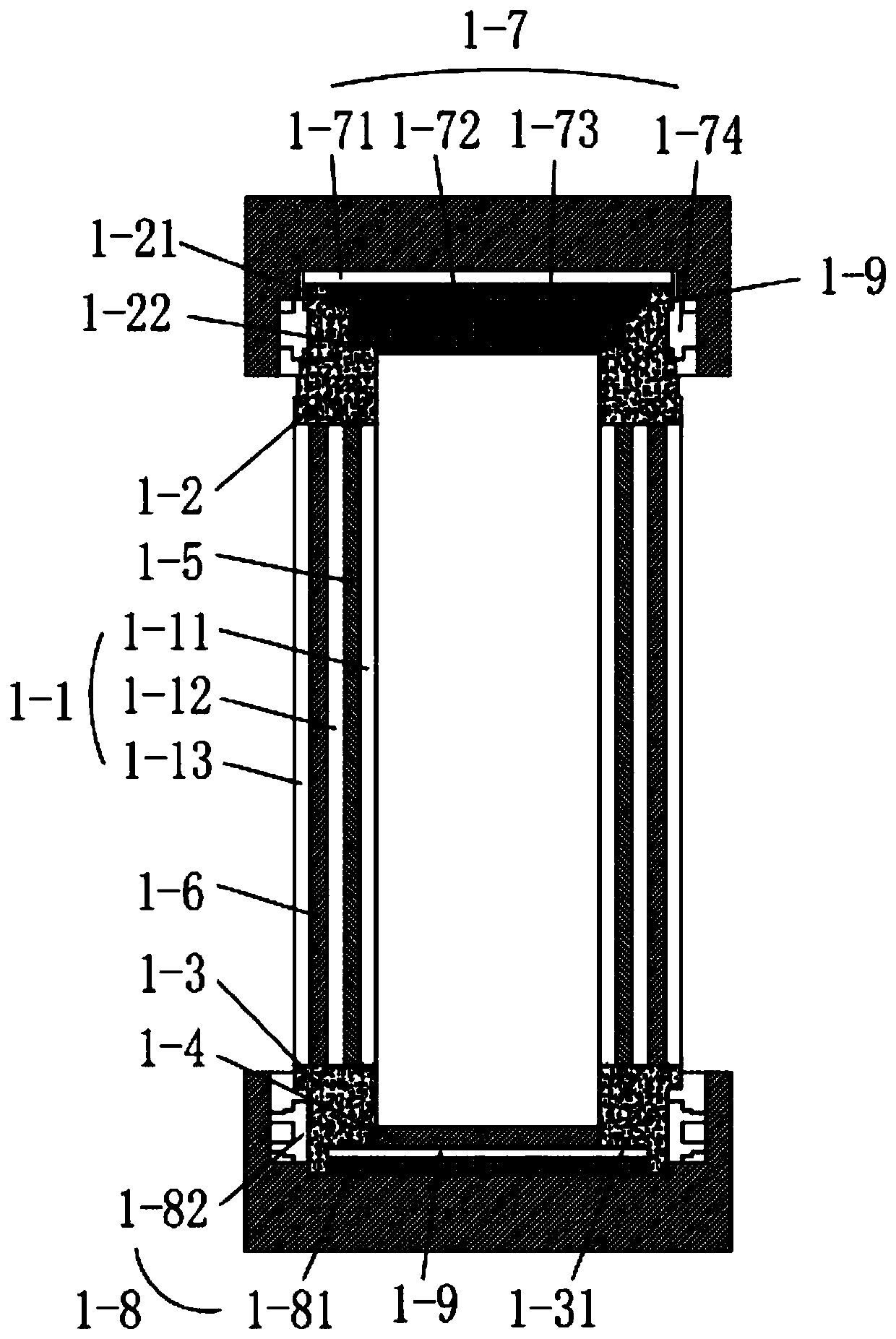

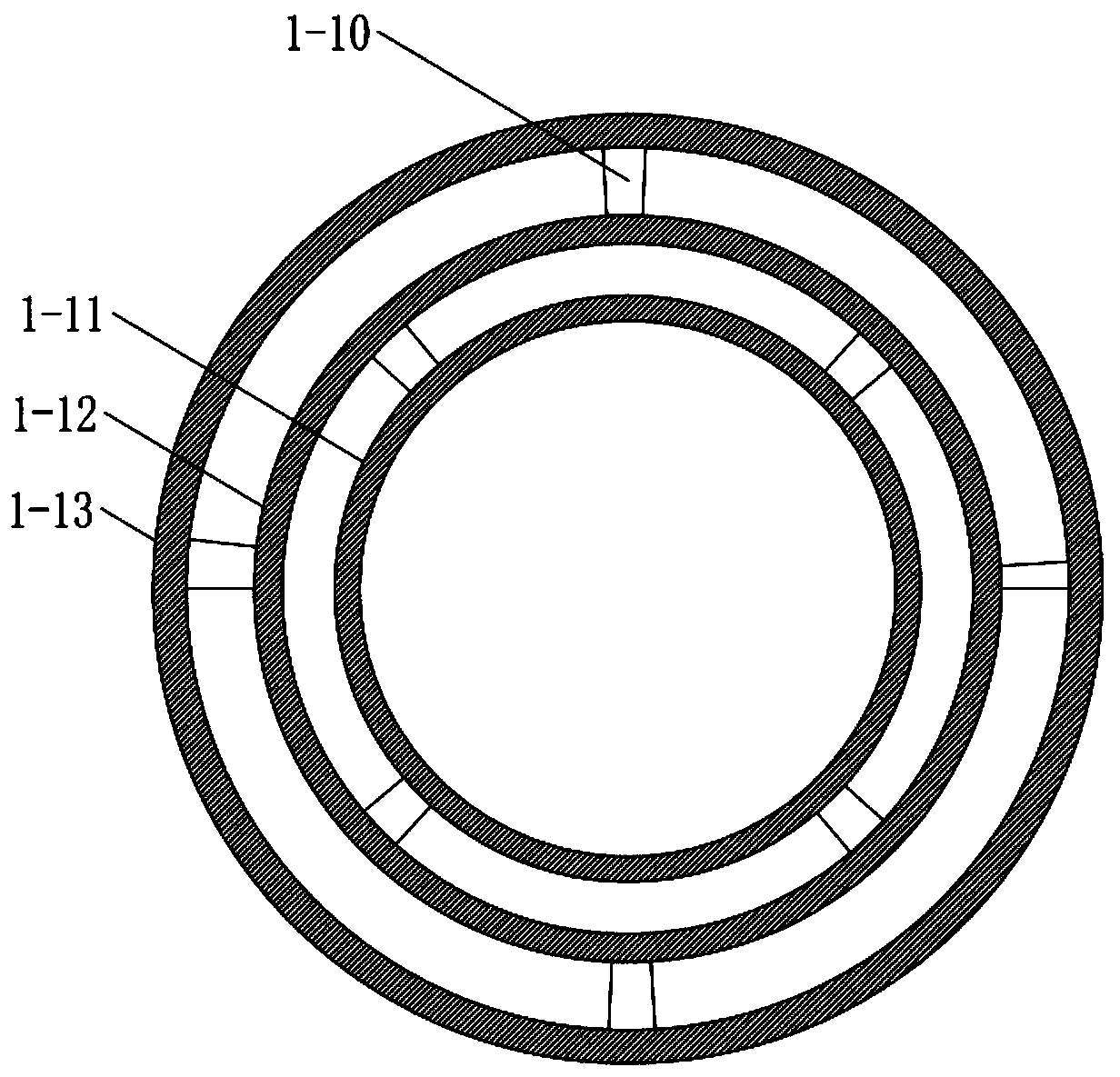

Spent fuel storage and transportation container

The invention relates to the technical field of the processing of nuclear waste and specifically relates to a spent fuel storage and transportation container. The container includes a container main body and buffer devices; and the buffer devices are arranged on the two ends of the container main body and used for absorbing impact energy under normal transportation and accident conditions. The buffer devices are installed on the two ends of the container and used for absorbing the impact energy under the normal transportation and accident conditions; the main buffer materials of the buffer devices are China fir and balsa wood, and the externals of the buffer devices are coated by stainless steel plates; and the wood can be deformed under pressure, so that buffer effects can be achieved, the vibration of the container main body under the normal transportation and accident conditions can be reduced, the tightness of the container main body can be guaranteed, and the leakage possibility of radioactive materials when collision occurs can be effectively reduced.

Owner:JIANGSU ZHONGHAI HUA HE ENVIRONMENTAL PROTECTION CO LTD

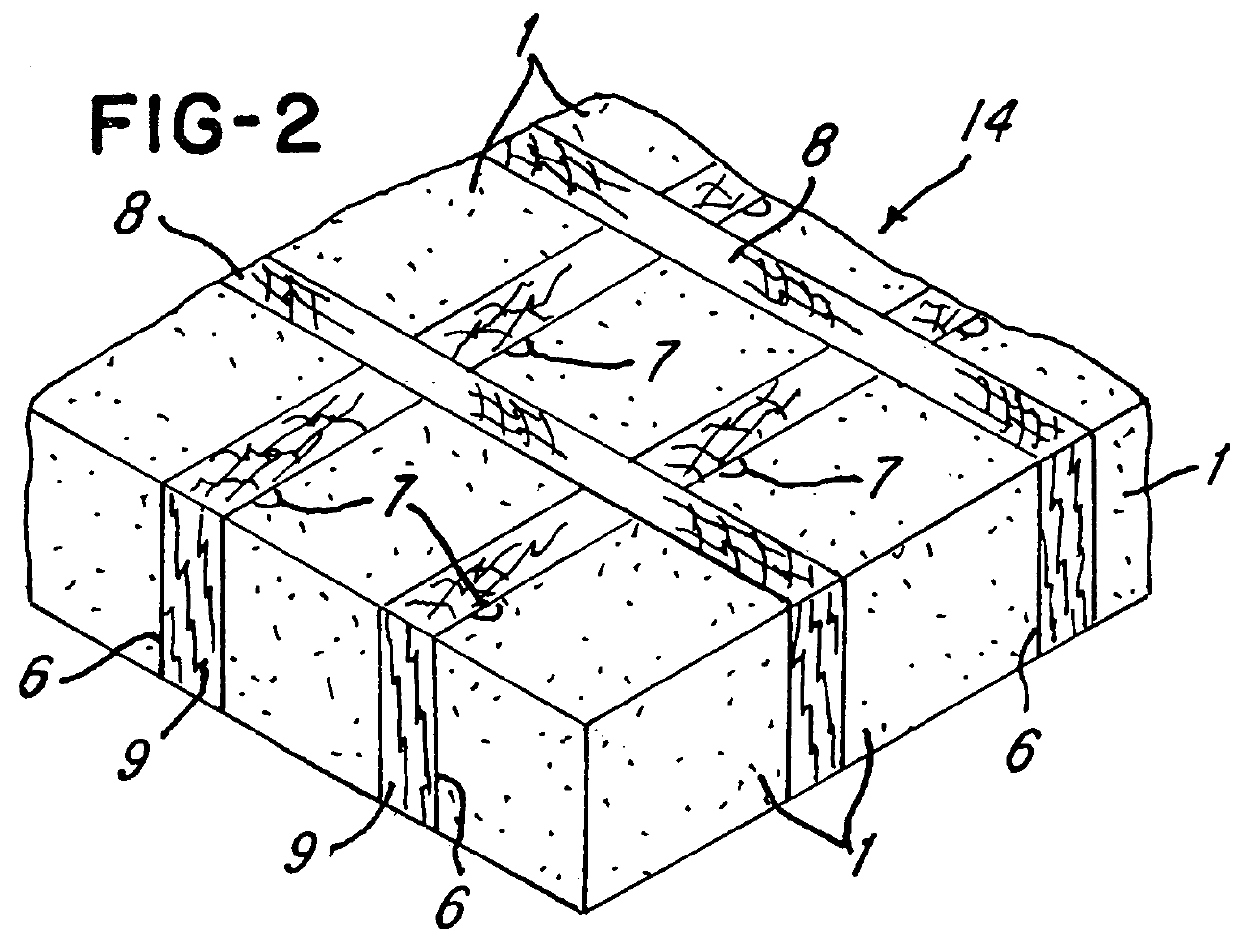

Composite cores and panels

InactiveUS20110081518A1Low propertyLow costPropellersMechanical working/deformationEdge surfaceHigh density

A composite core panel has opposite side surfaces for receiving skins to form a composite sandwich panel. The core panel includes a plurality of spaced blocks of low density cellular material such as foam plastics and have opposite side surfaces forming the side surfaces of the core panel and opposite edge surfaces extending between the side surfaces. A plurality of parallel spaced elongated primary strips of structural cellular material such as balsa wood or engineered foam have a higher density and extend between the blocks, and the blocks have side surfaces adhesively attached to edge surfaces of the blocks. A plurality of parallel spaced secondary strips of structural high density cellular material such as balsa wood or engineered foam extend transversely to the primary strips and have end surfaces adhesively attached to the primary strips and side surfaces adhesively attached to the blocks.

Owner:METYX USA INC

Preparation method of Balsa wood core material of wind driven generator blade web

ActiveCN111958711AMass does not increaseLow moisture absorptionFinal product manufactureWood veneer joiningWind drivenEngineering

The invention relates to the technical field of wind driven generator blades, and particularly relates to a preparation method of a Balsa wood core material of a wind driven generator blade web. The preparation method comprises the steps of slicing, accurate grinding, dehumidification, double-end sawing treatment and gluing, and after pretreatment, shallow groove forming, punching, cloth pasting,deep groove forming, finished product inspection, template manufacturing, line drawing, edge cutting, mark writing, chamfering, IPQC process inspection, plate separation, dehumidification, laying inspection and packaging and warehousing are sequentially conducted. According to shallow groove forming, a plurality of shallow grooves are formed in at least one surface of the core material and are staggered on the surface of the core material to be arranged in a rectangular grid shape, and through holes penetrating through the upper surface and the lower surface of the core material are punched inthe intersection points of the multiple shallow grooves. According to the preparation method, three times of humidity detection are set, the moisture absorption possibility of the core material in the preparation process is further reduced, the risk of corrosion of bacteria and the like sealed in the core material in the operation process is reduced, and therefore the defects of the Balsa wood core material are effectively overcome.

Owner:常州兆庚新材料有限公司

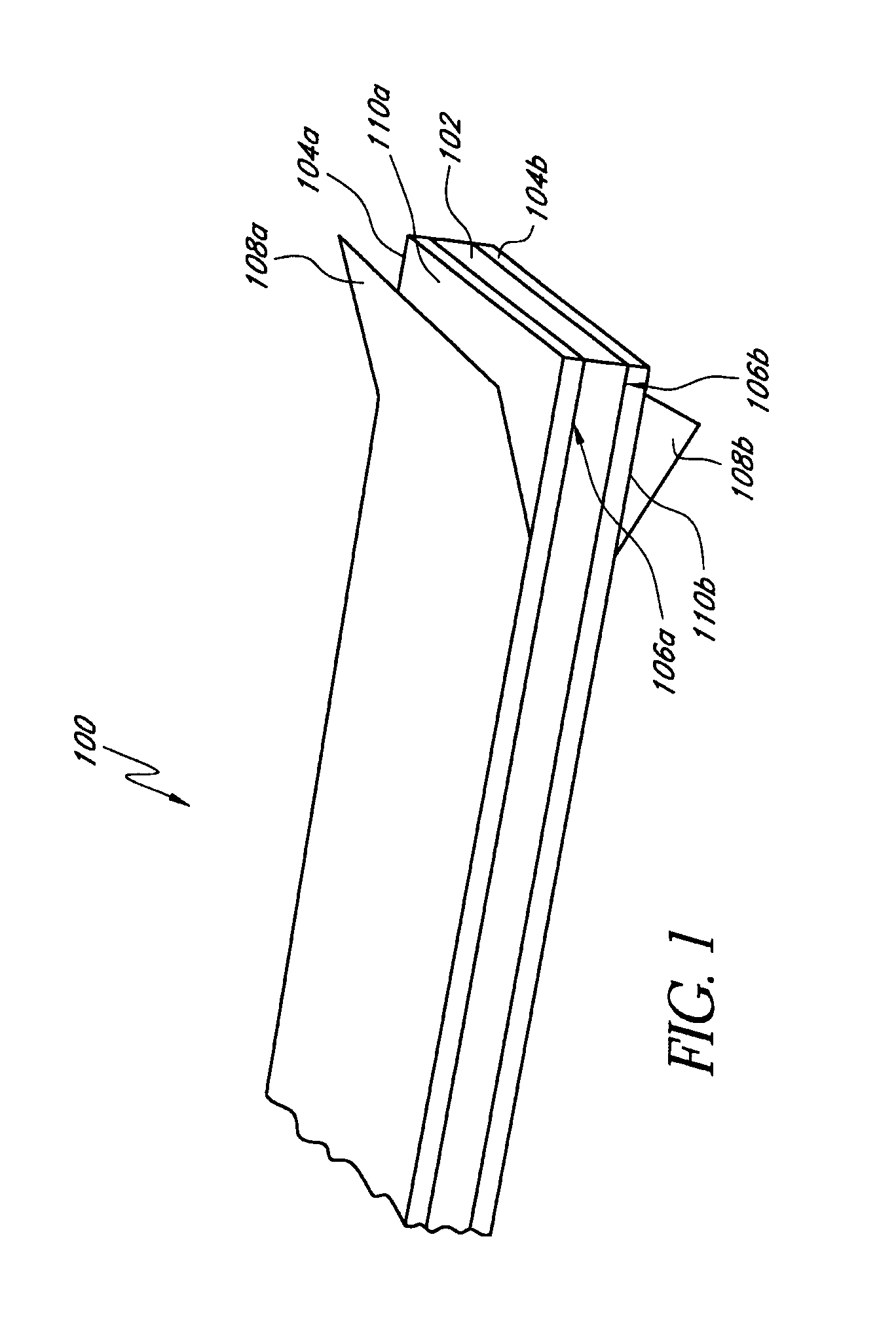

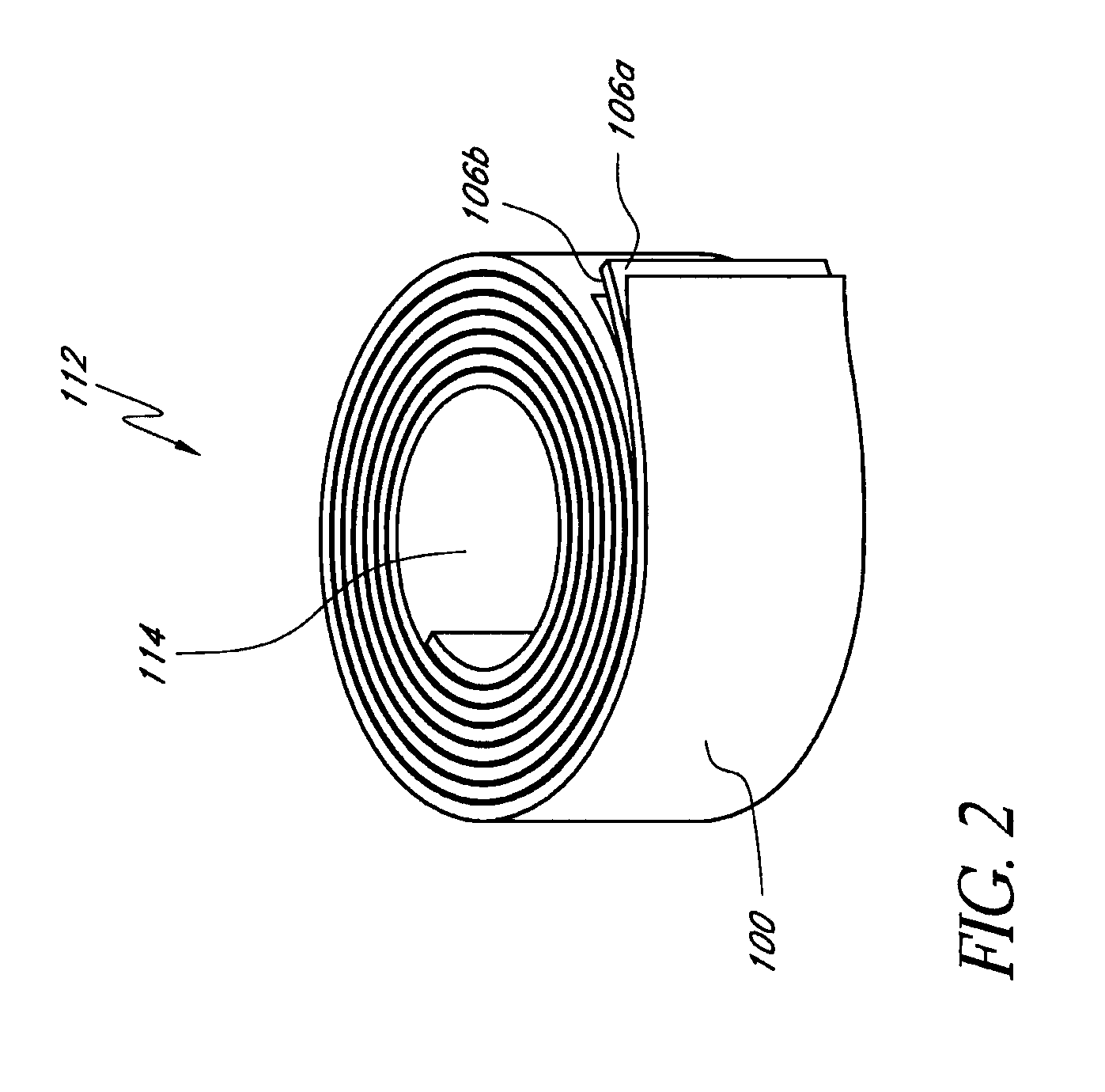

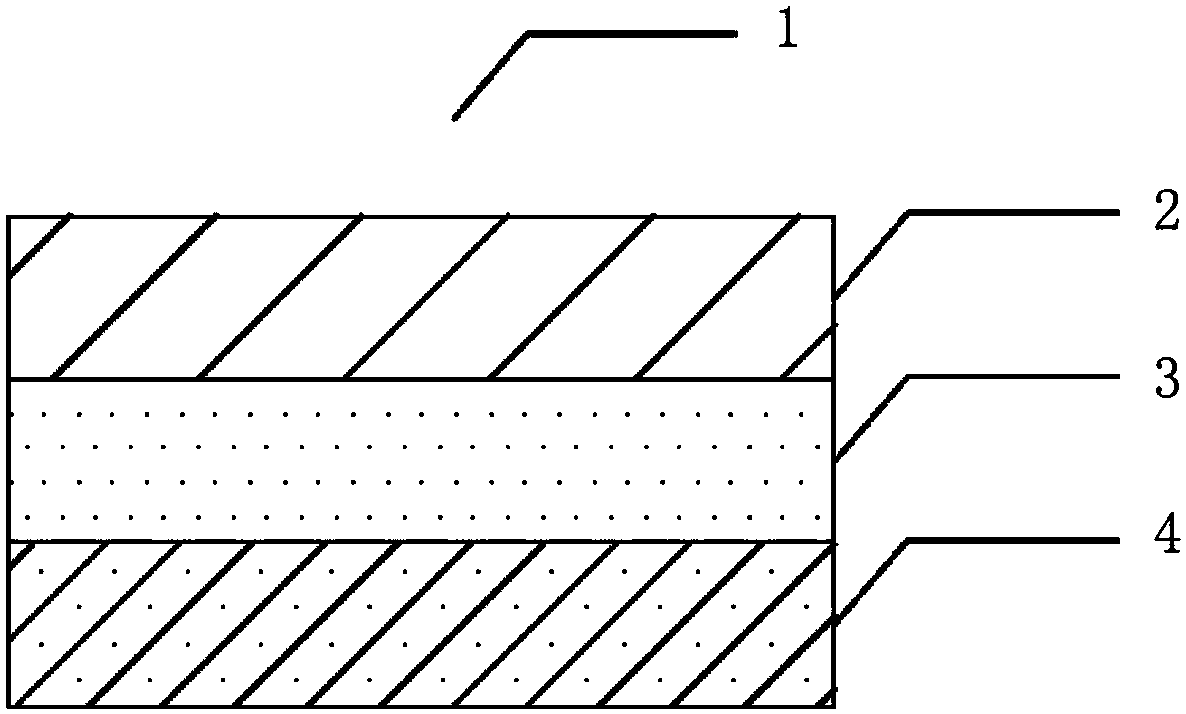

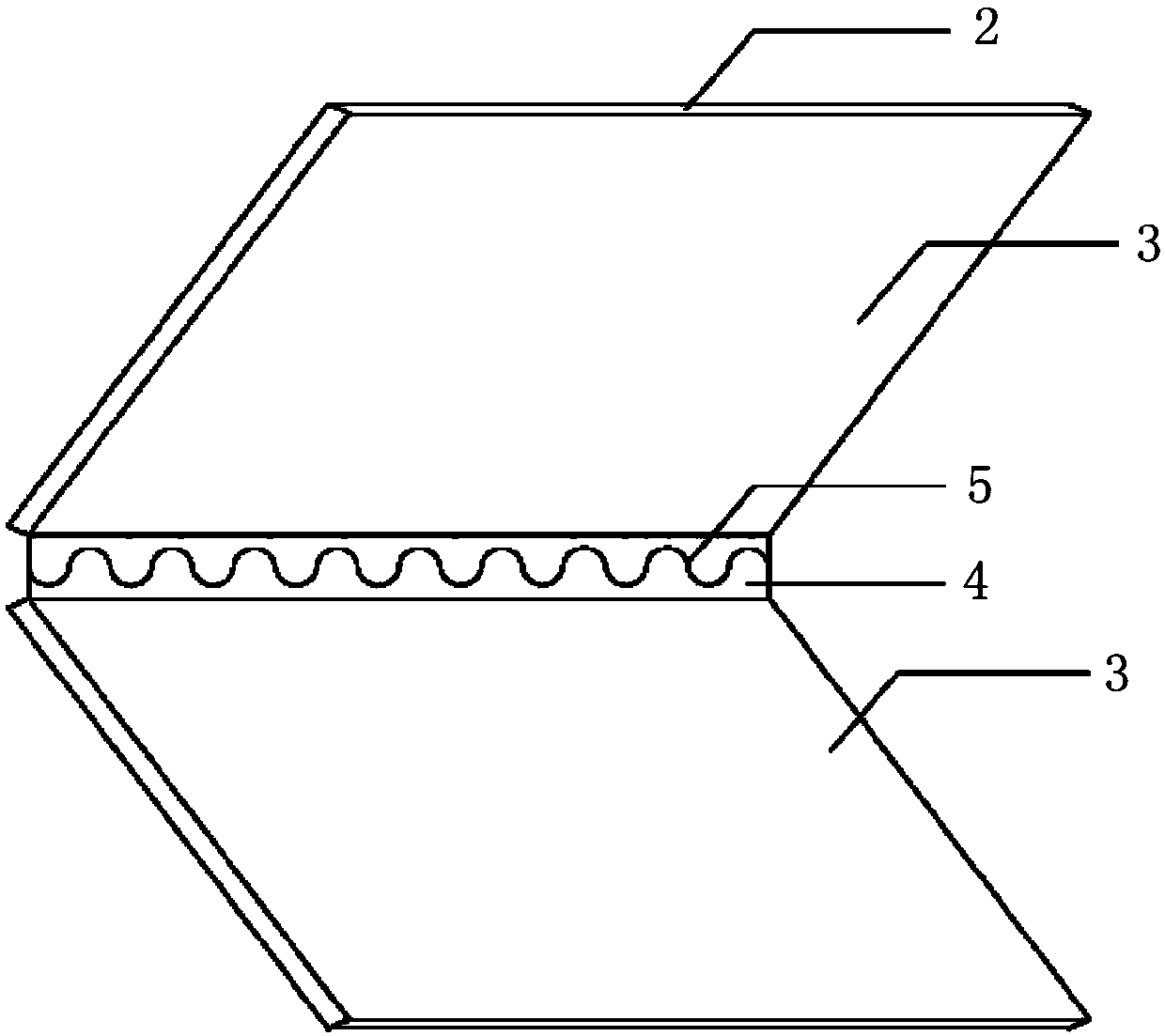

Composite packaging film, packaging system and packaging method

ActiveCN107628365AImprove mechanical propertiesExcellent water vapor barrierFlexible coversWrappersPolyurethane elastomerFiber

The invention provides a composite packaging film, a packaging system using the composite packaging film, and a packaging method in which the composite packaging film is applied to the packaging of balsa. The composite packaging film comprises an inner layer, an outer layer, and a middle layer located between the inner layer and the outer layer, wherein the principal component of the inner layer is a fiber-reinforced polyurethane elastomer composite; the fiber-reinforced polyurethane elastomer composite consists of polymer fiber fabric and a polyurethane elastomer; the middle layer is a bonding layer; and the outer layer is a nylon membrane and / or a polyethylene membrane. The composite packaging film has excellent mechanical properties and an excellent water-vapor isolation property, can be used for packaging any product having water-proof and mildewproof requirements, and is particularly suitable for the packaging of the balsa.

Owner:XINJIANG GOLDWIND SCI & TECH

Processing technology of sandwich balsa wood material for large fan blades

InactiveCN112318662AAvoid crackingAvoid deformationMechanical surface treatmentWood treatment detailsEngineeringFan blade

The invention discloses a processing technology of a sandwich balsa wood material for large fan blades. The processing technology comprises the following steps of preparation before processing, polishing of square timber, dust removal of the square timber, drying after coating on the surfaces of the square timber, shallow grooving of the square timber, punching in the square timber, cloth stickingof the square timber, film coating treatment on the surfaces of the square timber and post-treatment processing on the square timber. The processing technology of the sandwich balsa wood material forthe large fan blades relates to the field of processing of sandwich balsa wood materials, and has the beneficial effects that the water content is controlled to be 20% or below before processing, cracking and deformation of wooden products processed later can be avoided, the density of the timber can be controlled through pressure squaring, and related requirements are met; the surfaces of the square timber is coated and then dried, smeared preservative and smeared treating fluid can better permeate into the square timber at the temperature for drying, and therefore the better effect is achieved.

Owner:湖南伊索尔复合材料有限公司

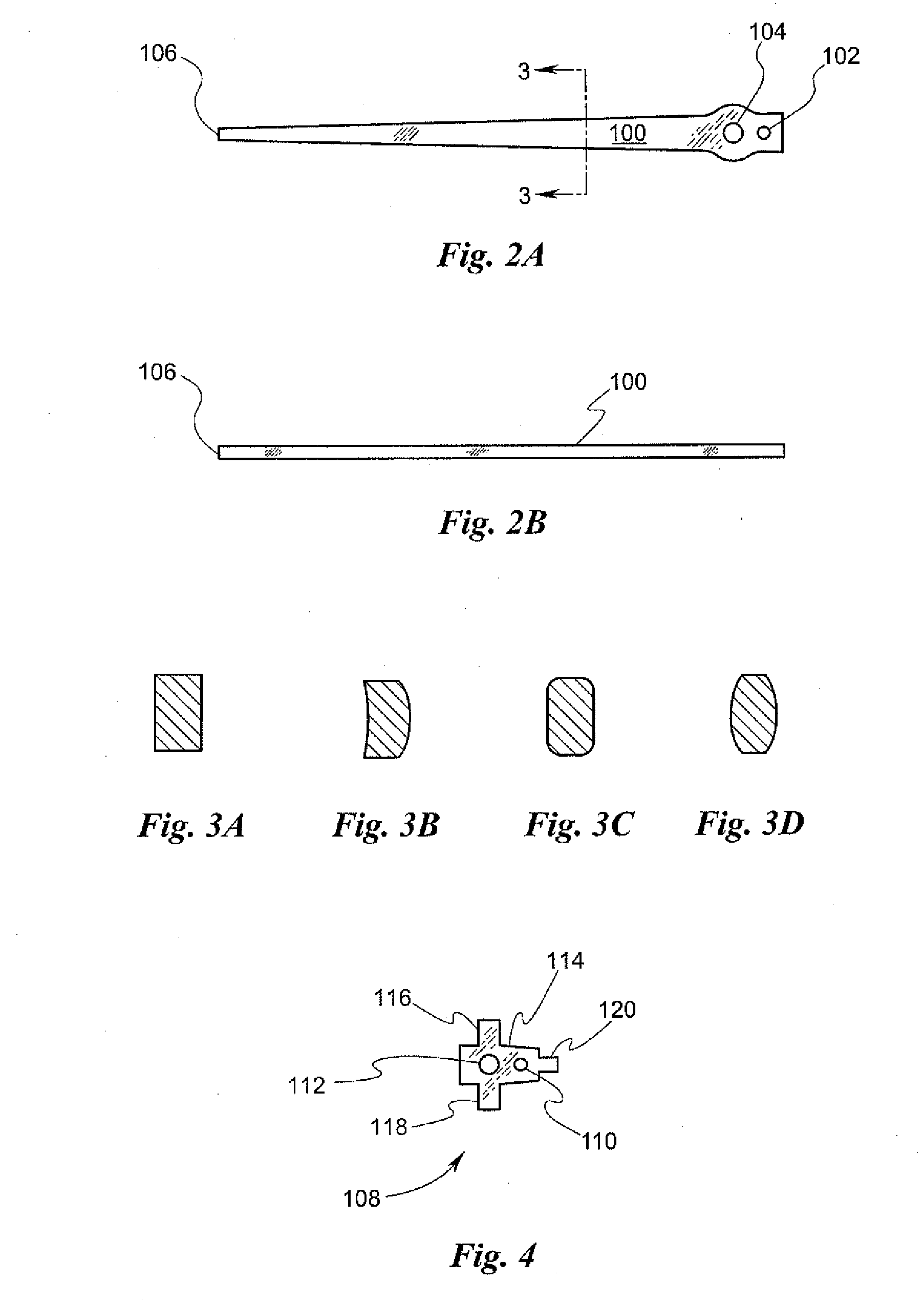

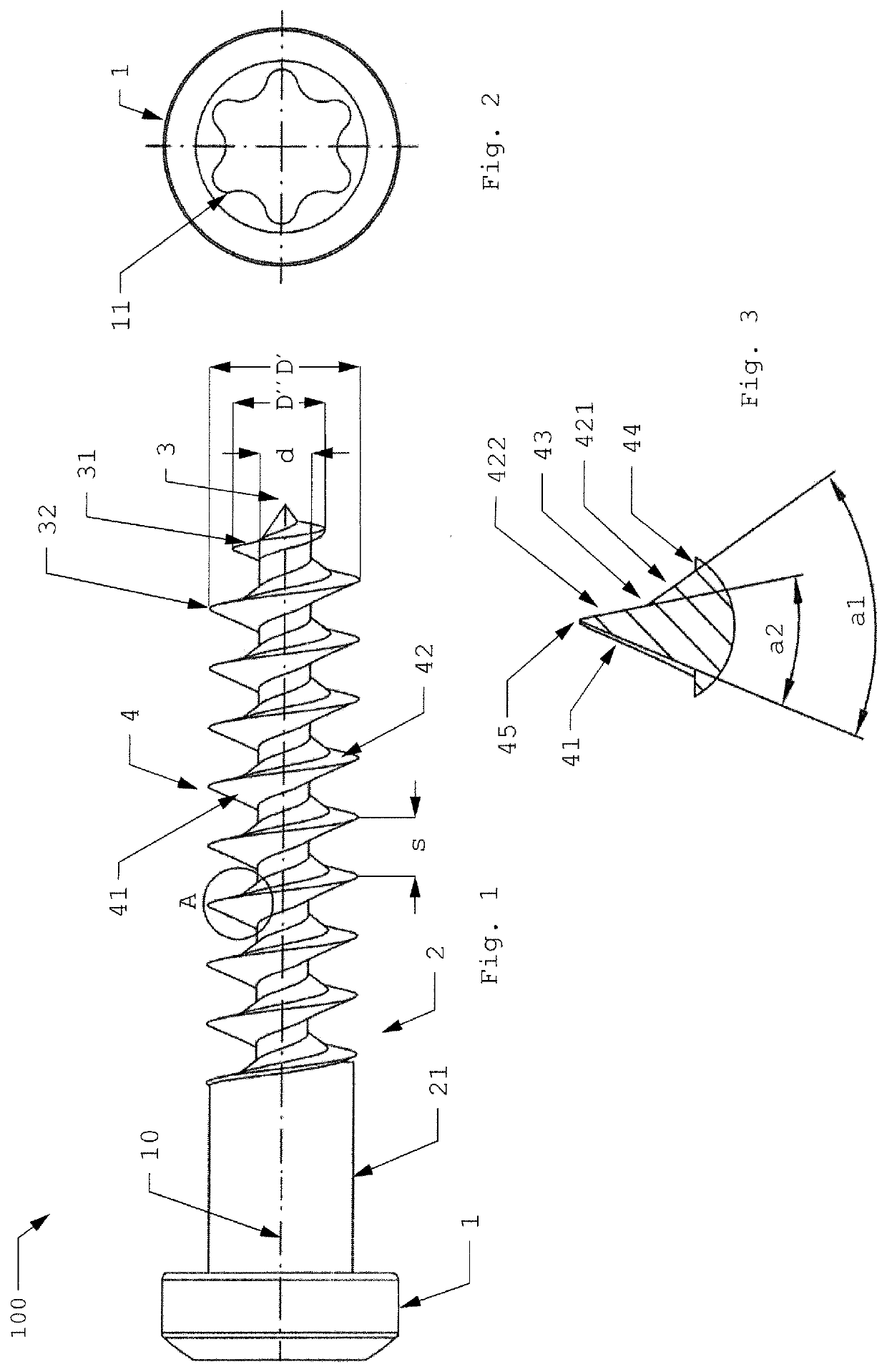

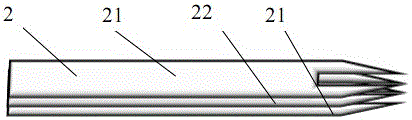

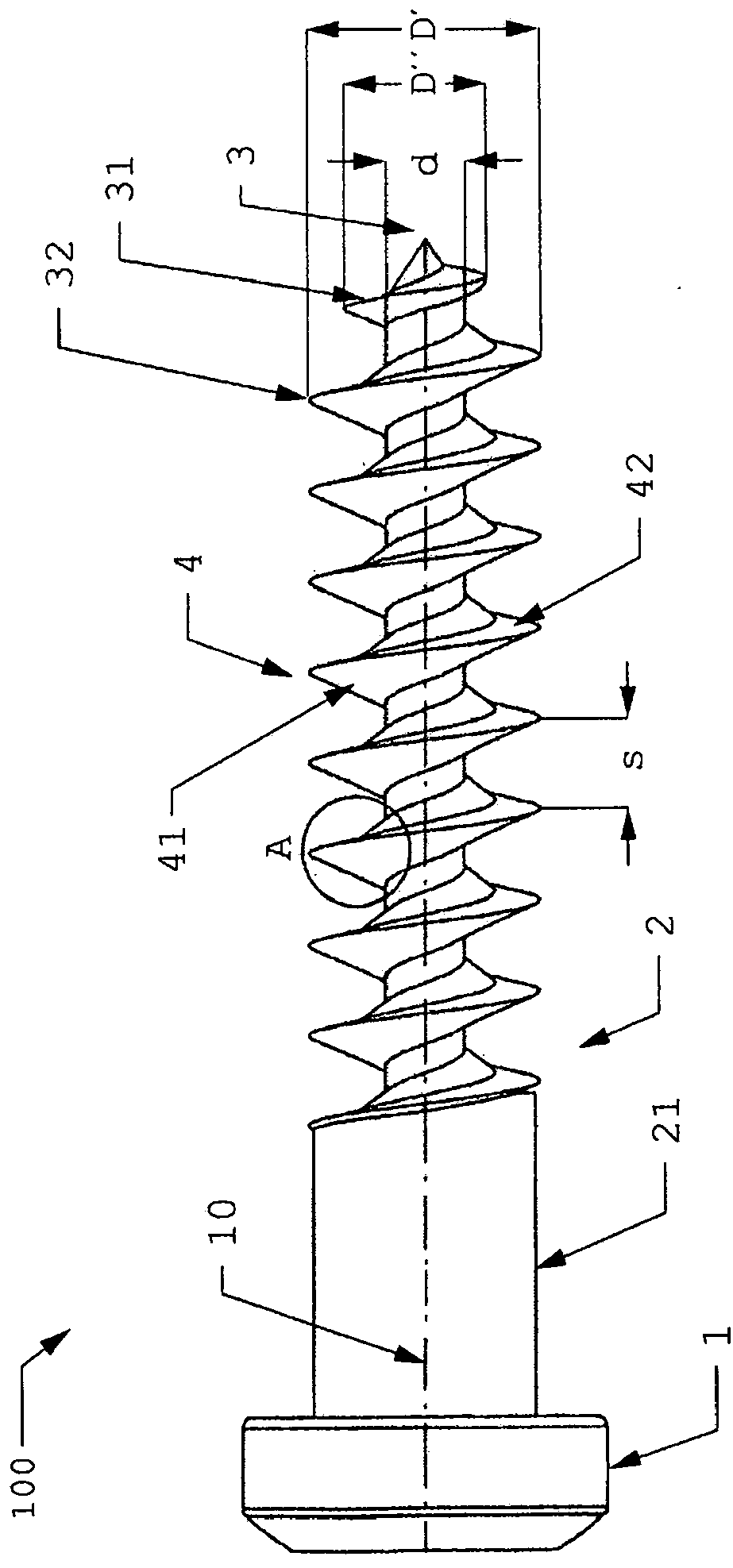

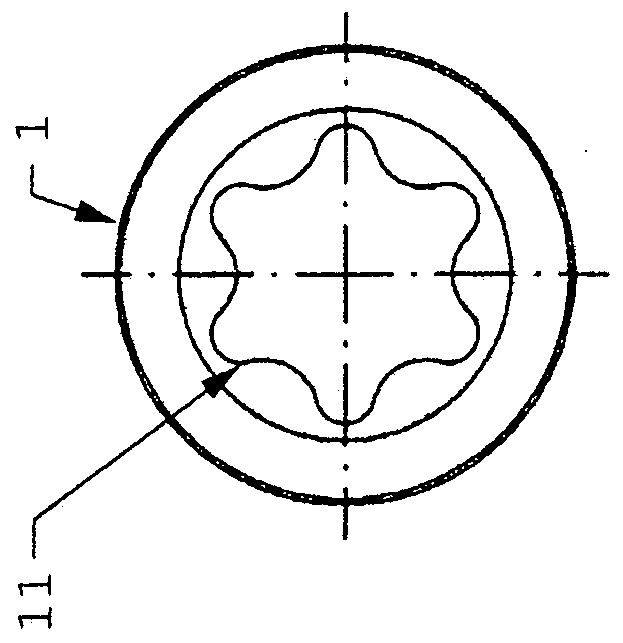

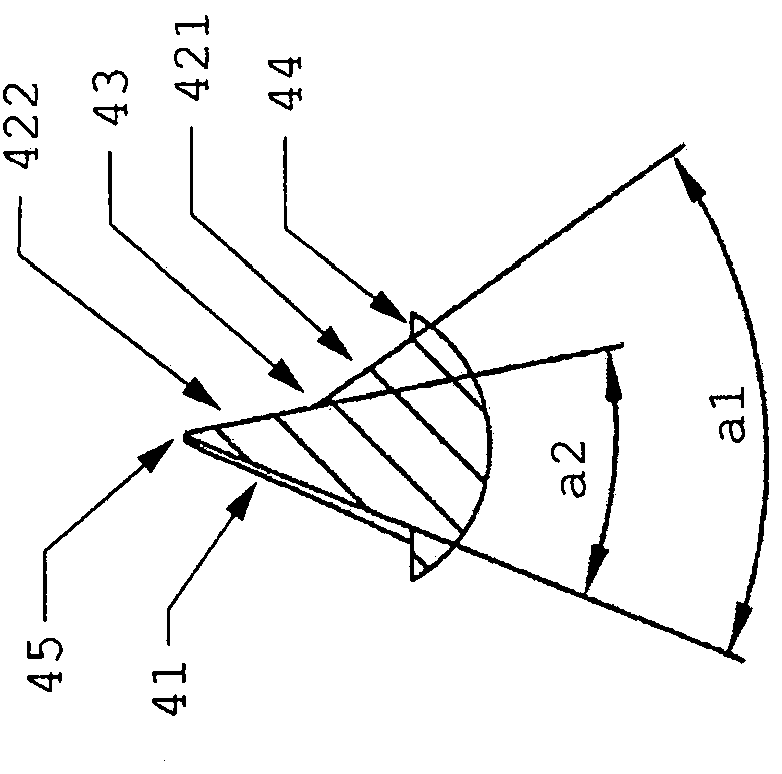

Fastening element

InactiveUS20210372454A1High load absorptionIncrease loadScrewsOchroma pyramidaleMechanical engineering

Fastening element (100) for a porous material, in particular for balsa wood, comprising a fastening head (1) configured to receive a torque in both rotational directions around a main axis (10) and a shank (2) that extends from the fastening head (1) and ends in a tip (3) at the end facing away from the fastening head. The shank (2) has an outer thread (4) along at least a section of its extension in a direction of the main axis (10), for screwing the fastening element (100) into the material.

Owner:BOSSARD AG

Novel hockey stick of hockey goalkeeper and manufacturing method of novel hockey stick

ActiveCN106390402AImprove shock absorptionImprove durabilityWood working apparatusRacket sportsFiberEpoxy

The invention relates to the technical field of sports goods and manufacturing thereof and particularly relates to a novel hockey stick of a hockey goalkeeper. The novel hockey stick comprises a front-section filling plate, a middle-section filling plate, a bolt filling block and a handle; a plurality of layers of glass fiber yarns or carbon fiber yarns cover the outer part of the connected front-section filling plate, middle-section filling plate, bolt filling block to form a goalkeeping plate, wherein the middle-section filling plate is formed by compounding three layers of materials including EPOXY, balsa wood and EPOXY in sequence; and the bolt filling block in the goalkeeping plate is inserted into the handle and the bolt filling block is fixedly connected with the handle. A manufacturing method of the novel hockey stick of the hockey goalkeeper comprises the following steps: manufacturing the front-section filling plate, the middle-section filling plate and the bolt filling block, and connecting the goalkeeping plate with the handle. The novel hockey stick of the hockey goalkeeper and the manufacturing method of the novel hockey stick, provided by the invention, have the beneficial effects that (1) the flexibility of kicking is increased; (2) the hockey control speed is improved; (3) the vibration resistance is improved; (4) the bounce of the goalkeeping plate is increased; (5) the goalkeeping plate is not easy to break, bend and deform when receiving a certain impact force; and (6) the service life is long.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE

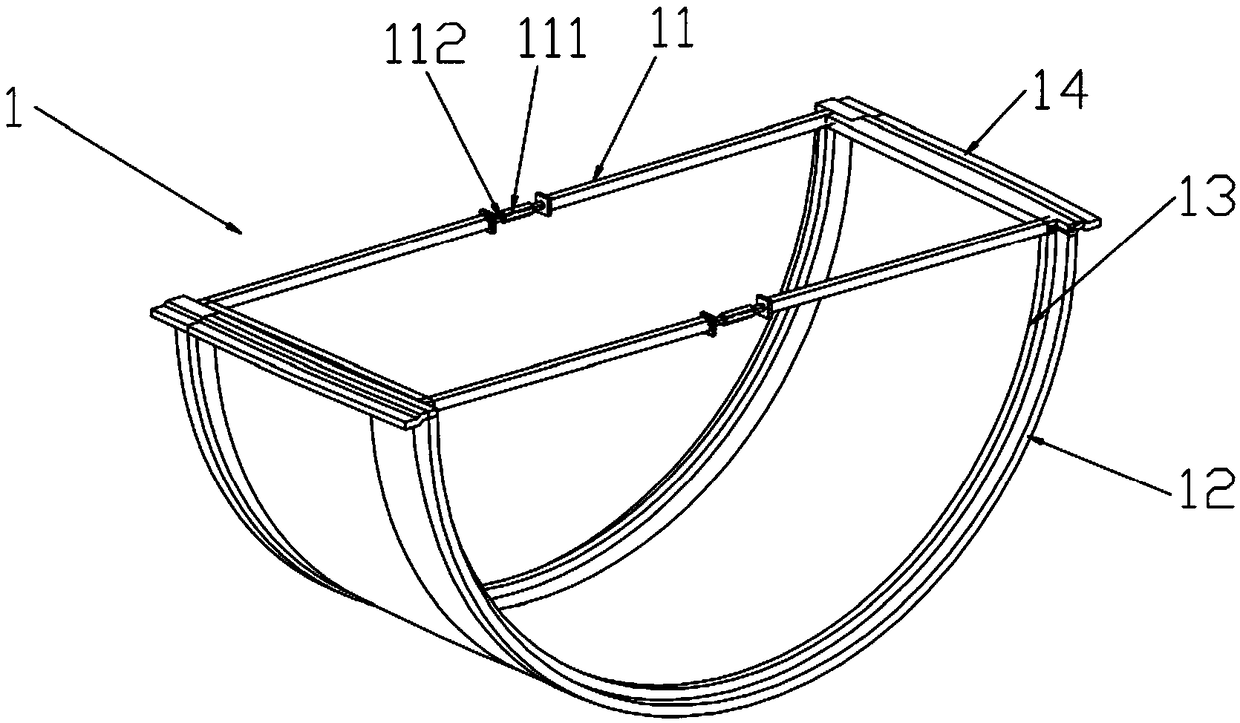

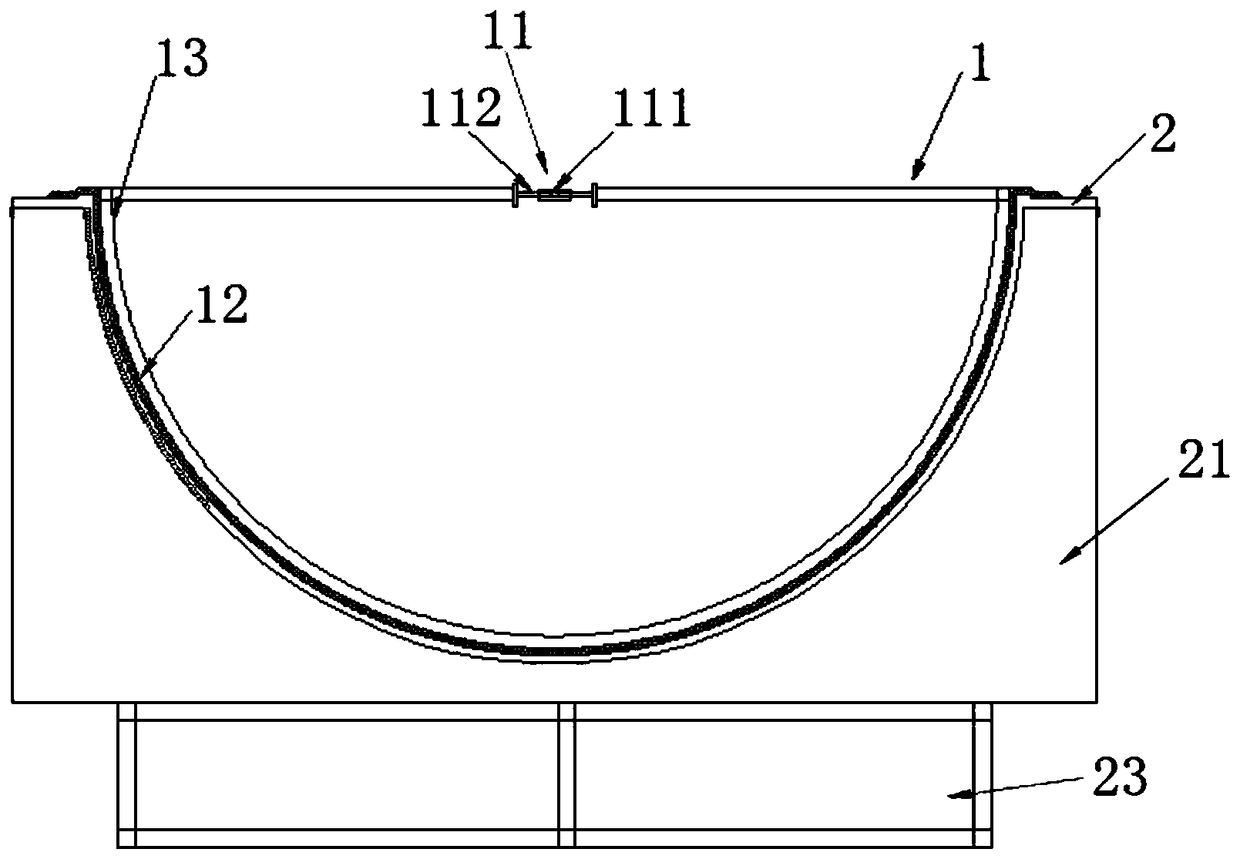

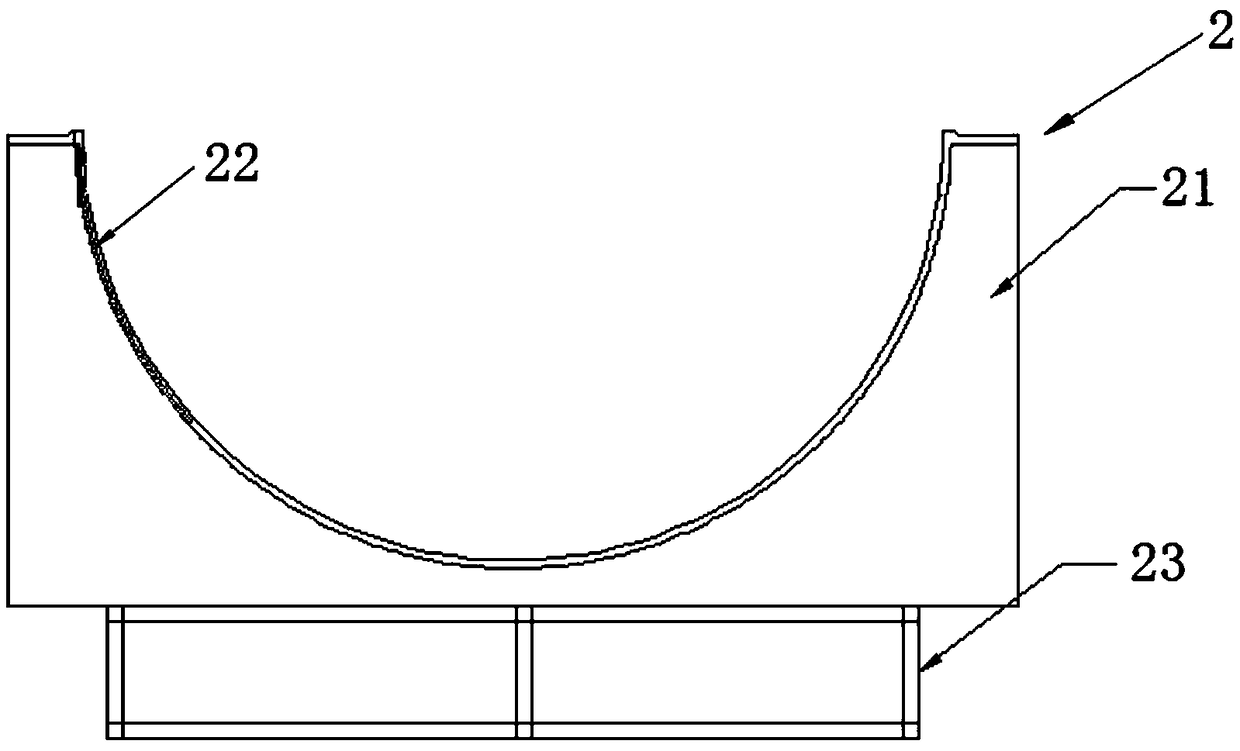

RTM change mold for changing root diameters of fan blade molds and change method of RTM change mold

The invention discloses an RTM change mold for changing root diameters of fan blade molds and change method of the RTM change mold. The mold comprises an RTM mold shell and two RTM mold diameter adjustment rods, wherein the RTM mold shell is made of an RTM mold male mold; the RTM mold shell is molded through vacuum infusion according to the shape size of a blade mold root section of the RTM mold male mold; a structure with balsa wood in the middle and multiple layers of four-axial cloth on the upper and lower sides is formed, and semicircular surfaces adapted to the blade root shape are formed; a square tube is manually pasted on the inner surface of the RTM mold shell to enhance the strength of the RTM mold shell; the two RTM mold diameter adjustment rods are horizontally arranged on thediameters of the semicircular surfaces on two sides of an opening of the RTM mold shell in parallel; the middles of the two RTM mold diameter adjustment rods are formed by positive and negative nuts and bolts via connection; through rotating the positive and negative nuts, the diameter of the RTM mold shell can be adjusted. The mold provided by the invention has the advantages of being reusable, low in cost and high in production efficiency.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

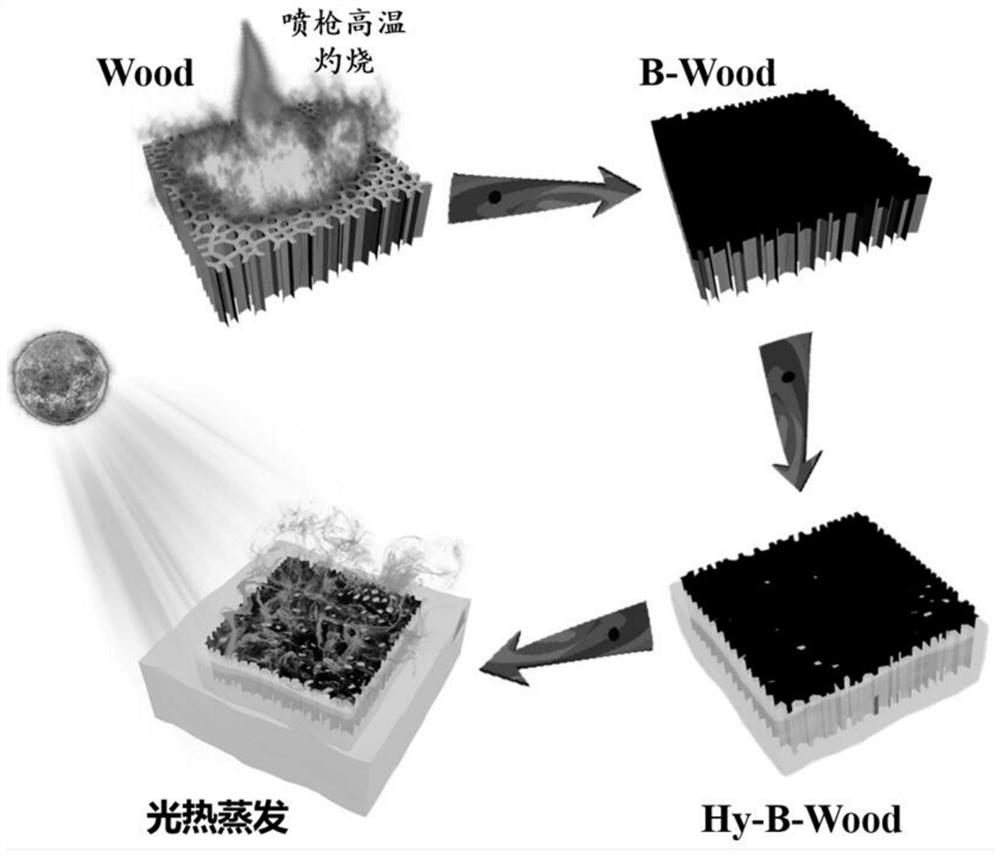

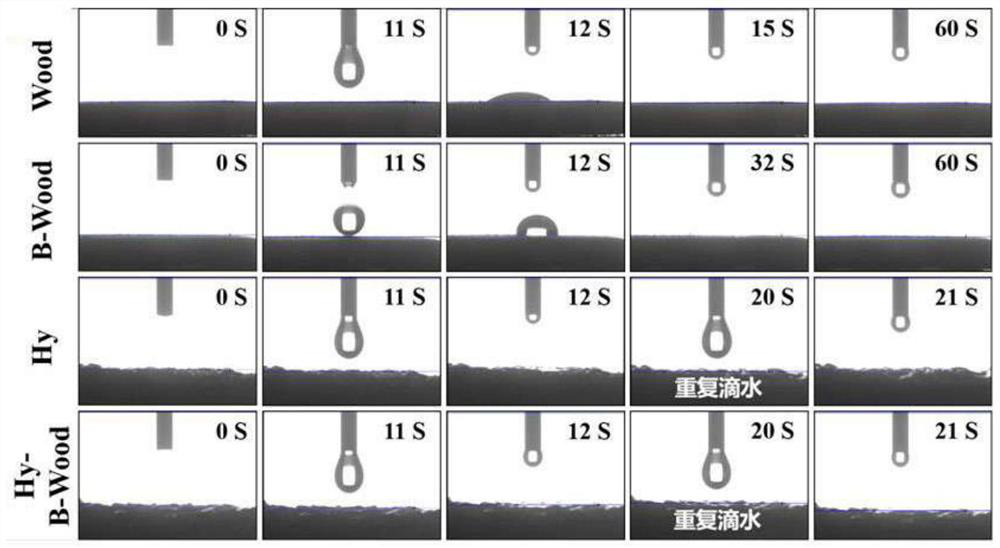

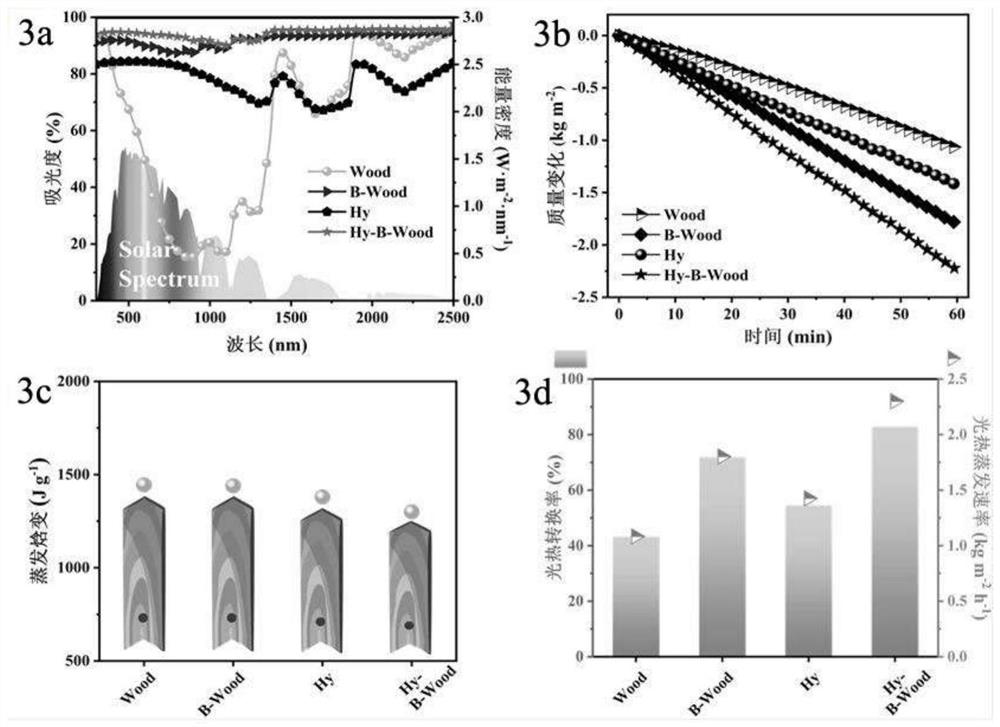

Self-floating wood-based hydrogel photo-thermal evaporator and preparation method and application thereof

PendingCN114100533AHigh photothermal conversion efficiencySignificant photothermal purification abilityGeneral water supply conservationSeawater treatmentPolymer sciencePolyvinyl alcohol

The invention discloses a self-floating wood-based hydrogel photo-thermal evaporator and a preparation method and application thereof, and belongs to the technical field of photo-thermal conversion. The preparation method comprises the following steps: mixing chitosan and polyvinyl alcohol to prepare an interpenetrating network polymer, and then combining a wood material with the polymer to prepare the photo-thermal wood-based hydrogel material. A wood material is subjected to surface treatment through high-temperature firing of a spray gun, the sunlight absorptivity of the surface of the balsa wood is improved, natural pore channels of the balsa wood are filled with a hydrogel photo-thermal material, energy needed by evaporation is reduced, evaporation enthalpy change is reduced, and efficient water production is achieved while rapid water delivery of the evaporator is ensured. The hydrogel material is simple in preparation process and has wide application prospects in the fields of sewage treatment, seawater desalination and the like.

Owner:NANJING FORESTRY UNIV

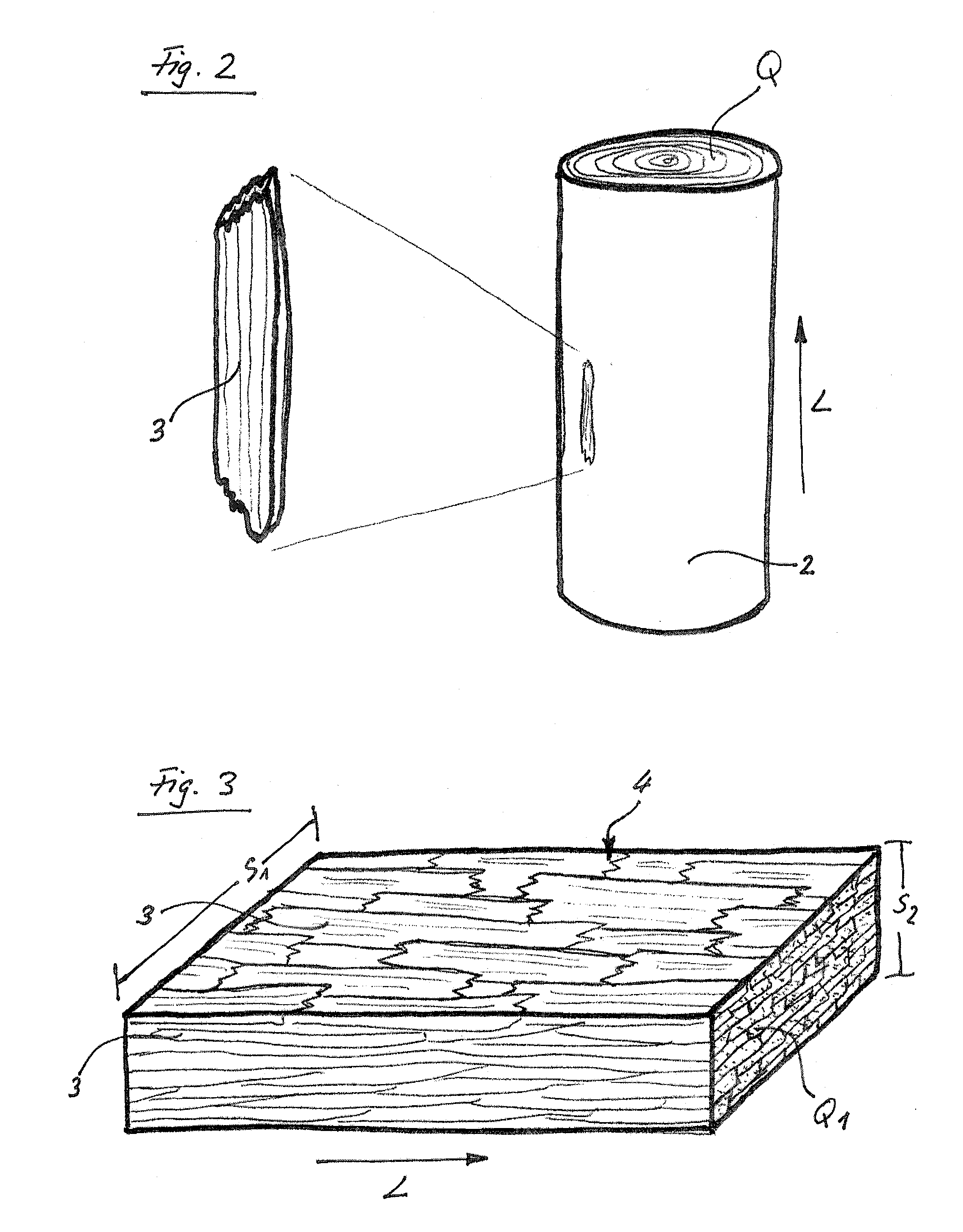

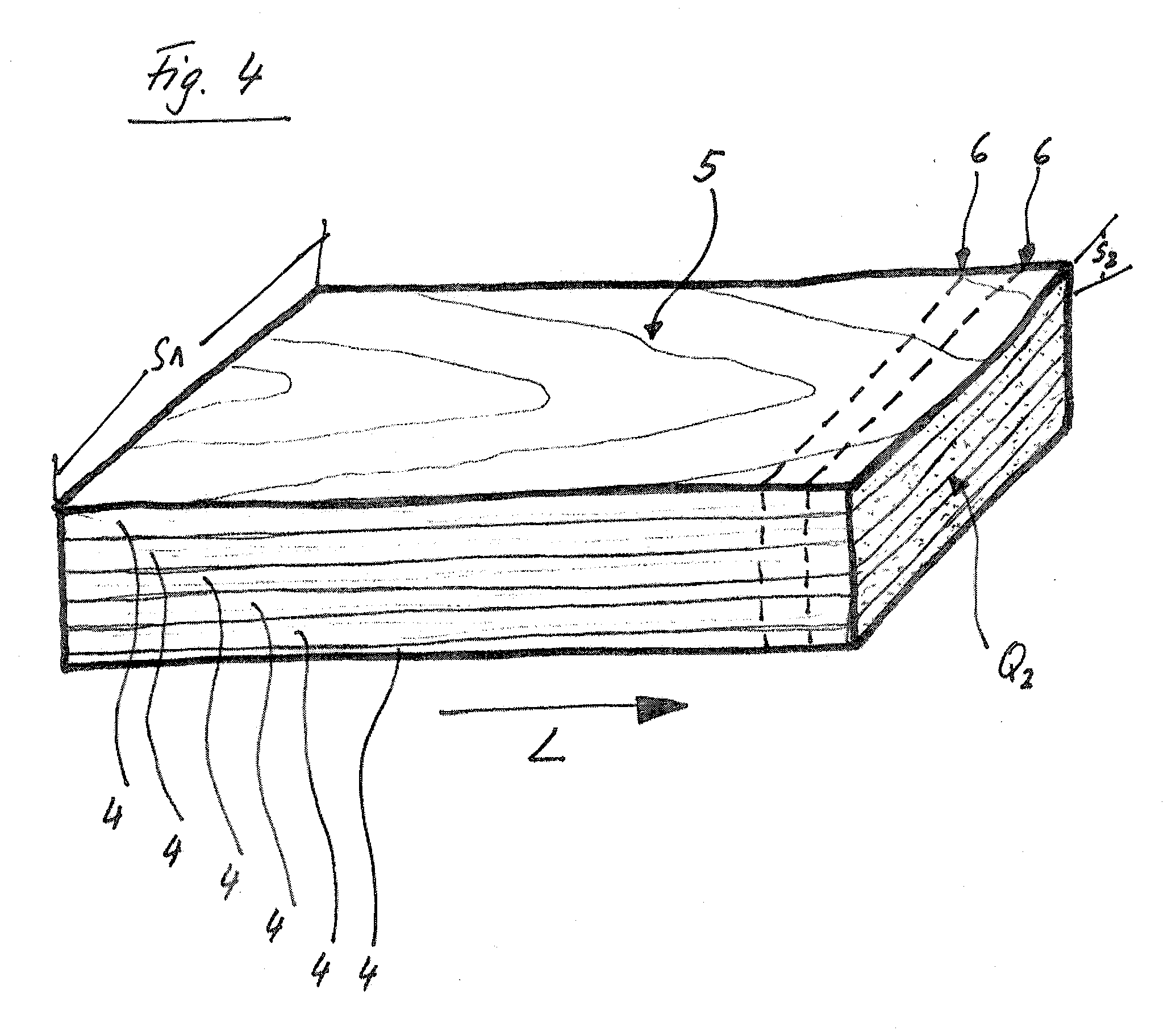

Shaped articles with balsa wood and method of producing them

ActiveUS8318319B2Cellulosic plastic layered productsWood working apparatusBalsa woodMaterials science

Shaped articles made of balsa veneers, balsa chips, balsa strands or balsa strips, which are oriented in the same direction according to their grain direction, and the grain direction of the individual chips deviates by 0° to 30° from the direction of the axis of the grain. The spaces of the adjacent balsa veneers, chips, strands or strips are filled with a, for example foamed, adhesive, the density of which may be the same as or close to the density of the surrounding balsa wood.

Owner:ALCAN TECH & MANAGEMENT LTD

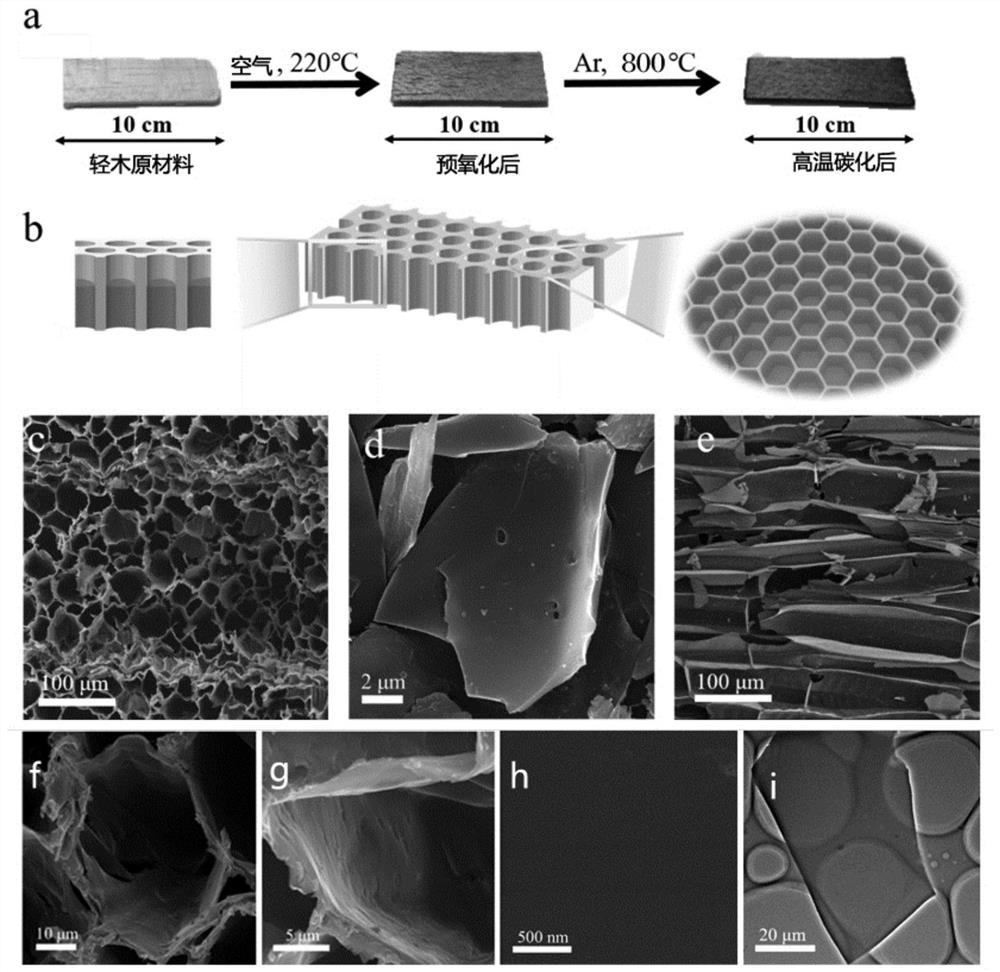

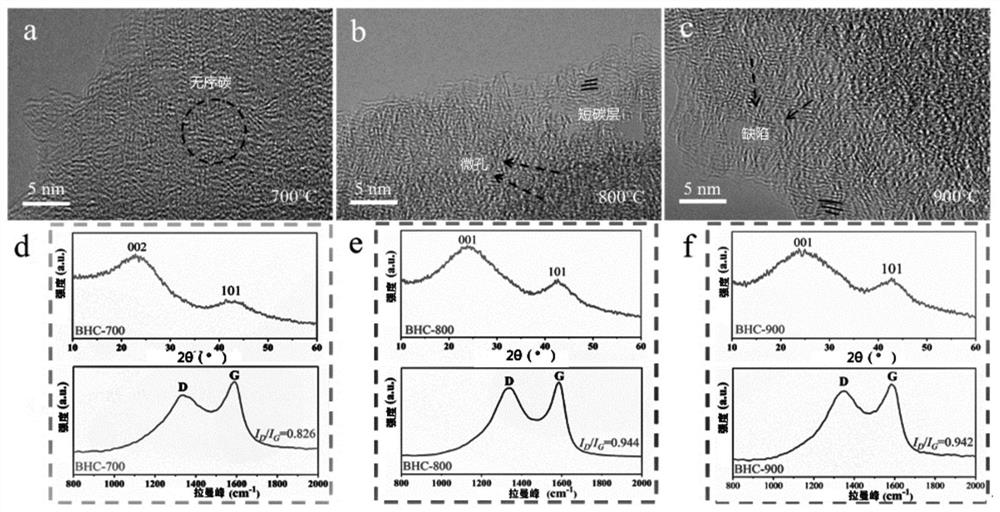

Balsa wood-derived binder-free self-standing carbon foam negative electrode material and preparation method thereof

InactiveCN112436138AIncrease energy densityIncrease loadCell electrodesSecondary cellsElectrolytic agentPolymer science

The invention provides a balsa wood-derived binder-free self-standing carbon foam negative electrode material and a preparation method thereof. The self-standing carbon foam negative electrode material is prepared by taking balsa wood as a precursor through a carbonization method; the self-standing carbon foam negative electrode material has a unique multi-layer and three-dimensional cross-linkedstructure of balsa wood; the three-dimensional cross-linked structure is composed of tubular structures which are evenly distributed and nanopores distributed in the inner wall of the pipeline, so thethree-dimensional cross-linked structure with the interiors connected with one another is formed; and the three-dimensional cross-linked structure of the self-supporting carbon foam negative electrode material can accelerate permeation of an electrolyte, provide a rapid transmission channel for electrons and ions and improve reaction kinetics. The method comprises the following steps: cleaning and drying the balsa wood precursor; carrying out pre-oxidation treatment on the balsa wood at the temperature of 210-230 DEG C; and then annealing and carbonizing for 1-3h at 700-1200 DEG C to obtain the binder-free self-standing carbon foam negative electrode material. The potassium ion battery negative electrode material which is safe and stable in electrochemical performance and does not need touse a binder can be obtained.

Owner:福建海峡石墨烯产业技术研究院有限公司

Fastening element

Fastening element (100) for a porous material, in particular balsa wood, comprising a fastening head (1) designed to absorb torque in both directions of rotation about a main axis (10), and a shaft (2) which extends from the fastening head (1) and ends in a tip (3) at the end opposite the fastening head. The shaft (2) has an external thread (4) along at least part of its extension in the directionof the main axis (10) in order to be able to screw the fastening element (100) into the material.

Owner:BOSSARD AG

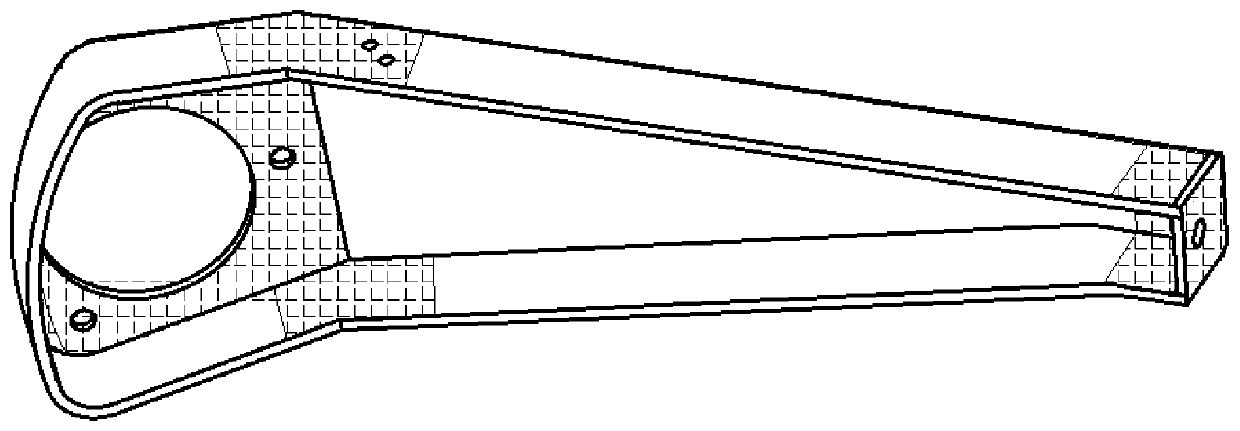

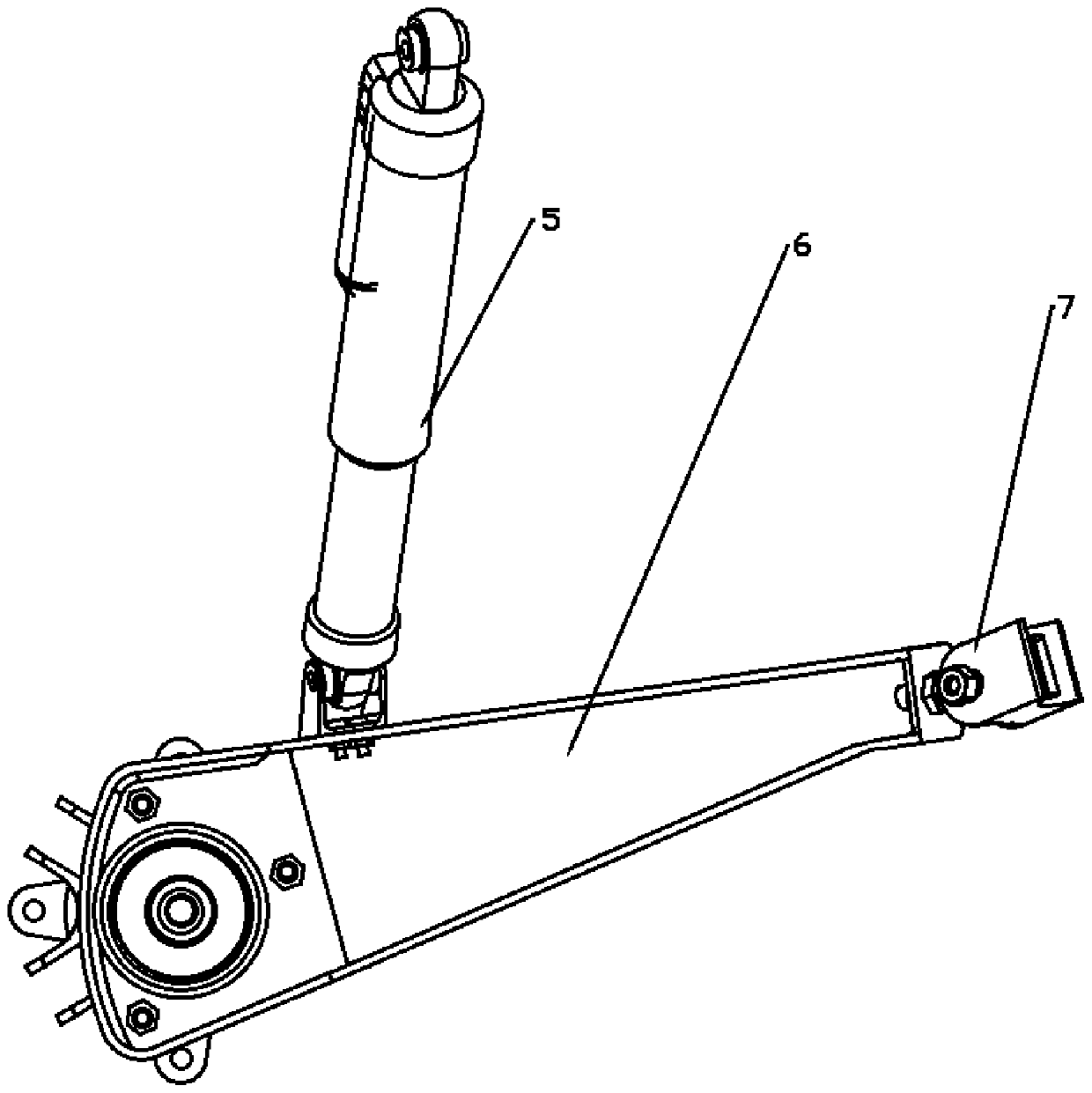

Off-road vehicle composite trailing arm and manufacturing method thereof

PendingCN111301074ALight in massImprove mechanical propertiesLaminationLamination apparatusFiberCarbon fibers

The invention belongs to the technical field of an automobile and particularly relates to an off-road vehicle composite trailing arm and a manufacturing method thereof. The trailing arm includes a support frame layer, an adhesive film layer and a carbon fiber material layer are laid on the outer side of the supporting frame layer, and a supporting frame is composed of a balsa wood material, an aluminum material and super glue. The trailing arm is advantaged in that the mass of the trailing arm is effectively reduced while good mechanical properties are guaranteed, and the trailing arm has goodimpact resistance, is not prone to breakage and breakage, still has a high safety coefficient under severe driving conditions and guarantees safety of a driver, a new structural connection form for the structure is provided, the aluminum material is partially pre-buried in the carbon fiber material layer, a part of the aluminum material is externally processed into the mounting hole, so a weldingerror of a traditional trailing arm structure is eliminated.

Owner:JILIN UNIV

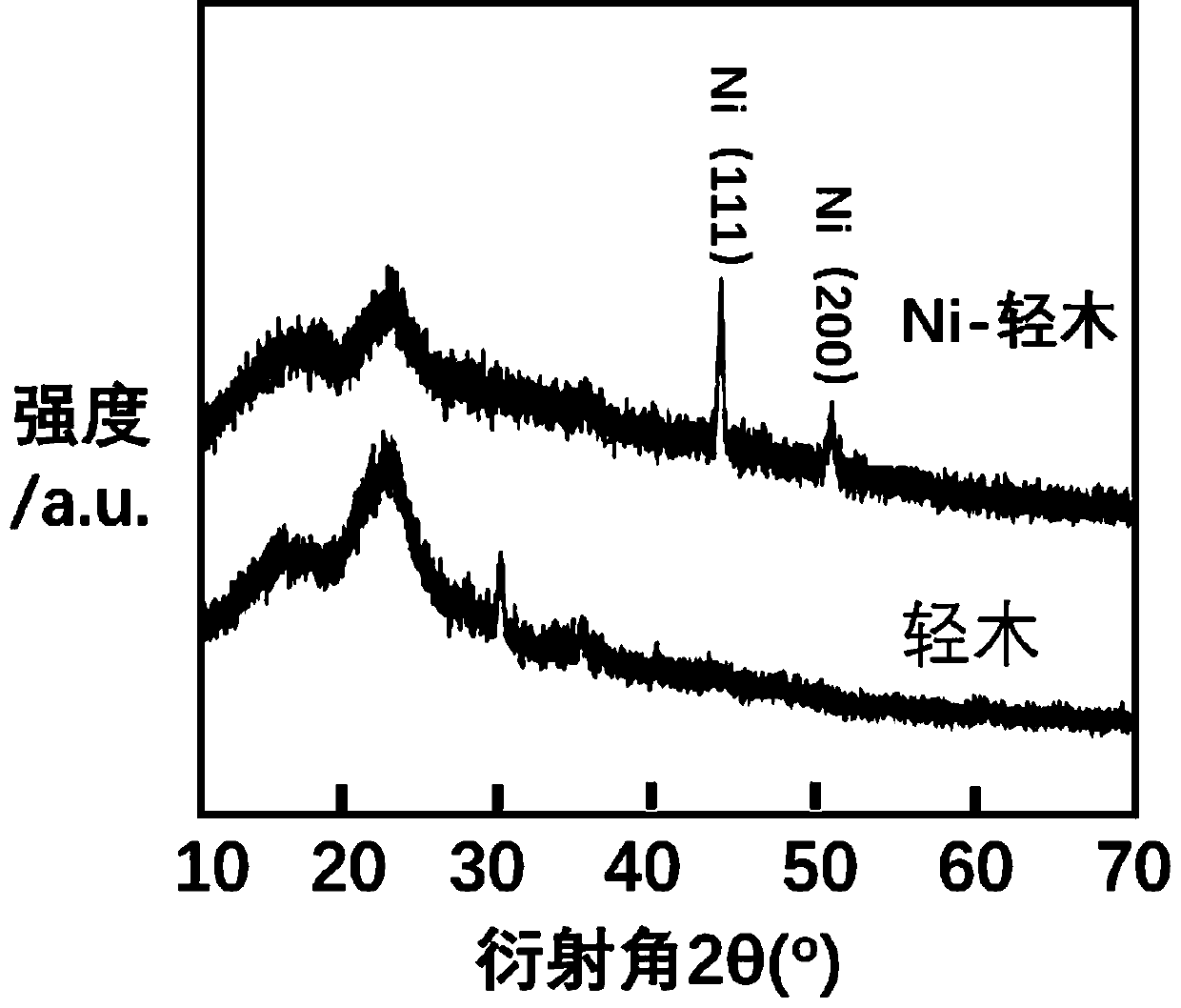

Preparation process for metallic nickel-balsa wood composite material

InactiveCN111086076AEasy accessLoose structureWood treatment detailsThermal wood treatmentEthylic acidSodium borohydride

The invention discloses a preparation process for a metallic nickel-balsa wood composite material. The preparation process comprises the following steps: putting balsa wood into a drying oven, and carrying out treating at 90-110 DEG C for 2-24 hours; preparing a nickel acetate solution, adding certain amounts of sodium borohydride and sodium hydroxide, and adjusting a pH value to 10-12; then placing heat-treated balsa wood into a prepared nickel acetate solution, and carrying out treating at 40-60 DEG C for 2-12 hours; and placing a treated balsa wood sample into an air blowing dryer for drying treatment, carrying out heat-preserved drying for 4-6 days at a temperature of 30 DEG C or below, carrying out cooling to a room temperature with a furnace, and carrying out drying until the weightof the sample is not changed. According to the metal-composite material treatment process for the balsa wood, the absolute dry density of the balsa wood is only 0.16 g / cm<3>; the structure of the balsa wood is loose; and a nickel precursor solution can enter the balsa wood easily. The treatment process is simple; treatment is safe and reliable; harmful gas is not released; and operation is convenient.

Owner:江苏林德曼新材料科技有限公司

Novel hockey goaltender stick and method of making the same

ActiveCN106390402BImprove shock absorptionImprove durabilityWood working apparatusRacket sportsEpoxyYarn

The invention relates to the technical field of sports goods and manufacturing thereof and particularly relates to a novel hockey stick of a hockey goalkeeper. The novel hockey stick comprises a front-section filling plate, a middle-section filling plate, a bolt filling block and a handle; a plurality of layers of glass fiber yarns or carbon fiber yarns cover the outer part of the connected front-section filling plate, middle-section filling plate, bolt filling block to form a goalkeeping plate, wherein the middle-section filling plate is formed by compounding three layers of materials including EPOXY, balsa wood and EPOXY in sequence; and the bolt filling block in the goalkeeping plate is inserted into the handle and the bolt filling block is fixedly connected with the handle. A manufacturing method of the novel hockey stick of the hockey goalkeeper comprises the following steps: manufacturing the front-section filling plate, the middle-section filling plate and the bolt filling block, and connecting the goalkeeping plate with the handle. The novel hockey stick of the hockey goalkeeper and the manufacturing method of the novel hockey stick, provided by the invention, have the beneficial effects that (1) the flexibility of kicking is increased; (2) the hockey control speed is improved; (3) the vibration resistance is improved; (4) the bounce of the goalkeeping plate is increased; (5) the goalkeeping plate is not easy to break, bend and deform when receiving a certain impact force; and (6) the service life is long.

Owner:TONGXIANG BONNY SCI & TECH COMPOSITE

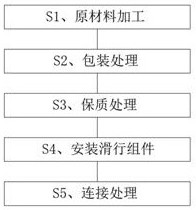

Storage, transportation and quality guarantee method for megawatt fan blade sandwich material balsa wood

InactiveCN114348410AImprove stabilityIncrease air flowWood working apparatusContainers preventing decayAgricultural engineeringPulp and paper industry

The invention discloses a storage, transportation and quality guarantee method for megawatt fan blade sandwich material balsa wood. The method comprises the following steps: processing raw materials, selecting proper balsa wood raw wood, drying the balsa wood, carrying out thicknessing treatment after drying, and carrying out preservative treatment and airing after thicknessing treatment. And packaging treatment is conducted, the balsa wood is placed on a tray, a plurality of limiting columns are fixedly installed on the top of the tray, and the limiting columns are located on the periphery of the balsa wood. The balsa wood tray has the beneficial effects that the stability of balsa wood on the tray is improved, meanwhile, air flow around the balsa wood is accelerated, the influence of damp air on the balsa wood is reduced, the tray can be moved through the rolling wheels when needing to be moved, the tray is supported through the supporting plates when not needing to be moved, transportation and storage of the balsa wood are facilitated, and the practicability of the balsa wood tray is improved. And the two adjacent trays are connected through the connecting plates, so that the placing stability of the trays is improved, the stability of balsa wood during transportation is improved, and the convenience is improved.

Owner:湖南伊索尔复合材料有限公司

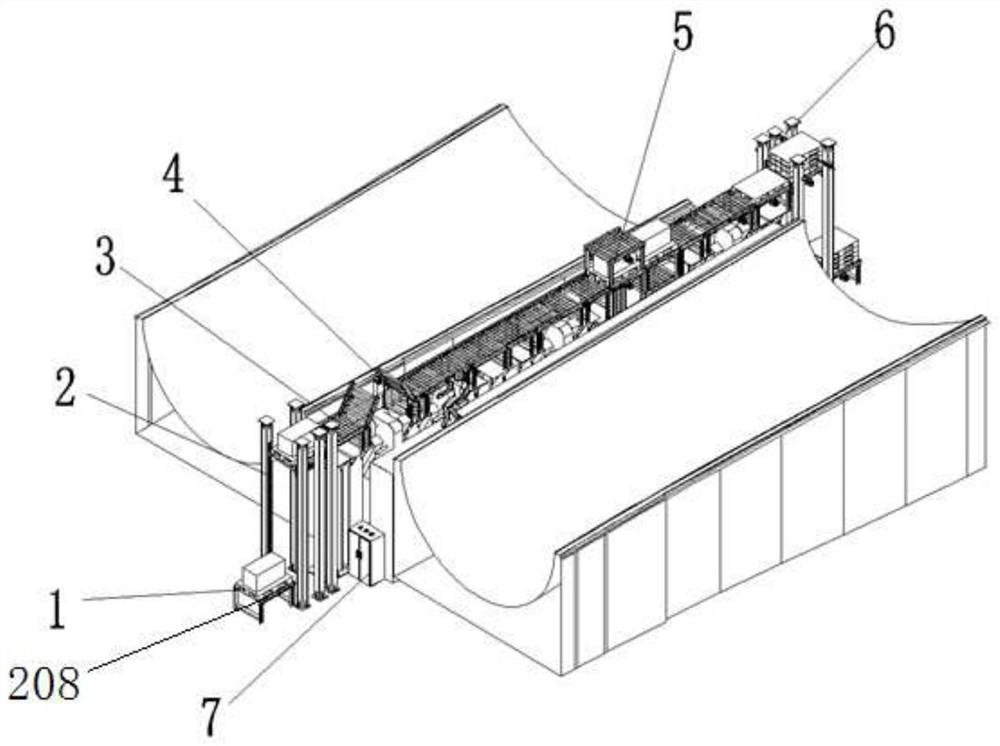

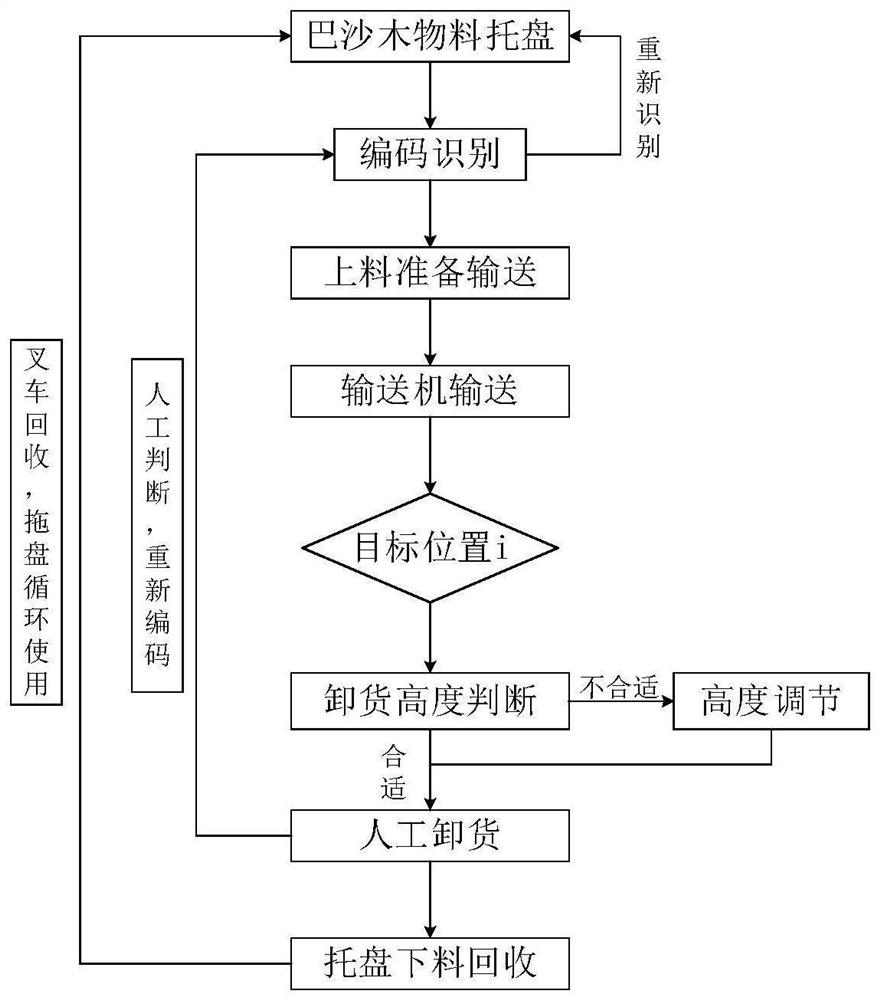

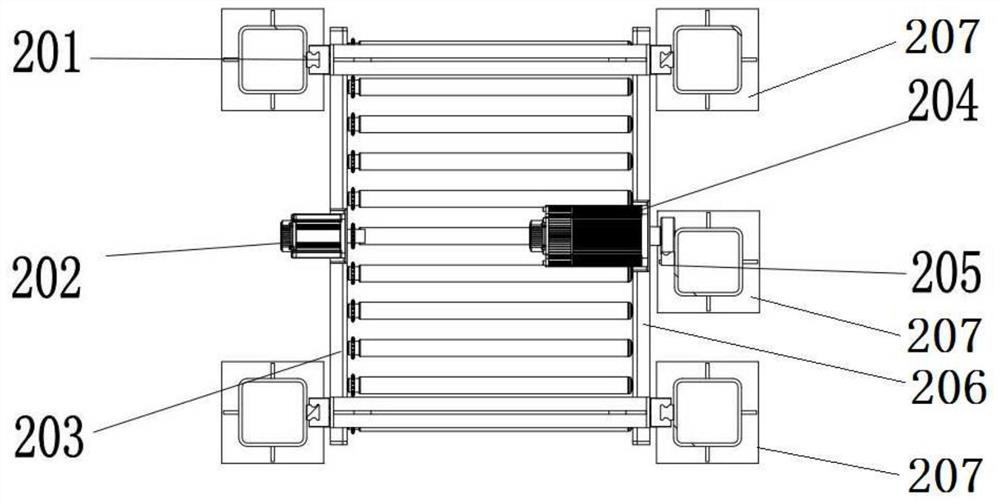

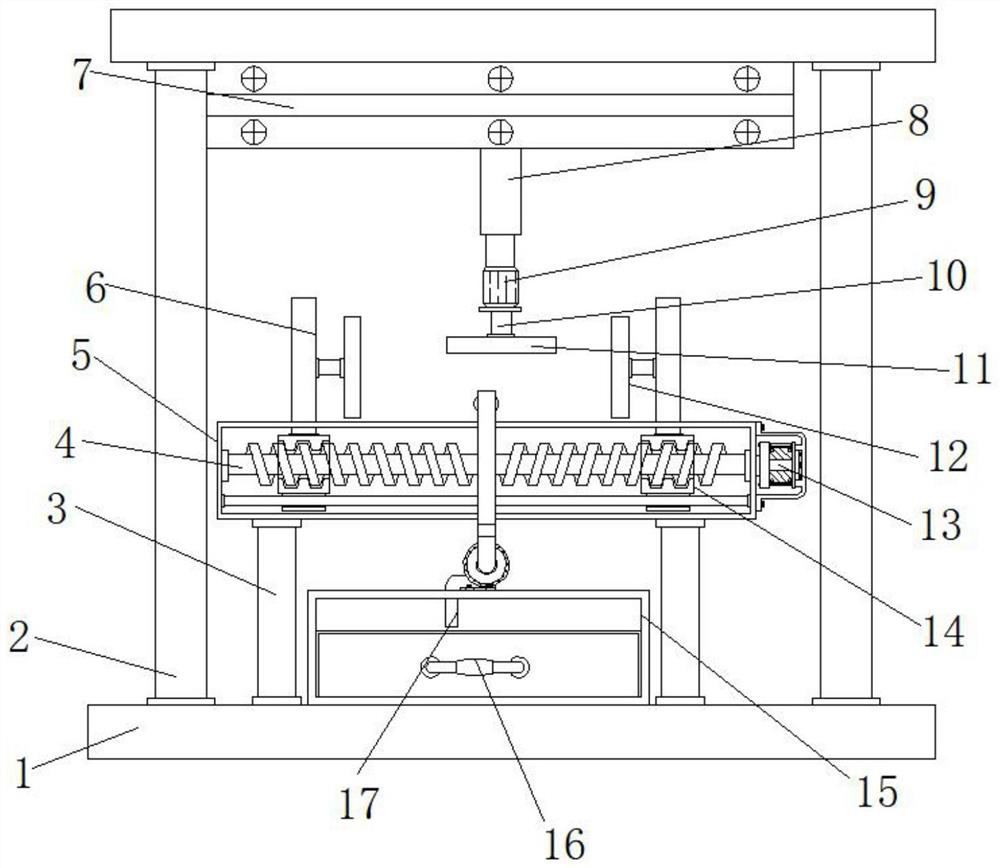

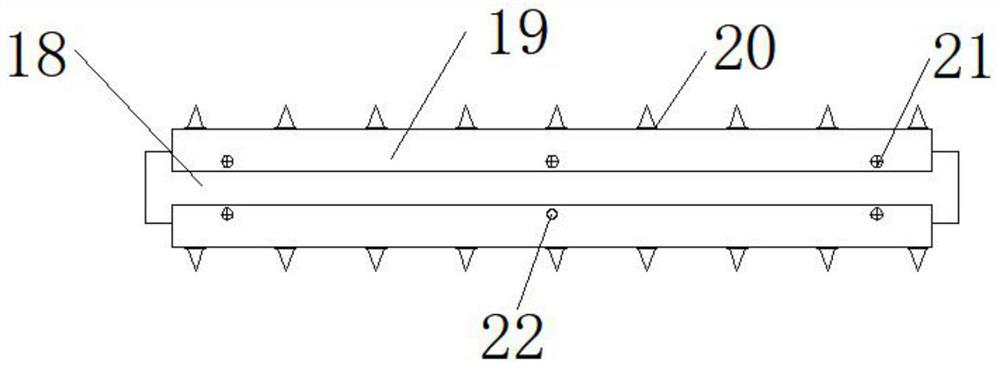

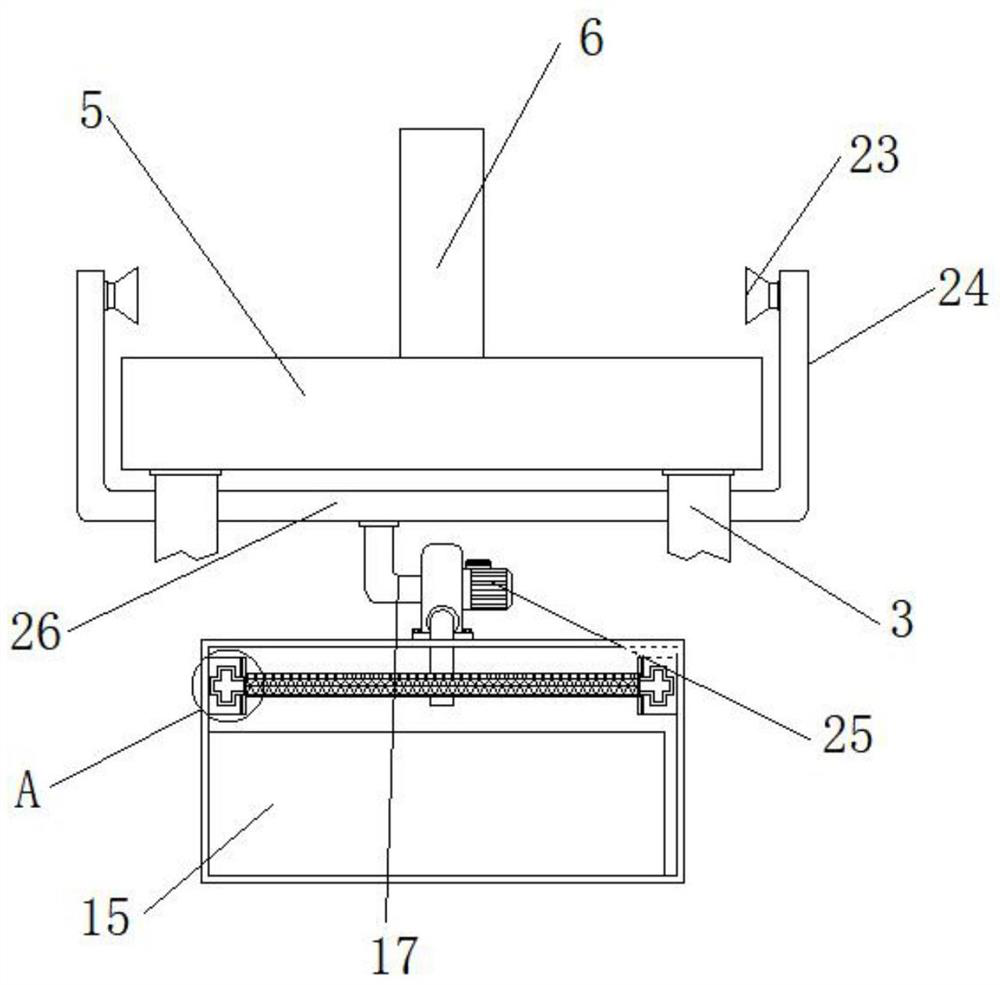

Automatic conveying and sorting mechanism of wind power blade balsa wood and its application

ActiveCN112938443BRealize fully automatic loading and unloadingImprove the working environment on siteEnergy industryControl devices for conveyorsProcess engineeringMechanical engineering

The invention discloses an automatic conveying and sorting mechanism for wind power blade balsa wood and its application. The mechanism comprises an automatic spreading and avoiding device, a conveyor unit and an automatic conveyor lifting unit connected in sequence, and the automatic conveyor lifting unit is connected in sequence. It is connected with the automatic unloading mechanism, and the automatic support and avoidance device is connected with the automatic feeding mechanism. The automatic feeding mechanism is provided with a code identifier. This device not only solves the automatic loading and unloading process of balsa wood at the head and tail ends of the mold and the mold turning process. The problem of mechanical interference in the blade production process is realized, and the fully automatic conveying and sorting of balsa wood in the blade production process is realized. The whole process does not require human intervention, which solves the problems of labor consumption, low efficiency and chaotic management in the process of balsa transportation, and greatly improves the transportation and distribution efficiency of balsa in the blade production process.

Owner:GURIT TOOLING (TAICANG) CO LTD

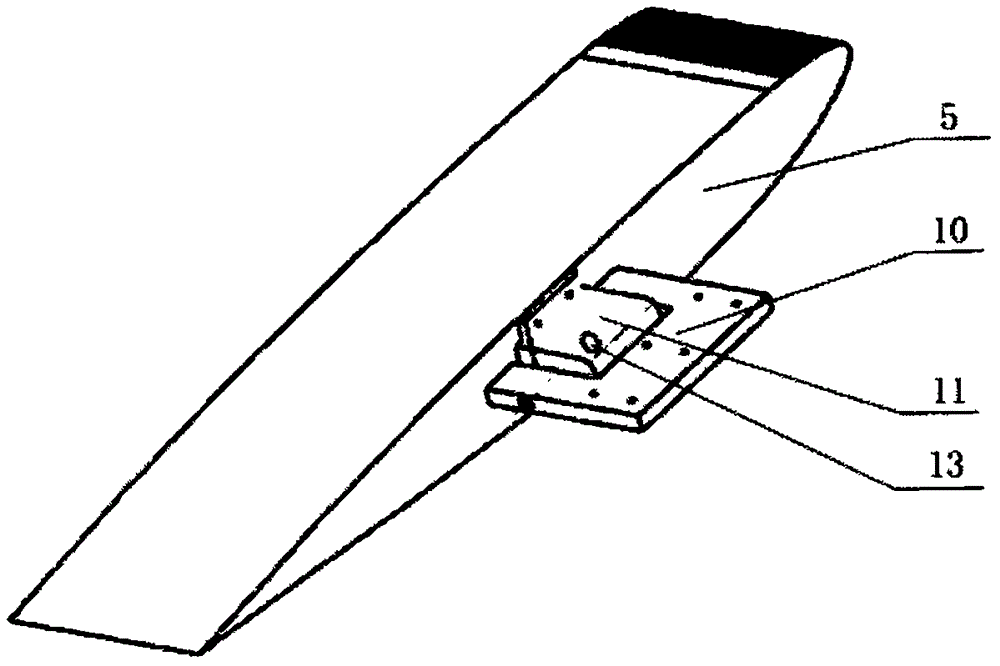

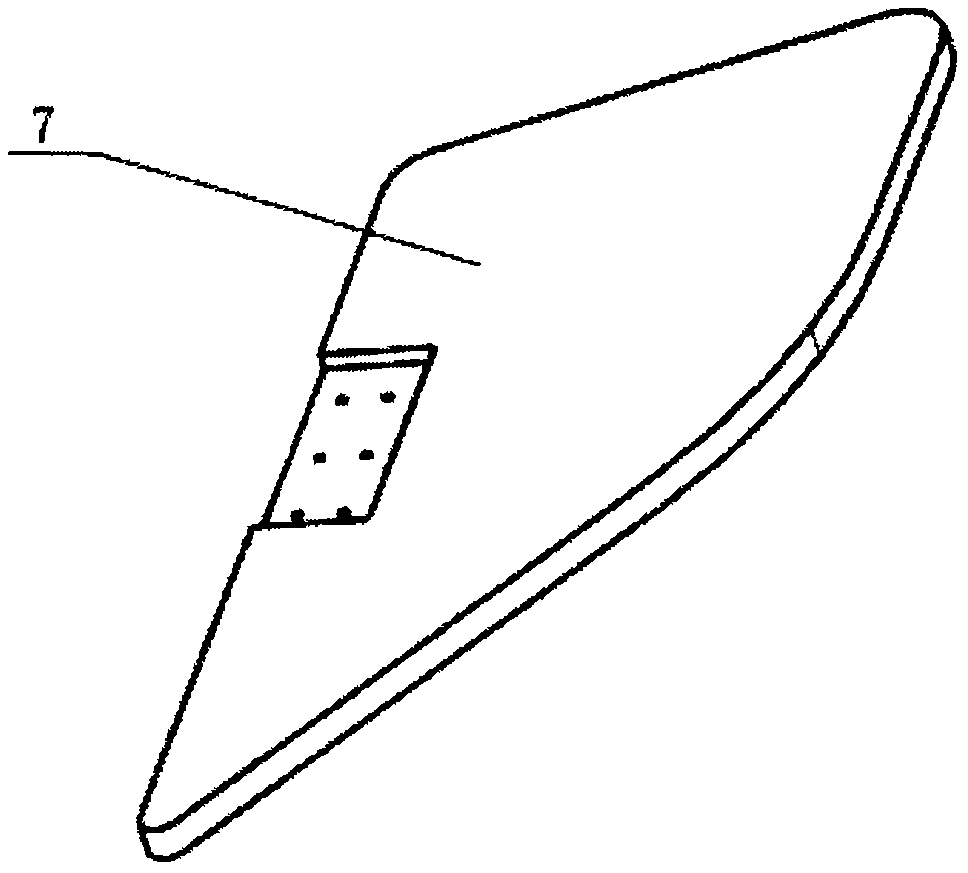

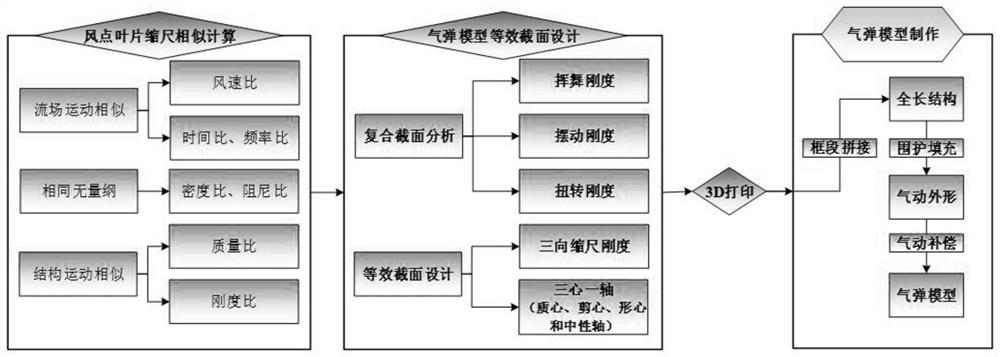

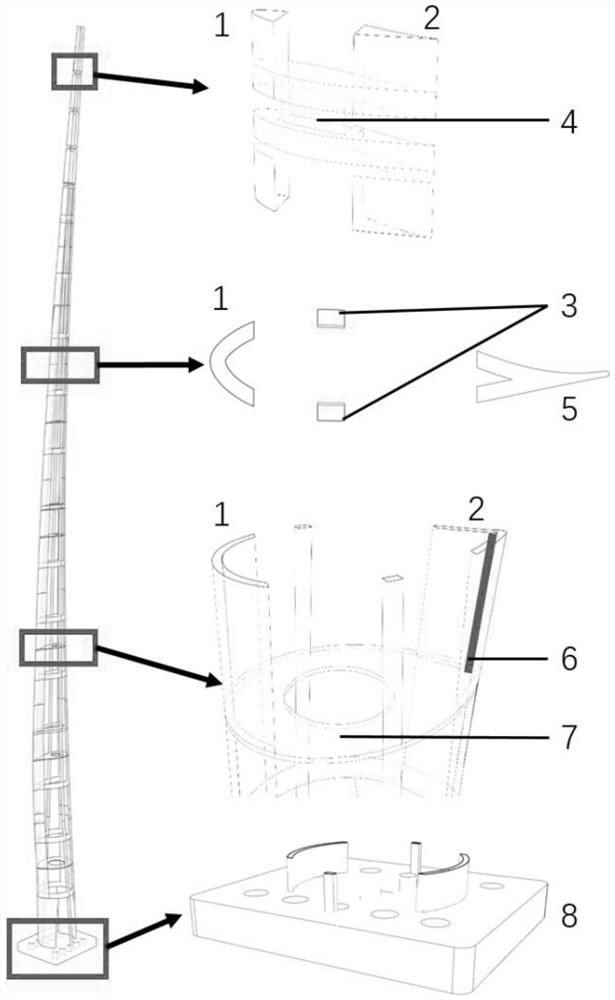

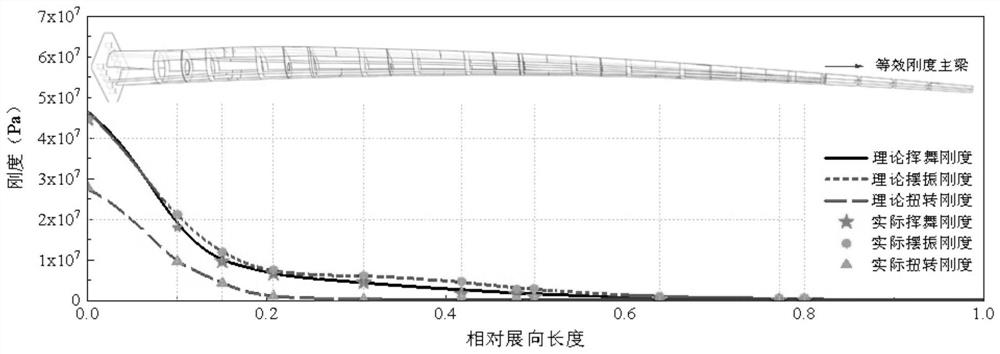

A method for making aeroelastic wind tunnel test model of wind turbine blade

ActiveCN113504027BAccurate acquisition of wind vibration characteristicsHigh precisionAerodynamic testingRenewable energy source integrationMarine engineeringTurbine blade

The invention discloses a method for making an aeroelastic wind tunnel test model of a wind turbine blade, including a reasonable simplification similarity criterion for aeroelastic model of a wind turbine blade, a design method for the equivalent section of the aeroelastic model, and a method for making a frame segment / coat of the aeroelastic model. Firstly, based on kinematic equivalence, a reasonable simplification similarity criterion for the aeroelastic model of wind turbine blades is derived. Then, the variational asymptotic equivalent section method is proposed to design a high-precision equivalent wind turbine blade model with special-shaped section, and realize the aero-stiffness-mass of the blade aeroelastic model. Scale-mapped aero-elastic model design; finally, relying on high-precision 3D printing to obtain the aero-elastic model frame segment, and then splicing the full-length model through the connecting ribs at a single point, filling the hollow area with balsa wood chips to polish the coat, pasting the weighted lead sheet on the trailing edge, and the front Edge paste rough strips and gap filling sponge to complete the inflatable model frame segment / outer garment. The invention supplements the deficiencies of the existing domestic and foreign wind turbine blade aeroelastic model design and manufacture methods.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Novel damp-proof balsa wood material for wind power blade and preparation process of novel damp-proof balsa wood material

PendingCN113977412AEasy to limitAchieve protectionGrinding drivesGrinding machinesStructural engineeringThreaded rod

The invention discloses a novel damp-proof balsa wood material for a wind power blade and a preparation process of the novel damp-proof balsa wood material. The novel damp-proof balsa wood material for the wind power blade comprises a base and a damp-proof balsa wood main body, supporting frames are arranged on the two sides of the top end of the base, and electric sliding rails are mounted at the top ends of the interiors of the supporting frames. According to the novel damp-proof balsa wood material for the wind power blade and the preparation process of the novel damp-proof balsa wood material, a threaded rod, limiting plates, a servo motor, an adjusting sleeve, a connecting block and a collecting box are arranged, the servo motor is started and drives the threaded rod to rotate, and the adjusting sleeve can move left and right outside the threaded rod by rotating the threaded rod; the diameter between the limiting plates can be adjusted by moving the adjusting sleeve left and right, and the novel damp-proof balsa wood material can be conveniently placed at the top end of a workbench to be limited by adjusting the diameter between the limiting plates; and the problem that the novel damp-proof balsa wood material is inconvenient to limit, and when the novel damp-proof balsa wood material is processed, the novel damp-proof balsa wood material is easy to shift is solved.

Owner:戴铂新材料(张家港)有限公司

Processing technology of large fan blade sandwich balsa wood material

InactiveCN113858369AAvoid crackingAvoid deformationPump componentsWood treatment detailsEngineeringFan blade

The invention discloses a processing technology of a large fan blade sandwich balsa wood material. The processing technology of the large fan blade sandwich balsa wood material comprises the following steps of preparation before processing, polishing of square timber, dust removal of the square timber, drying after coating conducted on the surface of the square timber, shallow groove forming of the square timber, punching of the square timber, cloth pasting of the square timber, film covering treatment of the surface of the timber and post-treatment processing of the square timber. The invention relates to the field of processing of sandwich balsa wood materials, in particular to the processing technology of the large fan blade sandwich balsa wood material, which has the beneficial effects that the water content is controlled to be below 20 percent before processing, so that cracking and deformation of wood products processed in the later period can be avoided, the density of the wood can be controlled through square cut, and relevant requirements are met; and the surface of the square timber is coated and then dried, so that the coated preservative and the treatment liquid can better permeate into the square timber at the drying temperature, and a better effect is achieved.

Owner:湖南伊索尔复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com